Page 1

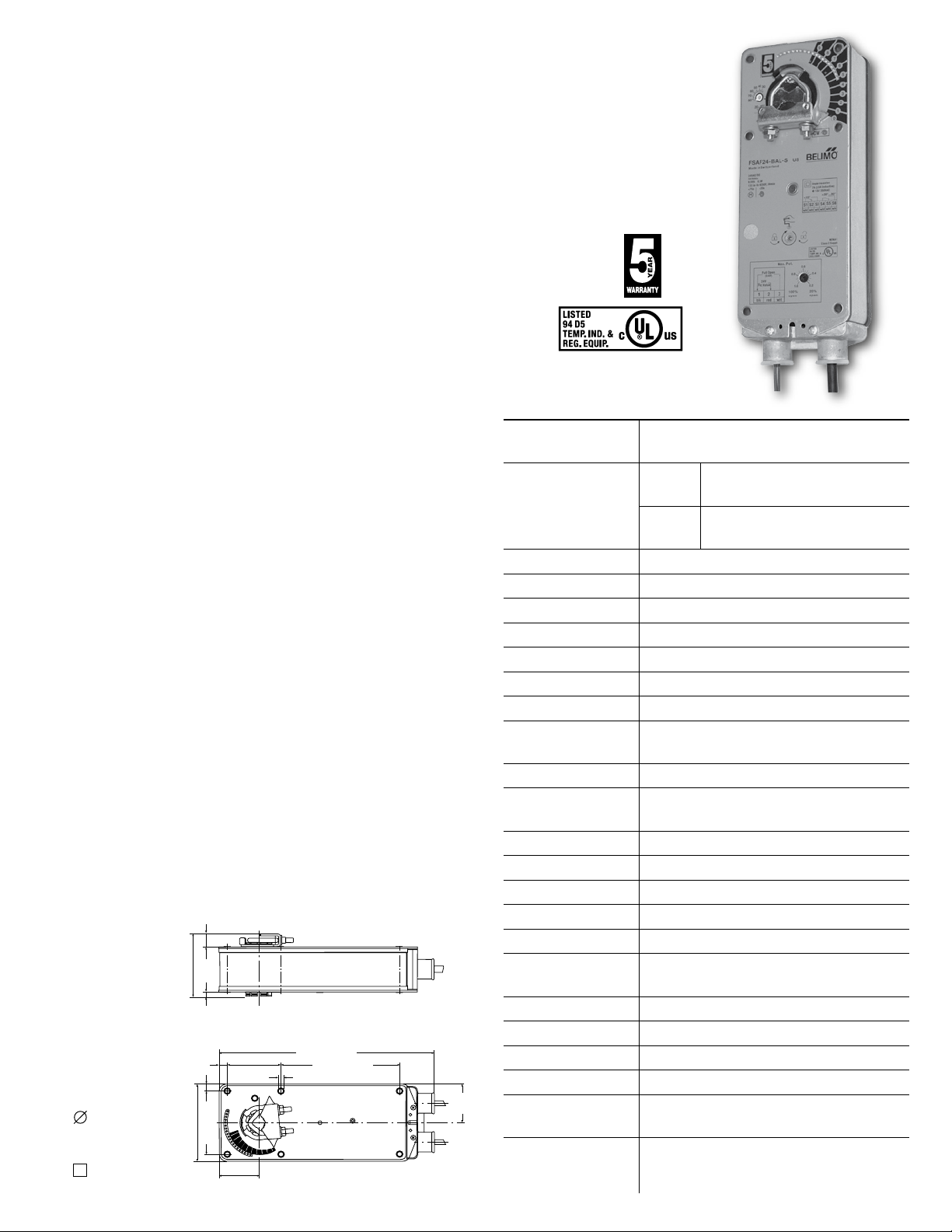

1.97"

3.

1

5"

[

80]

3.

8

6" [

9

8]

2

.

2

4

"

[57]

[50]

1.93"

[

4

9]

2.64"

[67]

0.26" [6.5]

5.85" [148.5]

10.59" [269]

0.35" [9]

0.39" [10]

0.65" [16.5]

0.19" [5]

3

.

