GREAT PLANES Ultra-Sport 40 ARF Instruction Manual

Almost Ready-to-Fly

Instruction Manual

WARRANTY

Great Planes Model Manufacturing Co. guarantees this kit to be free from defects in both material

and workmanship at the date of purchase. This warranty does not cover any component parts damaged

by use or modification. In no case shall Great Planes' liability exceed the original cost of the

purchased kit. Further, Great Planes reserves the right to change or modify this warranty without

notice.

In that Great Planes has no control over the final assembly or material used for final assembly, no

liability shall be assumed nor accepted for any damage resulting from the use by the user of the final

user-assembled product. By the act of using the user-assembled product, the user accepts all resulting

liability.

If the buyer is not prepared to accept the liability associated with the use of this product, they

are advised to return this kit immediately in new and unused condition to the place of purchase.

READ THROUGH THIS INSTRUCTION MANUAL

FIRST. IT CONTAINS IMPORTANT INSTRUCTIONS

AND WARNINGS CONCERNING THE ASSEMBLY

AND USE OF THIS MODEL.

GPMA1010 V1.2

P.O. BOX 788 URBANA, ILLINOIS 61801 (217) 398-8970

ENTIRE CONTENTS © Copyright 1993

TABLE OF CONTENTS

INTRODUCTION............................................. 3

PRECAUTIONS.............................................. 3

EXPLODED VIEW .......................................... 4

ITEMS REQUIRED......................................... 4

DIE-CUT PARTS............................................. 5

WING ASSEMBLY.......................................... 6

CENTER RIBS (OPTION A)........................... 6

WING JOINERS (OPTION

CENTER RIBS (OPTION B) ........................... 7

WING JOINERS (OPTION B)......................... 7

FIXED GEAR ASSEMBLY (OPTION A).......... 8

RETRACTS (OPTION B)................................ 10

AILERON ASSEMBLY.................................... 12

A)......................... 6

PRE

FLIGHT..................................................

FLYING...........................................................

AMA SAFETY CODE..................................... 27

FLIGHT TRIMMING........................................

FLIGHT TRIMMING CHART .. ........................ 30

TEMPLATES & GAUGES.............................. 31

26

26

29

FUSELAGE ASSEMBLY............................... 13

ENGINE INSTALLATION (2-stroke)

ENGINE INSTALLATION (4-stroke)

MOUNT THE WING

HORIZONTAL STABILIZER ........................... 15

VERTICAL STABILIZER.................................

TAIL GEAR .................................................... 16

GLUING THE HINGES................................... 17

STABILIZER SUPPORT BRACES

RADIO INSTALLATION................................. 19

PUSHRODS ...................................................

CONTROL SURFACE LINKAGE.................... 21

THROTTLE LINKAGE....................................

RECEIVER INSTALLATION........................... 22

FUEL TANK.................................................... 23

FINAL ASSEMBLY........................................ 24

CONTROL

BALANCE THE PLANE LATERALLY.............

THROWS..................................... 2 5

......................................14

............... 13

............... 13

16

................. 18

20

21

25

Metric Conversion Chart

Inches x 25.4 = mm (conversion factor)

1/64"

1/32"

1/16"

3/32"

5/32"

3/16"

3/8"

5/8"

3/4"

1/8" =

1/4"

1/2"

1" =

2" =

3" =

6"

12"

15" =

18"

21"

24"

30" =

36"

=

.4

=

.8

mm

mm

= 1.6mm

= 2.4

=

4

= 4.8

=

=

9.5

= 12.7mm

3.2

6.4

mm

mm

mm

mm

mm

mm

= 15.9mm

=

19

= 152.4mm

= 304.8 mm

= 457.2 mm

= 533.4 mm

= 609.6 mm

mm

25.4 mm

50.8 mm

76.2

mm

381

mm

762 mm

= 914.4mm

2

WARNING! THIS IS NOT A TOY!

THIS IS NOT A BEGINNER'S AIRPLANE!

This R/C kit and the model you will build is not a toy! It is capable of serious bodily harm and property damage.

IT IS YOUR RESPONSIBILITY AND YOURS ALONE — to build this kit correctly, to properly install all R/C

components and flying gear (engine, tank, pushrods, etc.) and to test the model and fly it only with experienced,

competent help, using common sense and in accordance with all safety standards as set down in the Academy of

Model Aeronautics Safety Code. It is suggested that you join the AMA and become properly insured before you

attempt to fly this model. IF YOU A R E JUST STARTING R/C MODELING, CONSULT YOUR LOCAL HOBBY SHOP

OR WRITE T O T H E ACADEMY OF M O D E L AERONAUTICS T O FIND AN EXPERIENCED INSTRUCTOR IN YOUR AREA.

Academy of Model Aeronautics

5151 E. Memorial Drive

Muncie, IN 47302-8252

(317)289-4236

Please inspect all parts carefully before

starting to build! If any parts are missing, broken or

defective, or if you have any questions about

building or flying this airplane, please call us a t (217)

398-8970 and we'll be glad to help. Please find the kit

Congratulations and thank you for purchasing

the Great Panes Ultra-Sport 40 ARF. The Ultra-Sport

incorporates several new design features never before

found in an ARF kit. It utilizes rod-in tube pushrods,

adjustable glass-filled nylon engine mount, multiple color

layers with a glossy, fuel-resistant outer coating and high

quality Great Planes hardware. Stronger and lighter than

a conventional, built-up balsa kit, it provides even better

overall performance!

identification number on the end of the carton and

have it ready when calling.

