Page 1

SPECIFICATIONS

Wingspan:

Length:

Wing Area:

Weight:

78.5 in [1995mm]

42 in [1065mm]

498 in

2

[32.1 dm

2

]

29– 31 oz [822– 879 g]

Loading:

Motor: RimFire .10 Outrunner

8.4 – 9.0 oz/ft

Wing

[25.6–27.5 g/dm2]

(Included with the Rx-R)

ESC: 40A

(Included with the Rx-R)

WARRANTY

Great Planes® Model Manufacturing Co. guarantees this kit to

be free from defects in both material and workmanship at the

date of purchase. This warranty does not cover any component

parts damaged by use or modication. In no case shall Great

Planes’ liability exceed the original cost of the purchased kit.

Further, Great Planes reserves the right to change or modify this

warranty without notice.

In that Great Planes has no control over the nal assembly or

material used for nal assembly, no liability shall be assumed nor

accepted for any damage resulting from the use by the user of

READ THROUGH THIS MANUAL BEFORE STARTING CONSTRUCTION. IT CONTAINS IMPORTANT

INSTRUCTIONS AND WARNINGS CONCERNING THE ASSEMBLY AND USE OF THIS MODEL.

INSTRUCTION MANUAL

2

the nal user-assembled product. By the act of using the

user-assembled product, the user accepts all resulting liability.

If the buyer is not prepared to accept the liability associated

with the use of this product, the buyer is advised to return

this kit immediately in new and unused condition to the

place of purchase.

To make a warranty claim contact:

greatplanes.com/support

Battery: 2S 2200mAh,

3S 1800mAh LiPo

(LiPo not included)

Propeller: 12 x 6.5 (included)

Radio: 4+ ch. radio, 4 servos

(Servos included with the Rx-R)

© 2018 Great Planes Model Mfg. A subsidiary of Hobbico,® Inc.

GPM A1818 /GP MA1819

Page 2

TABLE OF CONTENTS

Academy of Model Aeronautics

ELECTRIC MOTOR SAFETY PRECAUTIONS. . . . . . . . . 2

LITHIUM BATTERY WARNING. . . . . . . . . . . . . . . . . . . . . 3

ADDITIONAL ITEMS REQUIRED . . . . . . . . . . . . . . . . . . . 3

Radio/Servos . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Motor. ESC, Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

LiPo Battery Charger . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Adhesives, Hardware and Other Accessories . . . . . . . 4

REPLACEMENT PARTS LIST. . . . . . . . . . . . . . . . . . . . . . 4

KIT CONTENTS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

PREPARATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

ASSEMBLE THE WING. . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Hook Up the Ailerons. . . . . . . . . . . . . . . . . . . . . . . . . . 6

Install the Servo Covers. . . . . . . . . . . . . . . . . . . . . . . . 8

Join the Wing Halves . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Mount the Wing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

ASSEMBLE THE FUSELAGE . . . . . . . . . . . . . . . . . . . . . 10

Install the Fin and Stab . . . . . . . . . . . . . . . . . . . . . . . 10

Hook Up the Elevator and Rudder. . . . . . . . . . . . . . . 13

Install the Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Final Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

PREPARE THE MODEL FOR FLIGHT . . . . . . . . . . . . . . 18

Set the Control Throws . . . . . . . . . . . . . . . . . . . . . . . 18

Arm the ESC. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Set the Fail Safe and the Motor Brake. . . . . . . . . . . . 19

Check the C.G. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Balance the Model Laterally . . . . . . . . . . . . . . . . . . . 20

PREFLIGHT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Motor Safety Precautions . . . . . . . . . . . . . . . . . . . . . 20

Range Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

General Pre ight Information. . . . . . . . . . . . . . . . . . . 20

FLYING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

INTRODUCTION

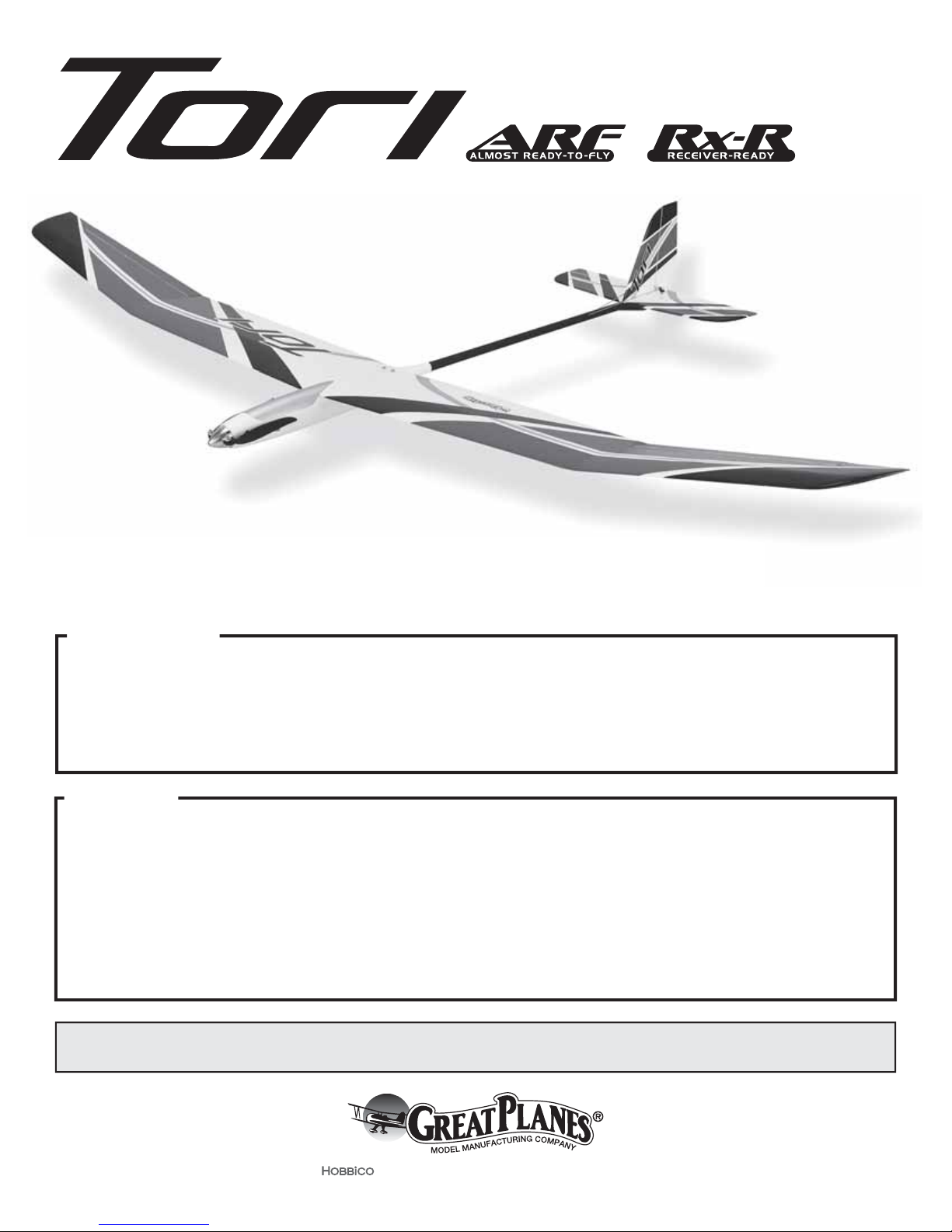

Thank you for purchasing the Great Planes Tori 2-meter EP

Sailplane! The Tori features a carbon boom, folding prop

and berglass fuselage. This gives you a glider that is steps

above a conventional foam or all-wood glider. The Tori can

be own with either a 2S or 3S LiPo for versatility. See the

Flying section on page 21 for more details.

