Gree GWH09AB-A3DNA1B, GWH12AB-A3DNA1B Service Manual

GREE ELECTRIC APPLIANCES,INC.OF ZHUHAI

Service Manual

MODEL:GWH09AB-A3DNA1B

GWH12AB-A3DNA1B

(Refrigerant R410A)

Table of Contents

Summary and Features

.................................................................................1

Part 1 Safety Precautions

..........................................................................................2

Part 2 Specifications

.....................................................................................................3

Part 3 Construction Views

........................................................................................5

3.1 Indoor Unit ........................................................................................................

.....5

3.2 Outdoor Unit ..........................................................................................................5

Part 4 Refrigerant System Diagram

.....................................................................6

5.1 Electrical Data........................................................................................................7

5.2 Electrical Wiring......................................................................................................7

Part 5 Schematic Diagram

........................................................................................7

6.1 Remote Control Operations..................................................................................11

6.2 Changing Batteries and Notices ..........................................................................13

6.3 Description of Each Control Operation.................................................................14

Part 6 Function and Control

...................................................................................11

Part 7 Installation Manual

........................................................................................19

7.2 Installation Drawing..............................................................................................21

7.3 Install Indoor Unit.................................................................................................22

7.4 Install Outdoor Unit ..............................................................................................24

7.5 Check After Installation and Operation Test.........................................................25

5.3 Printed Circuit Board...........................................................................................

....9

7.1 Notices for Installation...........................................................................................19

Table of Contents

Part 8 Exploded Views and Parts List

..............................................................26

Part 9 Troubleshooting

...............................................................................................32

9.1

Malfunction Analysis

.............................................................................................32

9.2

Flashing LED of Indoor/Outdoor Unit and Primary Judgement

............................36

9.3

How to Check Simply the Main Part

.....................................................................39

8.1 Indoor Unit............................................................................................................26

8.2 Outdoor Unit.........................................................................................................28

Part10 Removal Procedure

.......................................................................................48

10.1

Removal Procedure of Indoor Unit

.....................................................................48

10.2

Removal Procedure of Outdoor Unit

...................................................................51

1

Summary and Features

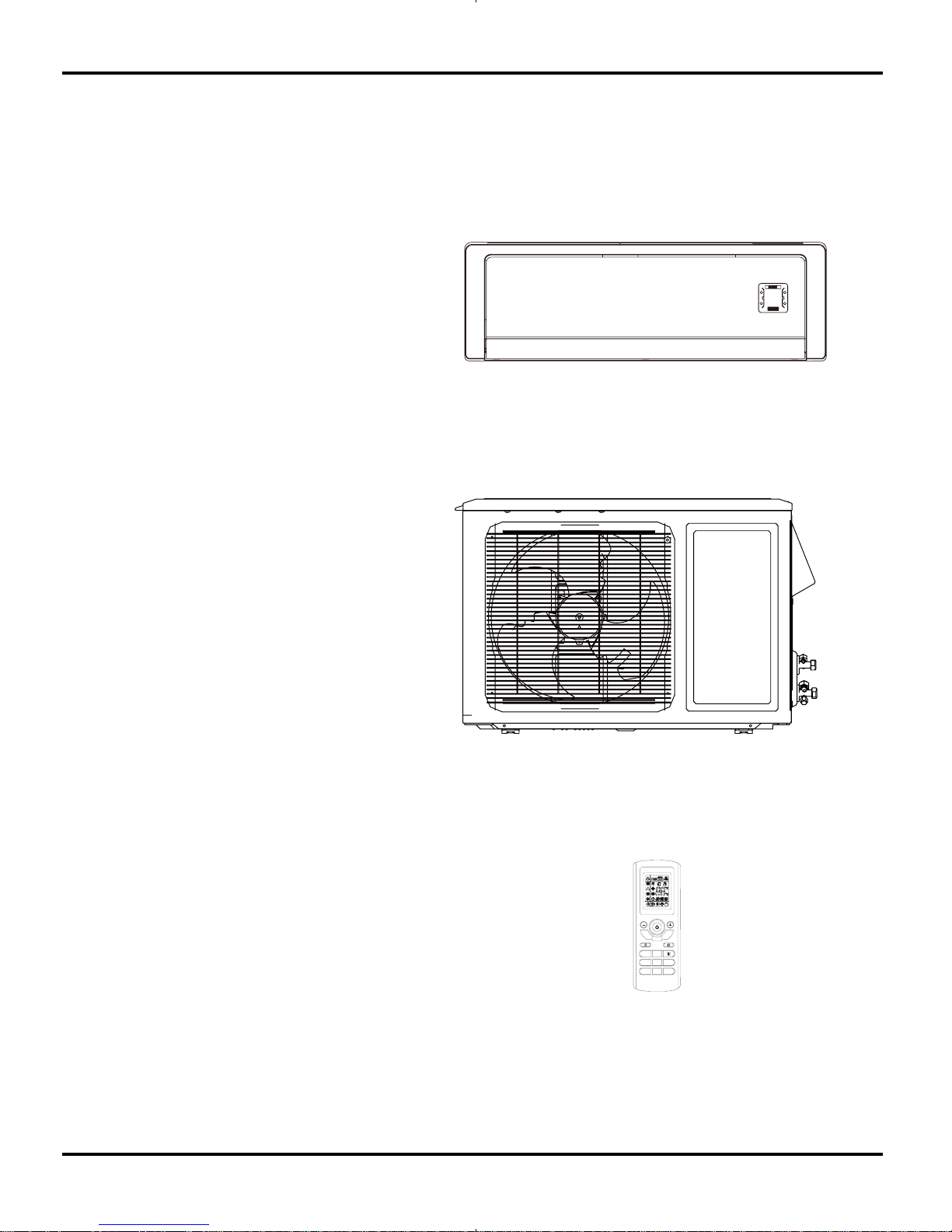

Indoor Unit

GWH09AB-A3DNA1B/I

GWH12AB-A3DNA1B/I

Outdoor Unit

GWH09AB-A3DNA1B/O

GWH12AB-A3DNA1B/O

Remote control window

YT1FF

Summary and Features

FAN

MODE

IFEEL

CLOCK

TIMER

ON

X-FAN TEMP

TIMER

OFF

TURBO SLEEP LIGHT

2

Safety Precautions

1.Safety Precautions

Important!

This air conditioning system meets strict safety and

operating standards. As the installer or service person,

it is an important part of your job to install or service the

system so it operates safely and efficiently.

Follow each installation or repair step exactly as shown.

Observe all local, state, and national electrical codes.

Pay close attention to all warning and caution notices

given in this manual.

To prevent injury to the user or other people and

property damage, the following instructions must

be followed.

About the pictures:

Erroneous handing gives a high possi-

bility to induce serious results such as

death or heavy injury.

Erroneous handing may induce serious

injury depending on the situation.

Do not supply power to the unit until all wiring and tubing

are completed or reconnected and checked.

Highly dangerous electrical voltages are used in this

system. Carefully refer to the wiring diagram and these

instructions when wiring. Improper connections and inad-

equate grounding can cause accidental injury or death.

Ground the unit following local electrical codes.

Connect all wiring tightly. Loose wiring may cause over-

heating at connection points and a possible fire hazard.

All electric work must be performed by licensed technician, ac-

cording to local regulations and the instructions given in this

manual.

There is risk of fire, electric shock, explosion, or injury.

Ask your dealer or specialized subcontractor for installation or

repair work.

Make sure the ceiling/wall is strong enough to hold the

unit’s weight. The outdoor unit should be installed in a

location where air and noise emitted by the unit will not

disturb the neighbors.

Properly insulate any tubing run inside a room to prevent

"sweating" that can cause dripping and water damage to

walls and floors.

The outdoor unit must be installed on stable, level surface,

in a place where there is no accumulation of snow, leaves

or rubbish.

The unit should be installed according to the instructions

in order to minimize the risk of damage from earthquakes,

typhoons or strong winds.

When the refrigerant touches the fire etc., it was decomposed

and a poisonous gas is generated.

Use only the specified refrigerant to charge the refrigerant

circuit.

Do not mix it with any other refrigerant and do not allow air to

remain in the circuit.

Air enclosed in the circuit can cause high pressure resulting

in a rupture and other hazards.

After completing installation work, make sure that refriger-

ant gas has not leaked.

The limit density is made not to be exceeded even if the refrig-

erant leaks by any chance.

Turn the power off at the main power box (mains) before open-

ing the unit to check or repair electrical parts and wiring.

Keep your fingers and clothing away from any moving parts.

Clean up the site after you finish, remembering to check that

no metal scraps or bits of wiring have been left inside the unit

being serviced.

The unit must be properly earth connected.

Caution

Warning

Warning

Caution

Never install on the place where a combustible gas might

leak. The gas may ignite or explode when the gas leaks and

collects in surround of the unit.

When the unit is installed at telecommunication centers or

hospitals, take a proper provision against noise.

When installing at a watery place, provide an electric leak

breaker.

Do not wash the unit with water.

Be very careful about unit transportation. The unit should not

be carried by only one person if it is more than 20kg. It occasion-

ally causes the damage of the unit and health to be impaired.

Do not touch the heat exchanger fins with your hands.

Doing so may cut your hands.