2

5

" [82.7]

FSAF24-BAL (-S) US

70793-00001

Balancing Fire and Smoke Actuator, Three Position

Damper Actuator, Spring Return Closed, 24V, for

UL555(S) Fire and Smoke Dampers. A maximum

position potentiometer is built-in. 100% open override.

Application

For three position control of UL555S rated dampers in HVAC. Actuator

sizing should be done in accordance with the damper manufacturer’s

tests. In the absence of other information, use 10 in-lb of torque per

square foot of area for opposed blade and 14 in-lb for parallel blade fire

and smoke dampers at 1000 fpm air velocity.

The FSAF24-BAL is specifically designed to balance the air flow in ducts

and simultaneously provide control of fire and smoke dampers. 0V =

spring closed. 24V on wire 2, not 3 = drive to the potentiometer position

(balanced flow). 24V on wire 3, regardless of the status of wire 2 = drive

full open (smoke control extraction or pressurization). See Application

drawings below.

Operation

The FSAF24-BAL actuator provides spring return operation. There is no

reversing switch. Mount in spring return closed position. The torque

is asymmetrical giving 180 in-lb drive and 133 in-lb spring. A manual

override winder and locking mechanism is provided. If the manual winder

is used when the actuator is powered, the actuator will release, drive

closed, and then go back to the potentiometer position. The actuator may

not be mechanically parallelled or “piggybacked.” Each damper section

should be controlled by a separate actuator.

The FSAF24-BAL uses a DC motor which is controlled by a microchip.

The actuator may be stalled anywhere during its rotation without damage.

If power is removed, the damper will spring closed. Interlocks must be provided

as necessary for life safety functions and to shut down fan if required.

Dimensions (All numbers in brackets are metric.)

Standard

½” to 1.05”

Optional

½”

Technical Data FSAF24-BAL US

Power supply 24 VAC ± 20% 50/60 Hz

24 VDC ±10%

Power consumption running: AC 9.5 VA 6.5 W

DC 6 W

holding: AC 5 VA 3 W

DC 3 W

Transformer sizing 10 VA (Class 2 power source 24V only)

Electrical connection 3 ft, 18 ga, ½” conduit connectors

Overload protection electronic throughout 0 to 95° rotation

Control signal 24 VAC/DC 3-position

Angle of rotation 20° to 95°, pot adjustable

Torque 133 in-lb [15 Nm]

Direction of rotation reversible with CW/CCW mounting

Position indication visual indicator, 0° to 95°

(0° is spring return position)

Manual override 3mm hex crank (shipped w/actuator)

Running time motor: <75 seconds @ 250°F [121°C]

spring return: <20 seconds

Humidity 5 to 95% RH non-condensing

Ambient temperature -22°F to +122°F [-30°C to +50°C]

Storage temperature -40°F to +176°F [-40°C to +80°C]

Housing NEMA type 1 / IP40 (with flex conduit)

Housing material zinc coated metal

Agency listings cULus to UL 873 and CAN/CSA C22.2

No. 24-93

Noise level running: <45 dB(A), spring: <62 dB(A)

Holding inaudible

Servicing maintenance free

Quality standard ISO 9001, 5 year Belimo warranty

Weight 5.3 lbs (2.4kg)

5.7 lbs (2.6kg) for -S model

Auxiliary switch

2 x SPDT, 7A resistive, 2.5A inductive at

120/250 VAC, UL listed, double-insulated, one

switch is fixed at 10°, one is adjustable 30° to 90°

Page 2

Accessories (AF series accessories may be employed)

S1

S2

S3

S4

S5

S6

IND-AF2 Damper position indicator

K4-1 US Universal clamp for up to 1.05” dia. jackshafts

KH-AF Crankarm for up to ¾” round shaft (Series 2)

KH-AF-1 Crankarm for up to 1.05” jackshaft (Series 2)

