Page 1

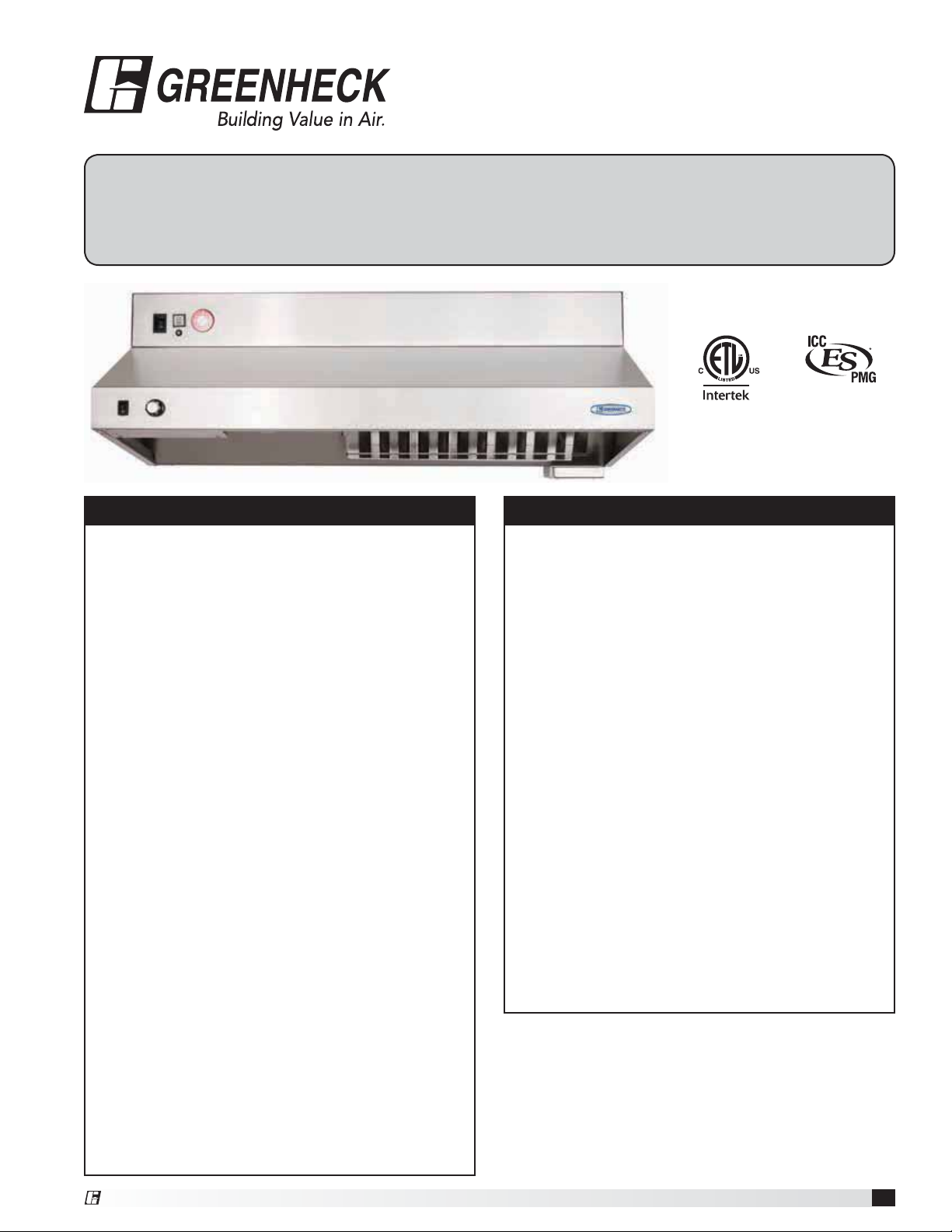

Model GRRS

Fire Ready Hood

®

Installation, Operation and Maintenance Manual

Please read and save these instructions for future reference. Read carefully before attempting to assemble, install,

operate or maintain the product described. Protect yourself and others by observing all safety information. Failure

to comply with instructions could result in personal injury and/or property damage!

REPORT #1293

Listed to UL 300A Standard

WARNING

To reduce the risk of fire, electric shock, or injury

to persons, observe the following:

• Use this unit only in the manner intended by the

manufacturer.

• Before servicing or cleaning unit, switch power off

at service panel and lock the service disconnecting

means to prevent power from being switched on

accidentally. When the service disconnecting means

cannot be locked, securely fasten a prominent

warning device, such as a tag, to the service panel.

• Installation work and electrical wiring must be

done by a qualified person(s) in accordance with all

applicable codes and standards, including fire rated

construction codes and standards.

• Sufficient air is needed for proper combustion

and exhausting of gases through the flue

(chimney) of fuel burning equipment to prevent

backdrafting. Follow the heating equipment

manufacturer’s guideline and safety standards such

as those published by the National Fire Protection

Association (NFPA), and the American Society

of Heating, Refrigeration and Air Conditioning

Engineers (ASHRAE), and the local code authorities.

• When cutting or drilling into wall or ceiling, do not

damage electrical wiring and other hidden utilities.

• To reduce the risk of fire or electric shock, do

not use this range hood with an additional speed

control device.

• Ducted fans must always be vented to the

outdoors.

• To reduce the risk of fire, use only metal ductwork.

• Use with approved wiring only.

• This unit must be grounded.

WARNING

To reduce the risk of range top grease fire:

• Never leave surface units unattended at high

settings. Boilovers cause smoking and greasy

spillovers that may ignite. Heat oils slowly on low or

medium settings.

• Always turn hood ON when cooking at high heat or

when cooking flaming foods.

• Clean ventilation fans frequently. Grease should not

be allowed to accumulate on fan or filter.

• Use proper pan size. Always use cookware

appropriate for the size of the surface element.

To reduce the risk of injury to persons in the event

of a range top grease fire, observe the following:*

• SMOTHER FLAMES with a close-fitting lid, cookie

sheet, or metal tray, then turn off the burner. BE

CAREFUL TO PREVENT BURNS. If the flames do

not go out immediately, EVACUATE AND CALL THE

FIRE DEPARTMENT.

• NEVER PICK UP A FLAMING PAN. You may be

burned.

• DO NOT USE WATER, including wet dishcloths or

towels - violent steam explosion will result.

* Based on “Kitchen Fire Safety Tips” published by

NFPA.

®

Fire Ready Hood

1

Page 2

Table of Contents

Receiving, Unpacking, Handling & Storage ....... 2

Model Number Code ......................... 3

Parts Checklist ............................. 3

Exploded View. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Sample Installations ......................... 4

Preparing the Install Location

Mounting Bracket .......................... 5

Ductwork ................................ 5

Static Pressure Testing ..................... 5

Fans .................................... 6

Accessories .............................. 6

Installation

Installation Elevation ....................... 7

Mounting Bracket .......................... 7

Installing Hood onto Mounting Bracket ......... 8

Installing the Fan .......................... 9

Range Element Disconnect Installation

Gas Disconnect Valve ..................... 10

Electrical Disconnect Box .................. 10

Installing Accessories

ClockBox ............................... 11

Remote ADA Switches ..................... 11

Manual Pull Station ....................... 11

Ductwork ............................... 11

Electrical Installation

Main Control Power ....................... 12

Electric Disconnect Box .................... 13

Gas Disconnect Valve ..................... 13

Inline/Wall Mount Fan ..................... 14

ClockBox ............................... 14

Remote ADA Switches ..................... 14

Fire Alarm System Connections ............. 14

Wiring Diagram .......................... 15

ClockBox Wiring Diagram .................. 16

Operation ................................. 17

Environmental Monitoring / Pre-Suppression

Functions ............................... 17

Accessing the Internal Components ............ 18

ClockBox Operation and Navigation ........... 19

Test Tank and Demonstration ................. 20

Controller Schematic ........................ 21

Alarm Connections ........................ 21

Self-Monitoring System ...................... 22

After an Actuation ........................ 23

How to Reset the Suppression System ......23-24

Maintaining the System ...................... 25

Inspection Procedures

Nozzle Caps ............................. 25

Fusible Link System ....................... 25

10 Year Maintenance ........................ 25

Lighting .................................. 25

Removing the Extinguisher Tank ............... 26

Service and Recertification Schedule ........... 26

Replacement Parts ......................... 26

Maintenance Log ........................... 27

Our Commitment ........................... 28

Receiving

Upon receiving the product, check to ensure all

items are accounted for by referencing the delivery

receipt or packing list. Inspect each crate or carton

for shipping damage before accepting delivery. Alert

the carrier of any damage detected. The customer will

make notation of damage (or shortage of items) on the

delivery receipt and all copies of the bill of lading which

is countersigned by the delivering carrier. If damaged,

immediately contact your Greenheck Representative.

Any physical damage to the unit after acceptance is not

the responsibility of Greenheck Fan Corporation.

Unpacking

Verify that all required parts and the correct quantity of

each item have been received. If any items are missing,

report shortages to your local representative to arrange

for obtaining missing parts. Confirmation of shipment(s)

must be limited to only items on the bill of lading.

Handling

Handle in such a manner as to keep from scratching or

chipping the coating. Damaged finish may reduce ability

of unit to resist corrosion.

Storage

Units are protected against damage during shipment. If

the unit cannot be installed and operated immediately,

precautions need to be taken to prevent deterioration of

the unit during storage. The user assumes responsibility

of the unit and accessories while in storage. The

manufacturer will not be responsible for damage during

storage. These suggestions are provided solely as a

convenience to the user.

The ideal environment for the storage of units and

accessories is indoors, above grade, in a low humidity

atmosphere which is sealed to prevent the entry of

blowing dust, rain, or snow. Temperatures should be

evenly maintained between 30°F (-1°C) and 110°F

(43°C). All accessories must be stored indoors in a

clean, dry location.