Do not touch the compressor or refrigerant piping without

wearing glove on your hands. Touching directly such part can

cause a burn or frostbite as it becomes high or low temperature

according to the refrigerant state.

Do not operate the air conditioner without the air filter set

place. Dust may accumulate, and cause a failure.

At emergency (if you smell something burning), stop opera-

tion and turn the power source switch off.

Please Read Before Srarting

3

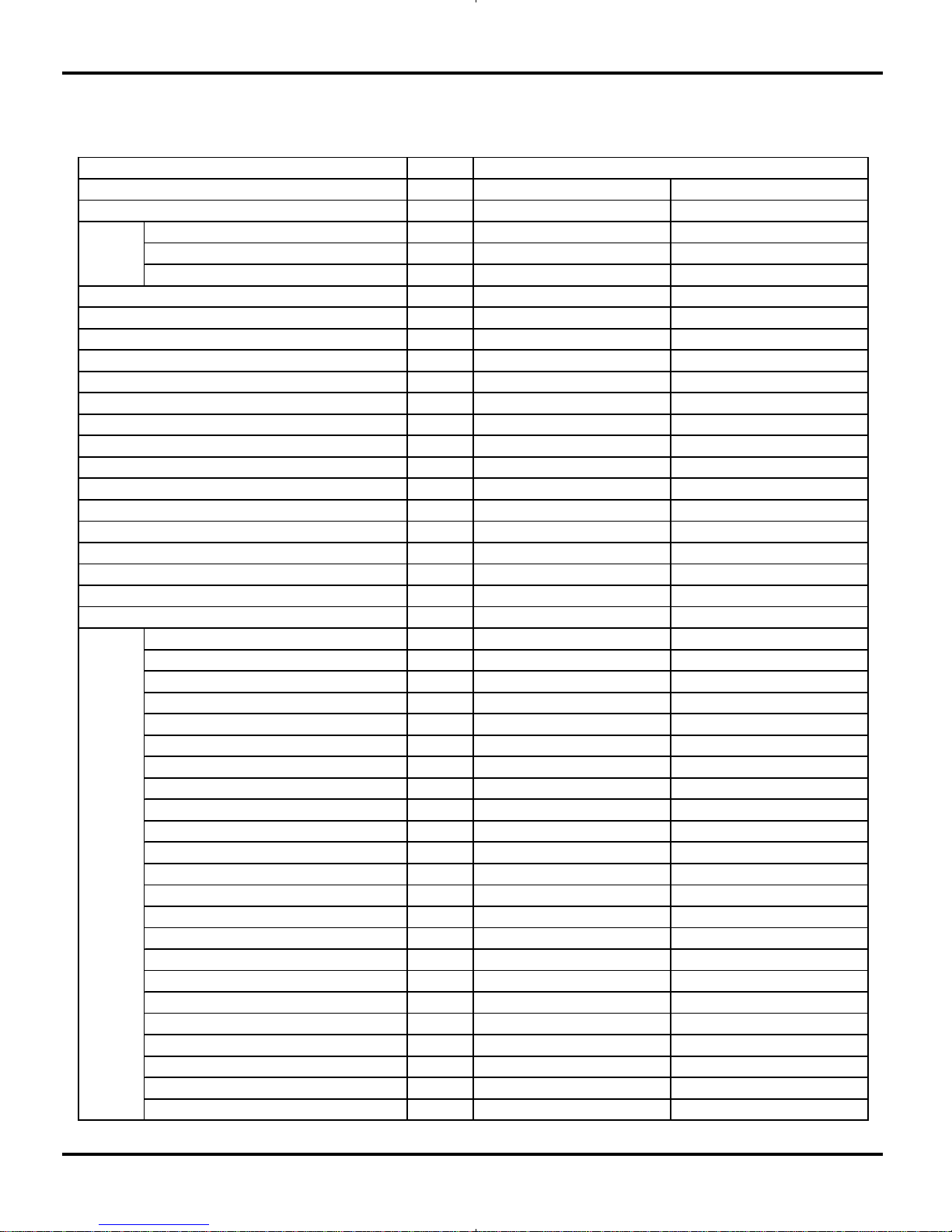

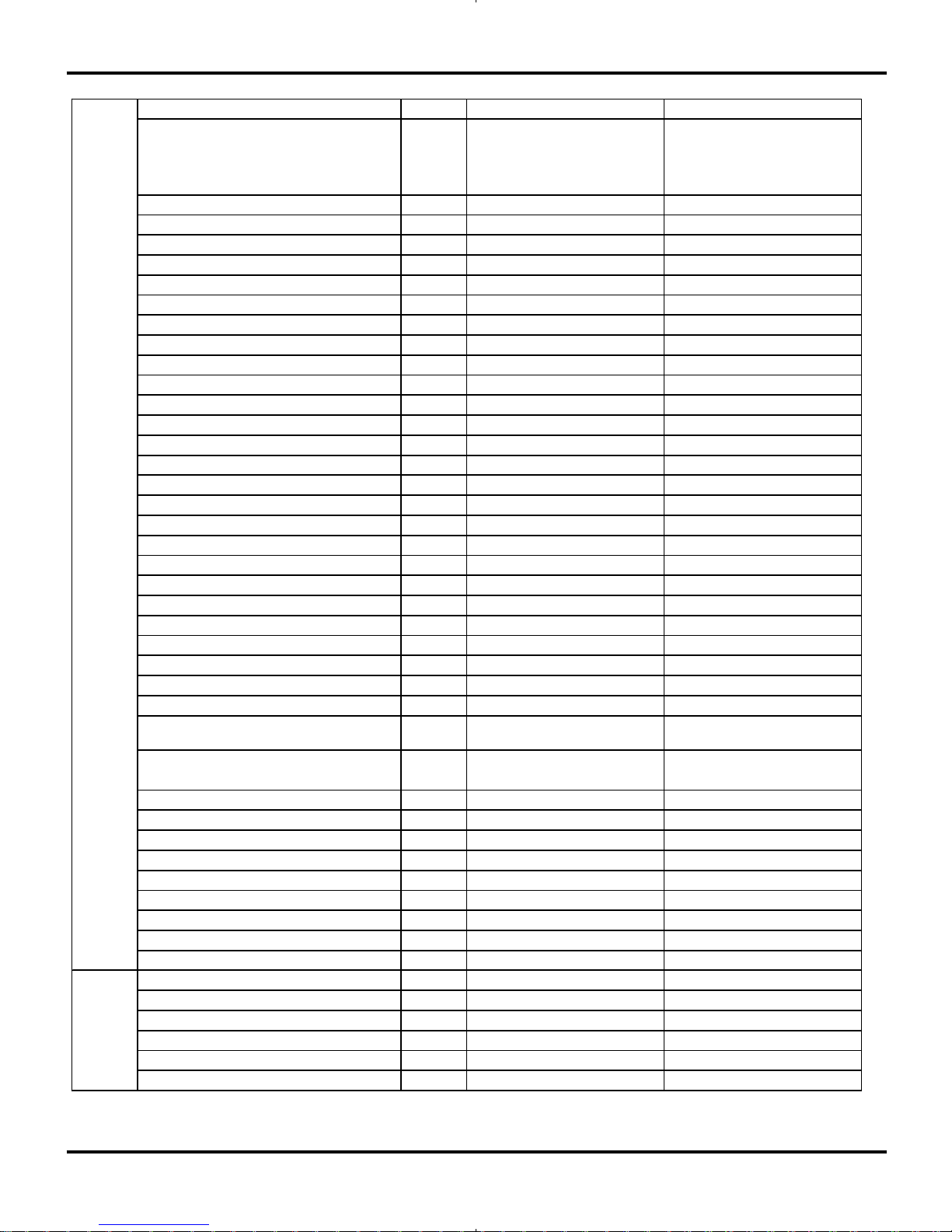

2.Specifications

Specifications

Unit

GWH09AB-A3DNA1B GWH12AB-A3DNA1B

CB11500550 CB11500570

Rated Voltage V

~

115 115

Rated Frequency Hz 60 60

Phases 1 1

Outdoor Outdoor

Btu/h 9000(4000~11950) 12000(4500~13000)

Btu/h 9500(3412~12500) 13000(3200~14000)

W 620(166~1180) 1000(160~1180)

W 680(200~1230) 1140(400~1250)

A5.3 8.70

A 6 10.00

W 1100 1300

A10 12

m

3

/h

520/430/370/290/- 560/490/430/350/-

L/h 1.2 1.4

W/W 4.33 3.52

W/W 4.04 3.34

W/W 23 22

W/W 9 9

m

2

12-18 16-24

Model of indoor unit GWH09AB-A3DNA1B/I GWH12AB-A3DNA1B/I

Fan Type Cross-flow Cross-flow

Diameter Length(DXL) mm Φ85X668 Φ85X668

Fan Motor Cooling Speed (SH/H/M/L/SL) r/min 1400/1150/1050/900/- 1500/1150/1050/900/-

Fan Motor Heating Speed (SH/H/M/L/SL) r/min 1450/1250/1150/1050/400 1450/1250/1150/1050/400

Output of Fan Motor W 10 10

Fan Motor RLA A / /

Fan Motor Capacitor μF/ /

Input of Heater W / /

Evaporator Form Aluminum Fin-copper Tube Aluminum Fin-copper Tube

Pipe Diameter mm Φ7 Φ7

Row-fin Gap mm 2-1.5 2-1.5

Coil Length (LXDXW) mm 657X25.4X285 657X25.4X285

Swing Motor Model MP28VB MP28VB

Output of Swing Motor W 2 2

Fus e A 3.15 3.15

Sound Press ure Level (SH/H/M/L/SL) dB (A) 42/38/30/28/- 47/38/30/28/-

Sound Power Level (SH/H/M/L/SL) dB (A) 52/48/40/38/- 57/48/40/38/-

Dimension (WXHXD) mm 872X283X178 872X283X178

Dimension of Carton Box (L/W/H) mm 935X260X375 935X260X375

Dimension of Package (L/W/H) mm 938X275X378 938X275X378

Net Weight kg 12 12

Gross Weight kg 15 15

ValueParam eter

Model

Product Code

Power

Supply

Power Supply Mode

Cooling Capacity (Min~Max)

Heating Capacity (Min~Max)

Cooling Power Input (Min~Ma x)

Heating Power Input (Min~Ma x)

Cooling Power Current

Heating Power Current

Rated Input

Rated Current

Air F l ow Vol u m e( SH/ H/M/L/SL)

Dehumidifying Volume

Application Area

Indoor

Unit

EER

COP

SEER

HSPF

4

The above data is subject to change without notice. Please refer to the nameplate of the unit.

