Page 1

®

:

3

]

2

]

g]

g:

8 oz/f

2

m

2

]

Length:

]

ad

Channe

cro servos

le

ctricMoto

SC:25

A br

ushles

s

Wingspan: 38 in [965mm]

Wingspan

Wing Area: 242 in2 [15.6dm2]

Wing Area:242 in2 [15.6dm

Weight: 23-25 oz [650-710g]

Wing Loading: 13.7-14.8 oz/ft2 [42-45 g/dm2]

Wing Loadin

Length: 28 in [710mm]

Radio: 4-Channel with four micro servos

R

Electric Motor: RimFire™ 400 (28-30-950kV)

E

ESC: 25A brushless

E

Weight:23-25 oz [650-710

8 in [965mm

.7-14.

28 in [710mm

: 4-

r:mFir

t

[42-45 g/d

l with four mi

400 (28-30-950kV)

WARRANTY

ARRAN

Great Planes® Model Manufacturing Co. guarantees this kit to be free from defects in both material and

workmanship at the date of purchase. This warranty does not cover any component parts damaged by use or

modifi cation. In no case shall Great Planes’ liability exceed the original cost of the purchased kit. Further,

Great Planes reserves the right to change or modify this warranty without notice.

In that Great Planes has no control over the fi nal assembly or material used for fi nal assembly, no liability shall be

assumed nor accepted for any damage resulting from the use by the user of the fi nal user-assembled product. By

the act of using the user-assembled product, the user accepts all resulting liability.

If the buyer is not prepared to accept the liability associated with the use of this product, the buyer is

advised to return this kit immediately in new and unused condition to the place of purchase.

To make a warranty claim Hobby Services

send the defective part 3002 N. Apollo Dr., Suite 1

or item to Hobby Services Champaign, IL 61822 USA

at this address: (217) 398-8970 Ext. 5

Include a letter stating your name, return shipping address, as much contact information as possible (daytime

telephone number, fax number, e-mail address), a detailed description of the problem and a photocopy of the

purchase receipt. Upon receipt of the package, the problem will be evaluated as quickly as possible.

READ THROUGH THIS MANUAL BEFORE STARTING CONSTRUCTION. IT CONTAINS IMPORTANT INSTRUCTIONS

AND WARNINGS CONCERNING THE ASSEMBLY AND USE OF THIS MODEL.

Page 2

TABLE OF CONTENTS

ADDITIONAL ITEMS REQUIRED

ADDITIONAL ITEMS REQUIRED .....................................2

Radio System .................................................................2

Batteries and Charger ....................................................2

Hardware and Accessories ............................................2

Adhesives & Building Supplies .......................................3

Optional Supplies and Tools ...........................................3

PREPARATION .................................................................. 3

ASSEMBLE THE WINGS ................................................... 4

Join the Ailerons and Mount the Servos ........................4

Hook Up the Ailerons .....................................................5

Join the Wings ................................................................5

Mount the Wheels and Landing Gear .............................6

ASSEMBLE THE FUSELAGE ...........................................7

Glue in the Horizontal Stabilizer (Stab) ..........................7

Hinge the Elevators and Rudder ..................................10

Hook up the Elevator and Rudder ................................11

Mount the Motor and ESC ............................................12

Mount the Battery and Receiver ...................................14

Optional: Install Pilot Figure (Not Included) ..................14

GET THE MODEL READY TO FLY ..................................15

Set the Control Throws .................................................15

Balance and Mount the Propeller .................................16

Apply the Decals ..........................................................16

Balance the Model (C.G.) .............................................16

Balance the Model Laterally .........................................17

FLYING .............................................................................17

Prefl ight ........................................................................17

Takeoff ..........................................................................17

Flight ............................................................................18

Landing ........................................................................18

REPLACEMENT PARTS ..................................................18

RADIO SYSTEM

The Chipmunk 400 ARF requires a four-channel radio with a

small receiver that will fi t into available space in the fuselage

not already occupied by the battery. The following servos

and servo extensions are also recommended:

(4) Futaba® S3114 micro servos (FUTM0414)

(2) Hobbico® Command™ 6" [150mm] extensions

(HCAM2000)

(1) Futaba dual servo extension (FUTM4130)

BATTERIES AND CHARGER

Most 3S (11.1V) LiPo batteries in the 1200mAh – 1500mAh

range should fi t fi ne in the Chipmunk. Following are a few

suitable recommendations:

11.1V ElectriFly 1300mAh 25C (GPMP0505)

11.1V ElectriFly BP 1250mAh 20C (GPMP0715)

11.1V FlightPower® 1200mAh 30C (FPWP6105)

11.1V ElectriFly 1200mAh 30C (GPMP0836)

11.1V ElectriFly 1300mAh 30C (GPMP0840)

Be certain to read and follow all the instructions and

precautions that come with LiPo batteries and chargers.

Charge LiPo batteries only with chargers intended for LiPo

batteries or with chargers that have a LiPo setting. Following

is a suitable charger:

Great Planes PolyCharge4™ DC-only LiPo battery

charger (GPMM3015)

Additionally, one (1) Great Planes ElectriFly

Equinox™ LiPo Cell Balancer w/3S battery adapter

(GPMM3160) for each battery to be charged

simultaneously is recommended. (If you wish to

charge three batteries simultaneously, three Equinox

balancers will be required.)

Finally, if charging the battery from a 120V AC outlet

is preferred (rather than using a 12V battery), a 12

Volt power supply will also be required (Hobbico 12

Volt Power Supply - HCAP0250).

HARDWARE AND ACCESSORIES

Following is the list of additional hardware and accessories

required to fi nish the Chipmunk 400. Order numbers are

provided in parentheses.

Great Planes RimFire 400 (28-30-950kV) out-runner

brushless motor with prop adapter (GPMG4560)

Great Planes Silver Series 25 Amp Brushless

Electronic Speed Controller (GPMM1820)

(1 pkg. of 3) Great Planes 3.5mm male/2mm female

bullet adapters (GPMM3122)

2

Page 3

Great Planes 8x6 Power Flow™ Slo-Flyer Elec Prop

(pkg. of 2, GPMQ6610)

(1 pkg) Great Planes adhesive-back Velcro®

(GPMQ4480)

Double-sided foam mounting tape (GPMQ4440)

Stick-on segmented lead weights (GPMQ4485)

Great Planes 3/8"x3" [10x80mm] heat shrink tubing

(GPMM1060)

ADHESIVES & BUILDING SUPPLIES

In addition to common household and hobby tools, this

is the “short list” of the most important items required to

assemble the Chipmunk 400. Great Planes Pro™ CA glue is

recommended.

