Page 1

Document 479826

Model RSF and RSFP

®

Roof Supply Fan

Installation, Operation and Maintenance Manual

Please read and save these instructions for future reference. Read carefully before attempting to assemble,

install, operate or maintain the product described. Protect yourself and others by observing all safety

information. Failure to comply with instructions could result in personal injury and/or property damage!

WARNING!

To reduce the risk of fire, electric shock, or injury,

observe the following:

• Some units suitable for use with solid state speed

controls.

• When cutting or drilling into wall or ceiling, do not

damage electrical wiring or other hidden utilities.

• If connecting cables are found to be cut or

defective, switch off the power supply and call

a professional technician to replace the wires/

connection.

• Never place a switch where it can be reached

from a tub or shower.

• Ducted fans must always be vented to the

outdoors.

• These fans are not recommended for cooking

exhaust applications. They are designed primarily

for low temperature, clean air applications only.

• Fan is not intended for mounting in outside

windows or walls.

CAUTION!

• For general ventilating use only. Do not use to

exhaust hazardous or explosive materials and

vapors.

127, 208 and 220-240V/60Hz/1-phase

• Black wire is “Hot”

• White wire is “Hot/Neutral” if present

• Green wire or Green and Yellow stripe wire is

“Ground” if present

380 and 400V/60Hz/3-phase

• Black wires are “Hot”

• Green and Yellow stripe wire is “Ground” if present

Use a device for disconnection from the

supply, having a contact separation of at least

3 mm in double poles switch, which must be

incorporated in the fixed wiring in accordance

with the local electrical wiring rules.

For this fan, precautions must be taken to

avoid the back-flow of gases into the room

from the open-flue of gas or other fuelburning appliances.

This product must be properly and

reliably grounded.

Use this fan at the rated voltage and

frequency indicated on the name plate.

Do not allow water to contact electrical

parts such as motors or switches.

Do not switch this product on or off

in case of gas leakage; otherwise, the

electric spark may result in an explosion.

Do not spray or clean this product directly

with water or other liquid; otherwise, a short

circuit or an electrical shock may occur.

Do not disassemble the unit for

reconstruction.

Make sure that its power switch is set

to OFF before you touch this product;

otherwise, an eletrical shock may occur.

This fan must be installed by a qualified

technician.

This fan should be installed so that the

blades are more than 2.3 m above the

floor.

Routine maintenance is required every

year. Ensure that the fan is switched

off from the main supply power source

before removing the guard.

This appliance is not intended for the use

by persons (including children) with reduced

physical, sensory or mental capabilities,

or lack of experience and knowledge,

unless they have been given supervision or

instruction concerning use of the appliance

by a person responsible for their safety.

Children should be supervised to ensure

that they do not play with the appliance.

®

Roof Supply Fan 1

Page 2

Model RSF/RSFP

Model RSF/RSFP are belt drive supply fans. These

fans are specifically designed for filtered roof supply

applications. Performance capabilities range up to

14,300 cfm (24,296 m3/hr) and up to 2.0in.wg (498Pa)

of static pressure. RSF/RSFP fans are available in

six sizes ranging from a size 90 to a size 200. Each

fan shall bear a permanently affixed manufacturer’s

engraved metal nameplate containing the model

number and individual serial number.

General Safety Information

Only qualified personnel should install this fan.

Personnel should have a clear understanding of these

instructions and should be aware of general safety

precautions. Improper installation can result in electric

shock, possible injury due to coming in contact with

moving parts, as well as other potential hazards.

Other considerations may be required if seismic

activity is present. If more information is needed,

contact a licensed professional engineer before

moving forward.

1. Follow all local electrical and safety codes, as

well as the National Electrical Code (NEC) and the

National Fire Protection Agency (NFPA), where

applicable. Follow the Canadian Electric Code

(CEC) in Canada.

2. The rotation of the wheel is critical. It must be free

to rotate without striking or rubbing any stationary

objects.

3. Motor must be securely and adequately grounded.

4. Do not spin fan wheel faster than max cataloged

fan RPM. Adjustments to fan speed significantly

effects motor load. If the fan RPM is changed, the

motor current should be checked to make sure it is

not exceeding the motor nameplate amps.

5. Do not allow the power cable to kink or come in

contact with oil, grease, hot surfaces or chemicals.

Replace cord immediately if damaged.

6. Verify that the power source is compatible with the

equipment.

7. Never open access doors to a duct while the fan is

running.

DANGER

Always disconnect, lock and tag power source

before installing or servicing. Failure to disconnect

power source can result in fire, shock or serious

injury.

CAUTION

When servicing the fan, motor may be hot enough

to cause pain or injury. Allow motor to cool before

servicing.

CAUTION

Precaution should be taken in explosive

atmospheres.

DANGER

Pour écarter les risques d’incendie, de choc

électrique ou de blessure grave, veiller à toujours

débrancher, verrouiller et étiqueter la source de

courant avant l’installation ou l’entretien.

ATTENTION

Lors de toute intervention sur la soufflante, le moteur

peut être suffisamment chaud pour provoquer une

douleur voire une blessure. Laisser le moteur refroidir

avant toute maintenance.

ATTENTION

Faire preuve de précaution dans les atmosphères

explosives.

Roof Supply Fan2

®

Page 3

Receiving

Upon receiving the product, check to ensure all

items are accounted for by referencing the delivery

receipt or packing list. Inspect each crate or carton

for shipping damage before accepting delivery. Alert

the carrier of any damage detected. The customer will

make notification of damage (or shortage of items)

on the delivery receipt and all copies of the bill of

lading which is countersigned by the delivering carrier.

If damaged, immediately contact your Greenheck

Representative. Any physical damage to the unit after

acceptance is not the responsibility of Greenheck Fan

Corporation.

Unpacking

Verify that all required parts and the correct quantity

of each item have been received. If any items are

missing, report shortages to your local representative

to arrange for obtaining missing parts. Sometimes it

is not possible that all items for the unit be shipped

together due to availability of transportation and truck

space. Confirmation of shipment(s) must be limited to

only items on the bill of lading.

Handling

Fans are to be rigged and moved by the lifting

brackets provided or by the skid when a forklift is

used. Location of brackets varies by model and size.

Handle in such a manner as to keep from scratching

or chipping the finish. Damaged finish may reduce the

ability of the fan to resist corrosion.

Fans should never be lifted by the shaft, fan housing,

motor, belt guard, windband or accessories.

Storage

Fans are protected against damage during shipment. If

the unit cannot be installed and operated immediately,

precautions need to be taken to prevent deterioration

of the unit during storage. The user assumes

responsibility of the fan and accessories while in

storage. The manufacturer will not be responsible

for damage during storage. These suggestions are

provided solely as a convenience to the user.

Indoor - The ideal environment for the storage of

fans and accessories is indoors, above grade, in a

low humidity atmosphere which is sealed to prevent

the entry of blowing dust, rain or snow. Temperatures

should be evenly maintained between 30° to 110°F

(-1° to 43°C). Wide temperature swings may cause

condensation and “sweating” of metal parts. All

accessories must be stored indoors in a clean, dry

atmosphere.

Remove any accumulations of dirt, water, ice or snow

and wipe dry before moving to indoor storage. To

avoid “sweating” of metal parts allow cold parts to

reach room temperature. To dry parts and packages

use a portable electric heater to get rid of any moisture

buildup. Leave coverings loose to permit air circulation

and to allow for periodic inspection.

The unit should be stored at least 3½ in. (89 mm) off

the floor on wooden blocks covered with moisture

proof paper or polyethylene sheathing. Aisles between

parts and along all walls should be provided to permit

air circulation and space for inspection.

Outdoor - Fans designed for outdoor applications may

be stored outdoors, if absolutely necessary. Roads or

aisles for portable cranes and hauling equipment are

needed.

The fan should be placed on a level surface to prevent

water from leaking into the fan. The fan should be

elevated on an adequate number of wooden blocks so

that it is above water and snow levels and has enough

blocking to prevent it from settling into soft ground.

Locate parts far enough apart to permit air circulation,

sunlight and space for periodic inspection. To minimize

water accumulation, place all fan parts on blocking

supports so that rain water will run off.

Do not cover parts with plastic film or tarps as these

cause condensation of moisture from the air passing

through heating and cooling cycles.

Fan wheels should be blocked to prevent spinning

caused by strong winds.

Inspection & Maintenance During Storage

While in storage, inspect fans once per month. Keep a

record of inspection and maintenance performed.

If moisture or dirt accumulations are found on parts,

the source should be located and eliminated. At

each inspection, rotate the wheel by hand ten to

fifteen revolutions to distribute lubricant in motor and

bearings. If paint deterioration begins, consideration

should be given to touch-up or repainting. Fans with

special coatings may require special techniques for

touch-up or repair.

Machined parts coated with rust preventive should be

restored to good condition promptly if signs of rust

occur. Immediately remove the original rust preventive

coating with petroleum solvent and clean with lintfree cloths. Polish any remaining rust from surface

with crocus cloth or fine emery paper and oil. Do not

destroy the continuity of the surfaces. Thoroughly wipe

clean with Tectyl

®

506 (Ashland Inc.) or the equivalent.

For hard to reach internal surfaces or for occasional

use, consider using Tectyl

®

511M Rust Preventive,

WD-40® or the equivalent.

Removing from Storage

As fans are removed from storage to be installed

in their final location, they should be protected and

maintained in a similar fashion until the fan equipment

goes into operation.

®

Roof Supply Fan 3

Page 4

Table of Contents

General Safety Information . . . . . . . . . . . . .2

Receiving, Unpacking, Handling, Storage . . . . . .3

Inspection and Maintenance During Storage . . . .3

Dimensional Data . . . . . . . . . . . . . . . . . .4

Lifting. . . . . . . . . . . . . . . . . . . . . . . . .5

Installation . . . . . . . . . . . . . . . . . . . . . .5

Mounting for Severe Duty Installation . . . . . . . .6

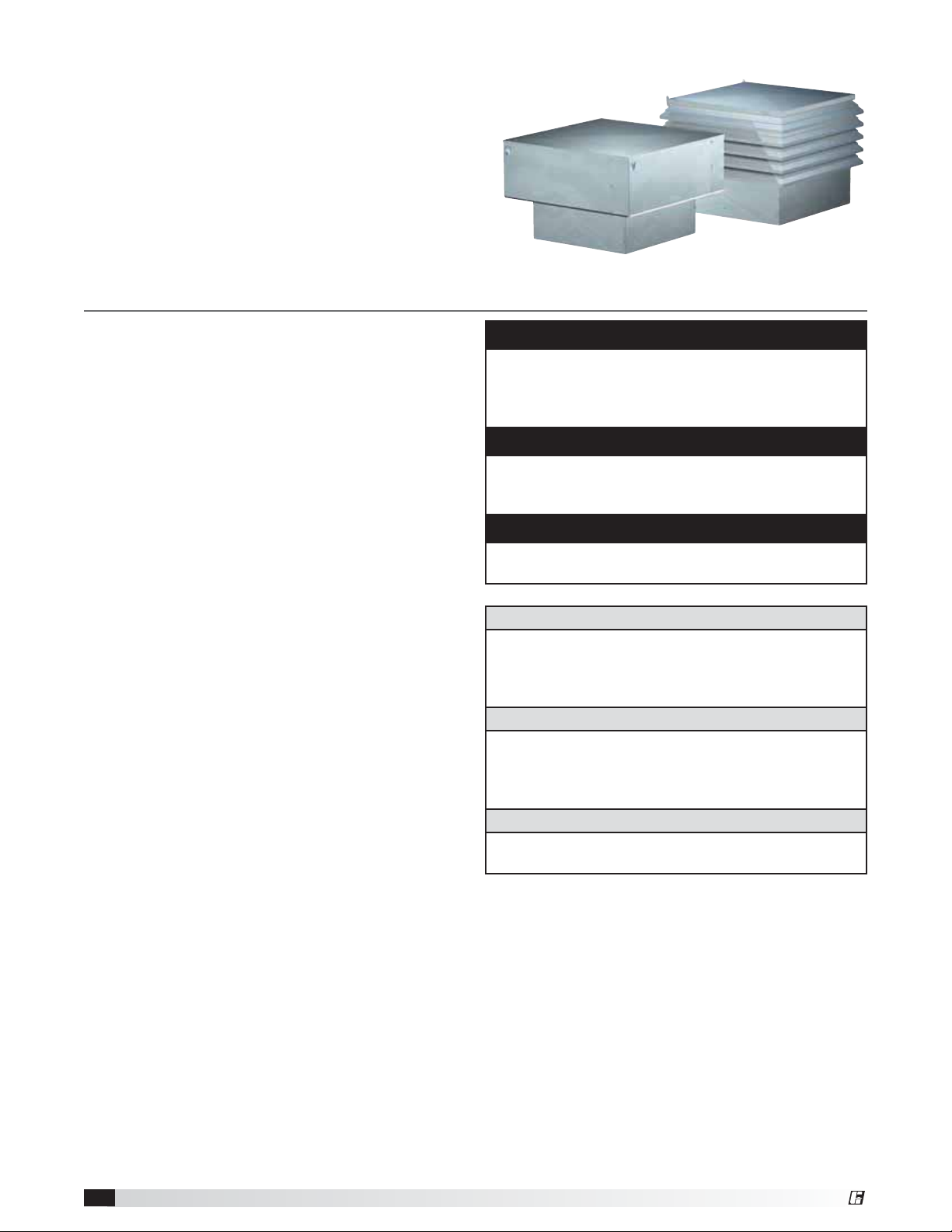

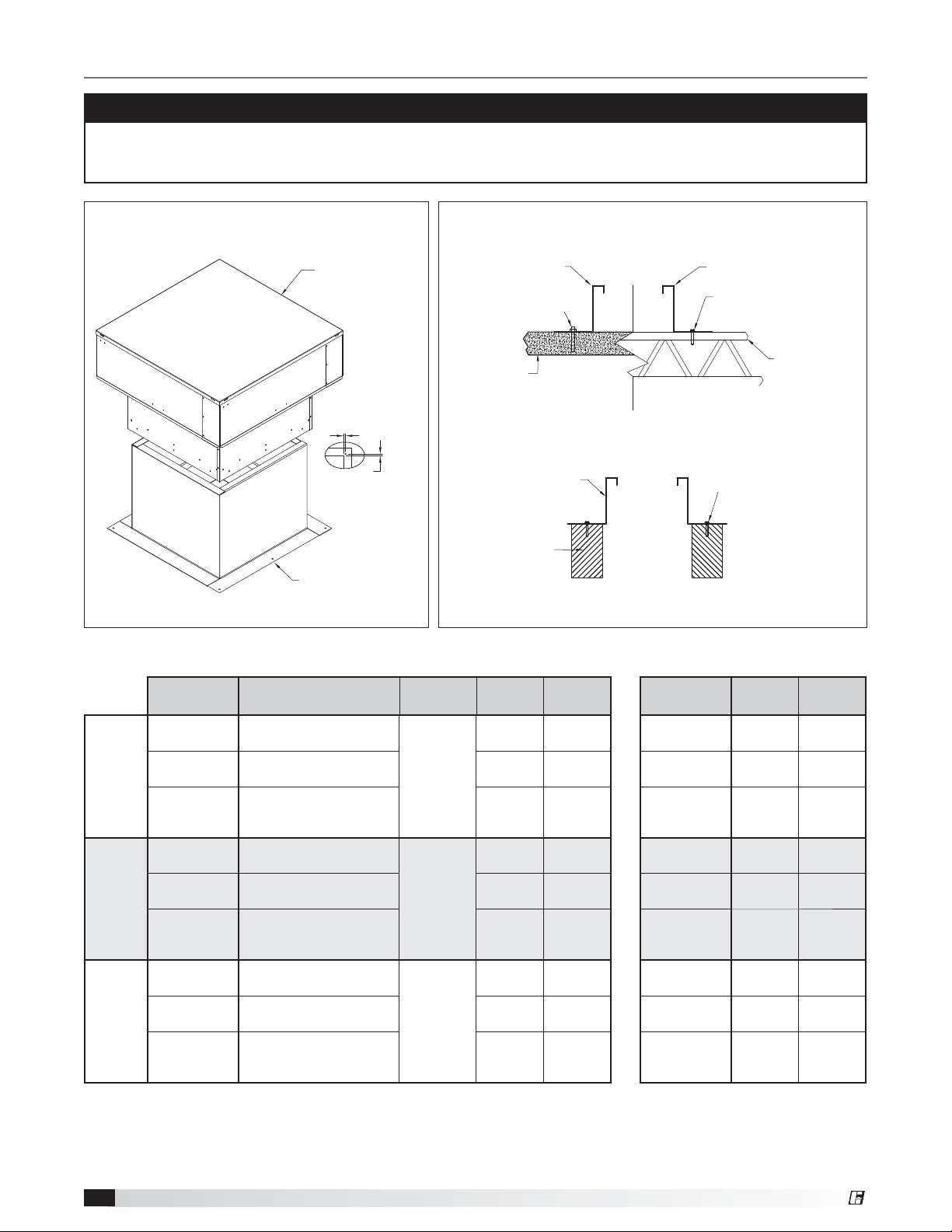

Dimensional Data

RSF

B SQ.

