Great Planes Super Sportster User Manual

Sportster

20

40

66

Engine

Wing Span

Wing Area

Length

Weight

.19-.25

48"

400

sq.

in.

39-1/2"

3-1/2-4 lbs.

.35..45

56"

550

sq.

43"

5

lbs.

in.

.45-.61

61-1/2"

675

sq.in.

48"

6-7-1/2 lbs.

MATERIALS NEEDED TO COMPLETE THIS KIT:

4 channel radio Wheel collars Covering

Engine Wheels Instant glue

Fiberglass cloth/resins Epoxy White glue

Engine mounting bolts Fuel tank

Propeller Spinner

The Super Sportster was designed for the sport flier The Sportster is fast, stable and aerobatic It has good looks, good performance and

stability at low speeds For the creative builders it can be detailed to resemble a war bird, Formula 1 racer or a CAP 21 type aerobatic ship Materials

are included for both trike gear and conventional gear (taildragger) to help you create your own Sportster

The parts are machine cut and sanded for accurate fit Some parts are razor cut in the 20 size for accuracy Should you notice a difference in

size between plans and parts, it is usually because paper plans change size with moisture Most of the parts are self aligning and do not require

building over the plans except where specified in the instructions

Different types of glues may be used such as epoxy, Cyanoacrylate or aliphatic (white) resin Be careful when using any kind of glue Make sure

you have enough ventilation CA glues (instant) are especially harmful if not used correctly

We suggest that you build on a flat surface to insure a straight wing and fuselage When you build over the plans, cover them with waxed paper

so the wood parts are not glued to the plans'

The following tools will be helpful when you build and X-Acto knife, razor plane, saw sanding block, flat building board T Pins hinge slotting

kit, drill and drill bits, tap and tap holder, covering iron and heat gun, Dremel tool and cutter tor wire and router bits, soldering iron, screw drivers, needle

nose pliers, files, clamps and a good square or right triangle

We recommend a plastic heat shrink covering such as Super Monokote to keep your Sportster light Follow the manufacturer's instructions

concerning the use of this covering material

Please read through this step by step instruction book before you start building so you will get an overall idea of the construction steps and avoid

mistakes Since these instructions do pertain to the 20, 40 and 60 size Sportsters, refer to the plan and parts list to help you identify the various parts

Any differences in the instructions for the various size models will be noted at the appropriate steps with a star (•*)

These instructions and plans were intended tor 2 cycle engine use However starting on page 26 of this booklet, you will find adaptation

instructions for the installation of 4-cycle engines

Please inspect all parts carefully before starting to build! If any parts are missing, broken or defective, or it you have any questions

about building or flying this airplane, please call us at (217) 398-8970 and we'll be glad to help. It you are calling tor replacement parts,

please look up the part numbers and the kit identification number (stamped on the end of the carton) and have them ready.

WARRANTY

Great Planes Model Manufacturing Co., Inc. guarantees this kit to be free of defects in both material and workmanship at the date of purchase This warranty does not cover any component parts damaged by use or modification In no

case shall Great Planes' liability exceed the original cost of the purchased kit Further, Great Planes reserves the right to

change or modify this warranty without notice.

In that Great Planes has no control over the final assembly or material used for final assembly, no liability shall be

assumed nor accepted for any damage resulting from the use by the user of the final user-assembled product.

By the act of using the user-assembled product the user accepts all resulting liability.

If the buyer is not prepared to accept the liability associated with the use of this product, he Is advised

to immediately return this kit in new and unused condition to the place of purchase.

READ THROUGH THIS INSTRUCTION BOOK FIRST. IT CONTAINS

IMPORTANT INSTRUCTIONS AND WARNINGS CONCERNING THE

ASSEMBLY AND USE OF THIS MODEL.

(SEE WARNING ON BACK COVER)