The Great Planes Ultra-Sport 40 ARF is like the

Ultra-Sport 40 kit. This almost ready to f l y version is one

of the easiest-flying, most aerobatic aircraft ever

designed. It combines the design expertise and high

quality standards of Great Planes kits with state-of-theart AR F technology—for craftsmanship and performance

superior to all other prebuilt models. However, this is

not a beginner's airplane! While the Ultra-Sport 40

AR F is easy to assemble, we must discourage you from

selecting this kit as your first R/C airplane. It is highly

maneuverable, and lacks the self-recovery characteristics

of a good basic trainer such as the Great Planes PT

Series airplanes. On the other hand, if you are confident

with your flying skills and can safely handle aileron

airplanes such as the Great Planes Big Stick Series, the

Ultra-Sport 40 ARF is a n excellent choice.

Precautions

1. You must assemble the plane according to the

instructions. Do not alter or modify the model, as doing

so may result in an unsafe or unflyable model. In a few

cases the instructions may differ slightly from the photos.

In those instances you should assume the written

instructions are correct.

2. You must take time to build straight, true and

strong. IMPORTANT - Glue should never be substituted

for a good-fitting joint. Take a little extra time to get a

and

glue

it

good-fitting joint

neater, and much lighter than a poor fitting joint held

together with an excess of glue!

3

properly.

It

will

be

stronger,

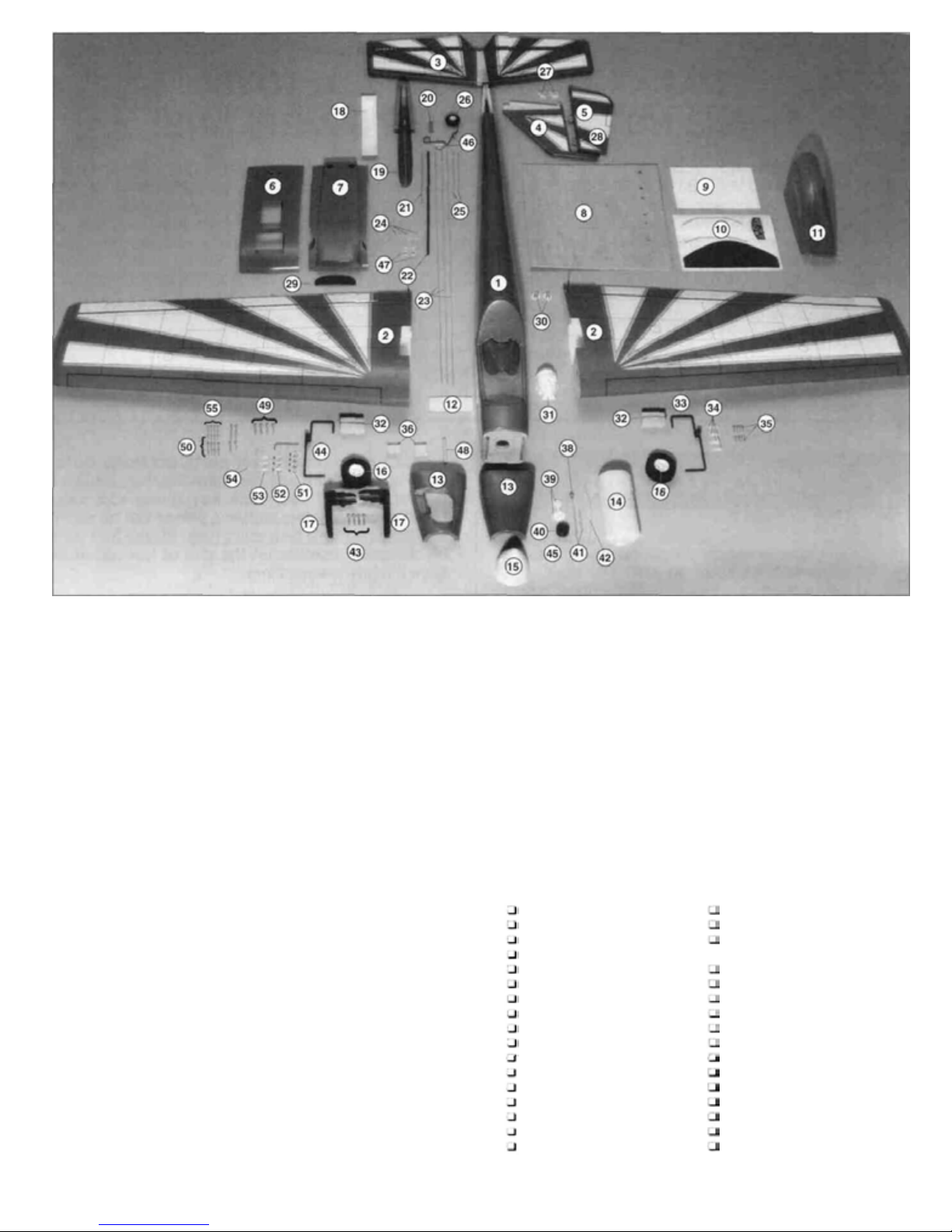

Part# Description Quantity

1........................................Fuselage .....................................................1

2........................................Wing Right & Left ........................................2

3........................................Horizontal Stabilizer & Elevator...................1

4........................................Vertical Stabilizer........................................1

5........................................

