Page 1

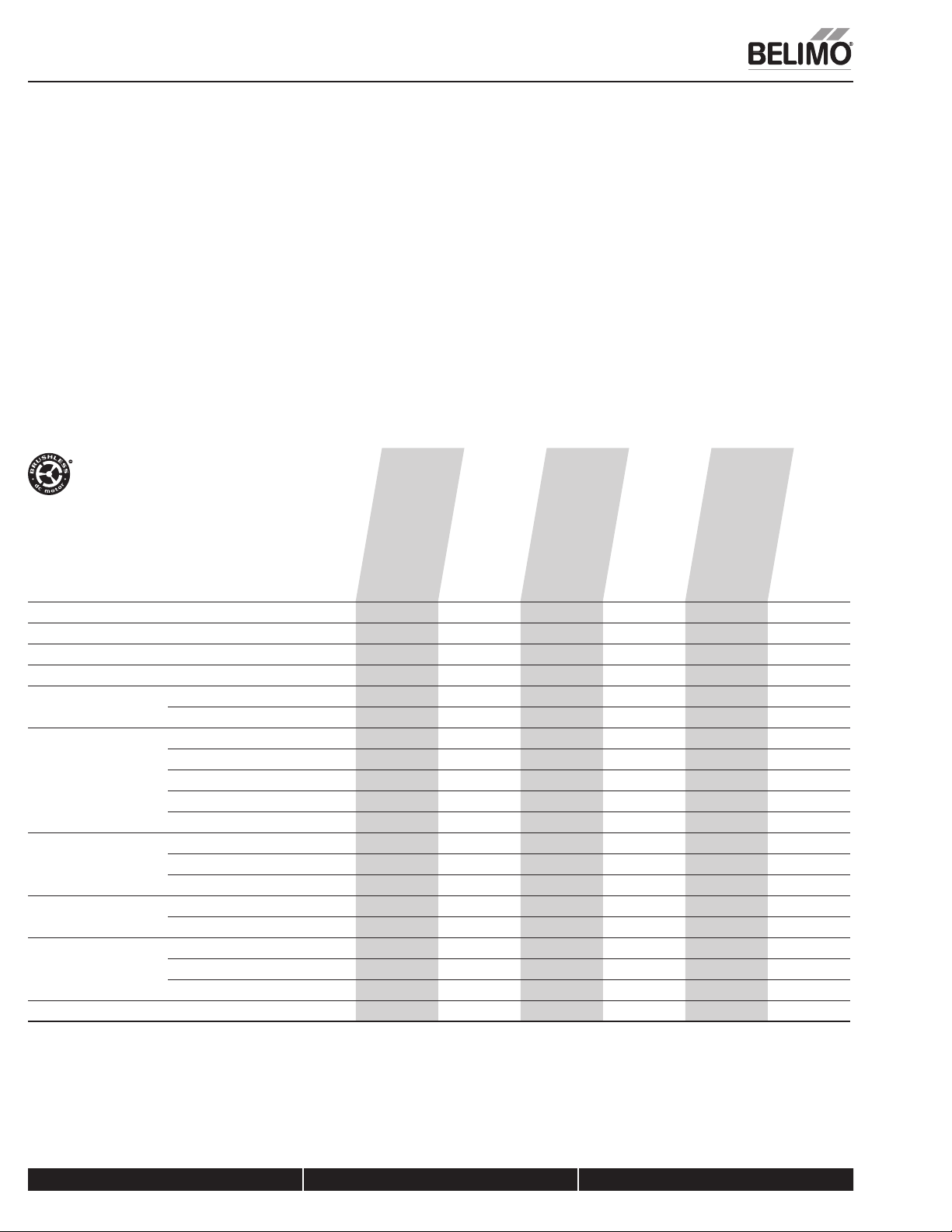

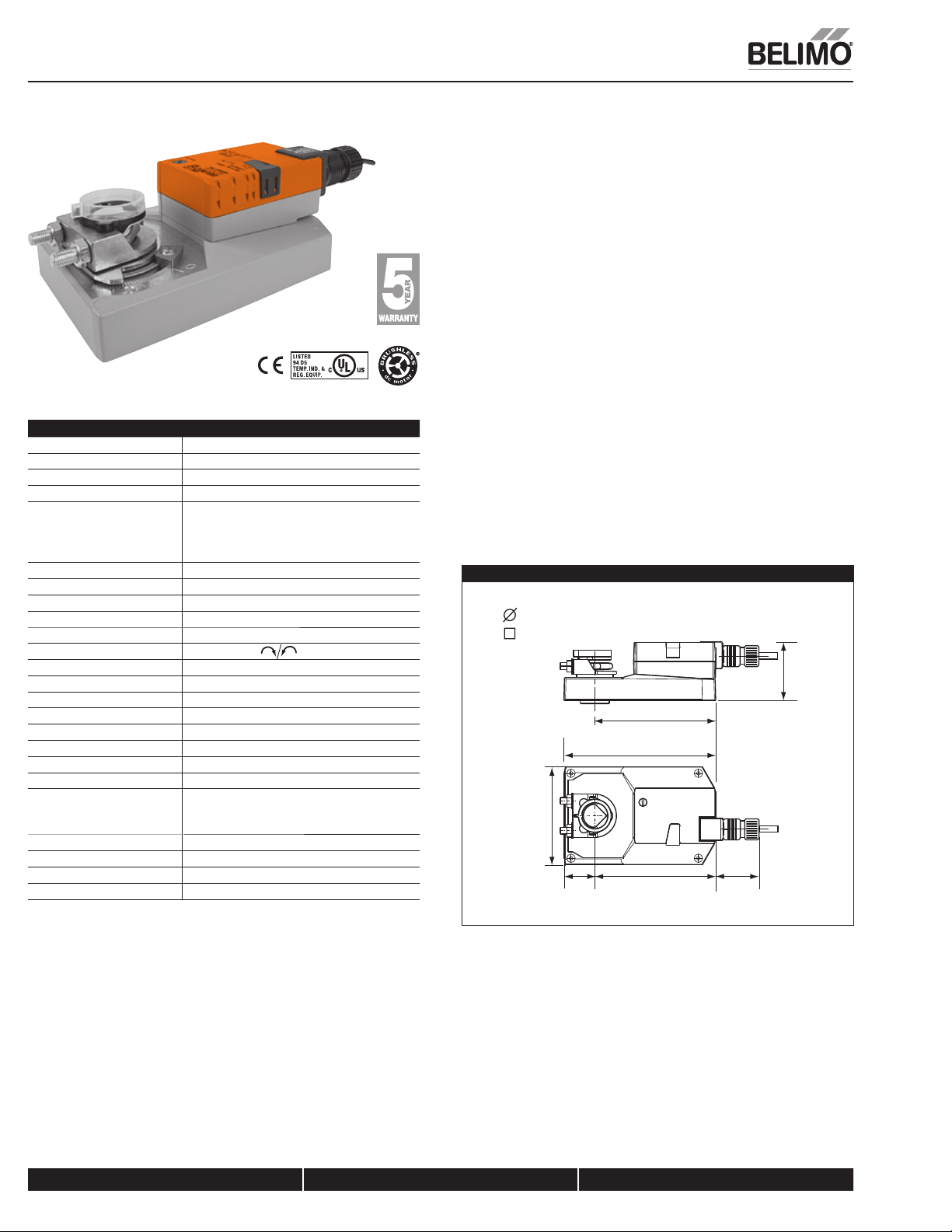

GM Series Direct Coupled Actuator

Minimum 360 in-lb torque

L For damper areas up to 90 sq-ft*

All Actuators

have BDCM

GM Series - At A Glance

Basic Product

Flexible Product

Torque 360 in-lb [40 Nm]

Angle of Rotation 95 degrees

Power Supply 24 VAC/DC

100 to 240 VAC

Control Input On/Off, Floating Point

2 to 10 VDC (4 to 20mA)

Multi-Function Technology

0 to 135 Ohm

0 to 20V Phasecut

Feedback None

2 to 10 VDC

Variable (0 to 10 VDC)

Running Time 150 seconds

Adj. 75 to 280 seconds

Wiring Plenum Rated Cable

Appliance Rated Cable

Conduit Fitting

Auxiliary Switch Add-On

Installation and Operations…(page 267).