POBOX788 URBANA, ILLINOIS 61801 (217)398-8970

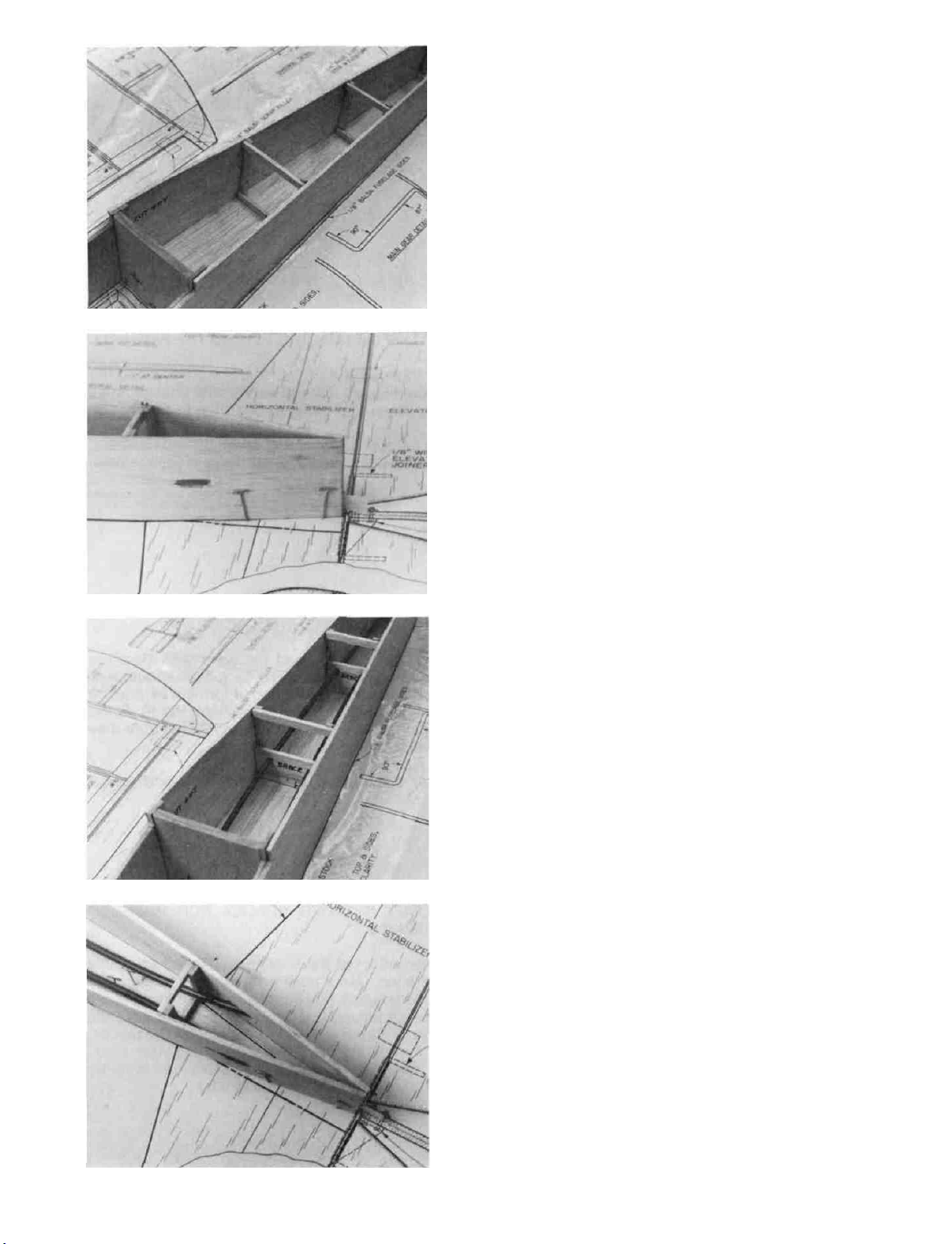

BUILDING THE TAIL SECTION

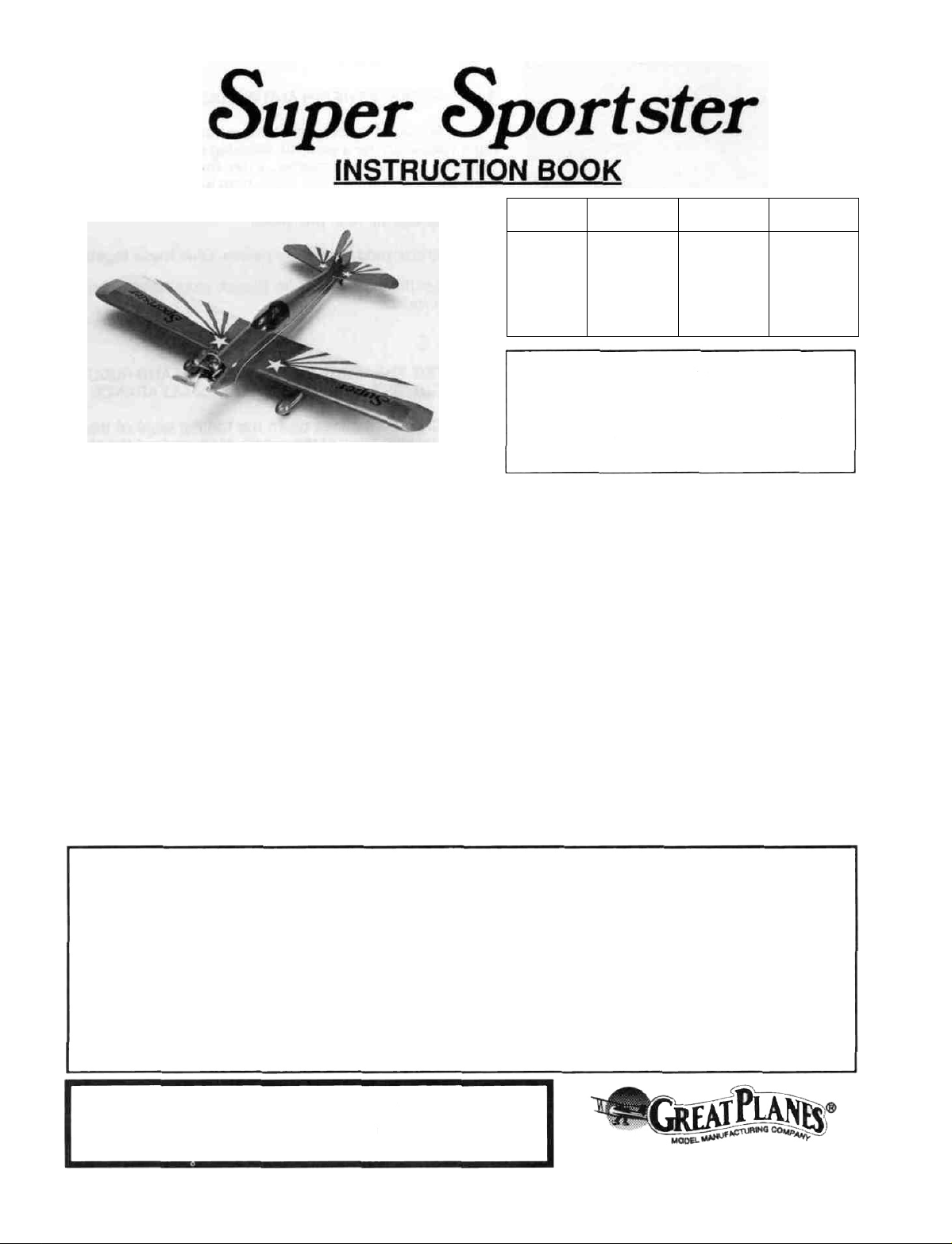

1. D PREPARE THE FIN AND RUDDER

Prepare the forward and rear fin sections by sand-

ing if necessary for a good fit. Working over the plans, butt

glue the fin section together. After the glue is dry, sand

both sides of the fin. Also sand both sides of the rudder.

* The 20 size fin is in one piece.

* The 60 size rudder is in two pieces. Glue these together.

Note: Specific instructions for tricycle gear installation are

in italics.

2. D CUT THE HINGE SLOTS IN THE FIN AND RUDDER;

CUT OUT RUDDER FOR JOINER CLEARANCE

Draw centerlines down the trailing edge of the fin

and the leading edge of the rudder. Mark and cut the hinge

slots. Two hinges are used above the stabilizer. For conventional gear (Tail dragger) the third hinge should be just

below the stab and above the tailwheel strut tab. (For tri-

cycle gear the third hinge should be near the bottom of the

rudder. Check the plans.) Relieve (cut out) the leading edge

of the rudder for elevator joiner wire clearance. (Shape the

rudder leading edge to a "V"now for tricycle gear.) For con-

ventional gear wait to shape the leading edge until the

hole is drilled for the tailwheel tiller arm later.

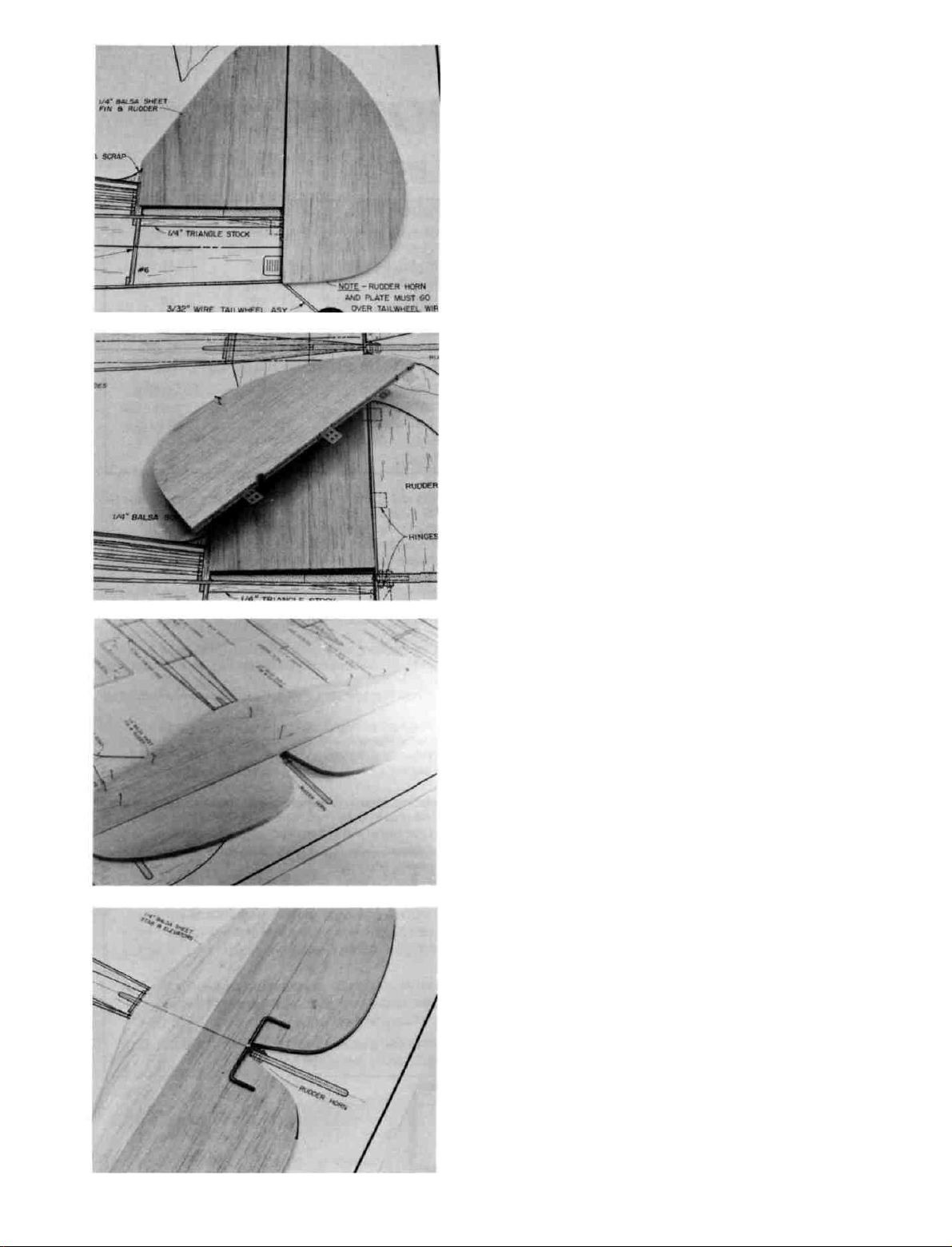

3. D GLUE THE STAB PARTS TOGETHER; SAND THE

STAB AND ELEVATORS

Check the fit and butt glue the stabilizer forward and

rear sections together. Sand both sides of the stabilizer

and elevator halves.

* The 20 size stab is in one piece.

4. D DRILL HOLES IN THE ELEVATOR HALVES FOR

ELEVATOR JOINER WIRE

Draw a front to back centerline down the top side of

the stab and a centerline down the leading edges of the

elevator halves. Mark the center of the elevator joiner wire.

Align the stab, elevator and joiner wire and mark the hole

locations for the joiner wire arms on the centerline of the

elevator leading edge. Drill the holes.

2

5. D GROOVE OUT THE ELEVATORS FOR JOINER WIRE

CLEARANCE

Cut a groove in the elevator leading edge inboard

(inside) of the hole so when the joiner wire is installed it

will be flush with the leading edge of the elevator. Groove

both elevator halves.

6. D TRIAL FIT THE JOINER WIRE

Temporarily install the elevator joiner wire into the

elevator halves. Check to make sure that this assembly is

aligned properly. Bend the joiner arms if necessary for a

perfect fit. DO NOT GLUE THE JOINER WIRE TO THE ELEVATOR HALVES UNTIL AFTER THE PIECES ARE COVERED

LATER.

7. D CUT HINGE SLOTS FOR THE STAB AND ELEVATOR

Mark and cut the hinge slots for the stab and eleva-

tor halves as you did with the fin and rudder. See the plans

for locations. Shape the leading edges of the elevator

halves to a "V".

BUILDING THE WING PANELS

READ THIS FIRST BEFORE YOU START BUILDING THE

WING PANELS: It is very important that you build a straight

wing with no warps or twists or you will get some flying

characteristics you didn't expect! Be very careful when

you align the ribs, spars, leading edges and trailing edges

and sheeting at the various steps below. All these parts

should be in their correct positions before you glue them in

place. Hold or pin the parts in place, then glue. Use the

following instructions to help you build the wing straight

and warp free.

Remember: Anyone can build a wing. Only a careful builder

can build a straight wing.

1. D NOTCH THE RIBS FOR LANDING GEAR BLOCK

CLEARANCE

Notch the ribs to be installed at locations 2 and 3 for

the hardwood main landing gear blocks. Conventional

gear block notches are forward on the ribs. (Tricycle gear

notches are the rear cutouts.) Check the fit with the block.

