Greenheck GFSD Installation Manual

Part # 462100

®

Installation Instruction Supplement for

Refer to:

‘Installation Instructions for FD, DFD, SSFD, SSDFD, & KFD

Series Curtain Fire Dampers’ (Part #452763)

or

‘Installation Instructions for FD and DFD 150X Series Curtain

Fire Dampers’ (Part #453946)

or

‘Installation Instructions for FSD and SSFSD Series

Combination Fire Smoke Dampers’ (Part #461336)

or

'Installation Instructions for DFDR, SSDFDR, FDR and

SSFDR Round Fire Dampers' (Part# 462721)

or

'FSDR-XXX, SEFSDR-XXX and SSFSDR-XXX Round

Combination Fire Smoke Dampers' (Part# 461868)

or

'GFSD-XXX Series Grille Access Out of Wall/Floor

Combination Fire Smoke Dampers' (Part# 472477)

or

'OFSD-XXX, ODFD-XXX, OFD-XXX and OSSFD-XXX Out of

Wall/Floor Combination Fire Smoke and Fire Dampers'

(Part # 461337)for additional details.

Notes

1. Gypsum panels must be screwed 12 in. (305mm) on center

maximum to all stud and runner flanges surrounding

opening. (See Figure 1 and Figure 2 for Opening

Preparation Details).

2. Fire damper and sleeve assemblies 80 in. W x 50 in. H

(2032mm x 1270mm), 50 in. W x 80 in. H (1270mm x

2032mm), or 40 in. W x 100 in. H (1016mm x 2540mm)

and smaller only require retaining angles on one side

of the partition (See Figure 3 and Figure 4). Retaining

angles must be attached to the sleeve and the partition.

Larger damper assemblies require retaining angles on

both sides of the partition. Retaining angles must be

attached to the sleeve.

• Retaining angles for 1½ hour rated dampers with a width

and height 48 in. (1219mm) or less must be a minimum

of 20 ga. (1mm). Retaining angles for all 3 hour rated

dampers and all dampers with a width or height greater

than 48 in. (1219mm) must be a minimum of 16 gauge

(1.5mm). The leg of the retaining angle on the damper

sleeve shall be a minimum of 1¼ in. (32mm). The leg of

the retaining angle on the wall/floor shall be long enough

to cover the annular space and overlap the wall/floor by

at least 1 in. (25mm).

• Retaining angles must be attached to the partition and

sleeve using one of the methods shown below.

• tack or spot welds

• #10 sheet metal screws and bolts

• Drywall screws of a length such that the screw

engages the stud/track by a minimum of 1/2 in.

(13mm)

• A minimum of two connections per side, top, and

bottom, 12 in. on center maximum for openings of

48 in. W x 36 in. H (1219mm x 914mm) and less, and

6 in. (152mm) on center for openings 80 in. W x 50 in.

H (2032mm x 1270mm), 50 in. W x 80 in. H (1270mm x

2032mm), and 40 in. W x 100 in. H (1016mm x 2540mm)

or less.

Grille Installations (Dampers up to 36 in. x 36 in.

[914mm x 914mm] maximum)

FD, DFD,ODFD, and OFD Series

1 1/2 Hour Curtain Fire Dampers and

FSD, OFSD and GFSD Series

1 1/2 hour Combination Fire Smoke Dampers

Vertical Mount

DFDR, FDR, FSDR Series

1 1/2 hour Round Fire and Combination Fire

Smoke Dampers and

Metal Stud Framing for Fire Dampers in

Cavity Shaftwall Partitions

“UL CLASSIFIED (see complete marking on

product)”

“UL CLASSIFIED to Canadian safety standards

(see complete marking on product)”

Standard 555 (Listing #R13317)

Standard 555S (Listing #R13447)

• Angle legs may be reversed and one leg inserted into

the wall opening. Retaining angles used in conjunction

with grille installations must be a minimum of 20 gauge

(1mm) steel and have a minimum of 5/8 x 1 in. (16mm x

25mm) legs (See Figure 5 and Figure 6).

OR

• Using #10 sheet metal screws, screw from inside of

sleeve into the studs. Space screws a maximum of 6 in.

(152mm) on center and a maximum of 2 in. (51mm) from

the corners (minimum of 2 screws per side). (See Figure

7 and Figure 8).

3. These installation instructions apply to the following wall

design numbers as detailed in the UL Fire Resistance

Directory: U438, U469, U497,U499, V473 System A.