Fire Ready Hood

2

®

Page 3

Model Number Code

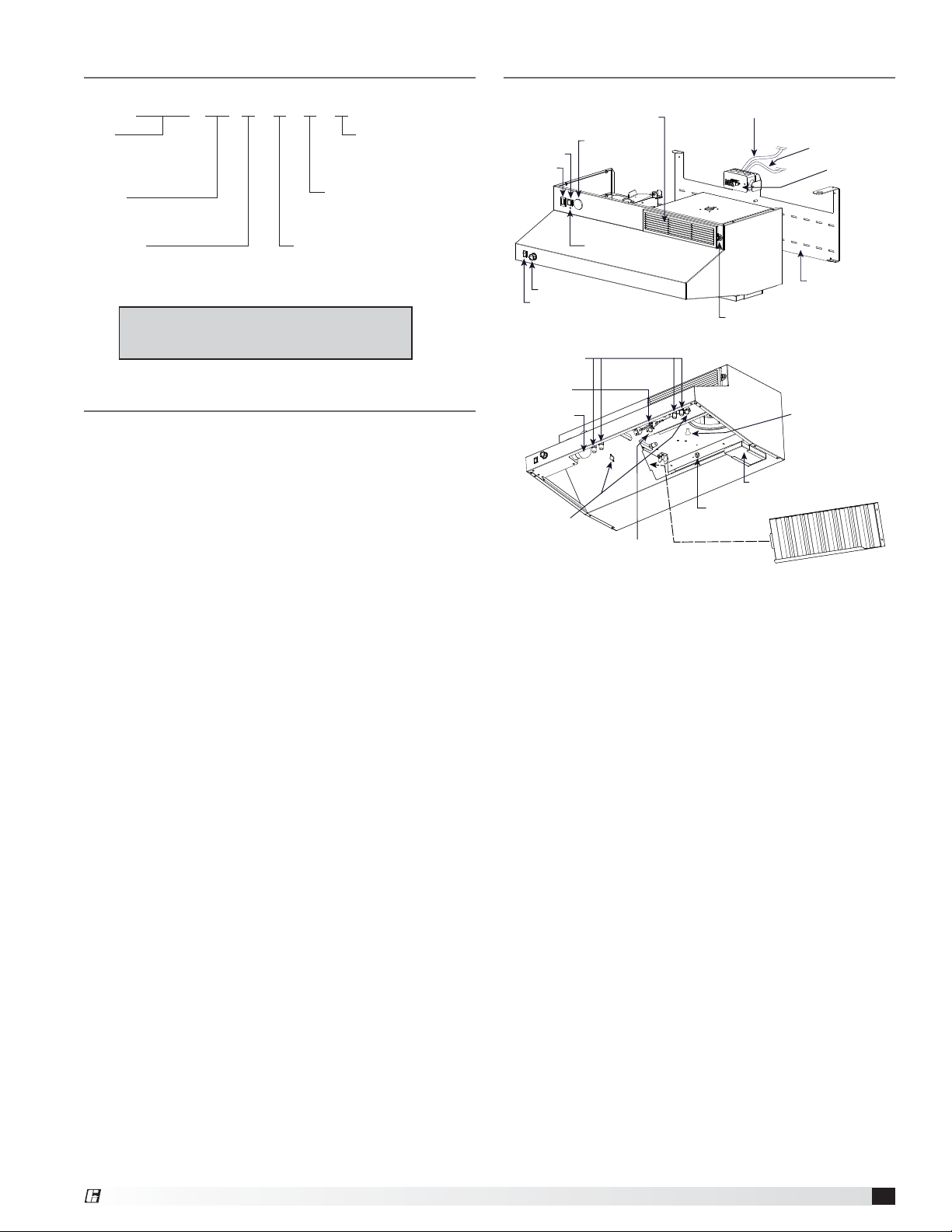

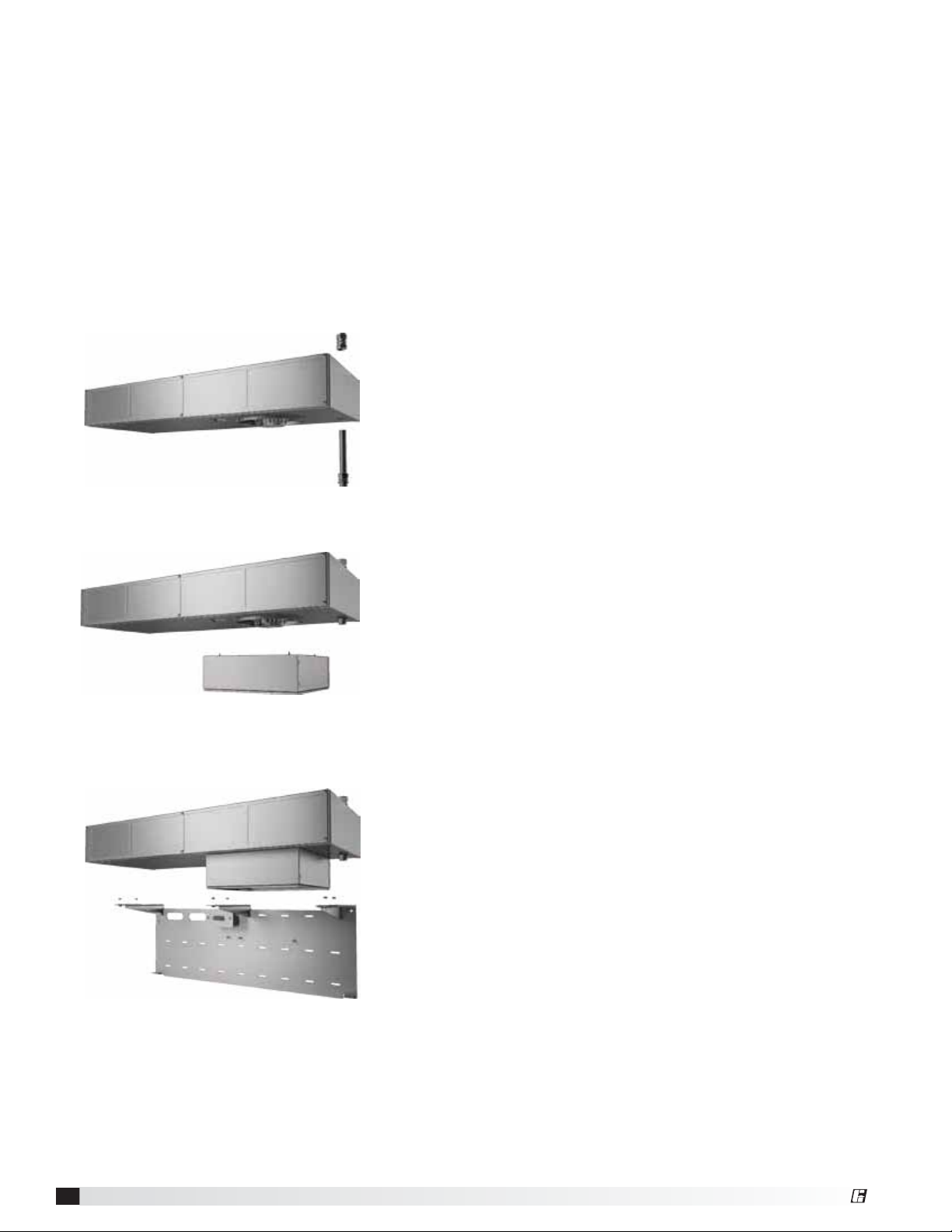

Exploded View

GRRS - 30 - F - E - D - N

Type

Residential

Range

Suppression

Length

30 inches

36 inches

Ventilation

F - Integral Fan - Front Recirculation

R - Integral Fan - Rear Discharge

T - External Fan - Top Discharge

Example: GRRS-30-F-D-N

Greenheck RRS, 30 inches long, with front fan discharge,

with dual element disconnect, NFPA 101 Compliant

Range Disconnect Type

E - Electric

G - Gas

D - Dual (gas and electric)

NFPA 101 Compliance

X - Noncompliant

N - Compliant

External Fan Type

D - Inlet Duct

W - Wall Mount

Parts Checklist

Hood

Back support mounting bracket

External fan (Inline / Wall Mount / None)

• 25 ft. plenum rated wire for plug and play

connection

8 ft. of metal clad wire for hood power connection

(marked with red tape)

Gas disconnect valve (optional)

• 6 ft. shielded control wire for plug and play

connection

Electrical disconnect box (optional)

• 6 ft. shielded control wire for plug and play

connection

8 ft. of metal clad wire for gas disconnect/electrical

disconnect connection (marked with black tape)

Remote switches, ADA (optional)

Manual Pull Kit (optional) consisting of the following:

• Pull Box (1)

• Pull Face (1)

• Elbow Pulley (3)

• 25 ft. Cable and Pin

The ClockBox (optional)

• 20 ft. shielded control wire for plug and play

connection

Reset Switch

Power Switch

Fan Speed Knob

Light Switch

Discharge Nozzles

with protective caps

Fusible Link

Light Bulb

Low Temperature

Switches

Recirculating Vent

(recirculating model)

Extinguisher

Pressure Gauge

LED Status Light

High Temperature

Switch

Electrical Disconnect

(Black Tape)

Thumbscrew to remove vent

on some models

Grease Tray

Thumb Nut (3x)

110 VAC Power Supply

(Red Tape)

Junction Box

Back Support

Mounting Bracket

Thumbscrews (2x)

(inline models)

Grease Filter

®

Fire Ready Hood

3

Page 4

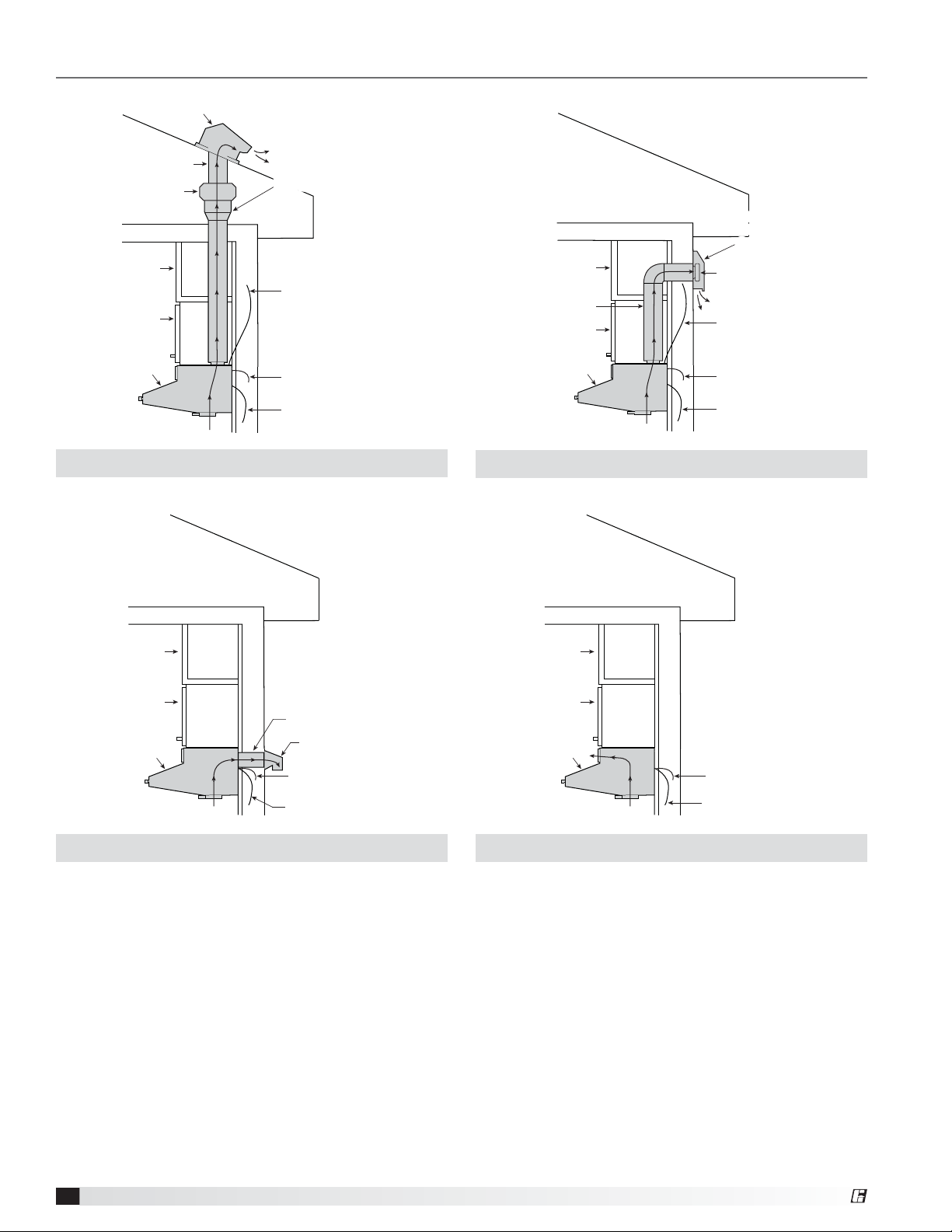

Sample Installations

Roof Cap

(by others)

