Page 1

1.0 bar

Standard setting

0.2 bar

0

0° 90°

Initial settings

Installation and

Operation

Pneumatic Positioner F10

CCW Direct

CW Reverse

Accredited by the

Dutch Council for

Certification

DOC.6.41.EI 10.98

Page 2

F 10 Pneumatic Positioner

Where to Find Information

Page

Product Description 1

Operating Principle 2

Installation, Rotary Actuators

- Mechanical 3

-Pneumatic, Double Acting 3

-Pneumatic, Single Acting 4

-Air Supply Requirement 4

Installation, Linear Actuators

-Mechanical installation 5

-Pneumatic installation 6

Calibration

-Initial Settings 7

-Cam Changes 7

-Zero Adjustment 8

-Range Adjustment 8

Trouble Shooting 9

General Specification:

Metric Imperial

Hysteresis : 0.6%

Linearity : 1.0%

Air Flow : 210 Nl/min (at 6 bar) : (7.4 SCFM at 87 psi)

Air Consumption : 15 Nl/min (at 6 bar) : (0.6 SCFM at 87 psi)

Min. volume

actuator : 0.1 Nl : 6.1 in

Temperature : -20° to +80° C : (-4° to +176°F)

Enclosure : IP54 (option IP65) : NEMA 3 (option NEMA 4)

Mounting : VDI/VDE 3845 or

IEC 534/6

Air Entry : G 1/4" : (1/4" NPT)

Air Supply : 1.4 to 8.6 bar : (21 to 125 psi).

Input Signal

- Standard : 0.2 to 1.0 bar : (3 to 15 psi).

- Adjustable : 0.2 to 0.6 bar : (3 to 9 psi).

: 0.6 to 1.0 bar : (9 to 15 psi).

3

Media : Non-lubricated instrument air, filtered at 25 micron.

: Dew point should be 10°C (18°F) below enviromental temperatur.

: Air quality class 3-2-3 accord. to ISO 8573-1.

