Page 1

Part #473380

Grease Grabber™ H2O

®

®

Auto-Cleaning Hood

Installation, Operation and Maintenance Manual

Please read and save these instructions. Read carefully before attempting to assemble, install, operate or maintain the

Please read and save these instructions. Read carefully before attempting to assemble, install, operate or maintain the

product described. Protect yourself and others by observing all safety information. Failure to comply with instructions

product described. Protect yourself and others by observing all safety information. Failure to comply with instructions

could result in personal injury and/or property damage! Retain instructions for future reference.

could result in personal injury and/or property damage! Retain instructions for future reference.

Installation, Operation and Maintenance Manual

Model GGH2O

General Safety Information

Only qualified personnel should install this unit.

Personnel should have a clear understanding of these

instructions and should be aware of general safety

precautions. Improper installation can result in electric

shock, possible injury due to coming in contact with

moving parts, as well as other potential hazards. Other

considerations may be required if seismic activity

is present. If more information is needed, contact a

licensed professional engineer before moving forward.

1. Follow all local electrical and safety codes, as well

as the National Electrical Code (NEC), the National

Fire Protection Agency (NFPA), where applicable.

Follow the Canadian Electric Code (CEC) in

Canada.

DANGER

Always disconnect power before working on or

near a unit. Lock and tag the disconnect switch or

breaker to prevent accidental power up.

CAUTION

When servicing the unit, motor may be hot enough

to cause pain or injury. Allow motor to cool before

servicing.

Model GGH20 Grease Grabber Auto-Cleaning Hood

1

®

Page 2

Receiving

Upon receiving the product check to make sure all

items are accounted for by referencing the bill of

lading to ensure all items were received. Inspect

each crate for shipping damage before accepting

delivery. Notify the carrier if any damage is noticed.

The carrier will make notification on the delivery

receipt acknowledging any damage to the product.

All damage should be noted on all the copies of the

bill of lading which is countersigned by the delivering

carrier. A Carrier Inspection Report should be filled out

by the carrier upon arrival and the Traffic Department.

If damaged upon arrival, file claim with carrier. Any

physical damage to the unit after acceptance is not

the responsibility of Greenheck Fan Corporation.

Unpacking

Verify that all required parts and the correct quantity

of each item have been received. If any items are

missing, report shortages to your local representative

to arrange for obtaining missing parts. Sometimes it

is not possible that all items for the unit be shipped

together due to availability of transportation and truck

space. Confirmation of shipment(s) must be limited to

only items on the bill of lading.

The unit should be stored at least 3½ in. (89 mm) off

the floor on wooden blocks covered with moisture

proof paper or polyethylene sheathing. Aisles between

parts and along all walls should be provided to permit

air circulation and space for inspection.

Inspection and Maintenance during Storage

While in storage, inspect once per month. Keep a

record of inspection and maintenance performed.

If moisture or dirt accumulations are found on parts,

the source should be located and eliminated.

REMOVING FROM STORAGE — As units are removed

from storage to be installed in their final location,

they should be protected and maintained in a similar

fashion, until the equipment goes into operation.

Prior to installing the unit and system components,

inspect the unit assembly to make sure it is in working

order.

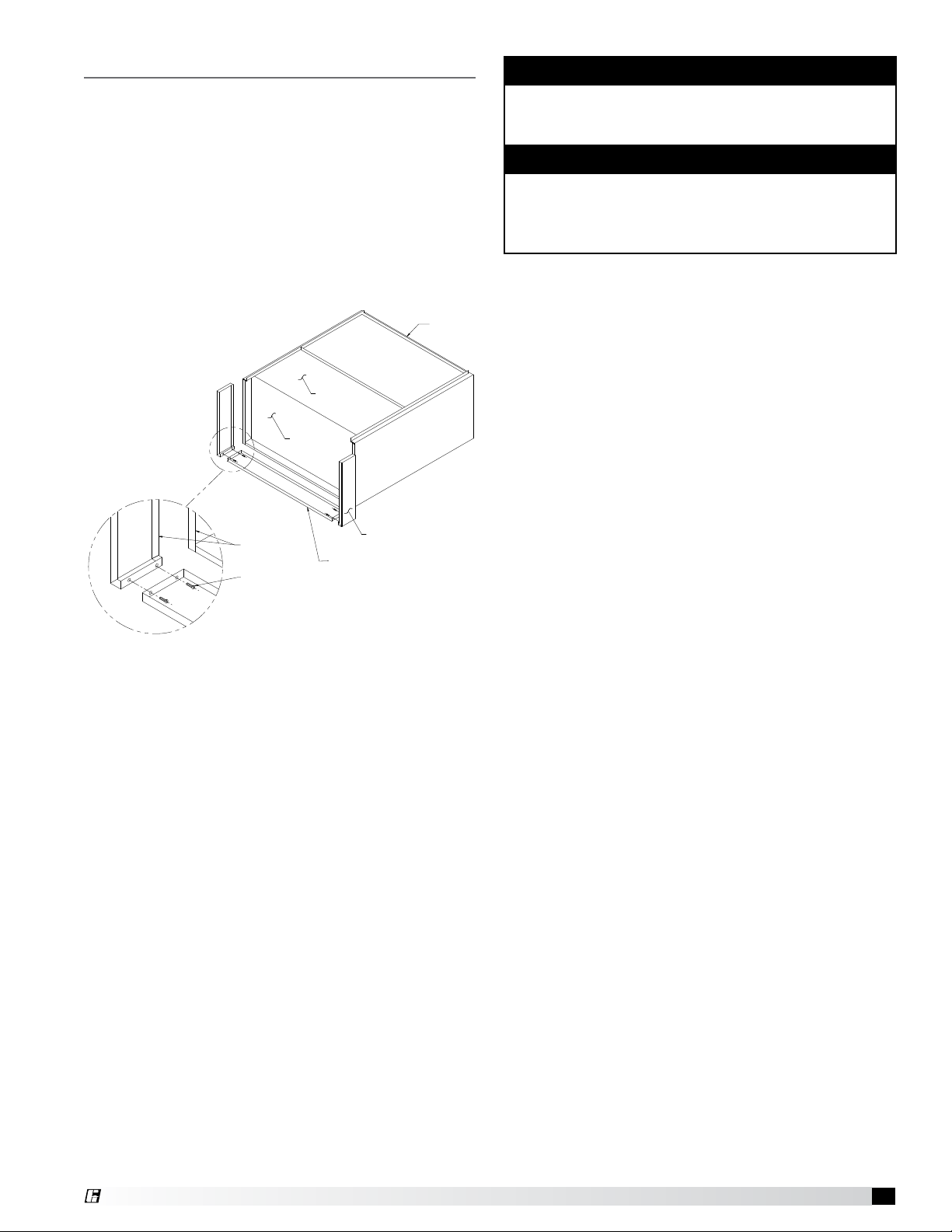

Handling

Units are to be rigged and moved by the lifting

brackets provided or by the skid when a forklift is

used. Location of brackets varies by model and size.

Handle in such a manner as to keep from scratching

or chipping the coating. Damaged finish may reduce

ability of unit to resist corrosion.

Storage

Units are protected against damage during shipment.

If the unit cannot be installed and operated

immediately, precautions need to be taken to prevent

deterioration of the unit during storage. The user

assumes responsibility of the unit and accessories

while in storage. The manufacturer will not be

responsible for damage during storage. These

suggestions are provided solely as a convenience to

the user.

The ideal environment for the storage of units and

accessories is indoors, above grade, in a low humidity

atmosphere which is sealed to prevent the entry of

blowing dust, rain, or snow. Temperatures should

be evenly maintained between 30°F (-1°C) and

110°F (43°C) (wide temperature swings may cause

condensation and “sweating” of metal parts). All

accessories must be stored indoors in a clean, dry

atmosphere.

Remove any accumulations of dirt, water, ice, or snow

and wipe dry before moving to indoor storage. To

avoid “sweating” of metal parts allow cold parts to

reach room temperature. To dry parts and packages

use a portable electric heater to get rid of any

moisture build up. Leave coverings loose to permit air

circulation and to allow for periodic inspection.

Model GGH2O

2

®

Page 3

Table of Contents

Grease Grabber™ H2O System Function .................... 3

Cleaning Cycle

Manual and Automatic Engagement ........................ 4

Fire Mode ...................................................................... 4

System Components

Hood .......................................................................... 5

Grease Grabber H2O Control Cabinet ...................... 5

Graphic Keypad ........................................................ 5

Unpacking ..................................................................... 6

Hood Widths and Base Weights .................................. 6

Installation Overview

Filler Panels ............................................................... 7

Back Supply Plenum ................................................. 7

Hood Hanging Height................................................ 8

Double Island Style ................................................... 8

Installing U-Channel Strip ...................................... 8

Continuous Capture Plenum ................................. 8

Ductwork ................................................................... 9

External Supply Plenums ..................................... 9-10

Supply Plenum Clip ............................................... 9

Uni-Strut ............................................................... 10

Threaded Rod ...................................................... 10

Supply Duct Collar .................................................. 10

UL Listed Fastener .................................................. 11

Back Supply Plenum ..........................................11-12

Supply Duct Collar ............................................... 11

Hanging the Back Supply Plenum .................11-12

Hanging the Hood ................................................ 12

Air Diffusers ............................................................. 12

Enclosure Panels ..................................................... 13

End Skirts ................................................................ 13

Backsplash Panels .................................................. 14

Duct Collar ............................................................... 15

Plumbing

Pump Installation .................................................... 16

Connections ............................................................ 16

Detergent Tank ........................................................ 17

Electrical

Wiring ....................................................................... 17

Timer Programming – 24 Hour / 7 Day

Programming / Operation ....................................... 18

Initial System Start-Up ............................................... 19

Sequence of Operation .............................................. 20

Airflow Testing Procedure .......................................... 21

Wiring Schematic

Amerex® .................................................................. 22

Ansul® ..................................................................... 23

Wiring Diagram ........................................................ 24

Maintenance

Filters ....................................................................... 25

Floats ....................................................................... 25

Troubleshooting .......................................................... 26

Replacement Parts ..................................................... 26

Grease Grabber H2O Start-Up Checklist ................... 27

Maintenance Log ...........................................Backcover

Warranty .........................................................Backcover

Grease Grabber™ H2O System

Function

Greenheck GGH2O hoods are designed for three

primary functions:

• Capture and contain the effluent produced by the

cooking process.