Thin CA (1/2 oz. [15g] Thin Pro CA, GPMR6001)

Medium CA (1/2 oz. [15g] Medium Pro CA+,

GPMR6007)

30-minute epoxy (Pro 30-minute epoxy, GPMR6047)

CA applicator tips (HCAR3780)

Threadlocker thread locking cement (GPMR6060)

#11 blades (5-pack, HCAR0211)

#1 Hobby knife (HCAR0105)

The following drill bits were also used: 1/16" [1.6mm],

1/8" [3.2mm], 5/64" [2mm]. For precision, the following

“numbered” drills were also used, but if you cannot

get numbered drills a hobby knife could be used

instead: #57 (.043" [1mm]), #55 (.052" [1.3mm])

PREPARATION

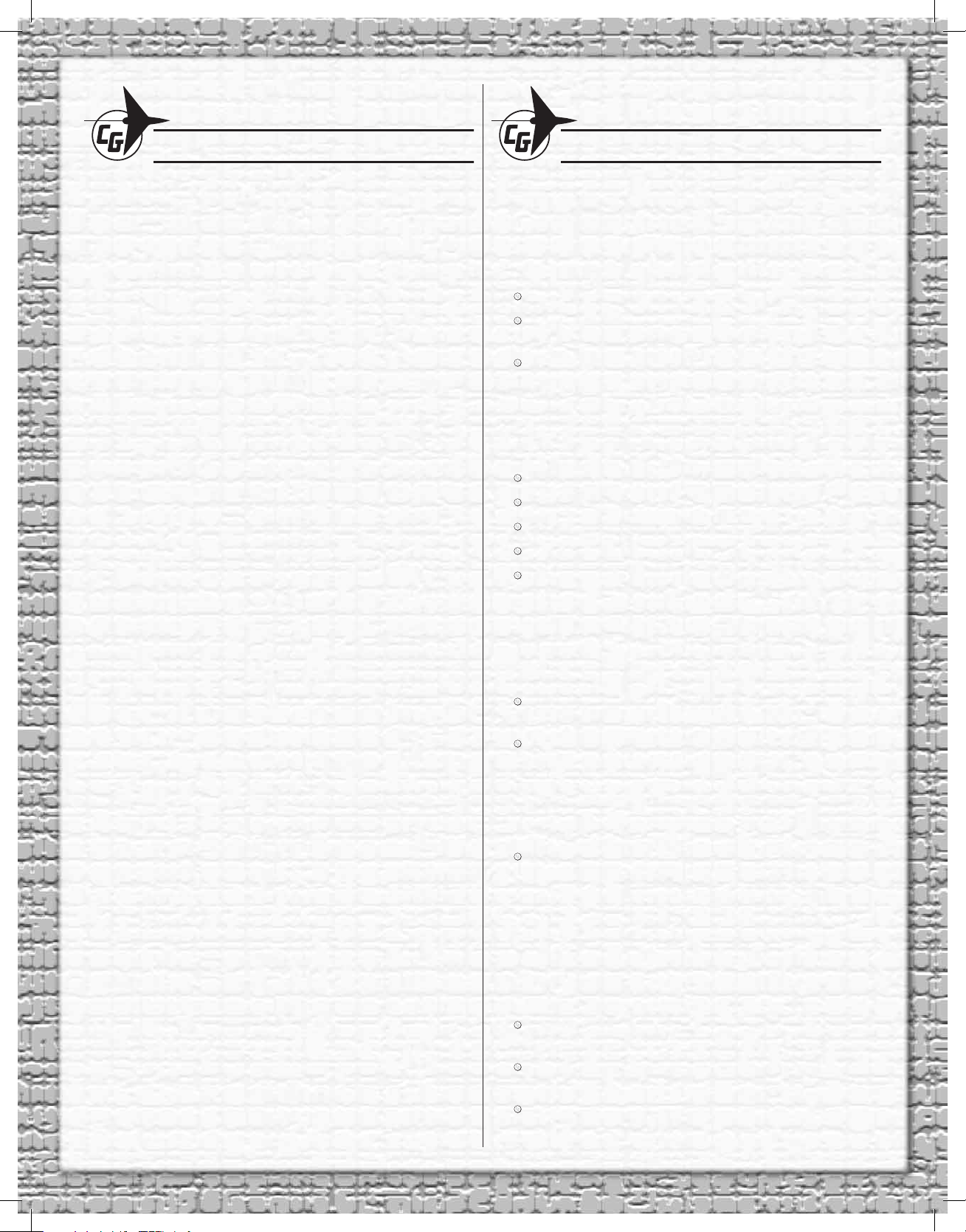

1. Lay three or four

paper towels over each

other and cut the stack

into small squares.

These small paper towel

squares, dampened with

denatured alcohol, will

come in handy for epoxy

cleanup and other general

cleanup during assembly.

OPTIONAL SUPPLIES AND TOOLS

Here is a list of optional items mentioned in the manual that

will help you build the Chipmunk 400.

Williams Brothers 1/8-scale Sportsman pilot

(WBRQ1130)

#2x1/4" [6mm] or #2x1/2" [12mm] screws and #2

washers (for mounting optional pilot)

Hobby paints/paint brushes (for painting pilot)

2 oz. [57g] spray CA activator (GPMR6035) or 4 oz.

[113g] aerosol CA activator (GPMR6034)

CA debonder (GPMR6039)

CG Machine™ (GPMR2400)

Power Point Prop Balancer (TOPQ5700)

A model airplane covering iron with a protective

covering sock may also be necessary to retighten

the covering and remove any wrinkles that may have

formed after the model was originally covered at the

factory. If you don’t already have a covering iron,

the 21st Century® sealing iron (COVR2700) and 21st

Century iron cover (COVR2702) are recommended.

2. Remove the masking tape holding all the control

surfaces to their main parts. If necessary, clean off any

residual tape glue with a couple of your paper towel squares

dampened with naphtha (lighter fl uid).

