Gree GPE12AF-K3NNA7A, GPE12AF-K3NNA7D, GPC12AF-K3NNA7D, GPC12AF-K3NNA7A, GPH12AF-K3NNA7E Service Manual

...

Service Manual

GREE ELECTRIC APPLIANCES,INC.OF ZHUHAI

Change for Life

Service Manual

Models: GPC12AF-K3NNA7A

GPC12AF-K3NNA7D

GPE12AF-K3NNA7A

GPE12AF-K3NNA7D

GPH12AF-K3NNA7A

GPH12AF-K3NNA7D

GPH12AF-K3NNA7E

(Refrigerant R410A)

Service Manual

Table of Contents

Table of Contents

Part

Ⅰ

: Technical Information

.......................................................................1

1. Summary

......................................................................................................................1

2. Specications

..........................................................................................................2

3. Outline Dimension Diagram

........................................................................8

4. Refrigerant System Diagram

......................................................................9

5. Electrical Part

.........................................................................................................10

5.1 Wiring Diagram ...............................................................................................................10

5.2 PCB Printed Diagram .....................................................................................................12

6. Function and Control

......................................................................................14

6.1 Remote Controller Introduction ......................................................................................14

6.2 Introduction of Basic Mode Function ..............................................................................18

Part

Ⅱ

: Maintenance

..........................................................................................20

7. Notes Maintenance

...........................................................................................20

8. Installation

................................................................................................................23

9. Maintenance

............................................................................................................32

9.1 Error Code ......................................................................................................................32

9.2 Malfunction Detection Flowchart ....................................................................................34

9.3 Maintenance Method for Common Malfunction ..............................................................39

10. Exploded View and Parts List

..............................................................41

11. Removal Procedure

.......................................................................................52

Appendix:

........................................................................................................................58

Appendix 1: Reference Sheet of Celsius and Fahrenheit ....................................................58

Appendix 2: Resistance Table of Ambient Temperature Sensor...........................................59

Appendix 3: Resistance Value Table of Humidity Sensor ..................................................... 62

1

Technical Information

Service Manual

GPC12AF-K3NNA7A

GPC12AF-K3NNA7D

GPE12AF-K3NNA7A

GPE12AF-K3NNA7D

GPH12AF-K3NNA7A

GPH12AF-K3NNA7D

GPH12AF-K3NNA7E

YB1F2(X-FAN)

1. Summary

Part

Ⅰ

: Technical Information

FAN

AUTO

OPER

HEALTH

AIR

FILTER

TURBO

ON/OFF

X-FAN

HOUR

HUMIDITY

ON/OFF

MODE

FAN

X-FAN

TURBO

TEMP

TIMER

SLEEP

LIGHT

Remote Controller

Models:

2

Technical Information

Service Manual

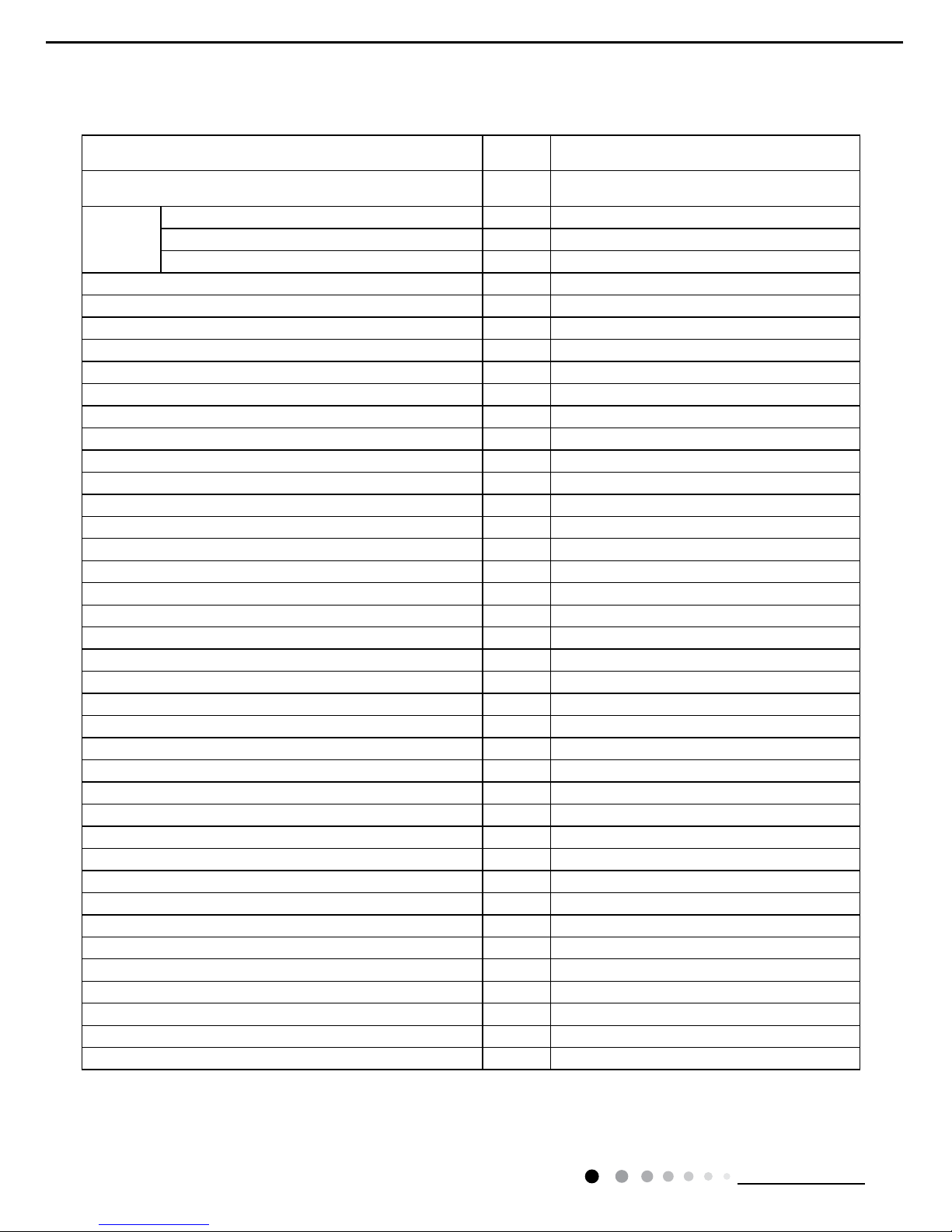

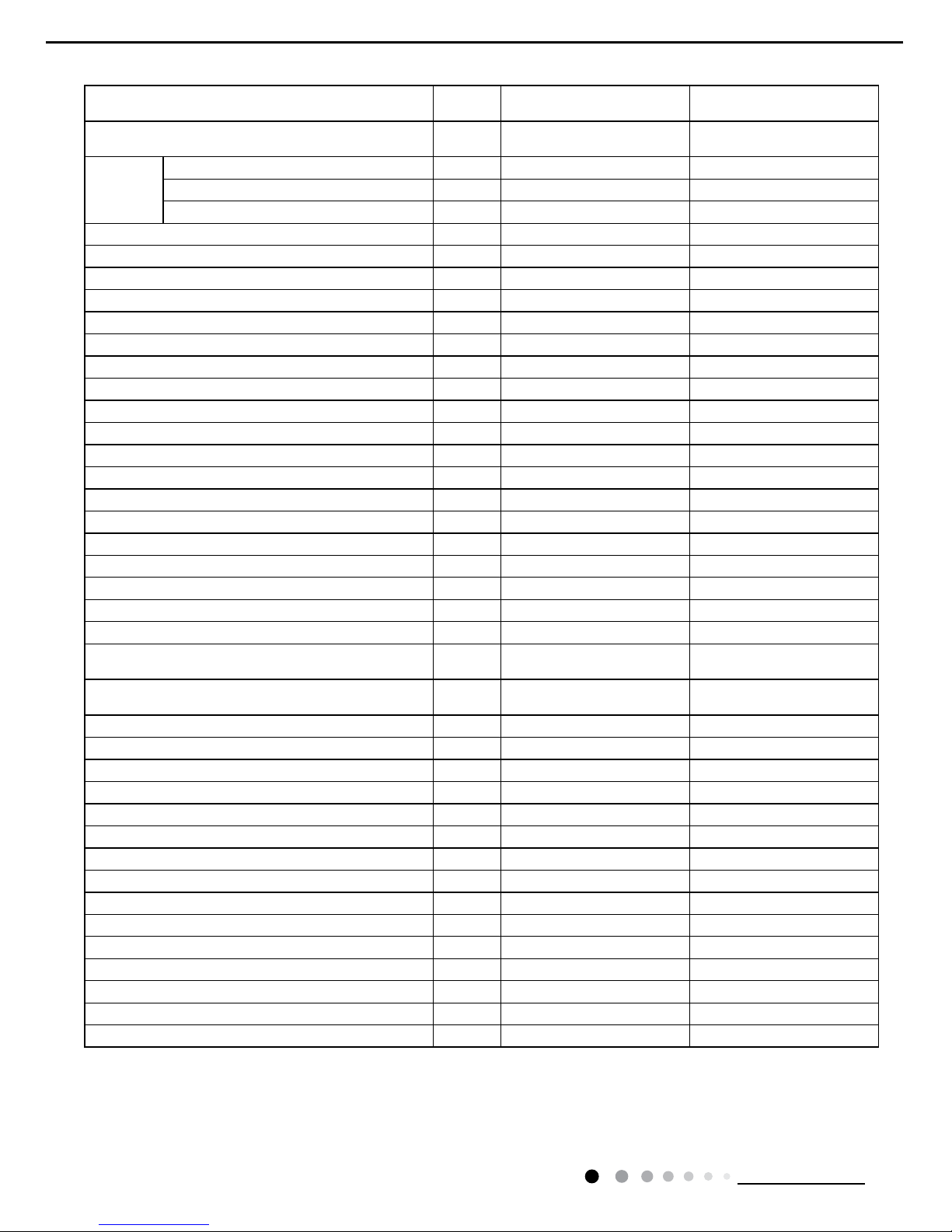

2. Specications

Model

1.GPC12AF-K3NNA7A

2.GPC12AF-K3NNA7D

Product Code

1.CK01001212

2.CK010021500 CK010021501

Power

Supply

Rated Voltage V~ 220-240

Rated Frequency Hz 50

Phases 1

Cooling Capacity W 3500

Heating Capacity W /

Cooling Power Input W 1340

Heating Power Input W /

Cooling Power Current A 7.50

Heating Power Current A /

Rated Input W 1550

Rated Current A 6.7

Input of Heater W /

Air Flow Volume(H/M/L) m

3

/h 450/420/390

Dehumidifying Volume L/h 1.5

EER W/W 2.61

COP W/W /

SEER W/W /

HSPF W/W /

Application Area m

2

15-22

Climate Type T1

Isolation I

Moisture Protection IPX0

Permissible Excessive Operating Pressure for the Discharge Side MPa 3.8

Permissible Excessive Operating Pressure for the Suction Side MPa 1.2

Throttling Method Capillary

Defrosting Method /

Fuse A 3.15

Operation Temp

℃

16~30

Ambient Temp (Cooling)

℃

10~35

Ambient Temp (Heating)

℃

/

Sound Pressure Level (H/M/L) dB (A) 58/56/52

Sound Power Level (H/M/L) dB (A) 68/66/62

Dimension (WXHXD) mm 500X840X460

Dimension of Carton Box (LXWXH) mm 581X536X862

Dimension of Package (LXWXH) mm 584X539X877

Net Weight kg 45

Gross Weight kg 52.5

Refrigerant R410A

Refrigerant Charge kg 0.8

3

Technical Information

Service Manual

The above data is subject to change without notice. Please refer to the nameplate of the unit.