Page 3

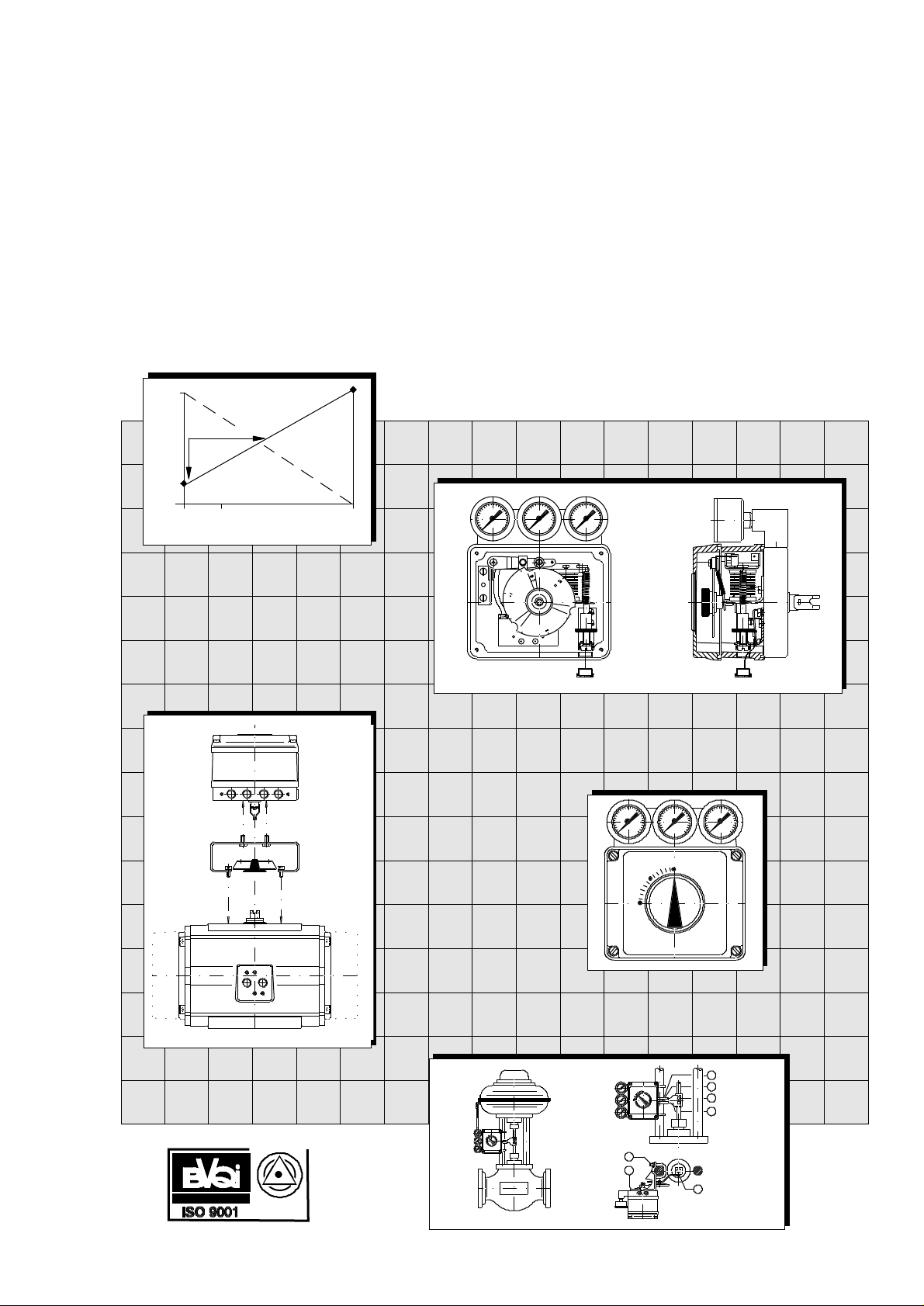

Product Description

The F10 positioner provides the means for a pneumatic actuator to be positioned to any point between

full open and full closed position. This allows accurate setting of rotary and linear control valves as

well as a wide range of dampers and similar devices. The actuator’s movement is controlled in

proportion to a 0.2 to 1 bar (3-15 psi) incoming

pressure signal.

The Posiflex F10 positioner provides:

-A single model covers both single acting and

double acting actuators.

- External Zero Adjustment.

- High accuracy due to “high gain” amplification.

-Four Position Cam for Linear Actuators

provides for linear, quick opening, equal percentage and split range characteristics.

- Three Position Cam for Rotary Actuators

provides for linear, quick opening and equal

percentage characteristics. A special cam for

rotary actuator provides for split range.

- Direct or Reverse Acting.

F 10 positioners are available for both rotary and

linear applications and because of the standardized mounting interface (VDI/VDE 3845 or IEC 534/

6), installation is simple and trouble free. Mounting

kits are available for most actuator types.

The purely Pneumatic mode of operation means

that F10 positioners may be used in explosion

hazardous areas without any additional protection

being necessary.

A wide range of modular control options are available: These cover the addition of gauges, indicating switches, position transmitters, etc.

F10

Pneumatic

POSITIONER

Open

Closed

1.

