Page 1

Grille

®

Application and Design

Greenheck Bar Grilles are custom designed and manufactured to function as

architectural accents or as entire facades to prevent sight or serve as solar screens

or security barriers. Bar Grilles are manufactured in configurations from 2 in. (50.88

mm) to 6 in. (152.4 mm) deep and with extruded aluminum members that range in

thicknesses from 0.081 in. (2.06 mm) to 0.250 in. (6.35 mm). Horizontal and vertical

bar spacing can be configured from 2 in. (50.8 mm) minimum to 12 in. (304.8 mm)

maximum center spacing to yield desired sightlines.

Standard Construction

Material . . . . . . . . . . . . . . . . .Extruded Aluminum, Alloy 6063T5

Material Thickness . . . . . . . .0.081 to 0.250 in. (2.06 to 6.35 mm)

Grille Depth . . . . . . . . . . . . . .2 to 6 in. (50.8 to 152.4 mm)

Perimeter Frame . . . . . . . . . .Aluminum Bar, Channel or Tube

Horizontal Bar Spacing . . . . . .2 to 12 in. (50.8 to 304.8 mm)

Vertical Bar Spacing . . . . . . . .2 to 12 in. (50.8 to 304.8 mm)

Minimum Dimension . . . . . . .10 in. (254 mm)

Maximum Dimension . . . . . . .120 in. (3048 mm)

One dimension not to exceed 72 in.

Options

• Anchor clips

• A variety of bird and insect screens

• A variety of architectural finishes including:

(at additional cost)

Clear anodize

Integral color anodize

Baked enamel paint

Kynar paint

BAR

Recommended Specifications

General

Where indicated on plan drawings or described in schedules, furnish

and install Bar Grilles as designed and manufactured by Greenheck

Fan Corporation, Schofield, WI. Grilles shall be furnished in the

configurations represented on the plan drawings and shall include

installation hardware and finishes as specified and required for a

complete installation.

Welded Assembly

All horizontal, vertical and perimeter frame members shall be joined

with slotted or tabbed connections. Where possible, connections

shall be secured with fillet welds concealed from view, unless the

size of the grille makes bolted connections between grille sections

necessary. Each weld shall be manufactured with the Pulsed Gas

Metal Arc Welding (GMAW Mig) process. Intermediate connections

shall be intermittently joined with a 1 in. (25.4 mm) long fillet weld

with a minimum 3/16 in. (4.76 mm) leg. Frames shall be joined at

each corner with a full-length GMAW fillet weld with a minimum 3/16

in. (4.76 mm) throat.

Products

Architectural grilles shall be Greenheck Bar Grilles as follows:

• Material: Extruded Aluminum, Alloy 6063T5

• Material Thickness: Specify 0.081 in. (2.06 mm) to 0.250 in.

(6.35 mm), or as indicated.

• Grille Depth: Specify 2 in. (50.8 mm) to 6 in. (152. 4 mm), or

as indicated.

• Perimeter Frame: Specify Bar, Channel or Tube, or as

indicated.

• Horizontal Bar Spacing: Specify 2 in. (50.8 mm) to 12 in.

(304.8 mm), or as indicated.

• Vertical Bar Spacing: Specify 2 in. (50.8 mm) to 12 in. (304.8

mm), or as indicated.

