Gree GWHD(18)NK3FOGWHD(24)NK3FOGWHD(24)NK3GO, GWHD(42)NK3AO, GWHD(28)NK3FO, GWHD(36)NK3BO Service Manual

Change for Life

Service Manual

Models: GWHD(18)NK3FO

GWHD(24)NK3FO

GWHD(24)NK3GO

GWHD(28)NK3FO

GWHD(36)NK3BO

GWHD(42)NK3AO

(Refrigerant:R410A)

GREE ELECTRIC APPLIANCES,INC.OF ZHUHAI

Table of Contents

Service Manual

Part

1. Summary

2. Specications

: Technical Information

Ⅰ

......................................................................................................................1

..........................................................................................................2

3. Outline Dimension Diagram

4. Refrigerant System Diagram

5. Electrical Part

5.1 Wiring Diagram ...............................................................................................................14

5.2 PCB Printed Diagram .....................................................................................................20

6. Function and Control

Part

: Installation and Maintenance

Ⅱ

.........................................................................................................14

......................................................................................24

7. Notes for Installation and Maintenance

8. Installation Manual

8.1 Electrical Connections ....................................................................................................32

............................................................................................31

.......................................................................1

......................................................................10

....................................................................12

.................................................29

..........................................29

8.2 Installing the Outdoor Unit ..............................................................................................35

8.3 Installation Dimension Diagram ......................................................................................36

8.4 Check after Installation ...................................................................................................37

9. Maintenance

9.1 Precautions before Performing Inspection or Repair .....................................................47

9.2 Flashing LED of Indoor/Outdoor Unit and Primary Judgement .....................................48

9.3 Malfunction Checking and Elimination ...........................................................................49

9.4 Maintenance Method for Normal Malfunction .................................................................73

10. Exploded View and Parts List

11. Removal Procedure

Appendix:

Appendix 1: Reference Sheet of Celsius and Fahrenheit ..................................................106

Appendix 2: Conguration of Connection Pipe ...................................................................106

Appendix 3: Pipe Expanding Method .................................................................................107

Appendix 4: List of Resistance for Temperature Sensor ....................................................108

......................................................................................................................106

............................................................................................................47

..............................................................75

.......................................................................................86

Table of Contents

Service Manual

Part

Ⅰ

: Technical Information

1. Summary

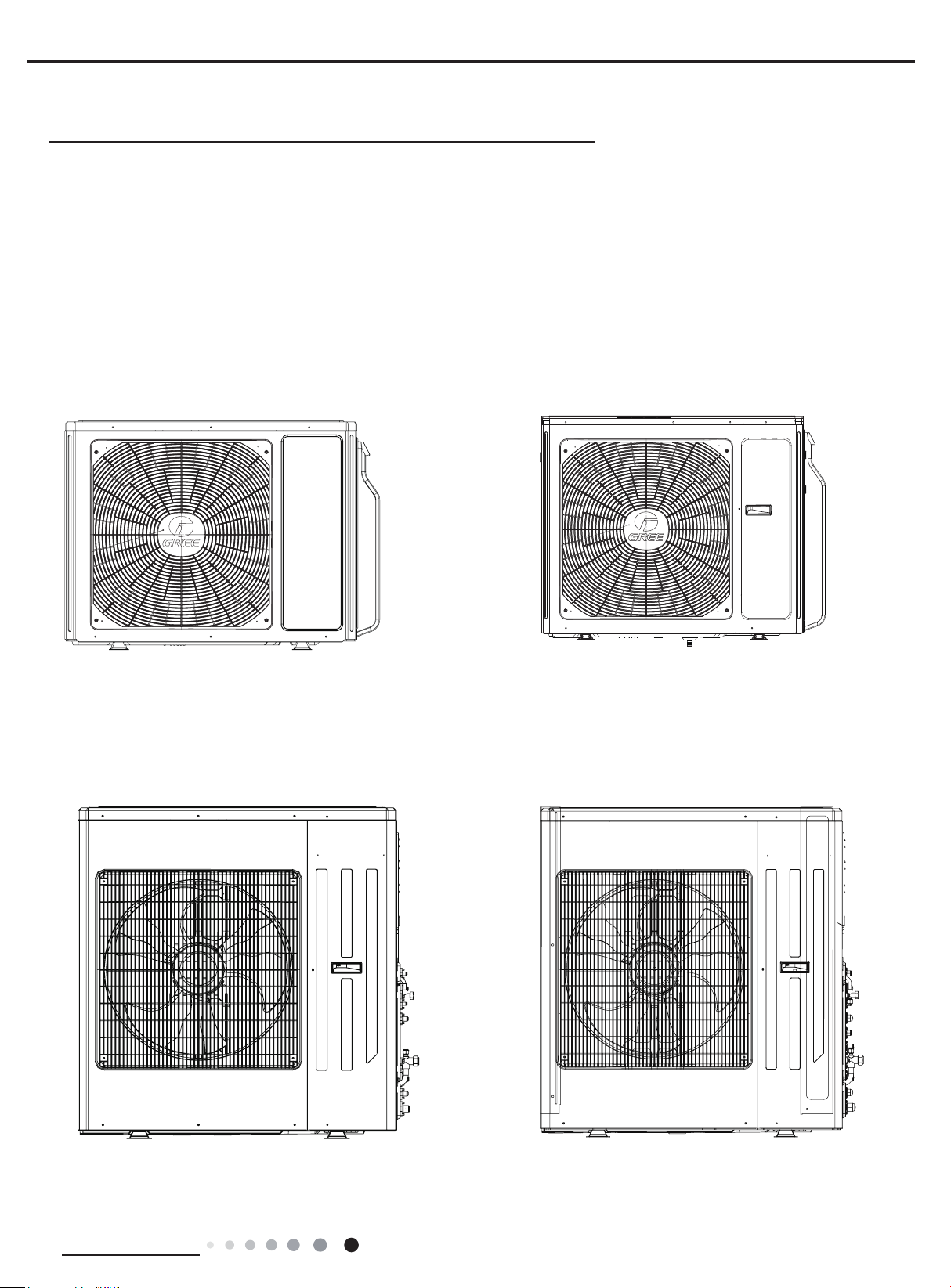

Outdoor Unit

GWHD(18)NK3FO GWHD(24)NK3FO

GWHD(24)NK3GO

GWHD(28) NK3FO

GWHD(42)NK3AOGWHD(36)NK3BO

Technical Information

1

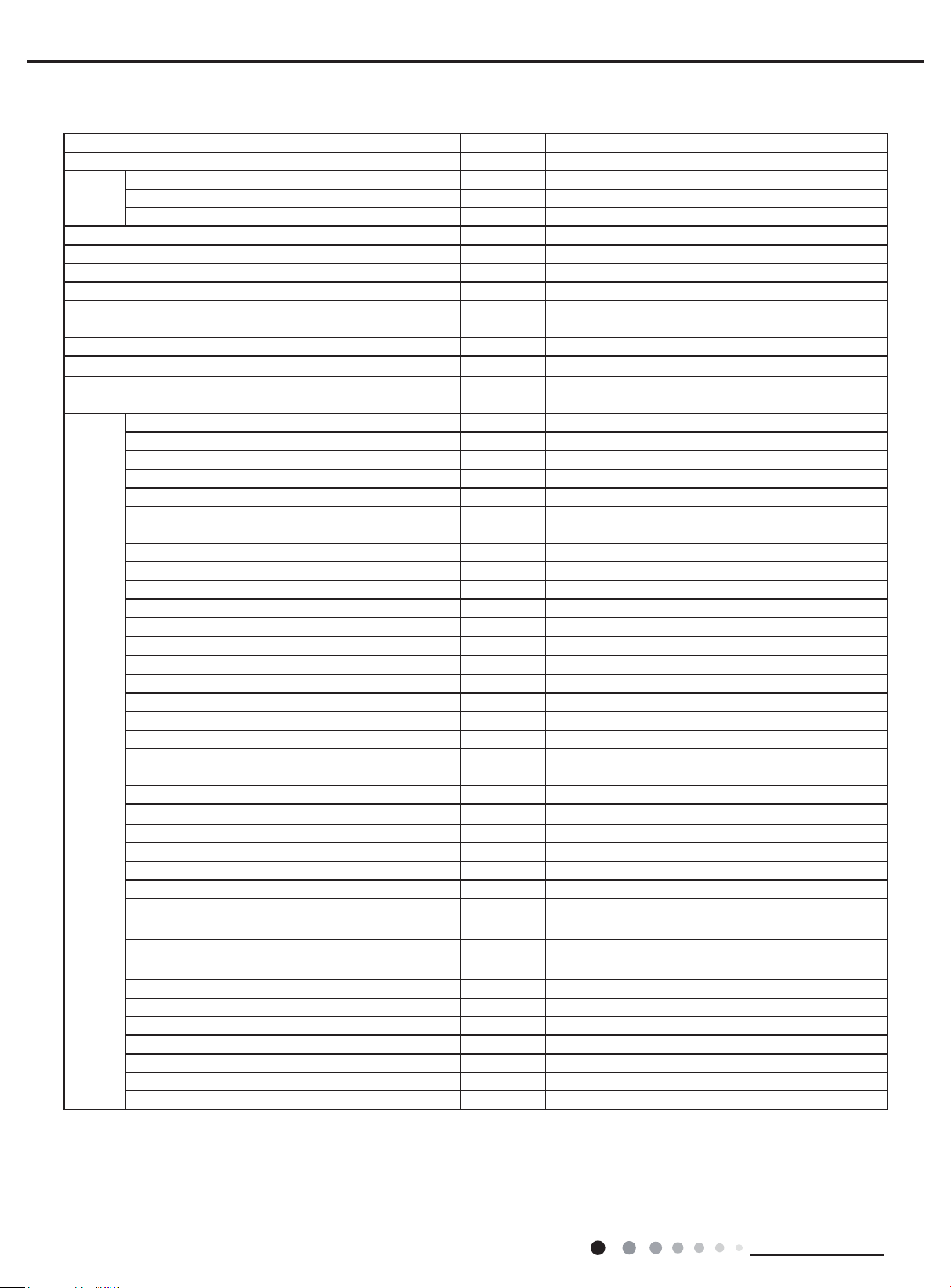

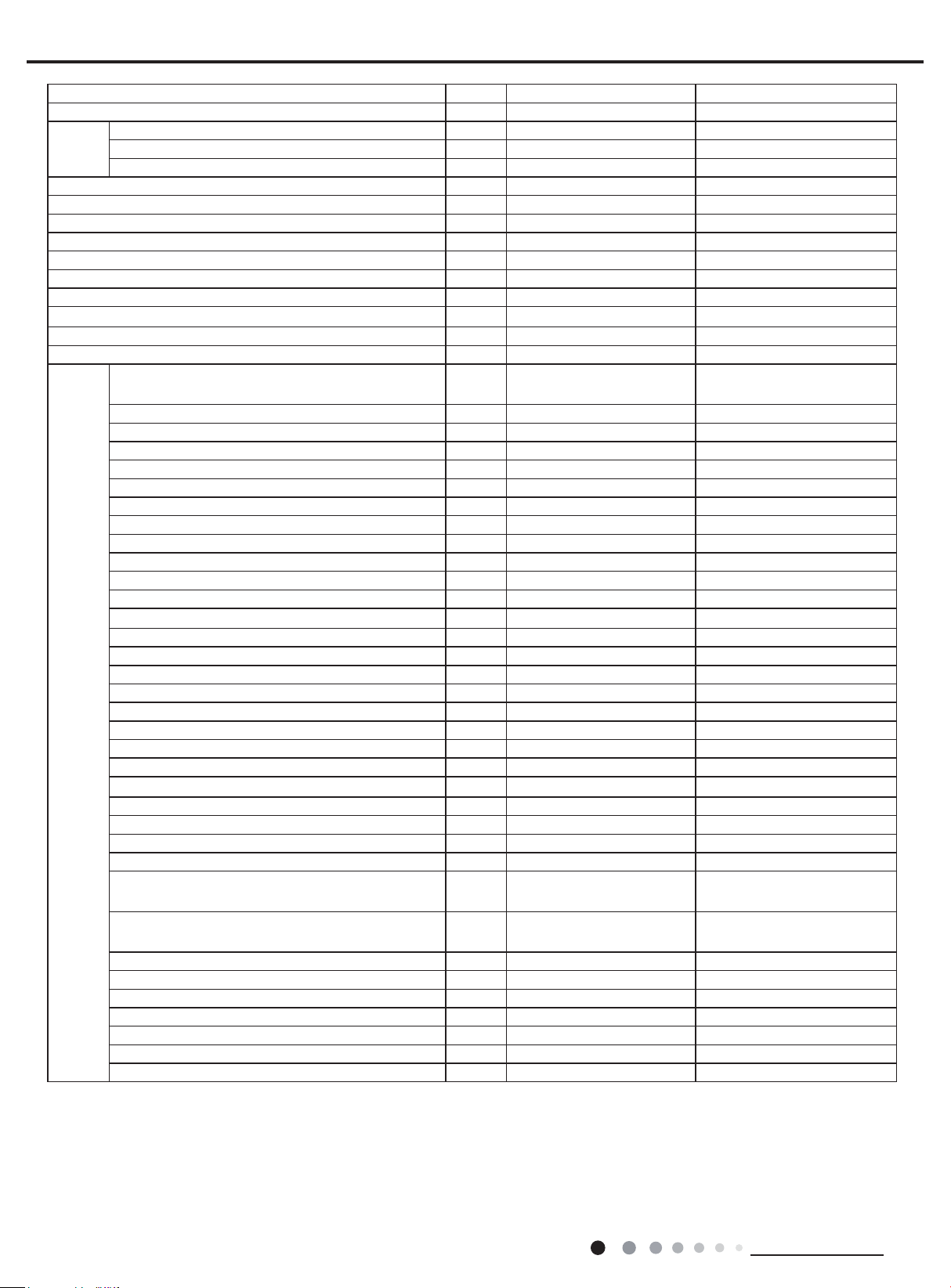

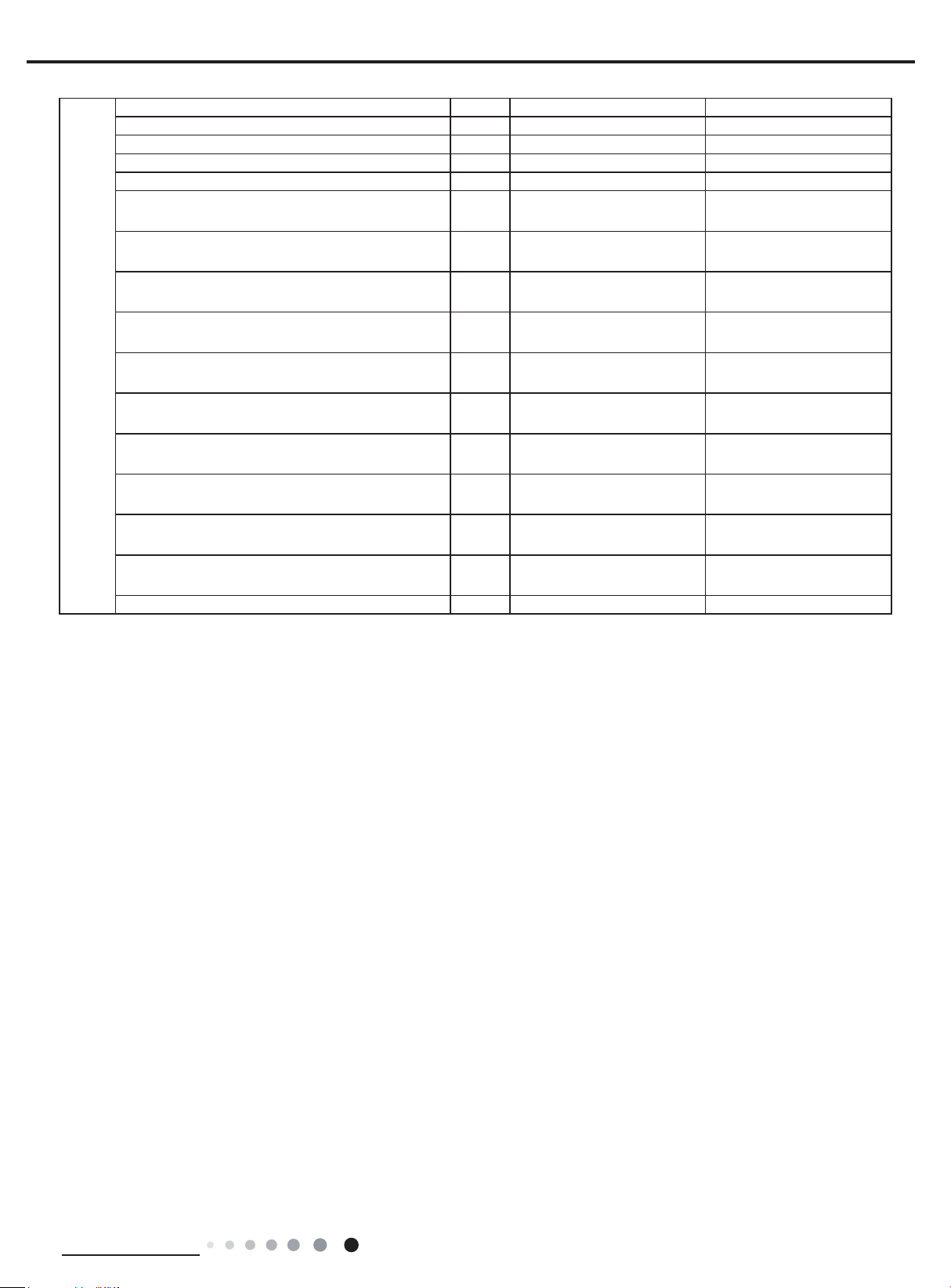

2. Specications

Model GWHD(18)NK3FO

Product Code CB228W03500/CB228W03501

Power

supply

Cooling capacity(max~min) W 5000(2050~6200)

