Page 1

BUILDING VALUE IN AIR.

October

2005

Recirculating Roof Fans

Models ESRMD, ESRMDF and ERD

Four-Way Fan

• Exhaust

• Supply

• Mix

• Recirculate

Page 2

2

Recirculating Roof Fans

Exhaust/Supply/Recirculation/Mix

Model ESRMD

Ventilation requirements are often subject to daily or seasonal changes in temperature. The

Greenheck Four-Way Fan offers the flexibility to meet changing needs and to maintain

comfortable temperatures in factories, warehouses and other facilities with high ceilings. When

temperatures change with production processes or seasonal shifts, the Four-Way fan can

exhaust, supply, recirculate or mix air as required.

• Model ESRMD fans are available in six direct drive sizes.

• Performance capacities range from 4,000 cfm to 40,000 cfm and up to 0.375 in. wg of static

pressure.

• Exhaust, supply and recirculate modes perform equally.

Cost Savings

By exhausting excess heat, supplying cool air, recirculating stratified warm air, and mixing supply air with recirculated air,

the Four-Way fan also saves heating and cooling costs. When one fan offers four functions, further cost reductions result.

Fewer fans required on the job means lower initial costs and lower installation costs, with fewer roof penetrations.

1. Exhaust

Evacuates excess heat to reduce

cooling costs.

The exhaust/supply damper is

open and the recirculation

dampers are closed.

3. Recirculation

Destratifies warm air accumulated

at ceiling level and directs it

downward to reduce heating costs.

The exhaust/supply damper is

closed and the recirculation

dampers are open.

4. Mix

Comfortable temperatures can be

maintained by tempering supply air

with warmer air trapped at ceiling

level.

The exhaust/supply damper and

the recirculation dampers are

linked to work in combination.

2. Supply

Fresh air can be supplied when

outside temperatures are cooler

(as at night) to reduce cooling

costs.

The exhaust/supply damper is

open and the recirculation

dampers are closed.

One Fan - Four Functions

Model ERD

The model ERD upblast fan is available for applications that

require exhaust and recirculation, and do not require supply or

mixed air. The model ERD has an upblast windband and

butterfly dampers in lieu of the Four-Way fan hood. The

windband is constructed of galvanized steel with butterfly

dampers constructed of aluminum. Aluminum construction is

optional for the windband.

The model ERD offers the same performance as the Four-Way

fan, except in the lower ranges where the minimum CFM must

be maintained to open the butterfly dampers.

Minimum CFM

required to open

butterfly dampers

Size CFM

24 3947

30 6034

36 7618

42 11045

48 12817

54 21425

Page 3

1. The roof curb is mounted and secured over

the roof opening.

2. The plenum (factory assembled) is lowered

through the curb and roof opening until its

mounting channels rest on the roof curb.

Lifting lugs are provided. (Fig. 1)

3. The fan hood is lowered onto the

curb/plenum assembly. (Fig. 1)

4. The hood and plenum are secured to the

roof curb. (Fig. 2)