6........................................Wing Fairing (top)........................................1

7........................................Wing Fairing (bottom)..................................1

8........................................Die-Cut Plywood......................................... 1

9........................................Die-Cut Plastic............................................1

10......................................Decal Sheet.................................................1

11......................................Canopy........................................................1

12......................................Rear Wing Joiner........................................1

13......................................Cowling .......................................................2

14......................................Fuel Tank....................................................1

15......................................Spinner........................................................1

16......................................Wheel (main gear).......................................2

17......................................Adjustable Engine Mount ............................1

18......................................Die-Cut Plastic Control Horn Backing..........1

19......................................Vertical Stabilizer Fairing ............................1

20......................................Tail Gear Bracket........................................1

21......................................Splined Plastic Tubing.................................1

22......................................Throttle Guide Tube ....................................1

23......................................Pushrod (throttle, elevator, rudder).............3

24......................................Clevis ..........................................................3

25......................................Pushrod (ailerons)......................................2

26......................................Tail Wheel...................................................1

27......................................Control Horn................................................2

28......................................CA Hinges...................................................2

29......................................Foam Rubber Seal......................................1

30......................................Blind Nut.....................................................2

31......................................Pilot.............................................................1

32......................................Landing Gear Mounting Block.....................2

33......................................Main Landing Gear Strut (L)........................2

34......................................Flat Nylon Strap ..........................................4

35......................................#2 x 3/8" Sheet Metal Screw.......................8

36......................................Wing Bolt Plate............................................1

38......................................Fuel Pick-up Weight (clunk) ........................1

39......................................Stopper Disc................................................2

40......................................Rubber Plug................................................1

Rudder

........................................................1

41......................................Aluminum Tube..........................................:2

42....................................... Fu el Tubing .................................................1

43......................................6-32 x 3/4" Machine Screw .........................4

44......................................Main Landing Gear Strut (R) .......................1

45......................................Tank Plug 3 x 18mm S/T Screw..................1

46......................................Tail Gear.....................................................1

47......................................Swivel Clevis...............................................2

48......................................Wing

49......................................#6 x 3/4" Sheet Metal Screw.......................4

50......................................#2 x 3/8" Sheet Metal Screw.....................12

51......................................5/32" Wheel Collar......................................4

52......................................3/32" Wheel Collar......................................2

53......................................Aluminum Spacer........................................2

54......................................#2

55......................................2-56 x 5/8" Machine Screw .........................4

56......................................1/4-20 Nylon Wing Bolt (not shown)............2

57......................................#4

Dowel.................................................1

Washer...................................................4

x 1/2" Sheet Metal Screw (not

shown) .10

Items Required

1 oz. Thin CA Adhesive

1 oz. Medium CA Adhesive

9 oz. 6-minute Epoxy

9 oz. 30-minute

Masking Tape

Petroleum Jelly

IsopropyI Rubbing Alcohol

Thread Locking Compound

Silicone Sealant

Sandpaper Fine/Medium

Pliers

String

Felt-Tip Pen

Clothespins

Mixing Sticks

T-Pins

Hobby Knife, #11

Epoxy

Blades

Ruler

Hand or Electric Drill

Drill Bits 1/16", 3/32", 5/64"

7/64", 1/4"

Foam Rubber

Wing Seating Tape

#64 Rubber Bands

Epoxy Brushes

Mixing Cups

Paper Towels

Files, Flat & Round

Screwdrivers

5/32" Adjustable

Pushrod Connectors (opt.)

Retract Servo (opt.)

Retracts (HCAP4010) (opt.)

Retract Pushrod Wire 2-56 (opt.)