KH-AFV V-bolt kit for KH-AF and KH-AF-1

Tool-01 10 mm wrench

ZDB-AF2 Angle of rotation limiter

ZG-100 Universal mounting bracket

ZG-101 Universal mounting bracket

ZG-103 Universal mounting bracket

ZG-104 Universal mounting bracket

ZG-106 Mounting bracket for Honeywell® Mod IV replace-

ment or new crankarm type installations

ZG-107 Mounting bracket for Honeywell® Mod III or

Johnson® Series 100 replacement or new crankarm

type installations

ZG-108 Mounting bracket for Barber Colman® MA 3../4..,

Honeywell® Mod III or IV or Johnson® Series 100

replacement or new crankarm type installations

ZG-AF Crankarm adaptor kit for AF/NF

ZG-AF108 Crankarm adaptor kit for AF/NF

ZS-100 Weather shield (metal)

ZS-150 Weather shield (polycarbonate)

ZS-300 NEMA 4X housing

22965-00001 12mm form fit square shaft adaptor

For an overview of how to apply the accessories, see Belimo Mechanical

Accessories and refer to the Belimo Mounting Methods Guide.

Safety Note

The actuator contains no

components which the user

can replace or repair.

FSAF24-BAL (-S) US Typical Specification

Where indicated on drawings, combination fire and smoke and balancing

dampers shall be controlled by Belimo FSAF24-BAL or equal actuators.

The actuators must be designed so that they may be used for either

clockwise or counter clockwise failsafe operation. Actuator shall open

damper in <75 seconds per UL555S and shall spring closed in under 20

seconds. Actuators shall have a 5-year warranty and be manufactured

under ISO9001 International Quality Control Standards.

Actuator shall have an adjustable Maximum Opening Potentiometer which

shall be used by the TAB contractor to adjust flow to that portion of the

system fed by the damper.

The actuator shall spring closed if either the smoke detector or alarm

system removes power from it. Actuator shall spring closed if the primary

temperature thermodisc opens due to high ambient of >165°F or as

otherwise indicted on drawings.

The actuator shall drive full open if either the smoke control system 100%

open override or Fire Fighters Smoke Control Station override is activated.

Damper shall spring closed again if the thermodisc of a combination fire

and smoke damper opens due to high temperature (typically 250°F).

NOTE: When using FSAF24-BAL (-S) actuators, only use

accessories listed on this page.