Installation Sequence

3

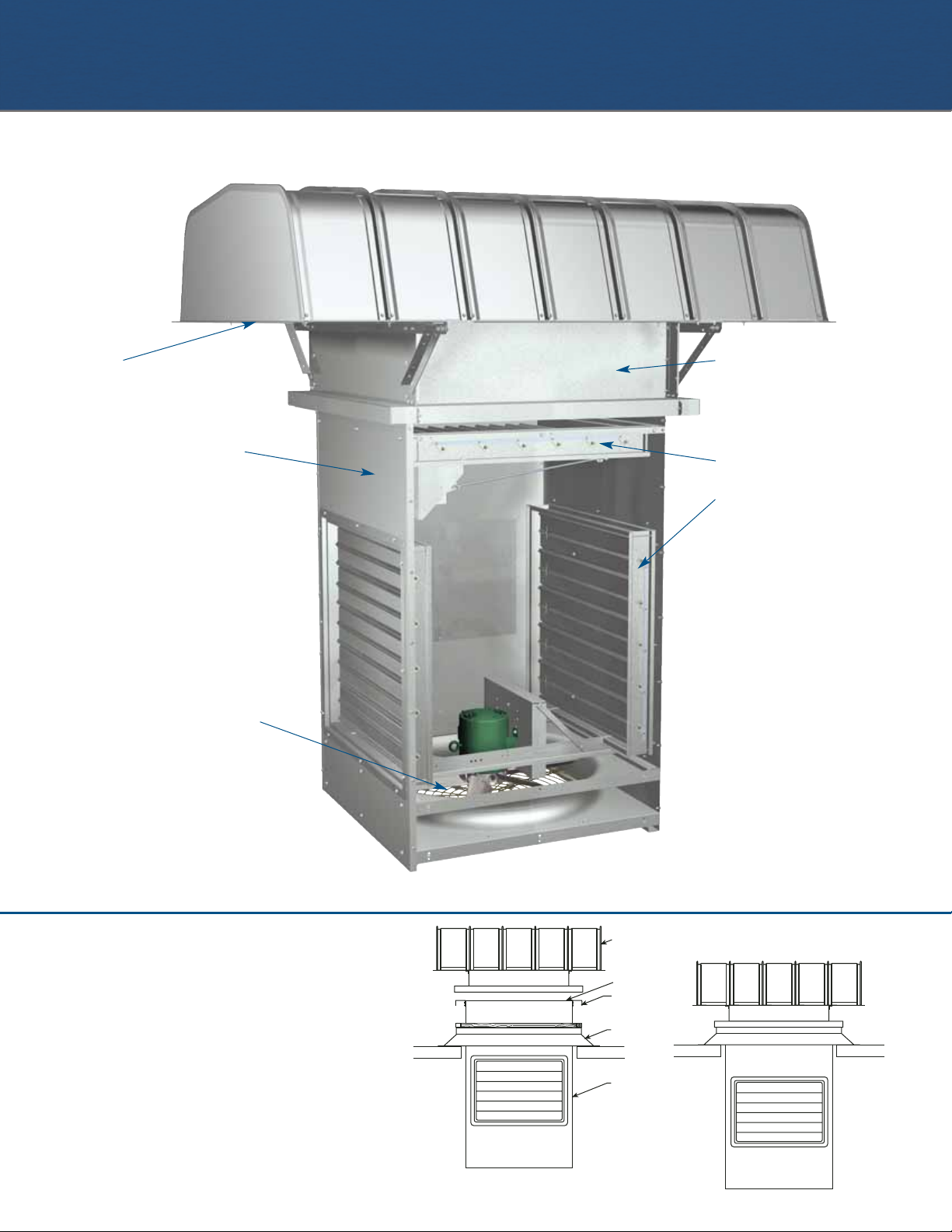

Standard Construction Features

Fan hoods and bases are constructed of galvanized steel. Optional aluminum construction is available. Hood panels are arched

and precision roll formed for strength and weather tightness. They are bolted to heavy gauge support angles. All hood sizes ship

fully assembled except for 54 in. non-filtered, 48 in. and 54 in. filtered.

Birdscreens are constructed

of 1/2 in. galvanized steel

mesh. Optional filters are

available.

Plenums are galvanized

steel, supported at the roof

curb by mounting channels.

For servicing the fan two

removable access panels are

provided. Four lifting lugs are

provided for ease of

installation. (See important

plenum height information on

pg. 4.)

Protective guards mount to

the bottom of the plenum to

protect the fan and nearby

personnel.

Propellers are designed to

produce a high level of

efficiency over a broad

selection range. Tapered

airfoil blades are cast of

aluminum alloy. The propeller

is designed to deliver equal

airflow in the exhaust, supply,

and recirculation modes.

Each propeller is balanced

prior to assembly.

Bases are standard at 12

in. high with pre-punched

mounting holes for easy

installation.

A low leakage control

damper (exhaust/supply)

and two standard control

dampers (recirculation) are

linked for recirculation and

mixing. Construction

consists of galvanized

steel.

Standard damper

actuators are modulating

spring return.

Heavy-duty ball bearing

motors are carefully

matched to the fan load.

Motor support frames are

constructed of heavy

gauge steel angles.

Fan panels are

constructed of heavy

gauge steel with a double

venturi for efficient airflow.