Page 4

Operating Principles

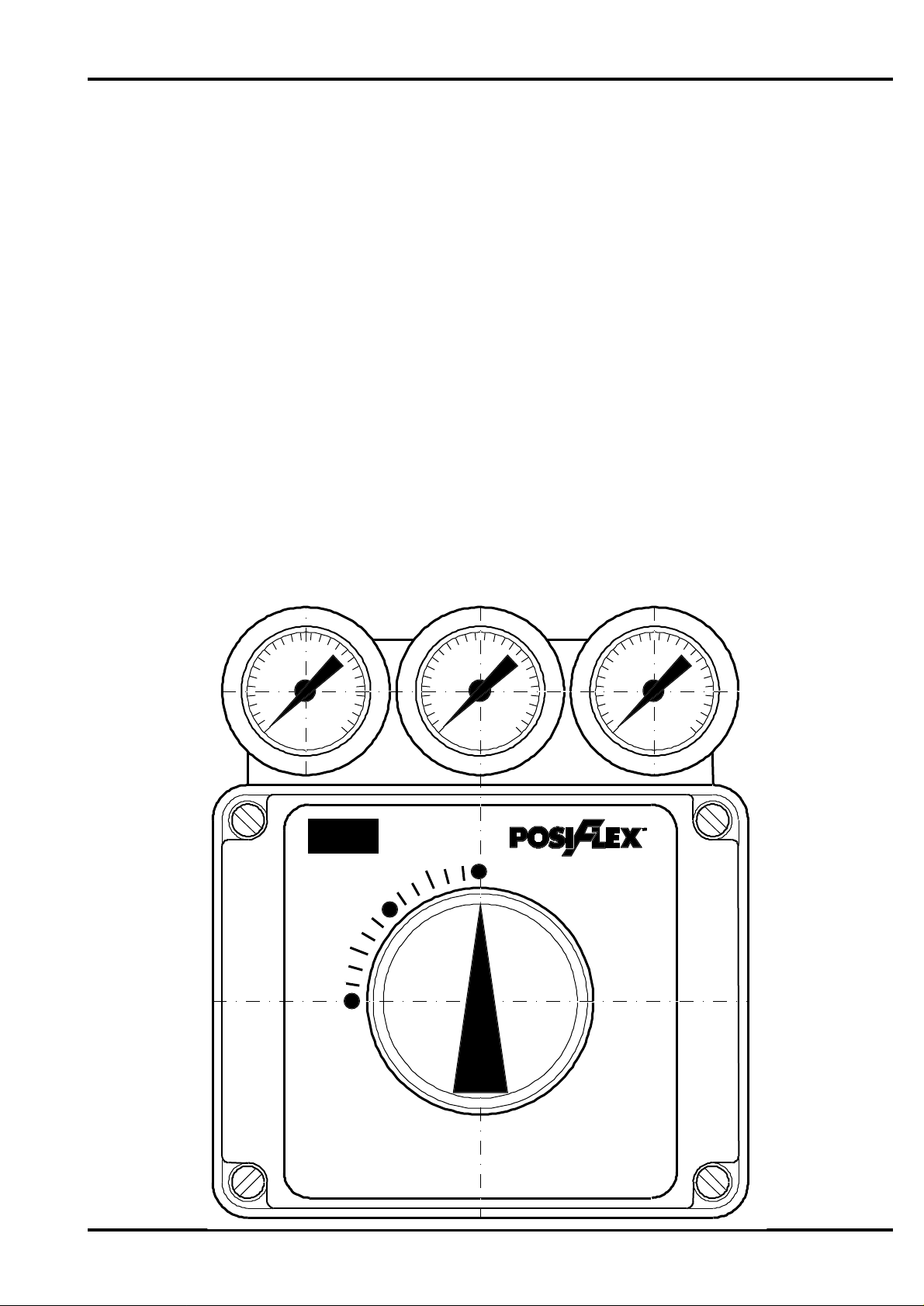

The Posiflex F10 Pneumatic Positioner is a high

gain, motion balance instrument, suitable for use

with a wide variety of single acting and double

acting rotary and linear actuators.

Referring to the diagram below: The positioner is

shown in a mid position with INSTRUMENT and

SUPPLY air connected. The flapper and nozzle (5)

maintains the instrument in it’s “balanced” state

with just enough pilot air pressure being applied to

the spool valve for it to hold the actuator in it’s “set”

position.

When the actuator is required to move to a new

“more open” position, the INSTRUMENT pressure

signal is increased accordingly. This closes the air

gap at the nozzle (5) causing an amplified pressure

1. Balance assembly.

2. Pneumatic valve block.

3. Actuator.

4. Mechanical feedback.

5. Flapper and nozzle.

6. Cam.

Output

increase at the spool valve end, this in turn displaces the spool and allowing an increasing air

pressure at the “open” side of the actuator and

exhausting air from the “close” side.