• Remove grease and other contaminants from the

airstream with two stages of mechanical filters

(Primary Grease X-Tractor filters and secondary

Grease Grabber filters).

• Wash the filters and other surfaces within the

exhaust plenum to remove contaminants.

NOTE

The wash sequence of the hood is not designed for

fire suppression and will not engage in the event of

a fire.

NOTE

The functions listed above require the control center

to be wired to the exhaust fan(s) and the hood

plumbed.

NOTE

For a complete list of functions, please refer to the

sequence of operations.

Normal Exhaust Operation and

Contaminant Collection

The system’s exhaust fan is manually controlled by

a press-button switch (FAN ON/OFF) on the graphic

keypad (included with hood). The exhaust system

operates until the FAN ON/OFF button is pressed. The

wash cycle can be manually engaged to run on a preprogrammed control sequence by pressing the CLEAN

HOOD button or automatically engaged to run at the

same time each day through a programmable timer.

®

Model GGH2O

3

Page 4

Cleaning Cycle

Manual Engagement

The wash function is triggered by pressing the Clean

Hood button after the exhaust fans are shut down at

the end of each day’s cooking operations (pressing

the Fans On/Off button).

Hot water and detergent will fill the hood reservoir.

The soapy water will then be cycled through the hood

by the attached recirculation pump, cleaning both the

filter banks and the exhaust plenum area on a timed

cycle.

When the cleaning cycle is complete, the water

is purged from the reservoir by the pump and the

reservoir will again fill with clean hot water.

A rinse cycle will then run on a timed cycle and the

water will again be purged by the pump.

When the cycle is complete, the controller runs the

exhaust fans briefly to remove steam and excess

moisture from the exhaust system.

Automatic Engagement

The hood is equipped with an automatic timer. The

timer will automatically initiate the wash sequence

at the programmed time each day. All other washing

functionality will be the same as the manual

engagement sequencing.

Fire Mode

In the event of a fire, the hood exhaust fan(s) will turn

on at full power and the supply fan will turn off (default

setting controlled by others) regardless of current fan

operation. If the hood is in a wash cycle, the hood will

drain and the fans will turn on.

NOTE

The wash sequence of the hood is not designed for

fire suppression and will not engage in the event of

a fire.

Model GGH2O

4

®

Page 5

System Components

Hood

The hood is shipped from the factory pre-piped and

ready to install. All wash components within the hood

are complete and ready for connection to hot water,

sanitary sewer drain and the electrical sources. Wiring

from the control panel to the hood (for lights) is by

Greenheck. All plumbing and wiring must conform to

plumbing and electrical codes. Duct collars are factory

mounted unless specified otherwise.

NOTE

Filters are shipped loose with the hood and installed

in the field. See page 25 for installation details.

Grease Grabber H2O Control Cabinet

The control cabinet contains all of the water and

electrical components, and connections including

the Programmable Logic Controller (PLC), that

controls the wash sequencing and operations. The

control cabinet also includes the detergent reservoir,

detergent pump, recirculation pump, solenoid valves

and other water piping.

NOTE

The recirculation pump is shipped loose with the

hood. See pages 16 for installation details.

Graphic Keypad

The graphic keypad is the interface between the

control functions of the GGH2O hood and the user.

This keypad is typically mounted on the Grease

Grabber H2O control cabinet, but can also be shipped

loose for remote mounting. The keypad consists

of three main buttons: hood lights, fan on/off and

clean hood. The keypad also has system fault and fill

detergent indicator lights to alert of any fault in the

system or when the detergent tank is low.

HOOD

LIGHTS

FILL

DETERGENT

After pressing “CLEAN HOOD”, Fans will automatically stop.

In case of emergency, the wash cycle can be stopped by pressing “CLEAN HOOD”.

GGH2O Keypad

If the GGH2O is being used with the Vari-Flow Air

Management system, there will be an additional

FAN 100% button for sending fan speeds to 100%.

For detailed information on the Vari-Flow Air

Management system, please refer to the Greenheck

website, www.greenheck.com

CLEAN

HOOD

FAN

ON/OFF

SYSTEM

FAULT

472619

NOTE

HOOD

LIGHTS

FILL

DETERGENT

After pressing “CLEAN HOOD”, Fans will automatically stop.

In case of emergency, the wash cycle can be stopped by pressing “CLEAN HOOD”.

FAN

100%

CLEAN

HOOD

FAN

ON/OFF

SYSTEM

FAULT

472620

GGH2O and Vari-Flow Keypad

CLEAN

HOOD

FILL

DETERGENT

After pressing “CLEAN HOOD”, Fans will automatically stop.

In case of emergency, the wash cycle can be stopped by pressing “CLEAN HOOD”.

SYSTEM

FAULT

LIGHTS

LUCES

CLEAN

FAULT

Melink Customer Service USA: 877-477-4190

%

FANS

VENTILADORES

HOOD

RESET

SETUP

Listed 33 x 7

100%

GGH2O and Melink® Intelli-Hood® Keypad

NOTE

If the GGH2O is being used with the Melink IntelliHood system, there will be two keypads. The Melink

Keypad will control the fans and lights. The GGH2O

Keypad will control the wash system.

NOTE

For information on PLC programming, please

consult the factory.

®

Model GGH2O

5

Page 6

Unpacking

1

2

Front Lifting

Skid

Profile of Hood

Profile of Hood

Remove side, back and top lumber.

Remove 3-inch lag screws.

Holding the front lifting skid in

place and position the skid in

front of bottom skid.

Carefully rotate hood

as shown.

1

2

3

Front Lifting

Skid

Profile of Hood

Profile of Hood

Profile of Hood

Remove side, back and top lumber.

Remove 3-inch lag screws.

Holding the front lifting skid in

place and position the skid in

front of bottom skid.

Carefully rotate hood

as shown.

Carefully slide the hood

onto the lifting skid.

The lifting skid should be used to

life the hood into it’s final position.

If the lifting skid is not used, the

hood will be damaged during the

installation process.

1

Front Lifting

Skid

Profile of Hood

Remove side, back and top lumber.

Remove 3-inch lag screws.

Holding the front lifting skid in

place and position the skid in

front of bottom skid.

Front Lifting

Skid

Remove side, back

and top lumber.

Remove 3-inch

lag screws while

holding the front

lifting skid in place.

When front lifting

skid is detached,

position it in front

of bottom skid.

Profile of Hood

Hood Width

inches

(cm)

48

(121.92)

51

(129.54)

54

(137.16)

57

(144.78)

60

(152.40)

63

(160.02)

66

(167.64)

69

(175.26)

72

(182.88)

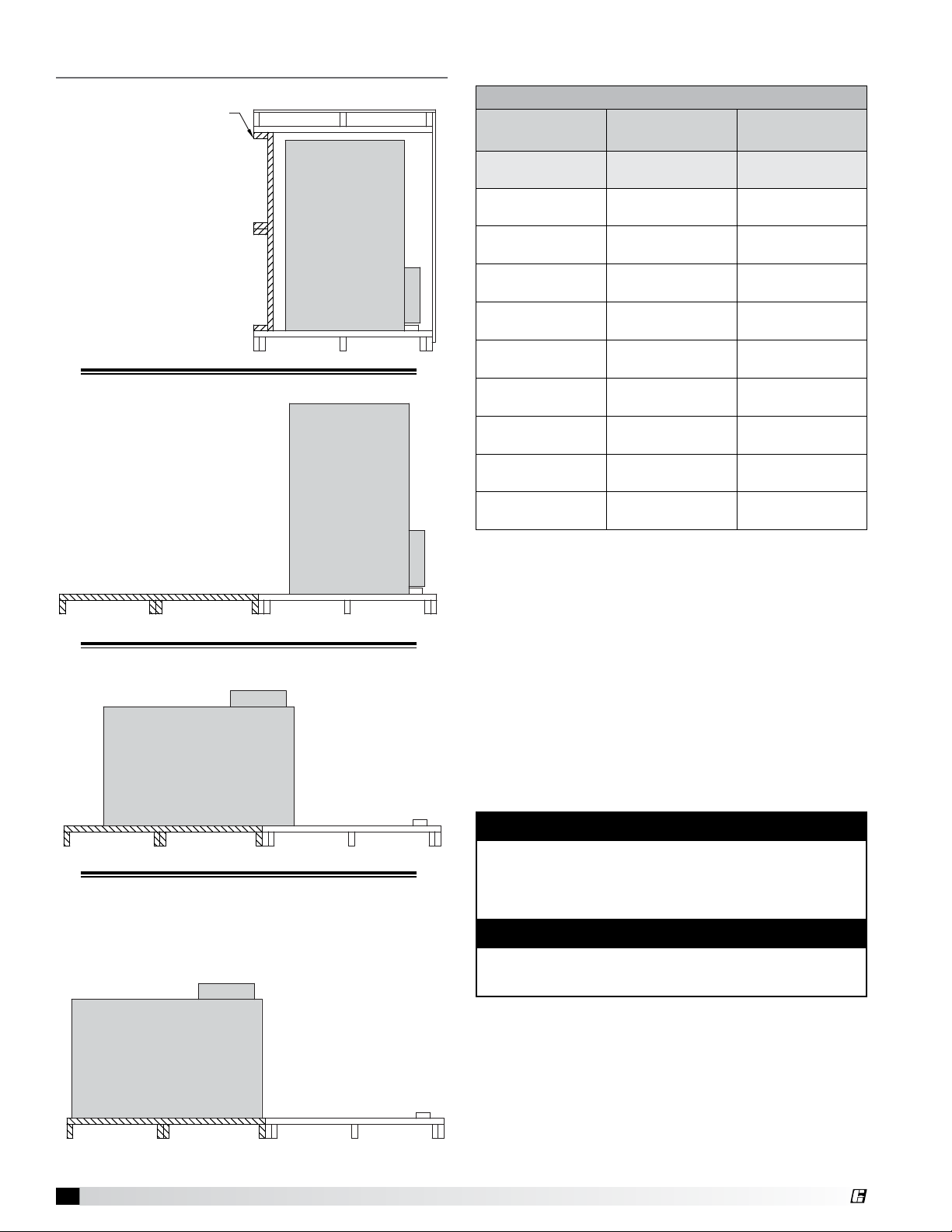

Hood Width and Base Weights

Base Weight

without Water

lbs.

