Greenheck G-240, G-300, G-200, G-200HP, G-180 User Manual

...

Centrifugal Roof Downblast Exhaust Fans

Models G and GB

• General Clean Air • Light Contaminants

• Seismic • High Wind • Variable Volume

performance data included

December

2020

Models G and GB

Spun Aluminum • Downblast

Centrifugal Roof Exhaust Fans

Contents

Model Comparison ......................3

Construction Features .................4-5

Emergency Smoke Control ...............6

Seismic ...............................6

High Wind & Hurricane ...................7

Vari-Green

Demand Control Ventilation ...............9

Roof Curbs, Options and Accessories . . 11-12

Typical Installations .................13-14

Model Number Code ...................14

®

Motor, Controls, Drive ......8-10

PERFORMANCE AND DIMENSIONS:

Direct Drive

Models G-060-160 ................15-28

Model G-180 ........................30

Models G-200-200HP ..............32-33

Model G-240 ........................36

Model G-300 ........................39

Belt Drive

Models GB-097-540 ...............19-47

Quick Build Programs ..................48

Our Commitment ......................48

Greenheck Fan Corporation certifies that the

Models G and GB fans shown herein are licensed

to bear the AMCA Seal. The ratings shown are

based on tests and procedures performed in

accordance with AMCA Publication 211 and

Publication 311 and comply with the requirements

of the AMCA Certified Ratings Program. The

certified ratings for Models G and GB are shown

on pages 15 - 47

G and GB models are listed for electrical

(UL/cUL 705) File no. E40001

GB models for Emergency Smoke Control Systems

(UL/cUL Listed for 500°F (260°C) for 4 hours and

1,000°F (538°C) for 15 minutes) File no. MH17511

*UL/cUL is optional

and must be specified

Enjoy Greenheck’s extraordinary service, before, during and after the sale.

Greenheck offers added value to our wide selection of top performing, energy-efficient

products by providing several unique Greenheck service programs.

• Our Quick Delivery program ensures shipment of our in-stock products within 24 hours of

placing your order. Our Quick Build made-to-order products can be produced in 1-3-5-1015-20 or 25-day production cycles, depending upon their complexity.

• eCAPS

projects. It includes fan, louver and dedicated outdoor air systems (DOAS) selection, as well

as a damper guide and toolbox.

• Greenheck’s free Computer Aided Product Selection (CAPS

best in the industry, helps you conveniently and efficiently select the right products for the

challenge at hand.

• Our 3D service allows you to download, at no charge, easy-to-use AutoDesk® Revit®

3D drawings for many of our ventilation products.

Find out more about these special Greenheck services at

®

online selection guides you to choose the best value product for your building

®

) program, rated by many as the

greenheck.com

2

Models G and GB

Spun Aluminum • Downblast

Centrifugal Roof Exhaust Fans

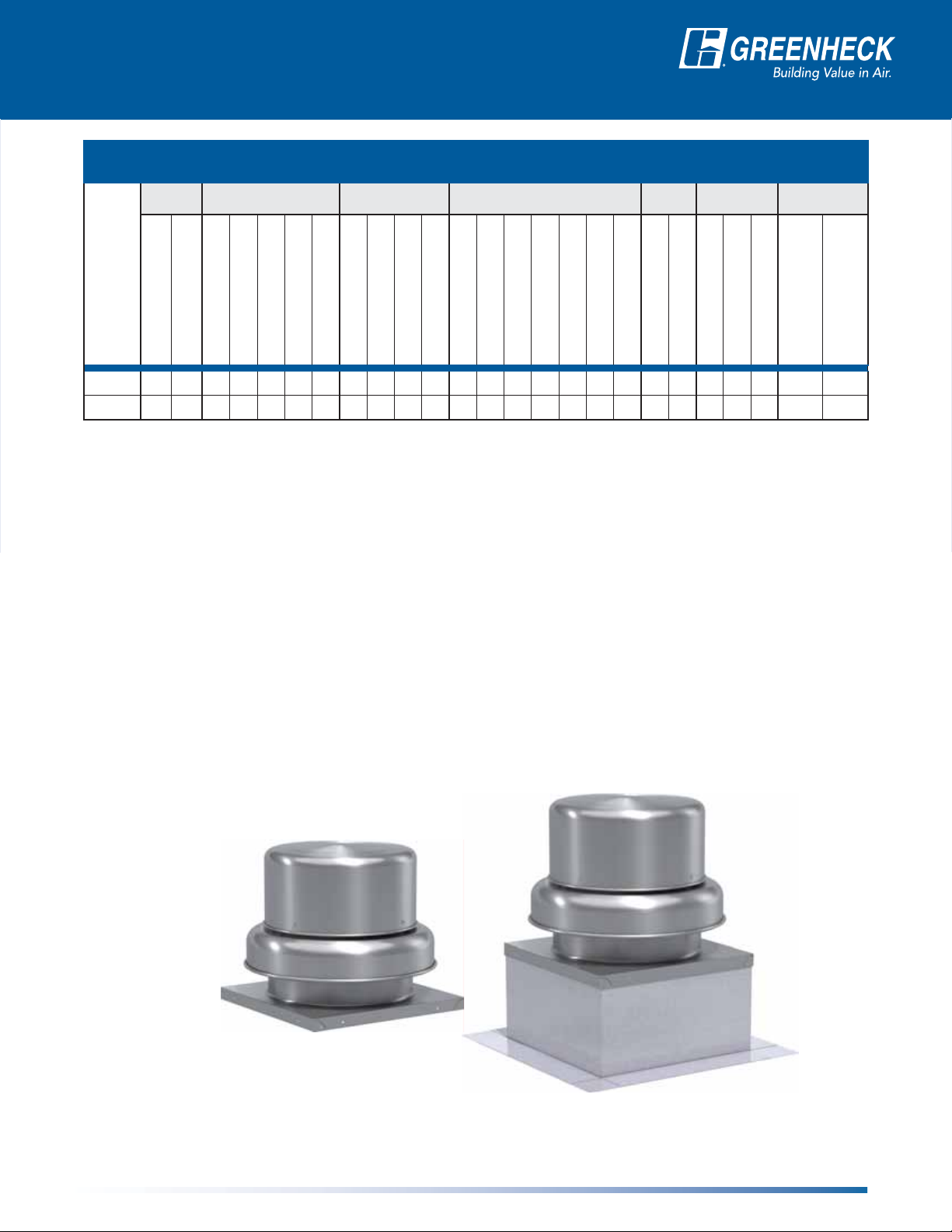

Model Comparison

Location Mounting Airflow Application

Model

Outdoor

Indoor

Roof Curb

Base/Floor

Hanging

Wall

Ceiling Mounted

Exhaust

Supply

Reversible

Recirculate

General/Clean Air

Contaminated Air

Spark Resistant

Grease (UL 762)

Smoke Control (UL)*High Wind**

Continuous High Temp

(above 200°F )

Drive

Type

Belt

Direct

Impeller

Type

Centrifugal

Propeller/Axial

Performance

Mixed Flow

Maximum Volume

(cfm)

Maximum Static

Pressure (in. wg)

G

99 9 99999

GB

9 9 9 999999

* Smoke control available on models: 100, 100HP, 120, 130, 140, 140HP, 160, 160HP, 200, 240, 300, 360, 420 and 480

** High wind limited to sizes 300 and smaller

Greenheck models G and GB centrifugal roof exhaust

fans provide the industry’s best performance and

durability for general clean air applications where air is

discharged downward, toward the roof surface.

• Broadest performance in the industry, up to

3.25in.wg (810 Pa) and 44,700 cfm (75,945 m

3

/hr).

• Most advanced motor cooling of any fan in its class.

Direct Drive, G

• Use for short and/or low resistance ductwork

Belt Drive, GB

• For average length and/or average

resistance ductwork

• High volume/average pressure

• Performance as cataloged is ensured. All fan sizes

are tested in our AMCA accredited laboratory, and

all models are licensed to bear the AMCA Sound

High Pressure, G-HP and GB-HP

• For long and/or high resistance ductwork

and Air Performance seals.

• Low volume/high pressure

• UL Listed for electrical.

• Greenheck subjects these products to extensive

life testing ensuring the fans will provide years of

reliable performance.

