Page 1

B

ENCHTOPPER

Workbench Organizer

Thank you for purchasing the Great Planes®BenchTopper

workbench organizer.In our busy workshop at Great Planes

we find it necessary to keep our bench tops well organized

and our tools readily accessible. Once we thought of the

idea for the BenchTopper and made the first prototype,

everybody in the shop wanted one! Now you can keep your

work area neat and organized too – you may even find that

you build your models a little f aster since it’ll be easier to find

all of your tools!

We’ve provided assembly instructions for the BenchTopper

and left the finishing up to you. You can build your

BenchTopper with no protective finish or go all out and paint

your BenchTopper your favorite color. If you choose to build

your BenchTopper without a finish and leave it bare wood,

then all you have to do is follow the instructions provided. If

you choose to add a finish to your BenchTopper , y ou'll hav e to

do a little planning ahead and think about parts that might be

easier to sand and/or paint before they are glued together. In

any case, we recommend sanding all the pieces before you

do any gluing. If you choose to paint your BenchTopper, at

least one coat of primer is recommended to fill the wood grain.

Pactra®Prep or a similar brush-on primer yields good results.

Any kind of glue that works on wood will work for your

BenchTopper.We built our prototypes with thin CA and CA

accelerator by first “priming”the glue joint with CA accelerator, then applying a few drops of thin CA to the “pre-primed”

joint. The CA will cure immediately before it has had a

chance to soak too far into the wood away from the glue

joint. Should you choose to use medium or thick CA, refrain

from making large fillets that are unnecessary and will

detract from the overall appearance of your BenchTopper.

Refer to the die-cut parts layout on page 4 to familiarize

yourself with what each part looks like. As you separate the

pieces from the sheets, lightly sand the edges. This will

improve glue adhesion.

Please inspect all parts carefully before starting to build! If

any parts are missing, broken or defective, or if you have

any questions about building this workbench organizer,

please call us at (217) 398-8970. If you are calling for

replacement parts, please reference the part numbers (see

the back cover) and the kit identification number (stamped

on the end of the carton) and have them ready when calling.

❏We recommend Great Planes Pro

™

Thin CA

(GPMR6002) and Accelerator (GPMR6035).

❏ Sanding block and assorted sandpaper.

❏ Razor saw.

❏ Hobby knife.

❏Wood filler.

❏ Paint.

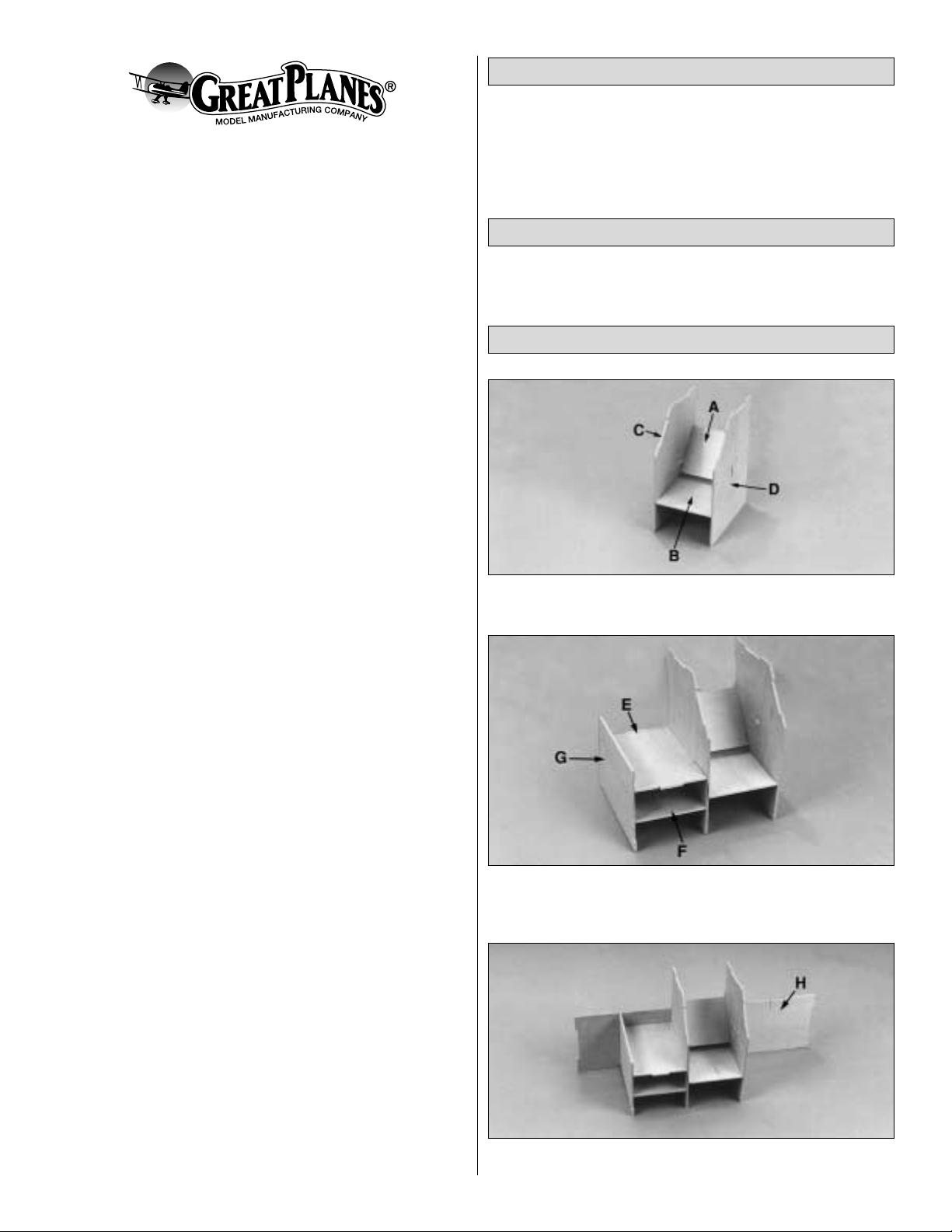

❏ Join A and B to C, then add D. Glue together.