C

D

21/2 in.

SQ.

A

Electrical Connection . . . . . . . . . . . . . . . .7

Pre-Starting Checks . . . . . . . . . . . . . . . . .7

Routine Maintenance . . . . . . . . . . . . . . . .8

Parts List . . . . . . . . . . . . . . . . . . . . . . .9

Maintenance Log. . . . . . . . . . . . . . . . . . 10

Our Commitment. . . . . . . . . . . . . . . . . . 10

Base of Unit

J

F

J

G

A

H

RSFP

BL SQ.

CL

D

21/2 in.

A

SQ.

Fan

SizeA SQ.B SQ.

26 351⁄8 317⁄8 231⁄4 253⁄8 101⁄4 121⁄4 103⁄4 75⁄8 67⁄8 241⁄2 121⁄4 61⁄8 (4) 12x20

90

(660) (892) (810) (591) (645) (260) (311) (273) (194) (175) (662) (311) (156) (305x508) (66) (57)

30 411⁄8 357⁄8 231⁄4 253⁄8 101⁄4 135⁄8 117⁄8 91⁄16 83⁄16 281⁄2 141⁄4 71⁄8 (4) 12x25

100

(762) (1045) (911) (591) (645) (260) (346) (302) (230) (208) (724) (362) (181) (305x635) (78.5) (66)

34 471⁄8 397⁄8 271⁄4 293⁄8 101⁄4 161⁄8 137⁄8 101⁄16 815⁄16 321⁄2 181⁄4 71⁄8 (4) 16x25

120

(864) (1197) (1013) (692) (746) (260) (410) (352) (256) (227) (826) (464) (181) (406x635) (102) (82)

40 531⁄8 457⁄8 311⁄4 333⁄8 101⁄4 191⁄8 161⁄2 111⁄4 107⁄16 381⁄2 201⁄4 91⁄8 (8) 16x20

150

(1016) (1349) (1165) (794) (848) (260) (486) (419) (286) (265) (978) (514) (232) (406x508) (152) (113)

46 611⁄8 5 17⁄8 341⁄4 353⁄8 121⁄4 221⁄2 191⁄2 101⁄8 113⁄4 441⁄2 261⁄4 91⁄8

180

(1168) (1153) (1318) (870) (899) (311) (571) (495) (257) (298) (1130) (667) (232) (4) 20x20 (181) (129)

52 731⁄8 583⁄16 391⁄4 403⁄8 121⁄4 231⁄4 251⁄4 133⁄8 143⁄8 501⁄2 301⁄4 101⁄8 (8) 20x25

200

(1321) (1857) (1478) (997) (1026) (311) (591) (641) (340) (365) (1283) (768) (257) (508x635) (281) (196)

BL

CCLDFGHJ

SQ.

All dimensions are in inches (millimeters). Pounds (kg).

Optional Duct Adapter

K

SQ.L SQ.

M

M

Nominal

Filter

(4) 16x20

(406x508)

(508x508)

M

L

SQ.KSQ.

M

Louver

Tiers

RSFP

3

3

4

5

5

6

Weights

RSF RSFP

145 126

173 146

225 180

336 250

400 285

620 431

Roof Supply Fan4

®

Page 5

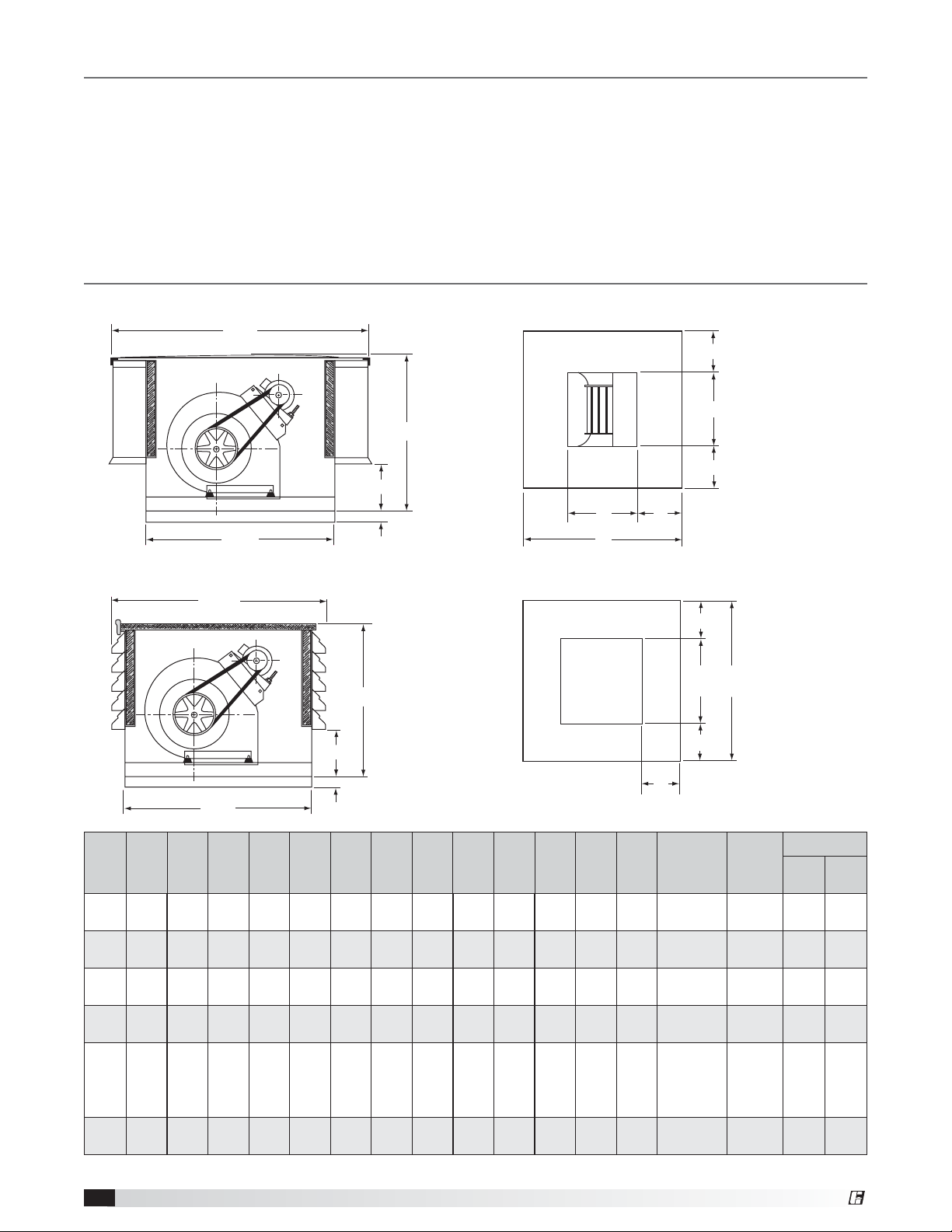

Lifting

Installation

Lifting the RSF and

Figure 1

RSFP fans must be

done with care to

avoid damaging the

housing. For model

RSF, attach four

lifting devices under

the outer housing,

Lift Here

Lift Here

each device beneath

the vertical row of fasteners as depicted in Figure 1.

Lifting devices should be a minimum of 3 inches wide

to avoid damaging the sheet metal housing.

Do not lift Model RSF near the center of the outer

housing.

For Model RSFP attach a minimum of four lifting

devices under an exterior louver panel, each device

near the corner of the louvered housing.

Move the fan to its intended location and fasten it

securely through mounting holes provided in the

fan base. Shims may be necessary depending

upon thickness of the roofing material. For ducted

applications, an optional duct adapter (if provided)

is attached and holds the ductwork in place prior to

installing the unit. The following diagram shows a

typical installation with prefab roof curb and ductwork.

Access to the motor compartment is made by

releasing four latches which secure the cover. The

cover should be placed in an area where wind will not

blow it off the roof.

Typical Installation

Prepunched mounting

holes and 21⁄2 in. skirt

to aid in installation.

Ductwork (by others)

Duct adapter (optional)

allows ductwork to

be completed prior to

setting unit on curb.

Roof curb

Fan Size Curb Size*

RSF/RSFP-90 24

RSF/RSFP-100 28

RSF/RSFP-120 32

RSF/RSFP-150 38

RSF/RSFP-180 44

RSF/RSFP-200 50

All dimensions are in inches (millimeters).

* Recommended curb size shown is outside curb dimension without roofing

and flashing.

Note: In cases where extreme snow depths may be encountered, extended

base may be required to raise unit or condensation pans may be required in

ductwork.

1

1

1

1

1

⁄2 (1130) 29 (737) 26 (660) 26 x 26 (737x737)

1

⁄2 (1283) 33 (838) 30 (762) 30 x 30 (838x838)

Recommended

Roof Opening

⁄2 (662) 15 (381) 12 (305) 12 x 12 (305x305)

⁄2 (724) 17 (432) 14 (356) 14 x 14 (356x356)

⁄2 (826) 21 (533) 18 (457) 18 x 18 (457x457)

⁄2 (978) 23 (584) 20 (508) 20 x 20 (508x508)

Duct Size ID Nominal Damper Size

®

Roof Supply Fan 5

Page 6

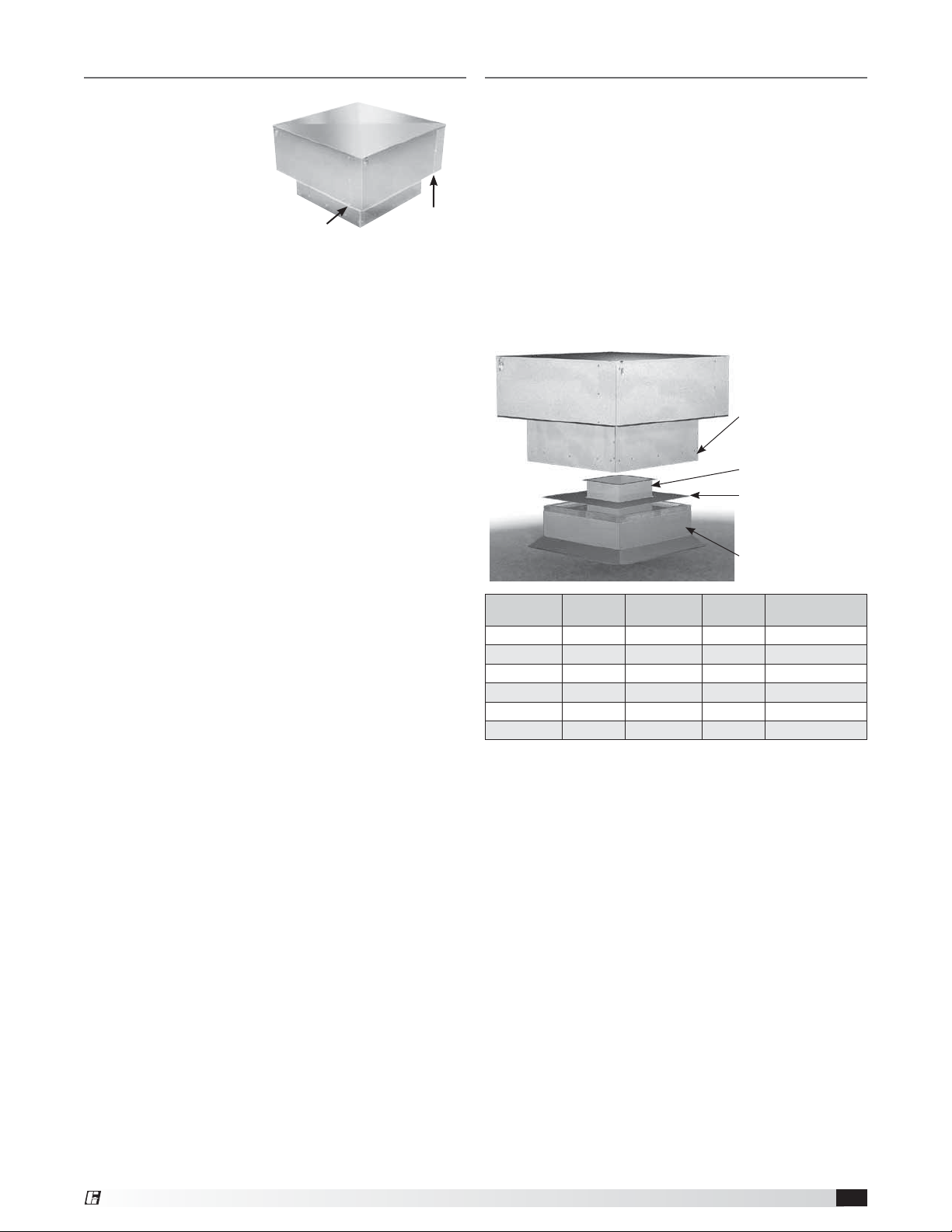

Mounting for Severe Duty Installations

IMPORTANT

Installation instructions for seismic ratings are only recommendations. Final design must be determined by

Structural Engineer of Record (SEOR) including requirements for curb construction, mounting of unit to curb

and mounting of curb to structure.

Fan to Curb: Three (3) fasteners are required

per side on all sides. Must be equally spaced.

RSF Series

1.25

1.25

Curb Corner

Anchor Detail

Roof Curb

Model SD, SDP, GPF or Equivalent

18 ga. Min.

24 in. (610 mm) Tall Max.

Welded Steel Construction

Curb to Deck: Fasteners need to be located on two

opposite ends of the curb.

Roof Curb Roof Curb

3/8 in. (10 mm) S.S. Hilti Kwik Bolt

Three Expansion Anchors

Min. 2-1/2 in. (64 mm) Engagement

2000 Min. PSI

Concrete

Concrete

Deck Anchoring

Roof Curb

Wood Timber

Min. 4 in. (102 mm)

Nominal Thickness

Min. G = 0.42

G = specific gravity

of lumber

Deck Anchoring

Timber Anchoring

1/4 in. - 14 Self-Drilling Screw

Min. 1/2 in. (13 mm) of Threads Through

Steel

3/8 in. (10 mm) Lag Bolt (Zinc Plated)

Min. 3 in. (76 mm) Thread Engagement

High Wind Ratings Seismic Ratings

Roof Truss

1/8 in. (3 mm) Thick

or 12 ga. Min.