10 in. Ductwork

Inline Duct Fan

(provided)

Soffit

Cabinet

Range Hood

(provided)

Airflow

7 in. to 10 in. Transition7 in. to 10 in. Transition

Plenum Ready

Supply Cable to Fan

(provided)

110 VAC Supply Cable

(provided)

Power Disconnect Cable

(provided)

Soffit

7 in. Ductwork

Cabinet

Range Hood

(provided)

Airflow

Wall Mount Fan Box

Wall Mount Fan Box

with Access Cover for

with Access Cover for

Service and Mounting

Service and Mounting

(provided)

(provided)

Fan

Plenum Ready

Supply Cable to Fan

(provided)

110 VAC Supply Cable

(provided)

Power Disconnect Cable

(provided)

Soffit

Cabinet

Range Hood

(provided)

External Fan | Inline Fan

External Fan | Wall Mount Fan

Soffit

Cabinet

3½ x 12-in. Ductwork

Airflow

Wall Cap

(by others)

110 VAC Supply Cable

(provided)

Power Disconnect Cable

(provided)

Range Hood

(provided)

Airflow

110 VAC Supply Cable

(provided)

Power Disconnect Cable

(provided)

Integral Fan | Rear Discharge Integral Fan | Front Recirculation

Fire Ready Hood

4

®

Page 5

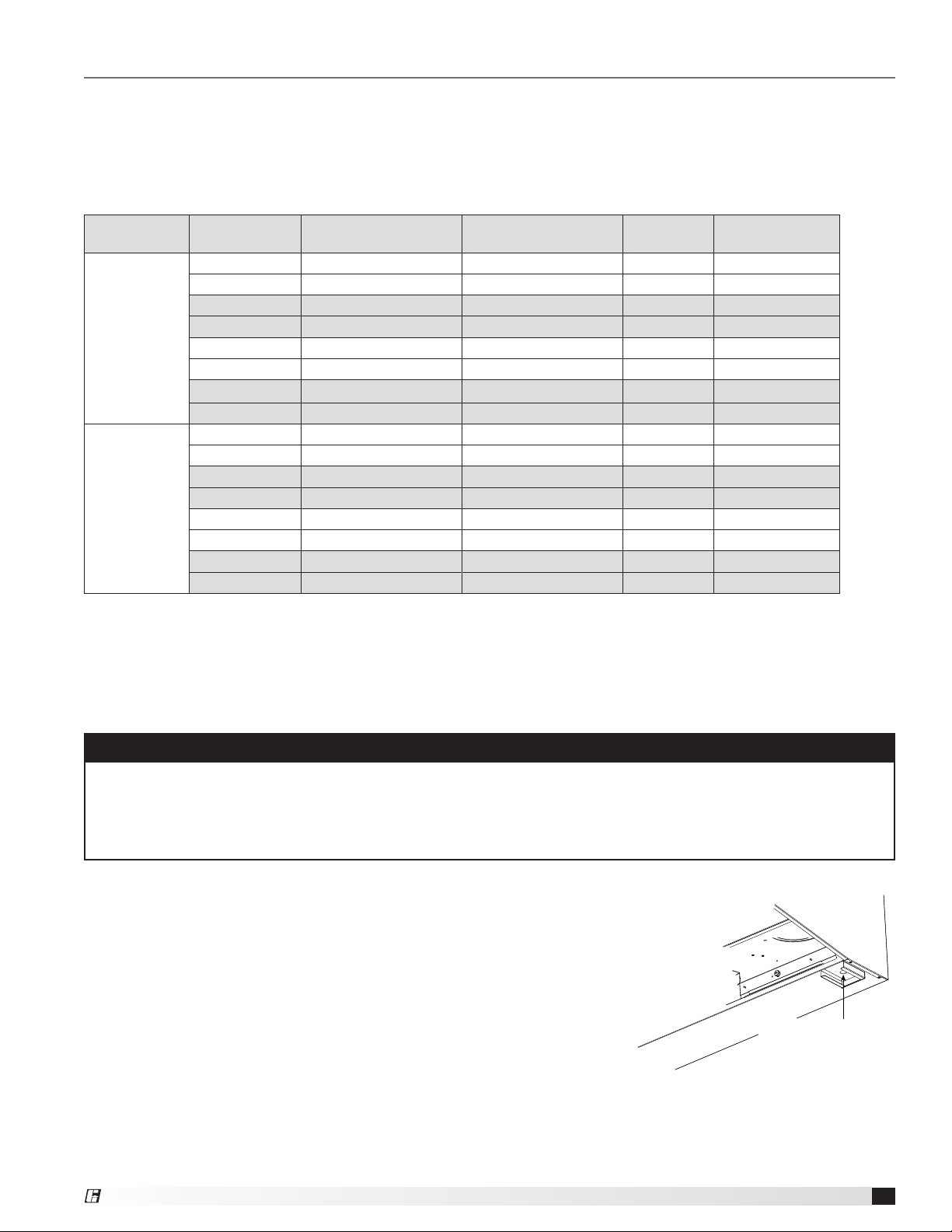

Preparing the Install Location

Mounting Bracket - The mounting bracket and hood must be centered over the range. If the range is not in place,

the center marking should be relative to it’s final position. Refer to page 7 for bracket mounting points, rear access

holes and access points.

Ductwork - The ductwork and fittings used for outside venting (if applicable) must be carefully selected to ensure

that the static pressure is in line with the fan parameters. The table below displays maximum duct length allowed for

the various fan options.

Hood

Width

30 inches

36 inches

Maximum duct length equals horizontal and vertical duct runs plus duct components such as fittings, elbows, and transitions.

NFPA 101

Compliance

No Internal Front (recirculating) 140 Not applicable

No Internal Rear Discharge 250 Not applicable

No Inline Duct Fan Vertical Duct 470 35 feet

No Exterior Wall Fan Vertical Duct 150 20 feet

Yes Internal Front (recirculating) 500 Not applicable

Yes Internal Rear Discharge 500 Not applicable

Yes Inline Duct Fan Vertical Duct 510 35 feet

Yes Exterior Wall Fan Vertical Duct 550 20 feet

No Internal Front (recirculating) 140 Not applicable

No Internal Rear Discharge 250 Not applicable

No Inline Duct Fan Vertical Duct 470 35 feet

No Exterior Wall Fan Vertical Duct 150 20 feet

Yes Internal Front (recirculating) 500 Not applicable

Yes Internal Rear Discharge 500 Not applicable

Yes Inline Duct Fan Vertical Duct 510 35 feet

Yes Exterior Wall Fan Vertical Duct 550 20 feet

Fan Type Venting

CFM

(at hood)

Duct Length

(maximum)

For installations requiring vertical duct venting to an inline fan and NFPA 101 compliance, the hood should be

adapted from a 7-inch round duct access hole to a minimum 12-inch duct.

For installations requiring vertical duct venting to an inline fan and NFPA 101 compliance is NOT required, the hood

can be adapted to a minimum 10-inch duct.

WARNING

The amount of fittings and ductwork directly affects the resistance or static pressure placed on the system. If the

system is not within the proper static pressure range, the heat sensors and controls will be adversely affected and

will impact the proper function of the safety controls. Therefore it is required that airflow testing be recorded along

with installation documentation. The air testing is accessed by the removal of the grease tray and measured with

an airflow pressure gauge.

Static Pressure Testing - The magnehelic gauge test port opening is located

beneath the grease tray. The static pressure needs to be measured to ensure

airflows meet design criteria. The airflow is measured by attaching the gauge

tubing to the magnehelic gauge inlet, and the hood fitting is attached to the

grease drain hole beneath the grease tray.

A reading of 0.45 to 0.85 inches wg. is required to meet design standards.

This reading will correspond to the static pressure of the ductwork, hood

and fan combination.

®

Magnehelic Gauge

Magnehelic Gauge

Test Port

Test Port

Fire Ready Hood

5

Page 6

Fans

For inline fans and exterior wall fans, fan location and

proper mounting will be required.

If the hood system is configured for front recirculation

discharge or rear discharge and NFPA 101 compliance,

the unit will come equipped with a fan box. If installing

under cabinets, keeping the fan box flush to the

underside of cabinet will guarantee correct spacing.

Otherwise, center and mark the installation area

according to wall mounting bracket prior to hanging.

The following steps will be required.

1. Insert/attach the top portion of the manual pull kit

conduit through the fan box.

Accessories

Location restrictions will apply if the hood system

supplied is provided with any of the optional

accessories:

• ClockBox

• Remote ADA Switches

• Manual Pull Station

2. Attach square duct collar to the bottom of the fan

box with included hardware.

3. Attach the fan box to the mounting bracket with

included 8/32 nuts, then complete the installation on

the manual pull kit conduit and top/bottom unions.

When prepping a space for installation, a 4-

9

⁄16 inch

space must be allowed between the top of the mounting

bracket and the bottom of the cabinet for the fan box.

The additional height of the unit should not result in

reduced range clearance. Cabinets should be installed

approximately 5 inches higher to accommodate the

additional size of the NFPA 101 fan box assembly.