(kg)

440

(199.58)

449

(203.66)

457

(207.29)

465

(210.92)

474

(215.00)

483

(219.09)

491

(222.71)

499

(226.34)

508

(230.43)

Base Weight

with Water

lbs.

(kg)

488

(221.35)

497

(225.44)

505

(229.06)

513

(232.69)

522

(236.78)

531

(240.86)

539

(244.49)

547

(248.12)

556

(252.20)

Profile of Hood

Profile of Hood

Carefully slide the

hood onto the lifting

skid. The lifting skid

should be used to lift

the hood into its final

position. If the lifting

skid is not used,

the hood will be

damaged during the

installation process.

Profile of Hood

Carefully rotate

the hood as

shown.

Base weight is based on 48 inches (121.92 cm) hood

length. For each additional foot of hood in length, add

55 lb/ft (24.95 kg/m) in weight of hood and 67lb/ft

(30.39 kg/m) in weight of hood filled with water.

Example of a 10 foot hood:

Dry: 48 inch width x 120 inch length

= 440 lbs. + (6 ft. x 55 lb/ft)

= 440 lbs. + 330 lbs.

= 770 lbs.

With Water: 48 inch width x 120 inch length

= 488 lbs. + (6 ft. x 67 lb/ft)

= 488 lbs. + 402 lbs.

= 890 lbs.

DANGER

The maximum weight (weight with water) should be

used for the maximum weight of the hood to ensure

the ceiling structure can support the weight of the

hood when filled with water.

CAUTION

To ensure proper structural support, all hanger

brackets must be used for hanging the hood.

Model GGH2O

6

®

Page 7

Installation Overview

Filler Panels

1. Unpack the hood and lay it on the lifting skid.

2. Bolt the filler panels together with 5/16 in. bolts

provided in the hardware package.

3. Position the filler panels to the hood back, and

tack-weld them into place.

4. To allow for ease of cleaning, caulk the external

seams with NSF Approved silicone caulk

(GESCS1000, or its equivalent). The caulk is not

provided.

Hood

Hood

Hood

NOTE

If you have a Back Supply Plenum (BSP), this must

be installed before the hood. Refer to page 11 for

instructions on installing the BSP.

NOTE

All hanger brackets must be used and the hood

must be properly supported while lifting to prevent

damage or distortion to the hood. The hood must be

hung level to operate properly.

After the hood is secured, make the exhaust duct

connections. The fire system distributor must be

contacted at this time. After the fire system has been

installed, mount the enclosures, then the supply

plenums. If an Horizontal Supply Plenum is provided,

it should be installed before the enclosures. The hood

and accessories are now installed.

Finally, make the electrical connections from the

controls to the fans and complete the fire system

circuits as required by the job specification (job

specific wiring diagram located inside the cabinet

cover).

Tack-welded to

hood back

5/16 inch x 3/4 inch bolts

with washers and nuts

Bottom Filler Panel

Right Filler Panel

®

Model GGH2O

7

Page 8

Hood

Bolt

Caulk

U-Clip

Acorn Nut

H

oo

d

F

ro

nt

F

ro

nt

Hood Hanging Height

Ho

o

d

-

1

B

Ho

o

d

-

1A

Ho

o

d

Fro

n

t

The hood hanging height is critical. Hanging the hood

at the incorrect height may significantly reduce the

ability for the hood to function properly and may be in

violation of codes. The hood hanging height (typically,

78 in. (198.12 cm) above the finished floor) is given on

the UL label located on the inside of the hood on the

end panel. The hood must be hung level to operate

properly.

NOTE

Before hanging the hoods, please verify the hood

marks to make sure the correct hood is hung on the

correct side.

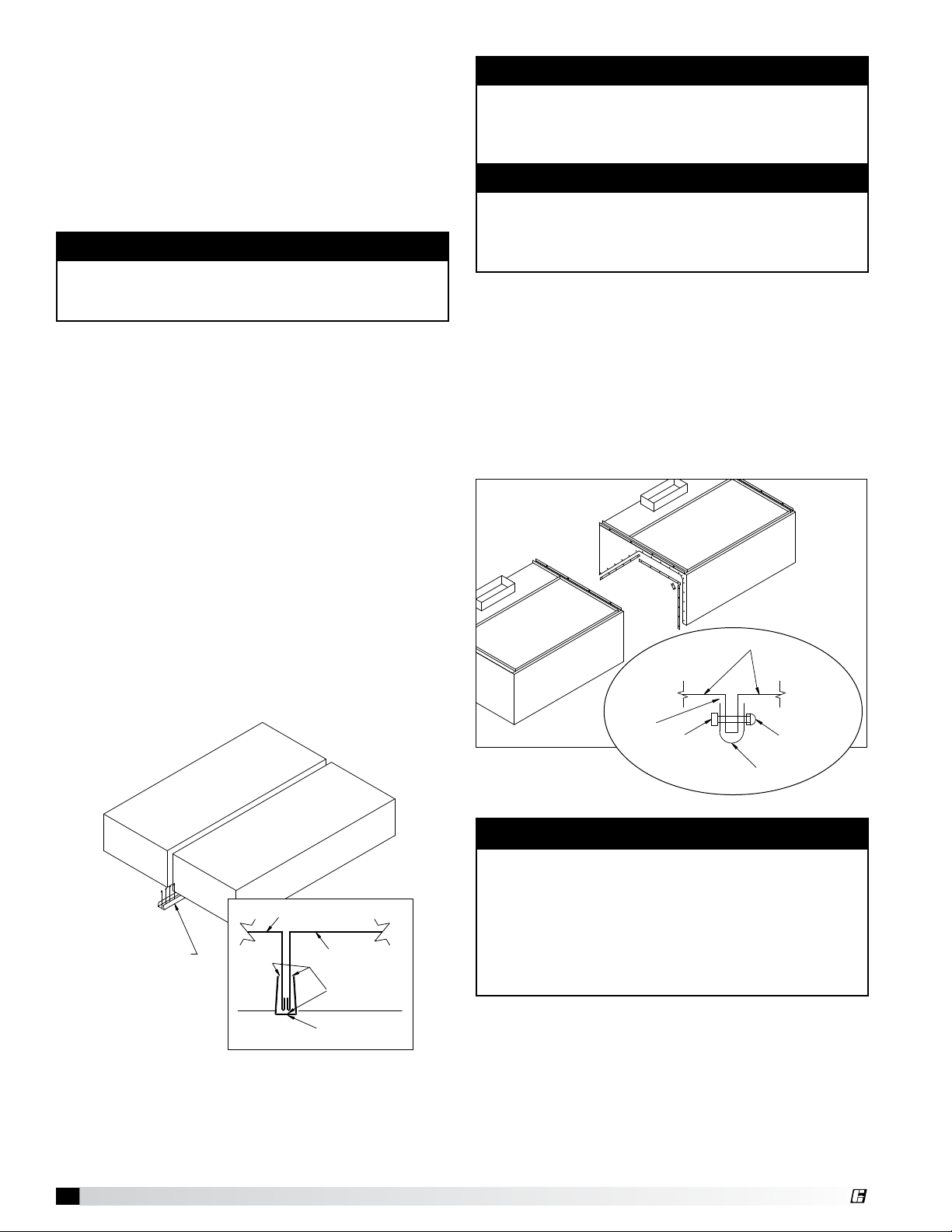

Double Island Style Hoods

A double island hood is created by installing two

wall style hoods back to back. Use the installation

procedure for single island hoods; install and level

both hoods. After leveling, secure the hoods together

by tack-welding and/or bolting the rear mounting

brackets. Caulk this joint with NSF Approved silicone

caulk (GE SCS1000 or its equivalent). The caulk is not

provided.

NOTE

The installation of the canopy hoods shall be

in accordance with NFPA 96 (latest edition),

Standard for Ventilation Control & Fire Protection of

Commercial Cooking Operations.

NOTE

Greenheck does not recommend walking or

standing on the hood top as damage can result. If

you must walk on the hood top, protect the hood

with additional support or planks for flooring.

Continuous Capture Plenum Hoods

Remove the support angles on the open end panels.

Use the installation procedure described for single

island hoods; install and level both hoods. After

leveling, secure the hoods together by tack-welding

and/or bolting the top angles. Fasten the hoods

together using u-clips and bolts. Caulk this joint with

NSF Approved silicone caulk (GE SCS1000 or its

equivalent). The caulk is not provided.

Installing U-Channel Strip

1. After the hood is hung in position and leveled,

apply caulk to the inside edge of the double island

clip.

2. Position and install the clip by tapping into

position along clip (friction fit).

3. Caulk edges to seal out grease and allow for ease

of cleaning. Caulk with NSF Approved silicone

caulk, GE SCS1000, or its equivalent. The caulk is

not provided.

B

1

-

d

o

Ho

1A

-

d

o

Double Island Clip

Ho

Ho

Hood-1A

Fro

d

o

t

n

Hood-1B

Silicone Caulk

nt

ro

F

d

oo

H

nt

ro

F

d

oo

H

Hood

NOTE

• For multiple hood systems that have more than

14 lights total (incandescent or fluorescent), the

hood lights must be wired to multiple circuits.

Each circuit must have less than 14 lights total.

• Light bulbs are not provided. Standard light bulbs

up to 100 watts may be used.

Model GGH2O

8

Double Island Clip

®

Page 9

Ductwork

Hood

UTILITY

CABINET

TOP VIEW

HOOD

TOP VIEW

SUPPLY PLENUM

END VIEW

Option #2

Uni-Strut supplied by others

Option #3

Threaded Rod

supplied by others

Threaded Rod

Option #2

The uni-strut (U channel) that holds the hood up,

cantilevers over the end of the hood and is

mounted to the Air Curtain Supply Plenum (ASP)

hanger brackets

Option #1

For plenums < than or = 96 inches

Two (2) clips are needed.

For plenums > than 96 inches

Three (3) clips are needed.

The third clip is located in the

center of the plenum length.

Option #1

Attach hanging clip to hood

standing seam with the

supplied ‘C’ clamps.