Heating capacity(max~min) W 5600(2500~6650)

Cooling Power Input(max~min) W 1550(500~2550)

Heating Power Input(max~min) W 1550(580~2700)

Cooling Current Input A 6.88

Heating Current Input A 6.88

Rated Power Input W 2700

Rated Current A 11.98

SEER W/W 5.6

SCOP W/W 3.8

Outdoor

Unit

Rated Voltage V~ 220-240V

Rated Frequency Hz 50

Phases 1

Compressor Trademark ZHUHAI LANDA COMPRESSOR CO.,LTD

Compressor Model QXA-B141zF030A

Compressor Refrigerant Oil Type RB68EP

Compressor Type Rotary

L.R.A A /

Compressor Rated Load Amp (RLA) A 7.2

Compressor Power Input W 1440

Compressor Thermal Protector 1NT11L-6233

Throttling Method Electron expansion valve

Cooling Operation Ambient Temperature Range

Heating Operation Ambient Temperature Range

Condenser Material Aluminum Fin-copper Tube

Condenser Pipe Diameter mm Φ7

Rows-Fin Gap(mm) mm 2-1.4

Coil length (l) X height (H) X coil width (L) mm 851X38.1X660

Fan Motor Speed (rpm) (H/M/L) rpm 630

Output of Fan Motor W 60

Fan Motor RLA A /

Fan Motor Capacitor μF /

Air Flow Volume of Outdoor Unit m3/h 3200

Fan Type-Piece Axial-ow

Fan Diameter mm Φ520

Defrosting Method Automatic Defrosting

Climate Type T1

Isolation I

Moisture Protection IP24

Permissible Excessive Operating Pressure for the

Discharge Side

Permissible Excessive Operating Pressure for the

Suction Side

Dimension (WXHXD) mm 963X700X396

Dimension of Package (LXWXH) mm 1026X455X735

Dimension of Package(LXWXH) mm 1029X458X750

Net Weight kg 50

Gross Weight kg 55

efrigerant Charge R410A

Refrigerant Charge kg 1.40

O

C -15~48

O

C -15~24

MPa 4.3

MPa 2.5

Service Manual

2

Technical Information

Service Manual

Cross-sectional Area of Power Cable Conductor mm

2

Recommended Power Cable(Core) N 3

Connection Pipe Connection Method - Flare Connection

Not Additional Gas Connection Pipe Length m 5

Connection Pipe Gas Additional Charge g/m 20

Outdoor

Unit

Outer Diameter of Liquid Pipe(GREE Allocation)

(Metric)

Outer Diameter of Gas Pipe(GREE Allocation)

(Metric)

Connection Pipe Max. Height Distance(indoor and

indoor)

Max. equivalent connection pipe length(outdoor to

last indoor)

mm Φ6

mm Φ9.52

m 5

m 10

Connection Pipe Max. Length Distance(total lenght) m 20

The above data is subject to change without notice; please refer to the nameplate of the unit.

2.50

Technical Information

3

Service Manual

Model GWHD(24)NK3FO GWHD(24)NK3GO

Product Code CB228W03301 CB228W03401/CB228W03400

Power

supply

Rated Voltage V~ 220-240V 220-240V

Rated Frequency Hz 50 50

Phases 1 1

Cooling capacity(max~min) W 7000(2200~10000) 7100(2200~10000)

Heating capacity(max~min) W 7700(2600~11000) 8500(3600~11000)

Cooling Power Input(max~min) W 2460(650~4550) 2400(650~4550)

Heating Power Input(max~min) W 2560(980~3950) 2350(980~3950)

Cooling Current Input A 10.91 10.91

Heating Current Input A 11.36 11.36

Rated Power Input W 4550 4550

Rated Current A 20.19 20.19

SEER W/W 5.1 5.1

SCOP W/W 3.8 3.8

Compressor Trademark

ZHUHAI LANDA

COMPRESSOR CO.,LTD

ZHUHAI LANDA

COMPRESSOR CO.,LTD

Compressor Model QXAS-D23zX090B QXAS-D23zX090B

Compressor Refrigerant Oil Type RB68EP RB68EP

Compressor Type Rotary Rotary

L.R.A A / /

Compressor Rated Load Amp (RLA) A 11.5 11.5

Compressor Power Input W 2550 2550

Compressor Thermal Protector 1NT11L-6233 1NT11L-6233

Throttling Method Electron expansion valve Electron expansion valve

Cooling Operation Ambient Temperature Range

Heating Operation Ambient Temperature Range

O

C -15~48 -15~48

O

C -15~24 -15~24

Condenser Material Aluminum Fin-copper Tube Aluminum Fin-copper Tube

Condenser Pipe Diameter mm Φ7 Φ7

Rows-Fin Gap(mm) mm 2-1.4 2-1.4

Coil length (l) X height (H) X coil width (L) mm 982.2X38.1X748 982.2X38.1X748

Fan Motor Speed (rpm) (H/M/L) rpm 710 710

Output of Fan Motor W 90 90

Outdoor

Unit

Fan Motor RLA A / /

Fan Motor Capacitor μF / /

Air Flow Volume of Outdoor Unit m3/h 4000 4000

Fan Type-Piece Axial-ow Axial-ow

Fan Diameter mm Φ552 Φ552

Defrosting Method Automatic Defrosting Automatic Defrosting

Climate Type T1 T1

Isolation I I

Moisture Protection IP24 IP24

Permissible Excessive Operating Pressure for the

Discharge Side

Permissible Excessive Operating Pressure for the

Suction Side

MPa 4.3 4.3

MPa 2.5 2.5

Dimension (WXHXD) mm 1001X790X427 1001X790X427

Dimension of Package (LXWXH) mm 1080X485X840 1080X485X840

Dimension of Package(LXWXH) mm 1083X488X855 1083X488X855

Net Weight kg 68 69

Gross Weight kg 73 74

efrigerant Charge R410A R410A

Refrigerant Charge kg 2.00 2.20

4

Technical Information

Service Manual

Cross-sectional Area of Power Cable Conductor mm

2

2.50 2.50

Recommended Power Cable(Core) N 3 3

Connection Pipe Connection Method - Flare Connection Flare Connection

Not Additional Gas Connection Pipe Length m 5 5

Connection Pipe Gas Additional Charge g/m 20 20

Outdoor

Unit

Outer Diameter of Liquid Pipe(GREE Allocation)

(Metric)

Outer Diameter of Gas Pipe(GREE Allocation)

(Metric)

Connection Pipe Max. Height Distance(indoor and

indoor)

Max. equivalent connection pipe length(outdoor to

last indoor)

mm Φ6 Φ6

mm Φ9.52 Φ9.52

m 5 10

m 10 20

Connection Pipe Max. Length Distance(total lenght) m 20 60

The above data is subject to change without notice. Please refer to the nameplate of the unit.

Technical Information

5

Model GWHD(28)NK3FO

Product Code CB228W03600/CB228W03601

Power

supply

Rated Voltage V~ 220-240V

Rated Frequency Hz 50

Phases 1

Cooling capacity(max~min) W 8000(2200~10000)

Heating capacity(max~min) W 9300(2800~11000)

Cooling Power Input(max~min) W 2490(650~4550)

Heating Power Input(max~min) W 2580(980~3950)

Cooling Current Input A 11.05

Heating Current Input A 11.45

Rated Power Input W 4550

Rated Current A 20.19

SEER W/W 5.1

SCOP W/W 3.8

Compressor Trademark ZHUHAI LANDA COMPRESSOR CO.,LTD

Compressor Model QXAS-D23zX090B

Compressor Refrigerant Oil Type RB68EP

Compressor Type Rotary

L.R.A A /

Compressor Rated Load Amp (RLA) A 11.5

Compressor Power Input W 2550

Compressor Thermal Protector 1NT11L-6233

Throttling Method Electron expansion valve

Cooling Operation Ambient Temperature Range

Heating Operation Ambient Temperature Range

O

C -15~48

O

C -15~24

Condenser Material Aluminum Fin-copper Tube

Condenser Pipe Diameter mm Φ7

Rows-Fin Gap(mm) mm 2-1.4

Coil length (l) X height (H) X coil width (L) mm 982.2X38.1X748

Fan Motor Speed (rpm) (H/M/L) rpm 710

Output of Fan Motor W 90

Outdoor

Unit

Fan Motor RLA A /

Fan Motor Capacitor μF /

Air Flow Volume of Outdoor Unit m3/h 4000

Fan Type-Piece Axial-ow

Fan Diameter mm Φ552

Defrosting Method Automatic Defrosting

Climate Type T1

Isolation I

Moisture Protection IP24

Permissible Excessive Operating Pressure for the

Discharge Side

Permissible Excessive Operating Pressure for the

Suction Side

MPa 4.3

MPa 2.5

Dimension (WXHXD) mm 1001X790X427

Dimension of Package (LXWXH) mm 1080X485X840

Dimension of Package(LXWXH) mm 1083X488X855

Net Weight kg 69

Gross Weight kg 74

efrigerant Charge R410A

Refrigerant Charge kg 2.20

Service Manual

6

Technical Information

Service Manual

Cross-sectional Area of Power Cable Conductor mm

2

Recommended Power Cable(Core) N 3

Connection Pipe Connection Method - Flare Connection

Not Additional Gas Connection Pipe Length m 5

Connection Pipe Gas Additional Charge g/m 20

Outdoor

Unit

Outer Diameter of Liquid Pipe(GREE Allocation)

(Metric)

Outer Diameter of Gas Pipe(GREE Allocation)

(Metric)

Connection Pipe Max. Height Distance(indoor and

indoor)

Max. equivalent connection pipe length(outdoor to

last indoor)

mm Φ6

mm Φ9.52

m 10

m 20

Connection Pipe Max. Length Distance(total lenght) m 70

The above data is subject to change without notice. Please refer to the nameplate of the unit.

2.50

Technical Information

7

Service Manual

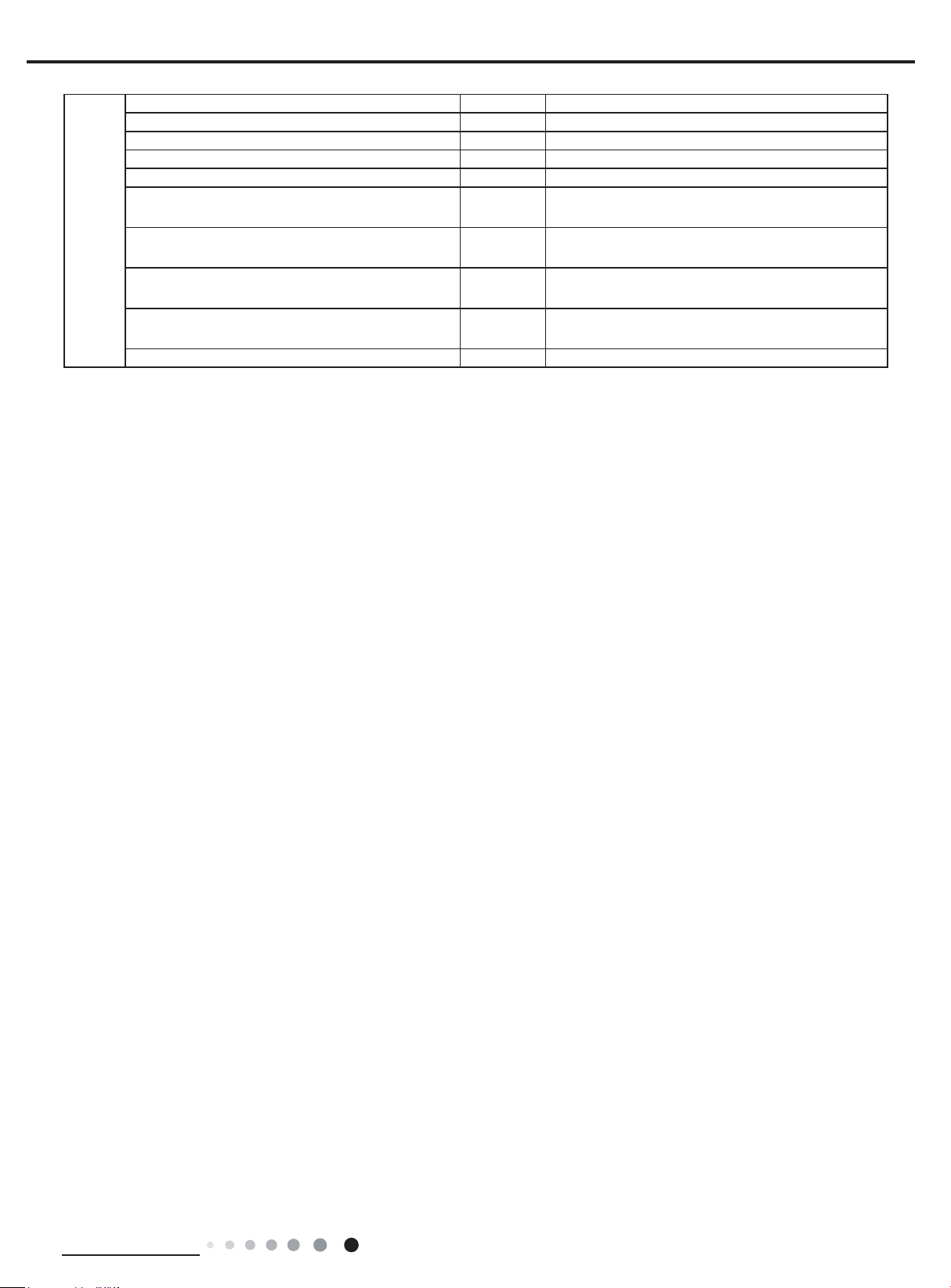

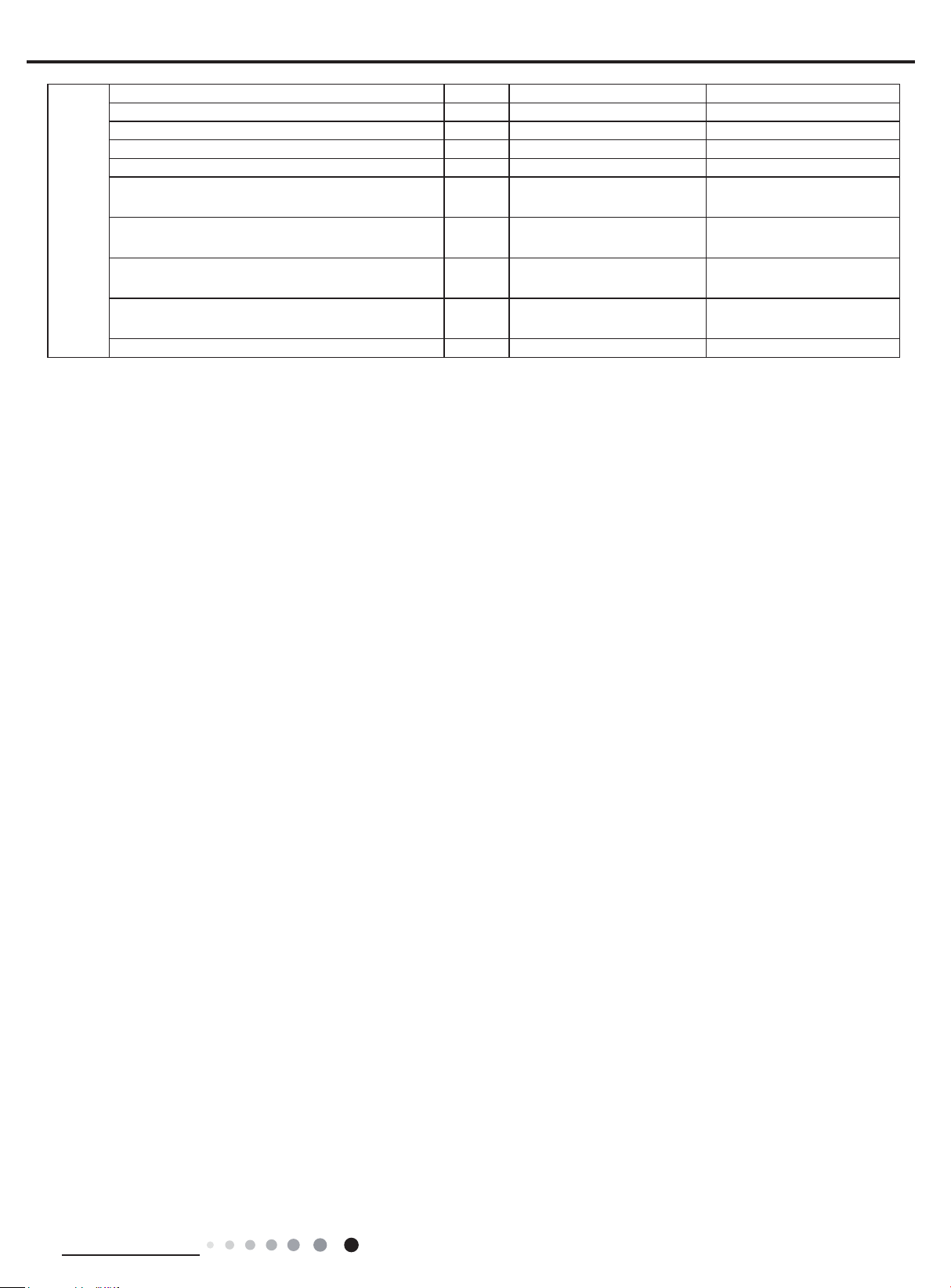

Model GWHD(36)NK3BO GWHD(42)NK3AO

Product Code CN860W0131 CN860W0021

Power

supply

Rated Voltage V~ 220-240V 220-240V

Rated Frequency Hz 50 50

Phases 1 1

Cooling capacity(max~min) W 10500(2100~11000) 12100(2100~13600)

