Gree GMV-Q504WM/B-X, GMV-Q280WM/B-X, GMV-Q615WM/B-X, GMV-Q560WM/B-X, GMV-Q400WM/B-X Owner's Manual

...

Heat Recovery DC Inverter Multi

VRF Unit

…

Owner's Manual

Air Conditioners

Models:

GMV-Q224WM/B-X

GMV-Q280WM/B-X

GMV-Q335WM/B-X

GMV-Q400WM/B-X

GMV-Q450WM/B-X

GMV-Q504WM/B-X

GMV-Q1800WM/B-X

Thank you for choosing Air Conditioners, please read this owner’s manual carefully before

operation and retain it for future reference.If you have lost the Owner’s Manual, please contact

the local agent or visit www.gree.com or send email to global@gree.com.cn or electronic

version.

GREE reserves the right to interpret this manual which will be subject to any change due to

product improvement without further notice.

GREE Electric Appliances, Inc. of Zhuhai reserves the final right to interpret this manual.

Preface

Gree DC Inverter Multi VRF System, with the most advanced technologies in the world,

uses eco-friendly refrigerant R410A as its cooling medium. For correct installation and

operation, please read this manual carefully. Before reading the manual, please note that:

(1) To ensure safety when operating the units, please strictly follow the instructions in this

manual.

(2) The total capacity of running indoor units must not exceed that of the outdoor units.

Otherwise, the cooling (heating) effect of each IDU would be poor.

(3) Make sure that this manual is kept by direct operators and maintainers.

(4) In case of malfunction, please examine the following items and contact our authorized

service centers as soon as possible.

1) Air conditioner’s nameplate (model, cooling capacity, product code, ex-factory date);

2) Malfunction status (detail description of conditions before and after malfunction occurs)

(5) All units have been strictly tested and proved to be qualified before ex-factory. To

avoid damage or operation failure which may be caused by improper disassembly, please do

not disassemble units by yourself. If disassembly is needed, please contact our authorized

service centers.

(6) All graphics and information in this manual are only for reference. Manufacturer

reserves the right for changes in terms of sales or production at any time and without prior

notice.

(7) Under the standby status, the unit will consume a little power for ensuring reliability of

the complete unit, maintaining normal communication and preheating refrigerant. When the

unit won’t be used for a long time, please cut off the power of the complete unit. However,

please preheat it when operating the unit next time.

This appliance can be used by children aged from 8 years and above and persons with

reduced physical, sensory or mental capabilities or lack of experience and knowledge if they

have been given supervision or instruction concerning use of the appliance in a safe way and

understand the hazards involved. Children shall not play with the appliance. Cleaning and

user maintenance shall not be made by children without supervision.

Correct Disposal of this product: This marking indicates that this product should not be

disposed with other household wastes throughout the EU. To prevent possible harm to the

environment or human health from uncontrolled waste disposal, recycle it responsibly to

promote the sustainable reuse of material resources. To return your used device, please use

the return and collection systems or contact the retailer where the product was purchased.

They can take this product for environmental safe recycling.

Contents

1 SAFETY PRECAUTIONS ................................................................................................................................... 1

2 PRODUCT INTRODUCTION ............................................................................................................................. 3

2.1 NAMES OF MAIN PARTS................................................................................................................................ 3

2.2 COMBINATIONS OF OUTDOOR UNITS ........................................................................................................... 3

2.3 COMBINATIONS OF INDOOR AND OUTDOOR UNITS ..................................................................................... 4

2.4 OPERATION RANGE ...................................................................................................................................... 6

3 PREPARATION BEFORE INSTALLATION ............................................................................................ 6

3.1 STANDARD PARTS ........................................................................................................................................ 6

3.2 INSTALLATION SITE....................................................................................................................................... 6

3.3 CONNECTION PIPE REQUIREMENT ............................................................................................................ 10

4 INSTALLATION INSTRUCTIONS .......................................................................................................... 11

4.1 DIMENSION OF OUTDOOR UNIT AND MOUNTING HOLE ............................................................................. 11

4.2 REFRIGERANT CONNECTION PIPE OF INDOOR AND OUTDOOR UNITS ...................................................... 12

4.3 INSTALLATION OF REFRIGERANT CONNECTION PIPE ................................................................................ 21

4.4 VACUUM PUMPING, REFRIGERANT ADDING .............................................................................................. 24

4.5 ELECTRIC WIRING ...................................................................................................................................... 26

4.6 SYSTEM COMMUNICATION FEATURES ....................................................................................................... 32

4.7 CONNECTION METHODS AND PROCEDURE OF COMMUNICATION SYSTEM .............................................. 38

4.8 DIAGRAM OF EXTERNAL ELECTRIC WIRING .............................................................................................. 45

5 CHECK ITEMS AFTER INSTALLATION AND TEST OPERATION .................................................... 47

5.1 CHECK ITEMS AFTER INSTALLATION ........................................................................................................... 47

5.2 TRIAL OPERATION ...................................................................................................................................... 47

6 COMMON MALFUNCTION AND TROUBLESHOOTING .................................................................... 59

7 ERROR INDICATION ............................................................................................................................... 60

8 MAINTENANCE AND CARE .................................................................................................................. 64

8.1 OUTDOOR HEAT EXCHANGER.................................................................................................................... 64

8.2 DRAIN PIPE ................................................................................................................................................. 64

8.3 NOTICE BEFORE SEASONAL USE ............................................................................................................... 64

8.4 MAINTENANCE AFTER SEASONAL USE ...................................................................................................... 64

8.5 PARTS REPLACEMENT ............................................................................................................................... 64

9 AFTER-SALES SERVICE ....................................................................................................................... 64

Heat Recovery DC Inverter Multi VRF Unit

Please install the unit

according to instructions

in this manual. Read this

manual carefully before

starting up or checking the

machine.

Installation should be

performed by distributor or

qualified personnel. Do

not install the product by

yourself. Improper

installation will result in

water leakage, electric

shock or fire hazard.

Before installation, please

check the power cord if it

complies with the power

supply requirement on the

nameplate. Make sure the

power supply is safe.

This air conditioner must

be properly grounded

through the receptacle to

avoid electric shock. The

ground wire shouldn’t be

connected with gas pipe,

water pipe, lightning

arrester or telephone line.

When installing,

specialized parts and

accessories must be

used. Otherwise, it may

result in water leakage,

electric shock or fire

hazard.

R410A refrigerant can

produce poisonous gas

once it meets fire, so

please ventilate the room

immediately if refrigerant

leaks out during

installation.

Diameter of power cord

must be large enough.

Damaged power cord or

connecting wire must be

replaced by specialized

electric cable.

After the power cord is

connected, please install

the cover of electric box to

avoid danger.

Nitrogen must be charged

according to technical

requirements.

Short circuit is forbidden.

Do not cancel the

pressure switch,

otherwise unit may be

damaged.

For units with wired

controllers, do not connect

power supply until the

wired controller is well

installed. Otherwise, the

wired controller cannot be

used.

When installation is

finished, please check

and make sure the drain

pipe, pipeline and electric

wire are all well connected

to avoid water leakage,

refrigerant leakage,

electric shock and fire

hazard.

Do not extend fingers or

objects into air outlet or

the return air grille.

If gas heater or petroleum

heater is used in the same

room, please open the

door or window to

maintain good air

circulation, otherwise an

oxygen shortage may

occur,

1 Safety Precautions

means items that must be forbidden! Otherwise, it may lead to personal injury or death or

serious damage.

means items that must be followed! Otherwise, it may lead to personal injury or property loss.

1

Heat Recovery DC Inverter Multi VRF Unit

Do not operate or stop the

unit by inserting or pulling

out the power plug.

Do not turn off the unit

until it runs for at least 5

minutes. Otherwise, oil

return of the compressor

will be affected.

Children are not allowed

to operate the air

conditioner.

Do not operate the air

conditioner with wet

hands.

Please turn off and unplug

your air conditioner before

cleaning. Otherwise,

electric shock or personal

injury may occur.

Do not spray water on the

air conditioner or clean it

with water, otherwise

malfunction or electric

shock may occur.

Do not expose the air

conditioner directly under

damp or corrosive

surroundings.

Connect power 8 hours

before operation. Do not

disconnect power when

you want to stop the unit

in a short period of time,

e.g. in one night. (This is

for protecting the

compressor.)

Volatile liquid like thinner

or gasoline will damage

the appearance of air

conditioner. (Please use

soft dry cloth and wet

cloth with mild detergent

to clean unit’s outer case.)

Under cool mode, do not

set the indoor temperature

too low. Keep the

difference between indoor

temp and outdoor temp

within 5℃.

If abnormal condition

occurs (e.g. unpleasant

smell), please turn off the

unit at once and

disconnect power supply.

Then contact Gree

authorized service center.

If the air conditioner

continues to operate

despite of abnormal

condition, it may be

damaged and cause

electric shock or fire

hazard.)

Do not repair the air

conditioner by yourself.

Improper repair will cause

electric shock or fire

hazard. Please contact

Gree authorized service

center and ask

professional personnel to

repair it.

Gree Electric Appliances, Inc. of Zhuhai will not assume responsibility for any personal injury or property

loss caused by improper installation, improper test running, and unnecessary repair or not following the

instructions of this manual.

