Page 1

Document number 472664

®

Flange Mounted Installation

INSTALLATION INSTRUCTION SUPPLEMENT

Refer to:

‘Installation Instructions for SMD, SESMD, SSSMD, SMDR,

SESMDR, and SSSMDR series Models’ (Part #)

for additional details.

“UL CLASSIFIED

(see complete marking on product)”

“UL CLASSIFIED to Canadian safety standards

(see complete marking on product)”

Standards UL 555 & 555S

Classifications Filed at UL under Listing #R13317

1. SMOKE DAMPER REQUIREMENTS AND

APPLICATION

Smoke dampers are required to close and prevent

the passage of air and smoke through ducts or

ventilation openings in smoke barriers. Smoke

dampers are also applied in engineered smoke

control systems to establish air pressure differentials

and thereby prevent the spread of smoke. These

dampers are designed to operate with blades running

horizontally. Dampers can be vertically or horizontally

installed at, in accordance with NFPA-90A, or

adjacent to the point where the duct passes thru the

smoke barrier.

2. LOCATION OF DAMPER IN DUCTWORK

Place the damper assembly in its proper position

relative to the barrier. The plane of the closed

damper blades must be within 24 in. (610mm) of the

rated smoke barrier and before any duct inlets or

outlets.

3. ATTACHING DAMPER TO THE DUCT

The damper is flange mounted to the duct, sleeve,

or wall opening with using #10 sheet metal screws,

1

/4 in. (6mm) diameter bolts and nuts, tack or spot

welds, or 3/16 in. (5mm) diameter steel pop rivets.

Attachments must be made at each flange spaced

a maximum of 6 in. (152mm) on centers and a

maximum of 2 in. (51mm) from corners.

4. SEALING THE INSTALLATION

The following duct sealants may be used to seal

between the dampers flange and the mating surface:

PA2084T duct sealant adhesive manufactured

by Precision, DP1010 water base duct sealant

manufactured by Design Polymetrics, Grey Pookie

or Ductmate PROseal® in accordance with SMACNA

recommendations.

5. ACTUATOR CONNECTIONS

Electrical and/or pneumatic connections to damper

actuators should be made in accordance with wiring

and piping diagrams developed in compliance with

applicable codes, ordinances and regulations.

Damper model

SMD-301, 302

SMD-301M, 302M

SMD-401

SMD-401M

SMD-xxx, SESMD-xxx,

SSSMD-xxx Series

Smoke Dampers

Maximum Single

Section Size

in. (mm)

32 x 50

(813 x 1270)

32 x 50

(813 x 1270)

48 x 60

(1219 x 7315)

48 x 36

(1219 x 914)

Maximum Overall

Size for Multiple

Section Dampers

in. (mm)

128 x 100 or 256 x 50

(3251 x 2540) or

(6502 x 1270)

128 x 100 or 256 x 50

(3251 x 2540) or

(6502 x 1270)

192 x 72, 48 x 288,

or 384 x 36

(4877 x 1829,

1219 x 7315 or

9754 x 914)

144 x 36

(3658 x 914)

