Page 1

Gravity Ventilators

Models FGI, FGR, GRS, WIH, WRH and RGU

Intake and Relief

June

2010

Page 2

Gravity Ventilators

Fabra Hood

Louvered Penthouse

4

Designed for intake or relief applications, the Fabra Hood

models FGI or FGR offer many important advantages over other

gravity roof ventilators. It is superior in load bearing strength,

weather-resistance, dimensional flexibility and appearance.

Models FGI and FGR ......... . . . .......... . . . .......... . 4-7

Dimensions and Performance Data ....... . . . ....8-13

14 Spun Aluminum

For natural gravity or positive pressure systems, intake model

GRSI or relief model GRSR, offers excellent performance and

durability. Featuring an exceptional low silhouette design and

rugged construction this model is both efficient and economical.

Model GRS ........ . . . .......... . . . .......... . . . .......... . . 14

Dimensions and Performance Data ....... . . . .. 14-15

16

Upblast Ventilator

The WIH intake or WRH relief penthouse units offer an

aesthetically pleasing design. This flexible design allows for

units to be shipped in pre-assembled sections that can be easily

assembled without special tools.

Models WIH and WRH ......... . . . .......... . . . .......... 16

Dimensions and Performance Data ....... . . . .. 16-17

18

Model RGU is designed for use as an outlet on vertical high

velocity exhaust systems. The RGU can be furnished with or

without the curb cap for mounting directly on round stacks.

Model RGU . . . .......... . . . .......... . . . .......... . . . ...... 18

Dimensions and Performance Data ....... . . . ...... 18

All Ventilator Specifications ........ . . . .......... . . . .. 19-20

2

Page 3

Quick Delivery and

Quick Build Programs

Greenheck’s Quick Delivery program

provides many options to help you

meet your project’s schedule. Stocking

warehouses and distribution centers around the

world ensure same-day pickup and same-day

shipment for orders in by 2 p.m. (CST). Hundreds

of custom products can be manufactured through

Quick Build in just days.

For available options and accessories please refer

to the Greenheck Stock & Quick Build Catalog.

Outstanding Customer Service

Greenheck’s experienced staff is ready to answer your questions

and delivers solutions. Our representatives have a wealth

of industry and product knowledge, they maintain the latest

information and can process orders directly to our factory.

Count on the personal service and expertise from our national

and international representative organizations. To locate the

Greenheck representative nearest you, call 715-359-6171 or visit

our Web site at www.greenheck.com.

Leading Edge

Technical Support

When product and IOM

(Installation, Operation

and Maintenance Manual)

information is needed, our products are supported

by the industry’s best product literature, electronic

media and Computer Aided Product Selection (CAPS)

program. You’ll also find this information on our

Web site at www.greenheck.com.

Our national and international representative

organization provide personal service and expertise.

To locate your nearest Greenheck representative,

call 715-359-6171 or visit our Web site at

www.greenheck.com.

World Class Manufacturing

Greenheck’s skilled production workers use cost-effective

machines and unique dies designed and built by our own

engineers to add innovative features and greater strength to

our gravity ventilators. Our advanced manufacturing processes

and quality control procedures always ensure the highest

product quality. And just to be sure you get the peace-ofmind you expect when you specify Greenheck, our assembly

inspectors test run and monitor every unit before it leaves

the factory.

3

Page 4

Fabra Hood

Models FGI and FGR

Fabra Hoods are designed

for intake (model FGI) or relief

(model FGR) applications. The Fabra

Hood design offers many important

advantages not found in other gravity roof

ventilators. It’s design is superior in appearance,

load-bearing strength, weather-resistance and

dimensional flexibility.

Appearance

The clean lines and uniform structural design of the

Fabra Hood complement any building’s appearance.

The Fabra Hood is designed with a low profile to

mount close to the roofline. The result is minimum

impact on the building silhouette.

Strength and Weather‑Resistance

These hoods are strong enough to handle the snow

loads found in even the harshest of northern climates

and they have proven their ruggedness. The key to

the Fabra Hood’s strength and rigidity is in the design

of the arched hood panels. Each panel provides its

own structural support and is formed with interlocking

edges. The result is a strong, rigid shell without the

obstruction and performance losses of excessive

internal support braces. The interlocking ribs also

create tight, weather-resistant joints. No caulking or

caps are required to seal out rain and snow.

Third Party Certified for High Wind

Miami Dade, Notice of Acceptance (NOA) - 09-0511.03

Florida Product Approval (FLPA) - FL12917

All standard models are hurricane certified

• Highest industry rating

• Fans are certified for static and cyclic wind loading

and missile impact

• Designed to withstand wind loads of up to

150 mph (241 k)

• No tie downs are needed

• Installation/mounting details are provided

Performance

The rounded inner surfaces of the Fabra Hood’s

arched panels promote a smooth, uninterrupted

flow of air to reduce pressure losses. Cataloged

performance data is assured through extensive air

testing of both ducted and non-ducted installations

with standard birdscreens in place. Intake and relief

units differ in size and performance. It is important

to note that the “free area” (the opening surrounding

the throat) is larger for intake hoods. This larger free

area (twice the area of the throat) limits the entry of

airborne debris and moisture by creating lower intake

air velocities. Since relief units are not affected by

velocity considerations, free area is equal to throat

area. Consequently, the smaller overall dimensions

of relief units result in lower cost.

Broad Range of Sizes

Model FGI (intake) and FGR (relief) are available in

throat sizes ranging from a minimum of 8 inches

(203 mm) wide by 8 inches (203 mm) long to a maximum

of 72 inches (1829 mm) wide by 180 inches (4572 mm)

long. The complete range of standard suggested

throat sizes is shown on pages 8-13. Other sizes are

also available in increments of one inch within the

limits shown.

Shipping

Most Fabra Hoods ship assembled until they are

too large to fit in a semitrailer. See page 8-13 for

specific dimensional data.

Assembly

With the Fabra Hood’s interlocking rib design, hoods

of long lengths can be constructed on the jobsite.

Where the appearance of a single unit is desired,

large roof openings can be covered using a single

hood. This also represents a cost savings in working

with a single roof penetration. Neither special tools

nor training are required for assembly.

See page 7 for details.

4

Page 5

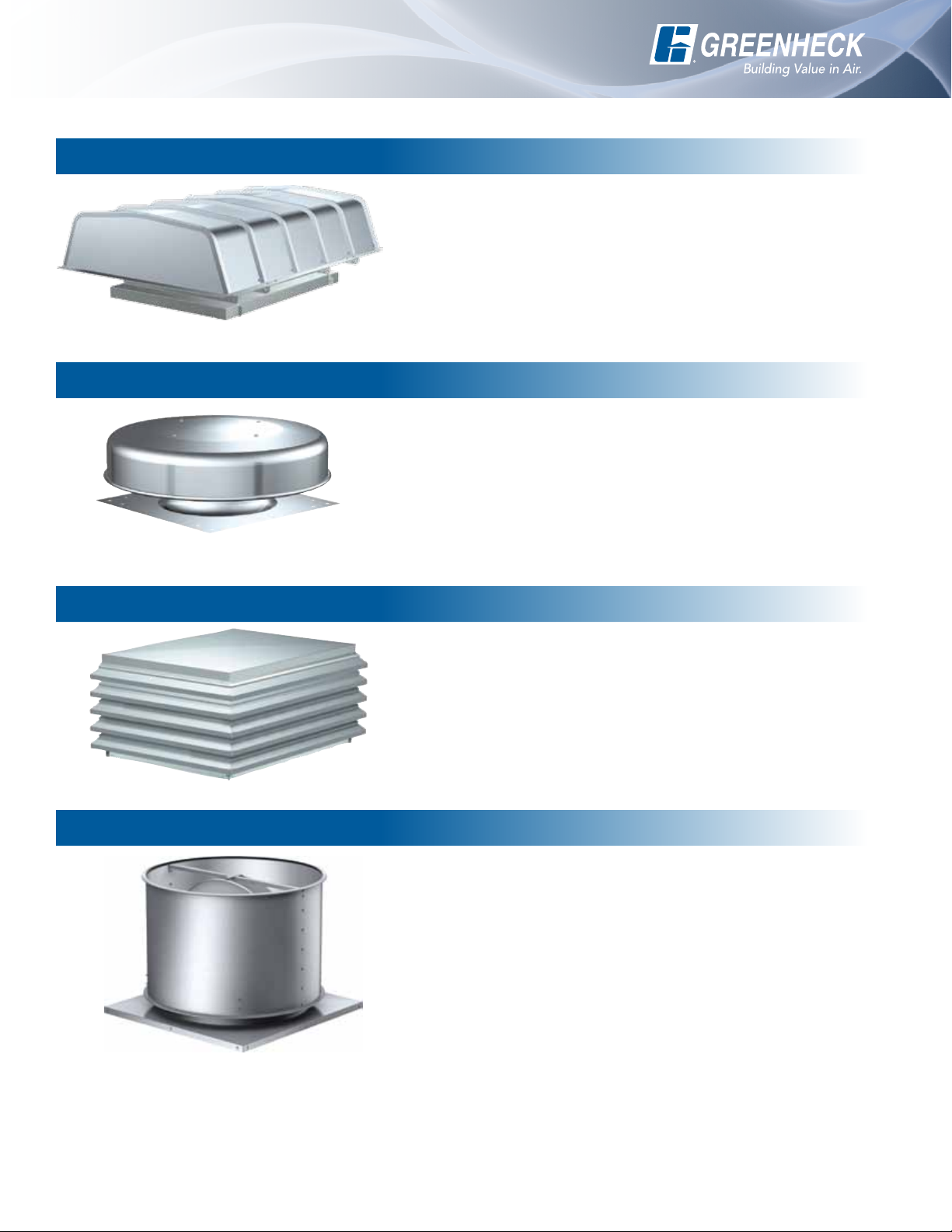

Fabra Hood

Construction Features

Precision Formed Locking Rib System

Strength, weather tightness and adjustable lengths

are the primary advantages of the Fabra Hood’s

arched, interlocking hood panels. A single precision

roll forming operation creates the rib, the adjacent

channel and the arch. All three features work in

combination for rigidity and efficient water drainage.

Fabra Hoods are

available with

hood panels and

bases constructed

of aluminum or

galvanized steel

as specified.

1

Accessibility

Fabra Hoods are designed for ease of access to

allow inspection and maintenance of screens, filters

and dampers. Removal of the two bolts on each

support angle permits the hood to be lifted off the

base. This construction also allows for a hinged

function. By removing bolts on the support angle on

one side of the unit’s panel length, the hood can swing

up and over to lie on the roof deck.

NOTE: For safety, it is not recommended to use this

hinging function with larger hoods or to prop any

hood part way open. Care should be taken to avoid

handling an unbolted hood in strong winds, especially

with larger size units.

5

2

3

4

Hood panels

1

Panels are arched and precision roll formed

for strength and weather tightness. The design

and construction provides sufficient structural

strength to allow inlet and outlet areas to be

virtually unobstructed by support members.

Birdscreens

2

Standard birdscreens are constructed of 1⁄2-inch

(13 mm) galvanized steel mesh for minimum

restriction of airflow.

Support members

3

Heavy-gauge galvanized steel support members

provide additional structural strength as well as

a hood/base interface. On larger hoods, truss

braces are added for increased strength.

Standard base

4

Standard base height is 5 inches (127 mm). Bases

include prepunched mounting holes for ease of

installation. The curb cap is 6 inches (152 mm)

larger than the throat size to minimize airflow

restrictions. Reinforced steel hood support

members are securely attached to the base and

direct hood loads to the roof curb. 12-inch (305

mm)

bases are optional. See page 6 for details.

Vertical end panels

5

Vertical panels are fully locked into the hood

end panels.