2

Heat Recovery DC Inverter Multi VRF Unit

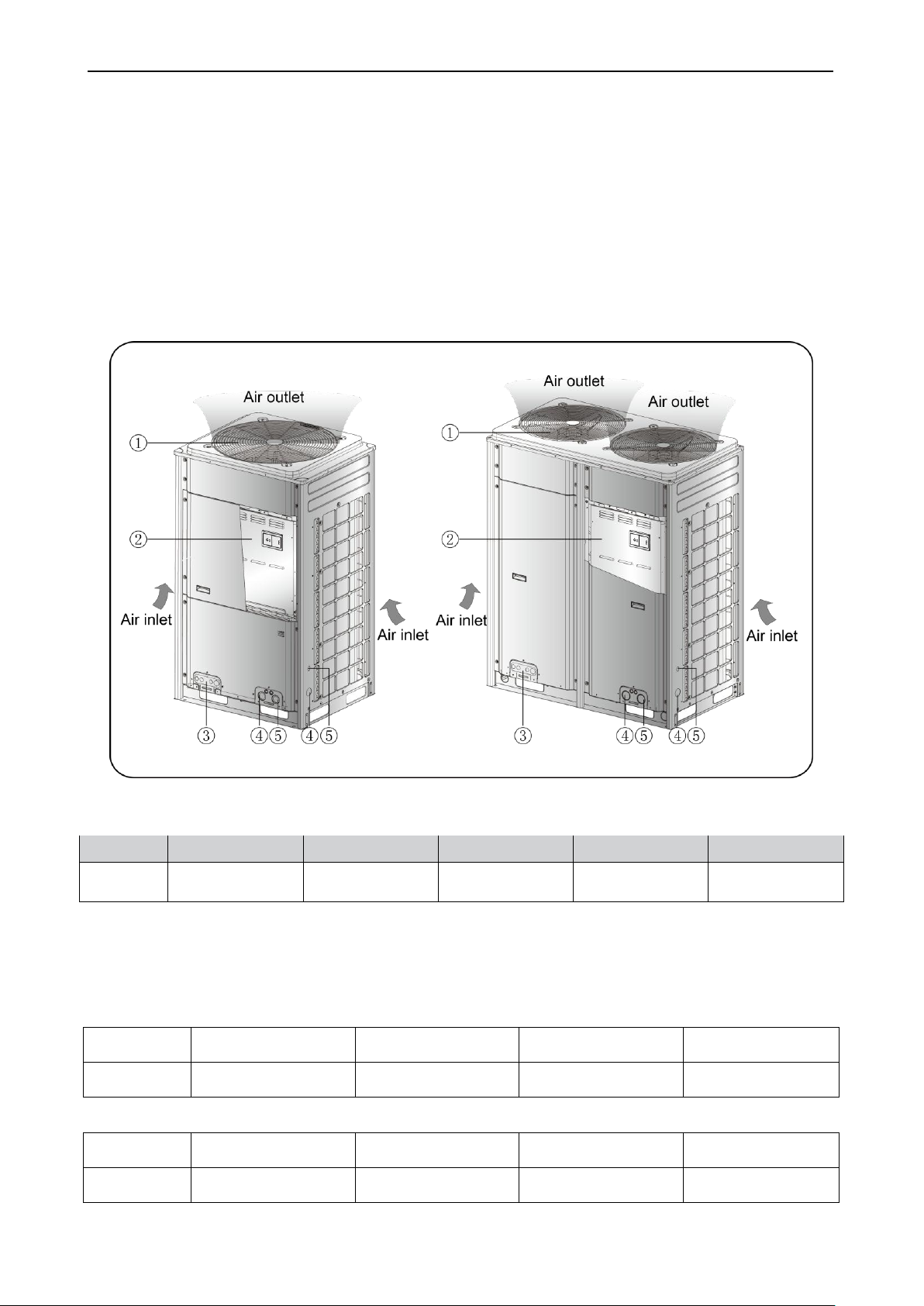

No,

① ② ③ ④ ⑤

Name

Fan motor, motor

Electric box

assembly

Valve interface

Power cord

through-hole

Communication wire

through-hole

Model

(Combined)

GMV-Q504WM/B-X

GMV-Q560WM/B-X

GMV-Q615WM/B-X

GMV-Q680WM/B-X

Model (Single)

GMV-Q224WM/B-X

+ GMV-Q280WM/B-X

GMV-Q280WM/B-X

+ GMV-Q280WM/B-X

GMV-Q280WM/B-X

+ GMV-Q335WM/B-X

GMV-Q280WM/B-X

+ GMV-Q400WM/B-X

Model

(Combined)

GMV-Q730WM/B-X

GMV-Q785WM/B-X

GMV-Q850WM/B-X

GMV-Q900WM/B-X

Model (Single)

GMV-Q280WM/B-X

+ GMV-Q450WM/B-X

GMV-Q335WM/B-X

+ GMV-Q450WM/B-X

GMV-Q400WM/B-X

+ GMV-Q450WM/B-X

GMV-Q450WM/B-X

+ GMV-Q450WM/B-X

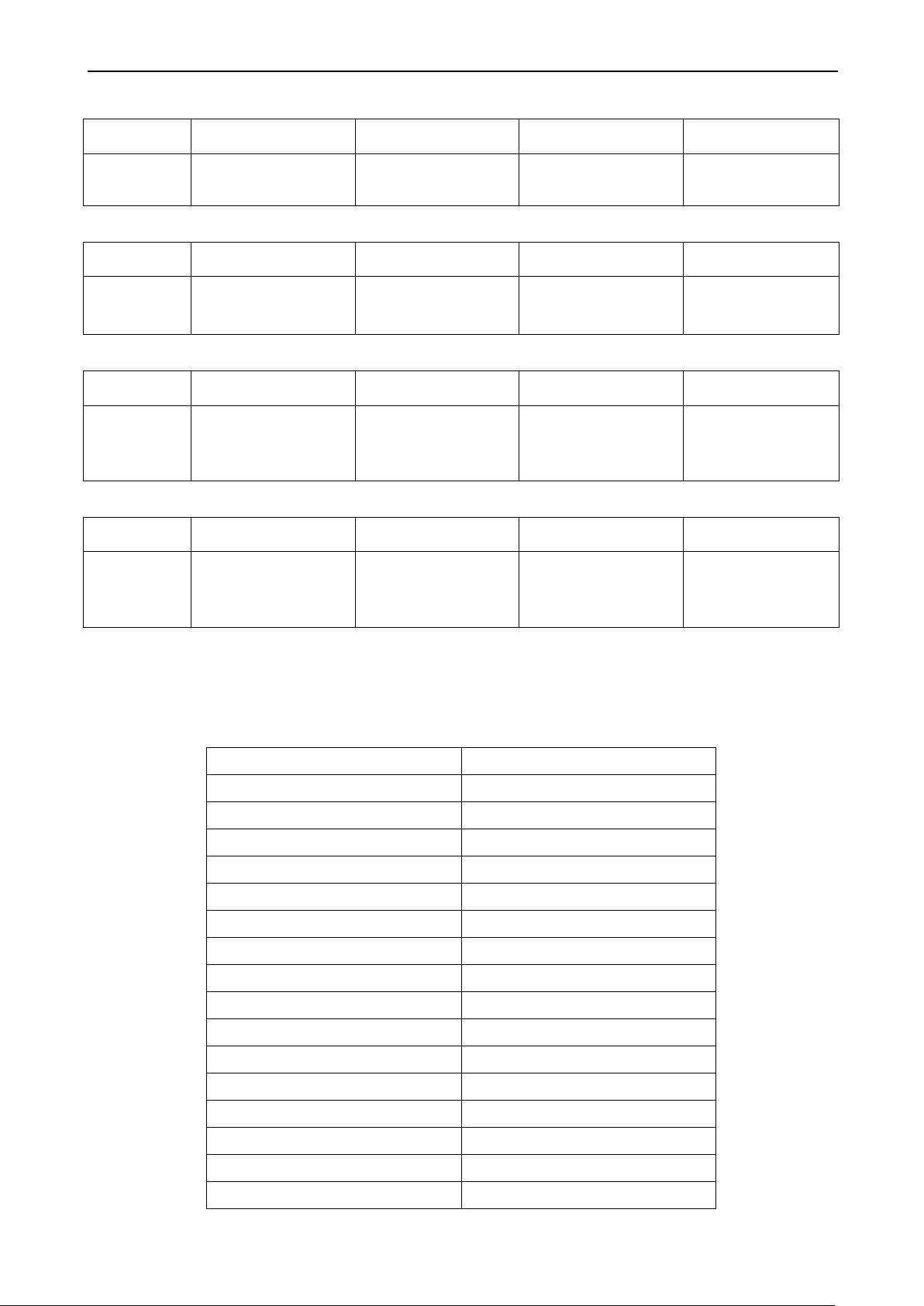

2 Product Introduction

Gree Modular Heat Recovery Multi VRF System adopts inverter compressor technology. By

changing the displacement of compressor, stepless capacity regulation can be realized. Various

product lineups are provided with capacity range from 22.4kW to 180kW, and indoor units within a

same system can operate in cooling or heating mode in the meantime. This system can be widely

used in commercial and working area and is especially applicable to places with big load change.

Gree commercial multi VRF system is absolutely your best choice.

2.1 Names of Main Parts

Figure 1

2.2 Combinations of Outdoor Units

2.2.2 GMV5 HR DC Inverter Heat Recovery Multi VRF Units

3

Heat Recovery DC Inverter Multi VRF Unit

Model

(Combined)

GMV-Q960WM/B-X

GMV-Q1010WM/B-X

GMV-Q1065WM/B-X

GMV-Q1130WM/B-X

Model (Single)

GMV-Q280WM/B-X

+ GMV-Q280WM/B-X

+ GMV-Q400WM/B-X

GMV-Q280WM/B-X

+ GMV-Q280WM/B-X

+ GMV-Q450WM/B-X

GMV-Q280WM/B-X

+ GMV-Q335WM/B-X

+ GMV-Q450WM/B-X

GMV-Q280WM/B-X

+ GMV-Q400WM/B-X

+ GMV-Q450WM/B-X

Model

(Combined)

GMV-Q1180WM/B-X

GMV-Q1235WM/B-X

GMV-Q1300WM/B-X

GMV-Q1350WM/B-X

Model (Single)

GMV-Q280WM/B-X

+ GMV-Q450WM/B-X

+ GMV-Q450WM/B-X

GMV-Q335WM/B-X

+ GMV-Q450WM/B-X

+ GMV-Q450WM/B-X

GMV-Q400WM/B-X

+ GMV-Q450WM/B-X

+ GMV-Q450WM/B-X

GMV-Q450WM/B-X

+ GMV-Q450WM/B-X

+ GMV-Q450WM/B-X

Model

(Combined)

GMV-Q1410WM/B-X

GMV-Q1460WM/B-X

GMV-Q1515WM/B-X

GMV-Q1580WM/B-X

Model (Single)

GMV-Q280WM/B-X

+ GMV-Q280WM/B-X

+ GMV-Q400WM/B-X

+ GMV-Q450WM/B-X

GMV-Q280WM/B-X

+ GMV-Q280WM/B-X

+ GMV-Q450WM/B-X

+ GMV-Q450WM/B-X

GMV-Q280WM/B-X

+ GMV-Q335WM/B-X

+ GMV-Q450WM/B-X

+ GMV-Q450WM/B-X

GMV-Q280WM/B-X

+ GMV-Q400WM/B-X

+ GMV-Q450WM/B-X

+ GMV-Q450WM/B-X

Model

(Combined)

GMV-Q1630WM/B-X

GMV-Q1685WM/B-X

GMV-Q1750WM/B-X

GMV-Q1800WM/B-X

Model (Single)

GMV-Q280WM/B-X

+ GMV-Q450WM/B-X

+ GMV-Q450WM/B-X

+ GMV-Q450WM/B-X

GMV-Q335WM/B-X

+ GMV-Q450WM/B-X

+ GMV-Q450WM/B-X

+ GMV-Q450WM/B-X

GMV-Q400WM/B-X

+ GMV-Q450WM/B-X

+ GMV-Q450WM/B-X

+ GMV-Q450WM/B-X

GMV-Q450WM/B-X

+ GMV-Q450WM/B-X

+ GMV-Q450WM/B-X

+ GMV-Q450WM/B-X

Model of ODU

Max number of connectable IDUs

GMV-Q224WM/B-X

13

GMV-Q280WM/B-X

16

GMV-Q335WM/B-X

19

GMV-Q400WM/B-X

23

GMV-Q450WM/B-X

26

GMV-Q504WM/B-X

29

GMV-Q560WM/B-X

33

GMV-Q615WM/B-X

36

GMV-Q680WM/B-X

39

GMV-Q730WM/B-X

43

GMV-Q785WM/B-X

46

GMV-Q850WM/B-X

50

GMV-Q900WM/B-X

53

GMV-Q960WM/B-X

56

GMV-Q1010WM/B-X

59

GMV-Q1065WM/B-X

63

2.3 Combinations of Indoor and Outdoor Units

(1) See below the number of indoor units that can be connected to an outdoor unit.