14,500 2.75

44,700 3.25

3

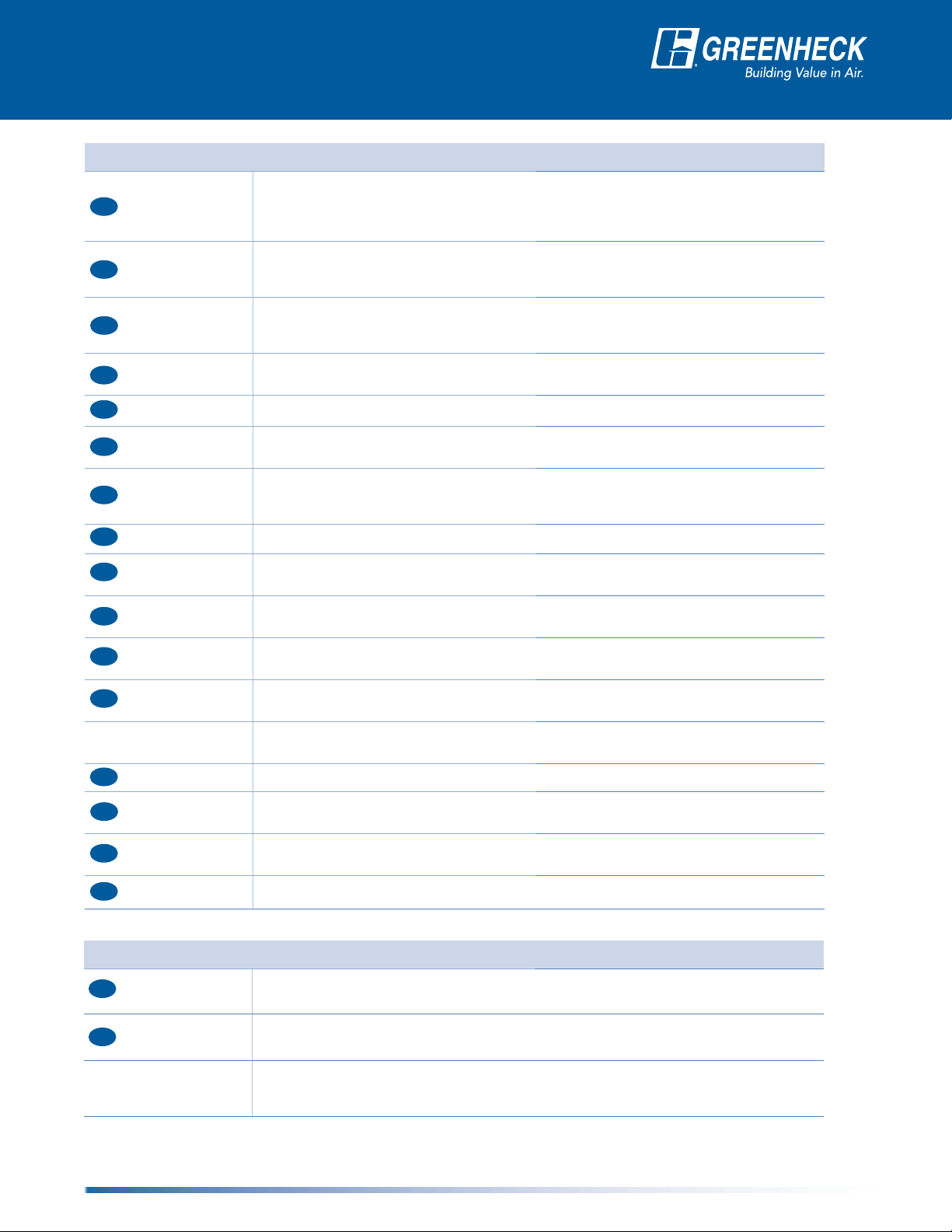

Construction Features

Models G and GB

Standard Construction Features

A backward-inclined, non-overloading centrifugal wheel is utilized to generate high-

Wheel

1

Disconnect

2

Switch

Fan Shaft

3

Bearings

4

5

Motor Carefully matched to the fan load and mounted out of the airstream.

efficiency and minimal sound. Wheel cones are carefully matched to the venturi for

maximum efficiency. Each wheel is robotically welded and statically and dynamically

balanced for long life and quiet operation.

NEMA-1 switch is factory-mounted and wiring is provided from the motor as standard

(other switches are available). All wiring and electrical components comply with the

National Electrical Code

Precisely sized, ground and polished, so the first critical speed is at least 25% over

the maximum operating speed. Where the shaft makes contact with bearings, tight

tolerances result in longer bearing life.

100% factory tested and designed specifically for air handling applications with a

minimum L

life in excess of 100,000 hours (L 50 life of 500,000 hours).

10

®

(NEC) and are either UL Listed or Recognized.

6

7

8

9

10

11

12

Not

Shown

13

14

15

Motor Cover

Motor Cooling

Lifting Points Various lifting points are located on the drive frame and bearing plate (on select sizes).

True Vibration

Isolation

Drive Assembly

Lower Windband

Curb Cap

Internal Conduit

Chase

Nameplate Permanent embossed aluminum plate for exact model and serial number identification.

Galvanized

Birdscreen

Fan Shroud

Constructed of aluminum and attached with fasteners for easy removal and access to

motor compartment and drive assembly.

Cooling fins located on top of the fan wheel draw outside air through a large space

between the fan shroud and the motor cover directly into the motor compartment.

Positive motor cooling with fresh air results in maximum motor life.

Vibration isolators, with no metal-to-metal contact, support the drive assembly and

wheel for long life and quiet operation.

Belts, pulleys, and keys are oversized 150% of driven horsepower. Machined-cast

pulleys are adjustable for final system balancing. Belts are static-free and oil-resistant.

Heavy-gauge aluminum with formed edges for added strength and provides

weather resistance.

Curb cap (with integral deep spun venturi) is constructed of aluminum and is one-piece for

a weather-tight fit.

A large diameter conduit for installing electrical wiring through the curb cap into the

motor compartment.

Rigid wire protects the fan discharge from birds and small objects.

One-piece, heavy-gauge aluminum with a rolled bead for extra strength directs exhaust

air downward.

Mounting Holes Curb cap has prepunched mounting holes to ensure correct attachment to the roof.

16

High Wind Construction Features

17

Internal Supports

Reinforced

18

Windband

Roof Curb

(page 11)

4

Heavy-gauge supports and bracing are added for additional strength to withstand

a load of 75 psf.

High wind fans include additional reinforcement for maximum strength.

High wind-load fans are certified for use with Greenheck model GPFHL, GPFHD, GPF or

equivalent in high wind applications. Roof curbs ship separate for field installation with

attachment details provided.

Construction Features

Models G and GB

6

7

5

MODEL G

DIRECT DRIVE

11

1

6

14

13

12

DRIVE FRAME

(BELT DRIVE)

3

10

8

8

9

MODEL GB

BELT DRIVE

17

8

18

4

2

16

15

5

Applications

s

Models G and GB

Emergency Smoke Control - GB

When you buy a Greenheck

model GB with the smoke

control option, you receive a

fan with the industry’s best

performance and durability for

smoke control applications

(as found in emergency smoke

control systems).

GB smoke control models are:

100, 100HP, 120, 130, 140, 140HP,

160, 160HP, 200, 240, 300, 360,

420, 480

Seismic - G and GB

• UL/cUL Listed for 500°F (260°C) for 4 hours and

1,000°F (538°C) for 15 minutes.

• Half the weight of traditional smoke control fans,

ideal choice for roof load concerns.

• Low profile, height is less than half of traditional

smoke control fans, maximum of 52

1

⁄2 inches

(1334 mm) from curb cap to top of the fan.

• Multiple applications, capable of exhausting

general clean air and satisfying emergency

smoke control regulations.

With changes in building codes and standards, more equipment is being

required to be seismically certified in areas of the country not commonly

thought of as being in seismically active zones.

The International Building Code (IBC) is designed to provide model

code regulations that safeguard public health and safety in all U.S.

communities. This code is intended to improve the performance and

design of nonstructural systems subject to seismic events.

The State of California, one of the most active seismic areas in the United

States, has the Office of Statewide Health Planning and Development

(OSHPD) to regulate the design and construction of health care facilities

to ensure they are safe and capable of providing

services to the public after a seismic event.