Compressor

Compressor Manufacturer/Trademark Zhuhai Landa Compressor Co., Ltd/GREE

Compressor Model QXA-C133B030gA

Compressor Oil RB68EP/FVC68D

Compressor Type Rotary

L.R.A. A 32

Compressor RLA A 5.05

Compressor Power Input W 1130

Overload Protector build in

Evaporator

Fan Type Centrifugal

Diameter Length(DXL) mm Φ218X109

Fan Motor Speed(H/ML) r/min 800/700/600

Output of Fan Motor W 23

Fan Motor RLA A 0.1

Fan Motor Capacitor μF 2

Form Aluminum Fin-copper Tube

Pipe Diameter mm Φ7

Row-n Gap mm 3-1.6

Coil Length (LXDXW) mm 363X38.1X285

Swing Motor Model MP28GA

Output of Swing Motor W 2

Condenser

Fan Type Centrifugal

Fan Diameter mm 218X109

Form Aluminum Fin-copper Tube

Pipe Diameter mm Φ7

Rows-n Gap mm 4-1.6

Coil Length (LXDXW) mm 350X50.8X350

Fan Motor Speed rpm 1160

Output of Fan Motor W 65

Fan Motor RLA A 0.28

Fan Motor Capacitor μF 3

4

Technical Information

Service Manual

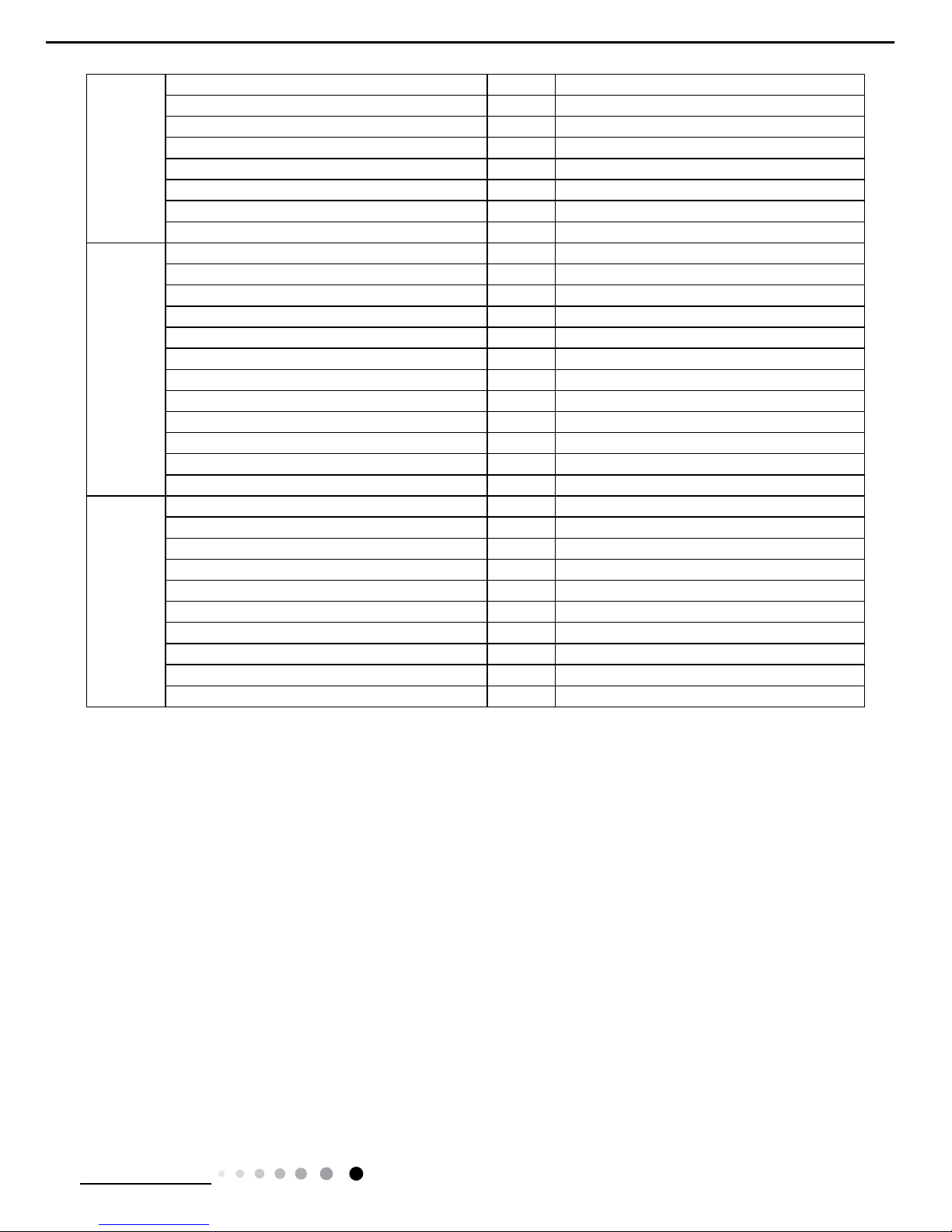

Model

1.GPE12AF-K3NNA7A

2.GPE12AF-K3NNA7D

GPE12AF-K3NNA7D

Product Code

1.CK01001452

2.CK010021600

CK010021601

Power

Supply

Rated Voltage V~ 220-240 220-240

Rated Frequency Hz 50 50

Phases 1 1

Cooling Capacity W 3500 3500

Heating Capacity W 2000 2000

Cooling Power Input W 1340 1340

Heating Power Input W 2100 2100

Cooling Power Current A 7.50 5.82

Heating Power Current A 9.00 9.13

Rated Input W 2200 2200

Rated Current A 11.00 9.57

Input of Heater W 1200 1200X2

Air Flow Volume(H/M/L) m

3

/h 450/420/390 450/420/390

Dehumidifying Volume L/h 1.5 1.5

EER W/W 2.61 2.61

COP W/W 0.95 0.95

SEER W/W / /

HSPF W/W / /

Application Area m

2

15-22 15-22

Climate Type T1 T1

Isolation I I

Moisture Protection IPX0 IPX0

Permissible Excessive Operating

Pressure for the Discharge Side

MPa 3.8 3.8

Permissible Excessive Operating

Pressure for the Suction Side

MPa 1.2 1.2

Throttling Method Capillary Capillary

Defrosting Method / /

Fuse A 3.15 3.15

Operation Temp

℃

16~30 16~30

Ambient Temp (Cooling)

℃

10~35 10~35

Ambient Temp (Heating)

℃

/ /

Sound Pressure Level (H/M/L) dB (A) 58/56/52 58/56/54

Sound Power Level (H/M/L) dB (A) 68/66/62 65/63/61

Dimension (WXHXD) mm 500/840/460 500X840X460

Dimension of Carton Box (LXWXH) mm 581X536X862 581X536X862

Dimension of Package (LXWXH) mm 584X539X877 584X539X877

Net Weight kg 45 45

Gross Weight kg 52.5 52.5

Refrigerant R410A R410A

Refrigerant Charge kg 0.8 0.8

5

Technical Information

Service Manual

The above data is subject to change without notice. Please refer to the nameplate of the unit.

Compressor

Compressor Manufacturer/Trademark

Zhuhai Landa Compressor Co., Ltd/

GREE

Zhuhai Landa Compressor Co., Ltd/

GREE

Compressor Model QXA-C133B030gA QXA-C133B030gA

Compressor Oil RB68EP/FVC68D RB68EP/FVC68D

Compressor Type Rotary Rotary

L.R.A. A 32.00 25

Compressor RLA A 5.05 5.05

Compressor Power Input W 1130 1120

Overload Protector build in HPA-525/UP3-22

Evaporator

Fan Type Centrifugal Centrifugal

Diameter Length(DXL) mm Φ218X109 Φ218X109

Fan Motor Speed(H/ML) r/min 800/700/600 800/700/600

Output of Fan Motor W 23 23

Fan Motor RLA A 0.10 0.25

Fan Motor Capacitor μF 2 2

Form Aluminum Fin-copper Tube Aluminum Fin-copper Tube

Pipe Diameter mm Φ7 Φ7

Row-n Gap mm 3-1.6 3-1.6

Coil Length (LXDXW) mm 363X38.1X285 363X38.1X285

Swing Motor Model MP28GA MP28GA

Output of Swing Motor W 2 2

Condenser

Fan Type Centrifugal Centrifugal

Fan Diameter mm 218X109 218

Form Aluminum Fin-copper Tube Aluminum Fin-copper Tube

Pipe Diameter mm Φ7 Φ7

Rows-n Gap mm 4-1.6 4-1.6

Coil Length (LXDXW) mm 350X50.8X350 324X25.4X350

Fan Motor Speed rpm 1160 1160 / 910

Output of Fan Motor W 65 65

Fan Motor RLA A 0.28 0.63

Fan Motor Capacitor μF 3 2

6

Technical Information

Service Manual

Model

GPH12AF-K3NNA7A

GPH12AF-K3NNA7D

GPH12AF-K3NNA7E

Product Code

CK01001491/CK01001492

CK010021700

CK010024400

Power

Supply

Rated Voltage V~ 220-240 220-240

Rated Frequency Hz 50 50

Phases 1 1

Cooling Capacity W 3500 3520

Heating Capacity W 3500 3520

Cooling Power Input W 1340 1345

Heating Power Input W 1200 1210

Cooling Power Current A 6.22 6.11

Heating Power Current A 5.57 5.19

Rated Input W 1550 1550

Rated Current A 7.20 7.2

Input of Heater W / /

Air Flow Volume(H/M/L) m

3

/h 450/420/390 450/420/390

Dehumidifying Volume L/h 1 1.5

EER W/W 2.61 2.62

COP W/W 2.92 2.91

SEER W/W / /

HSPF W/W / /

Application Area m

2

16-24 15-22

Climate Type T1 T1

Isolation I I

Moisture Protection IPX0 IPX0

Permissible Excessive Operating

Pressure for the Discharge Side

MPa 3.8 3.8

Permissible Excessive Operating

Pressure for the Suction Side

MPa 1 1.1

Throttling Method Capillary Capillary

Defrosting Method Auto Automatic Defrosting

Fuse A 3.15 3.15

Operation Temp

℃

16~30 16~30

Ambient Temp (Cooling)