4

Heat Recovery DC Inverter Multi VRF Unit

GMV-Q1130WM/B-X

64

GMV-Q1180WM/B-X

64

GMV-Q1235WM/B-X

64

GMV-Q1300WM/B-X

64

GMV-Q1350WM/B-X

64

GMV-Q1410WM/B-X

66

GMV-Q1460WM/B-X

69

GMV-Q1515WM/B-X

71

GMV-Q1580WM/B-X

74

GMV-Q1630WM/B-X

77

GMV-Q1685WM/B-X

80

GMV-Q1750WM/B-X

80

GMV-Q1800WM/B-X

80

(2) The total capacity of indoor units should be within 50%~135% of that of the outdoor unit.

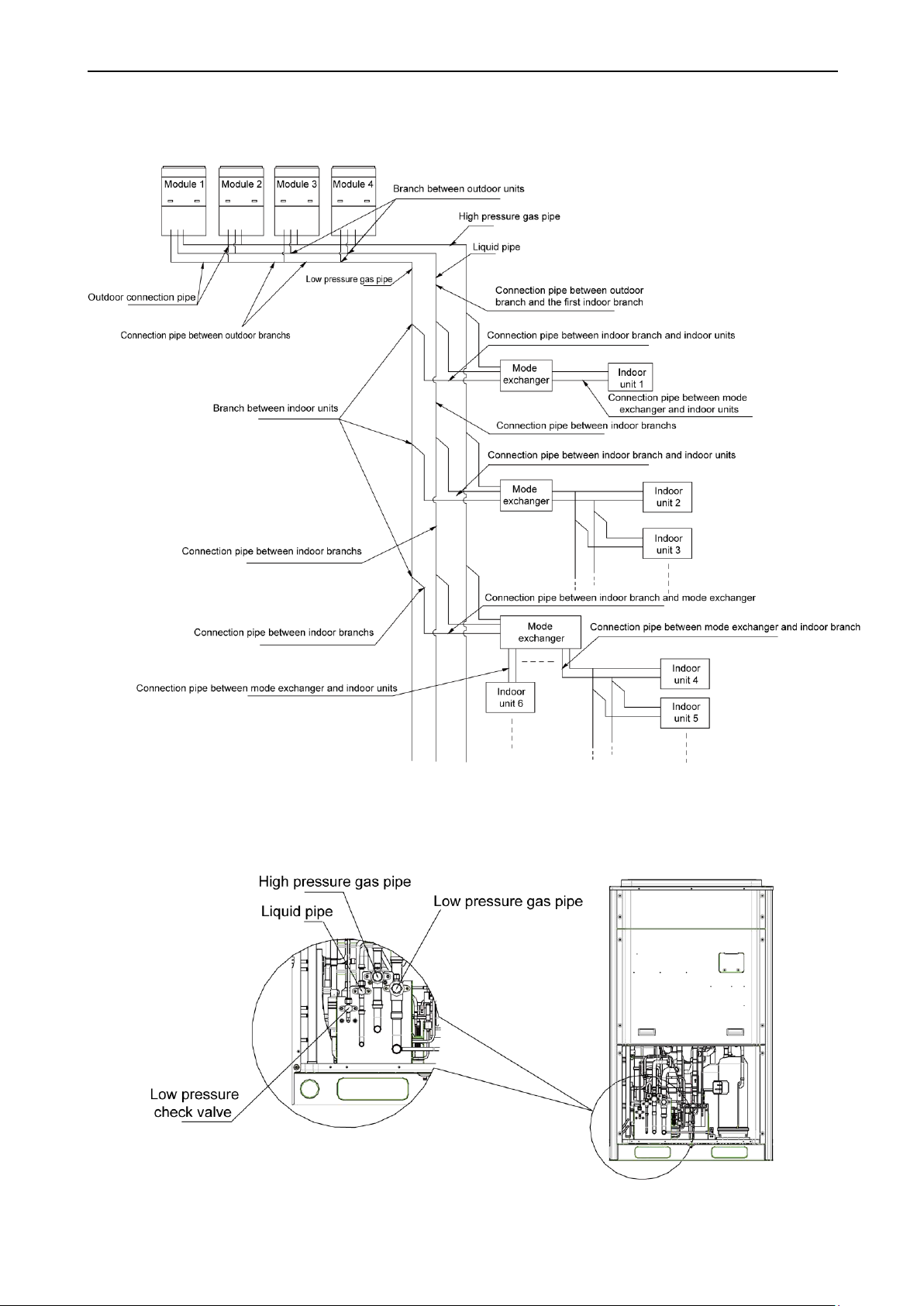

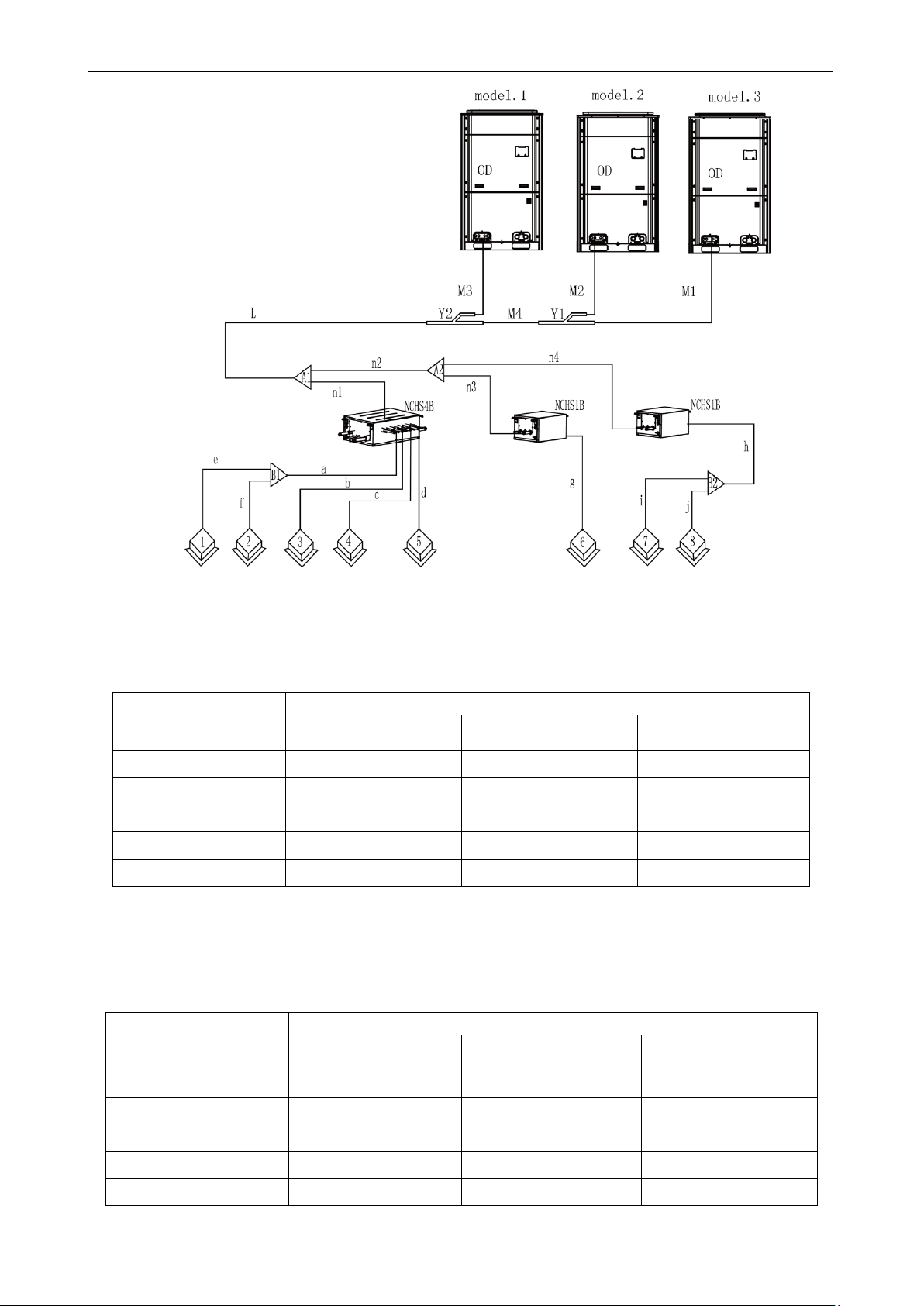

Figure 2

(3) Outdoor units of Modular DC Inverter Heat Recovery System can be connected to multi VRF

indoor units, including cassette type unit, one-way cassette type unit, wall-mounted unit and

duct type unit, as shown in figure 2. When any one of the indoor units receives operating

command, outdoor unit will start operation as per required capacity. When all indoor units stop,

outdoor unit will be shut off. Please note that outdoor unit can’t be connected to indoor unit

directly. Heat pump mode exchanger must be installed between outdoor unit and indoor unit.