Optional: Drill and bolt a

1/4-20 SS bolt through the

clip and hood standing seam

Option #1

Hanging clip could be 23.5 inches from end if there is a utility cabinet on the

end of the hood.

Hanger Bracket

Hanging methods for supply plenums

ASP: Air Curtain Supply Plenum

FSP: Face Supply Plenum

VSP: Variable Supply Plenum

Option #1: Hanging Clip

Option #2: Uni-Strut

Option #3: Threaded Rod

11.5

23.5

Exhaust

As specified in NFPA 96, Ch. 7.5 (latest edition),

exhaust duct systems must be constructed in the

following manner:

Materials: Ducts shall be constructed of and

supported by carbon steel not less than 1.37 mm

(0.054 in.) (No. 16 MSG) in thickness or stainless steel

not less than 1.09 mm (0.043 in.) (No. 18 MSG)

in thickness.

Installation: All seams, joints, penetrations, and duct

to hood collar connections shall have a liquid-tight

external weld. If you have an Automatic Fire Damper

please refer to that manual for installation instructions

now.

Supply

Supply ductwork (where applicable) should be

connected to the hood in a manner approved by the

local code authorities.

For proper installation of duct collars when they are

shipped unattached see Installing Duct Collars on

page10.

Installing External Supply Plenums

Option #2

Uni-Strut supplied by others

TOP VIEW

HOOD

Option #1

For plenums < than or = 96 inches

Two (2) clips are needed.

For plenums > than 96 inches

UTILITY

CABINET

11.5

23.5

Three (3) clips are needed.

The third clip is located in the

center of the plenum length.

Option #1

Attach hanging clip to hood

standing seam with the

supplied ‘C’ clamps.

Optional: Drill and bolt a

1/4-20 SS bolt through the

clip and hood standing seam

TOP VIEW

SUPPLY PLENUM

Hanger Bracket

NOTE

For hoods with fire dampers in the exhaust and

supply duct collars, an access panel for cleaning

and inspection shall be provided in the duct. This

panel shall be as close to the hood as possible but

should not exceed 18 in. (45.72 cm).

Option #1

Hanging clip could be 23.5 inches from end if there is a utility cabinet on the

end of the hood.

Using the Supply Plenum Clip - Option #1

1. Bolt the hanging clip to the supply plenum. Two

clips are needed for plenums less than 96 in.

(243.84 cm) long and three for plenums greater

than 96 in. (243.84 cm). The

third clip is located in the

center of the plenum length.

If there is a utility cabinet,

the hanging clip should be

23.5 in. (59.69 cm) from the

end to the hood.

2. Using the c-clamps provided, clamp the supply

plenum hanging clip to the hood standing seam.

Option: Drill and bolt a 1/4-20 SS bolt through the

clip and hood standing seam.

Option #1 : Hanging Clip

‘C’ Clamp

HOOD FRONT

Hood Standing Seam

SUPPLY PLENUM SHELL

NOTE

The supply plenum is provided with plenum clips

that assist in hanging the plenum. The plenum

should not be hung only with the plenum clips;

threaded rod or uni-strut must also be used.

Supply Plenum Clip

Hanging Clip bolted to plenum shell

Hanging Clip

®

Model GGH2O

9

Page 10

Using the Uni-Strut - Option #2

BACKSUPPLY BACKSHELF HOODBACKSUPPLY CANOPY STYLE HOODBACKSUPPLY CANOPY STYLE HOOD

ATTACHED AIR CURTAIN CANOPY STYLE HOOD ATTACHED AIR CURTAIN CANOPY STYLE HOOD

BACKSUPPLY BACKSHELF HOODBACKSUPPLY CANOPY STYLE HOODBACKSUPPLY CANOPY STYLE HOOD

UTILITY

CABINET

TOP VIEW

HOOD

Option #2

Uni-Strut supplied by others

Option #1

For plenums < than or = 96 inches

Two (2) clips are needed.

For plenums > than 96 inches

Three (3) clips are needed.

The third clip is located in the

center of the plenum length.

Option #1

Attach hanging clip to hood

standing seam with the

supplied ‘C’ clamps.

Optional: Drill and bolt a

1/4-20 SS bolt through the

clip and hood standing seam

11.5

Exhaust Duct

Connection

Exhaust duct connection is to be

a continuous liquid-tight weld to hood.

1. The uni-strut (supplied by others) that holds the

hood up cantilevers over the end of the hood and

is mounted to the supply plenum hanger brackets.

Option #3

Threaded Rod

Threaded Rod

Option #2

The uni-strut (U channel) that holds the hood up,

cantilevers over the end of the hood and is

mounted to the Air Curtain Supply Plenum (ASP)

hanger brackets

END VIEW

Hood

Variable Supply Plenum

(HSP or VSP)

supplied by others

Using the Threaded Rod - Option #3

1. Insert 1/2 in. (12.7 mm) diameter threaded rod (by

others) into hanger brackets on the supply plenum

top. Raise and hang the external supply plenum

from adequate roof or ceiling supports.

2. The external supply plenum should be resting

lightly against the hood. The hood is used to

position the plenum only, it is not intended to

support the plenum. All hanger brackets must be

used and the plenum must be properly supported

while lifting to prevent damage or distortion. The

supply plenum must be hung level to operate

properly.

(Optional fastening of supply plenum to hood. See

directions).

3. It is recommended that caulk be applied at the

mating seams and surfaces of the plenum, the

hood, and the wall. If the supply plenum is next

to a wall, you will also need to caulk around the

surface next to the wall. Caulk the joints with

NSF Approved silicone caulk (GE SCS1000, or its

equivalent). The caulk is not provided.

Installing the Supply Duct Collar to the

Plenum

1. Place the duct collar(s) over the opening, fastening

with tack-welds at 1 to 2 in. (2.54 to 5.08 cm)

intervals, or sheet metal screws at 3 to 6 in.

(7.62to 15.24 cm) intervals.

Supply duct connection to be

tack-welded with 1 to 2 inch

tacks or sheet metal screws

at 3 to 6 inch spacing to hood.

Air Curtain Supply Plenum

(ASP)

External Supply Plenum Weights, Dimensions and Supply Rates

Weight Width Height

External Supply

Plenum Type

(lbs/ft) (kg/ft) (in) (mm) (in) (mm) (ft) (m)

Back Supply 35.0 15.878 6 152.4 Variable Variable 3 to 16

Air Curtain Supply

• 14 inch

Air Curtain Supply

• 24 inch

9.5 4.31 14 355.6 10 254 3 to 16

12.5 5.67 24 609.6 10 254 3 to 16

Variable Supply 16.0 7.26 12 304.8 18 457.20 3 to 16

Horizontal Supply 14.0 6.35 12 304.8 18 457.20 3 to 16

Model GGH2O

10

Length per

section

.91 to

4.88

.91 to

4.88

.91 to

4.88

.91 to

4.88

.91 to

4.88

curtain

face

Supply Duct

Connection

Recommended

Supply Rate

145 cfm/ft

(246.36 m

110 cfm/ft

(186.89 m

145 cfm/ft

(246.36 m

3

3

3

/hr)

/hr)

/hr)

0-80 cfm/ft

(0-135.92 m

80-160 cfm/ft

(135.92 -271.84 m

150 cfm/ft

(254.85 m

3

/hr)

3

/hr)

3

/hr)

®

Page 11

Using the UL Listed Fastener Provided

Hole size 9/32-inch

STEP 2

L (MODULE LENGTH)

L/2

L/4

L/4

STEP 1

(IF MODULE > 6 ft.)

(IF MODULE < 6 ft.)

STEP 1

4 in. TO 6 in.

FASTEN WITH SCREWS, OR TACK WELDS EVERY

PLACE THE DUCT COLLAR OVER THE OPENING,

STEP 2

STEP 1

(IF MODULE > 6 ft.)

4 in. TO 6 in.

FASTEN WITH SCREWS, OR TACK WELDS EVERY

PLACE THE DUCT COLLAR OVER THE OPENING,

STEP 2

1. Drill a 9/32 in. hole for the 1/4 in. bolt from the

inside of the supply plenum to inside the hood.

Fasteners are to be located max. 6 in. (15.24cm)

from the end of the hood with max. spacing

between bolts 36 in. (91.44 cm)

DO NOT iNcluDe uTiliTy cabiNeTs Or fillers wheN

figuriNg bOlT placemeNT.

DO NOT bOlT The supply pleNum TO a fire/uTiliTy

cabiNeT.

2. Push bolt through hole, attach the washer and nut.

3. Hand tighten; then use a wrench until fully

tightened. Caulk around bolts from inside of hood

as necessary.

Hood

1/4 - 20 UNC - 2A

SS Bolt

1/4 inch SS Nut

3. If the back supply plenum is greater than 9 ft.

10 in. (299.72 cm) long, divide the length of the

back supply by four. This will give you the center

of each half. Cut openings at the suggested

location, centering the duct collar over the center

measurement of each half.

L/4

L (MODULE LENGTH)

L/2

L/4

SS Flat Washer

Installing the Back Supply Plenum

Installing the Supply Duct Collar

1. Find the center of the back supply plenum.

2. If the back supply plenum is less than 9 ft. 10 in.

(299.72 cm) long, cut opening at the suggested

location, centering the opening over the center of

the back supply plenum.

L (MODULE LENGTH)

L/2

L/2

4. Place the duct collar(s) over the opening, fastening

with screws or tack-welds every 4 to 6 in. (10.16 to

15.24 cm).

The 4 in. (10.16 cm)

high duct collar is to

be attached to the

back supply.