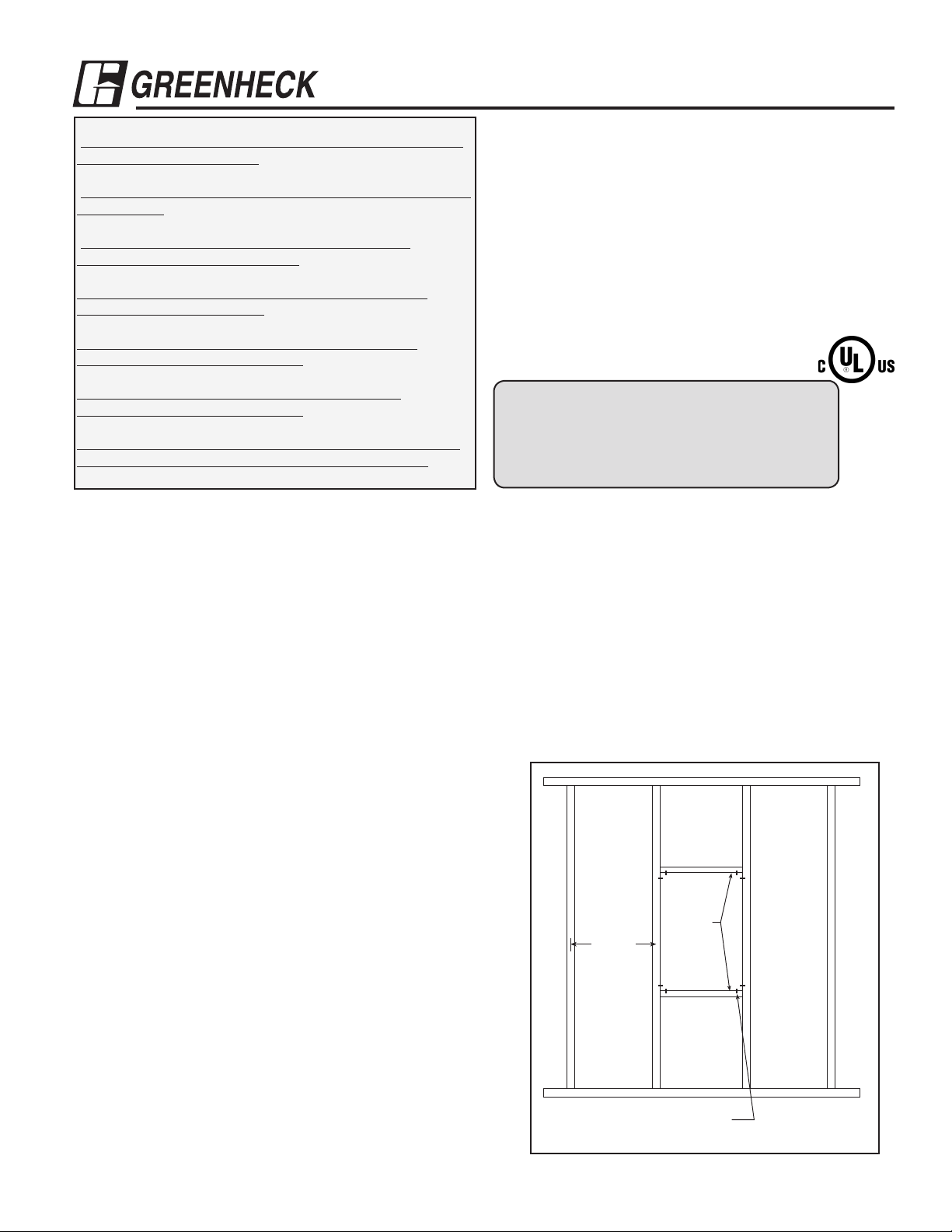

J-Runner

24 in. O.C.

Maximum

1 1⁄2 in. x 1 1⁄2 in. x 2 in. Min. angle

attached with

screws (min.)

Figure #1: Opening Preparation Detail

5

⁄8 in. type #12

J-Track Headers (Slot ends to fit into

I-Studs as shown in Detail ‘A’)

Detail ‘B’

Detail ‘A’

24 in. O.C.

Maximum

I-Studs

J-Track folded

as shown in

Detail ‘B’.