5

Page 6

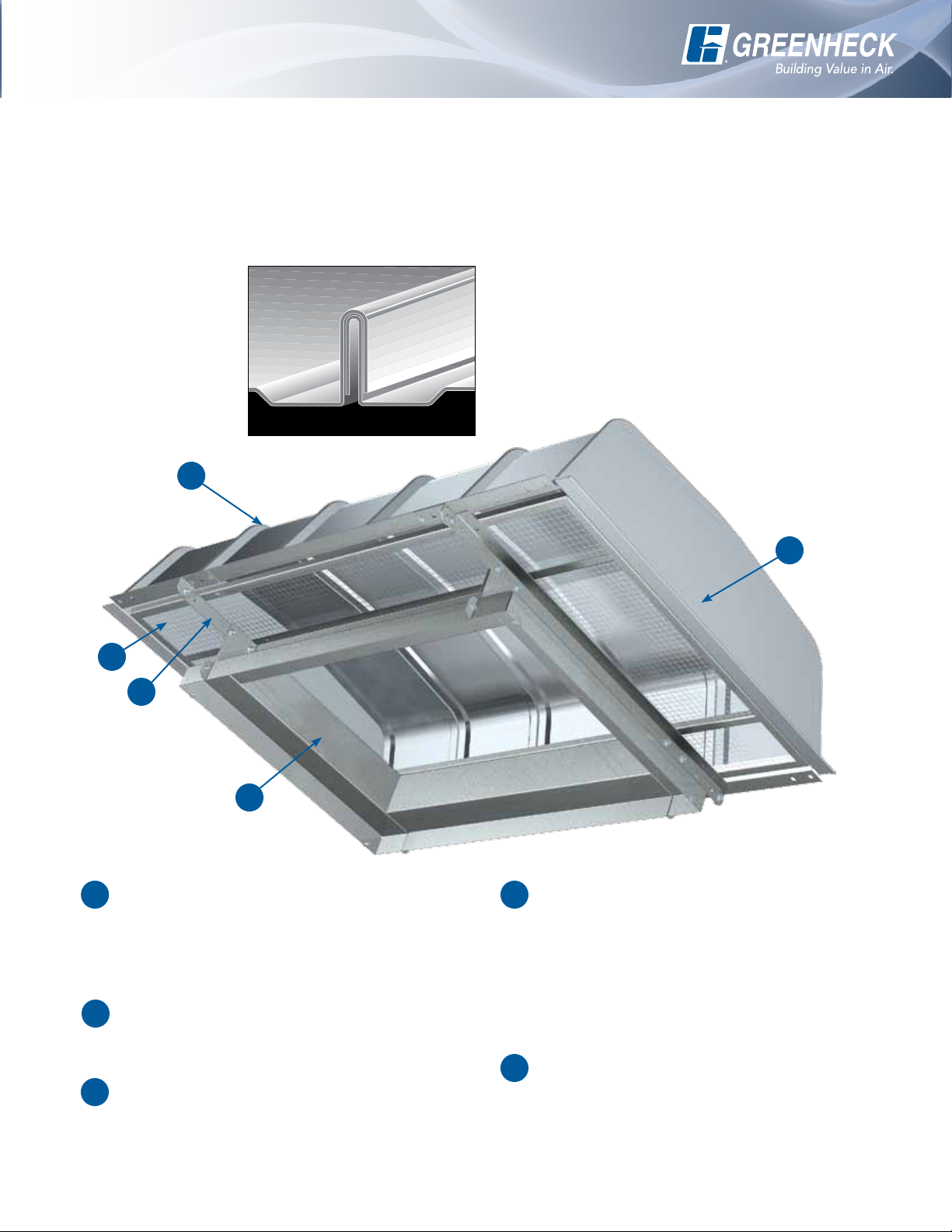

Fabra Hood

Construction Options

Hood Insulation

Aluminum Birdscreen

(Galvanized Standard)

5-inch Base

(127 mm)

12-inch tall bases

12-inch (305 mm) bases are recommended for intake

applications to prevent moisture entry and for all

applications where rain or snow may accumulate on

the roof deck. On larger size units, a 12-inch (305 mm)

base will provide more clearance space from the roof

deck and allow for better airflow.

Fiberglass hood insulation

Either ½-inch (13 mm) or 1-inch (25 mm) insulation

can be factory applied to the underside of the

hood to prevent condensation. Insulation is

also factory applied to individual panels of large

unassembled units.

Aluminum birdscreen

¾ x 1¼ inch (19 mm x 32 mm) diamond shape is

available in lieu of standard galvanized birdscreen.

Insect Screen

Filters

12-inch

(305 mm)

Tall Base Option

Tie-down points

Heavy-gauge galvanized steel tie-down points are

available as cable attachment points at the ends

of each hood support rail and prevent damage to

the Fabra Hood in locations where unusually strong

winds occur.

Special coatings

Several options are available for decorative or

protective purposes.

Factory primed for field application of final finish.

Baked enamel finish is applied to exterior surfaces

only to match or complement a building's color.

Protective coatings that include Greenheck’s

Permatector™ (a thermosetting polyester urethane)

are also available. Protective coatings are applied

to all surfaces. Refer to the Performance Coatings

catalog for complete coating options.

AluminumInsectScreen

A fine mesh aluminum insect screen tightly fitted

to the top of the throat, is available to prevent the

entry of insects. (This is in addition to the standard

birdscreen and is available on factory assembled units

only.) Use the curves on the graph below to determine

the static pressure drop for units with insect screen.

0.40

0.35

0.30

0.25

0.20

0.15

0.10

Static Pressure Drop (in. wg)

0.05

0.00

0 200 400 600 800 1000 1200

Aluminum Insect Screen

n

o

i

t

a

c

i

l

p

p

A

d

e

t

c

u

D

-

n

o

N

D

Throat Ve locity (ft./min)

c

i

l

p

p

A

d

e

t

c

u

s

s

n

o

i

t

a

Filters

Two-inch aluminum filters are available on model FGI

(intake) for applications where foreign material must

be removed from the airstream. Use the curves on the

graph below to determine the static pressure drop for

units with filters.

Filters

0.60

0.50

0.40

0.30

s

n

o

i

0.20

Static Pressure Drop (in. wg)

0.10

0.00

0 200 400 600 800 1000 1200

D

-

n

o

N

u

D

Throat Ve locity (ft./min)

t

a

c

i

l

p

p

A

s

d

n

e

o

t

i

t

c

a

u

c

i

l

p

p

A

d

e

t

c

6

Page 7

Fabra Hood

Accessories

Backdraft Dampers

Backdraft dampers are

available for intake or

relief with either gravity

or motorized operation.

Motorized dampers are

recommended for all intake

or low velocity relief applications. Damper sizes are

the same as throat sizes.

On‑Site Assembly

Flexibility is a primary feature of the Fabra Hood

design. Interlocking hood panels and extendible

throats allow units to be constructed to long lengths.

On-site assembly for these larger units is not difficult

and actually offers several advantages.

For jobs with large throat sizes, assembling hoods

on-site reduces costs. There is a cost savings in

carrying unassembled components to the roof versus

the expense of cranes or other equipment involved

in lifting a bulky assembled unit. The risk of damage

in transporting large assembled units is also reduced

when they are assembled on the roof deck.

In addition, the space saved by a compact crate

of knocked-down component parts reduces

shipping charges and final costs over large,

fully assembled units.

Roof Curbs

Prefabricated roof curbs

ensure compatibility

between the ventilator,

curb and roof opening.

Curb extensions are also

available. Curb models are available to meet a wide

range of applications and varying roof architecture

and construction. See the Greenheck Roof Curbs,

Extensions & Equipment Supports catalog for

complete details on these products.

Ease of Assembly

Hoods of any length can be easily constructed on the

jobsite. No special tools or training are required to

assemble a Greenheck Fabra Hood.

Fabra Hoods are assembled with the following

basic steps:

Step 1−Base ends, base sides and intermediate

hood supports (when required) are placed

in position and bolted together.

Step 2−Hood support angles are attached.

Step 3−All fasteners are tightened and all inside

base corners are caulked.

Step 4−Birdscreens are attached to hood

support angles.

Step 5−Hood rails are attached to hood

support angles.

Step 6−Hood panels and end panels are assembled

to hood rails.

All hardware is provided with each unit along with

complete, detailed and well illustrated instructions.

Hood End

Panel

Base End

Birdscreen

Sections

Hood Panel

Intermediate

Hood Support

Hood Rails

Base Side

Hood Support

Angle

7

Page 8

Fabra Hood ‑ Gravity Intake

Model FGI

7

/

A

Throat Width

Curb Cap Width

8

C

2

D

DD

All dimensions

shown in inches

B

1½

Throat Length

Curb Cap Length

Dimensional Data Performance Data

Throat

10.00 20 x 72 26 x 78 20 x 72 49 99 16 5 4747 6012 7349 8196 9494 10655 12199 Yes 162

10.83 20 x 78 26 x 84 20 x 78 47 111 16 5 5143 6513 7961 8880 10286 11543 13216 Yes 194

11.67 20 x 84 26 x 90 20 x 84 51 111 16 5 5538 7014 8573 9563 11077 12431 14232 Yes 203

Throat

Width x

Area

Length

2

ft

0.44 8 x 8 14 x 14 8 x 8 22 27 14 5 211 267 327 364 422 474 542 Yes 37

0.67 8 x 12 14 x 18 8 x 12 22 27 14 5 316 401 490 546 633 710 813 Yes 37

1.00 8 x 18 14 x 24 8 x 18 22 39 14 5 475 601 735 820 949 1066 1220 Yes 46

1.33 8 x 24 14 x 30 8 x 24 22 39 14 5 633 802 980 1093 1266 1421 1627 Yes 49

1.67 8 x 30 14 x 36 8 x 30 22 51 14 5 791 1002 1225 1366 1582 1776 2033 Yes 57

1.00 12 x 12 18 x 18 12 x 12 26 27 14 5 475 601 735 820 949 1066 1220 Yes 37

1.50 12 x 18 18 x 24 12 x 18 26 39 14 5 712 902 1102 1229 1424 1598 1830 Yes 46

2.00 12 x 24 18 x 30 12 x 24 28 39 14 5 949 1202 1470 1639 1899 2131 2440 Yes 49

2.50 12 x 30 18 x 36 12 x 30 27 51 14 5 1187 1503 1837 2049 2374 2664 3050 Yes 57

3.00 12 x 36 18 x 42 12 x 36 31 51 14 5 1424 1804 2205 2459 2848 3197 3660 Yes 63

3.50 12 x 42 18 x 48 12 x 42 29 63 14 5 1662 2104 2572 2869 3323 3729 4270 Yes 73

4.00 12 x 48 18 x 54 12 x 48 33 63 14 5 1899 2405 2939 3279 3798 4262 4880 Yes 79

1.36 14 x 14 20 x 20 14 x 14 29 27 16 5 646 818 1000 1116 1292 1450 1660 Yes 43

1.75 14 x 18 20 x 24 14 x 18 28 39 16 5 831 1052 1286 1434 1662 1865 2135 Yes 49

2.33 14 x 24 20 x 30 14 x 24 32 39 16 5 1108 1403 1715 1913 2215 2486 2846 Yes 55

2.92 14 x 30 20 x 36 14 x 30 30 51 16 5 1385 1753 2143 2391 2769 3108 3558 Yes 62

3.50 14 x 36 20 x 42 14 x 36 36 51 16 5 1662 2104 2572 2869 3323 3729 4270 Yes 70

4.08 14 x 42 20 x 48 14 x 42 33 63 16 5 1938 2455 3001 3347 3877 4351 4981 Yes 80

4.67 14 x 48 20 x 54 14 x 48 38 63 16 5 2215 2806 3429 3825 4431 4972 5693 Yes 87

5.25 14 x 54 20 x 60 14 x 54 36 75 16 5 2492 3156 3858 4303 4985 5594 6405 Yes 96

1.78 16 x 16 22 x 22 16 x 16 30 39 16 5 844 1069 1306 1457 1688 1894 2169 Yes 52

2.22 16 x 20 22 x 26 16 x 20 31 39 16 5 1055 1336 1633 1821 2110 2368 2711 Yes 54

2.67 16 x 24 22 x 30 16 x 24 36 39 16 5 1266 1603 1960 2186 2532 2841 3253 Yes 60

3.33 16 x 30 22 x 36 16 x 30 34 51 16 5 1582 2004 2450 2732 3165 3552 4066 Yes 68

4.00 16 x 36 22 x 42 16 x 36 40 51 16 5 1899 2405 2939 3279 3798 4262 4880 Yes 76

4.67 16 x 42 22 x 48 16 x 42 38 63 16 5 2215 2806 3429 3825 4431 4972 5693 Yes 87

5.33 16 x 48 22 x 54 16 x 48 36 75 16 5 2532 3206 3919 4371 5064 5683 6506 Yes 95

6.00 16 x 54 22 x 60 16 x 54 40 75 16 5 2848 3607 4409 4918 5697 6393 7320 Yes 104

6.67 16 x 60 22 x 66 16 x 60 38 87 16 5 3165 4008 4899 5464 6330 7103 8133 Yes 129

7.33 16 x 66 22 x 72 16 x 66 42 87 16 5 3481 4409 5389 6011 6963 7814 8946 Yes 136

2.25 18 x 18 24 x 24 18 x 18 32 39 16 5 1068 1353 1653 1844 2136 2397 2745 Yes 55

3.00 18 x 24 24 x 30 18 x 24 40 39 16 5 1424 1804 2205 2459 2848 3197 3660 Yes 64

3.75 18 x 30 24 x 36 18 x 30 38 51 16 5 1780 2254 2756 3074 3560 3996 4575 Yes 73

4.50 18 x 36 24 x 42 18 x 36 36 63 16 5 2136 2705 3307 3688 4272 4795 5490 Yes 83

5.25 18 x 42 24 x 48 18 x 42 42 63 16 5 2492 3156 3858 4303 4985 5594 6405 Yes 92

6.00 18 x 48 24 x 54 18 x 48 40 75 16 5 2848 3607 4409 4918 5697 6393 7320 Yes 101

6.75 18 x 54 24 x 60 18 x 54 45 75 16 5 3204 4058 4960 5533 6409 7192 8235 Yes 111