OSHPD developed their own unique certification

process to incorporate the IBC and ASCE

testing standards to ensure equipment remains

operable after a seismic event.

Note: All G and GB models meet seismic

requirements.

Protocols designed for seismic standards:

All Greenheck seismically certified models have been tested using the most severe seismic event that is

Seismic

Testing Criteria

California OSHPD

Test Protocols

OSHPD Certification

6

found on the Spectral Response Map per IBC Figures 1613.5 (1-2). Our testing is performed under the

worst case scenario using the highest mapped seismic load, highest level occupancy category, worst

case site class, and highest code mandated importance factor, thereby allowing Greenheck’s seismically

certified fans to be used anywhere in the United States under any conditions.

The California Office of Statewide Health Planning and Development (OSHPD) requires all certified

models be shake table tested in accordance with ICC ES AC-156, in which the fans are physically

subjected to the same or greater forces than they will see during a seismic event. Subjecting

Greenheck model G and GB fans to this type of testing ensures the fans will operate without

problems after a seismic event.

The OSHPD certification numbers and supporting documents can be viewed on OSHPD’s

website ensuring that the fan has been subjected to and passed rigorous testing standards.

Applications

U.S. continent

Models G and GB

High Wind and Hurricane - G and GB

Greenheck is leading the High Wind Standard for roof top fans and

ventilators. Forceful winds and wind-borne debris are the cause of most

hurricane damage. Hurricane winds start at 75mph and can exert a

force of 75poundspersquarefoot of pressure—or over 900pounds

on a fan and curb. Forceful winds are not the only problem; wind-borne

debris can also cause detrimental effects to objects and structures.

High winds and extreme forces are the cause of most storm damage.

By analyzing calculations, computer simulations, actual testing, and

other standards—Greenheck developed the High Wind Standard.

U.S. continent

averaged

tornado frequency.

Atlantic, Gulf and Pacific history of major hurricane tracks.

Protocols designed to protect against wind-borne debris and severe wind-loads:

Structural

Performance Load

Miami-Dade NOA

Numbers

Florida Product

Approval

A static load that is 1.5times the design load (91.5 pounds per square foot of pressure) is applied both

positively and negatively to simulate wind force loads in each direction. Structural Performance per

Dade County Protocol TAS-202 (ASTM-E330).

View the certifications on the Miami-Dade County website. Models G and GB are the first downblast

aluminum fans in the industry to have received a Miami-Dade NOA for high wind and hurricane zones.

Florida Product Approval ensures approved products can be used use anywhere in the State of Florida

which are not governed by the Miami-Dade County high wind regulations. More information is available

on the Florida Building Code website. Florida Product Approval FL13225.1 for models G and GB.

7

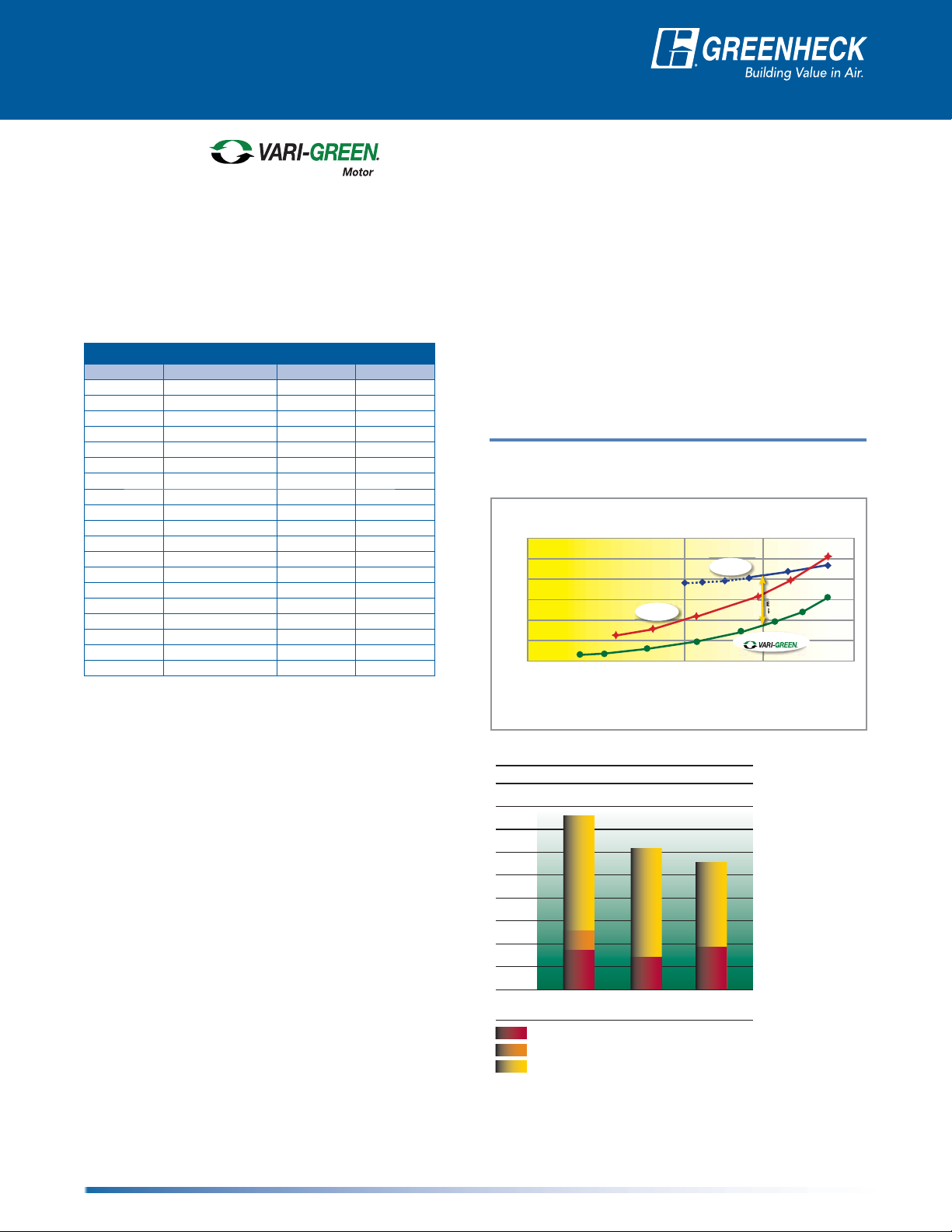

Vari-Green® Motor Option

E

S

GB120

G-

120-A5

G-

120-VG

Model G

Greenheck’s electronically commutated (EC)

Vari-Green (VG) motor is the industry’s first fully

controllable motor. It combines motor technology,

controllability and energy-efficiency into a single

low-maintenance unit. When combined with

Greenheck fans, all the CFM and static pressure

ranges of a belt drive can be attained with the

benefits of a direct drive.

Motor Information

HP Voltages Phase Enclosure

1/15 115, 208-230 1 TENV

1/10 115, 208-230, 277 1 TENV

1/10 115, 208-230, 277 1 ODP

1/6 115, 208-230, 277 1 TENV

1/6 115, 208-230, 277 1 ODP

1/4 115, 208-230, 277 1 ODP

1/2 115, 208-230, 277 1 ODP

3/4 115, 208-230, 277 1 ODP

1 115, 208-230, 277 1 ODP

1 115, 208-230, 277 1 TENV

1 115, 208-230 1 TEFC

1 208-240, 380-480 3 TEFC

2 208-230 1 TEFC

2 208-240, 380-480 3 TEFC

3 208-230 1 TEFC

3 208-240. 380-480 3 TEFC

5 208-240. 380-480 3 TEFC

7 1/2 380-480 3 TEFC

10 380-480 3 TEFC

Benefits

• The Vari-Green motor can attain up to IE5 efficiency

ratings and reduce energy consumption.

• Watt savings of 30-70% depending on RPM.

Note: As motor speed is turned down, efficiency stays

high as compared to an AC motor that decreases

dramatically.

• Operates cooler than a standard AC motor at lower

RPMs. A cooler motor has longer motor life and

reduces energy consumption.

• 75% usable RPM turndown versus 30%, see Motor

Turndown Comparison chart at right.