Axle

4

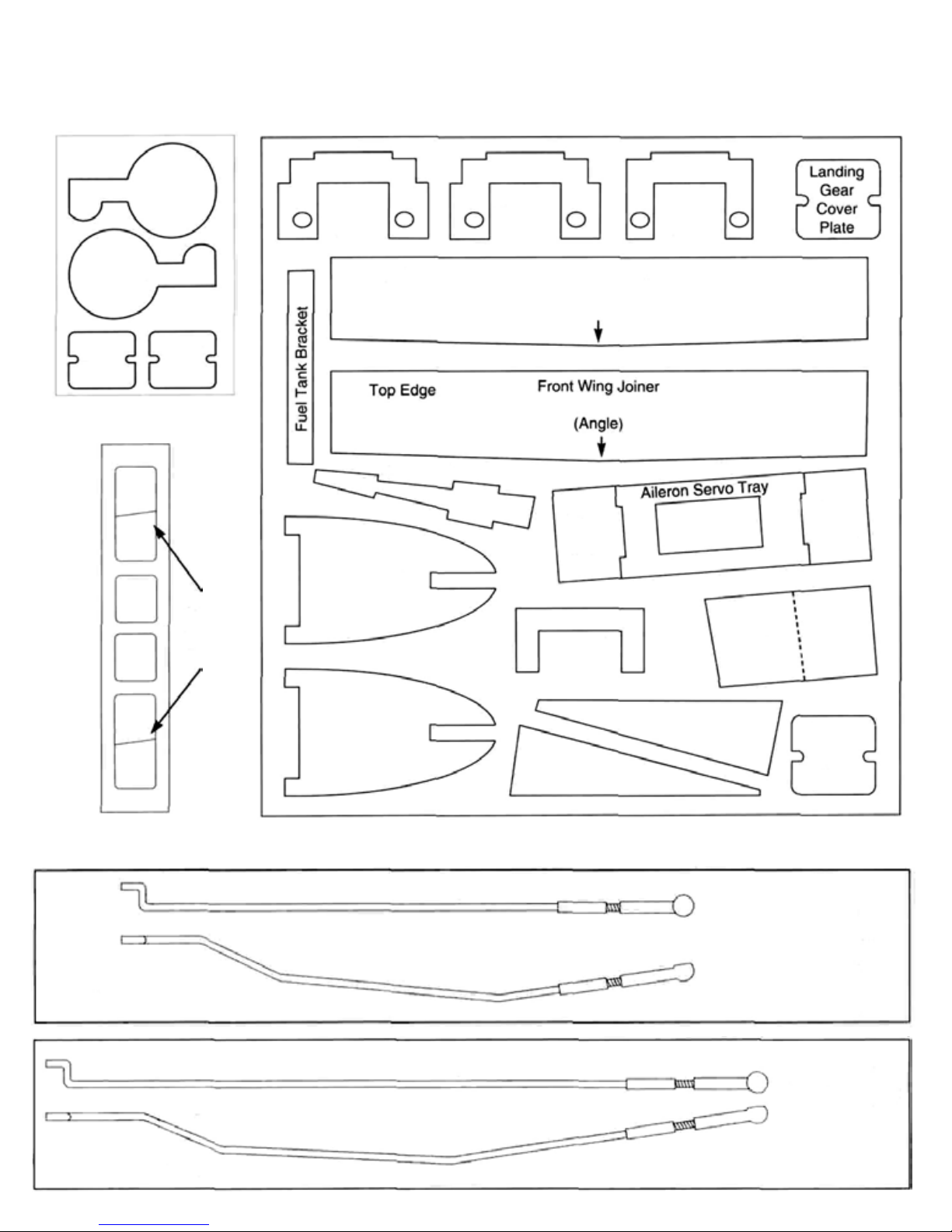

Die-Cut Parts

Plastic Sheet 1/8" (3mm) Plywood Sheet

Wheel Well

Wheel Well

Cover

Mount

Cover

Plastic Sheet

Cover

Mount

Cover

Support

Control

Horn

Plates

Wing

Mounting

Plate

Top Edge

Stabilizer Platform

Front Center Rib

Wing

Mounting

Plate

Front Wing Joiner

Retract

Servo Tray

(Angle)

Servo

Tray

Mount

Wing

Mounting

Plate

Servo

Tray

Mount

Wing

Bolt

Plates

Right Retract Pushrod

Front Center Rib

Top View

Side View

Top View

Side View

Aft Center Rib

Aft Center Rib

Landing

Gear

Cover

Plate

Not Actual Size

Template for

Hobbico Retract

Pushrod

(Not Included)

Actual Size

Template for

Hobbico Retract

Pushrod

(Not Included)

Left Retract Pushrod

Actual Size

5

Center Ribs and Wing Joiners

Fixed Gear (Option A)

(Skip Steps 1-6 Option A if retracts are to be installed.)

(Continue on page 7.)

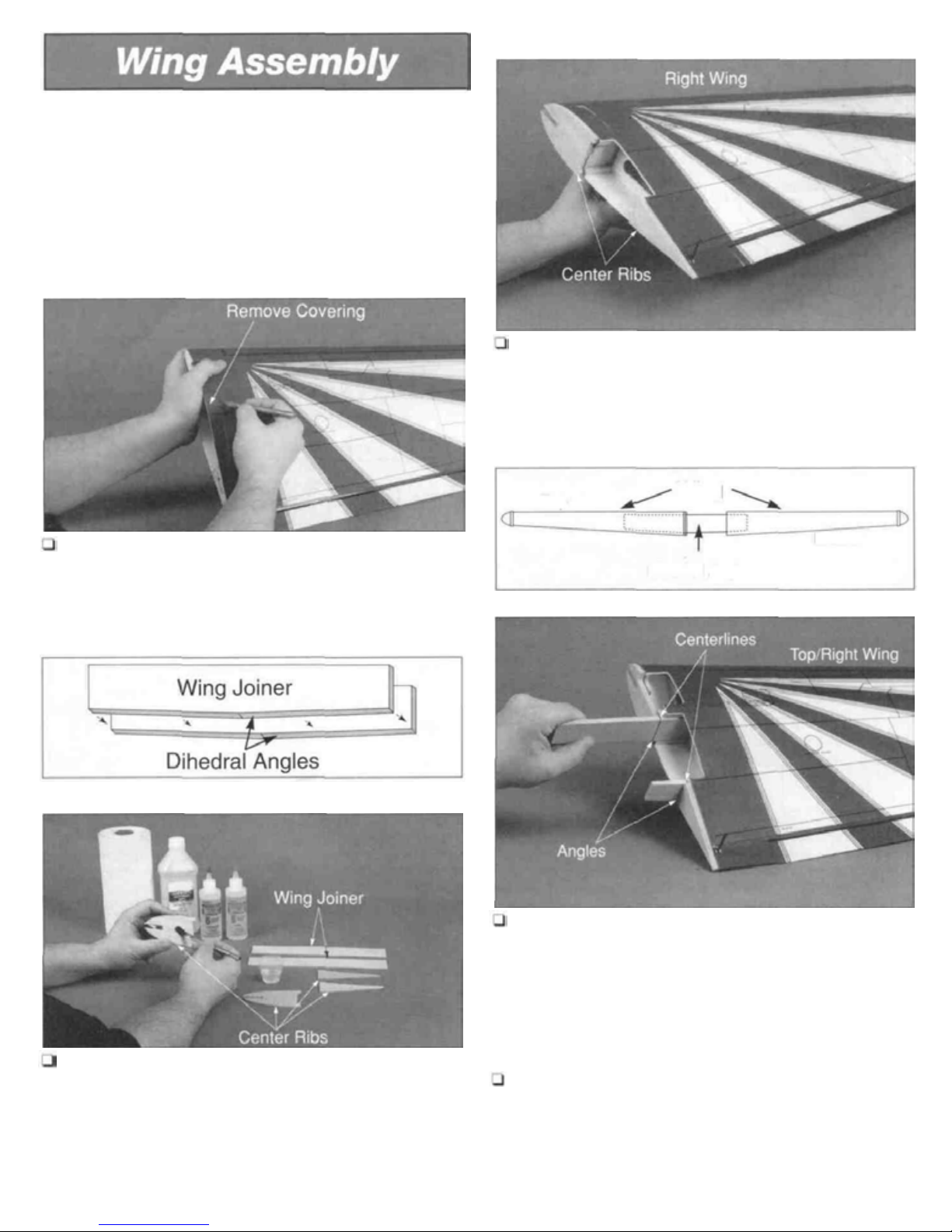

Remove the Foam Covering

Glue the Center Rib on the Wing

3. Trial fit the center ribs on both wing halves, the ribs

should not protrude beyond the outer covering of the wing.