Fig. 1

Hood

Lifting Lugs

Mounting

Channels

Roof

Curb

Plenum

Fig. 2

Page 4

Plenum Height Option

Plenum height can be increased in 12 in. increments to clear pitched roofs, beams and other solid obstructions

that may interfere with airflow into the

recirculation dampers. The standard

dimension from the top of the plenum

to the top of the recirculation

dampers is 20 in.

Installation Examples

Fig.1(left )- shows a truss type

that would not typically interfere with

airflow and does not require increasing

plenum height. Fig.1 (right )- shows a solid

beam obstruction requiring plenum

extension to clear.

The Fig. 2 installation requires extension

of the plenum to clear the pitch of the roof.

4

Options & Accessories

Filters

For applications where contaminants must be

removed from air supplied to the building, washable

2 in. aluminum mesh filters are available. Filters are

mounted in open end racks for easy removal. In fan

sizes 36 in. and larger, access panels are provided to

allow filter removal without raising the hood.

Roof Curbs

Prefabricated roof curbs are available to reduce

installation time and costs by ensuring compatibility

between the fan and the roof opening. See

Greenheck's roof curb catalog for

complete details. A wide

variety of roof curbs

are available, including:

flanged, pitched and

sound-absorbing.

Coatings

Special coatings are available for decorative or

protective purposes. Decorative coatings can be

applied to exterior surfaces of the hood, base and

plenum. Protection from corrosive atmospheres

requires individual consideration.

Disconnect Switches

NEMA 1 and NEMA 3R

disconnect switches are

available for positive electrical

shutoff and protection of

personnel. Disconnects are

shipped loose for field mounting.

Exhaust/Supply Damper Option

Insulated low leakage dampers are available for

applications where an indoor/outdoor temperature

differential must be maintained.

Hood Insulation

Hoods can be lined with 1/2 in. fiberglass insulation

to prevent condensation and reduce sound levels.

Motor Options

Motor enclosure options include open drip proof and

totally enclosed for single speed motors, and open

drip proof for two speed motors. Single phase motors

are available in 115/208/230 volt. Three phase motors

are available in 208/230/460 and 575 volt.

Tie-Down Points

Four galvanized steel brackets are available as cable

attachment points at the ends of each hood support

rail. Cable tie-downs prevent damage to the hood in

locations where unusually strong winds occur. (Cables

are by others.)

Diffusers

Discharge diffusers, mounted

to the bottom of the plenum,

offer the ability to direct the

airflow of the fan. Four

manually adjustable quadrants

can be set to direct air in any

direction desired. Construction

is galvanized steel. Guards are

necessary with or without

diffusers.

Fig. 2Fig. 1

20 in.

Standard

Dim. Req’d

to Clear Beam

Dim. Req’d to

Clear Roof Pitch

Page 5

5

The Control Center

Designed specifically for the Greenheck Four-Way fan,

the control center allows the operator to manually

change the modes of operation of the fan from a

convenient remote location.

This control center is more cost effective than controls

fabricated in the field. It offers savings in both time

and expense, since ease of installation, compatibility,

and qualities are assured. These units are complete,

self-contained control packages, with motor starters

included. (Wiring from the fan to the control center is

by others.)

Controls are housed in a NEMA 1 cabinet constructed

of heavy gauge steel and coated with Greenheck's

Permatector™ finish. A door interlocking disconnect

switch is provided to help prevent electrical shock

when the door is opened.

Operating Mode Combinations

Control centers are available in any one of the

following combinations, which must be specified when

ordering:

• ESRM-CC — Exhaust/Supply/Recirculate/Mix

• SRM-CC — Supply/Recirculate/Mix only

• ESR-CC — Exhaust/Supply/Recirculate only

• ER-CC — Exhaust/Recirculate only

Controls

Mode Selector

The mode selector switch is used to engage the

desired fan function. The four functions are described

below:

Exhaust Mode

Energizes the “reverse” contactor in the control center to allow the

fan to exhaust air from the building. The control also energies the

damper actuator, driving the top damper open, and the side dampers

closed. If the fan was previously running in the Supply, Recirculate, or

Mix mode, or the power was removed from the control center, there

will be a delay* before the fan starts again.

