Greenheck GRRS User manual

®

Document 483299

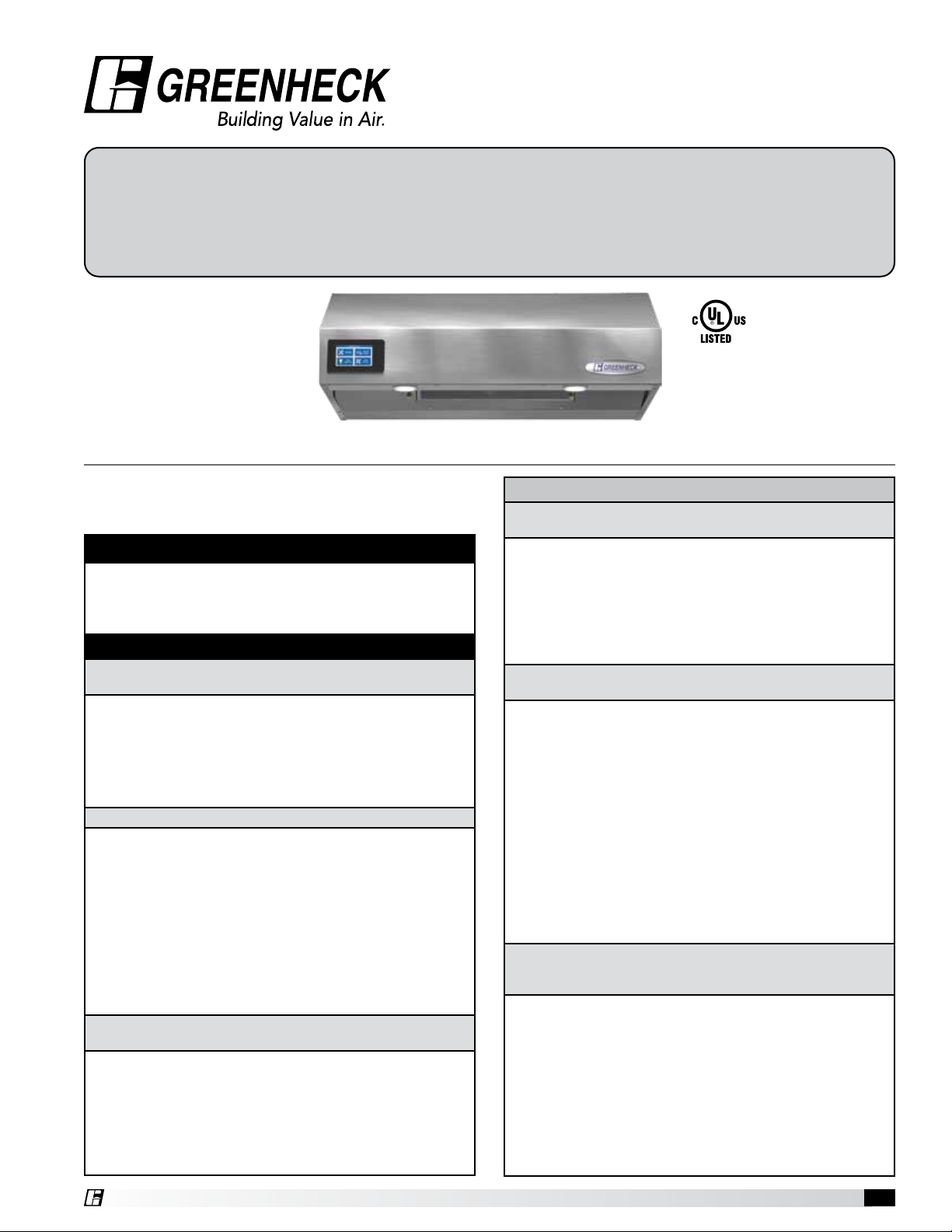

Model GRRS

®

Fire Ready Hood

Installation, Operation and Maintenance Manual

Please read and save these instructions for future reference. Read carefully before attempting to assemble, install,

operate or maintain the product described. Protect yourself and others by observing all safety information. Failure

to comply with these instructions will result in voiding of the product warranty and may result in personal injury

and/or property damage.

PRG VERSION: V1.00

Listed to UL Subject 300A

General Safety Information

Personnel should have a clear understanding of these

instructions and all applicable, current local and national

building and fire codes before installing this product.

NOTE

All service and maintenance on the fire suppression system

should be conducted by an authorized fire equipment

distributor. Do not tamper with fire suppression components

if not instructed to do so.

WARNING

To reduce the risk of fire, electric shock, or injury to

persons, observe the following:

• Use this product only in the manner intended by the manufacturer

(to cover domestic ranges used for domestic purposes).

• When cutting or drilling into wall or ceiling, do not damage

electrical wiring or other hidden utilities.

• Ducted exhaust fans must always be vented to the outdoors.

• Use only rigid, metal ductwork

• This unit must be properly grounded.

To reduce the risk of range top grease fire:

• Never leave the range unattended at high settings. Boil-overs

cause smoking and greasy spillovers that may ignite.

• Dense smoke from frying pans indicates cooking oil is near auto

ignition – turn the burner down or off.

• Always turn the hood fan ON when part of the cooking surface is

on

• Always make sure the hood grease filter is installed before cooking.

• Clean hood grease filter frequently. Do not allow grease to

accumulate on filter.

• Always use proper pan size. Use cookware appropriate for the size

of the surface element.

• Keep cooking areas clean and clear of combustible materials.

To reduce the risk of injury to persons in the event of a

range top grease fire, observe the following:*

• SMOTHER FLAMES with a close-fitting lid, cookie sheet, or metal

tray, then turn off the burner. BE CAREFUL TO PREVENT BURNS.

If the flames do not go out immediately, EVACUATE AND CALL

THE FIRE DEPARTMENT.

• NEVER PICK UP A FLAMING PAN. You may be burned.

• DO NOT USE WATER, including wet dishcloths or towels - violent

steam explosion will result.

* Based on “Kitchen Fire Safety Tips” published by NFPA.

AVERTISSEMENT

Pour réduire le risque d’incendie, de choc électrique ou

de blessure corporelle, respecter ce qui suit :

• Utiliser uniquement ce produit de la façon prévue par le fabricant

(pour couvrir les cuisinières domestiques utilisées à la maison).

• Lors de la découpe ou du perçage de murs ou plafonds, ne pas

endommager les câbles électriques et autres conduites masquées.

• Les caissons d’extraction à gaine d’évacuation doivent toujours

être évacués vers l’extérieur.

• Utiliser uniquement un réseau de gaine rigide, en métal.

• Cet appareil doit être bien raccordé à la terre.

Pour réduire le disque d’incendie de graisse sur le

dessus de la cuisinière :

• Ne jamais laisser la cuisinière sans surveillance à des réglages

élevés. Les débordements causent de la fumée et des

débordements de graisse qui peuvent s’enflammer.

• Une fumée dense provenant de poêles à frire indiquent que l’huile

à friture s’approche de son point d’inflammation spontanée. Régler

le bruleur plus bas ou l’éteindre.

• Toujours activer le ventilateur de la hotte lorsqu’une partie de la

surface de cuisson chauffe.

• Toujours s’assurer que le filtre de graisse de la hotte est installé

avant la cuisson.

• Nettoyer fréquemment la graisse du filtre de la hotte. Ne pas laisser

s’accumuler la graisse sur le filtre.

• Toujours utiliser la taille appropriée de poêle à frire. Utiliser une

batterie de cuisine proportionnelle à la surface de l’élément.

• Garder propre l’aire de cuisson et dégagée de toute matière

combustible.

Observer les points suivants pour réduire le risque

de blessures aux personnes advenant un incendie de

graisse sur le dessus de la cuisinière :*

• ÉTOUFFER LES FLAMMES à l’aide d’un couvercle ajusté,

d’une plaque à biscuits ou d’un plateau en métal, puis fermer le

brûleur. S’ASSURER D’ÉVITER DES BRÛLURES. Si les flammes

ne s’éteignent pas immédiatement, ÉVACUER LES LIEUX ET

APPELER LE SERVICE D’INCENDIE.

• NE JAMAIS SAISIR UNE POÊLE EN FLAMME. Vous pourriez vous

brûler.

• NE PAS UTILISER D’EAU, ni de linges à vaisselle ni de serviettes

mouillées car il pourrait se produire une violente explosion de

vapeur.

* Basé sur les « Kitchen Fire Safety Tips » (Conseils de sécurité sur

les incendies de cuisine) publiés par la NFPA

Fire Ready Hood 1

®

Receiving

Product should arrive in a large carton. Upon receiving

the product, check to ensure all items are accounted

for by referencing the delivery receipt or packing list.

Inspect each crate or carton for shipping damage before

accepting delivery. Alert the carrier of any damage

detected. The customer will make notation of damage

(or shortage of items) on the delivery receipt and all

copies of the bill of lading which is countersigned by the

delivering carrier. If damaged, immediately contact your

Greenheck Representative. Any physical damage to

the unit after acceptance is not the responsibility of the

manufacturer.

Unpacking

Verify that all required parts and the correct quantity of

each item have been received. If any items are missing,

report shortages to your local representative to arrange

for obtaining missing parts. Confirmation of shipment(s)

must be limited to only items on the bill of lading.

