Page 1

Figure 2 Fabra hood Form F 471322

Document #471322

Fabra Hood • Form F

®

Throat length less than or equal to 72 inches

Single Section with Filters

Assembly Instructions

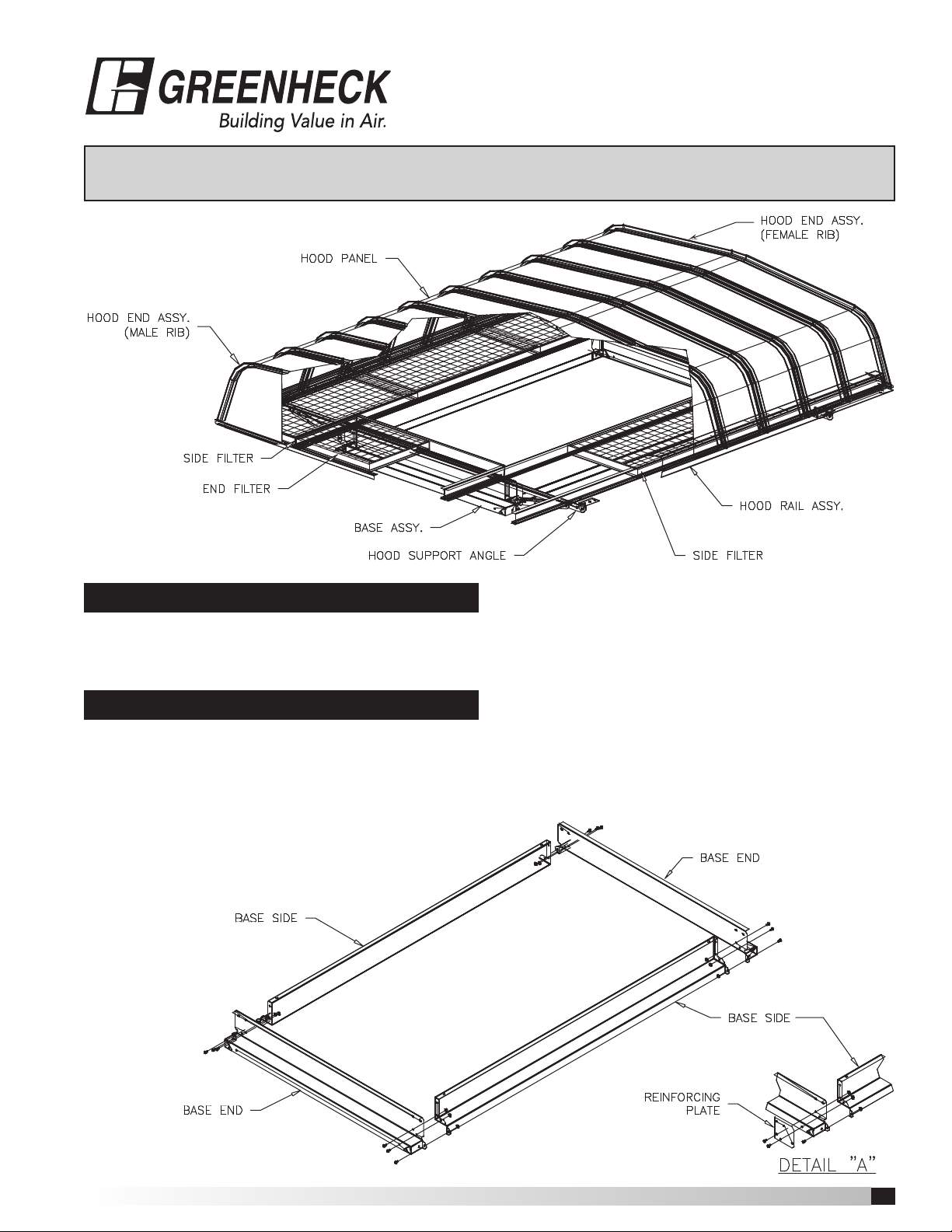

Open the shipping crates and separate the parts

according to the size of the unit (See figure No. 1 on

attached "PARTS LIST")

Place the two BASE ENDS and the two BASE SIDES in

their approximate relationship to each other.