Lightly sand the ribs until they are flush with the wing

covering. Use 6-minute epoxy to glue the plywood center

ribs to the right wing half.

Glue the Wing Joiners into the Wing

1. Remove the foam covering from the aileron servo

opening. The covering has been partially precut for exact

location.

Glue the Center Ribs & Wing Joiners

Top

4. Draw a centerline on both of the wing joiner pieces.

Trial fit the wing joiners into both wing halves. A snug fit is

desirable. If the joiners do not f it properly, lightly sand the

excess epoxy and uneven surface joints from the joiner

edges and sides. Note: The plywood and balsa wing

joiners have a slight dihedral angle on one edge. This

angle should be on the bottom of the wing.

Wing

Bottom

Dihedral Angles

2. Carefully glue the plywood center ribs and wing

joiners together using 6-minute epoxy. The plywood joiner

has a slight angle on one edge. Place these angles

adjacent with each other. Use clothespins to clamp the

joiner and ribs together. Remove the excess epoxy on the

edge of the ribs and joiner using a paper towel and rubbing

alcohol.

5. Use 6-minute epoxy to glue the front and rear wing

joiners into the right wing half. Before the epoxy cures,

make sure the joiners are straight and in good contact with

the wing spars. Wipe off any excess epoxy on the ribs or

on the wing covering with a paper towel and rubbing

alcohol.

6

Join the Wing

6. Trial f it the tw o wing halves together. The wing halves

should seat together without any gaps and the front and

back edges of each wing should line up with each other.

Completely cover the wing joiners, spars and center ribs

with 30-minute epoxy. Slide the two wing halves together,

using masking tape to hold the wing in proper alignment

until the epoxy cures.

2. Remove the precut area from the front center rib

before gluing. Carefully glue the plywood center ribs and

wing joiner together using 6-minute epoxy. The plywood

joiner has a slight angle on one edge. Place these angles

adjacent with each other. Use clothespins to clamp the

joiners and ribs together. Remove the excess epoxy on the

edge of the ribs and joiner using a paper towel and rubbing

alcohol.

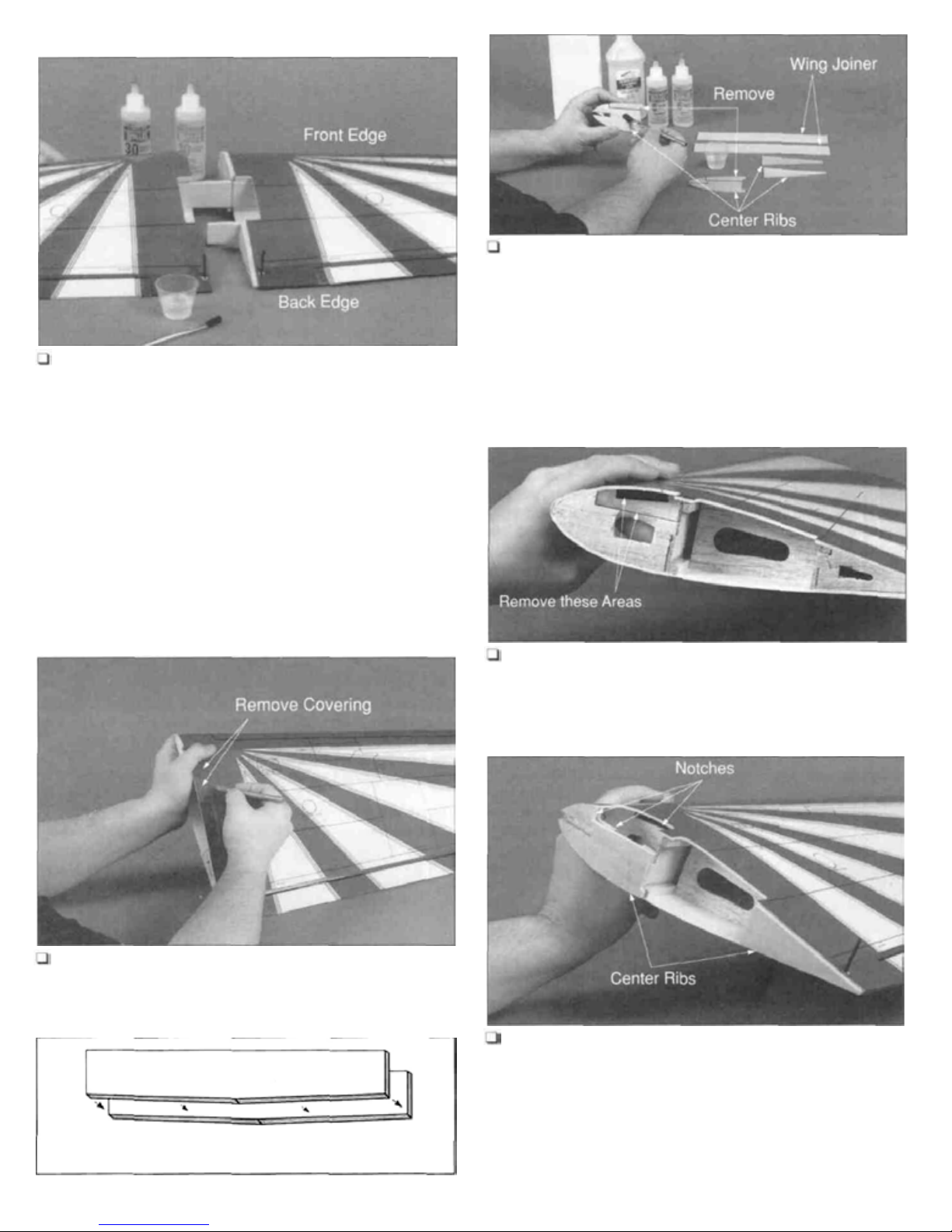

Modify the Wing Rib

Center Ribs and Wing Joiners

Retracts (Option B)

(Skip Steps 1 -7 Option B if fixed landing gear are to be installed.)