Specifications

Model of Outdoor Unit GWH09AB-A3DNA1B/O GWH12AB-A3DNA1B/O

Compressor Manufacturer/Trademark

CHINA

RESOURCES(SHENYANG)

SANYO COMPRESSOR CO.

LTD ./S ANYO

CHINA

RESOURCES(SHENYANG)

SANYO COMPRESSOR CO.

LTD ./S ANYO

Compressor Model C-6RZ110H1A C-6RZ110H1A

Compressor Oil FV50S FV50S

Compressor Type Rotary Rotary

L.R.A. A 33.00 33

Compressor RLA A 4.59 4.59

Compressor Power Input W 800 800

Overload Protector Int11l-3979 Int11l-3979

Throttling Method Electron expansion valve Electron expansion valve

Operation temp ºC 16~30 16~30

Ambient temp (cooling) ºC 18~43 18~43

Ambient temp (heating) ºC -7~24 -7~24

Condenser Form Aluminum Fin-copper Tube Aluminum Fin-copper Tube

Pipe Diameter mm Φ9.52 Φ9.52

Rows-fin Gap mm 2-1.4 2-1.4

Coil Length (LXDXW) mm 747X44X508 747X44X559

Fan Motor Speed rpm 830 830

Output of Fan Motor W 30 30

Fan Motor RLA A / /

Fan Motor Capacitor μF/ /

Air Flow Volume of Outdoor Unit

m

3

/h

1800 2000

Fan Type Axial-flow Axial-flow

Fan Diameter mm Φ400 Φ400

Defrosting Method Automatic Defrosting Automatic Defrosting

Clim ate Type T1 T1

Is ol ati on I I

Mois ture Protection IP24 IP24

Permissible Excessive Operating

Pressure for the Discharge Side

MPa 3 .8 3.8

Permissible Excessive Operating

Pressure for the Suction Side

MPa 1 .2 1.2

Sound Press ure Level (H/M/L) dB (A) 52/-/- 55/-/-

Sound Power Level (H/M/L) dB (A) 62/-/- 65/-/-

Dimension (WXHXD) mm 848X540X320 848X590X320

Dimension of Carton Box (L/W/H) mm 878X360X580 878X360X630

Dimension of Package (L/W/H) mm 881X363X595 881X363X645

Net Weight kg 40 41

Gross Weight kg 44 45

Refrigerant R410A R410A

Refrigerant Charge kg 1.35 1.35

Length m 7.5 7.5

Gas Additional Charge g/m 20 20

Outer Diameter Liquid Pipe mm Φ6 Φ6

Outer Diameter Gas Pipe mm Φ9.52 Φ12

Max Distance Height m 10 10

Max Distance Length m 15 20

Outdoor

Unit

Connecti

on Pipe

5

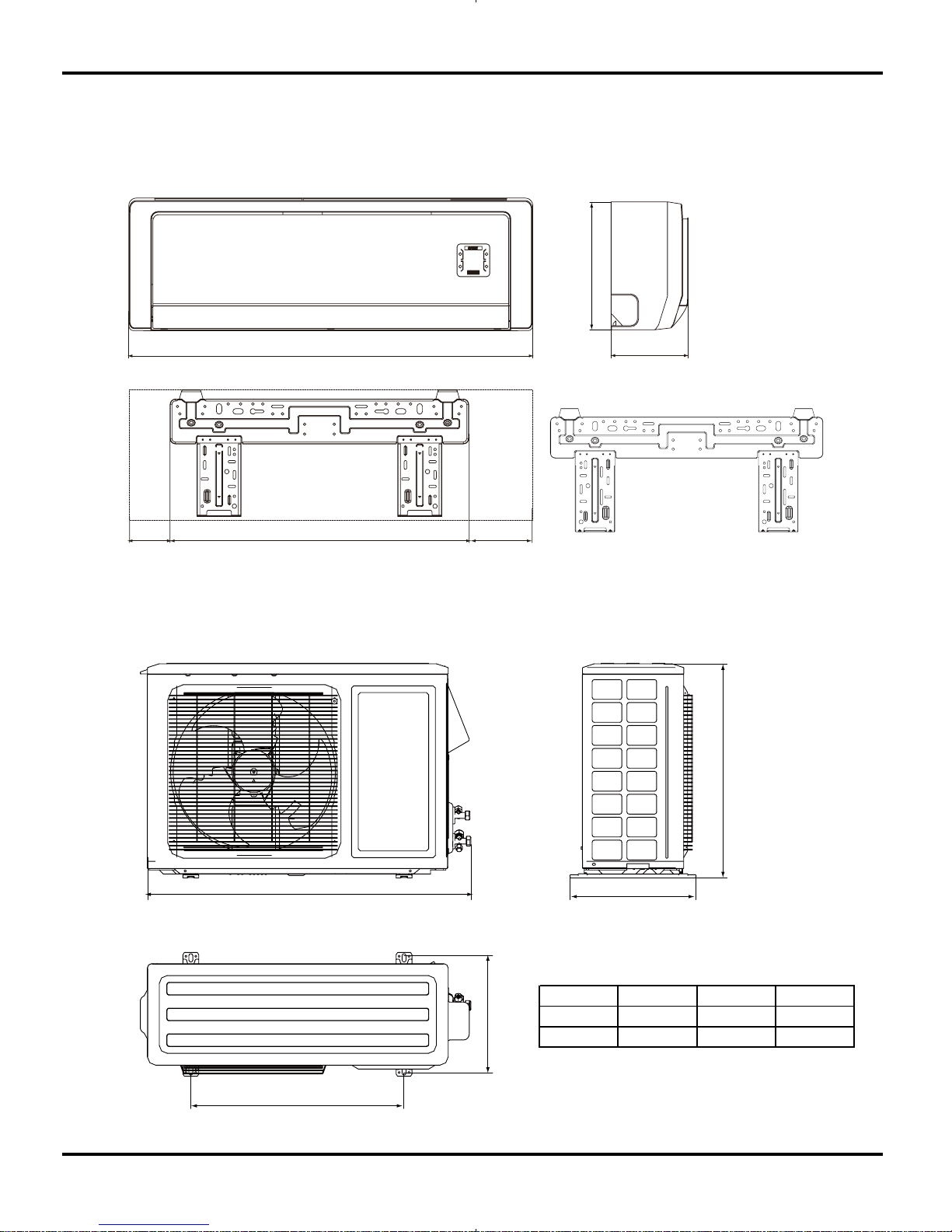

3. Construction Views

3.1 Indoor Unit

Constrction Views

Unit:mm

101

872

178

605 166

283

12K Unit:

