Page 1

Application

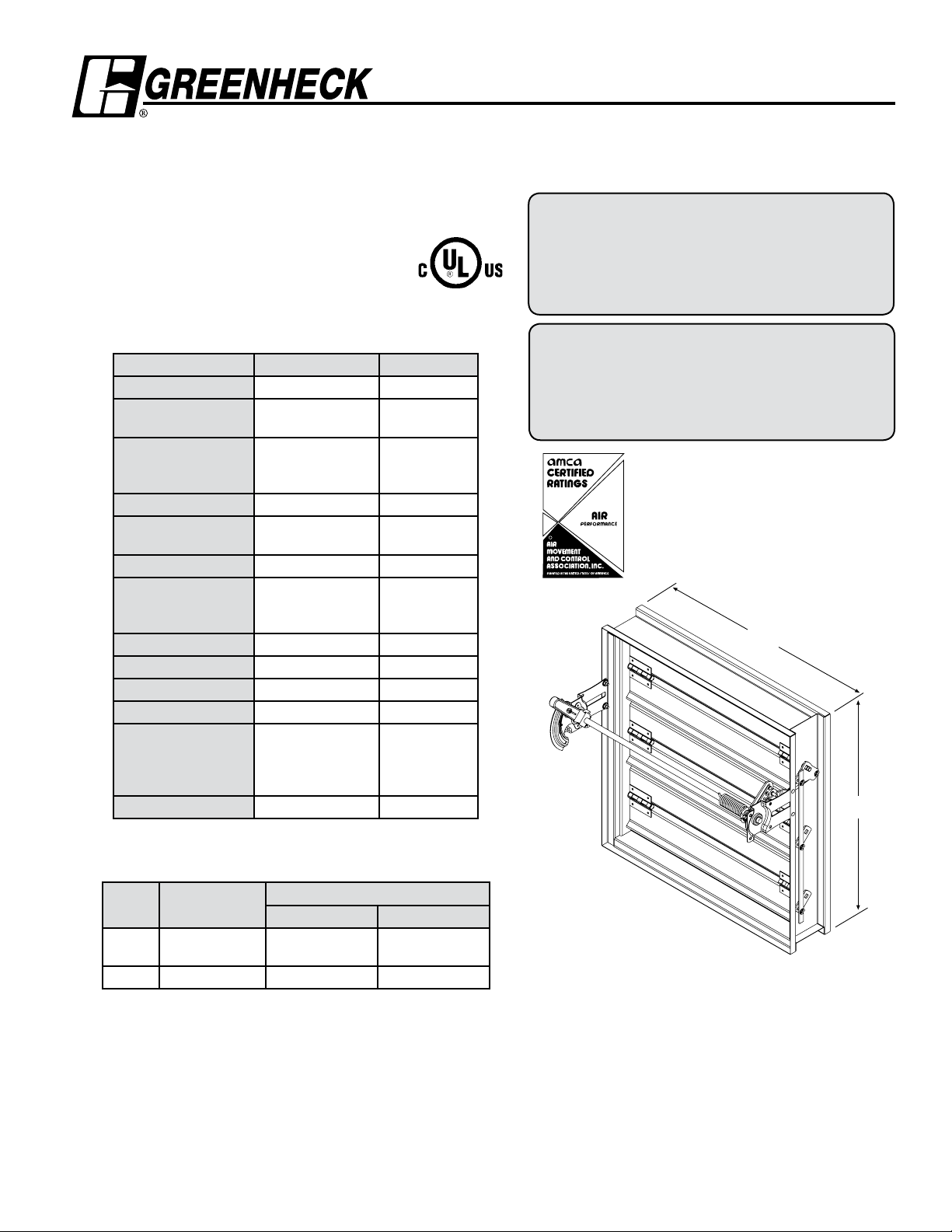

H

W

R

Model DFD-M230 is a multi-blade fire damper with 3V style blades.

The DFD-M230 has been qualified to 10.2 m/s (2000 fpm) and 1.0 kPa

(4 in. wg.) for dynamic closure in emergency fire situations. Model

DFD-M230 may be installed vertically (with blades running horizontal)

or horizontally and is rated for airflow in either direction.

