Page 1

™

SPECIFICATIONS

Wingspan:

Length:

Weight:

Wing Area:

Wing Loading:

39.5 in [1000mm]

30.5 in [775mm]

25–28 oz [710 – 795 g]

2

174 i n

20.7– 23.2 oz /ft

[11.2 dm2]

2

[63–71 g/dm2]

WARRANTY

Great Planes® Model Manufacturing Co. guarantees this kit to

be free from defects in both material and workmanship at the

date of purchase. This warranty does not cover any component

parts damaged by use or modification. In no case shall Great

Planes’ liability exceed the original cost of the purchased kit.

Further, Great Planes reserves the right to change or modify this

warranty without notice.

In that Great Planes has no control over the final assembly or

material used for final assembly, no liability shall be assumed nor

accepted for any damage resulting from the use by the user of

the final user-assembled product. By the act of using the

user-assembled product, the user accepts all resulting liability.

If the buyer is not prepared to accept the liability associated

with the use of this product, the buyer is advised to return

INSTRUCTION

MANUAL

Motor:

Radio:

this kit immediately in new and unused condition to the

place of purchase.

To make a warranty claim send the defective part or item to

Hobby Services at the address below:

Include a letter stating your name, return shipping address, as

much contact information as possible (daytime telephone

number, fax number, e-mail address), a detailed description of

the problem and a photocopy of the purchase receipt. Upon

receipt of the package the problem will be evaluated as quickly

as possible.

28-45-3600 Ammo

ESC:

50A for brushless motors

5-channel, 3 servos,

programmable mixing

Hobby Services

3002 N. Apollo Dr. Suite 1

Champaign IL 61822 USA

READ THROUGH THIS MANUAL BEFORE STARTING CONSTRUCTION. IT CONTAINS IMPORTANT

INSTRUCTIONS AND WARNINGS CONCERNING THE ASSEMBLY AND USE OF THIS MODEL.

Entire Contents © 2013 Hobbico,® Inc. All rights reserved.

Champaign, Illinois

(217) 398-8970, Ext 5

airsupport@greatplanes.com

GPMA1806 Mnl

Page 2

TABLE OF CONTENTS

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

ACADEMY OF MODEL AERONAUTICS . . . . . . . . . . . . . 2

SAFETY PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . 2

ADDITIONAL ITEMS REQUIRED . . . . . . . . . . . . . . . . . . . 3

Power System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Radio Control System . . . . . . . . . . . . . . . . . . . . . . . . . 3

Z-Bend Pliers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Tools and Building Supplies . . . . . . . . . . . . . . . . . . . . . 3

LiPo Charger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

KIT INSPECTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

ORDERING REPLACEMENT PARTS . . . . . . . . . . . . . . . . 4

KIT CONTENTS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

ASSEMBLY INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . 5

Test-Mount the Motor . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Prepare the Motor and ESC. . . . . . . . . . . . . . . . . . . . . 7

Hook Up the Elevator. . . . . . . . . . . . . . . . . . . . . . . . . . 8

Make the Aileron Pushrods . . . . . . . . . . . . . . . . . . . . 12

Hook Up the Ailerons . . . . . . . . . . . . . . . . . . . . . . . . . 13

INTRODUCTION

Congratulations and thank you for purchasing the Rifl e 1M

(1-meter). You probably know the “1M’s” little brother and

predecessor, the Rifl e. The Rifl e has been successful beyond

our expectations and we’ve incorporated everything we’ve

learned from it into the 1M. Conveniently, the updates also

make the 1M extraordinarily simple—its basic design and

layout (not to mention complete instruction manual!) make

assembly and installation straight forward without having to

do any scratch-building or fi guring out on your own. Although

the 1M is not made from exotic (and expensive) composites,

its ultra-simplicity will get you into the air easily, quickly

and economically. But don’t forget, it’s still wicked-fast too!

Someday you may aspire to step up to the big leagues and

buy one of those high-end, all-out racers you’ve heard about,

but even then you’ll want to keep your 1M on-hand and fl ightready for whenever you’re craving some fast and easy fun!

For the latest technical updates or manual corrections to the

Rifl e 1M visit the Great Planes web site at www.greatplanes.

com. Open the “Airplanes” link, then select the Rifl e 1M

ARF. If there is new technical information or changes to this

model a “tech notice” box will appear in the upper left corner

of the page.

ACADEMY OF MODEL AERONAUTICS

If you are not already a member of the AMA, please join! The

AMA is the governing body of model aviation and membership

provides liability insurance coverage, protects modelers’

rights and interests and is required to fl y at most R/C sites.

Academy of Model Aeronautics

5151 East Memorial Drive

Muncie, IN 47302-9252

Tele. (800) 435-9262

Fax (765) 741-0057

Or via the Internet at: http://www.modelaircraft.org

PREPARE THE MODEL TO FLY . . . . . . . . . . . . . . . . . . . 15

Check the C.G.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Set the Control Throws. . . . . . . . . . . . . . . . . . . . . . . . 16

FINAL PREPARATIONS . . . . . . . . . . . . . . . . . . . . . . . . . 17

Identify Your Model . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Propeller Balancing . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Prefl ight Ground Check . . . . . . . . . . . . . . . . . . . . . . . 18

Set a Flight Timer. . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Spare Propellers . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Select a Proper Flying Site . . . . . . . . . . . . . . . . . . . . 19

FLYING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Motor Safety Precautions. . . . . . . . . . . . . . . . . . . . . . 19

Hand Launch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Flying . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Landing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Lateral Balance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Final Thoughts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

IMPORTANT!!! Two of the most important things you can

do to preserve the radio controlled aircraft hobby are to

avoid fl ying near full-scale aircraft and avoid fl ying near or

over groups of people.

SAFETY PRECAUTIONS

Protect Your Model, Yourself & Others…

Follow These Important Safety Precautions

1. Your Rifl e 1M should not be considered a toy, but rather a

sophisticated, working model that functions very much like a

full-size airplane. Because of its performance capabilities, the

1M, if not assembled and operated correctly, could possibly

cause injury to your se lf or spect ator s and damage to prope rty.

2.

You must assemble the model according to the

instructions. Do not alter or modify the model, as doing so

may result in an unsafe or unfl yable model. In a few cases

the instructions may differ slightly from the photos. In those

instances the written instructions should be considered as

correct.

