Page 1

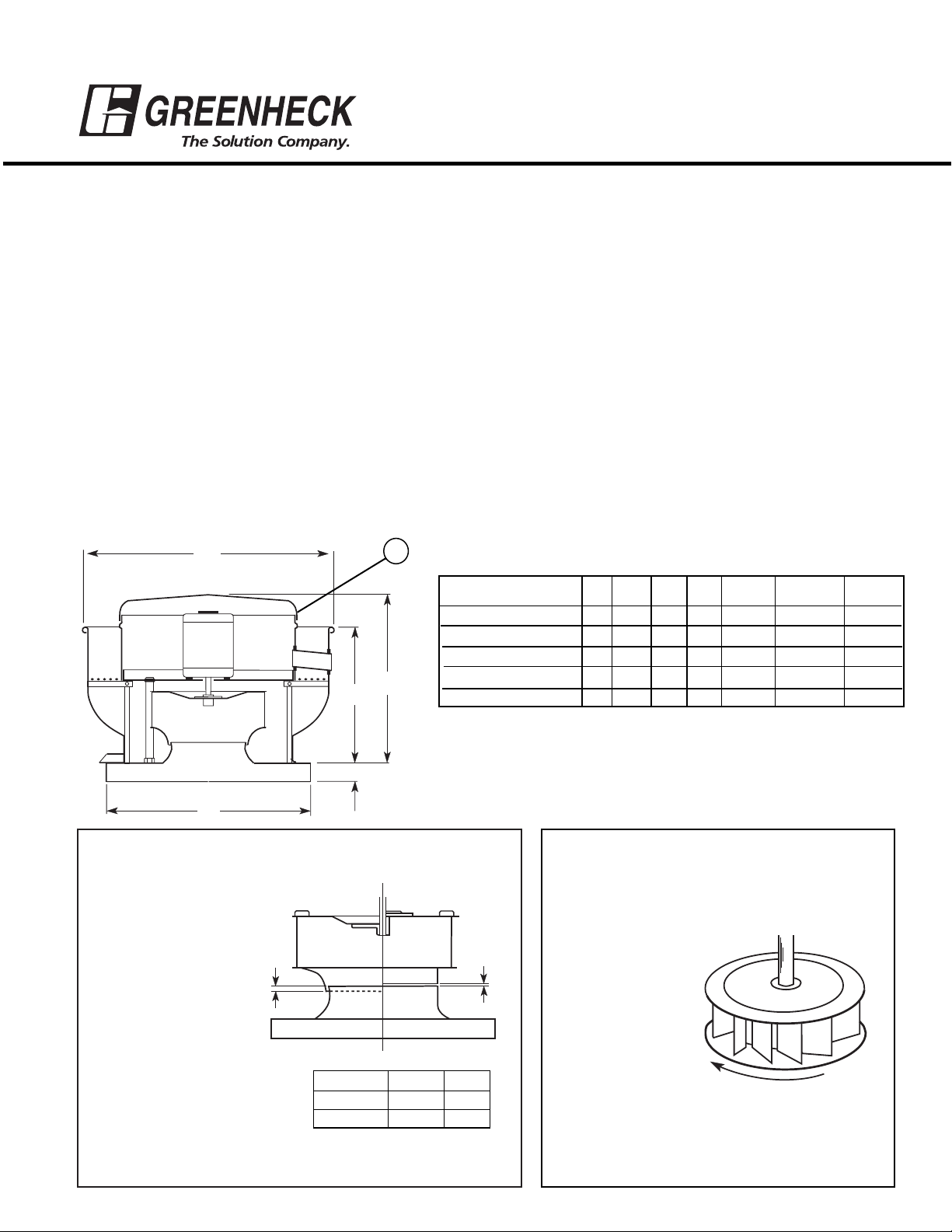

Model CUE Direct Drive

Upblast Centrifugal

Roof Exhaust Fan

Pre-Starting Checks

Check all fasteners for

tightness. The wheel

should rotate freely

and be aligned as

shown at right. Wheel

position is preset and

the unit tested at the

factory. However,

movement may occur

during shipment, and

realignment may be

necessary. Centering (height

alignment) may be

accomplished by loosening

the set screws in the wheel

and moving the wheel to

desired position.

Installation

Upon receiving unit, check for any damage and report it immediately to the shipper. Also check to see that all accessory items

are accounted for.

Move fan to desired location and fasten securely through mounting holes in base. Shims may be necessary depending upon

roofing material thickness. The diagram below shows dimensions for Model CUE.