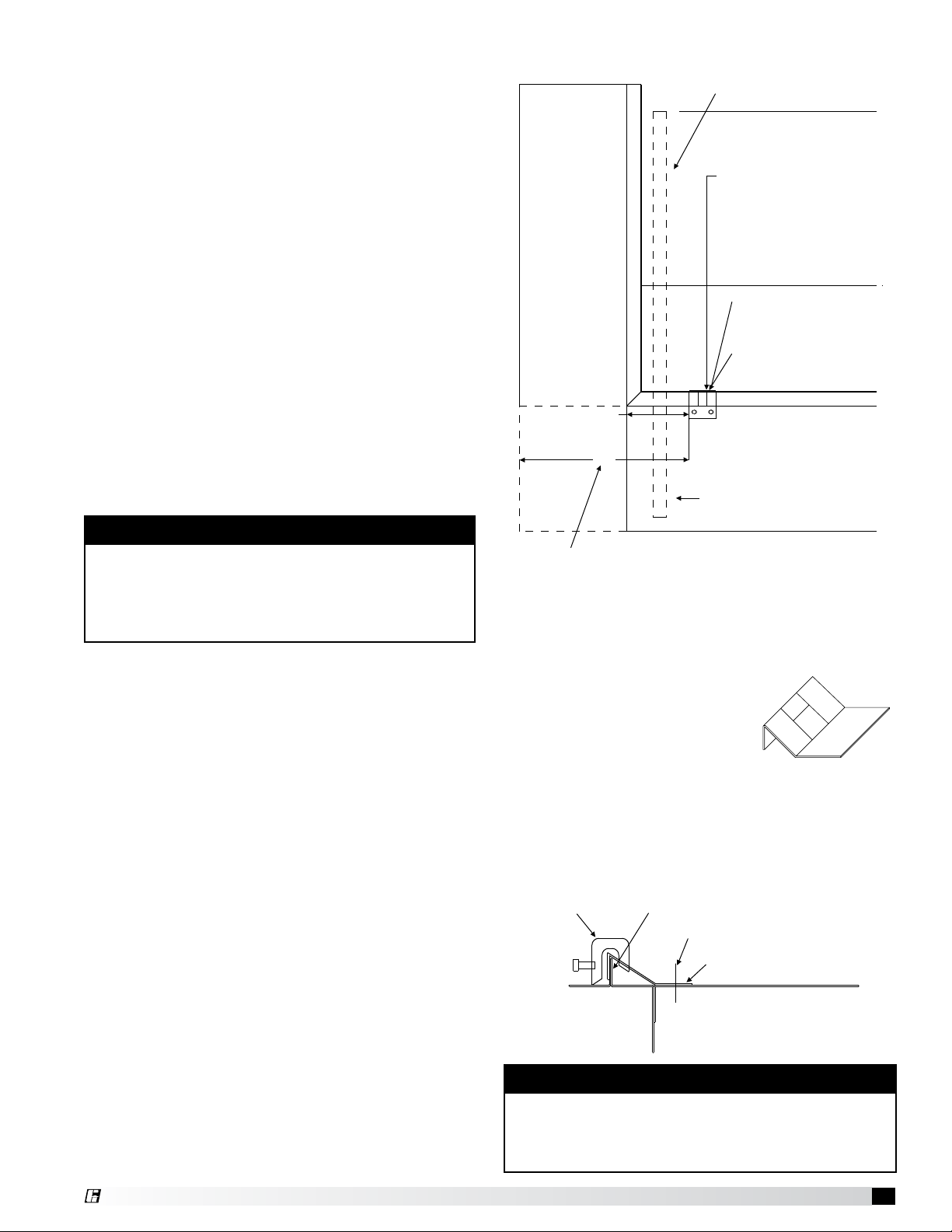

Hanging the Back Supply Plenum

5. Hang the back supply plenum from the ceiling.

The back supply plenum needs to be mounted

31.25 in. (79.375 cm) above the floor (based

upon a canopy hood that will be hung at 78in.

(198.12cm) above the finished floor. This is

measured from the lowest rear edge of the back

supply plenum to the finished floor. Leave 6 to

10inches (15.24 to 25.4 cm) of space below the

plenum for access to the air diffusers.

®

Model GGH2O

11

Page 12

6. Fasten the back supply to the wall, going through

STEP 3

Furnished by Others

0.500 in. Threaded &

0.500 in. Threaded Nuts

(Furnished by Others)

Hanger Bracket Detail

1) Hang Backsupply Modules from the

ceiling (the example shows the module

being supported with threaded rod)

The backsupply is to be 31.25 in. from the

floor. This is measured from the lowest

rear edge of the backsupply module to the

finished floor.

2) Fasten backsupply to wall through the

lower backsupply wall. These fasteners

are to help maintain location of the

backsupply, and are NOT intended to hold

any weight of the unit. Fasteners should

not interfere with the removable air diffuser.

31.25 in.

Critical

Dimension

Fasteners holding the

back supply to the wall

HANG THE HOOD

CANOPY STYLE HOOD

4. LIFT THE HOOD; POSITION IT SO THE TOP OF THE

HOOD IS LEVEL WITH THE TOP OF THE BACKSUPPLY; AFTER

THE HOOD IS HUNG FROM THE CEILING AS PER IT'S INSTALLATION

1. THE HOOD IS TO BE HUNG AS PER THE HOODS INSTALLATION

SHOULD BE CONNECTED BEFORE THE HOOD IS HUNG.

3. DUCTWORK FOR THE BACKSUPPLY; IF IT WILL NOT INTERFERE,

2. BEFORE THE HOOD IS HUNG THE BACKSUPPLY MUST BE SECURED

INSTRUCTIONS AND THE FOLLOWING.

PROPERLY, AS DESCRIBED IN "STEP 3 in.

STEP 4

Step 5 / Air Diffusers

a. Insert the air diffusers at an angle from the bottom.

b. Rotate the diffusers so teh forms are downward.

c. Rest the diffuser on the internal angles.

Step 5 / Air Diffusers

a. Insert the air diffusers at an angle from the bottom.

b. Rotate the diffusers so teh forms are downward.

c. Rest the diffuser on the internal angles.

the lower back supply wall.

• These fasteners are to help maintain the location

of the Back Supply, and are not intended to hold

the weight of the back supply unit.

• The fasteners should not interfere with the

removable air diffusers.

• The 31.25 in. (79.375 cm) height is based upon

the canopy hood hanging height of 78 in.

(198.12 cm)

5. Connect the remaining ductwork for the back

supply and the hood. It is recommended that

caulk be applied at the mating seams and

surfaces of the back supply, the hood, and the

wall.

Air Diffusers

The air diffusers, located at the bottom of the back

supply, will need to be cleaned as often as the

application dictates. Inspect periodically to determine

the cleaning schedule.

1. To clean the air diffusers, unfasten the screws.

Remove the air diffusers from the back supply

unit, and wash in the sink or dishwasher.

2. Insert the air diffusers at an angle from the bottom,

and rotate so the forms are downward. Rest the

diffuser on the internal angles.

3. Refasten with the stainless steel screws.

Hanging the Hood

Before hanging the hood according to the hood

installation instructions, please check the following:

1. Make sure the back supply plenum is properly

secured, as described in steps 5 and 6.

2. If the ductwork for the back supply plenum will not

interfere with the hood installation, it should be

connected now.

3. Any filler panels should be attached to the hood

before the hood installation.

4. Lift the hood, and position it so the filler panels

are resting lightly on the top outside edges of the

back supply. The back supply is used to position

the hood only. It is not intended to hold any hood

weight.

Model GGH2O

12

Removable Air Diffusers

®

Page 13

Installing Enclosure Panels

Before installing the enclosure panels, make sure

the hood is hung in position with all the ductwork

attached, electrical connections and fire system

connections completed.

1. Position the end enclosure panels on the hood,

and clamp into place with clamps provided or

tack-weld the panels into place.

2. Fasten the end enclosure panels to the wall,

method depends on wall construction. (Fasteners

are not provided).

If the hood is a double island, bolt the end

enclosure panels together. (Fasteners are not

provided).

3. Position the front enclosure panel(s) on the hood,

and bolt to the end enclosure panels with the

5/16in. bolts provided in the hardware package.

4. Tack-weld or clamp the front enclosure panel(s)

to the hood. If clamps are used, they must be

positioned 4 in. (100 mm) from the ends, and in the

center of the front enclosure panel.

5. To allow for ease of cleaning, caulk the external

seams with NSF Approved silicone caulk

(GESCS1000, or its equivalent). The caulk is not

provided.

Note: Installation instructions may not be applicable

for concrete ceilings.

Bolt panels together with 5/16-inch bolts.

Supplied by mfg.

Installing End Skirts

1. After the hood is hung in position, slide the

hemmed form on top of the end skirt onto the end

panels of the hood.

2. Drill a hole in the hood end panel to line up with

the hole in the end skirt. Attach the end skirt with

a 1/4 in. bolt and cap nut to the inside of the hood,

or tack-weld the end skirt to the hood.

3. Position the end skirt against the wall and attach.

The method depends on the wall construction.

(Fasteners for this are not provided).

4. Caulk the internal joint formed by the end skirt and

the hood end panel with NSF Approved silicone

caulk (GE SCS1000 or its equivalent). The caulk is

not provided.

5. To allow for ease in cleaning, also caulk all the

external seams.

H

OOD FR

O

NT P

ANE

L

Exploded

view

below

Full End Skirt

End Enclosure

Panel

Attach to wall.

Fasteners by others

H

Clamp panels to hood standing seam with hardware.

Supplied by mfg.

Front Enclosure Panel

H

OO

D

T

O

P

OOD

BA

C

K

End Enclosure

Panel

Attach to wall

Fasteners by others

Exploded View

Hemmed Edge

Holes drilled by installer

1/4-inch bolt and cap nut

Supplied by mfg.

®

Model GGH2O

13

Page 14

Installing Backsplash Panels

Wall

Heigth

Length

Flat backsplash panel

Material gauge – Stainless

Wall

Length

Heigth

1. After the hood is hung in position, slide the flat

flange of the backsplash panel behind the back of

the hood.

Note: If the backsplash panel length is greater

than 45 in. (114.3 cm), it will be shipped in multiple

pieces.

2. After the backsplash panel has been positioned,

drill holes in the panel and fasten to the wall.

(Fasteners provided by others).

Note: The holes should be spaced to adequately

secure the panel to the wall.

3. Caulk the joints between the hood and the

backsplash panel with NSF Approved silicone

caulk (GE SCS1000, or its equivalent). The caulk is

not provided.

4. Caulk the joint between the backsplash panels

when multiple panels are required, with NSF

Approved silicone caulk (GE SCS1000, or its

equivalent). The caulk is not provided.

NOTE

Panels up to 47 inches (119.4 cm) wide ship in one

piece. Over 47 inches (119.4 cm) in multiple pieces.

Insulated backsplash panel

Material gauge – Stainless

Insulation – 1 inch (25.4 mm)

1 inch (25.4 mm)

Wall

Height

Hood End Panel

Backsplash Panel

Hood Front Panel

Slide flange

behind back

of the hood.