3.2 Outdoor Unit

D

540

286

H

W

Model W H D

09K 848 540 320

12K 848 590 320

6

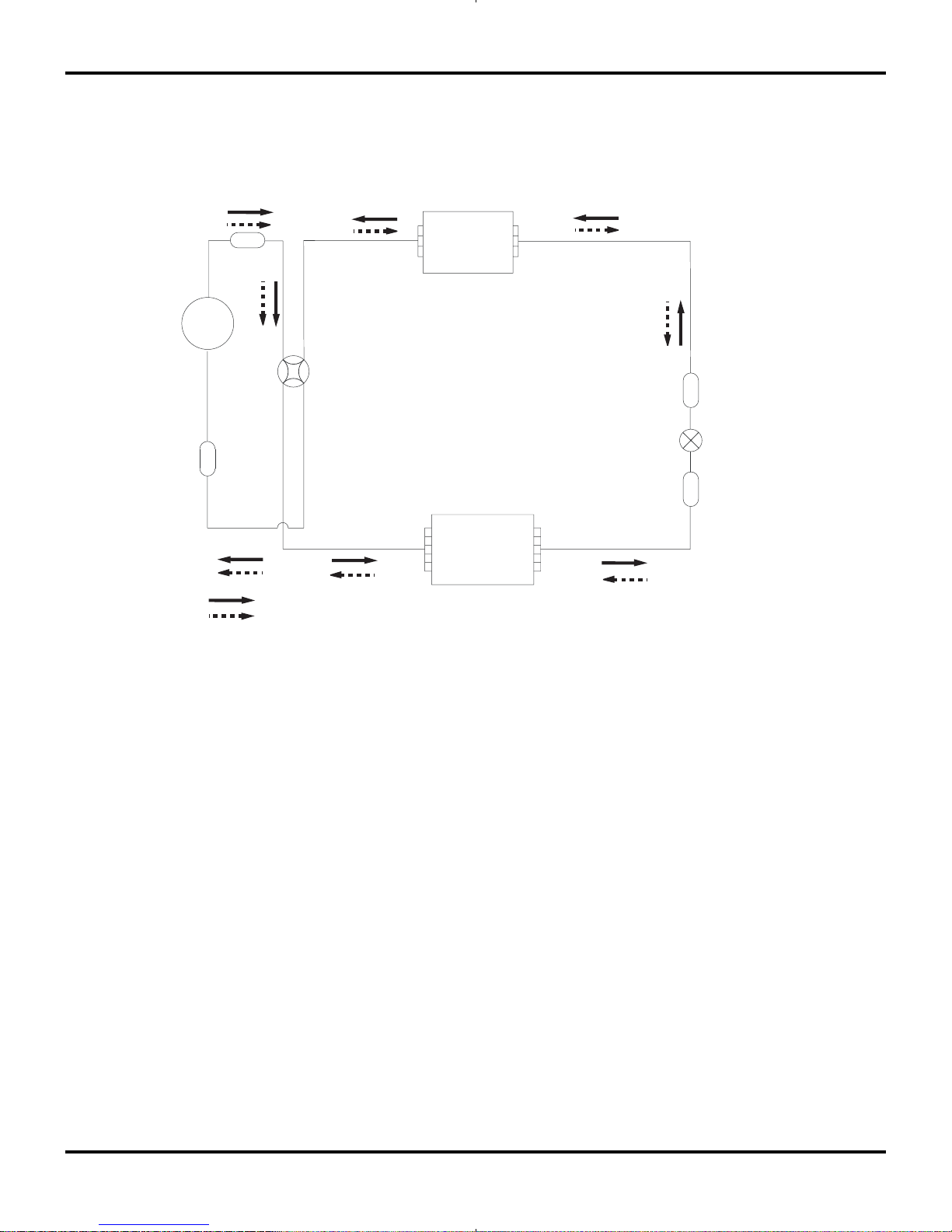

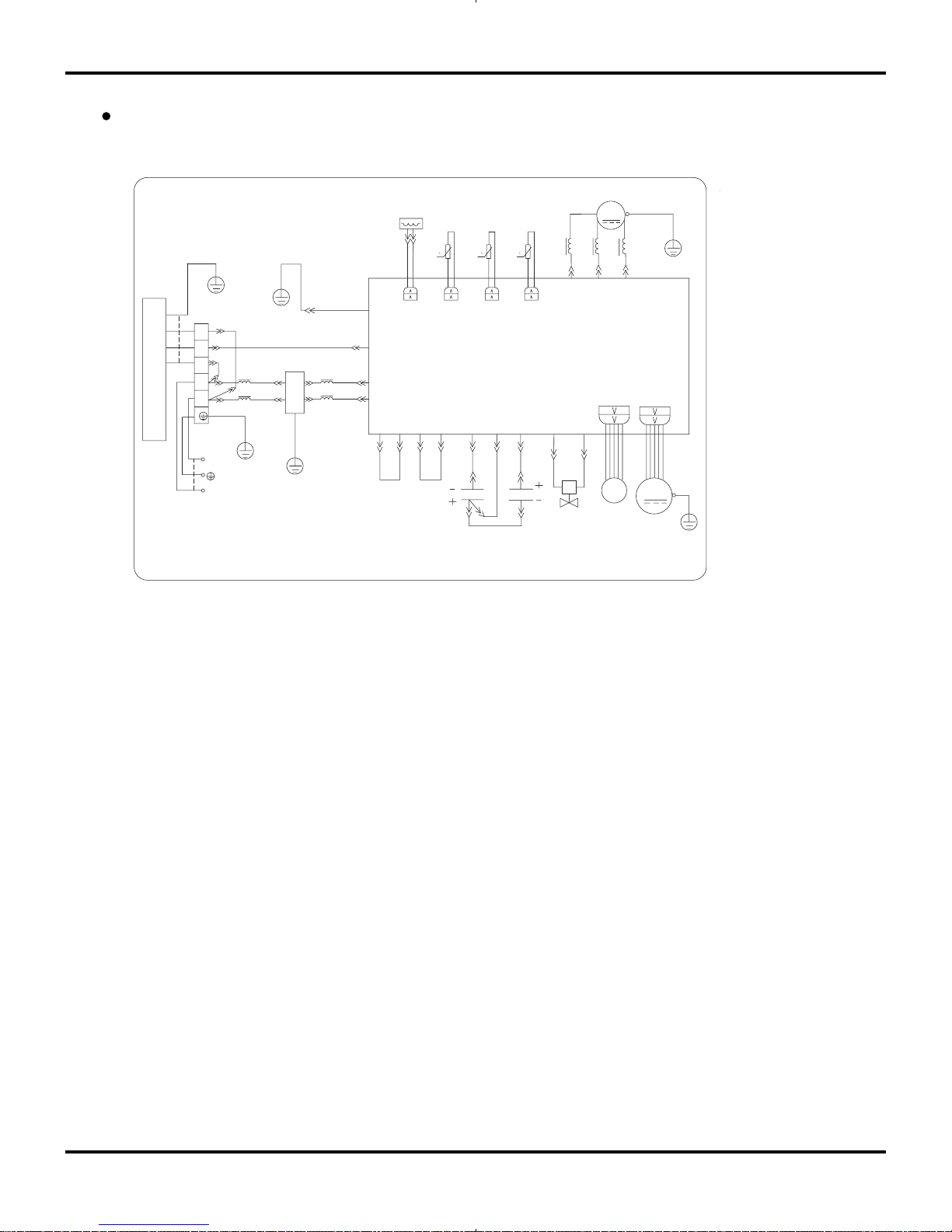

4. Refrigerant System Diagram

Refrigerant pipe diameter

09K Unit

Liquid : 1/4" (6 mm)

Gas : 3/8" (9.52 mm)

12K Unit

Liquid : 1/4" (6 mm)

Gas : 1/2" (12 mm)

Refrigerant System Diagram

Strainer

Strainer

Muffler

4-Way valve

Expansion valve

Heat exchanger

( INDOOR )

Heat exchanger

( OUTDOOR )