Supply Mode

Energizes the “forward” contactor in the control center to allow the

fan to supply air to the building and energizes the damper actuator,

driving the top damper open, and the side dampers closed. If the fan

was previously running in the Exhaust mode, or the power was

removed from the control center, there will be a time delay* before

the fan starts.

Recirculate Mode

Energizes the “forward” contactor in the control center to allow the

fan to recirculate air in the building. The damper actuator is not

energized, so the top damper remains closed and the side dampers

are open. If the fan was previously running in the Exhaust mode, or

the power was removed from the control center, there will be a time

delay* before the fan starts.

Mix Mode

Energizes the “forward”

contactor in the control center

to allow the fan to either

supply or recirculate the air in

the building. The damper

actuator is energized and is

modulated by the Honeywell

T775 temperature controller

located in the control cabinet.

The temperature controller is

programmable to either work in

a cool or heat mode, and to have temperature

setpoints. The operator would program the controller,

depending on the building needs, and the dampers would vary

position between supply and recirculate to try and maintain the

temperature programmed. If the fan was previously running in the

Exhaust mode, or the power was removed from the control center,

there will be a time delay* before the fan starts.

*Delay of 5 minutes for a 24 in. fan or 10 minutes for a 30 in. and larger.

Fans sized at 42 in. and smaller, one damper actuator motor is used in

the fan to position the dampers, with linkage tying them together.

For 48 in. and 54 in. fans, two actuator motors are used to position the

dampers, with linkage tying them together.

Temperature Control

Fans specified with the mix mode (ESRM or SRM only)

include a temperature controller . A remote

temperature sensor is field mounted below the fan

discharge in the airstream. The modulating damper

actuator(s) is driven by the solid state temperature

controller to open or close the exhaust/supply and

recirculation dampers as required to maintain the

preset temperature. In the other modes, it will display

the temperature at the plenum of the fan, but has no

effect on its operation.

Options

• An indicator light mounted on the control panel

door is available to indicate power to the fan.

• An access opening is provided in the door of units

with temperature controls to allow the control to be

adjusted with the door closed.

2

3

Control Center Model

(1 Speed, 3 Phase)

Number of Fans Per Control Center

1 2 3 4

ESRM-CC 24-42

ESRM-CC 48-54

SRM-CC 24-42

SRM-CC 48-54

ESR-CC 24-54

ER-CC 24-54

ES-CC 24-60

SR-CC 24-54

1

1

3

2

23 in.

6

4

⁄7

in.

Page 6

6

Performance Data

MODEL NUMBER RPM HP

MAX

BHP

SONES @

0.125

CFM / STATIC PRESSURE IN INCHES W.G.