Fire Ready Hood

6

®

Page 7

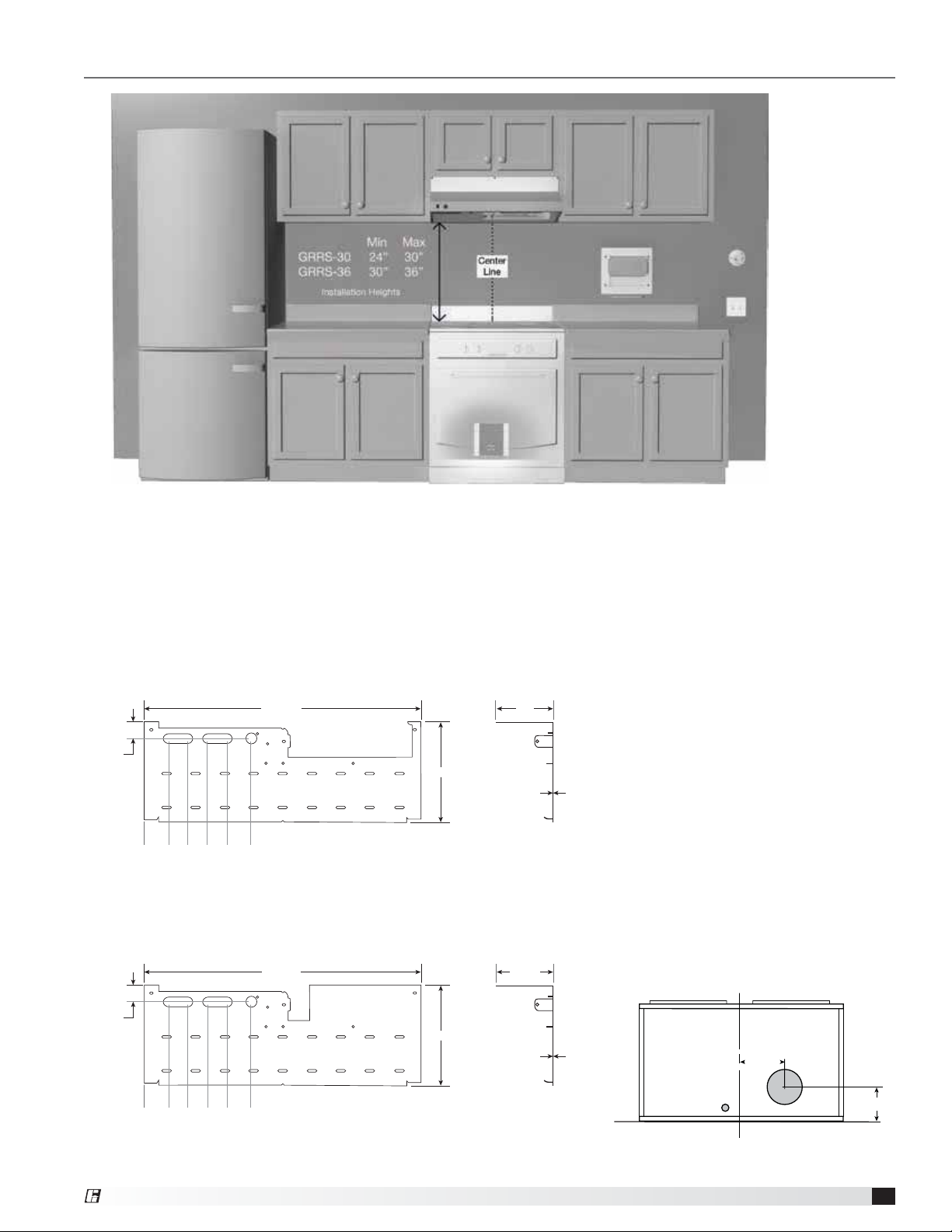

Installation

A

Installation Elevation

A. Hood (30 or 36 inches)

B. Appliance (for reference purposes)

C. Range Disconnect - electric, gas or dual (optional)

D. Gas Range Element Disconnect (not shown)

E. The ClockBox. Range Element Time-Out System (optional)

F. Handicapped Accessible Control Box (optional)

G. Manual Pull Station (optional)

Mounting Bracket for a 30-inch unit

28-5/8 in.

1-11/16 in.

B

DE

A

C

B

FFFFFFF

A

B

F

10-5/16 in.

0 in.

2-7/16 in.

4-7/16 in.

6-7/16 in.

8-7/16 in.

10-15/16 in.

Mounting Bracket for NFPA Installation

28-5/8 in.

1-5/8 in.

B

0 in.

2-1/2 in.

4-1/2 in.

DE

6-1/2 in.

8-1/2 in.

C

11 in.

A

B

A

FFFFFFF

B

F

10-5/16 in.

B

CD

4 in.

1/16 in.

5-7/8 in.

1/16 in.

E

G

F

Mounting Bracket

A. Center notches

B. Critical mounting points must be

secured to studs or drywall hangers.

C. Rear access to junction box

connection

D. Primary access point for

connections to junction box

E. Secondary access point for

connections to hood (options/

accessories)

F. Additional mounting points. Secure

minimum of three (3) screws per row.

Cabinet FrontCabinet Front

Cabinet Bottom

7-inch Round Duct

Access Hole

7-

13/16 in.

Electrical

Access Hole

C

L

5-15/16 in.

®

Fire Ready Hood

7

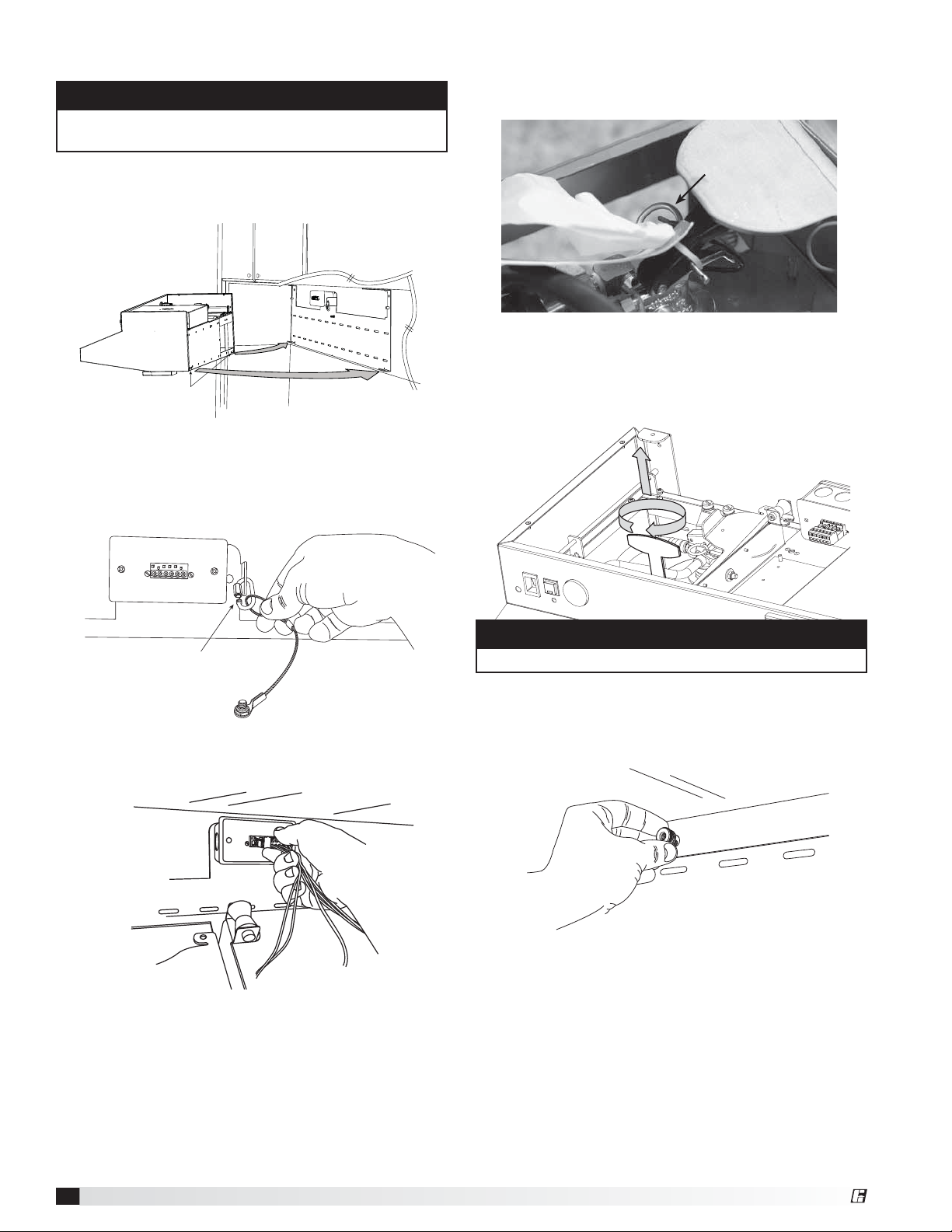

Page 8

Installing Hood onto Mounting Bracket

NOTE

Install manual pull station, if provided, before arming

the system.

4. Remove the safety pin - identified with the yellow

CAUTION flag from the trigger on top of the

extinguisher bottle.

1. Lift hood onto mounting bracket and seat the lower

tabs of the mounting bracket into slots in back of

hood.

Slots

Lower Tabs

2. While holding the hood up, hook safety cable to

chain link on mounting bracket and screw nut

to close the link. The hood is now in the service

position.

Safety Pin

5. Remove the safety key from the actuator arm by

rotating and lifting straight upwards. The system will

not actuate without completing steps 4 and 5.

Chain Link

3. Connect male plug from top of hood into female plug

mounted in junction box.

CAUTION

The system is now armed.

6. Rotate hood to wall and thread the three thumb nuts

to the bolts in the mounting plate. Check page 18 for

location of thumb nuts.