• G fans with Vari-Green motors can provide all the

CFM and static pressure ranges of a comparable

belt drive.

• Maintenance costs are reduced as there are no

belts or bearings to replace and no pulleys to adjust.

• Direct drive fans are often preferred where

maintenance access is difficult.

• Provides a solution for demand-controlled

ventilation applications.

8

Features

• Dial on Motor Control - a potentiometer (dial on

motor control) is mounted on the motor for easy

speed adjustment for system balance. Simply turn

the dial. There are no belts and pulleys to adjust.

•

Control Wire Inputs - the motor accepts a 0-10V DC

signal from Building Automated Systems or other

controls to adjust motor speed.

Vari-Green Advantages

• Initial cost is similar to a belt drive

• Lower operating cost

• No maintenance: no belts, pulleys or bearings

• Easy RPM adjustment

Comparisons: Belt, Direct Drive with PSC

and Direct Drive with Vari-Green

Motor Turndown Comparison

600

500

400

300

200

INPUT POWER (WATTS)

100

0

0 350

*

GB is a belt driven fan

The length of each curve indicates the practical turndown range.

Data is for 1/2 hp motors with load of 0.35 Bhp at full speed

Constant Volume Life Cycle Analysis

Three Year Cost Comparison

$

2,000

1,750

1,500

1,250

1,000

750

500

250

$

0

(#-

GB120

Initial Cost

Maintenance cost over three years

Operating cost over three years

Analysis is based on operating costs for a period of three years

where the fans operate continuously at 1725 rpm, 24/7, with an

energy rate of $0.10/kWh. Maintenance on the GB-120 is estimated

at $65/yr.

Note: Example is based on a relative cost. Use and installation

variables may produce different results.

(-"

120-A5

50% 75% 100%

G-120

with PSC

GB-120

FAN SPEED (RPM)

G-

Not recommended

G-

(7(

120-VG

Single Phase*

Energy

Savings

G-120 with

1750

Vari-Green

®

Control Options

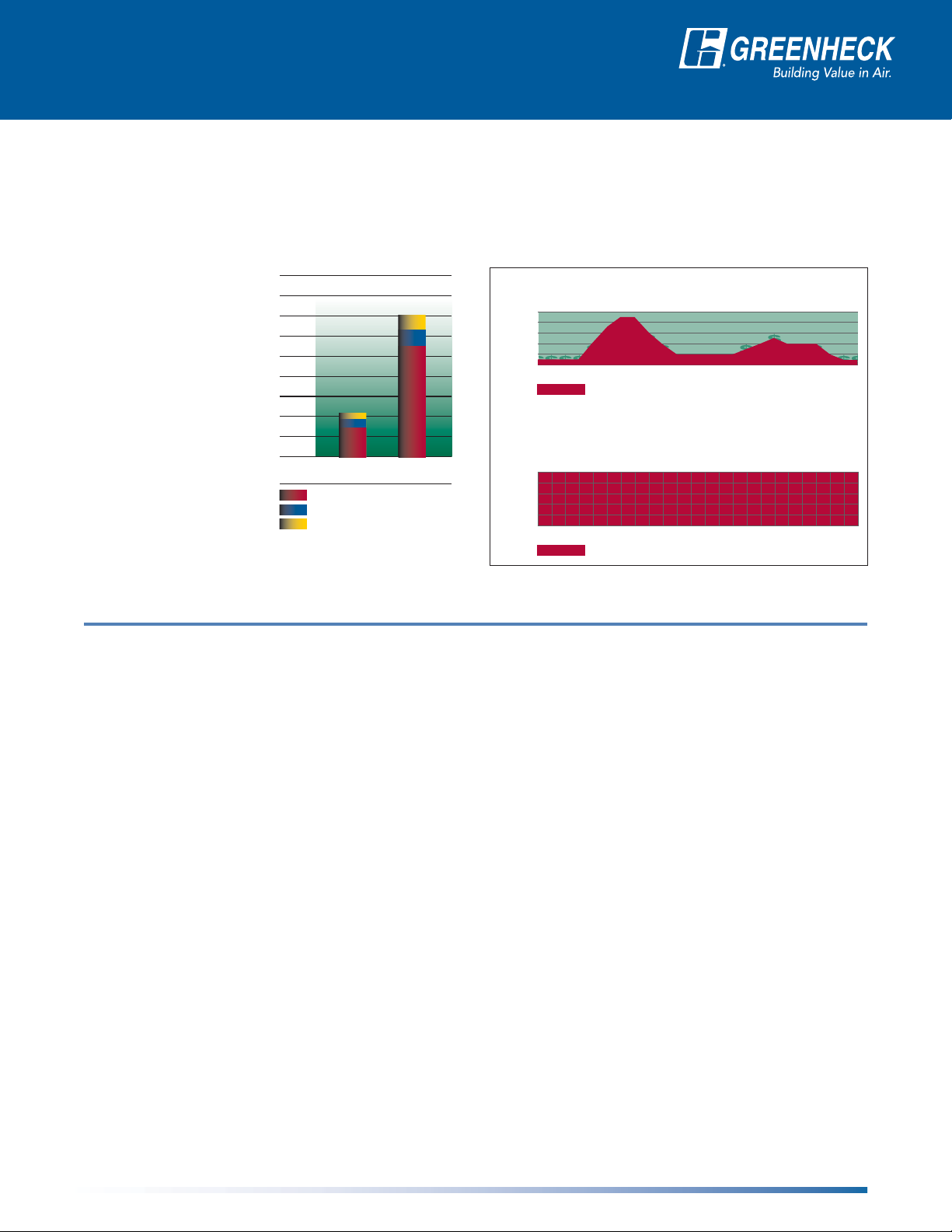

Demand Control Ventilation for

Multistory Buildings

Applications requiring constant pressure or variable

volume can utilize G fans with Vari-Green motors

and Vari-Green controls.

Demand control

ventilation systems

reduce the amount

of energy used by

decreasing the speed

of the fan when demand

is low. This lessens the

amount of conditioned

air exhausted, and

in turn, reduces the

total operating costs

associated with air

conditioning and heating

in multistoried buildings

including hotels,

multifamily complexes,

institutional facilities,

and high-rise

commercial buildings.

Variable Volume

Operating Cost Analysis

Variable Volume vs. Constant Volume

$

2,000

1,750

1,500

1,250

1,000

750

500

250

$

0

Variable

Volume

Heating Cost

Cooling Cost

Fan Operating Cost

Example of potential savings

based on a northeast city in

the USA using Vari-Green

components for variable volume.

Constant

Volume

The Vari-Green constant pressure control is

preprogrammed and easy to install for applications

that include venting dryers, bathrooms, residentialtype kitchen space, or industrial process exhaust.

Daily Operating Comparison:

Variable Volume and Constant Volume

Hypothetical

Variable Volume - Load Shape

100

$$$$$$$$$$$$$$$$$$$$$$$$

80

$$$$$$$$$$$$$$$$$$$$$$$$

60

$$$$$$$$$$$$$$$$$$$$$$$$

40

$$$$$$$$$$$$$$$$$$$$$$$$

20

$$$$$$$$$$$$$$$$$$$$$$$$

0%

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24

% of Operation

Series 1

Demand-controlled ventilation offers significant energy savings by

exhausting only the necessary amount of air throughout the day.

Constant Volume - Load Shape

100

80

60

40

20

0%

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24

% of Operation

Series 2

Note: A standard VFD compatible motor can also function within a

Variable Volume system.

(Hotel Bathroom)

Time of Day

Time of Day

Vari-Green® Controls

Transformer - Provides 24V power from the existing

line voltage at the fan to the Vari-Green motor and

controls. Dual voltage primary (120/240V) transformer

provided with the fan.

Remote Dial - Allows for remote, manual airflow

adjustments. Wall plate with dial may be mounted in a

standard 2x4 inch electrical junction box.

Two-Speed Control - Control allows motor RPM to

be set at two independent speeds (high or low). Meets

minimum airflow requirements with the ability to bump

up to high speed in an emergency or meet maximum

airflow requirements, or reset down to low speed for

energy conservation.

Constant Pressure Control - Control the Vari-Green

motor via static (variable volume) or velocity (constant

CFM) pressure on the inlet or outlet side of the fan.

