Gree GPC10AN-K5NNA1A, GPH12AN-K5NNA1A, GPC12AN-K5NNA1A Service Manual

Change for life

Service Manual

Models:

GPC10AN-K5NNA1A

GPC12AN-K5NNA1A

GPH12AN-K5NNA1A

(Refrigerant R290)

GREE ELECTRIC APPLIANCES, INC. OF ZHUHAI

Table of Contents

Service Manual

Part

1. Summary

2. Specications

: Technical Information

Ⅰ

...........................................................................................................16

.................................................................................................17

3. Outline Dimension Diagram

4. Refrigerant System Diagram

5. Electrical Part

5.1 Wiring Diagram ..................................................................................................23

5.2 PCB Printed Diagram ......................................................................................... 25

6. Function and Control

6.1 Introduction of control panel ............................................................................... 27

6.2 Remote Controller Introduction ..........................................................................29

6.3 Introduction of Basic Mode Function .................................................................. 33

Part

: Installation and Maintenance

Ⅱ

..................................................................................................23

.................................................................................. 27

................................................................... 16

.................................................................... 21

..................................................................22

..................................................35

7.Notes Maintenance Safety Precautions:

8. Installation Precaution

9. Install

9.1 Install Power cord Hooks ...................................................................................43

9.2 Removing Collected Water ................................................................................43

10. Maintenance

10.1 Error Code ........................................................................................................53

10.2 Malfunction Detection Flowchart ...................................................................... 55

10.3 Maintenance Method for Common Malfunction ...............................................59

...................................................................................................................43

.................................................................................................. 53

11. Exploded View and Parts List

12. Removal Procedure

Appendix:

Appendix 1: Reference Sheet of Celsius and Fahrenheit ........................................77

............................................................................................................... 77

............................................................................... 41

.............................................................. 61

..................................................................................67

.......................................... 35

Appendix 2: List of Resistance for Temperature Sensor ..........................................78

Table of Contents

Service Manual

ATTENTION

Abbreviations Used Within this Manual:

Abbreviation Clear Words

OFDN Oxygen free and dry nitrogen

PPE Personnel protective equipment

LFL Lower ammability level

UFL Upper ammability level

HC Hydrocarbon

INTRODUCTION

Please read this manual carefully before installing and operating the GREE Hydrocarbon Air– Conditioner unit.

Careless installation and operation could cause severe injuries to operators, workers and damage to the air-conditioner unit

itself.

Keep this manual in a location for easy access as it is needed for reference during installation, maintenance, service and

operation of the unit.

This manual does not cover all aspects of installation, maintenance and service of the chiller units; if additional information is

needed, contact the GREE Costumer Service or Sales Ofce.

Technical Information

General Information

Warning and cautions appear at appropriate locations throughout this manual book.

1

Service Manual

Notices

General Safety Instructions

Please pay careful attention to these safety instructions, to avoid risks to people and property. Before starting work on maintenance

read this manual thoroughly and pay particular attention to the relevant chapters.

Regardless of further requirements of the country, in which the equipment will be installed: assembly, rst start up, technical service,

maintenance and repair and as well as dismantling and disposal have to be carried out by authorised personnel only.

During every operation strictly follow the instructions within this manual. Pay attention to the specific rules of air conditioning,

electrics and refrigerant handling of the country within which the equipment is installed.

Key sections and/or sentences are highlighted with specic icons and symbols to the right side of the page. Please pay particular

attention to this information.

The Symbols Used in this Manual are as Follows

This is a specific

remark and

points out the

importance of a

specific section

Information window highlighting

important content of the specic

section or additional information

to consider.

This sign will indicate that you are

handling a ammable substance

and the surrounding environment

can possibly contain it.

This is a general warning sign.

The Label is used to indicate that

the ammable refrigerant is

present within the application and

service equipment.

Specic bans!

Specic commandments!

Instructions for rst aid!

Fire protection!

Images that indicate something

what you should strictly avoid.

2

Carefully read the

instructions!

Technical Information

Service Manual

Having a

malfunction

while

commissioning,

immediately

disconnect the

system from

mains!

Working on components with safety-relevant functions jeopardise the safe operation of the

installation. In case it is necessary to replace components, only use approved parts from GREE

Electric, the Original Equipment Manufacturer(OEM) or Gree released or authorised components.

The system contains the refrigerant R-290 (propane). This condition requires special safety

precautions to be observed. While working on the system, the presence of any kind of ignition

sources (e.g. sparks, open flames, hot surfaces, static electricity) are strictly prohibited. At the

installation site, no matter what kind of activities are executed, smoking is strictly prohibited!

Likewise, ensure the installation site is well ventilated. For further details as far as it concerns the

handling of the refrigerant R-290 (propane) .

Do not charge the system with any refrigerant which is not R-290! Do not mix any refrigerants!

Before filling the system, ensure that there is no air (or other non-condensable gases such as

nitrogen) left in the system, otherwise there is severe danger of damage to the system caused by

excessive high pressure.

After charging the system with refrigerant, carefully examine and conrm the tightness by the use

of an appropriate electronic leak detector!

The Symbols Used in this Manual are as Follows

Electric operations (installation, repair, modication, maintenance, adjustment) have to be fullled

by trained and authorised personnel only. When dealing with electrical issues, the specific

rules of the country within which the equipment is installed must be followed, in addition to the

instructions within this manual.

ONLY original

GREE (OEM)

spare-parts are

permitted for

Service and Re-

pair!

Proceed

according the

manuals

Instructions!

When working on the equipment or parts of it, the system has to be deenergised (by master

switch, circuit breaker or separate cut-out) and made safe against restart of the system. Do not

reconnect the system to the electric circuit until all work is done and all connections are tested.

If handled unsafely or unprofessionally, severe electric shocks can occur. Consider the wiring

diagram and follow the instructions of this manual very carefully whilst working on electrical parts.

Wrong connections or incorrect grounding may lead to severe injuries and mortal danger.

Ground the system according to the particular requirements of the country within which the

equipment is installed.

Connect all the wires properly and durably. Loose cables may lead to overheating or re

Minimum Room Size

HC R290 is a ammable refrigerant and can form explosive mixtures in low concentrations. To

minimise the risk of re or explosion, the system must be installed in a room with a minimum oor

area.

Unless there are further requirements, standards and legislation of the country within

which the equipment is installed may apply. Any technicians that works on GREE

hydrocarbon air– conditioners must be competent in the safe handling of flammable

refrigerants, in addition to being in possession of knowledge and skills to maintain best

refrigeration installation and servicing practices.

There are already training activities in place for engineers, technicians and sales staff

to provide professional knowledge and skills for the handling of HC refrigerants and

refrigeration systems operating with HCs.

Pay attention to

the room size for

indoor unit

installation!

For specific information refer

page XXX of this

manual.

Get your Best

Practices

knowledge and

skills update for

HC refrigerants

and be

certificated for

these jobs!

“HC Refrigeration Professional” certication!

Technical Information

Get trained and have your

3

Service Manual

Basics in RAC

Knowledge of the basic SI standard units for temperature, pressure, mass, density, energy.

Understanding of the basic theory of refrigeration systems including the functions of the main components in the system (compressor,

evaporator, condenser, thermostatic expansion valves).

Understanding how to read a refrigerant ow chart and an electrical circuit diagram.

The determination of non condensable gases in the refrigeration system and how to eliminate them.

The importance of the use of oxygen free dry nitrogen (OFDN) for system ushing, leak test and strength test.

The elimination of humidity from the refrigeration system and how to recover or vent HC refrigerant from a system.

Usage of tables and diagrams (log p/h diagram, saturation tables of a refrigerant, diagram of a single compression refrigeration cycle)

and interpretation of these tables and diagrams.

Knowledge of the basic operation of the following components in a refrigeration system and their role and importance for refrigerant

leakage prevention and identication:

· Temperature and pressure controls

· Sight class and moisture indicators

· Defrost controls, reverse cycle operation

· System protectors

· Measuring devices such as the pressure gauge manifold

· Thermometer

· Leak detector

· Refrigerant charging devices

· Vacuum pump

· Oxygen free dry nitrogen cylinder and pressure regulator

Fault nding – analysis and repair.

· Knowledge of ammable refrigerants

· Risk analysis for the application of ammable refrigerant and properties of

ammable refrigerants

· Electrical circuit assessment and repair

Read More!

SAFETY CODE

OF PRACTICE

FOR REFRIGE-

RATING SYS-

TEMS

UTILISING A2 &

A3 REFRIGE-

RANTS

ISBN

1 872719 15 5

Checks before putting in operation, after a long period of

nonuse, after maintenance or repair intervention or during

operation.

Carry out a pressure and leak test to check the strength and the tightness of the system.

Usage of a vacuum pump.

Evacuation of the system to remove air and moisture according to standard practice.

Checks for Leakage

Knowledge of potential leakage points of refrigeration, air-conditioning and heat pump equipment. Making a visual and manual

inspection of the whole system.

Carry out a check for leakage of the system using an indirect method and/or one of the direct methods.

Direct leak detection methods:

1. Fixed leakage detection systems

2. Portable electronic gas detectors

3. Ultraviolet (UV) indication uids

4. Weak soapy water solution (bubble test) also in combination with OFDN

5. New installation tightness test for leakage detection procedure e.g. H2/N2

6. Operational system tightness test for leakage detection procedure

Indirect refrigerant detection methods:

1. Visual

2. Manual checks

4

Technical Information

Service Manual

Use of portable measuring devices such as pressure gauges, thermometers and multimeters for measuring Volt/Amp/Ohm in the context of indirect methods for leakage

checking and interpretation of the measured parameters. It is very important to make

use of an electronic gas detection device. Take care that the electronic gas detector

is designed and certificated for the use with flammable refrigerants. Additionally, the

electronic HC gas detector must be part of the Personnel Protective Equipment (PPE)

of the technician because if this device is operational in the work area it will warn by

detection and signalling if HC refrigerant is in the atmosphere.

The use of OFDN

is important and

the HC gas de-

tector is indeed a

personnel pro-

tection device

(PPE)!

Handling of the refrigerant during installation, maintenance, servicing or recovery or

venting

Usage of scales to weigh refrigerant. Knowledge of requirements and procedures for handling, storage and transportation especially

of ammable refrigerants and especially of contaminated refrigerant and of oils. Safe HC refrigerant recovery and venting.

Installation, commissioning and maintenance of a compressor

The basic functioning of a compressor (including capacity control and lubricating system) and risks of refrigerant leakage to its

operation. Installing a compressor properly, including control and safety equipment. Adjusting the safety and control switches.

Checking the oil return system. Start up and shut down a compressor and checking the good working conditions

of the compressor, including by making measurements during operation of compressor.

Installation, commissioning and maintenance of condensers

The basic functioning of a condenser. Installing a condenser properly, including control and safety

equipment. Adjusting the safety and control switches. Checking the hot-gas and liquid lines in

correct positions. Start up and shut down a condenser and check the good working conditions,

including by making measurements during operation. Checking the surface of the condenser.

Methods for condenser surface cleaning and ns adjustments.

Installation, commissioning and maintenance of evaporators

The basic functioning of an evaporator (including defrosting system). Installation of an evaporator

including control and safety equipment. Adjusting the safety and control switches. Checking the

liquid and suction pipelines in the correct position and checking the hot gas defrost pipeline.

Start up and shut down an evaporator and check the good working of the evaporator, including

by making measurements during operation. Functional checking of the reverse cycling control

device. Checking the surface of the evaporator. Methods for evaporator surface cleaning and ns

adjustments.