Page 2

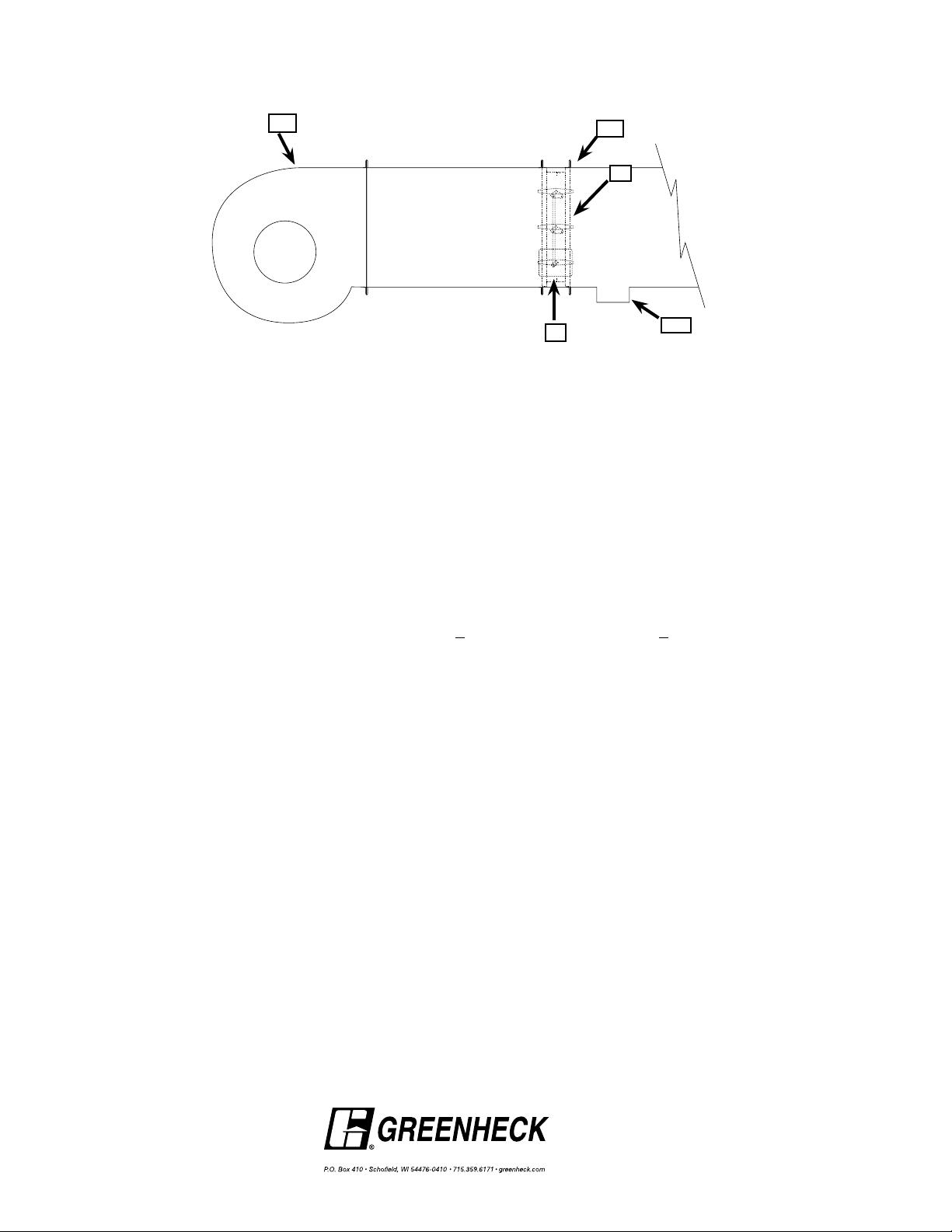

3

4

1

5

2

Item Description

1. Damper frame

2. Duct outlet

3. Fan (not limited to centrifugal)

4. #10 sheet metal screws

5. Actuator

The actuators are to be installed to function per system

requirements and to be controlled by smoke detection

devices.

FAN ISOLATION APPLICATION

For air handling equipment isolation, leakage rated dampers are designed to operate with blades running horizon-

tally. Dampers can be installed in a vertical or horizontal position. Sealants and damper seal materials meet the

requirements of NFPA90A for smoke developed rating (<50) and flame spread index (<25) as tested per UL723/

ASTME84-91A/NFPA 255. Dampers can be attached to the fan system discharge or inlet without being 24 in.

(610mm) of a smoke barrier when used as an air handling equipment isolation damper.

Copyright © 2009 Greenheck Fan Corporation

Double Flange SMD

Rev. 1 June 2009

Loading...

Loading...