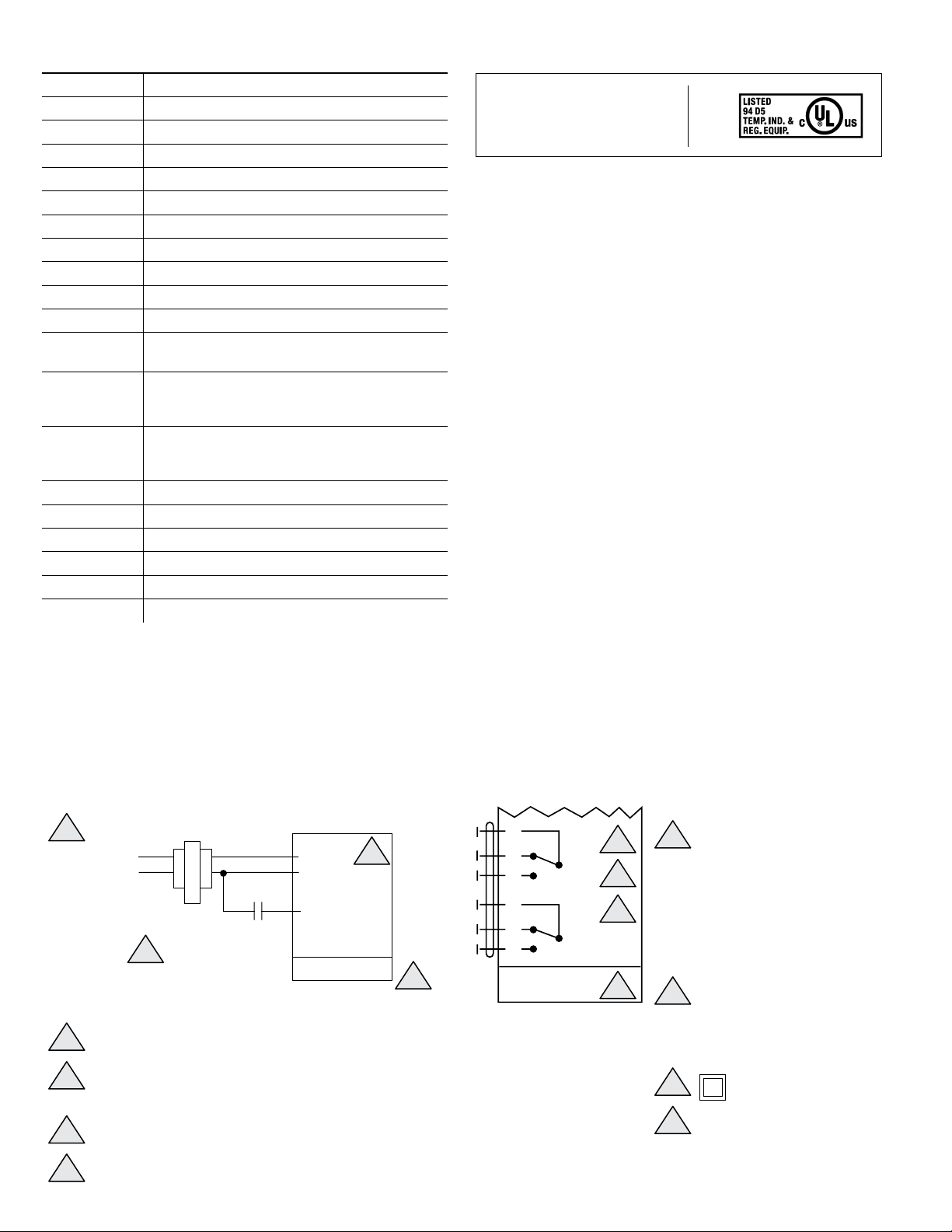

Wiring Diagrams Auxiliary switch wiring for FSAF24-BAL-S US

Line

Voltage

24 VAC Transformer

OVERRIDE CONTROL

See Wiring Diagrams

4

on following pages for

typical methods.

1 Blk Com

2 Red Hot

3 Override Open

FSAF24-BAL US

3

1

NC

10°

NO

NC

30° to 90°

NO

2

FSAF24-BAL-S US

1

3

2

4

For end position indication,

interlock control, fan start-up,

etc., FSAF24-BAL-S incorporates

two built-in auxiliary switches:

2 x SPDT, 7A resistive, 2.5A

inductive 120/250 VAC, UL

listed, one switch is fixed at 10°,

one is adjustable 30° to 90°.

2

Meets UL requirements without

1

the need of an electrical ground

1

Provide overload protection and disconnect as required.

2

Actuators may be connected in parallel. Power consumption

must be observed.

3

Actuator may also be powered by 24 VDC

4

Only connect Hot, Wire 2 to Wire 3 override control

2

connection. Actuator may also be

powered by 24 VDC

3

Double insulated.

4

Actuators may be connected

in parallel. Power consumption

must be observed.

Page 3

Wiring 1

Wiring 1 shows the basic operation of the FSAF24-BAL.

With 1 & 2 powered, actuator drives to

maximum potentiometer setting

Powering wire 3, regardless of

state of wire 2, drives actuator

full open.

Com24 VAC

Hot24 VAC

Close to override

full open

Maximum

Potentiometer

20% to 100%

1

2

3

FSAF24-BAL

Sequence of Operation for Wiring 1

If 1 & 2 are powered and 3 is not powered, actuator goes to Maximum

Potentiometer position. This is typically the balanced flow position.

If 1 & 3 are powered, regardless of the state of wire 2, the actuator goes

100% open. This is a purge mode.

Wiring 2

Wiring 2 shows one way to apply the FSAF24-BAL with a single thermodisc.

SMOKE DETECTOR

Hot24 VAC

SMOKE OVERRIDE

Hot24 VAC

1

2

3

100% OPEN

FSAF24-BAL

165°F

Com24 VAC

Sequence of Operation for Wiring 2

If 1 & 2 are powered, then actuator drives open to position as set by

potentiometer.

If smoke detector or other contact in wire 2 opens, then actuator springs

damper full closed.