Piping

Professional brazing is another key component for safe and state of the art HC system

installation and servicing. Brazing leak free joints on metallic tubes and pipes that can be

used in refrigeration, air-conditioning or heat pump systems. Make/check pipe and component

supports and vibration elimination. Knowledge about the designing and dimensioning of the

different refrigeration system section pipes including risers. The behaviour of lubricants within the

refrigeration system and the inuences of the dimensioning of pipe work in relation to lubricants.

Develop strategies to minimise mechanical connections like aring or anges and to provide a

sealed (hermetic) system.

Preventive

maintenance will

improve the sys-

tem efficiency

Regular

professional

brazing

experience is an

important pre-

condition for the

work with

hydrocarbon

refrigerants!

Technical Information

5

Service Manual

HC R290 Refrigerant Lssues

Please notice that the unit is filled with propane. Details to this refrigerant are found in chapter “refrigerant”. Propane is highly

ammable and leads to explosion under certain conditions. Inappropriate treatment of the unit involves the risk of severe damages

of people and material.

Basics

HC R-290 (propane) is an odourless and colourless gas of the group of hydrocarbons.

HC R-290 is heavier than air and at high concentrations can cause

narcotic effects and eventually asphyxiation.

R-290 is highly ammable within the range of 2,1% and 9,5% by volume, or 38

g/m3 to 170 g/m3 in air. The auto-ignition temperature is about 470°C.

Since R-290 is an odourless and colourless gas, it is difcult to perceive that it is

present (as with most other refrigerants).

Propane is often used as a fuel such as for heating or barbecues. However, for

use on refrigeration systems, fuel-grade propane is not suitable since it contains

high levels of impurities, which would damage the refrigeration system and may

not provide the desired refrigerating capacity or efciency.

The structural formula of HC R-290 (propane)

Important R efrigerant Properties and

Parameters:

Molecular formula C3H8

Melting point [°C] -188

Boiling point under atmospheric pressure [°C] -42

Molar mass [g mol -1] 44,10

Critical temperature [ °C] 96,8

Critical pressure [bar] 42

Practical limit [g/m3 ] 8

Lower ammability level LFL [g/m3 ] 38

Lower ammability level LFL [ %] 2,1

Upper ammability level UFL [ g/m3] 171

Upper ammability level UFL [ %] 9,5

Ignition temperature [ °C] 470

HC R-290 refrigerant has a high

grade of purity.

Propane as a

cooking gas is

not useful for

refrigeration

purpose!

Read More!

Guidlines for the

safe use of hydro-

carbon refrige-

rants

GIZ—PROKLIMA

http://www.gtz.de/

proklima

6

Technical Information

Service Manual

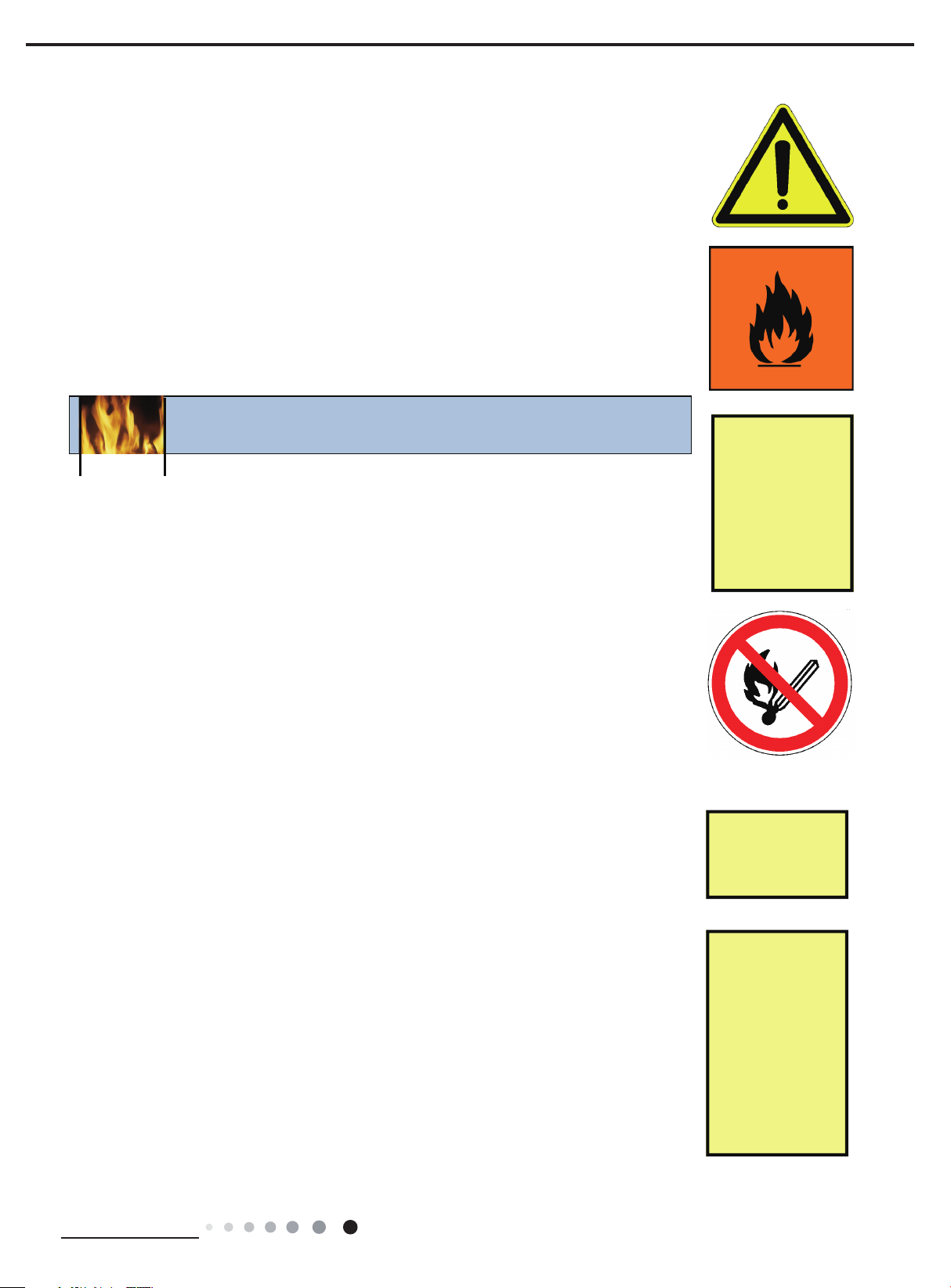

Refrigerant

Flammability

Three components are needed simultaneously for causing re:

1. Oxygen

2. Ignition source

3. The ammable concentration of HC

For ignition, the concentration of HC in air has to be between the lower and upper

ammable limits. If the concentration is below the lower ammability limit (LFL) of about

2% by volume in air, there is not enough HC for combustion. If the concentration is

above the upper ammability limit (UFL) of about 10% there is insufcient oxygen for

combustion.

2 % 10 %

HC R-290

Possible ignition sources are:

1. A flame, for example from brazing torch, halide torch leak lamp, match or

lighter, cigarette

2. A spark from an electrical component

3. Static electricity

4. Hot surfaces

By way of illustration please compare to the schematic view:

Safety Data

Hazard Identication

· Extremely ammable (F+).

· Readily forms an explosive air-vapour mixture at ambient temperatures.

· Vapour is heavier than air and may travel to remote sources of ignition (e.g.

along drainage systems, into basements etc).

· Liquid releases generate large volumes of ammable vapour (approx 250:1)

· Cold burns (frostbite) will result from skin / eye contact with liquid.

· Liquid release or vapour pressure jets present a risk of serious damage to

the eyes.

· Abuse involving inhalation of high concentrations of vapour, even for short

periods, which can produce unconsciousness or may prove fatal. Inhalation

may cause irritation to the nose and throat, headache, nausea, vomiting,

dizziness and drowsiness. In poorly ventilated areas unconsciousness or

asphyxiation may result.

Oxygen 0 % to 100 %

To ignite HC R-

290, three (3)

components

must exist at the

same time at

work area

to cause the

refrigerant

burning!

1 kg of liquid HC

R-290 refrigerant

creates about

250 litres of gas

Beside the flam-

mability, most

other safety

properties are

similar to other

refrigerants!

Rely always on

best service

practices in

refrigeration!

Technical Information

7

First Aid Measures

Inhalation:

Remove the affected person to fresh air. If breathing has stopped, administer

articial respiration. Give external cardiac massage if necessary. If the person is

breathing but unconscious, place them in the recovery position. Obtain medical

assistance immediately.

Skin:

In case of cold burns: ush with water to normalize temperature. Cover the burns

with sterile dressings Do not use ointments or powders. Obtain medical assistance

immediately.

Eyes:

Cold burns should be ushed with water to normalise temperature, cover the eye

with a sterile dressing and obtain medical assistance immediately.

Service Manual

Fire Fighting Measures

HC R-290 is delivered, stored, and used at temperatures above their ash point. Avoid all naked ames, sparks, cigarettes

etc.

· In case of re, immediately alert re brigade

· Ensure an escape path is always available from any re

· If gas has ignited do not attempt to extinguish but stop gas ow and allowto burn out.

· Use water spray to cool heat-exposed containers, and to protect surroundingareas and personnel effecting the shut off

· Every precaution must be taken to keep containers cool to avoid the possibilityof a boiling liquid expanding vapour

explosion (BLEVE)

Extinguishing Media:

In case of a large re:

Release must be stopped and container cooled by water spray.

Water mist should be used to assist approach to the source of the re.

Large res should only be handled by Fire Brigade.

DO NOT USE WATER JET

Small re:

Use dry powder extinguisher

8

Technical Information

Service Manual

DO NOT USE WATER JET

Special protective equipment for re ghters:

In conned spaces use self-contained breathing apparatus

Hazardous combustion products:

Incomplete combustion may form carbon monoxide.

Accidental Release Measures

Immediate emergency action:

· Clear people away from the area to a safe place

· Do not operate electrical equipment unless “Ex”-rated

· Summon the emergency services

· Treat or refer casualties if necessary

Further action (when release is made safe):

· Extinguish all naked lights – avoid creating sparks

· Position re ghting equipment

· Cover drains and disperse vapour with water spray.

Note: vapour may collectin conned spaces.

Further actions:

· Stop release

· Use dry powder or carbon dioxide extinguishers

· Cool containers exposed to re by using water / mist spray.

Accidental Release Measures

Due to the flammability of R-290 and the risk of fire or explosion during servicing,

special safety rules must be followed during operation. In order to avoid damage for

people and property, particular requirements are listed hereafter.

Before servicing the unit, the surrounding area were the work will be done must be

clear of safety hazards to ensure safe working. Nevertheless it is required to carry out

a risk assessment in order to minimise the risk of ignition of R-290.