Section view of

backsplash panel

overlap

Length

NOTE

Panels up to 45 inches (114.3 cm) wide ship in one

piece. Over 45 inches (114.3 cm) in multiple pieces.

Model GGH2O

14

Holes should be spaced

to adequately secure the

panel to the wall studs.

(Hole spacing and fasteners

provided by others).

®

Page 15

Exhaust Duct

Connection

Exhaust duct connection is to be

a continuous liquid-tight weld to hood.

Supply Duct

Connection

Supply duct connection to be

tack-welded with 1 to 2 inch

tacks or sheet metal screws

at 3 to 6 inch spacing to hood.

Installing Duct Collar

Overview of exhaust and supply plenum locations

TOP VIEW

Hanger Bracket

3.0

8.0

BACK VIEW

8.0

1.0

12.0

Dimensions are shown in inches.

Exhaust Plenum

Duct cut out area

Front of Hood

Hood Length

Top of Hood

Exhaust Plenum

Duct cut out area

14.0

Hood

Width

3.0

8.0

8.0

1. The exhaust duct connection needs to be located

within 48 in. (121.92 cm) from the center of the

hood length to the center of the duct connection.

2. The exhaust duct connection is to be a continuous

liquid-tight weld. Weld with a non-ferrous filler

wire, such as silicon bronze or stainless steel filler

wire. Protect all stainless steel areas from weld

splatter.

®

Model GGH2O

15

Page 16

Plumbing

Plumbing Connections

Once the hood is hung, the recirculation pump and

detergent tank (both shipped loose) must be installed

in the controls cabinet.

Pump Installation

• Remove bolts from pump mounting plate in cabinet.

• Place the pump on the isolators located on the

mounting plate with the bolts removed.

• Secure the pump to the mounting plate with the four

previously removed bolts.

• Wire pump motor to the control cabinet per wiring

diagram on the cabinet.

• The wires to power the motor are already connected

to the pump motor. It only needs to be wired to the

control cabinet.

Position pump on

(4) isolators and attach

using provided nuts.

Connect to control

cabinet per

Wiring Diagram

in panel

Field

1-inch female NPT

Connect to drain

connect

1-inch

unions

A

E

D

C

A. One-inch unions

B. Detergent tank

C. Mounting plate

D. Isolators (qty of four)

E. Detergent pump

1. Connect the inlet and outlet piping on the

recirculation pump to the respective piping in the

cabinet via the threaded 1 in. unions.

2. Bring the inlet water piping to the connection

located on the top of the hood and connect to the

threaded connection on the 3/4 in. solenoid valve.

A ball valve needs to be placed in the connection

line before the 3/4 in. solenoid valve. Depending

on water pressure, the inlet valve might need to

be closed slightly to reduce water pressure. Water

temperature should be 140°F.

A

B

Inlet Solenoid

Connection

3. Bring the drain piping connection to the 1 in.

solenoid valve in the control cabinet and connect

to the threaded connection. This is a pressurized

drain system and needs a properly sized drain to

accommodate the pressurized drain water.

NOTE

As the suggested detergent is non-caustic and

biodegradable, waste water from the hood can be

drained in any typical grease trap.

Model GGH2O

16

®

Page 17

Detergent Tank Installation

The detergent tank is located as shown in the photo.

When installing the detergent tank, the low detergent

indicator float and the detergent pump inlet tubing will

need to be lifted. Once the tank is in position, the low

detergent indicator float and detergent inlet tube must

be lowered into place inside the tank.

A. One-inch unions

B. Detergent tank

C. Mounting plate

D. Isolators (qty of four)

E. Detergent pump

Detergent Requirements

The detergent brand Formula G-510 (by 2010

Products, Inc.) is recommended by Greenheck for use

in the wash system. Use Formula G-510 full strength.

This product is biodegradable, non-caustic, and safe

for kitchen staff to use. If G-510 detergent is not

used, the cleanliness of the exhaust plenum and filters

cannot be guaranteed.

Preventative Maintenance

The following practices will prolong the life of the

detergent pump:

• Keep detergent tank filled.

• Avoid spilling detergent on the exterior of the

pump.

• Clean the detergent tank at least every six

months.

• Clean the detergent line strainer at least every six

months.

• Check tightness of all fittings periodically.

The detergent pump motor has sealed bearings which

do not require lubrication.

Electrical

Electrical Wiring

All wiring must be done according to NEC (National

Electrical Code NFPA #70) and local building codes.

Two sources of power need to be brought into

the electrical control cabinet. A 120 volt, 30 amp

service with 12 gauge wire needs to be connected

to terminals L1 on the disconnect switch and N. A

120volt, 15 amp service with 14 gauge wire needs to

be brought into the electrical cabinet and connected

to terminal L2 on the disconnect switch and N1.

NOTE

The wash control station will provide a dry contact

for a fan starter so the fans can be controlled by the

PLC. The fan starter is not provided with the wash

control station.

The main recirculating pump needs to be wired after it

is installed in the hood. There are three 12 gauge wires

in flexible conduit wired to the pump. Wiring to the

pump is complete from the factory. The whip from the

pump needs to be wired into the control cabinet.

NOTE

G-510 is manufactured by 2010 Products, Inc., Food

Service Division, Salem, Oregon 97303. For details

and ordering information, call 800-286-2010.

®

Model GGH2O

17

Page 18

Timer Programming –

24 Hour / 7 Day

Setting the Clock

1. Press and hold the CLOCK button.

2. Press and hold the DAY button until the display

shows the current day.

3. Press the HOUR button until the display shows the

current hour.

4. Press the MIN (minute) button until the display

shows the current minute.

Setting the Programs

1. Press the PROG (program) button once. You will

now set the time in which you want the wash to

start. The number 1 in the lower left hand corner

indicates that you are now programming Event 1.

2. Press the DAY button repeatedly until the display

shows the day(s) when you want the timer to turn

on. The options are:

- Days of the week

MO, TU, WE, TH, FR, SA, SU

- Individual days of the week

MO etc.

- Weekdays only

MO, TU, WE, TH, FR

- Weekends only

SA, SU

3. Press the HOUR and MIN (minute) buttons to set

the time when you want the timer to turn on.

4. Press the PROG (program) button again.

5. Repeat steps 2-4 to set the OFF time for Event 1.

This should be set one minute after the ON time.

6. When programming is complete, press the CLOCK

button to display the current time.

Things you should know about programming events:

•

You can repeat the ON and OFF programming

procedures outlined above for up to seven (7)

events as needed.

NOTE

While setting events, the timer may prematurely turn

on the load, if you press the MODE button.

• Three kinds of settings can cause the timer to

work in an unexpected way:

a. Set up events in progressive order of time, for

example:

8:00 pm ON, 9:00 pm ON, 10:00 pm ON

Not 8:00 pm ON, 10:00 pm ON, 9:00 pm ON

b. Do not overlap event times, for example:

8:00 pm ON / 12:00 pm OFF and

9:00 pm ON / 11:00 pm OFF

c. Set the OFF time for one minute after the ON

time.

Reviewing Events Programmed

In your current time display, press the PROG (program)

button repeatedly to check your settings.

When finished, press the CLOCK button to return the

display to the time of day.

Clearing (Deleting an Event)

1. Press the PROG (program) button as many times

as necessary to locate the setting you want to

clear.

2. Press and hold the MODE button.

3. Press the PROG button to clear the setting.

4. When finished, press the CLOCK button to return

the display to the time of day.

Operating the Time Switch

Press the MODE button repeatedly to set the timer to

Automatic, Random or Manual mode.

NOTE

For the time switch to run programmed events, it

must be set to AUTO mode.

• AUTO runs all events automatically according to the

schedule you have set. The word AUTO appears in

the display.

• RND (random) runs all events in a RANDOM mode.

This is a security feature in which ON and OFF

times randomly differ +/- 15 minutes from the

programmed times, creating a more “lived-in” look.

The word RND appears on the display.

NOTE

Do NOT set this timer to RND mode. It will not wash

at the exact time you programmed.

• MANUAL turns ON and OFF only when the user

presses the ON or OFF button. The display is blank,

showing neither RND or AUTO.

Overriding Timer Settings

The ON or OFF buttons override the current

programmed events. To override the current program

(either ON or OFF), press the ON or OFF button.

Model GGH2O

18

®

Page 19

Initial System Start-Up

1. Check electrical power (see wiring diagram)

• Correct supply voltage

• Proper connections to fire

suppression system

2. Check to make sure the

disconnect switch on the

electrical control cabinet is

switched to the “ON” position.

3. Prime the recirculation pump. Remove the plug on

top of pump and use a funnel to add water to the

pump. This only needs to be done one time prior to

initial start-up.

4. Add detergent to the detergent tank in the cabinet.

5. Clean the control cabinet of any debris that may

have entered the cabinet during installation.

6. Close the cabinet doors and press the Fan On/Off

button.

7. Check the exhaust and supply air volumes.

8. Press the Fan On/Off button to turn the fans off.

9. Press the Clean Hood button.

When the hood is filling, check to ensure water is not

leaking through the edges of the access doors. If so,

the inlet water pressure is too high. Slowly close ball

valve located before the inlet solenoid on the hood top

until no water leaks pasT the access doors.

After the hood fills with water and starts washing the

primary filters, open water valve slowly until water

mist is felt above equipment. Then slowly close valve

until water mist is no longer felt above equipment.

Once the valve is set it will not need to be moved

again.

Verify the Grease Grabber H2O sequence of operation

(see the diagram of wash sequence on page 20)

during the detergent pump cycle.

Daily Operation of the GGH2O Hood

Pressing the FAN ON/OFF button will start/stop the

exhaust and supply fans if interlocked.

Pressing the HOOD LIGHTS button will turn on/off the

hood lights.

Initiating the wash cycle:

The Grease Grabber H2O has an automatic timer

that can be set to control the wash schedule and

automatically start the cycle. See Timer Programming

on page 18.

To initiate the wash cycle manually, press the CLEAN

HOOD button on the keypad. If you press this button

while the fans are running, the system will stop the

fans and then start the wash cycle. When the wash is

completed, the system will automatically reset itself.