Fire Ready Hood

8

®

Page 9

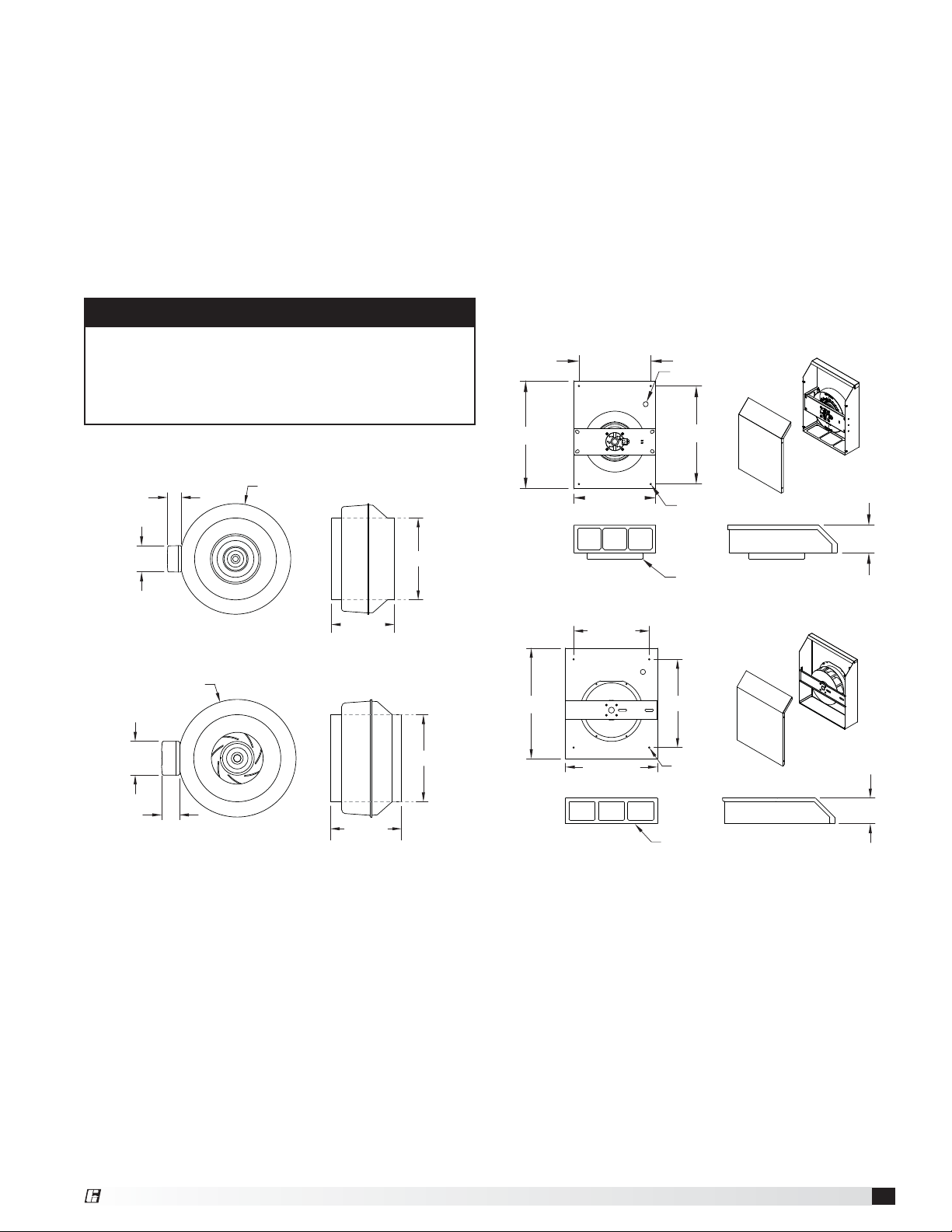

Installing Fan (if applicable)

Inline

Install fan vertically in ductwork running between the

unit and roof cap.

For best results, use as few elbows or transitions as

possible. If necessary, long radius elbows or bends are

recommended.

To attach ductwork, use duct tape at inlet and outlet to

assure a good seal. If using fan clamps, attach clamps

and insert screws through clamp into inlet and outlet

flanges.

CAUTION

Use sheet metal screws to secure ductwork to inlet

and outlet. It is critical that the screw penetrate the

metal of the flange, but not so far as to bind the

impeller. It may be necessary to angle screws away

from impeller.

Inline Exhaust Fan - NFPA

Wall Mounted Fan

Fasten the fan box to an external wall via the four

0.27-inch mounting holes.

Run electrical through the 0.81-inch hole towards the

top right corner of the box.

Attach ductwork using duct sealant, caulk, or tape

to all seams to prevent air leakage and maximize air

performance.

For best results use as few elbows or transitions as

possible. If necessary, long radius elbows or bends are

recommended.

Wall Fan - NFPA

11.625 in.

17.8125 in.

Ø0.81 in.

15.875 in.

2.4375 in.

3.75 in.

Ø16.00 in.

Inline Exhaust Fan - Non-NFPA

Ø13.375 in.

3.75 in.

2.00 in.

10.50 in.

8.25 in.

11.875 in.

10.00 in.

13.375 in.

Wall Fan - Non-NFPA

12.00 in.

17.50 in.

14.625 in.

Ø0.27 in. (4X)

MOUNTING HOLES

Ø8 IN. VENT DUCT CONNECTION

14.00 in.

Ø0.27 in. (4X)

MOUNTING HOLES

Ø8 IN. VENT DUCT CONNECTION

4.625 in.

4.0625 in.

®

Fire Ready Hood

9

Page 10

Range Element Disconnect Installation

Gas Disconnect Valve (if applicable)

The gas solenoid is designed for use with 3/4-inch NPT

pipe. Be sure to note the “IN” and “OUT” ends of the

solenoid body (as marked on the body). This determines

direction of gas flow. Refer to wiring diagram on pages

13 and 15 for details on electrical connection.

110 VAC Supply from Hood

- Electrical Connection

3/4-in. NPT

GAS FLOW

3/4-in. NPT

Electrical Disconnect Box (if applicable)

1. Cut a hole in the drywall for the relay box; refer to

the submittal for dimensions. Be sure to note the

1-1/4inch overhang on each side of the face plate.

Given this, the hole should be about 6-3/8 by 8-3/4

inch. The relay box has been designed to fit in a

standard 2x4 studded wall.

6-3/8 in.

8-3/4 in.

2. If you haven’t already done so, run wiring from the

junction box location (on the unit mounting plate) to

the power disconnect box location and string through

one of the knockouts in the box.

208-220 VAC

supply to appliance

120 VAC

120 VAC

from hood, black tape

from hood, black tape

3. Make all wiring connections and secure face plate to

box in wall. Wiring information is provided on pages

13 and 15.

Face P late

Fire Ready Hood

10

®

Page 11

Installing Accessories

Refer to your submittal for installation dimensions of

these accessories.

ClockBox (optional)

The ClockBox works by controlling the cooking element

(gas, electric and dual element ranges) and minimizes

the likelihood of an unattended cooking fire. The system

disables the cooking element until the operator unlocks

the cover and presses the GO button. After two hours

the cooking element is automatically disabled.

If this unit was provided with the ClockBox, a ClockBox

controller and Touchscreen user-interface will be

provided. Both will need to be remotely mounted near

the appliance (range) on a nearby wall.

Remote ADA Switches (optional)

If the unit is provided with the remote ADA switches,

these will have to be installed to be in compliance with

ADA standards for Accessible Design.

Manual Pull Station Installation (optional)

If the unit is provided with the remote ADA switches,

these will have to be installed to be in compliance with

ADA standards for Accessible Design.

Parts included in the kit:

Step 3: Install Cable and Pin to hood

Thread the cable through the conduit, with the pin

reaching the unit. Remove the grease filter. In the upper

right corner, find the two pulleys as illustrated. Hold the

rear-most pulley in

place. From the top

of the unit, replace

its pin with the one

on the cable. Push

the pin through the

pulley until you hear

it click in place. Go

back to the actuator

arm and rehook

cable onto the arm.

WARNING

You must allow for 8 to 12 inches of slack in the cable

to sit at the pull face. Failure to do so will cause the

unit to discharge the next time the unit is lowered into

its service position.

CAUTION

Make sure the cable does not become caught on any

part of the hood or conduit, or the cable will not be

able to be pulled, and the unit will not discharge.

Pull Box (x1)

Pull Face (x1)

Elbow Pulley (x3)

Cable and Pin (25 ft)

Step 1: Installing Conduit

Mount the pull box in an appropriate location according

to local building codes. Keep

in mind you are supplied with

25 feet of cable and three (3)

elbow pulleys. Install 1/2inch

conduit (not included)

Conduit attachment

to backplate

between the unit and the

pull box, using the pulleys as

needed. Pull cable through

the conduit, and allow 8 to

12 inches of slack to be left

at the hood unit end. Be sure

to abide by all local building

codes when installing

conduit.

Step 2: Replace Safety Pin and Key (to prevent

accidental discharge)

With the unit lowered

into its service position,

put the safety pin in

its slot at the top of

the extinguisher tank.

Also replace the safety

key in its slot in the

actuator arm. Then

remove the cable from

the actuator arm.

Step 4: Install Cable to Pull Face

With the unit in its lowered

position, attach the

cable to the pull face by

crimping a loop in the

cable through the hole

on the back side of the

handle. Be sure cable

is securely crimped to

Crimp

withstand at least 50 lbs.

of pull force. Leave no more than 12 inches of slack

in the line on the pull face end, but maintain 8 to 12

inches. To make this easier, the handle may be removed

by loosening the set screw in one of the studs, and

sliding the red plastic rod out. Attach the pull face to

the pull box already mounted on the wall, collecting

any slack into the pull box. Do not allow slack cable to

collect above the hood.

Installing Ductwork (optional)

Ductwork will need to be provided and installed if the

unit was provided with an external fan.

Installation work must be done by qualified person(s)

in accordance with all applicable codes and standards,

including fire-rated construction.

To minimize static pressure losses and promote

adequate airflow, minimize duct run lengths where

possible.

®

Fire Ready Hood

11

Page 12

Electrical Installation

Main Control Power

1. Determine mounting location of the appliance

disconnect (contactor box and/or gas valve) and

mounting bracket, if not already done.

2. Run factory-provided wire from junction box

through the wall to the appliance disconnect,

unless ClockBox option is provided. For electrical

installation information regarding the ClockBox, refer

to page 16. Wire the factory-provided 110 VAC main

power connection to a 15 amp rated circuit.

3. If the hood unit is to be linked to a fire alarm system,

accommodations for those wires will need to be

made at this time as well. Refer to fire alarm electrical

installation information on page 14.

Alarm Wire(s)

Alarm Wire(s)

NO/NC Local and Remote Alarm

NO/NC Local and Remote Alarm

by others

by others

CAUTION

Electrical installation should be performed by a

licensed electrician. Installation should be performed

according to all applicable codes and regulations. Shut

off power at the main breaker to prevent electrical

shock when accessing electrical connections.