NOTE: This instruction manual illustrates all the steps

necessary to assemble the ARF (almost ready-to- y) edition

of the Tori. However, the Rx-R (receiver-ready) edition

requires less assembly, so if assembling the Rx-R, simply

skim through the manual and perform only steps that apply.

For the latest technical updates or manual revisions, nd

the Tori on the Great Planes web site at www.greatplanes.

com. If there is new technical information or changes to this

model, a “Tech Notice” box will appear on the page for the

Tori on the Great Planes web site.

If you are not already a member of the AMA, please join! The

AMA is the governing body of model aviation and membership

provides liability insurance coverage, protects modelers’ rights

and interests and is required to y at most R/C sites.

Academy of Model Aeronautics

5151 East Memorial D rive

Muncie, IN 47302-9252

Tele. (800) 435-9262

Fax (765) 741-0057

Or via the Internet at: http://www.modelaircraft.org

IMPORTANT!!! Two of the most important things you can do to

preserve the radio controlled aircraft hobby are to avoid ying near

full-scale aircraft and avoid ying near or over groups of people.

FAA Info

As a new owner of an unmanned aircraft system (UAS) it is

your responsibility to operate this vehicle safely following the

FAA rules. Please contact your local authorities to nd out

the latest rules and regulations. As of this printing, the FAA

does not require an FAA number on your plane. In the United

States, please visit:

knowbeforeyou y.or g

faa.gov/uas.

ELECTRIC MOTOR

SAFETY PRECAUTIONS

WARNING! A spinning propeller has the potential to cause

serious and permanent injury.

WARNING! Once the motor batteries are connected, the

propeller can start spinning at any time. Make sure the Fail

Safe is set on your radio to prevent the motor from starting

if the signal is lost.

WARNING! Stand clear of the propeller when handling

the aircraft. Make sure the aircraft is held securely until the

battery has been disconnected.

While working on your plane, ALWAYS remove the propeller

when the battery is connected.

ALWAYS remove the motor batteries from the plane

when charging.

ALWAYS switch on the transmitter rst, then the receiver.

ALWAYS unplug the motor batteries rst before switching

off the receiver, then transmitter.

NEVER touch the motor during or right after operation. The

motor gets HOT!

NEVER switch off the transmitter with the motor batteries

plugged in.

NEVER reach through the arc of the propeller when plugging

or unplugging the battery into the ESC.

2

Page 3

LITHIUM BATTERY WARNING!

This product recommends the use of a lithium polymer

(LiPo) battery. Improper handling of a LiPo battery

could result in FIRE! A lithium battery re has the

potential to ignite surrounding areas and may cause property

damage or personal injury.

For safe LiPo handling, follow ALL of these guidelines:

MOST IMPORTANT! Never leave the battery or charger

unattended during charging or discharging.

WARNING: Read the entire instruction sheet included with

your motor batteries. Failure to follow the instructions could

cause permanent damage to the battery and its surroundings

and cause bodily harm!

NEVER charge the battery or set the charger on combustible

materials.

NEVER charge the battery inside a vehicle or in a location

that could be damaged in the event of a LiPo re.

NEVER put a LiPo battery in the pocket of any clothing.

NEVER charge the batteries in the plane. Disconnect the

batteries and remove them from the plane immediately

after landing.

NEVER allow the battery to short circuit by touching exposed

wires together. This may cause a re.

NEVER operate or store batteries below 40˚F (4˚C) or above

110˚F (43˚C).

ADDITIONAL ITEMS REQUIRED

ALWAYS follow the charging instructions included with your

charger for charging LiPo batteries. LiPo batteries can cause

serious damage or re if misused.

ALWAYS use a LiPo-approved charger.

ALWAYS set the charger’s output volts to match the

battery volts.

ALWAYS charge a LiPo battery in a reproof location.

ALWAYS balance charge the battery.

ALWAYS store and transport LiPo batteries in a reproof

container away from combustible materials.

ALWAYS KEEP OUT OF THE REACH OF CHILDREN.

ALWAYS keep LiPo batteries out of the reach of animals. A

punctured battery may cause a re.

ALWAYS disconnect the battery and unplug the charger

after the charge is complete.

ALWAYS keep a supply of sand accessible when charging

a LiPo battery. Dumping sand on the battery will assist in

extinguishing a LiPo chemical re.

ALWAYS remove the batteries from the plane after a crash.

Set them aside in a safe location for at least 20 minutes. If

the batteries are damaged in the crash, they could catch

re. If the battery starts to swell, quickly move the battery to

a safe location, preferably outside away from combustible

material. Place it in a bucket, covering the battery with sand.

NEVER use water to try and put out a LiPo re.

NEVER charge or use a battery that is deformed, bent,

crushed, swollen, or has any type of visible damage.

NEVER use a NiCd/NiMH peak charger to charge a

LiPo battery.

NEVER charge in excess of 4.20V p e r cell unless the battery

is rated for a higher voltage.

NEVER charge at currents greater than 1C unless the batte r y

is rated for a higher charge rate.

NEVER trickle-charge a LiPo battery.

NEVER allow the battery temperature to exceed 140°F (60°C).

NEVER disassemble or modify the pack wiring in any way

or puncture the cells, as this may result in a re.

NEVER discharge below 2.7V per cell. It is recommended

to not discharge below 3.7V per cell.

Radio/Servos

A minimum 4-channel radio is required to y the Tori. The

Tactic TTX660 is recommended because of its simple,

exible computer programming and multiple model memory.

The servo tray in the fuselage is sized for Tactic TSX5 micro

servos, but the cutout may be enlarged for other servos.

Because of the Tori’s capability to reach high altitudes, it

is also recommended to use a full-range, dual-diversity

receiver such as the Tactic TR625.

❍ Tactic TTX660 6-channel programmable radio

(TACJ2660)

❍ Tactic TR625 6-channel receiver (TACL0625)

❍ (4) Tactic TSX5 micro high speed servos (TACM0205)

❍ OPTIONAL*: Y-harness for ailerons (FUTM4130).