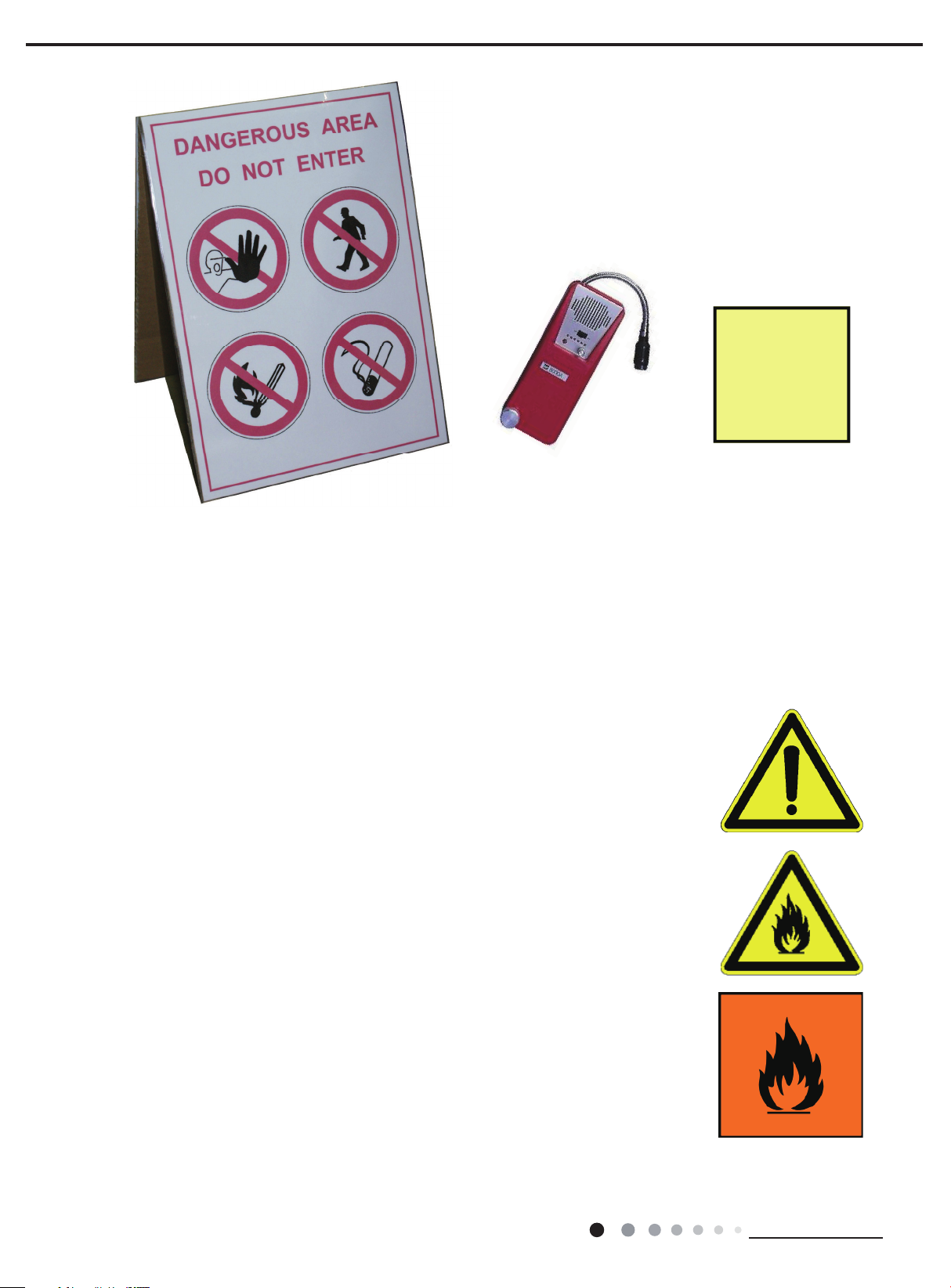

The following safety measures must be followed:

1. Any employees and other present persons must be informed about the service and the way the service is done, rst.

2. It is recommended to isolate the working environment in order to keep out any unauthorised personnel.

3. It is useful to set up signs such as „no smoking“ or „access denied“.

4. It is prohibited to store any combustible goods within the working environment.

5. Within two (2) metres radius, ignition sources are not allowed in the working area.

6. Fire extinguisher (dry powder) must be easily accessible at any time.

7. During service work, proper ventilation of the environment must be ensured.

Technical Information

9

Service Manual

The HC leak de-

tector is indeed

a Personal

Protective

Equipment

(PPE)

device!

Sign plate to protect and mark the working area.

Appropriate detectors, suitable for hydrocarbons, must be available and operational all the time. Appropriate tools and

appliances must be available and ready for operation.

Any employees need to be instructed extensively about the safety measures and the possible safety hazard.

Refrigerant Recovery

Before starting service work on the refrigerant circuit, the existing refrigerant must

be removed. When carrying out removal of the refrigerant, the following must be

considered:

· The recovery cylinder must be permitted for the use of R-290 (especially regarding the

pressure and the compatibility of the connectors and the valves).

· The recovery machine must be suitable for operation with R-290. Importantly, the

recovery machine must not itself be an ignition source.

· The lling of the recovery cylinder should be monitored closely by controlling the weight.

It is recommended to place and then to leave the cylinder on a digital scale. Pay attention

to not overfilling the cylinder. The cylinder is only allowed to be filled up to 80% of its

complete volume by liquid refrigerant.

· The pressure must be controlled in order to ensure that the permissible pressure of the

cylinder is not exceeded at any time.

· After filling, the cylinder must be marked with the mass and the type of refrigerant

recovered.

· The recovery machine should be operated until the pressure reduces to 0,3 bar

absolute pressure. R-290 is soluble to oil. This may lead to a rise of pressure because the

refrigerant vaporises from oil. It may be necessary to operate the recovery machine for a

second or even a third time.

· Small amounts of R-290 can be vented in safe manner to the environment.

· Remaining amounts of HC absorbed by the oil can be extracted from the system using

a vacuum pump in combination with an exhaust vent hose.

· A second “two way excess” recovery cylinder can be used in serial connection to act as

an oil-separator.

· After the systems‘ pump out, the system should be ushed with oxygenfree

dry nitrogen (OFDN) in order to ensure no ammable gas are inside

the system.

10

Technical Information

Service Manual

Repair of Leaks

System leaks must be immediately repaired by authorised personnel after becoming

acquainted. If they cannot be repaired immediately, the refrigerant charge should be

removed from the system until the point at which the leak can be properly repaired.

· Removing the refrigerant from the system in order to avoid an uncontrolled

discharge.

· Examine the leak source, determining the reason for the leak and carry out the

proper course of action

· Repair properly (NO „temporary repairing”)

· Based on the results of the systems’ examination, suitable measures need to be

identied in order to avoid a recurrent appearance of the leak.

· Before embarking on the repair, ensure that the refrigerant has been removed

and the system ushed with OFDN, especially if brazing is to take place

· After each intervention into a refrigeration system (repairing leaks, replacing

components, brazing) the system must be subject to a leak test and following

strength test of the system.

The use OFDN is

an important

precondition for

professional

leak repair!

1. System flush-

Regular

professional

brazing

experience is an

important pre-

condition for the

work with

hydrocarbon

refrigerants!

ing from HC

2. Inert gas brazing

3. Leak testing

4. Strength testing

5. Cleaning

(blowing)

agent

Gas Detection

While servicing the unit it is recommended for the whole period of work — before,during

and after — to monitor the gas concentration in the air within the work environment. By

monitoring the air within the work environment the danger of a possible formation of

ammable atmosphere can be detected early.

The HC leak detector is indeed

a PPE device!

Doing the monitoring, ensure that the gas detectors are suitable for hydrocarbon detection.

Never use open re or a device with an ignition source for the detection of gas or for leak

detection.

Technical Information

11

Before operation of the gas detector the instruction manual must be read carefully.

Portable HC Gas Detector

In case of any questions refer to the detector manufacturer. Furthermore ensure the

detector is correctly calibrated. Instructions for calibration can be found in the instruction

manual of the detector or upon request from the manufacturer.

A possible re-calibration must be done within an area which is free of refrigerants.

In case of a positive detection by the detector any work must be stopped immediately.

Any open ames or ignition sources must be extinguished or removed. In addition to a

suitable and approved HC gas detectors, portable gas detectors can be used.

Such a detector can be clipped to clothing or placed on the floor within the working

area. It should be switched on for the duration of the work, and set to alarm at 15% of

the lower ammability level (LFL), to warn that ammable concentration may be nearby.

In this way, technicians can be alerted whenever an inadvertent release of ammable

refrigerant occurs, and can immediately act upon the relevant emergency procedures.

Service Manual

Cylinder Handling

R-290 is available in a large variety of different cylinders which are to be distinguished

whether they are rellable or not. Most rellable cylinders are equipped with pressure relief

valves, often with own special construction of valves in order to distinguish them from the

cylinders of different refrigerants.

Often special legal requirements about the handling of ammable refrigerants exist in the

different countries. These requirements must be studied and adhered to. Principally the

following regulations in dealing with R-290 cylinders apply:

1. Do not remove or destroy ofcial stickers of the cylinder

2. Close the cylinder with a cap any time the cylinder is not used

3. Never expose the cylinder to direct heat

4. Do not repair or modify the cylinder or the cylinders‘ connections

5. Only use suitable equipment for transportation of the cylinder, even for short distances.

Never roll the cylinder across the ground.

6. Take appropriate measures in order to prevent impurities, water or oil from entering the

cylinder.

7. Should it be necessary to warm the cylinder, only use warm water or air which temperature

must not exceed 40 °C (104 °F). O pen ames or radiant heaters are not allowed at any

time.

12

Technical Information

Service Manual

8. Weigh the cylinder and compare it against the tare weight (normally stamped on the

cylinder) in order to make sure that it is empty. Pressure control is no secure method to nd

out if and how much refrigerant there is inside the cylinder.

9. For accurate charging, use a set of reliable scales with appropriate resolution (depending

on the size of system charged with refrigerant) and use the smallest size of cylinder

available.

10. For recovery of R-290, only use cylinders which are allowed to be lled with R-290.

11. Make sure that safety inspections are still valid (i.e. within date), specically with regards

to safety test certication.

12. For refillable recovery cylinders keep in mind that with recovered amounts of HC

refrigerant, oil will always be present specific amounts may remain in the cylinder after

emptying.

The storage of R-290 cylinders is controlled by regulations. These regulations take priority

over the present guidelines. Typically, such rules imply the following:

1. Cylinders should be stored in a separate area, preferably outside, otherwise in a dry, well

ventilated place far away from any ignition source.

2. Admission to storage area must only be given to authorised personnel only. Storage areas

must be labelled with “no smoking” and “no naked ames” sign.

3. Storage areas should be at ground level and never in the basement.

4. Access should be easy – exclude any obstacles.

5. Cylinders should be stored and operated only in an upright position.

6. Choose appropriate measures to prevent static charges

7. Please remember that the maximum quantity of stored refrigerant sometimes might be

regulated by national regulations.

Charging HC!

Always use the

smallest cylin-

der possible and

relay on appro-

priate accurate

and sensitive

scales

Read More!

Guidlines for the

safe use of hydro-

carbon refrige-

rants

GIZ—PROKLIMA

http://www.gtz.de/

proklima

The transport of cylinders is controlled by laws in most countries. These laws must always be regarded first before the

mentioned guidelines here. In many cases information about regulations for the transport of cylinders could be given by the

dealer of the refrigerant.

Basically the following must be regarded concerning the transport of R290 cylinders:

1. During the transportation of R290 always carry along printed information about the

refrigerant. In case of emergency these information must be easy accessible. There

are often different demands to the transporters carrying a great quantity of gas. Inform

yourself before the scheduled transport.

2. Make yourself familiar with the risks of the refrigerant and the emergency measures

in case of accident or emergency.

3. Always carry a re extinguisher during transportation with you. It should be a dry

powder re extinguisher with a capacity at least of 2 kg. Make sure that the driver is

experienced in re extinguisher operation.