Number these ribs 2 and 3. Cut the notches in the ribs for

the other wing panel at the same time. (Conventional gear

cut outs are shown.)

* 20 size ribs are notched already. Glue the scrap back into the notch you will not use.

3

2. D GLUE THE 1/16" PLYWOOD LANDING GEAR SUPPORTS TO THE RIBS

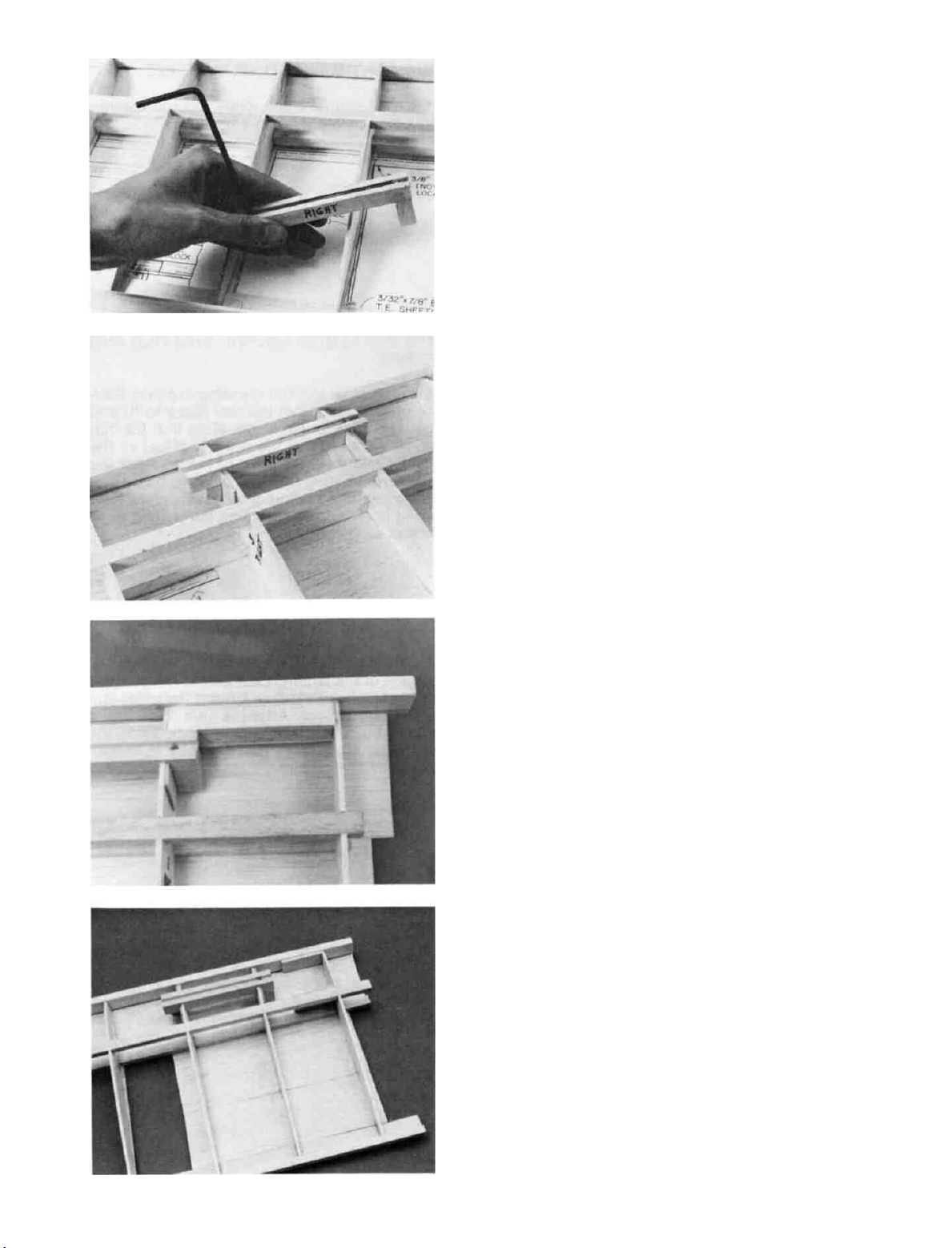

Start on the right wing panel by gluing the 1/16 ply

brace on the left side of rib 2 and on the right side of rib 3.

(For the left panel the brace glues on the right side of rib 2

and on the left side of rib 3.) When the glue is dry sand the

braces to the rib contour. Note that the landing gear block

will be flush with the bottom sheeting not the bottom of

the rib. (Conventional gear locations are shown throughout the instructions.)

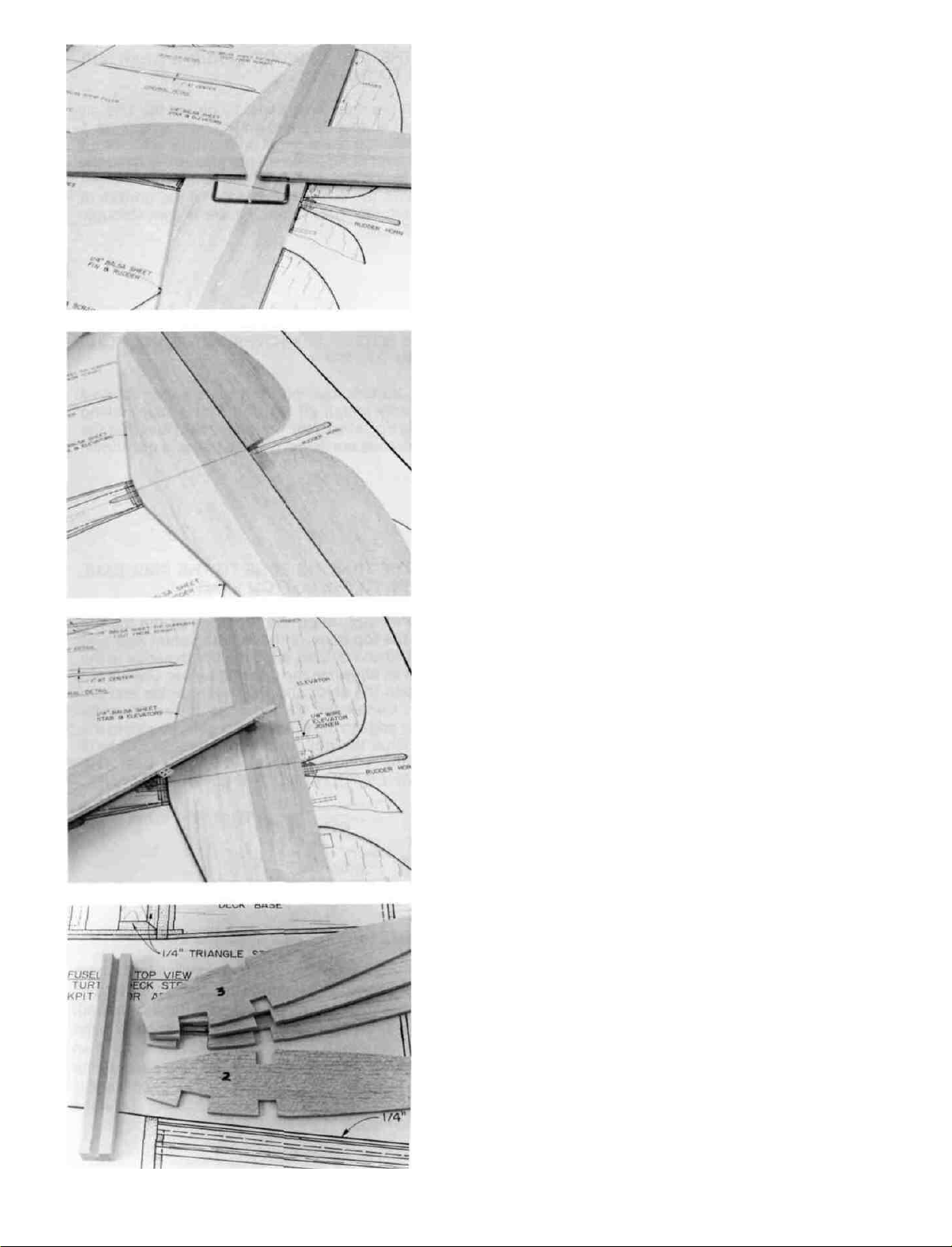

3. D PIN THE BOTTOM SPAR OVER THE PLANS; PLACE

RIBS ON THE SPAR

Pin the bottom spar on the waxed paper covered

plans. Temporarily install all the ribs to the spar making

sure they are 90 degrees to the building board and that the

landing gear notches are down. (Waxed paper is not shown

for clarity.)

4. D GLUE THE TRAILING EDGE TO THE RIBS; GLUE

THE RIBS TO THE BOTTOM SPAR

For the 40 size, align the top edge of the trailing

edge stock to the top edge of the building shim (see size

below). For the 20 and 60 size, align the trailing edge to the

top of the shim as shown in the drawing below. Use waxed

paper in between the shim and the trailing edge and pin

them together. Center the trailing edge to the rib ends.

Glue the trailing edge to the ribs with the shim pinned to the

work surface. Glue the ribs to the bottom spar. DO NOT

GLUE THE SHIM TO THE TRAILING EDGE! USE THE

SHIM AGAIN WHEN YOU BUILD THE LEFT WING PANEL.

