Greenheck GreenVent Installation Manual

Part #472864

®

Model GreenVent Constant

Pressure Controls

Installation, Operation and Maintenance Manual

Please read and save these instructions for future reference. Read carefully before attempting to

assemble, install, operate or maintain the product described. Protect yourself and others by observing

all safety information. Failure to comply with instructions could result in personal injury and/or

property damage!

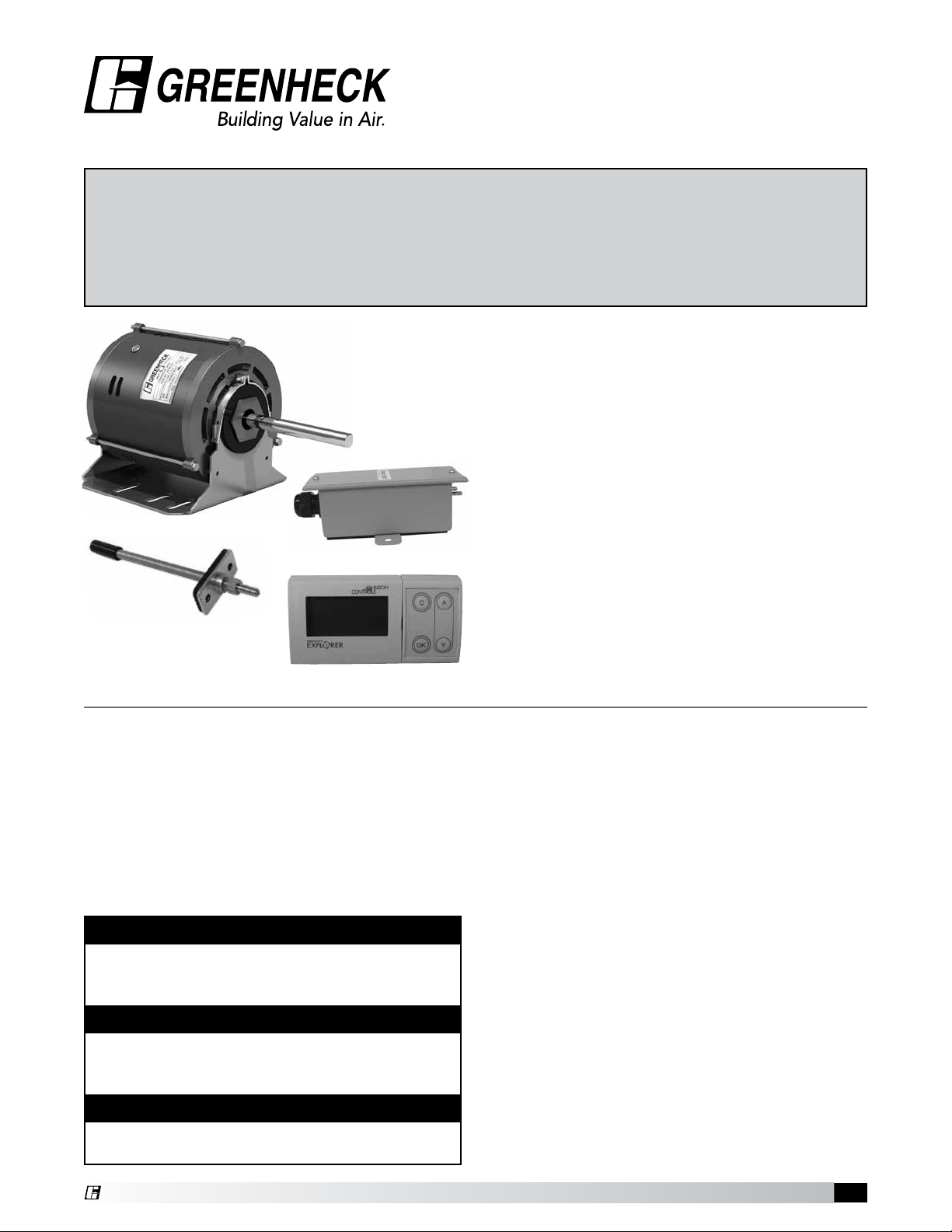

GreenVent Constant

Pressure Controls

GreenVent constant pressure control system is a

packaged system designed specifically to exhaust

air from high rise buildings, condos, dormitories

and hotels. The system includes an exhaust fan

with Vari-Green motor, pressure transducer,

pressure tap, and controller. The system is UL

listed and designed with considerations for lint

laden air. Performance ranges from 500-3000 CFM

and up to 1 inch of pressure. Fan models available

are G, CUE, CW, and SQ. Each system shall bear

a manufacturers nameplate.

General Safety Information

Only qualified personnel should install this product.

Personnel should have a clear understanding of these

instructions and should be aware of general safety

precautions. Improper installation can result in electric

shock, possible injury due to coming in contact with

moving parts, as well as other potential hazards.

Other considerations may be required if high winds

or seismic activity are present. If more information

is needed, contact a licensed professional engineer

before moving forward.