Parts Checklist

Hood with factory-installed Fire Suppression System

• Finished Top (optional)

• Ceiling Enclosures (optional)

Wall Mounting Bracket with J-Box

External Inline Fan (optional)

• One (1) 50 ft. Plug and Play Cable

Gas Disconnect (optional)

• 3/4 inch Gas Valve (plugs into gas shut off

assembly box)

• Gas Shut Off Assembly Box with 115VAC Range

Receptacle

• Two (2) 10 ft. Plug and Play Cables

Electrical Disconnect (optional)

• Electric Shut Off Assembly Box with 250VAC

Range Receptacle

• Two (2) 10 ft. Plug and Play Cables

Shipped Loose User Interface (optional)

• Recessed-Mount J Box

• One (1) 10 ft. Plug and Play Cable

Manual Pull Station (optional)

• One (1) 30 ft. Plug and Play Cable

Horn Strobe (optional)

• One (1) 8 ft. Cable

Wall Cap (optional)

K-Class Portable Fire Extinguisher (optional)

Fire Test Cylinder (optional)

Additional: Spare Fuse, Qty. 1 6A Fuse

Handling

Handle hood and accessories in such a manner as to

keep from scratching or chipping the coating. Damaged

finish may reduce ability of unit to resist corrosion.

Storage and Install Location Requirements

Units are protected against damage during shipment. If

the unit cannot be installed and operated immediately,

precautions need to be taken to prevent deterioration of

the unit during storage. The user assumes responsibility

of the unit and accessories while in storage. The

manufacturer will not be responsible for damage during

storage. The suggestions are provided solely as a

convenience to the user.

The ideal environment for the storage of units and

accessories is indoors, above grade, in a low humidity

atmosphere which is sealed to prevent the entry of

blowing dust, rain, or snow. Temperatures should be

evenly maintained between 32°F (0°C) and 120°F (49°C).

All accessories must be stored indoors in a clean, dry

location.

WARNING

The fire suppression system needs to be stored and

installed in locations where the temperature will not

fall below 32°F (0°C) and not exceed 120°F (49°C) for

proper operation.

AVERTISSEMENT

Le système extincteur d’incendie doit être entreposé

et installé dans des endroits où la température ne

descend pas sous 0°C (32°F) et ne dépasse pas

49°C (120°F) pour un bon fonctionnement.

Fire Ready Hood2

®

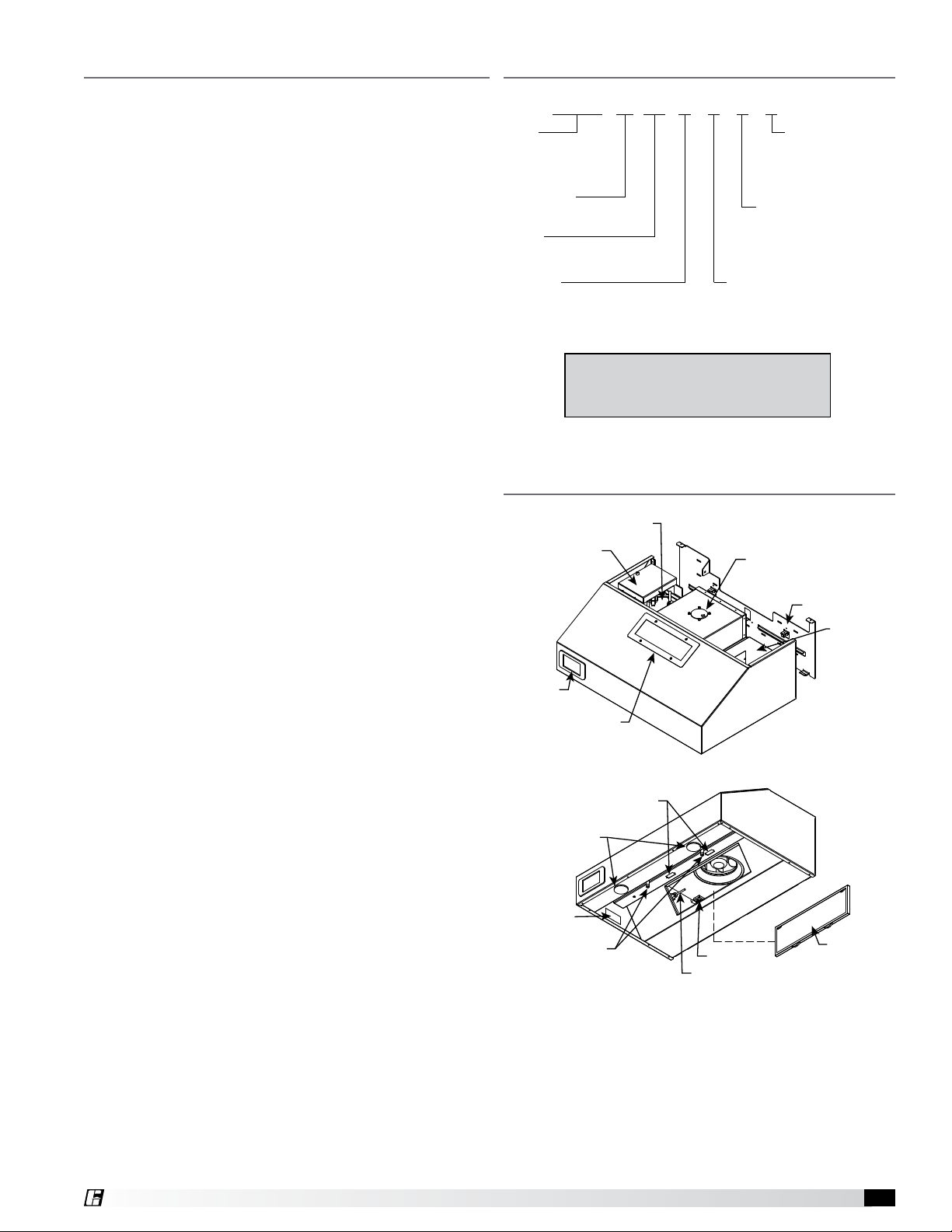

GRRS - W- 36 - T - E - O - N

TOUCHSCREEN

USER INTERFACE

WALL MOUNT

BRACKET

RECIRCULATING VENT

(FRONT RECIRCULATING MODEL)

LED LIGHTS

(QTY 2)

FIRE SUPPRESSION

TEMPERATURE SENSORS

(QTY 2)

GREASE FILTER

FIRE SUPPRESSION TANK AND

SOLENOID RELEASE

FIRE SUPPRESSION

CONTROL BOARD

INTERNAL EXHAUST FAN

(FOR FRONT RECIRCULATING

AND REAR DISCHARGE MODELS)

HOOD CONTROLS

(PLC, RELAYS, AND

TERMINAL BLOCKS)

FIRE SUPPRESSION

DROPS WITH NOZZLES

MODEL / SERIAL #

INFORMATION

STICKER

WALL CLAMP

(QTY 2)

HOOD TEMPERATURE

SENSOR

LED LIGHTS

(QTY 2)

FIRE SUPPRESSION

TEMPERATURE SENSORS

(QTY 2)

GREASE FILTER

FIRE SUPPRESSION

DROPS WITH NOZZLES

(QTY 2)

