Page 1

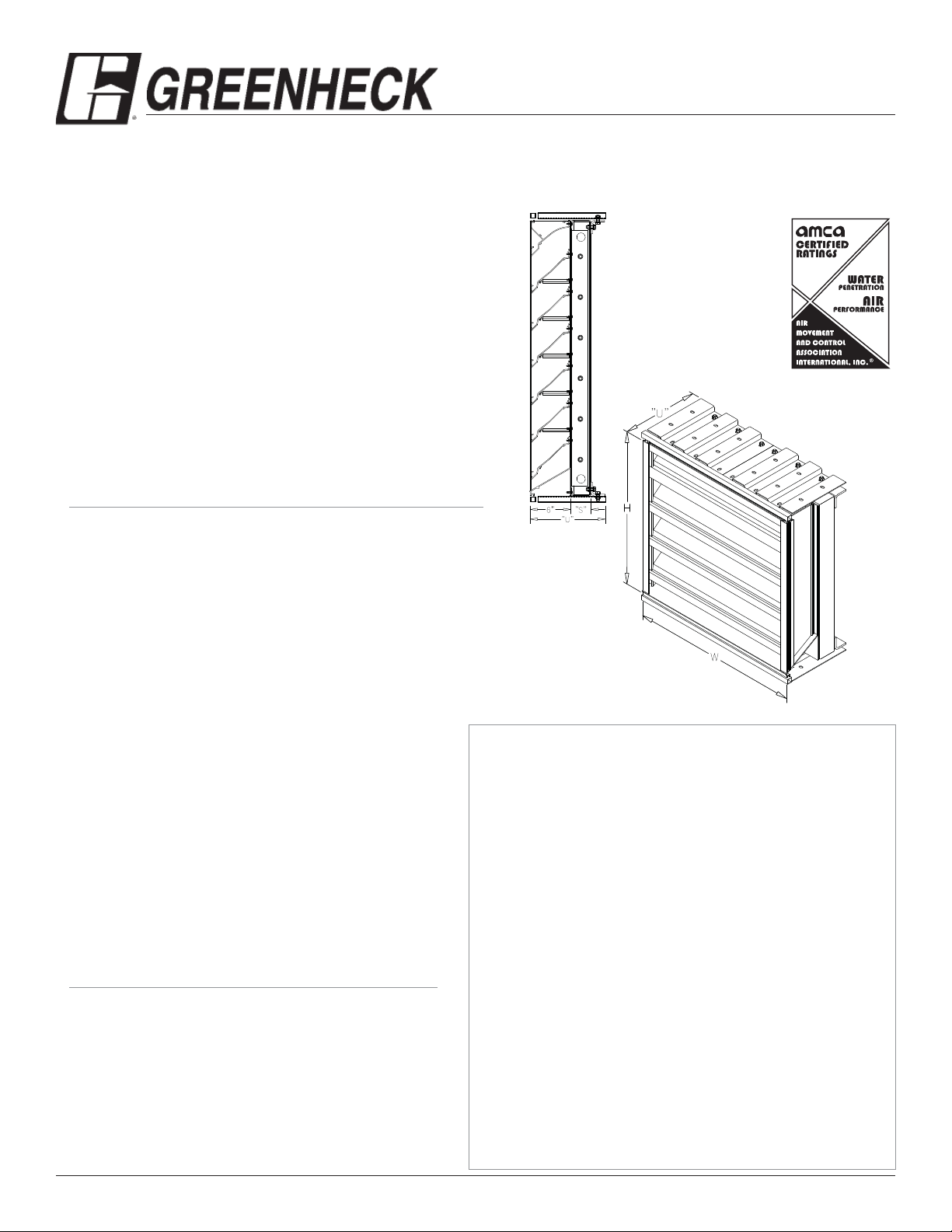

Miami-Dade Qualifi ed

Drainable Blade Louver

Application and Design

ESD-603D is an extruded aluminum drainable blade louver

designed to protect air intake and exhaust openings in building

exteriors specifically for applications requiring extremely high

structural design loadings. Design characteristics meet the

performance requirements established by the Florida Building

Code and Miami-Dade County. Tested in accordance with and

passes TAS 201 (Large Missile Impact), TAS 202 (Uniform Static

Air Pressure), TAS 203 (Cyclic Wind Loading) and TAS 100A

(Wind-Driven Rain) with optiononal HCD-240 damper. ESD-603D

may be installed in locations where the space behind the louver is

designed to accept water penetration and houses water resistant/

water proof equipment, components or supplies. Qualified for

installation within masonry/concrete or structural steel framed

building conditions.