Shim Sizes:

20 = 1/4 x 5/8

40 = 3/32 x 7/8

60 = 1/4 x 3/4

5. D GLUE THE RIBS TO THE LEADING EDGE

Use a straight edge and draw a straight line on the back

of the leading edge about 3/32" from the top. Using 1/4 x 1/4 x 36

balsa stock as a shim under the leading edge (for the 40 size),

align the top of the ribs to the line and glue them in place to the

leading edge. The leading edge is intentionally wider than

necessary to allow for slight warpage. Do not fight a slight warp

but instead glue the leading edge to the ribs making sure there is

at least 3/32" above and below the ribs for sheeting. Later the

excess will be carved off.

* Use an 1/8" shim for the 20 size.

* Use a 5/8" shim for the 60 size.

4

6. D ADD THE TOP SPAR, TOP LEADING EDGE SHEETING AND TOP TRAILING EDGE SHEETING

Glue the top spar in place. Glue the top leading

edge sheeting between the leading edge and the dotted

line on the top spar shown on the plans. Align the top trailing edge sheeting even with the back of the trailing edge

and glue it in place.

7. D ADD THE TOP CENTER SECTION SHEETING AND

CAP STRIPS

Glue the top center section sheeting in place. Glue

the front piece on first. Then cut the rear piece to fit and

glue it in place. Add the top cap strips. Note that the cap

strip on the tip rib (outer end of the wing) is offset so the

outer edge is flush with the outer edge of the rib. After the

glue sets up, remove the wing from the building board and

check all the glue joints. Add more glue if necessary. Now

remount the wing upside down reversing the trailing edge

shim on your work surface.

8. D PREPARE THE MAIN LANDING GEAR BLOCK

Glue the torque block to the inboard (inside) end of

the ungrooved side of the landing gear block. The grooved

side of the torque block should face toward the other end

of the long landing gear block. After the glue dries, drill a

5/32" hole down through the landing gear block, using the

groove in the torque block as a guide. Epoxy is recom-

mended for the above procedure.

9. D TRIAL FIT THE LANDING GEAR BLOCK ASSEMBLY

Temporarily install the landing gear support assembly into the wing. Custom fit the assembly as follows.

Shape the bottom end of the torque block to fit the contour

of the wing sheeting to which it mates. The top of the long

grooved block should be flush with the bottom sheeting (not

yet installed).

5

10. D

TRIAL

temporarily install the landing gear wire. The torque arm

should slide into the hole you drilled earlier with the long

arm resting in the groove in the long block. Custom fit as

necessary. Remove the wire.

11. D GLUE THE LANDING GEAR BLOCK AND GUSSET

block in place. Add the small gusset under the outer (outboard) end of the long block. Fill the groove at both ends of

the long block with scrap balsa so foreign matter does not

get into the wing.

* Go to step 13 for the 20 size model.

FIT THE

BLOCK

Remove the landing gear block from the wing and

IN PLACE

Use 5 minute expoxy to glue the main landing gear

MAIN

GEAR WIRE

INTO

THE GEAR

12. D (40 and 60 SIZE ONLY) GLUE THE HARDWOOD

HOLD DOWN PLATE AND BALSA FILLERS TO

THE WING PANEL

Add the maple wing hold down plate and balsa

fillers behind the leading edge between ribs 1 and 2.

Custom fit as necessary. Use 5 minute epoxy after you are

sure of the fit and glue the pieces in place.

13. D (20 SIZE ONLY) GLUE THE TWO 1/8" PLYWOOD

DOWEL PLATES TO THE WING PANEL

Remove the 1/8" Plywood dowel plates from the

razor cut sheet. The smaller dowel plate glues to the rear

of the wing panel leading edge. The larger dowel plate

glues to the front of the top and bottom spars. Use epoxy

and glue both plates in position between ribs 1 and 2 as

shown on the plan.

6

14. D ADD ALL THE BOTTOM SHEETING TO THE

WING PANEL

Add the bottom leading edge sheeting, the trailing

edge sheeting and the center section sheeting. Relieve

(cut away) the leading edge sheeting for landing gear block

clearance. (Relieve the center section sheeting for tricycle

gear.) Add the bottom cap strips. After the glue dries,

remove the wing from your building board and turn it over.

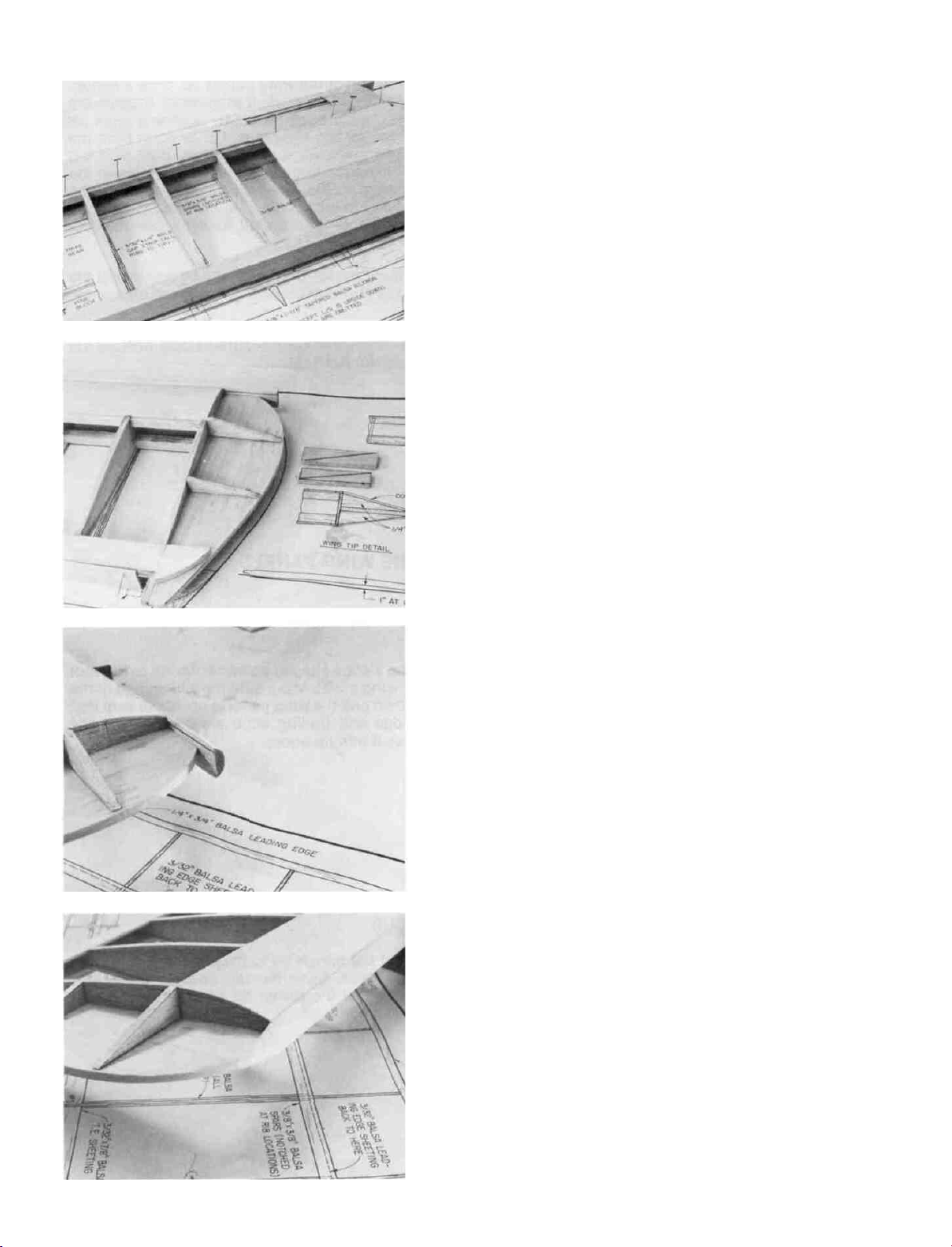

15. D ADD THE WING TIPS, WING TIP FILLERS AND

SUPPORT PIECES

Cut off spars and sheeting even with the outboard

edge of the tip rib. DO NOT CUT THE LEADING EDGE! Add

the wing tip. It should be centered on the tip rib and on the

leading edge. For the 40 and 60 size models, prepare and

install the upper and lower forward and rear wing tip supports. Using the wing tip detail drawing as a guide, cut two

rectangles from the 1/4" scrap piece. Cut the rectangles

diagonally and you have two forward and two rear pieces.

Custom fit all four supports and glue them in place. Use

1/4" scrap and make and glue the aileron filler piece. Glue

it to the inboard side of the wing tip. Add filler pieces to the

rear end of the wing tip, top and bottom. Sand these blocks

to the aileron contour later after installing hinging and centering the ailerons.

* The 20 size kit includes the above parts in the 1/8" razor

cut sheets.

16. D BUILD THE LEFT WING PANEL NOW

Build the left panel in the same manner except

build it upside down. Gear cut outs are "up" and landing

gear blocks are installed before any sheeting is added. Install the wing hold down plate and fillers in the 40 or 60

models (or the wing dowel plates in the 20 size) after you

turn the wing panel over and before the top leading edge

sheeting is installed.

17. D SAND THE LEADING EDGES OF THE WING

PANELS TO THE ROUNDED SHAPE SHOWN ON

THE PLANS

18. D FINISH SAND THE WING PANELS

Sand the leading edge to match the wing tip con-

tour. Remove the trailing edge building shim and cut and

sand the wing parts flush with the root rib (inner rib). Finish

sand the rest of the wing panel.