❏Fit E and F to G, then join to C.Note: The notch in Fgoes

toward the rear. Glue the assembly together.

❏ Fit, then glue the back H to the assembly.

Main Assembly

Optional Supplies

Tools & Supplies

™

Page 2

❏ Fit the front I to the assembly. Glue I only to G at this time.

❏Fit J and K together, then install but do not glue them to

the assembly. Glue the left side L

(see the following photo),

to J, H and I and then the right side M to H and I.

❏ Fit the 3/16" bottom to the assembly, then glue it only to

H, I, L and M (back, front and sides).

❏ Adjust D so it is centered on the edge of the opening for

the large drawer. Glue D to I in this position. Glue all other

joints not previously glued.

Note: Some modelers have the need for additional storage

for tools like hex wrenches, screwdrivers, etc. Glue 2 or

more of the circular pop-outs of the epoxy storage area in

place. Then drill 1/8" or larger holes through part “N” to

allow the tools to be inserted.

❏Test fit, then glue N in position. Accurately cut the paper

tubes in half.Fit but do not glue the paper tubes through the

holes in O so the “square end” (the end cut by the factory),

will be at the bottom and contact A. Adjust the paper tubes

so they are perpendicular to O and A and are parallel to

each other.Glue the paper tubes to O and A and then Glue

O into position.

❏ Glue P, then Q in position.

Page 3

❏ Glue the sides R and back S to the bottom T. Test fit the

partially assembled drawer in the BenchTopper. Make

adjustments, if necessary, so the drawer will easily slide in

and out. Caution: The tabs on R are offset and will fit T

properly only one way.

❏ Glue the drawer front U to the front edges of R and T

while the drawer is in the BenchTopper. Hint: Place a

piece of 1/16" scrap balsa or similar behind the drawer

so you do not inadvertently glue the drawer front to the

BenchTopper.

❏Make two drawers from the sides V, back W, and bottom

X. Glue all of the pieces together. Glue the front Y to one

drawer and the front Z to the other drawer. The drawer with

the front Y is the top drawer and the drawer with the front Z

is the bottom drawer. Test fit the drawers and make any

adjustments if necessary. Caution: The tabs on V are offset

and will fit X properly only one way

❏ Sand the fronts of the drawers so they are flat and

smooth. Cut the 1/4" x 1/4" x 6" basswood stick into three 2"

pieces, then glue one “handle”to the front of each dr awer.

❏ Use a sanding block and 220-grit sandpaper to sand the

fronts of the paper tubes and any protruding tabs and edges

so all the corners are flush.

❏ Sand all outside surfaces with 320-grit sandpaper. If you

plan to add a finish to your BenchTopper, use compressed

air, a v acuum, or a tac k cloth to remove all of the dust before

painting.

❏

(This step is optional):

Glue the pin cushion support AA

in position. After finishing, glue the foam pin cushion to the

support with spray adhesive or rubber cement.

Finishing

Build the Drawers

Page 4

❏Use your f a v orite paint and finishing techniques to put the

finishing touches on your BenchTopper. Fill your

BenchTopper with the tools you most often use.

Here's what we keep on hand in our BenchTopper:

❏ Denatured alcohol for wiping away uncured epoxy.

❏Thin, medium and thick CA.

❏ CA debonder.

❏ Drafting triangle.

❏ Hobby knives, ballpoint pen, pin vise.

❏ Paper towel scraps for wiping away epoxy or CA.

❏ 30-minute and 6-minute epoxy.

❏ #11 blades.

❏Three sizes of T-pins (make optional partitions from scrap

plywood).

❏ Single edge razor blades.

❏ Screwdrivers.

❏ Pliers.

❏ Short r uler.

❏ Razor saw.

❏ Epoxy brushes and mixing sticks.

❏ Epoxy mixing cups.

Suggested Tools & Supplies

Part # Qty Description

BTOPD01 1 Decal

BTOPB01 1 3/16" Ply Base

BTOPF01 1 Foam Pin Cushion

BTOPH01 1 1/4" x 1/4" x 6" Drawer Handle

PTUBE001 3 Paper Tube

BTOPDC01 1 1/8" Die-Cut Ply A, K, J, S, AA

Part # Qty Description

BTOPDC02 1 1/8" Die-Cut Ply B, E Q, P

BTOPDC03 1 1/8" Die-Cut Ply L, F

BTOPDC04 1 1/8" Die-Cut Ply D, C, T

BTOPDC05 1 1/8" Die-Cut Ply N, M, G, Y, Z

BTOPDC06 1 1/8" Die-Cut Ply H

BTOPDC07 1 1/8" Die-Cut Ply U, I

BTOPDC08 1 1/8" Die-Cut Ply W, R, V, X

Entire Contents © Copyright 2002 v1.1 – GPMR8500 Printed in USA

Parts List

DIE-CUT DRAWINGS

Loading...

Loading...