Heating capacity(max~min) W 12000(2600~13000) 13000(2600~14000)

Cooling Power Input W 3500 3590

Heating Power Input W 3750 3550

Cooling Current Input A 15.42 16.43

Heating Current Input A 15.20 16.22

Rated Power Input W 4880 5300

Rated Current A 21.65 23.50

SEER W/W 5.5 /

SCOP W/W 3.8 /

MITSUBISHI

ELECTRIC(GUANGZHOU)

COMPRESSOR CO.LTD

Compressor Trademark

ZHUHAI LANDA

COMPRESSOR CO.,LTD

Compressor Model QXAS-D32zX090A TNB306FPGMC

Compressor Refrigerant Oil Type RB68ER PVE(PV50S)

Compressor Type Inverter Rotary Inverter Rotary

L.R.A A / /

Compressor Rated Load Amp (RLA) A 14 13.5

Compressor Power Input W 3300 3010

Compressor Thermal Protector Internal Internal

Throttling Method Electron expansion valve Electron expansion valve

Cooling Operation Ambient Temperature Range

Heating Operation Ambient Temperature Range

O

C -15~48 -15~48

O

C -15~27 -15~27

Condenser Material Copper tube-Aluminum n Copper tube-Aluminum n

Condenser Pipe Diameter mm Φ7.94 Φ7.94

Rows-Fin Gap(mm) mm 2-1.4 2-1.4

Coil length (l) X height (H) X coil width (L) mm 1009.4X38.1X1056 1009.4X38.1X1056

Fan Motor Speed (rpm) (H/M/L) rpm 820 840/620/520

Outdoor

Unit

Output of Fan Motor W 170 140

Fan Motor RLA A / /

Fan Motor Capacitor μF / /

Air Flow Volume of Outdoor Unit m3/h 5200 5500

Fan Type-Piece Axial-ow Axial-ow

Fan Diameter mm Φ570-152 Φ570-152

Defrosting Method Automatic Defrosting Automatic Defrosting

Climate Type T1 T1

Isolation I I

Moisture Protection IPX4 IPX4

Permissible Excessive Operating Pressure for the

Discharge Side

Permissible Excessive Operating Pressure for the

Suction Side

MPa 4.3 4.3

MPa 2.5 2.5

Dimension (WXHXD) mm 1015X440X1103 1015X440X1103

Dimension of Package (LXWXH) mm 1155X490X1220 1155X490X1220

Dimension of Package(LXWXH) mm 1158X493X1235 1158X493X1235

Net Weight kg 94 102

Gross Weight kg 104 112

efrigerant Charge R410A R410A

Refrigerant Charge kg 4.3 4.8

8

Technical Information

Service Manual

Outdoor

Unit

Cross-sectional Area of Power Cable Conductor mm

2

4.0 4.0

Recommended Power Cable(Core) N 3 /

Connection Pipe Connection Method - Flare Connection Flare Connection

Not Additional Gas Connection Pipe Length m 40 50

Connection Pipe Gas Additional Charge g/m 22 22

Outer Diameter of Liquid Pipe(GREE Allocation)

(Metric)1

Outer Diameter of Gas Pipe(GREE Allocation)

(Metric)1

Outer Diameter of Liquid Pipe(GREE Allocation)

(Metric)2

Outer Diameter of Gas Pipe(GREE Allocation)

(Metric)2

Outer Diameter of Liquid Pipe(GREE Allocation)

(Metric)3

Outer Diameter of Gas Pipe(GREE Allocation)

(Metric)3

Outer Diameter of Liquid Pipe(GREE Allocation)

(Metric)4

Outer Diameter of Gas Pipe(GREE Allocation)

(Metric)4

Connection Pipe Max. Height Distance(indoor and

indoor)

Max. equivalent connection pipe length(outdoor to

last indoor)

mm Φ6 Φ6

mm Φ9.52 Φ9.52

Φ6 Φ6

Φ9.52 Φ9.52

Φ6 Φ6

Φ12 Φ12

Φ9.52 Φ6

Φ16 Φ12

m 7.5 7.5

m 20 25

Connection Pipe Max. Length Distance(total lenght) m 70 80

The above data is subject to change without notice. Please refer to the nameplate of the unit.