Available with duct or room probes for use in:

• Multifamily structures including apartments, condos,

hotels; residential kitchens and bathrooms

• Institutional facilities such as schools, prisons,

multistory office buildings; bathrooms

®

Air Quality, Volatile Organic Compounds (VOC) -

Control a Vari-Green motor via changes in VOCs.

VOCs are gasses that are emitted from humans,

building materials, perfumes, foods, and furniture

off-gassing. Range is 0-2000 CO

PPM equivalent.

2

• Institutional facilities including schools,

courthouses, hospital bathrooms, waiting

rooms, cafeterias

• Commercial buildings including office space in

conference rooms, bathrooms, or breakrooms

Air Quality for Temperature and Humidity - Control

the Vari-Green motor via changes in temperature,

humidity, or both. Range is 32° to 120°F and 0% to

100% relative humidity.

• Multifamily structures including apartments,

condos,hotels, with placement in bathrooms and

utility rooms

• Commercial buildings such as office buildings for

placement in general office space, conference

rooms, utility rooms, and bathrooms

9

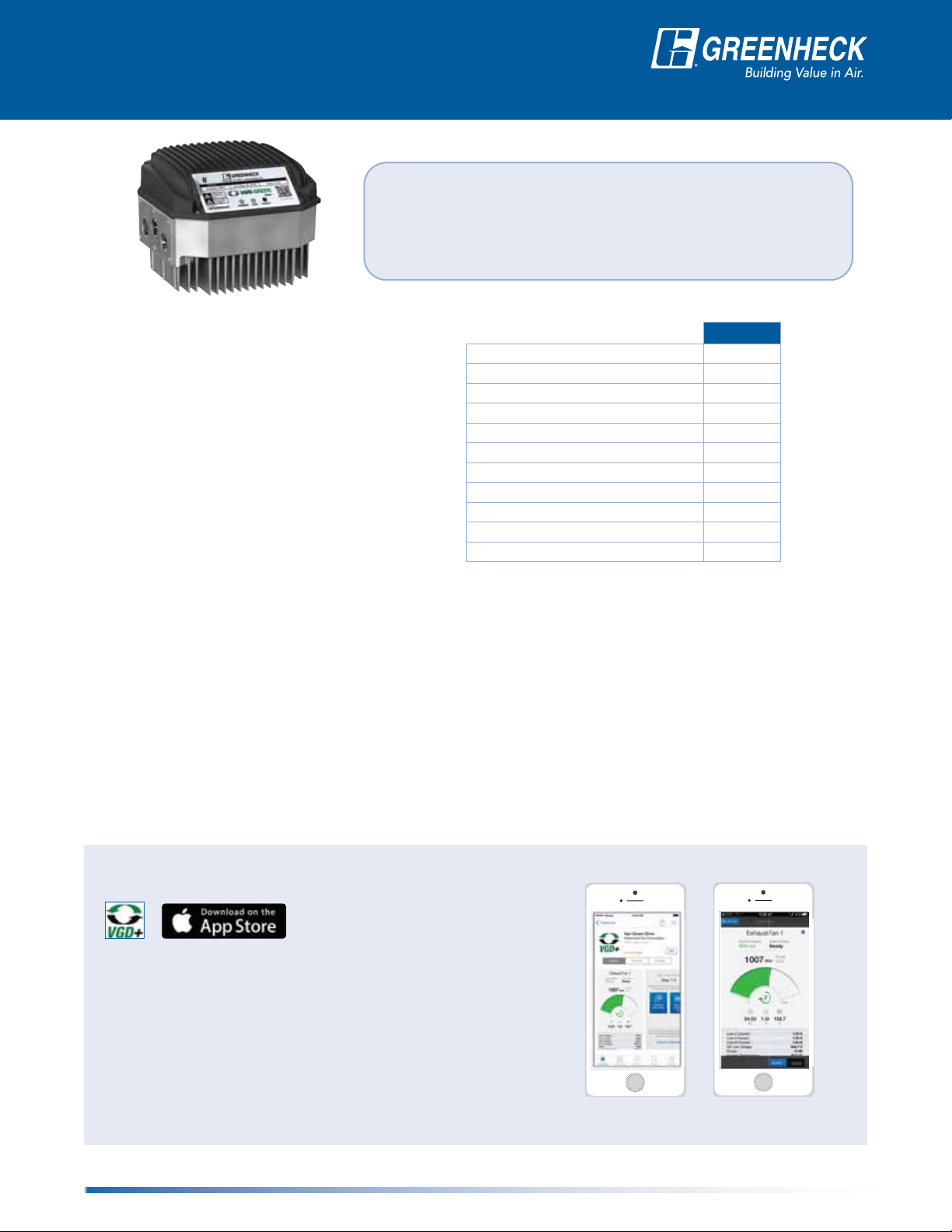

Vari-Green® Drive

6:23 AM

6:23 AM

6:23 AM

23 A

89%

%

Greenheck’s Vari-Green Drive is a factory-mounted, wired, and

programmed variable frequency drive. Specifically designed for

use in air handling applications, the Vari-Green Drive expands

variable volume operation and simplifies speed adjustment to

three phase applications.

Features

Vari-Green Drive model VGD-100+ is constructed

with a NEMA-4X rated enclosure to ensure a

long life operating under outdoor environmental

conditions. Every Vari-Green Drive is compatible

with all Vari-Green controls or any industry

control sending a 0-10V or 4-20mA signal.

Model VGD-100+ is also equipped with Modbus/

BACnet

®

communications allowing for seamless

integration to building management systems.

Benefits

• Variable volume control from the factory on

larger fan sizes where Vari-Green motors

are not available.

3

• R

filtering and short leads mitigate harmonics.

• Quick start-up and simplistic commissioning

as each drive comes preprogrammed and

installed from the factory.

Features

Analog Input (0-10V, 4-20mA)

Damper Actuator Output (24VDC)

Control Voltage Output (24VDC)

LED Indication Lights (3)

Relay Output (2)

Digital Input - Dry (2)

Digital Input - Voltage (2)

RS-485 (Modbus/BACnet)

Bluetooth/Smart Device Interface

On-Board PID Control

Optional Pressure Transducer

VGD-100

+

9

9

9

9

9

9

9

9

9

9

9

• Eliminate compatibility issues as the motor and

drive are factory-matched.

• Induction motors are reliable, efficient and readily

available if replacements are needed.

10

Vari-Green Drive 100+ App

Vari-Green Drive model VGD-100+ features a smartphone

companion app available for download from the app

store. Manually control and monitor the drive from the app

as well as access any advanced programming features.

For more information about the companion app and its

capabilities, reference the VGD-100+ Quick Start Guide

located on greenheck.com and the documentation section

of the app.

