Page 1

C

™

RT

INSTRUCTION MANUAL SUPPLEMENT

BEFORE YOU PROCEED WITH THE INSTRUCTION MANUAL

This Ready-to-Cover (RTC) version of the Great Planes Viper 500 is supplied to you without the pre-applied fi berglass of the

ARF version. Fiberglassing the fuse and wing is necessary for safety so it must be done, but in this RTC version we allow

you the choice of how and where you want to glass. You can also, of course, glass and paint the whole airplane, but this is

not necessary.

Fiberglassing takes a certain amount of skill, so if you’ve never done it before we recommend that you seek the help of an

experienced modeler. When you’re done glassing and covering, please proceed with the included ARF instruction manual.

Please note that when cutting dry fi berglass cloth, the best tool to use is a rotary cutter with a cutting mat. These can be

found at most fabric supply and art/craft stores.

ITEMS REQUIRED FOR COMPLETION

3/4oz [21g] Fiberglass Cloth (HCAR5000)

8oz [236cc] Coverite™ Balsarite™, fi lm (COVR2515)

4oz [118cc] Top Flite® Trim Solvent (TOPR6020)

9oz [255cc] Great Planes® Finishing Resin (GPMR6049)

Epoxy brushes (GPMR8060)

Mixing sticks (GPMR8055)

Mixing cups (GPMR8056)

Vaseline® petroleum jelly

Great Planes Easy-Touch™ hand sander 5.5" (GPMR6169)

220-grit Easy-Touch Sand Paper (GPMR6185)

400-grit sand paper

Tack cloth

Masking tape (TOPR8018)

Pi ece of 1/16" [1.6mm] scrap balsa sheet or an old credit

card for use as a squeegee

Plan Protector (GPMR6167) or waxed paper

Acetone (for clean-up)

Sharp scissors

Olfa® Rotary Cutter

Self-Healing Cutting Mat (HCAR0454)

HobbyLite™ White-Colored Balsa Filler (HCAR3400)

Page 2

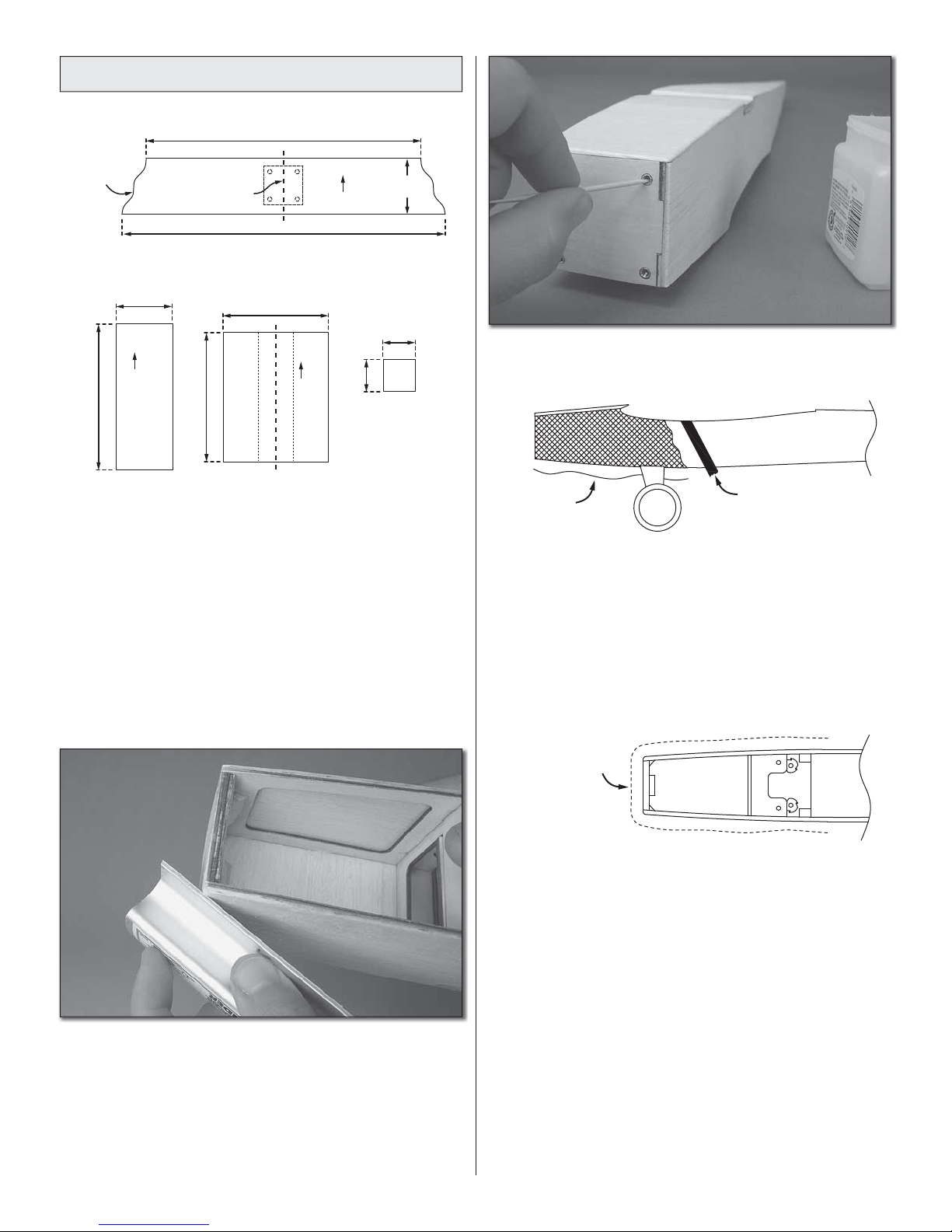

Fiberglass the Forward Fuselage

17" [432mm]

Cut the edges

like this.