4. Cylinders must be transported in an upright position and be tightly secured.

5. Make sure of a proper ventilation inside the van even though it might request a

change in the vans‘ body construction.

6. Place the security advise „ammable gas“ upon the rear side of the van.

7. Smoking or open re is strictly forbidden inside the van.

8. Do not leave cylinders in a locked van without surveillance longer than necessary.

Technical Information

13

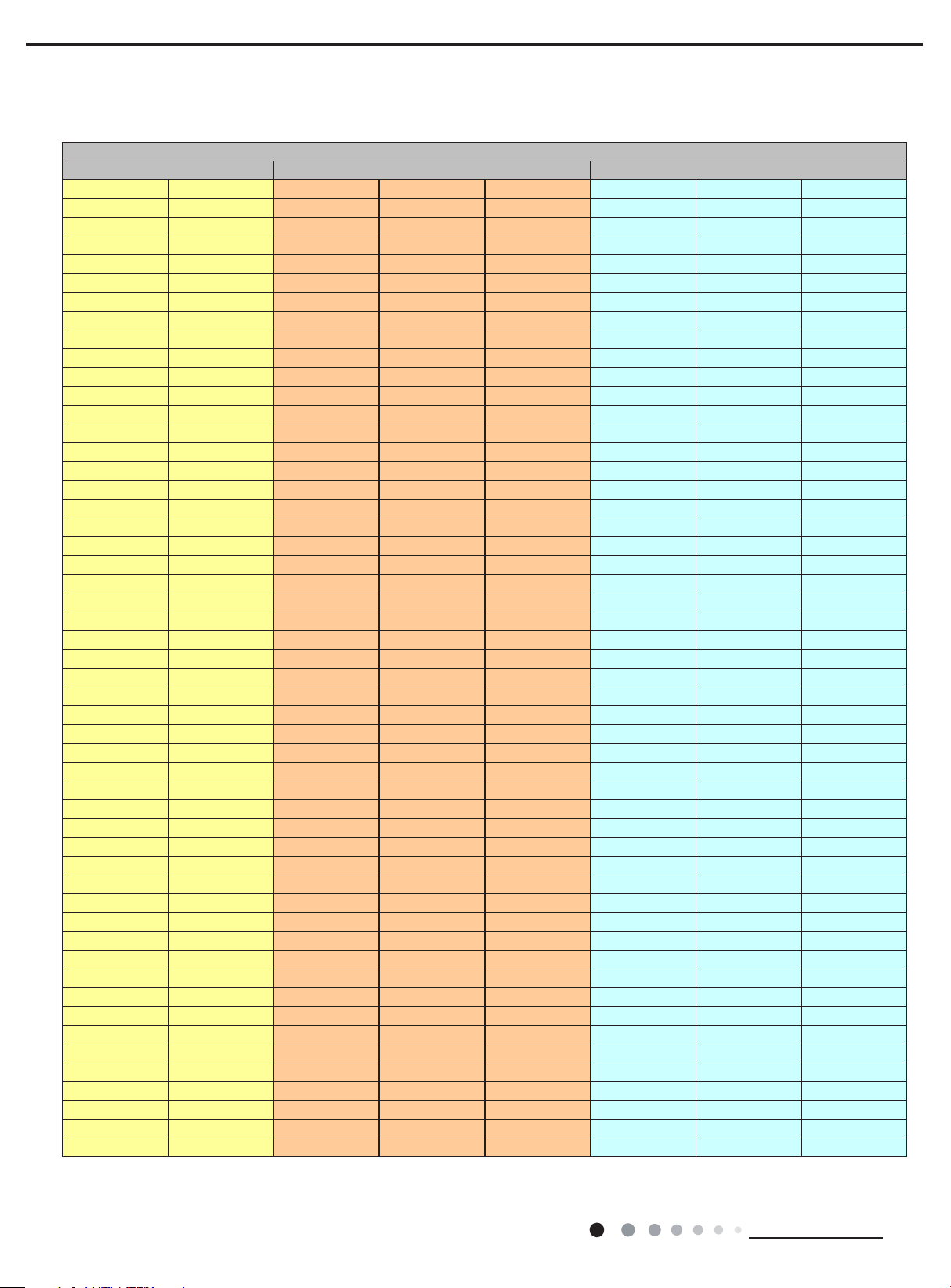

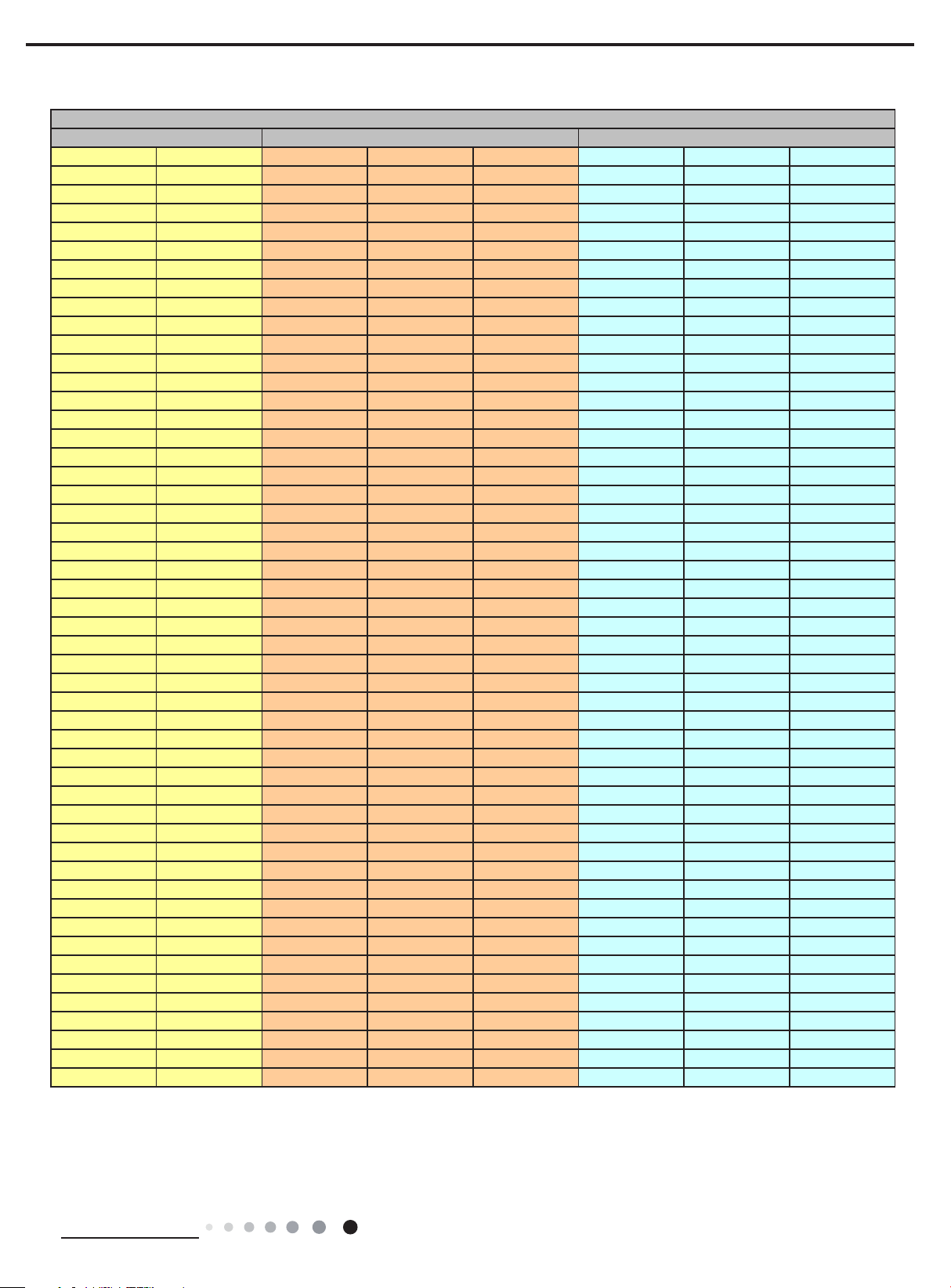

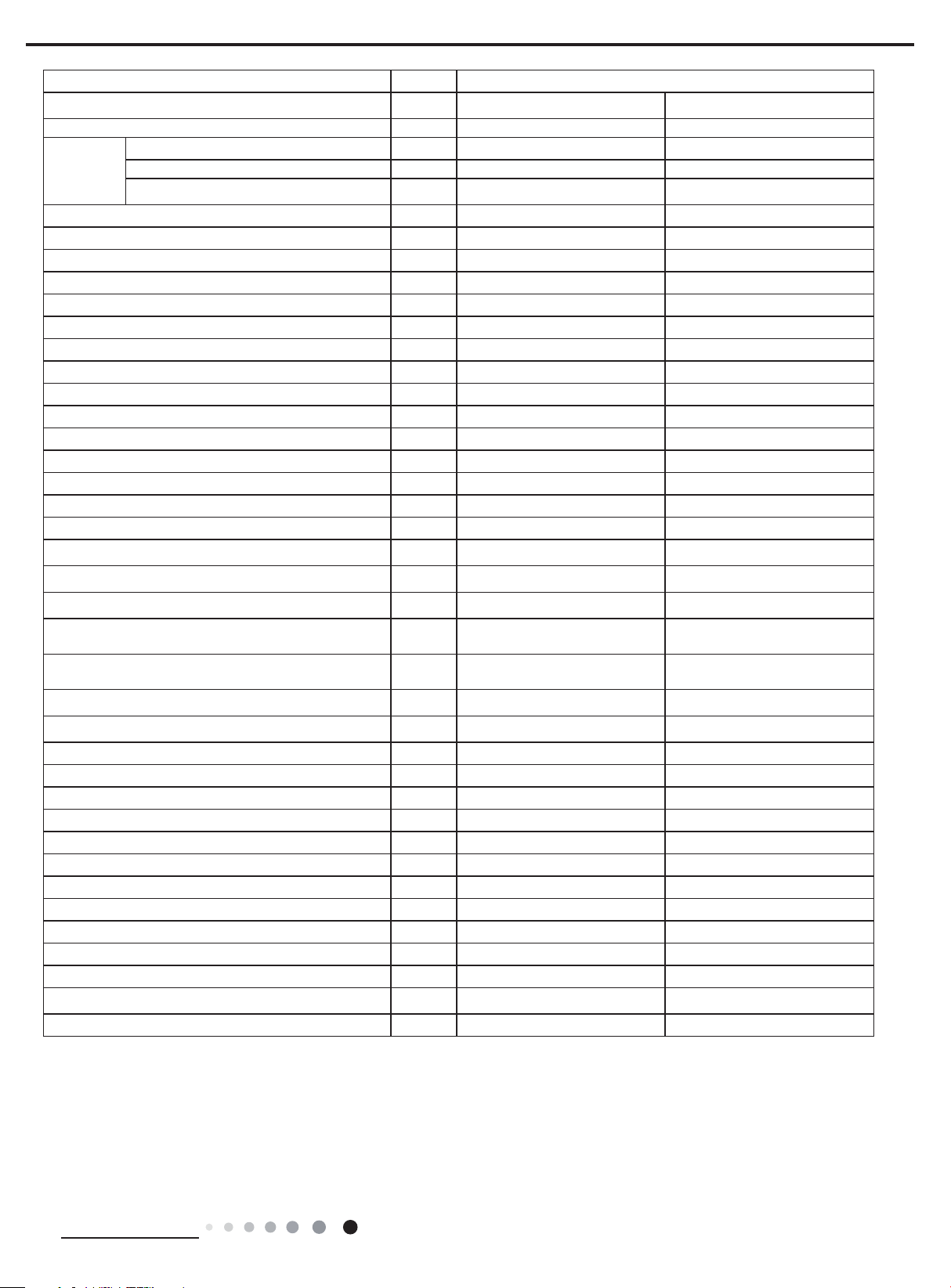

Pressure—Temperature Chart

HC Refrigerant R-290

Temperature Absolute pressure Gauge pressure

°C °F kPa bar PSI kPa(g) bar(g) PSI(g)