*If spoilerons are desired, 5-channels will be required and the

aileron servos will have to be connected to separate channels

in the receiver and mixed electronically through programming

in the transmitter. In this case a Y-harness is not used.

Motor , ESC, Battery

The Tori Rx-R includes the recommended RimFire motor and

an ESC with similar speci cations and performance to the

recommended ESC. With the included 12x6.5 folding propeller,

either version of the Tori may be own on a 2S or 3S battery.

The recommended motor, ESC and battery for the Tori:

❍ Great Planes RimFire .10 35-30-1250 Outrunner

Brushless (GPMG4595)

❍ Great Planes Programmable ESC 40A BL 2S-6S

(GPMM2140)

❍ 30C 3S 11.1V 1800mAh LiPo Star (ONXP2243)

OR 30C 2S 7.4V 2200mAh LiPo Star (ONXP2260)

LiPo Battery Charger

A charger capable of charging LiPo batteries is required.

The Triton EQ (GPMM3155) is a suitable charger as it has

plenty of power for charging the LiPos recommended for

the Tori (and larger LiPos as well). The Triton EQ is also

recommended for its versatility in charging all other types of

batteries used in RC and may be powered by either a 12V

DC power source or 110V AC.

3

Page 4

Adhesives, Hardware and

Other Accessories

Other than common hobby tools, here is a list of other items

required to assemble the Tori:

❍ 30-minute epoxy (GPMR6043)

❍ Epoxy brushes (GPMR8060)

❍ Mixin’ cups (GPMR8056)

❍ Mixin’ sticks (GPMR8055)

❍✱ Shoe Goo (DTXC2460)

❍ Threadlocker thread locking cement (GPMR6060)

❍✱ Thin CA (GPMR6001)

❍✱ Medium CA (GPMR6007)

❍✱ CA applicator tips (HCAR3780)

❍✱ CA accelerator (GPMR6035)

❍✱ Clear tape

❍✱

Drills: #55 (.052" [1.3mm]), 1/16" [1.5mm]

OPTIONAL:

❍ Great Planes C.G. Machine (GPMR2400)

❍✱ 3/16" Heat shrink tubing (GPMM1056) (see page 17)

✱ These items not needed for Tori Rx-R

A covering iron with a cover sock may be required for

tightening and re-bonding the covering that may have

loosened between the time the covering was applied and

the time the model was removed from the box. The 21

st

Century Iron is preferred because of its long cord, contoured

shoe and precisely adjustable temperature range.

❍ Coverite 21

st

Century Sealing Iron (COVR2700)

❍ Coverite 21st Century Cover Sock (COVR2702)

REPLACEMENT PARTS LIST

Order No. Description

GPMA4401

GPMA4402

GPMA4403

GPMA4404

GPMA4405

GPMA4406

GPMA4407

GPMA4408

For questions, contact: greatplanes.com/support

Fuselage

Wing Parts Set

Tail Surface Set

Hatch

Propeller Blade Set 12 x 6.5

Spinner/Blade Holder

Aileron Servo Cover

Decals

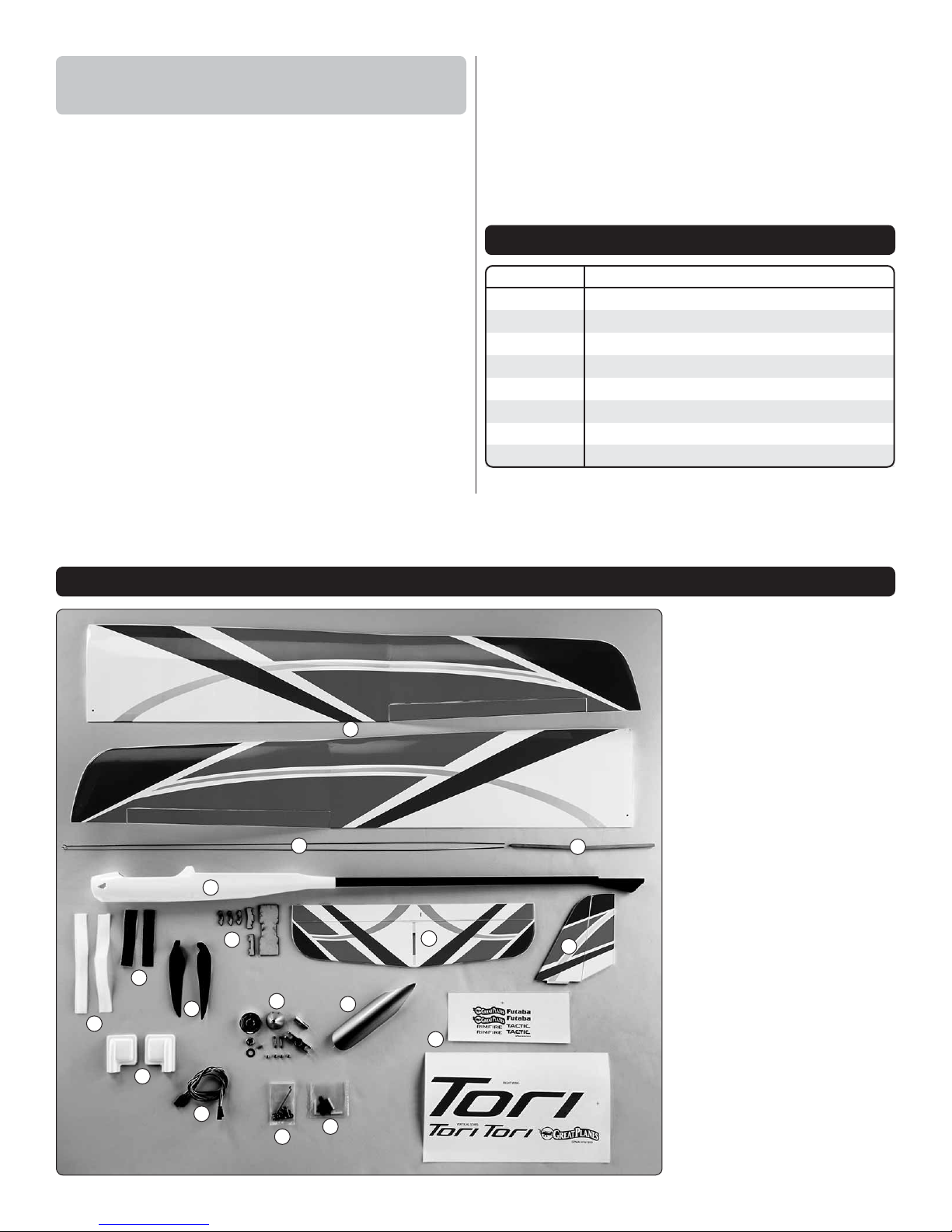

KIT CONTENTS

1. Wi ng Halves

2. Pushrods

1

2

4

7

6

5

10

13

14

11

15

12

16

8

17

3

9

3. Wing Joiner

4. Fuselage

5. Hook & Loop Material

6. Adhesive-Backed Hook

& Loop Material

7. Wire Holders, Pushrod

Brace, Battery Plate

8. Stab

9. Fin

10. Propeller Blades

11. Spinner/Blade Holder

12. Canopy Hatch

13. Aileron Servo Covers

14. Aileron Servo Extensions

(ARF only)

15. Hardware Pack

16. Control Horns

17. D e c al s

4

Page 5

PREPARATION

1. The canopy is held in place with wire rods at both

❏

ends. To remove the canopy, slide it forward and then lift

the back end up.