(See Figure 2) Fasten together using three (3) 1⁄4-20

fasteners per corner for 5 inch high base and four (4)

1

⁄4-20 fasteners per corner for 12 inch high base. Note:

Fasteners should be hand tightened only until step 4.

Figure 2

STEP 1

STEP 2

On some units where the difference between the

hood width and throat width is greater than 32 inches,

a REINFORCING PLATE is required in the corners of the

BASE (See Figure 2, DETAIL "A")

Fabra Hood • Form F

1

Page 2

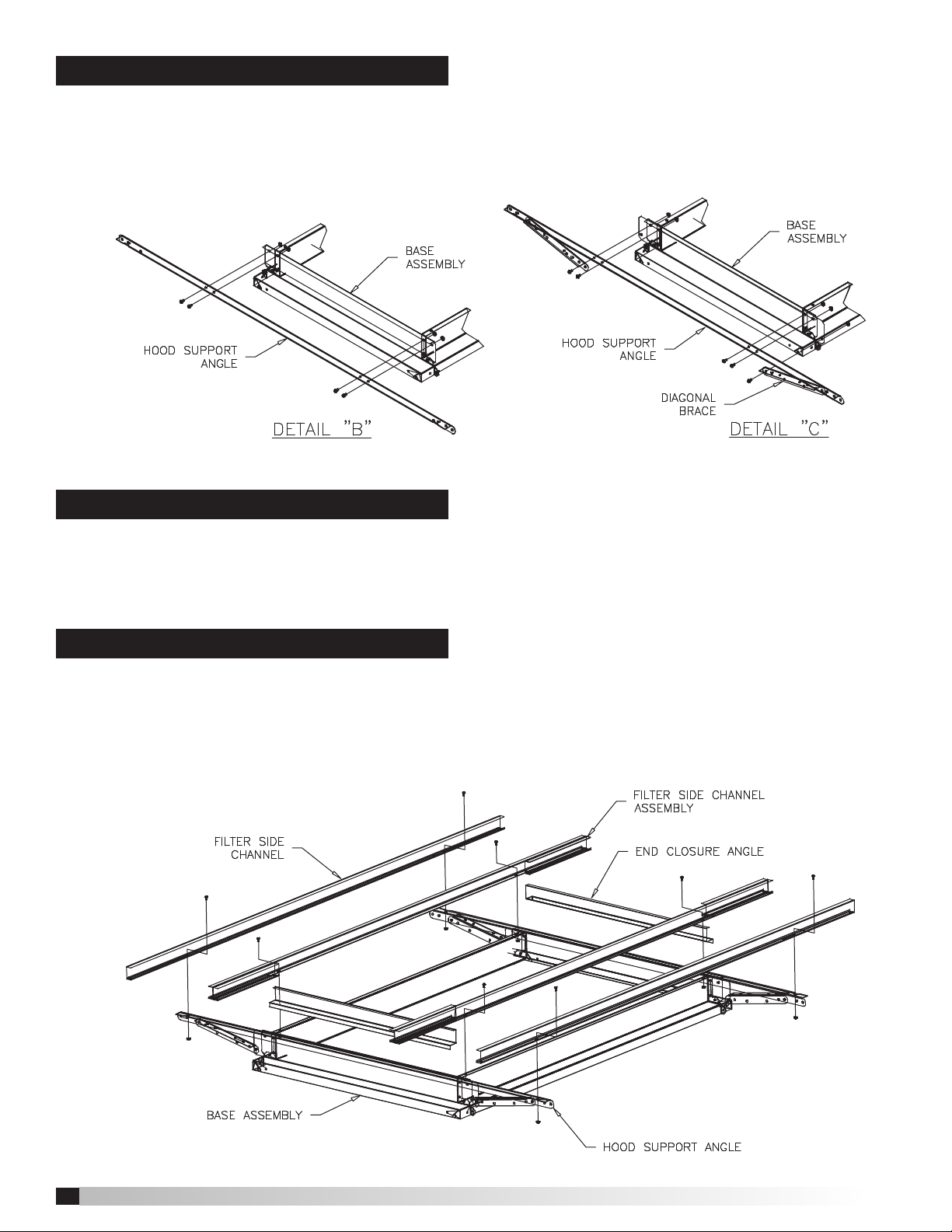

STEP 3

Attach the HOOD SUPPORT ANGLE to the BASE

ASSEMBLY, (hand tight) using four (4) 1⁄4-20 fasteners

per angle. (See Figure 3, DETAIL "B") On some units two

(2) DIAGONAL BRACES come pre-attached to

Figure 3

STEP 4

Tighten all BASE, SIDE and BASE END fasteners.