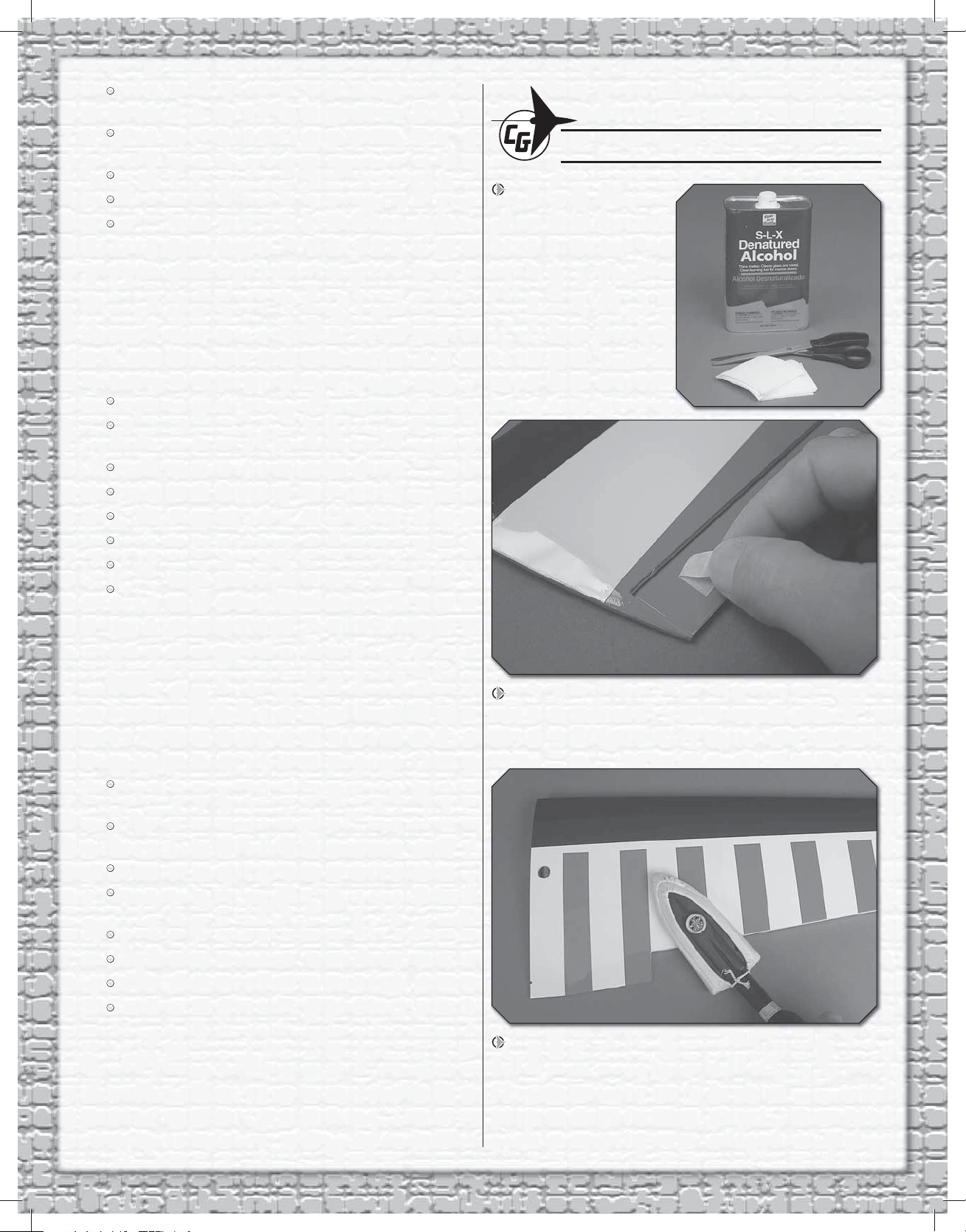

3. Refer to the separate instruction sheet titled How To

Tighten Covering On ARF Models. Follow the instructions

to tighten the covering. If you prefer to get started on

assembly right away, the tightening process could be done

later (but it is usually easiest to do while the model is still in

separate pieces).

3

Page 4

ASSEMBLE THE WINGS

JOIN THE AILERONS AND MOUNT THE SERVOS

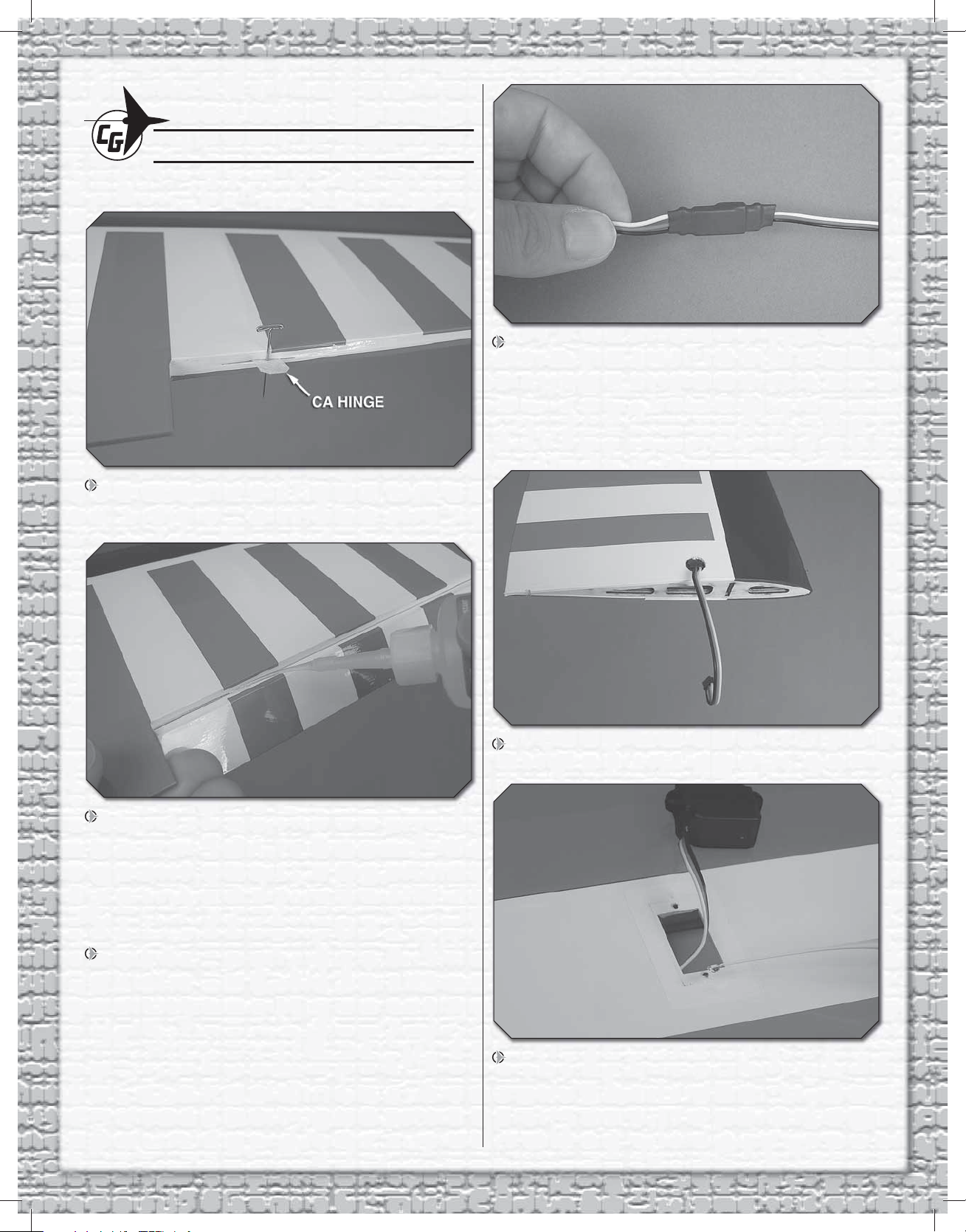

1. Stick a small pin through the middle of three CA hinges.

Insert the hinges up to the pins into the hinge slots in one of

the wings.

4. Connect a 6" [150mm] servo extension to one of

your aileron servos. Use a piece of Great Planes 3/8" x 3"

[10 x 80mm] heat shrink tubing (GPMM1060, not included)

cut in half (or tape or other suitable clips intended for

this purpose) to secure the servo plugs so they cannot

accidentally become disconnected. Use a hobby torch or a

heat gun to shrink the tubing.

2. Fit the matching aileron to the hinges in the wing and

take out the pins. Make sure there is a small gap between

the leading edge of the aileron and the wing—just enough

to see light through or to slip a piece of paper through. Add

three or four drops of thin CA to the top and bottom of each

hinge, waiting a few seconds between each drop to allow the

CA to wick all the way in.

3. Hinge the other aileron to the other wing the same way.

After the CA has hardened, rapidly move the ailerons up and

down several times to “break in” the hinges so the ailerons

will move more freely.