℃

18~43 16~35

Ambient Temp (Heating)

℃

5~24 10~27

Sound Pressure Level (H/M/L) dB (A) 53/51/48 53/51/49

Sound Power Level (H/M/L) dB (A) 63/61/58 65/63/61

Dimension (WXHXD) mm 500X840X460 500X840X460

Dimension of Carton Box (LXWXH) mm 581X536X862 581X536X862

Dimension of Package (LXWXH) mm 584X539X877 584X539X877

Net Weight kg 47 47

Gross Weight kg 55 55

Refrigerant R410A R410A

Refrigerant Charge kg 0.8 0.86

7

Technical Information

Service Manual

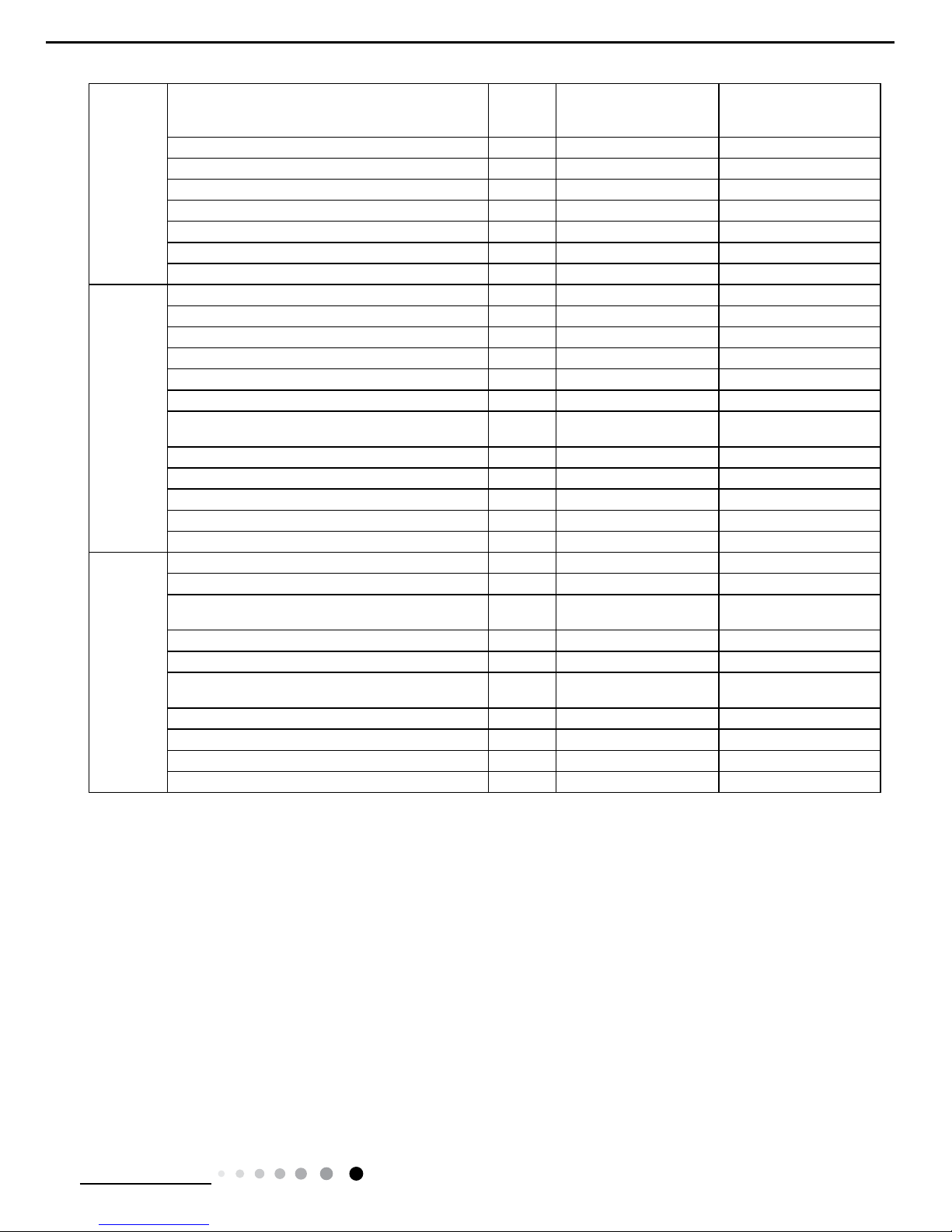

Compressor

Compressor Manufacturer/Trademark

Zhuhai Landa Compressor

Co., Ltd/GREE

ZHUHAI LANDA

COMPRESSOR CO.,

LTD/GREE

Compressor Model QXA-C133B030gA QXA-C136B030A

Compressor Oil RB68EP/FVC68D RB68EP/FVC68D

Compressor Type Rotary Rotary

L.R.A. A 32.00 27

Compressor RLA A 5.00 5.1

Compressor Power Input W 1130 1115

Overload Protector build in UP3-02

Evaporator

Fan Type Centrifugal Centrifugal

Diameter Length(DXL) mm Φ218X109 Φ218X109

Fan Motor Speed(H/ML) r/min 800/700/610 800/700/610

Output of Fan Motor W 23 23

Fan Motor RLA A 0.10 0.25

Fan Motor Capacitor μF 2 2

Form

Aluminum Fin-copper

Tube

Aluminum Fin-copper

Tube

Pipe Diameter mm Φ7 Φ7

Row-n Gap mm 3-1.6 3-1.6

Coil Length (LXDXW) mm 363X38.1X285 363X38.1X285

Swing Motor Model MP28GA MP28GA

Output of Swing Motor W 2 2

Condenser

Fan Type Centrifugal Centrifugal

Fan Diameter mm 218 218

Form

Aluminum Fin-copper

Tube

Aluminum Fin-copper

Tube

Pipe Diameter mm Φ7 Φ7

Rows-n Gap mm 4-1.6 4-1.6

Coil Length (LXDXW) mm 350X50.8X350

350X25.4X381

350X25.4X324

Fan Motor Speed rpm 1160/910 1160/910

Output of Fan Motor W 65 65

Fan Motor RLA A 0.28 0.63

Fan Motor Capacitor μF 3 3

The above data is subject to change without notice. Please refer to the nameplate of the unit.