7

19. D PREPARE THE CENTER TRAILING EDGE PIECES

With the top of the wing panels up, draw a centerline down the trailing edge of each wing panel. Prepare the

grooved center trailing edge pieces by notching them for

the servo arm torque rod clearance 3/8" or so in from the

wing center. See plans for location. Make right and left

pieces. Glue the aileron torque rods into the groove in the

center trailing edge pieces. Use vaseline at the ends of the

outer tube so only the tube is glued to the block. Notch the

trailing edge of the wing to permit forward movement of

the torque rod arms.

* The center trailing edge pieces for the 60 size model are

balsa. Cut a groove in the block for torque rod clearance.

20. D GLUE THE CENTER TRAILING EDGE PIECES TO

THE WING PANELS

JOINING THE WING PANELS

1. D GLUE THE CENTER RIB TO THE LEFT WING

PANEL

Glue the wedge-shaped balsa center rib to the root

end of the left wing panel. Make sure the wider edge of the

center rib is down and the wing panel is up. Make sure that

the leading edge and trailing edge are centered on the

tapered rib. Use 5 minute epoxy.

2. D SAND THE CENTER RIB TO THE WING PANEL

CONTOUR

Roughcut the center rib to the wing airfoil, leaving

it about 1/8" oversize. Sand the remainder away with a

sanding block so that the center rib edges are flush with

the wing sheeting surfaces.

8

3. D JOIN THE WING PANELS

Join the wing panels upside down. Refer to the di-

hedral detail on the plans. Align at the leading and trailing

edges. Use a straight edge to make sure the wing is

straight. Block up the wing 3/4" at the center for the 20

size, 1" for the 40 size and 1-1/4" for the 60 size model. Glue

the wing panels together using epoxy, rechecking the

alignment before the glue sets up. When the glue is dry,

mark the aileron servo well location. The servo well is

located directly behind the spar and in the center of the

top of the wing.

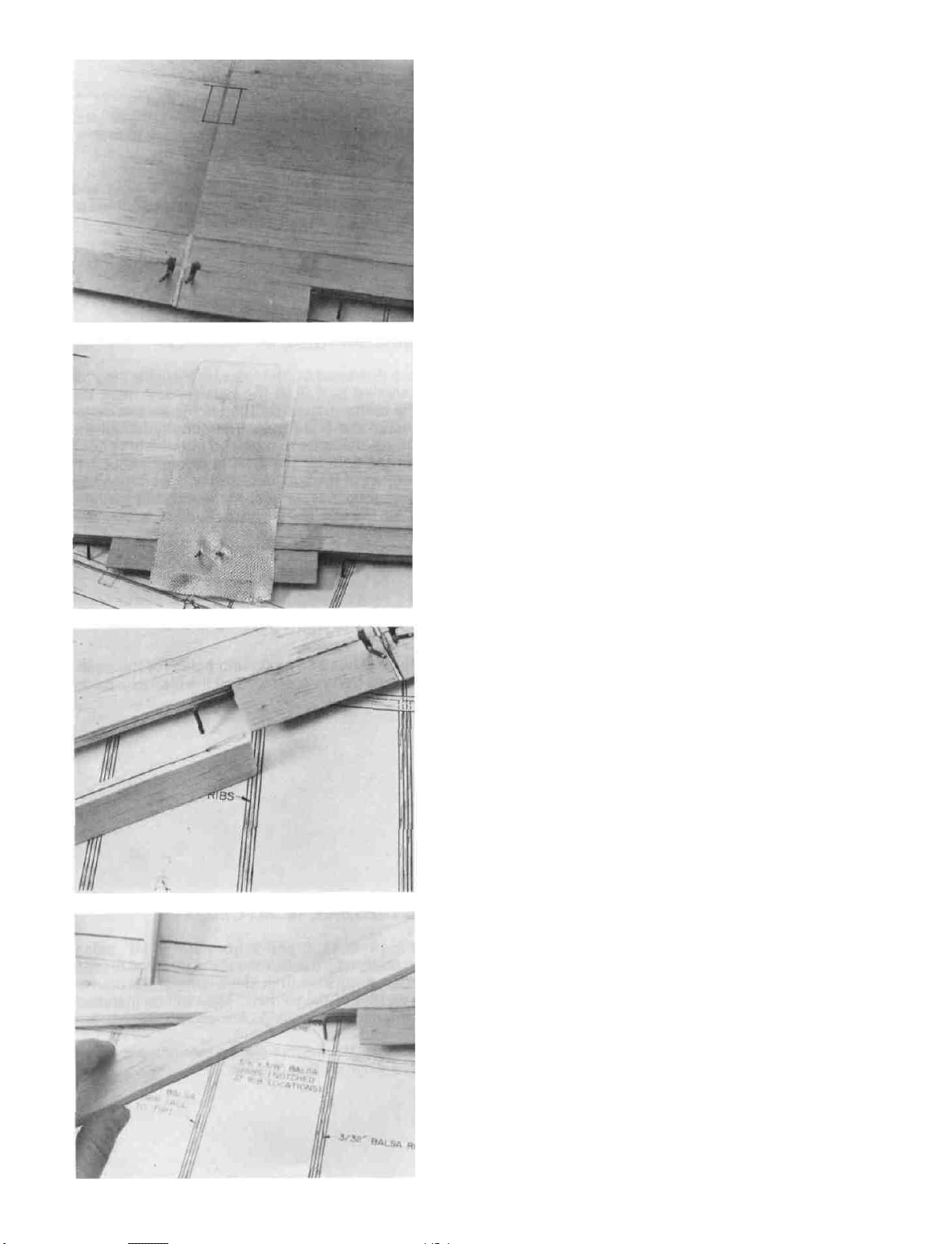

4. D GLASS THE CENTER SECTION OF THE WING

Use 6 ounce glass cloth (or nylon cloth) and glass

the center section glue joint. Use a 4" wide piece of cloth

and polyester resin or epoxy. Sand the center section when

dry. Apply a second coat of resin or epoxy if necessary.

IMPORTANT — Omitting this step will result in a wing fail-

ure during flight and result in a crash.

*Use a 5" wide piece of cloth in the 60 size.

THE AILERONS

1. D PREPARE THE AILERONS

Cut the aileron stock to length and draw a center-

line down the leading edge of the ailerons. Mark and drill

the torque rod holes. Groove the aileron for torque rod

clearance. Make right and left ailerons.

2. D CUT THE HINGE SLOTS; FINAL SAND THE

AILERONS

Mark and cut the hinge slots into the ailerons and

the wing trailing edge. Shape the leading edge of the aile-

rons to a "V". Temporarily install the ailerons with hinges to

check the fit. Final sand the wing tips to match the aileron

contour at neutral. Do not permanently hinge the ailerons

until after they are covered.

9

BUILDING THE FUSELAGE

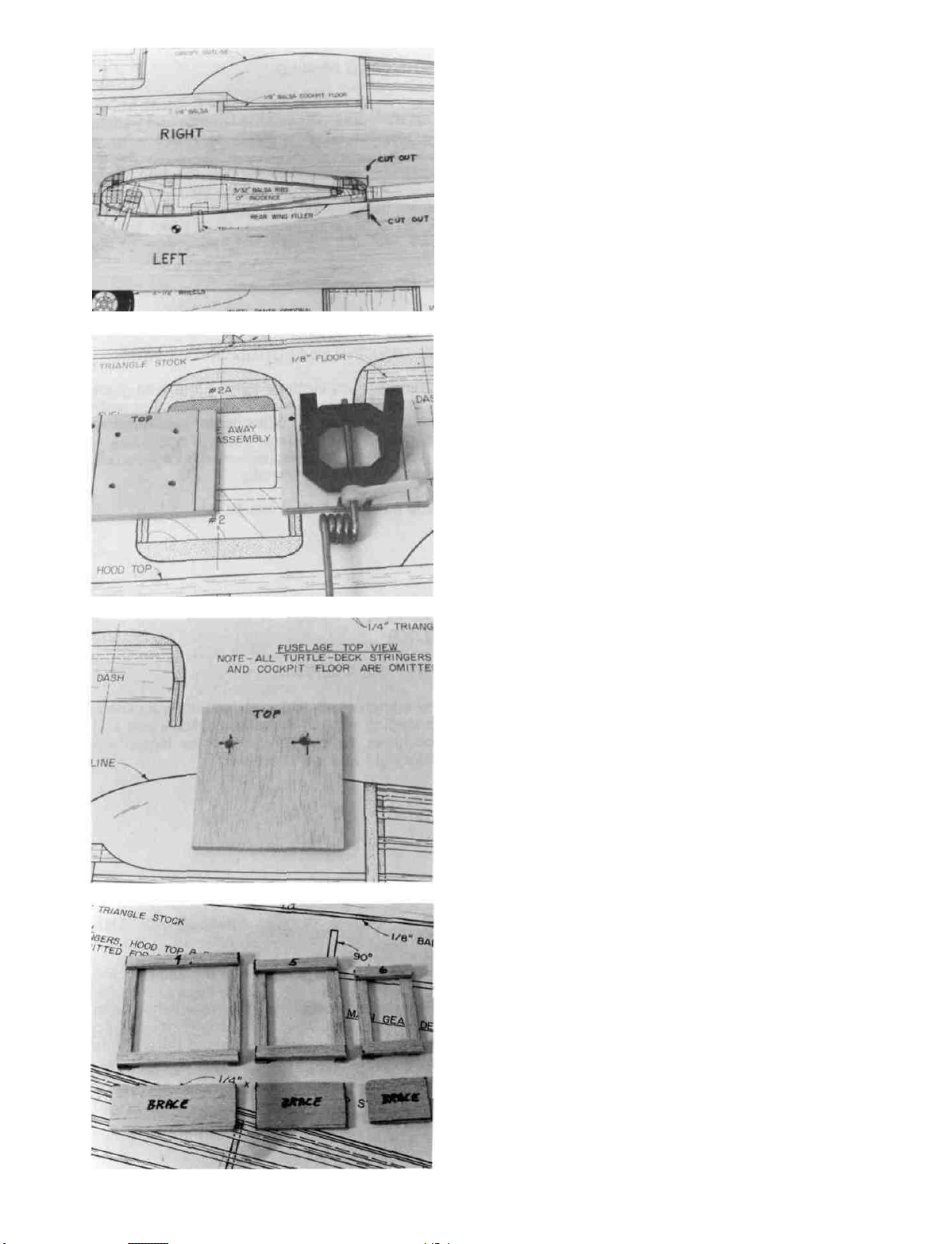

1. D PREPARE THE FUSELAGE SIDES

Mark the inside of the fuselage sides "right" and

"left". Relieve the wing saddle area as necessary to match

the plans.