Fan Size Curb Cap Size

Concrete

Steel

Timber

90, 100, 120

150

180, 200

90, 100, 120

150

180, 200

90, 100, 120

150

180, 200

(660x660 to 864x864 mm)

(1168x1168 to 1321x1321

(660x660 to 864x864 mm)

(1168x1168 to 1321x1321

(660x660 to 864x864 mm)

(1168x1168 to 1321x1321

All dimensions are in inches

26x26 to 34x34

40x40

(1016x1016 mm)

46x46 to 52x52

mm)

26x26 to 34x34

40x40

(1016x1016 mm)

46x46 to 52x52

mm)

26x26 to 34x34

40x40

(1016x1016 mm)

46x46 to 52x52

mm)

(millimeters)

.

Self-Drilling

Screw Size

3/8-inch

1/4” - 14

3/8-inch

Fasteners

Per Side

Total

Fasteners

Fan Size

Fasteners

per side

3 6 90, 100, 120 3 6

4 8 150 4 8

5 10 180, 200 5 10

3 6 90, 100, 200 3 6

4 8 150 4 8

5 10 180, 200 5 10

3 6 90, 100, 120 3 6

4 8 150 4 8

5 10 180, 200 5 10

Total

Fasteners

Roof Supply Fan6

®

Page 7

Electrical Connection

Pre-Starting Checks

The electrical supply must be compatible with the fan

motor with regard to voltage, phase and amperage

capacity. Moreover, the electrical supply line must

be properly fused and conform to local and national

electrical codes.

Electrical lead-in wires should be routed through the

pre-punched hole in the optional duct adapter (if

provided) and the punched hole in the bottom of the

fan housing. Electrical wires must be located so as not

to rub on moving components. The electrical supply

line is connected to an optional safety disconnect

switch (if provided) or wired directly to the motor.

Wiring should be secured inside the fan to prevent

interference with the drive components. All wiring must

conform to local and national codes.

DANGER

Disconnect and secure to the “off” position all

electrical power to the fan prior to inspection

or servicing. Failure to comply with this safety

precaution could result in serious injury or death.

DANGER

Pour écarter les risques de blessure grave ou

de mort, débrancher et verrouiller l’alimentation

électrique en position « Arrêt » avant tout contrôle ou

entretien.

Units with motor and drives shipped separate, refer to

Motor Mounting Instructions included in hardware bag.

Check all fasteners and set screws for tightness.

Rotate the fan wheel by hand to assure it turns freely

and is centered between the inlets. Check pulleys and

belts for proper alignment to avoid premature belt

wear, noise, vibration and power loss. Motor and fan

pulleys must be parallel and in alignment; Figure 2.

CORRECT WRONG WRONG WRONG

Figure 2

Adjustable motor pulley is set at the factory for the fan

RPM specified. Fan speed can be increased by closing

or decreased by opening the adjustable motor pulley.

Two groove variable pitch pulleys must be adjusted an

equal number of turns open. Any increase in fan speed

results in an increase in horsepower required for the

motor. Motor amperage should always be checked

and compared to nameplate rating when changing fan

speed.

Direction of fan wheel rotation is critical. A fan wheel

rotating in the wrong direction

will result in reduced airflow,

a

t

t

i

o

o

n

motor overloading and possible

R

burnout. Check wheel rotation

by momentarily turning the fan

on.

Rotation should be in the same

direction as airflow at the outlet.

See housing and wheel example

in Figure 3.

Figure 3

Airflow

IMPORTANT

RSF/RSFP fans should be operated only when

attached to the completed system. Without

proper static pressure loading, the motor may be

overloaded and burnout may occur.

®

Roof Supply Fan 7

Page 8

Routine Maintenance

DANGER

Disconnect and secure to the “off” position all

electrical power to the fan prior to inspection

or servicing. Failure to comply with this safety

precaution could result in serious injury or death.

DANGER

Pour écarter les risques de blessure grave ou

de mort, débrancher et verrouiller l’alimentation

électrique en position « Arrêt » avant tout contrôle ou

entretien.

To preserve the reliability and performance designed

into the fan, regularly scheduled maintenance

should be performed. Items to be checked at each

maintenance interval are filters, belts, bearings,

fasteners, lubrication and removal of dust and dirt.

Filters - One-inch washable aluminum mesh filters

are standard on model RSF and RSFP fans. Optional

two-inch filters may be supplied on some fans. Filters

should be cleaned on a regular basis for optimum

efficiency.

To remove the filters, first remove the fan cover by

releasing the four latches. Place the cover in an area

where wind will not blow it off the roof. The filters can

be lifted out and washed in a mild detergent solution.

If desired, an adhesive spray available at most filter

distributors can be applied to increase filter efficiency.

Belts - Belt tension should be checked two times

during the first 24 hours of operation and during each

scheduled maintenance thereafter. Premature belt

failures are frequently caused by improper belt tension,

either too tight or loose. The proper belt tension for

operating a V-belt is the lowest tension at which the

belt will not slip at peak load conditions. For initial

tensioning, belt deflection should be 1/64 inch for

each inch of belt span, determined by using moderate

thumb pressure half

way between pulley

centers. For example,

the belt deflection

should be 1/2 inch

if the belt span is

32inches; Figure 4.

Figure 4

Belt tension can be adjusted by loosening the motor

plate hinge bolts and adjusting the jack screws as

required. RSF/RSFP units are supplied with either a

painted steel motor bracket or a galvanized motor

plate for larger motor frames. To adjust belt tension on

units equipped with the painted steel motor bracket,

simply adjust the single jack screw.

For units equipped with a galvanized motor plate,

both jack screws must be adjusted equally. Check

pulley and belt alignment after adjusting belt tension;

Figure2.

Belt Span

Deflection =

Belt Span

64

Lubrication - Fan bearings on models RSF and

RSFP are permanently lubricated. Motor bearings

equipped with grease fittings should be lubricated in

accordance with instructions on the motor nameplate.

Motors without grease fittings are lubricated for life.

Cleaning - Motors and fan wheels require periodic

cleaning to remove dust and dirt which may

accumulate. Motor cleaning should be limited to the

exterior surface only. Removing dust and dirt from the

motor housing assists in motor cooling and prolongs

motor life. Motors should never be sprayed with

steam, water or solvents.

Fan wheels which are left to accumulate dust and dirt

will have poor air performance, loss of efficiency and

possible damaging vibration due to an unbalanced

condition.

Periodic cleaning is a good investment in preserving

the reliability and performance designed into the fan.

Roof Supply Fan8

®

Page 9

Parts List

Each fan bears a manufacturer’s nameplate with model number and serial number embossed. This information

will assist the local Greenheck representative and the factory in providing service and replacement parts. Before

taking any corrective action, make certain unit is not capable of operation during repairs.

CAUTION

A fan manufactured with an explosion resistant

motor does not certify the entire unit to be explosion

proof. Refer to ULListing Mark for the fans approved

usage.

Filters

Shaft Pulley

Belt

Vibration Isolators (4)

CAUTION

La présence d’un moteur antidéflagrant sur un

ventilateur ne garantit pas que tout l’appareil est

antidéflagrant. Pour connaître les emplois autorisés

de l’appareil, voir son marquage de conformité UL.

Blower Unit

*Motor Plate

Motor

Motor Pulley

Blower Mounting Angle

*Galvanized motor plate shown. Painted steel motor bracket used on units with smaller motor frame sizes.

®

Roof Supply Fan 9

Page 10

Maintenance Log

Date _______________ Time _________________AM/PM

Notes: __________________________________________

________________________________________________

________________________________________________

________________________________________________

Date _______________ Time _________________AM/PM

Notes: __________________________________________

________________________________________________

________________________________________________

________________________________________________

Date _______________ Time _________________AM/PM

Notes: __________________________________________

________________________________________________

________________________________________________

________________________________________________

Date _______________ Time _________________AM/PM

Notes: __________________________________________

________________________________________________

________________________________________________

________________________________________________

Date _______________ Time _________________AM/PM

Notes: __________________________________________

________________________________________________

________________________________________________

________________________________________________

Date _______________ Time _________________AM/PM

Notes: __________________________________________

________________________________________________

________________________________________________

________________________________________________

Date _______________ Time _________________AM/PM

Notes: __________________________________________

________________________________________________

________________________________________________

________________________________________________

Date _______________ Time _________________AM/PM

Notes: __________________________________________

________________________________________________

________________________________________________

________________________________________________

Our Commitment

As a result of our commitment to continuous improvement, Greenheck reserves the right to change specifications

without notice.

Specific Greenheck product warranties are located on greenheck.com within the product area tabs and in the

Library under Warranties.

Greenheck’s Centrifugal Roof Supply Fans catalog provides

additional information describing the equipment, fan

performance, available accessories, and specification data.

AMCA Publication 410-96, Safety Practices for Users and

Installers of Industrial and Commercial Fans, provides

additional safety information. This publication can be

obtained from AMCA International, Inc. at www.amca.org.

®

Phone: 715.359.6171 • Fax: 715.355.2399 • Parts: 800.355.5354 • E-mail: gfcinfo@greenheck.com • Website: www.greenheck.com

479826 • RSF/RSFP, Rev. 3, May 2015 Copyright 2015 © Greenheck Fan Corporation10

Page 11

ΔϧΎϳλϟϝΟγ

҄ҖһӪܜٙҖҪҖҙӂ _____________ҠӞӷӦҕ ______________ ҰӽҵҖҟӦҕ

ٙ

_____________________________________ ܐҝҖӏҪڔӪ

___________________________________________

___________________________________________

___________________________________________

҄ҖһӪܜٙҖҪҖҙӂ _____________ҠӞӷӦҕ ______________ ҰӽҵҖҟӦҕ

ٙ

_____________________________________ ܐҝҖӏҪڔӪ

___________________________________________

___________________________________________

___________________________________________

҄ҖһӪܜٙҖҪҖҙӂ _____________ҠӞӷӦҕ ______________ ҰӽҵҖҟӦҕ

ٙ

_____________________________________ ܐҝҖӏҪڔӪ

___________________________________________

___________________________________________

___________________________________________

҄ҖһӪܜٙҖҪҖҙӂ _____________ҠӞӷӦҕ ______________ ҰӽҵҖҟӦҕ

ٙ

_____________________________________ ܐҝҖӏҪڔӪ

___________________________________________

___________________________________________

___________________________________________

҄ҖһӪܜٙҖҪҖҙӂ _____________ҠӞӷӦҕ ______________ ҰӽҵҖҟӦҕ

ٙ

_____________________________________ ܐҝҖӏҪڔӪ

___________________________________________

___________________________________________

___________________________________________

҄ҖһӪܜٙҖҪҖҙӂ _____________ҠӞӷӦҕ ______________ ҰӽҵҖҟӦҕ

ٙ

_____________________________________ ܐҝҖӏҪڔӪ

___________________________________________

___________________________________________

___________________________________________

҄ҖһӪܜٙҖҪҖҙӂ _____________ҠӞӷӦҕ ______________ ҰӽҵҖҟӦҕ

ٙ

_____________________________________ ܐҝҖӏҪڔӪ

___________________________________________

___________________________________________

___________________________________________

҄ҖһӪܜٙҖҪҖҙӂ _____________ҠӞӷӦҕ ______________ ҰӽҵҖҟӦҕ

ٙ

_____________________________________ ܐҝҖӏҪڔӪ

___________________________________________

___________________________________________

___________________________________________

ӠҙһӪҵҖӓҾҏӭӶұҝҖӛӂҕӷڛҕӨӽҲҙҞڒҖӴӟҫҘGreenheckӐӛҟҫҞ܃ҶӽӷӋҟӦҕҜӧӂҕӷӫҘӬҒҕҲӦҕҖӯӪҕҸҟӦړҜҧӾҟӮ

ҜҙҟӣڛҕڒҖٙӇӽ҉ӶҨҟӯڛҕҜӟӋӯڛҚӽӷҙҟӦҕҝҖӪڔӒӥڔҮӰӪӤӦҳӶ܃greenheck.comӿӮӶٸӣӦڙҕӔӞӷڛҕڝӒGreenheckҝҖҧҟӯڛқұҲҫӪҝҖӮҖӫӆҲҦӷҞ

ӿӾӯӚӶۧӪҲүҟһڛҖҘҜӂҖүӦҕҜӪڔһӦҕҝҖҺҵҖӫӪҬӆӷӽ܃410ܞˀ6 ӬӞҵAMCAҵӷҿӯӪ

ӭҖӣӪڙҖҘҜӪڔһӦҖҘӠӧӓҟҞҜӾӚҖӆҏҝҖӪӷӧӓӪҖٙӇӽ҉ӶҜӾӒҖӯӃӦҕӶҜӽҵҖҧҟӦҕҩӶҕҶӫӧӦҚӾӢٸӦҕ

www.amca.orgӔӞӷڛҕڝӒҜӾڛҖӓӦҕ AMCAҜӢٿӰӪҵӷҿӯڛҕڝӒӥӷӃҫӦҕ

ҝҖӪӷӧӓӪGreenheckӰӪӼҸӢҶڛҕұҶӋӦҕҝҕҳӜӟһӦҕұҕҲӪҏҩӶҕҶӪҥӷӦҖҟӢҶӚӷӽ

ҝҖӛӂҕӷڛҕҝҖӮҖӾҘӶқҶӚӷҟڛҕҝҖӟҫӧڛҕӶҜҪӶҶڛҕ҄ҕұ҉ӶҸӾӴҧҟӧӦҖٙӛӂӶӿӋӓҞҜӾӚҖӆҏ

ҖӯӪҕҸҟӦҕ

ҝҖӮҖӫӇӦҕӨӛҺ҉

®

www.greenheck.comܐӿӮӶٸӣӦڙҕӔӞӷڛҕƷgfcinfo@greenheck.comܐӿӮӶٸӣӦڙҕҲӽٷӦҕƷ8003ʼʼʼ3ʼ4ܐҵҖӾӗӦҕӔӋӞƷʾ1ʼ3ʼʼ23ˀˀܐҼӢҖӚƷʾ1ʼ3ʼˀ61ʾ1ܐӜҞҖӳ

Greenheck Fan CorporationҜӢڀӦʛ2015ڀӯӦҕӶӔҙӋӦҕӝӷӟҪ 2015ӷӽҖӪ܃3ҜӓҦҕҶڛҕ܃RSF/RSFPƷ479826

10

Page 12

҄ҕҸҦڗҕҜӫҒҖӞ

GreenheckҜӢٿۥңӫӪӶӔӯӃڛҕҝҖӪӷӧӓڛҕӱҴӳҲӒҖһҞәӷҺӶۥһӧһҟӦҕӬӞҶӦҕӶҷҕҶӋӦҕӬӞҵӔӪҜӓӯӃڛҕҜӴҧӦҕӬҺҕҖӴӾӧӒҵӷӛҫӪӔӯӂҜҪӷӦӨӫҫҞҜҪӶҶӪӨӢ

ҬӾӧӃҟӦҕ҄ҖӯҢ҉ӨӫӓӦҕڝӒқҵұҖӞۦӖҜӾӯӓڛҕқҲҪӷӦҕӨӓҦҕ܃ҜӾҫӾҫӃҞҝҕ҄ҕҶҦҏӼ҉ҳҖүҞҕӨҙӞҵҖӾӗӦҕӔӋӞӶҜӪҲүӦҕۦӚӷҞڒ