When the actuator moves position it rotates the

cam (6) in a CCW (counter clockwise) direction

and in doing so it progressively opens the air gap

at the nozzle (5). On reaching the new set point the

pilot pressure is reduced to the “balanced” state

and again locks the actuator in new set position.

Similarly a decreasing INSTRUMENT pressure will

cause a CW (clockwise) positioner movement.

The operation for single acting actuators is the

same except that the unused pneumatic connection

OUTPUT 2 is plugged off.

2

5

Supply

Close

3

1

Open

4

Instrument

6

2.

Page 5

Mechanical installation - Rotary actuators

The positioner is mounted on to the top surface of the

pneumatic actuator using an appropriate mounting kit.

The positioner’s mounting configuration is to the VDE/

VDI 3845 standard, if the actuator is to the same

standard, a standard NAMUR mounting kit can be

used, otherwise a special mounting kit will have to be

obtained.

Assuming the installation will use the standard NAMUR

mounting kit, proceed as follows:

1. Fix the bracket to the top surface of the actuator

using the 4 screws provided.

2. Check that the spring clip is securely in place on the

bottom of the positioner shaft.

3. Locate the positioner in place on top of the bracket,

making sure that the 4 mm. tongue locates properly

into it’s slot in the actuator spindle and the centring

screw is in position.

4. Fix the positioner to the bracket using the 4 screws

provided.

Installation Rotary Actuators

Mechanical Installation

Pneumatic Connections - Double acting

This assumes a standard (direct acting) installation

with an increasing signal to open the valve in a CCW

(counter clockwise) direction.

Before connecting any air supply make sure that

the air available is clean dry instrument air filtered

to at least 25 microns - see page 4.

1. Connect an appropriate piece of air tubing between

the port 1. on the positioner to the “A” port on the

actuator. (The “A” port is the one that when air is

applied to it, rotates the actuator in a counter clockwise direction).

2. Connect an appropriate piece of air tubing between

the port 2. on the positioner to the “B” port on the

actuator. (The “B” port is the one that when air is

applied to it, rotates the actuator in a clockwise

direction).

3. Connect an air supply to the positioner port Marked

“Supply”.

4. If the positioner is required to meet enclosure rating

IP54, be sure that the "Exhaust" port is connected

with elements which prevent the input of water and

give no pressure rising inside the housing because

of throttling of exhaust flow (no sintered filters, but a

piece of tube or a special IP65 Exhaust plug with

diaphragm

Supply

Instrument

Exhaust

1

A

2

B

Pneumatic connections

Double acting

5. Connect the instrument air to the port marked

"INSTR".

Note: For a reverse acting assembly, both the air

connections and the cam plate must be

reversed - see page 7.

3.

Page 6

Installation Rotary Actuators

Pneumatic Connections - Single acting

This assumes a standard installation, direct acting

with an increasing signal to open the valve in a

CCW (counterclockwise) direction.

Before connecting any air supply make sure

that the air available is clean dry instrument air

filtered to at least 25 microns - see below.

1. Connect an appropriate piece of air tubing

between the port 1. on the positioner to the “A”

port on the actuator. (The “A” port is the one

that, when air is applied to it, rotates the actuator in a counter clockwise direction).

2. Connect an air supply to the positioner port

marked “Supply”.

3. The unused positioner port 2, should be

plugged using the pipe plug supplied with your

positioner.

Connect port "Exhaust" with elements, which

guarantee IP54.

4. If the positioner is required to meet enclosure

rating IP54, be sure that the "Exhaust" port is

connected with elements which prevent the

input of water and give no pressure rising inside

the housing because of throttling of exhaust flow

(no sintered filters, but a piece of tube or a

special IP65 Exhaust plug with diaphragm.

5. Connect the instrument air to the port marked

"INSTR".