Ratings

UL 555 Fire Resistance Rating

Fire Rating: 3 Hours

Dynamic Closure Rating: Actual limits are size dependent

Maximum Velocity: 10.2 m/s (2000 fpm)

Maximum Pressure: 1 kPa (4 in. wg)

Construction Standard Optional

Frame Material Galvanized steel -

Frame Material

Thickness

Frame Type 127mm x 25mm

Blade Material Galvanized steel -

Blade Material

Thickness

Blade Type 3V -

Linkage Plated steel out of

Axle Bearings Bronze -

Axle Material Plated steel -

Jamb Seals 304SS -

Closure Device Fusible link -

Closure Temperature

Actuator Manual quadrant -

1.5mm

(16 ga.)

(5 in. x 1in.)

hat channel

1.5mm

(16 ga.)

airstream, concealed

in jamb

74°C (165°F) UL 100°C (212°F),

-

-

-

-

141°C (286°F),

177°C (350°F)

UL

Model DFD-M230

Multi-Blade Fire Dampers

Steel 3V Blades

UL555 3 Hour Fire Resistance Rating

Model DFD-M230 is intended for installation in

accordance with fire damper requirements established

by:

National Fire Protection Association

NFPA Standards 80, 90A & 101

IBC International Building Codes

“UL CLASSIFIED (see complete marking on

product)”

“UL CLASSIFIED to Canadian safety standards

(see complete marking on product)”

Standard 555 (Listing #R13317)

Greenheck Kunshan Co. Ltd. and Greenheck

Fan Corporation certifies that the model DFDM230 shown herein is licensed to bear the AMCA

Seal. The ratings shown are based on tests and

procedures performed in accordance with AMCA

Publication 511 and comply with the requirements

of the AMCA Certified Ratings Programs. The

AMCA Certified Ratings Seal applies to air

performance ratings only.

LH

W x H Minimum Size

mm 203 x 152 914 x 914 or

Inches 8 x 6 36 x 36 or 32 x 48 64 x 48

Single Section Multi-Section

Features

• Frames are constructed with reinforced corners. Low

profile head and sill are used on sizes less than 432mm

(17 in.) high.

• Blades are reinforced with 3 longitudinal structurally

designed vee's.

Maximum Size

813 x 1219

1626 x 1219

RH

* W & H dimensions furnished approximately 6mm (1/4 in.) undersize.

(Add sleeve thickness for overall sleeved damper dimension)

Options

• Extra Fusible Links

• Flanges

• OCI (Open Closed Indication switches)

• POC retaining angles

• Sleeves

• Transitions (R, C)

Installation instructions available at www.greenheck.com

Page 2

Pressure Drop Data DFD-M230

5D 6D

5D

D

4 (W) (H

)