GMB(X)24-3 (p. 134)

LLL

LLLLLL

LLLLLL

LLLLLL

L LLLL

LL

LL

LLL L

L LLLL

LLLLLL

LLLLLL

GMX120-3 (p. 136)

L

L

GMB(X)24-SR (p. 138)

L

LL L

GMB(X)24-MFT (p. 140)

L

LL

GMX24-MFT95 (p. 142)

L

L

GMX24-PC (p. 144)

L

K20901 - 01/09 - Subject to change. © Belimo Aircontrols (USA), Inc.

*Based on 4 in-lb/ft2 damper torque loading. Parallel blade. No edge seals.

800-543-9038 USA 866-805-7089 CANADA 203-791-8396 LATIN AMERICA

132

Page 2

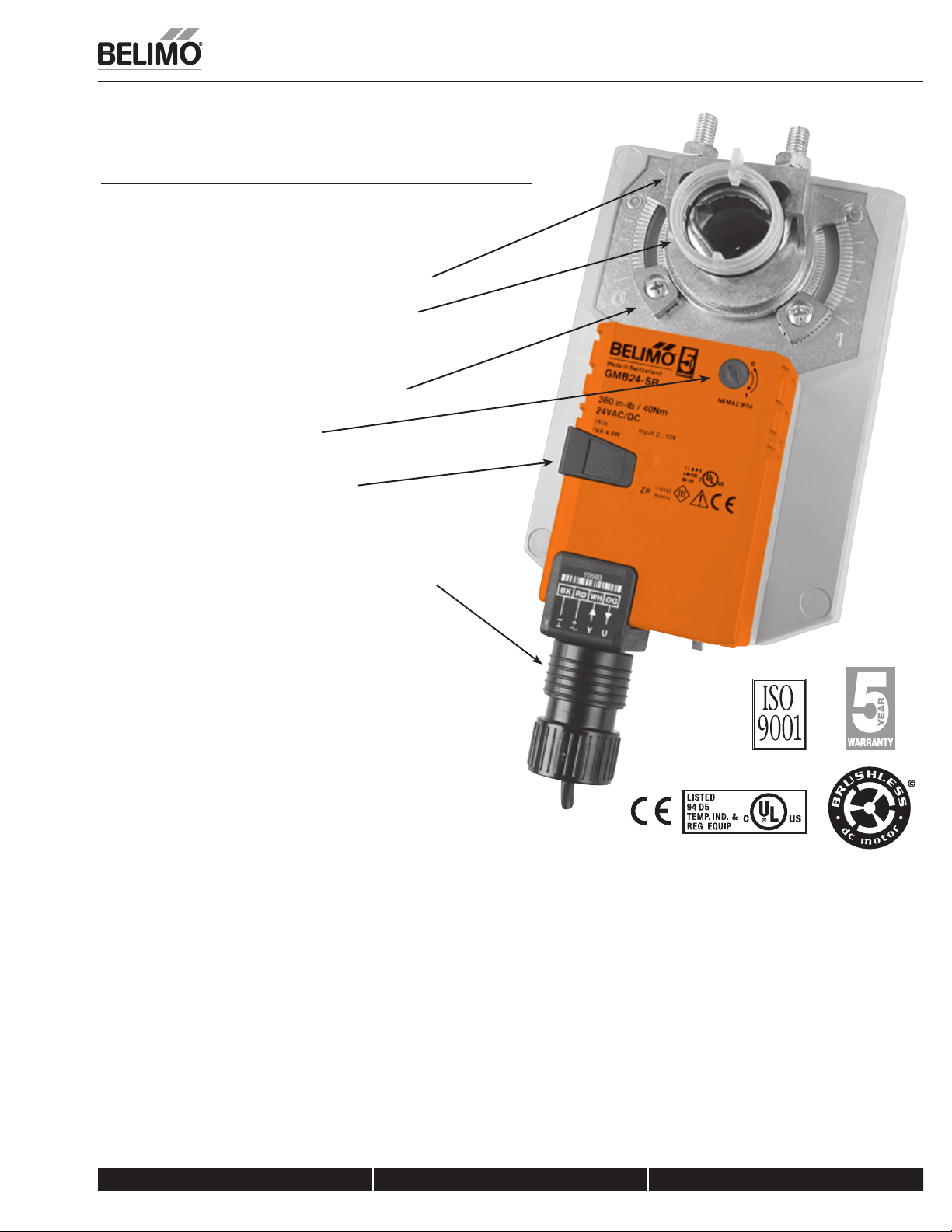

A CLOSER LOOK…

L

Brushless DC Motor for Added Accuracy and Controllability.

L

Cut Labor Costs with Simple Direct Coupling.

L

Self-Centers on 1.05" or 3/4” with the Standard Clamp.

L

Check Damper Position with Clear Position Indicator.

L

Don’t Worry about Actuator Burn-Out; Belimo is Overload

Proof throughout Rotation.

L

Enjoy Added Flexibility with Easy Mechanical Stops

to Adjust Angle of Rotation.

L

Need to Change Control Direction?

Do it easily with a Simple Switch.

L

Easily Accessible Manual Override Button

helps you Pre-Tension Damper Blades.

GM Series Direct Coupled Actuator

L

Auxiliary Switch and Feedback Potentiometer Add-Ons Mount

Directly on Clamp, Includes Conduit Connector.

L

Standard 3ft Plenum Rated Cable and Conduit Connector

Provided on Basic Models.

L

Added Flexibility to Select Clamp, Electrical Connection, and

Running Time to fit your Specific Application with Belimo’s

New Flexible Line of Actuators.

The Belimo Difference

L

Customer Commitment.

Extensive product range. Application assistance.

Same-day shipments. Free technical support. Five year warranty.

K20901 - 01/09 - Subject to change. © Belimo Aircontrols (USA), Inc.

L

Low Installation and Life-Cycle Cost.

Easy installation. Accuracy and repeatability.

Low power consumption. No maintenance.

L

Long Service Life.

Components tested before assembly. Every product tested before shipment.

30+ years direct coupled actuator design.