8

Technical Information

Service Manual

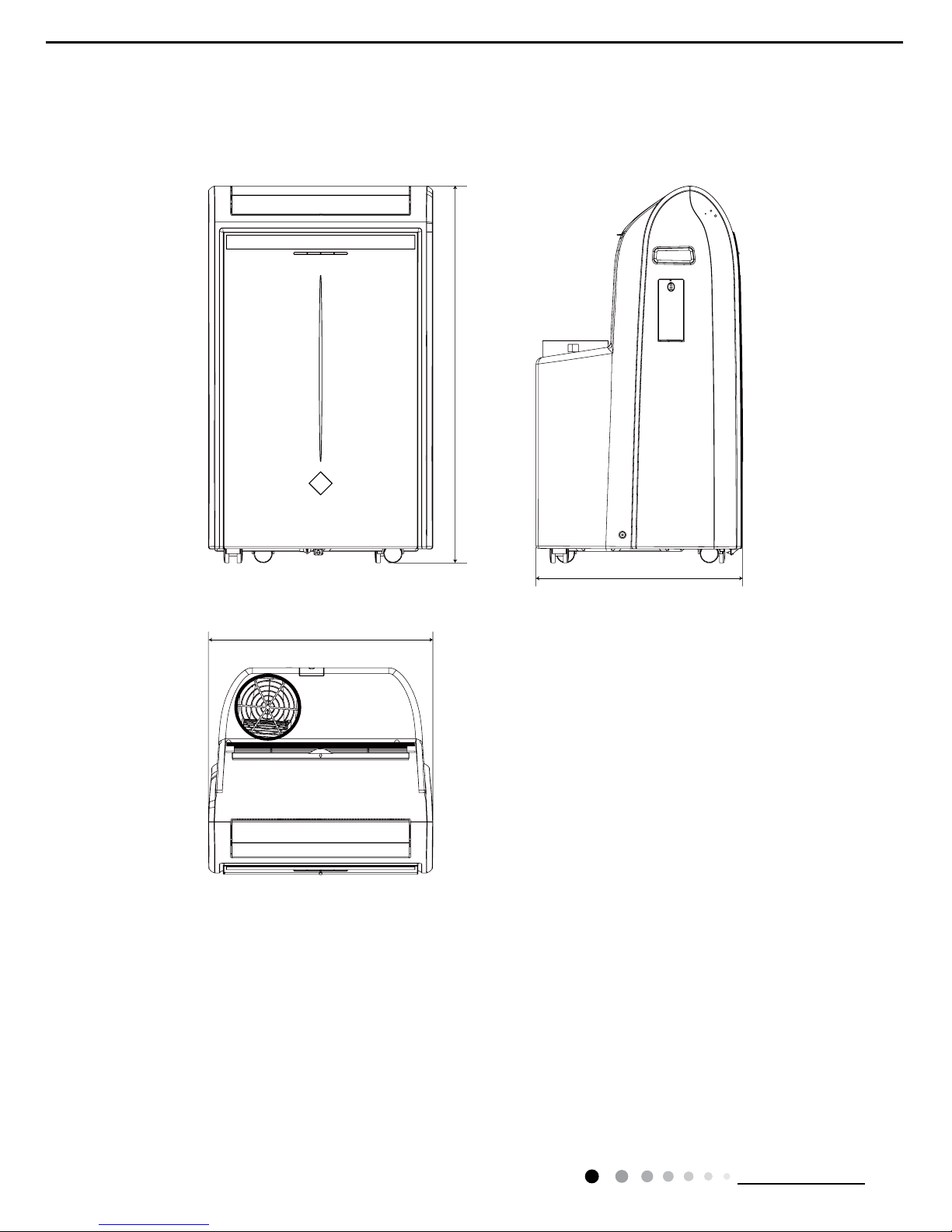

3. Outline Dimension Diagram

460

500

840

Unit: mm

9

Technical Information

Service Manual

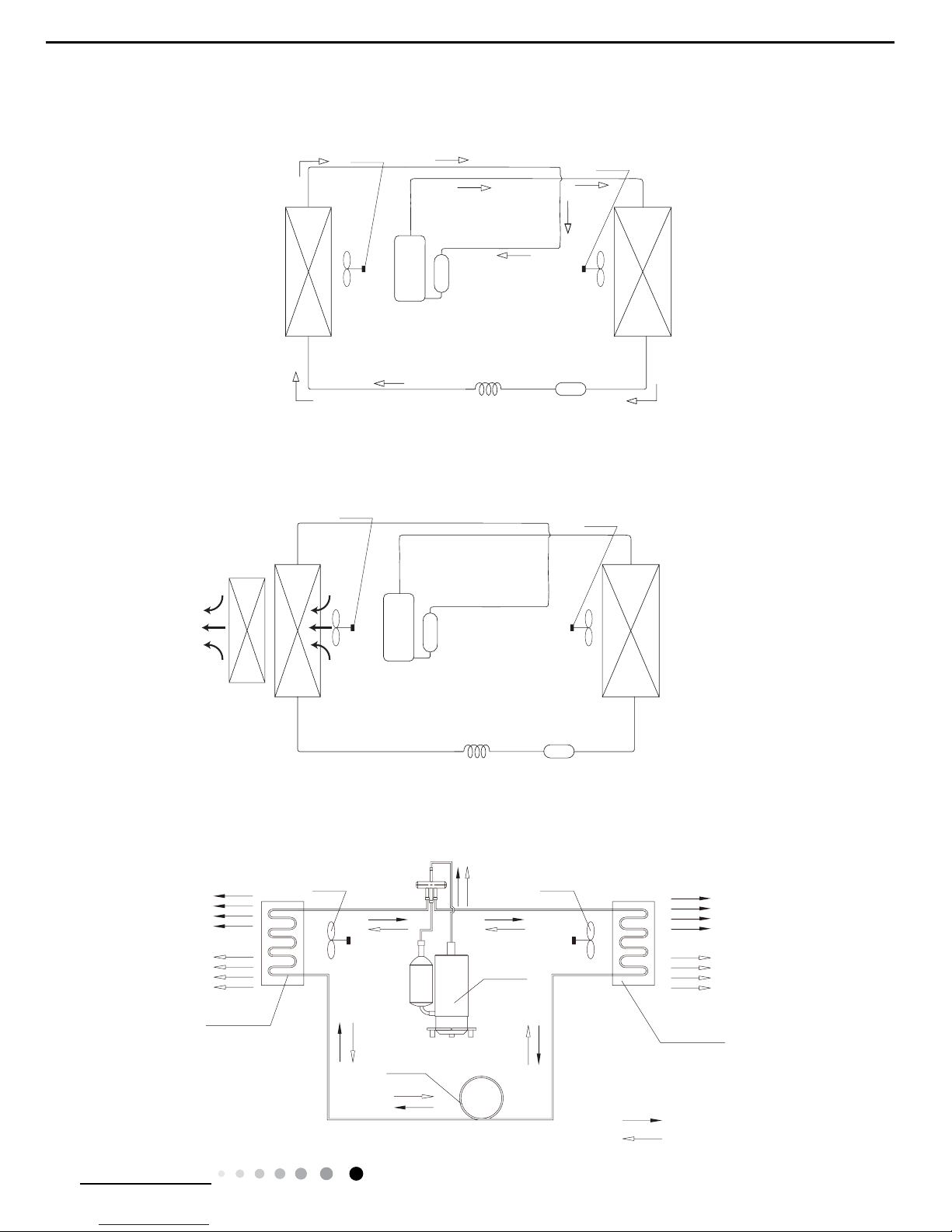

4. Refrigerant System Diagram

OUTDOOR COILS

HOT DISCHARGED AI

R

COOLED AIR

COMPRESSOR

CENTRIFUGAL FAN

CENTRIFUGAL FAN

CAPILLARY

REFRIGERANT FLOW DIRECTION

NOTES:

COOLING MODE

HEATING MODE

HOTAIR

COOLED AIR

INDOOR COILS

GPC12AF-K3NNA7A GPC12AF-K3NNA7D(CK010021500 CK010021501)

GPH12AF-K3NNA7A GPH12AF-K3NNA7D GPH12AF-K3NNA7E

GPE12AF-K3NNA7A GPE12AF-K3NNA7D

HEAT

EXCHANGE

(EVAPORATOR)

HEAT

EXCHANGE

(CONDENSER)

COMPRESSOR

CENTRIFUGAL FAN

CENTRIFUGAL FAN

Accumlator

Suction

Discharge

Capillary

Strainer

HEA

T

EXCHANG

E

(EVAPORATOR)

HEAT

EXCHANGE

(CONDENSER

)

COMPRESSOR

CENTRIFUGAL FAN

CENTRIFUGAL FAN

Accumlator

Suction

Discharge

Capillary

Strainer

10

Technical Information

Service Manual

Symbol Symbol Color Symbol Symbol Color Symbol Name

WH White GN Green COMP Compressor

YE Yellow BN Brown Grounding wire

RD Red BU Blue / /

YEGN Yellow/Green BK Black / /

VT Violet OG Orange / /

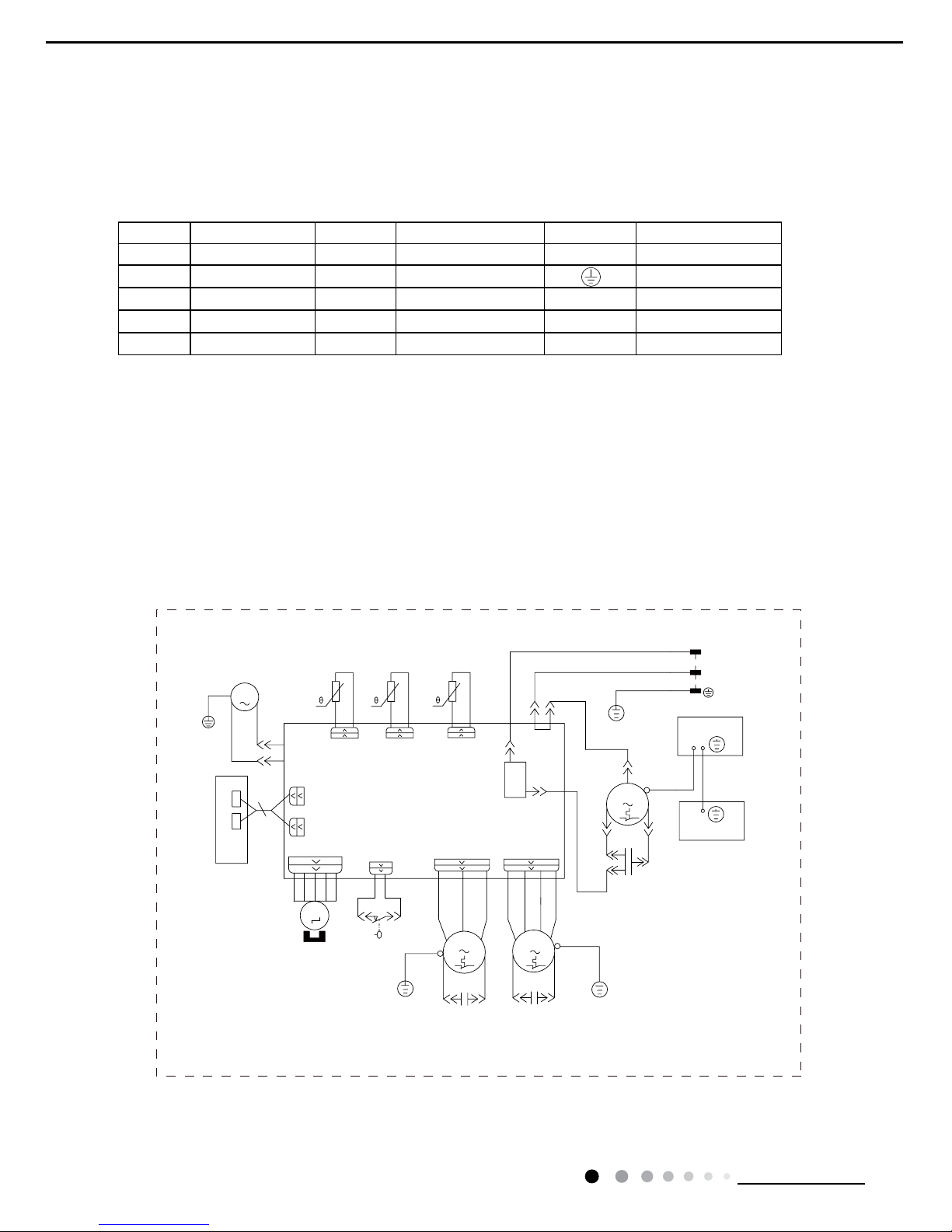

5. Electrical Part

5.1 Wiring Diagram

●Instruction

●Electric Diagram

GPC12AF-K3NNA7A GPC12AF-K3NNA7D

SWITCH

WATER LEVEL

ROOM

L

BN(BK)

N

YEGN(GN)

BU(WH)

BU

N3

S

YEGN

C

YE

C1

K201

L

COMP

AP1

N1

WATER1(WATER)

DISP2

RD

FAN

RD

YE

BK

WH

BU

DISP1

BU

SA

NC

COM

WH

BK

HIGH-WP

RD

DISP2

ROOM TEMP.