3.14

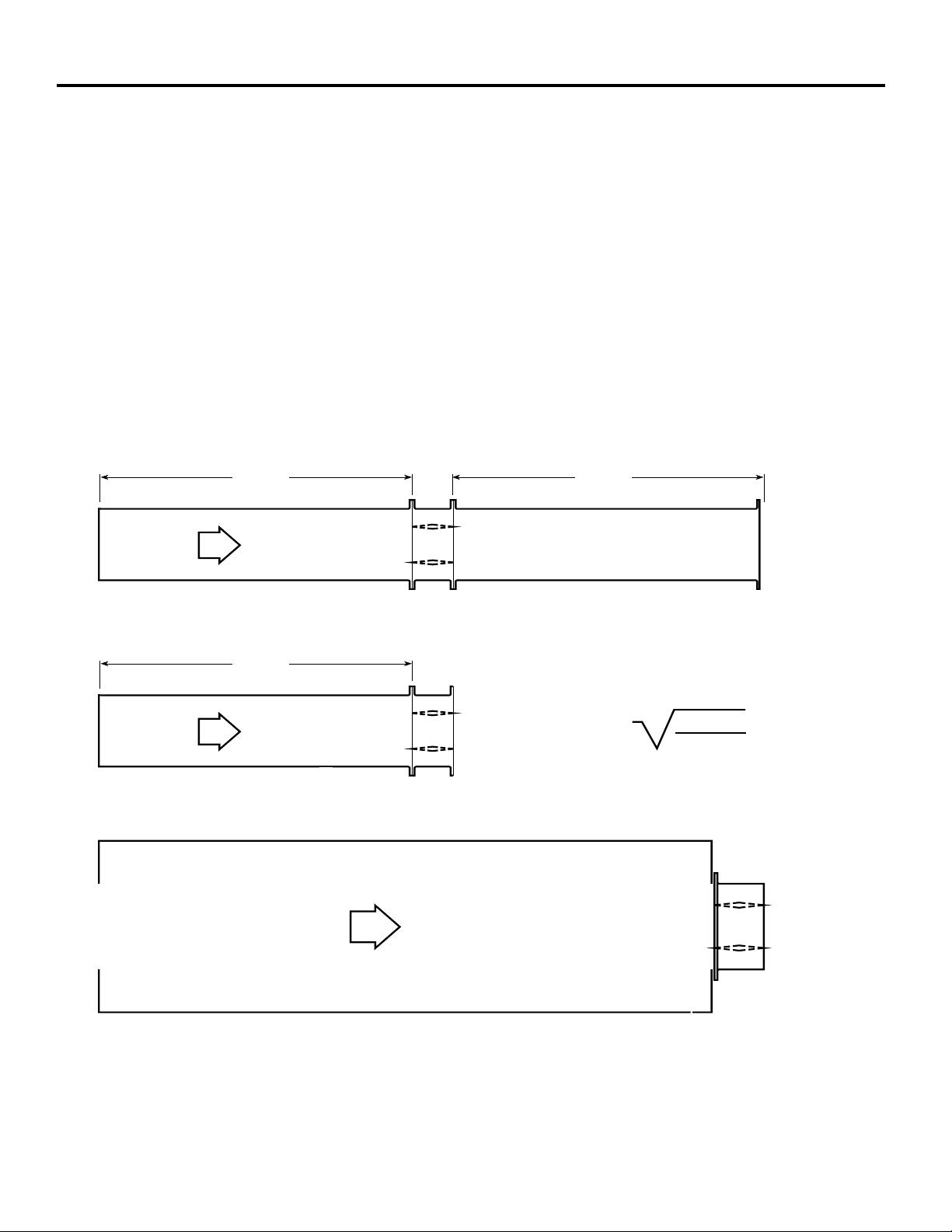

This pressure drop testing was conducted in accordance with AMCA Standard 500-D using the three configurations shown. All

data has been corrected to represent standard air at a density of 1.201 kg/m3.

Actual pressure drop found in any HVAC system is a combination of many factors. This pressure drop information along with an

analysis of other system influences should be used to estimate actual pressure losses for a damper installed in a given HVAC

system.

AMCA Test Figures

Figure 5.3 Illustrates a fully ducted damper. This configuration has the lowest pressure drop of the three test configurations

because entrance and exit losses are minimized by straight duct runs upstream and downstream of the damper.

Figure 5.2 Illustrates a ducted damper exhausting air into an open area. This configuration has a lower pressure drop than

Figure 5.5 because entrance losses are minimized by a straight duct run upstream of the damper.

Figure 5.5 Illustrates a plenum mounted damper. This configuration has the highest pressure drop because of extremely high

entrance and exit losses due to the sudden changes of area in the system.

Page 3

AMCA 5.2 Pressure Drop DFD-M230

5D 6D

5D

D

4 (W) (H)

3.14

R

2 5 10 30

10

100

1000

305mm x 305mm

610mm x 610mm

914mm x 914mm

305mm x 1219mm

1219mm x 305mm

PRESSURE DROP- PASCALS

FACE VELOCITY- METERS/SECOND

AMCA 5.2

VELOCITY VS. PRESSURE DROP

1219 x 305

305 x 305

610 x 610

305 x 1219

914 x 914

305mm x 305mm

Velocity

(m/s)

2.5 10

5.1 35

7.7 80

10 135

12.6 207

15.5 311

17.8 411

20.8 561

Pressure

Drop (Pa)

610mm x 610mm

Velocity

(m/s)

2.5 5

5.2 17

7.8 42

10.3 72

12.9 115

15.4 162

18.1 224

20.8 296

Pressure

Drop (Pa)

914mm x 914mm

Velocity

(m/s)

2.6 3

5.1 10

7.6 22

10.2 42

12.7 65

15.3 95

17.7 127

20.3 167

Greenheck Kunshan Co. Ltd. and Greenheck Fan

Corporation certifies that the model DFD-M230

shown herein is licensed to bear the AMCA Seal. The

ratings shown are based on tests and procedures

performed in accordance with AMCA Publication

511 and comply with the requirements of the AMCA

Certified Ratings Programs. The AMCA Certified

Ratings Seal applies to air performance ratings only.