All field installation and wiring of electrical equipment

must be done to meet NEC and local codes

Junction Box

Junction Box

with Connector

with Connector

Range Supply Line

208-220 VAC 50A max

supplied by others

Hood Supply 110-120 VAC 15A

Metal clad wire from 110-120 VAC supply line

12/2 8 ft length, marked with red tape

supplied by Greenheck

Run metal clad wire from junction box on mounting

plate to power disconnect box through wall

Metal clad wire from 110-120 VAC supply line

14/2 8 ft length, marked with black tape

supplied by Greenheck

Power disconnect mounted flush to wall

Power disconnect mounted flush to wall

50A 250V NEMA 14-50 receptacle

50A 250V NEMA 14-50 receptacle

supplied by Greenheck

supplied by Greenheck

Fire Ready Hood

12

®

Page 13

Electric Disconnect Box (if applicable)

50AMP 250V

NEMA 14-50

Wire Nut

Neutral

110 VAC Coil

50 AMP 208-240 VAC Single Phase

Supply Line (by others)

15 AMP 110-120 VAC

Supply Line (by others)

GND

N

Contactor 50A

L1

L3

Power Disconnect Box

H

8” x 6” x 4”

H

T1

T3

HH

Wire nut inside power

disconnect box

L1 208-220 VAC Black Hot

L3 208-220 VAC Red Hot

T1 208-220 VAC Black Hot

T3 208-220 VAC Red Hot

Green Ground

White Neutral

Black Hot

110-120 VAC 14/2

Metal Clad to 110-120 VAC

Power Disconnect

(Black Tape) - 14/2

Metal Clad Wire from 110-120 VAC

Supply Line (Red Tape)

By others

}

By Greenheck

}

Provided by Greenheck

Provided by others

Junction

Box

GND

NEUT

HOT

GND

NEUT

HOT

Back Support

Mounting Bracket

Green Ground

White Neutral

Black Hot 110-120 VAC

6 Position

Orange

Connector

6 Position

Grey

Connector

Supplied

}

Hood

Gas Disconnect Valve (if applicable)

110-120 VAC Gas Solenoid

15 AMP 110-120 VAC

Supply Line (by others)

Green

White

Black

Multiconductor

(4 Conductor)

Junction Box

Wire Nut

Metal Clad to 110-120 VAC

Power Disconnect

(Black Tape)

Green Ground

White Neutral

Black Hot 110-120 VAC

Metal Clad Wire from 110-120 VAC

Supply Line (Red Tape)

Green Ground

White Neutral

Black Hot 110-120 VAC

Junction

Box

GND

NEUT

HOT

GND

NEUT

HOT

Back Plate

6 Position

Orange

Connector

6 Position

Grey

Connector

Hood

®

Fire Ready Hood

13

Page 14

Inline/Wall Mount Fan Power (if applicable)

Twenty-five (25) feet of plenum rated wire is provided

with both the inline fan and wall mounted fan option.

The fan needs to be connected with the provided

connector within the hood controls. See wiring diagram

on page 15 for wiring information.

ClockBox (if applicable)

Twenty (20) feet of shielded control wire is provided with

the ClockBox option to connect the ClockBox controller

to the touchscreen interface. The ClockBox needs to be

connected back via the connector within hood controls.

See wiring diagram on page 15 for wiring information.

Remote ADA Switches (if applicable)

Eight (8) feet of shielded control wire is provided with

the ADA remote switch option. The switches need to be

connected back with the provided connector within the

hood controls. See wiring diagram on page 15 for wiring

information.

Fire Alarm System Connections

The hood unit has two fire alarm connections (discrete

switches), each with its own trigger. A connection is

made to one output (Y#) and one common (C#) at the

controller. The output labeled Y0 is triggered by a fault

from the high temperature switch (190°F), or pressure

switch, or hose switch. Output Y1 is triggered by a

high temperature switch (190°F) and a low pressure

fault in the extinguisher tank (the fire suppressant has

discharged). You may use either one connection or

both, depending on your situation. When there is a fault,

a buzzer in the unit will sound and the power disconnect

will turn off.

Local Alarm Connection: Connect to output Y0 and

common C0

Remote Alarm Connection: Connect to output Y1 and

common C1

To connect to the alarms, it is preferred that you use a

spade terminal connector (supplied), but a stripped wire

is acceptable.

Connecting the alarm system in the configuration

described above results in a normally open connection.

To switch these two alarm contacts to normally closed

connections, insert a jumper into the blue and the gray

terminal adjacent to it (terminal blocks 4 and 5). One

leg of the provided jumper is inserted into the blue

terminal and the other into the gray terminal.

Y0

Y1

C0

C1

Onboard Controller

In addition to the fire alarm system connections

described previously, a second connection may be

made to the fire alarm switch installed in the unit. Unlike

the connection above, this switch does not require

power to be fed to the hood in order to function. The

fire alarm switch is located above the actuator arm,

beside the controller assembly. The fire alarm switch is

activated when the actuator arm trips.

To connect the fire alarm switch, wire the fire alarm to

the common connector and normally open or normally

closed connection as shown.

Common

Normally Open

Normally Closed

Fire Alarm Switch

NOTE

Ensure jumper is inserted completely and the top of

the jumper is level with the other jumpers.

Fire Ready Hood

14

®

Page 15

Wiring Diagram

Description Value

CB ClockBox 2 HR

F1 Controller Fuse 1 AMP Fast Blow

F2 Fan Fuse 2 AMP Slow Blow

F3 Dual Disconnect 1 AMP Slow Blow

F3 Disconnect Fuse 0.5 AMP Slow Blow

F4 Main Fuse 8 AMP Slow Blow

F5 ClockBox Fuse 8 AMP Slow Blow

MP1 Main Power Connector

FP2 Fan Connector

SW1 Main Power Switch

SW2 Light Switch

SW3 Service Switch

SW4 Reset Switch

SW5 Optional ADA Light

SW6 Optional ADA Fan

HSW1 Hose Switch

HITH1 High Temp Thermostat 190°F

LOTH1,2 Low Temp Thermostat 150°F

FSP1 Fan Speed Controller 4.0 FLA

FAN Inline or Recirc Fan

CAP1 Capacitor for Recirc Fan 10 UF

M1 Stove Disconnect 40 FLA 50 A RES

LIGHT Hood Light 60 WATT

Controller Computer Driving Hood

BUZZER Alarm in Hood 90 DB

®

Fire Ready Hood

15

Page 16

ClockBox Wiring Diagram (if applicable)

CLOCKBOX

Green

GND

120VAC

INPUT

Supply Line

White

N

Black

H

T5

T3

T4

Fuse

5.5 Amps

L N GND -V +V

POWER SUPPLY

Blue

24 VDC

Brown

T5

Green/

Yellow

Circ DIN

(NEG)

(POS)

PLC

Y0

Y1

Y2

Y3

COM

Y4

COM

Y5

COM

1. An independent 110 VAC supply line is provided to

the ClockBox.

a. This supply line provides power to the ClockBox,

which is independent from the supply line to the

hood.

2. The ClockBox provides 110 VAC to the Power

Disconnect Assembly

3. The ClockBox provides control signal voltage (5VDC)

and logic control to the Touchscreen [HMI]

4. The Power Disconnect Assembly supplies the input

line to the stove/range as follows:

a. If an Electric Disconnect

- Controls the 110 VAC contactor coil allowing the

220 VAC supply line to the stove/range via the

NEMA 14-50 receptacle.

b. If a Gas Disconnect

- Open the solenoid valve allowing gas to flow to

the input line of the stove/range

c. If Dual Disconnect

- Both conditions 6.a.i and 6.b.i will apply

d. The above reference will be maintained for as long

as there is time left at the ClockBox, it will open

the contact in the timer, stopping the supply line

to the Power Disconnect, which in turn, will shut

off the stove.

Black

Black

5 VDC

Black

White

Green

T5

T4

T1

T2

H

A1

PWR DISC

OUTPUT

Supply Line

White

Brown

Green

Black

Red

H

N

GND

N

A2

1 - SG

2 - SD

3 - RD

4 - (NEG)

5 - (POS)

HOOD 120VAC

INPUT

Supply Line

TOUCH

SCREEN

ClockBox System Interface Diagram

110VAC

110VAC

Supply Cable

Supply Cable

110VAC to Hood110VAC to Hood

110VAC

110VAC

Supply Cable

Supply Cable

Communication

Communication

Clock

Clock

Box

Box

110VAC to

110VAC to

Disconnect

Disconnect

5VDC

5VDC

Wire

Wire

ClockBox

ClockBox

Touchscreen

Touchscreen

NOTE

Some electric stoves/ranges have a warning light

to alert the user that the burners/coils are hot.

These warning lights will be off since the supply line

powering the stove/range is not present.

Fire Ready Hood

16

®

Page 17

Operation - How it Works

The GRRS functions as a standard ventilation range

hood with the added capability to suppress stove top

fires.

Designed for use over a standard 30 and 36 inch

residential range, it uses a mechanical, commercial style

automatic fire suppression system.

Refer to the illustration below to familiarize yourself with

the following functions.

• A controller provides an internal alarm plus

connections for up to two external alarms that may go

to a local alarm panel and/or remote location, i.e. the

local fire department.

• The unit is powered from standard 115 VAC / 60 Hz /

single phase. A main Power Switch is located at the

upper left of the front surface. (Remote ADA switches

provided).

• For normal daily use, the unit provides a fan speed

control knob and a light switch for the light.

• A Reset Button (white) is provided to energize the

controller and the main power disconnect contactor

(electric range) or valve (gas stove). Upon initial power

up, the control system is not enabled and this reset

button needs to be pressed. In doing so the Status

LED below the reset switch will turn from red to green.

Environmental Monitoring / Pre-Suppression

Functions

The controller operating system is designed to enhance

the functionality of the unit and the safety of the cooking

environment.

The system relies on input from a set of thermostats to

control the fan and shutoff power to the stove when the

temperature reaches preset points.

As the temperature rises, the controller monitors the

environment with the three (3) thermostats. The board is

programmed to respond to two temperature thresholds.

The first at 150°F and the second at 190°F.

At the first temperature threshold of 150°F, the

ventilation fan will turn on, regardless of the front

panel switch setting.

At the second temperature threshold of 190°F:

1. The power disconnect to the stove (valve or

contactor) is de-energized, shutting off power to the

stove.

2. The “local” alarm output is tripped, indicating a

trouble condition with the unit. This output is from

contacts C0 and Y0 on the controller.

3. The on-board audible alarm sounds (high pitched

tone).

NOTE

See page 21 for controller schematic.

®

Fire Ready Hood

17

Page 18

Accessing the Internal Components

Thumb nut locations

fo

f

l

y

y

Moving the unit between ‘operating’ and ‘service’

positions.

All GRRS models have been configured as a stand

alone unit mounted to a wall plate. As such, the unit

may easily be tilted down into a service position, giving

you access to the electronics and extinguisher tank, or

be removed completely for maintenance and cleaning.

Provisions have been made to facilitate easy removal

including a minimal amount of fasteners and modular

electrical connections.

To place the unit in the service position, a few simple

steps are required. Be sure to wear safety glasses at all

times during this process:

1. Shut the unit off with the power switch on the front of

the hood.

2. Remove the grease tray and the grease entrapment

filter.

3. For non-ducted installation, loosen and remove

the thumb nuts that are on the rear inside wall of fan

housing compartment.

CAUTION

• Be careful while working with the unit in the service

position. Release of the cable system or applying

force to the tank valve assembly may cause

discharge of the tank. The high pressure discharge

has the potential to cause skin or eye damage and

injury!

• An electrical shock hazard is present at the

electrical compartment whenever there is power to

the hood. Use caution when working around this

device while the unit has power.

Three thumb nut locations

for non-ducted fan

On ducted installations, remove the two thumb nuts

located at the top inside near the fan intake. Slowly

lower the unit.

r ducted fan on

4. The unit will now freely pivot downward to a stop

position. A safety cable is provided to prevent the

unit from falling or lowering too far.