3. You must use an R/C radio system that is in good condition,

a correctly sized motor, and other components as specifi ed

in this instruction manual. All components must be correctly

installed so that the model operates correctly on the ground

and in the air. You must check the operation of the model

and all components before every fl i g h t .

4. While this kit has been fl ight tested to exceed normal use,

if the plane will be used for extremely high stress fl ying, or if

a motor larger than one in the recommended range is used,

the modeler is responsible for taking steps to reinforce

the high stress points and/or substituting hardware more

suitable for the increased stress.

5. WARNING: The fuselage, wing and horizontal stabilizer

included in this kit are made of fi berglass, the fi bers of which

may cause eye, skin and respiratory tract irritation. Never

blow into a part to remove fi berglass dust, as the dust will

2

Page 3

blow back into your eyes. Always wear safety goggles, a

particle mask and rubber gloves when grinding, drilling and

sanding fi berglass parts. Vacuum the parts and the work

area thoroughly after working with fi berglass parts.

We, as the kit manufacturer, provide you with a top quality,

thoroughly-tested kit and instructions, but ultimately the

quality and fl yability of your fi nished model depends on how

you build it; therefore, we cannot in any way guarantee the

performance of your completed model, and no representations are expressed or implied as to the performance or

safety of your completed model.

NOTE: Some technically-minded modelers who wish to

check the wing, stab and motor thrust angles may do so by

visiting the web site at www.greatplanes.com and clicking

on “Technical Data.”

Remember:

to end up with a well-built model that is straight and true.

Take your time and follow the instructions

ADDITIONAL ITEMS REQUIRED

Power System

Radio Control System

To take full advantage of the dual aileron servos, a 5-channel

programmable radio is required. It will let you operate the

aileron servos separately as ailerons, and together as

“spoilerons” to aid in landing. You could also use a regular,

non-programmable 4-channel radio and link the aileron

servos with a Y-connector, but spoilerons will not be available.

Three micro servos in the 20 oz-in [1.5 kg-cm] torque range

are also required. Futaba digital, metal gear S3156 servos

(FUTM0656) could be considered slightly overkill, at 28 oz-in

[2.0 kg-cm] torque. But their durability has been proven in this

type of plane and will give you peace of mind. Metal gears aren’t

absolutely necessary, however. Futaba S3157 digital servos

(FUTM0657) or S3117 servos (FUTM0417) are also suitable.

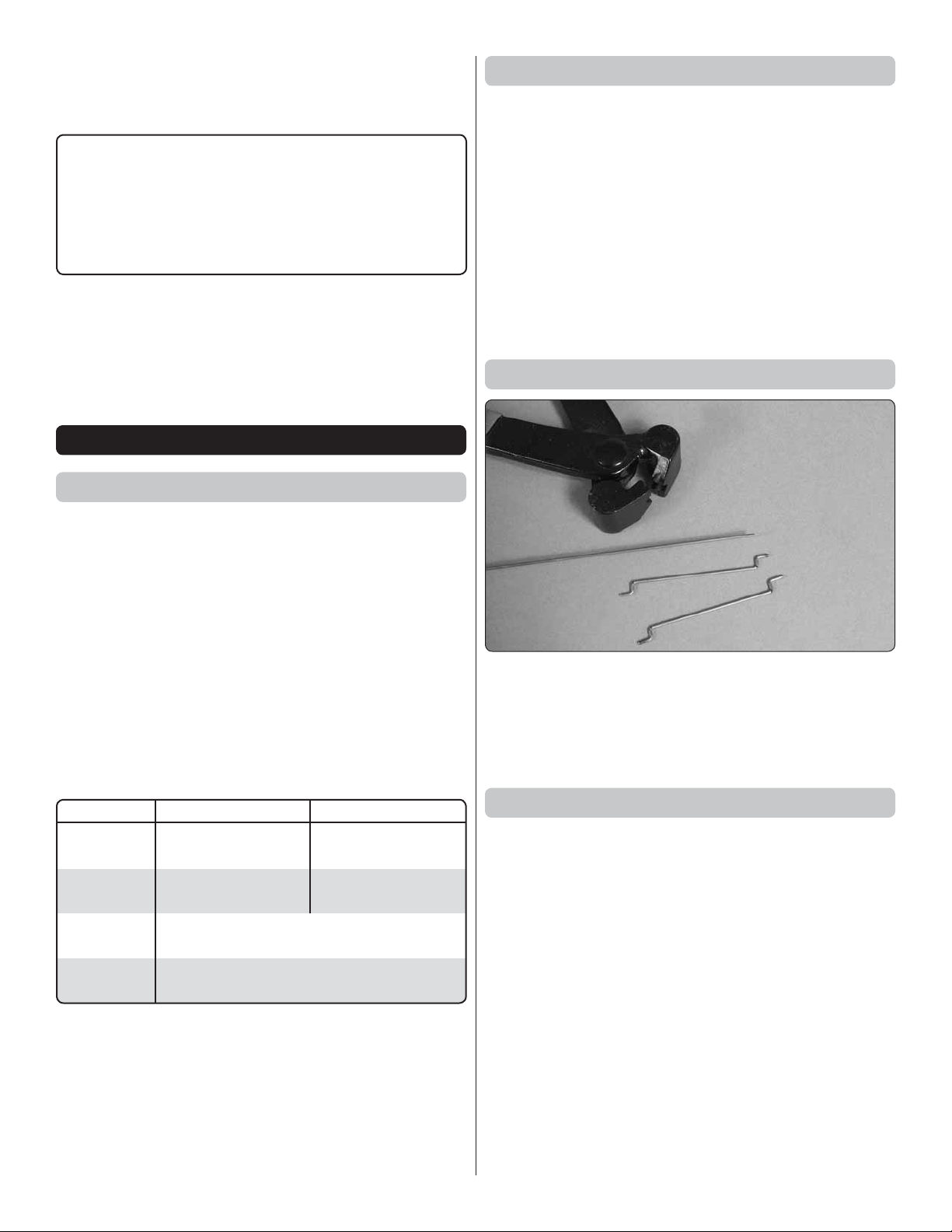

Z-Bend Pliers

Two power setups are recommended for the Rifl e 1M; a

speed setup and a sport setup. Simply, the speed setup

will get you approximately 130mph and the sport setup will

get you approximately 100mph. If you’re all about speed,

then you’ve already made your decision! But for those who

may be unsure, the beauty of the sport setup is that the

1M will still have that thrilling “zip,” but will be less powerful

and lighter—making it natural to fl y and land slower and

closer and perform conventional aerobatics such as loops,

rolls and inverted circuits almost the same as a “regular”

plane. Conveniently, the only difference between the two

setups is the propeller and battery, so when you’re ready

to step up all you’ll have to do is mount a new prop, slip in

a different battery and recheck the C.G.! Following are the

recommended power components for each:

SPEED setup SPORT setup

BATTERY

PROPELLER

MOTOR

ESC*

*Note: The Castle Creations Ice Lite 50 features in-

fl ight data logging. To take advantage of Data Logging

and view important information such as current, Watts,

RPM, etc., the Castle Link USB Programming Kit is

also required (CSEM9999).