ASSEMBLE THE WING

Hook Up the Ailerons

You can assemble one wing at a time, or work on both wing

halves simultaneously. The left wing is shown in the photos.

2.

Use a covering iron with a protective cover sock to bond

❏

areas of loose covering back down to the framework or remove

any wrinkles that may have developed after the covering was

applied. Start with low or medium heat to nd the setting that

works best (approximately 275ºF measured on the surface of

the cover sock). Gradually increase the heat as necessary, but

too much heat may cause seams and edges to pull away or

damage the color graphics printed onto the covering, so

proceed with care. As you go, push down on the iron over

sheeted areas to bond the covering to the wood underneath.

3. Stack two or three

❏

paper towel squares on

top of each other and

cut them into small

squares. These squares

may be dampened

with denatured alcohol

when epoxy cleanup is

needed.

5

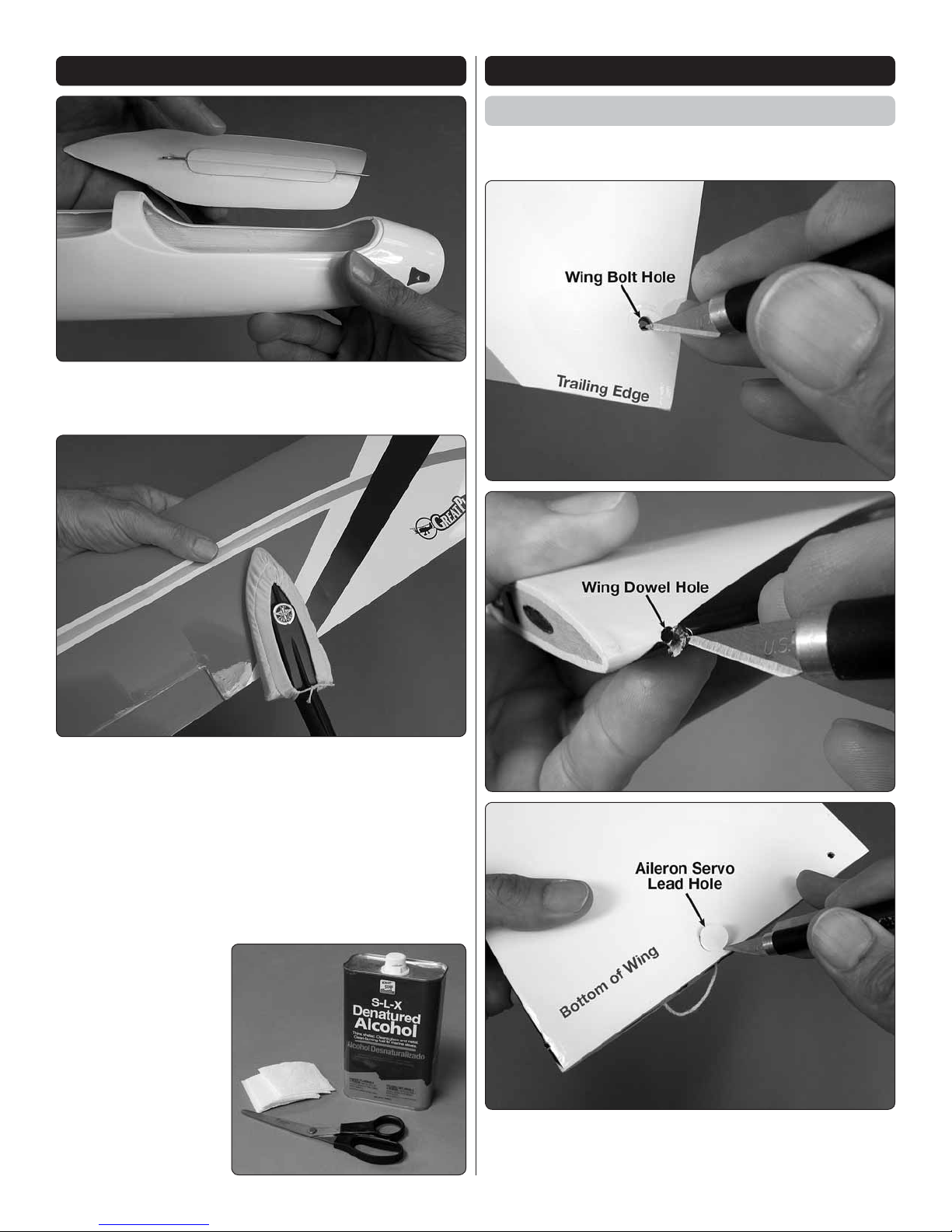

1. Cut the covering from the wing over the wing bolt

❏

holes, the leading edge dowel holes and the servo wire

holes in both wing halves.

Page 6

2. Use an epoxy brush to apply a thin coat of epoxy or

Cut off

Trim

7/16" [11mm]

(4

th

hole in Tactic

servo arm)

❏

medium CA to the inside of the top wing skin in the aileron

servo opening. Allow epoxy to harden before continuing.