DANGER

Always disconnect, lock and tag power source before

installing or servicing. Failure to disconnect power

source can result in fire, shock or serious injury.

CAUTION

When servicing the fan, motor may be hot enough

to cause pain or injury. Allow motor to cool before

servicing.

CAUTION

Precaution should be taken in explosive

atmospheres.

Follow all local electrical and safety codes, as well as

the National Electrical Code (NEC) and the National

Fire Protection Agency (NFPA). Where applicable,

follow the Canadian Electric Code.

1. The rotation of the wheel is critical. It must be free

to rotate without striking or rubbing any stationary

objects.

2. Motor must be securely and adequately grounded.

3. Do not spin fan wheel faster than maximum

cataloged fan RPM. Adjustments to fan speed

significantly affects motor load. If the fan RPM

is changed, the motor current should be checked

to make sure it is not exceeding the motor

nameplate amps.

4. Do not allow the power cable to kink or come in

contact with oil, grease, hot surfaces, or chemicals.

Replace cord immediately if damaged.

5. Verify that the power source is compatible with

the equipment.

6. Never open access doors to a duct while the

fan is running.

®

®

GreenVent Constant Pressure Controls

1

Receiving

Upon receiving the product check to make sure all

items are accounted for by referencing the bill of

lading to ensure all items were received. Inspect

each crate for shipping damage before accepting

delivery. Notify the carrier if any damage is noticed.

The carrier will make notification on the delivery

receipt acknowledging any damage to the product.

All damage should be noted on all the copies of the

bill of lading which is countersigned by the delivering

carrier. A Carrier Inspection Report should be filled out

by the carrier upon arrival and reported to the Traffic

Department. If damaged upon arrival, file a claim

with carrier. Any physical damage to the unit after

acceptance is not the responsibility of Greenheck

Fan Corporation.

Unpacking

Verify that all required parts and the correct quantity

of each item have been received. If any items are

missing, report shortages to your local representative

to arrange for obtaining missing parts. Sometimes it

is not possible that all items for the unit be shipped

together due to availability of transportation and truck

space. Confirmation of shipment(s) must be limited to

only items on the bill of lading.

Handling

The motor amperage and voltage ratings must be

checked for compatibility to supply voltage prior to

final electrical connection. Wiring must conform to

local and national codes. Consult local code authorities

for specific requirements.

use a portable electric heater to get rid of any moisture

buildup. Leave coverings loose to permit air circulation

and to allow for periodic inspection. The unit should

not be stored on the floor.

Inspection and Maintenance

During Storage

While in storage, inspect product once per month.

Keep a record of inspection and maintenance

performed. If moisture or dirt accumulations are found

on parts, the source should be located and eliminated.

GreenVent Installation and

Setup Guide

This guide provides instructions for how to

install, wire and program the GreenVent control

system for use when constant pressure in a duct

system is required. This does not cover ductwork

recommendations or other considerations. When

installed, this control system will automatically vary

the speed of a booster fan to maintain a constant

pressure within the system. A Greenheck exhaust

fan with a Vari-Green motor is required for use with

the controls and must be ordered separately.

Parts List (Provided by Greenheck)

1. Pressure Tap

Storage

Product is protected against damage during shipment.

If the product cannot be installed and operated

immediately, precautions need to be taken to prevent

deterioration of the product during storage. The

user assumes responsibility of the product and

accessories while in storage. The manufacturer will

not be responsible for damage during storage. These

suggestions are provided solely as a convenience

to the user.

Indoor Only

Do not store this product outdoors. The ideal

environment for the storage of this product is indoors,

above grade, in a low humidity atmosphere which

is sealed to prevent the entry of blowing dust, rain

or snow. Temperatures should be evenly maintained

between 30° to 110°F (-1° to 43°C) (wide temperature

swings may cause condensation and “sweating” of

metal parts). All accessories must be stored indoors in

a clean, dry atmosphere.

Remove any accumulations of dirt, water, ice, or

snow and wipe dry before moving to indoor storage.

Allow cold parts to reach room temperature to avoid

“sweating” of metal parts. To dry parts and packages,

2. Pressure

Transducer

3. Control Box

Parts Needed

(Not provided by

Greenheck)

• 18 - 20 gauge 3-wire plenum rated control wire

• 1/4 inch inside diameter plastic tubing

• Switch for optional remote override

2

®

Installation

Pressure Tap

• In the duct of the system that you intend to

control, drill a 13/32 inch hole. The location will

depend on the layout of the system. For stacked

systems, locate the pressure tap 1/3 of the way

from the bottom of the duct.

• Install pressure tap using two screws. Orientation

does not matter.

Wiring

See diagram on page 6 for wiring overview.