5. Place safety pin in the tank valve to avoid accidental

discharge.

With the unit in this position, basic servicing and

cleaning may be performed, including servicing the

extinguisher tank assembly.

To move the unit back to the operating position, simply

reverse the process as outlined above.

Fire Ready Hood

18

®

Page 19

ClockBox Operation and Navigation (if applicable)

FIGURE 1

1. Press Start/Reset to allow the

2 hour timer to begin. This will

prompt to the password screen.

See Figure2.

2. Press Pause to pause the timer,

press again to continue.

3. Press STOP to stop the timer.

4. If the timer is running, pressing

the Start/Reset button will reset

the timer at the original timer value

and start running the timer again.

5. The Greenheck logo is a hidden

button which allows access to

background menus. Press the

Greenheck logo to access hidden

menu to modify timer values and

passwords. See Figure 3.

NOTE: Main Screen will always

show available time. System is preset to countdown remaining time.

FIGURE 2

1. Factory preset master password:

06412

2. Enter password 06412 and then

press the enter symbol ().

FIGURE 4

1. To adjust hours, minutes, or

seconds of cook timer, press on

respective number. Enter the new

value and press enter symbol ()

to store the value.

FIGURE 5

1. Adjust pasword number and level.

Press under New Pass to key

new password. To validate the

password, re-type the password

under Re-Type Pass. Press the

Change/Add key to add or adjust

a password or Delete to omit a

stored password.

FIGURE 3

1. Press Timer Mgmt to modify the

timer value. See Figure 4 for timer

management screen.

2. Press Password Mgmt to add/

modify/delete passwords.

See Figure 5 for password

management screen.

®

Fire Ready Hood

19

Page 20

Test Tank and Demonstration

Once the hood has been installed, it may be necessary

or desired to test the unit with a test tank filled with

pressurized nitrogen (optional).

1. Following the “Removing the Extinguisher Tank”

instructions on page 25, remove the extinguisher tank

and replace it with a test tank.

WARNING

The safety pin must be in place in the extinguisher

tank until the unit is ready to be returned to service

or to be tested. Always wear safety glasses during

this procedure.

2. The unit can be actuated one of two ways:

A. Cut Test Links

Replace the actuator arm’s safety key. Loosen the

turnbuckle in the fusible link cable assembly (underside

of hood). Replace one of the fusible links with a test link.

Retighten the turnbuckle to the proper tension. Remove

the safety key and raise the unit to its operational

position. To test, cut the test link with wire cutters or

similar.

Safety Pin

B. Manual Pull Kit (if installed)

Raise the unit to its operational position after the test

tank has been installed. Remove the plastic break rod

from the pull face with an allen wrench (refer to manual

pull station appendix for

more detailed information

on this). Pull the handle

to actuate the unit. Refer

to the “Manual Pull Kit”

section on the method to

return the pull station to an

operational state.

3. Nitrogen should be released from each nozzle

simultaneously.

WARNING

Be careful of the protective caps on the nozzles.

These will fly off the nozzles when the unit is actuated.

Always wear safety glasses during this procedure.

4. Replace the test tank with the extinguisher tank, the

test link with a fusible link, and place the unit to its

operational position. The unit is now ready to be put

into service.

Safety Key

Turnbuckle Fusible Link

Fire Ready Hood

20

®

Page 21

Controller Schematic

On the controller, there are two rows of LED indicators

next to the X (inputs) and two rows of LED’s on the Y

area (outputs).

LED

Label

X0

X1

X2

X3

X4

Input

Function

Hose

Switch

Reset

Switch

Pressure

Switch

Service

Switch

Low

Temperature

Switch

Scenario

Hose in place On

Hose disconnected Off

When switch is depressed On

Switch not pressed Off

Pressure okay On

Pressure failure Off

Servicing unit On

Normal operation Off

Both low temp thermostats

below 150°F

Either thermostat at or above

150°F

Alarms are configured for

normally closed (jumper

installed)

Alarms are configured for

X5

Remote

and

Local Alarms

normally open (no jumper)

High temperature thermostat

below 190°F

High temperature thermostat

at or above 190°F

Scenario

X6

LED

Label

High

Temperature

Switch

Output

Function

Low gas switch activates OR

Y0

Output for

Local Alarm

hose switch activates OR high

temperature switch activates

Normal operation Off*

Loss of pressure AND high

temperature (fire suppression

discharge)

Normal Operation Off*

Alarm condition On

Normal condition Off

Y1

Y2

Output for

Remote

Alarm

Normal

Condition

When controller turns the fan

Y3 Fan

on

When controller is not running

the fan

When power is being set

to gas/electric disconnect

(normal operation)

When power is lost to gas/

Y4

Power

Disconnect

electric disconnect

Y5 Horn

Horn is on On

Horn is off Off

* The LED’s state depends on whether the alarm contacts are

set up for normally open or normally closed. These contacts

are set up for normally open from the factory (LED’s illuminate

during alarm). To configure the fire contacts for normally

closed state (LED’s illuminate on no alarm), a jumper must

be placed between two terminals. Please see page 14 for

additional information.

LED

State

On

Off

On

Off

On

Off

LED

State

On*

On*

On

Off

On

Off

Status display

Input/output

display

RUN

0

X

0

Y

4

PROG.

5

ERR.

3

74

3

COM

LN

X0 X2 X4 X6

RUN PROG. ERR.

0

3

X

74

0

3

Y

4

5

Panasonic

RUN

FP-X C14

PROG.

max.min.

V1

V0

Y1

Y0

0V

24VY5C0C1C2 C3 Y4

X1

X3 X5 X7

Y3Y2

The controller’s operating system is designed to

enhance the functionality of the unit and the safety of

the cooking environment.

Alarm Connections

Alarm Outputs: The other function of the controller

is to report alarms from the system either for a system

fault or as a result of a system discharge. Refer to

Fire Alarm System Connections on page 14 in this

installation manual for information on how to connect

the alarm outputs.

Output Y1 and common C1 are configured to close with

the discharge of the extinguisher tank. This condition is

determined by the controller with the low pressure input

from the switch and a high temperature condition from

the 190°F rated thermostat. Both conditions must be

present in order for this output to trigger.

Note that the microswitch outputs are dry contact type,

rated for low voltage, and can be normally open (NO) or

normally closed (NC), with a common. Therefore do not

produce any current or voltage output.

NOTE

Pressing the reset button will not turn off alarm. Unit

needs to be recharged to reset alarm.

Service Switch: The black switch next to the controller

and internal audible alarm is the service switch. It can

be switched on or off. When it is switched to on, the

remote alarm and local

alarm are deactivated. Its

purpose is to allow service

to be conducted and

components tested without

setting off the alarm. Once

testing or service is done,

turn the service switch to

off for normal operation.

NOTE: LED will flash orange

and green.

Service Switch

in the OFF position

®

Fire Ready Hood

21

Page 22

Self-Monitoring System

These functions are to be checked at start-up.

Low Pressure

HOW TO TEST FUNCTION

a. Unplug one of the wire terminal connections

attached to the pressure switch.

b. LED turns from green to orange blinking with buzzer.

c. Power for gas valve or disconnect turns off.

d. Audible buzzer inside of hood beeps 4 times.

e. Local Alarm Activation “Y0-C0”.

f. Hood remains powered.

Loose Connection on Discharge Hose

HOW TO TEST FUNCTION

a. Unplug the hose quick disconnect coupling to

discharge manifold.

b. LED turns from green to orange blinking with buzzer.

c. Power for gas valve or disconnect turns off.

d. Audible buzzer inside of hood beeps 3 times.

e. Local Alarm Activation “Y0 to C0”.

f. Hood remains powered.

High Temperature Switch

HOW TO TEST FUNCTION

a. Unplug red wire terminal located on terminal strip

#4. NOTE: Do not remove the wire, just unplug the

terminal. You can also use a heat gun on the center

of the hood to simulate a high temperature.

b. LED turns from green to orange blinking with buzzer.

c. Power for gas valve or disconnect turns off.

d. Audible buzzer inside of hood beeps 5 times.

e. Local Alarm Activation “Y0 to C0”.

f. Fan turns on.

g. Fan remains on for 3 minutes after you lower

temperature or put red wire back on.

h. Hood remains powered.

Low Temperature Switches

HOW TO TEST FUNCTION

a. Use heat gun on either left or right low temp switch.

b. Fan turns on.

c. Fan remains on for three minutes after temperature

falls below 150ºF.

High Temperature and Low Pressure Switches

HOW TO TEST FUNCTION

a. Unplug red wire terminal located on terminal strip

#4. NOTE: Do not remove wire, just unplug it’s

round connector. Unplug one of the wire terminal

connection attached to pressure switch.

b. Fan turns on.

c. LED turns from green to orange.

d. Power for gas valve or disconnect turns off.

e. Audible buzzer inside of hood on continuously.

f. Local Alarm Activation “Y0 to C0”.

g. Remote Alarm Activation “Y1 to C1”.

h. Hood remains powered.

Alarm Discharge Switch

HOW TO TEST FUNCTION

a. Depress actuator lever located at the micro-switch

next to tank.

b. Check continuity of both normally open and closed

contacts.

Service Switch in ON (1) Position

HOW TO TEST FUNCTION

a. LED turns from green to blinking orange/green.

b. Power for gas valve or disconnect turns off.

c. No alarm closure at Y1-C1 or Y0-C0.

d. Pressing the reset button will not reset the hood

until the service switch is put back in the off (normal)

position.

Fire Ready Hood

22

®

Page 23

After an Actuation

The fire suppression system must be recharged and

restored to service immediately after any discharge for

continued fire suppression protection.

WARNING

• Safety glasses and gloves must be worn for all the

following operations. Flush thoroughly with clean

water if agent comes in contact with skin or eyes.

• Allow time for cooling before attempting any

cleaning. Using water to clean any appliance that

contains hot grease or cooking oils, may result in

violent steaming or splattering.

Clean-Up Procedures

Due to the alkaline nature of the fire suppressing agent,

kitchen surfaces must be cleaned immediately after

system discharge. The wet chemical agent discharged

produces a foamy by-product that can be wiped up with

a cloth or sponge.

Clean-up procedures are as follows:

1. Before clean-up ensure that all fuel or electrical

sources to the equipment to be cleaned have been

shut off. Unplug exhaust hood and all appliance

electrical controls to avoid any chance of electrical

shock resulting from the cleaning process or from

an electrically conductive liquid agent.

2. Discard food and cooking oil that has contacted the

extinguishing agent since it is no longer suitable for

consumption.

3. Wipe up as much of the agent as possible with

paper towel or disposable rags.

4. Use hot, soapy water to clean away all residue and

any surfaces that the agent has come in contact

with.