Technical Information

9

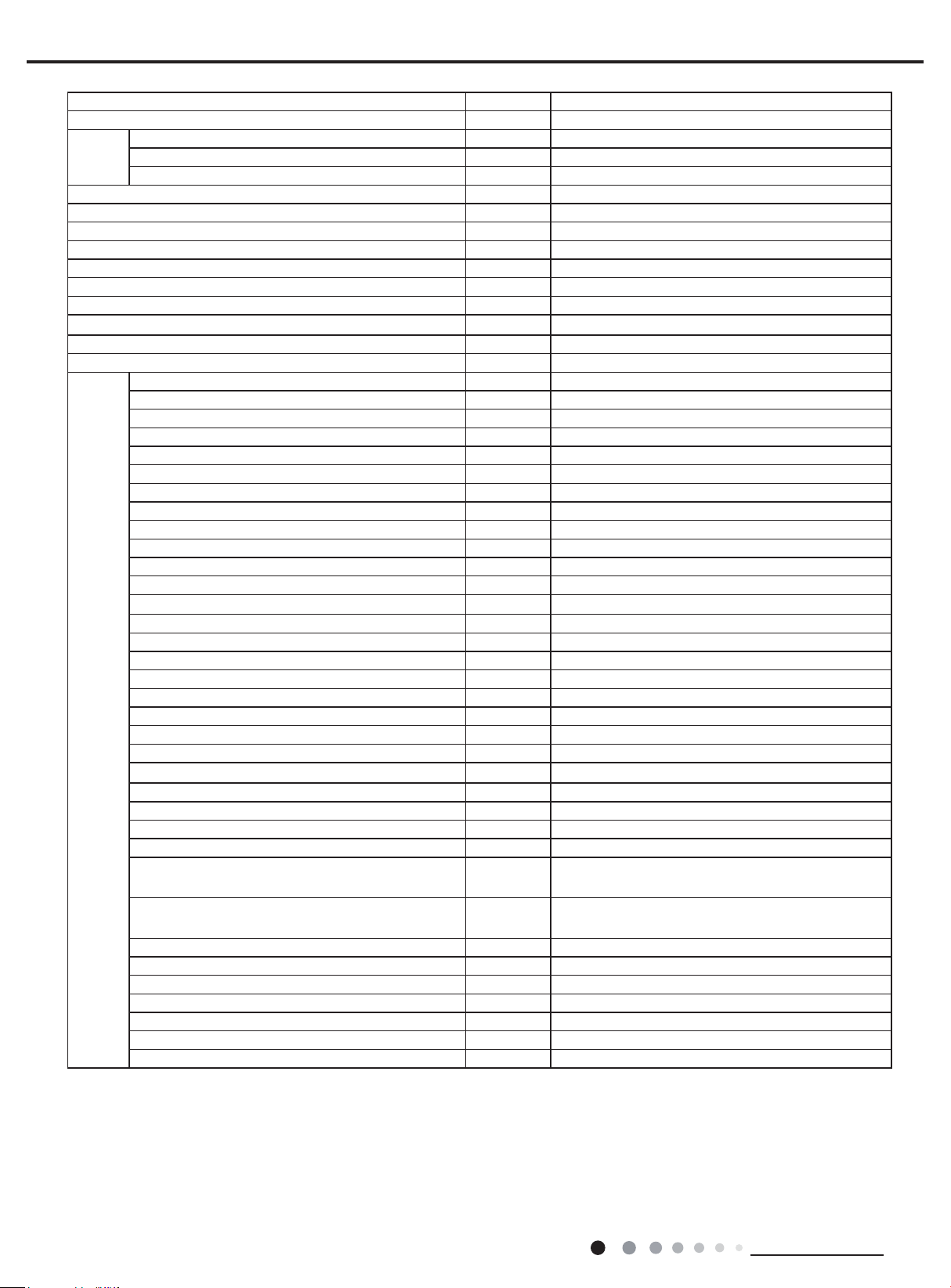

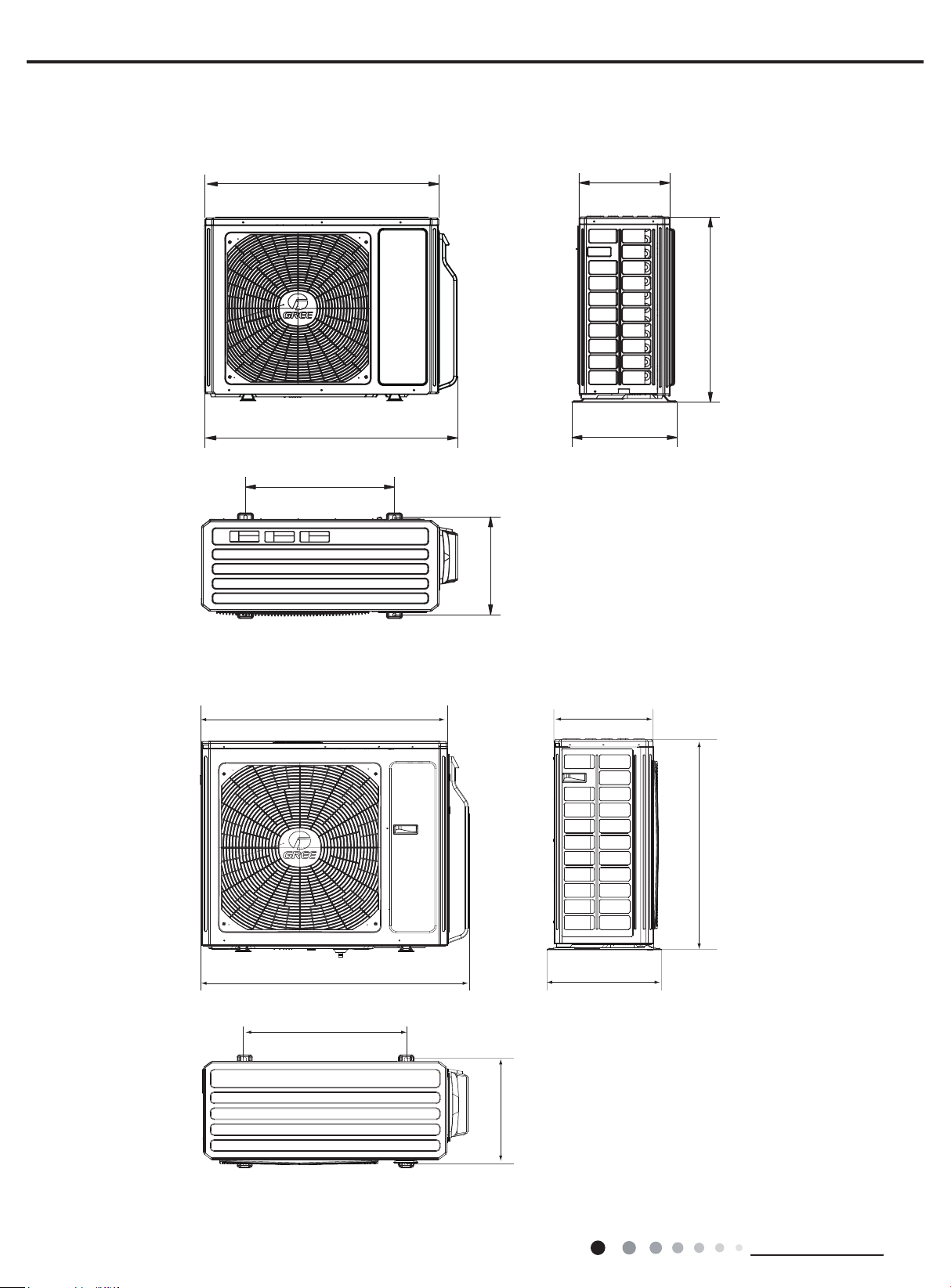

3. Outline Dimension Diagram

(1)Model:GWHD(18)NK3FO

Service Manual

892

963

560

341

700

396

368

(2)Models:GWHD(24)NK3FO GWHD(24)NK3GO GWHD(28) NK3FO

924 370

610

399

790

4271001

10

Unit:mm

Technical Information

Service Manual

950 341

4121022

572

840

378

Unit:mm

1103

360

1103

1015

(3)Model:GWHD(36)NK3BO

(4)Model:GWHD(42)NK3AO

1087

631

1015 360

401

440

Unit:mm

Technical Information

631

4401087

401

Unit:mm

11

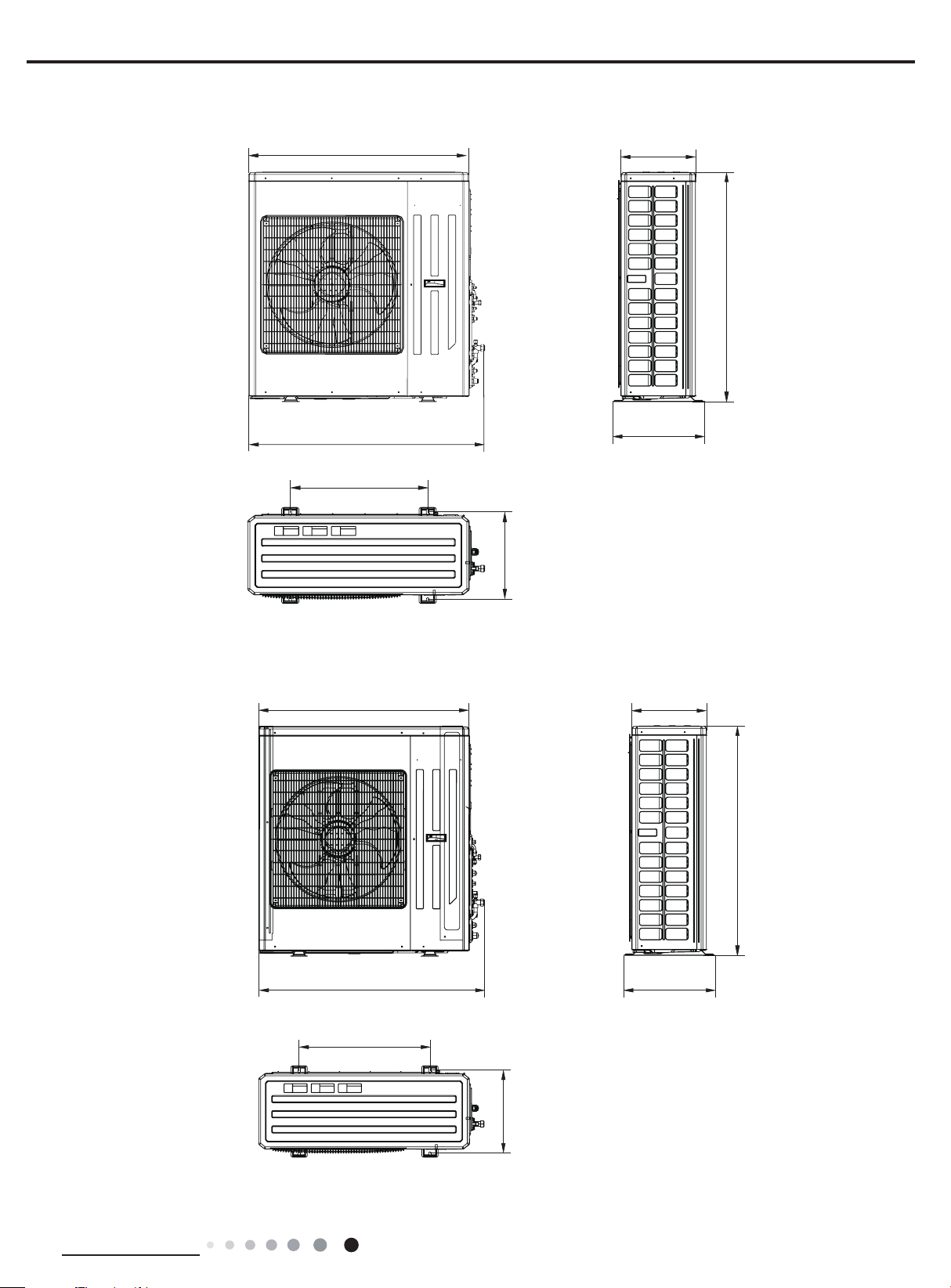

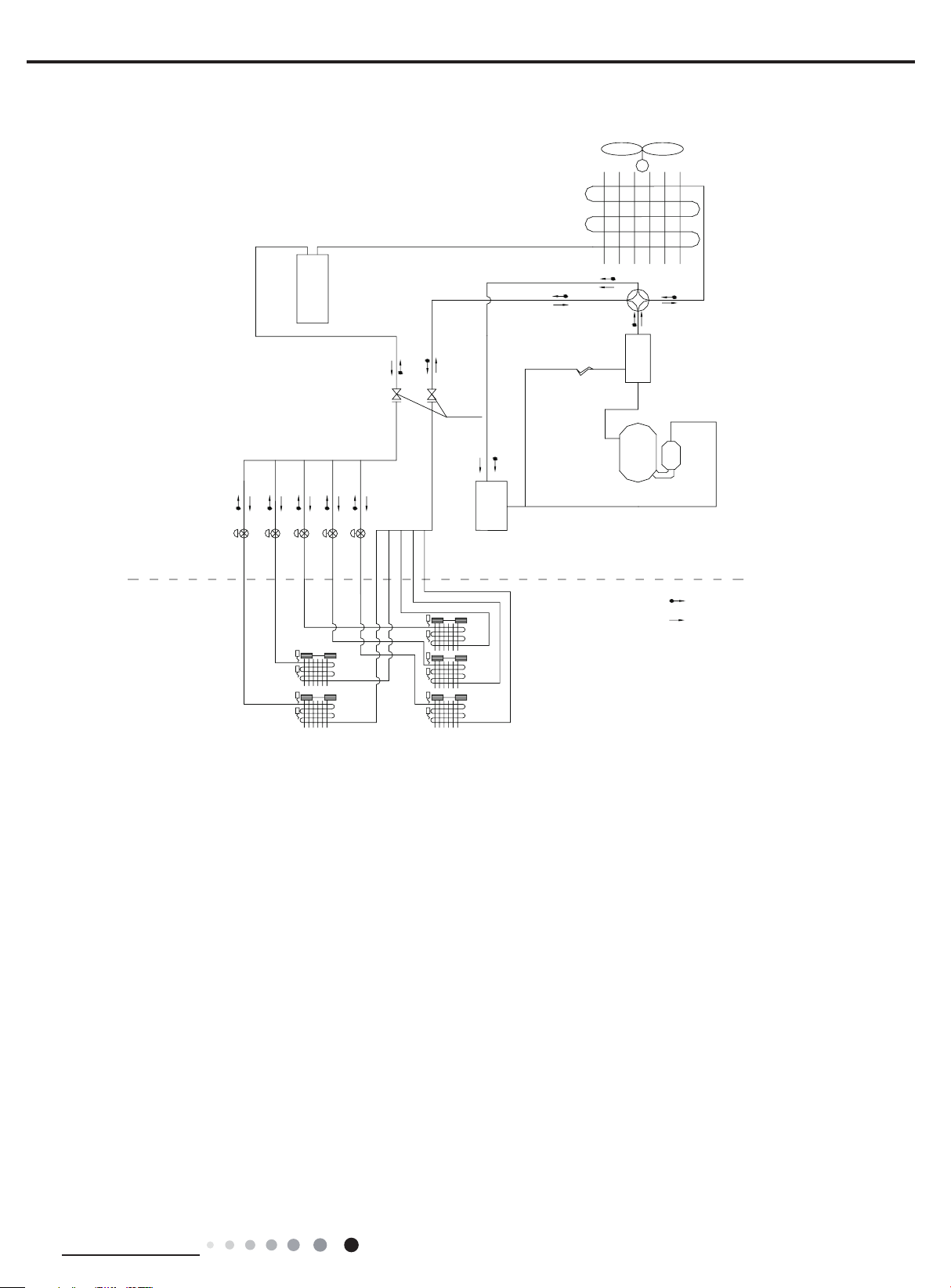

4. Refrigerant System Diagram

outdoor

indoor

A1:

C1:C-unit electronic expansion valve D1:D-unit electronic expansion valve

A2:A-unit gas pipe temperature sensor B2:B-unit gas pipe temperature senso

C2:C-unit gas pipe temperature sensor D2:D-unit gas pipe temperature senso

A3:

C3:C-unit liquid pipe temperature sensor D3:D-unit liquid pipe temperature senso

Models:GWHD(18)NK3FO GWHD(24)NK3FO GWHD(24)NK3GO GWHD(28) NK3FO

Service Manual

A heat exchanger

B heat exchanger

C heat exchanger

D heat exchanger

A3

B3

C3

D3

filter

filter

filter

A1

B1

C

D1

filter

A2

B2

1

C2

outdoor heat exchanger

fan

4-way valve

SP

high pressure switch

Note: Not available for 14K/18K

model

discharge silencer

discharge temperature

sensor

inverter compressor

filter

A-unit electronic expansion valve B1:B-unit electronic expansion valve

A-unit liquid pipe temperature sensor B3:B-unit liquid pipe temperature sensor

12

D2

Note: Not available for 18K model

gas -liquid separator

r

r

r

Technical Information

Service Manual

Electronic

Expansion V

Models:GWHD(36)NK3BO,GWHD(42)NK3AO

Liquid Receiver

M

Heat Exchanger

Four-way Valve

Outdoor Unit

Capillary

Oil Separator

Stop Valve

Compressor

Gas/Liquid Separator

alve

Heating

Cooling

Indoor Unit

Heat Exchanger

Heat Exchanger

The outdoor and indoor units start to work once the power is switched on. During the cooling operation, the low

temperature, low pressure refrigerant gas from the heat exchanger of each indoor unit gets together and then is

taken into the compressor to be compressed into high temperature, high pressure gas, which will soon go to

the heat exchanger of the outdoor unit to exchange heat with the outdoor air and then is turned into refrigerant

liquid. After passing through the throttling device, the temperature and pressure of the refrigerant liquid will further

decrease and then go the main valve. After that, it will be divided and go to the heat exchanger of each indoor

unit to exchange heat with the air which needs to be conditioned. Consequently, the refrigerant liquid become low

temperature, low pressure refrigerant gas again. Such a refrigeration cycle goes round and round to achieve the

desired cooling purpose. During the heating operation, the four-way valve is involved to make the refrigeration

cycle run reversely. The refrigerant radiates heat in the heat exchanger of the indoor unit (so do the electric

heating devices) and absorb heat in the heat exchanger of the outdoor unit for a heat pump heating cycle so as to

achieve the desired heating purpose.