6:23 AM

6:23 AM

89%

89%

89%

6:23 AM

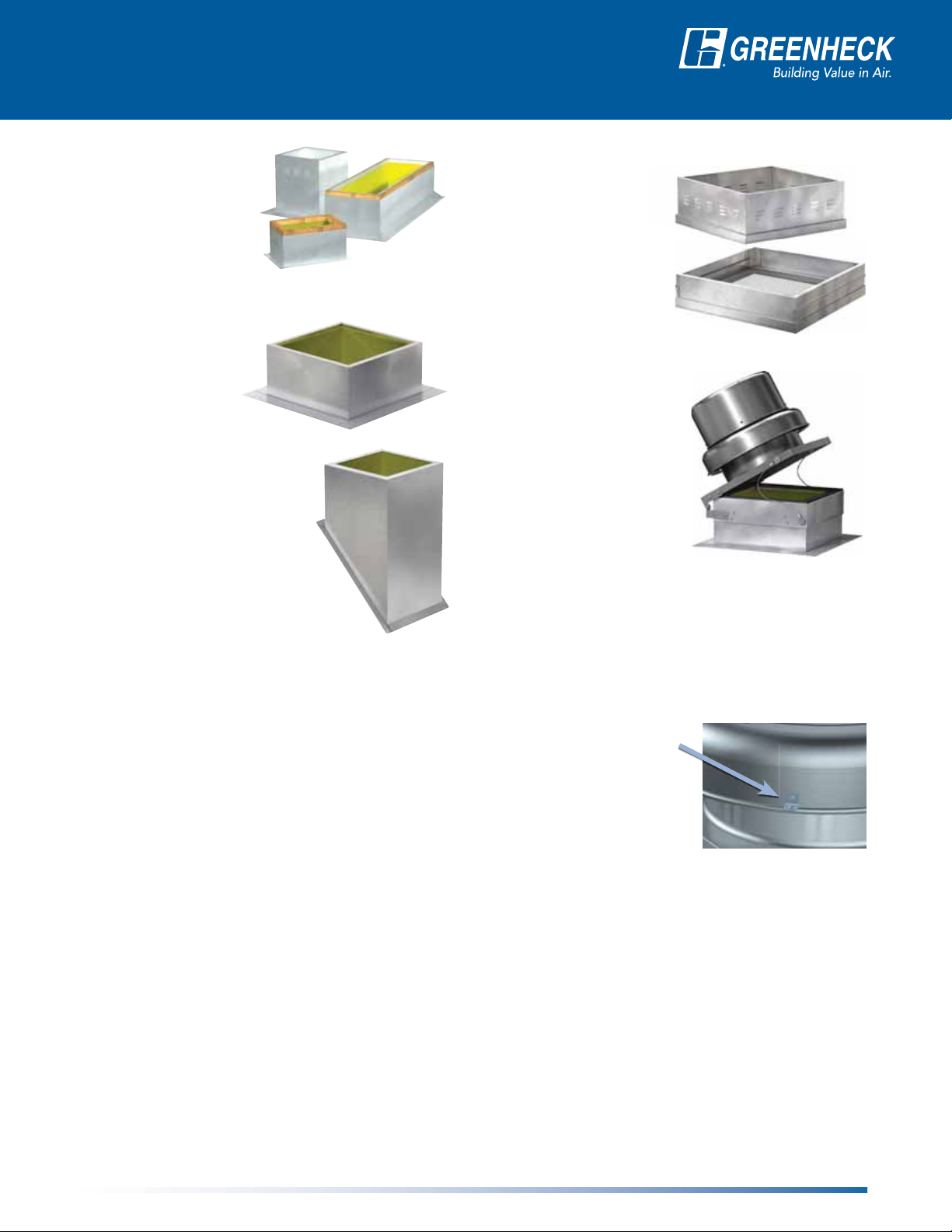

Roof Curbs, Options and

Accessories

Roof Curbs

A wide variety of roof

curbs are available for

mounting the fan to the

roof including: vented,

flanged, pitched and

sound-absorbing.

High Wind and Severe Duty Roof Curbs

GPF/GPFP/GPFR

Approved for high

wind applications up

to a 75 psf wind-load

rating. Constructed

of 18-gauge steel,

formed and welded

sides, and a 5-inch flashing

flange. GPF is available up

to 42 inches inheight. GPFP

and GPFR areavailable up to

24inches in height.

GPFHL (Heavy Load) 14-gauge galvanized steel

with internal vertical support

members and a 5-inch flashing

flange. Available up to 24 inches

inheight.

GPFHD (Heavy-Duty) - 12-gauge galvanized steel

with internal vertical support members and a double

thick 5-inch flashing flange. Available up to 24 inches

in height.

Note: Maximum 24 inch height restriction on all curb

models certified for high wind.

For detailed curb information refer to Roof Curbs,

Extensions and Equipment Supports catalog.

Mounting details for the roof curb to the roof

substrate and the fan to the curb are included with

each model G and GB installation manual.

Curb Extensions

Extensions raise the

fan discharge above

the roof line and

provide an accessible

mounting location for

dampers. Insect screen

bases, constructed with

a removable fine mesh,

are recommended for

applications where insect

entrymust be prevented.

Hinged Curb Cap with

Cables (Field Installed)

Mounted to the curb cap,

allows entire fan to tilt

away from curb for access

to wheel and ductwork.

Includes restraint cables.

Hinged Base

(Factory-Mounted)

Allows for easy maintenance. Hinge and restraining

cables are factory-mounted to a subbase attached

directly to curb without additional height added.

Curb Seal

Rubber seal between fan and curb to ensure proper

sealing when attached to a curb.

Tie-Down Points

Four brackets located on

the shroud for securing

the fan in high wind

applications. Cables and

anchors by others.

11

Roof Curbs, Options and

Accessories

Speed Controllers for

Standard Motors

Available for use with shaded

pole and permanent split

capacitor (PSC) motors

on model G fans. They provide

an economical means of system

balancing with direct drive fans.

Disconnect Switches

A wide selection of NEMA rated

switches are available for positive

electrical shutoff and safety

including: dust-tight, rainproof,

and corrosion-resistant.

Switches may be internally

or externally mounted.

Dampers

Designed to prevent

outside air from entering

back into the building

when fan is off. Includes

gravity and motorized

dampers. Damper sizes

are shown on each

performance data page.

Motor Starters

The fundamental

function of a motor

starter is to protect the

motor from damage

that can occur from

overheating. With

a-Greenheck motor

starter, you receive

the best motor

protection available.

Specific model

components may include:

SmartStart™ technology, physical interface, overload

protection, disconnect, magnetic contactor, NEMA-1

or NEMA-3R steel enclosures and pre-engineered

easy system integration. For complete information on

specific Greenheck motor starter models, refer to

greenheck.com, motor starter page.

Birdscreen

Galvanized mesh is standard.

Optional aluminum or stainless

steel rigid wire are also available.

G and GB models are Listed for electrical

(UL/cUL705) File no. E40001

GB models for Emergency Smoke Control Systems

(UL/cUL Listed for 500°F (260°C) for 4 hours and

1,000°F (538°C) for 15 minutes) File no. MH17511

Note: UL/cUL is optional and must be specified.

Coatings

A wide variety of coatings and colors are available.

Greenheck coatings and resistance charts can be

found in the Performance Coatings Commercial

and Industrial Fans catalog and in our Product

Application Guide—Performance Coatings for

Ventilation Products.

Permatector™ is our standard coating.

PERMATECTOR

TM

Typically used for applications that

require corrosion resistance in indoor

and outdoor environments.

Hi-Pro Polyester is resistant to salt

water, chemical fumes and moisture

in more corrosive atmospheres.

Typically used for applications that

require superior chemical resistance,

excellent abrasion and outdoor UV

protection. This coating exceeds

protective qualities of air dried Heresite

and air dry phenolic. Customers can

choose from seven standard decorative

colors or color match any color.

Macropoxy with UV topcoat

is a two-coat extreme duty coating

system. The base coat of Macropoxy

is designed specifically for harsh

environments, while the topcoat is used

for its chemical and UV resistance.

Together this system offers the greatest

protection in adverse environments,

such as marine or chemical processing

applications. Customers can choose

from seven standard decorative colors.