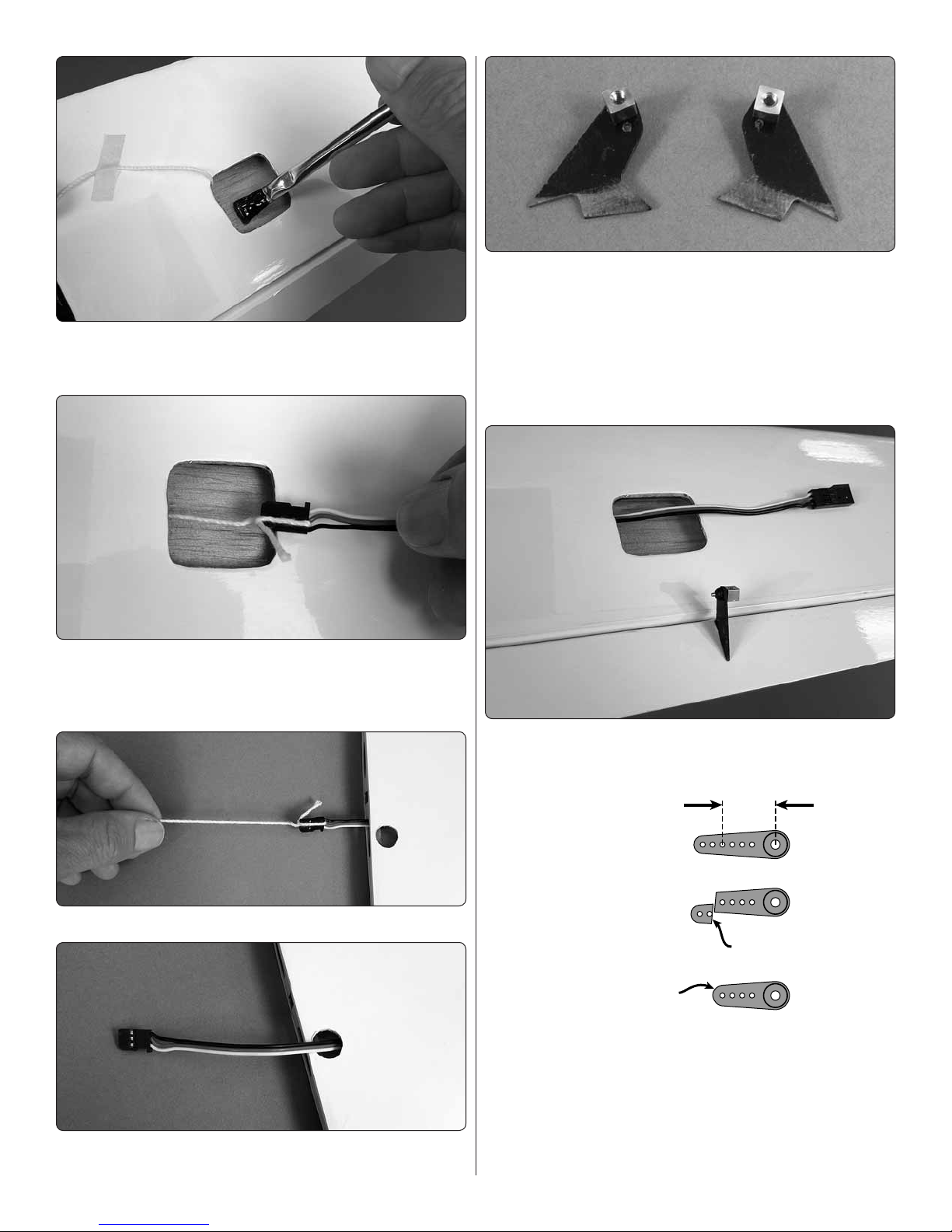

3. Tie the string in the wing around the end of the included

❏

aileron servo extension as shown – a small drop of thin CA

will ensure that the knot doesn’t come undone when you are

drawing the servo wire through the wing.

6. Use medium-grit sandpaper to roughen the bottom

❏

portion of the two larger control horns so glue will adhere.

Install a brass screw-lock connector into the top hole of

both horns and secure with a nylon retainer as shown. Be

certain the retainer snaps on securely. If the retainer ts

loose, replace it with another – four spares included.

7. Cut and remove the covering from the bottom of the

❏

aileron over the slots for the horns.

8.

Insert the horn into the aileron as shown (with the screw-

❏

lock body on the outside of the horn toward the tip of the

wing), then use thin CA to securely glue the horn into place.

4. Carefully pull the servo wire out as you pull the string.

❏

5. Guide the servo connector and the wire out the hole in

❏

the bottom of the wing.

9.

Identify a hole in the servo arm that is 7/16" [11mm]

❏

out from the center (this would be the 4th hole out for Tactic

servos), or the next hole closest in. Use a #55 (.052" [1.3mm])

drill to enlarge the hole to t the aileron pushrod. Then, cut

off the rest of the servo arm so it will not interfere with the

servo hatch cover.

10. Connect the aileron servo to the servo extension in

❏

the wing.

6

Page 7

90°

90°

Left Right

11. Connect the other end of the aileron servo extension

❏

wire to the receiver. Turn on the transmitter and power

the receiver with a separate receiver battery (or the ESC

connected to the receiver and your motor battery). With the

servo powered and centered, install the servo arm to the

servo so it will be perpendicular to the case—if necessary,

use the Sub Trims in your transmitter programming to get

the servo arm perpendicular.

14.

Operate the aileron with the radio to make sure everything

❏

operates smoothly. Make any adjustments necessary.

If working on one wing at a time, now would be a good

time to go back and assemble the second wing so both

servos can be glued in at the same time.

12.

Connect the Z-bend end of an aileron pushrod to the

❏

servo arm as shown. Double the excess servo wire beside

itself in a zigzag pattern so it will t in the wing alongside the

servo. Temporarily place the servo in the wing.

13. Connect the pushrod to the screw-lock connector on

❏

the aileron horn with an M2x3 Phillips machine screw.

15. Use Shoe Goo® or similar exible cement to glue the

❏

servo to the top wing skin (or use tape to hold the servo

in place). Allow the glue to dry at least a few hours before

handling the wing and at least overnight before ying.

NOTE: CA may also be used to glue in the servos, but

should the occasion to remove the servo ever arise, it is

likely the servo bay in the wing will be damaged. With Zap

Goo and similar types of rubbery cement it will be easier to

remove the servo without damaging the wing.

7

Page 8

16. After the glue holding the servos to the wing has

❏

dried, turn on the radio to center the servos. Holding the

ailerons centered, connect the pushrods to the screw-lock

connectors with an M2x3 Phillips machine-thread screw

and a drop of threadlocker. Operate the aileron with your

radio to make sure everything moves smoothly. Make any

adjustments necessary. Trim the excess pushrod material.

Install the Servo Covers

1.

Use curved-tip scissors

❏

or any other kind of small

hobby scissors to trim the

hatches down to the at

base lip that will be taped to

the wing.

2.

❏

over the servo. Operate the

ailerons with your radio to

make sure the servo arm

and/or pushrod do not

interfere with the cover. Make

any adjustments necessary.

Position the hatch

2. Make certain you have everything on-hand to glue the

❏

wings together including 30-minute epoxy, a mixing cup, a

mixing stick, an epoxy brush, masking tape and those paper

towel squares and denatured alcohol mentioned earlier in

the manual.

NOTE:

working time to glue the wing halves together, make sure

you have everything ready and work ef ciently so you don’t

run out of working time before the epoxy begins to harden.

Even though 30-minute epoxy provides enough

3. Mount the hatch to the wing with clear tape.

❏

Join the Wing Halves

3. Mix approximately 1/4 oz. of 30-minute epoxy.

❏

Working quickly, pour some epoxy into the spar cavities in

both wings.

4. Coat one end of the joiner and insert it into one of the

❏

wing halves, pushing it in and out several times to thoroughly

coat the entire spar cavity. Remove the joiner and perform

the same procedure for the other wing, but this time leave

the joiner in place.

5. Coat the protruding end of the joiner and both ends of

❏

both wing halves with epoxy. Then, join the wings together

and wipe away excess epoxy.

1. Test- t the wing halves together with the wing joiner

❏

and the nylon alignment dowel. Make any adjustments

necessary for a good t.