Heat Exchanger

Heat Exchanger

Heat Exchanger

Technical Information

13

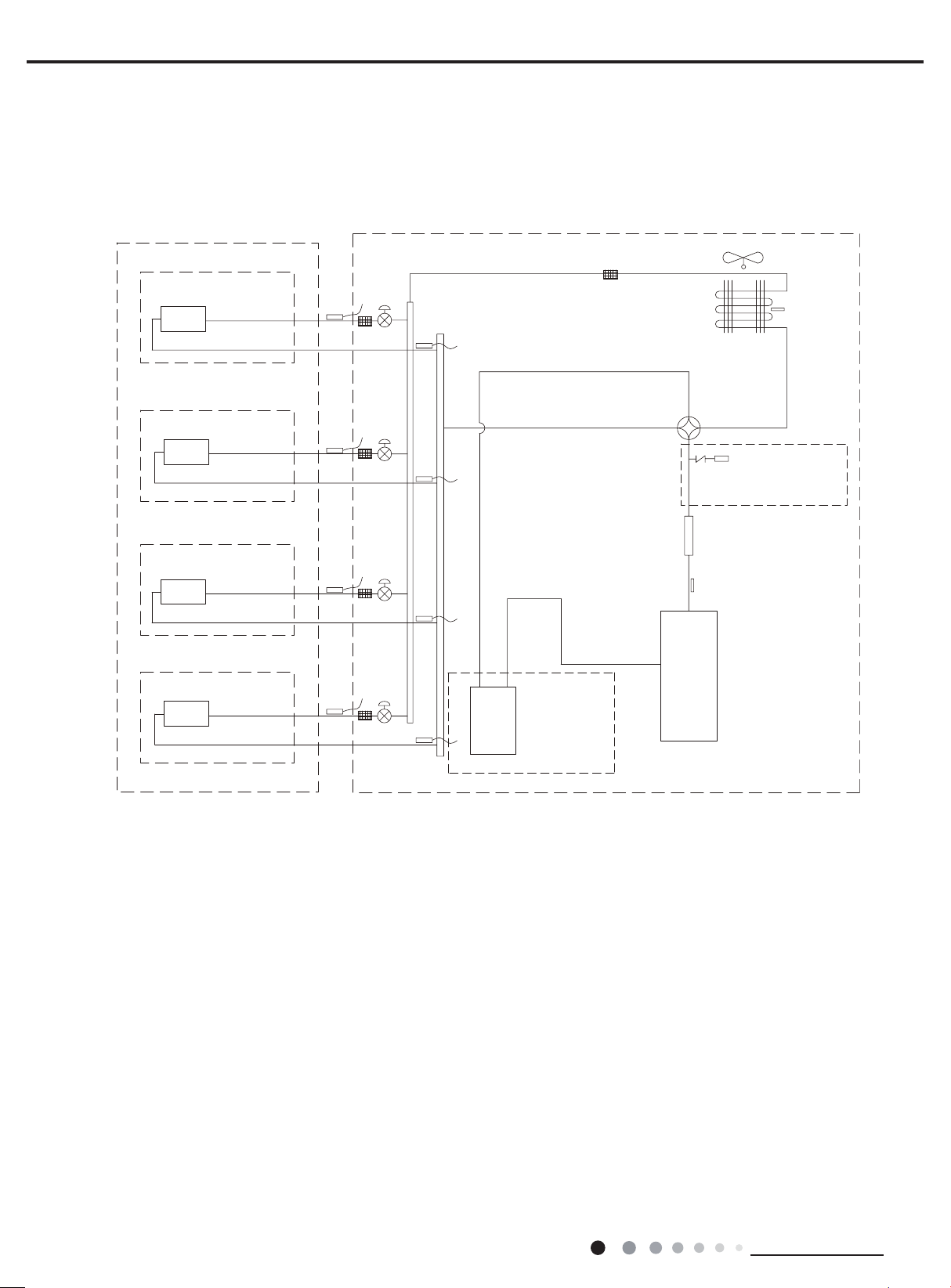

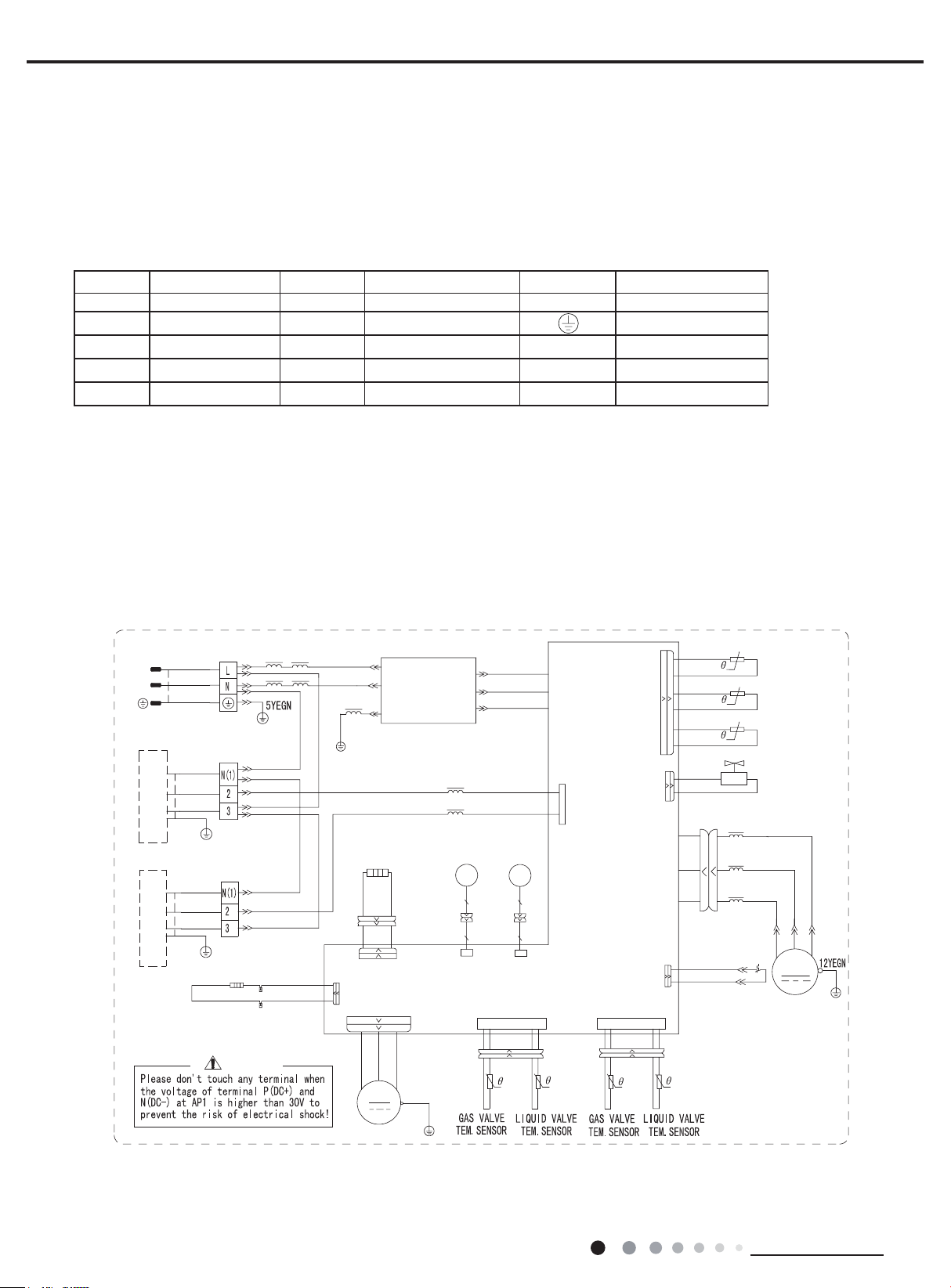

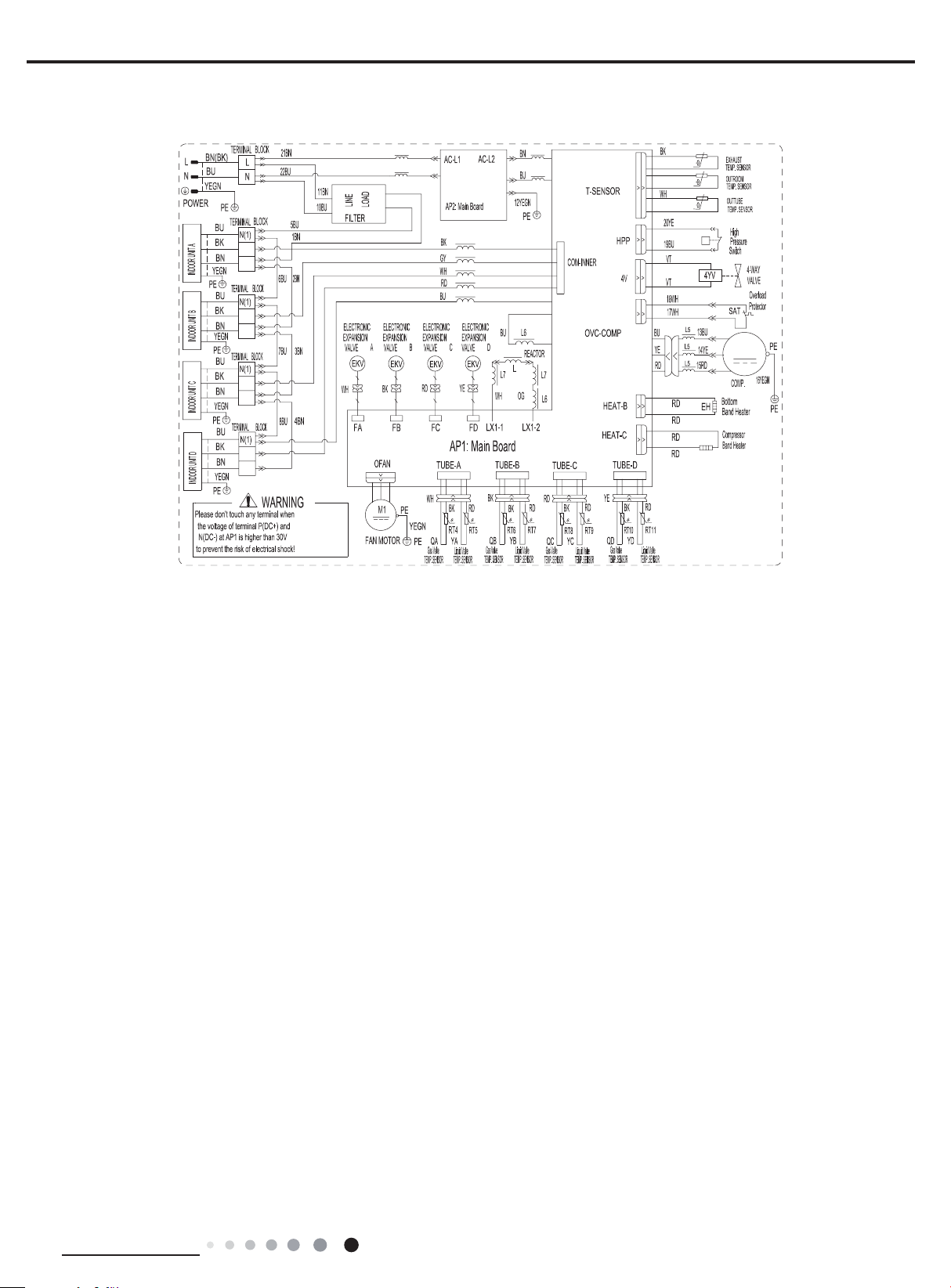

5. Electrical Part

5.1 Wiring Diagram

●Instruction

Symbol Symbol Color Symbol Symbol Color Symbol Name

WH White GN GREEN COMP Compressor

YE Yellow BN Brown Grouding wire

RD Red BU Blue

YEGN Yellow/Green BK Black

VT Violet OG Orange

Service Manual

●

Outdoor Unit

(1)Model:GWHD(18)NK3FO(CB228W03501)

7(50,1$/

32:(5

/

1

,1'22581,7$

,1'22581,7%

&2035(6625

%$1'+($7(5

%1

%8

<(*1

<(*1

<(*1

%8

%.

%1

3(

%8

%.

%1

3(

%/2&.

;7

7(50,1$/

%/2&.

;7$

7(50,1$/

%/2&.

;7%

(+

3(

%8

%8

%1

/

5'

5'

/

%1

%8

/

<(*1

3(

%1

%21'+($7(5

5'

+($7&

$&/

1

(3(

%27720

(+

+($7%

2)$1

5'

%.

*<

$3

$&/

/

/

:+

1

1

)$

(.9

)$

0DLQ%RDUG$3

%8

%1

%8

)%

(.9

%.

78%($

)%

1

$&/

1

&20,11(5

76(1625

:$<

29&&203

78%(%

%.

:+

%8

8

<(

9

5'

:

&211(&725

:+

:+

57

57

57

97

97

;

<9

:$<9$/9(

/

%8

/

<(

/

5'

:

6$7

29(5/2$'

3527(&725

(;+$867

7(06(1625

2875220

7(06(1625

28778%(

7(06(1625

8

9

&203

&203

3(

14

:$51,1*

0

)$102725

<(*1

3(

:+

%.

4$ <$

57 57

5'

4%

<%

%.

5'%.

5757

287'22581,7

Technical Information

Service Manual

(2)Model:GWHD(18)NK3FO(CB228W03500)

7(50,1$/

32:(5

/

1

&2035(6625

%$1'+($7(5

%/2&.

%1

%8

<(*1

7(50,1$/

%/2&.

%8

%.

%1

<(*1

,1'22581,7$

3(

%8

%.

%1

<(*1

,1'22581,7%

3(

;7

;7$

7(50,1$/

%/2&.

;7%

(+

3(

%8

%8

%1

/

5'

5'

57

:$<

%.

:+

%8

8

<(

9

5'

:

&211(&725

:+

:+

57

57

97

97

;

<9

:$<9$/9(

/

%8

/

<(

/

5'

6$7

29(5/2$'

3527(&725

(;+$867

7(06(1625

2875220

7(06(1625

28778%(

7(06(1625

8

:

9

&203

&203

3(

/

%1

%8

$&/

1

/

$3

(3(

$&/

%8

1

%1

%8

1

1

$&/

1

76(1625

<(*1

3(

%1

+($7&

2)$1

/

%.

/

*<

)$

(.9

:+

)%

(.9

%.

)$

)%

$30DLQ%RDUG

78%($

&20,11(5

29&&203

78%(%

(3)Model:GWHD(24)NK3FO

XT1

XTA

XTB

2

3

2

3

:$51,1*

57 57

<%

%.

U

V

W

287'22581,7

RT1

RT2

RT3

HPS

X1

CONNECTOR

P

U

V

COMP

W

:+

%.

0

<(*1

)$102725

L1

L1

L'

L

N'

N

3(

N1

E(PE)

L4

L4

L3

5'

%. 5'

4%

5757

<$4$

L2

AC-L

L2

N2

N2

N1

LX2-2

LX2-1

Technical Information

Please don't touch any terminal when the voltage of

terminal P(DC+) and N(DC-) at AP1 is higher than

30V to prevent the risk of electrical shock!

M1

TUBE-A

TUBE-B

15

(4)Model:GWHD(24)NK3GO(CB228W03401)

L1

L2

Service Manual

XT1

L

N

2

3

XTA

2

3

XTB

2

3

XTC

Please don't touch any terminal when the voltage of

terminal P(DC+) and N(DC-) at AP1 is higher than

30V to prevent the risk of electrical shock!

L1

N1

L'

AC-L

L2

N2

N'

L4

L4

L4

L3

N1

RT1

RT2

RT3

HPS

P

LX2-2

LX2-1

U

V

W

CONNECTOR

X1

U

V

COMP

W

(5)Model:GWHD(24)NK3GO(CB228W03400)

7(50,1$/%/2&.

%1%.

/

%8

1

<(*1

32:(5

3(

7(50,1$/%/2&.

%8

%.

%1

<(*1

,1'22581,7$

3(

7(50,1$/%/2&.

%8

%.

%1

<(*1

3(

7(50,1$/%/2&.

%8

%.

%1

<(*1

,1'22581,7& ,1'22581,7%

3(

3OHDVHGRQWWRXFKDQ\WHUPLQDOZKHQ

WKHYROWDJHRIWHUPLQDO3'&DQG

1'&DW$3LVKLJKHUWKDQ9WR

SUHYHQWWKHULVNRIHOHFWULFDOVKRFN

/

1

;7

1

;7$

1

;7%

1

;7&

%1

%8

%8

%1

%1

%8

%8

%1

:$51,1*

%1

%8

/

1

),/7(5

/,1(

/

/

/

/2$'

1

(/(&7521,&

(;3$16,21

(.9

:+

2)$1

0

)$102725

$&/

1

$30DLQ%RDUG

/

%.

/

*<

/

:+

/

%8

(/(&7521,&

(/(&7521,&

(;3$16,21

(;3$16,21

9$/9(%9$/9($

9$/9(&

(.9

(.9

5'

%.

)&

)%)$

$30DLQ%RDUG

78%($

:+

3(

<(*1

57

3(

4$

<$

*DV9DOYH

/LTXLG9DOYH

7(036(16257(036(1625

%1

$&/

%8

1

(3(

<(*1

3(

%8

/

5($&725

/

/

2*

:+

/;/;

78%(%

%.

5'%.

57

*DV9DOYH

7(036(1625 7(036(1625

/

$&/

/

1

&20,11(5

1

/;

/;

/

/

5'

%.

57

57

<%4%

/LTXLG9DOYH

%.

76(1625

:+

<(

+33

%8

97

:$<

97

:+

29&&203

%8

8

<(

9

5'

:

&211(&725

:+

;

+($7&

78%(&

5'

5'

%.

57

57

<&4&

*DV9DOYH

/LTXLG9DOYH

7(036(1625 7(036(1625

5'

5'

57

57

57

+36

/

/

/

%8

<(

5'

3

<9

9

:

(;+$867

7(036(1625

2875220

7(036(1625

28778%(

7(036(1625

+LJK

3UHVVXUH

6ZLWFK

:$<

9$/9(

2YHUORDG

3URWHFWRU

6$7

8

&203

<(*1

&203

&RPSUHVVRU

%DQG+HDWHU

3(

3(

16

Technical Information

Service Manual

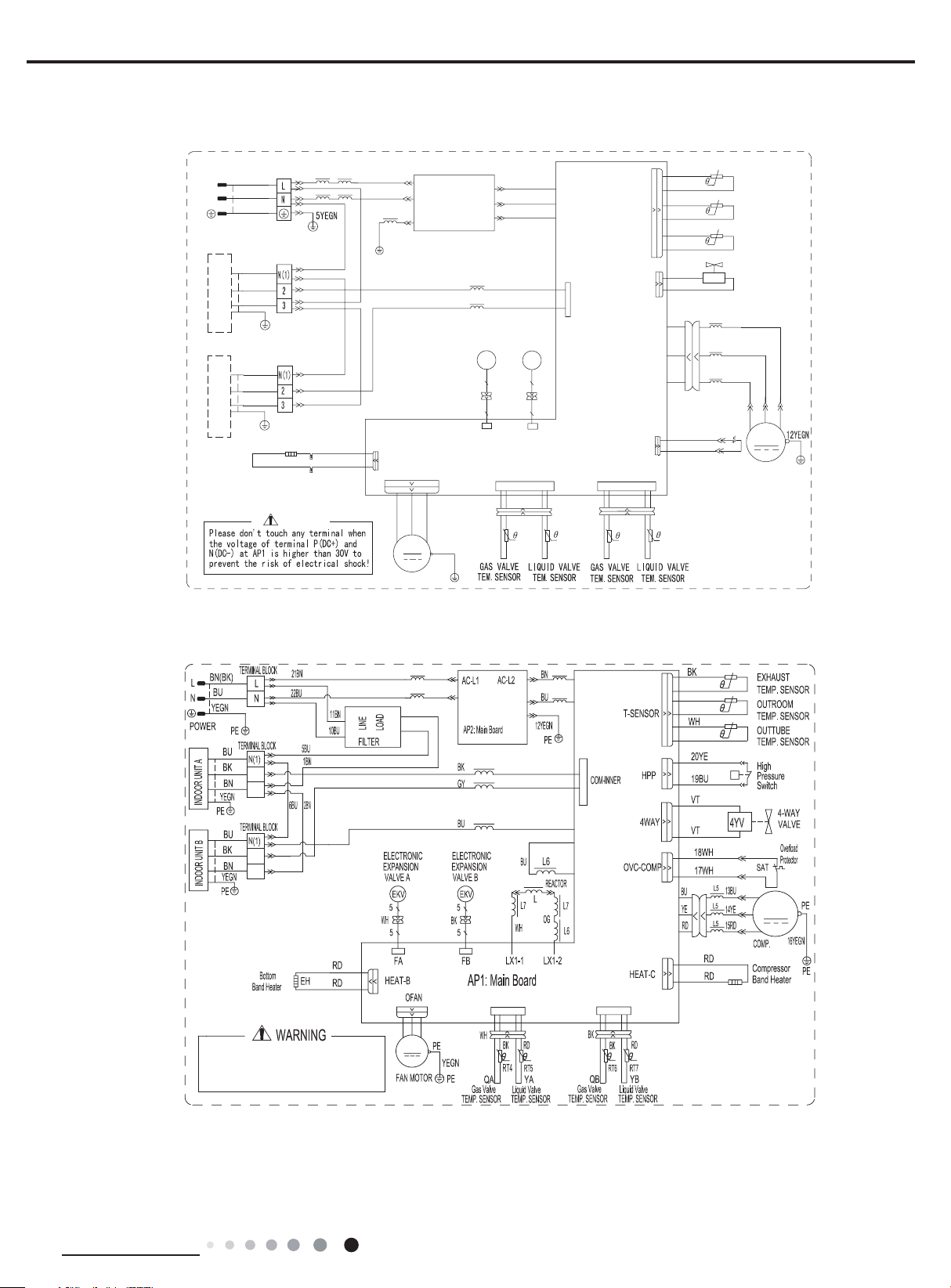

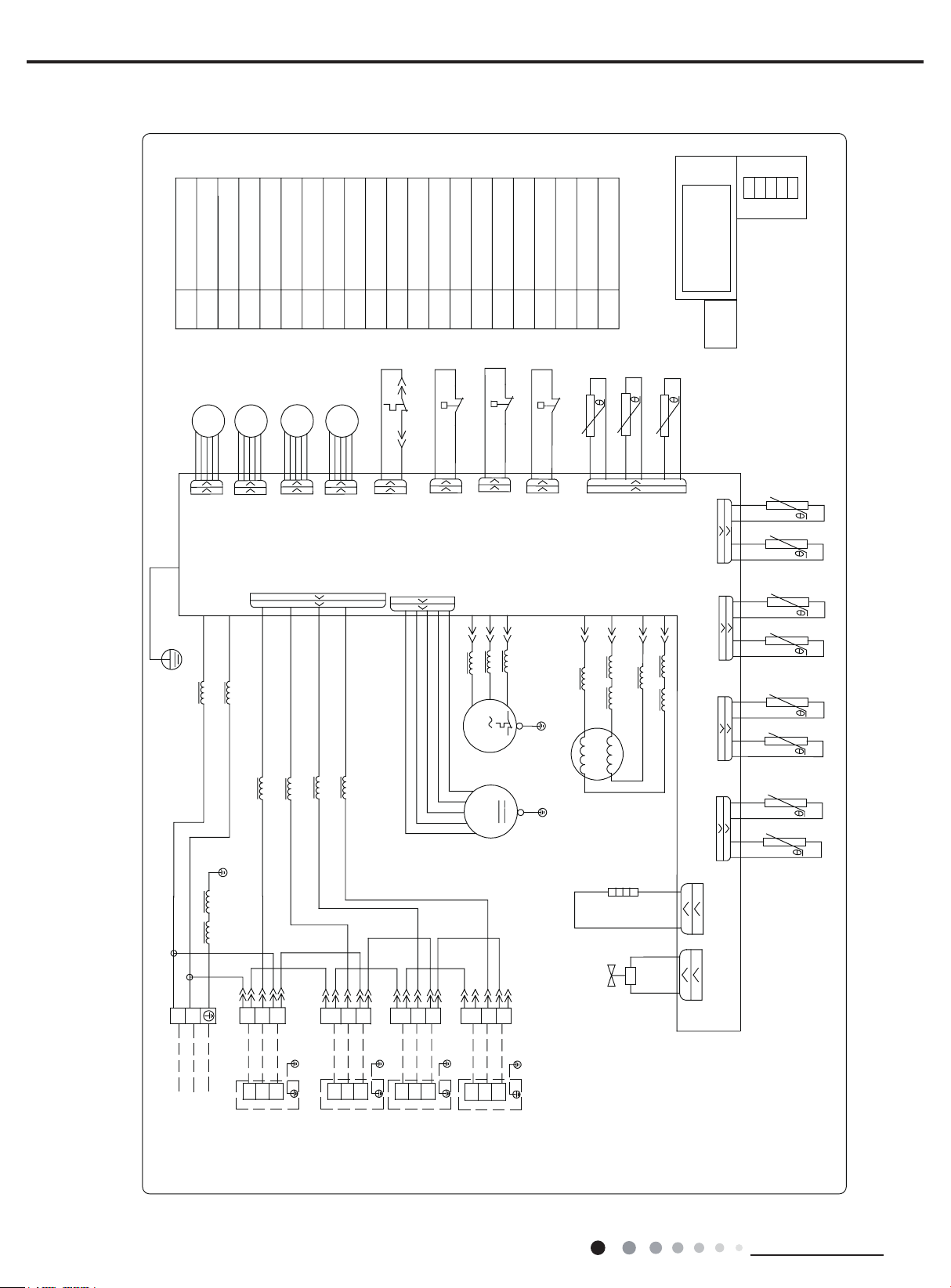

(6)Model:GWHD(28) NK3FO(CB228W03601)(CB228W03600)

XTA

XTB

XTC

XTD

XT1

L1

L1

N1

L'

L

N'

N

2

3

2

3

2

3

2

3

555

E(PE)

L4

L4

L4

L4

L3

5

555 5

L2

AC-L

L2

N2

N2

N1

LX2-2

LX2-1

U

V

W

RT1

RT2

RT3

HPS

X1

CONNECTOR

P

U

V

COMP

W

Technical Information

17

(7)Model:GWHD(36)NK3BO

29(5/2$'3527(&725

6$7

,12873,3(7(036(1625'

,12873,3(7(036(1625&

,12873,3(7(036(1625%

57

57

57

7(50,1$/%2$5'

3,3(7(036(1625

(19,5210(177(036(1625

',6&+$5*(*$67(036(1625

,12873,3(7(036(1625$

57

57

57

57

;7

:$<9$/9(

7(50,1$/%2$5'

&203&5$1.&$6(+($7(5

(+

;7

<9

&2035(6625

,1'8&7$1&(

/

&203

)$102725

/2:35(6685(6:,7&+

0

/3

<.%&

+,*+35(6685(6:,7&+

+3

<.%&

+,*+35(6685(6:,7&+

(/(&7521,&,1)/$7(9$/9(

+3

(.9

1$0(

0$,1%2$5'

$3

6<0%2/

&20321(17

326,7,21',$*5$0

$3

/

;7

Service Manual

;7

;7

;7

;7

3(

(

/

(.9

)$

$&/

/

(.9

(.9

(.9

57

3

6$7

:

:

3

+3

/3

3

+3

.