7.50 18 x 60 24 x 66 18 x 60 43 87 16 5 3560 4509 5511 6147 7121 7991 9149 Yes 136

8.25 18 x 66 24 x 72 18 x 66 46 87 16 5 3916 4960 6063 6762 7833 8790 10064 Yes 145

9.00 18 x 72 24 x 78 18 x 72 45 99 16 5 4272 5411 6614 7377 8545 9590 10979 Yes 155

2.78 20 x 20 26 x 26 20 x 20 37 39 16 5 1319 1670 2041 2277 2637 2960 3389 Yes 61

3.33 20 x 24 26 x 30 20 x 24 44 39 16 5 1582 2004 2450 2732 3165 3552 4066 Yes 69

4.17 20 x 30 26 x 36 20 x 30 42 51 16 5 1978 2505 3062 3415 3956 4440 5083 Yes 77

5.00 20 x 36 26 x 42 20 x 36 40 63 16 5 2374 3006 3674 4098 4747 5328 6100 Yes 89

5.83 20 x 42 26 x 48 20 x 42 48 63 16 5 2769 3507 4287 4781 5538 6215 7116 Yes 98

6.67 20 x 48 26 x 54 20 x 48 44 75 16 5 3165 4008 4899 5464 6330 7103 8133 Yes 107

7.50 20 x 54 26 x 60 20 x 54 49 75 16 5 3560 4509 5511 6147 7121 7991 9149 Yes 117

8.33 20 x 60 26 x 66 20 x 60 47 87 16 5 3956 5010 6124 6830 7912 8879 10166 Yes 143

9.17 20 x 66 26 x 72 20 x 66 45 99 16 5 4352 5511 6736 7513 8703 9767 11183 Yes 154

Curb Cap

Width x

Length

Optional

Damper

Width x

Length

Inches CFM

Width

Length

Overall

A B C D 235/475 297/600 364/735 406/820 470/950 527/1065 604/1220

0.030 0.047 0.071 0.089 0.119 0.149 0.196

Base

0.053 0.085 0.127 0.158 0.212 0.267 0.350

Height

Height

DUCTED STATIC PRESSURE DROP (IN. WG)

NON-DUCTED STATIC PRESSURE DROP (IN. WG)

HOOD INTAKE VELOCITY / THROAT VELOCITY (FT/MIN)

Shipped

Assembled

POUNDS

Galvanized

Unit Weight

8

Page 9

Fabra Hood ‑ Gravity Intake

Model FGI

7

/

A

Throat Width

Curb Cap Width

8

C

2

D

DD

All dimensions

shown in inches

B

1½

Throat Length

Curb Cap Length

Dimensional Data Performance Data

Throat

10.00 24 x 60 30 x 66 24 x 60 55 87 19 5 4747 6012 7349 8196 9494 10655 12199 Yes 163

11.00 24 x 66 30 x 72 24 x 66 54 99 19 5 5222 6613 8083 9016 10444 11721 13419 Yes 174

12.00 24 x 72 30 x 78 24 x 72 58 99 19 5 5697 7214 8818 9836 11393 12786 14639 Yes 185

13.00 24 x 78 30 x 84 24 x 78 56 111 19 5 6171 7815 9553 10655 12343 13852 15859 Yes 220

14.00 24 x 84 30 x 90 24 x 84 60 111 19 5 6646 8417 10288 11475 13292 14917 17079 Yes 230

15.00 24 x 90 30 x 96 24 x 90 58 123 19 5 7121 9018 11023 12295 14242 15983 18299 Yes 244

10.00 30 x 48 36 x 54 30 x 48 64 75 19 5 4747 6012 7349 8196 9494 10655 12199 Yes 143

11.25 30 x 54 36 x 60 30 x 54 62 87 19 5 5341 6763 8267 9221 10681 11987 13724 Yes 174

12.50 30 x 60 36 x 66 30 x 60 60 99 19 5 5934 7515 9186 10246 11868 13319 15249 Yes 186

13.75 30 x 66 36 x 72 30 x 66 66 99 19 5 6527 8266 10104 11270 13055 14651 16774 Yes 200

15.00 30 x 72 36 x 78 30 x 72 64 111 19 5 7121 9018 11023 12295 14242 15983 18299 Yes 225

16.25 30 x 78

17.50 30 x 84 36 x 90 30 x 84 67 123 19 5 8308 10521 12860 14344 16615 18646 21349 Yes 264

18.75 30 x 90 36 x 96 30 x 90 72 123 19 5 8901 11272 13779 15368 17802 19978 22874 Yes 278

10.50 36 x 42 42 x 48 36 x 42 67 75 19 5 4985 6312 7716 8606 9969 11188 12809 Yes 147

12.00 36 x 48 42 x 54 36 x 48 66 87 19 5 5697 7214 8818 9836 11393 12786 14639 Yes 176

13.50 36 x 54 42 x 60 36 x 54 73 87 19 5 6409 8116 9921 11065 12817 14384 16469 Yes 196

15.00 36 x 60 42 x 66 36 x 60 72 99 19 5 7121 9018 11023 12295 14242 15983 18299 Yes 208

16.50 36 x 66 42 x 72 36 x 66 78 99 19 5 7833 9920 12125 13524 15666 17581 20129 Yes 224

18.00 36 x 72 42 x 78 36 x 72 76 111 19 5 8545 10821 13227 14754 17090 19179 21959 Yes 252

19.50 36 x 78 42 x 84 36 x 78 74 123 19 5 9257 11723 14330 15983 18514 20777 23789 Yes 280

21.00 36 x 84 42 x 90 36 x 84 80 123 19 5 9969 12625 15432 17213 19938 22376 25618 Yes 295

22.50 36 x 90 42 x 96 36 x 90 78 135 19 5 10681 13527 16534 18442 21362 23974 27448 Yes 311

24.00 36 x 96 42 x 102 36 x 96 83 135 19 5 11393 14428 17637 19672 22787 25572 29278 Yes 324

25.50 36 x 102 42 x 108 36 x 102 81 147 19 5 12105 15330 18739 20901 24211 27170 31108 No 340

12.25 42 x 42 48 x 48 42 x 42 78 75 23 5 5815 7365 9002 10041 11631 13052 14944 Yes 178

14.00 42 x 48 48 x 54 42 x 48 76 87 23 5 6646 8417 10288 11475 13292 14917 17079 Yes 221

15.75 42 x 54 48 x 60 42 x 54 85 87 23 5 7477 9469 11574 12909 14954 16782 19214 Yes 252

17.50 42 x 60 48 x 66 42 x 60 83 99 23 5 8308 10521 12860 14344 16615 18646 21349 Yes 261

19.25 42 x 66 48 x 72 42 x 66 81 111 23 5 9138 11573 14146 15778 18277 20511 23484 Yes 291

21.00 42 x 72 48 x 78 42 x 72 88 111 23 5 9969 12625 15432 17213 19938 22376 25618 Yes 320

22.75 42 x 78 48 x 84 42 x 78 86 123 23 5 10800 13677 16718 18647 21600 24240 27753 Yes 355

24.50 42 x 84 48 x 90 42 x 84 84 135 23 5 11631 14729 18004 20081 23261 26105 29888 Yes 373

26.25 42 x 90 48 x 96 42 x 90 90 135 23 5 12461 15781 19290

28.00 42 x 96 48 x 102 42 x 96 88 147 23 5 13292 16833 20576 22950 26584 29834 34158 No 412

29.75 42 x 102 48 x 108 42 x 102 93 147 23 5 14123 17885 21862 24385 28246 31699 36293 No 429

31.50 42 x 108 48 x 114 42 x 108 91 159 23 5 14954 18937 23148 25819 29907 33563 38428 No 450

16.00 48 x 48 54 x 54 48 x 48 86 87 25 5 7596 9619 11758 13114 15191 17048 19519 Yes 257

18.00 48 x 54 54 x 60 48 x 54 85 99 25 5 8545 10821 13227 14754 17090 19179 21959 Yes 278

20.00 48 x 60 54 x 66 48 x 60 94 99 25 5 9494 12024 14697 16393 18989 21310 24399 Yes 299

22.00 48 x 66 54 x 72 48 x 66 92 111 25 5 10444 13226 16167 18032 20888 23441 26838 Yes 332

24.00 48 x 72 54 x 78 48 x 72 90 123 25 5 11393 14428 17637 19672 22787 25572 29278 Yes 353

26.00 48 x 78 54 x 84 48 x 78 98 123 25 5 12343 15631 19106 21311 24685 27703 31718 No 383

28.00 48 x 84 54 x 90 48 x 84 92 135 25 5 13292 16833 20576 22950 26584 29834 34158 No 412

30.00 48 x 90 54 x 96 48 x 90 98 135 25 5 14242 18036 22046 24589 28483 31965 36598 No 430

32.00 48 x 96 54 x 102 48 x 96 96 147 25 5 15191 19238 23515 26229 30382 34096 39038 No 452

34.00 48 x 102 54 x 108 48 x 102 94 159 25 5 16140 20440 24985 27868 32281 36227 41478 No 475

36.00 48 x 108 54 x 114 48 x 108 100 159 25 5 17090 21643 26455 29507 34180 38358 43917 No 495

38.00 48 x 114 54 x 120 48 x 114 98 171 25 5 18039 22845 27924 31147 36079 40489 46357 No 517

Throat

Width x

Area

Length

2

ft

4.00 24 x 24 30 x 30 24 x 24 52 39 19 5 1899 2405 2939 3279 3798 4262 4880 Yes 82

5.00 24 x 30 30 x 36 24 x 30 49 51 19 5 2374 3006 3674 4098 4747 5328 6100 Yes 91

6.00 24 x 36 30 x 42 24 x 36 47 63 19 5 2848 3607 4409 4918 5697 6393 7320 Yes 104

7.00 24 x 42 30 x 48 24 x 42 54 63 19 5 3323 4208 5144 5738 6646 7459 8539 Yes 114

8.00 24 x 48 30 x 54 24 x 48 52 75 19 5 3798 4809 5879 6557 7596 8524 9759 Yes 125

9.00 24 x 54 30 x 60 24 x 54 50 87 19 5 4272 5411 6614 7377 8545 9590 10979 Yes 154

6.25 30 x 30 36 x 36 30 x 30 60 51 19 5 2967 3757 4593 5123 5934 6659 7625 Yes 108

7.50 30 x 36 36 x 42 30 x 36 58 63 19 5 3560 4509 5511 6147 7121 7991 9149 Yes 119

8.75 30 x 42 36 x 48 30 x 42 57 75 19 5 4154 5260 6430 7172 8308 9323 10674 Yes 131

9.00 36 x 36 42 x 42 36 x 36 69 63 19 5 4272 5411 6614 7377 8545 9590 10979 Yes 134

Curb Cap

Width x

Length

36 x 84 30 x 78 69 111 19 5 7714 9769 11941 13319 15428 17314 19824 Yes 251

Optional

Damper

Width x

Length

Inches CFM

Width

Length

Overall

A B C D 235/475 297/600 364/735 406/820 470/950 527/1065 604/1220

0.030 0.047 0.071 0.089 0.119 0.149 0.196

Base

0.053 0.085 0.127 0.158 0.212 0.267 0.350

Height

Height

DUCTED STATIC PRESSURE DROP (IN. WG)

NON-DUCTED STATIC PRESSURE DROP (IN. WG)

HOOD INTAKE VELOCITY / THROAT VELOCITY (FT/MIN)

21516 24923 27970 32023 Yes 392

Shipped

Assembled

POUNDS

Galvanized

Unit Weight

9

Page 10

Fabra Hood ‑ Gravity Intake

Model FGI

7

/

A

Throat Width

Curb Cap Width

Dimensional Data Performance Data

Throat

Area

20.25 54 x 54 60 x 60 54 x 54 95 99 26 5 9613 12174 14881 16598 19226 21576 24704 No 304

22.50 54 x 60 60 x 66 54 x 60 105 99 26 5 10681 13527 16534 18442 21362 23974 27448 No 341

24.75 54 x 66 60 x 72 54 x 66 103 111 26 5 11749 14879 18188 20286 23499 26371 30193 No 370

27.00 54 x 72 60 x 78 54 x 72 101 123 26 5 12817 16232 19841 22131 25635 28769 32938 No 394

29.25 54 x 78 60 x 84 54 x 78 109 123 26 5 13886 17585 21495 23975 27771 31166 35683 No 433

31.50 54 x 84 60 x 90 54 x 84 107 135 26 5 14954 18937 23148 25819 29907 33563 38428 No 457

33.75 54 x 90 60 x 96 54 x 90 105 147 26 5 16022 20290 24801 27663 32044 35961 41173 No 481

36.00 54 x 96 60 x 102 54 x 96 112 147 26 5 17090 21643 26455 29507 34180 38358 43917 No 502

38.25 54 x 102 60 x 108 54 x 102 110 159 26 5 18158 22995 28108 31352 36316 40756 46662 No 528