6. Use strips of masking tape on the top and bottom

❏

of the wing to tightly pull the wing halves together while

using the paper towel squares dampened with denatured

alcohol to wipe away excess epoxy as you proceed. Allow

the epoxy to fully harden before removing the tape.

8

Page 9

7.

After the epoxy has hardened, carefully peel off the tape.

❏

Any residual masking tape adhesive may be cleaned with

another paper towel square dampened with naphtha (lighter

uid). Areas of covering that may have lifted from removing

the tape should be re-tightened with your covering iron.

Mount the Wing

ASSEMBLE THE FUSELAGE

Install the Fin and Stab

1. Same as was done with the aileron horns, use

❏

sandpaper to roughen both sides of the tabs on the elevator

and rudder horns, then install screw-lock connectors with

retainers as shown.

1. Roughen the remaining nylon dowels with medium-grit

❏

sandpaper. Then, test- t the dowels into the wing leading

edge.

2. Mount the wing to the fuselage with the dowels and

❏

the M3x14 Phillips screws and M3 at washers. Make any

adjustments so the wing ts the fuselage well—if necessary,

it’s okay to clean out the dowel holes in the wing with a 1/8"

[3mm] drill.

3. Remove, then reinstall the dowels with 30-minute epoxy—

❏

if the dowels t into the wing slightly loosely, micro balloons or

similar ller may be mixed in with the epoxy to ll any voids

to assure a secure bond. Working quickly, wipe away residual

epoxy, then reinstall the wing to the fuselage with the wing

bolts. Do not glue the wing to the fuselage. Allow the epoxy to

fully harden before removing the wing.

4.

Remove the wing from the fuselage. Remove any residual

❏

glue that may have seeped out of the wing past the dowels.

9

2. Cut and remove the covering from the horn slots in

❏

the top of the elevator and right side of the rudder. Glue the

horns into position with thin or medium CA.

3. Apply a strip of masking tape to the bottom of the stab

❏

so epoxy from gluing on the vertical stab ( n) will not get

through.

Page 10

4.Check for proper alignment of the n to the stab. Use

❏

30-minute epoxy to glue the n into the stab (if the t is

loose, add micro balloons to the epoxy). Use a small square

to make sure the n is perpendicular to the stab while the

epoxy hardens.

5. After the epoxy has hardened, remove the masking

❏

tape from the bottom of the stab.

A. Tie a small loop in one end of the line.

B. Fold a piece of masking tape over the line near the

other end. Draw a line on the masking tape. The tape will

be slipped along the line to equalize the stab as described

below.

Make a dry run of the stab alignment process using the

pin and string.

6. Mount the wing to the fuselage. Position and hold the

❏

stab on the stab saddle on the fuselage. View the stab and

wing from behind to see if the stab is parallel with the wing.

If necessary, sand the high side of the stab saddle on the

fuselage to get the stab to align with the wing.

Pin-and-String Technique

We use the pin-and-string technique is used for centering

the stab. To do this, you’ll need an approximately 45" [1.2m]

length of non-elastic line such as Sullivan Kevlar® thread or

Kevlar shing line.

7. Center the exposed balsa portion on the bottom of the

❏

stab over the wing saddle. Use a T-pin to hold the front of

the stab to the balsa plug in the stab saddle.

10

Page 11

8.

AA = A

B = B

A

BB

Insert a T-pin into the front of the wing centered between

❏

the two adjoining ribs. Loop the string over the T-pin.

11. Remove the stab. Glue the stab into position with

❏

30-minute epoxy using the pin and string to check alignment

as done in the previous steps. A couple extra T-pins may be

inserted through the stab and into the balsa saddle to tightly

hold everything in position until the epoxy hardens.

12. After the epoxy from the previous step has hardened

❏

and the T-pins removed, any visible pinholes may be

reduced by going over them with your sealing iron.

9. Pull the string back to one end of the stab. Slide the

❏

masking tape along the string until the line is even with the

trailing edge of the stab.

10. Swing the string over to same spot on the other side

❏

of the stab. Adjust the stab and the tape on the string until

the stab is “equalized” and rotationally centered.

13. Use thin or medium CA glue to attach the tail skid.

❏

11

Page 12

Hook Up the Elevator and Rudder

Elevator

9/32" [7mm]

(2

nd

hole in Tactic

servo arm)

Rudder

7/16" [11mm]

(4

th

hole in Tactic

servo arm)

1.

Mount the elevator and rudder servos as shown. (If your

❏

servos do not t, the servo tray may be trimmed as necessary.)

Drill 1/16" [1.5mm] holes for the servo mounting screws and

mount the servos with the screws that came with them.

4. Straighten the pushrod by removing the bend.

❏

5. Prepare and install the other pushrod through the other

❏

slot in the boom the same way – don’t forget to install the

small plastic tube rst!

❏

pushrods. Make a slight bend 2" [50mm] from the back end

of the pushrod.

❏

slots in the boom – the bend in the wire will allow the end of

the wire to poke up through the slot.

2. Slide one of the small, plastic tubes onto one of the

3. Guide the pushrod down through and out one of the

6. Same as was done for the aileron servo arms, enlarge

❏

the holes in the elevator and rudder servo arms with a #55

(.052" [1.3mm]) drill. It may be necessary to trim the servo

arms, but only enough so they don’t interfere with the inside

of the fuselage when the arms are on the servos.

7. Fit the pushrods into the holes in the servo arms

❏

indicated in the previous illustration. Temporarily install the

servo arms to the servos.

12

Page 13

8.

Fit, then glue the top portion of the pushrod brace into

❏

position all the way up against the “lip” around the wing

saddle—it isn’t critical where the brace is located forward

and aft—where it ts best is ne. Make sure the brace doesn't

interfere with the exit holes of the aileron servo leads.

9. Center the plastic tubes in the brace, then add and

❏

glue the bottom portion of the pushrod brace and the tubes

into place.

11. Still with the radio on, hold the rudder and elevator

❏

centered and tighten the pushrods in the screw-lock

connectors with the M2x3 Phillips screws and a drop of

threadlocker on the threads.

We’ll nish radio installation after the motor has

been installed.

Install the Motor

10. Connect the servos to your receiver and power up the

❏

radio with the transmitter. With the servos centered, adjust

the servo arms on the pushrods so they are perpendicular

to the servo arms. Fasten the servo arms to the servos with

the screws that came with them.

1. On the RimFire .10 use a 1.5mm hex driver to loosen

❏

the set screw in the collar and remove the collar. (If ever

using the motor in a reverse con guration in the future, be

certain to reinstall the collar.)

13

Page 14

2. Mount the motor with four M3x6 Phillips screws and a

❏

small drop of threadlocker on the threads.The motor wires

should be oriented along the bottom of the fuselage.

3. Assemble the folding propeller as shown. Fit the

❏

propeller blades into the hub and then install the pins. The

locknuts should be just tight enough so the blades still

rotate freely on the pins.

5.