5. Guide the servo wire down through the ribs and out the

hole in the top of one of the wings.

6. Temporarily mount the servo in the wing with two of the

included 2 x 4mm Phillips wood screws—the screw holes

are predrilled. Remove the screws and take the servo out of

the mount. Add a few drops of thin CA to the screw holes,

allow to harden, and then remount the servo.

4

Page 5

7. Mount your other aileron servo in the other wing the

WING TRAILING EDGE

PARALLEL WITH WING

TRAILING EDGE

HORN MOUNTING PLATE

CONTROL HORN

2x10mm MACHINE THREAD

PHILLIPS SCREWS

ADJUST THE “V” BEND

same way.

HOOK UP THE AILERONS

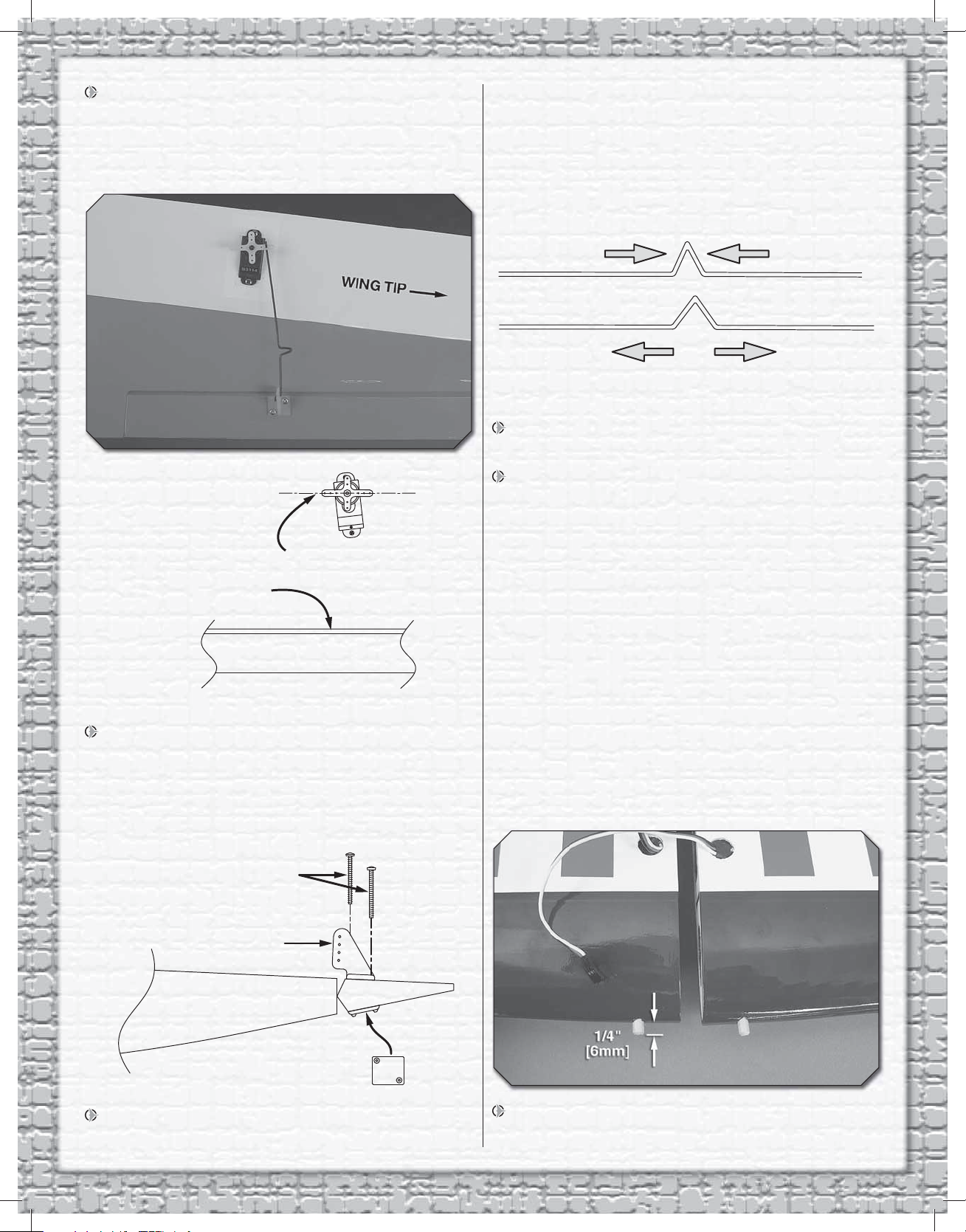

Refer to this photo while hooking up the ailerons.

the aileron pushrod wire will fi t. Drill 5/64” [2mm] (or 3/32”

[2.4mm]) holes through the aileron for the horn mounting

screws and hook up the aileron as shown—note in the photo

that the horn is located on the aileron so the pushrod will be

perpendicular to the wing trailing edge and the servo arm.

3. Use pliers to adjust the V-bend in the wire so the aileron

will be centered.

4. Hook up the other aileron the same way. Note that the

aileron pushrods are connected to the servo arms nearest

the wing tips. This will allow the ailerons to move in opposition

(as they should).

1. Connect one of the aileron servos in the wing to your

receiver. Turn on the transmitter and hook up a charged

battery and the ESC so you can operate the servo with

the transmitter. With the trims on the transmitter centered,

mount the arm to the servo so it will be parallel (or as close

to parallel as you can reasonably get) with the trailing edge.