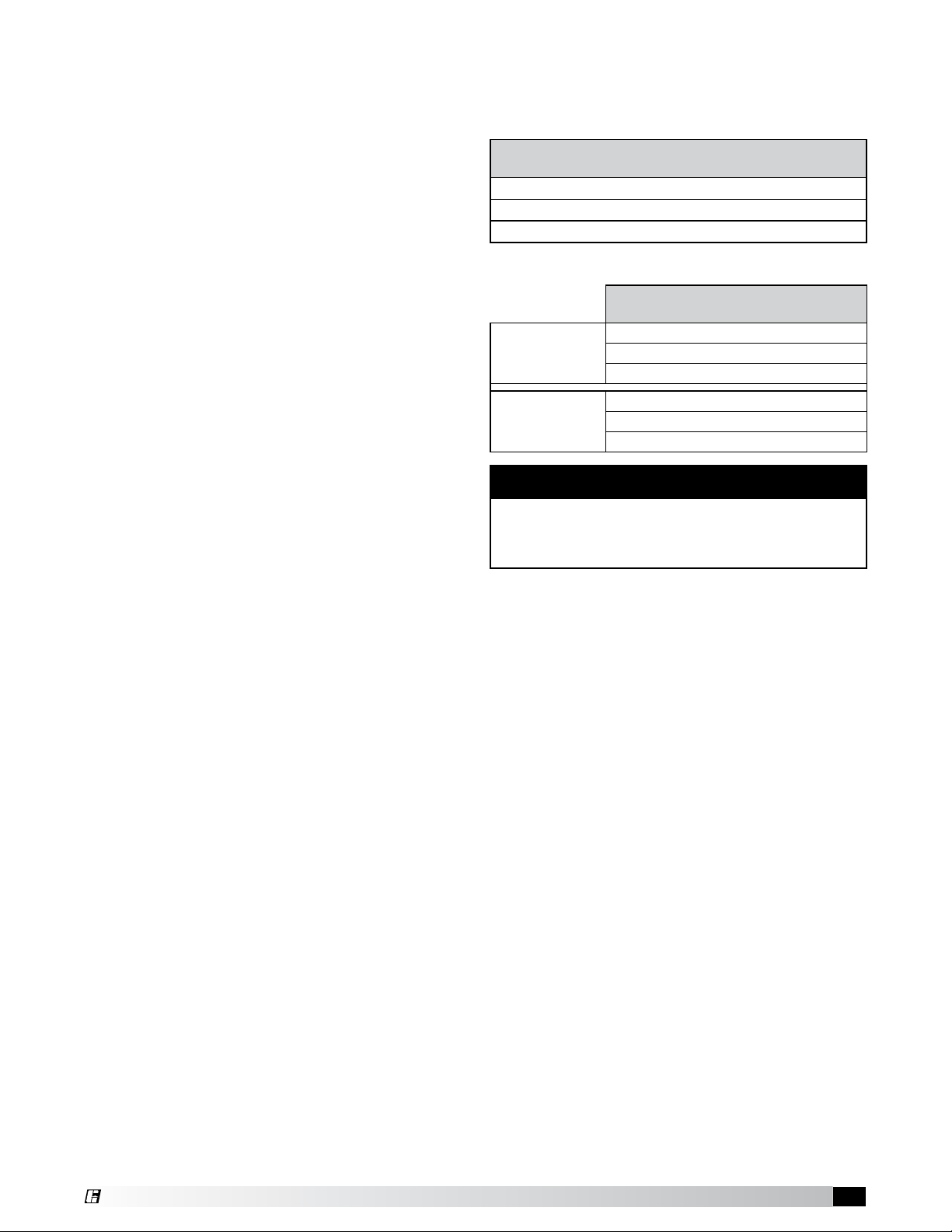

• Pressure Transducer to Control Box

Pressure Transducer

Terminal

+ to 1

- to 2

0 to 4

Controller Terminal

Pressure Transducer

• The pressure transducer should be mounted

as close as possible to the pressure tap in an

accessible location to minimize the length of

tubing necessary to connect them. This will

minimize chances of kinks or punctures in

the tubing.

• Mount the pressure transducer in the vertical

position with the tubing connectors in the

down position.

• Connect the pressure tap to the pressure

transducer using 1/4-inch tubing. Connection

to the pressure transducer is made on the high

connector. The low connector remains open

to atmosphere.

Control Box

• The control box should be securely mounted

in an accessible location that will allow for

programming and use of the controller. Common

locations include: utility closet, mechanical

room, etc. The enclosure is also NEMA-3R rated

for outdoor mounting such as on a roof curb

provided that liquid-tight conduit is used.

Additionally, the control box should be mounted

in a location less than 100 feet from the exhaust

fan and the pressure transducer to avoid signal

losses in the low-voltage control wire.

• Control Box to Motor

Low-voltage

control wiring

High-voltage

power wiring

Controller

Terminal

1 to Black

2 to White

3 to Red

L1 to Black

L2 to White

G to Green

Motor

IMPORTANT

Low-voltage control wire and high-voltage power

wiring must be run from the controller to the fan in

separate conduit.

• Connect 115 volt, single-phase power to the

disconnect switch on the outside of the

control box.

• Optional Remote Override:

Connect a normally-open switch between

connection 11 and 12 on the top of the controller.

Closing this switch will activate the remote

override feature. Opening the switch will

de-activate the override.

®

3

Loading...

Loading...