Temporarily test- t the propeller/spinner assembly and

❏

check the gap between the front of the fuselage and the

spinner back plate. The gap should be approximately 1-2mm.

Whenever removing the propeller assembly in the future,

do not tap or apply pressure to the front of the backplate.

Instead, insert a sheet of hard plastic or wood between

the spinner gap to push the backplate forward—it also

helps to sand a bevel to the edge of the plastic or wood

part so it can be wedged into the gap.

4. Apply a light lm of oil to the colleted propeller shaft

❏

so the spinner back plate will be easier to remove after the

prop nut has been tightened.

6. Bevel the edges of the battery plate to conform to the

❏

fuselage when in position.

14

Page 15

7.

Cut a strip of the rougher, hook side of the included

❏

adhesive-back hook-and-loop strip to a length of 3-3/8"

[85mm] and apply to the top of the battery plate with CA glue.

8. Roughen the bottom of the fuselage in the area of

❏

the battery plate. Then, use medium CA to glue the battery

plate into position so the aft edge will be approximately 1/2"

[13mm] from the former at the wing LE.

A. Cut the motor wires to the desired length – about 1/2"

[13mm] is ne.

B. Strip approximately 1/8" [3mm] of the insulation from

the end of the wires and tin the exposed wire.

C. Cut and remove the shrink tubing from the bullet

connectors on the cut off ESC wires. Then, unsolder the

three bullets from the old wires.

9. Determine whether you will shorten the wires on

❏

your ESC, or leave the ESC wires as-is. The ESC may be

installed as supplied with the long motor wires, but removal

and installation of the battery will be easier without excess

wire in the way. Follow these instructions to shorten the

ESC wires:

D.

Re-solder the bullets to the shortened wires on the ESC.

15

Page 16

E. Cover the bullets with 3/16" [4.8mm] shrink tubing (not

included).

10. Remove the propeller from the motor before

❏

connecting the ESC! Then, connect the ESC to the motor

and your receiver and power up the radio so you can run the

motor. Make sure the motor is turning in the correct direction.

If not, simply swap any two of the wires between the ESC

and the motor.

Final Assembly

11. Mount the ESC to the side of the fuselage with double-

❏

sided foam mounting tape. If necessary, the included liteply wire holder may be glued into position to keep the motor

terminal wires from contacting the motor.

1.

Install the receiver so it will be secure, somewhat

❏

cushioned and so the antennas will be positioned according

to the manufacturer’s instructions. In this Tori, we taped one

of the antennas to the bottom of the fuselage before installing

the receiver, then t the receiver under the pushrod guide

brace with 1/4" RC foam under the receiver. A hole was

drilled in the fuselage side for a plastic guide tube (cut from a

tube from a spray can or similar – not included) for the other

antenna to achieve the 90° separation speci ed for the Tactic

receiver. (Note that the antennas do not have to be outside

the fuselage, but doing it this way was quick and simple.)

2. Trim the softer, “loop” side of the included adhesive-

❏

back hook-and-loop material to t the battery, and then

attach to the battery.

16

Page 17

2. Test- t the battery in place. Make sure it can be

❏

installed so that the discharge and balance leads will not

contact the spinning motor.

PREPARE THE MODEL FOR FLIGHT

Set the Control Throws

CAUTION: The propeller should not yet be installed.

If the propeller is installed on the motor, remove the

propeller while operating the radio to check the throws.

1. Measure and set the control throws according to

❏

the measurements provided below. If necessary, adjust

the throws with the programming in your transmitter and/

or adjusting where the pushrods connect to the servo

arms and/or control horns. NOTE: The control throws are

measured at the widest part of each control surface.

3. Optional: Make a battery strap from the included

❏

hook-and-loop strap material. For typical ying, a battery

strap is not necessary. But if for some reason you have a

battery that does not conform well to the battery mount

plate, or if you plan on ying inverted or aggressively, you

may want to use the battery strap.

These are the recommended control surface throws:

HIGH RATE LOW RATE

Up

ELEVATOR

RUDDER

AILERONS

2. OPTIONAL: Set up spoilerons. Spoilerons are up

❏

de ection of both ailerons to “spoil” lift causing the model

to sink. Spoilerons are not necessary, but can be an aid in

landing (to shorten the approach) or to get out of thermals

more quickly.

To program spoilerons in most radios, the aileron servos will

have to be connected to separate channels in the receiver.

Typically, the channels are mixed in the radio programming,

then another mix introduced to mix both aileron servos to

a switch, dial or slider for extending the spoilerons. Check

your radio to see if it has a dedicated spoiler function.

17

1/2"

[13mm]

25°

Right

1"

[25mm]

28°

Up

5/8"

[16mm]

33°

Down

1/2"

[13mm]

25°

Left

1"

[25mm]

28°

Down

3/8"

[10mm]

19°

Up

5/16"

[8mm]

15°

Right

3/4"

[19mm]

20°

Up

3/8"

[10mm]

19°

Down

5/16"

[8mm]

15°

Left

3/4"

[19mm]

20°

Down

1/4"

[6mm]

13°

Page 18

The degree of spoilerons is not critical and how much is

2-1/2" [63mm]

2-1/2" [63mm]

Recommended starting C.G.

2" [50mm]

2" [50mm]

3" [75mm]

3" [75mm]

Recommended C.G. range

needed is up to your personal taste. About 3/8" [9.5mm] is

a good place to start. If possible, control the spoilerons with

a proportional dial or slider so you can extend the spoilerons

proportionally (instead of using a switch which is all or nothing).

Arm the ESC

Before the motor will rotate, the ESC must be armed rst:

1. To arm the ESC, move the throttle stick to the lowest

position, turn the transmitter on, and wait for the initiation

tones followed by a single beep. Note: The ESC will autocalibrate the low throttle stick position when powered on.

Be sure that throttle stick is at its lowest point when you

plug the ight battery in (or at the highest point for setting

the brake function- see below).

2. Move the throttle stick to full throttle and the ESC will

con rm this position with a double beep.

3. Lower the throttle again and the ESC will con rm this

lowest position with a sequence of four beeps. THE ESC

IS NOW ARMED. Advancing the throttle stick will cause

the motor to rotate. The propeller blades should not be

installed on the motor until you are ready for ight and

you have con rmed the Fail Safe is operating correctly!

Check the C.G.

1. Set the rulers on a Great Planes C.G. machine to 2-1/2"

❏

[63mm], or mark the recommended, starting C.G. location

on the bottom of the wing where shown.

Set the Fail Safe and the Motor Brake

FAIL SAFE: While you have your radio operational and without

the propeller mounted, now would also be a good time to

set and check the Fail Safe function of your transmitter. Refer

to the instructions that came with your radio control system

to set Fail Safe on the throttle channel so that, in the event of

loss of signal, the motor will stop. To test the Fail Safe, with

the propeller removed and the radio control system turned on,

advance the throttle slightly (just enough to make the motor

turn) and turn off the transmitter. If the Fail Safe is set correctly,

the motor will stop when the transmitter is turned off.