See page 18 for discussion and more data about

these two setups including Watts, current, fl ight time,

propellers options, etc.

3S 2200mAh 30C

LiPo (GPMP0861)

APC 4.5x4.1

(APCQ4840)

28–45– 3600 Ammo Brushless

Inrunner (GPMG5220)

Castle Creations Ice Lite 50

(CSEM6900)

2S 2200mAh 30C

LiPo (FPWP6197)

APC 5.25x6.25

(APCQ4096)

In addition to the list of tools and building supplies listed below,

we wanted to specifi cally note that Z-bend pliers (HCAR2000)

will be required to make the aileron pushrods. A length of

straight wire is included, but the wires must be cut to length

and Z-bends made on both ends. Don’t skimp on this important

tool which is a “must-have” for your hobby work bench anyway.

Tools and Building Supplies

Other than ordinary hobby tools, the following items were

used to assemble the Rifl e 1M as illustrated in this manual:

❍ Zap Goo (for gluing in servos) (PAAR3200)

❍ Electrical solder, soldering iron

❍ Great Planes 3/16" heat shrink tubing (GPMM1056)

❍ Du-Bro 1/8" [3mm] double-sided foam mounting tape

(DUBQ3551)

❍ Deans® Ultra Plug® Male connector (WSDM1302)

❍ 30-Minute Epoxy (GPMR6043)

❍ (2) 6" [150mm] servo extensions for aileron servos to

receiver (FUTM4506 for Futaba)

❍ Spare propellers (See page 19 for more about

propellers)

OPTIONAL: M3 x 5 button-head motor mounting screws (to

upgrade the M3 x 5 Phillips screws included with the Ammo

motor) (HPIC3250). If button-head screws are used, a

quality, 2.0mm Allen hex driver such as a Duratrax Ultimate

Hex Driver (DTXR0289) is also recommended.

3

Page 4

LiPo Charger

A balancing LiPo battery charger is required. Both the Triton

EQ (GPMM3155) and Triton 2 EQ (GPMM3156) are perfect

for the size of batteries used in the Rifl e 1M. At 50 watts

AC the EQ can charge a 3S 2200mAh battery at nearly 2C

taking a little less than 30 minutes. At 100 watts AC the 2 EQ

can charge batteries even faster. Both chargers also require

a banana plug-to-Deans charge lead (GPMM3418).