Access to the motor compartment is accomplished by removing the screws designated “R” in the drawing below. The cover

can then be removed and placed on a flat surface in an area protected from strong winds that could blow it off the roof.

The voltage rating of the motor must be checked for compatibility to supply voltage prior to final electrical connection. For

NFPA - restaurant applications, the electrical supply must enter the motor compartment through the breather tube. For other

non-flammable applications, the electrical supply can be routed through the conduit chase between the curb cap and the

bottom of the motor compartment. Consult local code authorities for your specific requirements.

IMPORTANT: UL/cUL 762 Installations are for Restaurant Applications.

A, B, and C motor RPMs are only approved for this installation. All must include the suffix “G”.

A drain trough is provided on all CUE fans for one point drainage of residue. Some means of collection of this residue must be

provided by either placing a container directly under the trough or by utilizing an adapter to direct the residue to another

location.

B

C*

D

A

13/4"

R

Dimension “A” is the inside dimension of the curb cap.

The roof curb should be 1-1/2" less than the curb cap to allow for

roofing and flashing.

*May vary depending on motor size.

Dimensional Data

Wheel Rotation

Direction of rotation is very critical. Improper

rotation will result in loss of performance,

excessive horsepower and possible motor

burnout. Check

rotation by

energizing the unit

only momentarily.

The rotation should

be as shown in the

diagram at right and

should be in the

same direction as

the rotation decals

affixed to the unit.

Fig. 1 Fig. 2

CUE Models 060-161

Roof Approx.

Model A B C D Damper

Opening Unit Wt.

CUE-060,065,070,075 17 18

3

/8 131/2 113/8 8x8 101/2x101/2 26

CUE-080,085,090 19 21 133/8 111/2 10x10 121/2x121/2 33

CUE-095 19 21 151/4 137/16 10x10 121/2x121/2 36

CUE-098,101,121,131 19 247/8 233/4 173/8 12x12 141/2x141/2 67

CUE-141,161 22 287/8 243/4 193/8 16x16 181/2x181/2 85

MODEL G H

060-095 - 3/32 in.