Supply

Exhaust

1

A

Instrument

2

Pneumatic Connections

Single acting

Note: For a reverse acting assembly, use the

same procedure but remember that a reverse acting actuator must be used - see

page 7.

Air Supply Requirements

CAUTION: Pressure in excess of 8.6 bar (125 psi)

will cause damage to the Positioner.

Positioner supply air must be clean, dry

and oil free.

The air should be filtered to at least 25 microns

(as defined in the Instrument Society of America

standard ISA S7.3 specifications). The filter should

be installed as close to the positioner as possible

to ensure maximum efficiency.

4.

Page 7

Mechanical Installation - Linear Actuators

The mountings for linear positioners will vary dependent

on the type of control valve.

The simplest assembly is where the control valve yoke is

to the standard IEC 534-6 and has type “C” (Pillar) yoke

design. A standard mounting kit is available for this and

will provide a suitable mounting for most valves in this

category.

Installation - Linear Actuators

7

6

3

Typical installation for a direct acting assembly. (Increasing signal opens the valve with a rising spindle).

1. Fix the bracket (1) to the positioner base, using the four

bolts provided.

2. Move the valve spindle into a mid-stroke position.

3. Fix the lever (2) to the valve connection block (3) using

the two M6 bolts. The carrier bolt (5) should be positioned loosely in the lever (2).

4. Assemble the slider on the feed back lever (7). Use

assembly "a" (below) for strokes 60 to 100 mm. or

assembly "b" for strokes 10 to 40 mm.

5. Locate the positioner, together with the bracket (1) on

the left-hand pillar using the "U"-bolt clamps (4). (Use

the right-hand pillar for reversacting assemblies). pass

the carrier bolt (5) through the feedback lever slot,

taking care to keep the anti-backlash spring (6) in it's

correct position.

2

4

1

5

Linear mounting

Slider installation for 100 mm. stroke

6. Slide the positioner up or down the pillar until the lever

(2) and the feedback lever (7) are parallel. Fix in position.

7. Adjust the linkage to the correct stroke by moving the

slider until the appropriate position on the feedback

lever is indicated. Then tighten the carrier bolt (5).

8. Let the actuator make a full stroke and check that the

linkage moves freely within the bracket.

9. Move the actuator to it's "zero" position. Turn the

positioner shaft counterclockwise (CCW) to the end of

stroke. Fasten the feedback lever to the positioner

shaft.

5.

Installation mark for 60 and 100 mm. stroke

a) Lever for 60 to 100 mm. Stroke

Installation mark for 10 and 16 mm. stroke

Installation mark for 20 and 40 mm. stroke

Slider installation for 25 mm. stroke

b) Lever for 10 to 40 mm. Stroke

Page 8

Installation - Linear Actuators

Pneumatic Connections - Double acting

Assuming a standard installation, direct acting with an

increasing signal to open the valve (rising spindle).

Before connecting any air supply make sure that

the air available is clean dry instrument air filtered

to at least 25 microns.

1. Connect an appropriate piece of air tubing between

the port 1. on the positioner to the “A” port on the

actuator. (The “A” port is the one that, when air is

applied to it, opens the valve).

2. Connect an appropriate piece of air tubing between

the port 2. on the positioner to the “B” port on the

actuator. (The “B” port is the one that when air is

applied to it, closes the valve).

3. Connect an air supply to the positioner port marked

“S”.

4. If the positioner is required to meet enclosure rating

IP54, be sure that the "Exhaust" port is connected

with elements which prevent the input of water and

give no pressure rising inside the housing because

of throttling of exhaust flow (no sintered filters, but a

piece of tube or a special IP65 Exhaust plug with

diaphragm

5. Connect port "Instrument" with pneumatic input

signal.

Double acting

Note: For a reverse acting assembly, both the air

connections and the cam must be reversed see page 7.

Pneumatic Connections - Single acting

Assuming a standard installation, with direct acting an

increasing signal to open the valve (rising spindle).

Before connecting any air supply make sure that

the air available is clean dry instrument air filtered

to at least 25 microns.