CAUTION

La ÆróÉence ºƠËn moteËr antiºófÂagrant ÉËr Ën

ÌentiÂateËr ne garantit ÆaÉ ÇËe toËt ÂƠaÆÆarei eÉt

antiºófÂagrantoËr connaČtre ÂeÉ emÆÂoiÉ aËtoriÉóÉ

ºe ÂƠaÆÆareiÂƑÌoir Éon marÇËage ºe conformitó UL

ҶҞڔӛӦҕ

ӭҕҵӶҲӦҕұӷӫӒқҶӣҘ

ۦһӦҕ

(4) ҷҕҸҟӳړҕӥҷҕӷӒ

ӵӾҙӯҞ

қҲҪӷӦҕҜӪӶҖӟӪӭҖӫӆӿӯӓҞړҵҖҧӛӮڔӦөӶҖӟӪӡҶҫӫҘҜӓӯӃӫӦҕҜҪӶҶӫӦҕ

өҕҲүҟҺڔӦҜҙһӯӦҖҘULӄӾҮҶҟӦҕҜӪڔӒӻӦҏӔҦҵҕҵҖҧӛӮڔӦӨӪҖӣӦҖҘ

ҩӶҕҶӫӧӦҲӫҟӓӫӦҕ

ӔӚҲӦҕҜҪӶҶӪқҲҪӶ

ӡҶҫӫӦҕҜҪӷӦdž

ӡҶҫӫӦҕ

ӡҶҫӫӦҕқҶӣҘ

ӔӚҲӦҕҜҪӶҶӪҠӾҙңҞҜӽӶҕҷ

Ҷӗӂ҉ӡҶҫӪҵҖӊҏөҖҧҪ҉ӔӪҝҕҲҪӷӦҕڒҜӪҲүҟһڛҕҜӾӧӋڛҕҜӽҳړӷӛӦҕӡҶҫڛҕҼӽұҕӷӞөҲүҟһҞӰӛӧҧڛҕӡҶҫڛҕҩӷӦӅҶӒӬҟӽdž