2. Enlarge the holes in one of the control horns included

with this kit with a #57 (.043” [1mm]) drill or a hobby knife so

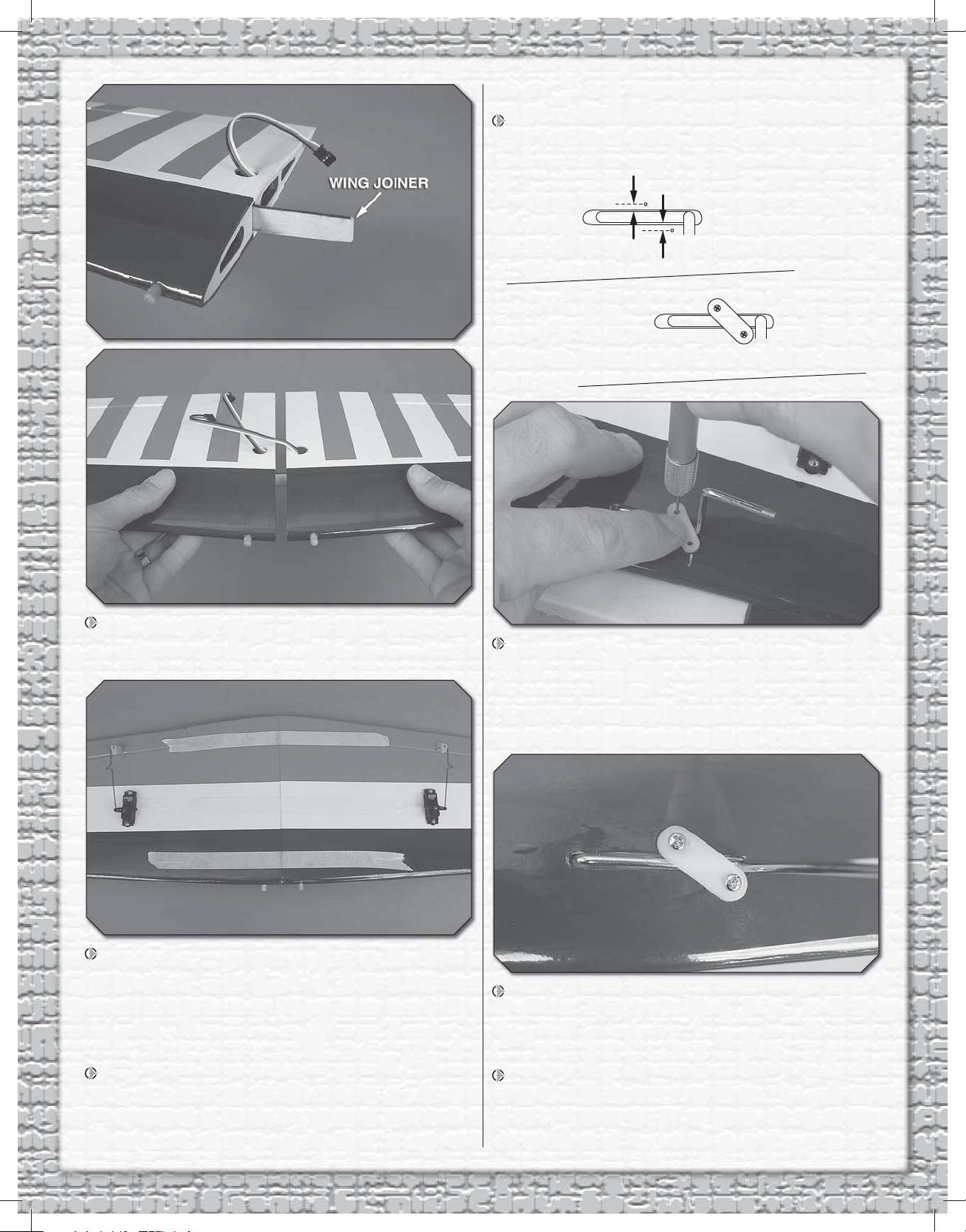

JOIN THE WINGS

1. Use epoxy to glue the wing dowels into each wing with

1/4" [6mm] protruding.

5

Page 6

MOUNT THE WHEELS AND LANDING GEAR

3/32" [2mm]

3/32" [2mm]

1. Insert the right and left main landing gear wires into

the wing so they will be angled forward.

2. Without using any glue, test fi t the wing halves together

with the plywood wing joiner. Make sure the wings fi t well

with no gap. Make any adjustments necessary for a good fi t.

3. Use 30-minute epoxy to glue the wings together with

the joiner—be certain to coat all mating surfaces—inside

the pockets where the joiner goes, all the way around the

joiner and the ends of both wing halves. Use masking tape to

hold the halves together and wipe away excess epoxy before

it hardens.

2. Holding a fl at landing gear strap over one of the gears

in the wing, drill a 1/16" [1.6mm] hole into the bottom of

the wing using the hole in the strap as a guide—note that

the strap must be mounted at an angle so the holes will be

no farther than 3/32" [2mm] from the wire. Otherwise, the

screws will miss the hardwood rail inside.

3. Mount the strap to the wing with a 2 x 8mm Phillips

wood screw. Holding the strap at an angle so the second

hole will be no farther than 3/32” [2mm] from the front of the

wire, drill the hole and install the second screw.

4. After the epoxy has hardened, carefully peel off the

masking tape. If necessary, use your covering iron to reattach

any lifted covering back down to the balsa underneath.

4. Mount the other strap over the other gear the same way.

Remove all the screws, add a drop of thin CA to each hole,

allow to harden, and then reinstall the straps and screws.

6

Page 7

Now you can mount the wheel pants…

5. Use a hobby knife to chamfer the top of the hole on the

inside of both wheel pants so it will fi t all the way to the wire

gear leg.

1. Use a hobby knife with a sharp blade to cut the covering

from the fuselage over the exit slot for the elevator pushrod

guide tube (located just under the leading edge of the slot

for the horizontal stabilizer) and from the exit slot for the

rudder pushrod guide tube (located just behind and below

the slot for the vertical stabilizer). The stab is shown already

in position, but yours should not yet be in place.

6. Mount the pants and wheels to the landing gears with

a humped mounting strap and two 2 x 4mm Phillips wood

screws in the predrilled holes. Same as has been done all

along, remove the screws, add a drop of thin CA to the screw

holes, allow to harden, and then remount the pants.

ASSEMBLE THE FUSELAGE

GLUE IN THE HORIZONTAL STABILIZER (STAB)

Disregard the elevator and stab in the fi rst two pictures. They

are not actually installed until step 16.

2. Temporarily join the elevators to the horizontal

stabilizer (stab) with two hinges in each side—at this time,

the centering pins aren’t required—they will be used when

permanently installing the hinges later. Make certain there

is a small gap between the ends of the elevators and the

balance tabs on the elevators. Center the elevator joiner

wire on the stab as shown on the previous page. Mark both

elevators at the ends of the wire.

3. Drill a 1/16" [1.6mm] hole into the leading edge of both

elevators at the marks. Use a hobby knife or a 1/16" [1.6mm]

drill to cut grooves in the leading edge of the elevators to

accommodate the joiner wire.

7

Page 8

4. Test fi t the joiner wire and make sure it goes all the way

A A'

A = A'

B = B'

B

B'

into both elevators.

5. Test fi t the elevators to the stab with the joiner wire and

the hinges. Be certain the elevators are parallel with each

other and that the gaps still exist between the ends of the

stab and the elevator balance tabs. If necessary, remove the

wire and bend it so the elevators will be parallel with each

other and lie fl at on your workbench.

7. Once the stab is centered, stick pins into the trailing

edge tightly to both sides of the fuselage, holding the trailing

edge in place.

8. Stick another pin into the top of the front of the

fuselage centered over the stringer. Tie a loop in one end of

an approximately 30" [760mm] length of K+S #801 Kevlar

thread or similar non-elastic line.

6. Separate the elevators from the stab and take out the

hinges. Install the stab into the fuselage. Taking accurate

measurements from side-to-side, center the trailing edge by

equalizing the distance between both ends of the stab and

the fuselage.

9. Wrap a piece of masking tape over the line near the

other end and mark an arrow or a line on it. Slide the tape

8

Page 9

along the string until the arrow aligns with one end of the

stab. Swing the string over to the same spot on the other side

of the stab to see if the distances are equal as shown in the

sketch. Adjust the stab and slide the tape along the string

until the stab is aligned.

10. Once the stab is centered, use a fi ne-point felt-tip pen

to mark the fuselage sides around the top and bottom of

the stab.

ink with a few of your paper towel squares dampened with

denatured alcohol.