MODEL / SERIAL #

INFORMATION

STICKER

Receiving, Unpacking, Parts Checklist,

Handling and Storage ...................... 2

Model Number Code ......................... 3

Hood Exploded View ......................... 3

Ventilation and Fan Type Configurations ......... 4

Installation

General Information and Hood Weights ........ 7

Dimensional Data and Mounting Bracket ....... 8

Ductwork ................................ 9

Hood ................................... 9

External Fan ............................. 10

Range Disconnect

Gas / Electric ........................... 10

Accessories

Remote Mounted User Interface ............ 11

Finished Top ............................ 11

Ceiling Enclosures ....................... 11

Wall Cap ............................... 11

Manual Pull Station ...................... 12

Horn Strobe ............................ 12

Fire Extinguisher ........................ 12

Electrical Connections

Hood Power ............................. 13

Fan Power - Integral or External Fan .......... 13

Range Disconnect

Gas / Electric .........................13-14

Accessories

Remote Mounted User Interface ............ 15

Manual Pull Station ...................... 15

Horn Strobe ............................ 15

Other External Devices

Supply Fan Interlock Contacts ............. 15

Fire/Fault Contacts ...................... 15

Fan Calibration ........................... 16

Aiming the Nozzles ....................... 17

Operation ................................. 17

Unit Pre-Suppression Functions ............. 17

Arming the System. . . . . . . . . . . . . . . . . . . . . . . . 18

User Interface Navigation

Hood Lights Operation ................... 20

Fan Operation .......................... 20

Range Operation ........................ 20

Fire System Discharge .................... 21

System Faults .......................... 21

Service Settings .......................21-23

Fire Prevention Tips ...................... 23

Service and Maintenance

Accessing Internal Components ............. 24

Fire System Diagnostics ................... 25

Fire System Shut Off Sequence ............. 25

Fire System Detect Mode .................. 25

Fire Alarm Sequence ...................... 26

After Actuation ........................... 26

Routine Maintenance ....................... 27

Troubleshooting ..........................28-29

Parts List ................................. 29

Our Commitment .....................Backcover

Model Number CodeTable of Contents

Model

Residential

Range

Suppression

Configuration

W - Wall

Length

30 inches

36 inches

Ventilation

F - Integral Fan - Front Recirculation

R - Integral Fan - Rear Discharge

T - External Fan - Top Discharge

Example: GRRS-W-36-T-E-O-N

Greenheck GRRS, wall mount, 36 inches long, with top

discharge, with electric element disconnect, fan

provided by others, NFPA 101 Compliant

Hood Exploded View

NFPA 101 Compliance

X - Noncompliant

N - Compliant

External Fan Type

D - Inline Duct

O - Fan by Others

Range Disconnect Type

E - Electric

G - Gas

Fire Ready Hood 3

®

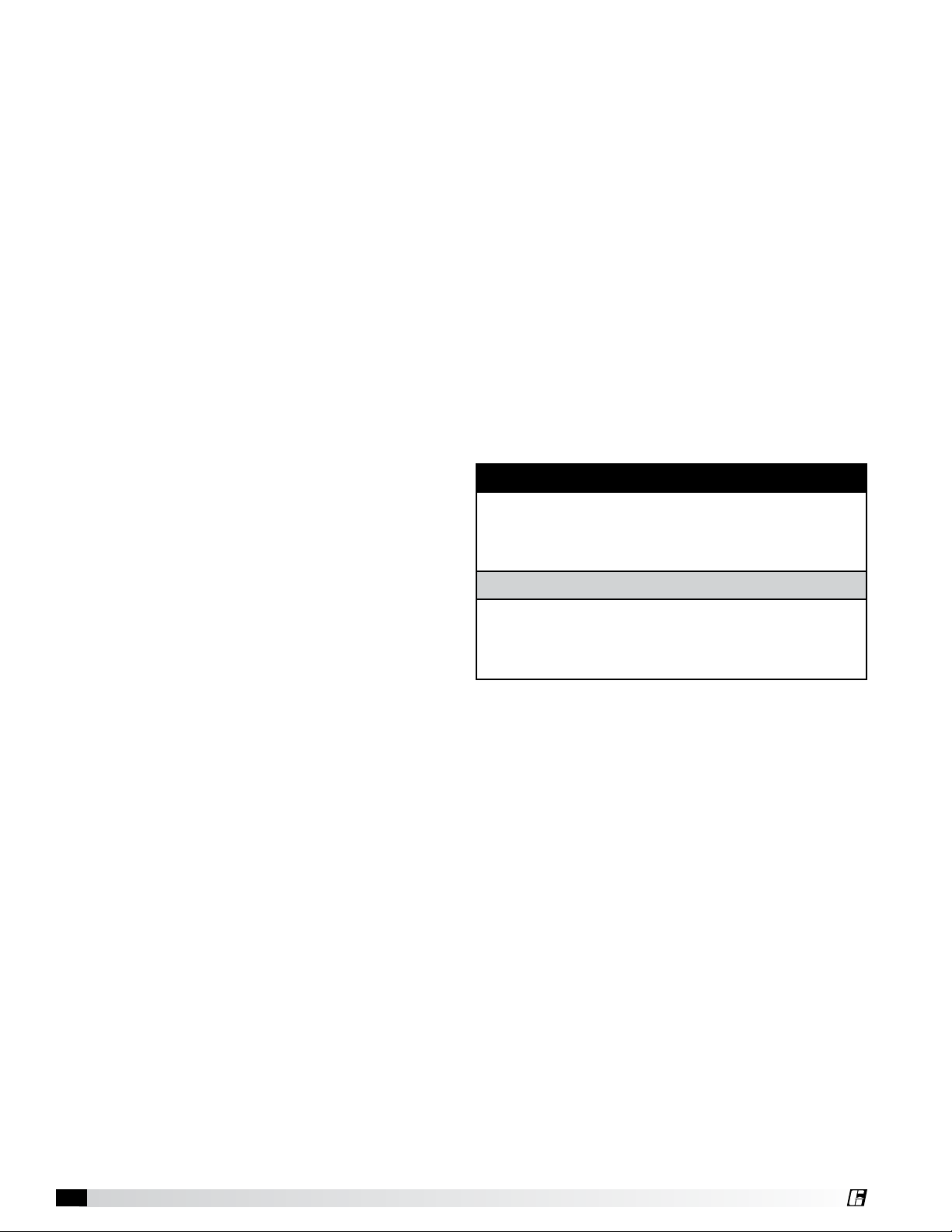

Ventilation and Fan Type Configurations

Range Hood

(provided)

Airflow

Kitchen Cabinets

Soffit

500 CFM

External Inline Fan

(provided)

Roof Cap

(by others)

12 in. Ductwork

(by others)

12 in. Ductwork

(by others)

Airflow

Kitchen Cabinets

Soffit

Wall Cap

(optional)

5 in. x 12 in.

Ductwork

(by others)

Range Hood

(provided)

8 in. to 12 in.

Transition

(by others)

EXTERNAL FAN

CONFIGURATIONS

INTEGRAL FAN

CONFIGURATIONS

Range Hood

(provided)

Airflow

Kitchen Cabinets

Soffit

Wall Cap

(optional)

5 in. x 12 in.

Ductwork

(by others)

Range Hood

(provided)

Airflow

Kitchen Cabinets

Soffit

Vent with Charcoal Filter

(provided)

INTEGRAL FAN

CONFIGURATIONS

Range Hood

(provided)

Airflow

Kitchen Cabinets

Soffit

External Inline Fan

(provided)

Roof Cap

(by others)

10 in. Ductwork

(by others)

12 in. to 10 in.

Transition

(by others)

10 in. to 12 in.

Transition

(by others)

10 in. Ductwork

(by others)

Range Hood

(provided)

Airflow

Kitchen Cabinets

Soffit

500 CFM

External Inline Fan

(provided)

Roof Cap

(by others)

12 in. Ductwork

(by others)

12 in. Ductwork

(by others)

Airflow

Kitchen Cabinets

Soffit

Wall Cap

(optional)

5 in. x 12 in.

Ductwork

(by others)

Range Hood

(provided)

8 in. to 10 in.

Transition

(by others)

8 in. to 12 in.

Transition

(by others)

Range Hood

(provided)

Airflow

Kitchen Cabinets

Soffit

12 in. Ductwork

(by others)

12 in. Ductwork

(by others)

500 CFM

External Fan

(by others)

8 in. to 12 in.

Transition

(by others)

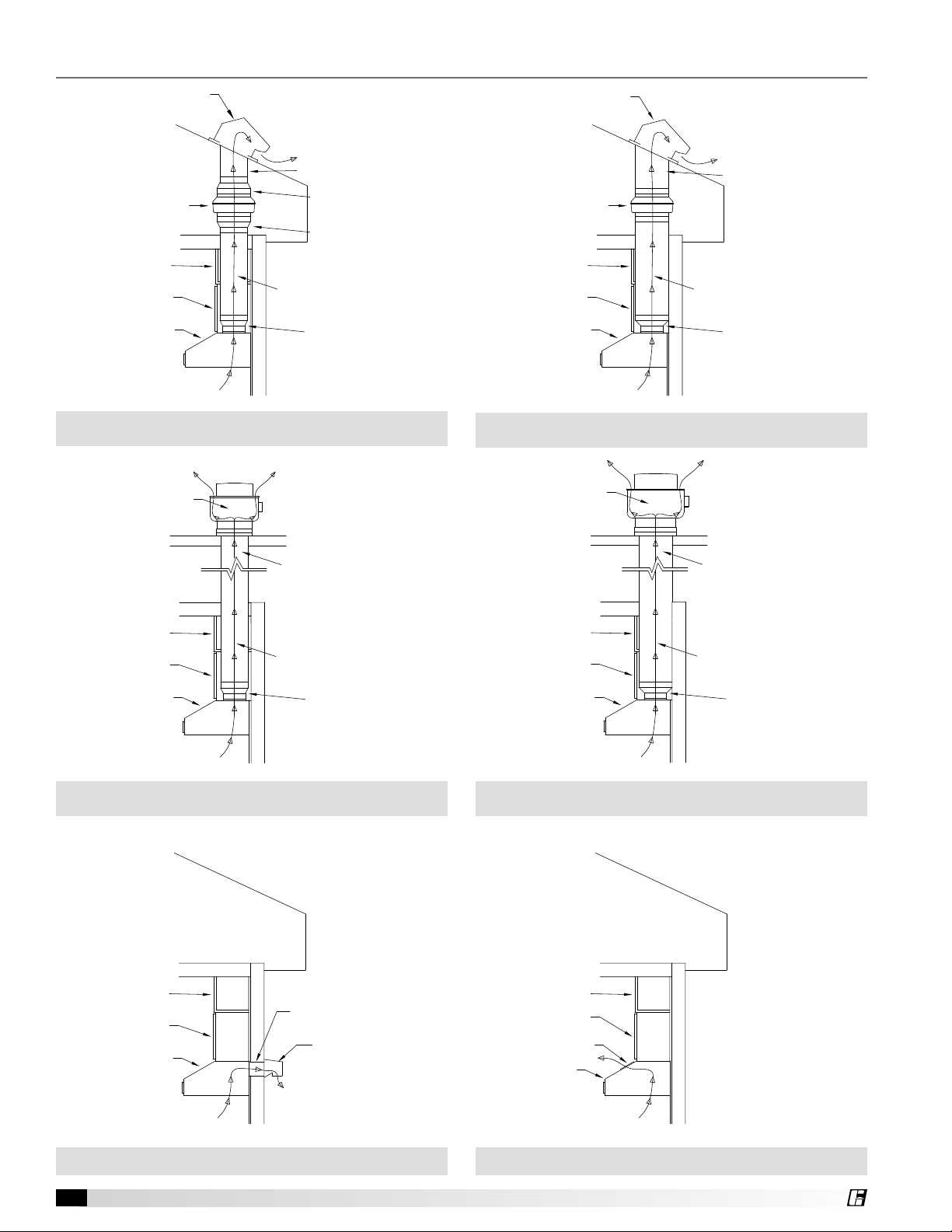

External Fan | Top Discharge

(with Non-NFPA 101 Compliant Inline Fan)

External Fan | Top Discharge

(with NFPA 101 Compliant 500 CFM Inline Fan)

Integral Fan | Rear Discharge Integral Fan | Front Recirculation

EXTERNAL FAN

CONFIGURATIONS

INTEGRAL FAN

CONFIGURATIONS

Range Hood

(provided)

Airflow

Kitchen Cabinets

Soffit

500 CFM

External Inline Fan

(provided)

Roof Cap

(by others)

12 in. Ductwork

(by others)

12 in. Ductwork

(by others)

Range Hood

(provided)

Airflow

Kitchen Cabinets

Soffit

Wall Cap

(optional)

5 in. x 12 in.