If the fans are controlled by a building management

system (BMS), the steps above still apply unless a

special program is requested to bypass having to

initiate the wash cycle by pushing the FAN ON/OFF

and CLEAN HOOD buttons.

Refer to the Grease Grabber™ H

on page 27 for detailed instructions on start-up

operations.

O Hood checklist

2

C

E

D

A

B

Interior of Cabinet

A. Recirculating pump

B. Detergent tank

C. Water valve to adjust front primary filter nozzles

D. Pump plug for priming

E. Detergent pump

®

Model GGH2O

19

Page 20

SEQUENCE OF OPERATION - GREASE GRABBER H2O

Shut OFF exhaust fan(s)

Turn ON exhaust fan(s)

Turn OFF exhaust fan(s)

Stage 1:

Fill hood tank (hot water)

Stage 2:

Wash primary filters

Detergent pump ON

Stage 3:

Wash secondary filters

Detergent pump ON

Stage 5:

Wash secondary filters

Detergent pump OFF

Stage 6:

Drain soapy/dirty water

Stage 10:

Drain rinse water

Stage 4:

Wash primary filters

Detergent pump OFF

2 minute delay for

water settling

Spray for 5 minutes

Spray for 5 minutes

NORMAL FAN OPERATION

Hot Water Recovery:

(0 min.) Adjustable

Spray for 5 minutes

Spray for 5 minutes

Stage 7:

Fill hood tank (hot water)

Stage 8:

Rinse primary filters

Detergent pump OFF

Stage 9:

Rinse secondary filters

Detergent pump OFF

Spray for 5 minutes

Spray for 5 minutes

20 minute dry time

Wash, rinse & dry complete

Sequence of Operation - Grease Grabber™ H2O

WASH

Hot Water Recovery:

(0 min.) Adjustable

Shut OFF exhaust fan(s)

Stage 1:

Fill hood tank (hot water)

Stage 2:

Wash primary filters

Detergent pump ON

Spray for 5 minutes

Stage 3:

Wash secondary filters

Detergent pump ON

Spray for 5 minutes

2 minute delay for

water settling

Stage 4:

Wash primary filters

Detergent pump OFF

Spray for 5 minutes

Stage 5:

Wash secondary filters

Detergent pump OFF

RINSE DRY

Stage 7:

Fill hood tank (hot water)

Stage 8:

Rinse primary filters

Detergent pump OFF

Spray for 5 minutes

Stage 9:

Rinse secondary filters

Detergent pump OFF

Spray for 5 minutes

Stage 10:

Drain rinse water

Turn ON exhaust fan(s)

20 minute dry time

Turn OFF exhaust fan(s)

Wash, rinse & dry complete

Spray for 5 minutes

Stage 6:

Drain soapy/dirty water

Normal Fan Operation

START FAN Fan(s) OFF

Fan(s) will run

No

FIRE

Yes

Exhaust

Fan(s) remain

ON

START FAN

Fan(s) will run

No

FIRE

Yes

Exhaust

Fan(s) will

turn OFF

Temperature Interlock Exhaust Mode in Fire -- STOP Exhaust Mode in Fire -- RUN

Exhaust Fan(s)

Temperature

> 95°F.

(Adjustable)

will turn ON

Model GGH2O

20

®

Page 21

Airflow Testing Procedure

After the appropriate number of readings have been

taken from the inlet slot of the hood, an average

reading can be calculated by summing the velocity

readings and dividing the total value by the number of

readings taken.

Short Ridge Meter Components

For measuring exhaust airflow rates (cubic feet per

minute = CFM), use a short ridge meter to measure

velocities along the inlet slot of the hood. To ensure

accurate data, all appliances should be on. Multiple

locations need to be tested as outlined below to

ensure an accurate reading.

Average Velocity =

Sum of Velocity Readings

Number of Readings

Next calculate the total hood airflow volume (CFM) by

using the following equation:

Hood CFM = [(Length of Hood in inches x 4.846) x

(Average inlet slot velocity x 2.47)] 144

NOTE

The constants 4.846 and 2.47 are factory derived for

use with the Grease Grabber™ H2O.

Calculation Example:

Five (5) inlet slot velocity readings (minimum)

Hood Length 96 inches

Test Location

(off left; in inches)

Velocity Reading (fpm) 175 210 250 190 160

Average Velocity (FPM) =

(175 + 210 + 250 + 190 + 160) 5 = 197 FPM

6 27 48 69 90

Hood Length

Minimum Number

of Test Locations

48 to 72

inches

3 5 7

72 to 120

inches

120 to 192

inches

To take velocity readings along the length of the hood,

the edge of the short ridge meter must start/stop six

(6) inches from the end of the hood. Vertical placement

of the short ridge meter along the inlet is shown.

Hood Exhaust Rate (CFM) =

[(96 x 4.846) x (197 x 2.47)] 144 = 1572 CFM

®

Model GGH2O

21

Page 22

Amerex® Wiring Plan View

PRM

MICROSWITCH

INSTALLER PROVIDED JUNCTION BOXES

BASIC WIRING DIAGRAM

RED (COMMON)

YELLOW (N.O)

POWER SOURCE

POWER SOURCE

BLACK (N.C.)

MANUAL RESET RELAY

ELECTRIC GAS VALVE

MANUAL RESET RELAY

MICROSWITCH

NOTE: DO NOT USE YELLOW WIRE ON MICROSWITCH IN NORMAL

INSTALLATION. THE YELLOW WIRE IS TO BE USED ONLY FOR

EXTINGUISHER ALARM, LIGHTS, CIRCUITS, ETC.

BASIC WIRING DIAGRAM

MANUAL RESET RELAY

RED (COMMON)

YELLOW (N.O)

MICROSWITCH

NOTES:

1. DENOTES FIELD INSTALLATION

2. DENOTES FACTORY INSTALLATION

3. GAS VALVE: UL LISTED ELECTRICALLY-OPERATED SAFETY VALVE FOR NATURAL OR LP GAS AS NEEDED OF

APPROPRIATE PRESSURE AND TEMPERATURE RATING, 110V/60HZ OR AMEREX GAS VALVES, PN 12870, 12871,

12872, 12873, 12874, 12875 and 12876.

4. K1a and K1b ARE N.0. WHEN K1 IS DE-ENERGIZED.

120V/60HZ

BLACK (N.C.)

L1

L2

K1b

CURRENT DRAW MAX:

8A RESISTIVE

8A INDUCTIVE

120VAC

K1

Ka

GAS VALVE

PUSHBUTTON SWITCH

GAS VALVE

SEE NOTE 3

Model GGH2O

22

®

Page 23

TYPICAL WIRING SCHEMATIC ELECTRIC EQUIPMENT SHUTDOWN

ANSUL file name: Typicalwiringschematicelectricgasshut-offvalveshutdowndetail.ai / File received on August 4, 2010

TEMPERATURE RATING, 110V/60HZ OR ANSUL GAS VALVES, PART NUMBERS 13707, 13708, 13709, 13710. AND 17643.

GAS VALVES: "UL LISTED ELECTRICALLY-OPERATED SAFETY VALVE FOR NATURAL, OR LP GAS AS NEEDED OF APPROPRIATE PRESSURE AND

DO NOT USE BLACK WIRE ON SNAP-ACTION SWITCH IN NORMAL INSTALLATION. (USED ONLY FOR EXTRANEOUS ALARM, LIGHT CIRCUITS, ETC.

DENOTES FACTORY INSTALLATION

DENOTES FIELD INSTALLATION

TYPICAL WIRING SCHEMATIC ELECTRIC EQUIPMENT SHUTDOWN

4.

1.

2.

3.

AUTOMAN IN THE COCKED POSITION)

(SWITCH CONTACTS SHOWN WITH ANSUL

13 AMP, 28 VDC

1/3 HP, 10 AMP, 120 VAC

1/2 HP, 10 AMP, 240 VAC

MANUAL RESET RELAY

ANSUL SNAP-ACTION SWITCH

RESET

BA

RELAY COIL

ELECTRICAL RATING

PART NO. 426151

6

9

3

4

7

1

SCREW

INDICATOR

POWER

RED

GND

5

4

3

2

1

BLACK

RED

BROWN

110V/60HZ

NEUTRAL

HOT

1

L

2

L

NOTE:

ANSUL file name: Typicalwiringschematicelectricgasshut-offvalveshutdowndetail.ai / File received on August 4, 2010

TYPICAL WIRING SCHEMATIC ELECTRICAL EQUIPMENT SHUTDOWN

ANSUL file name: Typicalwiringschematicelectricequipmentshutdowndetail.ai / File received on August 4, 2010

Ansul® Wiring Plan View

POWER

INDICATOR

RED

GND

SCREW

BLACK

RED

BROWN

5

4

110V/60HZ

3

2

1

ANSUL SNAP-ACTION SWITCH

(SWITCH CONTACTS SHOWN WITH ANSUL

AUTOMAN IN THE COCKED POSITION)

MANUAL RESET RELAY

PART NO. 426151

ELECTRICAL RATING

RESET

BA

RELAY COIL

1/3 HP, 10 AMP, 120 VAC

1/2 HP, 10 AMP, 240 VAC

13 AMP, 28 VDC

6

9

3

4

7

1

NOTE:

1.

2.

GAS VALVES: "UL LISTED ELECTRICALLY-OPERATED SAFETY VALVE FOR NATURAL, OR LP GAS AS NEEDED OF APPROPRIATE PRESSURE AND

3.

DENOTES FIELD INSTALLATION

DENOTES FACTORY INSTALLATION

TEMPERATURE RATING, 110V/60HZ OR ANSUL GAS VALVES, PART NUMBERS 13707, 13708, 13709, 13710. AND 17643.

DO NOT USE BLACK WIRE ON SNAP-ACTION SWITCH IN NORMAL INSTALLATION. (USED ONLY FOR EXTRANEOUS ALARM, LIGHT CIRCUITS, ETC.

4.

NEUTRAL

L

2

L

HOT

1

ANSUL SNAP-ACTION SWITCH

(SWITCH CONTACTS SHOWN WITH ANSUL

AUTOMAN IN THE COCKED POSITION)

RESET

POWER

INDICATOR

BA

RELAY COIL

6

9

3

4

7

1

MANUAL RESET RELAY

PART NO. 426151

ELECTRICAL RATING

1/3 HP, 10 AMP, 120 VAC

1/2 HP, 10 AMP, 240 VAC

13 AMP, 28 VDC

NOTE:

1.