(Continue on page 8.)

Remove the Foam Covering

1. Remove the foam covering from the aileron and

retract servo openings. The skin has been partially precut

for exact location.

3. Using a hobby knife, remove the precut areas of the

wing ribs on the two closest ribs to the wing root in both

wing halves.

Glue the Center Rib on the Wing

Glue the Center Ribs & Wing Joiners

Wing Joiner

Dihedral Angles

for a proper fit. The ribs should not protrude past the outer

skin of the wing. Lightly sand the edges of the center ribs

until they are flush with the wing covering. Glue the

plywood center ribs t o the right wing half. Note: Notice the

positions of the notches removed from the center and wing

ribs for the retract pushrods when gluing the plywood rib

onto the wing.

7

Glue the Wing Joiners

Landing Gear Assembly

Top

Wing

Bottom

Wing Joiner

5. Draw a centerline on both of the wing joiner pieces.

Trial fit the wing joiners in both wing halves. A snug fit is

desirable. If the joiners do not fit properly, lightly sand the

excess epoxy and uneven surface joints from the joiner

edges and sides. The plywood joiner has a slight angle

on one side, which should face the bottom of the wing.

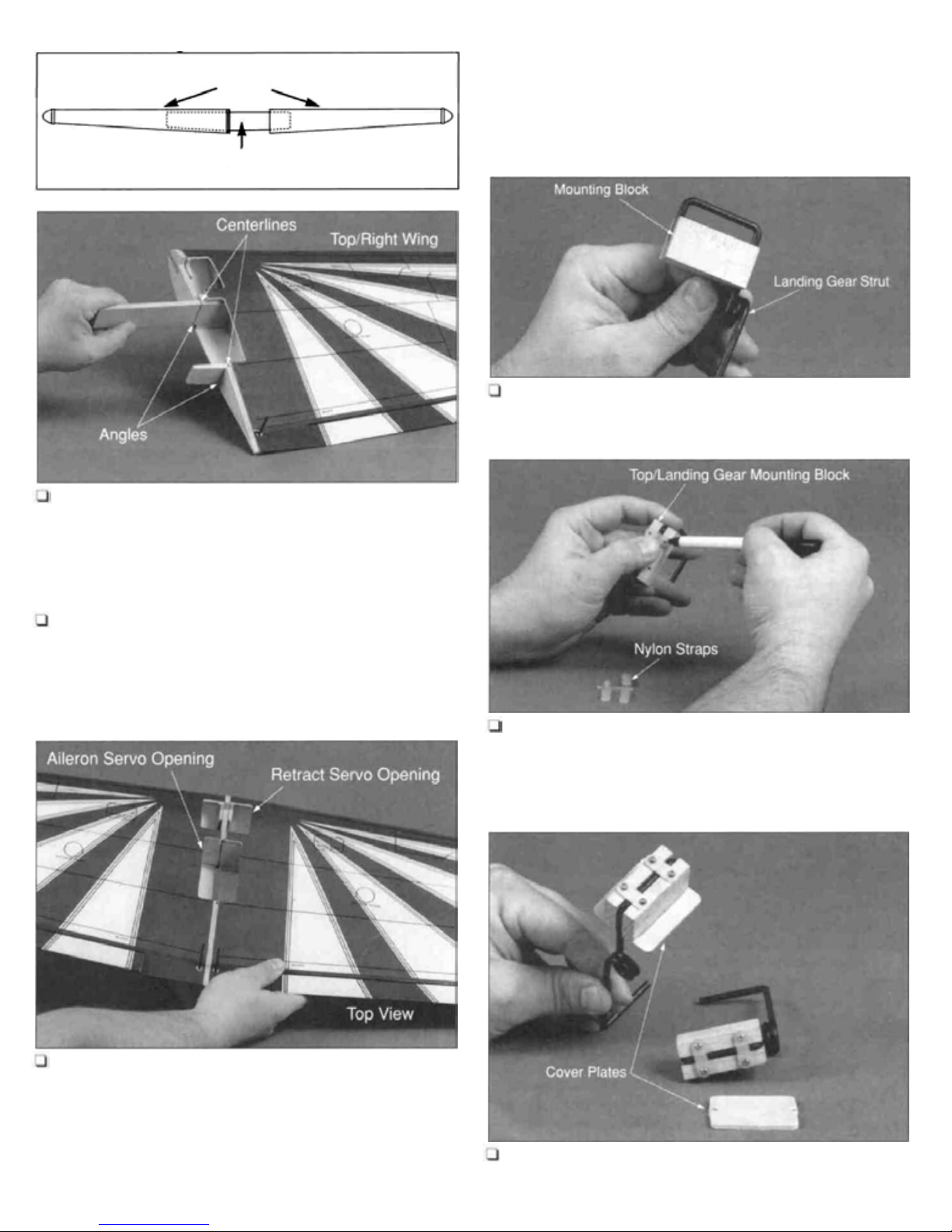

Fixed Gear (Option A)

(Skip Steps 1-11 Option A if retracts are being installed.)

(Continue on page 10.)

Assemble the Fixed Landing Gear

1. Place the landing gear mounting block between the

U-bend on the top portion of the main landing gear strut.