Ductwork

(by others)

Range Hood

(provided)

Airflow

Kitchen Cabinets

Soffit

Vent with Charcoal Filter

(provided)

8 in. to 12 in.

Transition

(by others)

External Fan | Top Discharge

(with NFPA 101 Compliant 500 CFM Inline Fan)

Integral Fan | Rear Discharge Integral Fan | Front Recirculation

INTEGRAL FAN

CONFIGURATIONS

Range Hood

(provided)

Airflow

Kitchen Cabinets

Soffit

Vent with Charcoal Filter

(provided)

INTEGRAL FAN

CONFIGURATIONS

Roof Cap

(by others)

Roof Cap

(by others)

External Inline Fan

(provided)

Soffit

Kitchen Cabinets

Range Hood

(provided)

Airflow

External Fan | Top Discharge

(with Non-NFPA 101 Compliant Inline Fan)

External Fan

(by others)

Soffit

Kitchen Cabinets

Range Hood

(provided)

External Fan | Top Discharge

Airflow

(with Non-NFPA 101 Compliant Fan by Others)

10 in. Ductwork

(by others)

12 in. to 10 in.

Transition

(by others)

10 in. to 12 in.

Transition

(by others)

10 in. Ductwork

(by others)

8 in. to 10 in.

Transition

(by others)

10 in. Ductwork

(by others)

10 in. Ductwork

(by others)

8 in. to 10 in.

Transition

(by others)

External Inline Fan

Kitchen Cabinets

Range Hood

(provided)

(with NFPA 101 Compliant 500 cfm Inline Fan)

Kitchen Cabinets

Range Hood

(provided)

(with NFPA 101 Compliant 500 cfm Fan by Others)

500 CFM

(provided)

Soffit

12 in. Ductwork

(by others)

Airflow

External Fan | Top Discharge

500 CFM

External Fan

(by others)

12 in. Ductwork

(by others)

Soffit

12 in. Ductwork

(by others)

Airflow

External Fan | Top Discharge

12 in. Ductwork

(by others)

8 in. to 12 in.

Transition

(by others)

8 in. to 12 in.

Transition

(by others)

Soffit

Kitchen Cabinets

Range Hood

(provided)

Airflow

Integral Fan | Rear Discharge

5 in. x 12 in.

Ductwork

(by others)

Wall Cap

(optional)

Vent with Charcoal Filter

Soffit

Kitchen Cabinets

(provided)

Range Hood

(provided)

Airflow

Integral Fan | Front Recirculation

Fire Ready Hood4

®

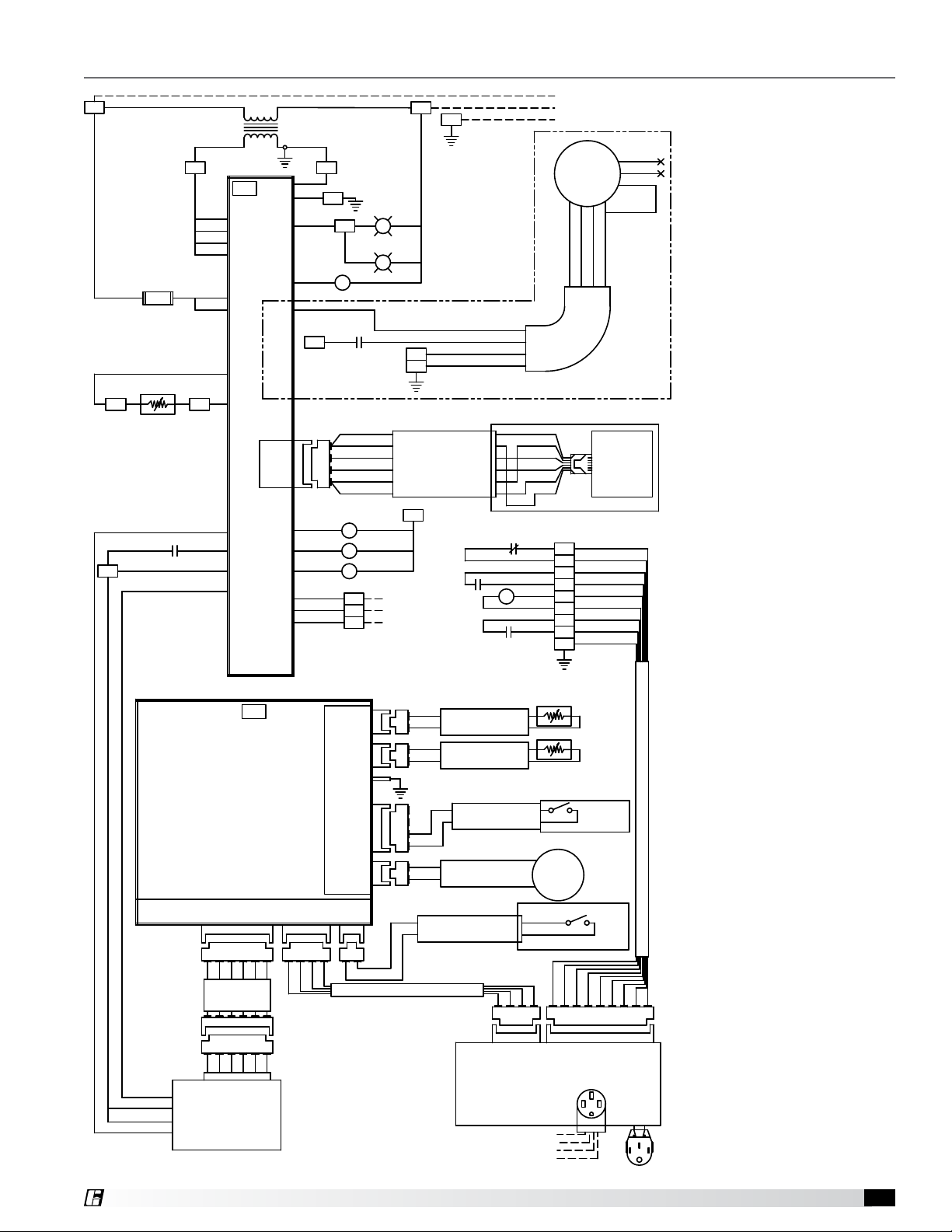

L1

CONTROL INPUT:

Wiring Diagram: Electric Disconnect

H1

BK 14GA

T1-B

YW

CM

R2

B1

120VAC

11

R3

R4

R5

NO6

NC6

A2

R2

BL 22GA

WH 22GA

GR 22GA

RD 22GA

YW 22GA

BK 22GA

A2

A2

A2

C6

WH 14GABK 14GA

LIGHT 1

LIGHT 2

14

N1

WH

14GA

N1

GND

TOUCH SCREEN

INTERNAL HOOD

LIGHT BLUE

24C

YW 18GA

YW 18GA

YW 18GA

GAS RESET

GAS STATUS

FIRE

STATUS

115 VAC, 15AMPS

N

FROM BREAKER

GND

GND

INTERNAL

EC FAN

BL 115V (N)

YW 22GA (E1)

BR 115V (L1)

GR/YW (GND)

0-10VDC

YW

115VAC

BR

GR/YW

FAN CABLE

BL

NEUTRAL

GROUND

CHANGES BASED ON FAN SELECTION

BL

CABLE

8.5 FT

POWER

RESET

POWER

21

TRIP

R3

24

A2 A1

11

YW

GR

RD

BK

WH

BL

R3

PR1

12

11

BL

PR2

BL

GR1

BL

GR2

BL

R1

GL1

YW

GL2

BL

PT1

R5

BL

PT2

14

GND

INTERFACE

1

2

3

4

5

6

7

8

GR

TOUCH

SCREEN

USER

WH 22GA

RD 22GA

BL 22GA

TR1

115VAC

40VA

BL YW

24VAC

GO

NO1

U10

C6

24C

YW 18GA

YW 18GA

GND

BK 14GA

BK 14GA

A1

BK 14GA

H1

1

-

2

3

+

O

4

BL 18GA

A1

BL 18GA

A1

BL 18GA

A1

RD 14GA

RD 14GA

RD 14GA

24H

U1

G

C3

C4

C5

C1

C2

GND

U1

Disp.