Caulk all inside corners where the base sections came

together. At this point, the base may be lifted onto the

roof curb before proceeding with further assembly.

the HOOD SUPPORT ANGLE. Fasten the loose end of

the DIAGONAL BRACES to the BASE ASSEMBLY using

one (1) 3⁄8-16 FASTENER PER diagonal brace. (See

Figure 3, DETAIL "C'')

STEP 5

Attach the FILTER SIDE CHANNEL (hand tight) to

the HOOD SUPPORT ANGLE and the FILTER SIDE

CHANNEL ASSEMBLY (hand tight) to the BASE SIDE,

using two (2) 5⁄16 X 1 inch weldstud fasteners per

Figure 4

channel. (See Figure 4) Sandwich the END CLOSURE

ANGLE between the BASE END and the SIDE FILTER

CHANNEL ASSEMBLY. (See Figure 4)

2

Fabra Hood • Form F

Page 3

STEP 6

Attach the END ANGLE (hand tight) to the ends of

the SIDE FILTER CHANNEL ASSEMBLIES and SIDE

CHANNELS using four (4) 5⁄16 X 1 weldstud fasteners per

END ANGLE. (See Figure 5) In addition, units with throat

widths greater than 36 inches will require

FILTER END CHANNEL ASSEMBLIES.

Figure 5

(See Figure 5, DETAIL ''D'') Fasten FILTER END

CHANNEL ASSEMBLY (hand tight) to the END

CLOSURE ANGLE and END ANGLE, using two

5

⁄16 X 1 weldstud fasteners per assembly.

STEP 7

Slide FILTERS in from both ends of unit. Tighten all

FILTER CHANNEL and END ANGLE fasteners only after

FILTERS are in place.

STEP 8

Attach the HOOD RAIL ASSEMBLY to the HOOD

SUPPORT ANGLES using two (2) 3⁄8 X 3⁄4 inch fasteners

per HOOD RAIL ASSEMBLY. (See Figure 6) NOTE:

Fasteners should be hand tightened only until step 9.

Figure 6

Fabra Hood • Form F

3

Page 4

STEP 9

Assemble HOOD PANELS to HOOD RAIL ASSEMBLY.

The HOOD END ASSEMBLY with the MALE RIB is to

be installed first. (See Figure 7, DETAIL "E") Place the

remaining HOOD PANELS in place, interlocking panels

as you go. (See DETAIL "E") Secure each HOOD PANEL

to the HOOD RAIL ASSEMBLY as it is put in place

using four (4) No. 12 X 3⁄8 inch sheet metal screws with

sealing washers per HOOD PANEL. The HOOD END

ASSEMBLY with the FEMALE RIB is to be installed last.

Figure 7

NOTE: Hoods over 9 feet wide are supplied with

special HOOD CLIPS. (See DETAIL "F'') HOOD

PANELS have predrilled holes for HOOD CLIP

installation. Install CLIPS as HOOD PANELS are being

put in place, using one (1) No. 12 X 5⁄8 inch sheet metal

screw with sealing washer per HOOD CLIP. To install

CLIPS in the last panel, remove the end FILTERS to

provide access to the underside of the hood. The

FILTERS can be easily replaced after the hood is

completely assembled.

STEP 10

Tighten all pivot bracket fasteners. NOTE: There may be extra fasteners.

®

Phone: (715) 359-6171 • Fax: (715) 355-2399 • E-mail: gfcinfo@greenheck.com • Website: www.greenheck.com

4

Fabra Hood Form F Assembly Instructions, Rev. 2, October 2012 Copyright © 2012 Greenheck Fan Corp.

Loading...

Loading...