rotalumucca-buS

rosserpmoC

Cooling

Heating

7

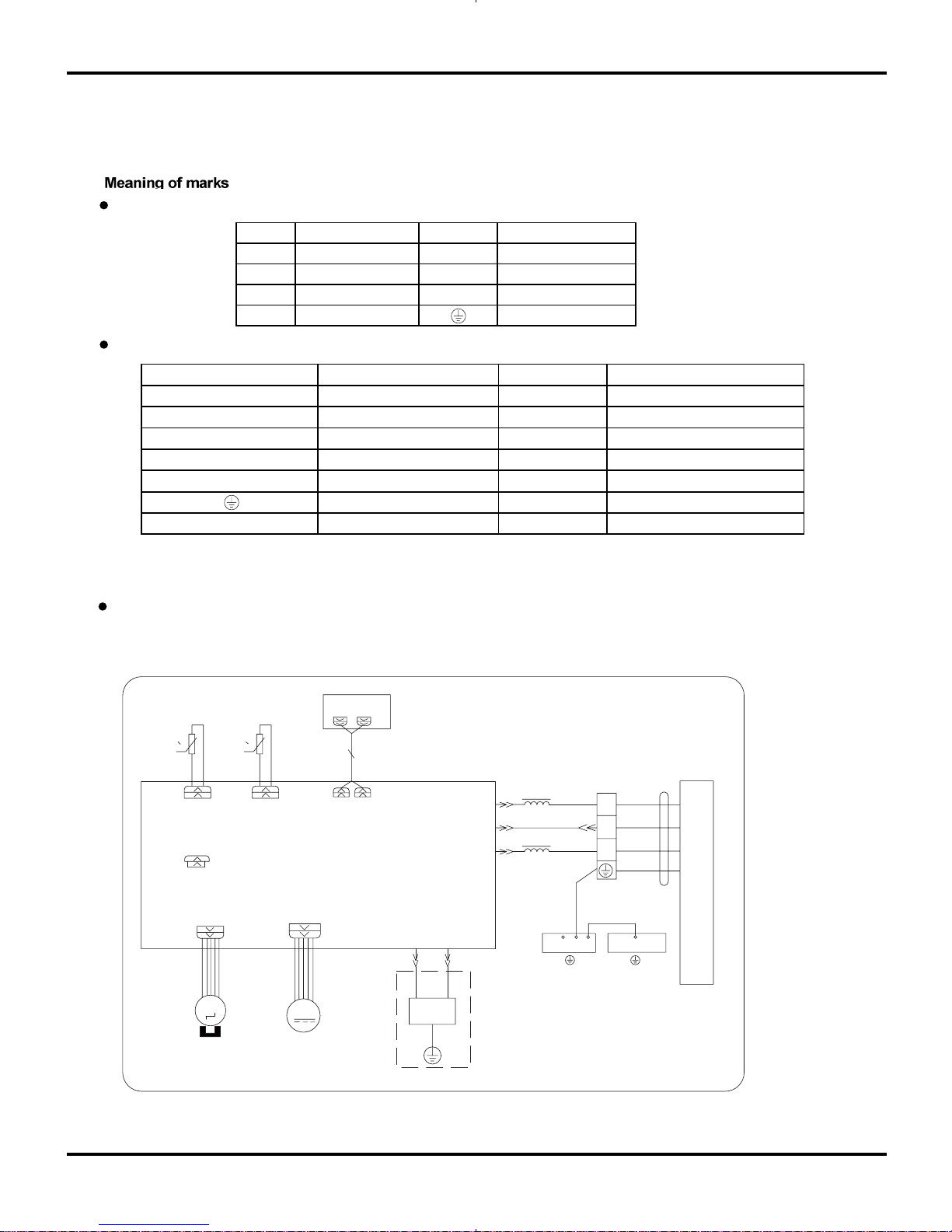

5. Schematic Diagram

5.1 Electrical Data

5.2 Electrical wiring

Outdoor Unit

Symbol Color symbol Symbol Color symbol

WH

WHITE

BN

BROWN

YE

YELL OW

BU

BLUE

RD

RED

BK

BLACK

YEGN

YELLOW GREEN PROTECTIVE EARTH

Indoor Unit

Indoor Unit

Schematic Diagram

Symbol Parts name Symbo l Col o r symbo l

L1 L2 WH

WHITE

4YV YE

YELLOW

EKV RD

RED

L BN

SAT OVERLOAD BN BROWN

COMP

COMPRESSOR

BU

BLUE

PROTECTIVE EARTH

BK

BLACK

YEGN

YELLOW GREEN

AP1 DISPLAY

EVAPORATOR

ELECTRIC BOX

W5

BK

N1

W2 YEGN

W1YEGN

COM-INNER

3

2

OUTDOOR UNIT

N(1)

AP2

L

W3

BN

W4

BU

XT1

G

HEALTH-LHEALTH-N

YEGN

BURD

GG

FAN MOTOR

STEP MOTOR

ROOM TUBE

DISP3 DISP4

00

TEM.SENSOR

TUBE

ROOM

TEM.SENSOR

RT1 RT2

JUMP

L1

L1

COOL PLASMA

GENERATOR

M

M

SWING-UD CN1

NEUTRAL WIRE, LIVE WIRE

4-WAY VALVE

ELETRIC EXPANSION VALVE

REACTOR

8

Outdoor Unit

Schematic Diagram

4YV

RT5

0

0

RT4

0

RT3

OUTROOM

EXHAUST

OUTTUBE

OFAN

E

OVERHEAT

R

E

C

S

U

V

W

CT1,2

AP1

W3YEGN

W10 RD

COMP

W8 YEGN

FAN MOTOR

W5 BU

W6 YE

W7 BK

AC-N1

AC-L1

4V

AC-N2

COMU

EKV

CN1

TEM.SENSOR

OUTROOM

EXHUAST

TEM.SENSOR

TEM.SENSOR

TUBE

W2 BU

W1 BN

W4 BK

G

G

I

N

D

O

O

R

U

N

I

T

W13 YEGN

POWER

N

L

L

N

N(1)

3

2

L2L2L2

L1

L1

G

G

G

W15 BU

W14 BN

W16 WH

W17 RD

G

L4

L4

W23 OGW20 BU

W22 WH

W21 BN

AC-L2 AC-L4AC-N5AC-N3 AC-N4 AC-L2AC-L3

W19 BU W24 RD

W18 YEGN

COMP

M

XT2

3

4

E

2

1

FILTER

C4

C3

2

1

2

1

These circuit diagrams are subject to change without notice, please refer to the one supplied with the unit.