U3

U2

GND

U4

J3

GND

NO2

+Vterm

NO3

NO4

NO5

NO6

NC6

BL 18GA

BL 18GA

BL 18GA

BL 18GA

FU1

6A

T3

GR

BK 14GA

BR

OR

RD

T1-A

BL

R1

11

BL

14

YW

BL

U2

SENSE1

SENSE2

RD

1

1

2

1

2

BK

2

RD

1

BK

2

SENSOR 1 CABLE

SENSOR 2 CABLE

T1

T2

GND

1

1

2

GAUGE

VALV E

BLDG

ALARM

2

1

3

123

1

2

3

INTERNAL

CABLE,

3 FT

2

3

1

123

1

2

3

N/C

FIRE

BL

N/O

DETECT

YW

COM

YW

COM

TROUBLE

BL

N/O

DETECT

N/C

4

5

4

5

4

5

4

5

4

5

4

5

G502INT

SHUT-OFF

6

612

6

6

6

6

REMOTE

PULL

4

2

1

RD

1

3

4

3

1

BL

GR

YW

2

WH

3

3

BK

4

4

WH

1

1

BK

2

2

WH

2

QC4

2

PULL STATION CABLE

BK

10FT CABLE

RANGE 14-50R RECEPTACLE

(208-240VAC 50A POWER TO RANGE)

PRESSURE

GAUGE CABLE

SOLENOID

CABLE

30FT

RD

1

123

RANGE

DISCONNECT 1

TANK

SOLENOID

MANUAL PULL STATION

BL

GR

YW

4

2

3

QC5 QC6

4

DISCONNECT

CONTROL

BOX

BK

BK

WH

GN

PRESSURE

1

2

3

123

123

DISCONNECT 2

TANK

GAUGE

4

567

4

567

4

567

RANGE

8

8

899

RANGE

4-PRONG

POWER

CORD

10FT CABLE

GR

Fire Ready Hood 5

®

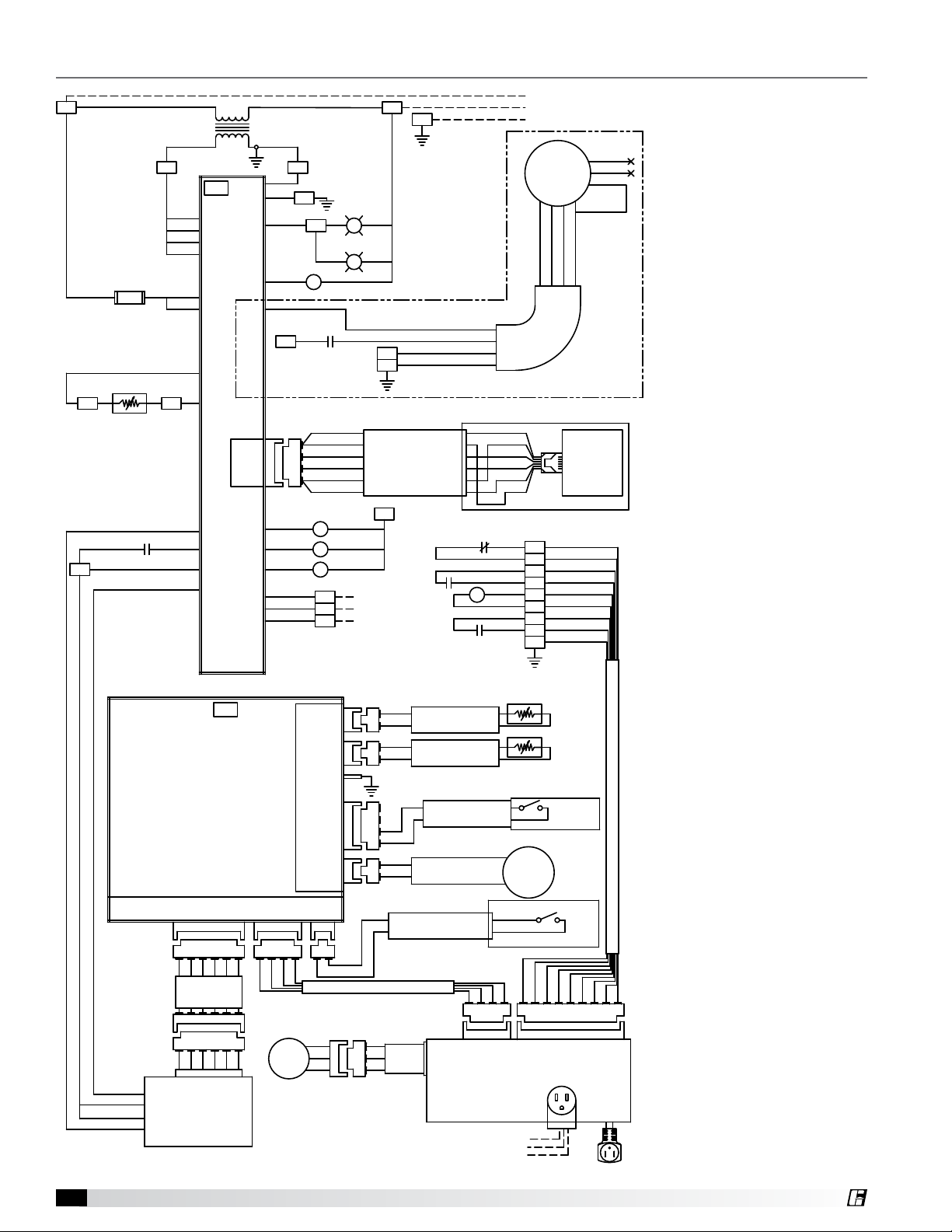

L1

CONTROL INPUT:

Wiring Diagram: Gas Disconnect

H1

BK 14GA

T1-B

YW

CM

R2

B1

R3

R4

R5

120VAC

A2

R2

11

BL 22GA

WH 22GA

GR 22GA

RD 22GA

YW 22GA

BK 22GA

C6

NO6

NC6

LIGHT 1

LIGHT 2

14

A2

A2

A2

WH 14GABK 14GA

N1

WH

14GA

N1

GND

TOUCH SCREEN

INTERNAL HOOD

24C

YW 18GA

YW 18GA

YW 18GA

GAS RESET

FIRE

STATUS

115 VAC, 15AMPS

N

FROM BREAKER

GND

GND

INTERNAL

EC FAN

BL 115V (N)

YW 22GA (E1)

BR 115V (L1)

0-10VDC

YW

115VAC

BR

GR/YW

BL

FAN CABLE

NEUTRAL

GROUND

CHANGES BASED ON FAN SELECTION

BL

YW

CABLE

LIGHT BLUE

8.5 FT

POWER

RESET

GAS STATUS

POWER

TRIP

21

R3

24

A2 A1

GR

RD

BK

WH

BL

R3

12

11

BL

BL

BL

BL

R1

YW

BL

R5

BL

14

11

PR1

PR2

GR1

GR2

GL1

GL2

PT1

PT2

GND

INTERFACE

1

2

3

4

5

6

7

8

GR

WH 22GA

RD 22GA

BL 22GA

GR/YW (GND)

TOUCH

SCREEN

USER

TR1

115VAC

40VA

BL YW

24VAC

GO

NO1

U10

C6

24C

YW 18GA

YW 18GA

GND

BK 14GA

BK 14GA

A1

BK 14GA

H1

1

-

2

3

+

O

4

BL 18GA

A1

BL 18GA

A1

BL 18GA

A1

RD 14GA

RD 14GA

RD 14GA

24H

U1

G

C3

C4

C5

C1

C2

GND

U1

Disp.

U3

U2

GND

U4

J3

GND

NO2

+Vterm

NO3

NO4

NO5

NO6

NC6

BL 18GA

BL 18GA

BL 18GA

BL 18GA

FU1

6A

T3

GR

BK 14GA

BR

OR

RD

T1-A

BL

R1

11

BL

14

YW

BL

U2

SENSE1

SENSE2

RD

1

1

2

1

2

BK

2

RD

1

BK

2

SENSOR 1 CABLE

SENSOR 2 CABLE

T1

T2

GND

TANK

1

2

3

123

123

DISCONNECT 2

BK

GN

TANK

PRESSURE

GAUGE

4

567

4

567

4

567

RANGE

3-PRONG

10FT CABLE

8

GR

8

899

RANGE

POWER

CORD

1

1

2

GAUGE

VALV E

2

YW

VALV E

3

3

BL

GAS

REMOTE

4

4

GR

PULL

1

1

BK

WH

GR

BLDG

ALARM

2

3

1

123

1

2

3

INTERNAL

CABLE,

3 FT

2

3

1

123

1

2

3

N/C

FIRE

BL

N/O

DETECT

YW

COM

YW

COM

TROUBLE

BL

N/O

DETECT

N/C

4

5

4

5

4

5

4

5

4

5

4

5

G502INT

SHUT-OFF

6

1

612

6

RD

6

6

6

2

WH

3

3

BK

4

4

WH

1

1

BK

2

2

WH

2

QC4

2

PULL STATION CABLE

BK

10FT CABLE

BK

121

WH

2

CABLE

GR

33

RANGE 5-15 RECEPTACLE

(115VAC 15A POWER TO RANGE)