Page 2

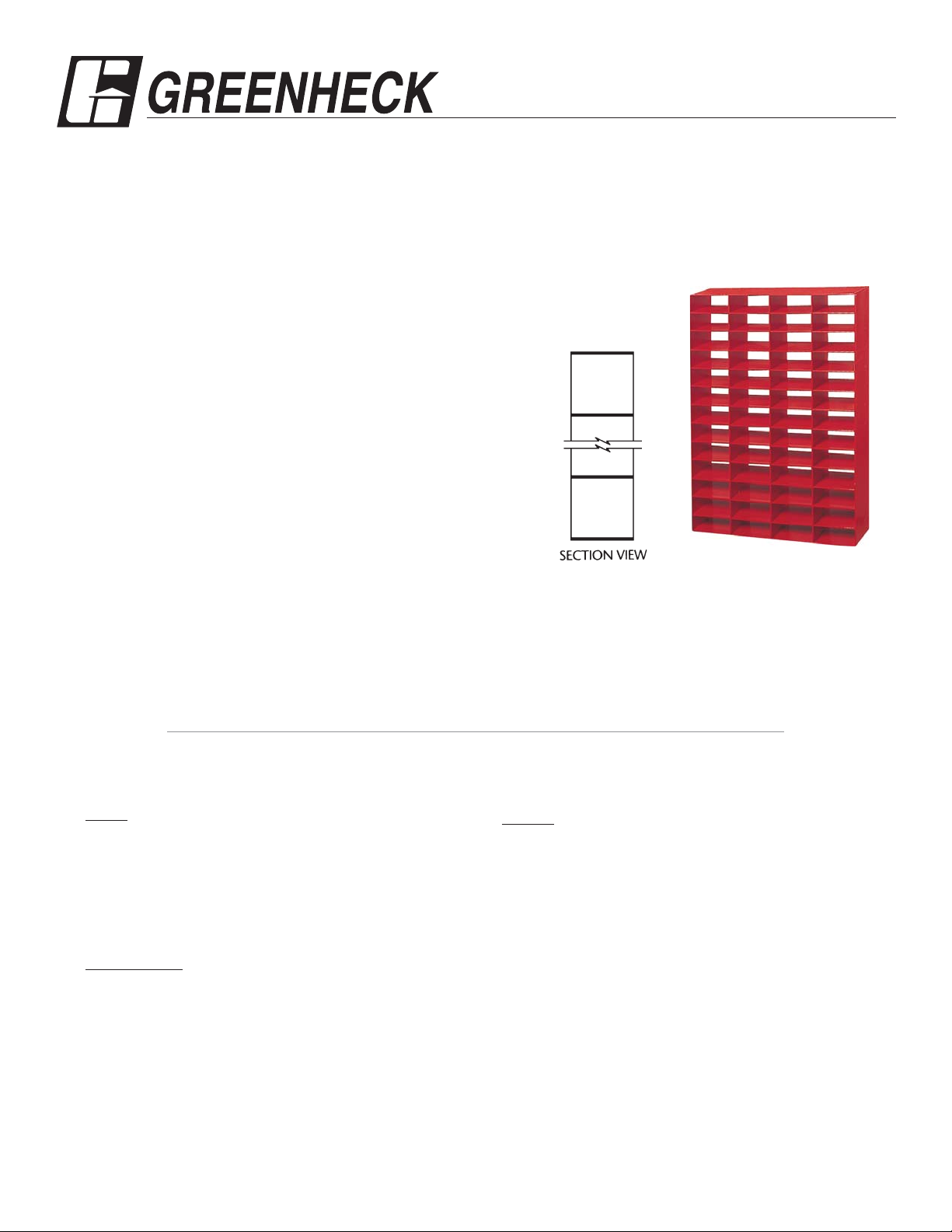

A - Horizontal Bar Spacing

Specify horizontal members on minimum 2 in. (50.8 mm) to maximum 12 in. (304.8 mm) center spacing.

B - Vertical Bar Spacing

Specify vertical members on minimum 2 in. (50.8 mm) to maximum

12 in. (304.8 mm) center spacing.

C - Grille Depth

Specify minimum 2 in. (50.8 mm) to maximum 6 in. (152.4 mm)

depth.

D - Aluminum Thickness

Specify minimum 0.081 in. (2.06 mm) to maximum 0.250 in. (6.35

mm) Extruded Aluminum (alloy 6063T5) wall thickness.

Grille

BARDETAIL DRAWINGS

FINISHES

Finish Type Description/Application Color Selection

2-coat 70% KYNAR 500®/HYLAR 5000® AAMA 2605 –

Dry fi lm thickness 1.2 mil. (AKA: Duranar®, Fluoropon®,

Trinar®, Flouropolymer, Polyvinylidene Fluoride, PVDF2)

2-coat 50% KYNAR 500®/HYLAR 5000® AAMA 2604

– Dry fi lm thickness 1.2 mil. (AKA: Acrofl ur®, Acrynar®)

Baked Enamel AAMA 2603 – Dry fi lm thickness 0.8 mil.

(AKA: Acrabond Plus®, Duracron®)

Integral Color Anodize AA-M10C22A42 (>0.7 mil)

Clear Anodize 215 R-1 AA-M10C22A41 (>0.7 mil)

Clear Anodize 204 R-1 AA-M10C22A31 (0.4-0.7 mil)

Industrial coatings

Mill

Finishes meet or exceed AAMA 2605, AAMA 2604, and AAMA 2603 requirements. Please consult www.greenheck.com for complete information on standard and

extended paint warranties. Paint fi nish warranties are not applicable to steel products.

“Best.” The premier fi nish for extruded aluminum. Tough,

long-lasting coating has superior color retention and

abrasive properties. Resists chalking, fading, chemical

abrasion and weathering.

“Better.” Tough, long-lasting coating has excellent color

retention and abrasive properties. Resists chalking, fading,

chemical abrasion and weathering.

“Good.” Provides good adhesion and resistance to

weathering, corrosion and chemical stain.

“Two-step” anodizing is produced by following the normal

anodizing step with a second, colorfast process.

Clear, colorless and hard oxide aluminum coating that resists

weathering and chemical attack.

Clear, colorless and hard oxide aluminum coating that resists

weathering and chemical attack.

Greenheck offers a number of industrial coatings such as Hi-Pro Polyester, Epoxy, and Permatector®.

Consult a Greenheck Product Specialist for complete color and application information.

Materials may be supplied in natural aluminum or galvanized steel fi nish when normal weathering is

acceptable and there is no concern for color or color change.

Standard Colors: Any of the 24

standard colors shown can be

furnished in 70% or 50% KYNAR

500®/HYLAR 5000® or Baked Enamel.

2-Coat Mica:

Greenheck offers 9 standard 2coat Mica colors. Other colors are

available. Consult Greenheck for

possible extra cost when selecting

non-standard colors or special

fi nishes.

Light, Medium or Dark Bronze;

Champagne; Black

Clear 5 years

Clear 1 Year

Standard Warranty

(Aluminum)

10 Years

(Consult Greenheck for

availability of extended

warranty)

5 Years

1 Year

5 years

Consult Greenheck

n/a

Copyright © 2007 Greenheck Fan Corporation

Bar Grille March 2007

Greenheck Fan Corporation reserves the right

to make product changes without notice.

Loading...

Loading...