098-161 1/4 in. -

®

READ AND SAVE THESE INSTRUCTIONS

PN 457692

Installation, Operation and Maintenance Manual

G

H

Cl

o

c

e

s

i

k

w

Page 2

IOM CUE FS

Rev. 3 February 2001

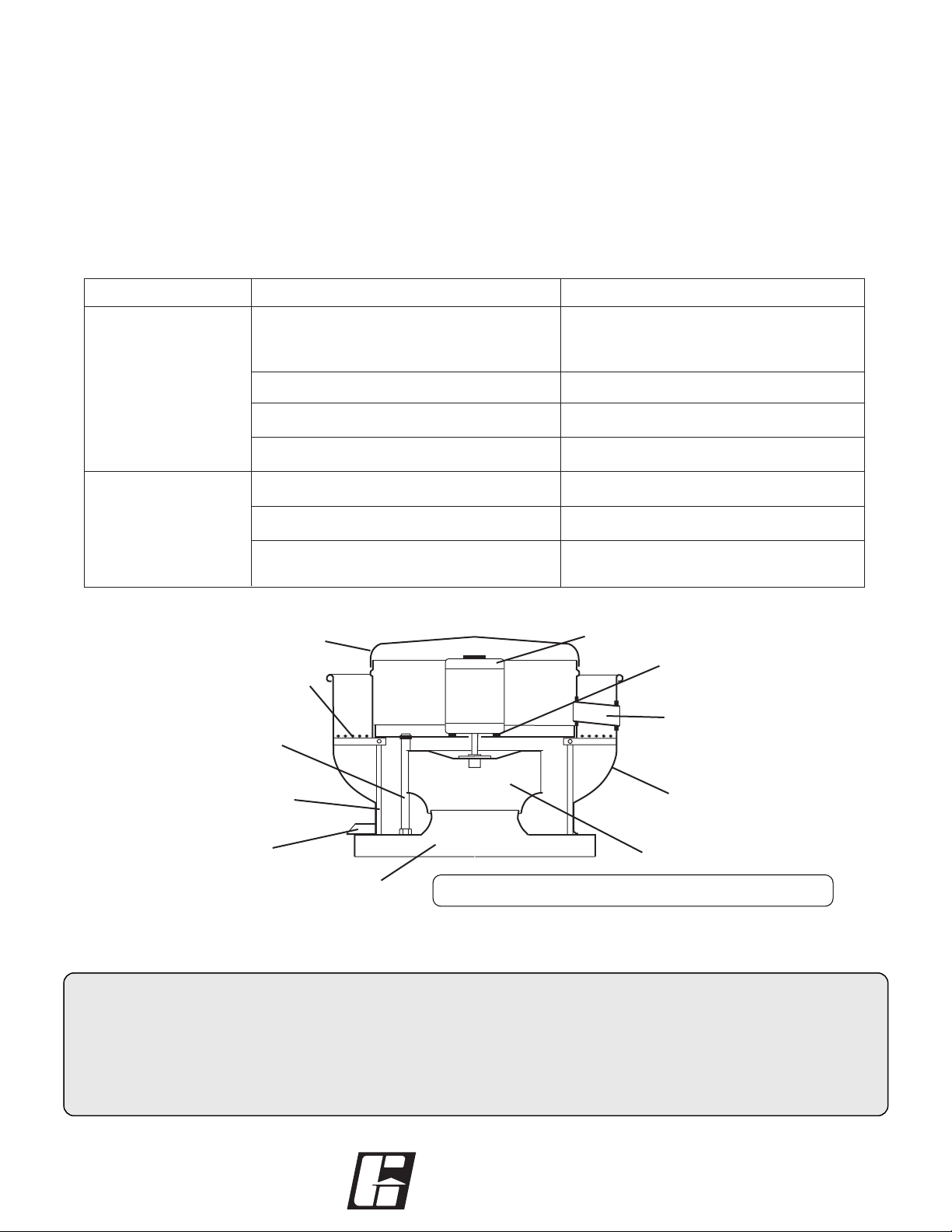

NOTE: Each fan bears a manufacturer’s nameplate with model number and serial number embossed. This information

will assist the local Greenheck representative and the factory in providing service and replacement parts.

CAUSE CORRECTIVE ACTION

System resistance too high. Check system: Proper operation of

backdraft or control dampers,

obstruction in ductwork, etc.

Unit running backwards. Correct as shown in Fig. 2.

Excessive dirt buildup on wheel. Clean wheel.

Improper wheel alignment. See Fig. 1 and Pre-Starting Checks.

Wheel improperly aligned and rubbing. See Fig. 1 and Pre-Starting Checks.

Foreign objects in wheel or housing. Remove objects, check for damage.

Unbalance of wheel caused by excessive Remove buildup.

dirt and grease buildup.

REDUCED

AIRFLOW

PROBLEM

EXCESSIVE

NOISE OR

VIBRATION

Maintenance

Motor maintenance is generally limited to cleaning and lubrication (where applicable). Cleaning should be limited to exterior

surfaces only. Removing dust buildup on motor housing ensures proper motor cooling. Greasing of motors is only intended

when fittings are provided. Many fractional motors are permanently lubricated and should not be lubricated after installation.

Motors supplied with grease fittings should be greased in accordance with manufacturers’ recommendations. With motor

temperatures under 104°F (40°C), the grease should be replaced after 2000 hours of running time as a general rule.

Wheels require very little attention when moving clean air. Occasionally, oil and dust may accumulate causing imbalance.

When this occurs, the wheel and housing should be cleaned to ensure smooth and safe operation.

All fasteners should be checked for tightness each time maintenance checks are performed prior to restarting unit.

A proper maintenance program will help these units deliver years of dependable service.

Troubleshooting

NOTE: Before taking any corrective action, make certain unit is not capable of operation during repairs.

Replacement

Parts

MOTOR

SHOCK

MOUNTS

WHEEL

BREATHER

TUBE

BIRDGUARD

*CURB CAP /

VENTURI

CONDUIT

CHASE

HOOD

*WINDBAND

*VERTICAL

SUPPORTS

*DRAIN

TROUGH

*For replacement, the windband, vertical supports, drain trough and curb

cap/venturi come as one complete assembly.

GREENHECK

P.O. BOX 410 SCHOFIELD, WISCONSIN 54476-0410

PH. 715-359-6171

www.greenheck.com

®

Warranty

Greenheck warrants this equipment to be free from defects in material and workmanship for a period of one year from the purchase

date. Any units or parts which prove defective during the warranty period will be replaced at our option when returned to our

factory, transportation prepaid.

Motors are warranted by the motor manufacturer for a period of one year. Should motors furnished by Greenheck prove defective

during this period, they should be returned to the nearest authorized motor service station. Greenheck will not be responsible for

any removal or installation costs.

Copyright © 2001 Greenheck Fan Corp.

Loading...

Loading...