5FT

PRESSURE

GAUGE CABLE

SOLENOID

CABLE

30FT

RD

1

123

RANGE

GAS

DISCONNECT 1

VALV E

SOLENOID

MANUAL PULL STATION

BL

GR

YW

4

2

3

QC5 QC6

4

DISCONNECT

CONTROL

BOX

WH

Fire Ready Hood6

®

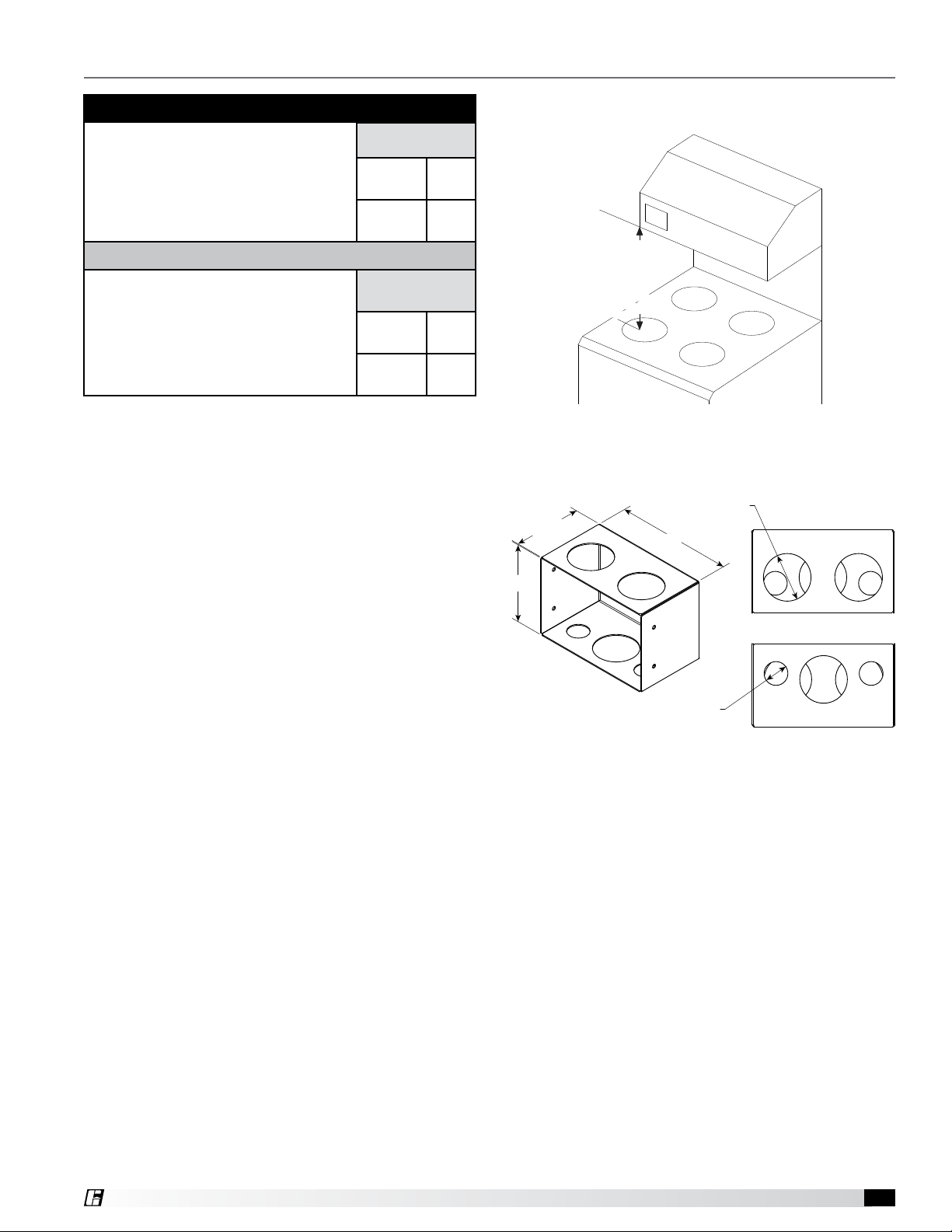

Installation

Ø2.000"

Control J-Box Dimensions

WARNING

Failure to affix the mounting bracket

to studs correctly can lead to

structural damage and/or serious

injury. The structural integrity of

the wall is the responsibility of the

contractor.

AVERTISSEMENT

Si le support de fixation est mal posé

sur les montants, il peut y avoir des

dommages structuraux et/ou de

graves blessures. L’entrepreneur est

responsable de l’intégrité structurale

du mur.

Hood Weight

30 inches 86 lbs.

36 inches 93 lbs.

Poids de la hotte

76 cm

(30 po)

91,4 cm

(36 po)

39 kg

(86 lb)

42,2 kg

(93 lb)

Minimum Spacing:

24 inches

Maximum Spacing:

30 inches

Measure vertical distance

Measure vertical distance

from bottom of hood to

from bottom of hood to

cooking surface

cooking surface

It is recommended that before drywall is hung, all

electrical cables that need to be run within the wall

should be run through the wall to their corresponding

components. Mount the control j-box to line up with

the right corner of the hood mounting bracket and run

cables for these components into this box through the

grommets. Confirm all critical mounting points will need

to be secured through studs or utilize dry wall hangers.

Hood weight should be supported by at least two (2)

studs. Hood needs to be centered above the range

and within the height requirements shown. Make sure

that with integral fan – rear discharge configurations,

the studs and control j-box (see picture on right) do not

interfere with the rear discharge duct.

After drywall is hung, affix mounting bracket to wall

using the necessary field provided fasteners through the

critical mounting points.

4.00"

3.50"

Hood to Cooking Surface

Spacing Recommendation

6.00"

x3

Top View of Box

Bottom View of Box

Ø1.000"

x2

Fire Ready Hood 7

®

B

A

A

A

A

E

B

C

A

A

E

B

D D

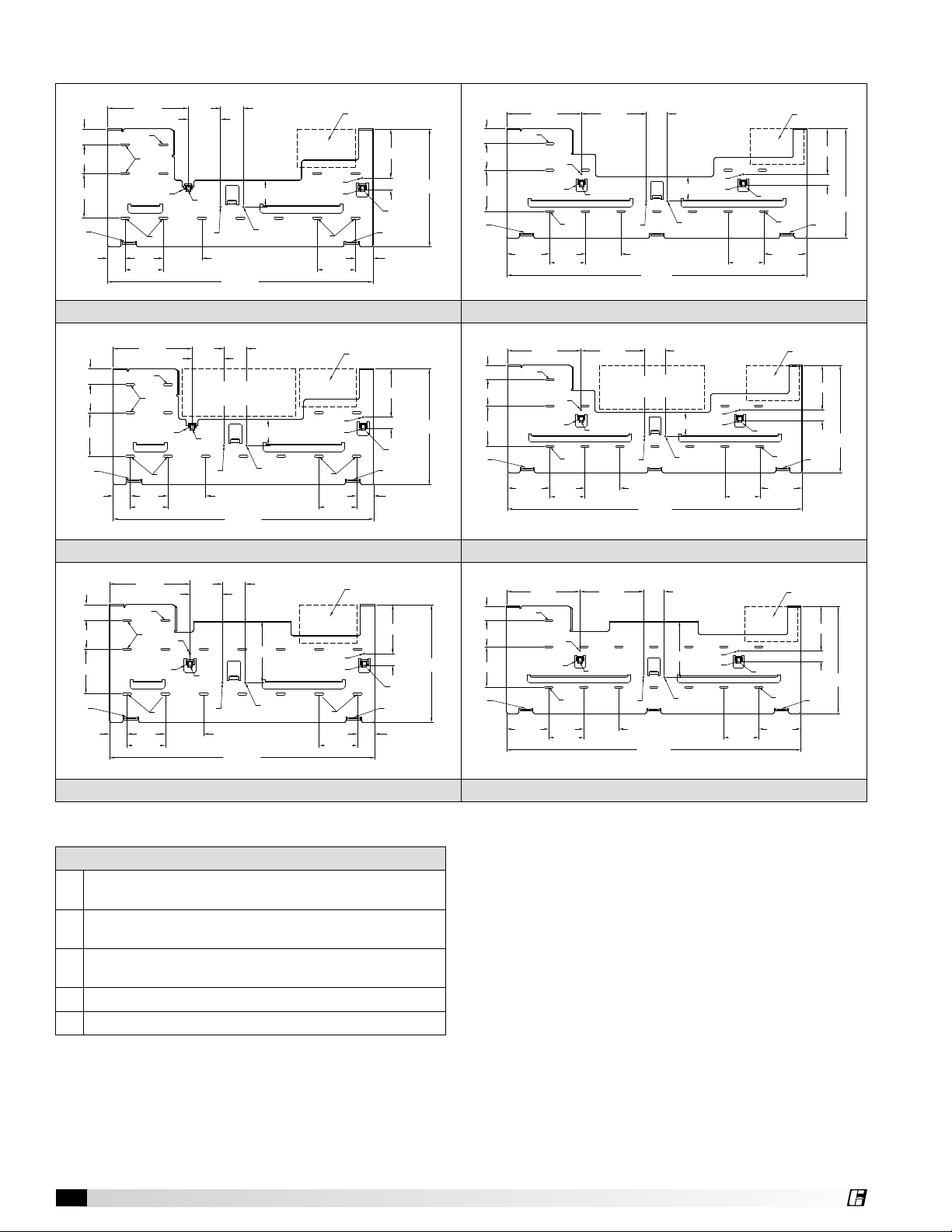

30" Integral Fan | Rear Discharge

27.625

12.275

1.650

3.000

4.625

8.375

3.375

2.376

1.813

4.000

4.000

5.114

1.223

1.813

4.000

2.750

5 x 12 INCH

REAR DISCHARGE

FAN DUCT

5 x 12 INCH

REAR DISCHARGE

FAN DUCT

B

A

A

A

A

E

B

C

A

A

E

B

D D

B

A

A

A

A

E

B

C

A

A

E

B

D D

C

A

A

A

A

E

A

A

E

D D

A

A

A

30" Integral Fan | Front Recirculation

30" Integral Fan | Rear Discharge

36" Integral Fan | Front Recirculation

36" Integral Fan | Rear Discharge

12.275

27.625

12.275

1.650

3.000

4.625

8.375

3.375

2.376

1.813

4.000

4.000

5.114

1.223

1.813

4.000

2.750

27.625

12.275

1.650

3.000

4.625

8.375

3.375

2.376

1.813

4.000

4.000

5.114

1.223

1.813

4.000

2.750

33.625

12.275

1.650

3.000

4.625

4.813

4.000

4.000

8.375 7.248 2.376

5.114

1.223

4.813

4.000

2.750

5 x 12 INCH

REAR DISCHARGE

FAN DUCT

5 x 12 INCH

REAR DISCHARGE

FAN DUCT

5 x 12 INCH

REAR DISCHARGE

FAN DUCT

5 x 12 INCH

REAR DISCHARGE

FAN DUCT

B

A

A

A

A

E

B

C

A

A

E

B

D D

A

30" External Fan | Top Discharge

27.625

27.625

1.650

3.000

4.625

8.375

3.375

2.376

1.813

4.000

4.000

5.114

1.223

1.813

4.000

6.389

B

A

A

A

A

E

B

C

A

A

E

B

D D

B

A

A

A

A

E

B

C

A

A

E

B

D D

A

C

A

A

A

A

E

A

A

E

D D

A

A

A

30" External Fan | Top Discharge

36" External Fan | Top Discharge

27.625

12.275

1.650

3.000

4.625

8.375

3.375

2.376

1.813

4.000

4.000

5.114

1.223

1.813

4.000

2.750

27.625

12.275

1.650

3.000

4.625

8.375

3.375

2.376

1.813

4.000

4.000

5.114

1.223

1.813

4.000

6.389

33.625

12.275

1.650

3.000

4.625

4.813

4.000

4.000

8.375 7.248 2.376

5.114

1.223

4.813

4.000

6.389

5 x 12 INCH

REAR DISCHARGE

FAN DUCT

5 x 12 INCH

REAR DISCHARGE

FAN DUCT

30" External Fan | Top Discharge

MOUNTING BRACKET KEY

A. CRITICAL MOUNTING POINTS (MUST BE SECURED TO STUDS

OR DRY WALL HANGERS)