STOP! If you plan to install a 4-cycle engine read and

follow the instructions on installation of 4-cycle engines at

the end of this instruction book starting on page 26.

2. D PREPARE BULKHEAD #1

Prepare Bulkhead #1, the firewall. Mark the "top" of

the firewall (slanted part is at the bottom) and mark the

position of the motor mount. Drill the holes for the motor

mount and install the blind nuts. Temporarily install the

mount and cut off the bolts that extend into the tank compartment. Drill the hole for the throttle linkage about 1/4"

from the top corner of the bulkhead (left or right depending

on your engine). (For tricycle gear mark and drill the hole

for the steering linkage in the firewall. Also relieve the

firewall for steering arm clearance.

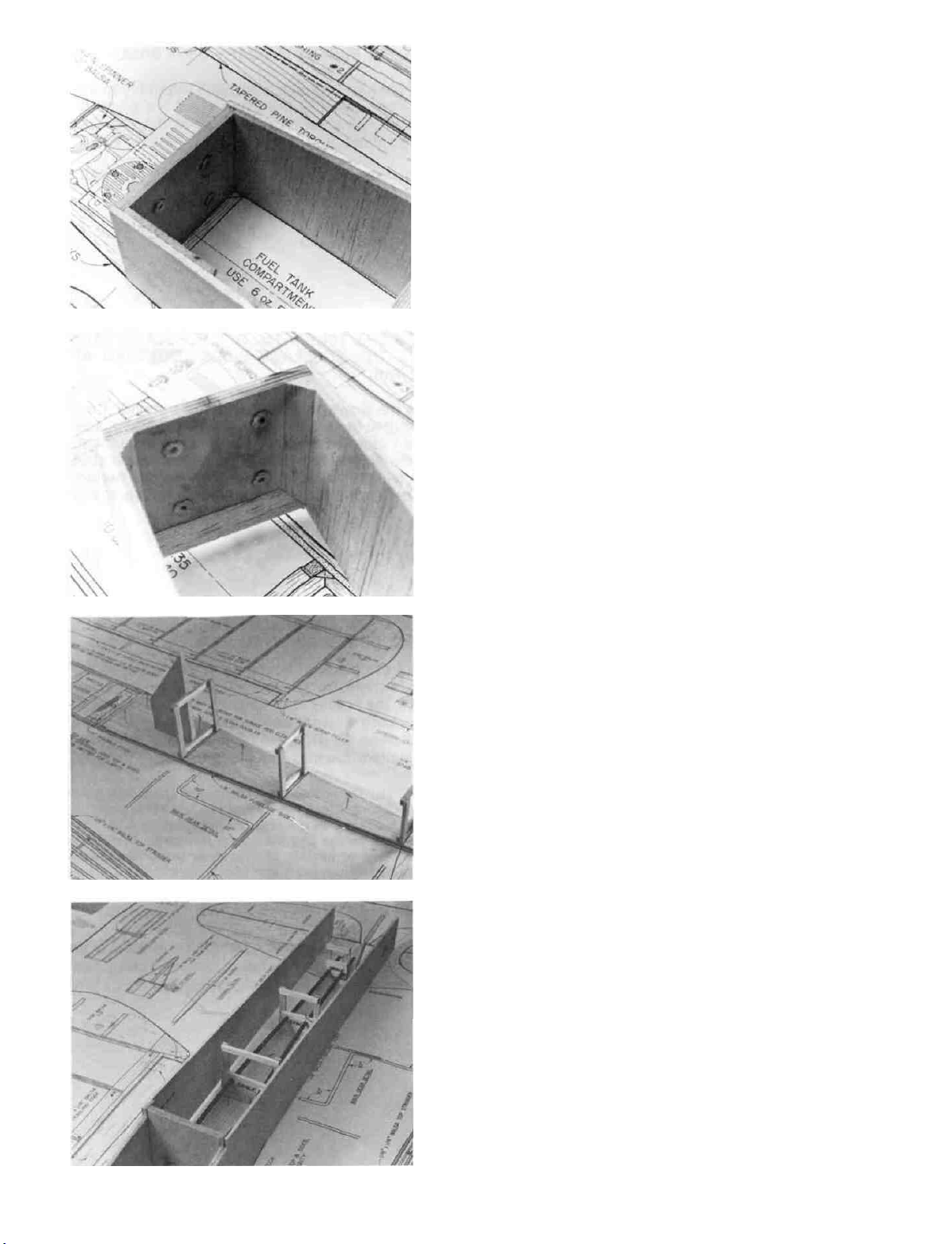

3. D PREPARE BULKHEAD #3

Prepare bulkhead #3 by drilling holes for the push-

rod outer housings. Use your servos and the plan as a guide

to placement.

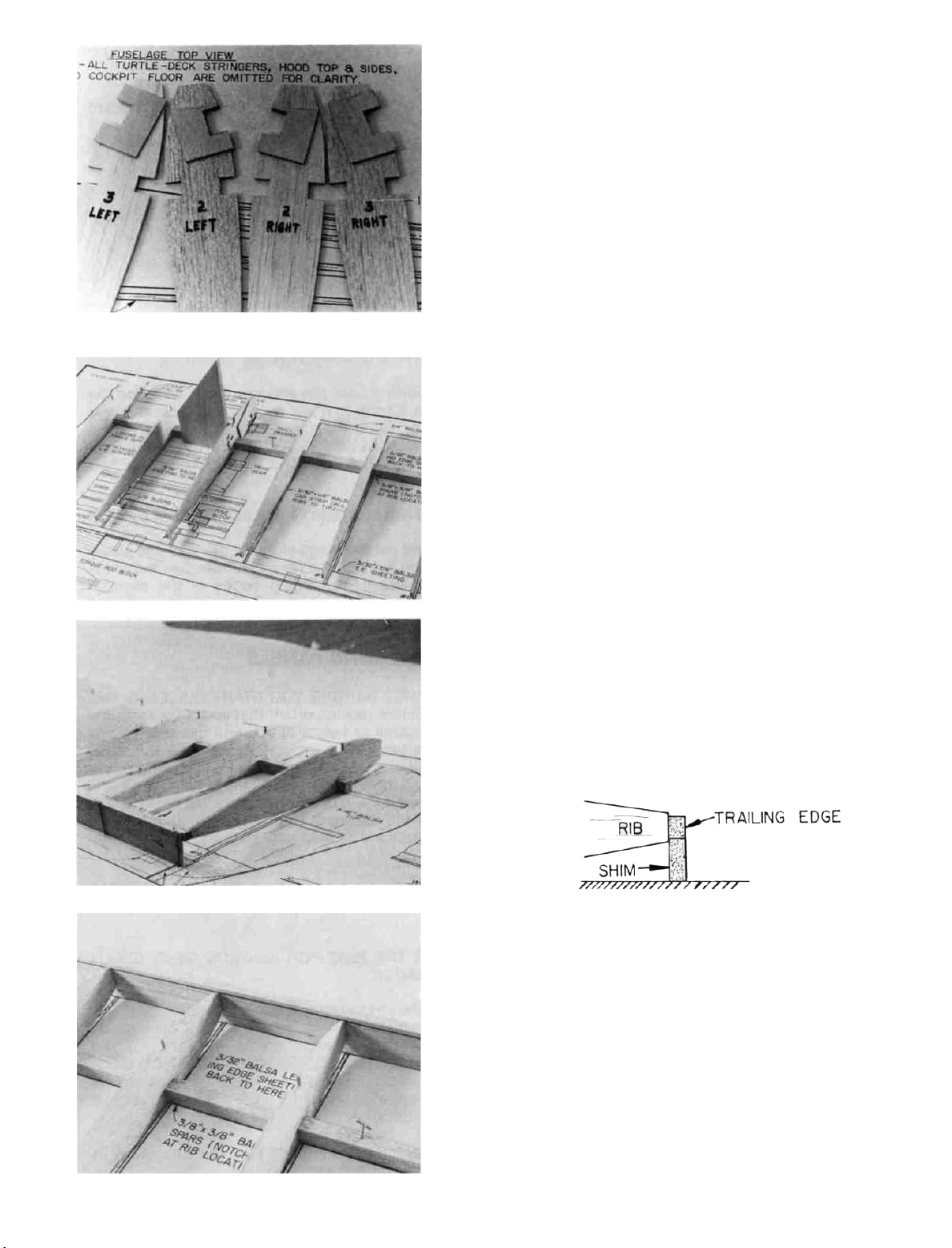

4. D BUILD THE THREE REAR FORMERS

Make formers #4, 5 and 6 from 1/4" x 1/8" balsa

stock. Use the plans as a guide. Also make pushrod braces

from 1/8" or 3/32" scrap sheeting. The widths of the braces

are the same as that of the formers. They will be installed

later when the pushrods housings are added.