800-543-9038 USA 866-805-7089 CANADA 203-791-8396 LATIN AMERICA

133

Page 3

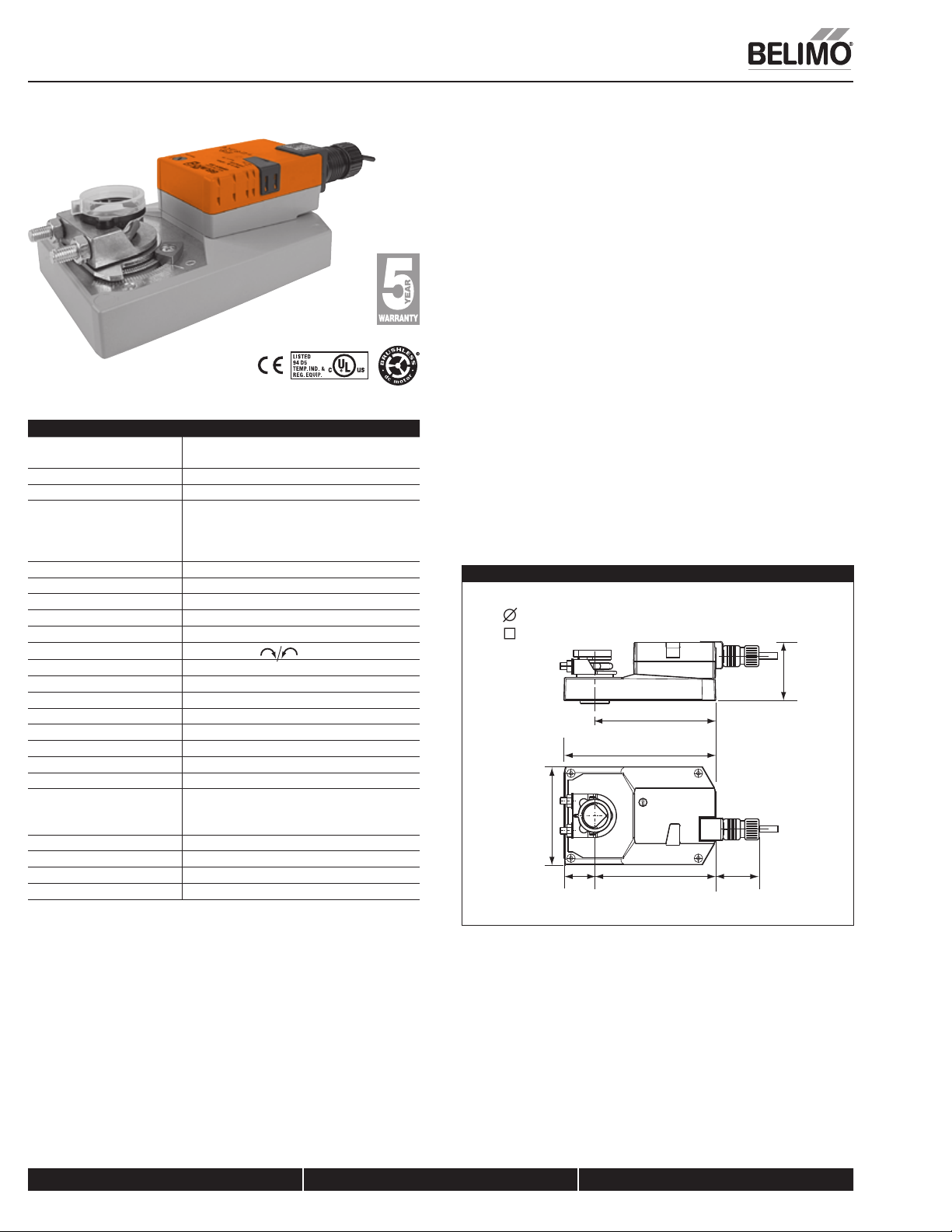

GMB(X)24-3

On/Off, Floating Point Control, Non-Spring Return, Direct Coupled, 24V

Torque min. 360 in-lb for control of damper surfaces up to 90 sq ft.

Application

For on/off and floating point control of dampers in HVAC systems. Actuator

sizing should be done in accordance with the damper manufacturer’s

specifications.

The actuator is mounted directly to a damper shaft up to 1.05” in diameter by

means of its universal clamp. A crankarm and several mounting brackets are

available for applications where the actuator cannot be direct coupled to the

damper shaft.

Operation

The actuator is not provided with and does not require any limit switches, but is

electronically protected against overload. The anti-rotation strap supplied with

the actuator will prevent lateral movement.

The GMB(X) series provides 95° of rotation and a visual indicator indicates

position of the actuator. When reaching the damper or actuator end position, the

actuator automatically stops. The gears can be manually disengaged with a

Technical Data GMB(X)24-3

Power Supply 24 VAC ± 20% 50/60 Hz

Power Consumption 4 W (2 W)

Transformer Sizing 6 VA (Class 2 power source)

Electrical Connection 18 GA plenum rated cable

Overload Protection electronic throughout 0 to 95° rotation

Control on/off, floating point

Input Impedance 600 7

Angle of Rotation max. 95°, adjust. with mechanical stop

Torque 360 in-lb [40 Nm]

Direction of Rotation

Position Indication reflective visual indicator (snap-on)

Manual Override external push button

Running Time 150 seconds, constant independent of load

Humidity 5 to 95% RH non condensing (EN 60730-1)

Ambient Temperature -22°F to +122°F [-30°C to +50°C]

Storage Temperature -40°F to +176°F [-40°C to +80°C]

Housing NEMA 2, IP54, UL enclosure type 2

Housing Material UL94-5VA

Agency Listings† cULus acc. to UL 60730-1A/-2-14,

Noise Level <45dB(A)

Servicing maintenance free

Quality Standard ISO 9001

Weight 3.4 lbs [1.55 Kg]

† Rated Impulse Voltage 800V, Type of action 1, Control Pollution Degree 3.

24 VDC ± 10%

1/2” conduit connector

Protected NEMA 2 (IP54)

Q 3 ft [1m] Q 10 ft [3m] Q 16 ft [5m]

reversible with

switch

CAN/CSA E60730-1:02,

CE acc. to 2004/108/EEC and 2006/95/EC

button on the actuator cover.

The GMB(X)24-3... actuators use a Brushless DC motor, which is controlled by

an Application Specific Integrated Circuit (ASIC). The ASIC monitors and

controls the actuator’s rotation and provides a digital rotation sensing (DRS)

function to prevent damage to the actuator in a stall condition. Power

consumption is reduced in holding mode.

Add on auxiliary switches or feedback potentiometers are easily fastened directly

onto the actuator body for signaling and switching functions.

Dimensions (Inches [mm])

1/2” to 1.05” [12.7 to 26.67]

2/5” to 1.05” [10 to 26.67]

7.02” [178.4]

4.55” [115.6]

1.42”

[36]

5.37” [136.4]

5.6” [142.4]

To center of

mounting slot.

2” [50.8]

D123

2.9” [72.9]

134

K20901 - 01/09 - Subject to change. © Belimo Aircontrols (USA), Inc.

800-543-9038 USA 866-805-7089 CANADA 203-791-8396 LATIN AMERICA

Page 4

GMB(X)24-3

On/Off, Floating Point Control, Non-Spring Return, Direct Coupled, 24V

Accessories

K-GM20 1/2”-1.05 [12.7 to 26.67 mm] Shaft Clamp

ZG-102 Multiple Actuator Mounting Bracket

Z-GMA GM to GM Retrofit Mounting Bracket

ZG-GMA Crankarm Adaptor Kit

ZG-JSA (-1, 2, 3) Jackshaft Adaptors for Hollow Jackshafts

ZS-100 Weather Shield - Steel

ZS-150 Weather Shield - Polycarbonate

ZS-260 Explosion Proof Housing

ZS-300 (-1) (-5) NEMA 4X Housing

Tool-07 13 mm Wrench

S1A, S2A Auxiliary Switch (es)

P370 Shaft Mount Auxiliary Switch

P…A Feedback Potentiometers

NOTE: When using GMB(X)24-3... actuators, only use accessories listed on this page.