DISP1

AP2

RT1

WATER MOTOR

M4

YEGN

M1

BN

MOTOR

UP FAN

BN

RD

RD

C2

C3

DOWN FAN

MOTOR

YEGN

BU WHBK

OFAN

RT2

TUBE

SENSOR SENSOR

TUBE TEMP.

PE

SWING

M3

STEPPING

MOTOR

M2

PE

PE

UNDERPROP

ELECTRIC BOX

PE

YEGN

PE

POWER

PE

YEGN

OUTTUBE TEMP.

SENSOR

OUTTUBE

RT3

COMP.

R(M)

COMP.

MOTOR

11

Technical Information

Service Manual

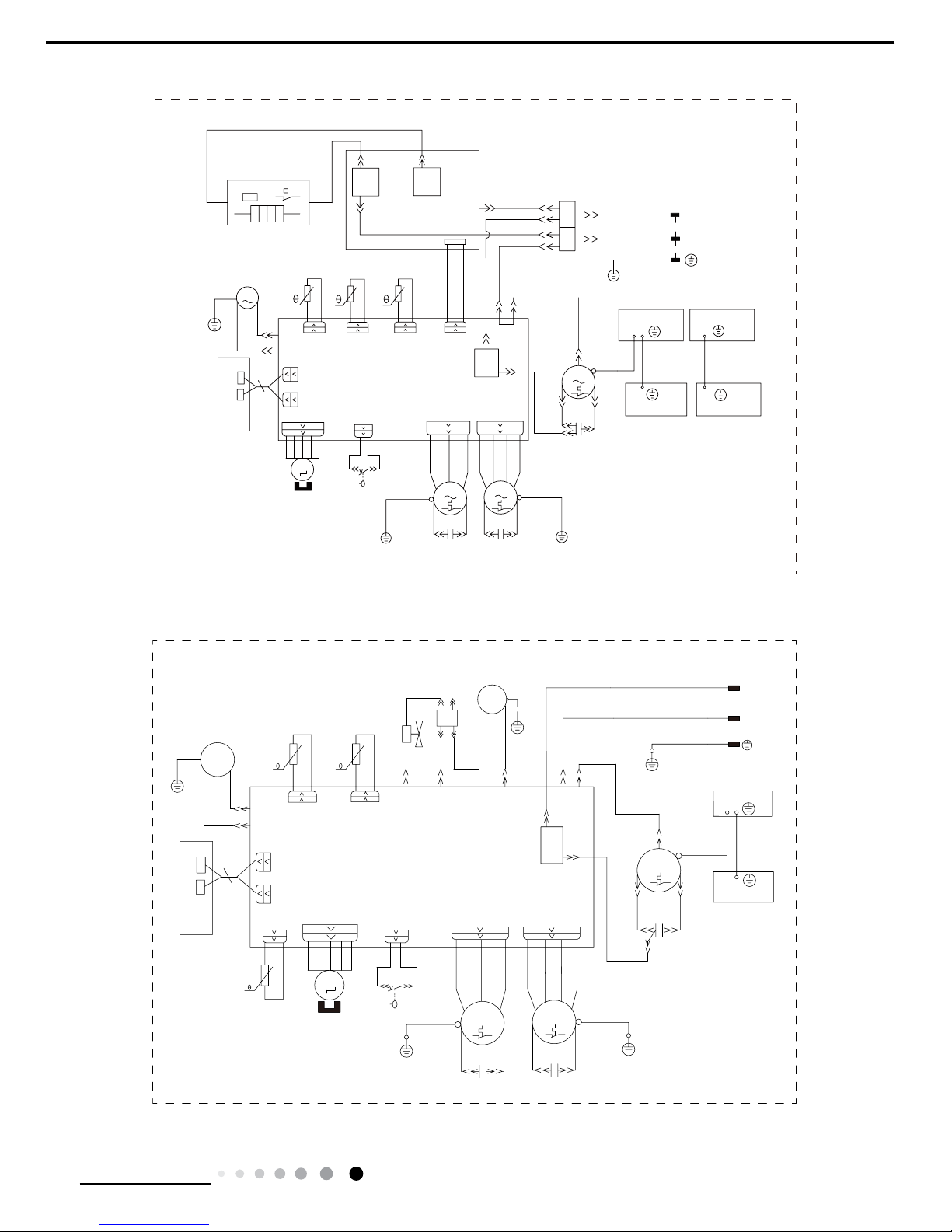

GPE12AF-K3NNA7A GPE12AF-K3NNA7D

SWITCH

WATER LEVEL

YEGN

PE

EVAPORATOR

PE

UNDERPROP2

BU

RD

BU

BN

BN

BU

AP3

CN1

HEAT-CTRL

I-HEAT-N

I-HEAT-L

K206

O-HEAT-N

K202

O-HEAT-L

ROOM

POWER

L

BN(BK)

N

YEGN(GN)

BU(WH)

N3

S

YEGN

C

YE

C1

K201

L

COMP

R(M)

AP1

N1

WATER1(WATER)

DISP2

RD

FAN

RD

YE

BK

WHBU

DISP1

BU

BU

SA

NC

COM

WH

BK

HIGH-WP

RD

DISP2

ROOM TEMP.

DISP1

AP2

RT1

WATER MOTOR

M4

YEGN

M1

BN

MOTOR

UP FAN

BN

RD

RD

C2

C3

DOWN FAN

MOTOR

YEGN

BUWHBK

OFAN

RT2

TUBE

SENSOR

SENSOR

TUBE TEMP.

PE

SWING

STEPPING

MOTOR

M2

PE

PE

UNDERPROP1

ELECTRIC BOX

PE

YEGN

PE

YEGN

PE

HEATER

TERMINAL

BLOCK

OUTTUBE TEMP.

SENSOR

OUTTUBE

RT3

COMP.

M3

1

XT

2

EH

ST

FUT

COMP.

MOTOR

These wiring diagrams are subject to change without notice; please refer to the one supplied with the unit.

GPH12AF-K3NNA7A GPH12AF-K3NNA7D GPH12AF-K3NNA7E

4YV

M3

PE

W8

YEGN

PE

ELECTRIC BOX

UNDERPROP

PE

PE

M2

~

MOTOR

STEPPING

SWING

PE

PIPE TEMP.

SENSORSENSOR

TUBE

RT2

OFAN

BK

WHBU

N3

YEGN

MOTOR

DOWN FAN

C3:3uF

C2:2uF

RD

RD

BN

UP FAN

MOTOR

BN

~

M1

YEGN

M4

WATER MOTOR

17

RT1

PCB2

DISP1

ROOM TEMP.

DISP2

RD

W7

W6

HIGH-WP

~

BK

WH

COM

NC

SA

BU

BU

COMP.

MOTOR

DISP1

BU WH

BK

YE

RD

W4

FAN

RD

W2

DISP2

WATER

N1

PCB

R(M,V)

COMP(4)

L(3)

K201

C1

YE

W3

1

2

C(T,U)

YEGN

COMP

~

S(W,X)

W5

N3

W1

BU(WH)

YEGN(GN)

N

BN(BK)

POWER

ROOM

L

N2

N2

~

WATER PUMP

M5

4V

XT

W9

VT

VT

VT

RT3

OUTTUBE

SENSOR

PIPE TEMP.

