Page 1

Energy Recovery Ventilator

Model MiniVent

• Commercial • Institutional

• 300 to 800 cfm

• Ideal for classroom ventilation

December

2004

Page 2

MiniVent-450 & 750

®

The MiniV

ventilators used for commercial and institutional

applications that r

ventilation air. The compact design provides an

economical solution for individual spaces, such as

school classrooms and small offices.

The MiniVent is designed for indoor installations

and may be floor mounted or ceiling hung. A

removable panel enables easy access to filters

and enthalpy wheel. Pleated 1-inch deep filters

and backdraft dampers are standard.

ent-450 & 750 are energy recovery

equire 300 cfm to 800 cfm of

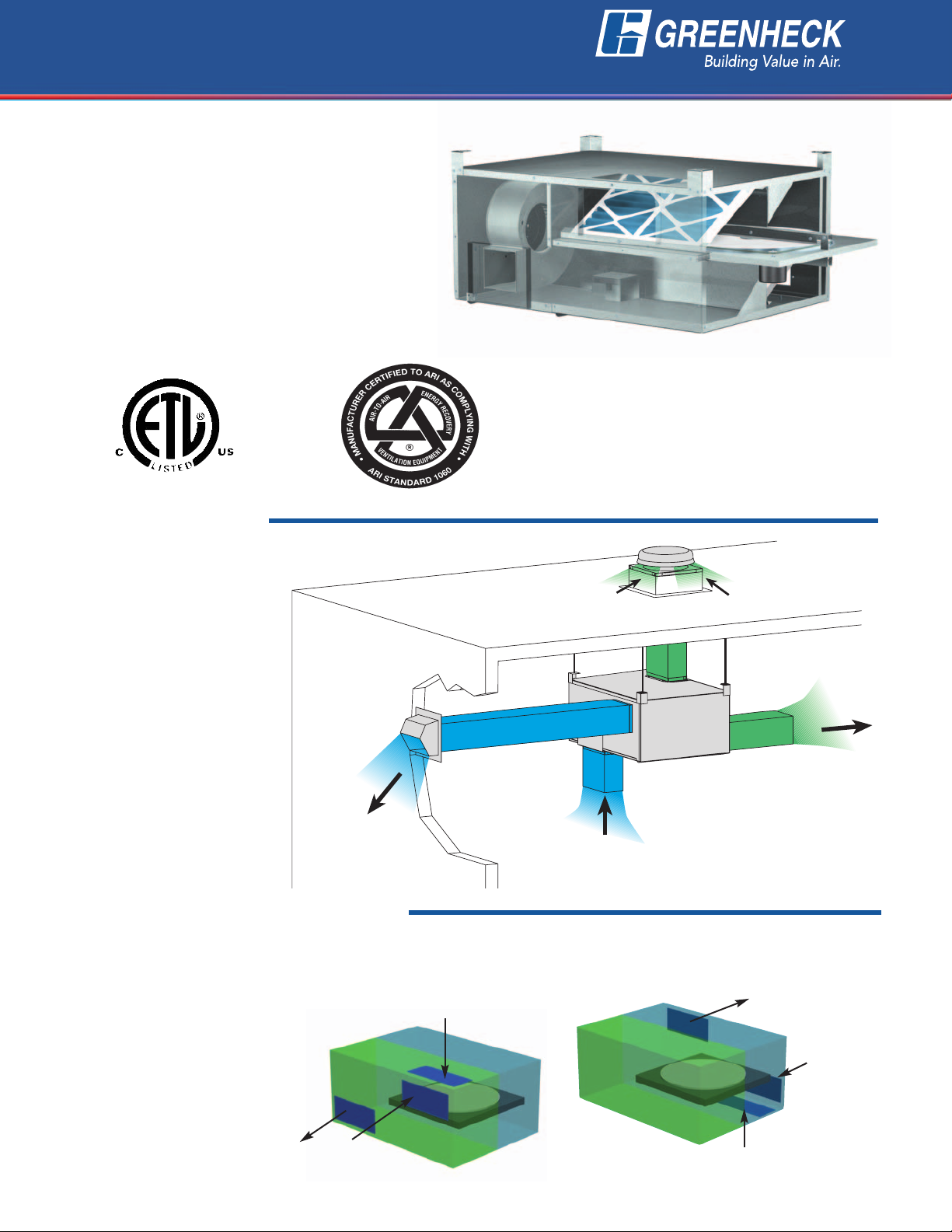

Typical Installation

The illustration shows a

MiniVent in a typical ceiling

hung installation.