5

Heat Recovery DC Inverter Multi VRF Unit

Cooling operation

Outdoor temperature -5℃~50℃

Heating operation

Outdoor temperature -20℃~24℃

Heat recovery operation

Outdoor temperature -10℃~20℃

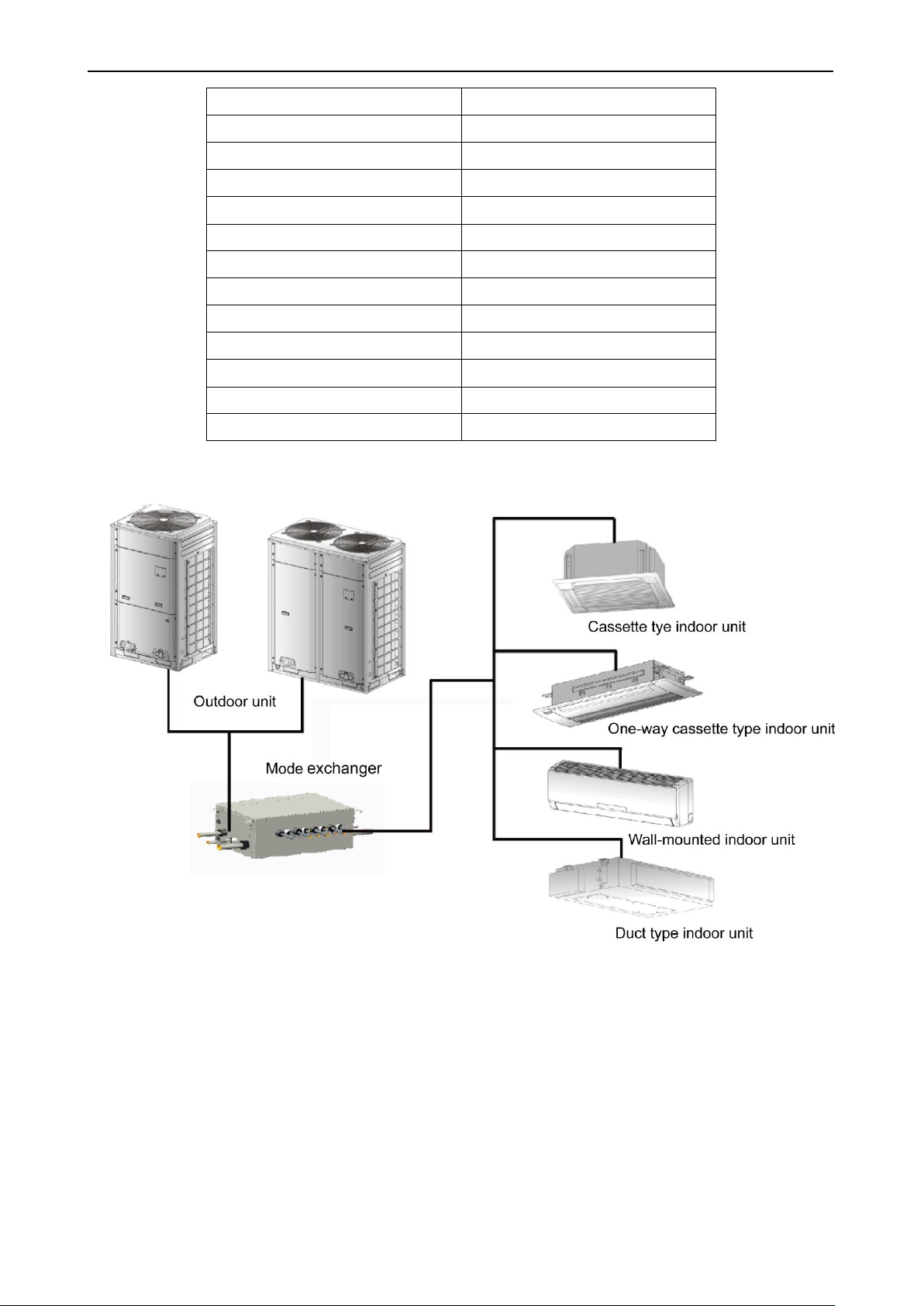

Parts of Outdoor Unit

No.

Name

Appearance

Qty

Remarks

1

User Manual

1( pc)

2

Wire (match with

resistance)

1( pc)

Must be connected to

the last heat pump

mode exchanger of

communication

connection

Select a location which is

strong enough to hold

unit’s weight so that unit

can stand still and erect.

Make sure the unit is not

exposed to sun and rain.

And the location can resist

dust, typhoon and

earthquake.

Please keep the unit away

from inflammable,

explosive and corrosive

gas or waste gas.

Make sure the location

has space for heat

exchange and

maintenance so that unit

can operate reliably with

good ventilation.

ODU and IDU should stay

together as close as

possible to shorten the

length of refrigerant pipe

and reduce bend angles.

Select a location which is

out of children’s reach.

Keep the unit away from

children.

2.4 Operation Range

3 Preparation before Installation

Note: Graphics here are only for reference. Please refer to actual products. Unspecified dimensions

are all in mm.

3.1 Standard Parts

Please use the supplied standard parts as required.

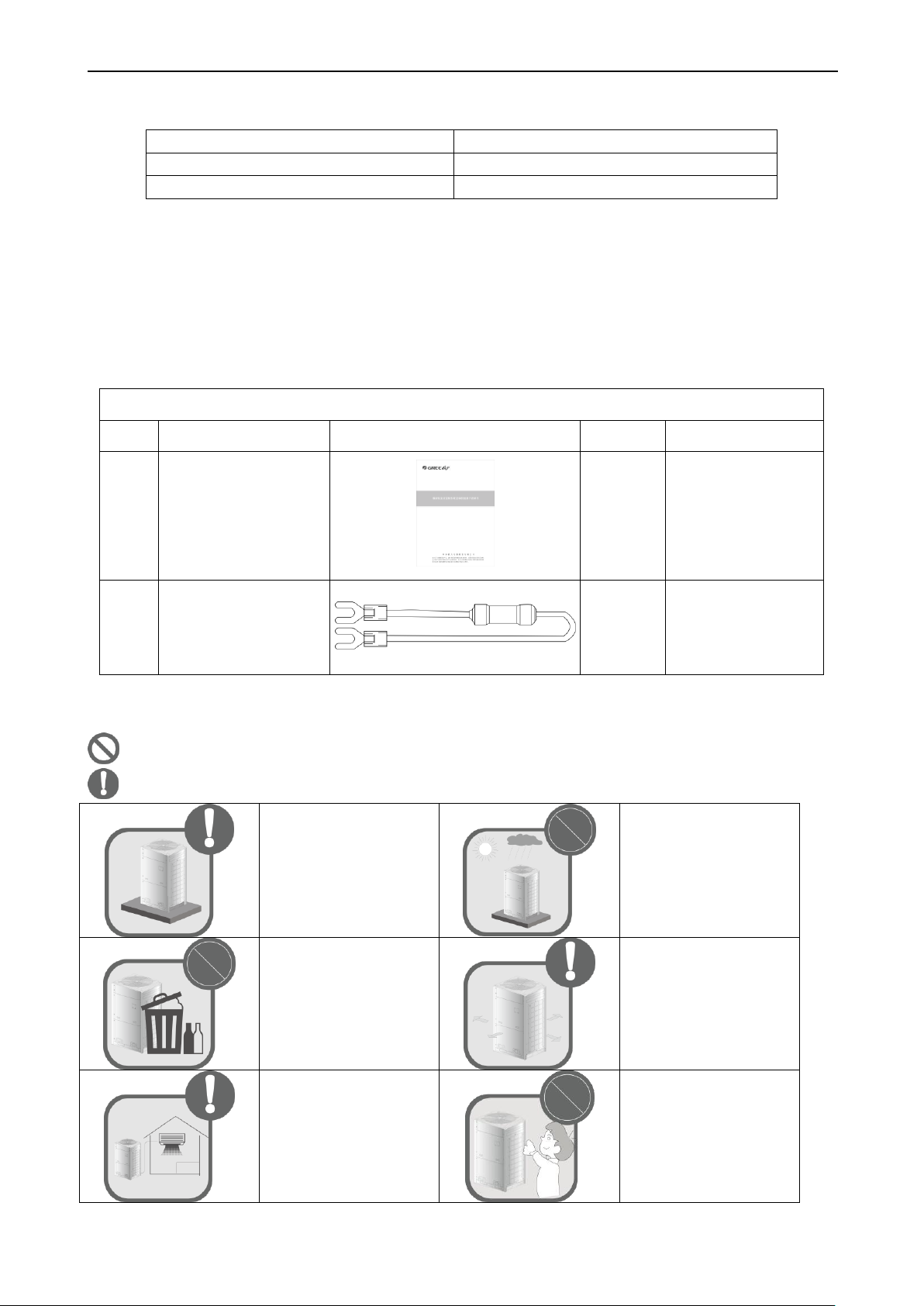

3.2 Installation Site

Never do this! This symbol indicates the possibility of death or serious injury.

Always do this! This symbol indicates the possibility of personal injury or property damage.