9

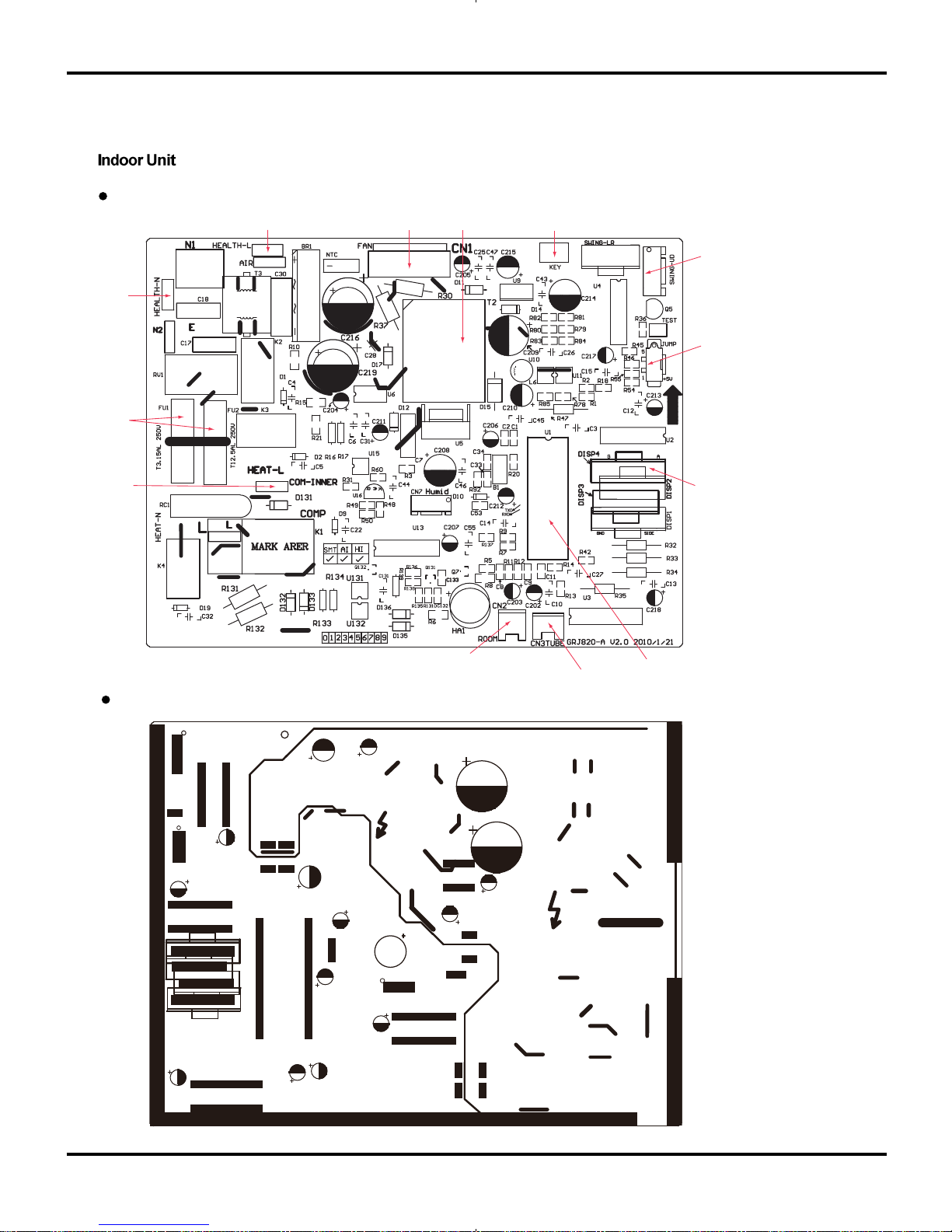

5.3 Printed Circuit Board

TOP VIEW

BOTTOM VIEW

Schematic Diagram

interface of health function live wire

indoor fan interface

high frequency

transformer auto button

indoor ambient temperature sensor

indoor tube temperature sensor

main chip

communication interface

fuse

interface of health function nuetral wire

up & down swing jumper cap

display interface

10

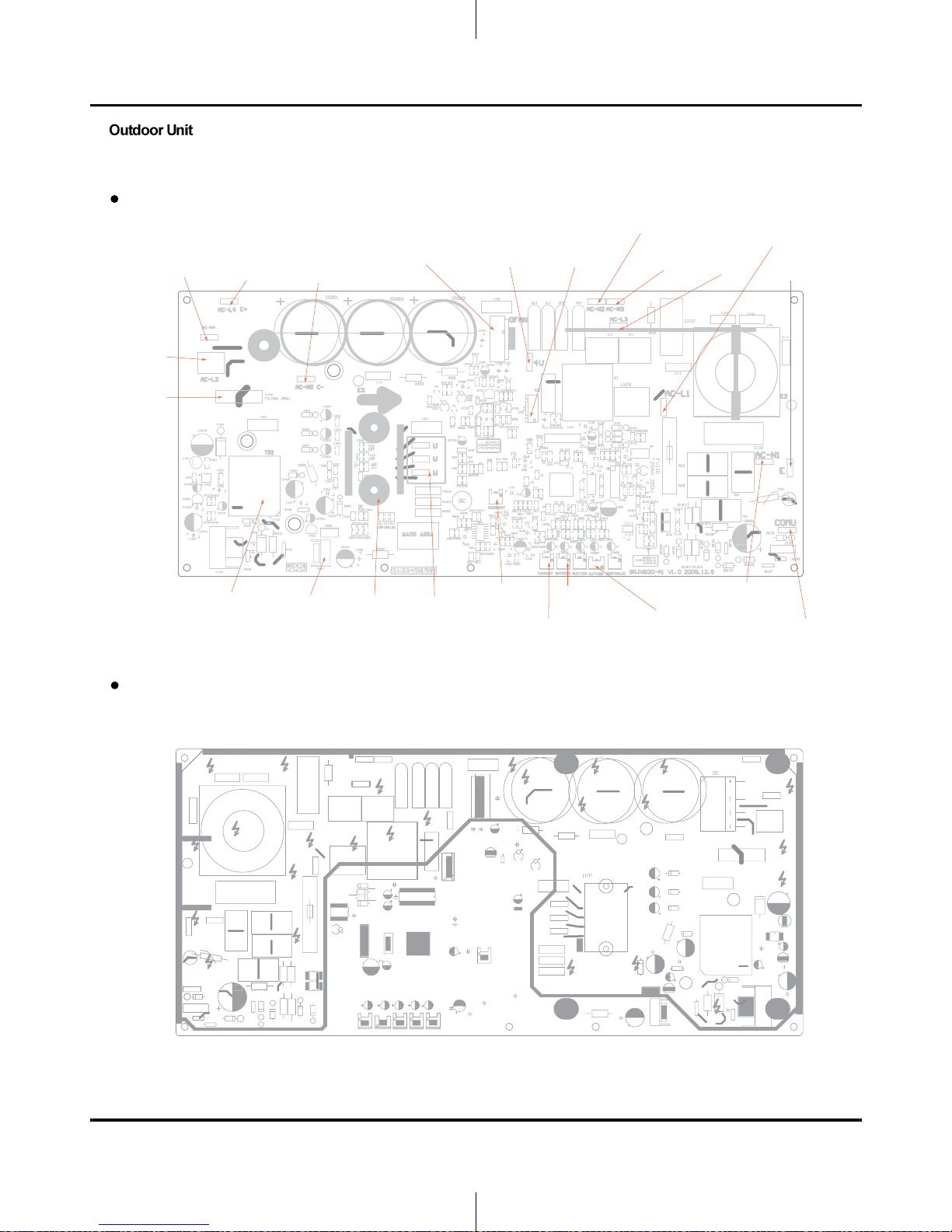

TOP VIEW

BOTTOM VIEW

Models GWH09AB-A3DNA1B/O , GWH12AB-A3DNA1B/O

Schematic Diagram

jumper

neutral wire

big capacitor

positive pole

(brown wire)

big capacitor

negative pole

(blue wire)

fan termina

l

4-way

valve terminal

electri

c

expansion

valve

jumper

neutral wire

jumper

liv

e wire terminal

live wire

earthing wire terminal

4-way valve

neutral wire

terminal

jumper live wire,

connection

terminal

of big capacitor positive

pole and negative

pole(orange

wire)

power switch fus

e

high frequenc

y

transformer

regulator

7805

IPM modula

r

compressor

3-ph

ase terminals

U phase is blue wir

e

V phase is yellow wir

e

W phase is red wire

overload temperature senso

r

outdoor

ambient

temperature

sensor

outdoor

tube

temperature

sensor

temperature

sensor

compressor discharg

e

neutral wire termina

l

communication

wire

terminal connected

to

indoor black

communication

wire

11

6. Function and Control

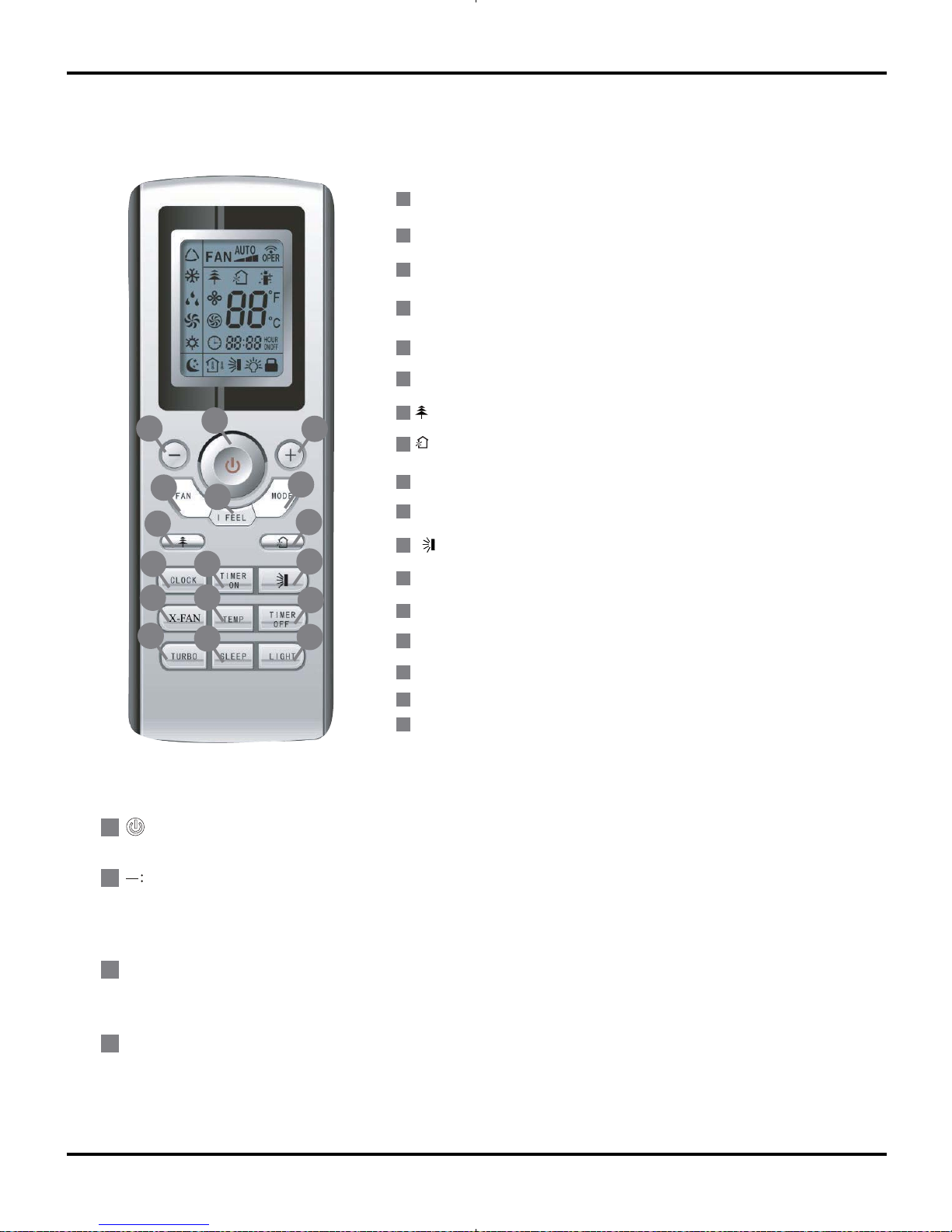

6.1 Remote Control Operations

Function and Control

Timer ON Button

TIMER OFF Button

Clock Button

X-FAN Button

Temperature Displaye Button

TURBO Button

Sleep Mode Button

Light Mode Button

ON/OFF Button

1

7

6

I FEEL Button

MODE Button

5

3

Setpoint Temperature DOWN Button

2

FAN Speed Button

4

11

10

14

9

12

13

15

16

17

8

3

14

9

10

13

16

12

5

4

15

11

8

17

7

2

1

6

+

:

FAN :

1

3

2

4

Press this button, the unit will be turned on, press it once more, the unit will be turned off.

For presetting temperature decreased. Press this button, can set up the temperature,when unit is on . Continuously

press and hold this button for more than 2 seconds,the corresponding contents will be changed rapidly,but in AUTO

mode, set temperature is not adjustable.

.

For presetting temperature increasing. Press this button, the temperature can be set up, continuously press this button

and hold for two seconds, the relative contents can quickly change, but in AUTO mode, set temperature is not adjustable.

Setpoint Temperature UP Button

HEALTH function Button

AIR function Button

Press this button, Auto, Low, Middle, High speed can be circularly selected. After powered on, Auto fan speed is default.

Under Dehumidify mode, Low fan speed only can be set up.

(

X-FAN is the alternative expression of

BLOW for the purpose of understanding.)

12

Function and Control

CLOCK

:

9

8

7

I FEEL :

5

MODE

:

6

Press this button, I FEEL On and I FEEL Off can be selected. When turn on I FEEL function.

The unit will adjust temperature automatically according to the sensed temperature.

TIMER ON

:

11

10

X-FAN :

12

OFF

This is an universal use remote controller. If remote controller sends the following three kinds of status , or , the swing

status of mainunit will be which indicates the guide louver swings upand down between that all five positions:

:

Press this button, Auto, Cool,Dry, Fan, Heat mode can be selected circularly. Auto mode is default while power on. Under Auto

mode, the temperature will not be displayed; In this mode, the unit will automatically select the suitable operation mode in accordance with the room temperature to make the room more comfortable for you.