Typical Specification

Floating point, on/off control damper actuators shall be electronic direct-coupled

type, which require no crankarm and linkage and be capable of direct mounting

to a shaft up to 1.05” diameter. Actuators shall have Brushless DC motor

technology and be protected from overload at all angles of rotation. Actuators

shall have reversing switch and manual override on the cover. If required,

actuator will be provided with screw terminal strip for electrical connections

(GMX24-3-T). Run time shall be constant and independent of torque. Actuators

shall be cULus listed, have a 5-year warranty, and be manufactured under ISO

9001 International Quality Control Standards. Actuators shall be as manufactured

by Belimo.

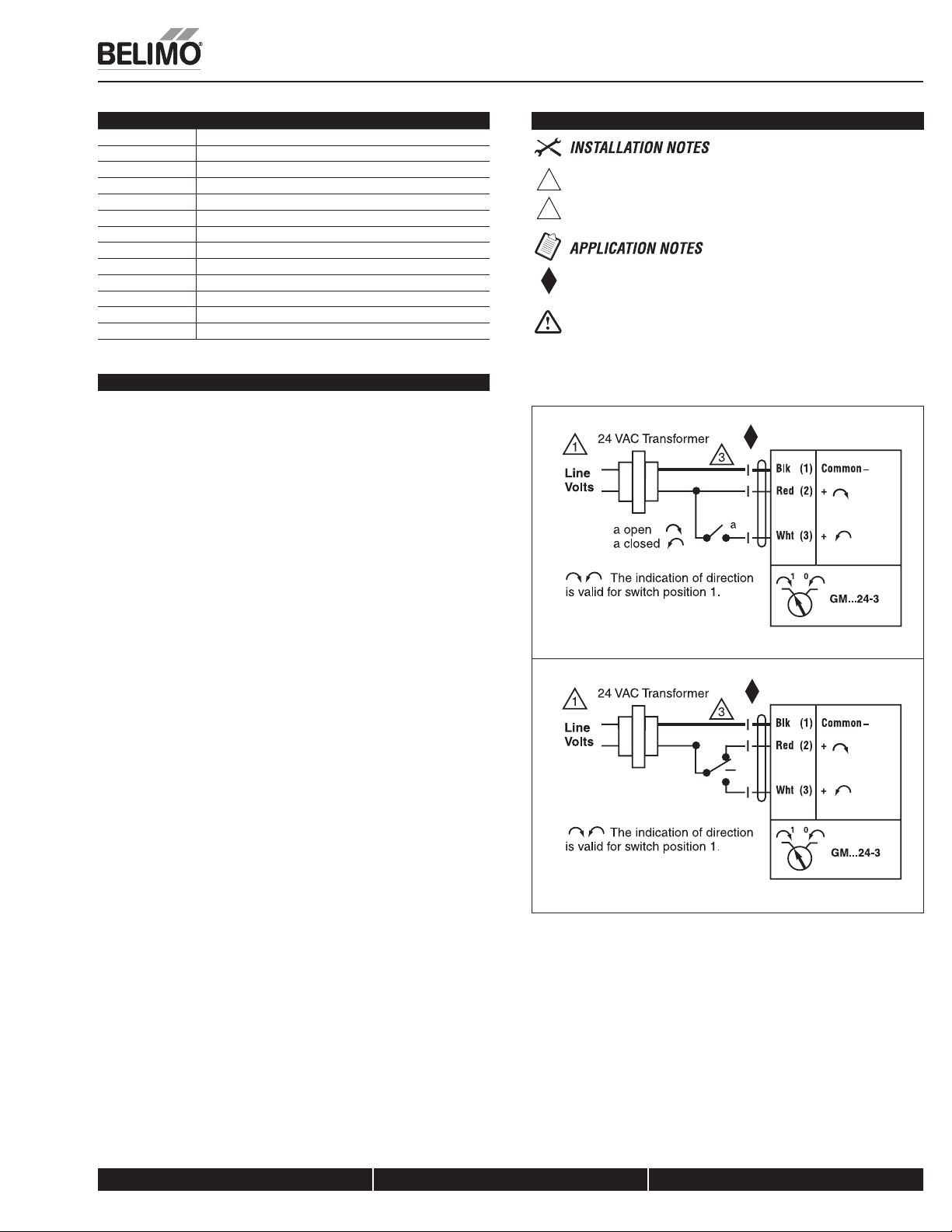

Wiring Diagram

Provide overload protection and disconnect as required.

1

Actuators may also be powered by 24 VDC.

3

Meets cULus requirements without the need of an electrical ground

connection.

WARNING Live Electrical Components!

During installation, testing, servicing and troubleshooting of this product, it maybe

necessary to work with live electrical components. Have a qualified licensed electrician

or other individual who has been properly trained in handling live electrical components

perform these tasks. Failure to follow all electrical safety precautions when exposed to live

electrical components could result in death or serious injury.

W254_08

K20901 - 01/09 - Subject to change. © Belimo Aircontrols (USA), Inc.

On/Off control

W255_08

Floating Point or On/Off control

800-543-9038 USA 866-805-7089 CANADA 203-791-8396 LATIN AMERICA

135

Page 5

GMX120-3

On/Off, Floating Point Control, Non-Spring Return, Direct Coupled, 100 to 240 VAC

Torque min. 360 in-lb for control of damper surfaces up to 90 sq ft.

Application

For on/off and floating point control of dampers in HVAC systems. Actuator

sizing should be done in accordance with the damper manufacturer’s

specifications.

The actuator is mounted directly to a damper shaft up to 1.05” in diameter by

means of its universal clamp. A crankarm and several mounting brackets are

available for applications where the actuator cannot be direct coupled to the

damper shaft.

Operation

The actuator is not provided with and does not require any limit switches, but is

electronically protected against overload. The anti-rotation strap supplied with

the actuator will prevent lateral movement.

The GMX series provides 95° of rotation and a visual indicator indicates position

of the actuator. When reaching the damper or actuator end position, the actuator

automatically stops. The gears can be manually disengaged with a button on the

Technical Data GMX120-3

Power Supply 100 to 240 VAC, 50/60 Hz (nominal)

85 to 265 VAC, 50/60 Hz (tolerance)

Power Consumption 4 W (2 W)

Transformer Sizing 7 VA (Class 2 power source)

Electrical Connection 18 GA appliance rated cable

Overload Protection electronic throughout 0 to 95° rotation

Control on/off, floating point

Input Impedance 600 7

Angle of Rotation max. 95°, adjust. with mechanical stop

Torque 360 in-lb [40 Nm]

Direction of Rotation reversible with

Position Indication reflective visual indicator (snap-on)

Manual Override external push button

Running Time 150 seconds, constant independent of load

Humidity 5 to 95% RH non condensing (EN 60730-1)

Ambient Temperature -22°F to 122°F [-30°C to 50°C]

Storage Temperature -40°F to 176°F [-40°C to 80°C]

Housing NEMA 2, IP54, UL enclosure type 2

Housing Material UL94-5VA

Agency Listings† cULus acc. to UL 60730-1A/-2-14,

Noise Level <45dB(A)

Servicing maintenance free

Quality Standard ISO 9001

Weight 3.4 lbs [1.55 Kg]

† Rated Impulse Voltage 2.5kV, Type of action 1, Control Pollution Degree 3.

1/2” conduit connector

Protected NEMA 2 (IP54)

Q 3 ft [1m] Q 10 ft [3m] Q 16 ft [5m]

switch

CAN/CSA E60730-1:02,

CE acc. to 2004/108/EEC and 2006/95/EC

actuator cover.

The GMX120-3 actuators use a sensorless Brushless DC motor, which is

controlled by an Application Specific Integrated Circuit (ASIC). The ASIC

monitors and controls the actuator’s rotation and provides a digital rotation

sensing (DRS) function to prevent damage to the actuator in a stall condition.