6

Heat Recovery DC Inverter Multi VRF Unit

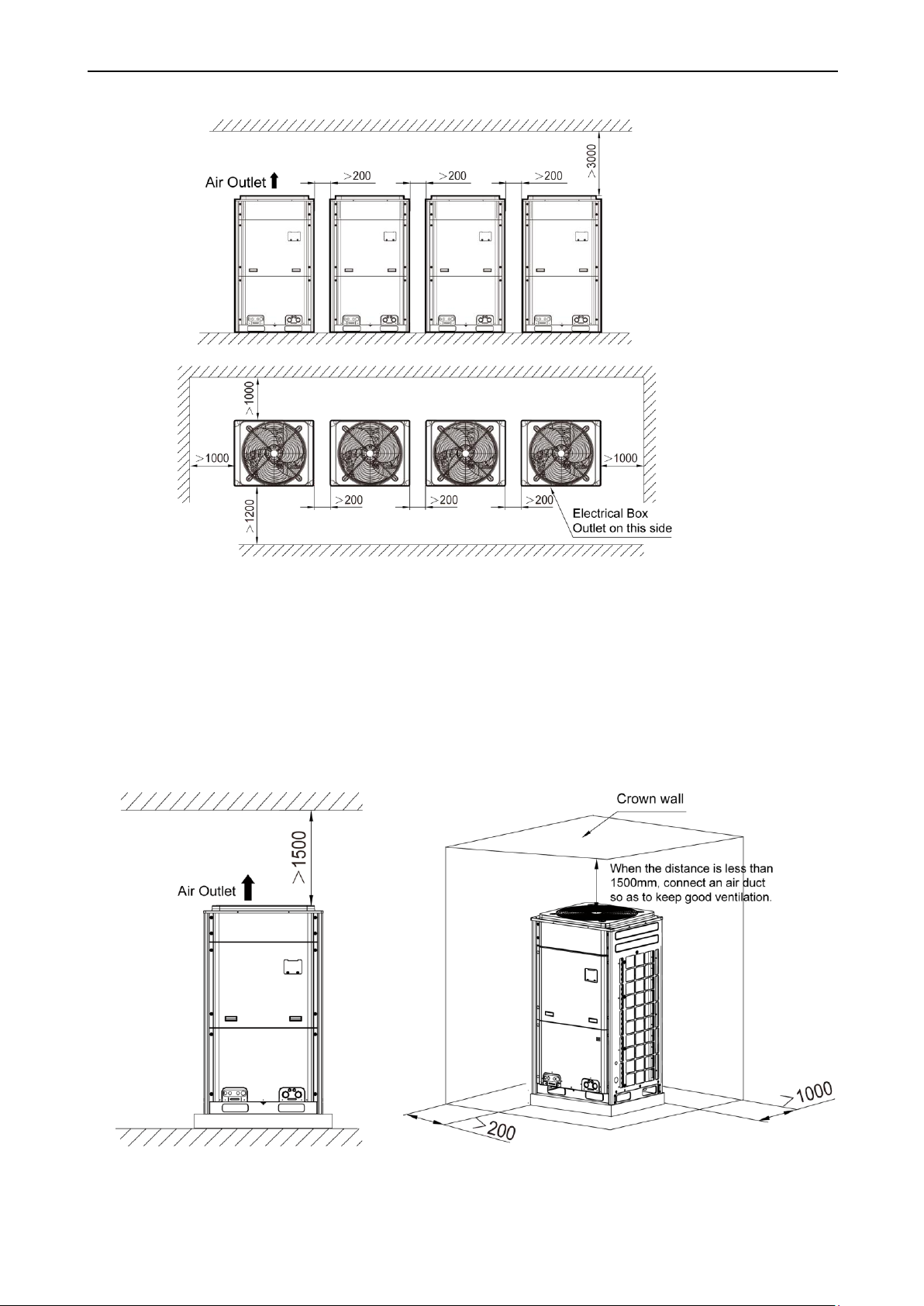

3.2.1 If the ODU is totally surrounded by walls, please refer to the following figures for

space dimension:

3.2.1.1 Installation space requirement for a single module

Unit: mm

Figure 3

3.2.1.2 Installation space requirement for twin modules

Figure 4

3.2.1.3 Installation space requirement for three modules

Unit: mm

Figure 5

7

Unit: mm

3.2.1.4 Installation space requirement for four modules

Heat Recovery DC Inverter Multi VRF Unit

Unit: mm

Figure 6

3.2.2 When there is wall (or similar obstruction) above the unit, keep the distance between

the unit top and the wall at least 3000mm or above. When the unit is located in an open

space with no obstruction from front, back, left and right, keep the distance between the

unit top and wall at least 1500mm or above (See Fig.7). When the distance is limited within

1500mm or the unit is not set in an open space, air return pipe is required to be installed in

order to keep good ventilation (See Fig.8).

Figure 7 Figure 8

8

Unit: mm

Heat Recovery DC Inverter Multi VRF Unit

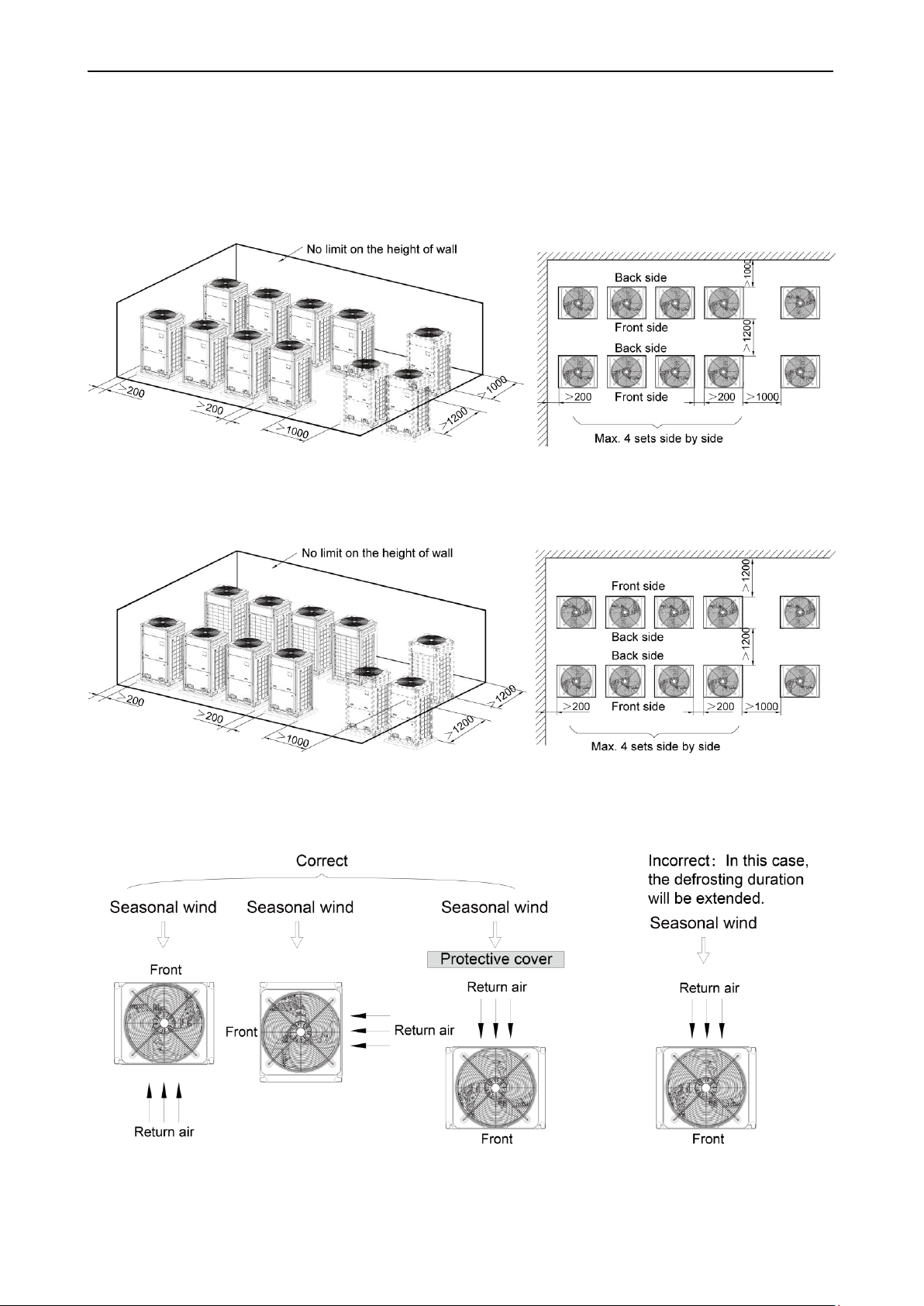

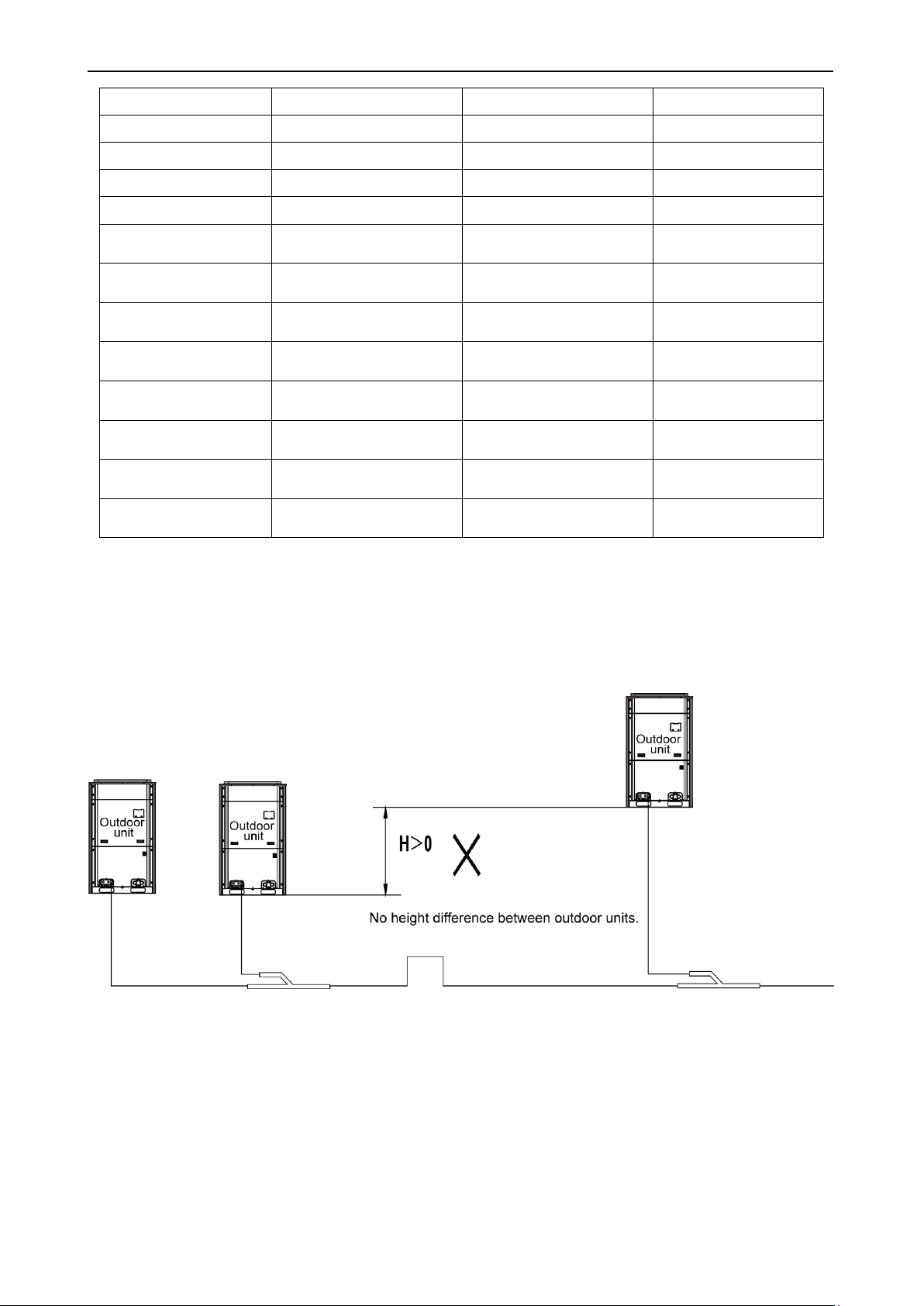

3.2.3 Installation space requirement for multiple outdoor units

In order to keep good ventilation, make sure there is no obstruction above the units.