Energy recovery wheels certified by the ARI Air-to-Air

Energy Recovery Ventilation Equipment Certification

Program in accordance with ARI Standard 1060.

Actual performance in packaged equipment may vary.

Certified Ratings are available in the Certified Product

Directory at http://www.ari.org/directories/erv

Outdoor air is drawn through

a model GRS roof mounted

gravity intake hood and preconditioned by the enthalpy

wheel. Outdoor air is then

supplied either to an air

handler or directly to the

space. Energy is recovered

from stale room air before it

is exhausted through a

model WC wall cap.

See opposite page for other

intake and discharge

accessories.

Exhaust Air

Intake and Discharge Locations

Outdoor Air

Outdoor air and

exhaust air intake

and discharge

locations are shown.

Both intake locations

are capable of being

elocated to suit

field r

installation needs

(see optional

locations).

2

Intake & Discharge Locations

Discharge

Intake

Intake

(Optional)

Outdoor Air

Pre-conditioned

Supply Air

Room Air

Exhaust Air

Intake & Discharge Locations

Discharge

Intake

Intake

(Optional)

Page 3

Performance Data

A

B

C

®

MiniVent-450

RPM

EXTERNAL STATIC PRESSURE (in. wg)

0.125 0.250 0.375 0.500 0.625 0.750 0.875 1.00

Supply & Exhaust

1250 CFM 386 362 335 300 245 2.6

1680 CFM 542 512 480 442 402 352 294 227 3.6

Direct Drive

* Sones @

0.25 in. wg

MiniVent-750

RPM

0.125 0.250 0.375 0.500 0.625 0.750 0.875 1.00

Supply & Exhaust

EXTERNAL STATIC PRESSURE (in. wg)

Direct Drive

1250 CFM 693 678 657 631 597 559 527 497 5.9

1550 CFM 865 854 842 825 807 785 761 731 6.5

* Sone values are at a distance of 5 feet from the exhaust air intake.

Intake and Exhaust Accessories

Wall Mounted

Model BV

• Intake or exhaust

• Anodized aluminum

construction

• Built in aluminum

mesh insect screen

Model WC

• Exhaust only

• Aluminum construction

• Built in damper

Model GRS

• Intake or exhaust

• All aluminum exterior

construction

• Integral birdscreen

• For roof curb mounting

Roof Mounted

Model GRSF

• Intake or exhaust

• All aluminum exterior

construction

• Integral birdscreen

• Built in flashing flange

Other Accessories

Speed Control

A solid state speed control

is available for adjusting

airflow to desired volume.

One speed contr

supplied for each outdoor

air and exhaust air fan.

Requir

es a 4x4 handy box

by others.

ol is

Motion Detector - MiniVent-450 Only

Model MBW is a wall mounted passive infrared

motion detector that automatically turns on the

MiniVent when a change in temperatur

sensed. The MiniVent will automatically turn off

after the r

oom has been vacant past the

adjustable time delay setting of 1 minute to 20

minutes. The detector must be installed in the

line-of-sight of the subject personnel and requires

a 2x4 handy box to be supplied by others.

e is

* Sones @

0.25 in. wg

Timed Exhaust Fr

Control Kit

Timed Exhaust fr

includes an Outdoor Air Sensor

and Timer for field installation.

Timed Exhaust frost control turns

the supply blower power of

on using field adjustable timer

settings when outdoor air

temperatur

eshold.

thr

Timed Exhaust is appropriate for

climates with limited HVAC

system operation when outdoor

air temperatures are below 0°F.

ost contr

e falls below the frost

ost

ol kit

f and

DIMENSIONS

MiniVent

Model

450 40 29 20

750 46 36 22

All dimensions shown ar

ABC

e in inches.