13. If necessary, use a 1/8" [3.2mm] drill to clear any

epoxy from the wing bolt hole near the trailing edge of the

wing. Cut the covering from the bottom of the wing around

the wing bolt hole for the plywood wing bolt washer. Glue

the washer into position while simultaneously mounting the

wing to the fuselage with a 3 x 20mm Phillips screw and a

3mm washer. (The wing will be used as a reference for stab

alignment in the following steps.)

11. Remove the stab from the fuselage. Using a soldering

iron with a fi ne tip guided by a metal straightedge, cut through

the covering 1/32" [1mm] inside the lines. If you have an iron

with an adjustable temperature, set it to approximately 400°

F [200° C]. Gliding the iron at just the right speed will cut the

covering without melting a wide path or without burning into

the wood. If you don’t have a soldering iron, a hobby knife

with a sharp, new blade could be used, but care must be

taken not to cut into the wood.

14. Use coarse sandpaper to roughen the elevator joiner

wire so glue will adhere. Place the joiner wire in the slot in

the fuselage for the stab.

15. When ready to glue in the stab, mix 1/4 oz. [5cc] of

30-minute epoxy. Thoroughly coat the middle of the top and

bottom of the stab with epoxy. Slide the stab into position.

Use a piece of cardstock or your fi nger to work some of the

epoxy that was wiped off the stab back in. Then, wipe off

any excess. Reinsert the pins into the trailing edge of the

stab on both sides of the fuselage and use the pin and string

to re-align the stab the same way you did before. Proceed

immediately to the next step.

12. Peel the covering from the middle of the stab to

expose the bare balsa underneath. Wipe off any residual

16. View the model from the rear and see if the stab is

parallel with the wing. If necessary, place small weights

(coins, lead ballast) on the “high side” of the stab to bring it

into alignment with the wing. Once the stab has been perfectly

aligned, use a few more paper towel squares dampened with

denatured alcohol to wipe off any remaining epoxy. Doublecheck the stab alignment one last time. Do not disturb the

model until the epoxy has hardened.

9

Page 10

HINGE THE ELEVATORS AND RUDDER

1. If you haven’t yet done so, remove the wing from the

fuselage. Coat the “arms” of the joiner wire where they go into

the elevators with epoxy and use a piece of wire to work some

epoxy into the holes in the elevators. Join the elevators to the

stab and joiner wire with the hinges—this time using the pins

to center the hinges the same as when hinging the ailerons.

Double-check to make certain the elevators are parallel with

each other and make any adjustments necessary. Wipe away

any excess epoxy that comes out of the elevators and use

thin CA to permanently glue in the hinges.

as shown. Once you get the gear up into position through

the slot in the horizontal stab turn it around the other way

as shown.

3. The same as was done for the horizontal stabilizer, fi t

the vertical stabilizer (fi n) into the fuselage. Use a fi ne-point

felt-tip pen to mark the fuselage on both sides and cut the

covering from the fi n.

4. Glue the fi n into position, making certain it is

perpendicular to the stab—use strips of tape—varying the

tension on whichever side necessary, to hold it vertical.

2. Cut the covering from the tail gear hole on the bottom of

the fuselage, then insert the tail gear assembly “backwards”

5. After the epoxy from the previous step has hardened,

cut a 5-3/4" [145mm] long, 1/16" [2mm] wide strip of covering

from the top of the fuselage for the dorsal fi n. Glue the dorsal

fi n into position, tightly contacting the leading edge of the fi n.

10

Page 11

the rudder the same way the horns were mounted to the

ailerons (by drilling 5/64" [2mm] or 3/32" [2.4mm] holes

for the screws and mounting the horn with two 2 x 10mm

machine-thread Phillips screws and the horn mounting plate

on the other side).

3. Connect the other pushrod to the last control horn and

mount it to the elevator the same way.

6. Same as was done for the elevator joiner wire, drill

the hole and cut the slot in the rudder for the tail gear wire,

making sure the plastic washer and the collar are up against

the bottom of the fuselage. Permanently join the rudder to

the vertical stabilizer using epoxy to glue the joiner wire into

the rudder and thin CA for the hinges.

HOOK UP THE ELEVATOR AND RUDDER

1. Enlarge the holes in the remaining two control horns

with a #57 (.043" [1mm]) drill or a hobby knife so the pushrod

wires will fi t.

4. Use the included 2 x 4mm Phillips wood screws to mount

your elevator and rudder servos in the plywood servo tray.

Refer to this photo for the following fi ve steps.

2. Connect one of the pushrod wires to the second-fromthe-outer hole of a control horn. Slide the wire up into the

rudder guide tube in the fuselage. Then, mount the horn to

5. Fit the servo tray into the fuselage where shown, but do

not yet glue it into position.

11

Page 12

90˚

90˚

6. Connect the servos to your receiver and power up the

SCREW

RETAINER

SCREW-LOCK

CONNECTOR

system with the trims on the transmitter centered. Fit the

servo arms on the servos so they will be as close to 90

degrees as possible to the pushrods (but they don’t have to

be perfect). Cut off the unused servo arms.

7. Use a #55 (.052"

[1.3mm]) drill or a

hobby knife to enlarge

the holes in the servo

arms. Then, mount a

screw-lock connector

to each arm using

the nylon retainer as

shown.

8. Fit the pushrods

into the screw-lock

connectors on the

servo arms. Position

the servo tray wherever the servos align with the pushrods.

Securely glue the servo tray into place.

9. One last time, turn on your radio and power the

servos. Center the elevator and rudder. Next, add a drop

of threadlocker to the screws in the screw-lock connectors

and tighten them down. Cut the pushrods approximately 1/2"

[10mm] past the screw-locks.

2. Fit, then glue the plywood ESC mounting plate

into position.

3. Mount the ESC to the ESC mounting plate with double-

side foam mounting tape (not included).

MOUNT THE MOTOR AND ESC

1. Guide the motor wires through the hole in the fi rewall

and mount the motor with three 3 x 8mm Phillips screws and

a drop of threadlocker on the threads.

4. Using 3.5mm male bullet to 2.0mm female bullet

adapters (GPMM3122, not included), connect the ESC wires

to the motor wires, keeping as much of the wiring as you

can in front of the fuselage in the cowl area so it will not be

in the way of the battery—when installing the battery later, it

should be placed forward to reduce any nose ballast that will

be required to get the proper C.G.

5. Turn on the radio and connect the battery to momentarily

power up the system. Make certain the motor turns and does

12

Page 13

so in the correct direction when you advance the throttle

stick. If necessary, reverse the servo direction for the throttle

channel (to get the motor to turn when you advance the

throttle). If the motor turns, but in the wrong direction, switch

any two motor wires with each other connected to the ESC.

Once the motor has been properly set up, disconnect the

battery and turn off the Tx.

Now the cowl can be mounted…

6. Draw a vertical line on both sides of the fuselage 1/8"

[3mm] back from the front edge. Make four templates from

thin cardstock or heavy paper as shown. Tape them to the

fuselage so the holes in the template are centered over the

lines near the top and bottom of the fuselage.

8. Using the holes in the templates as a guide, drill 1/16"

[1.6mm] holes through the cowl into the fuselage.

9. Remove the cowl. Temporarily screw four 2 x 8mm

Phillips wood screws into the holes drilled in the fuselage.

Remove the screws and add a drop of thin CA to each hole.