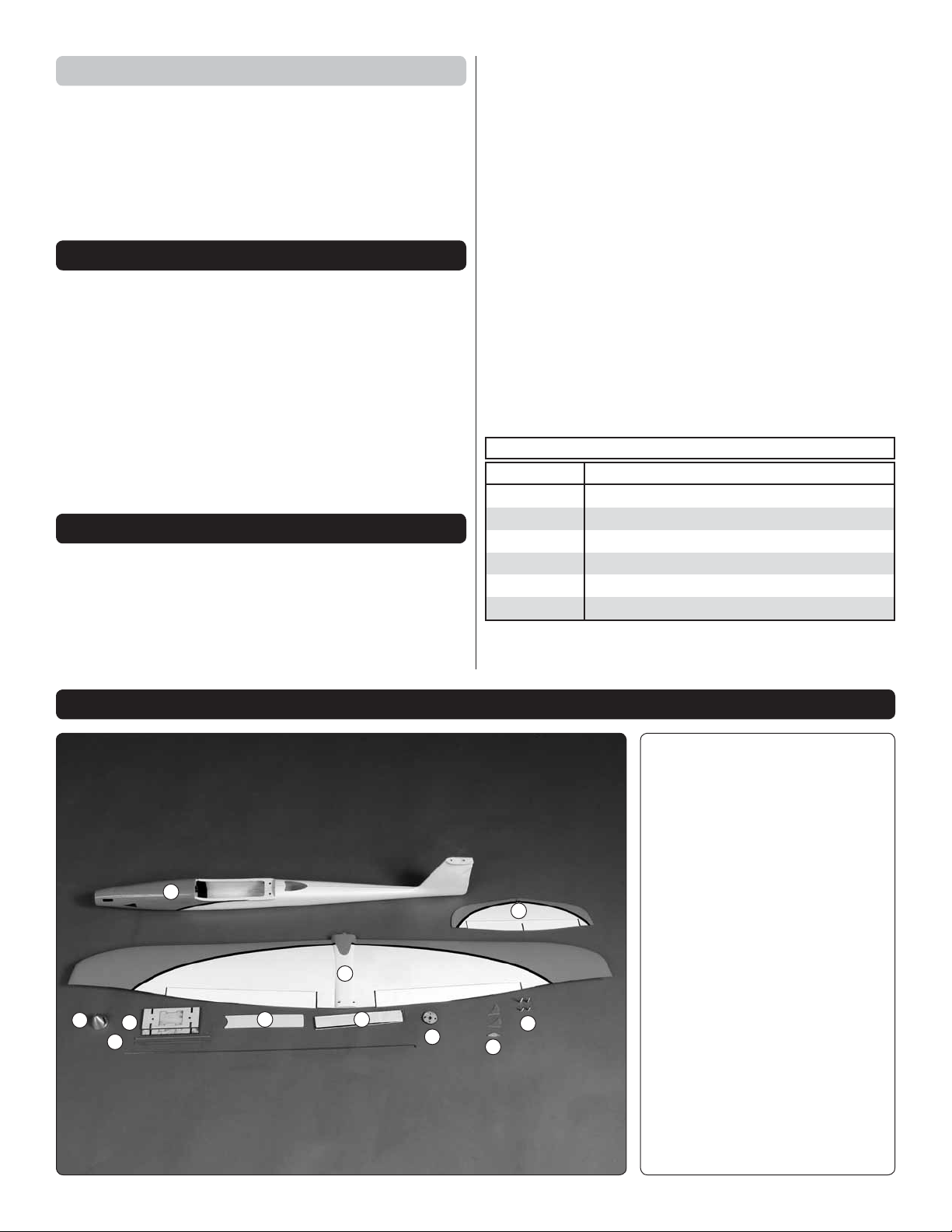

KIT INSPECTION

Before starting to build, take an inventory of this kit to make

sure it is complete, and inspect the parts to make sure they

are of acceptable quality. If any parts are missing or are

not of acceptable quality, or if you need assistance with

assembly, contact Product Support. When reporting

defective or missing parts, use the part names exactly as

they are written in the Kit Contents list.

Great Planes Product Support

3002 N Apollo Drive, Suite 1 Ph: (217) 398-8970, ext. 5

Champaign, IL 61822 Fax: (217) 398-7721

E-mail: airsupport@greatplanes.com

ORDERING REPLACEMENT PARTS

Replacement parts for the Great Planes Rifl e 1M are available

using the order numbers in the Replacement Parts List

that follows. The fastest, most economical service can be

provided by your hobby dealer or mail-order company.

To locate a hobby dealer, visit the Great Planes web site

at www.greatplanes.com. Choose “Where to Buy” at the

bottom of the menu on the left side of the page. Follow the

instructions provided on the page to locate a U.S., Canadian

or International dealer.

Parts may also be ordered directly from Hobby Services by

calling (217) 398-0007, or via facsimile at (217) 398-7721,

but full retail prices and shipping and handling charges will

apply. Illinois and Nevada residents will also be charged

sales tax. If ordering via fax, include a Visa or MasterCard

number and expiration date for payment.

Mail parts orders Hobby Services

and payments by 3002 N Apollo Drive, Suite 1

personal check to: Champaign IL 61822

Be certain to specify the order number exactly as listed in

the Replacement Parts List. Payment by credit card or

personal check only; no C.O.D.

If additional assistance is required for any reason contact

Product Support by e-mail at productsupport@greatplanes.

com, or by telephone at (217) 398-8970.

REPLACEMENT PARTS LIST

Order No. Description

GPMA3400

GPMA3401

GPMA3402

GPMA3403

GPMA3404

GPMA3405

Wing Set

Fuselage Set

Horizontal Stabilizer Set

Aileron Hatch Covers

Spinner

Decal Set

KIT CONTENTS

Kit Contents

1.

Fuselage

2.

Wing

3.

Horizontal Stabilizer

4.

1

3

2

4

5

6

7

8

9

11

10

Spinner Assembly

5.

Balance Stand

6.

Elevator Pushrod

7.

Battery Spatula

8.

Velcro

9.

Motor Drill Guide

10.

Control Horns

11.

Screws

4

Page 5

ASSEMBLY INSTRUCTIONS

ESC

Bullet

Battery

Motor

wires

19mm dia.

16mm dia.

45°

Plywood motor mount template

(for Ammo and other motors with

standard 16mm/19mm spacing)