.

57

57

.

.

76(1625

)&

&20

:

/

)'

29&&203

+33

/33

+35(66

$3

78%($78%(%

2)$1

8

:

9

:

:

:

/

/

/

8

9

:

:

:

&203

/B

%1

/

3(

/

/

<(

/B

%8

/

/B

:+

/

/

/B

78%(&

/

0

/

3(

.

.

.

.

.

.

.

57

57

575757

57

57

)%

1

:

:

/

/

18

:

:

/

;7

32:(5

3(

78%('

:

(+

/ /

:

:

1

1

;7

1

,1'22581,7$

:

:

3(

1

;7

1

,1'22581,7%

:

:

;7

1

3(

1

,1'22581,7&

:

:

;7

1

3(

1

,1'22581,7'

3(

<9

+($7

9

57

Technical Information

Service Manual

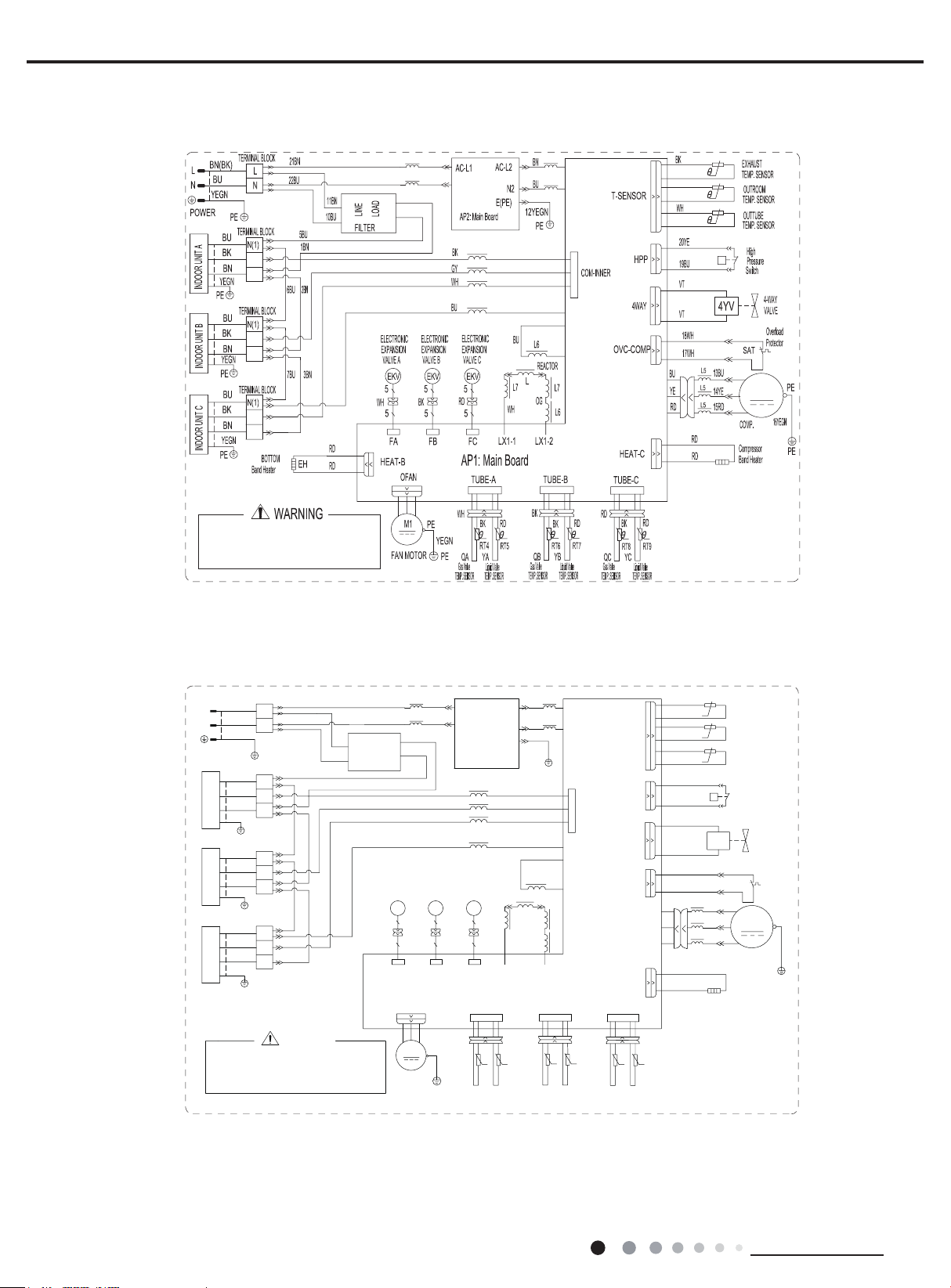

(8) Model:GWHD(42)NK3AO

C

AP

XT1

XT2

XT3

XT4

XT5

XT6

IN/OUT PIPE TEMP. SENSOR E

CAPACITOR FOR FAN MOTOR

OVERLOAD PROTECTOR

C

SAT

RT14/15

EKV1

IN/OUT PIPE TEMP. SENSOR C

IN/OUT PIPE TEMP. SENSOR D

RT12/13

RT10/11

EKV2

IN/OUT PIPE TEMP. SENSOR A

IN/OUT PIPE TEMP. SENSOR B

RT8/9

RT6/7

EKV3EKV4

PIPE TEMP.SENSOR

ENVIRONMENT TEMP.SENSOR

RT1

TERMINAL BOARD 2-6

TERMINAL BOARD 1

DISCHARGE GAS TEMP.SENSOR

RT2

RT3

COMP.CRANK CASE HEATER

INDUCTANCE

COMPRESSOR

L

FAN MOTOR

COMPMLP

4-WAY VALVE

XT2-6

XT1

EH

4YV

ELECTRONIC INFLATE VALVE 1-5

LOW PRESSURE SWITCH

HIGH PRESSURE SWITCH

HP

RT1

EKV5

W25

HP

SAT

W26

LP

θ

20K

MAIN BOARD

AP

EKV1-5

RT2

θ

15K

NAME

SYMBOL

RT3

θ

50K

COMPONENT POSITION DIAGRAM

L

20K

PE

T-SENSOR2

FB

FC

1

3

W16

W15

W14

FA

E1

AC-L

N

PE

W5

FE

FD

HPP

LPP

OVC-COMP

TUBE-ATUBE-B

TUBE-C

WH

OFAN

3

1

BK

YE

7

5

BU

V

W

W20

W21

V

W

3~

COMP

COM

5

7

9

W17

W18

AP

L1_1

BN

L2_1

YE

U

W19

U

PE

W22

L1

L2

BU

L2_2

WH

L1_2

L

TUBE-DTUBE-E

W23

BN

~

M

C

PE

RD

RT6

20K

RT7RT8

θθ

20K

20K

RT9

20K

RT10

θθ θ

20K

RT11RT12

θ

20K

θ

20K

RT13

θ

20K

RT14

θ

20K

RT15

θ

PE

INDOOR UNIT E

EH

4YV

W24

W2

W1

W6

W3

W4

L

N

XT1

POWER

N(1)

XT2

N(1)

W7

2

3

2

3

N(1)

XT3

PE

N(1)

INDOOR UNIT A

W8

W9

2

3

N(1)

XT4

PE

2

3

N(1)

INDOOR UNIT B

W10

W11

3

2

2

N(1)

XT5

PE

3

N(1)

INDOOR UNIT C

W12

W13

3

2

3

2

3

2

N(1)

XT6

PE

2

3

N(1)

INDOOR UNIT D

These circuit diagrams are subject to change without notice, please refer to the one supplied with the unit.