12

Typical Installations

Models G and GB

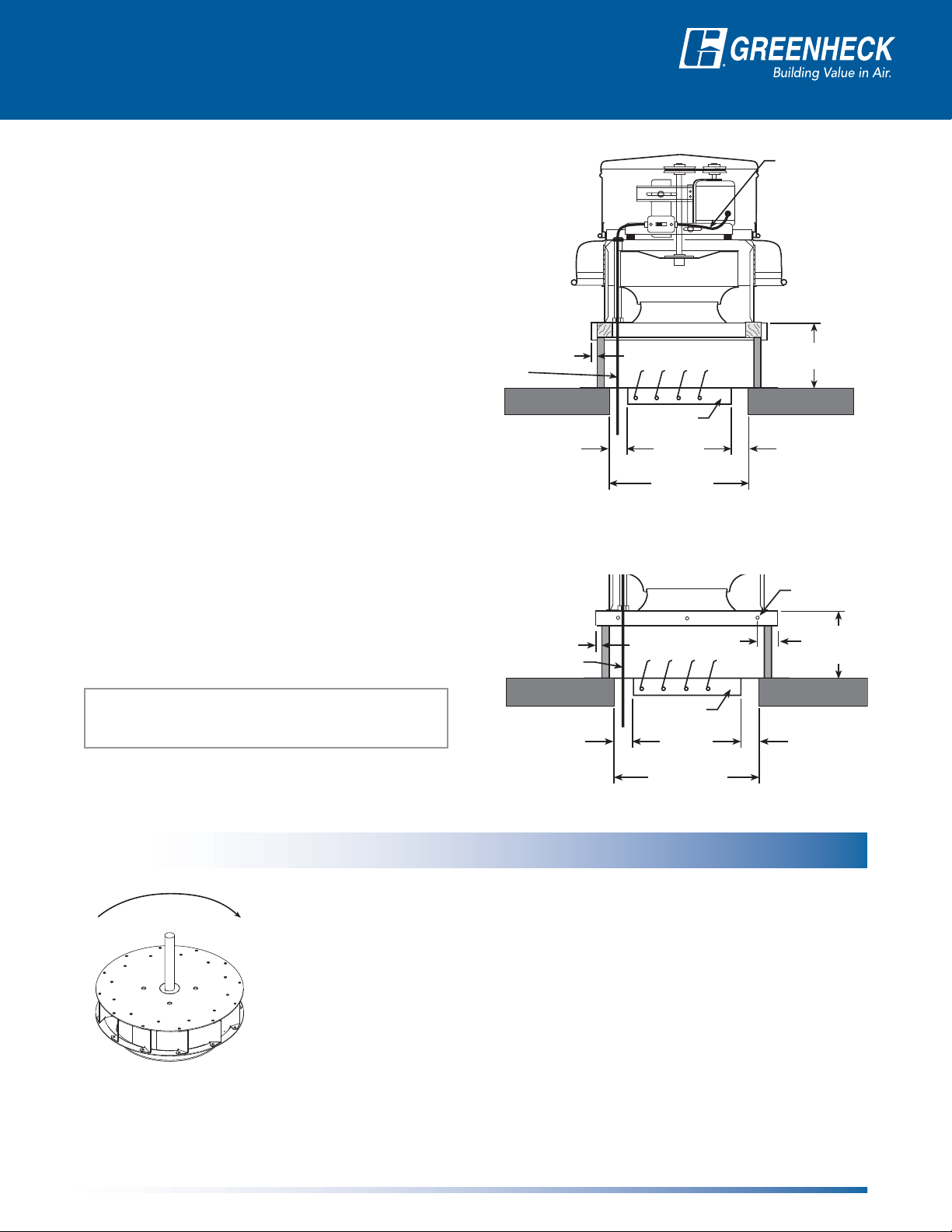

General Clean Air (Figure 1)

Models G and GB exhaust fans meet the needs of

general clean air applications. Tests were conducted

to ensure safe, rugged and reliable fans.

Due to the varying types of airstreams encountered

in commercial ventilation, system designers must

be aware of national, state, and local codes and

guidelines governing these installations. Consult

local code authorities before proceeding with any

ventilation project.

• When roofing materials extend to the top of the

curb, roof curbs should be 1

each side) less than the unit curb cap to allow for

roofing and flashing.

• For recommended duct size, damper size, and

roof opening dimensions, refer to the performance

data pages (starting on page 15).

• Installation must include a means for inspecting,

cleaning and servicing the exhaust fan.

High Wind, Hurricane and Seismic (Figure 2)

• Roofing materials can extend to the top of the

curb, roof curbs should be 1 inch (25 mm) total,

or 1⁄2inch (13 mm) on each side, less than the unit

curb cap to allow for roofing and flashing.

1

⁄2 inches (3⁄4 inch on

Figure 1

Wiring by

Others

Figure 2

¾ in.

(19 mm)

1

(32 mm)

½ in. (13 mm)

Wiring by

Others

1

/4 in.

Damper

Recommended

Duct and

Damper Size

Recommended

Roof Opening

4 in. (102 mm)

From Curb Edge

Factory Wired

from Motor to

Disconnect

8 or 12 in.

(203 or 305 mm)

1

1

/4 in.

(32 mm)

1

/4 in. (6 mm)

Fastener

8 - 24 in.

(203 - 610 mm)

GPF

Note: The typical installations shown are recommendations

based on national codes. Local authority may supersede these

recommendations.

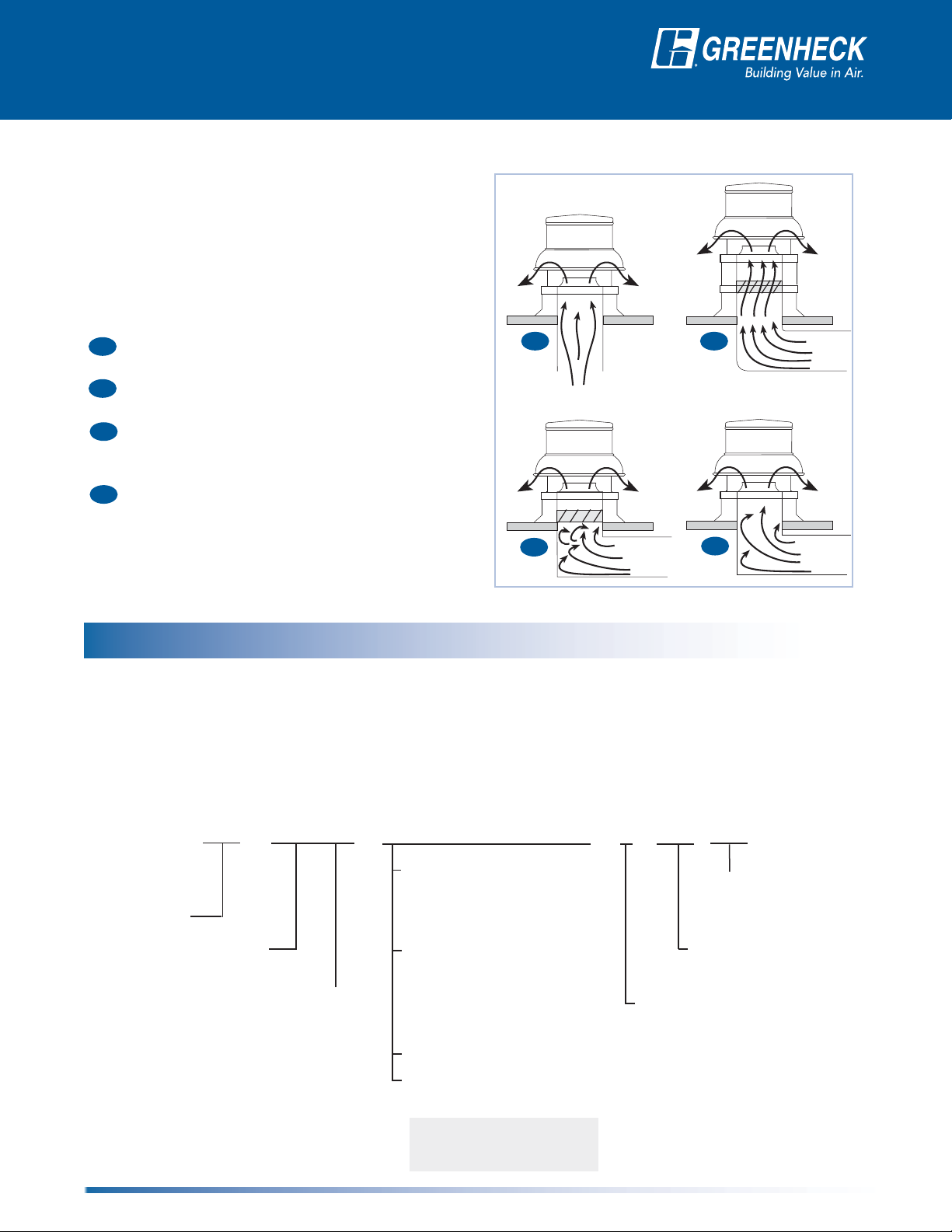

Wheel Rotation

Direction of rotation is very critical. Rotation in the wrong direction will result in

excessive horsepower, possible motor burnout, and increased noise levels.

Check rotation by energizing the unit momentarily. The rotation should be the same

as the rotation decals affixed to the unit and is clockwise when viewed from the top

of the unit.

Clockwise

1

/4 in. (32 mm)

1

Damper

Recommended

Duct and

Damper Size

Recommended

Roof Opening

11/4 in. (32 mm)

13

Typical Installations

Models G and GB

Fan Inlet Connections

To ensure proper fan performance, exercise caution

in fan placement and connection to the ventilation

system. Obstructions, transitions, poorly designed

elbows, improperly selected dampers, etc., can

cause reduced performance, excessive noise, and

increased mechanical stress. For performance to be

as published, the system must provide uniform and

stable airflow into the fan.