40.50 54 x 108 60 x 114 54 x 108 108 171 26 5 19226 24348 29762 33196 38452 43153 49407 No 550

42.75 54 x 114 60 x 120 54 x 114 114 171 26 5 20294 25701 31415 35040 40589 45550 52152 No 572

25.00 60 x 60 66 x 66 60 x 60 104 111 29.5 5 11868 15030 18371 20491 23736 26638 30498 No 379

27.50 60 x 66 66 x 72 60 x 66 114 111 29.5 5 13055 16533 20209 22540 26110 29301 33548 No 404

30.00 60 x 72 66 x 78 60 x 72 112 123 29.5 5 14242 18036 22046 24589 28483 31965 36598 No 429

32.50 60 x 78 66 x 84 60 x 78 110 135 29.5 5 15428 19539 23883 26639 30857 34629 39648 No 473

35.00 60 x 84 66 x 90 60 x 84 119 135 29.5 5 16615 21042 25720 28688 33230 37293 42697 No 500

37.50 60 x 90 66 x 96 60 x 90 117 147 29.5 5 17802 22544 27557 30737 35604 39956 45747 No 525

40.00 60 x 96 66 x 102 60 x 96 115 159 29.5 5 18989 24047 29394 32786 37978 42620 48797 No 552

42.50 60 x 102 66 x 108 60 x 102 122 159 29.5 5 20176 25550 31231 34835 40351 45284 51847 No 576

45.00 60 x 108 66 x 114 60 x 108 120 171 29.5 5 21362 27053 33068 36884 42725 47948 54897 No 601

47.50 60 x 114

50.00 60 x 120 66 x 126 60 x 120 124 183 29.5 5 23736 30059 36743 40982 47472 53275 60996 No 761

30.25 66 x 66 72 x 72 66 x 66 113 123 29.5 5 14360 18186 22229 24794 28721 32232 36903 No 431

33.00 66 x 72 72 x 78 66 x 72 123 123 29.5 5 15666 19839 24250 27048 31332 35162 40258 No 504

35.75 66 x 78 72 x 84 66 x 78 121 135 29.5 5 16971 21492 26271 29302 33942 38092 43612 No 555

38.50 66 x 84 72 x 90 66 x 84 120 147 29.5 5 18277 23146 28292 31557 36553 41022 46967 No 632

41.25 66 x 90 72 x 96 66 x 90 128 147 29.5 5 19582 24799 30313 33811 39164 43952 50322 No 643

44.00 66 x 96 72 x 102 66 x 96 126 159 29.5 5 20888 26452 32334 36065 41775 46882 53677 No 663

46.75 66 x 102 72 x 108 66 x 102 133 159 29.5 5 22193 28105 34354 38319 44386 49812 57032 No 726

49.50 66 x 108 72 x 114 66 x 108 131 171 29.5 5 23499 29759 36375 40573 46997 52742 60386 No 753

52.25 66 x 114 72 x 120 66 x 114 129 183 29.5 5 24804 31412 38396 42827 49608 55673 63741 No 784

55.00 66 x 120 72 x 126 66 x 120 136 183 29.5 5 26110 33065 40417 45081 52219 58603 67096 No 823

57.75 66 x 126 72 x 132 66 x 126 134 195 36.5 12 27415 34719 42438 47335 54830 61533 70451 No 900

60.50 66 x 132 72 x 138 66 x 132 132 207 36.5 12 28721 36372 44459 49589 57441 64463 73806 No 916

36.00 72 x 72 78 x 78 72 x 72 134 123 29.5 5 17090 21643 26455 29507 34180 38358 43917 No 587

39.00 72 x 78 78 x 84 72 x 78 132 135 29.5 5 18514 23446 28659 31966 37028 41555 47577 No 641

42.00 72 x 84 78 x 90 72 x 84 130 147 29.5 5 19938 25250 30864 34425 39876 44751 51237 No 670

45.00 72 x 90 78 x 96 72 x 90 136 159 29.5 5 21362 27053 33068 36884 42725 47948 54897 No 733

48.00 72 x 96 78 x 102 72 x 96 136 171 29.5 5 22787 28857 35273 39343 45573 51144 58556 No 771

51.00 72 x 102 78 x 108 72 x 102 135 171 29.5 5 24211 30661 37478 41802 48421 54341 62216 No 791

54.00 72 x 108 78 x 114 72 x 108 136 183 29.5 5 25635 32464 39682 44261 51270 57537 65876 No 811

57.00 72 x 114 78 x 120 72 x 114 136 195 29.5 5 27059 34268 41887 46720 54118 60734 69536 No 848

60.00 72 x 120 78 x 126 72 x 120 136 207 29.5 5 28483 36071 44091 49179 56966 63930 73196 No 886

63.00 72 x 126 78 x 132 72 x 126 136 207 36.5 12 29907 37875 46296

66.00 72 x 132 78 x 138 72 x 132 136 219 36.5 12 31332 39678 48500 54097 62663 70323 80515 No 973

69.00 72 x 138 78 x 144 72 x 138 136 219 36.5 12 32756 41482 50705 56556 65511 73520 84175 No 976

72.00 72 x 144 78 x 150 72 x 144 136 231 36.5 12 34180 43285 52910 59015 68360 76716 87835 No 1015

75.00 72 x 150 78 x 156 72 x 150 136 231 36.5 12 35604 45089 55114 61474 71208 79913 91495 No 1116

78.00 72 x 156 78 x 162 72 x 156 136 243 36.5 12 37028 46893 57319 63933 74056 83109 95154 No 1228

81.00 72 x 162 78 x 168 72 x 162 136 243 36.5 12 38452 48696 59523 66392 76905 86306 98814 No 1351

84.00 72 x 168 78 x 174 72 x 168 136 255 36.5 12 39876 50500 61728 68851 79753 89502 102474 No 1486

87.00 72 x 174 78 x 180 72 x 174 136 255 36.5 12 41301 52303 63932 71310 82601 92699 106134 No 1634

90.00 72 x 180 78 x 186 72 x 180 136 267 36.5 12 42725 54107 66137 73768 85450 95895 109793 No 1798

Throat

Width x

Length

2

ft

Curb Cap

Width x

Length

66 x 120 60 x 114 126 171 29.5 5 22549 28556 34906 38933 45098 50611 57947 No 733

Optional

Damper

Width x

Length

Inches CFM

Width

Length

A B C D 235/475 297/600 364/735 406/820 470/950 527/1065 604/1220

Overall

Base

Height

8

C

2

D

DD

All dimensions

shown in inches

0.030 0.047 0.071 0.089 0.119 0.149 0.196

0.053 0.085 0.127 0.158 0.212 0.267 0.350

Height

DUCTED STATIC PRESSURE DROP (IN. WG)

NON-DUCTED STATIC PRESSURE DROP (IN. WG)

HOOD INTAKE VELOCITY / THROAT VELOCITY (FT/MIN)

51638 59815 67127 76855 No 934

B

Throat Length

Curb Cap Length

Shipped

Assembled

POUNDS

1½

Galvanized

Unit Weight

10

Page 11

Fabra Hood ‑ Gravity Relief

Model FGR

7

/

A

Throat Width

Curb Cap Width

8

C

2

D

DD

All dimensions

shown in inches

B

1½

Throat Length

Curb Cap Length

Dimensional Data Performance Data

Throat

Area

0.67 8 x 12 14 x 18 8 x 12 22 27 14 5 279 372 441 520 586 661 717 Yes 37

1.00 8 x 18 14 x 24 8 x 18 22 39 14 5 418 559 661 779 880 991 1075 Yes 46

1.33 8 x 24 14 x 30 8 x 24 22 39 14 5 557 745 881 1039 1173 1321 1434 Yes 48

1.67 8 x 30 14 x 36 8 x 30 22 51 14 5 697 931 1101 1299 1466 1651 1792 Yes 56

1.00 12 x 12 18 x 18 12 x 12 26 27 14 5 418 559 661 779 880 991 1075 Yes 37

1.50 12 x 18 18 x 24 12 x 18 26 39 14 5 627 838 991 1169 1319 1486 1613 Yes 46

2.00 12 x 24 18 x 30 12 x 24 26 39 14 5 836 1117 1322 1559 1759 1982 2151 Yes 48

2.50 12 x 30 18 x 36 12 x 30 26 51 14 5 1045 1396 1652 1948 2199 2477 2688 Yes 56

3.00 12 x 36 18 x 42 12 x 36 26 51 14 5 1254 1676 1983 2338 2639 2972 3226 Yes 58

3.50 12 x 42 18 x 48 12 x 42 26 63 14 5 1463 1955 2313 2727 3079 3468 3764 Yes 69

4.00 12 x 48 18 x 54 12 x 48 26 63 14 5 1672 2234 2643 3117 3518 3963 4301 Yes 71

1.36 14 x 14 20 x 20 14 x 14 28 27 16 5 569 760 900 1061 1197 1349 1464 Yes 42

1.75 14 x 18 20 x 24 14 x 18 28 39 16 5 731 977 1157 1364 1539 1734 1882 Yes 50

2.33 14 x 24 20 x 30 14 x 24 28 39 16 5 975 1303 1542 1818 2052 2312 2509 Yes 53

2.92 14 x 30 20 x 36 14 x 30 28 51 16 5 1219 1629 1928 2273 2565 2890 3136 Yes 60

3.50 14 x 36 20 x 42 14 x 36 28 51 16 5 1463 1955 2313 2727 3079 3468 3764 Yes 62

4.08 14 x 42 20 x 48 14 x 42 28 63 16 5 1707 2281 2699 3182 3592 4046 4391 Yes 74

4.67 14 x 48 20 x 54 14 x 48 28 63 16 5 1951 2606 3084 3637 4105 4624 5018 Yes 76

5.25 14 x 54 20 x 60 14 x 54 28 75 16 5 2194 2932 3470 4091 4618 5202 5645 Yes 87

1.78 16 x 16

2.22 16 x 20 22 x 26 16 x 20 30 39 16 5 929 1241 1469 1732 1955 2202 2390 Yes 53

2.67 16 x 24 22 x 30 16 x 24 30 39 16 5 1115 1489 1762 2078 2346 2642 2868 Yes 55

3.33 16 x 30 22 x 36 16 x 30 30 51 16 5 1393 1862 2203 2598 2932 3303 3584 Yes 64

4.00 16 x 36 22 x 42 16 x 36 30 51 16 5 1672 2234 2643 3117 3518 3963 4301 Yes 66

4.67 16 x 42 22 x 48 16 x 42 30 63 16 5 1951 2606 3084 3637 4105 4624 5018 Yes 78

5.33 16 x 48 22 x 54 16 x 48 30 63 16 5 2229 2979 3525 4156 4691 5284 5735 Yes 80

6.00 16 x 54 22 x 60 16 x 54 30 75 16 5 2508 3351 3965 4676 5277 5945 6452 Yes 91

6.67 16 x 60 22 x 66 16 x 60 31 75 16 5 2786 3724 4406 5195 5864 6605 7169 Yes 95

7.33 16 x 66 22 x 72 16 x 66 30 87 16 5 3065 4096 4846 5715 6450 7266 7886 Yes 120

2.25 18 x 18 24 x 24 18 x 18 32 39 16 5 940 1257 1487 1753 1979 2229 2419 Yes 55

3.00 18 x 24 24 x 30 18 x 24 32 39 16 5 1254 1676 1983 2338 2639 2972 3226 Yes 57

3.75 18 x 30 24 x 36 18 x 30 32 51 16 5 1567 2094 2478 2922 3298 3715 4032 Yes 67

4.50 18 x 36 24 x 42 18 x 36 32 51 16 5 1881 2513 2974 3507 3958 4458 4839 Yes 69

5.25 18 x 42 24 x 48 18 x 42 32 63 16 5 2194 2932 3470 4091 4618 5202 5645 Yes 81

6.00 18 x 48 24 x 54 18 x 48 33 63 16 5 2508 3351 3965 4676 5277 5945 6452 Yes 84

6.75 18 x 54 24 x 60 18 x 54 32 75 16 5 2821 3770 4461 5260 5937 6688 7258 Yes 95

7.50 18 x 60 24 x 66 18 x 60 34 75 16 5 3135 4189 4956 5845 6597 7431 8065 Yes 99

8.25 18 x 66 24 x 72 18 x 66 32 87 16 5 3448 4608 5452 6429 7256 8174 8871 Yes 124

9.00 18 x 72 24 x 78 18 x 72 35 87 16 5 3762 5027 5948 7013 7916 8917 9678 Yes 129

2.78 20 x 20 26 x 26 20 x 20 34 39 16 5 1161 1551 1836 2165 2443 2752 2987 Yes 58

3.33 20 x 24 26 x 30 20 x 24 34 39 16 5 1393 1862 2203 2598 2932 3303 3584 Yes 60

4.17 20 x 30 26 x 36 20 x 30 34 51 16 5 1742 2327 2754 3247 3665 4128 4480 Yes 69