-40 -40 111,12 1,11 16,12 11,12 0,11 1,61

-39 -38,2 116,00 1,16 16,83 16,00 0,16 2,32

-38 -36,4 121,05 1,21 17,56 21,05 0,21 3,05

-37 -34,6 126,27 1,26 18,31 26,27 0,26 3,81

-36 -32,8 131,66 1,32 19,10 31,66 0,32 4,59

-35 -31 137,23 1,37 19,90 37,23 0,37 5,40

-34 -29,2 142,97 1,43 20,74 42,97 0,43 6,23

-33 -27,4 148,90 1,49 21,60 48,90 0,49 7,09

-32 -25,6 155,02 1,55 22,48 55,02 0,55 7,98

-31 -23,8 161,33 1,61 23,40 61,33 0,61 8,89

-30 -22 167,83 1,68 24,34 67,83 0,68 9,84

-29 -20,2 174,54 1,75 25,31 74,54 0,75 10,81

-28 -18,4 181,44 1,81 26,32 81,44 0,81 11,81

-27 -16,6 188,56 1,89 27,35 88,56 0,89 12,84

-26 -14,8 195,89 1,96 28,41 95,89 0,96 13,91

-25 -13 203,43 2,03 29,51 103,43 1,03 15,00

-24 -11,2 211,19 2,11 30,63 111,19 1,11 16,13

-23 -9,4 219,18 2,19 31,79 119,18 1,19 17,29

-22 -7,6 227,39 2,27 32,98 127,39 1,27 18,48

-21 -5,8 235,84 2,36 34,21 135,84 1,36 19,70

-20 -4 244,52 2,45 35,46 144,52 1,45 20,96

-19 -2,2 253,44 2,53 36,76 153,44 1,53 22,26

-18 -0,4 262,61 2,63 38,09 162,61 1,63 23,58

-17 1,4 272,03 2,72 39,45 172,03 1,72 24,95

-16 3,2 281,70 2,82 40,86 181,70 1,82 26,35

-15 5 291,62 2,92 42,30 191,62 1,92 27,79

-14 6,8 301,81 3,02 43,78 201,81 2,02 29,27

-13 8,6 312,27 3,12 45,29 212,27 2,12 30,79

-12 10,4 323,00 3,23 46,85 223,00 2,23 32,34

-11 12,2 334,00 3,34 48,44 234,00 2,34 33,94

-10 14 345,28 3,45 50,08 245,28 2,45 35,58

-9 15,8 356,85 3,57 51,76 256,85 2,57 37,25

-8 17,6 368,70 3,69 53,48 268,70 2,69 38,97

-7 19,4 380,85 3,81 55,24 280,85 2,81 40,73

-6 21,2 393,29 3,93 57,04 293,29 2,93 42,54

-5 23 406,04 4,06 58,89 306,04 3,06 44,39

-4 24,8 419,09 4,19 60,78 319,09 3,19 46,28

-3 26,6 432,45 4,32 62,72 332,45 3,32 48,22

-2 28,4 446,13 4,46 64,71 346,13 3,46 50,20

-1 30,2 460,13 4,60 66,74 360,13 3,60 52,23

0 32 474,46 4,74 68,82 374,46 3,74 54,31

1 33,8 489,11 4,89 70,94 389,11 3,89 56,44

2 35,6 504,10 5,04 73,11 404,10 4,04 58,61

3 37,4 519,43 5,19 75,34 419,43 4,19 60,83

4 39,2 535,10 5,35 77,61 435,10 4,35 63,11

5 41 551,12 5,51 79,93 451,12 4,51 65,43

6 42,8 567,49 5,67 82,31 467,49 4,67 67,80

7 44,6 584,22 5,84 84,74 484,22 4,84 70,23

8 46,4 601,31 6,01

9 48,2 618,77 6,19 89,75 518,77 5,19 75,24

10 50 636,60 6,37 92,33 536,60 5,37 77,83

87,21 501,31 5,01 72,71

Service Manual

14

Technical Information

Service Manual

Temperature Absolute pressure Gauge pressure

11 51,8 654,81 6,55 94,97 554,81 5,55 80,47

12 53,6 673,40 6,73 97,67 573,40 5,73 83,17

13 55,4 692,38 6,92 100,42 592,38 5,92 85,92

14 57,2 711,75 7,12 103,23 611,75 6,12 88,73

15 59 731,51 7,32 106,10 631,51 6,32 91,59

16 60,8 751,68 7,52 109,02 651,68 6,52 94,52

17 62,6 772,25 7,72 112,01 672,25 6,72 97,50

18 64,4 793,24 7,93 115,05 693,24 6,93 100,55

19 66,2 814,64 8,15 118,16 714,64 7,15 103,65

20 68 836,46 8,36 121,32 736,46 7,36 106,82

21 69,8 858,71 8,59 124,55 758,71 7,59 110,04

22 71,6 881,39 8,81 127,84 781,39 7,81 113,33

23 73,4 904,51 9,05 131,19 804,51 8,05 116,69

24 75,2 928,07 9,28 134,61 828,07 8,28 120,10

25 77 952,07 9,52 138,09 852,07 8,52 123,58

26 78,8 976,53 9,77 141,64 876,53 8,77 127,13

27 80,6 1001,45 10,01 145,25 901,45 9,01 130,75

28 82,4 1026,83 10,27 148,93 926,83 9,27 134,43

29 84,2 1052,68 10,53 152,68 952,68 9,53 138,18

30 86 1079,00 10,79 156,50 979,00 9,79 141,99

31 87,8 1105,79 11,06 160,38 1005,79 10,06 145,88

32 89,6 1133,08 11,33 164,34 1033,08 10,33 149,84

33 91,4 1160,85 11,61 168,37 1060,85 10,61 153,87

34 93,2 1189,12 11,89 172,47 1089,12 10,89 157,97

35 95 1217,88 12,18 176,64 1117,88 11,18 162,14

36 96,8 1247,16 12,47 180,89 1147,16 11,47 166,38

37 98,6 1276,94 12,77 185,21 1176,94 11,77 170,70

38 100,4 1307,24 13,07 189,60 1207,24 12,07 175,10

39 102,2 1338,07 13,38 194,07 1238,07 12,38 179,57

40 104 1369,42 13,69 198,62 1269,42 12,69 184,12

41 105,8 1401,31 14,01 203,25 1301,31 13,01 188,74

42 107,6 1433,73 14,34 207,95 1333,73 13,34 193,44

43 109,4 1466,71 14,67 212,73 1366,71 13,67 198,23

44 111,2 1500,23 15,00 217,59 1400,23 14,00 203,09

45 113 1534,31 15,34 222,54 1434,31 14,34 208,03

46 114,8 1568,96 15,69 227,56 1468,96 14,69 213,06

47 116,6 1604,18 16,04 232,67 1504,18 15,04 218,17

48 118,4 1639,97 16,40 237,86 1539,97 15,40 223,36

49 120,2 1676,34 16,76 243,14 1576,34 15,76 228,63

50 122 1713,30 17,13 248,50 1613,30 16,13 233,99

51 123,8 1750,86 17,51 253,94 1650,86 16,51 239,44

52 125,6 1789,02 17,89 259,48 1689,02 16,89 244,98

53 127,4 1827,79 18,28 265,10 1727,79 17,28 250,60

54 129,2 1867,17 18,67 270,81 1767,17 17,67 256,31

55 131 1907,17 19,07 276,62 1807,17 18,07 262,11

56 132,8 1947,80 19,48 282,51 1847,80 18,48 268,01

57 134,6 1989,07 19,89 288,49 1889,07 18,89 273,99

58 136,4 2030,98 20,31 294,57 1930,98 19,31 280,07

59 138,2 2073,54 20,74 300,75 1973,54 19,74 286,24

60 140 2116,75 21,17

HC Refrigerant R-290

307,01 2016,75 20,17 292,51

Technical Information

15

Service Manual

Part

Ⅰ

: Technical Information

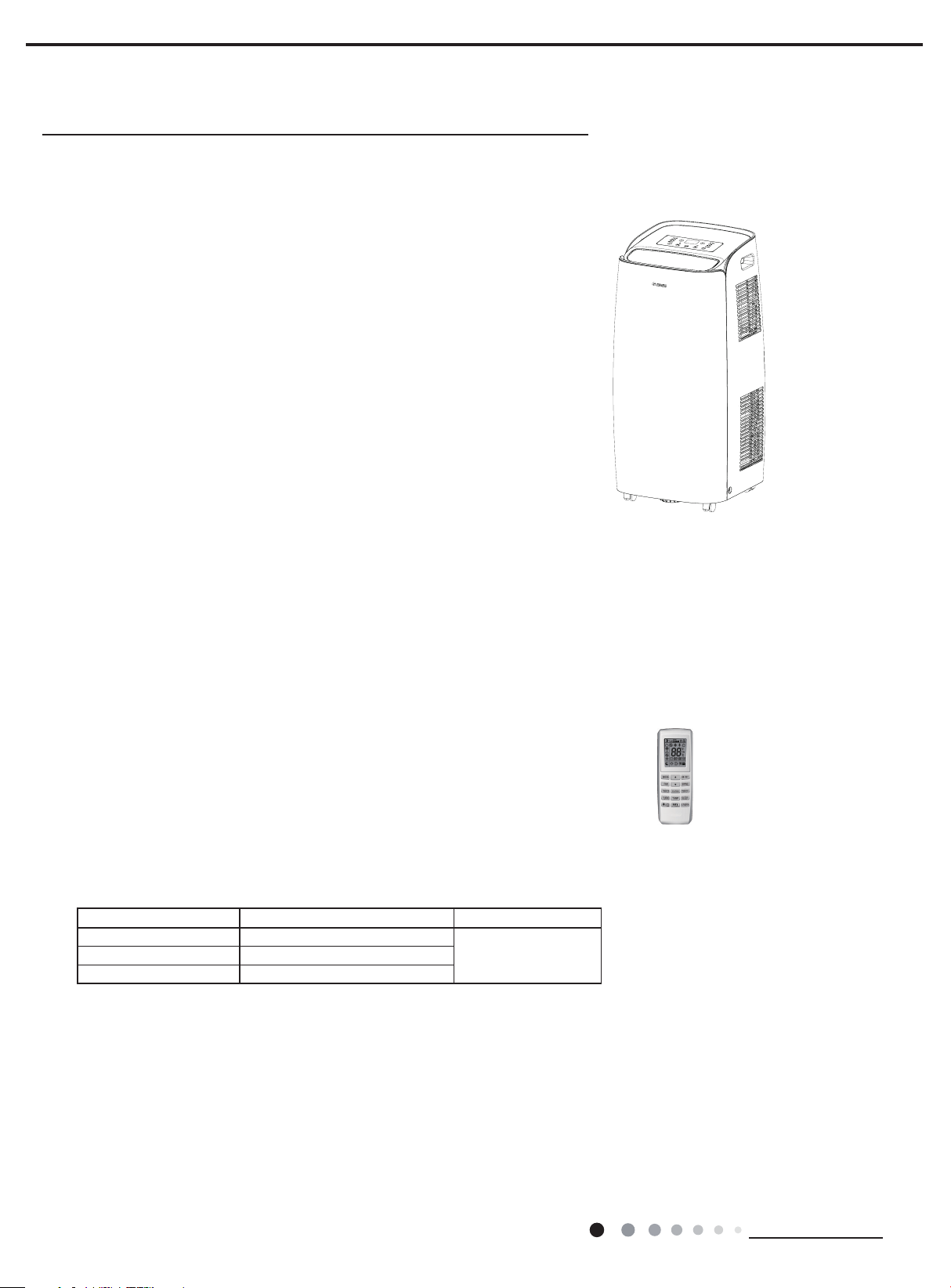

1. Summary

GPC10AN-K5NNA1A

GPC12AN-K5NNA1A

GPH12AN-K5NNA1A

Remote Controller:

YV1F9(WiFi)

Models Product Code Remote Controller

GPC12AN-K5NNA1A CK010032400/CK010032401

GPH12AN-K5NNA1A CK010031300

YV1F9(WiFi)GPC10AN-K5NNA1A CK010032300

16

Technical Information

Service Manual

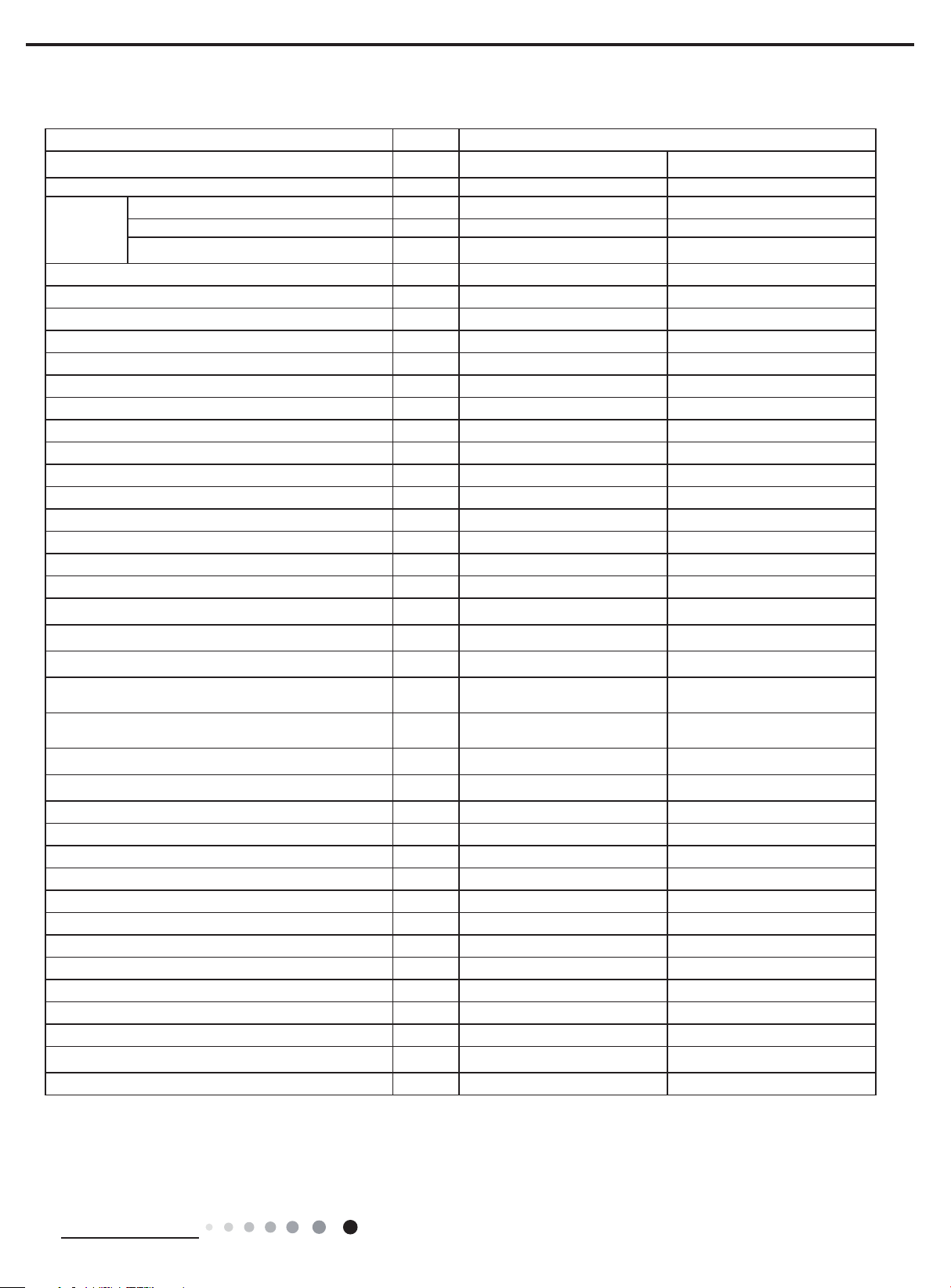

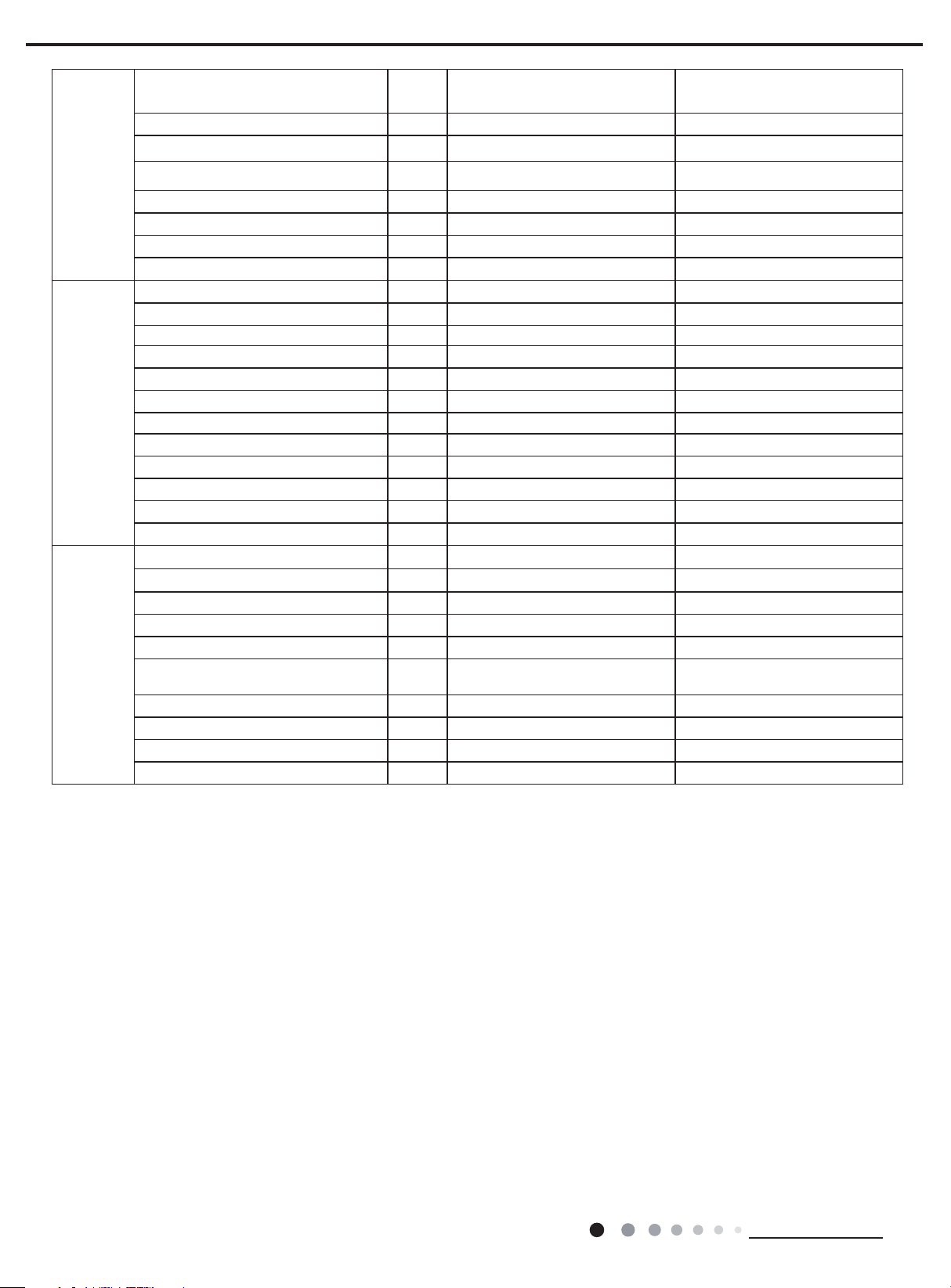

2. Specications

Parameter Unit Value

Model GPC10AN-K5NNA1A GPC12AN-K5NNA1A

Product Code CK010032300 CK010032400

Power

Supply

Rated Voltage V

Rated Frequency Hz 50 50

Phases 1 1

~

Cooling Capacity W 2900 3500

Heating Capacity W / /

Cooling Power Input W 935 1345

Heating Power Input W / /

Cooling Power Current A 4.1 5.9

Heating Power Current A / /

Rated Input W 1100 1550

Rated Current A 5.2 8.0

Air Flow Volume(H/M/L) m

3

/h 380/330/280 380/330/280

Dehumidifying Volume L/h 1.5 1.8

EER W/W 3.1 2.6

COP W/W / /

SEER / /

HSPF / /

Application Area m

2

Climate Type T1 T1

Isolation I I

Moisture Protection IPX0 IPX0

Permissible Excessive Operating Pressure for the

Discharge Side

Permissible Excessive Operating Pressure for the

Suction Side

MPa 3 3

MPa 1.5 1.5

Throttling Method Capillary Capillary

Defrosting Method / /

Fuse current A 3.15 3.15

o

Operation Temp

Ambient Temp (Cooling)

Ambient Temp (Heating)

C 16~30 16~30

o

C 16~35 16~35

o

C / /

Sound Pressure Level (H/M/L) dB (A) 53/51/49 53/51/49

Sound Power Level (H/M/L) dB (A) 64/62/60 64/62/60

Dimension (WXHXD) mm 405X835X385 405X835X385

Dimension of Carton Box (LXWXH) mm 577X451X864 577X451X864

Dimension of Package (LXWXH) mm 580X454X879 580X454X879

Net Weight kg 35.5 35.5

Gross Weight kg 41 41

Refrigerant R290 R290

Refrigerant Charge kg 0.3 0.28

220-240 220-240

15-22 15-22

Technical Information

17

Service Manual

Compressor

Evaporator

Condenser

Compressor Manufacturer/Trademark

Compressor Model QXD-B172A030A QXD-B222A030

Compressor Oil 5GSD-TB or equivalent 5GSD-TB or equivalent

Compressor Type Rotary Rotary

L.R.A. A 21.5 26

Compressor RLA A 3.4 4.5

Compressor Power Input W 770 1000

Overload Protector HPA-022 HPA-030

Fan Type Centrifugal Centrifugal

Diameter Length(DXL) mm Φ204.6X72 Φ204.6X72

Cooling Speed(H/M/L) rpm 1000/860/730 1000/860/730

Heating Speed(H/M/L) W 1000/860/730 1000/860/730

Fan Motor RLA A 0.29 0.29

Fan Motor Capacitor μF 2.5 2.5

Form Aluminum Fin-copper Tube Aluminum Fin-copper Tube

Pipe Diameter mm Φ7 Φ7

Row-n Gap mm 2-1.4 2-1.4

Coil Length (LXDXW) mm 591X25.4X228.6 591X25.4X228.6

Swing Motor Model / /

Output of Swing Motor W / /

Fan Type Centrifugal Centrifugal

Fan Diameter mm Φ224.5X80 Φ224.5X80

Form Aluminum Fin-copper Tube Aluminum Fin-copper Tube

Pipe Diameter mm Φ5 Φ5

Rows-n Gap mm 3-1.3 + 1-1.4 2-1.3 + 1-1.4

Coil Length (LXDXW) mm 592X34.2X304.8/475X11.4X266.7 576X22.8X304.8/ 475X11.4X266.7

ZHUHAI LANDA COMPRESSOR

CO., LTD

ZHUHAI LANDA COMPRESSOR

CO., LTD

Fan Motor Speed rpm 980/800 980/800

Output of Fan Motor W 50 50

Fan Motor RLA A 0.5 0.5

Fan Motor Capacitor μF 2.5 2.5

The above data is subject to change without notice. Please refer to the nameplate of the unit.