MOTOR BRAKE: While you still have your radio system

powered up and without the propeller mounted, check

the motor brake.

Advance the throttle stick to run the motor, and then move

the throttle stick down to stop the motor. The motor should

stop abruptly (not coast gradually to a stop). If the motor

does not come to an abrupt stop and the brake in the ESC

is not activated, activate the brake as described below:

A. Disconnect the battery from the ESC so it will not

receive power.

B.

With the transmitter turned on, advance the throttle stick.

C.

Connect the battery to the ESC to power the motor. Listen

for the series of beeps. There will be three single beeps

separated by pauses (for brake OFF), then a series of

three double beeps separated by pauses (for brake ON).

To turn the brake ON, lower the throttle during the series

of double beeps. If you wish to turn the brake OFF, lower

the throttle during the three single beeps. Now the brake

is set to the desired function and you may disconnect

the battery and turn off the transmitter.

NOTE: The recommended C.G. range is from 2" to 3"

[50mm - 75mm] back from the leading edge of the wing

approximately where it meets the fuselage. As long as the

Tori is balanced within this range it will y and respond well.

Balanced nearer the front end of the C.G. range the Tori will

be more stable and penetrate wind a little better. Balanced

nearer the aft end of the C.G. range the Tori will “ oat” and

respond to lifting air a little better.

2. Mount the wing to the fuselage and install the propeller

❏

assembly, battery, and the canopy. Do not connect the

battery at this time.

3. At this point the Tori should be completely ready to y.

❏

Check the C.G. by placing the model on the C.G. machine,

18

Page 19

or lift at the lines you marked indicating the recommended,

starting C.G. Depending on the battery you are using, there

should be a little leeway to shift the battery forward or aft

to change the C.G. so it balances at the recommended

starting C.G.

4. Once the location of the battery has been determined,

❏

make a mental note of this location, or mark the inside of the

fuselage or the battery tray to position the battery here for

the proper C.G. when ying the model.

Balance the Model Laterally

WARNING: For brushless electric motors, never have the

motor battery connected to the ESC without the transmitter

turned on – after each ight (or any time after running the

motor) always disconnect the battery before turning off

the transmitter. And when ready to y (or whenever running

the motor for any reason), always turn on the transmitter

rst before connecting the motor battery.

Also make certain your Fail Safe is programmed

correctly so in the event the receiver ever loses signal

(or, if you inadvertently turn off the transmitter before

disconnecting the battery or vice-versa) the motor will

not turn. Follow the instructions that came with your radio

control system to check and set the Fail Safe.

CAUTION: Never run the motor on the ground for more

than a few seconds. Otherwise, you may overload the

motor, battery or ESC.

Range Check

1. Leaving the tail skid on the work surface, lift the Tori

❏

several times by the propeller shaft to see if one wing drops.

2.

If one wing drops consistently, add weight to the opposite

❏

tip by sticking it to the outside or strategically concealing

it inside the balsa tip. An airplane that has been laterally

balanced will track better in ight and maintain its heading

better during maneuvers when the plane is climbing.

PREFLIGHT

Motor Safety Precautions

Failure to follow these safety precautions may result

in severe injury to yourself and others.

● Use safety glasses when starting or running motors.

● Do not run the motor in an area of loose gravel or sand;

the propeller may throw such material in your face or eyes.

●

Keep your fac e and body as well as all spectator s away from

the plane of rotation of the propeller as you run the motor.

● Keep these items away from the prop: loose clothing, shirt

sleeves, ties, scarfs, long hair or loose objects such as

pencils or screwdrivers that may fall out of shirt or jacket

pockets into the prop.

Don’t forget to perform your usual ground range checks as

written in the instruction manual that came with your radio

system to be certain it is operating correctly.

General Pre ight Information

The RimFire .10 is rated for 30A constant current and 35A

surge current. The included 12x6.5 folding propeller draws

an average maximum (in ight) current of about 29A on a

3S battery and about 23A on a 2S battery, so there is no

danger of overloading the motor and it can be run fullthrottle for extended periods (during massive ascensions

to altitude). With a 3S 1800mAh battery this should provide

approximately three minutes of full-throttle run time and with

a 2S 2200mAh battery about 4-1/2 minutes of full-throttle run

time. On 3S the Tori “specs out” in about twenty seconds.

You may experiment with 2S and 3S batteries to nd the

combination you like best. With lighter 2S batteries the Tori

may not climb as quickly, but it will be lighter and have a

farther aft C.G. for detecting thermals easier.

Either way, it is recommended to use a ight timer to indicate

when to stop running the motor so as not to over-discharge

the battery. In the case of a glider such as the Tori, it is

desirable to link the timer to the throttle stick so only motor

run time—not the total time the model is airborne—will be

counted. Until you know what time to set the timer for, start

with a conservative number: say two-minutes for a 3S setup

and three-minutes for a 2S setup.

19

Page 20

When the timer sounds, land. Use a LiPo battery checker

to measure the resting (unloaded) voltage after you land.

Each cell in the pack should not be below 3.7V/cell. When

you charge the battery also note how much capacity it took

to recharge (indicating how much was used for the ight).

Strive to use no more than 80% of the battery’s capacity.

Adjust your timer according to the voltage and capacity

used for the ight.

You can use the worksheet below to determine optimum

ight times based on your ying style and battery capacity.

FLYING

The Tori is not necessarily fragile, but it is a light-weight

motor glider designed for catching thermals, so y it to that

purpose, not as an indestructible, toss-around, foam sport

model. Full throttle ight should be reserved for climbing

to thermal-hunting altitudes only. Be responsible using the

throttle.

Experienced pilots may launch the Tori themselves, but for

the maiden ight, intermediate pilots might want to solicit

the assistance of another pilot to launch the Tori for them. It

may be a good idea to add a few clicks of up elevator trim

so the Tori will be sure to initially climb when released. Once

the Tori is trimmed for straight-and-level ight it will not be

necessary to add up elevator trim.

Typically, the Tori would be launched at full-throttle, but

anything from about half-throttle to full-throttle is ne.

The rst objective will be to get the Tori trimmed. Once trimmed

and at altitude, extend the spoilerons (if programmed) to see

how the Tori behaves. Eventually, you’ll get a feel for when

(and if) to extend the spoilerons so you can land your Tori

right on the spot!

The Tori has no particular ight characteristics that you

need to be made aware of. It’s just an honest- ying, wellmannered oater glider.

Have fun chasing thermals with your Tori!

1

2

3

4

5

6

7

8

A

FORMULAS

Flight Time

(.10 ths )

BCDEFG

Recharge

Capacity

B / A D x .8 E / C

mAh/minute

Battery

Capacity

Target Capacity

to Use in Flight

Recommended

Name

Flight Time

Address

B/1000 / (A/60)

City, State, Zip

Avg. In-Flight

Current

AMA Number

Phone Number

FAA Number

This model belongs to:

Loading...

Loading...