10. Enlarge the holes in the cowl only with a 5/64” [2mm]

drill. After the CA from the previous step has hardened,

mount the cowl to the fuselage with the screws. Turn the

motor and make certain it is not rubbing in the cowl. Make

any adjustments required.

7. Slide the cowl over the fuselage under the cardstock

templates. Mount the propeller (not included). Checking to

be sure the red and white paint line on the cowl aligns with

the red and white covering on the fuselage, tape the cowl

into position—also make sure the cowl is centered over the

propeller shaft and there will be approximately 1/8" [3mm]

clearance between the front of the propeller and the cowl.

11. Cut an air inlet hole in the cowl to help cool the ESC.

12. Cut the covering from the holes in the bottom of the

fuselage to allow cooling air to exit.

13

Page 14

MOUNT THE BATTERY AND RECEIVER

4-1/2" [110mm]

“HOOK” SIDE

1"

[25mm]

3-1/2" [90mm]

“LOOP” SIDE

1. If using the recommended 1250 or 1500mAh 11.1V

ElectriFly Power Series battery, cut a 4-1/4" [110mm] strip

from the rougher, “hook” side and a 3-1/2" [90mm] strip from

the softer, “loop” side of the included hook-and-loop material.

Connect the pieces with a 1" [25mm] overlap to make the

battery strap. If using a different battery, make the battery

strap as necessary to fi t.

3. Connect the servo wires and a dual aileron extension

wire to the receiver. Use double-sided foam mounting tape

to mount the receiver where desired. If your receiver is small

enough, it could be mounted next to the battery on the

left side of the fuselage, but this one was mounted behind

the battery.

2. As noted previously, it is best to get the battery forward.

Keeping this in mind, attach a strip of Great Planes adhesivebacked Velcro (GPMQ4480, not included) to the battery

and opposing patches to the battery mounting plate in the

fuselage. Place the battery on the mounting plate and hold it

down with the strap.

4. If using a 2.4GHz receiver, cut pieces of the small

tubing supplied and glue the tubes inside the fuselage for

guiding the antennas. If using a 72MHz receiver, guide the

antenna down through the antenna tube in the fuselage.

OPTIONAL: INSTALL PILOT FIGURE (NOT INCLUDED)

1. If installing an optional pilot fi gure, cut the pilot access

hatch the rest of the way through the cockpit fl oor (shown in

the photo in step 4).

2. Glue together and

paint your pilot. The pilot

used for this model was

a William’s Brother’s

1/8-scale Sportsman pilot

(WBRQ1130). Cut 1/16"

[2mm] from both shoulders

so the fi gure will fi t between

the canopy sides. Test fi t the

pilot, adjust if necessary,

and paint using waterbase acrylic paint and craft

brushes available at hobby

shops or craft stores.

14

Page 15

3. Drill 1/16" [1.6mm]

These are the recommended control surface throws:

ELEVATOR

HIGH RATE LOW RATE

5/16"

[8mm]

9˚

Up

5/16"

[8mm]

9˚

Down

3/16"

[5mm]

6˚

Up

3/16"

[5mm]

6˚

Down

RUDDER

1"

[26mm]

18˚

Right

1"

[26mm]

18˚

Left

3/4"

[19mm]

13˚

Right

3/4"

[19mm]

13˚

Left

AILERONS

1/4"

[6mm]

13˚

Up

1/4"

[6mm]

13˚

Down

1/8"

[3mm]

7˚

Up

1/8"

[3mm]

7˚

Down

holes through the bottom of the pilot 1-1/8"

[29mm] apart to align

with the holes in the

bottom of the cockpit

fl oor for the pilot mounting screws.

4. Mount the pilot to the cockpit fl oor with two #2 x 1/4"

[6mm] or #2 x 1/2" [12mm] screws and #2 washers

(not included).

4. Use the transmitter to move the elevator up and move

the ruler forward so it will still be touching the trailing edge.

The distance the elevator moves is the “up elevator” control

throw. Use the endpoint adjustment in your transmitter

or move the screw-lock pushrod connector in the elevator

servo arm to a new hole to increase or decrease the throw

as necessary.

5. Measure and set the up and down and left and right

control throws for all of the control surfaces. If your radio does

not have dual rates, we recommend setting the throws at the

high rate setting. NOTE: The elevator and rudder throws are

measured at the widest part.

GET THE MODEL READY TO FLY

SET THE CONTROL THROWS

1. If measuring the control throws in degrees, follow the

instructions that came with your throw measuring tool to set

the throws according to the measurements that follow. If

using a ruler, proceed with the following instructions.

2. Set the throws on the elevator fi rst. Use a small box or

something similar to prop up the bottom of the fuselage until

the wings and horizontal stabilizer are level.

3. With the transmitter and receiver on and the elevator

centered, hold a ruler up to the trailing edge of the elevator

at the widest part (nearest the fuselage).

IMPORTANT: The Carl Goldberg Chipmunk 400 ARF

has been extensively fl own and tested to arrive at the throws

at which it fl ies best. Flying your model at these throws

will provide you with the greatest chance for successful

fi rst fl ights. If, after you have become accustomed to the

way the Chipmunk fl ies, you would like to change the

throws to suit your taste, that is fi ne. However, too much

control throw could make the model diffi cult to control, so

remember, “more is not always better.”

15

Page 16

BALANCE AND MOUNT THE PROPELLER

1. For optimum performance and motor effi ciency,

balance the propeller using a Top Flite Precision Magnetic

Prop Balancer (TOPQ5700) or other suitable balancer. Use

a hobby knife or sandpaper to sand the one side of the heavy

blade until you can get the prop to balance.

2. Mount the propeller with the propeller washer and

propeller nut. Tighten the nut with an 8mm or 5/16" wrench.

APPLY THE DECALS

1. Use scissors or a sharp hobby knife to cut out the

decals.

2. Be certain the model is clean and free from oily

fi ngerprints and dust. Prepare a dishpan or small bucket with

a mixture of liquid dish soap and warm water—about one

teaspoon of soap per gallon of water. Submerse the decal

in the soap and water and peel off the paper backing. Note:

Even though the decals have a “sticky-back” and are not the

water transfer type, submersing them in soap & water allows

accurate positioning and reduces air bubbles underneath.

1. If using a Great Planes C.G. Machine to balance the

Chipmunk, set the rulers to 2.5" [63mm]. If not using a C.G.

Machine, use a fi ne-point felt-tip pen to draw short lines

marking the balance point on the top of the wing 2.5" [63mm]

back from the leading edge at the fuselage sides. Place 1/16"

[1.5mm] strips of tape over the marks so you will be able to

feel the balance point with your fi ngers when you turn the

model upside-down.

This is where your model should balance for the fi rst

fl ights. Later, you may wish to experiment by shifting the

C.G. up to 1/4" [6mm] forward or 1/4" [6mm] back to change

the fl ying characteristics. Balancing the Chipmunk at the

forward C.G. location will increase its stability, making

it easier to fl y for beginners but less maneuverable and

aerobatic. Balancing the Chipmunk at the aft C.G. location

will decrease its stability, making it more aerobatic for

advanced pilots. In any case, start at the recommended

balance point and never fl y the Chipmunk outside the

recommended range.