3-1/2" [89mm]

9" [229mm]

FUSE BOTTOM PIECE

(OUTER)

Mark the center line

of the cloth. You will

center this on the firewall.

20" [508mm]

FIREWALL & FUSE SIDES PIECE (OUTER)

6-1/2" [165mm]

Fwd

8" [203mm]

FUEL TANK

COMPARTMENT

PIECE

Fwd

Up

3-1/2"

[89mm]

2" [51mm]

2" [51mm]

FIREWALL PIECE

(FUEL TANK

COMPARTMENT,

INSIDE)

❏ 1. Cut out the following pieces for the fuselage from 3/4oz

[21g] fi berglass cloth:

A. One 3-1/2" x 20" [89 x 508mm] strip and trim the sides

as shown

B. One 3-1/2" x 9" [89 x 229mm] rectangular piece (for

the fwd fuse bottom)

C. One 6-1/2" x 8" [165 x 203mm] rectangular piece (for

the fuel tank compartment sides and bottom)

D. One 2" x 2" [51 x 51mm] square (for the back side of

the fi rewall)

❏ 4. Fill the threads of the blind nuts with petroleum jelly

using a toothpick.

MASKING TAPE HERE

APPLY THE 9" [229mm]

BOTTOM PIECE FIRST

❏ 5. Mix up about 3/4oz [22cc] of fi nishing resin. Brush on

a thin coat of resin to the bottom of the forward fuse. Apply

the 3-1/2" x 9" [89 x 229mm] rectangular piece of fi berglass

to the bottom of the forward fuse. Align the forward edge of

the glass with the edge of the fi rewall. Stipple the glass cloth

down to the fuse. Squeegee any excess resin out of the glass

so that the surface is smooth. Allow the resin to cure. Sand

the fi berglass smooth feathering the glass into the balsa.

❏ 2. Lightly sand the forward part of the fuselage where you

will apply the fi berglass. Round the edges of the fuse sides

slightly. Use compressed air or a tack cloth to clean any dust

from the fuse before you begin glassing.

❏ 3. Apply masking tape to the fuselage sides and bottom

about 1" [25.4mm] back from where you will be applying

fi berglass. See the sketches for more details.

CENTER THE GLASS

ON THE FIREWALL.

FIREWALL/FUSE SIDES PIECE WILL

WRAP AROUND THE FIREWALL LIKE THIS.

❏ 6. Mix up another batch of fi nishing resin and brush a

thin coat onto the fi rewall and forward fuse sides. Center

the 3-1/2" x 20" [89 x 508mm] piece of glass cloth on the

fi rewall and wrap it around to cover the fuse sides. Stipple

and squeegee the glass cloth smooth. Allow the resin to cure

and sand the fi berglass smooth.

❏ 7. Fiberglass the inside of the fuel tank compartment using

the 6-1/2" x 8" [165 x 203mm] rectangular piece for the fuse

bottom and sides, and the 2" x 2" [51 x 51mm] square piece

for the back side of the fi rewall. Allow the resin to cure. Use

your hobby knife to open up the front and back sides of the

blind nuts on the fi rewall. Clean out any remaining petroleum

jelly from the threads of the nuts.

Page 3

Fiberglass the Wing Center Section

4-1/2" [114mm] 11-1/2" [292mm]

Fold the cloth at

the LE of the wing

along this line.

INNER

LAYER

10"

[254mm]

9" [228mm]

16" [406mm]

OUTER

LAYER

❏ 1. Cut out the following pieces for the wing from 3/4oz

[21g] fi berglass cloth:

A. One 9" x 20" [229 x 508mm] piece (center wing,

inner layer)

B. One 16" x 20" [406 x 508mm] piece (center wing,

outer layer)

10"

[254mm]

❏ 2. Study the sketch below. Notice that the smaller piece

of glass cloth (inner layer) is applied fi rst. Lightly sand the

center section of the wing and dust it off. Apply masking

tape where shown. Mix up enough fi nishing resin to wet out

the inner layer shown in the sketch. If you are confi dent with

the working time of the resin, you may mix up enough to

laminate both the inner and outer layers simultaneously. If

not, apply only the inner layer now. Center the cloth on the

wing along the leading edge of the wing and fold it over so

that it covers the top and bottom surfaces of the wing. Stipple

and squeegee out the excess resin and allow the resin to

cure. Trim the excess fi berglass from the trailing edge of the

wing and sand the surface and edges of the glass smooth.

If you applied the inner layer only, go ahead and apply the

outer layer now.

❏ 3. Trim the wing bolt holes open. Sand the surface smooth

feathering the edges of the glass into the balsa sheeting. Use

HobbyLite™ balsa fi ller (HCAR3400) to fi ll in any imperfections.

Finish-sand the model using 400-grit sandpaper.

❏ 4. Apply one or two coats of Coverite Balsarite (COVR2515)

per the manufacturer’s instructions.

❏ 5. Apply your choice of fi lm covering to each part per the

manufacturer’s instructions.

16" [406mm]

OUTER LAYER

9" [228mm]

INNER LAYER

Masking tape here Masking tape here

4-1/2" [114mm]

INNER LAYER

Page 4

Copyright © 2009 GPMA1267INSTR v1.0

Loading...

Loading...