5.00 20 x 36 26 x 42 20 x 36 34 51 16 5 2090 2793 3304

5.83 20 x 42 26 x 48 20 x 42 34 63 16 5 2438 3258 3855 4546 5131 5779 6273 Yes 84

6.67 20 x 48 26 x 54 20 x 48 36 63 16 5 2786 3724 4406 5195 5864 6605 7169 Yes 89

7.50 20 x 54 26 x 60 20 x 54 34 75 16 5 3135 4189 4956 5845 6597 7431 8065 Yes 98

8.33 20 x 60 26 x 66 20 x 60 37 75 16 5 3483 4654 5507 6494 7330 8256 8961 Yes 104

9.17 20 x 66 26 x 72 20 x 66 35 87 16 5 3831 5120 6058 7143 8063 9082 9857 Yes 128

10.00 20 x 72 26 x 78 20 x 72 38 87 16 5 4180 5585 6609 7793 8796 9908 10753 Yes 135

10.83 20 x 78 26 x 84 20 x 78 37 99 16 5 4528 6051 7159 8442 9529 10733 11649 Yes 153

11.67 20 x 84 26 x 90 20 x 84 39 99 16 5 4876 6516 7710 9092 10262 11559 12545 Yes 158

Throat

Width x

Length

2

ft

0.44 8 x 8 14 x 14 8 x 8 22 27 14 5 186 248 294 346 391 440 478 Yes 37

Curb Cap

Width x

Length

22 x 22 16 x 16 30 39 16 5 743 993 1175 1385 1564 1761 1912 Yes 52

Optional

Damper

Width x

Length

Inches CFM

Width

Length

Overall

A B C D 420 560 660 780 880 990 1075

0.024 0.043 0.060 0.084 0.107 0.136 0.160

Base

0.042 0.075 0.105 0.146 0.186 0.236 0.278

Height

Height

DUCTED STATIC PRESSURE DROP (IN. WG)

NON-DUCTED STATIC PRESSURE DROP (IN. WG)

HOOD AND THROAT VELOCITY (FT/MIN)

3896 4398 4954 5377 Yes 71

Shipped

Assembled

POUNDS

Unit Weigh

Galvanized

11

Page 12

Fabra Hood ‑ Gravity Relief

Model FGR

7

/

A

Throat Width

Curb Cap Width

8

C

2

D

DD

All dimensions

shown in inches

B

1½

Throat Length

Curb Cap Length

Dimensional Data Performance Data

Throat

Area

10.00 24 x 60 30 x 66 24 x 60 44 75 19 5 4180 5585 6609 7793 8796 9908 10753 Yes 120

11.00 24 x 66 30 x 72 24 x 66 42 87 19 5 4598 6144 7269 8572 9675 10898 11829 Yes 146

12.00 24 x 72 30 x 78 24 x 72 45 87 19 5 5016 6702 7930 9351 10555 11889 12904 Yes 152

13.00 24 x 78 30 x 84 24 x 78 43 99 19 5 5434 7261 8591 10131 11434 12880 13979 Yes 171

14.00 24 x 84 30 x 90 24 x 84 46 99 19 5 5852 7819 9252 10910 12314 13871 15054 Yes 178

15.00 24 x 90 30 x 96 24 x 90 44 111 19 5 6269 8378 9913 11689 13194 14861 16130 Yes 202

10.00 30 x 48 36 x 54 30 x 48 52 63 19 5 4180 5585 6609 7793 8796 9908 10753 Yes 116

11.25 30 x 54 36 x 60 30 x 54 49 75 19 5 4702 6283 7435 8767 9895 11146 12097 Yes 128

12.50 30 x 60 36 x 66 30 x 60 54 75 19 5 5225 6982 8261 9741 10995 12385 13441 Yes 136

13.75 30 x 66 36 x 72 30 x 66 51 87 19 5 5747 7680 9087 10715 12094 13623 14786 Yes 162

15.00 30 x 72 36 x 78 30 x 72 49 99 19 5 6269 8378 9913 11689 13194 14861 16130 Yes 172

16.25 30 x 78

17.50 30 x 84 36 x 90 30 x 84 51 111 19 5 7314 9774 11565 13637 15393 17338 18818 Yes 216

18.75 30 x 90 36 x 96 30 x 90 54 111 19 5 7837 10472 12391 14611 16492 18577 20162 Yes 223

10.50 36 x 42 42 x 48 36 x 42 54 63 19 5 4389 5865 6939 8182 9236 10403 11291 Yes 119

12.00 36 x 48 42 x 54 36 x 48 62 63 19 5 5016 6702 7930 9351 10555 11889 12904 Yes 130

13.50 36 x 54 42 x 60 36 x 54 58 75 19 5 5643 7540 8922 10520 11874 13375 14517 Yes 142

15.00 36 x 60 42 x 66 36 x 60 55 87 19 5 6269 8378 9913 11689 13194 14861 16130 Yes 168

16.50 36 x 66 42 x 72 36 x 66 61 87 19 5 6896 9216 10904 12858 14513 16348 17743 Yes 178

18.00 36 x 72 42 x 78 36 x 72 58 99 19 5 7523 10054 11895 14027 15832 17834 19356 Yes 190

19.50 36 x 78 42 x 84 36 x 78 63 96 19 5 8150 10891 12887 15196 17152 19320 20969 Yes 211

21.00 36 x 84 42 x 90 36 x 84 60 111 19 5 8777 11729 13878 16365 18471 20806 22582 Yes 235

22.50 36 x 90 42 x 96 36 x 90 64 111 19 5 9404 12567 14869 17534 19790 22292 24195 Yes 244

24.00 36 x 96 42 x 102 36 x 96 62 123 19 5 10031 13405 15861 18703 21110 23778 25808 Yes 258

25.50 36 x 102 42 x 108 36 x 102 65 123 19 5 10658 14242 16852 19872 22429 25265 27421 Yes 266

12.25 42 x 42 48 x 48 42 x 42 63 63 23 5 5120 6842 8096 9546 10775 12137 13173 Yes 144

14.00 42 x 48 48 x 54 42 x 48 60 75 23 5 5852 7819 9252 10910 12314 13871 15054 Yes 157

15.75 42 x 54 48 x 60 42 x 54 67 75 23 5 6583 8797 10409 12274 13853 15605 16936 Yes 169

17.50 42 x 60 48 x 66 42 x 60 64 87 23 5 7314 9774 11565 13637 15393 17338 18818 Yes 197

19.25 42 x 66 48 x 72 42 x 66 70 87 23 5 8046 10752 12722 15001 16932 19072 20700 Yes 208

21.00 42 x 72 48 x 78 42 x 72 67 99 23 5 8777 11729 13878 16365 18471 20806 22582 Yes 222

22.75 42 x 78 48 x 84 42 x 78 72 99 23 5 9509 12707 15035 17729 20010 22540 24463 Yes 245

24.50 42 x 84 48 x 90 42 x 84 69 111 23 5 10240 13684 16191 19092 21550 24274 26345 Yes 270

26.25 42 x 90 48 x 96 42 x 90 67 123 23 5 10972 14661 17348

28.00 42 x 96 48 x 102 42 x 96 71 123 23 5 11703 15639 18504 21820 24628 27741 30109 Yes 296

29.75 42 x 102 48 x 108 42 x 102 69 135 23 5 12434 16616 19661 23183 26167 29475 31991 Yes 311

31.50 42 x 108 48 x 114 42 x 108 73 135 23 5 13166 17594 20817 24547 27707 31209 33873 Yes 321

16.00 48 x 48 54 x 54 48 x 48 68 75 25 5 6687 8936 10574 12468 14073 15852 17205 Yes 168

18.00 48 x 54 54 x 60 48 x 54 76 75 25 5 7523 10054 11895 14027 15832 17834 19356 Yes 187

20.00 48 x 60 54 x 66 48 x 60 73 87 25 5 8359 11171 13217 15586 17591 19815 21506 Yes 216

22.00 48 x 66 54 x 72 48 x 66 79 87 25 5 9195 12288 14539 17144 19351 21797 23657 Yes 246

24.00 48 x 72 54 x 78 48 x 72 76 99 25 5 10031 13405 15861 18703 21110 23778 25808 Yes 242

26.00 48 x 78 54 x 84 48 x 78 73 111 25 5 10867 14522 17182 20261 22869 25760 27958 Yes 281

28.00 48 x 84 54 x 90 48 x 84 79 111 25 5 11703 15639 18504 21820 24628 27741 30109 Yes 319

30.00 48 x 90 54 x 96 48 x 90 76 123 25 5 12539 16756 19826 23378 26387 29723 32260 Yes 310

32.00 48 x 96 54 x 102 48 x 96 81 123 25 5 13375 17873 21148 24937 28146 31704 34410 Yes 350

34.00 48 x 102 54 x 108 48 x 102 78 135 25 5 14211 18990 22469 26495 29905 33686 36561 Yes 367

36.00 48 x 108 54 x 114 48 x 108 83 135 25 5 15047 20107 23791 28054 31665 35668 38711 Yes 381

38.00 48 x 114 54 x 120 48 x 114 80 147 25 5 15883 21224 25113 29612 33424 37649 40862 No 398

Throat

Width x

Length

2

ft

4.00 24 x 24 30 x 30 24 x 24 38 39 19 5 1672 2234 2643 3117 3518 3963 4301 Yes 69

5.00 24 x 30 30 x 36 24 x 30 38 51 19 5 2090 2793 3304 3896 4398 4954 5377 Yes 79

6.00 24 x 36 30 x 42 24 x 36 40 51 19 5 2508 3351 3965 4676 5277 5945 6452 Yes 84

7.00 24 x 42 30 x 48 24 x 42 38 63 19 5 2926 3910 4626 5455 6157 6935 7527 Yes 95

8.00 24 x 48 30 x 54 24 x 48 42 63 19 5 3344 4468 5287 6234 7037 7926 8603 Yes 102

9.00 24 x 54 30 x 60 24 x 54 40 75 19 5 3762 5027 5948 7013 7916 8917 9678 Yes 113

6.25 30 x 30 36 x 36 30 x 30 44 51 19 5 2612 3491 4130 4870 5497 6192 6721 Yes 88

7.50 30 x 36 36 x 42 30 x 36 49 51 19 5 3135 4189 4956 5845 6597 7431 8065 Yes 95

8.75 30 x 42 36 x 48 30 x 42 46 63 19 5 3657 4887 5783 6819 7696 8669 9409 Yes 107

9.00 36 x 36 42 x 42 36 x 36 58 51 19 5 3762 5027 5948 7013 7916 8917 9678 Yes 110

Curb Cap

Width x

Length

36 x 84 30 x 78 53 99 19 5 6792 9076 10739 12663 14293 16100 17474 Yes 191

Optional

Damper

Width x

Length

Inches CFM

Width

Length

Height

Overall

A B C D 420 560 660 780 880 990 1075

0.024 0.043 0.060 0.084 0.107 0.136 0.160

Base

0.042 0.075 0.105 0.146 0.186 0.236 0.278

Height

DUCTED STATIC PRESSURE DROP (IN. WG)

NON-DUCTED STATIC PRESSURE DROP (IN. WG)

HOOD AND THROAT VELOCITY (FT/MIN)

20456 23089 26008 28227 Yes 284

Shipped

Assembled

POUNDS

Galvanized

Unit Weight

12

Page 13

Fabra Hood ‑ Gravity Relief

Model FGR

7

A

Throat Width

Curb Cap Width

/

C

2

D

DD

All dimensions

shown in inches

8

B

1½

Throat Length

Curb Cap Length

Dimensional Data Performance Data

Throat

Area

20.25 54 x 54 60 x 60 54 x 54 85 75 26 5 8464 11310 13382 15780 17811 20063 21775 Yes 223

22.50 54 x 60 60 x 66 54 x 60 81 87 26 5 9404 12567 14869 17534 19790 22292 24195 Yes 266

24.75 54 x 66 60 x 72 54 x 66 78 99 26 5 10345 13824 16356 19287 21769 24521 26614 Yes 285

27.00 54 x 72 60 x 78 54 x 72 85 99 26 5 11285 15080 17843 21040 23748 26751 29034 Yes 300

29.25 54 x 78 60 x 84 54 x 78 82 111 26 5 12225 16337 19330 22794 25727 28980 31453 Yes 345

31.50 54 x 84 60 x 90 54 x 84 88 111 26 5 13166 17594 20817 24547 27707 31209 33873 Yes 363

33.75 54 x 90 60 x 96 54 x 90 85 123 26 5 14106 18850 22304 26301 29686 33438 36292 Yes 380

36.00 54 x 96 60 x 102 54 x 96 90 123 26 5 15047 20107 23791 28054 31665 35668 38711 Yes 396

38.25 54 x 102 60 x 108 54 x 102 87 135 26 5 15987 21364 25278 29807 33644 37897 41131 Yes 416

40.50 54 x 108 60 x 114 54 x 108 85 147 26 5 16928 22620 26765 31561 35623 40126 43550 No 433

42.75 54 x 114 60 x 120 54 x 114 90 147 26 5 17868 23877 28252 33314 37602 42355 45970 No 450