BUBN

PE

PE

YEGN

YEGN

W10

12

Technical Information

Service Manual

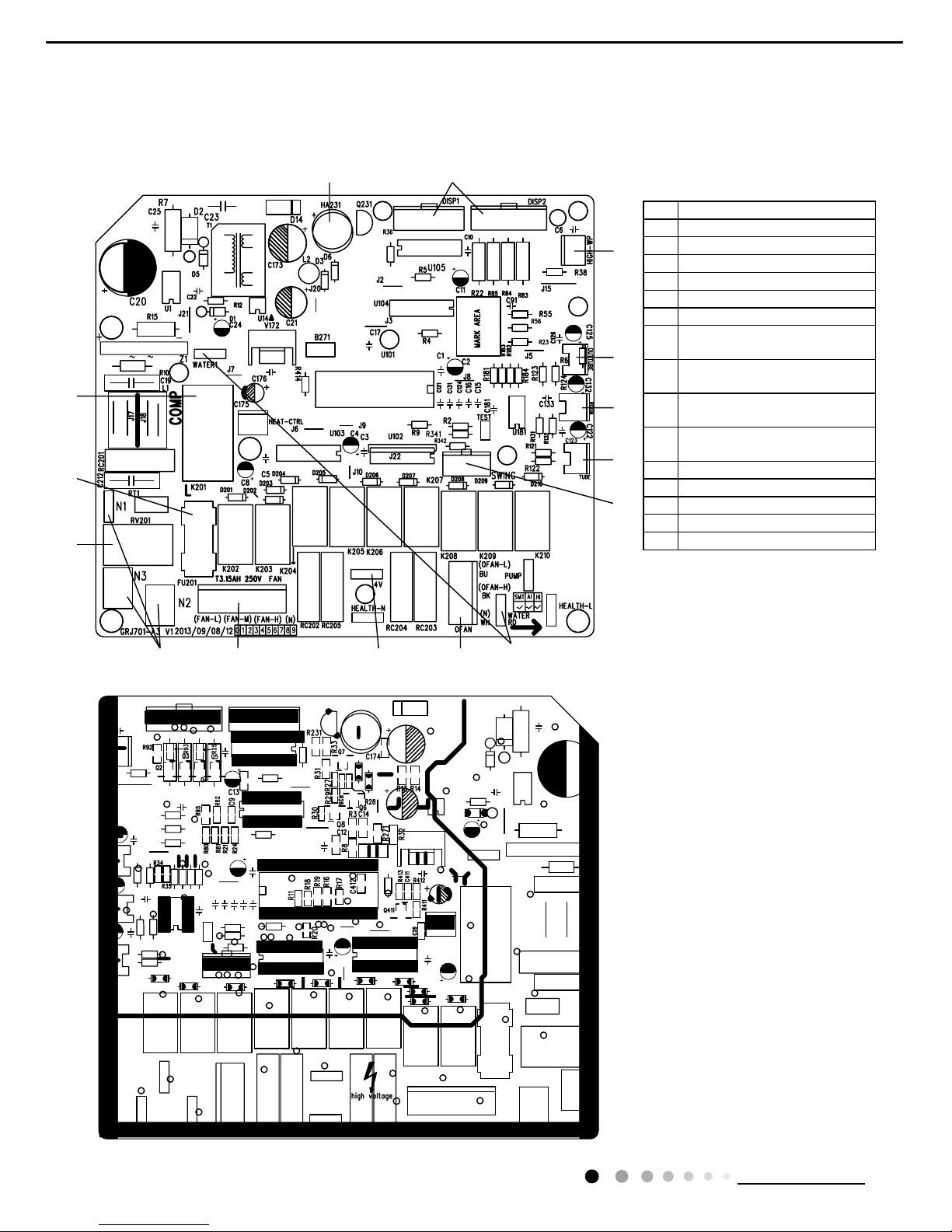

5.2 PCB Printed Diagram

(1)Silk screen on main board

7

5

6

9

4

3

2

1

15

11

10

8

13

12

14

No.Name

1connect neutral wire

2piezoresistance

3Fuse

4drive replay of compressor

5buzzer

6interface of display board

7

interface of high-level detection

switch

8

terminal of outdoor t ube

temperature sensor

9

terminal of ambient

temperature

sensor

10

terminal of tube temperatur

e

sensor

11 interface of swing motor

12 interface of draw water motor

13 interface of outdoor fan

14 interface of 4-way valve

15 interface of fan

● Top view

● Bottom view

13

Technical Information

Service Manual

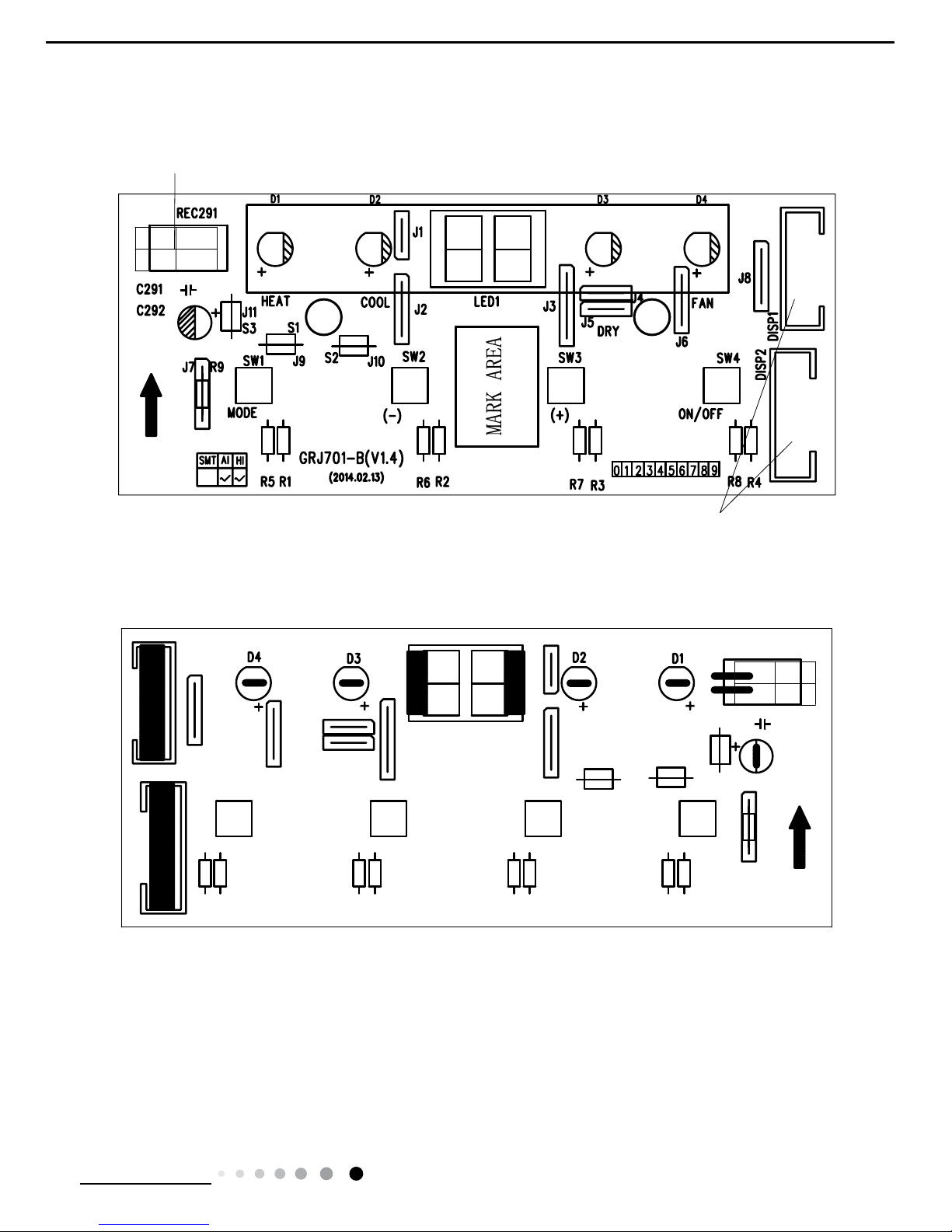

(2)Silk screen on display board

● Top view

● Bottom view

receiving head

connect with main baor

d

14

Technical Information

Service Manual

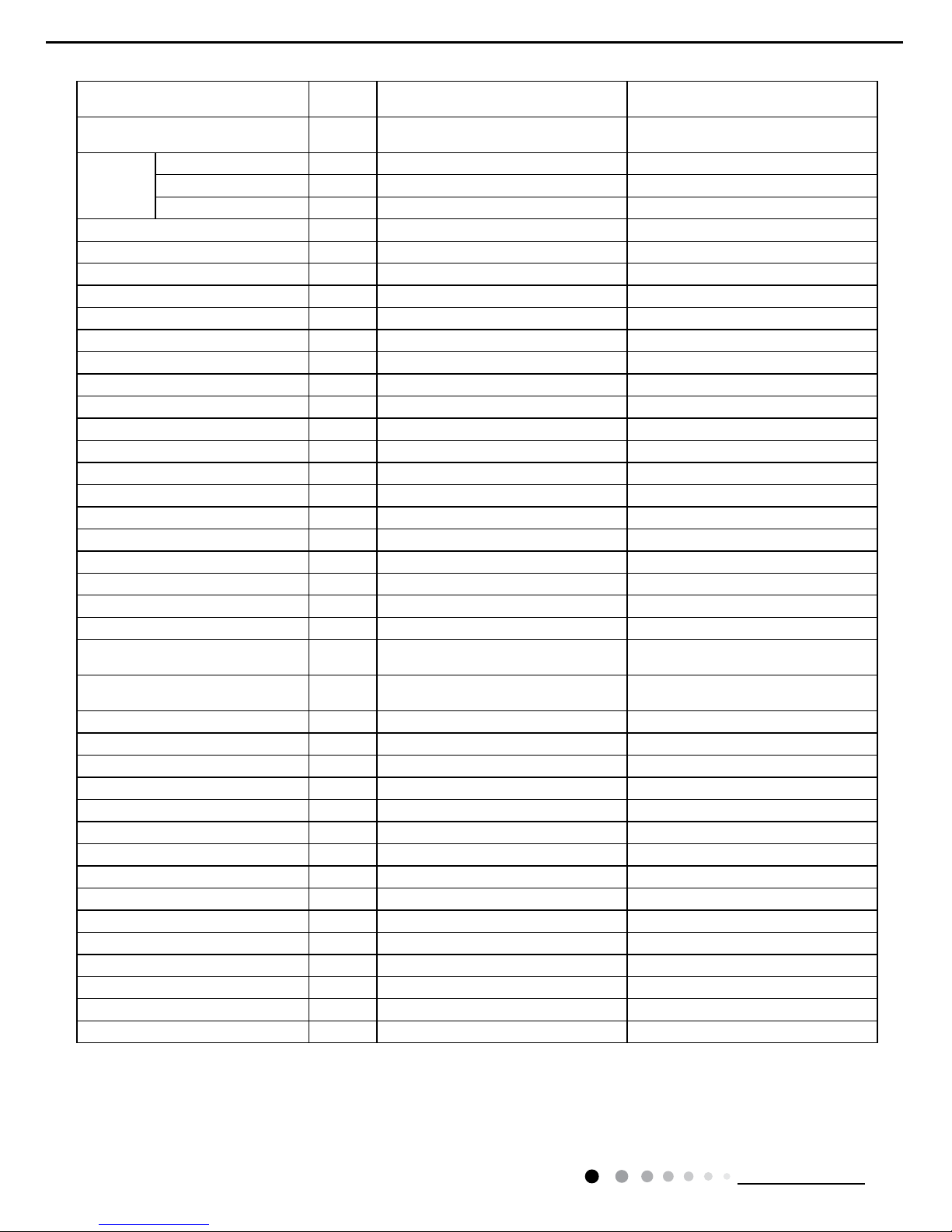

6. Function and Control

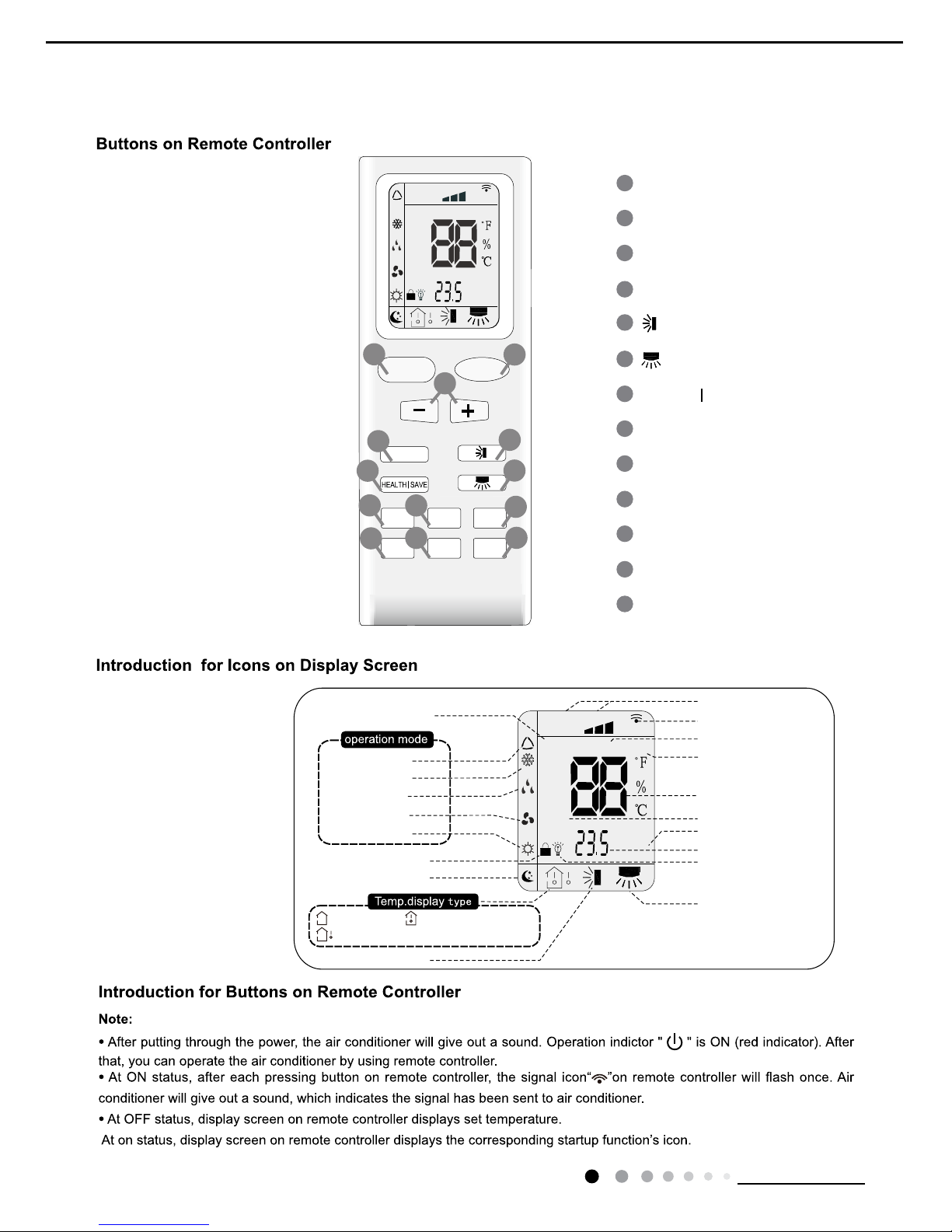

6.1 Remote Controller Introduction

ON/OFF Button

2

3

1

5

6

4

9

10

8

12

13

11

MODE Button

+/- Button

X-FAN Button

TEMP Button

TURBO Button

SLEEP Button

LIGHT Button

Button

HEALTH SAVE Button

7

Button

TIMER Button

FAN Button

FAN

AUTO

OPER

HEALTH

AIR

FILTER

TURBO

ON/OFF

X-FAN

HOUR

HUMIDITY

ON/OFF

MODE

FAN

X-FAN

TURBO

TEMP

TIMER

SLEEP

LIGHT

2

10

7

9

12

8

3

11

6

5

13

4

1

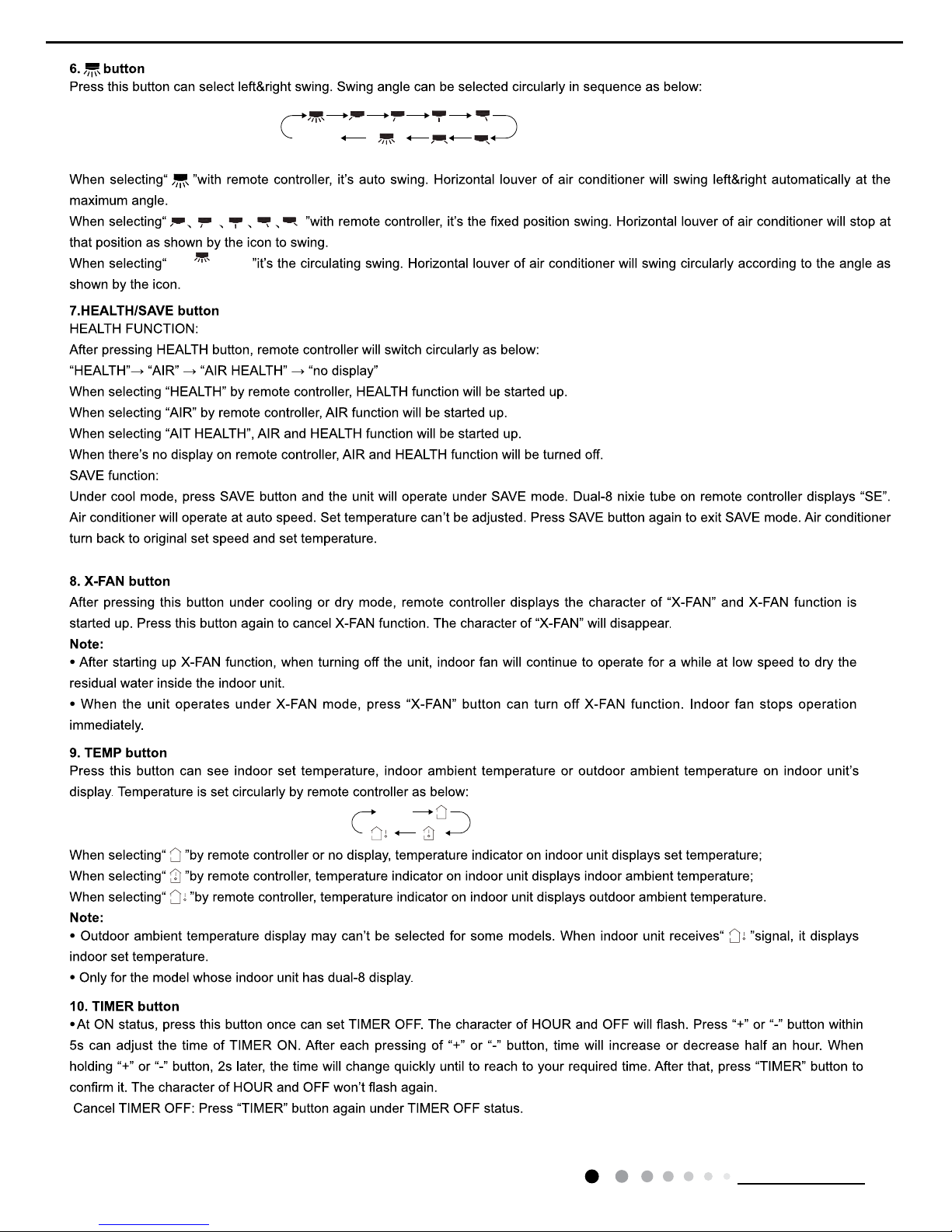