Secure the Mounting Blocks

6. Use 6-minute epoxy to glue the front and rear wing

joiners into the right wing half. Before the epoxy cures,

make sure the joiners are straight and in good contact with

the wing spars. Wipe off any epoxy on the ribs or on the

wing covering using a paper towel and rubbing alcohol.

Join

the

Wing 2. Using a pen, place marks on the mounting blocks

7. Trial fit the two wing halves together. The wing halves

should seat together without any gaps and the front and

back edges of each wing should lineup with each other.

Completely, cover the wing joiners, spars and center

ribs.with 30-minute epoxy. Slide the two wing halves

together, using masking tape to hold the wing in proper

alignment until the epoxy cures.

using the flat nylon straps as templates. Predrill the screw

holes using a 1/16" drill bit and secure the strut with two

nylon straps and four #2 x 3/8" sheet metal screws.

Final Assembly

3. Use 6-minute epoxy to glue the plywood landing gear

cover plate to the mounting block.

8

Install the Gear into the Wing Mount the Wing Bolt Plates

4. Place the landing gear into position in the wing.

Locate the plastic landing gear mount covers and glue

them to the plywood mounting plates with thick CA. Trim

out and use the template on page 31 to locate and drill

eight 3/32" holes in both landing gear mounts. Install eight

#4 x 1/2" sheet metal screws into t he holes you just drilled.

Note: The inner four screws secure the plywood plate to

the grooved landing gear block and the outer four screws

secure the plywood plate to the mounting rails in the wing.

7. Using 6-minute epoxy, glue the plywood wing bolt

plates to the bottom of the wing aligned with the trailing edge.

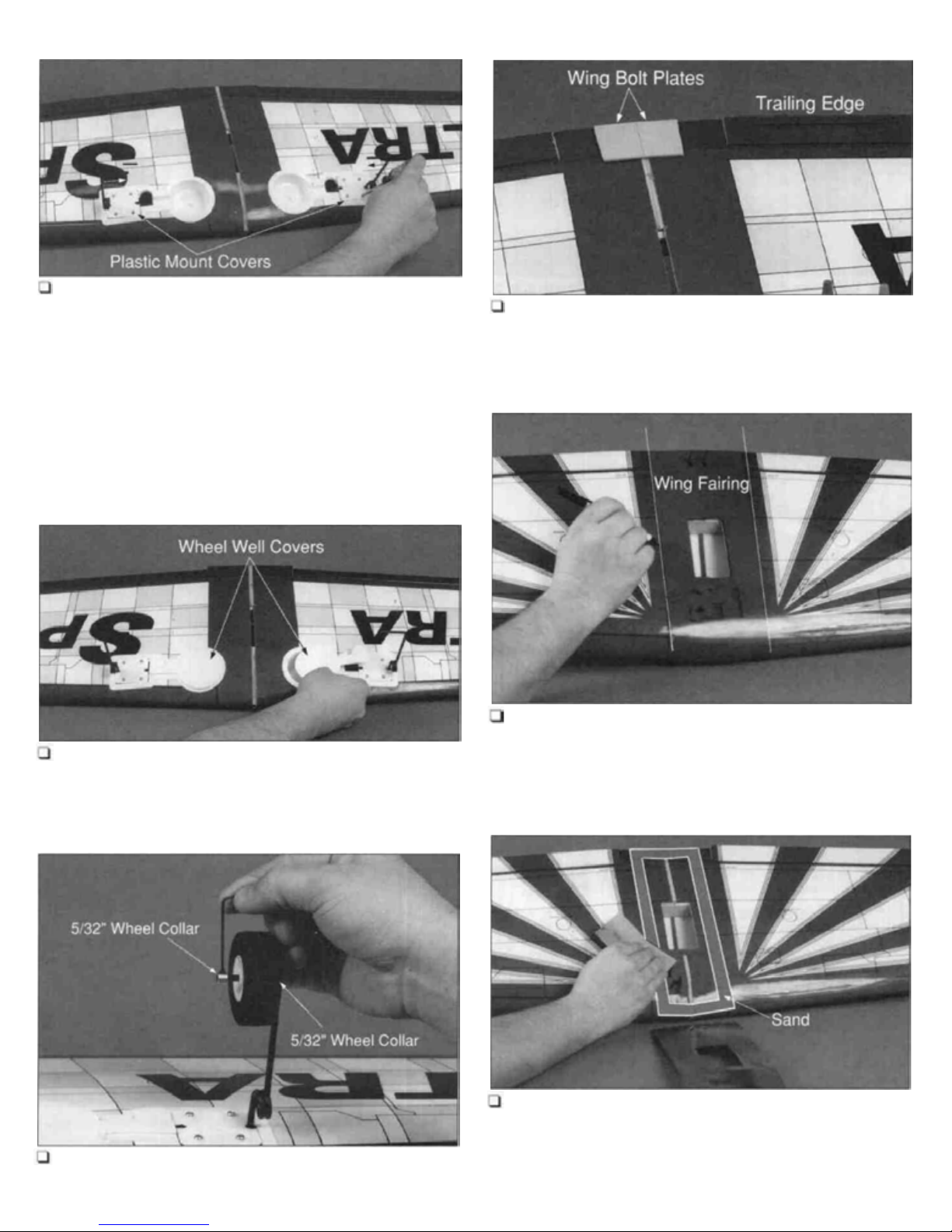

Prepare the Wing Fairing

Install the Wheel Well Covers

5. Locate and glue the two white plastic retract wheel

well covers in place using medium CA.

Mount the Wheel

8. Individually place the top and bottom plastic wing

fairings on the wing and lightly trace its outline onto the wing.