25.00 60 x 60 66 x 66 60 x 60 90 87 29.5 5 10449 13963 16521 19482 21989 24769 26883 Yes 284

27.50 60 x 66 66 x 72 60 x 66 87 99 29.5 5 11494 15360 18174 21430 24188 27246 29571 Yes 304

30.00 60 x 72 66 x 78 60 x 72 94 99 29.5 5 12539 16756 19826 23378 26387 29723 32260 Yes 320

32.50 60 x 78 66 x 84 60 x 78 91 111 29.5 5 13584 18152 21478 25326 28586 32200 34948 Yes 367

35.00 60 x 84 66 x 90 60 x 84 97 111 29.5 5 14629 19548 23130 27275 30785 34677 37636 Yes 387

37.50 60 x 90 66 x 96 60 x 90 94 123 29.5 5 15674 20945 24782 29223 32984 37154 40324 Yes 403

40.00 60 x 96 66 x 102 60 x 96 91 135 29.5 5 16719 22341 26434 31171 35183 39631 43013 Yes 423

42.50 60 x 102 66 x 108 60 x 102 97 135 29.5 5 17763 23737 28087 33119 37382 42108 45701 No 444

45.00 60 x 108 66 x 114 60 x 108 94 147 29.5 5 18808 25134 29739 35067 39581 44584 48389 No 460

47.50 60 x 114

50.00 60 x 120 66 x 126 60 x 120 96 159 29.5 5 20898 27926 33043 38964 43979 49538 53766 No 496

30.25 66 x 66 72 x 72 66 x 66 95 99 29.5 5 12643 16895 19991 23573 26607 29971 32528 No 322

33.00 66 x 72 72 x 78 66 x 72 103 99 29.5 5 13793 18431 21808 25716 29026 32695 35486 No 342

35.75 66 x 78 72 x 84 66 x 78 99 111 29.5 5 14942 19967 23626 27859 31445 35420 38443 No 388

38.50 66 x 84 72 x 90 66 x 84 96 123 29.5 5 16092 21503 25443 30002 33864 38144 41400 No 410

41.25 66 x 90 72 x 96 66 x 90 103 123 29.5 5 17241 23039 27260 32145 36282 40869 44357 No 430

44.00 66 x 96 72 x 102 66 x 96 100 135 29.5 5 18390 24575 29078 34288 38701 43594 47314 No 449

46.75 66 x 102 72 x 108 66 x 102 106 135 29.5 5 19540 26111 30895 36431 41120 46318 50271 No 471

49.50 66 x 108 72 x 114 66 x 108 103 147 29.5 5 20689 27647 32713 38574 43539 49043 53228 No 489

52.25 66 x 114 72 x 120 66 x 114 109 147 29.5 5 21839 29183 34530 40717 45958 51767 56185 No 509

55.00 66 x 120 72 x 126 66 x 120 106 159 29.5 5 22988 30719 36347 42860 48376 54492 59143 No 530

57.75 66 x 126 72 x 132 66 x 126 103 171 36.5 12 24137 32255 38165 45003 50795 57217 62100 No 595

60.50 66 x 132 72 x 138 66 x 132 108 171 36.5 12 25287 33791 39982 47146 53214 59941 65057 No 616

36.00 72 x 72 78 x 78 72 x 72 112 99 29.5 5 15047 20107 23791 28054 31665 35668 38711 No 365

39.00 72 x 78 78 x 84 72 x 78 108 111 29.5 5 16301 21783 25774 30392 34303 38640 41937 No 412

42.00 72 x 84 78 x 90 72 x 84 105 123 29.5 5 17555 23458 27756 32730 36942 41612 45163 No 434

45.00 72 x 90 78 x 96 72 x 90 112 123 29.5 5 18808 25134 29739 35067 39581 44584 48389 No 457

48.00 72 x 96 78 x 102 72 x 96 109 135 29.5 5 20062 26809 31721 37405 42219 47557 51615 No 479

51.00 72 x 102 78 x 108 72 x 102 115 135 29.5 5 21316 28485 33704 39743 44858 50529 54841 No 497

54.00 72 x 108 78 x 114 72 x 108 112 147 29.5 5 22570 30161 35686 42081 47497 53501 58067 No 519

57.00 72 x 114 78 x 120 72 x 114 109 159 29.5 5 23824 31836 37669 44419 50136 56474 61293 No 541

60.00 72 x 120 78 x 126 72 x 120 115 159 29.5 5 25078 33512 39652 46757 52774 59446 64519 No 607

63.00 72 x 126 78 x 132 72 x 126 112 171 36.5 12 26332 35187 41634

66.00 72 x 132 78 x 138 72 x 132 117 171 36.5 12 27586 36863 43617 51432 58052 65390 70971 No 648

69.00 72 x 138 78 x 144 72 x 138 114 183 36.5 12 28840 38538 45599 53770 60690 68363 74197 No 670

72.00 72 x 144 78 x 150 72 x 144 119 183 36.5 12 30093 40214 47582 56108 63329 71335 77423 No 690

75.00 72 x 150 78 x 156 72 x 150 117 195 36.5 12 31347 41890 49564 58446 65968 74307 80649 No 759

78.00 72 x 156 78 x 162 72 x 156 121 195 36.5 12 32601 43565 51547 60784 68607 77280 83875 No 834

81.00 72 x 162 78 x 168 72 x 162 118 207 36.5 12 33855 45241 53530 63121 71245 80252 87101 No 918

84.00 72 x 168 78 x 174 72 x 168 116 219 36.5 12 35109 46916 55512 65459 73884 83224 90327 No 1010

87.00 72 x 174 78 x 180 72 x 174 120 219 36.5 12 36363 48592 57495 67797 76523 86197 93553 No 1111

90.00 72 x 180 78 x 186 72 x 180 118 231 36.5 12 37617 50268 59477 70135 79161 89169 96779 No 1222

Throat

Width x

Length

2

ft

Curb Cap

Width x

Length

66 x 120 60 x 114 99 147 29.5 5 19853 26530 31391 37016 41780 47061 51078 No 479

Optional

Damper

Width x

Length

Inches CFM

Width

Length

Height

Overall

A B C D 420 560 660 780 880 990 1075

0.024 0.043 0.060 0.084 0.107 0.136 0.160

Base

Height

0.042 0.075 0.105 0.146 0.186 0.236 0.278

DUCTED STATIC PRESSURE DROP (IN. WG)

NON-DUCTED STATIC PRESSURE DROP (IN. WG)

HOOD AND THROAT VELOCITY (FT/MIN)

49094 55413 62418 67745 No 629

Shipped

Assembled

POUNDS

Galvanized

Unit Weight

13

Page 14

Spun Aluminum

Model GRS

Construction Features

When you buy a Greenheck model GRS, you receive

a ventilator with the industry’s best performance and

durability for intake (model GRSI) or relief (model GRSR)

on natural gravity or positive pressure systems. Exceptional

low silhouette design and construction features make this

unit a rugged, efficient and economical air inlet or outlet.

• Broadest performance in the industry, up to

18,400 cfm (31,300 m3/hr)

• Most advanced weather protection of any ventilator

in its class

• Greenheck subjects these products to extensive life

testing, assuring the ventilator will provide years of

reliable performance

• All aluminum exterior for corrosion-resistant construction

• Integral birdscreen to prevent entry of birds and/or

small objects

• Built-in curb cap with prepunched holes for easy

attachment to roof curbs

Optional built-in flashing flange (model GRSF) with

prepunched holes for quick and easy installations without a

roof curb.

Optional

Flashing

Flange

Integral

Birdscreen

Dimensions

1

⁄4

8

1

⁄4

1

⁄4

1

⁄4

1

⁄4

1

⁄4

1

⁄4

1

⁄2

1

⁄2

1

⁄2

1

⁄2

Damper

Size

8 x 8

(203 x 203)

10 x 10

(254 x 254)

12 x 12

(305 305)

16 x 16

(406 x 406)

16 x 16

(406 x 406)

18 x 18

(457 x 457)

18 x 18

(457 x 457)

24 x 24

(610 x 610)

30 x 30

(762 x 762)

36 x 36

(914 x 914)

42 x 42

(1067 x 1067)

48 x 48

(1219 x 1219)

Model A B C D E Dia.

1

1

19

20

⁄2

56

29

29

29

48

72

1

⁄2

1

⁄2

1

⁄2

1

⁄4

3

⁄4

1

⁄4

7

(184)

7

(197)2 (51)

10

(254)

10

(254)

11

(279)

9

(248)

11

(286)

11

(279)4 (102)

18

(476)

21

(540)6 (152)

24

(616)

26

(667)

GRS-8

GRS-10

GRS-12

GRS-15

GRS-16

GRS-18

GRS-20

GRS-24

GRS-30

GRS-36

GRS-42

GRS-48

All dimensions in inches (millimeters) and the weight in pounds (kilograms). NOTE: Models GRS-8 through GRS-24 have

a one-piece cover and shroud. Access is gained through the removal of screws. Models GRS-30 through GRS-48 have

a removable cover, separate from the shroud, to facilitate maintenance and servicing of dampers.

(483)

19

(483)

22

(559)

22

(559)

26

(660)

30

(762)

30

(762)

34

(864)

40

(1016)

46

(1168)

52

(1321)

58

(1473)

(521)

20

(521)

(737)

(737)

(737)

35

(902)

35

(902)

38

(972)

(1219)

(1441)

63

(1607)

(1829)

1

⁄4

1

(38)

3

⁄4

1

3

(89)

1

3

(89)

1

4

(108)

3

3

⁄4

1

(44)

1

3

⁄4

3

(95)

3

7

⁄4

5

(138)

1

⁄4

1

1

⁄4

6

(159)

1

1

⁄4

6

(165)

1

⁄2

⁄2

⁄2

⁄4

⁄4

⁄4

⁄16

⁄4

⁄2

20

(514)

20

(514)

23

(591)

23

(591)

27

(692)

31

(794)

31

(794)

35

(895)

-

-

-

-

⁄4

(210)

1

⁄4

10

(260)

1

⁄4

12

(311)

1

⁄4

14

(362)

1

⁄4

16

(413)

1

⁄4

20

(514)

1

⁄4

20

(514)

1

⁄4

24

(622)

30

(775)

36

(927)

421⁄2

(1089)

48

(1232)

Curb

Material

0.051

(1.3)

0.051

(1.3)

0.064

(1.6)

0.064

(1.6)

0.064

(1.6)

0.064

(1.6)

0.064

(1.6)

0.064

(1.6)

0.064

(1.6)

0.064

(1.6)

0.064

(1.6)

0.064

(1.6)

Shroud

Material

0.051

(1.3)

0.051

(1.3)

0.064

(1.6)

0.064

(1.6)

0.064

(1.6)

0.064

(1.6)

0.064

(1.6)

0.064

(1.6)

0.064

(1.6)

0.080

(2.0)

0.080

(2.0)

0.080

(2.0)

Unit

Weight

7

(3)

8

(4)

10

(5)

13

(6)

16

(7)

19

(9)

24

(11)

29

(13)

35

(16)

45

(20)

60

(27)

80

(36)

GRS - Sizes 8 thru 24

B

C

D

Dia.

A

GRS - Sizes 30 thru 48

B

C

D

1

Dia.

A

GRSF - Sizes 8 thru 24

with optional Flashing Flange

B

C

D

Dia.

E

3

1

3

⁄4 (44)

⁄4 (44)

14

Page 15

Spun Aluminum

Model GRSI & GRSR

Performance

Performance data for these units was obtained through actual testing.

The information is presented in capacity versus total pressure drop

through the GRS. Total pressure drop includes the static and velocity

pressure drops. To find the static drop alone, use the following equations.

Throat Velocity =

Static Pressure =

CFM

[ ]

Throat Area

Total

[ ]

Pressure

−

Velocity

[ ]

Pressure

Velocity

= [ ]

Pressure

Throat Velocity

4008.6

The data is presented for both discharge and intake units. The intake

velocity of the intake unit should not exceed 600 feet per minute.

Above this velocity, airborne particles may be carried into the building.

The table below displays the maximum recommended values for the

respective intake units. In areas where snow depths may be a problem,

12 inch

(305 mm) or higher curbs are recommended.