Power consumption is reduced in holding mode.

Add on auxiliary switches or feedback potentiometers are easily fastened directly

onto the actuator body for signaling and switching functions.

Dimensions (Inches [mm])

1/2” to 1.05” [12.7 to 26.67]

2/5” to 1.05” [10 to 26.67]

4.55” [115.6]

1.42”

[36]

5.37” [136.4]

7.02” [178.4]

5.6” [142.4]

To center of

mounting slot.

2” [50.8]

D123

2.9” [72.9]

136

K20901 - 01/09 - Subject to change. © Belimo Aircontrols (USA), Inc.

800-543-9038 USA 866-805-7089 CANADA 203-791-8396 LATIN AMERICA

Page 6

GMX120-3

On/Off, Floating Point Control, Non-Spring Return, Direct Coupled, 100 to 240 VAC

Accessories

K-GM20 1/2”-1.05 [12.7 to 26.67 mm] Shaft Clamp

ZG-102 Multiple Actuator Mounting Bracket

Z-GMA GM to GM Retrofit Mounting Bracket

ZG-GMA Crankarm Adaptor Kit

ZG-JSA (-1, 2, 3) Jackshaft Adaptors for Hollow Jackshafts

ZS-100 Weather Shield - Steel

ZS-150 Weather Shield - Polycarbonate

ZS-260 Explosion Proof Housing

ZS-300 (-1) (-5) NEMA 4X Housing

Tool-07 13 mm Wrench

S1A, S2A Auxiliary Switch (es)

P370 Shaft Mount Auxiliary Switch

P…A Feedback Potentiometers

NOTE: When using GMX120-3 actuators, only use accessories listed on this page.

Typical Specification

Floating point, on/off control damper actuators shall be electronic direct-coupled

type, which require no crankarm and linkage and be capable of direct mounting

to a shaft up to 1.05” diameter. Actuators shall have Brushless DC motor

technology and be protected from overload at all angles of rotation. Actuators

shall have reversing switch and manual override on the cover. Run time shall be

constant and independent of torque. Actuators shall be cULus listed, have a

5-year warranty, and be manufactured under ISO 9001 International Quality

Control Standards. Actuators shall be as manufactured by Belimo.

Wiring Diagram

Provide overload protection and disconnect as required.

1

CAUTION Equipment damage!

2

Actuators may be connected in parallel.

Power consumption and input impedance must be observed.

Actuators may also be powered by 24 VDC.

3

Meets cULus requirements without the need of an electrical ground

connection.

WARNING Live Electrical Components!

During installation, testing, servicing and troubleshooting of this product, it maybe

necessary to work with live electrical components. Have a qualified licensed electrician

or other individual who has been properly trained in handling live electrical components

perform these tasks. Failure to follow all electrical safety precautions when exposed to live

electrical components could result in death or serious injury.

W375_08

K20901 - 01/09 - Subject to change. © Belimo Aircontrols (USA), Inc.

On/Off control

W376_08

Floating Point or On/Off control

800-543-9038 USA 866-805-7089 CANADA 203-791-8396 LATIN AMERICA

137

Page 7

GMB(X)24-SR

Proportional Control, Non-Spring Return, Direct Coupled, 24V, for 2 to 10 VDC and 4 to 20 mA

Torque min. 360 in-lb for control of damper surfaces up to 90 sq ft.

Application

For proportional modulation of dampers in HVAC systems. Actuator sizing should

be done in accordance with the damper manufacturer’s specifications.

The actuator is mounted directly to a damper shaft up to 1.05” in diameter by

means of its universal clamp. A crankarm and several mounting brackets are

available for applications where the actuator cannot be direct coupled to the

damper shaft.

The actuator operates in response to a 2 to 10 VDC, or with the addition of a

500 7 resistor, a 4 to 20 mA control input from an electronic controller or

positioner. A 2 to 10 VDC feedback signal is provided for position indication or

master-slave applications.

Operation

The actuator is not provided with and does not require any limit switches, but is

electronically protected against overload. The anti-rotation strap supplied with the

actuator will prevent lateral movement.

Technical Data GMB24-SR

Power Supply 24 VAC ± 20% 50/60 Hz

Power Consumption 4.5 W (2W)

Transformer Sizing 6.5 VA (Class 2 power source)

Electrical Connection 18 GA plenum rated cable

Overload Protection electronic throughout 0 to 95° rotation

Operating Range Y 2 to 10 VDC, 4 to 20 mA

Input Impedance 100 k7 (0.1 mA), 5007

Feedback Output U 2 to 10 VDC (max 0.5 mA)

Angle of Rotation max. 95°, adjust. with mechanical stop

Torque 360 in-lb [40 Nm]

Direction of Rotation

Position Indication reflective visual indicator (snap-on)

Manual Override external push button

Running Time 150 seconds, constant independent of load

Humidity 5 to 95% RH non condensing (EN 60730-1)

Ambient Temperature -22°F to 122°F [-30°C to 50°C]

Storage Temperature -40°F to 176°F [-40°C to 80°C]

Housing NEMA 2, IP54, UL enclosure type 2

Housing Material UL94-5VA

Agency Listings† cULus acc. to UL 60730-1A/-2-14,

Noise Level <45dB(A)

Servicing maintenance free

Quality Standard ISO 9001

Weight 3.4 lbs [1.55 Kg]

† Rated Impulse Voltage 800V, Type of action 1, Control Pollution Degree 3.

24 VDC ± 10%

1/2” conduit connector

Protected NEMA 2 (IP54)

Q 3 ft [1m] Q 10 ft [3m] Q 16 ft [5m]

reversible with switch

Actuator will move:

=CCW with decreasing control signal (10 to 2V)

=CW with decreasing control signal (10 to 2V)

CAN/CSA E60730-1:02,

CE acc. to 2004/108/EEC and 2006/95/EC

The GMB(X) series provides 95° of rotation and a visual indicator indicates

position of the actuator. When reaching the damper or actuator end position, the

actuator automatically stops. The gears can be manually disengaged with a

button on the actuator cover.

The GMB(X)24-SR… actuators use a sensorless Brushless DC motor, which is

controlled by an Application Specific Integrated Circuit (ASIC). The ASIC

monitors and controls the actuator’s rotation and provides a digital rotation

sensing (DRS) function to prevent damage to the actuator in a stall condition.

Power consumption is reduced in holding mode.

Add on auxiliary switches or feedback potentiometers are easily fastened directly

onto the actuator body for signaling and switching functions.

Dimensions (Inches [mm])

1/2” to 1.05” [12.7 to 26.67]

2/5” to 1.05” [10 to 26.67]

4.55” [115.6]

1.42”

[36]

5.37” [136.4]

7.02” [178.4]

5.6” [142.4]

To center of

mounting slot.

2” [50.8]

D123

2.9” [72.9]

138

K20901 - 01/09 - Subject to change. © Belimo Aircontrols (USA), Inc.