Rotate 45° for

Neu motors

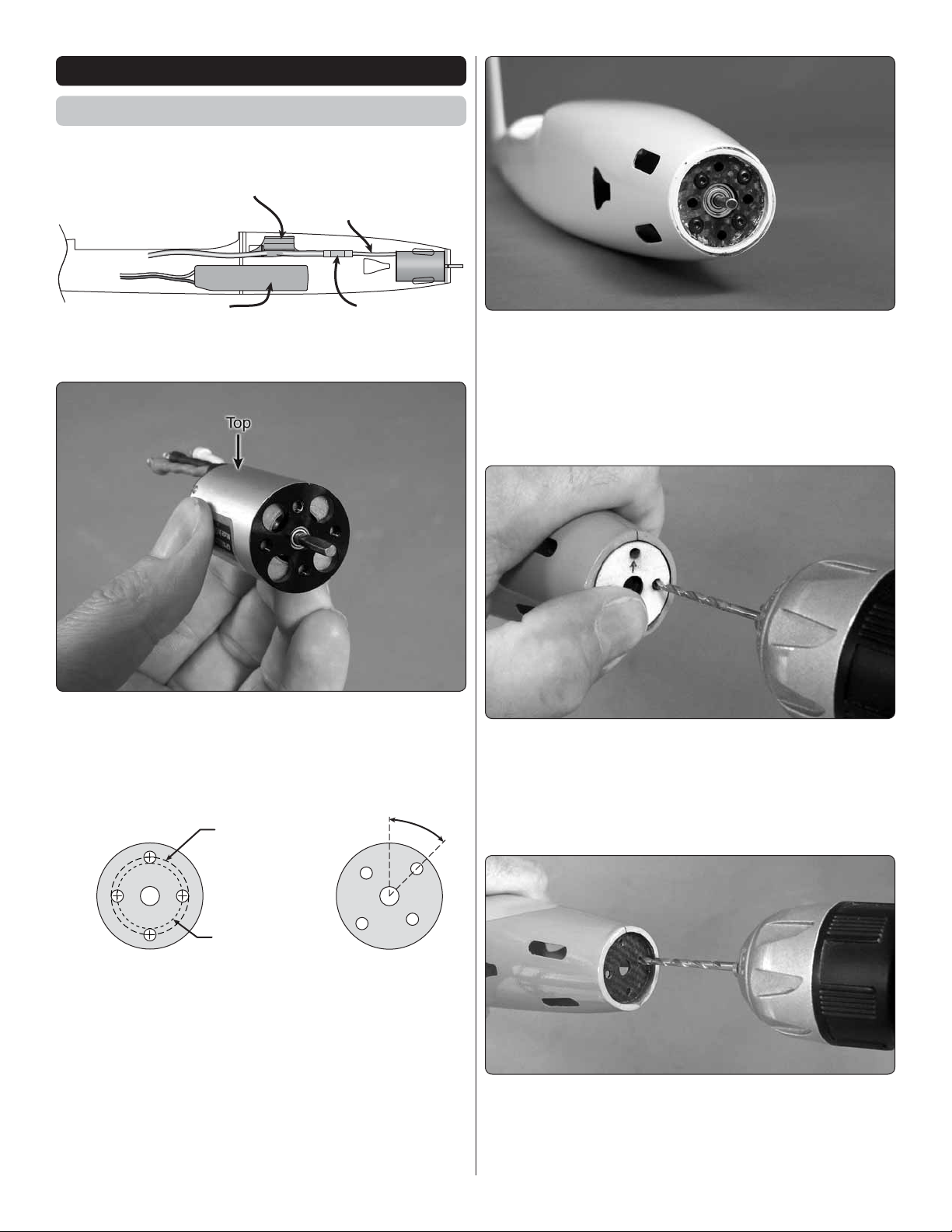

Test-Mount the Motor

connectors

1. Determine how to orient the mounting holes in your

❏

motor so the wires will be positioned as preferred—usually

it’s best to have the wires coming out the top positioning the

ESC over the battery.

NOTE: If contemplating switching to a different motor in the

future, don’t be too concerned about the possibility of new

motor mounting screw holes that may overlap or interfere with

the old holes. Most of the mounting patterns are standard.

We’ve mounted both Ammo motors and other motors to a

couple of different Rifl es, and although four more holes were

required, this didn’t present any problems.

3. Using the plywood template as a guide, drill #40 – #37

❏

(.098" – .104" [2.5mm – 2.6mm]) pilot holes through the

motor mount. Note: The motor mount is made from carbon

fi ber which can be diffi cult to drill, so although the fuselage

is held horizontally in the image, it will be easier to drill the

holes if holding the fuselage vertically resting on its tail.

2. If using the recommended Ammo motor (or any other

❏

motor with the same, standard “16mm/19mm” screw hole

spacing), position the included plywood motor mount

template on the motor mount in the fuselage to get the

mounting holes oriented as described in the previous step.

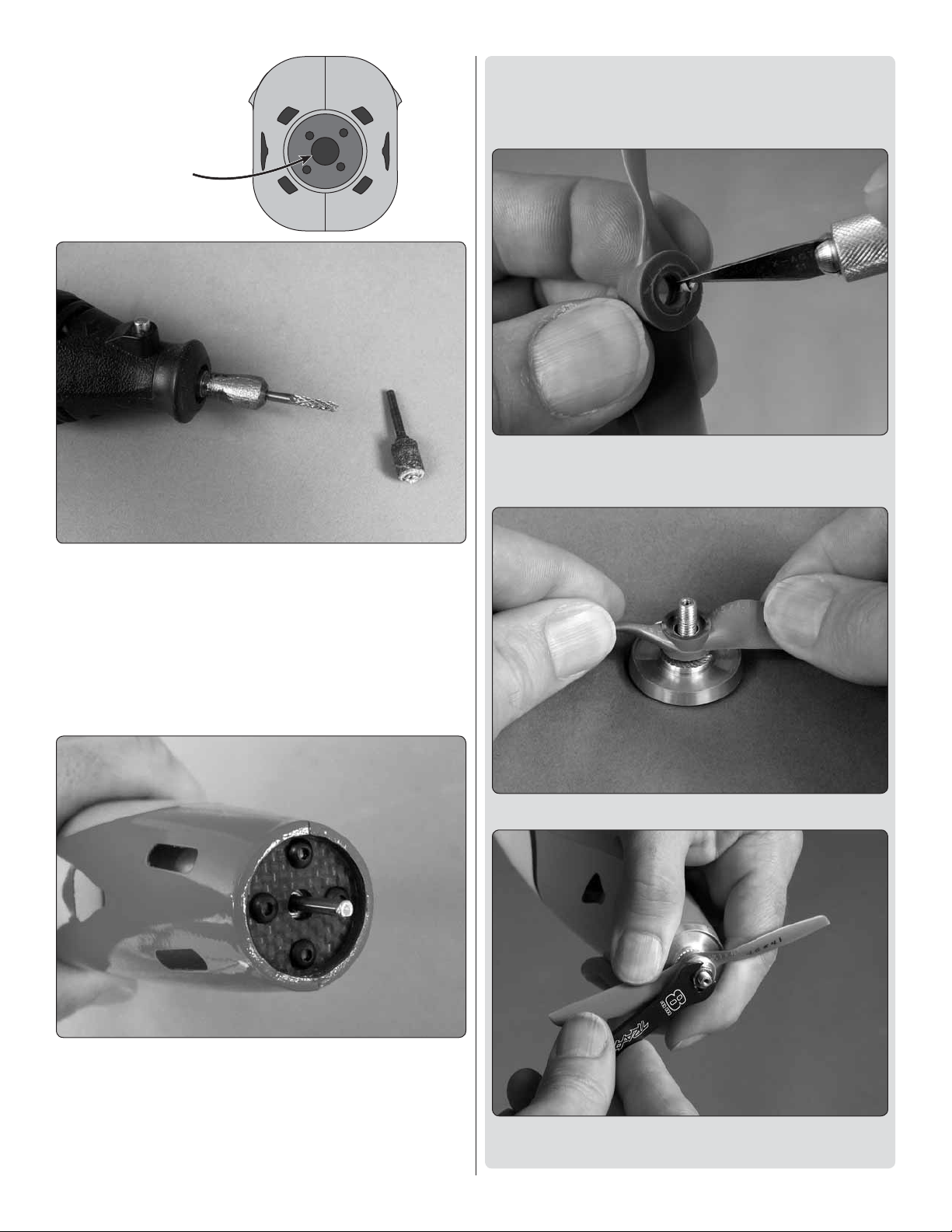

4. If using a motor that uses 2.5mm mounting screws

❏

skip this step. If using an Ammo motor (or any other motor

that uses 3mm mounting screws), remove the template and

enlarge the pilot holes with a #32 – #30 (.116" – .128") or

1/8" [3.2mm] drill.

5

Page 6

Enlarge as

necessary

PROPELLER MOUNTING

The collet shaft included with your Rifl e spinner is designed

to work with the small O.D. propeller spacer ring that comes

with all APC speed 400 propellers.

A. To prep the prop, press the spacer all the way into

❏

the propeller hub. Then use a #11 blade to carefully trim

any fl ashing from around the inside of the spacer.