Child lock

Left&right swing

Sleep mode

Auto mode

Air mode

Cool mode

Heat mode

Fan mode

Dry mode

Up&down swing

:Indoor ambient temp.:Set temp.

:Outdoor ambient temp.

FAN

OPER

AUTO

HEALTH

AIR

FILTER

TURBO

ON/OFF

X-FAN

HOUR

HUMIDITY

TIMER ON/TIMER OFF

Set time

Light

Send signal

Health mode

X-fan

Set fan speed

Set temperature

Turbo mode

Temp. display type

Operation mode

15

Technical Information

Service Manual

AUTO COOL DRYFAN HEAT

Auto

no display

(horizontal louvers

stops at current position)

high speed.

Pressing this button can set fan speed circularly as: auto (AUTO),low( ),medium( ), high( ).

Under

AUTO Speed,IDU fan motor will adjust the fan speed (high, medium or low speed) according to ambient temperature.

Fan speed under dry mode is low speed.

Operation indicator

is ON.

16

Technical Information

Service Manual

no display

no display

(swing angle is

displayed dynamically)

(horizontal louvers

stops at current position)

(swing angle is

displayed dynamically)

This function is applicable to partial of models

.

17

Technical Information

Service Manual

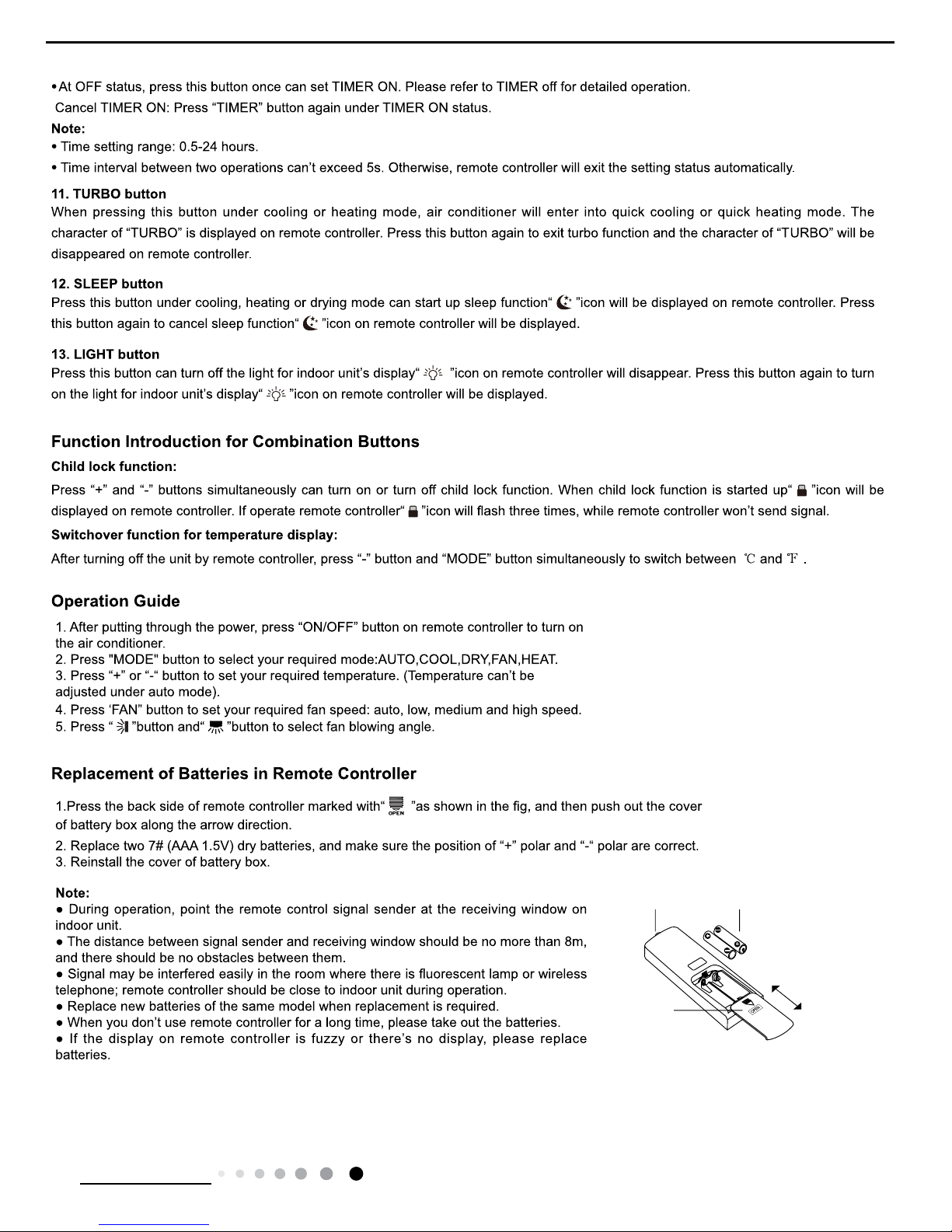

Signal sender

Battery

Cover of

battery box

Remove

Reinstall

18

Technical Information

Service Manual

6.2 Introduction of Basic Mode Function

1 Cooling mode

Cooling condition and process

When

Tamb.≥Tpreset+1ć(2), the unit operates in cooling mode. Meanwhile, compressor, draw water motor start operation. Indoor