800-543-9038 USA 866-805-7089 CANADA 203-791-8396 LATIN AMERICA

Page 8

GMB(X)24-SR

Proportional Control, Non-Spring Return, Direct Coupled, 24V, for 2 to 10 VDC and 4 to 20 mA

Accessories

K-GM20 1/2”-1.05 [12.7 to 26.67 mm] Shaft Clamp

ZG-102 Multiple Actuator Mounting Bracket

Z-GMA GM to GM Retrofit Mounting Bracket

ZG-GMA Crankarm Adaptor Kit

ZG-JSA (-1, 2, 3) Jackshaft Adaptors for Hollow Jackshafts

ZS-100 Weather Shield - Steel

ZS-150 Weather Shield - Polycarbonate

ZS-260 Explosion Proof Housing

ZS-300 (-1) (-5) NEMA 4X Housing

Tool-07 13 mm Wrench

PS-100 Actuator Power Supply Simulator

S1A, S2A Auxiliary Switch (es)

P370 Shaft Mount Auxiliary Switch

P…A Feedback Potentiometers

SGA24 Min positioners in NEMA 4 housing

SGF24 Min positioners for flush panel mounting

PTA-250 Pulse Width Modulation Interface

IRM-100 Input Rescaling Module

ADS-100 Analog to Digital Switch

ZG-R01 Resistor for 4 to 20 mA Conversion

NSV24 US Battery Back-Up Module

ZG-X40 Transformer

NOTE: When using GMB(X)24-SR… actuators, only use accessories listed on this page.

Typical Specification

Proportional control damper actuators shall be electronic direct-coupled type,

which require no crankarm and linkage and be capable of direct mounting to a

shaft up to 1.05” diameter. Actuators must provide proportional damper control

in response to a 2 to 10 VDC or, with the addition of a 500 7 resistor, a 4 to 20

mA control input from an electronic controller or positioner. Actuators shall have

Brushless DC motor technology and be protected from overload at all angles of

rotation. Actuators shall have reversing switch and manual override on the cover.

If required, actuator will be provided with screw terminal strip for electrical

connections (GMX24-SR-T). Run time shall be constant and independent of

torque. A 2 to 10 VDC feedback signal shall be provided for position indication.

Actuators shall be cULus listed, have a 5-year warranty, and be manufactured

under ISO 9001 International Quality Control Standards. Actuators shall be as

manufactured by Belimo.

Wiring Diagram

Provide overload protection and disconnect as required.

1

CAUTION Equipment damage!

2

Actuators may be connected in parallel.

Power consumption and input impedance must be observed.

Actuators may also be powered by 24 VDC.

3

Only connect common to neg. (–) leg of control circuits.

5

Meets UL requirements without the need of an electrical ground

connection.

The ZG-R01 500 7 resistor converts the 4 to 20 mA control signal to

2 to 10 VDC, up to 2 actuators may be connected in parallel.

WARNING Live Electrical Components!

During installation, testing, servicing and troubleshooting of this product, it maybe

necessary to work with live electrical components. Have a qualified licensed electrician

or other individual who has been properly trained in handling live electrical components

perform these tasks. Failure to follow all electrical safety precautions when exposed to live

electrical components could result in death or serious injury.

2 to 10 VDC control

W253_08

K20901 - 01/09 - Subject to change. © Belimo Aircontrols (USA), Inc.

W253_08

4 to 20 mA control

800-543-9038 USA 866-805-7089 CANADA 203-791-8396 LATIN AMERICA

139

Page 9

GMB(X)24-MFT

Proportional Control, Non-Spring Return, Direct Coupled, 24V, Multi-Function Technology

Torque min. 360 in-lb for control of damper surfaces up to 90 sq ft.

Application

For proportional modulation of dampers in HVAC systems. Actuator sizing should

be done in accordance with the damper manufacturer’s specifications.

The actuator is mounted directly to a damper shaft up to 1.05” in diameter by

means of its universal clamp. A crankarm and several mounting brackets are

available for applications where the actuator cannot be direct coupled to the

damper shaft.

The default parameters for 2 to 10 VDC applications of the …MFT actuator are

assigned during manufacturing. If necessary, custom versions of the actuators

can be ordered. The parameters can be changed by two means: pre-set and

custom configurations from Belimo or on-site configurations using the Belimo

PC-Tool software.

Operation

The actuator is not provided with and does not require any limit switches, but is

electronically protected against overload. The anti-rotation strap supplied with the

Technical Data GMB(X)24-MFT

Power Supply 24 VAC ± 20% 50/60 Hz

Power Consumption 4.5 W (1.5 W)

Transformer Sizing 7 VA (Class 2 power source)

Electrical Connection 18 GA plenum rated cable

Overload Protection electronic throughout 0 to 95° rotation

Operating Range Y 2 to 10 VDC, 4 to 20 mA (default)

Input Impedance 100 k7 (0.1 mA), 500 7

Feedback Output U 2 to 10 VDC, 0.5 mA max

Angle of Rotation max. 95°, adjust. with mechanical stop

Torque 360 in-lb [40 Nm]

Direction of Rotation

Position Indication reflective visual indicator (snap-on)

Manual Override external push button

Running Time 150 seconds (default)

Humidity 5 to 95% RH non condensing (EN 60730-1)

Ambient Temperature -22°F to +122°F [-30°C to +50°C]

Storage Temperature -40°F to +176°F [-40°C to +80°C]

Housing NEMA 2, IP54, UL enclosure type 2

Housing Material UL94-5VA

Agency Listings† cULus acc. to UL 60730-1A/-2-14,

Noise Level <45dB(A)

Servicing maintenance free

Quality Standard ISO 9001

Weight 3.4 lbs [1.55 kg]

† Rated Impulse Voltage 800V, Type of action 1, Control Pollution Degree 3.

24 VDC ± 10%

1/2” conduit connector

Protected NEMA 2 (IP54)

Q 3 ft [1m] (Q 10 ft [3m] Q 16 ft [5m])

Variable (VDC, PWM, Floating Point, On/Off)

1500 7 (PWM, Floating Point, On/Off)

VDC Variable

electronically variable

reversible with

switch

Variable (70 to 280 secs)

CAN/CSA E60730-1:02,

CE acc. to 2004/108/EEC and 2006/95/EC

actuator will prevent lateral movement.

The GMB(X) series provides 95° of rotation and a visual indicator indicates

position of the actuator. When reaching the damper or actuator end position, the

actuator automatically stops. The gears can be manually disengaged with a

button on the actuator cover.

The GMB(X)24-MFT actuators use a Brushless DC motor, which is controlled by

an Application Specific Integrated Circuit (ASIC). The ASIC monitors and controls

the actuator’s rotation and provides a digital rotation sensing (DRS) function to

prevent damage to the actuator in a stall condition. Power consumption is

reduced in holding mode.

Add on auxiliary switches or feedback potentiometers are easily fastened directly

onto the actuator body for signaling and switching functions.

Dimensions (Inches [mm])

1/2” to 1.05” [12.7 to 26.67]

2/5” to 1.05” [10 to 26.67]

4.55” [115.6]

1.42”

[36]

®

7.02” [178.4]

5.37” [136.4]

5.6” [142.4]

To center of

mounting slot.

2” [50.8]

D123

2.9” [72.9]

K20901 - 01/09 - Subject to change. © Belimo Aircontrols (USA), Inc.

140

800-543-9038 USA 866-805-7089 CANADA 203-791-8396 LATIN AMERICA

Page 10

GMB(X)24-MFT

Proportional Control, Non-Spring Return, Direct Coupled, 24V, Multi-Function Technology

®

Accessories

K-GM20 3/4" [20 mm] Shaft Clamp

ZG-102 Multiple Actuator Mounting Bracket

ZG-GMA Crankarm Adaptor Kit

ZG-JSA (-1, 2, 3) Jackshaft Adaptors for Hollow Jackshafts

ZS-100 Weather Shield - Steel

ZS-150 Weather Shield - Polycarbonate

ZS-260 Explosion Proof Housing

ZS-300 (-1) (-5) NEMA 4X Housing

Tool-07 13 mm Wrench

PS-100 Actuator Power Supply Simulator

S1A, S2A Auxiliary Switch (es)

P370 Shaft Mount Auxiliary Switch

P…A Feedback Potentiometers

SGA24 Min positioners in NEMA 4 housing

SGF24 Min positioners for flush panel mounting

ADS-100 Analog to Digital Switch

ZG-R01 Resistor for 4 to 20 mA Conversion

NSV24 US Battery Back-Up Module

ZG-X40 Transformer

NOTE: When using GMB(X)24-MFT actuators, only use accessories listed on this page.