3. Position decal on the model where desired. Holding the

decal down, use a paper towel to wipe most of the water away.

4. Use a piece of soft balsa or something similar to

squeegee remaining water from under the decal. Apply the

rest of the decals the same way.

BALANCE THE MODEL (C.G.)

More than any other factor, the C.G. (balance point)

can have the greatest effect on how a model fl ies, and

may determine whether or not your fi rst fl ight will be

successful. If you value this model and wish to enjoy it for

many fl ights, DO NOT OVERLOOK THIS IMPORTANT

PROCEDURE. A model that is not properly balanced will

be unstable and possibly unfl yable.

At this stage the model should be completely ready-to-fl y with

all of the systems in place including the motor, propeller, motor

battery, ESC, a pilot (if used) and the complete radio system.

16

Page 17

2. Place the model on your C.G. Machine or lift it with

your fi ngers at the balance point you marked on the top of

the wing. When the model is balanced correctly the wing and

horizontal stabilizer will be level as shown in the photo. If

the tail is low additional ballast will be required in the nose.

To fi nd out how much, carefully lay segments of Great

Planes “stick-on” lead (GPMQ4485) on the fuselage over the

location where it will be permanently attached inside.

FLYING

The Carl Goldberg Chipmunk 400 ARF is a great-fl ying

model that fl ies smoothly and predictably. The Chipmunk

does not, however, possess the self-recovery characteristics

of a primary R/C trainer and should be fl own only by R/C

pilots who have some experience.

PREFLIGHT

Monitor and limit your fl ight time using the timer in your

transmitter or the timer on your wrist watch. When the

batteries are getting low you will usually notice a performance

drop before the ESC cuts off motor power, so when you

notice the plane fl ying slower you should land. Often (but

not always!), power can be briefl y restored after the motor

cuts off by holding the throttle stick all the way down for a

few seconds.

To avoid an unexpected dead-stick landing on your fi rst fl ight

set your alarm or timer to a conservative 4 minutes. When

the alarm sounds you can land your model; or, if you are

an experienced pilot, you may continue to fl y but plan for a

dead-stick landing to see just how long the motor will run.

Circle the plane upwind of the landing area until the motor

quits. Note the run time, then land.

3. Once you know how much weight is required, attach it

to the model—do not attach nose weight to the cowl because

it will place too much stress on the wood and cowl around

the cowl mounting screws. Nose weight may be attached

to the “engine box” next to the motor. Tail weight may be

attached to the fuselage under the horizontal stabilizer.

For the Chipmunk, it is likely that approximately 1/2 oz.

[15 g] will be needed in the nose.

4. IMPORTANT: If you found it necessary to add any

weight, recheck the C.G. after it has been attached.

BALANCE THE MODEL LATERALLY

1. With the model sitting in the assembly stand, lift the

model by the tail skid and the propeller shaft several times

and note which wing tip drops.

2. If one wing always drops, it means that side is heavy.

Balance the airplane by adding weight to the bottom of

the opposite wing near the tip. An airplane that has been

laterally balanced will track better in loops and other

maneuvers.

When you learn how much fl ight time you are getting you

can adjust your timer accordingly. Always be conservative so

the motor won’t quit unexpectedly and you will have enough

battery to land under power.

TAKEOFF

The Chipmunk may take off from very short grass or

pavement, but short grass is best because it will track better.

Taking off from a paved surface should be no problem as

long as the model is pointing directly into any prevailing

wind. If the nose is not pointing into the wind, and if there

is anything stronger than a slight breeze, the model may

“weathervane” into the wind as soon as you advance the

throttle. If the conditions do not allow for a ROG (rise off

ground) takeoff, the Chipmunk may be hand-launched

instead. After checking the controls, simply advance the

throttle to full power and have an assistant launch the model

into the air at a straight-and-level or slightly nose up attitude.

Keep the wings level, but allow the model to briefl y sink until

it gains enough airspeed to climb.

If taking off from the runway, smoothly but rapidly advance

the throttle until the model gains enough speed. The rudder

will not be very effective until the model is almost ready to

take off. Once the plane has built up enough speed, apply

“up” elevator to lift the model into the air. Continue to climb

until the model has reached an altitude that is comfortable

for you and make the fi rst turn away from the runway.

17

Page 18

FLIGHT

Continue to fl y around for a minute while getting used to how

the Chipmunk responds. The next priority will be to adjust the

trims to get it to fl y straight-and-level. Continue to fl y around,

getting the model properly trimmed while you learn its

characteristics and get a good feel for how it fl ies. While still

at a high altitude, test to see how it handles when it’s time

to land by cutting motor power to check the glide path. Allow

it to glide as long as you like. Then, apply power and climb

again to altitude. Perform this exercise a few times so you will

be ready to make a good landing. Remember to monitor your

fl ight time so the motor doesn’t cut off.

LANDING

Landing any model directly into the wind is always preferred,

but with a small, lightweight plane such as this it is even more

important. A headwind will help keep the wings level, make

the controls more effective and allow for a slower ground

speed for softer touchdowns. When ready to land and on

the downwind leg, cut or reduce motor power to allow the

model to descend. Make the turn across the wind toward the

runway, simultaneously keeping the nose down so the model

maintains airspeed. Add power if the model is too far away

and not going to reach the runway. When the model is a few

feet [1 meter] off the ground, apply increasing amounts of

up elevator allowing the model to slow while it continues to

descend. Ideally, in calm conditions, you will be holding full

up elevator at the point of touchdown. If the conditions are

breezy you may have to “fl y” the model to the ground with a

small amount of motor power and less up elevator. Once the

model touches down and has lost fl ying speed, hold full up

elevator to keep the tail down.

One fi nal note about fl ying your Chipmunk. Have a goal or

fl ight plan in mind for every fl ight. This can be learning a new

maneuver(s), improving a maneuver(s) you already know,

or learning how the model behaves in certain conditions

(such as on high or low rates). This is not necessarily to

improve your skills (though it is never a bad idea!), but more

importantly so you do not surprise yourself by impulsively

attempting a maneuver and suddenly fi nding that you’ve run

out of time, altitude or airspeed. Every maneuver should be

deliberate, not impulsive. For example, if you’re going to do a

loop, check your altitude, mind the wind direction (anticipating

rudder corrections that will be required to maintain heading),

remember to throttle back at the top, and make certain you

are on the desired rates (high/low rates). A fl ight plan greatly

reduces the chances of crashing your model just because of

poor planning and impulsive moves.

REPLACEMENT PARTS

Replacement parts for the Super Chipmunk EP ARF are

available from your hobby dealer or mail-order company:

GPMA4270 . . . . Fuselage

GPMA4271 . . . . Wing

GPMA4272 . . . . Canopy

GPMA4273 . . . . Landing Gear

GPMA4274 . . . . Tail Set

GPMA4275 . . . . Cowl

GPMA4276 . . . . Wheel Pants

GPMA4277 . . . . Decals

18

Page 19

19

Page 20

www.carlgoldbergproducts.com

Entire Contents © 2012 Hobbico,® Inc. All rights reserved. GBGA1023

Loading...

Loading...