2.

GAS VALVES: "UL LISTED ELECTRICALLY-OPERATED SAFETY VALVE FOR NATURAL, OR LP GAS AS NEEDED OF APPROPRIATE PRESSURE

3.

DENOTES FIELD INSTALLATION

DENOTES FACTORY INSTALLATION

RED

GND

SCREW

5

4

3

2

1

SWITCH OR

THERMOSTAT

(CUSTOMER

SUPPLIED)

BLACK

RED

BROWN

TO HEATING

ELEMENT LOAD

CONTACTOR

(CUSTOMER SUPPLIED)

AND TEMPERATURE RATING, 110V/60HZ OR ANSUL GAS VALVES, PART NUMBERS 13707, 13708, 13709, 13710. AND 17643.

DO NOT USE BLACK WIRE ON SNAP-ACTION SWITCH IN NORMAL INSTALLATION. (USED ONLY FOR EXTRANEOUS ALARM, LIGHT CIRCUITS, ETC.

4.

L

NEUTRAL

110V/60HZ

TO POWER SUPPLY

220V/440V

2

L

HOT

1

®

Model GGH2O

23

Page 24

ECO

P.O.BOX 410 SCHOFIELD, WISCONSIN 54476-0410

CAD DRAWING NO.

REV.

PART NO.

-

IAN31295

LADDER DIAGRAM,

GGH2O

473596

Wiring Diagram

Wiring diagram is located on the inside cover of the control cabinet located on the end of the hood.

120VAC 1PH. 30 AMPS

SUPPLY POWER

WATER WASH

120VAC 1PH. 15AMPS

SUPPLY POWER

HOOD LIGHTS

FAN INTERLOCK

CONTACT

3POLE 32 AMPS

DISC

L1

L2

E1

E1

L3

12 GA

BK

L1

PR

L1

BK

BK

12 GA

BK

12 GA

AR

C

NO

21

Interlock

BK

Hood Lights

R1

Fan

83

BL

BL

BL

BL

L1

L1

BK

H1

14 GA

24

E2E1

PR

SC

GGH20/VAV Fan Mode

Interlock Connection

0VDC - Fan Auto

5VDC - Fan OFF

10VDC - Fan On for Dry

OR

OR

OR

41

Recirculating Pump

Motor Wiring

Recirculating Pump Size

1.0 HP

1.5 HP

67

67

67

3 AMP

25 AMP

H1

E2

WHT

FU3

FU1

LF1

(H)

L2

BK

18 GA

FU2

18 GA

5 AMP

41

RD

RD

BK

(IMC Interlock)

14

BK

BK

FL1

FL2

FL3

Temp Sensor

(Freeze

Protection)

(If used)

Temp Sensor

(If used)

R1

R5

R3

T1

18 GA

12 GA

H1

14 GA

18 GA 18 GA

BL

83

BK

41

BK

41

BK

41

41

41

83

83

67

67

25

Tank Full

WHT

Tank Low

RD

Safety

BK

+VDC

COM

60

20

30

83

83

83

83

Timer

RD

C1 120VAC

L2 L3

Recirculating

Pump

Contactor

PUMP

ON RECIRCULATING

WIRED FROM MOTOR

M2

F1

F2

F3

V1

VC

TS

TC

I1

IC

Brown

White

Blue

Orange

Yellow

PR

51

BK

BK

BL

BL

OR

OR

PR

PR

27

PR

28

PR

36

OR

72

BR

73

OR

2

BR

4

OR

5

BR

6

T2

LF3

11

1114

1114

FLA

17

22

Melink Fan

Stop Common

OR

OR

OR

Contact

BK

PR

BL

83 - 24V (H)

41 - DO1 COM

47 - DO3 COM

51 - DO4 COM

54 - DO5 COM

57 - DO6 COM

64 - DO8 COM

67 - DO9 COM

3 - Ext V

25 - DI

COM

27 - DI5

28 - DI6

36 - DI12

72 - AO1

73 - AO COM

2 - AI1

4 - AI COM

5 - AI2

6 - AI COM

6

2

3

15

RD

T2

Hood Lights

TR1

(N)

(H)

120VAC

24VAC

U1 (FX-14)

44 - DO2

COM

61 - DO7

COM

Lights Indicator

Low Det Indicator

R3 24 VAC

A2

R4 24 VAC

Fire Mode

R6 120 VAC

Wash Timer

Relay

T3 T3T2 T2L1 T1 T1

RP

RP

N

R5 120 VAC

A2

Hood Lights

LED Relay

BK

YW

82 - 24V (C)

1 - AI COM

Fan Indicator

Det Low

Lights On/O

A1A2

RP

42 - DO1

45 - DO2

48 - DO3

52 - DO4

55 - DO5

58 - DO6

62 - DO7

65 - DO8

68 - DO9

21 - DI

23 - DI2

24 - DI3

22 - DI1

26 - DI4

32 - DI9

7 - AI3

6 - AI COM

81 - Earth

L2

L1

L4

A1

A1A2

PB1

N

14 11

A1

COM

YW

YW

R2

BK

Hood Lights

N1

YW

RD

42

RD

45

RD

48

PR

52

RD

55

RD

BL

BL

RD

68

BR

PR

PR

PR

PR

PR

PR

OR

7

BR

6

F4

F4 C

FS

N

BK

DP

WHT

S1 120 VAC

S1 N

S2 120 VAC

S2

Nozzle 1

S3 120 VAC

S3 N

Nozzle 2

Melink Fan Stop

M1

S4 120 VAC

S4 N

58

62

65

5

Clean Hood

10

23

Start-Stop Fan

11

24

22

Wash Timer

26

Fire Mode

32

I2

Temp Sensor

(IMC Interlock)

IC

FL4

Fire System

FS FC

AR 24 VAC

BL

14

14

WHT

P2

DP

Detergent

Pump

Motor

P1

Recirculating

Pump

Motor

WHT

N1

82

Fill

Drain

C1 120 VAC

Recirc Pump

R1 24 VAC

Fan

R2 24 VAC

Detergent Pump

A2

Clean Hood

Indicator

1

21

PB3

PB2

R6

14

11

R4

24

21

R3

24

21

Det Low

(If used)

Det Low

YW

32

6

BK

WHT

FIELD INSTALLED WIRING

MOLEX PLUG FOR KEYPAD

(IF KEYPAD IS REMOTE MOUNTED, PLUG IS FIELD CONNECTED)

WHT

WHT

N

WHT

WHT

C1

95

96

95

A2A1

A1A2

A1

L3

PR

PR

PR

YW

YW

N

N

N

WHT

Overload

YW

82

YW

82

13

21

21

21

1

1

82

82

82

WHT

WHT

N

N

N

N

N

N

N

N

WHT

12 GA

18 GA

Model GGH2O

24

®

Page 25

Maintenance

Capture Tank

The interior surfaces of the hood capture tank should

be wiped down weekly.

Filters

The Grease Grabber filters (bead filters) require

visually inspection (not removed from hood) two

weeks after start-up, then once a month thereafter to

make certain the filters are positioned correctly in the

plenum. Positioned correctly means there are no gaps

between the filters.

To inspect the bead filters, remove the fasteners

holding the access doors; each door has five (5)

fasteners. Remove every other door to inspect the

filters.

After inspecting the filters, put the access doors

back on and put the fasteners back in. Be careful not

to over-tighten or cross thread the fasteners when

putting them back in.

The Grease Grabber filters

(bead filters) need to be

removed from the hood

once every three months to

visually inspect and ensure

the filters are structurally

sound.

Remove all the doors

and remove the filters for

inspection. Depending on

the equipment under the

hood, it will probably be

easier to remove the filters

from the right side of each

hood. Slide the other filters

down to the end access

door for removal.

After inspecting the filters,

place them back in the

hood. Be careful to install

the filters with the handles

up and make sure not to

hit the fire detection line

when removing or installing

the filters. Ensure no gaps

are between filters after

installation.

If any filter appears damaged, consult factory for

replacement.

Floats

The floats need to be

inspected two weeks after

start-up and then once a

month thereafter.

The float can be inspected

by first turning the

disconnect switch on the

control cabinet to the ‘OFF’

position. Then remove the

large access panel door.

Once the access panel

is removed, you will have

access to the floats.

Slide each float (Low Float,

High Float and Safety Float)

up the stem to its stop with

your finger and let go. If float

slides freely down the stem

with minimal resistance, the

float is operating as it should.

Put the access panel back

on and turn the disconnect

switch to the ‘ON’ position.

If the float does not slide

freely down the stem, the

stem and floats are dirty

and need to be wiped off with a clean cloth. Cleaning

the stem involves removing all the clips (stops). Slide

floats up and down on the shaft as required to access

and clean the entire length of the shaft. Return floats

to their location and reinstall stops.

Make sure all float stops are securely located in their

grooves and floats are located in their designated

spots.

If for some reason the floats

get taken off the stem, the

stamped circle on the top

side of the float needs to

face up.

Access Panel Door

Float Installed

Safety Float

High Float

Low Float

NOTE

Be careful when handling the float stops. These are

small clips and can easily be dropped. If you loose

one of these clips, consult factory for a replacement.

®

Model GGH2O

25

Page 26

Troubleshooting Replacement Parts

Hood is not cleaning

If the hood does not seem to be adequately cleaned,

look for the following:

Detergent tank — is it empty or filled with wrong

detergent?

Detergent pump — is the detergent pump running?

Is there power to the pump? Is the detergent level

low? If the hood plenum area is not sufficiently

cleaning, consult factory for information on

increasing duration of wash cycle and detergent

pump.

Nozzles — are any of them clogged? If so, they can

be removed and cleared using a small wire.

Water temperature — is it at least 140°F.

Hardness of water — test water for hardness level.

It is recommended that soft water be used.

Hood not draining properly — plugged drain.

Ensure all floats have stamped circles facing up.

Water leaks — water leaking through the access

panels when filling. Ensure access panels are securely

in place. If leak persists, partially close inlet water ball

valve (by others) upstream of fill solenoid to reduce

water pressure.

Condensation in the hood — large amounts of

condensation while hood is washing. Hood should

be washed after the hood and equipment is warm,