STOP! Did you read the 4-cycle engine instructions if you

plan to install a 4-cycle? See page 26.

10

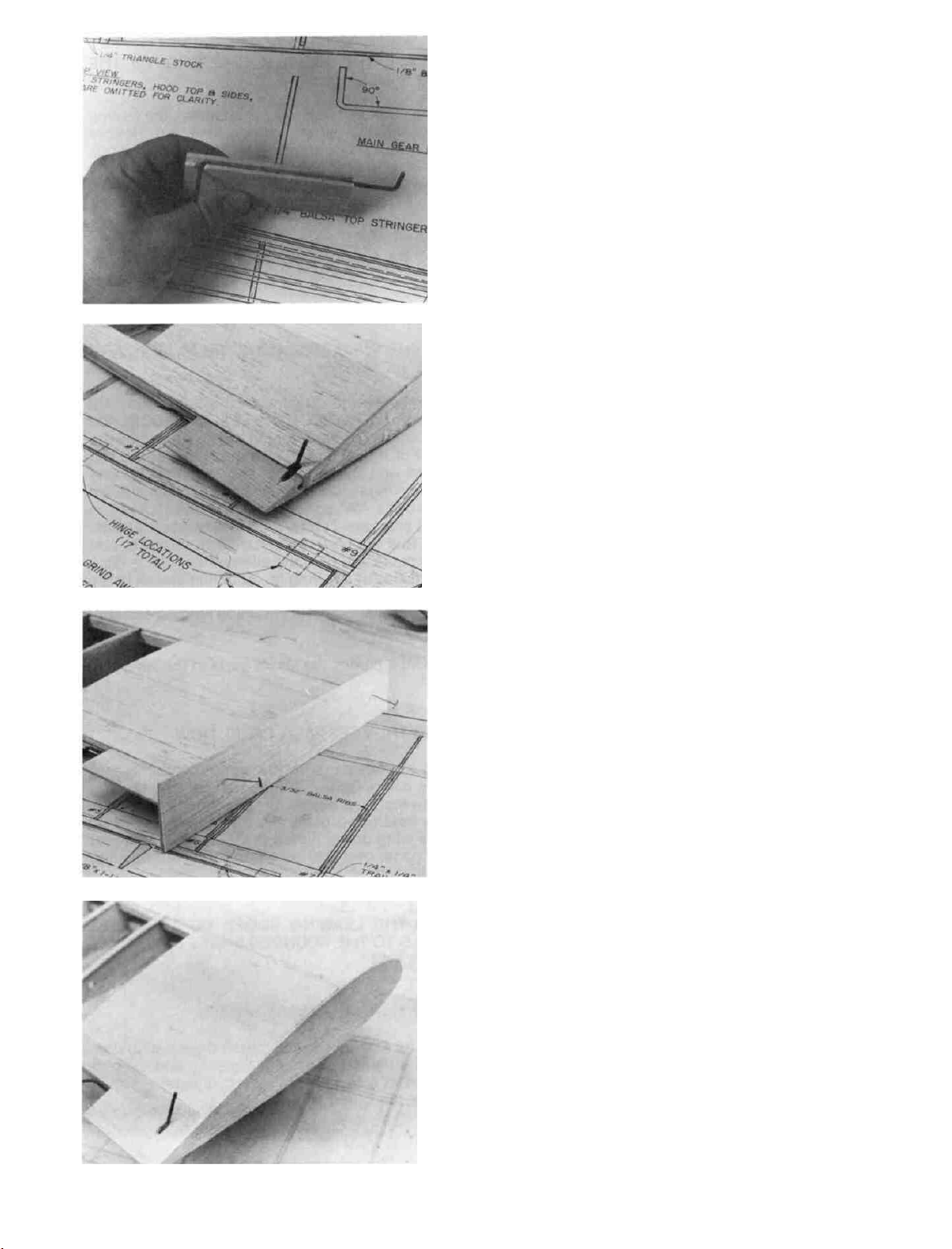

5. D GLUE THE DOUBLERS TO THE FUSELAGE SIDES

Using bulkhead #1 as a spacer, install the 1/8" balsa

doublers (1/16" for the 20 size) cross-grain on the inside of

the fuselage sides. Custom cut pieces from the stock provided. Use slow set epoxy glue or thick Cyanoacrylate. The

doubler should extend 5/8" beyond the position of

bulkhead #3. Trim and sand the doublers to match the

fuselage contour.

6. D MARK BULKHEAD POSITIONS ON THE INSIDE OF

THE FUSELAGE SIDES

Mark the positions of Bulkhead #2 and 3 on the fuse-

lage sides. Also mark the position of the balsa dash be-

tween #2 and #3 on the fuselage sides.

* Bulkhead #2 in the 20 size is located 1/8" forward of the

wing saddle opening to allow for the dowel jig.

7. D DRILL PUSHROD EXIT HOLES

Mark and drill the holes in the fuselage sides for the

pushrod exits for the elevator and rudder. See the plans for

the locations. A piece of brass tubing sharpened on the inside with an X-acto blade and chucked in an electric drill

makes a neat, clean angled hole for tube-style pushrods.

8. D TRIAL FIT THE WING INTO THE WING SADDLE

Pin the fuselage sides together perfectly aligned.

Check the fit to the wing saddle cutout by placing the fuse

sides on the wing. Custom sand if necessary but do not

change the wing incidence.

11

9. D SAND FUSELAGE TAIL; GLUE BULKHEADS #2

AND #3 TO THE RIGHT FUSELAGE SIDE

Slightly relieve the inside edges of the fuse sides at

the tail for a better glue joint. Notch a hole for the throttle

linkage in the side of bulkhead #2 first before gluing it to

the fuselage side. Align and glue bulkheads #2 and #3 to

the inside of the right fuse side which you have pinned

down to your work surface. Make sure the bulkheads are

90 degrees to the fuselage side and that the tops of the

bulkheads are toward the straight edge of the fuselage

sides. Bulkhead #2 has an angled cut on the bottom edge

in the 40 and 60 models. (The straight edge of the fuselage

side is called the Fuselage Reference Line and will be used

later to align the wing and stab to the fuselage.)

* Be careful to locate Bulkhead #2 1/8" forward of the wing

saddle opening in the Sportster 20.