Pressure

Drop (Pa)

305mm x 1219mm

Velocity

(m/s)

2.5 3

5.1 15

7.6 32

10.3 57

12.9 90

15.3 125

18 174

20.5 227

Pressure

Drop (Pa)

1219mm x 305mm

Velocity

(m/s)

2.5 8

5.1 27

7.7 57

10.3 105

12.9 164

15.6 242

17.9 316

20.7 424

Pressure

Drop (Pa)

Page 4

R

AMCA 5.3 Pressure Drop DFD-M230

5D 6D

2 5 10 30

10

100

1000

305mm x 305mm

610mm x 610mm

914mm x 914mm

305mm x 1219mm

1219mm x 305mm

PRESSURE DROP- PASCALS

FACE VELOCITY- METERS/SECOND

AMCA 5.3

VELOCITY VS. PRESSURE DROP

305 x 305

1219 x 305

305 x 1219

610 x 610

914 x 914

305mm x 305mm

Velocity

(m/s)

2.4 5

5.1 22

7.8 52

10.3 92

12.9 145

15.4 209

17.7 274

20.8 379

Pressure

Drop (Pa)

610mm x 610mm

Velocity

(m/s)

2.5 3

7.7 22

10.3 40

12.8 62

15.5 92

17.9 122

20.8 167

Pressure

Drop (Pa)

5 10

914mm x 914mm

Velocity

(m/s)

2.5 3

5.1 8

7.6 15

10.1 27

12.8 42

15.3 62

17.7 82

20.3 107

Greenheck Kunshan Co. Ltd. and Greenheck Fan

Corporation certifies that the model DFD-M230

shown herein is licensed to bear the AMCA Seal. The

ratings shown are based on tests and procedures

performed in accordance with AMCA Publication

511 and comply with the requirements of the AMCA

Certified Ratings Programs. The AMCA Certified

Ratings Seal applies to air performance ratings only.

Pressure

Drop (Pa)

305mm x 1219mm

Velocity

(m/s)

2.5 3

5.1 10

7.7 25

10.3 42

12.9 67

15.7 100

18.7 140

20.9 174

Pressure

Drop (Pa)

1219mm x 305mm

Velocity

(m/s)

2.5 5

5.1 20

7.6 40

10.1 72

12.7 112

15.3 164

18 227

20.6 299

Pressure

Drop (Pa)

Page 5

R

AMCA 5.5 Pressure Drop DFD-M230

5D 6D

5D

D

4 (W) (H)

3.14

2 5 10 30

10

100

1000

305mm x 305mm

610mm x 610mm

914mm x 914mm

305mm x 1219mm

1219mm x 305mm

PRESSURE DROP- PASCALS

FACE VELOCITY- METERS/SECOND

AMCA 5.5

VELOCITY VS. PRESSURE DROP

305 x 305

1219 x 305

610 x 610

305 x 1219

914 x 914

305mm x 305mm

Velocity

(m/s)

2.5 13

5 55

7.5 122

10.2 222

12.7 349

15.4 508

17.9 688

20.6 907

Pressure

Drop (Pa)

610mm x 610mm

Velocity

(m/s)

2.5 8

7.6 75

10.3 140

12.8 217

15.3 309

17.7 409

20.8 568

Pressure

Drop (Pa)

5 35

Greenheck Kunshan Co. Ltd. and Greenheck Fan

Corporation certifies that the model DFD-M230

shown herein is licensed to bear the AMCA Seal. The

ratings shown are based on tests and procedures

performed in accordance with AMCA Publication

511 and comply with the requirements of the AMCA

Certified Ratings Programs. The AMCA Certified

Ratings Seal applies to air performance ratings only.