5. The front bearing on some motors protrudes slightly

❏

from the front of the motor. If this is the case for your motor,

use a Dremel with a tile cutter bit and/or a small drum sander

to enlarge the hole as necessary. Proceed slowly and with

care to keep the hole centered and so as not to over enlarge

the hole—this may require test-fi tting the motor as you

proceed. CAUTION: Wear protective gloves, a long-sleeve

shirt and breathing and eye protection whenever working

with carbon fi ber.

B. Firmly press the propeller onto the collet shaft.

❏

❏

screws—if using the recommended Ammo motor you may

use the M3 x 5 screws included with the motor, but some

prefer button-head Allen screws instead (such as the screws

shown in the photo—HPIC3250).

6. Test-mount the motor with your motor mounting

C. An 8mm wrench is a must for your tool box. A Traxxas

❏

8mm fl at wrench is pictured here (TRAR5478).

6

Page 7

13mm-14mm

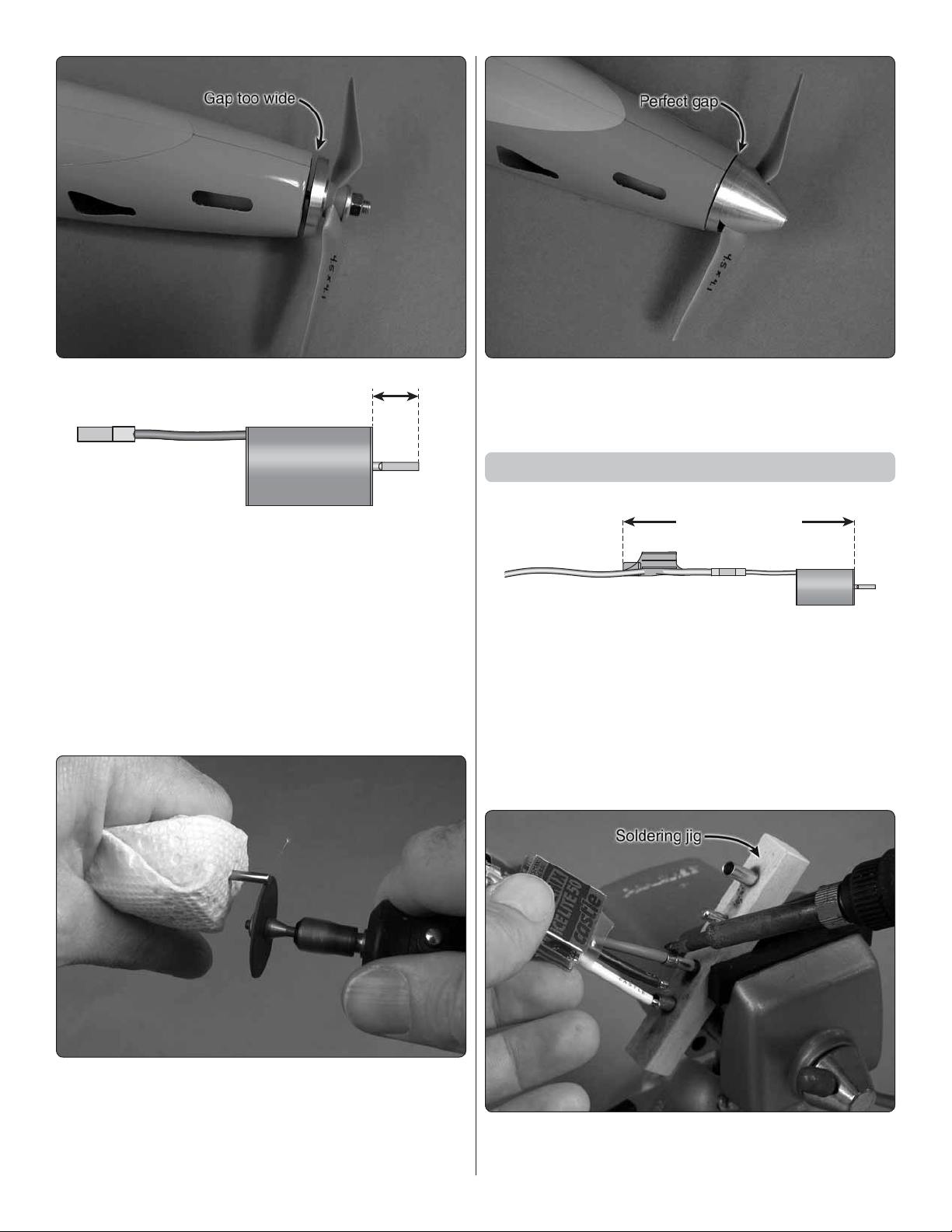

7. Test-mount the propeller and spinner to the motor. It is

6-1/2" – 7"

[165mm-175mm]

❏

likely that the motor shaft will have to be shortened to set the

spinner close enough to the fuselage—it is desirable to have

the shaft as long as possible to give the collet shaft as much

material as possible to “grab” onto, yet still have the desired

spacing between the fuselage and spinner. The proper

spacing is such that the spinner is as close to the fuselage

as possible without touching—a gap just wide enough to see

light through. Typically, a maximum of 13mm—14mm and a

minimum of about 10mm—11mm of motor shaft will work. In

the case of the Ammo motor used here, approximately 2mm

will have to be cut.

9. Use a metal fi le or sandpaper to deburr the end of the

❏

shaft. Remount the motor and test-fi t the spinner to see if the

gap is right. Make adjustments if necessary.

Prepare the Motor and ESC

1. As shown in the illustration at step 1 on page 5, the

❏

ESC fi ts best inside the fuselage resting over the battery

ahead of the wing. Usually, this requires cutting the three

motor wires from the ESC just about as short as practically

possible—the distance available between the front of

the motor and the back of the ESC is about 6-1/2" to 7"

[165mm - 175mm]. Determine the length of wires needed

from your ESC (taking into account the length of the bullet

connectors), and then cut the wires to length.

8. Remove the motor from the fuselage and cut the

❏

shaft—a Dremel with a reinforced cutoff wheel works best.

Wear safety glasses and protect the motor from metal dust

while cutting.