9

ӜӟһӦҕ ұҕҲӪҏ ҜҪӶҶӪ

®

Page 13

ҜӾӯӾҞӶҶӦҕҜӮҖӾӃӦҕ

қҵӷӃҘҖӴҟӾӽҸҞӬҟӽRSFӶRSFҝڔӽұӷڛҕڒӨӪҖҫӫӧӦҜҙһӯӦҖҘܞҠӾӽҸҟӦҕ

ٙҖӟӚӶҖӴҟӾӽҸҞҚҧӽӬӾҫҿҟӧӦҥҖҟҫҞҝҖҙӾӢٸҘқұӶҸڛҕӡҶҫڛҕҝڔӫҫӪҜӫҒҕұ

ӼӷҟҫҞړӿҟӦҕҝҖӢҶҫڛҕӬӾҫҿҞӬҟӽӡҶҫڛҕӔӯӂҜҪӷӦڝӒқұӷҦӷڛҕҝҖӫӾӧӓҟӧӦ

ӥҕӷӊӸҶҮ҉қҶӪҖӴӫӾҫҿҞڜҏҥҖҟҫҞړҤӾҫҘӬӾҫҿҞڜҏҥҖҟҫҞҝҖҙӾӢҶҞڝӒ

қҖӾҫӦҕ

ҜҘҶҞڗҕҜӦҕҷڙӼҵӶұӜӾӏӯҞҜҪӶҶڛҕҝڔҧӒӶҝҖӢҶҫڛҕҚӧӋҟҞܞ

ӜӾӏӯҟӦҕ

ڝӒқچҟӟӪӡҶҫڛҕҜӚҖӏӮӭӷӣҞӭ҉ӿӗҙӯӽӬӢҕٸҞӭ҉ӰӣӫӽӿҟӦҕқҵҕҴӟӦҕӶ

ҲӽٷҞڒӡҶҫڛҕҠӾҙӪӰӪҵҖҙӗӦҕӶҜҘҶҞڗҕҜӦҕҷҏҲӒҖһҞӌӟӚҜӾҦҵҖүӦҕҬӋҺڗҕ

ӨӾӦҖҫڛҕӶ҉҄ҖڛҕӶ҉ҵҖүҙӦҖҘҝҖӢҶҫڛҕҽҵٙҖӪҖӫҞҶӏҫӽӱҶӫӒқұҖӽҷӶӡҶҫڛҕ

҄ҕұ҉ҝҕҳҖӴӾӧӒҵҖҙӗӦҕӶҗҕٸӦҕӬӢҕٸӽӻҟҪӡٸҞӿҟӦҕҜҪӶҶڛҕҝڔҧӒӭӷӣҟҺ

ҜӦҖҫӦҕҚҙһҘҜӧӫҟҫڛҕқҶӪҲڛҕҝҕҷҕҸҟӳړҕӶҖӴҞ҄ҖӛӢӜӓӆӰӒٙڔӇӚ҄ٽӿҒҕӷӳ

ҜӮҸҟڛҕۦӖ

ڒӬӫӃڛҕ҄ҕұڗҕӶҜӾӞӷҢӷڛҕڝӒӍҖӛҫӦҕڒٙҕҲӾҦٙҕҵҖӫңҟҺҕӼҵӶҲӦҕӜӾӏӯҟӦҕҲӓӽӶ

ҜҪӶҶڛҕ

ҶӋҮ

ӔӆӶӿӚҜӾҒҖҘҶӴӣӦҕҜӞҖӋӦҕҵұҖӃӪӨӢӔӆӶӰӪӠӟҫҟӦҕӶӨӃӛҘӬӞ

ҝҖӾӧӫӒ҄ҕҶҦҏӨҙӞҜҪӶҶӫӦҕӻӦҏҜӞҖӋӦҕӨӂӷҞӿҟӦҕͲӨӾӗҿҟӦҕәҖӟӽҏͲ

ӠӧӓҟӫӦҕӉҖӾҟҪړҕҕҴӴҘөҕҸҟӦړҕөҲӒӼұҎӽӭ҉ӰӣӫӽҜӮҖӾӃӦҕӶ҉ӄҫӛӦҕ

қҖӚӷӦҕӻӦҏӶ҉қҶӾӋҮҝҖҘҖӂҏҡӶҲҪӻӦҏҜӪڔһӦҖҘ

DANGER

oËr ócarter ÂeÉ riÉÇËeÉ ºe ¸ÂeÉÉËre graÌe oË ºe

mortƑºó¸rancher et ÌerroËiÂÂer ÂƠaÂimentation

óÂectriÇËe en ÆoÉitionܔArrôtܕaÌant toËt contrĥÂe oË

entretien

ҜӫӏҟӯڛҕҜӮҖӾӃӦҖҘөҖӾӟӦҕҚҧӽ܃қӷҦҶڛҕڒӬӫӃڛҕ҄ҕұڗҕӶҜӾӞӷҢӷڛҕڝӒӍҖӛҫӧӦ

ҜӪҸҪړҕӶҝҖҫҾҶڛҕӿӳҜӮҖӾӂҜӧҪҶӪӨӢڒҖӴӯӪӠӟҫҟӦҕҚҧӽӿҟӦҕڅҖӯӓӦҕ

ҵҖҙӗӦҕӶҜҘҶҞړҕҜӦҕҷҏӶӬӾҫҿҟӦҕұҕӷӪӶҝҖҟҙңڛҕӶӨӪҖҫڛҕӶ

ӰӪҜӒӷӯӃڛҕҜӂӷҘҲҪҕӶҹҖӟӪҜӾӣҙҿӦҕҝҖҫҾҶڛҕӿҞҋҞ

ӶRSFӨӽұӷڛҕӰӪҩӶҕҶڛҕڒҜӾҺҖӾӞқҵӷӃҘӨһӗӧӦҜӧҘҖӟӦҕӶөӷӾӯӪӷӦڗҕ

ҩӶҕҶڛҕӈӓҘڒҜӽҵҖӾҟҮҕҜӂӷҘ2ҹҖӟӪҝҖҫҾҶӪҲӽӶҸҞӰӣӫӽRSF

ҜӾӦҖңڛҕ҄ҖӛӣӦҕӨҦ҉ӰӪӼӷӯҺҹҖҺ҉ڝӒҝҖҫҾҶڛҕӜӾӏӯҞҚҧӽ

ӠӦҕҸӪӔҘҵڗҕӝҖҟӒҏӥڔҮӰӪҜҪӶҶڛҕ҄ҖӋӖӥҕҷҐҘړӶ҉ӬӞ܃ҝҖҫҾҶڛҕҜӦҕҷڙ

ӔӚҵӰӣӫӽӜӟһӦҕӰӒٙҕҲӾӓҘҖӴӓӚұڝӒҩҖӽҶӦҕӨӫӓҞӰӦҜӟӋӯӪڒ҄ҖӋӗӦҕӔӆ

ҳҕҳҵөҕҲүҟҺҕӰӣӫӽ܃ҜҙӖҶӦҕҲӯӒӥҲҟӓӪӜӏӯӪӥӷӧҫӪڒҖӴӧһӖӶҝҖҫҾҶڛҕ

ҬҾҶڛҕқ҄ҖӛӢқұҖӽҸӦӰҫҾҶڛҕҝҖӓӽҷӷҞӬӏӓӪڒӠӂړ

ӰӪҜӒҖҺ24ӨӢۧҞҶӪөҕҸҫӦҕҲҾӥҲӓӪӰӪӠӟҫҟӦҕҚҧӽ

ӭҕӶڗҕӰӒҶӣҙڛҕӜӧҟӦҕӬҧӯӽӤӦҳҲӓҘқҵҶӟӪҜӮҖӾӂҜӾӧӫӒӥڔҮӶӨӾӗҿҟӦҕ

ӰӒҲҒҕҷӨӣҿҘқұӶҲҿӪҠӮҖӢҕҳҏٙ҄ҕӷҺҵӷӾһӧӦҬӾҫӃӦҕۦӖҲҿӦҕӰӒҵӷӾһӧӦ

ڝӒҵӷӾһӦҕӨӾӗҿҟӦҚҺҖӯڛҕҲҿӦҕӸӷҟһӪӶҲҫӦҕӰӒҲҒҕҷӨӣҿҘҜҙҒҖҺӶ҉ҲҫӦҕ

әӶҶӎڒҵӷӾһӦҕӱҲӯӒӠӦҸӯҞړӼҴӦҕӻӮұڗҕҲҿӦҕұҕҲӒҏӷӳVәҶҪӨӣҾ

өҕҸҫӦҕәҕҶҫӮҕӭӷӣӽӭ҉Қҧӽ܃ӿҒҲҙڛҕҲҿӦҕқұҖӒڙқӶҵҴӦҕҝړҖҪڒҜӦӷӫҫӦҕ

өҕҸҪӸҲӪӨӣӦҜӂӷҘ1ܜ64

ﲑﺴﻟا داﺪﺘﻣا

ӌӗӆөҕҲүҟҺҕӥڔҮӰӪұҲҫӽӶ

ӜӃҟӯӪڒӥҲҟӓڛҕӔҙӂړҕ

ڝӓӚқҶӣҙӦҕҸӢҕҶӪۧҘҜӚҖһڛҕ

ӭӷӣӽӭ҉Қҧӽ܃ӥҖңڛҕӨӾҙҺ

ҕҳҏқӷӃҘ1ܜ2өҕҸҫӦҕәҕҶҫӮҕ

܃ҜӂӷҘ32өҕҸҫӦҕӸҲӪӭҖӢ

4ӨӣҿӦҕ

ﲑﺴﻟا داﺪﺘﻣا

64

= فاﺮﺤﻧﻻا

ӨӽҲӓҞӶӡҶҫڛҕҩӷӦӠӾӧӓҞۦӪҖһӪӤӚӥڔҮӰӪөҕҸҫӦҕҲҾӨӽҲӓҞӰӣӫӽ

ҜғӾӳڝӒRSFƭRSFҝҕҲҪӶҲӽҵӷҞӬҟӽҗӷӧӋڛҕӷҫӯӦҕڝӒӌҘҶӦҕۦӪҖһӪ

ٷӢ҉ҝҕҵҖӊҏӨҦ҉ӰӪҜӯӛӧҧӪӡҶҫӪҩҕӷӦ҉Ӷ҉ҜӾӧӋӪҜӽҳړӷӚӡҶҫӪҼӽұҕӷӞ

ҜӽҳړӷӚӡҶҫӪҼӽұҕӷӟҘқұӶҸڛҕҝҕҲҪӷӦҕڒөҕҸҫӦҕҲҾӨӽҲӓҟӦӡҶҫӫӧӦ

ӼұҶӛӦҕӿҙӦӷӧӦҕҵҖӫһڛҕӨӽҲӓҟҘҜӊҖһҙҘӬӞ܃ҜӮӷӳҲӪ

ӰӽҵҖһڛҕڔӢӨӽҲӓҞۧӓҟӽ܃ҜӯӛӧҧӪӡҶҫӪҩҕӷӦҋҘқұӶҸڛҕҝҕҲҪӷӧӦҜҙһӯӦҖҘ

ҲҾӨӽҲӓҞҲӓҘөҕҸҫӦҕӶқҶӣҙӦҕқҕҳҖҫӪӰӪӠӟҫҞҜӽӶҖһҟӪқҵӷӃҘۧӾҙӦӷӧӦҕ

ܞҝҖҫҾҶڛҕ

ܞҜӪҸҪړҕ

4ӨӣҿӦҕ

2ӨӣҿӦҕ܃өҕҸҫӦҕ

®

ӜӟһӦҕ ұҕҲӪҏ ҜҪӶҶӪ

8

Page 14

ӨӾӗҿҟӦҕӨҙӞҖӪҝҖӂӷҫӚ

ӿӮӶٸӣӦڙҕӨӾӂӷҟӦҕ

ҶӋҮ

ӔӆӶӿӚҜӾҒҖҘҶӴӣӦҕҜӞҖӋӦҕҵұҖӃӪӨӢӔӆӶӰӪӠӟҫҟӦҕӶӨӃӛҘӬӞ

ҝҖӾӧӫӒ҄ҕҶҦҏӨҙӞҜҪӶҶӫӦҕӻӦҏҜӞҖӋӦҕӨӂӷҞӿҟӦҕͲӨӾӗҿҟӦҕәҖӟӽҏͲ

ӠӧӓҟӫӦҕӉҖӾҟҪړҕҕҴӴҘөҕҸҟӦړҕөҲӒӼұҎӽӭ҉ӰӣӫӽҜӮҖӾӃӦҕӶ҉ӄҫӛӦҕ

қҖӚӷӦҕӻӦҏӶ҉қҶӾӋҮҝҖҘҖӂҏҡӶҲҪӻӦҏҜӪڔһӦҖҘ

DANGER

oËr ócarter ÂeÉ riÉÇËeÉ ºe ¸ÂeÉÉËre graÌe oË ºe

mortƑºó¸rancher et ÌerroËiÂÂer ÂƠaÂimentation

óÂectriÇËe en ÆoÉitionܔArrôtܕaÌant toËt contrĥÂe oË

entretien

ҝҖӫӾӧӓҞڜҏӔҦҵҕ܃ӨӃӛӯӪӨӣҿҘӔӚҲӦҕҝҕҲҪӶӶӡҶҫڛҕҝҕҳҝҕҲҪӷӦҕӰҫҿҞ

қҲҪӷӦҕқӷҙӒڒқұӷҦӷڛҕӡҶҫڛҕҠӾҙңҞ

ҜҪӶҶڛҕҜӧҧӒҵұ҉ҜӫӣҫӪҖӴӮ҉ӰӪҲӢҋҟӧӦӨӽҲӓҟӦҕӨӾӪҕӷӂӶҝҖҟҙңڛҕӨӢӄҫӛҞ

ҝҕҶӣҙӦҕқҕҳҖҫӪӰӪӠӟҫҞӨҮҕҲڛҕۧҘҖӳҸӢҶӫҞӶҜӽҶҫҘҖӴҞҵҕҲҟҺҕӭҖӫӇӦҲӾӦҖҘ

ӭӷӣҞӭ҉ҚҧӽҜӞҖӋӦҕҲӟӚӶҷҕҸҟӳړҕӶ҄ҖӆӷӇӦҕӶۦһӦҕӨӢ҇ҞҚӯҧҟӦҵӷӾһӦҕӶ

2ӨӣҿӦҕҶӏӮҕ܃ӼҳҖҫӪӨӣҿҘӶҜӽҷҕӷӪӡҶҫڛҕӶҜҪӶҶڛҕҝҕҶӣҘ

ҬӾҫӂ ҋӋҮ ҋӋҮ ҋӋҮ

ӠӧӓҟӽҖӫӾӚҜҪӶҶڛҕӡҶҫӪӔӪٙҖӟӚҕӷҟӪҜӞҖӋӦҖҘұҕҲӪڙҕҵҲӃӪӭӷӣӽӭ҉Қҧӽ

ұҕҲӪҏӌҮۦӚӷҞҚҧӽӤӦҳӰӒٙڔӇӚӿҘҶӴӣӦҕҵҖӾҟӦҕҜӓҺӶҜӧҪҶڛҕӶҜӾҟӦӷӛӦҖҘ

ҜӾӧҫڛҕҜӾӮӶٸӣӦڙҕۧӮҕӷӟӦҕӔӪӤӦҳӠӚҕӷҟӽӭ҉ҚҧӽҖӫӢҬӾҫӂӨӣҿҘӿҘҶӴӢ

ҜӾӯӊӷӦҕӶ

ҔӽҖӴӪڒٙҖӟҙһӪҩӷҟӛڛҕҚӟңӦҕٷӒҜӧӂӷڛҕҜӾҘҶӴӣӦҕӡڔҺڗҕӵӾҦӷҞҚҧӽ

ۧӓҟӽҜҪӶҶڛҕҠӾҙӪӨӛҺ҉ҩӷҟӛڛҕҚӟңӦҕӶܖٙҕҶӚӷҟӪӭҖӢҕҳҏܗӼҵҖӾҟҮړҕҗӷҙӮڗҕ

ӬҟӽҜӢҶҫҟڛҕҝҖӮӷӣڛҕӔӪӡҖӣҟҪҕҖӴӦҡҲҫӽړҜӾҘҶӴӣӦҕӡڔҺڗҕӭҖӣӪҲӽҲҫҞ

ӬҟӽӶ҉ܖөҲӞҕҳҏܗӼҵҖӾҟҮړҕҜӪڔһӦҕӨӃӚҩҖҟӛӫҘӿҘҶӴӣӦҕұҕҲӪڙҕӌҮӨӾӂӷҞ

ӡҶҫڛҕڜҏқٿҖҙӪӵӧӾӂӷҞ

ҝҖӮӷӣӪӔӪӨҮҕҲҟӦҕӔӯӪӨҦ҉ӰӪҜҪӶҶڛҕӨҮҕұӡڔҺڗҕҠӾҙңҞӬҟӽӭ҉ҚҧӽӶ

ҜӾӯӊӷӦҕӶҜӾӧҫڛҕۧӮҕӷӟӦҕӔӪӡڔҺڗҕӔӾӫҦӠӛҟҞӭ҉ҚҧӽӔӚҲӦҕқҲҪӶ

2ӨӣҿӦҕ

ӭҕҵӶҲӦҕҝҕҶӪұҲӒڝӒӥӷӃҫӧӦӔӯӃڛҕӔӆӶӠӚӶӡҶҫڛҕқҶӣҘۧӾӓҞӬҟӽ

ҬҟӚӶ҉ӝڔӖҏӠӽҶӊӰӒҖӴӇӛҮӶ҉ҜҪӶҶڛҕҜӒٹӔӚҵӰӣӫӽҜӟӾӞҲӦҕڒқұҲҫڛҕ

ۦӗҟӪӸӷҟһӫҘӭҖҞҷҸҫӪӭҖҞҶӣҘӌҙӇҞӭ҉ҚҧӽӨӽҲӓҟӧӦҜӧҘҖӟӦҕқҶӣҙӦҕӸҶҧӪ

құҖӽҷڜҏӼұҎҞҜҪӶҶڛҕҜӒٹڒқұҖӽҷӼ҉ҬҟӛӦҕҝҕҶӪұҲӒҼӛӮӔӪҖӟӚҕӷҟҟӦ

ҜӦӷӫҪҜӽۦҙӪ҉ӰӪӠӟҫҟӦҕٙҖӫҒҕұҚҧӽӡҶҫڛҕӰӪҜҘӷӧӋڛҕҜӾӮҖӃҫӦҕқҵҲӟӦҕڒ

ҜҪӶҶڛҕҜӒٹۦӾӗҞҲӯӒӔӯӃӦҕҜҪӷӦӜӾӯӃҟҘҖӴӮҵҖӞӶӡҶҫڛҕ

Ҳ

ҟ

Ӷ

Ӧ

ӽ

ҕ

Ҷ

ӼұҎҞҜҺҖһҪҜӦҋһӪқҵҖӋӦҕӭҕҵӶұӱҖҧҞҕӭҏ

ڜҏҔӊҖүӦҕӱҖҧҞړҕڒҵӶҲҞӿҟӦҕҜҪӶҶڛҕҜӧҧӒ

ӡҶҫڛҕڝӒӉҶӛڛҕӨӫҫӦҕӶӿҒҕӷӴӦҕӠӚҲҟӦҕӈӛҮ

ӰӪҜӧҧӓӦҕӭҕҵӶұӰӪӠҫҞӝҶҫӧӦҜӾӦҖӫҟҪҕӶ

қҸӾҦӶқٸӛӦҜӞҖӋӦҖҘқҲҪӷӦҕӨӾӂӷҞӥڔҮ

ҲӯӒӭҕҵӶҲӦҕӱҖҧҞҕҼӛӮڒҖٙҙӦҖӖӭҕҵӶҲӦҕӭӷӣӽӶ

ڒқҵҖӋӦҕӶҠӾҙڛҕҜӧңӪ҉ڝӒӔӧӊҕҥҶүڛҕ

3ӨӣҿӦҕ

҄ҕӷӴӦҕӠӚҲҞ

3ӨӣҿӦҕ

өҖӳ

ӭӶұӨӫҟӣӫӦҕөҖӏӯӦҖҘҖӴӞҖҫӦҏҕҳҏړҏRSFƭRSFҩӶҕҶӪӨӾӗҿҞҶӏҫӽ

ҡҲҫӽҲӞӶӨӫҫӦҕӉҶӚӰӪӡҶҫӫӦҕӿӮҖӓӽҲӟӚ܃ҚҺҖӯӪӿӣӾҞҖҟҺӌӗӆӨӫҪ

ӝҕҶҟҪҕ

7

ӜӟһӦҕ ұҕҲӪҏ ҜҪӶҶӪ

®

Page 15

ҜӞҖҿӦҕҜӪҲүӦҕҝҖҙӾӢҶҞڒҚӾӢٸӦҕ

өҖӳ

ӤӦҳӿӚҖӫҘܖSEORܗҝڔҧһӧӦҝҕ҄ҖҿӮڙҕҹҲӯӴӪӥڔҮӰӪӿҒҖӴӯӦҕӬӾӫӃҟӦҕҶӽҶӟҞӬҟӽӭ҉ҚҧӽҝҖӾӂӷҞұҶҧӪړҏӿӳҖӪҜӾӦҕҸӦҸӦҕҝҖӫӾӾӟҟӦҕҚӾӢҶҞҝҖӫӾӧӓҞ

ӨӣӾӴӦҕӻӧӒҸҦҖҫӦҕҚӾӢҶҞӶҸҦҖҫӦҕӻӧӒқҲҪӷӦҕҚӾӢҶҞӶҸҦҖҫӦҕ҄ҖҿӮҏҝҖҙӧӋҟӪ

ӰӒҝҖҟҙңӪܖ3ܗҜҢڔҢұӷҦӶөҸӧӽܐҸҦҖҫӦҕڝӒҜҪӶҶڛҕҚӾӢҶҞ

ҜӽӶҖһҟӪҖӴӯӾҘҜӚҖһڛҕӭӷӣҞӭ҉ҚҧӽҚӮҕӷҧӦҕӨӢڒҚӮҖҦӨӢ

RSF ҜһӧһӦҕ

1.25

1.25

ҸҦҖҫӦҕҜӽӶҕҷ

ҠӾҙңҟӦҕӔӆӷӪӨӾӂҖӛҞ

ӵӦұҖӓӽҖӪӶ҉ GPF Ӷ҉ SDP Ӷ҉ SD Өӽұӷڛҕ

ڈӞ҉ҲҫҘ (ӬӧӪ 610) ҜӂӷҘ 24 ӥӷӋӦҕ

ӜӟһӦҕҸҦҖҪ

ҜӟӾӞҲӦҕڒӭӷӦҖӖ 18

өӷҫӧӪӼҳړӷӚӨӣӾӳ

ۧҟӧҘҖӟҟڛҕۧҟӽҖӴӯӦҕڝӒҝҖҟҙңڛҕҲҦҕӷҟҞӭ҉ҚҧӽܐҜӃӯӪڝӒҸҦҖҫӦҕҚӾӢҶҞ

ӜӟһӦҕҸҦҖҪӜӟһӦҕҸҦҖҪ

ӤӽӷӢӿҟӧӾӳҵҖӫһӪ S.S. (ӬӧӪ 10) ҜӂӷҘ 3/8

(ӬӧӪ 64) ӻӮұ҉ҲҫҘҜӂӷҘ 2-1/2 ӌҘҵ

Өӊҵ 2000 ҜӮҖҺҶҮ

ӻӮұ҉ҲҫҘҜӂӷҘӨӣӦ

ӔӾҺӷҞҝҖҟҙңӪҜҢڔҢ

ҜӾӮҖҺҶҮҜӃӯӫҘҠӾҙңҞ ҜӽҳړӷӚҜӃӯӫҘҠӾҙңҞ

ӜӟһӦҕҸҦҖҪ

(ӬӧӪ 102) ӻӮұ҉ҲҫҘҜӂӷҘ 4

0.42 =ӿӒӷӯӦҕӭҷӷӧӦӻӮұڗҕҲҫӦҕ

ҹӻӃӳڟҙܒҞӃҳӫӪܒҵҶүڟҙ ܒԃӖӻӳӪҙܒӱһӻӪҙ = G

҄ҖӯҙӦҕҚҿҮ

ӿӫҺړҕӤӫһӦҕ

ҚҿүӦҕҠӾҙңҞ

ҜӂӷҘ 1/2 ӻӮұҕҲҫҘ -14 ҜӂӷҘ 1/4 ҚӟңӦҕӿҞҕҳҵҖӫһӪ

Ӷ҉ (ӬӧӪ 3) ҜӂӷҘ 1/8 ӤӫҺ

ҜӂӷҘ 3/8 ҹҖӟӪҜؿҺҕҲҺҹ҉ҶҘӿҙӦӷӦҵҖӫһӪ

ӥӷҮҲӦҖӾӮҲӦҕҜӚҖһڛҕӶ (ӤӮҸӦҖҘۥӋӪ) (ӬӧӪ 10)

(ӬӧӪ 76 ) ҜӂӷҘ 3 ӭҖӯҺڗҕ

ҸҦҖҫӧӦ

ҜӾҙӦӷӧӦҕҖӯӯһڛҕӰӪ (ӬӧӪ 13)