1. Connect an appropriate piece of air tubing between

the port 1. on the positioner to the “A” port on the

actuator. (The “A” port is the one that when air is

applied to it, opens the valve).

2. Connect an air supply to the positioner port marked

“S”.

3. If the positioner is required to meet enclosure rating

IP54, be sure that the "Exhaust" port is connected

with elements which prevent the input of water and

give no pressure rising inside the housing because

of throttling of exhaust flow (no sintered filters, but a

piece of tube or a special IP65 Exhaust plug with

diaphragm

Single acting

4. Connect port "Instrument" with pneumatic input

signal.

Note: For a reverse acting assembly, both the air

connections and the cam must be reversed see page 7.

6.

Page 9

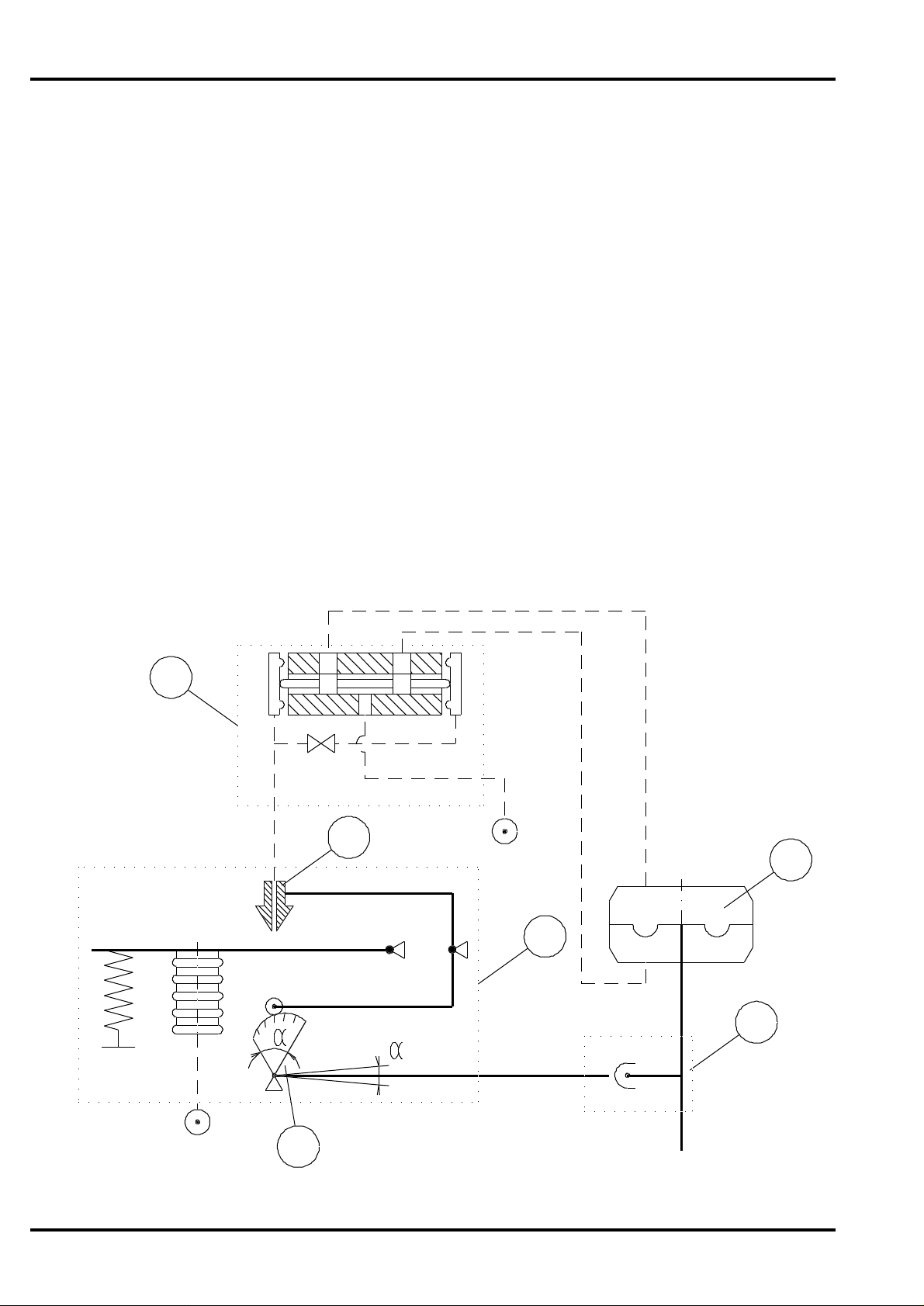

Initial Settings

Cam Segment

Rotary actuator

Linear actuator

40° CCW

40° CW

lin

=%

QO

SR

Calibration - Initial Settings - Cam Changes

The factory settings provide the positioner with an initial

range of settings that will allow the operation of positioners on most applications.

Signal Input - 0.2 to 1.0. bar. (3-15 psi).

Range - 0% to 100%

Control Function - Linear.

Action - Direct Acting.

(Opening on increasing Signal in

CCW-direction).

The F10 positioner is provided with the following features

for making changes to the initial settings:

Zero By the external zero adjustment screw.

Range By the internal range adjustment ring.

Range Spring The standard range spring is suitable for

normal operation and split ranging.

Cam Segment Six segments are provided for the rotary

positioner and eight segments for the

linear positioner (see table).

Cam Changes

Remove the cover and indicator from the positioner

exposing the Cam. The Cam is double sided: CCW for

direct acting, CW for reverse acting.

If the actuator is fully clockwise and the actuator is to

rotate CCW on instrument signal increase, the Cam

should be on the “CCW” side and the start marking

should be in line with the Cam Follower Bearing. If the

actuator is fully counterclockwise and the actuator is to

rotate CW on instrument signal increase, the Cam should