Typical Specification

Proportional control damper actuators shall be electronic direct-coupled type,

which require no crankarm and linkage and be capable of direct mounting to a

shaft up to 1.05” diameter. Actuators must provide proportional damper control

in response to a 2 to 10 VDC or, with the addition of a 500 7 resistor, a 4 to 20

mA control input from an electronic controller or positioner. Actuators shall have

Brushless DC motor technology and be protected from overload at all angles of

rotation. Actuators shall have reversing switch and manual override on the cover.

Run time shall be constant and independent of torque. Actuators shall be cULus

listed, have a 5-year warranty, and be manufactured under ISO 9001 International

Quality Control Standards. Actuators shall be as manufactured by Belimo.

WARNING Live Electrical Components!

During installation, testing, servicing and troubleshooting of this product, it maybe

necessary to work with live electrical components. Have a qualified licensed electrician

or other individual who has been properly trained in handling live electrical components

perform these tasks. Failure to follow all electrical safety precautions when exposed to live

electrical components could result in death or serious injury.

VDC/4-20 mA

PWM

W399_08

W399_08

Wiring Diagrams

Provide overload protection and disconnect as required.

1

CAUTION Equipment damage!

2

Actuators may be connected in parallel if not mechanically mounted to the

same shaft. Power consumption and input impedance must be observed.

Actuators may also be powered by 24 VDC.

3

Position feedback cannot be used with Triac sink controller.

4

The actuator internal common reference is not compatible.

Control signal may be pulsed from either the Hot (source)

5

or the Common (sink) 24 VAC line.

Contact closures A & B also can be triacs.

8

A & B should both be closed for triac source and open for triac sink.

For triac sink the common connection from the actuator

9

must be connected to the hot connection of the controller.

K20901 - 01/09 - Subject to change. © Belimo Aircontrols (USA), Inc.

Meets UL requirements without the need of an electrical ground

connection.

The ZG-R01 500 7 resistor may be used.

W399_08

On/Off control

W399_08

Floating Point control

800-543-9038 USA 866-805-7089 CANADA 203-791-8396 LATIN AMERICA

141

Page 11

GMX24-MFT95

Proportional Control, Non-Spring Return, Direct Coupled, 24V, 0 to 135 7 Input

Torque min. 360 in-lb for control of damper surfaces up to 90 sq ft.

Application

For proportional modulation of dampers in HVAC systems. Actuator sizing should

be done in accordance with the damper manufacturer’s specifications.

The actuator is mounted directly to a damper shaft up to 1.05” in diameter by

means of its universal clamp. A crankarm and several mounting brackets are

available for applications where the actuator cannot be direct coupled to the

damper shaft.

The default parameters for 0 to 1357 input applications of the …MFT95 actuator

are assigned during manufacturing. If necessary, custom versions of the

actuators can be ordered. The parameters can be changed by two means: pre-set

and custom configurations from Belimo or on-site configurations using the

Belimo PC-Tool software.

Operation

The actuator is not provided with and does not require any limit switches, but is

electronically protected against overload. The anti-rotation strap supplied with the

Technical Data

Power Supply 24 VAC ± 20% 50/60 Hz

Power Consumption 4.5 W (1.5 W)

Transformer Sizing 7 VA (Class 2 power source)

Electrical Connection 18 GA plenum rated cable

Overload Protection electronic throughout 0 to 95° rotation

Operating Range WRB 0 to 135 7 Honeywell Electronic

Feedback Output U 2 to 10 VDC, 0.5 mA max

Angle of Rotation max. 95°, adjust. with mechanical stop

Torque 360 in-lb [40 Nm]

Direction of Rotation reversible with

Position Indication reflective visual indicator (snap-on)

Manual Override external push button

Running Time 150 seconds (default)

Humidity 5 to 95% RH non condensing (EN 60730-1)

Ambient Temperature -22°F to 122°F [-30°C to 50°C]

Storage Temperature -40°F to 176°F [-40°C to 80°C]

Housing NEMA 2, IP54, UL enclosure type 2

Housing Material UL94-5VA

Agency Listings† cULus acc. to UL 60730-1A/-2-14,

Noise Level <45dB(A)

Servicing maintenance free

Quality Standard ISO 9001

Weight 3.4 lbs [1.55 kg]

† Rated Impulse Voltage 800V, Type of action 1, Control Pollution Degree 3.

24 VDC ± 10%

1/2” conduit connector

Protected NEMA 2 (IP54)

Q 3 ft [1m] Q 10 ft [3m] Q 16 ft [5m]

Series 90, 0 to 1357 Input

VDC Variable

electronically variable

switch

Variable (70 to 280 secs)

CAN/CSA E60730-1:02,

CE acc. to 2004/108/EEC and 2006/95/EC

actuator will prevent lateral movement.

The GMX series provides 95° of rotation and a visual indicator indicates position

of the actuator. When reaching the damper or actuator end position, the actuator

automatically stops. The gears can be manually disengaged with a button on the

actuator cover.

The GMX24-MFT95 actuators use a Brushless DC motor, which is controlled by

an Application Specific Integrated Circuit (ASIC). The ASIC monitors and controls

the actuator’s rotation and provides a digital rotation sensing (DRS) function to

prevent damage to the actuator in a stall condition. Power consumption is

reduced in holding mode.

Add on auxiliary switches or feedback potentiometers are

easily fastened directly onto the actuator body for signaling and switching

functions.

Dimensions (Inches [mm])

1/2” to 1.05” [12.7 to 26.67]

2/5” to 1.05” [10 to 26.67]

7.02” [178.4]

4.55” [115.6]

1.42”

[36]

5.37” [136.4]

5.6” [142.4]

To center of

mounting slot.

2” [50.8]

D123

2.9” [72.9]

K20901 - 01/09 - Subject to change. © Belimo Aircontrols (USA), Inc.

142

800-543-9038 USA 866-805-7089 CANADA 203-791-8396 LATIN AMERICA

Page 12

GMX24-MFT95

Proportional Control, Non-Spring Return, Direct Coupled, 24V, 0 to 135 7 Input

Accessories

K-GM20 1/2”-1.05 [12.7 to 26.67 mm] Shaft Clamp

ZG-102 Multiple Actuator Mounting Bracket

ZG-GMA Crankarm Adaptor Kit

ZG-JSA (-1, 2, 3) Jackshaft Adaptors for Hollow Jackshafts

ZS-100 Weather Shield - Steel

ZS-150 Weather Shield - Polycarbonate

ZS-260 Explosion Proof Housing

ZS-300 (-1) (-5) NEMA 4X Housing

Tool-07 13 mm Wrench

PS-100 Actuator Power Supply Simulator

S1A, S2A Auxiliary Switch (es)

P370 Shaft Mount Auxiliary Switch

P…A Feedback Potentiometers

NSV24 US Battery Back-Up Module

ZG-X40 Transformer

NOTE: When using GMX24-MFT95 actuators, only use accessories listed on this page.

Typical Specification

Proportional control damper actuators shall be electronic direct-coupled type,

which require no crankarm and linkage and be capable of direct mounting to a

shaft up to 1.05” diameter. Actuators must provide proportional damper control

in response to 0 to 135 7 input from an electronic controller or positioner.