Technical Information

HEAT

4V1

19

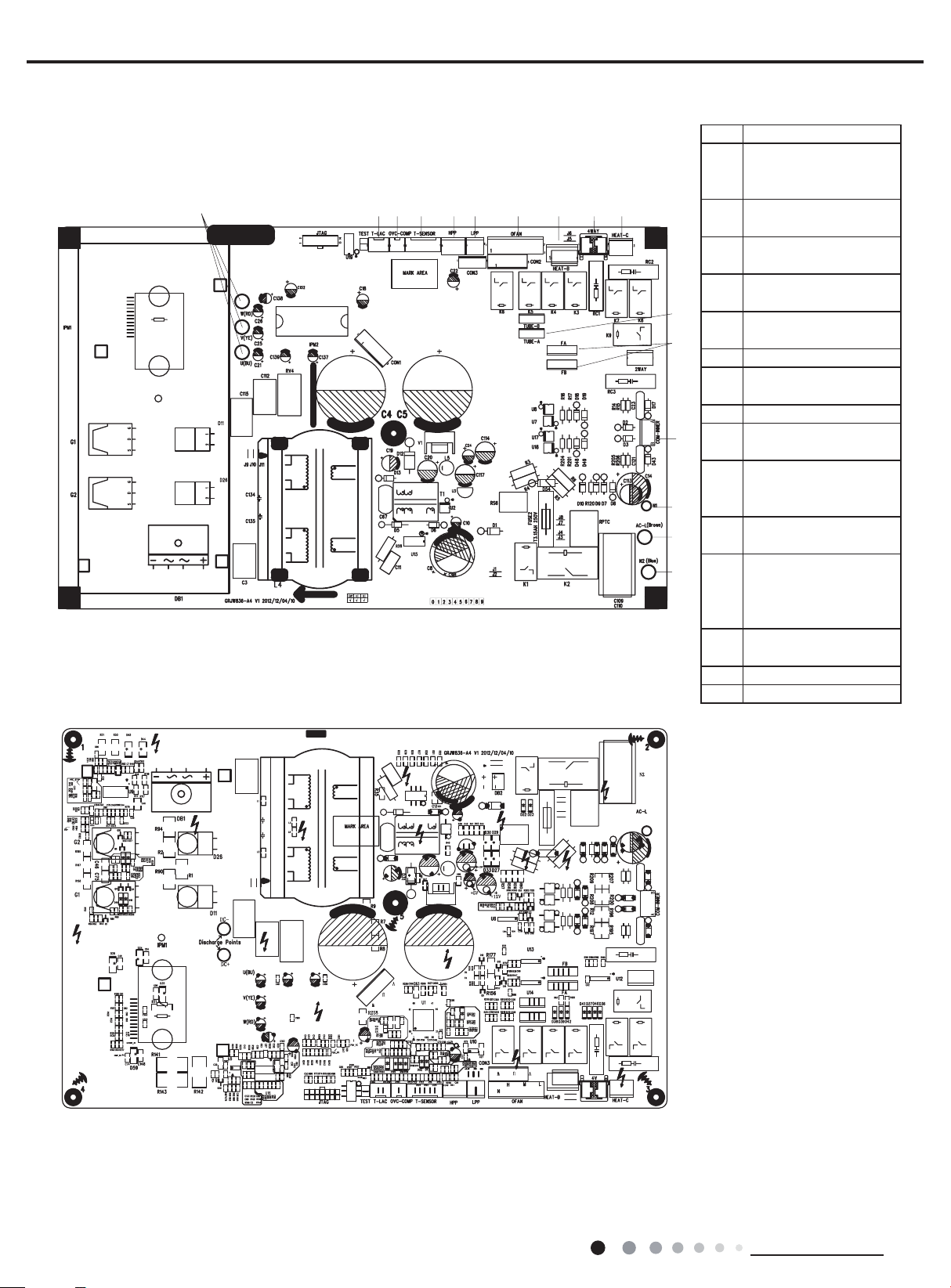

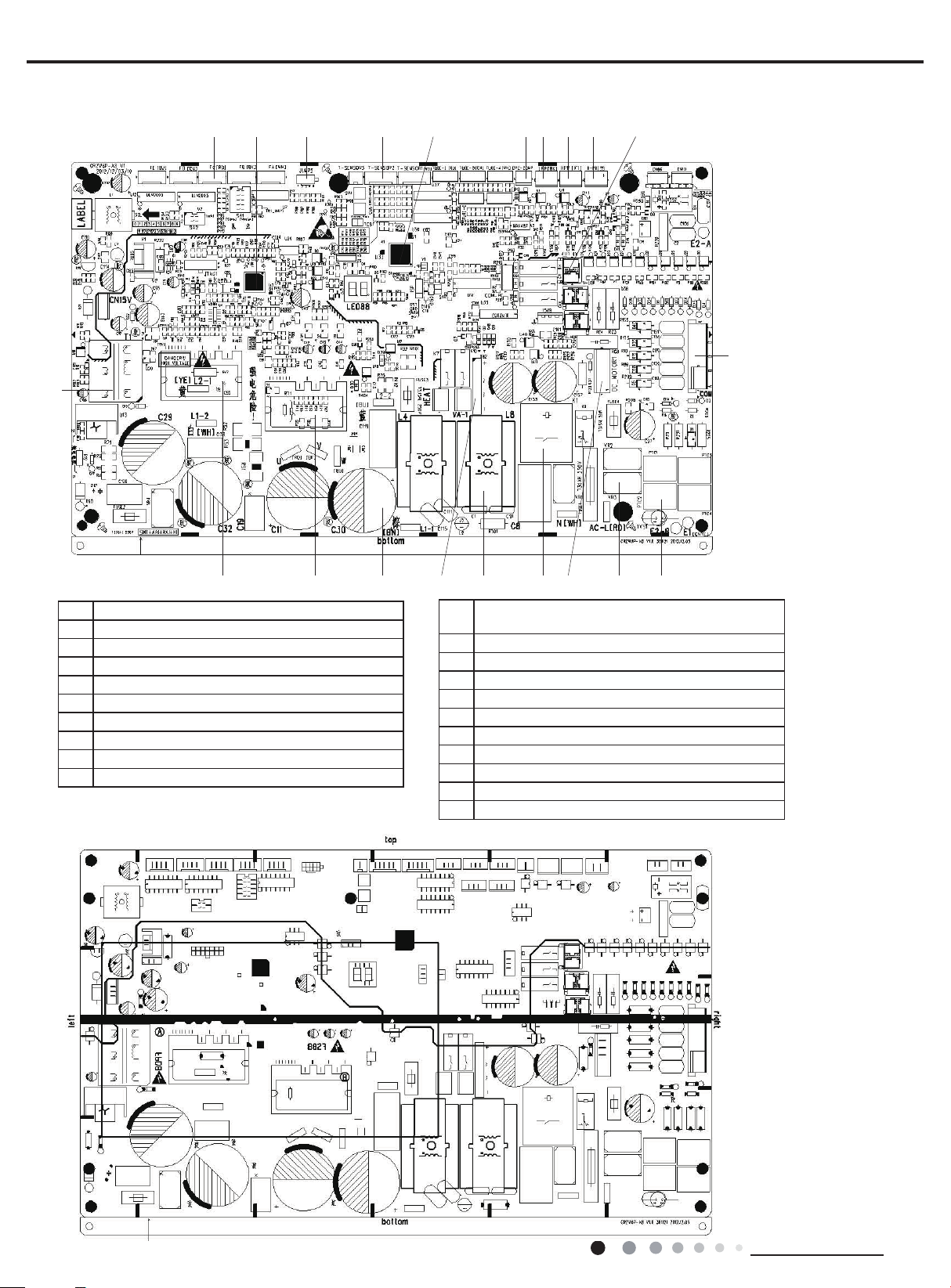

5.2 PCB Printed Diagram

Service Manual

(1)Model:GWHD(18)NK3FO

● Top view

1

● Bottom view

23 45678910

1

1 Terminal of compressor

Terminal of low-

2

temperature cooling

temperature sensor

Overload protection

3

terminal of compressor

Terminal of temperature

4

sensor for outdoor unit

High-pressure protection

5

11

12

13

14

15

16

terminal

Low-pressure protection

6

terminal

7 Terminal of outdoor fan

Electric heating terminal

8

of chassis

9 4-way valve terminal

Electric heating terminal

10

of compressor

Terminal of temperature

11

sensor wire for gas

valve and liquid valve

Terminal of electronic

12

expansion valve

Terminal of

communication wire

13

between indoor unit and

outdoor unit

Terminal of neutral wire

14

for communication

15 Terminal of live wire

16 Terminal of neutral wire

20

Technical Information

Service Manual

1234 56 879

10

12

13

14

15

16

17

18

19

20

21

1234 56 879

10

11

12

13

14

15

16

17

18

19

20

21

22

23

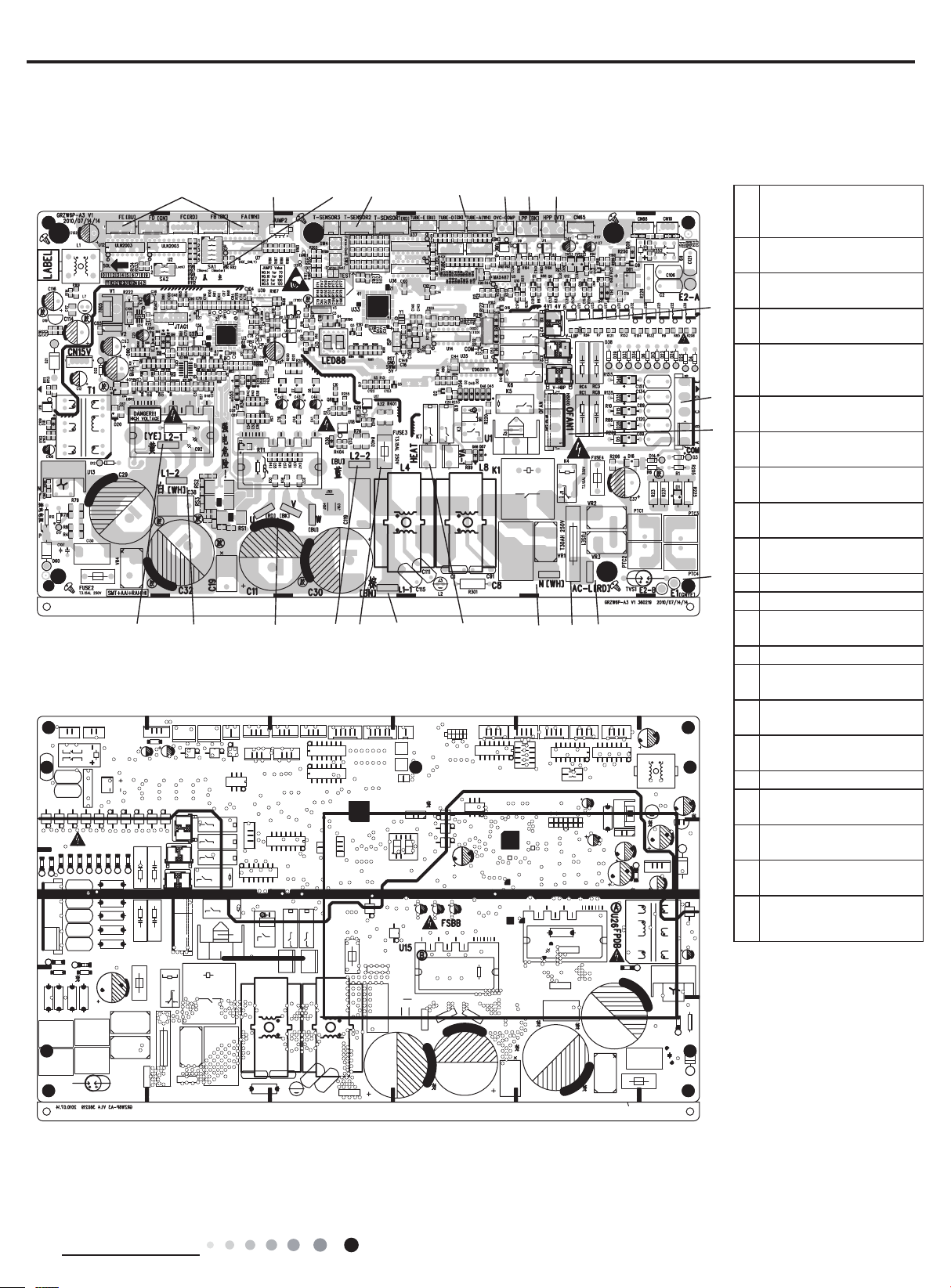

(2)Models:GWHD(24)NK3FO GWHD(24)NK3GO GWHD(28) NK3FO

● Top view

23

1 Compressor terminal

2 Low-pressure protection terminal

3 High-pressure protection terminal

4 Overload protection terminal of compressor

5 Terminal of temperature sensor of outdoor unit

6 Electric heating terminal of chassis

7 Electric heating terminal of compressor

8 Terminal of outdoor fan

9 Terminal of 4-way valve

10 Temperature sensor of liquid valve and gas valve for unit A

11 Temperature sensor of liquid valve and gas valve for unit B

12 Temperature sensor of liquid valve and gas valve for unit C

● Bottom view

11

22

13 Temperature sensor of liquid valve and gas valve for unit D

14 Electronic expansion valve for unit A

15 Electronic expansion valve for unit B

16 Electronic expansion valve for unit C

17 Electronic expansion valve for unit D

18 Communication wire with indoor unit

19 Neutral wire for communication

20 Live wire

21 Neutral wire

22 Reactor wire 1

23 Reactor wire 2

Technical Information

21

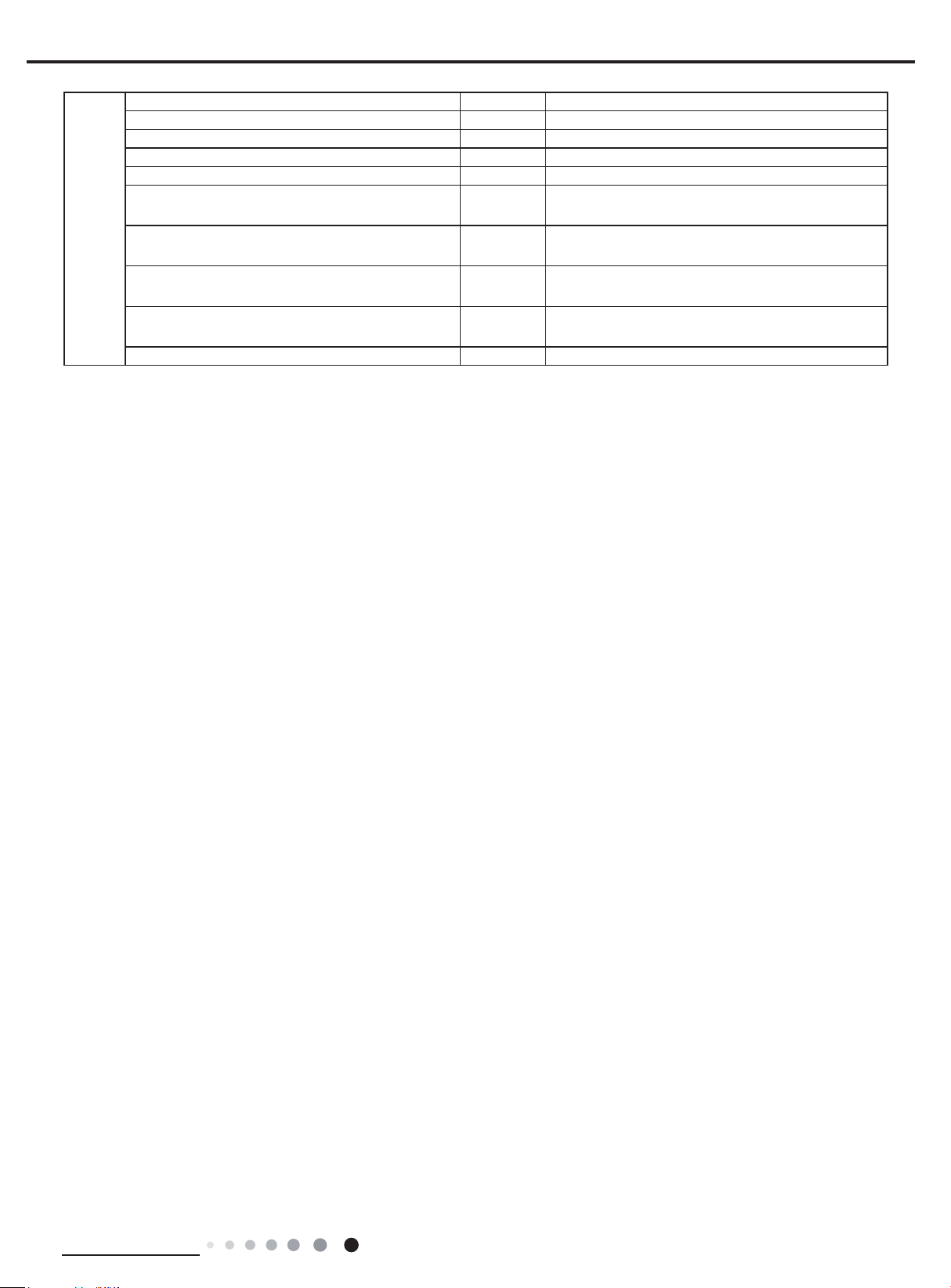

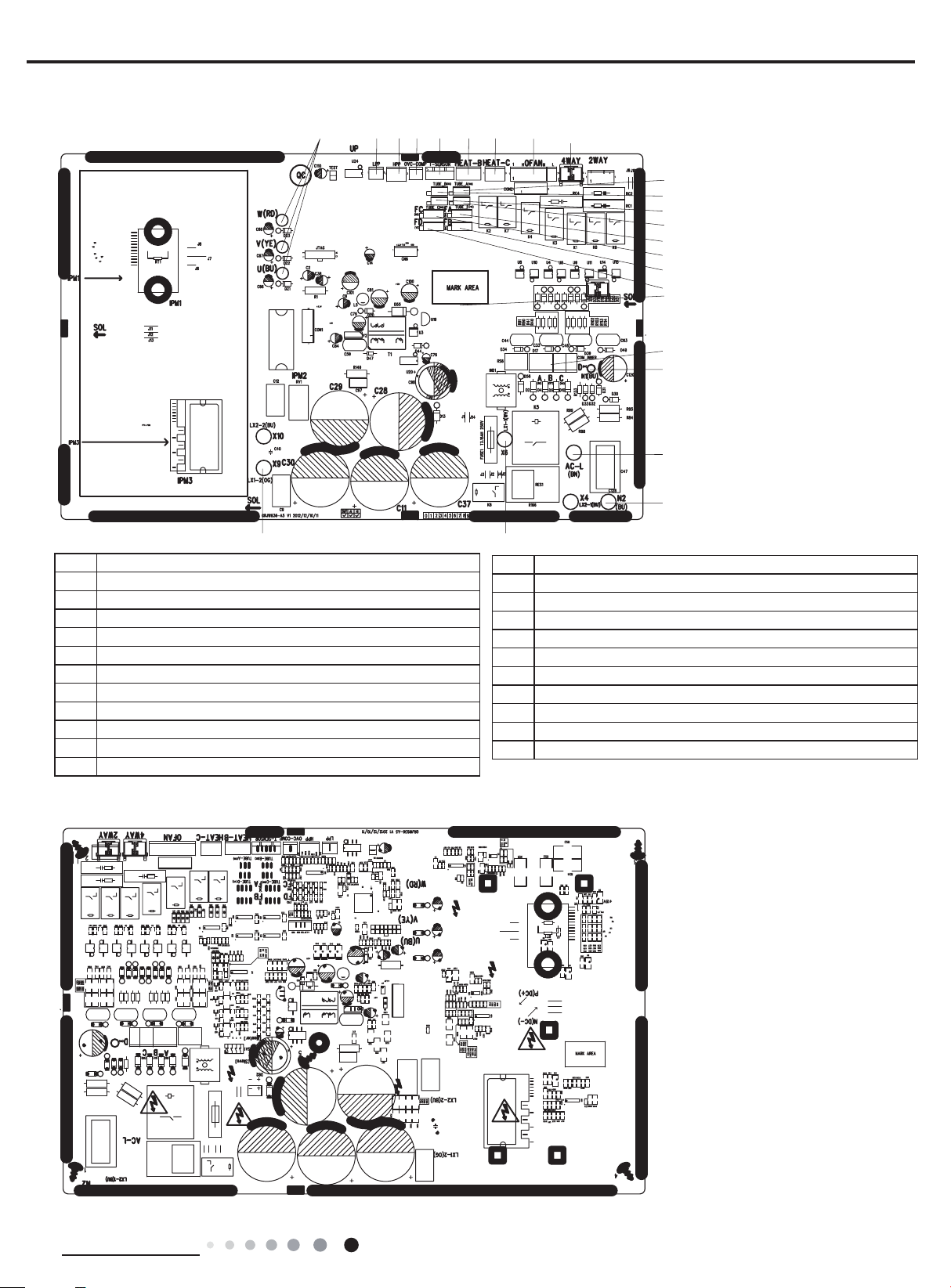

(3)Model:GWHD(36)NK3BO

● Top view

21

1 2 3 4 5 6 7 8

Service Manual

9 10

11

1 Terminal of expansion valve

2 G-MatrikII chip

3 Jumper cap

4 Terminal of temperature sensor

5 STM8S207 chip

6 Overload protection terminal of compressor

7 Low-pressure protection terminal

8 Low-pressure switch 1

9 High-pressure switch 2

10 Terminal of 4-way valve

● Bottom view

121314151617181920

11 Communication interface between indoor unit

and outdoor unit

12 PTC resistance

13 Piezoresistor

14 DC fan terminal

15 Relay

16 Common-mode induction

17 Rectier

18 Electrolytic capacitor

19 IPM module

20 PFC module

21 Transformer

22

Technical Information

Service Manual

minals of reactor's

minals of reactor's

minals of reactor's

minals of reactor's

● Top view

● Bott

(4)Model:GWHD(42)NK3AO

om view

1234

5

67 8

FA-FE: Teminals

1

of EXV(Electronic

expansion Valve)

JUMP2:the code of

2

capcity

SA1: Master select

3

9

switch

T-SENSOR2:Teminals of

4

temperature sensor

TUBE-A - TUBE-

5

E:Teminals of tube

10

11

12

temperature sensor

OVC-COMP:Teminals of

6

overload protector

LPP:Teminals of low

7

pressure switch

HPP:Teminals of high

8

pressure switch

4V1:Teminals of 4-way

9

valve

COM:Teminals of

10

communication

11 OFAN1:Te minals of fan

12 E1:Teminals of Earth

AC-L:Teminals of line

13141516171819202122

13

wire

14 FUSE1: Fuse

N:Teminals of neureal

15

wire

HEAT:Teminals of

16

compressor band heater

L1-1:Te

17

brown wire

18 FUSE3: Fuse of fan

L2-2:Te

19

blue wire

U/V/W:Te minals of

20

compressor

L1-2:Te

21

white wire

L2-1:Te

22

yellow wire

Technical Information

23

6. Function and Control

1 Basic functions of the system

1.1 Cooling Mode

1.1.1 Cooling conditions and process:

If

operation

the

compressor start operation.

1.1.2 Stop in cooling operation

1.1.2.1 Compressor stops

The compressor stops imme

1.1.2.2 Some of the indoor units reach the stop condition (the compressor does not stop)

The

corresponding electronic expansion valve is closed to OP.

1.1.3 Cooling mode transfers to heating mode

When

are the same as stopping in cooling mode.

1.1.4 4-

1.1.5 Outdoor fan control in cooling mode

The

then

changed, the unit

When the compressor stops, the outdoor fan runs at present speed and stops after 1min.

1.2 Dry Mode

1.2.1 The dr

1.2.2 The status of 4-

1.2.3 The temperature setting range: 16 ~ 30

1.2.4 Protection function: the same as those in cooling mode;

1.2.5 In dr

The open co

1.3 Heating Mode

1.3.1 Heating conditions and process:

When one of the indoor units reaches the heating operation condition, the unit starts heating operation.