18

Technical Information

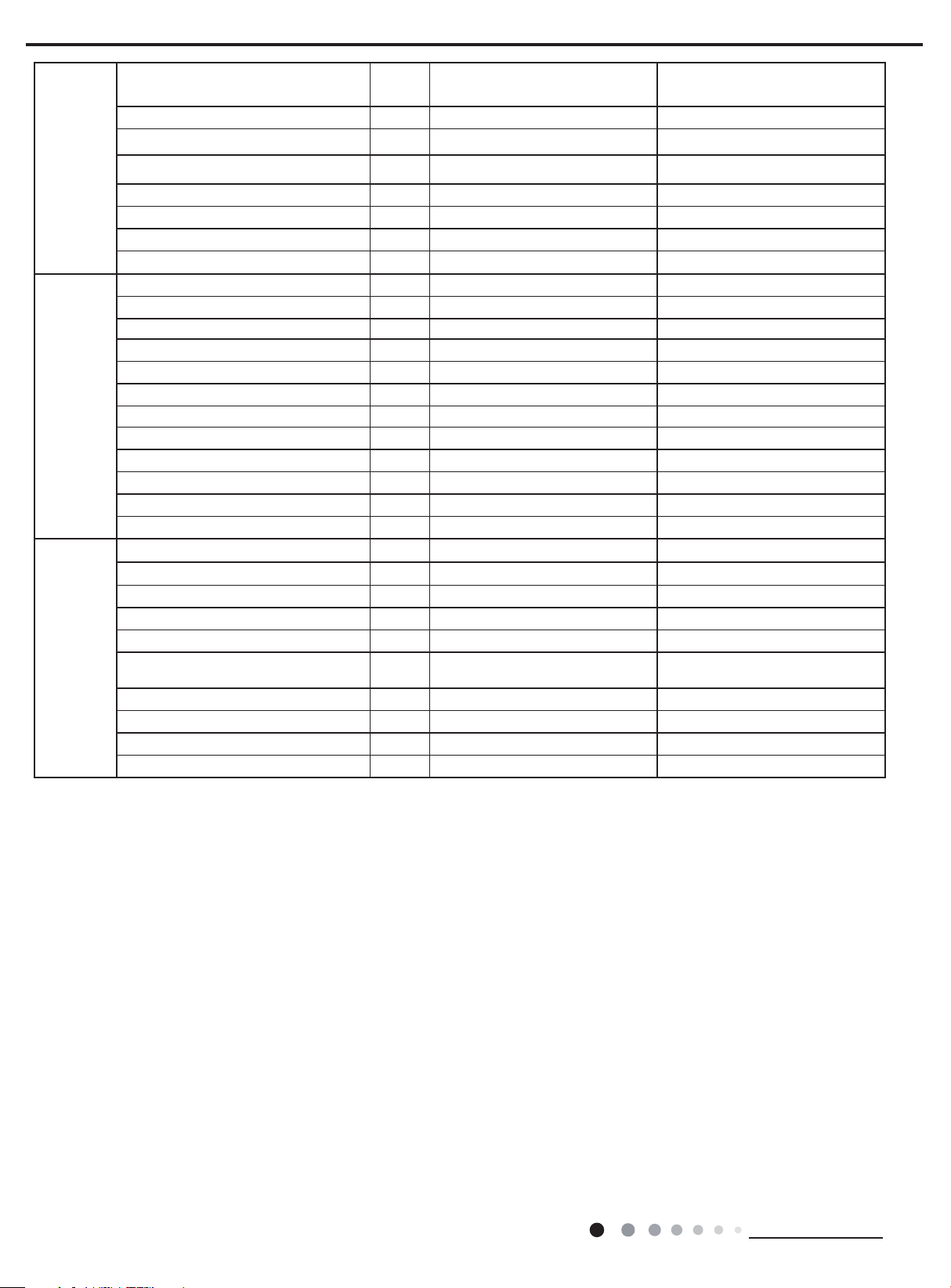

Service Manual

Parameter Unit Value

Model GPC12AN-K5NNA1A GPH12AN-K5NNA1A

Product Code CK010032401 CK010031300

Power

Supply

Rated Voltage V

~

Rated Frequency Hz 50 50

Phases 1 1

220-240 220-240

Cooling Capacity W 3500 3500

Heating Capacity W / 3500

Cooling Power Input W 1345 1345

Heating Power Input W / 1130

Cooling Power Current A 5.9 5.9

Heating Power Current A / 4.9

Rated Input W 1550 1650

Rated Current A 8.0 8.4

Air Flow Volume(H/M/L) m

3

/h 380/330/280 380/330/280

Dehumidifying Volume L/h 1.8 1.8

EER W/W 2.6 2.6

COP W/W / 3.1

SEER / /

HSPF / /

Application Area m

2

15-22 15-22

Climate Type T1 T1

Isolation I I

Moisture Protection IPX0 IPX0

Permissible Excessive Operating Pressure for the

Discharge Side

Permissible Excessive Operating Pressure for the

Suction Side

MPa 3 3

MPa 1.5 1.5

Throttling Method Capillary Capillary

Defrosting Method / /

Fuse current A 3.15 3.15

o

Operation Temp

Ambient Temp (Cooling)

Ambient Temp (Heating)

C 16~30 16~30

o

C 16~35 16~35

o

C / 10~27

Sound Pressure Level (H/M/L) dB (A) 53/51/49 53/51/49

Sound Power Level (H/M/L) dB (A) 64/62/60 65/63/61

Dimension (WXHXD) mm 405X835X385 405X835X385

Dimension of Carton Box (LXWXH) mm 577X451X864 577X451X864

Dimension of Package (LXWXH) mm 580X454X879 580X454X879

Net Weight kg 35.5 36.0

Gross Weight kg 41 41.5

Refrigerant R290 R290

Refrigerant Charge kg 0.28 0.3

Technical Information

19

Service Manual

Compressor

Evaporator

Condenser

Compressor Manufacturer/Trademark

Compressor Model QXD-B222A030 QXD-B222A030

Compressor Oil 5GSD-TB or equivalent 5GSD-TB or equivalent

Compressor Type Rotary Rotary

L.R.A. A 26 26

Compressor RLA A 4.5 4.5

Compressor Power Input W 1000 1000

Overload Protector HPA-030 HPA-030

Fan Type Centrifugal Centrifugal

Diameter Length(DXL) mm Φ204.6X72 Φ204.6X72

Cooling Speed(H/M/L) rpm 1000/860/730 1000/860/730

Heating Speed(H/M/L) W / 1000/860/730

Fan Motor RLA A 0.29 0.29

Fan Motor Capacitor μF 2.5 2.5

Form Aluminum Fin-copper Tube Aluminum Fin-copper Tube

Pipe Diameter mm Φ7 Φ7

Row-n Gap mm 2-1.4 3-1.4

Coil Length (LXDXW) mm 591X25.4X228.6 520X38.1X228.6

Swing Motor Model / /

Output of Swing Motor W / /

Fan Type Centrifugal Centrifugal

Fan Diameter mm Φ224.5X80 Φ224.5X80

Form Aluminum Fin-copper Tube Aluminum Fin-copper Tube

Pipe Diameter mm Φ5 Φ5

Rows-n Gap mm 2-1.3 + 1-1.4 2-1.3 + 1-1.4

Coil Length (LXDXW) mm 576X22.8X304.8+475X11.4X266.7 576X22.8X304.8+475X11.4X266.7

ZHUHAI LANDA COMPRESSOR

CO., LTD

ZHUHAI LANDA COMPRESSOR

CO., LTD

Fan Motor Speed rpm 980/800 980/800

Output of Fan Motor W 50 50

Fan Motor RLA A 0.5 0.5

Fan Motor Capacitor μF 2.5 2.5

The above data is subject to change without notice. Please refer to the nameplate of the unit.