Actuators shall have Brushless DC motor technology and be protected from

overload at all angles of rotation. Actuators shall have reversing switch and

manual override on the cover. Run time shall be constant and independent of

torque. Actuators shall be cULus listed, have a 5-year warranty, and be

manufactured under ISO 9001 International Quality Control Standards. Actuators

shall be as manufactured by Belimo.

Wiring Diagrams

Provide overload protection and disconnect as required.

1

Actuators and controller must have separate transformers.

2

Consult controller instruction data for more detailed installation

3

information.

Resistor value depends on the type of controller and the number of

actuators. No resistor is used for one actuator. Honeywell resistor kits

4

may also be used.

To reverse control rotation, use the reversing switch.

5

W418_08

K20901 - 01/09 - Subject to change. © Belimo Aircontrols (USA), Inc.

Override

W418_08

Wiring multiple actuators to a Series 90 controller

using a minimum position potentiometer.

Low Limit Control

High Limit Control

800-543-9038 USA 866-805-7089 CANADA 203-791-8396 LATIN AMERICA

W418_08

W418_08

143

Page 13

GMX24-PC

Proportional Control, Non-Spring Return, Direct Coupled, 24V, 0 to 20V Phasecut

Torque min. 360 in-lb for control of damper surfaces up to 90 sq ft.

Application

For proportional modulation of dampers in HVAC systems. Actuator sizing should

be done in accordance with the damper manufacturer’s specifications.

The actuator is mounted directly to a damper shaft up to 1.05” in diameter by

means of its universal clamp. A crankarm and several mounting brackets are

available for applications where the actuator cannot be direct coupled to the

damper shaft.

The actuator operates in response to 0 to 20V phasecut control input from an

electronic controller or positioner. A 2 to 10 VDC feedback signal is provided for

position indication.

Operation

The actuator is not provided with and does not require any limit switches, but is

electronically protected against overload. The anti-rotation strap supplied with the

actuator will prevent lateral movement.

Technical Data

Power Supply 24 VAC ± 20% 50/60 Hz

Power Consumption 4.5 W (1.5 W)

Transformer Sizing 7 VA (Class 2 power source)

Electrical Connection 18 GA plenum rated cable

Overload Protection electronic throughout 0 to 95° rotation

Operating Range Y 0 to 20 V Phasecut

Input Impedance 8 k7 (50 mW)

Feedback Output U 2 to 10 VDC, 0.5 mA max

Angle of Rotation max. 95°, adjust. with mechanical stop

Torque 360 in-lb [40 Nm]

Direction of Rotation reversible with

Position Indication reflective visual indicator (snap-on)

Manual Override external push button

Running Time 150 seconds (default)

Humidity 5 to 95% RH non condensing (EN 60730-1)

Ambient Temperature -22°F to 122°F [-30°C to 50°C]

Storage Temperature -40°F to 176°F [-40°C to 80°C]

Housing NEMA 2, IP54, UL enclosure type 2

Housing Material UL94-5VA

Agency Listings† cULus acc. to UL 60730-1A/-2-14,

Noise Level <45dB(A)

Servicing maintenance free

Quality Standard ISO 9001

Weight 3.4 lbs [1.55 kg]

† Rated Impulse Voltage 800V, Type of action 1, Control Pollution Degree 3.

24 VDC ± 10%

1/2” conduit connector

Protected NEMA 2 (IP54)

Q 3 ft [1m] Q 10 ft [3m] Q 16 ft [5m]

electronically variable

switch

CAN/CSA E60730-1:02,

CE acc. to 2004/108/EEC and 2006/95/EC

The GMX series provides 95° of rotation and a visual indicator indicates position

of the actuator. When reaching the damper or actuator end position, the actuator

automatically stops. The gears can be manually disengaged with a button on the

actuator cover.

The GMX24-PC actuators use a Brushless DC motor, which is controlled by an

Application Specific Integrated Circuit (ASIC). The ASIC monitors and controls

the actuator’s rotation and provides a digital rotation sensing (DRS) function to

prevent damage to the actuator in a stall condition. Power consumption is

reduced in holding mode.

Add on auxiliary switches or feedback potentiometers are easily fastened directly

onto the actuator body for signaling and switching functions.

Dimensions (Inches [mm])

1/2” to 1.05” [12.7 to 26.67]

2/5” to 1.05” [10 to 26.67]

4.55” [115.6]

1.42”

[36]

5.37” [136.4]

7.02” [178.4]

5.6” [142.4]

To center of

mounting slot.

2” [50.8]

D123

2.9” [72.9]

144

K20901 - 01/09 - Subject to change. © Belimo Aircontrols (USA), Inc.

800-543-9038 USA 866-805-7089 CANADA 203-791-8396 LATIN AMERICA

Page 14

GMX24-PC

Proportional Control, Non-Spring Return, Direct Coupled, 24V, 0 to 20V Phasecut

Accessories

K-GM20 1/2”-1.05 [12.7 to 26.67 mm] Shaft Clamp

ZG-102 Multiple Actuator Mounting Bracket

ZG-GMA Crankarm Adaptor Kit

ZG-JSA (-1, 2, 3) Jackshaft Adaptors for Hollow Jackshafts

ZS-100 Weather Shield - Steel

ZS-150 Weather Shield - Polycarbonate

ZS-260 Explosion Proof Housing

ZS-300 (-1) (-5) NEMA 4X Housing

Tool-07 13 mm Wrench

PS-100 Actuator Power Supply Simulator

S1A, S2A Auxiliary Switch (es)

P370 Shaft Mount Auxiliary Switch

P…A Feedback Potentiometers

NSV24 US Battery Back-Up Module

ZG-X40 Transformer

NOTE: When using GMX24-PC actuators, only use accessories listed on this page.

Typical Specification

Proportional control damper actuators shall be electronic direct-coupled type,

which require no crankarm and linkage and be capable of direct mounting to a

shaft up to 1.05” diameter. Actuators must provide proportional damper control

in response to 0 to 20 V phasecut control input from an electronic controller or

positioner. Actuators shall have Brushless DC motor technology and be protected

from overload at all angles of rotation. Actuators shall have reversing switch and

manual override on the cover. Run time shall be constant and independent of

torque. Actuators shall be cULus listed, have a 5-year warranty, and be

manufactured under ISO 9001 International Quality Control Standards. Actuators

shall be as manufactured by Belimo.

Wiring Diagrams

Provide overload protection and disconnect as required.

1

CAUTION Equipment damage!

2

Actuators may be connected in parallel.

Power consumption and input impedance must be observed.

Actuators may also be powered by 24 VDC.

3

Meets UL requirements without the need of an electrical ground

connection.

WARNING Live Electrical Components!

During installation, testing, servicing and troubleshooting of this product, it maybe

necessary to work with live electrical components. Have a qualified licensed electrician

or other individual who has been properly trained in handling live electrical components

perform these tasks. Failure to follow all electrical safety precautions when exposed to live

electrical components could result in death or serious injury.

1

24 VAC Transformer

Line

Volts

Control Signal

0 to 20 V Phasecut

(–)

(+)

Blk (1) Common

Red (2) Hot +

Pnk (6) Y Input,

Org (5) U

–

3

0 to 20V phasecut

Output, 2 to 10V

W185

K20901 - 01/09 - Subject to change. © Belimo Aircontrols (USA), Inc.

Proportional Control

…PC

2

800-543-9038 USA 866-805-7089 CANADA 203-791-8396 LATIN AMERICA

145

Loading...

Loading...