Hanging Vibration

Isolators

ibration isolator kits ar

V

available for suspended

installations. Kits include

e necessary to

dwar

all har

mount one unit, with the

exception of threaded

ods to be supplied by

r

others. Brackets for

mounting vibration

isolators are factory

installed on the unit.

e

3

Page 4

Typical Specifications

General:

Energy Recovery V

manufactured by Greenheck or approved equal,

provided all specifications are met. Units shall be

listed per ANSI/UL 1995, Heating and Cooling

Equipment. Energy transfer ratings of the energy

recovery wheel shall be ARI Certified. Performance

shall be as scheduled on plans.

Casing and Access:

Unit shall be constructed of G90 galvanized steel.

All components shall be easily accessible through

removable access panels. Access to filters and

energy wheel shall not require tools. Energy

recovery wheel shall be mounted in a slide-out

track for ease of inspection, removal and cleaning.

Housing shall be insulated with 1/2-inch insulation.

Outdoor air and exhaust air discharges shall have

integral backdraft dampers. Duct adapters shall be

factory installed on all four intake/discharge ports.

Intake Locations:

Both the outdoor air and exhaust air intakes shall

be designed for optional relocation in the field.

Alternate intake location on adjacent side of the

unit enables duct installation flexibility.

entilator shall be as

Silica gel desiccant shall be

permanently bonded to wheel

media to retain latent heat

recovery after cleaning. Wheels

with sprayed on desiccant

coatings are not acceptable.

Wheels with desiccant applied

after wheel formation are not

acceptable. Energy recovery

device shall transfer moisture

entirely in the vapor phase.

Energy recovery drive belt

material shall be high strength

urethane and shall be factory

installed in a pre-stretched state,

eliminating the need for field belt

tension adjustment. Link style belts are not

acceptable.

Fans and Motors:

Fans shall be double width, double inlet centrifugal

forward curved type. Fans shall be statically and

dynamically balanced. Fan motors shall be single

phase, thermally protected and be compatible for

use with speed controller.

Energy Recovery Wheel:

Wheel shall be of the enthalpy type for both

sensible and latent heat recovery, and be designed

to insure laminar flow. Energy transfer ratings must

be ARI Certified to Standard 1060 and bear the ARI

certification symbol for ARI Air-to-Air Energy

Recovery V

Program based on ARI 1060. Ratings “in

accordance with 1060” without certification are not

acceptable. Desiccant shall be silica gel for

maximum latent energy transfer. Wheel shall be

constructed of light weight polymer media to

minimize shaft and bearing loads. Polymer media

shall be mounted in a stainless steel rotor for

osion r

corr

entilation Equipment Certification

esistance.

Filters:

The outdoor air shall be filtered with a 1-in. deep,

30% effective disposable filter. Filter rack shall be

internal to the unit and factory installed.

Electrical:

All internal electrical components shall be factory

wired for single point power connection. All

electrical components shall be UL listed, approved

or classified where applicable and wired in

accordance with the National Electrical Code.

Ventilators shall be model MiniVent as

manufactured by Greenheck, in Schofield,

Wisconsin.

Our Warranty

Greenheck warrants this equipment to be free from defects in material and workmanship for a period of one year from the

purchase date. The energy recovery wheel is warranted to be free from defects in material and workmanship for a period of five

years from the purchase date. Any units or parts which prove defective during the warranty period will be replaced at our option

when returned to our factory, transportation prepaid. Motors are warranted by the motor manufacturer for a period of one year.

Should motors furnished by Greenheck prove defective during this period, they should be returned to the nearest authorized motor

service station. Greenheck will not be responsible for any removal or installation costs.

As a result of our commitment to continuous improvement, Greenheck reserves the right to change specifications without notice.

Greenheck P.O. Box 410 • Schofield, WI 54476-0410 • Phone (715) 359-6171 • greenheck.com

Copyright © 2004 Greenheck Fan Corp. • Catalog MiniVent RG Rev. 4 December 2004

Loading...

Loading...