Sand the Fairing and Wing

6. Mount the wheels using the four 5/32" wheel collars.

(One on each side of the wheel.)

9. Use medium grit sandpaper to lightly roughen the

inside of each fairing where it wil l be glued to the wing. The

area to be sanded is shown as a lightened area in the

photograph. This will insure better adhesion of the fairing

to the wing.

9

Glue the Fairing to the Wing

Mark the Retract

10. Use thick CA+ to glue the top fairing to the top

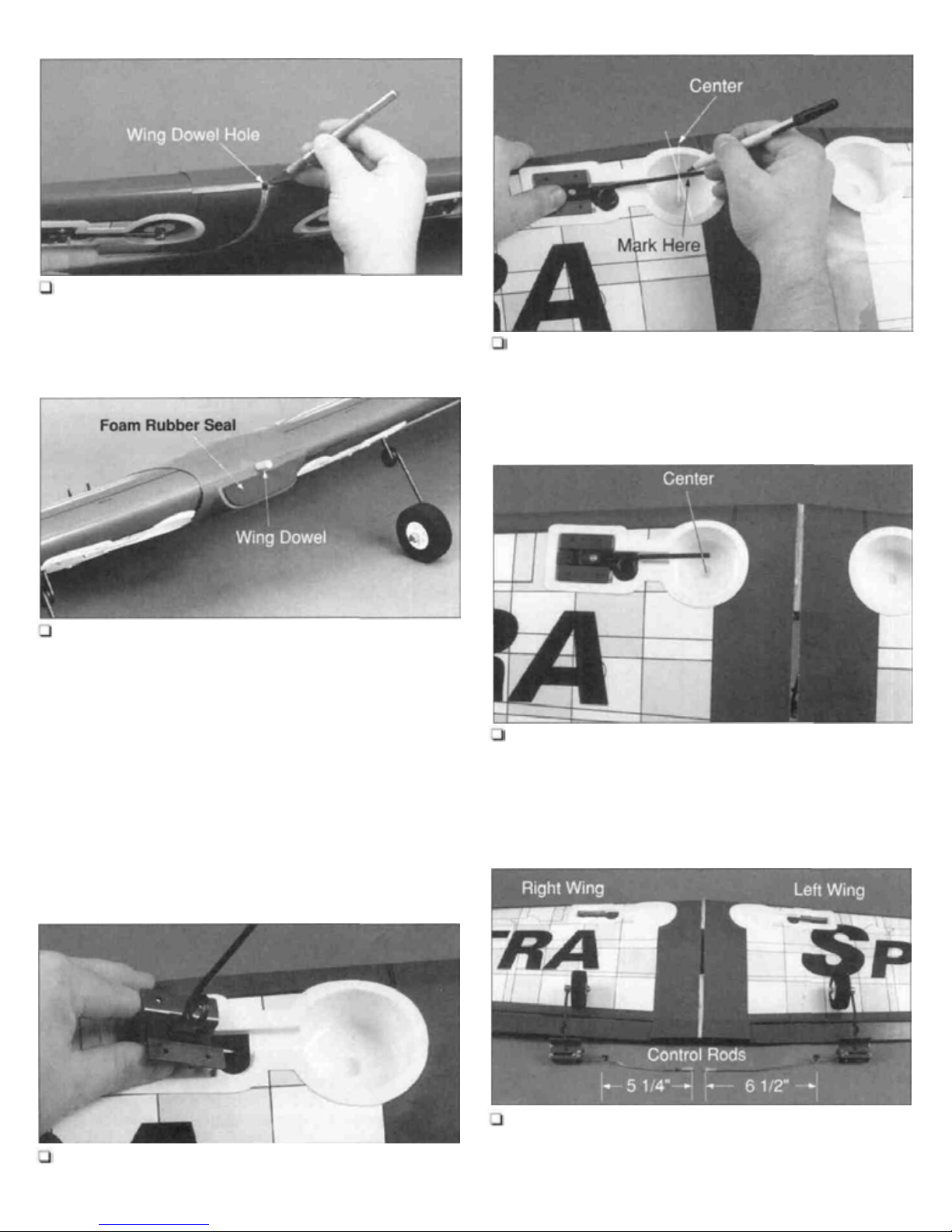

the wing. Remove the plastic that is covering the wing

dowel hole on the leading edge of the wing. Proceed to

glue the bottom fairing to the bottom side of the wing

remove the remaining plastic covering the dowel hole.

of

and

Glue the Wing Dowel

11. Use 6-minute epoxy to glue the hardwood wing

dowel into the leading edge of the wing. Work epoxy into

the dowel hole. Apply epoxy to the dowel itself and insert

the dowel. Leave 1/2" of dowel protruding from the wing.

Clean the excess epoxy from the dowel using a paper

towel and rubbing alcohol. Apply the foam rubber seal to

the front edge of the wing fairing. It will help prevent

exhaust residue from leaking into the fuselage.

Landing Gear Assembly

2. Using a pen, mark the landing gear wire at the

center of the wheel well when the retracts are folded into

the wing.

Cut the Gear Wire

3. Bend the landing gear wire at the mark. Install the

wheel on the landing gear wire securing it with a 5/32"

wheel collar. Cut off the excess landing gear wire and file

the end to remove any rough edges.

Retracts (Option B)

(Skip Steps 1-13 Option B if fixed gear has been installed.)

(Continue with Aileron Assembly on page 12.)

Retract Modification

1. Insert the retract into the wing with the main landing gear

wire facing toward the root of the wing when it i s folded down.

Bend the Pushrods

4. Bend the pushrods to match the line drawing on page

5. The pushrods should look like the assembled retracts

shown in the photograph above, if you are using Hobbico

Main Retracts (HCAP4010).

10

Loading...

Loading...