When units are located in a semi-open space (front and left/right sides are open), install units as

per the same or opposite direction.

Figure 9

Figure 10

3.2.4 Take seasonal wind into consideration when installing outdoor units

Unit: mm

Unit: mm

Figure 11

9

Heat Recovery DC Inverter Multi VRF Unit

R410A Refrigeratn System

Outer diameter (mm/inch)

Wall thickness (mm)

Type

Φ6.35(1/4)

≥0.8

0

Φ9.52(3/8)

≥0.8

0

Φ12.70(1/2)

≥0.8

0

Φ15.9(5/8)

≥1.0

0

Φ19.05(3/4)

≥1.0

0

Φ22.2(7/8)

≥1.2

1/2H

Φ25.40(1/1)

≥1.2

1/2H

Φ28.60(9/8)

≥1.2

1/2H

Φ31.80(5/4)

≥1.3

1/2H

Φ34.90(11/8)

≥1.3

1/2H

Φ38.10(12/8)

≥1.5

1/2H

Φ41.30(13/8)

≥1.5

1/2H

Φ44.5(7/4)

≥1.5

1/2H

Φ51.4(7/4)

≥1.5

1/2H

Φ54.1(17/8)

≥1.5

1/2H

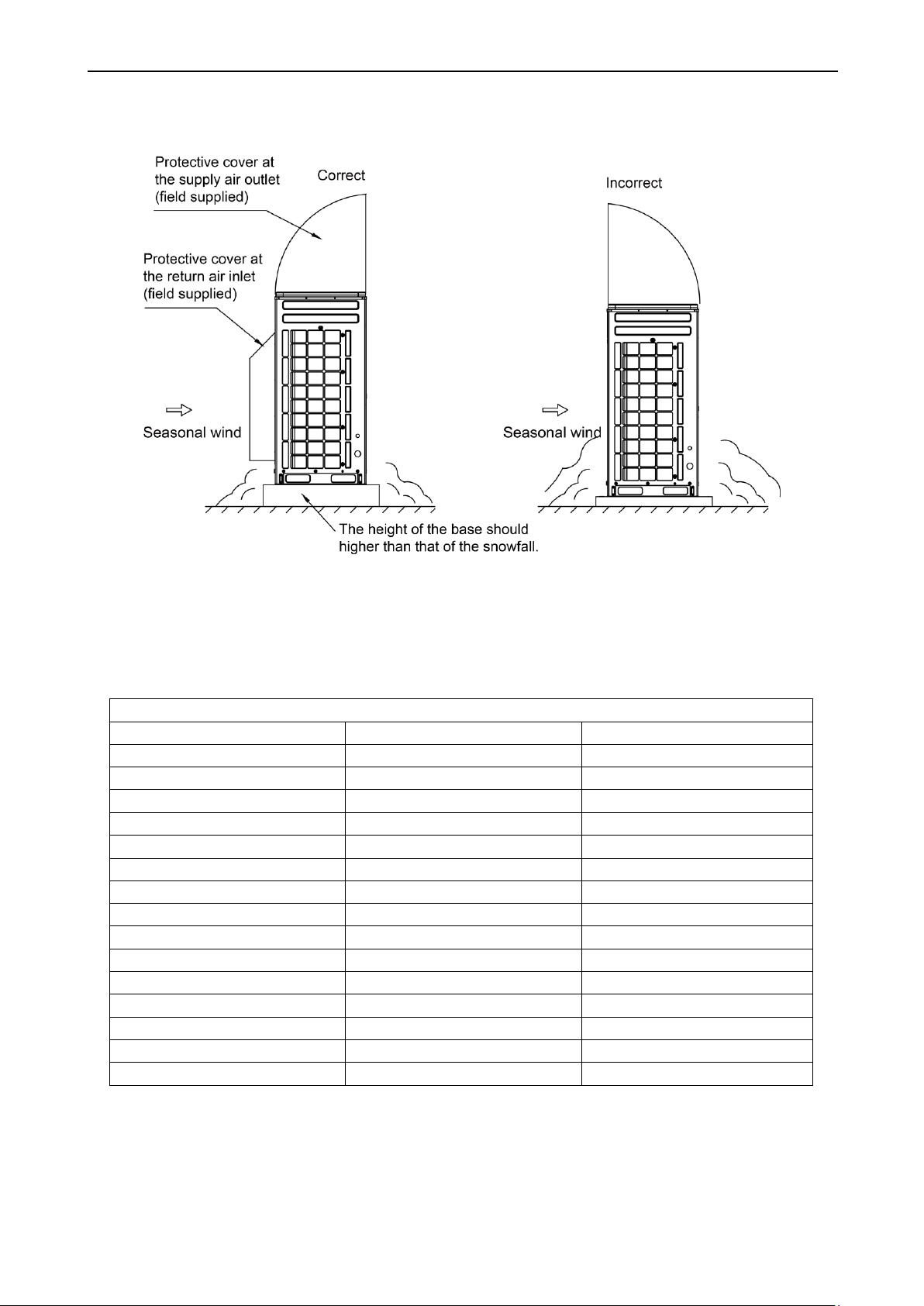

3.2.5 Take snow into considertaion when installation outdoor units

Figure 12

3.3 Connection Pipe Requirement

Refer to the table below for connection pipe requirement:

10

Heat Recovery DC Inverter Multi VRF Unit

4 Installation Instructions

Note: Graphics here are only for reference. Please refer to actual products. Unspecified dimensions

are all in mm.