2. If using the recommended Ammo motor, solder the

❏

female bullets that came with the motor onto the motor wires

on the ESC. You can make a handy soldering jig by drilling

7

Page 8

holes in a wood block for anchoring spare male bullets to

hold the female bullets while you solder. (You may also

solder the motor wires directly to the ESC if this is your

preference, but don’t forget to slide on the heat shrink tubing

fi rst and check the motor direction.)

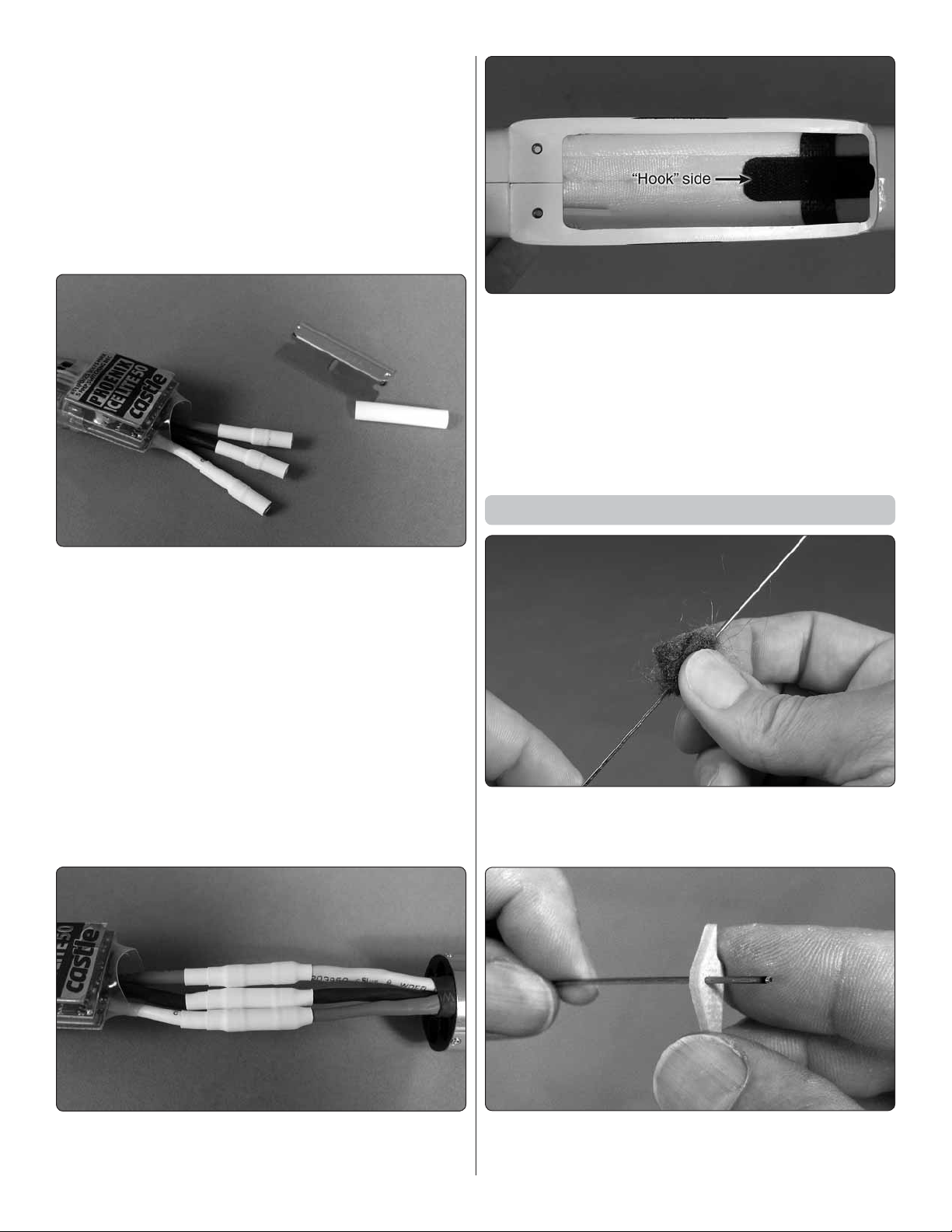

3. Slide pieces of heat-shrink tubing over the battery

❏

wires on the other end of the ESC. Then solder your battery

connector to the wires—ElectriFly and ThunderPower

batteries use Deans Ultra Plug connectors, so a Deans Ultra

Plug male was used on the ESC in this manual.

8. Before mounting the motor, apply the rougher, “hook”

❏

side of the included Velcro strip to the bottom of the fuselage

in the approximate location shown. Apply just a couple of

drops of thin CA around the edges of the Velcro to securely

hold it in place.

9.

Mount the motor with the mounting screws lightly “wetted”

❏

with non-permanent threadlocker, but do not mount the prop

and spinner until later after the radio has been set up.

Hook Up the Elevator

4. Slip pieces of 3/16" [5mm] heat shrink tubing over the

❏

bullet connectors. Then use a heat gun to shrink the tubing.

Also shrink the tubing over the wires on the battery connector.

5. If you haven’t yet done so, set up a program in your

❏

radio dedicated to this model. Be certain the fl ight trims

and sub trims are zeroed. In most cases you’ll also have to

reverse the direction of the throttle channel.

6. Temporarily connect the motor to the ESC and hook

❏

up the receiver and a battery so you can run the motor with

the transmitter. Make sure the motor is turning in the correct

direction. If not, disconnect the ESC from the motor and re

connect it with the wires in a different order so the motor will

be turning the correct direction.

1. Use steel wool or fi ne sandpaper to polish the elevator

❏

pushrod and remove any contaminants or oxidation. Remove

any burrs on the end of the wire with a metal fi le or sandpaper.

7. IMPORTANT!: Slip three more pieces of 3/16" [5mm]

❏

shrink tubing over each bullet connection and shrink with a

heat gun to make sure the connections will remain secure.

2. Test-fi t the pushrod into the elevator horn to make sure

❏

it fi ts—it should fi t with no free play. If necessary, enlarge the

hole with a #56 (.046") [1.18mm] drill.

8

Page 9

3. Use medium-grit sandpaper to roughen the elevator

6mm-8mm

90°

❏

horn and the bottom of the elevator around both sides of the

slot for the horn (if preferred, the rest of the elevator can be

protected with masking tape).

5. Temporarily connect your elevator servo and ESC to

❏

the receiver with a battery and turn on the transmitter so you

can power the servo. Again, make certain there are no mixes

setup in your transmitter and that all the trims and sub trims

are zeroed.