Standard Construction

Frame . . . . . . . . .Heavy gauge extruded 6063T5 aluminum,

6 in. x 0.125 in. nominal wall thickness

Blades . . . . . . . . .Drainable design, heavy gauge extruded

aluminum, 0.125 in. nominal wall thickness,

positioned at 37º and 45º angles on

approximately 6 in. centers

Construction . . . .Welded and mechanically fastened

Birdscreen . . . . . .3/4 in. x 0.051 fl attened expanded aluminum in

removable frame, inside mount (rear)

Finish . . . . . . . . . .Mill

Anchor Plates . . .Factory attached, heavy gauge steel,

Permatector fi nish

Structural

Supports . . . . . .Heavy gauge steel, Permatector fi nish

Minimum Rough

Opening Size . . .12 in. W x 15 in. H

Maximum Rough

Opening Size . . .Unlimited in. W x 120 in. H

Maximum Single Section Rough

Opening Size . . .60 ½ in. W x 120 in. H

Options (at additional cost)

• A variety of bird and insect screens

• Extended sill

• A variety of architectural finishes including:

Clear anodize

Integral color anodize

Baked enamel

Kynar

Optional factory attached HCD-240 damper

Minimum Rough

Opening Size . . .12 in. W x 15 in. H

Maximum Rough

Opening Size . . .Unlimitedin. W x 120 in. H

Maximum Single Section Rough

Opening Size . . .60½ in. W x 120 in. H

ESD-603D

Florida Product Approval No: FL4826.1

Miami-Dade NOA No.: 06-0526.02

Maximum Wind-load: 138 PSF

• May be installed in locations up to 33 ft. above grade

where the space behind the louver is not designed

to accept water penetration and houses non-water

resistant/water proof equipment, components or

supplies.

• Vertical blade axis

• Parallel blade action

• Galvanized steel linkage

• Silicone blade seals

• Stainless steel compression jamb seals

• Plated steel axles

• Stainless steel sleeve bearings

• Viton O-ring shaft seals

• Manual quadrant actuator (in airstream)