be on the “CW” side and the start marking should be in

line with the Cam Follower Bearing.

If the cam is not in the correct position, change as follows:

1.0 bar

0.2 bar

0

Standard setting

CCW Direct

CW Reverse

0°

Initial settings

90° CCW 90° CW

lin lin lin

=% =% =%

QO QO QO

* * SR

lin = linear

=% = equal percentage

QO = Quick Opening

SR = Split Range

* = Special cam split range

90°

2

1

1. Remove the cam nut (1).

2. Re-install the cam plate in the correct position, taking

3. Replace the cam nut and fix it.

4. Replace the indicator disk, taking care that it in the

care that the correct segment is adjacent to the cam

follower (2).

correct position.

7.

Top view of cam

Rotary actuator

Cam 90°

Linear actuator

Cam 40° (49°)

Page 10

Calibration - Zero and Range

Before making any adjustments positioner should

be properly mounted, the cam should be in the

correct sector on the correct side as determined

from the cam markings.

Zero Adjustment

The zero adjustment is carried out externally, this is

located at the right hand side of the positioner

casing and is accessed by means of a removable

plug.

1. Remove the access plug (1).

2. Adjust the instrument signal to its minimum value

(0.2 bar for a 0.2-1.0 bar range),

(3 psi for a 3-15 psi range).

3. Rotate the Zero adjusting screw (2) until the

actuator just begins to move. Turning the adjusting nut clockwise raises the start value.

4. After adjustment, replace the access plug (1).

Range Adjustment

Remove the cover from the positioner exposing the

knurled range adjuster ring, this is located at the

righthand side of the assembly.

The factory set range is so that a 0.2 to 1.0 bar (315 psi) instrument pressure produces a full stroke

movement. This may be changed by resetting the

full stroke position (max. opening) at the 1.0 bar

(max. instrument) pressure. To adjust the range

carry out the following:

1. Increase the instrument signal to its maximum

value (1.0 bar for a 0.2 to 1.0 bar range), (15 psi

for a 3-15 psi range).

2. If the actuator does not reach its final position,

rotate the knurled adjusting ring (3) in CCWdirection until the full stroke position is reached.