ӜӟһӦҕӭӷӦҖӫҦ

ӻӮұ҉ҲҫҘӭӷӦҖӖ 12

ۤҖӫҦڙҕ

ҝҖҟҙңڛҕ

ҝҖҟҙңڛҕұҲӒ

ҚӮҖҦӨӢڒ

ҜҪӶҶڛҕҹҖӟӪ

ۤҖӫҦҏ

ҝҖҟҙңڛҕ

ҝҖҟҙңڛҕұҲӒ

ҚӮҖҦӨӢڒ

36120܃100܃ˀ036

481ʼ048

ʼ10200܃180ʼ10

36200܃100܃ˀ036

481ʼ048

ʼ10200܃180ʼ10

36120܃100܃ˀ036

481ʼ048

ʼ10200܃180ʼ10

ҜӾҞҕҳӿӖҕٷӦҕҹҖӟӪ

ҠӾҙңҟӦҕӶҚӟңӦҕ

ҜӂӷҘ3ܜ8ҹҖӟӪ

14ܞҜӂӷҘ1ܜ4

ҜӂӷҘ3ܜ8ҹҖӟӪ

34ܣ34ڜҏ26ܣ26

ܖӬӧӪ864ܣ864ڜҏ660ܣ660ܗ

40ܣ40

ܖӬӧӪ1016ܣ1016ܗ

ʼ2ܣʼ2ڜҏ46ܣ46

ܖӬӧӪ1321ܣ1321ڜҏ1168ܣ1168ܗ

34ܣ34ڜҏ26ܣ26

ܖӬӧӪ864ܣ864ڜҏ660ܣ660ܗ

40ܣ40

ܖӬӧӪ1016ܣ1016ܗ

ʼ2ܣʼ2ڜҏ46ܣ46

ܖӬӧӪ1321ܣ1321ڜҏ1168ܣ1168ܗ

34ܣ34ڜҏ26ܣ26

ܖӬӧӪ864ܣ864ڜҏ660ܣ660ܗ

40ܣ40

ܖӬӧӪ1016ܣ1016ܗ

ʼ2ܣʼ2ڜҏ46ܣ46

ܖӬӧӪ1321ܣ1321ڜҏ1168ܣ1168ܗ

қҲӽҲҿӦҕҩҖӽҶӦҕҝҖӫӾӾӟҞҜӾӦҕҸӦҸӦҕҝҖӫӾӾӟҟӦҕ

ҜҪӶҶڛҕҹҖӟӪҸҦҖҫӦҕ҄ҖӋӖҹҖӟӪ

120܃100܃ˀ0

1ʼ0

200܃180

120܃100܃ˀ0

1ʼ0

200܃180

120܃100܃ˀ0

1ʼ0

200܃180

ܖٸӫӾӧӧڛҕܗ

ҜӂӷҙӦҖҘұҖӓҘڗҕӨӢҚһҫҞ

Ҭӧһڛҕ

ҚӧӃӦҕ

ҚҿүӦҕ

®

ӜӟһӦҕ ұҕҲӪҏ ҜҪӶҶӪ

6

Page 16

ҚӾӢٸӦҕ

ӔӚҶӦҕ

ڒҠӾҙңҟӦҕҝҖҫҟӚӥڔҮӰӪөҖӣҪҐҘҖӴҟҙҢӶҖӴӦұҲҫڛҕӭҖӣڛҕڜҏҜҪӶҶڛҕӡҶҪ

ҜӮӷӣڛҕұҕӷڛҕӤӫҺڝӒҕٙұҖӫҟӒҕҝҕӷҿҫӦҕөҕҲүҟҺҕөҸӧӽҲӞӶҜҪӶҶڛҕқҲӒҖӞ

҄ӼҖӴӪӝҖҫӦҏӬҟӽ܃ҚӾҘҖӮ҉ұӷҦӶҚӧӋҟҞӿҟӦҕҝҖӪҕҲүҟҺړҜҙһӯӦҖҘӜӟһӧӦ

ҚӾӢҶҞӨҙӞҖӴӮҖӣӪڒҚӾҘҖӮڗҕҜӣҙҾӬӣҫӽӶܖٙҕҶӚӷҟӪӭҖӢҕҳҏܗӼҵҖӾҟҮҕҚӾҘҖӮ҉

ӜӟһӦҕҚӾҘҖӮ҉ҜӣҙҾӶҸҦҖҪӔӪӼұҖӾҟӒҕҚӾӢҶҞӿӮҖӾҙӦҕӬҺҶӦҕӅҶӓӽқҲҪӷӦҕ

ҸӾӴҧҟӦҕҜӟҙһӪ

ӬӣҫҞӿҟӦҕҝҖӊҖӟҺҜӓҘҵ҉ҝڔӚҏӥڔҮӰӪӡҶҫڛҕҜӚҶӖڜҏӥӷӂӷӦҕӰӣӫӽ

ٙҕҲӾӓҘҖӴӓӚұڝӒҩҖӽҶӦҕӨӫӓҞӰӦҜӟӋӯӪڒ҄ҖӋӗӦҕӥҕҲҙҟҺҕҚҧӽ҄ҖӋӗӦҕҠӾҙңҞ

ӜӟһӦҕӰӒ

ӿҦҳӷӫӯӦҕҚӾӢٸӦҕ

ҚӟңӦҕҜӟҙһӪҚӾӢҶҟӦҕҝҖҫҟӚ

қҲӒҖһӫӧӦҜӂӷҘ 2-1/2 ҜӚҖҪӶ

.ҚӾӢҶҟӦҕӿӚ

(ӰӽҶҮڕҕӨҙӞӰӪ) ҚӾҘҖӮڗҕҜӣҙҾ

(ҵҖӾҟҮҕ) ҚӾҘҖӮڗҕҔӽҖӴӪҬӫһӽ

ӨҙӞҖӴӦҖӫӢҏӬҟӽӭҋҘҚӾҘҖӮڗҕҜӣҙҿӦ

.ҸҦҖҫӦҕӻӧӒқҲҪӷӦҕӔӆӶ

ӜӟһӦҕҸҦҖҪ

1ӨӣҿӦҕ

ӶRSFҩӶҕҶӪӔӚҵҚҧӽ

ӝҖҫӦҏҚӯҧҟӦҜӽҖӯӓҘRSFP

ӨӽұӷӫӧӦҜӧһӯӦҖҘҠӾҙڛҖҘҵڌӦҕ

қҸӴҦ҉ҜӓҘҵ҉ӝҖҫӦҐҘӬӞ܃RSF

ӨӢҲҦӷӽӶӿҦҵҖүӦҕҠӾҙڛҕҠҫҞ

ӷӳҖӫӢٽ҉ҶӦҕӜӃӦҕӨӛҺ҉ҷҖӴҦ

ҖӯӳӰӪӔӚҵҕ

ҖӯӳӰӪӔӚҵҕ

ӔӚҶӦҕқҸӴҦ҉ӑҖһҞҕӨӟӽړҚҧӽ

1ӨӣҿӦҕڒӔӆӷӪ

ҠӾҙڛҕҚӯҧҟӦҝҖӂӷҘ3ӰӒ

ҜӾӮҲӓڛҕҬҒҖӛӃӦҕӰӪӑӷӯӃڛҕ

ӿҦҵҖүӦҕҠӾҙڛҕҸӢҶӪӰӪҗҶӟӦҖҘRSFӨӽұӷڛҕӔӚҶҞړ

ҜҪӷӧӦҕӨӛҺ҉ӨӞڗҕڝӒӔӚҵқҸӴҦ҉ҜӓҘҵ҉ӝҖҫӦҐҘӬӞRSFPӨӽұӷӫӧӦҜҙһӯӦҖҘ

ҜӽӷӴҞҜҫҟӛҘұӶҸڛҕҠӾҙڛҕҜӽӶҕҷӰӪҗҶӟӦҖҘҷҖӴҦӨӢ܃ҜӽӷӴҟӦҕҜҫҟӚҝҕҳ

ӿӫҺړҕҲӫүڛҕӬҧҪ

ӿӚӜӾңӣҟӦҕҝҕӶұ҉Ӷ҉қҲҪӷӦҕӔӚҶӦқҲҟӫӪқҲӒҖӞұӷҦӶөҸӧӽҲӞ ܃ӘӦҖҘӿҧӧҢӠӫӓӦӅҶӓҟӦҕҜӦҖҪӿӚ ܐҜӏҪڔӪ

ӬҧҪәҶӓӪ

җӷҙӮڗҕ

.ӈӾӪӷӦҕӶӜӟһӦҕӥҖӫӒ҉ӭӶұӿҦҵҖүӦҕҸҦҖҫӦҕҲӓҘӷӳӅӶҶӓӫӦҕӵҘӻӂӷӫӦҕҸҦҖҫӦҕӬҧҪ dž

ӜӟһӦҕҜҫҟӚ

ҖӴҘڇӷڛҕ

1

24

⁄2(381) 15(305) 12(305×305) 12 × 12

1

28

⁄2(432) 17(356) 14(356x356) 14 × 14

1

32

⁄2(533) 21(457) 18(457×457) 18 × 18

ܖ

ٸӫӾӧӧڛҕ

ܗҜӂӷҙӦҖҘұҖӓҘڗҕӨӢҚһҫҞ

ҜҪӶҶڛҕҹҖӟӪdžҸҦҖҫӦҕӬҧҪ

RSF/RSFP-90(662)

RSF/RSFP-100(724)

RSF/RSFP-120(826)

RSF/RSFP-150(978) 381⁄2(584) 23(508) 20(508×508) 20 × 20

RSF/RSFP-180(1130) 441⁄2(737) 29(660) 26(737×737) 26 × 26

RSF/RSFP-200(1283) 501⁄2(838) 33(762) 30(838x838) 30 × 30

.ҚӾҘҖӮڗҕҜӣҙҾ

5

ӜӟһӦҕ ұҕҲӪҏ ҜҪӶҶӪ

®

Page 17

ҝҖӽӷҟҫڛҕӥӶҲҦ

7 . . . . . . . . . . . . . . . . . . . . . ӿӮӶҶҟӣӦڙҕӨӾӂӷҟӦҕ

7 . . . . . . . . . . . . . . . . . . . ӨӾӗҿҟӦҕӨҙӞҖӪҝҖӂӷҫӚ

8 . . . . . . . . . . . . . . . . . . . . . . .ҜӾӯӾҞӶҶӦҕҜӮҖӾӃӦҕ

ˀ . . . . . . . . . . . . . . . . . . . . . . . . ҄ҕҸҦڗҕҜӫҒҖӞ

10. . . . . . . . . . . . . . . . . . . . . . . . ҜӮҖӾӃӦҕӨҧҺ

10. . . . . . . . . . . . . . . . . . . . . . . . . . . ҖӯӪҕҸҟӦҕ

қҲҪӷӦҕқҲӒҖӞ

J

F

J

G

A

H

2 . . . . . . . . . . . . . . . . . . . . ҜӪҖӓӦҕҜӪڔһӦҕҝҖӪӷӧӓӪ

3 . . . . . . . . . . . . . . ӰӽҸүҟӦҕӶҜӦӶҖӯӫӦҕӶӘӽҶӛҟӦҕӶөڔҟҺړҕ

3 . . . . . . . . . . . . . . ӰӽҸүҟӦҕқҶҟӚӥڔҮҜӮҖӾӃӦҕӶӄҫӛӦҕ

4 . . . . . . . . . . . . . . . . . . . . . . . . ұҖӓҘڗҕҝҖӮҖӾҘ

ʼ . . . . . . . . . . . . . . . . . . . . . . . . . . . ӔӚҶӦҕ

ʼ . . . . . . . . . . . . . . . . . . . . . . . . . . ҚӾӢҶҟӦҕ

6 . . . . . . . . . . . . . . . ҜӞҖҿӦҕҜӪҲүӦҕҝҖҙӾӢҶҞӿӚҚӾӢҶҟӦҕ

ұҖӓҘڗҕҝҖӮҖӾҘ

RSF

B SQ.

C

D

1

ҜӂӷҘ 2

/2

SQ.

A

ӭҕҷӶڗҕ

RSFRSFP

145126

173146

22ʼ180

3362ʼ0

40028ʼ

620431

ҝҕҵҖӊҏ

ҜӽӷӴҞҜҫҟӛҘ

RSFP

3

3

4

ʼ

ʼ

6

ܖ4ܗ16ܣ2ʼ

(4) 16×20

ܖ406ܣʼ08ܗ

ܖʼ08ܣʼ08ܗ

ӼҵҖӾҟҮړҕҗӷҙӮڗҕҔӽҖӴӪ

M

L

SQ.KSQ.

M

M

K

L

MӿӫҺړҕҬҾҶڛҕ

1

8

7

1

8

18

1

1

4

32

RSFP

BL SQ.

CL

D

1

ҜӂӷҘ 2

/2

A

SQ.

ҹҖӟӪ

A

B

BL

CCLDFGHJ

1

3

1

1

7

1

1ʼ

16

2

10

8

8

16

13

16

4

8

10

ܖ

2ˀ

ӬҧӢ

8

27

ܗӨӊҵܖ

4

ٸӫӾӧӧڛҕ

1

8317823142ʼ381014121410347ʼ867824121214618ܖ4ܗ12ܣ20

1

83ʼ7823142ʼ38101413ʼ81178ˀ116831628121414718ܖ4ܗ12ܣ2ʼ

1

7

8

8

3ˀ

1

845783114333810141918161⁄2111⁄4107⁄1638122014918(8) 16×20

1

8ʼ17834143ʼ38121422121ˀ121018113444122614ˀ

1

8ʼ83163ˀ144038121423142ʼ1413381438ʼ01230141018ܖ8ܗ20ܣ2ʼ

ܗҜӂӷҙӦҖҘұҖӓҘڗҕӨӢҚһҫҞ

(660)(892)(810)(591)(645)(260)(311)(273)(194)(175)(662)(311)(156)(305×508)(66)(57)

(762)(1045)(911)(591)(645)(260)(346)(302)(230)(208)(724)(362)(181)(305×635)(78.5)(66)

(864)(1197)(1013)(692)(746)(260)(410)(352)(256)(227)(826)(464)(181)(406×635)(102)(82)

(1016)(1349)(1165)(794)(848)(260)(486)(419)(286)(265)(978)(514)(232)(406×508)(152)(113)

(1168)(1153)(1318)(870)(899)(311)(571)(495)(257)(298)(1130)(667)(232)(4) 20×20(181)(129)

(1321)(1857)(1478)(997)(1026)(311)(591)(641)(340)(365)(1283)(768)(257)(508×635)(281)(196)