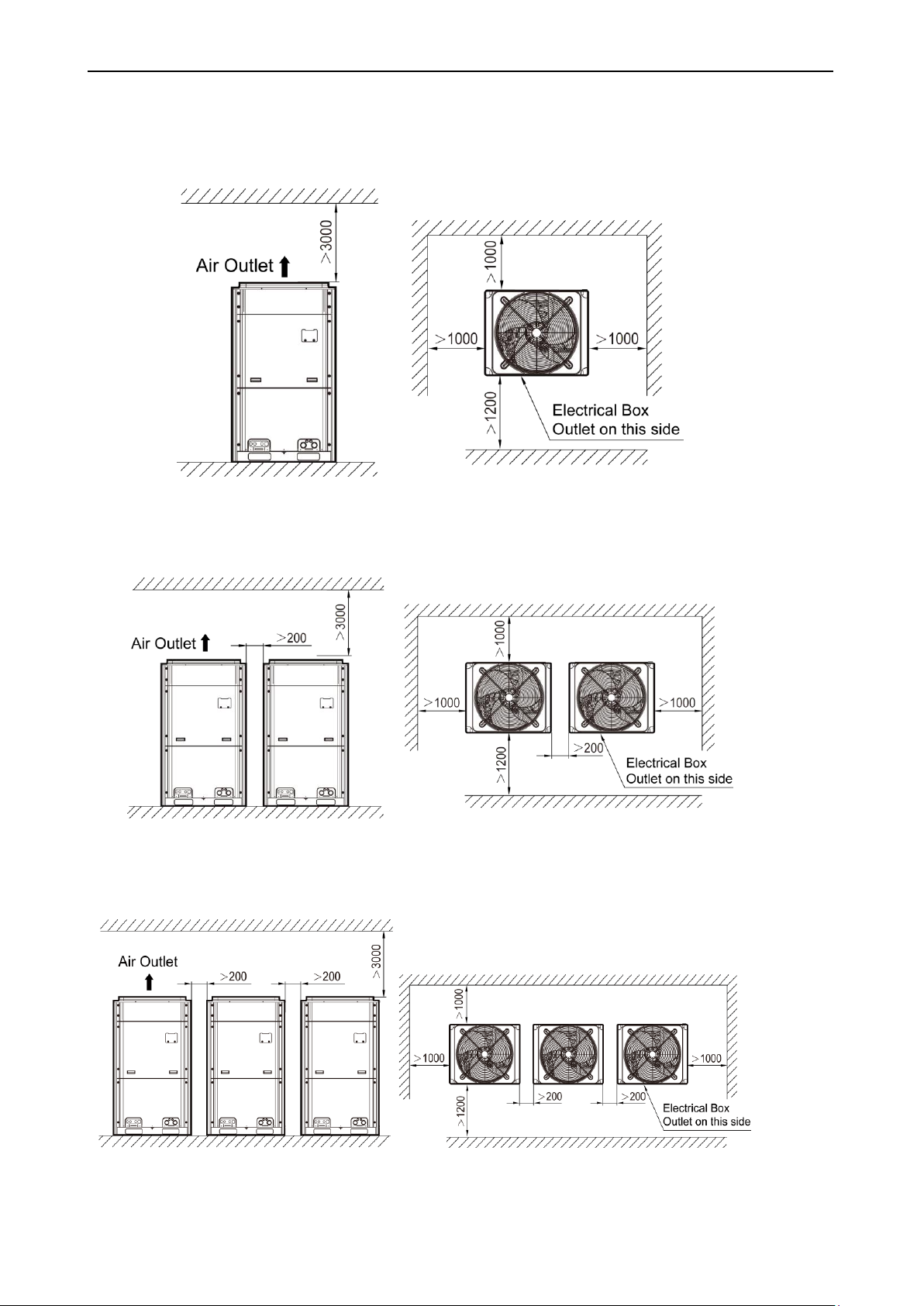

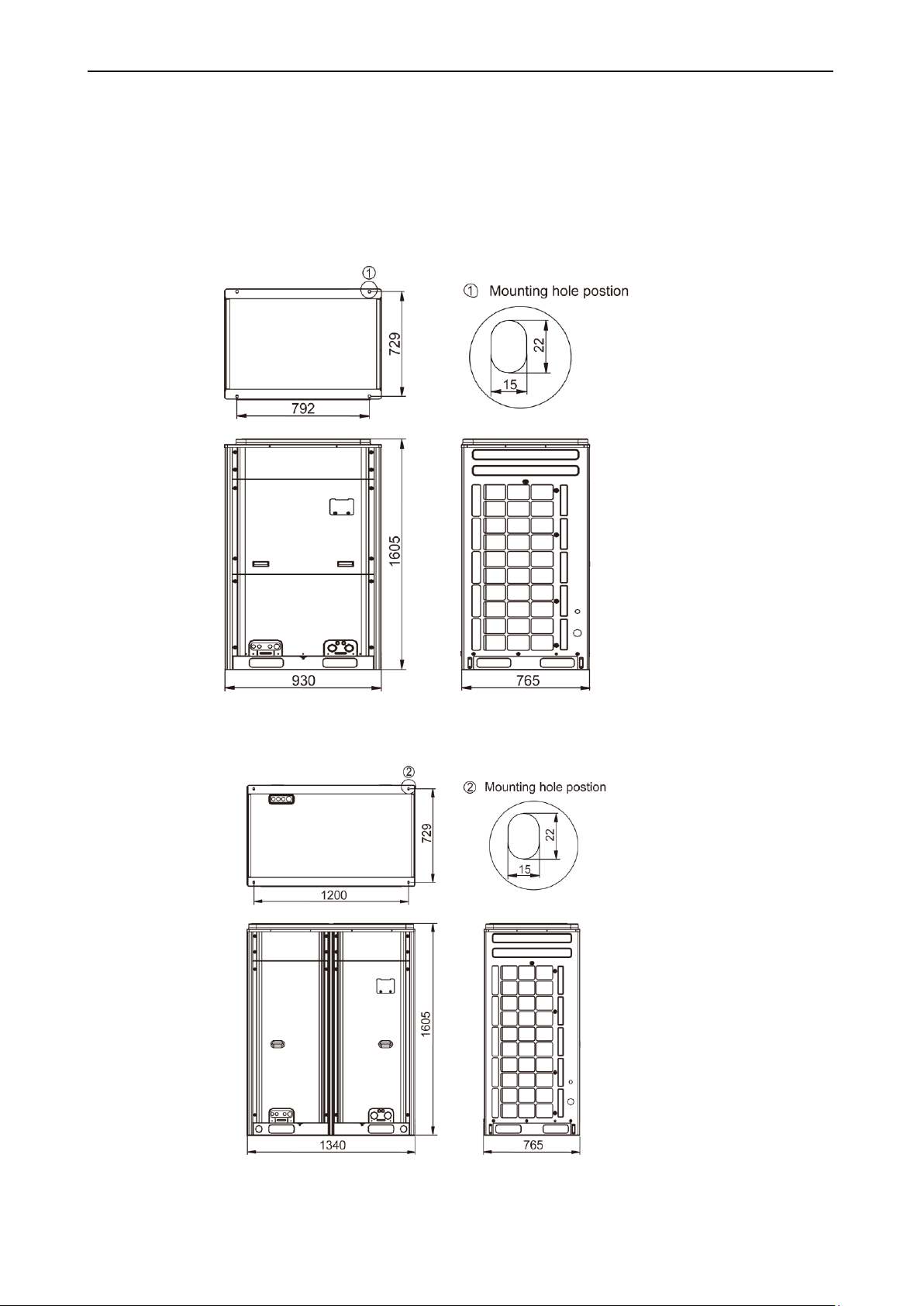

4.1 Dimension of Outdoor Unit and Mounting Hole

Outline and installation dimension of GMV-Q224WM/B-X, GMV-Q280WM/B-X

Unit: mm

Figure 13

Outline and installation dimension of GMV-Q335WM/B-X, GMV-Q400WM/B-X, GMV-Q450WM/B-X

Figure 14

11

Unit: mm

Heat Recovery DC Inverter Multi VRF Unit

4.2 Refrigerant Connection Pipe of Indoor and Outdoor Units

4.2.1 Schematic diagram of piping connection

Figure 15

4.2.2 Schematic diagram of piping sequence

GMV-Q224WM/B-X, GMV-Q280WM/B-X

Figure 16

12

Heat Recovery DC Inverter Multi VRF Unit

GMV-Q335WM/B-X, GMV-Q400WM/B-X, GMV-Q450WM/B-X

Figure 17

4.2.3 Allowable pipe length and height difference between indoor and outdoor units

Y type branch joint is adopted to connect indoor and outdoor units. Connection method is shown

below:

Note: Length of one Y-type branch is equivalent to 0.5m.

Figure 18

Distance from the first branch to the farthest indoor unit;

Distance from the first branch to the nearest indoor unit;

Length of indoor branch is equivalent to 0.5m.

13

Length(m)

Remarks

Total length (actual length) of connection pipe

≤ 1000

L1+L2+L3+L4+…+L12+a11+b12+…+d2

1+d22

Length between outdoor unit

and the farthest indoor unit

Actual length

≤ 165

L

Equivalent length

≤ 190

Difference between the pipe length from the first

indoor branch to the farthest indoor unit and the pipe

length from the first indoor branch to the nearest

indoor unit

≤ 40

L12-L11

Length from the first indoor branch to the farthest

indoor unit (1)

≤ 40

L7+L8+L10+D22

Maximum height difference

between indoor and outdoor

units: H

Outdoor unit at upper

side

≤ 50

——

Outdoor unit at lower

side

≤ 90

——

Maximum height difference between indoor units: h

≤ 30

h1

Maximum length of Main pipe (2)

≤ 90

L1

Note:

Outdoor model

Diameter of low pressure

gas pipe (mm)

Diameter of liquid pipe (mm)

Diameter of high pressure

gas pipe (mm)

GMV-Q224WM/B-X

No need to enlarge pipe

diameter

No need to enlarge pipe

diameter

No need to enlarge pipe

diameter

GMV-Q280WM/B-X

No need to enlarge pipe

diameter

Φ12.7

Φ22.2

GMV-Q335WM/B-X

Φ28.6

Φ15.9

Φ22.2

GMV-Q400WM/B-X

Φ31.8

Φ15.9

Φ25.4

GMV-Q450WM/B-X

Φ31.8

Φ15.9

Φ25.4

GMV-Q504WM/B-X

Φ34.9

Φ19.05

Φ28.6

GMV-Q560WM/B-X

Φ34.9

Φ19.05

Φ28.6

GMV-Q615WM/B-X

Φ34.9

Φ19.05

Φ28.6

GMV-Q680WM/B-X

No need to enlarge pipe

diameter

Φ19.05

Φ28.6

GMV-Q730WM/B-X

Φ38.1

Φ22.2

Φ31.8

GMV-Q785WM/B-X

Φ38.1

Φ22.2

Φ31.8

GMV-Q850WM/B-X

Φ38.1

Φ22.2

Φ31.8

GMV-Q900WM/B-X

Φ38.1

Φ22.2

Φ31.8

GMV-Q960WM/B-X

Φ41.3

Φ22.2

Φ31.8

GMV-Q1010WM/B-X

Φ44.5

Φ22.2

Φ34.9

GMV-Q1065WM/B-X

Φ44.5

Φ22.2

Φ34.9

Heat Recovery DC Inverter Multi VRF Unit

Normally, the pipe length from the first indoor branch to the farthest indoor unit is 40m. Under

(1)

the following conditions, the length can reach 90m:

1)Actual length of pipe in total: L1+L2×2+L3×2+L4×2+…+L9×2+a11+b11+…+d21+d22≤1000m;

2)Difference between the pipe length from the first indoor branch to the farthest indoor unit and

the pipe length from the first indoor branch to the nearest indoor unit: L12-L11≤40m.

When the maximum length of the main pipe from outdoor unit to the first indoor branch ≥90m,

(2)

then adjust the size of high pressure gas pipe, gas pipe and liquid pipe of main pipe according

to the following table.

14

Heat Recovery DC Inverter Multi VRF Unit

GMV-Q1130WM/B-X

Φ44.5

Φ22.2

Φ34.9

GMV-Q1180WM/B-X

Φ44.5

Φ22.2

Φ34.9

GMV-Q1235WM/B-X

Φ44.5

Φ22.2

Φ34.9

GMV-Q1300WM/B-X

Φ44.5

Φ22.2

Φ34.9

GMV-Q1350WM/B-X

Φ44.5

Φ22.2

Φ34.9

GMV-Q1410WM/B-X

No need to enlarge pipe

diameter

Φ25.4

Φ41.3

GMV-Q1460WM/B-X

No need to enlarge pipe

diameter

Φ25.4

Φ41.3

GMV-Q1515WM/B-X

No need to enlarge pipe

diameter

Φ25.4

Φ41.3

GMV-Q1580WM/B-X

No need to enlarge pipe

diameter

Φ25.4

Φ41.3

GMV-Q1630WM/B-X

No need to enlarge pipe

diameter

Φ25.4

Φ41.3

GMV-Q1685WM/B-X

No need to enlarge pipe

diameter

Φ25.4

Φ41.3

GMV-Q1750WM/B-X

No need to enlarge pipe

diameter

Φ25.4

Φ41.3

GMV-Q1800WM/B-X

No need to enlarge pipe

diameter

Φ25.4

Φ41.3

If the length between indoor unit and its nearest branch is above 10m, then double the size of

(3)

the liquid pipe of indoor unit (only for the pipe size that is less than or equal to 6.35mm).