• Mill fi nish only

Page 2

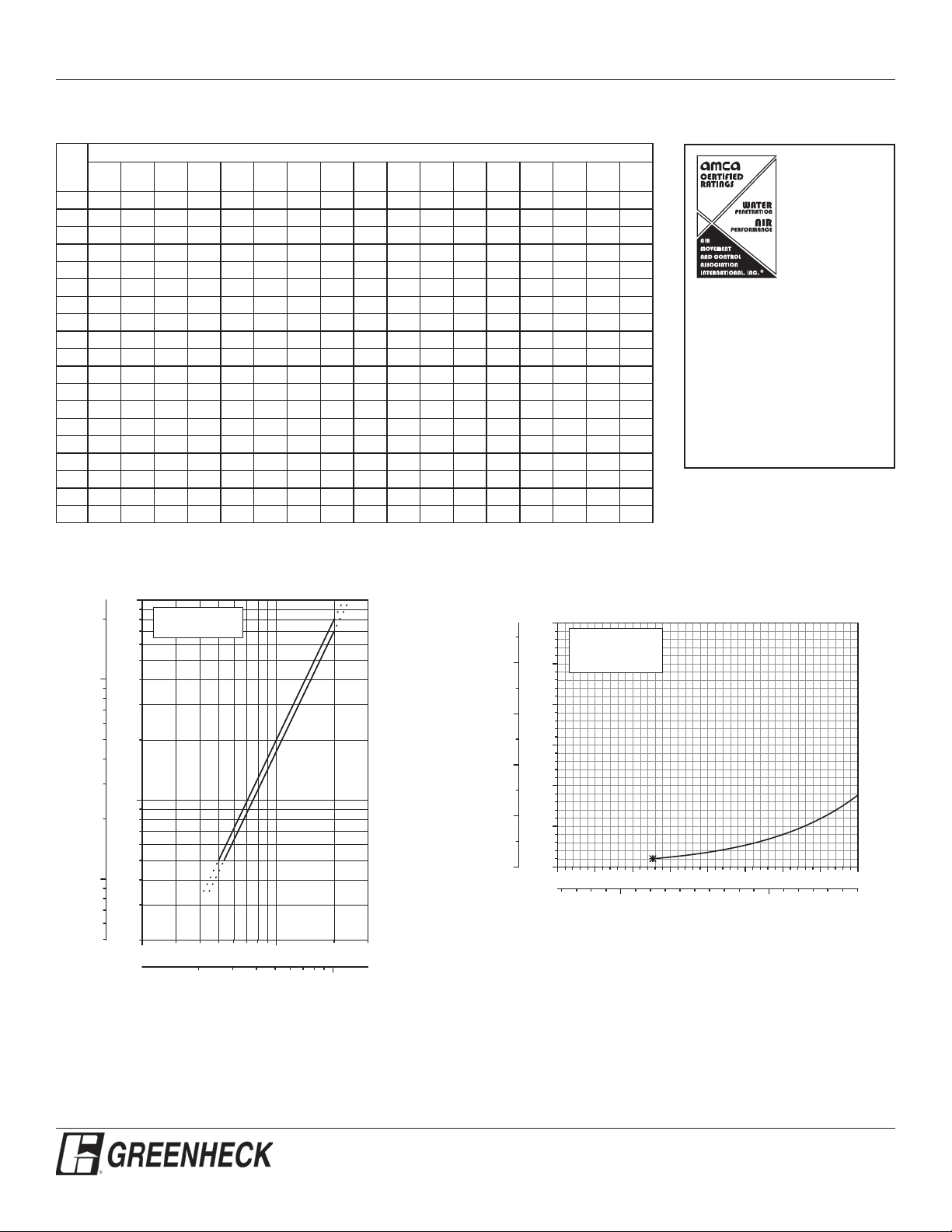

Free Area Chart

y

R.O

Height

Inches

12.5 15.5 18.5 21.5 24.5 27.5 30.5 33.5 36.5 39.5 42.5 45.5 48.5 51.5 54.5 57.5 60.5

15 0.27 0.36 0.45 0.54 0.63 0.72 0.80 0.89 0.98 1.03 1.11 1.20 1.29 1.38 1.47 1.56 1.65

18 0.44 0.59 0.73 0.88 1.02 1.16 1.31 1.45 1.60 1.67 1.81 1.96 2.10 2.24 2.39 2.53 2.68

24 0.70 0.93 1.15 1.38 1.61 1.84 2.06 2.29 2.52 2.63 2.86 3.08 3.31 3.54 3.77 3.99 4.22

30 0.96 1.27 1.58 1.89 2.20 2.51 2.82 3.13 3.44 3.59 3.90 4.21 4.52 4.83 5.14 5.45 5.76

36 1.21 1.60 2.00 2.39 2.78 3.17 3.57 3.96 4.35 4.55 4.94 5.33 5.73 6.12 6.51 6.90 7.30

42 1.37 1.81 2.25 2.70 3.14 3.59 4.03 4.47 4.92 5.14 5.58 6.03 6.47 6.91 7.36 7.80 8.24

48 1.62 2.15 2.67 3.20 3.73 4.25 4.78 5.30 5.83 6.09 6.62 7.15 7.67 8.20 8.72 9.25 9.78

54 1.87 2.48 3.09 3.69 4.30 4.91 5.52 6.12 6.73 7.03 7.64 8.25 8.86 9.46 10.07 10.68 11.28

60 2.12 2.81 3.50 4.19 4.88 5.56 6.25 6.94 7.63 7.97 8.66 9.35 10.04 10.73 11.42 12.10 12.79

66 2.38 3.15 3.92 4.69 5.46 6.23 7.00 7.77 8.54 8.93 9.70 10.47 11.24 12.01 12.78 13.55 14.32

72 2.63 3.48 4.34 5.19 6.04 6.90 7.75 8.60 9.46 9.88 10.74 11.59 12.44 13.30 14.15 15.00 15.85

78 2.89 3.82 4.76 5.69 6.63 7.57 8.50 9.44 10.37 10.84 11.78 12.71 13.65 14.59 15.52 16.46 17.39

84 3.14 4.16 5.18 6.20 7.22 8.24 9.26 10.27 11.29 11.80 12.82 13.84 14.86 15.88 16.90 17.92 18.94

90 3.40 4.50 5.60 6.70 7.81 8.91 10.01 11.11 12.21 12.77 13.87 14.97 16.07 17.17 18.28 19.38 20.48

96 3.65 4.84 6.02 7.21 8.40 9.58 10.77 11.95 13.14 13.73 14.91 16.10 17.28 18.47 19.65 20.84 22.02