If 1 & 3 are powered, regardless of state of wire 2, actuator drives

damper open 100%.

If 165°F thermodisc opens, actuator springs closed.

Manual reset required.

Wiring 3

Wiring 3 shows one method of wiring a Reopenable Damper using the

Fire Fighters override switch and two thermodiscs.

Dual Sensor Reopenable Damper

SMOKE DETECTOR

HOA Switch

Hot

24 VAC

FIRE FIGHTERS SMOKE

CONTROL STATION

165°F

A

O

H

250°F

COMBINATION FIRE SMOKE DAMPER

1

2

3

FSAF24-BAL

Com

24 VAC

Wiring 4

Wiring 4 shows an alternate wiring method to that shown in Wiring 3.

SMOKE DETECTOR

HOA Switch

Hot

24 VAC

FIRE FIGHTERS SMOKE

CONTROL STATION

165°F

A

O

H

FSAF24-BAL

250°F

1

2

3

Com

24 VAC

Sequence of Operation for Wiring 3 and Wiring 4

If HOA switch is in Auto position, smoke detector or other series contact

is closed and temperature is <165°F at thermodisc sensor, then actuator

wire 2 is powered and damper is driven open to adjustable position as set

by Maximum Potentiometer. If smoke detector or other contact in wire 2

opens or if the manual reset 165°F sensor opens, then actuator springs

damper closed.

If Hand-Off-Auto switch at FSCS is moved to Off, power to wire 2 is

removed and actuator springs damper closed.

If HOA switch is moved to the Hand position, power bypasses wire 2

and goes to wire 3. This reopens the damper for smoke evacuation or

pressurization control to the 100% open position.

If the 250°F thermodisc opens, the actuator springs closed and cannot be

overridden. Manual reset of each thermodisc is required.

WARNING: For UL555S Listed dampers and actuators,

follow damper manufacturer recommended field wiring

diagrams. Do not bypass high temperature limits.

3

Page 4

FSAF24-BAL (-S) US Balancing Fire and Smoke Actuator

Typical Applications

Most shafts carrying conditioned air from air handling equipment rooms

to multiple stories are installed in fire and smoke barriers. In addition, the

air to the floor must be balanced.

The FSAF24-BAL actuator allows one damper and actuator to do the job

that once required three dampers – a fire damper, a smoke damper, and

a balancing damper. See Figure 1.

From air handling unit

Wall is fire and smoke barrier. Duct

requires fire damper, smoke damper, and

the duct must be balanced for the space

air quantity requirement.

Wiring 3 and 4 show actuated damper wiring for Engineered Smoke

Control Systems. Where a smoke control damper is required in the wall

and a balancing damper is required for volume-temperature control, the

FSAF24-BAL provides a superior technical and economic solution.

See Figure 2. Other applications exist which are not covered here.

Fire Mode

Zone 1

Open 100% in fire Closed in fire

Shaft

To space

Smoke detector and

power wiring.

Figure 1

The two most common applications are dampers installed to contain

smoke and those installed in full engineered smoke control systems.

Wiring 2 on the preceding page shows the damper installed with a

smoke detector for containment. Figure 1 shows this application.

Closed in fire Open 100% in fire

Zone 2

Open 100% in fire Closed in fire

Zone 3

Figure 2

Non-dedicated smoke control system

The supply dampers are fire, smoke, and balancing. Three dampers in one.

Normally, the damper is balanced for the design supply air quantity. If a

fire occurs, the smoke zone supply damper closes and the adjacent zone

supply dampers open 100%.

The return dampers are not typically balanced and are normal fire and

smoke combination dampers.

In normal operating conditions, the BALANCING actuator is set to open

by the Maximum Potentiometer on the cover of the actuator. This is the

balancing position. It can be set as low as 20% open.

If the sensor detects ambient above 165°F (or as specified), the actuator

springs closed.

Belimo Air Controls • 203.791.9915 • www.belimo.com

If wired for smoke barrier protection or purge control, wire 3 may be

powered to open the damper actuator 100% to maximize the amount of

air to pressurize a space or remove smoke.

4

Loading...

Loading...