Provide uniform airflow at fan inlet to ensure

A

optimum performance.

Provide uniform airflow at fan inlet and through

B

the damper to ensure optimum performance.

Dampers must open fully. Use motorized

C

dampers in low airflow applications to

reduce losses.

Avoid sharp turns or entrance conditions that

D

cause uneven flow. Use turning vanes in elbows

to reduce adverse effects.

Good

Good

A

Poor

C

B

Poor

D

Model Number Code

The model number code system is designed to completely identify the fan. The correct code letters

must be specified to designate belt or direct drive. The remainder of the model code is determined by

the size and performance

GB - 240HP - A - 5 - VG/VGD - 1 - 34 - X

Configuration

G - Direct Drive

GB - Belt Drive

Fan Size

060 through 540

Wheel Pressure Level

HP - High Pressure

Motor RPM (Direct Drive only)

A = 1725 D = 1550

B = 1140 E = 1050

C = 860 G = 1300

Motor HP

6 = 1/6 10 = 1 50 = 5

4 = 1/4 15 = 1½ 75 = 7½

3 = 1/3 20 = 2 100 = 10

5 = 1/2 30 = 3 150 = 15

7 = 3/4

VG = Vari-Green

VGD = Vari-Green Drive

International

(See CAPS for performance)

K = 950 RPM J = 1475 RPM

®

®

Performance Revision

X = UL 705

F = UL Smoke

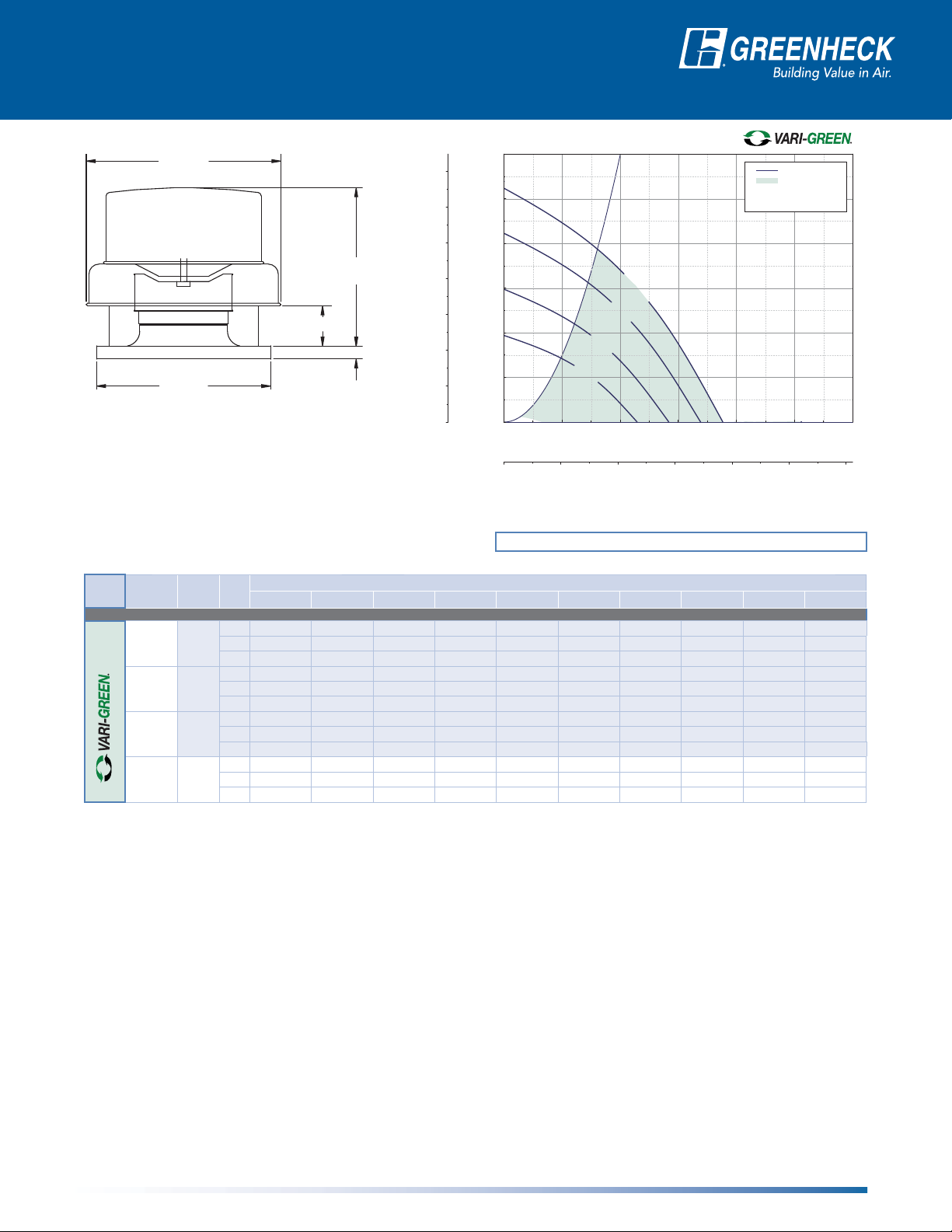

Control Systems

Curb Cap Size (inches)

14

Roof Downblast Exhaust

Size-060: G

193⁄8

(492)

140

120

100

*121⁄8

(308)

3 (76)

13⁄4 (44)

Static Pressure (Pa)

17

(432)

Damper Size = 8 x 8 (203 x 203)

Roof Opening = 10½ x 10½ (267 x 267)

Shroud Thickness = 0.064 (1.6)

Motor Cover Thickness = 0.040 (1.0)

Curb Cap Thickness = 0.064 (1.6)

^Approximate Unit Weight = 15 lbs. (7 kg)

All dimensions in inches (millimeters). *May be greater depending on motor.

^Weight shown is largest cataloged Open Drip-Proof motor.

Direct

Motor HPFan

Drive

060

VG1/10

E-1/200 1050

G-1/100 1300

D-1/60 1550

RPM

1725

CFM

BHP

Sones

CFM

BHP

Sones

CFM

BHP

Sones

CFM

BHP

Sones

0 0.05 0.1 0.125 0.15 0.2 0.25 0.3 0.375 0.4

138 116 90 73 53

0.00 0.00 0.01 0.01 0.01

1.7 1.7 1.7 1.7 1.7

170 153 135 125 113 85

0.01 0.01 0.01 0.01 0.01 0.01

2.9 2.8 2.8 2.7 2.7 2.6

203 188 173 166 158 140 120 92

0.01 0.01 0.01 0.01 0.02 0.02 0.02 0.02

4.3 3.9 3.8 3.8 3.8 3.7 3.7 3.6

226 213 199 193 186 173 155 137 101 89

0.02 0.02 0.02 0.02 0.02 0.02 0.02 0.02 0.02 0.02

5.4 4.9 4.9 4.8 4.8 4.8 4.7 4.6 4.5 4.4

0.6

0.5

0.4

80

0.3

60

0.2

40

Static Pressure (in. wg)

20

0

0.1

0.0

0 60 120 180 240 300 360

0 100 200 300 400 500 600

Direct Drive RPM

E-1050-RPM G-1300-RPM D-1550-RPM VG-1725-RPM

Static Pressure in Inches wg

RPM (Direct)

RPM (Vari-Green)

Density 0.075 lb/ft

Density 1.2 kg/m

E

V

R

U

C

M

E

T

S

Y

S

S

060-VG

I

H

T

F

O

T

060-D

F

E

L

E

H

T

O

060-G

T

T

C

E

L

E

S

060-E

T

O

N

O

D

3

3

Volume (cfm)

3

Volume (m

/hr)

Performance certified is for installation type A: Free inlet, Free outlet. Power rating (BHP) does not include transmission losses. Performance ratings include the effects

of a birdscreen. The sound ratings shown are loudness values in hemispherical sones at 5 ft. (1.5 m) in a hemispherical free field calculated per AMCA Standard 301.

Values shown are for installation type A: free inlet hemispherical sone levels.

15

Loading...

Loading...