20

Technical Information

Service Manual

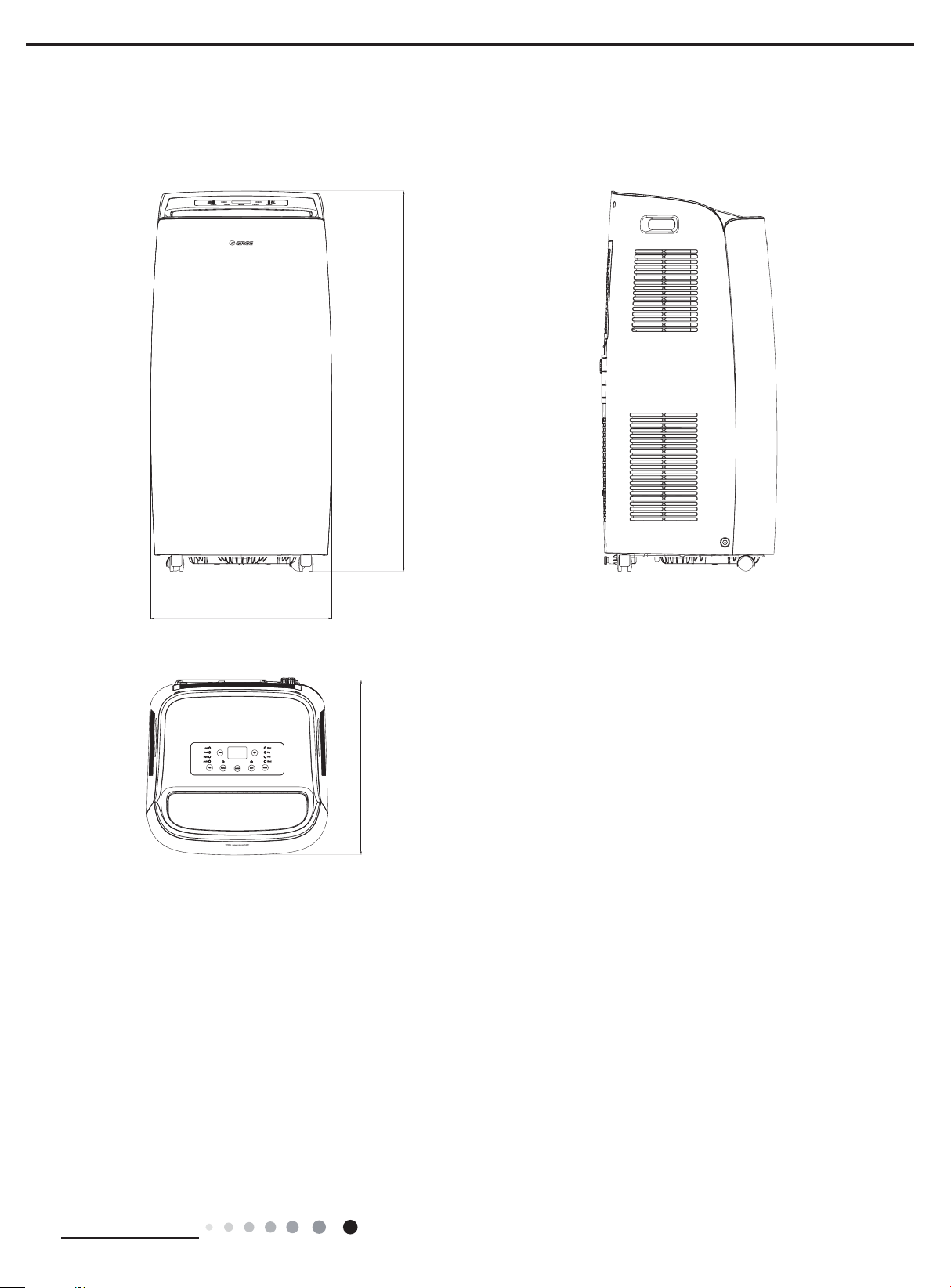

3. Outline Dimension Diagram

835

405

385

Unit:mm

Technical Information

21

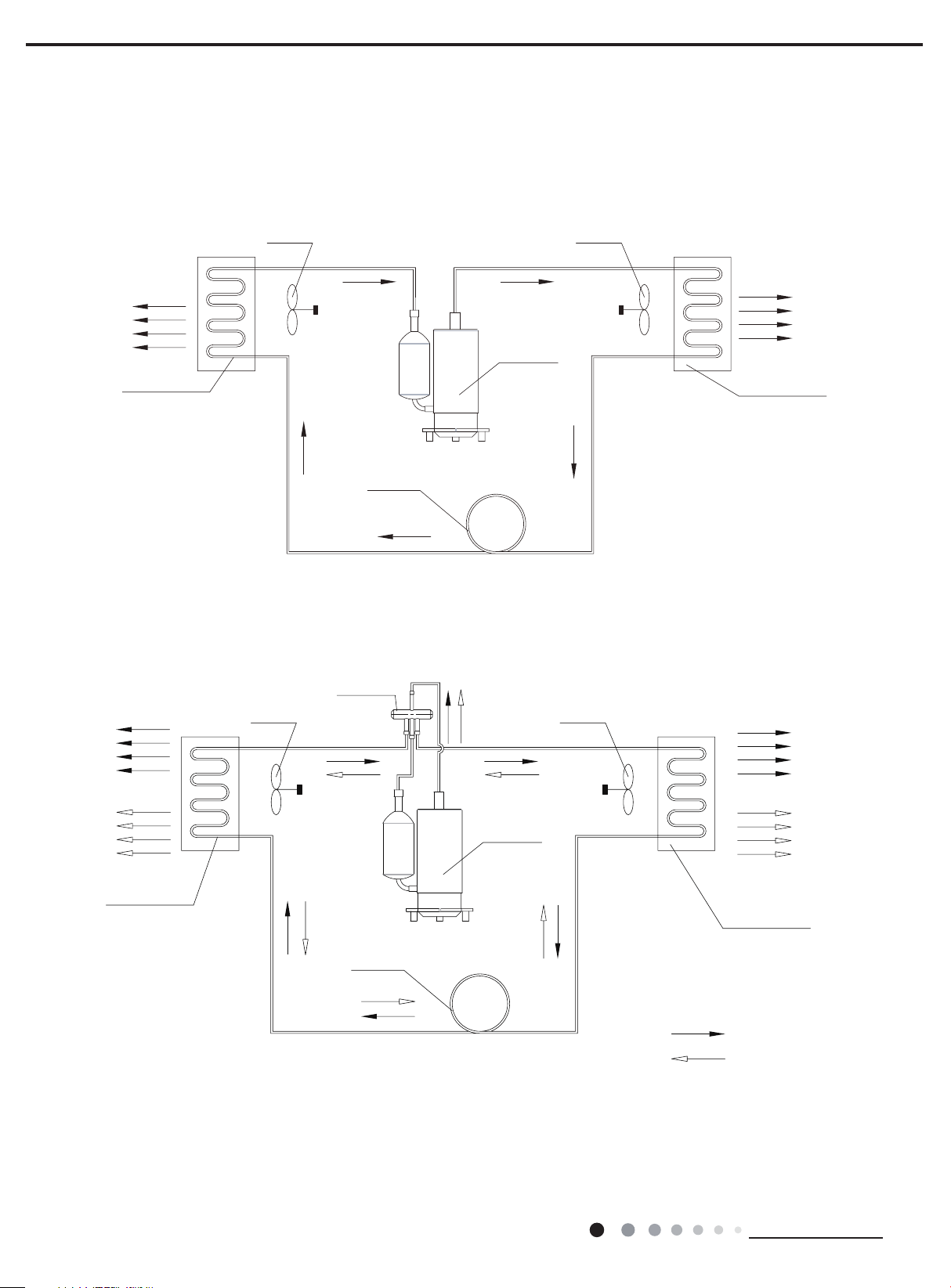

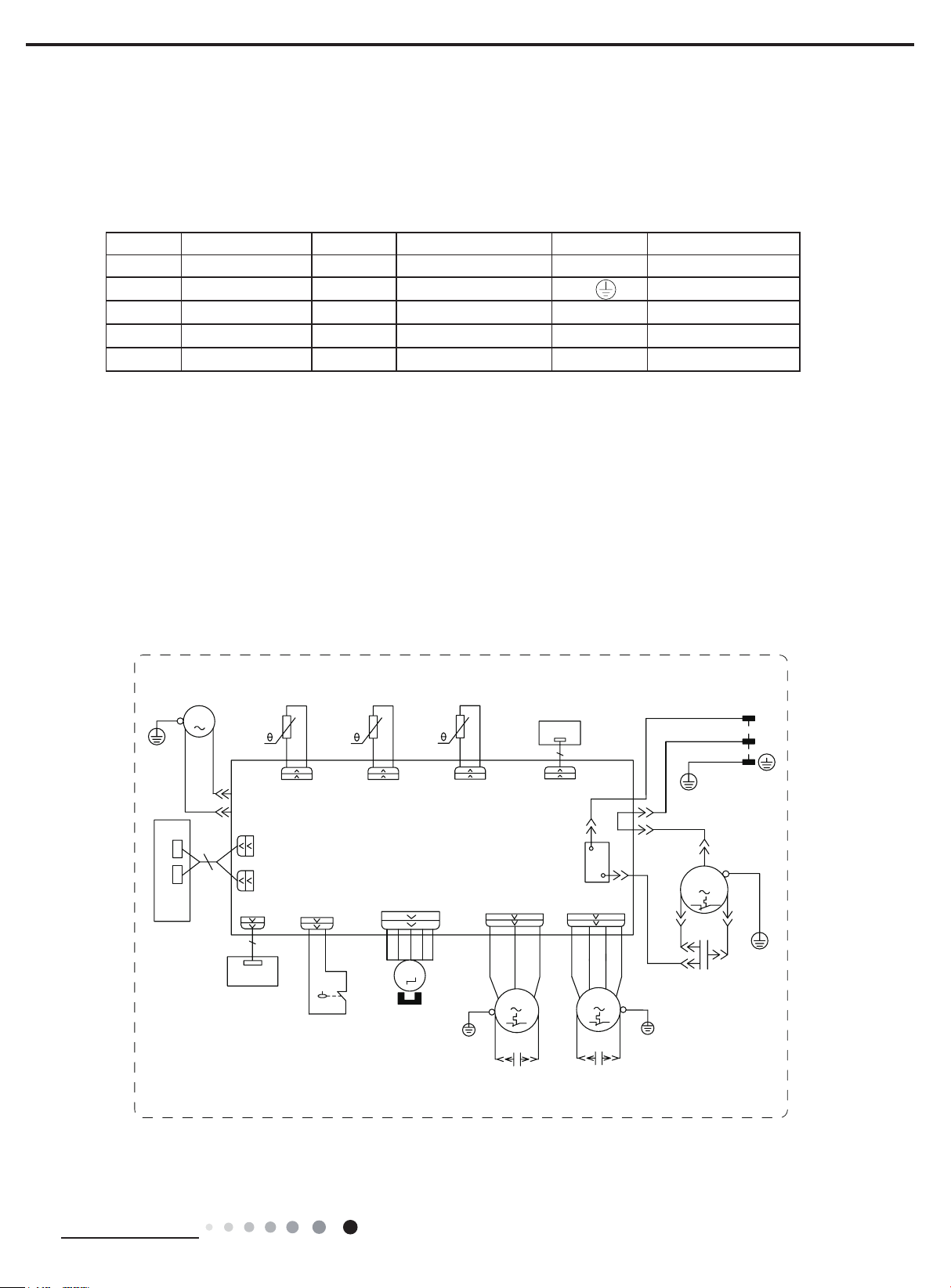

4. Refrigerant System Diagram

Cooling Only Model

Cooling & Heating Model

AIR

Service Manual

COOLED AIR

INDOOR COILS

COOLED AIR

CENTRIFUGAL FAN

CENTRIFUGAL FAN

CAPILLARY

REFRIGERANT FLOW DIRECTION

4-Way valve

COMPRESSOR

CENTRIFUGAL FAN

CENTRIFUGAL FAN

HOT DISCHARGED

OUTDOOR COILS

HOT DISCHARGED AIR

HOT AIR

INDOOR COILS

CAPILLARY

REFRIGERANT FLOW DIRECTION

COMPRESSOR

NOTES:

COOLED AIR

OUTDOOR COILS

COOLING MODE

HEATING MODE

22

Technical Information

Service Manual

5. Electrical Part

5.1 Wiring Diagram

●Instruction

Symbol Symbol Color Symbol Symbol Color Symbol Name

WH White GN Green COMP Compressor

YE Yellow BN Brown Grounding wire

RD Red BU Blue / /

YEGN Yellow/Green BK Black / /

VT Violet OG Orange / /

●Electric Diagram

GPC10AN-K5NNA1A

GPC12AN-K5NNA1A(CK010032400/CK010032401)

:$7(502725

<(*1

0

5'

3(

',63

%8

1

:$7(5

',63

52207(03

6(1625

5220

78%(7(03

6(1625

5757

78%(

$3

0$,1%2$5'

',63

$3

',63/$<

%2$5'

:,),

$3

:,),

02'8/(

',63

+,*+:3

%.

5'

:$7(5/(9(/

6:,7&+

6$

6:,1*

0

67(33,1*

02725

28778%(7(03

6(1625

57

28778%(

2)$1

<(*1

3(

5'

0

&$3

5(&(,9(5

%2$5'

$3

5(&

$&/

.

5'

%1

&203

)$1

0

&$3

1

<(*1

%1

%8

&203

50

5'

5'

3(

%1%.

%8:+

<(*1*1

3(

&

&203

&$3

&

32:(5

/

1

<(*1

6

<(

3(

600007061240

Technical Information

&

'2:1)$1

02725

&

83)$1

02725

23

Loading...

Loading...