B. UTILIZE ONE OF THESE TWO CRITICAL POINTS FOR SECURING

TO STUD OR DRY WALL HANGERS (THREE TOTAL)

C. LOCATION FOR FACTORY PROVIDED 4" H x 6" W x 3.5" D

B

A

A

A

A

E

B

C

A

A

E

B

D D

A

30" External Fan | Top Discharge

MOUNTING BRACKET KEY

A. CRITICAL MOUNTING POINTS (MUST BE SECURED TO STUDS

OR DRY WALL HANGERS)

B. UTILIZE ONE OF THESE TWO CRITICAL POINTS FOR SECURING

TO STUD OR DRY WALL HANGERS (THREE TOTAL)

C. LOCATION FOR FACTORY PROVIDED 4" H x 6" W x 3.5" D

CONTROL J-BOX

D. HOOD SUPPORT TABS

E. HOOD LATCH CONNECTIONS

NOTES:

1) BEFORE MOUNTING, SITUATE MOUNTING BRACKET ON WALL,

MAKING SURE CRITICAL MOUNTING POINTS ARE MET AND

DISTANCE FROM BOTTOM OF BRACKET TO COOKING SURFACE

IS BETWEEN 24 AND 30 INCHES.

2) CUT OUT SPACE IN WALL FOR FACTORY PROVIDED CONTROL

J-BOX AND SECURE IN PLACE.

3) SECURE MOUNTING BRACKET TO WALL USING THE PROPER

FIELD PROVIDED FASTENERS USING CRITICAL MOUNTING

POINTS SHOWN ABOVE.

27.625

12.275

1.650

3.000

4.625

8.375

3.375

2.376

1.813

4.000

4.000

5.114

1.223

1.813

4.000

6.389

Dimensional Data

8.375

1.650

3.000

A

B

4.625

D D

1.813

4.000

3.375

E

A

B

A

4.000

27.625

2.376

2.750

A

A

A

B

4.000

C

30 Inch Integral Fan | Front Recirculation 36 Inch Integral Fan | Front Recirculation

8.375

1.650

3.000

4.625

D D

1.813

A

B

4.000

3.375

E

A

B

A

4.000

2.376

5 x 12 INCH

5 x 12 INCH

REAR DISCHARGE

REAR DISCHARGE

FAN DUCT

FAN DUCT

2.750

C

A

A

A

B

4.000

30 Inch Integral Fan | Rear Discharge 36 Inch Integral Fan | Rear Discharge

5.114

1.223

E

1.813

5.114

1.223

E

1.813

12.275

12.275

8.375 7.248 2.376

1.650

3.000

4.625

D D

1.650

3.000

4.625

D D

A

A

E

A

A

4.813

4.000

8.375 7.248 2.376

A

A

E

A

4.813

4.000

4.000

A

4.000

A

33.625

5 x 12 INCH

5 x 12 INCH

REAR DISCHARGE

REAR DISCHARGE

FAN DUCT

FAN DUCT

A

33.625

2.750

A

2.750

A

A

A

4.000

A

A

4.000

C

E

A

4.813

C

E

A

4.813

5.114

1.223

5.114

1.223

12.275

8.375

1.650

3.000

A

B

4.625

D D

1.813

Dimensions shown are in inches.

4.000

30 Inch External Fan | Top Discharge 36 Inch External Fan | Top Discharge

3.375

A

E

A

B

A

4.000

27.625

2.376

6.389

A

B

4.000

A

A

C

5.114

1.223

E

1.813

Mounting Bracket Key

Critical mounting points must be secured to studs or

A

drywall hangers

Utilize one of these two critical points for securing to

B

stud or drywall hangers. (three total)

Location for factory provided 4 inch high x 6 inch wide

C

x 3-1/2 inches deep control j-box

Hood support tabs

D

Hood latch connections

E

Fire Ready Hood8

12.275

8.375 7.248 2.376

1.650

3.000

4.625

D D

A

A

E

A

A

4.813

4.000

4.000

A

33.625

6.389

A

A

A

4.000

C

5.114

1.223

E

12.275

A

4.813

1. Before mounting, situate mounting bracket on wall

making sure critical mounting points are met and

distance from bottom of bracket to cooking surface is

between 24 and 30 inches.

2. Cut out space in wall for factory provided control

j-box and secure in place.

3. Secure mounting bracket to wall using the proper

field provided fasteners through all critical mounting

points shown in the drawings. Select fasteners that

will properly support the total weight of the hood

(hood weight shown on page 7).

®

Ductwork (if applicable)

Running ductwork will be required for hoods configured for external fans. A small rectangular piece of duct spanning

the width of the wall will be required for integral fan – rear discharge configurations (discharging through the back

wall). For integral fan - rear discharge, the duct cannot be permanently attached to the hood, as the hood does drop

into a service potion, so we recommend using a high temperature gasket where the back of the hood and rear duct

through the wall meet to provide a good seal during operation. Check the individual hood drawings to see what fan

type is provided with your system.

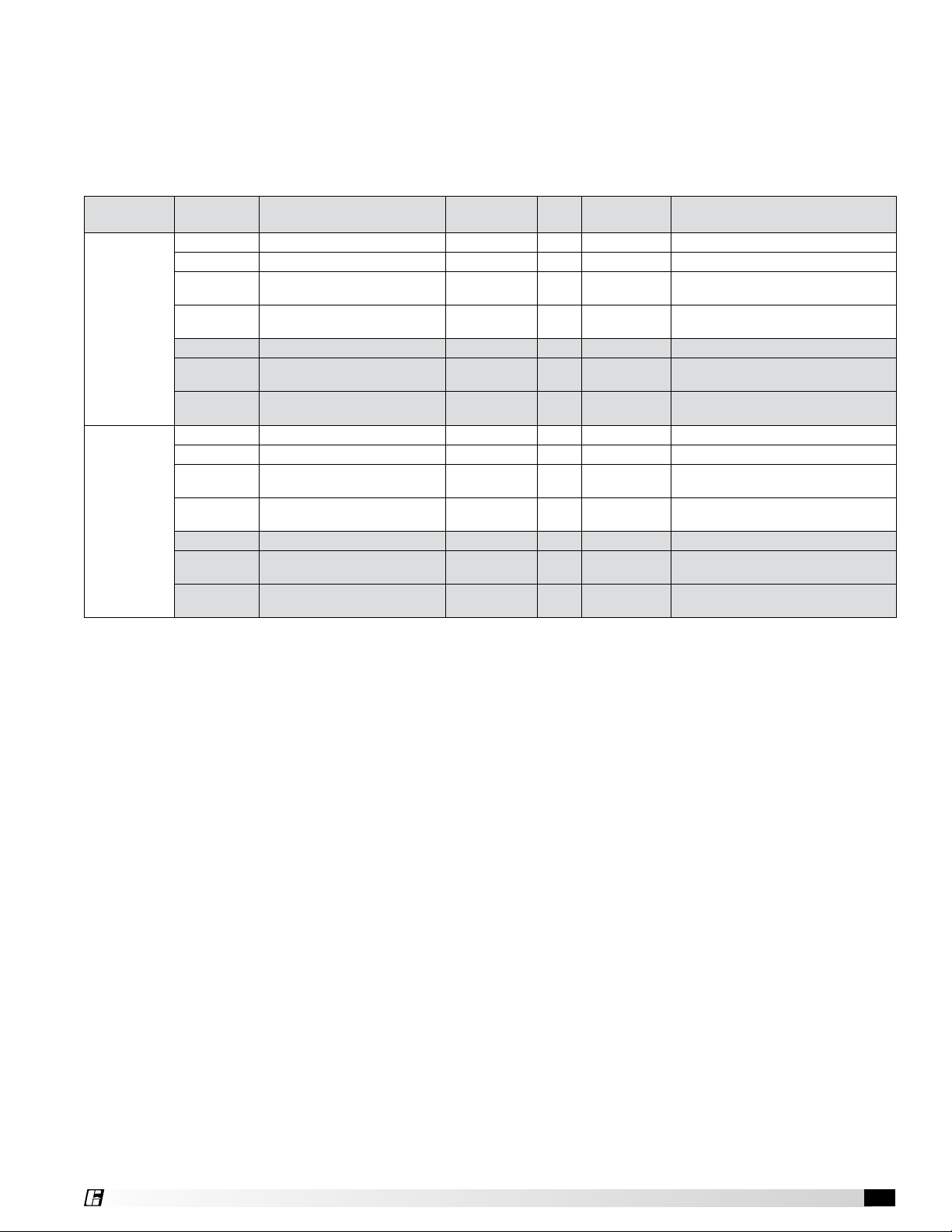

Hood Length

(in.)

30

36

NFPA 101

Compliance

No Integral Fan – Front Recirculating Not applicable 250 Not applicable Not applicable

No Integral Fan – Rear Discharge Not applicable 250 5 x 12 in. 2 ft.

No External Fan - Top Discharge Inline 250

No External Fan - Top Discharge Fan by Others 250

Yes Integral Fan - Rear Discharge Not applicable 500 5 x 12 in. 2 ft.