0.000 0.125 0.250 0.375

ESRMD-24-420-B3 1160 1/3 0.37 20 4733 4023 2810

ESRMD-24-430-B5 1160 1/2 0.60 22 5525 4589 3109

ESRMD-24-415-A7 1750 3/4 0.89 33 6096 5700 5244 4685

ESRMD-24-420-A10 1750 1 1.26 42 7140 6711 6213 5659

ESRMD-24-622-A15 1750 11⁄2 1.77 43 8005 7747 7327 6921

ESRMD-30-427-C5 870 1/2 0.55 18.0 7595 5735 3303

ESRMD-30-418-B7 1160 3/4 0.85 29 8995 7945 6448 4393

ESRMD-30-425-B10 1160 1 1.15 30 9965 8698 7195 5192

ESRMD-30-625-B15 1160 11⁄2 1.59 35 11325 10326 9026 6757

ESRMD-30-415-A20 1750 2 2.30 59 12005 11398 10695 9985

ESRMD-30-420-A30 1750 3 3.23 61 14054 13328 12576 11768

ESRMD-30-625-A50 1750 5 5.46 73 17085 16463 15782 15046

ESRMD-36-410-C5 870 1/2 0.55 23 7899 5850 3156

ESRMD-36-614-C7 870 3/4 0.88 25 10062 8676 6800

ESRMD-36-620-C10 870 1 1.37 26 11554 10164 7440

ESRMD-36-626-C15 870 11⁄2 1.73 28 13424 11956 9487

ESRMD-36-615-B20 1160 2 2.39 45 13966 12858 11454 9974

ESRMD-36-623-B30 1160 3 3.66 46 17261 15948 14605 13369

ESRMD-42-413-C10 870 1 1.14 26 13175 11069 7950 4200

ESRMD-42-615-C15 870 11⁄2 1.73 27 16063 14358 12205 9001

ESRMD-42-620-C20 870 2 2.29 33 18275 16513 14260 11465

ESRMD-42-629-C30 870 3 3.38 35 21264 19373 17171 13941

ESRMD-42-621-B50 1160 5 5.63 55 24776 23430 22078 20377

ESRMD-48-618-F15 680 11⁄2 1.71 26 19446 16442 11939

ESRMD-48-616-F20 680 2 2.20 28 20886 18974 16481

ESRMD-48-623-F30 680 3 3.56 32 24368 22235 17320 14516

ESRMD-48-612-C20 870 2 2.31 38 20218 17864 15156 11386

ESRMD-48-617-C30 870 3 3.29 41 23020 20817 17930 14322

ESRMD-48-619-C50 870 5 5.66 45 28511 26885 25194 23287

ESRMD-48-618-B75 1160 71⁄2 8.52 66 32435 29892 29139 27139

ESRMD-48-620-B100 1160 10 11.85 74 36151 35143 34085 32966

ESRMD-54-615-F20 680 2 2.34 35 23198 19758 13768

ESRMD-54-620-F30 680 3 3.49 37 25875 22129 17205 11627

ESRMD-54-429-F50 680 5 5.70 44 32002 28710 24070 19075

ESRMD-54-614-C50 870 5 5.75 58 32687 30673 28684 26153

ESRMD-54-422-C75 870 71⁄2 8.39 60 37995 35786 33443 30137

ESRMD-54-624-C100 870 10 11.92 63 42762 40340 38331 35529

Shading indicates sound levels in excess of 50 sones (85 dBA) and are subject to OSHA regulations.

This catalog shows fan performance ratings with BHP's as much as 20% over the motor's nameplate horsepower. Motor life

is dependent on the operating temperature of the motor. Motors provided are sufficiently cooled to allow operation up to 20%

above their horsepower ratings. This does not reduce motor life or performance and therefore is economically desirable.

The model numbering system is designed to completely identify the fan. The correct code letters and numbers must be specified

to designate function, size, no. of blades, pitch, RPM & HP.

Model Number Code

Propeller Diameter

ESRMDF - 24 - 624 - B3

Model

Filter

(Optional)

Motor HP

4 = 1/4 7 = 3/4 30 = 3 100 = 10

3 = 1/3 10 = 1 50 = 5

5 = 1/2 20 = 2 75 = 7

1

⁄2

Number of Blades

Motor RPM

A = 1725 C = 870

B = 1140 F = 680

Propeller

Pitch

Page 7

7

Dimensional Data

All dimensions are in inches.

Due to Greenheck's policy of continuous product improvement, dimensions are subject to change without notice.

For complete dimensional information refer to the applicable submittals for this product.

Control Damper

OPTIONAL DIFFUSER

H

F

C

A Sq.

B Sq.

Roof Opening

*

20"

5"