AUTO

COOL

DRY

FAN

Note:Only for models with heating function.

HEAT

Pressthisbutton to setHEALTHfunction ON or OFF. After the unit is turned on, it defaults to HEALTH function ON.

Press thisbutton to select AIR function ON or OFF.

Press this button, the clock can be set up,signal blink and display.Within 5 seconds, the value can be adjusted by pressing

+ or - button, if continuously press this button for 2 seconds above,in every 0.5 seconds, the value on ten place of Minute will

be increased 1. During blinking, repress the Clock button, signal will be constantly displayed and it denotes the setting succ-

eeded. After powered on, 12:00 is defaulted to display and signal will be displayed. If there is signal be displayed that

denotes the current time value is Clock value, otherwise is Timer value.

Timer On setting: Signal “ON” will blink and display, signal will conceal, the numerical section will become the timer on setting

status. During 5 seconds blink,by pressing + or - button to adjust the time value of numerical section, every press of that button, the value will be increased or decreased 1 minute. Hold pressing + or -button, 2 seconds later, it quickly change, the way

of change is:During the initial 2.5 seconds, ten numbers change in the one place of minute, thenthe one place is constant, ten

numbers change in the tens place of minute at 2.5 seconds speed and carry. During 5s blink, press the Timer button, the timer

setting succeeds. The Timer On has been set up, repress the timer On button, the Timer On will be canceled. Before setting the

Timer, please adjust the Clock to the current actual time.

Press this button, to set up swing angle, which circularly changes as below:

When the guide louver start to swing up and down, if turn off the Swing, the air guide louver will stop at current position.

Pressing X -FAN button in COOL or DRY mode,the icon is displayed and the indoor fan will continue operation for 10 minutes in

order to dry the indoor unit even you have turned off the unit.After energization, X-FAN OFF is defaulted. X-FAN is not available

in AUTO,FAN or HEAT mode.

Auto

Low speed

Medium speed

High speed

(The function is not for the models mentioned in the manual.)

(The function is not for the models mentioned in the manual.)

13

Function and Control

ƾ

●

●

●

●

●

When replacing the batteries, do not use used or different types of batteries,otheerwise,

If the remote controller will not be used for a long time, please

it may cause malfunction.

remove batteries

to prevent batteries from leaking.

The operation should be performed in its receiving range.

It should be kept 1m away from the TV set or stereo sound sets.

If the remote controller does not operate normally, please take the

batteries out

and replace them after 30 seconds. If it still can't operate properly, replace the batteries.

Notes:

Sketch map for

replacing batteries

18

19

SLEEP:

LIGHT:

16

17

Press this button, Sleep On and Sleep Off can be selected. After Sleep function set up, the unit will automatically select

the suitable operation mode to maintain the most comfortable temperature for you. This function is available in COOL ,

HEAT or DRY mode

TURBO:

15

Press this button to activate / deactivate the Turbo function which enables the unit to reach the preset temperature in

shortest time. Such as in COOL mode, the unit will blow strong cooling air at super high fan speed. In HEAT mode, the

unit will blow strong heating air at super high fan speed.

(This function is not applicable for some models)

Press this button to select LIGHT on or off in the displayer. When the LIGHT on is set,the icon will be displayed and

the indicator light in the displayer will be on. When the LIGHT off is set, the icon will be displayed and the indicator

light in thedisplayer will be off.

"+" and "–"button about lock:

Press "+ " and "-" buttons simultaneously to lock or unlock the keypad. If the remote controller is locked, is displayed .

In this case, pressing any button , blinks three times.

"MODE" and " - " buttons About switch between fahrenheit and cenrigrade:

At unit OFF, press "MODE" and " - " buttons simultaneously to switch between ℉ and ℃.

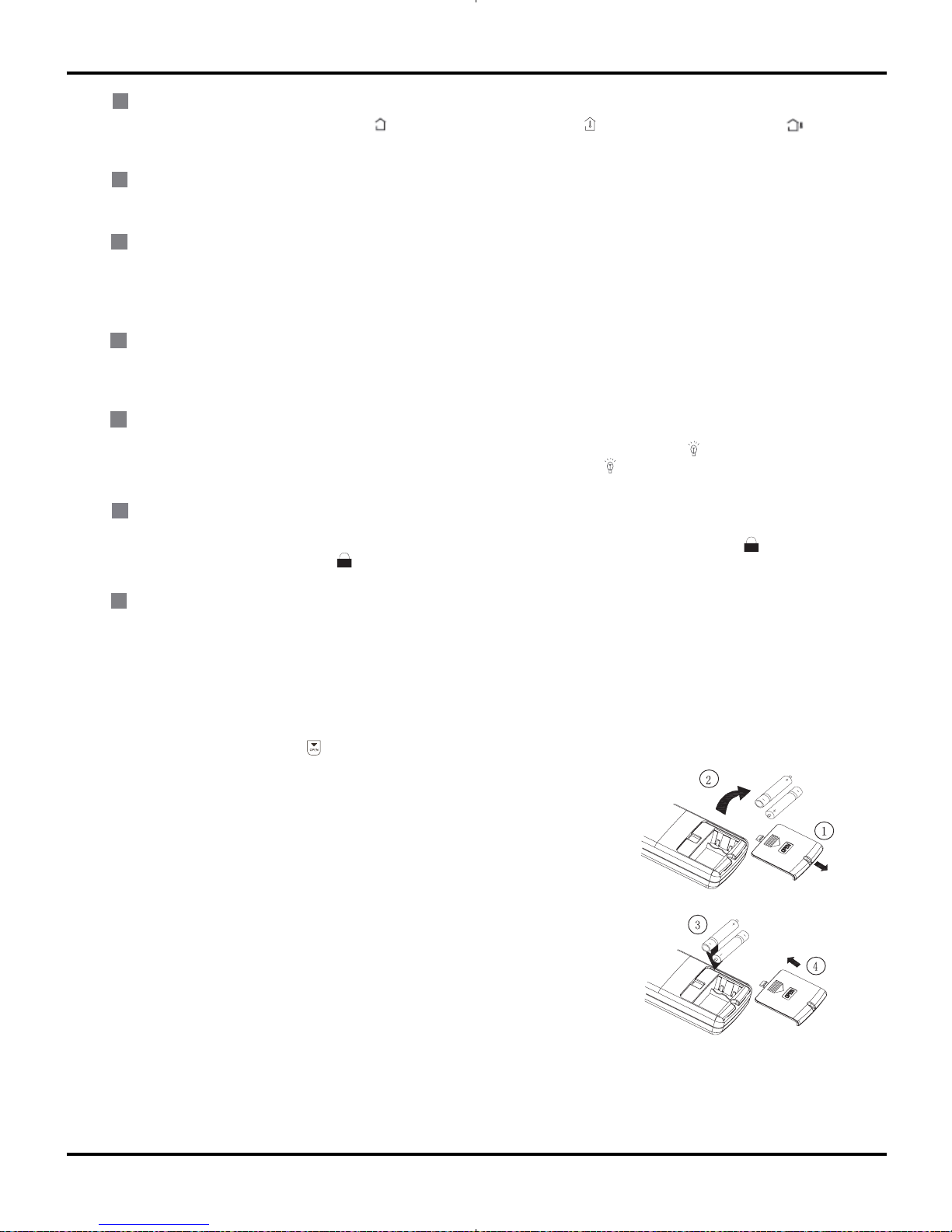

1.Slightly to press the place with , along the arrowhead direction to push the back

cover of wireless remote control. (As show in figure)

2. Take out the

used batteries. (As show in figure)

3. Insert two new AAA1.5V dry batteries, and pay attention to the polarity.

(As show in figure)

4. Reinstall the battery cover plate. (As show in figure)

TIMER OFF :

14

13

TEMP :

Once press this key to enter into TIMER OFF setup, in which case the TIMER OFF icon will blink.The method of setting

is the same as TIMER ON.

Press this button, could select displaying (the indoor setting temperature) , (indoor ambient temperature )or (

outdoor am-bient temperature) .The unit defaults not to display the icon. During operation of TEMP button, the set temperature is always displayed

6.2 Changing batteries and notices

14

6.3 Description of Each Control Operation

Function and Control

1. Temperature Parameters

Indoor preset temperature (Tpreset)

Indoor ambient temperature (T

amb.)