102 3.91 5.18 6.44 7.71 8.98 10.25 11.51 12.78 14.05 14.68 15.95 17.22 18.49 19.75 21.02 22.29 23.56

108 4.07 5.38 6.70 8.02 9.34 10.66 11.98 13.30 14.61 15.27 16.59 17.91 19.23 20.55 21.87 23.18 24.50

114 4.32 5.72 7.12 8.52 9.92 11.33 12.73 14.13 15.53 16.23 17.63 19.03 20.43 21.83 23.23 24.63 26.04

120 4.57 6.05 7.53 9.02 10.50 11.98 13.46 14.95 16.43 17.17 18.65 20.13 21.62 23.10 24.58 26.06 27.54

Rough Opening Width in Inches

ESD-603DPERFORMANCE DATA

Florida Product Approval No.: FL4826.1

Miami-Dade NOA No.: 06-0526.02

Maximum Wind-load: 138 PSF

Greenheck Fan

Corportation

certifies that

the ESD603D louvers

shown herein

are licensed

to bear the

AMCA Seal. The

ratings shown are based

on tests and procedures

performed in accordance with

AMCA Publication 511 and

comply with the requirements

of the AMCA Certified Ratings

Program. The AMCA Certified

Ratings Seal applies to air

performance and water

penetration ratings.

Airflow Resistance (Standard Air - .075 lb/ft

Pa

in. wg

1

0.9

200

100

90

80

70

60

50

40

30

20

Stat ic Pressure Drop

10

9

8

7

6

5

ft/min

m/s

Test S ize 48 in. x 48 in.

0.8

Standard Air - .075 lb/ ft

0.7

0.6

0.5

0.4

0.3

0.2

0.1

0.09

0.08

0.07

0.06

0.05

0.04

0.03

0.02

200200 300 400 500 600 700 800 900 1000 2000 3000

3

Intake

Exh aust

2345678910

3

)

Free Air Velocit

Model ESD-603D resistance to airflow (pressure drop)

varies depending on louver application (air intake or air

exhaust). Free area velocities (shown) are higher than average

velocity through the overall louver size. See louver selection

information.

Water Penetration (Standard Air - .075 lb./ft.3)

Test size 48 in. x 48 in. Test duration of 15 min.

ml/m2 oz/ft2

0.30

Test Size 48 in. x 48 in.

80

60

40

20

Water Penetration per Unit Free Area

0

ft/min:

m/s:

Test Period 15 minutes

0.25

Standard Air - .075 lb/ft

0.20

0.15

0.10

0.05

0.00

900 950 1000 1050 1100 1150 1200 1250 1300

4.6 4.7 4.8 4.9 5.0 5.1 5.2 5.3 5.4 5.5 5.6 5.7 5.8 5.9 6.0 6.1 6.2 6.3 6.4 6.5 6.6

The AMCA Water Penetration Test provides a method for comparing various

louver models and designs as to their efficiency in resisting the penetration

of rainfall under specific laboratory test conditions. The beginning point of

water penetration is defined as that velocity where the water penetration

curve projects through .01 oz. of water (penetration) per sq. ft. of louver

free area. *The beginning point of water penetration for Model ESD-

603D is 1027 fpm free area velocity. These perfor mance ratings do not

guarantee a louver to be weather proof or stormproof and should be used

in combination with other factors including good engineering judgement in

selecting louvers.