914mm x 914mm

Velocity

(m/s)

2.5 8

5.1 30

7.7 67

10.2 115

12.9 184

15.5 269

18.1 354

20.6 471

Pressure

Drop (Pa)

305mm x 1219mm

Velocity

(m/s)

2.6 8

5.1 32

7.7 75

10.2 130

12.7 202

15.5 301

18.1 416

20.6 536

Pressure

Drop (Pa)

1219mm x 305mm

Velocity

(m/s)

2.5 1

5 42

7.7 95

10.3 172

12.7 264

15.3 381

17.9 521

20.8 707

Pressure

Drop (Pa)

Page 6

Damper Sizing Information

127mm

Right hand drive is shown

Left hand drive available upon request

LH RH

A

Sleeve Length

Varies

152mm

38mm max.

95mm

137mm

GREENHECK

Greenheck Kunshan Co Ltd.

17 Qunyi Minying District • Kunshan Economic &

Technical Development Zone

Kunshan, Jiangsu, China 215300

Tel: 0512-573-66666 • Fax: 0512-573-78633

H

w

1219mm

813mm

1626mm

914mm x 914mm

or

813mm x 1219mm

The following figure shows maximum damper section size.

Multi Section

Single Section

Damper Sleeve Dimensional Data

The drawings below and corresponding table show the position of the DFD-M230 damper when mounted in a factory sleeve.

The standard mounting locations provide enough space for the mounting of manual quadrant, controls and allow space for

installation of retaining angles and duct connections.

The “A” dimension is the location of the damper mounted

in a factory sleeve. The table below shows the Standard,

Minimum, and Maximum “A” dimensions.

Specifications

Fire Dampers meeting the following specifications shall be furnished and

installed where shown on plans and/or as described in schedules. Dampers

shall meet the requirements of the latest edition of NFPA 80, 90A, and 101.

Dampers shall be tested , rated and labeled in accordance with the latest

edition of UL Standard 555. Dampers shall have a UL 555 fire rating of

3 hours. Each damper shall be equipped with a heat responsive device

which has been tested and approved for use with the damper assembly

in accordance with UL 555. The heat responsive device shall have a temperature rating of (specifier select one of the following) 74ºC, 100ºC, 141ºC,

or 177ºC. Dampers shall be UL labeled for use in dynamic systems. The

damper shall have a dynamic closure pressure rating of 1 kPa.

Damper actuator shall be manual quadrant. Manufacturers submittal data

shall indicate actuator space requirements around the damper.

UL 555 Dynamic Closure Ratings shall be qualified for airflow and pressure

in either direction through the damper. UL ratings shall allow for mounting

damper vertically (with blades running horizontal) or horizontally.

"A" Dimension

Standard Minimum Maximum

All Dampers 183mm 137mm 406mm

1

All dampers w/o OCI.

Note: Entire damper frame is not required to be installed

within the wall.

The damper blades, when closed, should be contained

in the wall.

The Damper Manufacturers submittal data shall certify all air performance

pressure drop data is licensed in accordance with the AMCA Certified Ratings Program for Test Figures 5.2, 5.3 and 5.5. Damper air performance

data shall be developed in accordance with the latest edition of AMCA

Standard 500-D.

Damper blades shall be 1.5mm galvanized steel 3V type with three longi-

tudinal grooves for reinforcement. Blades shall be completely symmetrical

relative to their axle pivot point, presenting identical resistance to airflow

and operation in either direction through the damper (blades that are nonsymmetrical relative to their axle pivot point or utilize blade stops larger

than 13mm are unacceptable).

Damper frame shall be 1.5mm galvanized steel formed into a structural hat

channel shape with reinforced corners. Bearings shall be sintered bronze

sleeve type rotating in extruded holes in the damper frame for maximum

service. Axles shall be square and positively locked into the damper blade.

Jamb seals shall be stainless steel compression type.

Basis of design is Greenheck Model DFD-M23

Copyright © 2009 Greenheck Fan Corporation

0.

DFD-M230 Rev. 5 April 2009

Loading...

Loading...