5. Completely dry all areas before continuing the

service procedure.

Inspect the Unit for Damage

Be sure no components of the hood were damaged

from fire/heat.

Determine Cause of Discharge

Determining the reason for the system discharge before

recharging the fire suppression system and resetting the

unit is critical to ensure either the system performed as

designed, or was caused by a component malfunction.

Great care has been taken to simplify field installations,

so system malfunctions should be extremely rare.

• A fire may have caused the fusible links to melt,

causing the system to discharge. In case of fire,

inspect the electrical system and all wiring for heat

damage.

• The remote pull station (optional) may have been

pulled.

• If fusible links have not been changed within the past

12 months, they may have stretched and released the

actuation cable.

How to Reset the Suppression System

Resetting and testing release mechanisms, remote

pull, and fusible links.

Reset detection system by completing the following

steps:

1. Remove extinguisher tank

2. Make sure tension arm cable is in the released slack

position.

3. Remove the 3 fusible links from the cable assembly

and replace links with 2 new properly rated links

and one test link at terminal end.

4. Return tension arm and cable mechanism to a

cocked position.

5. Using wire snips, cut the test link at the terminal end

to simulate an actuation.

6. If system actuates successfully, go to Step 8.

7. If the release mechanism does not actuate, check

the following components and remedy any disorder

as follows:

a. Check the detector links for correct positioning

through pulleys in system and for possible twists

or knots in the cable

b. Ensure that actuator arm is in place and is

cocked.

c. Retest the system after installing a new test link

on the terminal end.

d. Verify that safety pin is removed from suppression

tank. If problems persist call the factory at 1-800371-6858.

8. Upon successful actuation of the system, complete

the following steps:

a. Release cable from actuation lever and install a

properly rated fusible link in the terminal location.

b. Replace extinguisher tank and reattach cable to

actuation lever to place it into its “ready” position.

Recharge Tank

1. Placing the hood into the service position allows for

removal of tank and examination of components.

2. Disconnect the tank pressure switch and the hose

discharge assembly connection and remove the

tank from the hood. It is recommended to replace

the pin back into the tank in case of left over

suppression media.

3. Remove the tank valve assembly and inspect the

valve and O-rings for damage. Thoroughly flush the

valve and O-ring with water.

4. Once flushing is complete, refill the tank with

the measured amount in the recharge and refill

kit, screw on valve assembly, and recharge with

nitrogen to a pressure of 100-105 psi (green zone on

pressure gauge).

5. Reinstall tank and ensure all systems have been

thoroughly checked and retested with new links.

The system can now be put into service.

®

Fire Ready Hood

23

Page 24

The pressure gauge is directly plumbed to the wet

chemical tank valve assembly and indicates the

pressure status of the nitrogen in the tank. The tank

includes a pressure switch that closes if pressure is in

the “green” or normal operation range.

Resetting Gas Shut-Off Valve

Before the gas supply is turned back on, extinguish any

open flames and turn off all burners and any electrical or

mechanical devices that are capable of igniting gas to

reduce the risk of explosion due to leaking gas. Check

to ensure the power switch is on.

Reset gas shut-off valve by completing the following

steps:

1. On the top of the hood press the white manual reset

button. The gas valve will energize into its normal

operating (open) position.

2. Examine burners for gaseous odor. If gas odor exists,

turn off power switch which will cause the gas valve

to close and shut off gas supply. Clear gas fumes by

opening windows and doors and then correct gas

leak before proceeding.

3. Reset gas valve again and if there is no gaseous

odor, pilot lights may be ignited at this time. Gas

stoves with a pilot light that is always on require

added caution. The pilot light must be relit manually.

Resetting Electrical Relay Shut-Off

1. Check to ensure the power source is on.

2. Press the white manual reset switch on the top of the

hood.

3. Status LED will turn from red to green.

If the system does not reset, one of the following

possibilities may be the problem:

• Tank hose not connected properly

• Tank pressure sensor wire disconnected

• Tank not to adequate pressure

• Electric power is shut off

Fire Ready Hood

24

®

Page 25

Maintaining the System

Pressure

Ga

ug

g

e

rg

e

e

Ho

se

S

Sa

ty

Pi

Tan

Valve

Presure

Sw

w

h

MoMoununti

ng

g

Bracke

t

Actuator a

undede

sio

ininreaea

dy

dy

p

p

it

ioio

n

Cleaning the Hood

To remove built up grease and cooking debris, clean

the unit thoroughly with mild detergent and water. Be

careful when using abrasive cleaning pads as they may

scratch or mar the stainless steel surfaces. The grease

entrapment filter, front discharge grille and grease

tray are dishwasher safe. The carbon filter cannot be

washed and should be replaced periodically as needed.

Inspection Procedures

Inspect the Nozzle Caps

The nozzle caps should be inspected and cleaned. All

five (5) nozzles should have protective caps installed.

If necessary, remove the caps and check for build up

of debris or any signs of clogging of the nozzle orifice.

If clogging is suspected, remove the nozzle with a

7/16-inch wrench, and flush with hot water until it flows

freely through the nozzle.

Replace the nozzle and protective cap.

Replacement caps and nozzle O-rings are available

from Greenheck or through your representatives.

WARNING

The protective caps stay on the nozzles at all times. In

the event of a discharge, the caps will blow off.

Inspect Fusible Link System*

Periodic inspection of the fusible link system ensures

the unit is ready to work in the case of a fire.

1. Place safety pin

in tank valve.

2. Remove tank

from hood.

3. Remove tension

from cable

system by

loosening the turnbuckle.

4. If the fusible links need to be replaced, call 1-800355-5354 or contact your representative.

5. Inspect pulleys and cable. Pulleys should rotate freely

and cable should be flexible. Everything should be

free of grease build-up.

6. Tighten the turnbuckle, reapplying tension to the

stainless steel rope, making sure the cable is running

through the pulleys properly and there are no kinks or

knots.

7. Reposition the tank.

8. Remove safety pin from tank valve.

*Each fusible link is date-stamped and must be replaced

if expired or after 12 months of use.

WARNING

If grease build-up on the cable system is not kept to

a minimum, the cable could become stiff and will not

discharge the suppressant in the event of a fire.

r ten

rm

n

os

10 Year Maintenance

Hydrostatic testing and new liquid agent, or tank

replacement is recommended at ten-year intervals. The

manufactured date is stamped on the top of the tank.

This should be performed by an authorized technician

or at the manufacturer’s facilities. Material safety data

sheets are available from Greenheck.

WARNING

Rubber gloves and safety glasses should be worn

during service or inspection of the tank. If contact

with the chemical agent skin or eyes occurs, flush

immediately with water for 15 minutes. If irritation

persists, contact a physician. If taken internally, do not

induce vomiting. Dilute with water or milk and contact

a physician.

Lighting

Illumination is provided by a 60 watt medium-base

shatterproof incandescent light bulb. To replace, make

sure the light switch is in the “OFF” position and then

gently unscrew the bulb. (Bulb: 60A15/TF)

Removing the Extinguisher Tank

1. Lower the hood to its service position

2. Insert the safety pin in the valve head so that

accidental release of the suppressant does not occur.

3. Unplug the pressure switch wire and move it out of

the way for now.

4. Disconnect the discharge hose from its fitting located

inside the unit closest to the user.

5. Unscrew the two wingnuts holding the bracket for the

tank.

6. Lift the tank out of the hood.

7. To replace the tank, simply reverse these steps.

fe

n

itc

Discha

®

Fire Ready Hood

25

Page 26

and Recertification Schedule

WARNING

Safety glasses must be worn whenever service

operations are performed.

Monthly Annually

Cleaning Yes Yes

Suppression Nozzles Inspect Inspect

Fusible Links Inspect Replace

Extinguisher Tank Inspect Recertify Replace

Every

10 years

Replacement PartsRecommended Service

Part

Number

479683

479684

479685

479686

479687

479688

479689

479690 Fire Ready 60W Shatterproof Bulb, pack of 2

479691 Fire Ready Fusible Links, 212°F, 3 links

479692 Fire Ready Fusible Links, 280°F, 3 links

479693 Fire Ready Nozzle Caps, set of 10

479694

479695

479696

479697 Fire Ready Grease Entrapment Filter

479698 Fire Ready Grease Filter Cup

479699

Description

Fire Ready Annual Service Kit

(3) Links and Service Tag

Fire Ready Recharge Kit

Tank Assembly fully charged with adapter

Fire Ready Test Kit, Tank Assembly

Nitro only with adapter and test link

Fire Ready Tank Kit, Tank Assembly

Empty with adapter

Fire Ready Test Kit

Set of 2 Test Links, 4 Nozzle Caps and

1 Safety Key

Fire Ready Electrical Disconnect Box

208-240VAC/50A (as replacement)

Fire Ready 3/4-inch Gas Valve

115VAC (as replacement)

Fire Ready Wire Rope Assembly Set

Hood Width of 30 inches

Fire Ready Wire Rope Assembly Set

Hood Width of 36 inches

Fire Ready Replacement Charcoal Filters

“F” Calibrations, pack of 10

Fire Ready Replacement Fuse Kit for Control

Systems

Fire Ready Hood

26

®

Page 27

Maintenance Log

Date ___________________Time _____________ AM/PM

Notes: ___________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

Date ___________________Time _____________ AM/PM

Notes: ___________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

Date ___________________Time _____________ AM/PM

Notes: ___________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

Date ___________________Time _____________ AM/PM

Notes: ___________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

Date ___________________Time _____________ AM/PM

Notes: ___________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

Date ___________________Time _____________ AM/PM

Notes: ___________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

Date ___________________Time _____________ AM/PM

Notes: ___________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

Date ___________________Time _____________ AM/PM

Notes: ___________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

Date ___________________Time _____________ AM/PM

Notes: ___________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

Date ___________________Time _____________ AM/PM

Notes: ___________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

Date ___________________Time _____________ AM/PM

Notes: ___________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

Date ___________________Time _____________ AM/PM

Notes: ___________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

®

Fire Ready Hood

27

Page 28

Our Commitment

As a result of our commitment to continuous improvement, Greenheck reserves the right to change specifications

without notice.

Specific Greenheck product warranties are located on greenheck.com within the product area tabs and in the

Library under Warranties.

Greenheck’s Fire Ready Residential Range Hood, Model

GRRS catalog provides additional information describing the

equipment, available accessories, and specification data.

®

Phone: 715.359.6171 • Fax: 715.355.2399 • Parts: 800.355.5354 • E-mail: gfcinfo@greenheck.com • Website: www.greenheck.com

GRRS, Rev. 2, December 2014 Copyright 2014 © Greenheck Fan Corporation

28

AMCA Publication 410-96, Safety Practices for Users and

Installers of Industrial and Commercial Fans, provides

additional safety information. This publication can be obtained

from AMCA International, Inc. at www.amca.org.

Loading...

Loading...