3

Free Area Velocity

Page 3

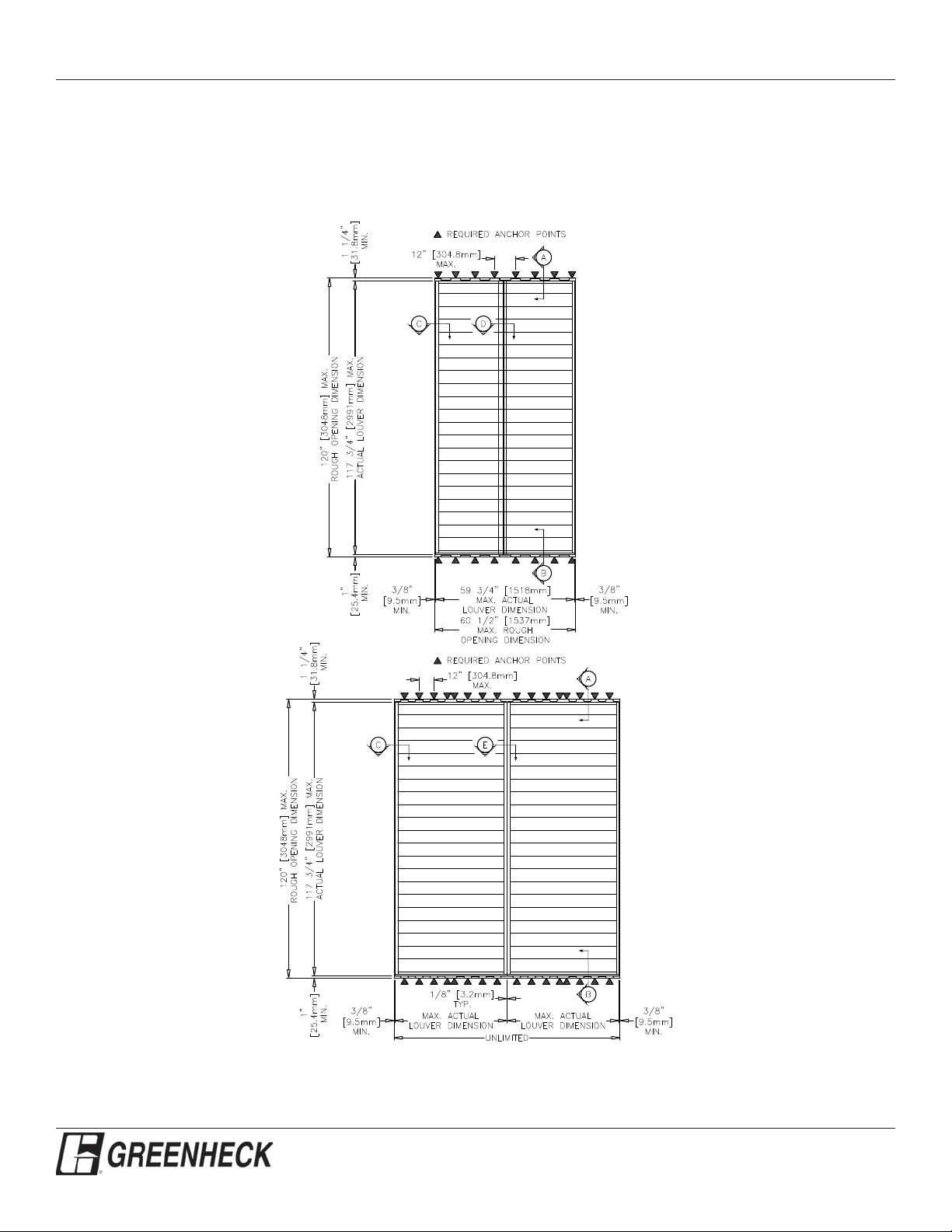

INSTALLATION DETAILS

Florida Product Approval No.: FL4826.1

Miami-Dade NOA No.: 06-0526.02

Maximum Wind-load: 138 PSF

Model ESD-603D is a Miami-Dade Qualified and Florida Product Approved louver and must be installed in accordance with the installation instructions shown herein.

Model ESD-603D is qualified for installation within concrete/masonry and structural steel building conditions. Model ESD-603D is structurally calculated to withstand

positive and negative wind-loads up to 138 PSF. The maximum single section rough opening width is 60½ in. The maximum rough opening height is 120 in. While the

maximum rough opening height is limited to 120 in., the rough opening width may be unlimited as multiple sections may be installed side by side in accordance with

installation instructions.

ESD-603D

Minimum Rough

Opening Size

12 in. W x 15 in. H

Maximum Single Section

Rough Opening Size

60½ in. W x 120 in. H

Page 4

PRODUCT DETAILS

ESD-603D

Florida Product Approval No.: FL4826.1

Miami-Dade NOA No.: 06-0526.02

Maximum Wind-load: 138 PSF

Page 5

PRODUCT DETAILS

ESD-603D

Florida Product Approval No.: FL4826.1

Miami-Dade NOA No.: 06-0526.02

Maximum Wind-load: 138 PSF

Page 6

OPTION DRAWINGS

ESD-603D

Florida Product Approval No.: FL4826.1

Miami-Dade NOA No.: 06-0526.02

Maximum Wind-load: 138 PSF

Page 7

INSTALLATION DETAILS

Maximum Size and Installation Information

Model ESD-603D/HCD-240 is a Miami-Dade Qualified and Florida Product Approved louver and must be installed in accordance with the installation instructions shown

herein. Model ESD-603D/HCD-240 is qualified for installation within concrete/masonry, structural steel building conditions. Model ESD-603D/HCD-240 is structurally

calculated to withstand positive and negative wind-loads up to 138 PSF. The maximum single section rough opening width is 60½ in. The maximum rough opening

height is 120 in. While the maximum rough opening height is limited to 120 in., the rough opening width may be unlimited as multiple sections may be installed side by

side in accordance with installation instructions.