Yes External Fan - Top Discharge Inline 500

Yes External Fan - Top Discharge Fan by Others 500

No Integral Fan – Front Recirculating Not applicable 300 Not applicable Not applicable

No Integral Fan – Rear Discharge Not applicable 300 5 x 12 in. 2 ft.

No External Fan - Top Discharge Inline 300

No External Fan - Top Discharge Fan by Others 300

Yes Integral Fan - Rear Discharge Not applicable 500 5 x 12 in. 2 ft.

Yes External Fan - Top Discharge Inline 500

Yes External Fan - Top Discharge Fan by Others 500

Ventilation

External Fan

Type

CFM

Duct Size

(Minimum)

10 in. round

(diameter)

10 in. round

(diameter)

12 in. round

(diameter)

12 in. round

(diameter)

10 in. round

(diameter)

10 in. round

(diameter)

12 in. round

(diameter)

12 in. round

(diameter)

Duct Length

(Maximum)

External fan by others should be sized

based on hood and duct static pressure

External fan by others should be sized

based on hood and duct static pressure

External fan by others should be sized

based on hood and duct static pressure

External fan by others should be sized

based on hood and duct static pressure

35 ft.

35 ft.

35 ft.

35 ft.

All ductwork will need to be provided in the field. Installing ductwork must be done by qualified person(s) in

accordance with all applicable codes and standards, including fire-rated construction. All ductwork, per IMC Section

505 should be constructed of sheet metal, have smooth inner walls, be air tight, and be independent of all other

exhaust ductwork systems.

To minimize static pressure losses and promote adequate airflow, minimize duct run lengths where possible.

For external fan configurations, duct should be connected to the 8 inch collar adapter on the hood mounting bracket.

Transitions should be utilized to expand duct to duct size minimum requirements noted in table above.

Hood

1. Remove hood from crating. Remove the grease filter.

2. Carefully lift it onto the lower hood tabs on the wall mounting bracket.

2. While holding the hood up, hook the safety cable to the chain link on the mounting bracket and screw nut to close

the link. The hood is now in the service position.

3. To put the hood into operation position, lift the hood up, and one at a time re-hook the clamps and pull the clamps

tight until they lock. Make sure the safety bolt lever is located inside the notch in the hood mounting bracket. See

page 22 for pictures and more information.

4. When all construction is complete, remove protective plastic sheeting from hood stainless steel. Clean (using

alcohol and rag) and polish (using stainless steel polish) the hood. When cleaning or polishing, be sure to wipe

with the grain and not against it.

Fire Ready Hood 9

®

External Fan (if applicable)

External Fan – Inline

Install fan vertically or horizontally in ductwork running

between the unit and roof cap. Make sure the fan

installed with the airflow arrow on the side of the fan

directed away from the hood (to the outside).

For best results, use as few elbows or transitions as

possible. If necessary, long radius elbows or bends are

recommended.

To attach ductwork, use duct tape at inlet and outlet to

assure a good seal. If using fan clamps, attach clamps

and insert screws through clamp into inlet and outlet

flanges.

CAUTION

Use sheet metal screws to secure ductwork to inlet

and outlet. It is critical that the screw penetrate the

metal of the flange, but not so far as to bind the

impeller. It may be necessary to angle screws away

from impeller.

ATTENTION

Utiliser des vis autotaraudeuses pour fixer le réseau de

gaines à l’entrée et à la sortie. Il est essentiel que la vis

pénètre le métal du rebord, mais pas assez pour faire

saisir la turbine. Il peut être nécessaire de faire dévier

les vis pour les éloigner de la turbine.

External Fan – Fan By Others

Follow all installation instructions provided with the fan.

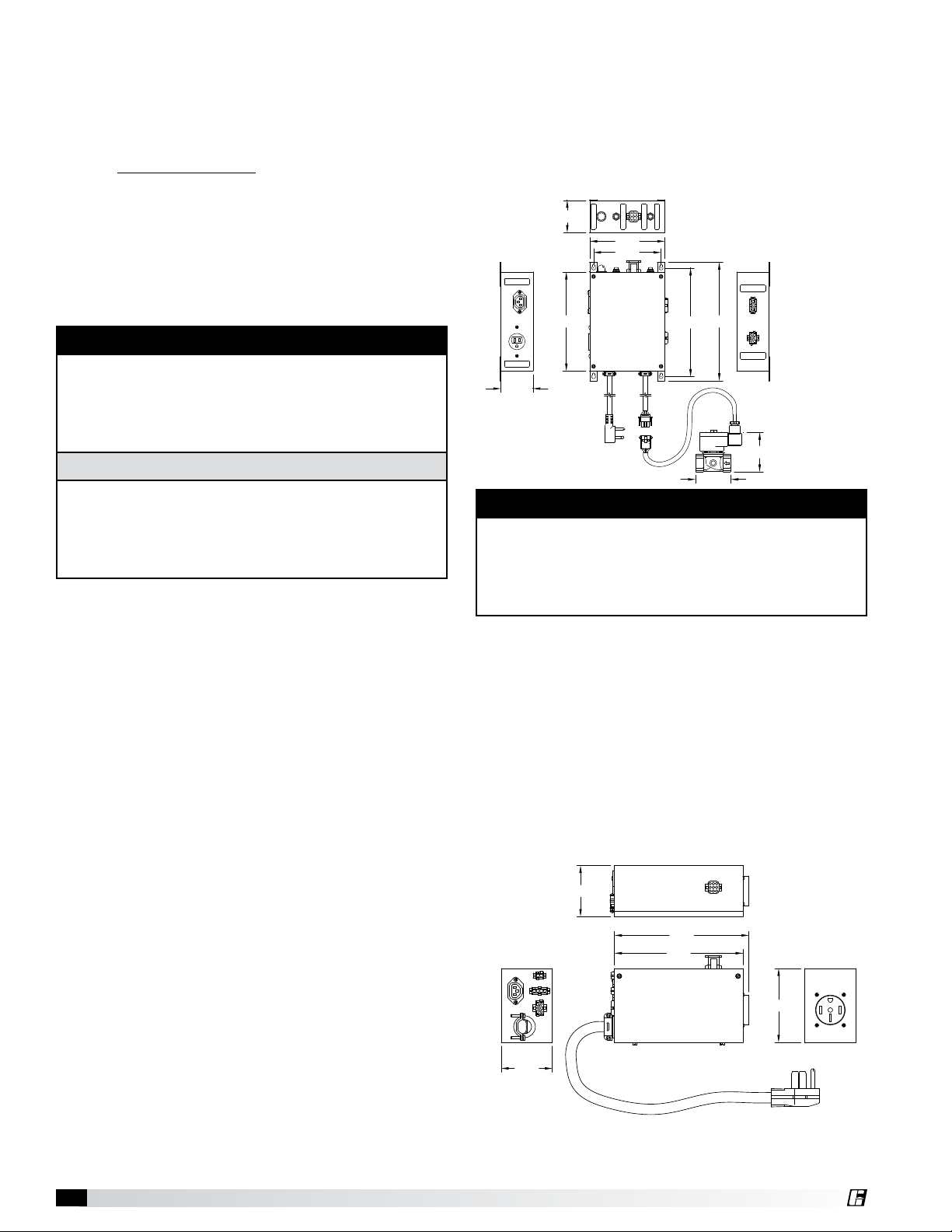

Range Disconnect

Gas (if applicable)

1. Locate gas shut off assembly box and gas valve.

2. Using the four (4) appropriate sized fasteners, mount

and fasten gas shut off assembly box behind range

through mounting holes provided. Unit dimensions

shown:

2.70

GAS FLOW

LEFT SIDE

VIEW

ALARM / STROBE

115 VOLT - 5 AMP

RANGE

115 VOLT - 15 AMP

2.70

8.25

60 IN. (5 FT)

POWER CORD

WITH 5-15R PLUG

6.25

5.60

GAS SHUT OFF

ASSEMBLY BOX

(FRONT VIEW)

Dimensions shown

are in inches.

Cables provided to connect the gas and electric

assembly boxes back to the hood are 10 ft. long. Do

not mount the gas shut off assembly box too far away

from the hood, as these cables will not reach. Make

sure to mount shutoff within 5ft of 115VAC 5-15 outlet.

3. If not already done, plug gas valve 1.5 ft. whip into

5 ft. gas valve cord coming off of bottom of the gas

shut off assembly box. Install ¾ inch (NPT fittings)

gas valve in-line with gas line to range.

4. Follow electrical installation instructions for gas range

disconnect on pages 13 and 14.

VALVE RESET

TOP VIEW

CABLE

POWER RESET

GAS /ELEC DISC

60 IN. (5 FT)

GAS

VALV E

CORD

NOTE

9.19

3/4"

10.00

3.00

RIGHT SIDE

VIEW

FUEL ACTIVATION

CONTACT RATING

12 VAC - 5 AMP

AUXILIARY INTERFACE

CONTACT RATING

115 VAC - 5 AMP

18 IN. (1.5 FT)

WHIP TO

GAS VALVE

3.32

3/4 IN. NPT

GAS

VALV E

Electric (if applicable)

1. Locate electric shut off assembly box.

2. Electric shut off assembly should be situated behind

the range (on floor) or in cabinet next to range. Unit

dimensions shown:

BACK VIEW

3.75

LEFT SIDE

VIEW

3.75

Dimensions shown are in inches.

3. Follow electrical installation instructions for electric

range disconnect on page 14.

Fire Ready Hood10

9.38

9.00

ELECTRIC SHUT OFF

ASSEMBLY BOX

(TOP VIEW)

WITH 14-50 PLUG

30" (2.5 FT)

POWER CORD

5.32

RIGHT SIDE

VIEW

Loading...

Loading...