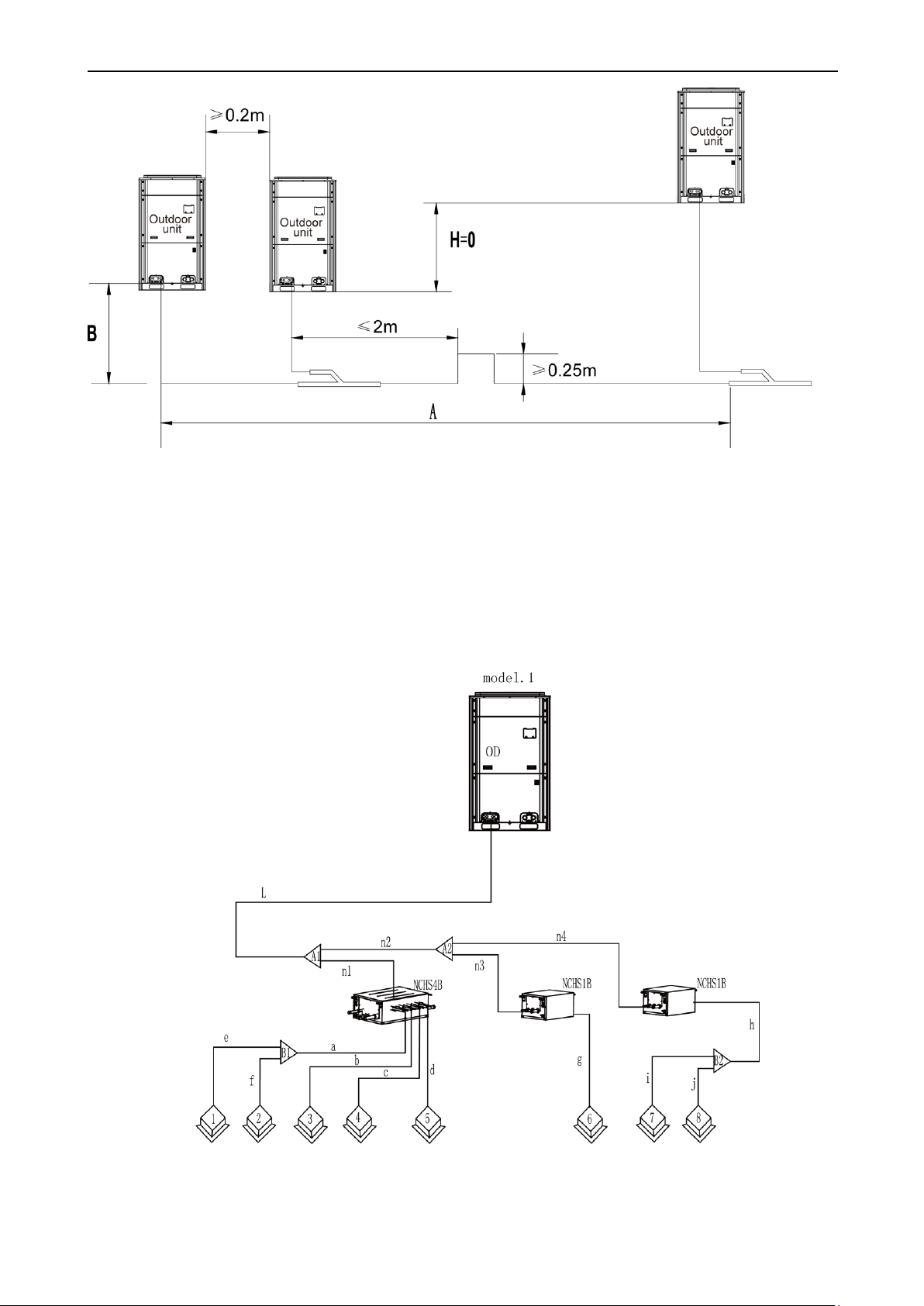

4.2.4 Pipe connection of outdoor modules

Figure 19

15

A+B ≤10m。

Heat Recovery DC Inverter Multi VRF Unit

Figure 20

Note: When the distance between outdoor units exceeds 2m, U-type oil trap should be added at

low pressure gas pipe. A+B≤10m.

4.2.5 Size requirement for branch pipe and piping (main pipe)

4.2.5.1 Connection sketch map of single-module system

Figure 21

Connection sketch map of multi-module system

16

Heat Recovery DC Inverter Multi VRF Unit

Basic module

Pipe between outdoor unit and the first indoor branch

Low pressure gas pipe

(mm)

Liquid pipe (mm)

High pressure gas pipe

(mm)

GMV-Q224WM/B-X

Φ19.05

Φ9.52

Φ15.9

GMV-Q280WM/B-X

Φ22.2

Φ9.52

Φ19.05

GMV-Q335WM/B-X

Φ25.4

Φ12.7

Φ19.05

GMV-Q400WM/B-X

Φ25.4

Φ12.7

Φ22.2

GMV-Q450WM/B-X

Φ28.6

Φ12.7

Φ22.2

Basic module

Size of the pipe between module and outdoor branch

Low pressure gas pipe

(mm)

Liquid pipe (mm)

High pressure gas pipe

(mm)

GMV-Q224WM/B-X

Φ19.05

Φ9.52

Φ15.9

GMV-Q280WM/B-X

Φ22.2

Φ9.52

Φ19.05

GMV-Q335WM/B-X

Φ25.4

Φ12.7

Φ19.05

GMV-Q400WM/B-X

Φ25.4

Φ12.7

Φ22.2

GMV-Q450WM/B-X

Φ28.6

Φ12.7

Φ22.2

Figure 22

4.2.5.1 Select appropriate pipe between outdoor unit and the first indoor branch (“L”) as per the pipe

size of outdoor unit. Pipe size of basic outdoor module is shown as follows:

between outdoor unit and the first indoor branch

4.2.5.2 For multi-module system, select appropriate branch (”M1、M2、M3”)connected to outdoor

module as per the pipe size of basic outdoor module. Pipe size of basic outdoor module is shown as

follows:

Pipe between module and outdoor branch ”M1、M2、M3”

17

Heat Recovery DC Inverter Multi VRF Unit

Module’s capacity (C)

Model

Selection of branch of outdoor

modules

504≤C

ML01R

Total rated capacity of upstream

modules: Q (kW)

Size of connection pipe between branches of outdoor module

Low pressure gas pipe

(mm)

Liquid pipe (mm)

High pressure gas pipe

(mm)

22.4≥Q

Φ19.05

Φ9.52

Φ15.9

28.0≥Q

>

22.4

Φ22.2

Φ9.52

Φ19.05

40.0≥Q

>

28.0

Φ25.4

Φ12.7

Φ19.05

45.0≥Q

>

40.0

Φ28.6

Φ12.7

Φ22.2

68.0≥Q

>

45.0

Φ28.6

Φ15.9

Φ25.4

96.0≥Q

>

68.0

Φ31.8

Φ19.05

Φ28.6

135.0≥Q

>

96.0

Φ38.1

Φ19.05

Φ31.8

Q>135.0

Φ44.5

Φ22.2

Φ38.1

Basic module (single-module system)

Size of connection between outdoor unit and the first indoor branch

Low pressure gas pipe (mm)

Liquid pipe (mm)

High pressure gas

pipe (mm)

GMV-Q224WM/B-X

Φ19.05

Φ9.52

Φ15.9

GMV-Q280WM/B-X

Φ22.2

Φ9.52

Φ19.05

GMV-Q335WM/B-X

Φ25.4

Φ12.7

Φ19.05

GMV-Q400WM/B-X

Φ25.4

Φ12.7

Φ22.2

GMV-Q450WM/B-X

Φ28.6

Φ12.7

Φ22.2

GMV-Q504WM/B-X

Φ28.6

Φ15.9

Φ25.4

GMV-Q560WM/B-X

Ф28.6

Ф15.9

Φ25.4

GMV-Q615WM/B-X

Ф28.6

Ф15.9

Φ25.4

GMV-Q680WM/B-X

Ф28.6

Ф15.9

Φ25.4

GMV-Q730WM/B-X

Ф31.8

Ф19.05

Φ28.6

GMV-Q785WM/B-X

Ф31.8

Ф19.05

Φ28.6

GMV-Q850WM/B-X

Ф31.8

Ф19.05

Φ28.6

GMV-Q900WM/B-X

Ф31.8

Ф19.05

Φ28.6

GMV-Q960WM/B-X

Ф31.8

Ф19.05

Φ28.6

GMV-Q1010WM/B-X

Ф38.1

Ф19.05

Φ31.8

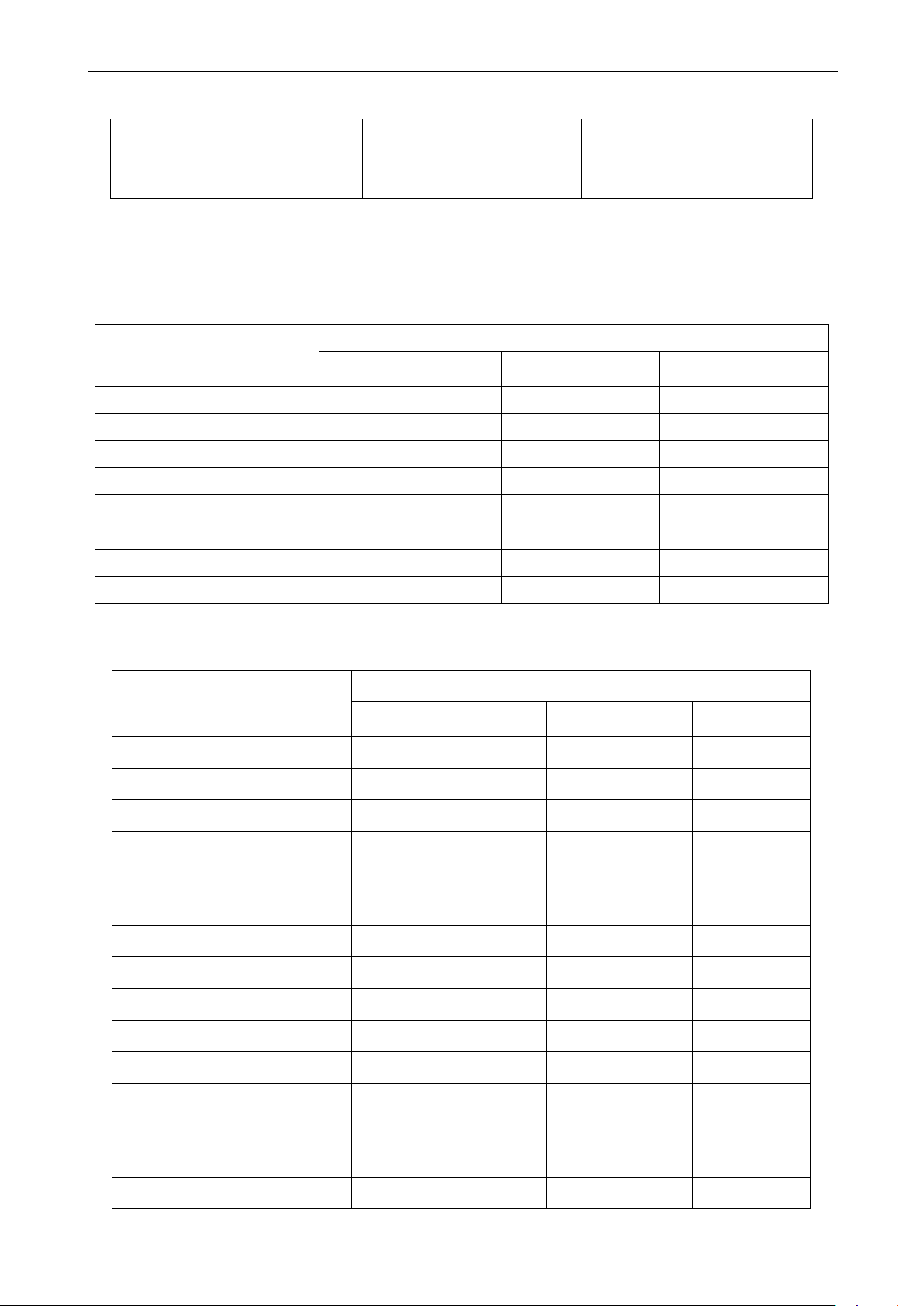

Selection of branch

“Y1、Y2”

4.2.5.3 Size of connection pipe

of outdoor modules:

”M4”

between branches of each basic module

Size of connection pipe between branches of each basic module is determined by the total rated

capacity of upstream modules.

Connection pipe ”M4” between branches of outdoor module

4.2.5.4 Size of connection pipe ”L” between the terminal outdoor branch and the first indoor branch

Connection pipe “L”between outdoor unit and the first indoor branch

18

Loading...

Loading...