1.3.2 Stop in heating operation:

1.3.2.1 When all the indoor units reach the stop condition, the compressor stops and the outdoor fan stops after 1min;

1.3.2.2 Some of the indoor units reach the stop condition

The compressor redu

1.3.2.3 Heating mode transfers to cooling mode(dry mode), fan mode

a.

4-

For 18/24/28K

the compressor is in stop status and start the unit for cooling operation, when one of the indoor units reaches the cooling

condition, the unit start cooling operation; in this case, the electronic expansion valve, the outdoor fan and

Service Manual

compressor operates immediately according to the required frequency. For the indoor unit with no requirement, the

the unit transfers to heating mode, the 4-way valve is energized after the compressor stops for 2min. The other disposals

way valve: in this mode, the 4-way valve is closed.

outdoor fan starts before 5s of the starting of compressor. The outdoor fan will run in high speed for 3min after starting and

it will run in set speed. The fan shall run at every speed for at least 80s. (When the quantity of running indoor unit is

will enter the control described in 1.3.5.1 and 1.3.5.2);

y conditions and process are the same as those in cooling mode;

y mode, the maximum value A of the capacity requirement percentage of single unit is 90% of that in cooling mode.

ndition of the electronic expansion valve, outdoor fan and compressor is the same as those in cooling mode.

24

The compressor stops; b. the power of 4-way valve is cut off after 2min; c. the outdoor fan stops after 1min; d. the status of

way valve: energized;

diately, the outdoor fan stops after 1min.

way valve: closed;

ć;

ces the frequency immediately and operates according to the required frequency;

Technical Information

Service Manual

1.3.3 Outdoor fan control in heating mode

The outdoor fa

The fan shall run at every speed for at least 80s;

When the compressor stops, the outdoor fan stops after 1min.

1.3.4 Defrosting function

When

the

valve

compressor rises to reach the defrosting frequency.

1.3.5 Oil-returned control in heating mode

1.3.5.1 Oil-returned condition

The

1.3.5.2 Oil-returned process in heating mode

The indoor

1.3.5.3 Oil-returned finished condition in heating mode

The duration re

1.4 Fan Mode

The compressor, the outd

2. Protection Function

2.1 Mode Conflict Protection of indoor unit

When the setting mode is different of different indoor unit, the unit runs in belo

a. The mode of the first operating indoor unit is the basic mode, then compare the mode of the other indoor units to see if th

is a conflict. Cooling mode (dry mode) is in conflict

b.

the unit

2.2 Overload protection function

When

high,

compressor protection stops running.

If

compressor

compressor is longer than 7min, the protection times record will be cleared)

2.3 Discharge Protection Function

When

is a little high, the compressor frequency is

too high, the compressor protection stops running.

If

compressor

compressor is longer than 7min, the protection times record will be cleared)

n starts before 5s of the starting of compressor and then it will run in high speed for 40s;

the defrosting condition is met, the compressor stops; the electronic expansion valve of all indoor units open in big angle;

outdoor fan stops after 40s of the stop of compressor, meanwhile, the 4-way valve reverses the direction; after the 4-way

reverses the direction, the compressor starts; then begin to calculate the time of defrosting, the frequency of the

whole unit is operating in low frequency for a long time

unit displays “H1”

aches 5min

oor fan and the 4-way valve are closed; temperature setting range is 1630ć.

w status:

Fan mode is in conflict with heating mode and the heating mode is the basic mode. No matter which indoor unit operates first,

will run in heating mode.

with heating mode.

the tube temperature is a little low, the compressor raises the operation frequency; when the tube temperature is a little

the compressor frequency is restricted or lows down the operation frequency; when the tube temperature is too high, the

the discharge temperature protection continuously appears for 6 times, the compressor can’t resume running. The

can resume running after cutting off the power and then putting through the power. (if the running time of the

the discharge temperature is a little low, the compressor raises the operation frequency; when the discharge temperature

restricted or lows down the operation frequency; when the discharge temperature is

the discharge temperature protection continuously appears for 6 times, the compressor can’t resume running. The

can resume running after cutting off the power and then putting through the power. (if the running time of the

Technical Information

ere

25

2.4 Communication malfunction

Detection of the quantity

of installed indoor units:

After 3min of energizing, if the outdoor unit does not receive the communication data

ll

j

that indoor unit later, the outdoor unit

2.5 Overcurrent Protection

a. Overcurrent protection of complete unit; b. phase

2.6 Compressor high-pressure protection

2.6.1

as

e

indoor units;

2.6.2

,

the compressor can resume running only after cutting off the po

2.7 Compressor overload protection

If the compressor overload switch is detected having movement, the indoor unit

stops

the

compressor overload

an

6 times (if the running time of the compressor is longer than 30min, the protection times record

not

resume

the

po

2.8 Compressor Phase-lacking Protection

When

protection.

The

n. If the

phase-lacking

r

cutting

the

protection times record

2.9 IPM Protection

2.9.1

closed,

automatically;

longer

o

indoor unit.

d

then putting through the po

2.9.2 IPM module overheating protection

2.9.2.1 When

2.9.2.2

present

capacity

f

T

run at this frequency;

2.9.2.3

the

outdoor fan

udge that indoor unit is not installed and will treat it as it is not installed. If the outdoor unit receives the communication data of

will treat that unit as it is installed.

wire current protection; c. compressor phase current protection

When the high-pressure switch is detected cut off for 3s continuously, the compressor will enter high-pressure protection

it stops when reaching set temperature. Meanwhile, the outdoor unit will send the signal of “high-pressure protection” to th

After the appearance of high-pressure protection, when the high-pressure switch is detected closed for 6s continuously

wer and then putting through the power.

when the indoor temperature reaching set temperature. When the compressor stops for more than 3min and

switch is reset, the unit will resume operation status automatically. If the protection appears for more th

will display the corresponding malfunction as it

26

operation status automatically, but can resume running only after cutting off the power and then putting through

wer.

the compressor starts, if one of the three phases is detected open, the compressor will enter phase-lacking

malfunction will be cleared after 1min, the unit will restart and then detect if there is still has phase-lacking protectio

protection is detected for 6 times continuously, the compressor will not restart but can resume running only afte

off the power and then putting through the power. If the running time of the compressor is longer than 7min,

will be cleared.

When the IPM module protection is detected, the unit will stop as the indoor temperature reaching set temperature, PFC is

display IPM protection malfunction. After the compressor stops for 3min, the unit will resume operation status

if the IPM protection is detected for more than 6 times continuously (If the running time of the compressor is

than 7min, the protection times record will be cleared), the system will stop and send the signal of module protection t

The unit can not resume operation status automatically, but can resume running only after cutting off the power an

wer.

η85ć, prohibit to raise frequency;

T

IPM

When T

≥90ć, the operation frequency of compressor lows down by 15% every 90s according to the

IPM

requirement of the complete unit. It will keep 90s after lowing down the frequency. After lowing down the frequency, i

≥90ć, the unit will circulate the above movement until reaching the minimum frequency; if 85ćζT

IPM

When T

when T

≥95ć, the compressor stops. After the compressor stops for 3min, if T

IPM

≤85ć, the unit will run at the frequency according to the capacity requirement;

IPM

will resume operation.

Service Manual

of certain indoor unit, the outdoor unit wi

will be cleared), the unit can

ζ90ć, the unit will

IPM

ζ85ć, the compressor and

IPM

Technical Information

Service Manual

For 36K/42K

1.Function Control

1) Cooling mode

a. Turning on the unit for cooling operation, and if any one of the indoor units satisfy the cooling operation condition, the system will

start for cooling operation; and the electronic expansion valve, the outdoor fan and the compressor start operation.

b. When some of the indoor units satisfy the stop-condition while some indoor units does not satisfy the stop-condition, the

compressor does not stop, the compressor adjust the frequency according to demand. For the indoor unit with stop-condition satises,

the corresponding electronic expansion valve will be closed.

c. Change Cooling mode to heating mode

When change the unit to heating mode from cooling mode, the whole system will stop rst. Then the system will restart in heating

mode after the compressor stops.

d. 4-way valve

In this mode, the 4-way valve is closed.

e. Outdoor fan control in cooling mode

The outdoor fan starts before 5s of the starting of compressor. The outdoor fan will run in midlle speed after starting and then it will run

in set speed.

2) Dry mode (dehumidication mode)

this mode is the same as cooling mode;

3) Heating mode

a. Turning on the unit for heating operation, If any one of the indoor unit satisfy the heating condition, the system will start to run in

heating mode

b. If all the indoor units satisfy the stop-condition, the compressor stops and the outdoor fan stops after 1min;

c. If only part of the indoor units satisfy the stop-condition, the compressor decrease the frequency immediately and operates

according to demand.

d. Change Heating mode to cooling mode or dehumidication mode, the whole system will stop rst, then restart under the required

mode.

e. Defrosting function

When the defrosting condition is satised, the 4-way valve reverses the direction, the outdoor fan stop.After the 4-way valve reverses

the direction, the frequency of compressor rises, and the unit

will start defrosting under cooling cycle.

f. Oil-return control in heating mode

a)If the whole system runs in low frequency for a long time, the system will run a oil-return operation in high frequency, the indoor unit

displays “H1”, the oil-return operation will runs for 3 minutes.

4) Fan mode

Only indoor fan run. Compressor, outdoor fan and 4-way valve are closed .

2.Protection Function

1) Mode conict protection of indoor units

When the setting mode is different of different indoor unit, the unit runs in below status:

a. The system mode is determined by the rst turning on indoor unit except indoor unit is in fan mode. Cooling mode (dry mode) is in

conict with heating mode.

b. If the rst turning on unit is fan mode, and the second turning on unit is cooling or heating mode, then the system will run in cooling

or heating mode

2) Overload protection

If the tube temperature at the high pressure side is higher than normal, the compressor frequency is restricted or decreased to normal

operation frequency.

3) High exhaust temperature protection

If the exhaust temperature is higher than protection value, the compressor stops running.

If the exhaust temperature protection continuously appears for 6 times, the compressor can’t resume running. In this case, only by

cutting off the power and then reenergize that the compressor can restart. If the running duration of the compressor is longer than

7min, the protection times will be cleared to zero time.

4) Communication malfunction

Technical Information

27

Service Manual

Detection of the quantity of installed indoor units: after 3min of energizing, if the outdoor unit does not receive the communication data of

certain indoor unit, the outdoor unit will judge that indoor unit is not installed. If the outdoor unit receives the communication data of that

indoor unit later, the communication malfunction will be cleared.

5) System high-pressure protection

a. When the high-pressure switch detects the system pressure higher than limit ,then the high-pressure switch cuts off, the system will stop

to run.

b.If high-pressure protection is detected for two times within one hour, only by cutting off the power and then reenergize that the compressor

can restart.

6)System low-pressure protection

a. When the low-pressure switch detects the system pressure lower than limit ,then the los-pressure switch cuts off , the system will stop to

run.

b. If low-pressure protection is detected for two times within one hour, only by cutting off the power and then reenergize that the compressor

can restart.

7) Compressor overload protection

No matter the compressor is on or off, when the compressor overload switch is detected activated, the system will stop and indoor unit

will display H3. If the compressor overload protection appears for more than 6 times, in this case, only by cutting off the power and then

reenergize that the compressor can restart. If the running duration of the compressor is longer than 30min, the protection times will be

cleared to zero.

3.Other function

1) Refrigerant Recovery

When the unit is powered on and runs under the COOL mode, it is available within ve minute to go the refrigerant recovery mode by

pressing three times the “LIGHT” button on the wireless controller in three seconds with “Fo”displayed.

How to quit the refrigerant recovery:

When the refrigerant recovery has started, it will quit when there is a signal from the wireless controller or it has run for ten minutes.

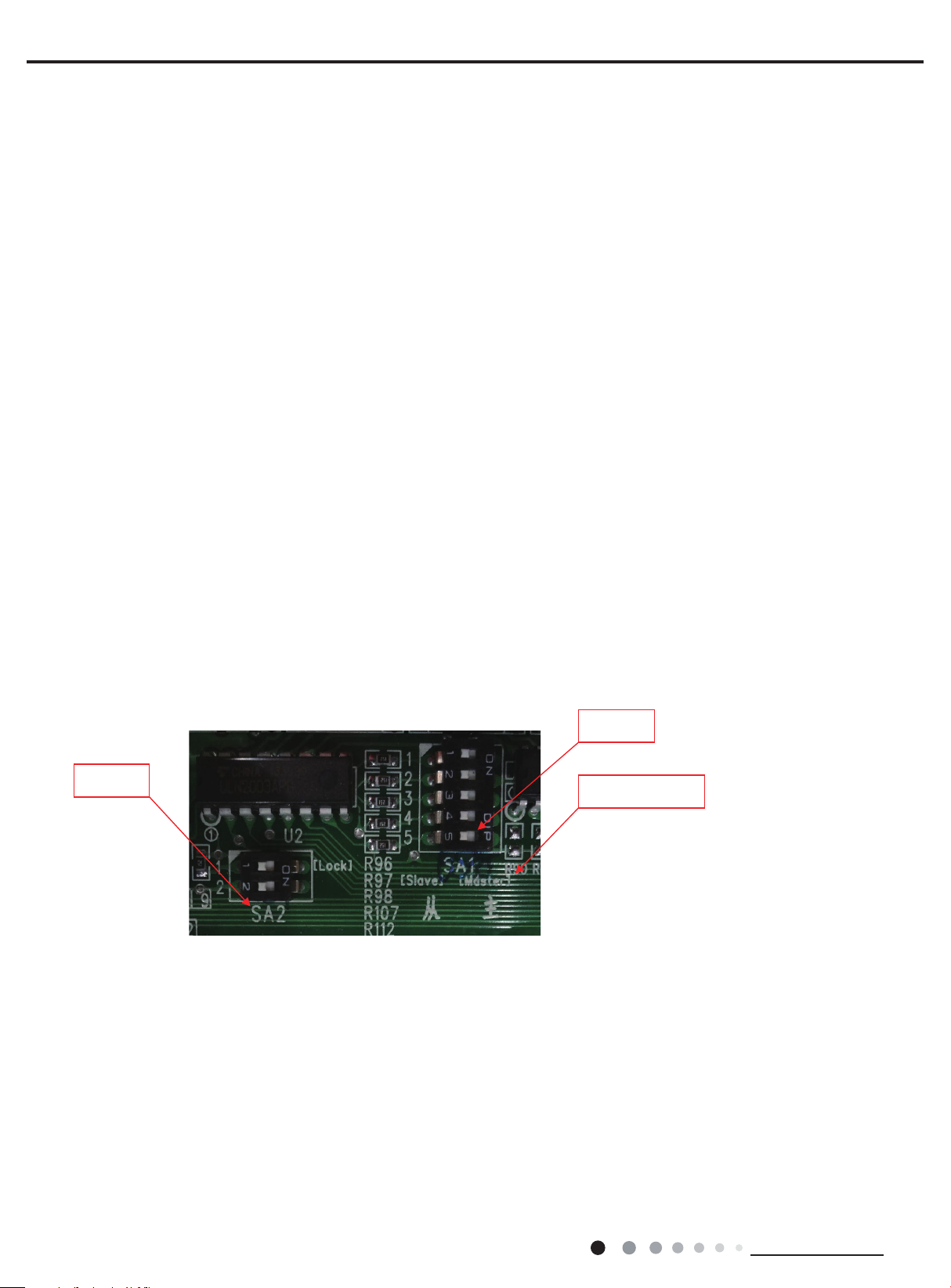

2) Setting function of master/slave indoor unit

Picture of DIP switch on outdoor mainboard :

SA1(5-bit): dial-switch for master/slave indoor unit,

SA2(2-bit): dial-switch for mode locking (not for wall mounted indoor units)

SA1

SA2

5-bit dial-switch to set master/slave indoor unit: it is corresponding to indoor units of no.1 to no.5. Dial the switch to ON(master side. Right

side) to set that indoor unit as master indoor unit , and dial the switch to slave side(left side) to set indoor unit as slave indoor unit. There

can be only one master unit in a system, If more than one indoor units are set as master unit, the unit with biggest number is the master

unit. (biggest number here means number 1 to number 5 on the switch)

2-bit dial-switch to set mode locking

(note:

1.only use no.1 bit. no.2 bit is for future use

2.this function is only for duct and cassette unit, not for wall mounted unit:

Locked mode: Switch no.1 bit to “ON”side(lock side, or right side on the picture): even the master indoor unit is off, the system will run

according to the mode before the master unit off.

Unlocked mode: Switch no.1 bit to left side on the picture: If the master indoor unit is off , the system will not care what the master unit

mode was, it will run according to the mode of the rst turning on slave indoor unit.

Note: For wall-mounted indoor unit, unlocked model is default, and locked mode is invalid.

master/slave

28

Technical Information

Loading...

Loading...