Attach to JTrack header

Figure #2: Optional Opening Preparation

Detail for I-Stud Assembly

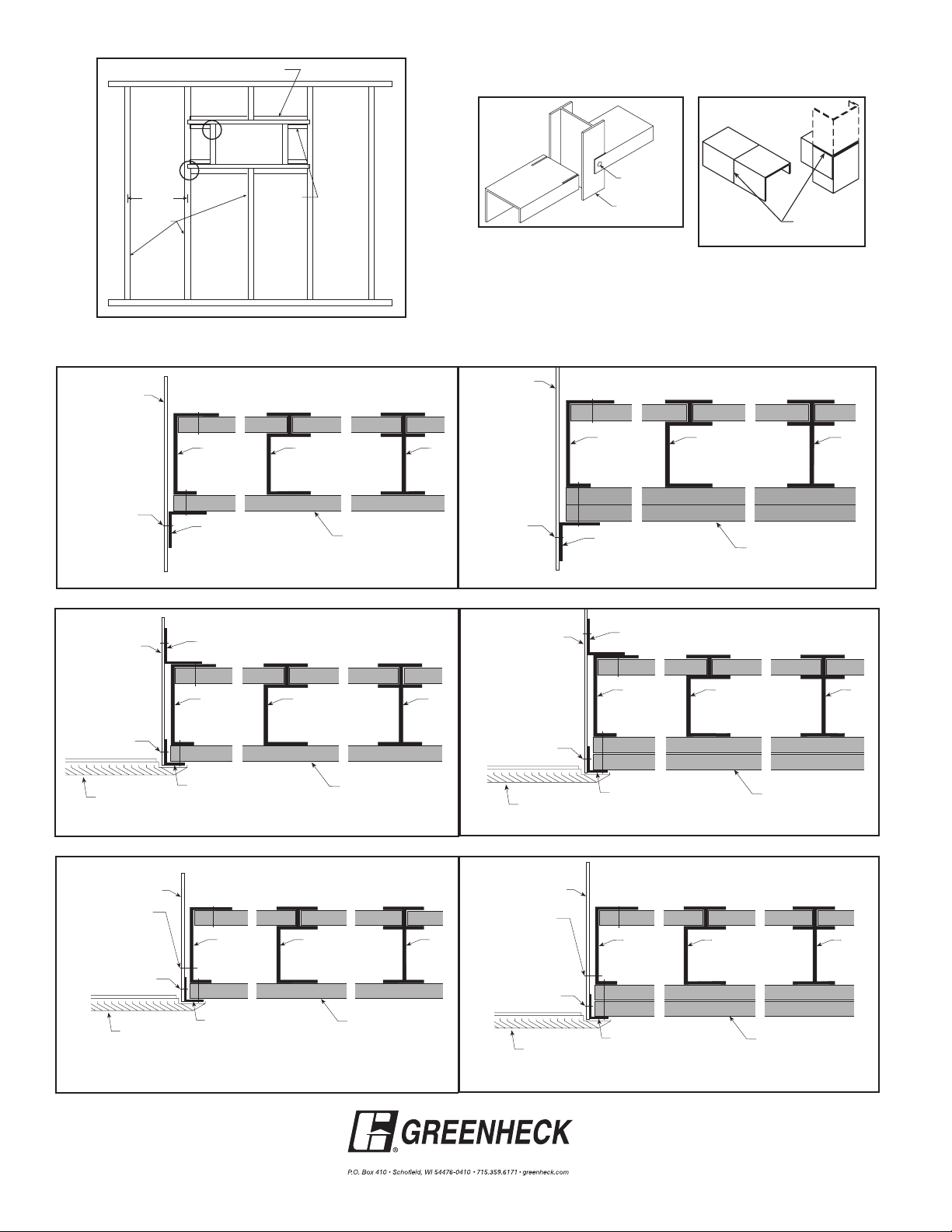

Damper

Sleeve

J-Runner C-H Stud I-Stud

Angle Fastener

(see Note 2)

Retaining Angle

(See Note 2)

Figure #3: 1 Hour Shaftwall Rating

Damper

Sleeve

Retaining angle

(See Section 2)

5

/8 in. UL Classified

Gypsum Wallboard (see UL

Rated Wall Design for

Additional Details)

Fasten J-Track

in this manner

I-Stud

Detail ‘A’: J-Track to I-Stud

Damper

Sleeve

Angle Fastener

(see Note 2)

Connection

J-Runner C-H Stud I-Stud

Retaining Angle

(See Note 2)

Detail ‘B’: Forming J-Track

Figure #4: 2 Hour Shaftwall Rating

Retaining Angle

Damper

Sleeve

(See Section 2)

Cut here and

bend down

Two layers of 5/8 in. UL

Classified Gypsum Wallboard

(see UL Rated Wall Design for

Additional Details)

J-Runner C-H Stud I-Stud

Angle Fastener

(see Note 2)

Retaining angle

Grille (supplied

by others)

(See Note 2)

Figure #5: 1 Hour Shaftwall Rating

Damper

#10 sheet metal screws

spaced 6 in. on center and

a maximum of 2 in. from

the corners (minimum of 2

screws per side). Screw

into studs so as to avoid

space conflicts with the

grille assembly.

Sleeve

Angle Fastener

(see Note 2)

Grille (supplied

by others)

J-Runner C-H Stud I-Stud

Retaining angle

�

(See Note 2)

Figure #7: 1 Hour Shaftwall Rating

5

/8 in. UL Classified

Gypsum Wallboard (see UL

Rated Wall Design for

Additional Details)

5

/8 in. UL Classified

Gypsum Wallboard (see UL

Rated Wall Design for

Additional Details)

J-Runner C-H Stud I-Stud

Angle Fastener

(see Note 2)

Retaining Angle

Grille (supplied

by others)

(See Note 2)

Figure #6: 2 Hour Shaftwall Rating

Damper

Sleeve

#10 sheet metal screws

spaced 6 in. on center and

a maximum of 2 in. from

the corners (minimum of 2

screws per side). Screw

into studs so as to avoid

space conflicts with the

grille assembly.

Angle Fastener

(see Note 2)

Grille (supplied

by others)

J-Runner C-H Stud I-Stud

Retaining angle

(See Note 2)

Figure #8: 2 Hour Shaftwall Rating

Two layer of 5/8 in. UL

Classied Gypsum

Wallboard (See UL

Rated Wall Design for

Additional Details)

Two layers of 5/8 � in. UL

Classified Gypsum Wallboard

(see UL Rated Wall Design

for Additional Details)

462100 Metal Stud in Cavity Shaftwall Rev. 11 June 2010

Copyright © 2010 Greenheck Fan Corporation.

Loading...

Loading...