Capacities (CFM)

Throat

Model

GRSI-8 0.37 178 218 252 282 345 398 445 488 527 1.30 780

GRSI-10 0.57 279 342 395 442 541 624 698 765 826 1.72 1032

GRSI-12 0.82 400 490 566 633 775 895 1001 1097 1184 2.52 1512

GRSI-15 1.12 553 677 782 874 1071 1237 1383 1515 1636 2.57 1542

GRSI-16 1.45 742 908 1049 1173 1436 1658 1854 2031 2194 3.02 1812

GRSI-18 1.83 901 1104 1274 1425 1745 2015 2253 2468 2665 3.42 2052

GRSI-20 2.25 1096 1343 1550 1733 2123 2452 2741 3002 3243 4.43 2658

GRSI-24 3.24 1542 1888 2180 2438 2985 3447 3854 4222 4560 4.95 2970

GRSI-30 5.03 2013 2465 2847 3183 3898 4501 5032 5512 5954 7.49 4496

Model GRSI

Intake Performance

GRSI-36 7.29 2921 3577 4130 4618 5656 6531 7301 7998 8639 10.19 6111

GRSI-42 9.77 3911 4791 5532 6185 7574 8746 9779 10712 11570 11.93 7159

GRSI-48 12.83 5139 6294 7268 8126 9952 11491 12848 14074 15201 15.48 9286

Model

GRSR-8 0.37 231 282 326 365 446 516 576 631 682

GRSR-10 0.57 331 406 468 524 641 741 828 907 980

GRSR-12 0.82 468 573 662 740 907 1047 1171 1282 1385

GRSR-15 1.12 663 811 937 1048 1283 1481 1656 1814 1960

GRSR-16 1.45 870 1065 1230 1375 1685 1945 2175 2382 2573

GRSR-18 1.83 1060 1298 1499 1676 2052 2370 2649 2902 3135

GRSR-20 2.25 1284 1572 1815 2029 2486 2870 3209 3515 3797

GRSR-24 3.24 1879 2301 2657 2971 3638 4201 4697 5145 5558

GRSR-30 5.03 2281 2794 3226 3607 4418 5101 5703 6247 6748

Model GRSR

Relief Performance

GRSR-36 7.29 3279 4016 4637 5184 6349 7331 8197 8979 9699

GRSR-42 9.77 4672 5722 6607 7387 9047 10447 11680 12795 13820

GRSR-48 12.83 6211 7607 8783 9820 12027 13888 15527 17009 18372

Area

2

)

(ft

Throat

Area

2

)

(ft

0.04 0.06 0.08 0.1 0.15 0.2 0.25 0.3 0.35

0.04 0.06 0.08 0.1 0.15 0.2 0.25 0.3 0.35

Total Pressure Drop in inches of wg

Total Pressure Drop in inches of wg

2

Recommended Maximum

Intake Capacities

Intake Area (ft

maximum intake velocity. Above

these values (numbers in gray),

provisions should be made to

2

) Max. CFM Intake

Table is based on 600 fpm

contain incoming moisture.

15

Page 16

Louvered Penthouse

Models WIH & WRH

DIMENSIONAL DRAWING FOR CHARTS

B

Throat

Curb Cap (A)

Greenheck designs penthouse units for aesthetically

pleasing gravity intake or relief applications.

• Clean horizontal lines blend perfectly with modern

architecture.

• The special louver design results in low pressure

drops, low hood heights, and maintains maximum

weather resistance.

• All-aluminum construction assures lasting durability

and appearance.

• The removable cover is equipped with insulation to

prevent condensation.

The flexible design of the WIH (intake) and WRH

(relief) allow the units to be shipped in pre-assembled

sections. These sections are easy to assemble on the

jobsite without special tools. All required fasteners

C

and complete assembly instructions are shipped with

each unit.

Use these tables for specific product dimensions

Dimensional & Performance Data

Dimensions

Throat

12 x 12 1.00 20 x 20 26 x 26 12

12 x 14 1.20 20 x 22 26 x 28 12

12 x 16 1.30 20 x 24 26 x 30 12

12 x 18 1.50 20 x 26 26 x 32 12

12 x 22 1.80 20 x 30 26 x 36 12

12 x 24 2.00 20 x 32 26 x 38 12

14 x 14 1.36 22 x 22 28 x 28 12

14 x 16 1.55 22 x 24 28 x 30 12

14 x 18 1.75 22 x 26 28 x 32 12

14 x 20 1.95 22 x 28 28 x 34 12

14 x 24 2.34 22 x 32 28 x 38 12

14 x 28 2.70 22 x 36 28 x 42 12

16 x 16 1.78 24 x 24 30 x 30 12

16 x 20 2.22 24 x 28 30 x 34 12

16 x 24 2.68 24 x 30 30 x 36 12

16 x 28 3.11 24 x 36 30 x 42 12

16 x 30 3.33

16 x 32 3.55 24 x 40 30 x 46 12

18 x 18 2.25 26 x 26 32 x 32 12

18 x 24 3.00 26 x 32 32 x 38 12

18 x 26 3.25 26 x 34 32 x 40 12

18 x 30 3.74 26 x 38 32 x 44 16 4 748 1496 1870 2244 2618 2992 1496 2004 2618 2992 3366 3740 4488

18 x 32 4.00 26 x 40 32 x 46 16 4 800 1600 2000 2400 2800 3200 1600 2400 2800 3200 3600 4000 4800

18 x 36 4.50 26 x 44 32 x 50 16 4 900 1800 2250 2700 2150 3600 1800 2700 3150 3600 4050 4500 5400

22 x 22 3.37 30 x 30 36 x 36 16 4 674 1348 1685 2022 3359 2696 1348 2022 2359 2696 3033 3370 4044

22 x 26 3.97 30 x 34 36 x 40 16 4 794 1588 1985 2382 2779 3176 1588 2832 2779 3176 3573 3970 4764

22 x 30 4.60 30 x 38 36 x 44 16 4 920 1840 2300 2760 3220 3680 1840 2760 3220 3680 4140 4600 5520

22 x 36 5.50 30 x 44 36 x 50 19

22 x 40 6.10 30 x 48 36 x 54 19

22 x 44 6.73 30 x 52 36 x 58 19

24 x 24 4.00 32 x 32 38 x 38 16 4 800 1600 2000 2400 2800 3200 1600 2400 2800 3200 3600 4000 4800

24 x 30 5.00 32 x 38 38 x 44 19

24 x 36 6.00 32 x 44 38 x 50 19

24 x 40 6.67 32 x 48 38 x 54 19

24 x 44 7.35 32 x 52 38 x 58 19

24 x 48 8.00 32 x 56 38 x 62 19

Area

(ft

A B C

2

)

24 x 38 30 x 44 121⁄4 3 666 1332 1665 1998 2331 2664 1328 1992 2324 2656 2988 3320 3984

(inches)

Number

of Louvers

1

⁄4 3 200 400 500 600 700 800 400 600 700 800 900 1000 1200

1

⁄4 3 240 480 600 720 840 960 480 720 840 960 1080 1200 1440

1

⁄4 3 260 520 650 780 910 1040 520 780 910 1040 1170 1300 1560

1

⁄4 3 300 600 750 900 1050 1200 600 900 1050 1200 1350 1500 1800

1

⁄4 3 360 720 900 1080 1260 1440 720 1080 1260 1440 1620 1800 2160

1

⁄4 3 400 800 1000 1200 1400 1600 800 1200 1400 1600 1800 2000 2400

1

⁄4 3 272 544 680 816 952 1088 544 816 952 1088 1224 1360 1632

1

⁄4 3 310 620 775 930 1085 1240 620 930 1085 1240 1395 1550 1860

1

⁄4 3 350 700 875 1050 1225 1400 700 1050 1225 1400 1575 1750 2100

1

⁄4 3 390 780 975 1170 1365 1560 780 1170 1365 1560 1755 1950 2340

1

⁄4 3 468 936 1170 1404 1638 1872 936 1404 1638 1872 2106 2340 2808

1

⁄4 3 540 1080 1350 1620 1890 2160 1080 1620 1890 2160 2430 2700 3240

1

⁄4 3 356 712 890 1068 1246 1424 712 1068 1246 1424 1602 1780 2136

1

⁄4 3 444 888 1110 1332 1554 1776 888 1332 1554 1776 1998 2220 2664

1

⁄4 3 536 1072 1340 1608 1876 2144 1072 1608 1876 2144 2412 2680 3216

1

⁄4 3 622 1244 1555 1866 2177 2488 1244 1866 2177 2488 2799 3110 3732

1

⁄4 3 710 1420 1775 2130 2485 2840 1420 2130 2485 2840 3195 3550 4260

1

⁄4 3 450 900 1125 1350 1575 1800 900 1350 1575 1800 2025 2250 2700

1

⁄4 3 600 1200 1500 1800 2100 2400 1200 1800 2100 2400 2700 3000 3600

1

⁄4 3 650 1300 1625 1950 2275 2600 1300 1950 2275 2600 2925 3250 3900

3

⁄4 5 1100 2200 2750 3300 3850 4400 2200 3300 3850 4400 4950 5500 6600

3

⁄4 5 1220 2440 3050 3660 4270 4880 2440 3660 4270 4880 5490 6100 7320

3

⁄4 5 1346 2692 3365 4038 4711 5384 2692 4038 4711 5384 6057 6730 8076

3

⁄4 5 1000 2000 2500 3000 3500 4000 2000 3000 3500 4000 4500 5000 6000

3

⁄4 5 1200 2400 3000 3600 4200 4800 2400 3600 4200 4800 5400 6000 7200

3

⁄4 5 1334 2668 3335 4002 4669 5336 2668 4002 4669 5336 6003 6670 8004

3

⁄4 5 1470 2940 3675 4410 5145 5880 2940 4410 5145 5880 6615 7350 8820

3

⁄4 5 1600 3200 4000 4800 5600 6400 3200 4800 5600 6400 7200 8000 9600

Intake (WIH) CFM Relief (WRH) CFM

Total Pressure Drop in inches of wg* Total Pressure Drop in inches wg*

.008 .030 .048 .069 .094 .123 .024 .055 .075 .097 .123 .152 .220

THROAT VELOCITY (ft/min) THROAT VELOCITY (ft/min)

200 400 500 600 700 800 400 600 700 800 900 1000 1200

* Total pressure drop includes velocity pressure losses at outlet of throat but does not include birdscreen loss.

Increase the total pressure drop with a 1.15 multiplier to allow for birdscreen pressure drop.

16

Page 17

Louvered Penthouse

Models WIH & WRH

Construction Features

Weathershield

The interior vertical edge of the

curb cap forms the throat and

weathershield. Each corner is also

shielded to prevent leakage. The

Weather Resistant Louver Blades

Each unit features weather resistant aluminum

louver blades with mitered corners. The sturdy

extruded aluminum louver blade has a material

thickness of 0.080 inches.

louvers are

mounted

4 inches

from

the roof

opening

for added

weather

protection.

Assembled Sides and Cover

The unit is made into four side sections and

a reinforced cover. A factory assembled side

consists of the curb cap, vertical supports,

and the quantity of louvers required for the

specified height.

The sides are joined at the four corners

by stainless steel screws in each louver.

Throat

4 inches

These screws are countersunk to maintain

the appearance of the mitered corner.

The cover is securely fastened to the

unit by stainless steel fasteners.

Note: For other sizes please consult factory

Dimensional & Performance Data

Dimensions

Throat

28 x 28 5.44 36 x 36 42 x 42 19

28 x 36 7.00 36 x 44 42 x 50 19

28 x 40 7.80 36 x 48 42 x 54 19

28 x 44 8.55 36 x 52 42 x 58 19

28 x 50 9.75 36 x 58 42 x 64 19

28 x 56 10.9 36 x 64 42 x 70 23

32 x 32 7.10 40 x 40 46 x 46 19

32 x 36 8.00 40 x 44 46 x 50 19

32 x 40 8.90 40 x 48 46 x 54 19

32 x 48 10.70 40 x 56 46 x 62 23

32 x 54 12.00 40 x 62 46 x 68 23

32 x 64 14.20 40 x 72 46 x 78 27

36 x 36 9.00 44 x 44 50 x 50 19

36 x 40 10.0 44 x 48 50 x 54 23

36 x 48 12.0 44 x 56 50 x 62 23

36 x 54 13.5 44 x 62 50 x 68 23

36 x 60 15.0 44 x 68

36 x 72 18.0 44 x 80 50 x 86 27

42 x 42 12.3 50 x 50 56 x 56 23

42 x 48 14.0 50 x 56 56 x 62 27

42 x 54 15.8 50 x 62 56 x 68 27

42 x 60 17.5 50 x 68 56 x 74 31 8 3500 7000 8750 10500 12250 14000 7000 10500 12250 14000 15750 17500 21000

42 x 72 21.0 50 x 80 56 x 86 31 8 4200 8400 10500 12600 14700 16800 8400 12600 14700 16800 18900 21000 25200

42 x 84 24.5 50 x 92 56 x 98 34

48 x 48 16.0 56 x 56 62 x 62 27

48 x 54 18.0 56 x 62 62 x 68 31 8 3600 7200 9000 10800 12600 14400 7200 10800 12600 14400 16200 18000 21600

48 x 64 21.4 56 x 72 62 x 78 31 8 4280 8560 10700 12840 14980 17120 8560 12840 14980 17120 19260 21400 25680

48 x 72 24.0 56 x 80 62 x 86 34

48 x 84 28.0 56 x 92 62 x 98 38

48 x 96 32.0 56 x 104 62 x 110 38

54 x 54 20.3 62 x 62 68 x 68 31 8 4050 8100 10125 12150 14175 16200 8100 12150 14175 16200 18225 20250 24300