fan operates at set fan speed. If indoor fan operates at high fan speed or middle fan speed, outdoor fan operates at high fan

speed. If

indoor fan operates at low fan speed, outdoor fan operates at low fan speed.

When

Tamb.≤Tpreset-1ć(2), compressor, outdoor fan and draw water motor stop operation, while indoor fan operates at set fan

speed.

Tp

reset-1ć(2)<Tamb.<Tpreset+1ć(2), the unit keeps original operation status.

Under this mode, 4-way valve is de-energized.

The temperature setting range is 16-30ć(61-86).

2 Dry mode

Drying condition and process

Under this mode, set temperature and ambient temperature won’t be displayed. Indoor fan operates at low fan speed. Compressor,

outdoor fan and draw water motor operates continuousl

y.

3 Heating mode

Working conditions and process for heat pump unit

When

Tamb.≤Tpreset+3ć(6), the unit operates in heating mode. Meanwhile, 4-way valve, compressor operates, and indoor fan

operates

at cold air prevention condition; if indoor fan operates at high fan speed or middle fan speed, outdoor fan operates at high fan

speed. If indoor fan operates at low fan speed, outdoor fan operates at low fan speed.

When

Tpreset+3ć(6)<Tamb.<Tpreset+5ć(10), the unit keeps original operation status,

When

Tamb.≥Tpreset+5ć(10), compressor and outdoor fan stop operation simultaneously. 4-way valve stop operation after the

compressor has stopped for 2 minutes. Indoor fan operates at blowing residual heat conditioner.

Under this mode, the temperature setting range is 16-3

0ć(61-86).

Working conditions and process for electric heating ty

pe unit

When

Tamb.≤Tpreset+3ć, the unit enters heating operation. In that case, electric heater starts up and the indoor fan operates at

setting speed;

When

Tpreset+3ć˘Tamb.˘Tpreset+5ć,the unit will keep its original status.

When

Tamb.≥Tpreset+5ć, electric heater will be turned off and indoor fan will stop after it operates at low speed for 60s.

Th

e temperature setting range is 16~30ć(61~86) under this mode.

4 Fan mode

Under this mode, set temperature and ambient temperature won’t be displayed. Indoor fan operates at set fan speed. Compressor,

outdoor fan, 4-way

valve and draw water motor operates continuously.

Under this mode, the temperature setting range is 16-3

0ć(61-86).

5

Auto mode

5.1 Under auto mode, standard cooling Tpreset=25

ć(77); standard heating Tpreset=20ć(68)

5.2 Heat pump unit: Tamb.>26

ć(79), the unit turns into auto cooling mode; Tamb.< 20ć(68), the unit turns into heating mode;

23

ć(73)≥Tamb. ≥20ć(68), if the unit operates at heating mode previously, the unit keeps heating operation status. If the unit

didn’t operate at heating mode previously, the unit will turn to dr

y mode; 26ć(79)≥Tamb. ≥24ć(74), the unit turns into auto dry

mode. For the first energization, 26

ć(79)≥Tamb. ≥20ć(68), the unit turns into drying operation mode.

5.3 Cooling only

unit: Tamb.>26ć(79), the unit turns into auto cooling mode; Tamb.< 20ć(68), the unit turns into auto fan

mode;2

0ć(68)≥Tamb. ≥23ć(73), if the unit operates at fan mode previously, the unit keeps fan mode operation status. If the unit

didn’t ope

rate at fan mode previously, the unit will turn to dry mode; 26ć(79)≥Tamb. ≥24ć(74), the unit turns into auto dry mode.

Fo

r the first energization, 26ć(79)≥Tamb. ≥20ć(68), the unit turns into drying operation mode.

6 Other function

6.1 Timer

6.1.1 General Timer

Ti

mer ON can be set at unit OFF. If selected ON time is reached, the unit will start to operate according to previous setting status. Time

setting range is 0.5-24hr in 30-minute increments.

Ti

mer OFF can be set at unit ON. If selected OFF time is reached, the unit will stop operation. Time setting range is 0.5-24hr in

30-minute increments.

6.1.2 Clock Timer

Ti

mer ON:

If

timer ON is set during operation of the unit, the unit will continue to operate. If timer ON is set at unit OFF, upon ON time reaches the

unit will start to operate according to previous setting status.

Ti

mer OFF:

If timer OFF is set at unit OFF, the sy

stem will keep standby status. If timer OFF is set at unit ON, upon OFF time reaches the unit will

stop operation.

19

Technical Information

Service Manual

6.2 Sleep function

When setting sleep function under cooling mode, Tpreset will increase

1ć (2) after 1 hours. 2 hours later, Tpreset will increase

2

ć(4) automatically. The upper limit of temperature is 30ć (86).

When setting sleep function under heating mode, Tpreset will decrease

1ć (2) after 1 hours. 2 hours later, Tpreset will decrease

2

ć (4) automatically. The lower limit of temperature is 30ć (86).

6.3 Buzzer: Upon energization or operation, the buzzer will give out sound.

6.4 Control button

ON/OFF button: turn on or turn off unit.

Mode button: the mode will be switched as below sequence:

Heat pump unit: cooling-drying-fan-heating

Cooling only unit: Cooling-drying-fan

Temperature “-“ button: If set temperature under ON status, temperature will decrease

1ć or after each pressing of this button. The

temperature can’t be set lower than 16

ć or 61. The button is invalid under auto, drying and fan mode.

Temperature “+“ button: If set temperature under ON status, temperature will increase

1ć or after each pressing of this button. The

temperature can’t be set higher than 30

ć or 86. The button is invalid under auto, drying and fan mode.

6.5 Display

6.5.1 Display of indicator

When turning of the unit, the current operation mode indicator will be displayed.(LED lamps for Cooling, Heating, Drying and Fa

n)

6.5.2 Dual-8 display

When the unit is turned on for the first time, niexie tube is defaulted to display set temperature. When the unit received the

signal of set

temperature, nixie tube display set temperature. When the unit received the signal of ambient temperature, the nixie tube disp

lays

current indoor ambient temperature.

6.5.3 Light control

When the unit is turned on for the first time, light is defaulted ON. If setting light ON by remote controller, indicator and

dual-8 nixie tube

displays current set status. If setting light OFF by remote controller, light will be turned off immediately. If there’s operat

ion for button

on panel and remote controller when setting light OFF by remote controller, indicator and dual-8 nixie tube will display set st

atus for 5s

and then turn off the light.

6.6 Auto fan speed control

6.6.1 Heating mode: under auto heating or normal heating mode, auto fan speed will operate as below mode:

When Tamb.≤Tpreset+Tcompensation-

2ć(4), indoor fan operates at high fan speed;

When Tpreset+ Tcompensation-

2ć(4)<Tamb.<Tpreset + Tcompensation, indoor fan operates at middle fan speed;

When Tamb.≥Tpreset+Tcompensation, indoor fan operates at low speed;

6.6.2 Cooling mode: under auto cooling or normal cooling mode, auto fan speed will operate as below mode:

When Tamb.≥Tpreset+ Tcompensation+

2ć(4), indoor fan operates at high fan speed;

When Tpreset+ Tcompensation<Tamb.<Tpreset + Tcompensation +

2ć(4), indoor fan operates at middle fan speed;

When Tamb.≤Tpreset+Tcompensation, indoor fan operates at low speed;

Auto fan under fan mode is as the same of cooling mode;

6.7 Power-off memory function

Memory content: mode, light, set temperature, set fan speed, swing. When power failure, the unit will operate at previous oper

ation

status automatically after power recovered.

6.8 Swing motor control

After energization, the swing blade will rotate to OFF position. If swing function hasn’t been set after turning on unit, the

swing blade

will rotate to ON position. If swing function has been set when turning on unit, swing blade will rotate to-and-fro.

6.9 X-FAN control mode

X-FAN function can be set under cooling and dry mode (X-FAN function is unavailable under auto, heating and fan mode)

7 Protection function

7.1.1 Water overflow protection

Buzzer will give out sound for 8 times for warning. The complete unit will stop operation. Error code H8 is displayed and heat

ing

indicator OFF 3s and blinks 8 times.

7.2 Malfunction of indoor ambient temp sensor

“Dual 8” nixie tube displays F1, LED lamp for cooling blinks once. Compressor, electric heater, draw water motor, 4-way valve

and

outdoor fan stop. Indoor fan will operate at set speed.

7.3 Malfunction of outdoor pipe temp sensor

“Dual 8” nixie tube displays F2, LED lamp for cooling blinks twice. Compressor, electric heater, draw water motor, 4-way valve

and

outdoor fan stop. Indoor fan will operate at set speed.

7.4 Freeze prevention protection

Under freeze prevention protection, compressor, outdoor fan and draw water motor stop operation. Indoor fan operates at set fa

n

speed.

7.5 Compressor protection

Compressor can be restarted only after 3 minutes delayed.

Loading...

Loading...