3. Turning the range screw cw reduces the range;

ccw increases the range.

4. After range adjustment, reset the zero position

and adjust it if necessary.

3

2

1

8.

Page 11

Troubleshooting

If it is suspected that the positioner is not operating correctly, check

the following :

1. Is the Cam in the proper orientation for your

application ? (See page 5).

2 Is the positioner properly mounted ? (See page

3).

3. Is the coupling or NAMUR shaft in proper

alignment with the Positioner Cam shaft and

actuator ?

4. Is the positioner piped correctly ? (See page 3

and 4).

5. Make sure supply pressure exceeds minimum

pressure required to move the actuator.

6. Is there instrument and output pressure at the

Positioner ? (If the Positioner is equipped with

a Gauge Block, check the instrument and

output pressure readings. If the positioner is

not equipped with a Gauge Block, connect

gauges to the instrument and output ports and

note readings.)

7. Is the actuator working properly ? (Disconnect

the supply pressure from the Positioner and

connect the supply pressure to the actuator.

Does the actuator move full stroke ?)

Maintenance

If additional help is needed, contact your local Elo-matic office or representative, (see back page).

9.

Page 12

INTERNATIONAL BENELUX UNITED KINGDOM

EL-O- MATI C B.V. EL-O- MATI C Benelux EL-O- MATIC Ltd.

P. O . Bo x 223 P. O . Bo x 223 16/1 7 Beedi ng Cl ose

7550 AE Hengelo (O) 7550 AE Hengelo (O) Southern Cross Trading Estate

Asvel dweg 19 Asvel dweg 11 Bognor Regis

7556 BR Hengelo (O) 7556 BT Hengelo (O) West Sussex, PO 22 9TS

Holland Holland Tel. +44 1243 830 3 63

Tel. +31 74 256 10 10 Tel. +31 74 256 10 20 Fax. +44 1243 830 843

Fax. +31 74 291 09 38 Fax. +31 74 243 86 90

FRANCE GERMANY U.S.A.

EL-O- MATI C France EL -O- MATI C GmbH. EL-O- MATIC U.S.A. Inc.

Z.A. Créapole 1 Postfach 460234 . 47856 Willich 1 35 Engl ish Street

32 R ue de Tour nenfi ls Si eme nsr ing 112 . 4 7877 W i ll ich Hackensack NJ 0 7601

91540 Mennecy Tel. +49 2154 499660 Tel. +1 201 489 5550

Tel. +33 1 69 900 734 Fax. +49 2154 427669 Fax. +1 201 489 9171

Fax. +3 3 1 69 900 709

VENEZUELA INDIA SINGAPORE

EL-O- MATI C INTERNAT IO NAL EL-O- MATIC I ndia Pv t Ltd. EL-O -MATIC Valve Actuators

Av. Princ ipal Los Ruices 296 /A/1/5, St. Patrick ’s T own Fa r East Pte L td.

Edif. stemo piso 1 Ofc. 1A Near Railway Crossing 28 Third Lok Yang Road

Caracas Had apsar In dustrial Estate Si ngapor e 628016

Venezuela Pune 411 013 Tel. +65 26 24 515

Tel. +58 2 237 77 51 Tel. +91 212 672916 Fax. +65 2680028 / 770 80 80

Fax. +5 8 2 238 9023 Fax. +9 1 212 674465

SOUTH AFRICA AUSTRALIA / NEW ZEALAND

EL-O-MATI C (Pty) Ltd. EL-O-MATIC Austral-Asia

Teknipark, 62 Lower Germiston Road 329 Brighton Road, Brighton 5048

Heriotd ale, Jo hannesburg P. O . Bo x 12

P.O. Box 40348 Glenelg 5045

Cleveland 2022 South Australia

Tel. +27 11 626 2880/1/2 Tel. +61 8 377 2744

Fax. +2 7 11 626 2905 Fax. +6 1 8 377 2576

Loading...

Loading...