2. Basic Functions

Once energized, in no case should the compressor be restarted within less than 3 minutes. In the situation that memory function

is available, for the first energization, if the compressor is at stop before de-energization, the compressor will be started without

a 3-minute lag; if the compressor is in operation before de-energization, the compressor will be started with a 3-minute lag; and

once started, the compressor will not be stopped within 6 minutes regardless of changes in room temperature;

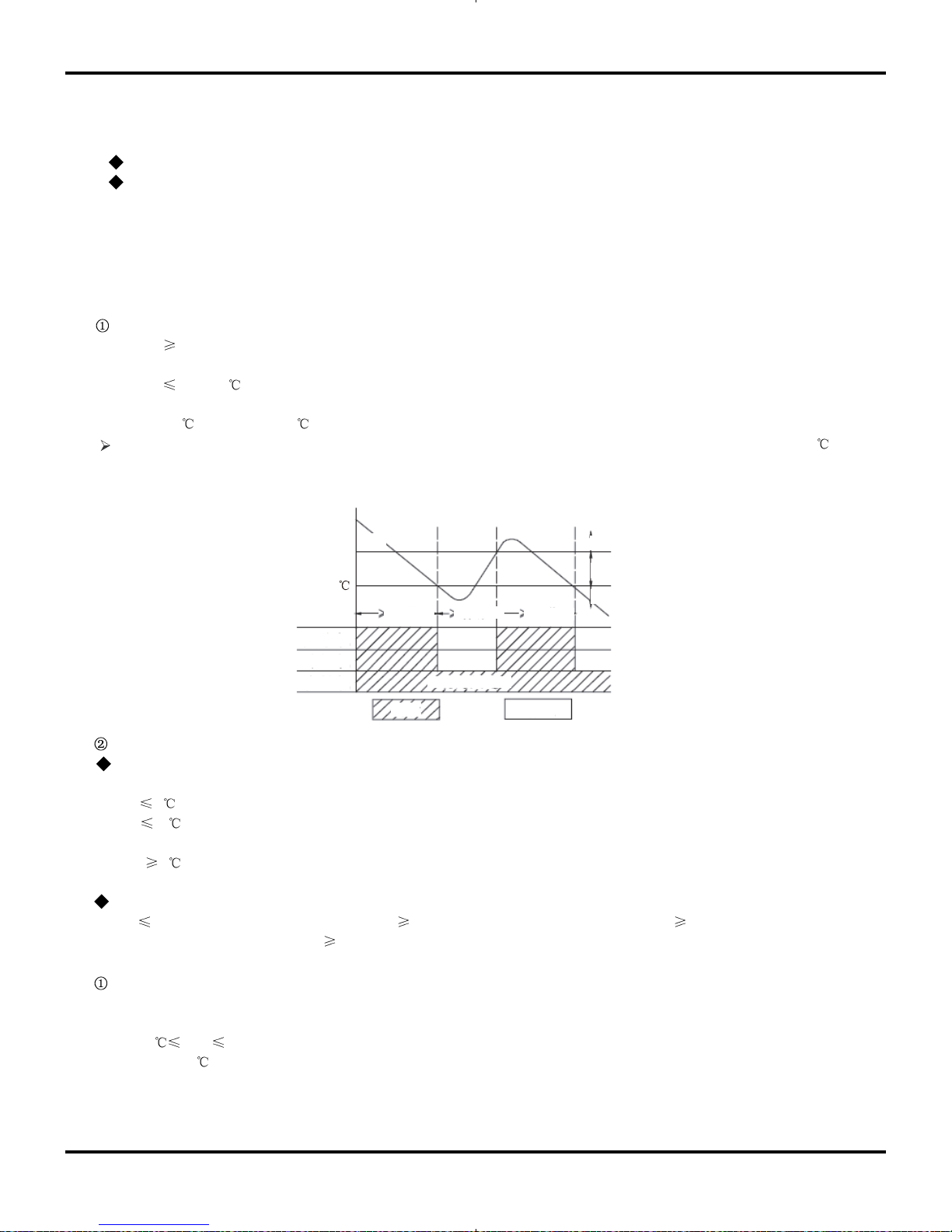

(1) Cooling Mode

Working conditions and process of cooling

When T

amb Tpreset, the unit will enter cooling operation, in which case the indoor fan, the outdoor fan and the compressor will

work and the indoor fan will run at preset speed.

When Tamb Tpreset -2 , the compressor will stop, the outdoor fan will stop with a time lag of 30s, and the indoor fan will run at

preset speed.

When Tpreset -2 < Tamb.< Tpreset +1 , the unit will remain at its previous state.

Under this mode, the four-way valve will be de-energized and temperature can be set within a range from 16 to 30

.

If the compressor is shut down for some reason, the indoor fan and the swing device will operate at original state.

Start cooling

Stop cooling

Compresso

r

Original working state

Run

Stop

Outdoor fan

Indoor fan

T

preset

T

reset

-2

T

amb

Preset fan speed

6 minutes

6 minutes

3 minutes

Protection

Freeze protection

Under cooling and dehumidifying mode, 6 minutes after the compressor is started:

If T

evap 2 , the compressor will operate at reduced frequency.

If T

evap -1 is detected for durative 3 minutes, the compressor will stop, and after 30 seconds, the outdoor fan will stop;

and under cooling mode, the indoor fan and the swing motor will remain at the original state.

If T evap. 6 and the compressor has remained at OFF for at least 3 minutes, the compressor will resume its original

operation state.

Total current up and frequency down protection

If Itotal

A, frequency rise will be allowed; if Itotal B, frequency rise will not be allowed; ifItotal C, the compressor will

run at reduced frequency; and if Itotal

D, the compressor will stop and the outdoor fan will stop with a time lag of 30s.

(2) Dehumidifying Mode

Working conditions and process of dehumidifying

If T

amb>Tpreset, the unit will enter cooling and dehumidifying mode, in which case the compressor and the outdoor fan will

operate and the indoor fan will run at low speed.

If Tpreset -2 Tamb Tpreset, the compressor remains at its original operation state.

If T

amb.< Tpreset -2 , the compressor will stop, the outdoor fan will stop with a time lag of 30s, and the indoor fan will

operate at low speed.

15

Function and Control

Protection

Protection is the same as that under the cooling mode.

(3) Heating Mode

Working conditions and process of heating

If T

amb. Tpreset +2 , the unit enters heating mode, in which case the four-way valve, the compressor and the outdoor fan will

operate simultaneously, and the indoor fan will run at preset speed in the condition of preset cold air prevention.

If T amb. Tpreset +5 , the compressor will stop, the outdoor fan will stop with a time lag of 30s, and the indoor fan will stop after 60-

second blow at low speed

If Tpreset +2 <T amb.< Tpreset +5 , the unit will maintain its original operating status.

Under this mode, the four-way valve is energized and temperature can be set within a range of 16 - 30

. The operating

symbol, the heating symbol and preset temperature are revealed on the display.

Condition and process of defrost

When duration of successive heating operation is more than 45 minutes, or accumulated heating time more than 90 minutes, and

one of the following conditions is reached, the unit will enter the defrost mode after 3 minutes.

a. T

outdoor amb. A , Toutdoor tube W ;

b. A

Toutdoor amb. <B , Toutdoor tube X ;

c. B

Toutdoor amb. <C , Toutdoor tube Y ;

d. T

outdoor amb.<C , Toutdoor tube Z

At that time, the indoor fan stops and the compressor stops, and after 30 seconds the outer fan will stop, and then after 30

seconds, the four-way valve will stop. After 30 seconds, the compressor is initiated for raising the frequency to defrost frequency.

When the compressor has operated under defrost mode for 7.5 minutes, or Touter tube E, the compressor will be converted to 53Hz

operation. After 30 seconds, the compressor will stop. And after another 30 seconds, the four-way valve will be opened, and after

60 seconds, the compressor and the outer fan will be started, the indoor fan will run under preset cold air prevention conditions,

and H1 will be displayed at temperature display area on the display panel. Defrost frequency is 70Hz.

3.Protection

Cold air prevention

The unit is started under heating mode (the compressor is ON):

In the case of T indoor amb. <24 : if T tube 40 and the indoor fan is at stop state, the indoor fan will begin to run at low speed with

a time lag of 2 minutes. Within 2 minutes, if T

tube>40 , the indoor fan also will run at low speed; and after 1-minute operation at

low speed, the indoor fan will be converted to operation at preset speed. Within 1-minute low speed operation or 2-minute non-

operation, if T tube>42 , the fan will run at present speed.

In the case of T indoor amb. 24 : if T tube 42 , the indoor fan will run at low speed, and after one minute, the indoor fan will be

converted to preset speed. Within one-minute low speed operation, if T

tube>42 , the indoor fan will be converted to preset speed.

Note: T

indoor amb. indicated in and refers to, under initially heating mode, the indoor ambient temperature before the

command to start the compressor is performed according to the program, or after the unit is withdrawn from defrost, the

indoor ambient temperature before the defrost symbol is cleared.

Total current up and frequency down protection

If the total current Itotal W, frequency rise will be allowed; if Itotal X, frequency rise will not be allowed; if Itotal Y, the compressor

will run at reduced frequency; and if I

total Z, the compressor will stop and the outdoor fan will stop with a time lag of 30s.

(4) Fan Mode

Under the mode, the indoor fan will run at preset speed and the compressor, the outdoor fan, the four-way valve and the electric

heater will stop.

Under the mode, temperature can be set within a range of 16 - 30 .

(5) AUTO Mode

Working conditions and process of AUTO mode

a. When Tamb. ≥26℃, the unit will run at cooling mode and the implied set temperature at this moment is 25℃.

b. When Tamb. ≤22℃, the cooling and heating unit will run at heating mode and the implied set temperature at this

moment is 20℃; cooling only unit will run at fan mode and the set temperature displayed is 25℃.

c. When 23℃≤Tamb. ≤25℃, the unit will keep the previous running mode; if it is first energized, it will run at fan mode.

d. After running at auto mode, the frequency of compressor in cooling operation is the same as that in cooling mode;

the frequency of compressor in heating operation is the same as that in heating mode.

Loading...

Loading...