ҜҪӶҶڛҕ

263ʼ

90

3041

100

3447

120

40 53

150

4661

180

ʼ273

200

®

ӜӟһӦҕ ұҕҲӪҏ ҜҪӶҶӪ

4

Page 18

ӝӷӚ

ܖӬӪ8ˀܗ

ҜӂӷҘ3½ӰӒҖӴӒҖӛҞҵҕӨӟӽړҜӚҖһӫҘқҲҪӷӦҕӭҸүҞӭ҉Қҧӽ

ҩҕӷӦڗҕӶ҉ҜҘӷӊҶӧӦӔӮҖڛҕӝҵӷӦҖҘқҖӋӗӪҜӾҙҿҮҚӦҕӷӞڝӒӔӆӷҞӭ҉ӶҜӾӆҵڗҕ

ӥӷӊڝӒӶ҄ҕҸҦڗҕۧҘҝҕҶӫӪۦӚӷҞҚҧӽۧӧӾңӽҏۤӷҙӦҖҘқҖӋӗڛҕҜӾҙҿүӦҕ

ҜӯӽҖӓڛҕӨҦ҉ӰӪӔһҟӪ҄ҖӟҘڙӶ҄ҕӷӴӦҕҶӽӶҲҟҘҩҖӫһӧӦӭҕҵҲҧӦҕ

ҝҖӪҕҲүҟҺڔӦҜӫӫӃڛҕҩӶҕҶӫӧӦӰӣӫӽӸӷӃӟӦҕқҵӶڌӦҕҜӦҖҪڒܞٙҖӾҦҵҖҮ

ӥӷҮҲӦҝҕҶӫӪӶ҉ӝҶӊۦӚӷҞҚҧӽҥҵҖүӦҕڒҖӴӯӽҸүҞӬҟӽӭ҉ҜӾҦҵҖүӦҕ

ҜӢҶҫҟڛҕҚҫһӦҕҝҕҲӓӪӶҝҖӓӚҕҶӦҕ

Ӭҟӽӭ҉ҚҧӽҜҪӶҶڛҕڜҏ҄ҖڛҕҗٺҞӔӯڛӼӷҟһӪҬӋҺڝӒҜҪӶҶڛҕӔӆӶҚҧӽ

҄ҖڛҕӸӷҟһӪӰӪڝӒ҉ӻӟҙҟӦҜӾҙҿүӦҕҚӦҕӷӟӦҕӰӪٜәҖӢٜұҲӒڝӒҜҪӶҶڛҕӔӚҵ

ҖӫҘқҲӒҖҙҟӪ҄ҕҸҦڗҕ҄ҖӟҘҐҘӬӞқӷҮҵҜӾӆҵ҉ڒҜҪӶҶڛҕӥӶҸӮӔӯӫҟӦӶҨӧңӦҕӶ

ҜӯӽҖӓڛҖҘҬӫһҞҜӚҖһӪӡҖӯӳӭӷӣӽҤӾҫҘӶҼӫҿӦҕ҄ӷӆӶ҄ҕӷӴӦҕҶӽӶҲҟӦӿӛӣӽ

ӻҟҪҜӓӮҖӪҝҖӪҖӒұڝӒҜҪӶҶڛҕ҄ҕҸҦ҉ҜӚҖӢҸӢҵ҄ҖڛҕӬӢҕҶҞӰӪӨӧӟҟӦҜӽҵӶҲӦҕ

ҖӴӯӒҕٙҲӾӓҘҵҖӋӪڗҕӱҖӾӪҶӫҞ

ҜҘӷӊҵӜңӣҞҚҙһӽӤӦҴӚҜҿӫӞڗҖҘӶ҉ҜӾӣӾҟҺڔҘҜӾӋӖҋҘ҄ҕҸҦڗҕҜӾӋӗҟҘӬӟҞړ

ۧүһҟӦҕӶҲӽٷҟӦҕҝҕҵӶұٷӒҵҖڛҕ҄ҕӷӴӦҕ

ҜӽӷӟӦҕҩҖӽҶӦҕۦҢҋҟҘҖӴӮҕҵӶұӔӯڛҜҪӶҶڛҕҝҕҵҖӊӥҖӛӞҏҚҧӽ

ӰӽҸүҟӦҕқٸӚӥڔҮҜӮҖӾӃӦҕӶӄҫӛӦҕ

ҝҖӾӧӫӓӦӨҧһҘӐӛҟҪҕӰӽҸүҟӦҕқٸӚӥڔҮҶӴҾӨӢқҶӪҩӶҕҶڛҕӄҫӛҟҘӬӞ

ҖӳҍҕҶҦҏӬҞӿҟӦҕӄҫӛӦҕӶҜӮҖӾӃӦҕ

ҵҲӃڛҕҲӽҲҫҞҚҧӽҜҘӷӊҶӦҕӶ҉ҭҖҺӶژӦҝҖӫӢҕҶҞڝӒҵӷңӓӦҕӬҞӥҖҪڒ

ӨӢڒқҶӪқڀӒҼӫҮӻҟҪҝҕҶӪڀӒӰӪҖٙӽӶҲӽқҵҖӋӦҕҶӽӶҲҟҘӬӞӵҟӦҕҷҏӶ

҉ҲҘҕҳҏӨӪҖҫڛҕӶӡҶҫڛҕڒҠӾӽҸҟӦҕӶӬӾҫҿҟӦҕұҕӷӪӑҷӷҟҞӿӣӦ܃ӄҫӚҜӾӧӫӒ

ҽӷҞҶӦҕӈӓҘ҄ҕҶҦҏҵҖҙҟӒړҕۧӓҘҴҮڗҕҚҧӽӜӧҟӦҕӿҦҵҖүӦҕ҄ڔӋӦҕڝӒҶӴӏӽ

ҝҖӾӯӟҞҜӂҖүӦҕҜӾҦҵҖүӦҕҜӟҙӋӦҕҝҕҳҩӶҕҶڛҕӈӓҘҚӧӋҟҞ҄ڔӋӦҕқұҖӒҏӶ҉

ҬӾӧӃҟӦҕӶ҉ҽӷҞҶӦҕ҄ҕҶҦҏҜӾӧӫӓӦҜӂҖҮ

ӿӗҙӯӽ܃҉ҲӃӧӦӔӮҖӫҘқӷһӣڛҕҜӢҶҫҟڛҕ҄ҕҸҦڗҕڒ҉ҲӃӧӦҶҢ҉ұӷҦӶӥҖҪڒ

҉ҲӃӧӦҜӓӮҖڛҕҜӾӧӂڗҕҜӟҙӋӦҕҜӦҕҷҐҘҵӷӛӦҕڝӒӬӞҜӒٺҘқҲӾҦҜӦҖҪڜҏҖӴҞұҖӒҏ

ӰӪҜӾӦҖҮҽҖӫӞҜӓӋӞөҕҲүҟҺҖҘӜӾӏӯҟӦҖҘӬӞӬҢҜӾӦӶٸҙӦҕҝҖҙӽҴڛҕөҕҲүҟҺҖҘ

қҶӛӯӃӦҕӝҵӶӶ҉ӬӒҖӮҗӷҢөҕҲүҟҺҖҘҬӋһӦҕӰӒ҉ҲӃӦҕҖӽҖӟҘӤҫҘӬӞҶҘӷӦҕ

өҕҲүҟҺҖҘӜӾӏӯҟӦҖҘӬӞҬӋҺڗҕҜӽҵҕҶӫҟҺҕӜӧҟҞړҠӽҸӦҕӶӬӒҖӯӦҕ

ڒҜҘӷӓӂҝҲҦӶҕҳҏӵӦұҖӓӽҖӪӶ҉Te c t y l

®

ʼ06ܖAÉhlanº ncܗ

өҕҲүҟҺҕӤӯӣӫӽӔӋӟҟڛҕөҕҲүҟҺړҕҜӦҖҪڒӶ҉ҜӾӧҮҕҲӦҕҬӋҺڗҕڜҏӥӷӂӷӦҕ

ӤӦҳҔӚҖӣӽҖӪӶ҉Dܞ40®Ӷ҉܃҉ҲӃӧӦҜӓӮҖڛҕTe c t y l®ʼ11M

ӰӽҸүҟӦҕӰӪҥҕҶҮڙҕҜӾӧӫӒ

ӭ҉ҚҧӽӿҒҖӴӯӦҕҖӴӓӞӷӪڒҖӴҙӾӢҶҞӬҟӽӿӣӦӰӽҸүҟӦҕӰӪҩӶҕҶڛҕҥҶүҞҖڛҖҪ

ҜҪӶҶڛҕӨӾӗҿҞۧҫӦҜӟӽҶӋӦҕҼӛӯҘҜӎӷӛҫӪӶҜӾӫҫӪӻӟҙҞ

өڔҟҺړҕ

ڜҏӑӷҦҶӦҕӥڔҮӰӪڅҖӯӓӦҕӔӾӫҦұٹӰӪӠӟҫҟӧӦӵӃҫӚҕ܃ҷҖӴҧӦҕөڔҟҺҕҲӯӒ

ӨҙӞӰҫҾҜӮӷҞҶӢӶ҉ӝӶҲӯӂӨӢӄҫӛҟҘӬӞҜғҙӓҟӦҕҜӫҒҖӞӶ҉ӬӾӧһҟӦҕӥҖӃӽҏ

ӵӾҙӯҟҘӬӞӰҫҿӦҕ҄ҖӯҢ҉ҡҲҪӜӧҞұӷҦӶөҲӒӰӪҲӢҋҟҟӦөڔҟҺړҕڝӒҜӟӚҕӷڛҕ

ӜӧҟӦҖҘҵҖӓҾҏӨӾҧһҟҘӨӾӫӓӦҕөӷӟӽҖӴӚҖҿҟӢҕӬҟӽҵҕڋ҉ӼҋҘӨӟӯӦҕҜӢٿ

ӝҲӃҞӿҟӦҕӰҫҿӦҕқҵӷҞҖӚҰһӮӨӢӶӬӾӧһҟӦҕӥҖӃӽҏڝӒܖڅҖӯӓӦҕӄӟӮӶ҉ܗ

ҵӷӛӦҕڝӒӨӃҞҕ܃ӜӧҞұӷҦӶҜӦҖҪڒҖӴӾӧӒӔӾӞӷҟӦҖҘӰҫҿӦҕҜӢٿҖӴӾӧӒ

Greenheck FanҜӢٿӭҏӵӓӪӨӪҖӓҟҞӼҴӦҕGreenheckҗӶҲӯӫҘ

өڔҟҺړҕӥӷҙӞҲӓҘқҲҪӷӦҕڒҡҲҫӽҵڋӼ҉ӰӒҜӦӶҎһӪҠһӾӦ

ӘӽҶӛҟӦҕ

ӄӟӮҜӦҖҪڒӵӪڔҟҺҕӬҞچӯӒӨӣӦҜӽҵӶڌӦҕ҄ҕҸҦڗҕӔӾӫҦөڔҟҺҕӰӪҲӢҋҞ

ҜӃӞҖӯӦҕ҄ҕҸҦڗҕҲӽҵӷҞҚӾҞٸӦӤӦҴҘۥҫڛҕҜӢڀӦҕӨңӫӪӕڔҘҐҘӬӞ܃چӯӒӼ҉

ҵӷӪ҉ҚҙһҘҖٙҪҖҟӪҕٙҶӪ҉қҲҪҕӶٙҜӓӚұқҲҪӷӦҕڅҖӯӒҜӚҖӢӰҫҾӭӷӣӽړҲӞ

ҜӾӧӫӒҲӾӢҋҞӭӷӣӽӭ҉ҚҧӽҜӯҪҖҿӦҕҜҪҖһӪӶӨӟӯӦҕҜӧӾҺӶҶӚӷҟҘӠӧӓҟҞ

ӰҫҿӦҕҜӃӾӦӷҙҘҜӮӶҲڛҕڅҖӯӓӦҕڝӒӌӟӚҕٙҵӷӃӟӪӰҫҿӦҕܖҝҖӾӧӫӒܗ

ӨӪҖӓҟӦҕ

ҲӯӒҜӟӦҸڛҕӶ҉ҜӪҲӟڛҕӔӚҶӦҕҼӽұҕӷӞӥڔҮӰӪҖӴӧӟӮӶҩӶҕҶڛҕҸӾӴҧҞҵҶӟڛҕӰӪ

ӬҟӽӬҧҫӦҕӶӨӽұӷڛҕәڔҟҮҖҘҼӽұҕӷӟӦҕӭҖӣӪӜӧҟүӽҜӾӢӷҾҜӓӚҕҵөҕҲүҟҺҕ

҄ڔӋӦҕӿӏҿҞӶ҉ҽҲүӧӦӅҶӓҟӦҕӰӪҖӴӾӧӒӍҖӛҫӧӦҚҺҖӯӪӷҫӯҘҖӴӓӪӨӪҖӓҟӦҕ

ӨӢ҇ҟӦҕҜӪӶҖӟӪڝӒҜҪӶҶڛҕқҵҲӞӰӪӨӧӟӽӭ҉ҵڌҟڛҕ҄ڔӋӧӦӰӣӫӽ

ҜӽҖӫҪ҄ҖӋӖӶ҉ӡҶҫڛҕӶ҉ҜҪӶҶڛҕҠӾҙӪӶ҉ұӷӫӓӦҕӥڔҮӰӪҩӶҕҶڛҕӔӚҵҶӏҫӽ

ҝҖӟҫӧڛҕӶ҉ҸҦҖҫӦҕӶ҉ۦһӦҕ

ӰӽҸүҟӦҕ

Ӷ҉ҚӾӢҶҞӰӪӰӣӫҟӦҕөҲӒӥҖҪڒӰҫҿӦҕҜӾӧӫӒ҄ҖӯҢ҉ӜӧҟӦҕӰӪҩӶҕҶڛҕҜӽҖӫҪӬҞ

ӜӧҞӭӶұҜӦӷӧӾҫӧӦҵҴҫӦҕӶҝҖӊҖӾҟҪړҕҴҮ҉Қҧӽ܃ҵӷӛӦҕڝӒқҲҪӷӦҕӨӾӗҿҞ

ҖӴҞҖӟҫӧӪӶҜҪӶҶڛҕڝӒӍҖӛҫӦҕҜӾӦӶҎһӪөҲүҟһڛҕӨӫҫҟӽӰӽҸүҟӦҕӥڔҮқҲҪӷӦҕ

қҲҪӷӦҖҘӠҫӧӽӜӧҞӼ҉ҜӾӦӶҎһӪҜӓӯӃڛҕҜӴҧӦҕӨӫҫҟҞӰӦӰӽҸүҟӦҕқٸӚӥڔҮ

өҲүҟһӫӧӦӨӾӴһҞҜӧӾҺӷӢӌӟӚҜӪҲӟӪҝҖҪҕٸӞړҕӱҴӳӰӽҸүҟӦҕқٸӚӥڔҮ

ڝӒ܃ҜӟӧӗӪӰӢҖӪ҉ڒӭӷӣҞҖӴҞҖӟҫӧӪӶҩӶҕҶڛҕӰӽҸүҟӦҜӾӦҖңڛҕҜғӾҙӦҕܞҖӾӧҮҕұ

ӥӷҮұӔӯڛӥӶҸӓӪӭҖӣӪڒӶҜӇӛүӯӪҜӽӷҦҜҘӷӊҵӸӷҟһӫҘӶҜӓӛҞҶӪҜӾӆҵ҉

30ۧҘқҵҕҶҫӦҕҝҖҦҵұӝҖһҞҕڝӒӍҖӛҫӦҕӬҟӽӭ҉ҚҧӽҨӧңӦҕӶ҉ҶӋڛҕӶҵҖҙӗӦҕ

ڒқҲӽҲҿӦҕҝҕۦӗҟӦҖӚ

ӭ҉ҚҧӽҜӾӮҲӓڛҕҝҖӮӷӣڛҕͲӝҶӓҞͲӶӜҢҖӣҟӦҕҚҙһҞӭ҉ӰӣӫӽқҵҕҶҫӦҕҝҖҦҵұ

ӨҙӞҖӴӛӾӛҧҟӦҖӴҫһӪҕӬҢҨӧңӦҕӶҲӾӧҧӦҕӶ҄ҖڛҕӶҭҖҺӶژӦҝҖӫӢҕҶҞӼ҉ҜӦҕҷҐҘӬӞ

құҵҖҙӦҕ҄ҕҸҦڗҕӑұҜӾӮҲӓڛҕ҄ҕҸҦڗҕͲӝ٠ҶӓҞͲӸұҖӛҟҞӿӣӦۥҮҕҲӦҕӰӽҸүҟӧӦҖӴӧӟӮ

ӭҖүҺөҕҲүҟҺҖҘӬӞҝҖӽӷҟҫڛҕӶ҄ҕҸҦڗҕӜӛҧҞӿӣӦҜӚҶӗӦҕқҵҕҶҪҜҦҵҲӦӨӃҞ

ӈӓҘҜӢӷӣӛӪҜӾӋӖڗҕӡҶҞҕҜҘӷӊҶӧӦӬӢҕҶҞӼ҉ӰӪӄӧүҟҟӦӨӟӯҟӪӿҒҖҘҶӴӢ

ܖҜӽӷғӪҜҦҵұ43ڜҏ1ܞܗ

ҠӽҖӴӮҶӴӚҜҦҵұ110ڜҏ

ӜӾӏӮӶәҖҦӷҦڒӶӨҮҕҲӦҕڒҝҖӟҫӧڛҕҜӚҖӢӭҸүҞ

ҜӽҵӶҲӦҕҜӯӽҖӓڛҖҘҩҖӫһӧӦҖٙӇӽ҉Ӷ҄ҕӷӴӦҕҶӽӶҲҟҘҩҖӫһӧӦ҄ڄӦҕ

3

ӜӟһӦҕ ұҕҲӪҏ ҜҪӶҶӪ

®

Page 19

RSF/RSFPӨӽұӷڛҕ

ӱҴӳӬӾӫӃҞӬҞۦһӦҖҘӨӫӓӽӼҴӦҕӑӷӯӦҕӰӪҩӶҕҶӪӵҘRSF/RSFPӨӽұӷڛҕ

ӻҟҪ҄ҕұڗҕҝҕҵҲӞҩӶҕٸҞҜҫҾҶڛҕӜӟҺڗҕҝҕұҕҲӪҏҝҖӪҕҲүҟҺڔӦҖٙӃӾӃҮҩӶҕҶڛҕ

ҜӂӷҘ20

RSFܜҩӶҕҶӪҶӚӷҟҞҠҘҖңӦҕӌӗӇӦҕӰӪܖ

ӔӯӂҜҪӷӦҜҪӶҶӪӨӢӨӫҫҞ200ڜҏˀ0ӬҧҪۧҘҩӶҕٸҞөҖҧҪ҉ҜҟһҘRSFP

ӬӞҶӦҕӶӨӽұӷڛҕӬӞҵӤӦҳڒҖӫҘҜӓӯӃڛҕҜӴҧӦҕӬҺҕҖӴӾӧӒٚҵӷӛҫӪӶҜӫҒҕұҜӛӃҘҜҟҙңӪ

ӻҟҪӶܖҜӒҖҺܜ3ٸӪ24Ƒ2ˀ6

ܗҜӟӾӞҲӦҕڒҚӓӣӪөҲӞ14,300