G

DxE

Access

Door

Models ESRMD & ESRMDF

Model ERD

Top Damper Recirc. Damper Access Doors

Roof

Size A B C*

VCD-2120 VCD-1020

DE

Opening

24 40 32 58

1

⁄2 29 x 29 27w x 26h 21 20 341⁄2

30 46 38 63 35 x 35 33w x 30h 27 20 401⁄2

36 52 44 715⁄8 41 x 41 39w x 38h 33 22 461⁄2

42 58 50 753⁄4 47 x 47 44w x 42h 38 36 521⁄2

48 64 56 825⁄8 53 x 53 50w x 48h 44 36 581⁄2

54 70 62 91 59 x 59 56w x 54h 50 36 641⁄2

Non-Filtered Hood Filtered Hood Upblast Hood Approximate Unit Weights

Size ESRMD Hood Size ESRMDF Hood Size ERD Hood Size ESRDM ESRMDF ERD

F G H F G H F G H Alum Galv Alum Galv Alum Galv

24 63 66 30 63 66 30 21⁄2 313⁄8 261⁄4 570 650 670 750 400 480

30 75 74 32 75 78 32 31⁄2 373⁄8 303⁄8 760 900 860 1000 490 630

36 87 76 33 87 94 33 41⁄2 433⁄4 333⁄4 1040 1200 1170 1330 715 875

42 99 86 361⁄2 99 100 361⁄2 41⁄2 50 381⁄2 1200 1400 1330 1530 850 1050

48 111 100 361⁄2 111 112 361⁄2 51⁄2 561⁄4 41 1470 1700 1620 1850 1110 1340

54 111 112 39 112 124 39 51⁄2 633⁄8 45 1770 2000 1920 2150 1405 1635

*Important: Plenum height can be increased in 12 in. increments (to clear solid ceiling obstructions, etc.) Increases

will effect dimension C*. See page 4 for more information on plenum height.

G

Low Leakage Control Damper

A Sq.

OPTIONAL DIFFUSER

B Sq.

Roof Opening

H

12 in.

20 in.

*

C

E

5 in.

F

Low Leakage Control Damper

ACCESS DOOR

Control Damper

D

OPTIONAL DIFFUSER

Control Damper

Page 8

Greenheck warrants this equipment to be free from defects in material and workmanship for a period

of one year from the purchase date. Any units or parts which prove defective during the warranty

period will be replaced at our option when returned to our factory, transportation prepaid. Motors are

warranted by the motor manufacturer for a period of one year. Should motors furnished by Greenheck

prove defective during this period, they should be returned to the nearest authorized motor service

station. Greenheck will not be responsible for any removal or installation costs.

As a result of our commitment to continuous improvement, Greenheck reserves the right to change

specifications without notice.

P.O. Box 410 • Schofield, WI 54476-0410 • Phone (715) 359-6171 • greenheck.com

ESRMD Catalog Rev. 2 October 2005 SN

Copyright © 2005 Greenheck Fan Corp.

Greenheck delivers value to

mechanical engineers by

helping them solve virtually any

air quality challenges their

clients face with a

comprehensive selection of top

quality, innovative air-related

equipment. We offer extra value

to contractors by providing

easy-to-install, competitively

priced, reliable products that

arrive on time. And building

owners and occupants value

the energy efficiency, low

maintenance and quiet

dependable operation they

experience long after the

construction project ends.

Building Value in Air

Our Warranty

All exhaust, supply,

recirculating and modulating

power roof ventilators shall be

direct drive axial type.

Propeller construction shall be

cast aluminum, airfoil,

reversible design. Propellers

shall be statically and

dynamically balanced.

Fan hood and base

construction shall be

galvanized steel (aluminum

optional). Bases shall be 12 in.

high. Hood panels shall be

arched with interlocking

seams for weather protection.

Birdscreens constructed of 1/2

in. galvanized steel mesh shall

be mounted horizontally

across the discharge/intake

area of the hood. Hood

support members shall be

heavy gauge galvanized steel

angles.

Plenums shall be constructed

of galvanized steel (painted

steel optional). Plenum

mounting channels shall be

heavy gauge galvanized steel.

Access panels shall be

provided in each of two

opposing sides of the plenum.

Dampers shall be constructed

with galvanized steel frames

and blades. Exhaust/ supply

dampers shall be Greenheck

model VCD 2120 low leakage

control dampers. Recirculation

dampers shall be Greenheck

model VCD 1020 control

dampers. Damper actuators

for exhaust, supply and

recirculation fans shall be

modulating type with spring

returns.

Motors shall be heavy duty

ball bearing type carefully

matched to the fan load and

furnished at the specified

voltage, phase and enclosure.

A standard square key and set

screws or tapered lock

bushing shall attach the

propeller securely to the motor

shaft.

Motor support frame

assemblies shall be

constructed of heavy gauge

steel angles. Fan panels shall

be heavy gauge steel with

formed flanges and a double

venturi.

Performance shall be equal for

exhaust, supply and

recirculate modes.

Each unit shall bear a

permanently affixed nametag

with a fan model number, a

serial number, and a mark.

Optional control centers shall

bear a nametag with identical

information.

Hooded axial roof ventilators

shall be direct drive model

ESRMD (Four-Way Fan) as

manufactured by Greenheck,

Schofield, Wisconsin.

Typical Specifications

Loading...

Loading...