ESD-603D with HCD-240

Florida Product Approval No.: FL4826.2

Miami-Dade NOA No.: 06-0526.03

Maximum Wind-load: 138 PSF

Minimum Rough

Opening Size

12 in. W x 15 in. H

Maximum Single Section Rough

Opening Size

60½ in. W x 120 in. H

Page 8

PRODUCT DETAILS

ESD-603D with HCD-240

Florida Product Approval No.: FL4826.2

Miami-Dade NOA No.: 06-0526.03

Maximum Wind-load: 138 PSF

Page 9

PRODUCT DETAILS

ESD-603D with HCD-240

Florida Product Approval No.: FL4826.2

Miami-Dade NOA No.: 06-0526.03

Maximum Wind-load: 138 PSF

Page 10

OPTION DRAWINGS

ESD-603D with HCD-240

Florida Product Approval No.: FL4826.2

Miami-Dade NOA No.: 06-0526.03

Maximum Wind-load: 138 PSF

FINISHES

Finish Type Description/Application Color Selection

2-coat 70% KYNAR 500®/HYLAR 5000® AAMA 2605 –

Dry fi lm thickness 1.2 mil. (AKA: Duranar®, Fluoropon®,

Trinar®, Flouropolymer, Polyvinylidene Fluoride, PVDF2)

2-coat 50% KYNAR 500®/HYLAR 5000® AAMA 2604 –

Dry fi lm thickness 1.2 mil. (AKA: Acrofl ur®, Acrynar®)

Baked Enamel AAMA 2603 – Dry fi lm thickness 0.8 mil.

(AKA: Acrabond Plus®, Duracron®)

Integral Color Anodize AA-M10C22A42 (>0.7 mil)

Clear Anodize 215 R-1 AA-M10C22A41 (>0.7 mil)

Clear Anodize 204 R-1 AA-M10C22A31 (0.4-0.7 mil)

Industrial coatings

Mill

“Best.” The premier fi nish for extruded aluminum. Tough,

long-lasting coating has superior color retention and

abrasive properties. Resists chalking, fading, chemical

abrasion and weathering.

“Better.” Tough, long-lasting coating has excellent color

retention and abrasive properties. Resists chalking, fading,

chemical abrasion and weathering.

“Good.” Provides good adhesion and resistance to

weathering, corrosion and chemical stain.

“Two-step” anodizing is produced by following the normal

anodizing step with a second, colorfast process.

Clear, colorless and hard oxide aluminum coating that resists

weathering and chemical attack.

Clear, colorless and hard oxide aluminum coating that resists

weathering and chemical attack.

Greenheck offers a number of industrial coatings such as Hi-Pro Polyester, Epoxy, and Permatector®.

Consult a Greenheck Product Specialist for complete color and application information.

Materials may be supplied in natural aluminum or galvanized steel fi nish when normal weathering is

acceptable and there is no concern for color or color change.

Finishes meet or exceed AAMA 2605, AAMA 2604, and AAMA 2603 requirements. Please consult www.greenheck.com for complete information on standard and

extended paint warranties. Paint fi nish warranties are not applicable to steel products.

Standard Colors: Any of the 24

standard colors shown can be

furnished in 70% or 50% KYNAR

500®/HYLAR 5000® or Baked Enamel.

2-Coat Mica:

Greenheck offers 9 standard 2-coat

Mica colors. Other colors are

available. Consult Greenheck for

possible extra cost when selecting

non-standard colors or special

fi nishes.

Light, Medium or Dark Bronze;

Champagne; Black

Clear 5 years

Clear 1 Year

Copyright © 2010 Greenheck Fan Corporation

Standard Warranty

(Aluminum)

10 Years

(Consult Greenheck for

availability of extended

warranty)

5 Years

1 Year

5 years

Consult Greenheck

n/a

ESD-603D

July 2010 Rev. 1

Greenheck Fan Corporation reserves the right

to make product changes without notice.

Loading...

Loading...