54 x 60 22.0 62 x 68 68 x 74 34

54 x 72 27.0 62 x 80 68 x 86 38

54 x 84 31.5 62 x 92 68 x 98 38

54 x 96 36.0 62 x 104 68 x 110 42

54 x 108 40.5 62 x 116 68 x 122 421⁄2 11 8100 16200 20250 24300 28350 32400 16200 24300 28350 32400 36450 40500 48600

60 x 60 25.0 68 x 68 74 x 74 34

60 x 72 30.0 68 x 80 74 x 86 38

60 x 84 35.0 68 x 92 74 x 98 42

60 x 96 40.0 68 x 104 74 x 110 46 12 8000 16000 20000 24000 28000 32000 16000 24000 28000 32000 36000 40000 48000

60 x 108 45.0 68 x 116 74 x 122 49

60 x 120 50.0 68 x 128 74 x 134 49

Area

(ft

A B C

2

)

(inches)

Number

of Louvers

3

⁄4 5 1088 2176 2720 3264 3808 4352 2176 3264 3808 4352 4896 5440 6528

3

⁄4 5 1400 2800 3500 4200 4900 5600 2800 4200 4900 5600 6300 7000 8400

3

⁄4 5 1560 3900 4680 5460 6240 7020 3120 4680 5460 6240 7020 7800 9360

3

⁄4 5 1710 3420 4275 5130 5985 6840 3420 5130 5985 6840 7695 8550 10260

3

⁄4 5 1950 3900 4875 5850 6825 7800 3900 5850 6825 7800 8775 9750 11700

1

⁄2 6 2180 4360 5450 6540 7630 8720 4360 6540 7630 8720 9810 10900 13080

3

⁄4 5 1420 2840 3550 4260 4970 5680 2840 4260 4970 5680 6390 7100 8520

3

⁄4 5 1600 3200 4000 4800 5600 6400 3200 4800 5600 6400 7200 8000 9600

3

⁄4 5 1780 3560 4450 5340 6230 7120 3560 5340 6230 7120 8010 8900 10680

1

⁄2 6 2140 4280 5350 6420 7490 8560 4280 6420 7490 8560 9630 10700 12840

1

⁄2 6 2400 4800 6000 7200 8400 9600 4800 7200 8400 9600 10800 12000 14400

1

⁄4 7 2840 5680 7100 8520 9940 11360 5680 8520 9940 11360 12780 14200 17040

3

⁄4 5 1800 3600 4500 5400 6300 7200 3600 5400 6300 7200 8100 9000 10800

1

⁄2 6 2000 4000 5000 6000 7000 8000 4000 6000 7000 8000 9000 10000 12000

1

⁄2 6 2400 4800 6000 7200 8400 9600 4800 7200 8400 9600 10800 12000 14400

1

50 x 74 231⁄2 6 3000 6000 7500 9000 10500 12000 6000 9000 10500 12000 13500 15000 18000

⁄2 6 2700 5400 6750 8100 9950 10800 5400 8100 9450 10800 12150 13500 16200

1

⁄4 7 3600 7200 9000 10800 12600 14400 7200 10800 12600 14400 16200 18000 21600

1

⁄2 6 2450 4900 6125 7350 8575 9800 4900 7350 8575 9800 11025 12250 14700

1

⁄4 7 2800 5600 7000 8400 9800 11200 5600 8400 9800 11200 12600 14000 16800

1

⁄4 7 3150 6300 7875 9450 11025 12600 6300 9450 11025 12600 14175 15750 18900

3

⁄4 9 4900 9800 12250 14700 17150 19600 9800 14700 17150 19600 22050 24500 29400

1

⁄4 7 3200 6400 8000 9600 11200 12800 6400 9600 11200 12800 14400 16000 19200

3

⁄4 9 4800 9600 12000 14400 16800 19200 9600 14400 16800 19200 21600 24000 28800

1

⁄2 10 5600 11200 14000 16800 19600 22400 11200 16800 19600 22400 25200 28000 33600

1

⁄2 10 6400 12800 16000 19200 22400 25600 12800 19200 22400 25600 28800 32000 38400

3

⁄4 9 4400 8800 11000 13200 15400 17600 8800 13200 15400 17600 19800 22000 26400

1

⁄2 10 5400 10800 13500 16200 18900 21600 10800 16200 18900 21600 24300 27000 32400

1

⁄2 10 6300 12600 15750 18900 22050 25200 12600 18900 22050 25200 28350 31500 37800

1

⁄2 11 7200 14400 18000 21600 25200 28800 14400 21600 25200 28800 32400 36000 43200

3

⁄4 9 5000 10000 12500 15000 17500 20000 10000 15000 17500 20000 22500 25000 30000

1

⁄2 10 6000 12000 15000 18000 21000 24000 12000 18000 21000 24000 27000 30000 36000

1

⁄4 11 7000 14000 17500 21000 24500 28000 14000 21000 24500 28000 31500 35000 42000

3

⁄4 13 9000 18000 22500 27000 31500 36000 18000 27000 31500 36000 40500 45000 54000

3

⁄4 13 10000 20000 25000 30000 35000 40000 20000 30000 35000 40000 45000 50000 60000

Intake (WIH) CFM Relief (WRH) CFM

Total Pressure Drop in inches of wg* Total Pressure Drop in inches wg*

.008 .030 .048 .069 .094 .123 .024 .055 .075 .097 .123 .152 .220

THROAT VELOCITY (ft/min) THROAT VELOCITY (ft/min)

200 400 500 600 700 800 400 600 700 800 900 1000 1200

17

Page 18

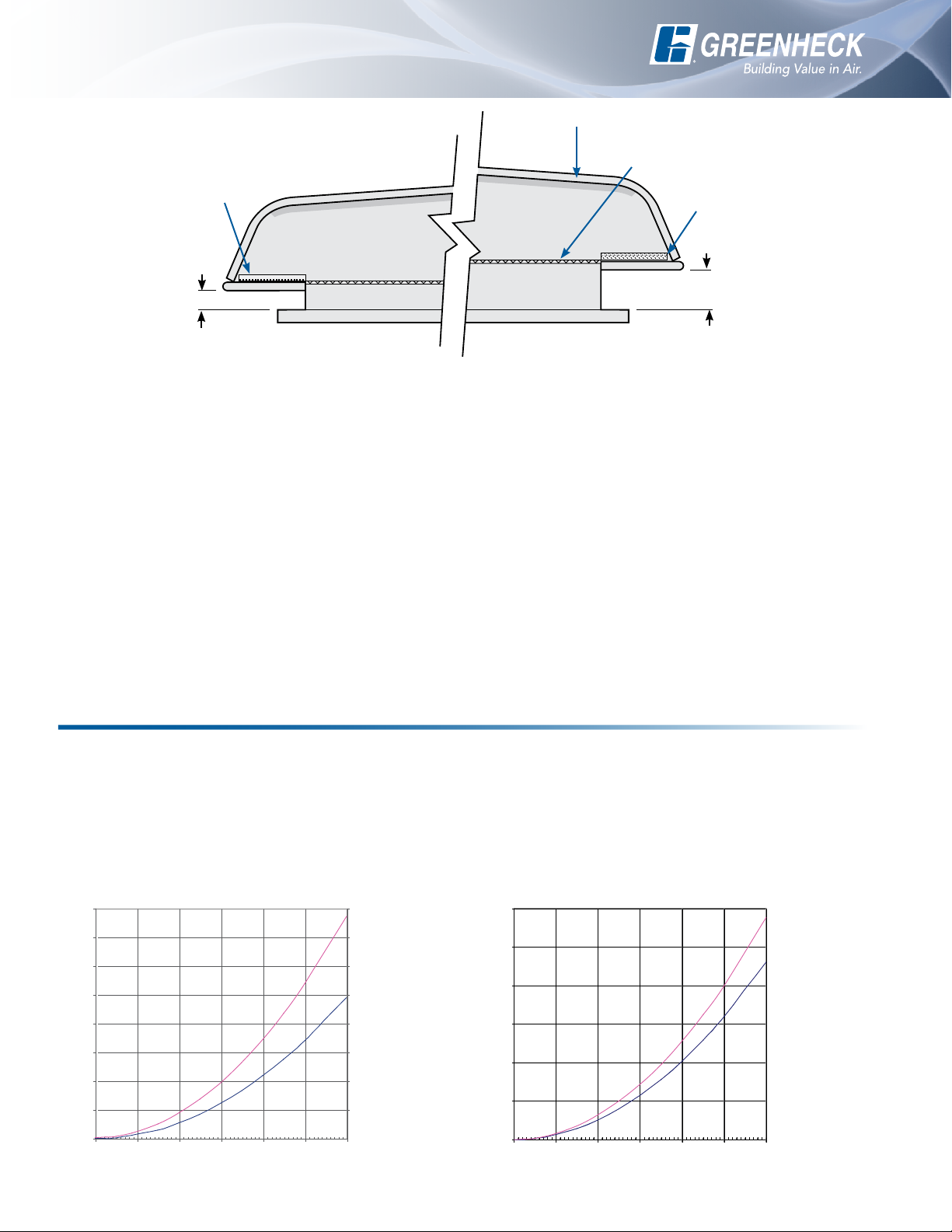

Upblast Ventilator

E

A

C

Model RGU

Model RGU is designed for use as a

weatherproof outlet on vertical high velocity

exhaust systems and can be furnished without

the curb cap to allow for direct mounting on

round stacks.

Standard construction is heavy-gauge

galvanized steel. Nine sizes are available,

corresponding to powered units in

sizes 18-60.

Fusible link damper lifters are available to allow

the RGU units to function as heat and smoke

relief vents.

0.7

0.6

0.5

0.4

0.3

0.2

Static Pressure (in. wg)

0.1

0

2500 2750 4750 5000 6750 7500 10000 12500

0.7

0.6

0.5

0.4

0.3

0.2

Static Pressure (in. wg)

0.1

0

7500 10000 11000 12500 15000 19000 20000 25000 30000 40000 45000 50000 57500

RGU Gravity Performance 18 - 30

RGU-18 RGU-20 RGU-24

Volume (cfm)

RGU Gravity Performance 36 - 60

RGU-36 RGU-42 RGU-48 RGU-54 RGU-60

Volume (cfm)

RGU-30

A

A

Minimum CFM Required to Open Dampers

Model Size Aluminum Galvanized

18 2750 3520

20 3170 4090

B

C

24 3950 5220

30 6050 7130

36 7620 10980

42 11050 13550

48 12820 16420

D

Curb

Cap

RGU with curb cap

RGU without curb cap

E

Model RGU Dimensional Data

Model Size A B C D E Curb Cap

54 21430 21430

60 24820 24820

Max.

Recommended

Roof Opening

*

18 25 (635) 22 (559) 201⁄4 (514) 13⁄4 (44) 181⁄2 (470) 28 (711) 22 (559) 120 (54)

20 271⁄4 (692) 24 (610) 211⁄4 (540) 13⁄4 (44) 201⁄2 (521) 30 (762) 24 (610) 140 (64)

24 311⁄8 (791) 26 (660) 24 (609) 13⁄4 (44) 241⁄2 (622) 34 (864) 28 (711) 160 (73)

30 373⁄8 (949) 30 (762) 263⁄4 (679) 13⁄4 (44) 305⁄8 (778) 40 (1016) 34 (864) 175 (79)

36 431⁄2 (1105) 33 (838) 291⁄4 (743) 13⁄4 (44) 365⁄8 (930) 46 (1168) 40 (1016) 190 (86)

42 487⁄8 (1241) 38 (965) 341⁄4 (870) 13⁄4 (44) 423⁄4 (1086) 52 (1321) 46 (1168) 245 (111)

48 56 (1422) 40 (1016) 341⁄4 (870) 13⁄4 (44) 481⁄2 (1232) 58 (1473) 52 (1321) 295 (114)

54 625⁄8 (1591) 45 (1143) 401⁄4 (1022) 13⁄4 (44) 55 (1397) 661⁄2 (1689) 60 (1524) 450 (204)

60 683⁄4 (1746) 48 (1219) 431⁄8 (1095) 13⁄4 (44) 61 (1549) 721⁄2 (1842) 66 (1676) 600 (272)

Minimum distance—actual distance determined by motor use. All dimensions shown in inches (millimeters).

*

Approximate

Weight (lb)

(kg)

18

Page 19

Specifications

Fabra Hood

Gravity roof ventilators shall be constructed of heavygauge aluminum or galvanized steel as specified.

Hoods shall be constructed of precision formed,

arched panels with interlocking seams.

Bases shall be constructed so that the curb cap is

6 inches (152 mm) larger than the throat size.

Standard base height shall be 5 inches (127 mm).

Optional 12-inch (305 mm) bases shall be furnished

as specified (and are recommended) for intake

applications to restrict entry of moisture and for all

applications where rain and snow may accumulate

on the roof deck.

Hood support members shall be constructed of

galvanized steel and fastened so that the hood can

be either removed completely from the base or

hinged open.

Birdscreens constructed of ½-inch (13 mm) galvanized