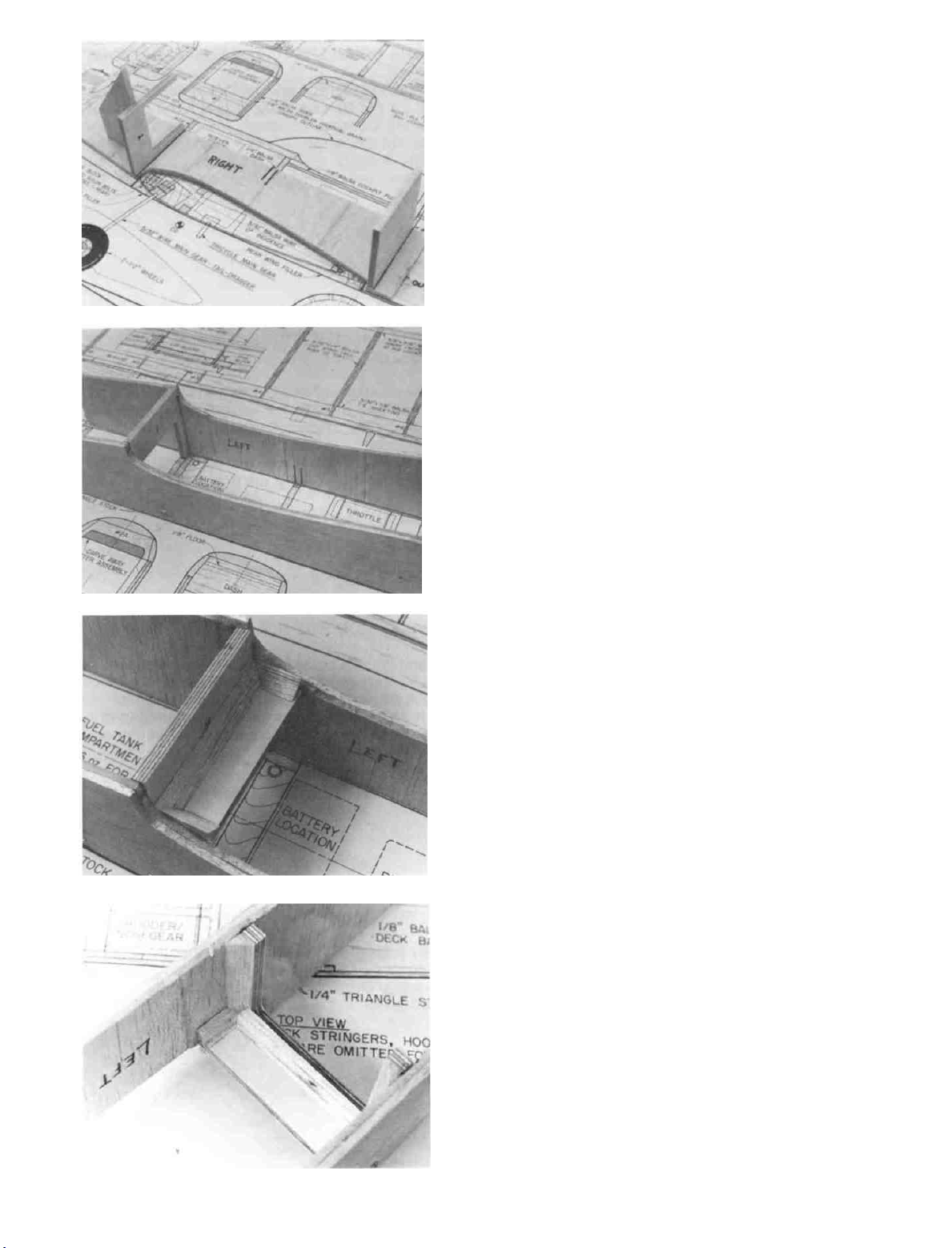

10. D GLUE LEFT FUSELAGE SIDE TO BULKHEADS

Align the fuselage side/bulkhead assembly upside

down over the top view of the plans. Make sure the flat side

is resting flat on the building board and that the bulkheads

are aligned to the plans. Pin in place. Glue the other fuse

side to bulkheads #2 and #3 making sure the second side

is also flat on the building board. Clamp or pin the fuse-

lage in place until the glue is dry.

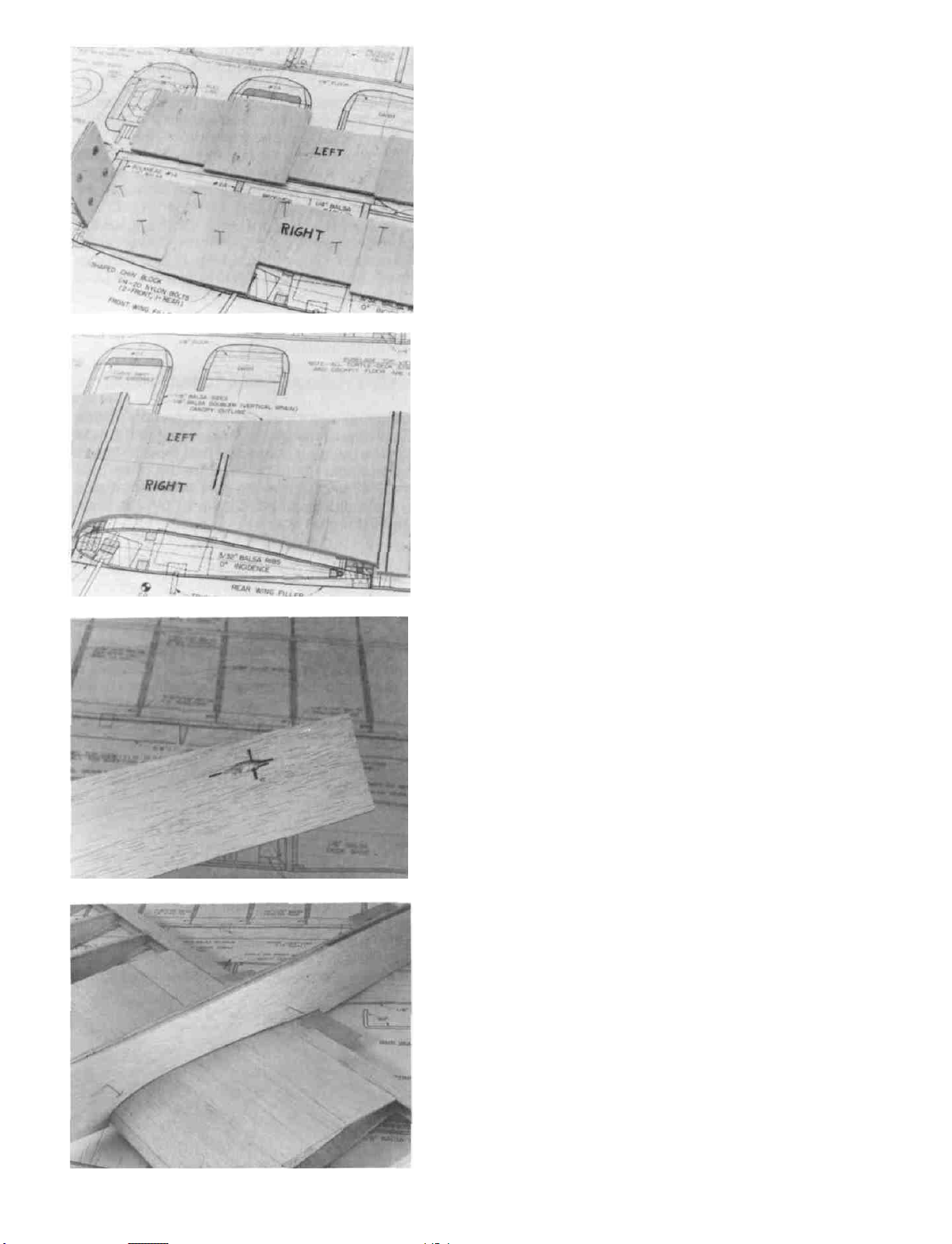

11. D GLUE IN THE HOLD DOWN PLATES

Add the 1/4" plywood front and rear wing hold

down plates and the 1/4" tri stock braces on the bottom of

the plates in the servo compartment as shown on the

plans. Use epoxy to glue in the plates. You may want to

saw or grind away the pushrod clearance area shown on

the rear plate now. Otherwise do this in step 23.

* The 20 size model has a rear hold down plate only and

uses 1/4" x 1/4" bracing.

12. D GLUE IN THE 1/4" BRACING

Turn the fuselage over and add the 1/4" triangle

stock (or 1/4" x 1/4" for the 20) on the front and rear hold

down plates. Add the 1/4" tri stock behind bulkhead #2. (40

and 60 only).

12

13. D GLUE IN BULKHEAD #1

Realign the fuselage over the plans and glue the

fuse sides to bulkhead #1. Make sure the top of the

bulkhead is flat on the building board and that the front of

the bulkhead is facing forward.

14. D ADD THE 1/4" BRACING BEHIND THE FIREWALL

Add three pieces of 1/4" triangle stock along the

back side of the firewall. Extend the throttle linkage holes

(and nosegear steering if used) through the tri stock.

* The 20 size model has 1/4" x 1/4" stock behind bulkhead

#1 and in front of bulkhead #2. Glue these pieces in now.

15. D GLUE FORMERS TO THE DECK BASE

Notch the deck base at the corners to clear the

doubler as shown on the plans. The deck base should butt

up to bulkhead #3. Mark the location of formers #4, 5 and 6

and pin the deck base to the plans. Check the fit of the

formers and glue them to the deck base making sure they

are 90 degrees to the base.

*The 20 size deck base is razor cut and has precut

notches.

16. D PREPARE FORMER BRACES FOR PUSHROD

HOUSINGS

Temporarily put the fuselage/bulkhead assembly

over the deck base. Use a pushrod housing and mark the

locations of the housing holes in the former braces. Make

sure the housing follows as straight a path as possible

from bulkhead #3 to the exit. Drill the holes in the braces.

Temporarily install the housings to check your work.

Remove the housings. Tube in a tube style pushrods are

shown here but other types may be used.

13

17. D GLUE THE FUSELAGE TO THE DECK BASE

Glue the fuselage sides/bulkhead assembly to the

deck base/former assembly. Fuselage sides are glued to

the sides of the deck base and the sides of the formers.

The deck base should glue to the rear of bulkhead #3.

DO NOT GLUE THE FUSELAGE TOGETHER AT THE TAIL

UNTIL YOU READ THE NEXT STEP!

18. D GLUE THE HINGE TO THE FUSELAGE TAIL;

GLUE THE FUSELAGE SIDES TOGETHER AT

THE TAIL

Glue the fuselage sides together at the tail. Con-

ventional gear-glue the rudder hinge just below stab placement. Use the rudder hinge slot as a guide to placement.

Do not glue the area at the tail where the tail wheel strut

mounting tab will glue later. (Tricycle gear-glue the bottom

hinge at the tail at this time. Use the rudder as a guide to

placement.)

late glue, glue both elevator and rudder housings in place

except at bulkhead #3. This will be glued later when the

servos are installed. You may trim the housings at the exits

now.

IMPORTANT NOTE: The pushrods supplied in this kit are steel rod-in-a-tube type We strongly recommend that you use these pushrods,

installing them as straight as possible, as they provide a very rigid

linkage between the servos and the control surfaces We do not

recommend the use of flexible plastic inner pushrods for this

model, as

their elasticity

may result

in

control surface flutter. See page

43 for recommended pushrod hookups.

20. D GLUE IN 1/4" BRACING AT THE TAIL

Glue 1/4" triangle stock (1/4" x 1/4" for the 20 size) at the

bottom sides of the deck base between former #6 and the tail.

Angle cut the ends of the tri stock at the tail for a good glue joint.

14

Loading...

Loading...