ӥҖӣҺҖҘ4ˀ8ܗ

҄ҖڛҕҗӷһӯӪҹҖӾӟӪ

ӼұҶӛӦҕӨһӧһҟӦҕ

ҜӪҖӓӦҕҜӪڔһӦҕҝҖӪӷӧӓӪ

ҶӋҮ

ҜӮҖӾӃӦҕӶ҉ҚӾӢҶҟӦҕӨҙӞӿҒҖҘҶӴӣӦҕҵҲӃӫӦҕӌҘҵӶӨӛӞӶӨӃӛҘҖٙӫҒҕұӬӞ

ҜҘҖӂҏӶ҉ҜӪҲӂӶ҉ӠӽҶҪӿӚҚҙһҟӽҲӞҜӞҖӋӦҕҵҲӃӪӨӃӚӿӚӝҖӛҮڙҕ

қҶӾӋҮ

ӵӾҙӯҞ

Ӷ҉ӬӦ҉ҡӶҲҪӿӚӡҶҫӫӦҕҜӮӷүҺҚҙһҟҞҲӞҜҪӶҶӫӦҕҜӮҖӾӃҘөҖӾӟӦҕҲӯӒ

ҜӮҖӾӃӦҕӥҖӫӒҋҘөҖӾӟӦҕӨҙӞұҶҙӽӡҶҫӫӦҕӑұҜҘҖӂҏ

ӵӾҙӯҞ

ҵҖҧӛӮڔӦҜӧҘҖӟӦҕ҄ҕӷҦڗҕӿӚҵҴҫӦҕӶҜӋӾҫӦҕӿҮӷҞҚҧӽ

DANGER

PoËr ócarter leÉ riÉÇËeÉ ºƠincenºie,ºe choc

ólectriÇËe oË ºe ¸leÉÉËre graÌe,Ìeiller Ñ toËÀoËrÉ

ºó¸rancher,ÌerroËiller et ótiÇËeter la ÉoËrce ºe

coËrant aÌant lƠinÉtallation oË lƠentretien

ATTENTION

LorÉ ºe toËte interÌention ÉËr la ÉoËfflante,le moteËr

ÆeËt ôtre ÉËffiÉamment cha˺ ÆoËr ÆroÌoÇËer Ëne

ºoËleËr Ìoire Ëne ¸leÉÉËreLaiÉÉer le moteËr refroiºir

aÌant toËte maintenance

ATTENTION

Faire ÆreËÌe ºe ÆrócaËtion ºanÉ leÉ atmoÉÆhòreÉ

exÆloÉiÌeÉ

ӼҴӦҕӄүҿӦҕڝӒҚҧӽӌӟӚӄӃүҟӪӄүҾҜҪӶҶڛҕҚӾӢٸҘөӷӟӽӭ҉Қҧӽ

ҝҖӊҖӾҟҪҖҘҜӽҕҵұڝӒӭӷӣӽӭ҉ӶҩӷӆӷҘҝҕұҖҾҵڙҕҚӒӷҟһӽӭ҉ҚӾӢٸӦҖҘөӷӟӾҺ

ҜӪҲӂӶ҉ҜҘҖӂҏҡӶҲҪҬӾҫӃӦҕۦӖҚӾӢٸӦҕӰӒҨҟӯӽӭ҉ӰӣӫӽҜӪҖӓӦҕҜӪڔһӦҕ

ҚӧӋҟӽҲӞҜӢҶҫҟڛҕ҄ҕҸҦڗҕҜһӪڔӪҜҧӾҟӮӸҶҮ҉ҶӊҖүӪӥҖӫҟҪҕӔӪҜӾҒҖҘҶӴӢ

ӰӪҕٙҲӽҸӪҠҧҟҪҕҕҳҏۤҕҸӦҷӉҖҿӮұӷҦӶӥҖҪڒӸҶҮ҉ҝҕҵҖҙҟӒҕҴҮ҉ҶӪڗҕ

қӷӋҮӼ҉ҳҖүҞҕӨҙӞҲӫҟӓӪӄӃүҟӪҹҲӯӴӫҘӥҖӃҞړҖҘӬӞҝҖӪӷӧӓڛҕ

ҜӾӯӊӷӦҕ҄ҖҘҶӴӣӦҕӭӷӮҖӞҖٙӇӽ҉ӶҜӪڔһӦҕӶҜӾӧҫڛҕ҄ҖҘҶӴӣӦҕۧӮҕӷӞӑҖҙҞҖҘӬӞ 1

ӰӣӪ҉ҖڛҖӊ܃ܖFPAܗӠҒҕҶҫӦҕӰӪҜӽҖӫҫӧӦҜӾӯӊӷӦҕҜӦҖӢӷӦҕӶܖNECܗ

ҕҲӯӢڒӠҙӋڛҕܖCECܗҜӽҲӯӣӦҕ҄ҖҘҶӴӣӦҕӭӷӮҖӞӑҖҙҞҖҘӬӞӤӦҳ

ӭ҉ӭӶұҵӶҲҟӦқҶҪӭӷӣҞӭ҉ҚҧӽӤӦҴӦҜҺҖһҪҜӦҋһӪқҵҖӋӦҕӭҕҵӶұ 2

ҜҟҘҖңӦҕ҄ҕҸҦڗҕҲҪҋҘӤҟҫҞӶ҉өҲӋӃҞ

ӬҒڔӪӶӰӪ҅ӨӣҿҘӅҵڗҕڝӒӡҶҫڛҕҸӣҞҶӽӭ҉Қҧӽ 3

ҜӟӾӞҲӦҕڒڈӞڗҕҝҖӛӧӦҕұҲӒڝӒҲӽҸҞҜӒٺҘҜҪӶҶڛҕқҵҖӊҶӽӶҲҟҘӬӟҞړ 4

ӨӣҿҘҶҢҎӽҜҪӶҶڛҕҜӒٹڒҝڔӽҲӓҞ҄ҕҶҦҏҥӷӦҖҟӣӦҕڒۧҙڛҕӶҜҪӶҶӫӧӦ

ڒҜҪӶҶڛҕӭҕҵӶұҜӒٹۦӾӗҞӥҖҪڒӡҶҫڛҕڝӒӔӞҕӷӦҕӨӫҫӦҕڝӒۦҙӢ

ӱҷӶҖҧҞөҲӒӰӪҲӢҋҟӧӦӡҶҫӫӧӦӿҒҖҘҶӴӣӦҕҵҖӾҟӦҕӄҫӛٞӽӭ҉ҚҧӽҜӟӾӞҲӦҕ

ӔӯӃӦҕҜҪӷӦڝӒқұҲҫڛҕۦҙӪڗҕҜӫӾӟӦ

ҬӋҺڗҕӶ҉өӷҫҿӦҕӶ҉ҝӷӽҸӦҕҼӪڔӽӶ҉ӿӯңӯӽҜӞҖӋӦҕӨҘҖӢӑҲҞړ ʼ

ҕٙҵӷӚҖӴӛӧҞҲӯӒӡڔҺڗҕӥҕҲҙҟҺҖҘӬӞҜӾҒҖӾӫӾӣӦҕұҕӷڛҕӶ҉ҜӯҮҖһӦҕ

ҷҖӴҧӦҕӔӪӠӚҕӷҟӪҜӞҖӋӦҕҵҲӃӪӭ҉ӰӪӠӟҫҞ 6

ҜҪӶҶڛҕӨӫӒ҄ҖӯҢ҉җӷҙӮڗҕڜҏӥӷӂӷӦҕҝҖҘҕӷҘҕٙҲҘ҉ҬҟӛҞړ 7

®

ӜӟһӦҕ ұҕҲӪҏ ҜҪӶҶӪ

2

Page 20

479826Ҳӯҟһڛҕ

RSFPӶRSFӨӽұӷڛҕ

ӜӟһӦҕұҕҲӪҏҜҪӶҶӪ

®

ҜӮҖӾӃӦҕӶӨӾӗҿҟӦҕӶҚӾӢٸӦҕҚӾҟӢ

ӰӪӶӤһӛӮӿӫҪҕҜӮҖӾӃӦҕӶ҉ӨӾӗҿҟӦҕӶҕҚӾӢٸӦҕӨҙӞҝҖӫӾӧӓҟӦҕқ҄ҕҶӞ҄ҖҦҶӦҕӨҙӟҟһڛҕڒӔҦҶӫӢҜүһӯҘӍҖӛҟҪړҕӶӨӾӗҿҟӦҕӨҙӞҝҖӫӾӧӓҟӦҕқ҄ҕҶӞ҄ҖҦҶӦҕ

ܑҜӂҖүӦҕҝҖӣӧҟӫڛҖҘӶ҉ӤӦڊүҿӦҕҵҕڋڙҖҘҚҙһҟӽҲӞҝҖӫӾӧӓҟӦҖҘҲӾӟҟӦҖҘӝҖӛҮڙҕӭ҉ҖӫӢҖӴӟӾҙӋҞӶҝҖӫӾӧӓҟӦҕқ҄ҕҶӟҘӤӦӷҪ

ҜҪӶҶڛҕӭҕӶҚӾӢٸӦҕҲӯӒӨҙӾӣӦҕӈӽҵҋҞҜӾӧӫӒӰӪҲӢҋҟӦҕҚҧӽ

ӈӽҵҋҟӦҕӤӧһҘҜӦӷӂӷӪ

ҝҖӮҖӾҙӦҕҜҪӷӦڒӵӾӧӒӁӷӃӯڛҕҵҖӾҟӦҖҘҜҪӶҶڛҕӨӾӂӷҞҚҧӽ

ҜҪӶҶڛҖҘҜӂҖүӦҕ

Ӷ҉ҜҪӶҶӫӧӦҜӾҒҖҘҶӴӣӦҕ҄ҕҸҦڗҕڒӱҖӾڛҖҘӡҖӣҟҪړҕӼұҖӛҞҚҧӽ

ҜҪӶҶڛҕ҄ҕҸҦ҉ӰӪӸҶҮ҉҄ҕҸҦ҉Ӽ҉

ӭڗҜҪӶҶڛҕӨӾӗҿҞӰӪҖӪҖӫҞҵҴҫӽҷҖӖҗٺҞұӷҦӶҜӦҖҪڒ

ҨҟӯӽәӷҺҖӫӪӿҒҖҘҶӴӢҵҕٿҖӴӯӒҨҟӯӽәӷҺӨӾӗҿҟӦҕҜӾӧӫӒ

ҵҖҧӛӮҕӵӯӒ

ٿҖҙӪӨӣҿҘҜҪӶҶڛҕӜӾӏӯҟӦҜӧҒҖҺұҕӷӪӼ҉ӥҖӫӓҟҺҕҵҴҫӽ

ӿҒҖҘҶӴӢӠӓӂҜӾӧӫӒڒҚҙһҟӽҲӞӵӮڗ

ҚӾӢٸӦҕҲӓҘҜҪӶҶڛҕӔӾӫҧҞқұҖӒҏӶ҉ӤӛҘҬӃӯӽړ

ܑҶӽҴҫҞ

ҜӛӧҟүڛҕҝҖҘҖӂڙҕҵҖӋҮ҉Ӷ҉ӿҒҖҘҶӴӣӦҕӠӓӃӦҕӶ҉ӠӽҶҫӦҕҵҖӋҮ҉ӨӾӧӟҟӦ

ܐۤҖҟӦҕӑҖҙҞҕ҄ҖҦҶӦҕ

ҜӒٺӦҕڒӬӣҫҞҝҕҲҪӶӔӪөҕҲүҟҺڔӦҜҙҺҖӯӪҝҕҲҪӷӦҕӈӓҘ Ʒ

ҜҟҘҖҢҜӦҖҫҘ

҄ҖҦҶӦҕҵҕҲҧӦҕڒҝҖҫҟӚӨӫӒӶ҉ۦһӣҞӡҖӯӳӭӷӣӽҖӪҲӯӒ Ʒ

ҜҪӶҶӫӧӦҜӾӧҮҕҲӦҕ҄ҕҸҦڗҕӶ҉ӡڔҺڗҕҩҶҦӰӪҵҴҫӦҖӾҮӷҞ

ӨӾӗҿҞәҖӟӽҐҘӬӞ܃ҜҙӾӓӪӶ҉ҜӒӷӋӟӪӨӾӂӷҟӦҕҝڔҙӢҠӮҖӢҕҳҏ Ʒ

ҝڔӂӷӦҕܜӡڔҺڗҕӥҕҲҙҟҺړӄӃүҟӪӿӯӛҘӨӃҞҕӶҜӞҖӋӦҕҵҲӃӪ

Ӷ҉ҽӶҶڛҕӨҮҕұӰӪҜӾӦҕӥӷӂӷӦҕӰӣӫӽҤӾҪӀҟӽӷҺӨӫӓҟһҞړ Ʒ

ҼӋӗڛҕ

҄ҖҦҶӦҕҝҖҘҖӂڙҕӶ҉ӿҒҖҘҶӴӣӦҕӠӓӃӦҕӶҕӠӽҶҫӦҕҶӊҖүӪӨӾӧӟҟӦ Ʒ

ܐۤҖҟӦҕӑҖҙҞҕ

ҜӫӫӃӪҖӴӮڗҰҘҖӋڛҕӶ҉ҰҙӋӦҕӰӢҖӪ҉ڒҖӴҘڇӷӽړҩҕӶҶڛҕӱҴӳ Ʒ

ӿӟӯӦҕ҄ҕӷӴӦҕӌӛҾӶҜӏӛүӯӪқҵҕҶҪҝҖҦҵҲӦ

ӭҕҵҲҧӦҕӶ҉ҴӚҕӷӯӦҕҥҵҖҮҚӾӢٸӧӦҜӃӃүӪۦӖҜҪӶҶڛҕ Ʒ

ܑҶӽҴҫҞ

ұҕӷڛҕӌӛҿӦҖӴӦҖӫӓҟҺҕҚҧӽړӤӦҴӦ҄ҕӷӴӦҕӌӛҿӦҜӃӃүӪҜҪӶҶڛҕ Ʒ

өұҕӷӒӶ҉ҵҖҧӛӮڔӦҜӧҘҖӞұҕӷӪӶ҉ҜӽӶҖӫӾӣӦҕ

ҜҪӶҶڛҕҜһӪڔӪӨҙӞӠӓӂӔӆӶڒҼҘҖӟӦҕӭҋҘҲӢҋҟӦҕҚҧӽ

ҵҖӾҟӦҖҘӠӓӂҜӾӧӫӒӨӃҫҞړӿӣӦқٿҖҙӪ

ӄҟүӪӿӯӚӨҙӞӰӪҚӢҶҞӭ҉ҚҧӽҜҪӶҶڛҕӱҴӳ

ӅҵڗҕӰӪٸӪ23ӨӟӽړҖӫҘҚӢҶҞӭ҉ҚҧӽҜҪӶҶڛҕӱҴӳ

ӨҙӞӰӣӦӶҜӯҺӨӢڒҜҪӶҶӫӧӦҜӽҵӶҲӦҕҜӮҖӾӃӦҕӨӫӒҚҧӽ

ҼҘҖӟӦҕӝڔӖҏӰӪҲӢҋҟӦҕҚҧӽҜӮҖӾӃӦҕ

ӬӴӾӚҖӫҘܗӁҖүҾ҉ӨҙٟӞӰӪҷҖӴҧӦҕҕҴӳөҲүҟһٞӽړ҉Қҧӽ

Ӷ҉ҜӇӛүӯӪҜӾӧӟӒӶҜӾһҪӶҜӽҲһҦҝҕҵҲӞӬӴӽҲӦܖӥҖӛӊڗҕ

ӰӒӥӶҎһڛҕӄүҿӦҕөҖӞҕҳҏ٠ړҏҜӚҶӓڛҕӶқٷүӦҕڒӄӟӮ

өҕҲүҟҺҕҜӾӛӾӢӥӷҪӬӴӴӾҦӷҞӶ҉ӬӴӾӧӒәҕٿڙҖҘӬӴҟӪڔҺ

ҷҖӴҧӦҖҘҤҙӓӦҕӰӪӬӴӓӯڛӥҖӛӊڗҕҜҙӞҕҶӪҚҧӽҖӫӢҷҖӴҧӦҕ

1

ӜӟһӦҕұҕҲӪҏҜҪӶҶӪ

ҵӷӋӦҕӼұҖҪ҉ܜҸҞҶӳ60ܜҠӦӷӚ240ܞ220Ӷ208܃127

ͲӰҮҖҺͲӨңӫӽұӷҺڗҕӤӧһӦҕƷ

ҲҦӶӭҏͲҲӽҖҫӪܜӰҮҖҺͲӨңӫӽӈӾҘڗҕӤӧһӦҕƷ

ҲҦӶӭҏͲڏҵ҉ͲӨңӫӽҶӛӂڗҕӶڌҮڗҖҘӌӋүڛҕӤӧһӦҕӶ҉ڌҮڗҕӤӧһӦҕƷ

ҵҕӷӊڗҕӿҢڔҢܜҸҞҶӳ60ܜҠӦӷӚ400Ӷ380

ͲӰҮҖҺ"ӨңӫӽұӷҺڗҕӤӧһӦҕƷ

ҲҦӶӭҏͲڏҵ҉ͲӨңӫӽҶӛӂڗҕӶڌҮڗҖҘӌӋүڛҕӤӧһӦҕƷ

ҖӫҘӡڔҺڗҕӨӃӚӶҵҖӾҟӦҕӨӾӂӷҟӦҚҺҖӯڛҕҼҙӟڛҕӥҖӫӓҟҺҕҚҧӽ

ҼӪڔҞөҲӒӰӫӇӽҖӫҘӈӓҙӦҕҖӴӇӓҘӰӒٸӾӫӧӪ3ӰӒӨӟӽړ

ҚһҪӡڔҺڗҕӶҼҙӟڛҕҚӾӢҶҞҚҧӽӶӈӓҙӦҕҖӴӇӓҘӔӪӡڔҺڗҕ

ҜӾӧҫڛҕۧӮҕӷӟӦҕӵӾӧӒӄӯҞҖӪ

ҜҪӷҟӛӪҷҖӖҜӋӟӮӼ҉ӰӪҜҪӶҶڛҕڜҏҷҖӗӦҕҗٺҞӰӪҵҴҫӦҕҚҧӽ

®

Loading...

Loading...