❏

30-minute epoxy to securely glue the horn to the elevator.

Note: If preferred, CA may also be used, but it must be

foam-safe CA.

4. Using care not to get any glue in the pushrod hole, use

6. Use a servo arm that has holes 6mm – 8mm out.

❏

Position the arm on the servo so it will be 90°, or as close as

90° as possible. If necessary, dial in some elevator sub trim

to get the arm 90°. Cut off the unused arms.

7. Install the screw that secures the servo arm—if using a

❏

servo with metal gears use threadlocker on the threads fi rst.

9

Page 10

8. Connect the elevator pushrod to the elevator servo and

❏

slide the pushrod into the guide tube placing the servo in the

fuselage. Position the servo so the arm will be approximately

1-1/2" [40mm] from the end of the guide tube as shown.

9. Once you have your servo where you want it, cut

❏

the other end of the pushrod protruding from the vertical

stabilizer to a length of 1" [25mm].

11. With the elevator servo laying fl at on the bottom of

❏

the fuselage, make a sharp, 90° bend to the left 1/4" [6mm]

from the end.

10. Remove the pushrod/servo assembly from the

❏

fuselage and de burr the end again. Add a thin fi lm of oil to

the pushrod, and then reinstall in the fuselage.

12. Temporarily connect the elevator horn to the pushrod

❏

and mount the horizontal stabilizer to the top of the fuselage

with the two included M3 x 10 fl at-head Phillips screws. Move

the elevator up and down with your fi ngers. You’ll probably

notice that the elevator is easier to move at the ends of its

throw than it is to move near center. This means the pushrod

needs one more slight bend backward about 1/4" [6mm]

ahead of the 90° bend.

10

Page 11

13. Remove the stabilizer and disconnect the pushrod,

❏

make that additional bend back, remount the stab and

then test the elevator movement again. Adjust the angle of

the bend as necessary until the elevator moves smoothly

around center. Note: If, for some reason, you ever need to

make a new elevator pushrod, one can be made from K&S

.047" [1.2mm] music wire.

14. Mount the wing to the fuselage and check the

❏

alignment of the horizontal stab. If necessary, remove the

stab and sand the “high side” of the stab saddle to get the

stab aligned with the wing.

15. Once you have the elevator working the way you want

❏

it, wet the threads of the stab screws with threadlocker and

remount.

Zap Goo (PAAR3200) is recommended for gluing in the

servos. “Goo” adheres extremely well, yet is just fl exible

enough so that if ever necessary, the servos can be extracted.

Any residual Goo can be peeled off the servos and the plane,

making it easier to remount new servos again.

16. Clean the servo mounting surface and the bottom of

❏

the fuselage with a cloth dampened with denatured alcohol.

Turn on your transmitter and power up the servo by connecting

a battery. With the radio on and the servo centered, use Zap

Goo to securely glue the servo to the bottom of the fuselage,

positioned so the elevator will be centered. Clamping or

sustained pressure is not necessary—just push down on the

servo, make sure some of the glue squeezes out, doublecheck that the elevator has remained centered, and then

disconnect the battery. Turn off the transmitter and allow the

glue to dry overnight.

11

Page 12

18. Connect the elevator servo, ESC and two 3" – 6"

❏

[75mm – 300mm] servo extensions for the aileron servos

to the receiver. Tip: If your ESC has data logging (as does

the recommended Ice Lite 50), connect the ESC to the

receiver via. another 3" [75mm] servo extension. This way,

when downloading data, all you will have to do is disconnect

the ESC from the extension (rather than disconnecting the

ESC from the receiver) simplifying the procedure. Also, label

the two aileron extensions coming from the receiver with the

appropriate channel numbers for easier identifi cation when

connecting the ailerons later.

Make the Aileron Pushrods

There may be other ways to make Z-bends on the ends of

wires without using Z-bend pliers, but Z-bend pliers make

the shortest, sharpest, most accurate bends, so Z-bend

pliers are strongly recommended.

17. Determine where you are going to mount your receiver

❏

and test-fi t it into position—there may be room ahead of the

elevator servo, but the receiver will be out of the way if you

can mount it through the cooling hole behind the wing. Apply

strips of 1/8" [3.2mm] double-sided adhesive foam mounting

tape to the bottom of your receiver. Then mount the receiver

in the fuselage.

1. Cut one 3" [75mm] wire from the included 1.2mm

❏

x 300mm pushrod wire. Use a fi ne-point felt-tip pen to

accurately mark two lines on the wire 1-7/8" [48mm] apart.

2. Use your Z-bend pliers to make the fi rst Z-bend at one

❏

of the marks.

12

Page 13

Hook Up the Ailerons

5–10° 5–10°

Right

aileron servo

Left

aileron servo

1. Connect the aileron servos to the extensions coming

❏

out of the fuselage from the receiver. Connect a battery

and turn on the transmitter so you can operate the servos.

Program a mix so the servos respond opposite each other in

the correct direction to aileron control stick inputs.

❏

as shown. View the wire from the end making sure the fi rst

Z-bend is laying horizontally to the next Z-bend (as shown in

the top photo). Squeeze the pliers to make the second bend.

❏

1-7/8" [48mm] apart. Cut the ends of the wires approximately

1/8" [3mm] from the ends of the Z-bends and use a metal fi le

or a reinforced cutoff wheel to square and de burr the ends.

❏

3. Load the other end of the wire into the Z-bend pliers

4. You should now have a pushrod wire with Z-bends

5. Make another aileron pushrod the same way.

2. Same as was done for the elevator servo, connect

❏

servo arms that will be angled slightly forward at about a 5°

to 10° angle. Cut off the unused arms. If necessary, use the

sub trims to get both arms the same angle.

3. Secure the servo arms to the servos with the screws—

❏

use threadlocker if the output shaft is metal.

4. Use medium-grit sandpaper to sand any residual foam

❏

from the underside of the top wing skin to which the aileron

servos will be glued. Tip: This is easily done with adhesiveback sandpaper stuck to your fi nger.

13

Page 14

5. Disconnect the servos and guide the leads through

❏

the channels in the wing out the hole in the middle. Lay the

servos down inside the wing and position the hatch covers

just to see how everything fi ts.

6. Same as was done for the elevator and elevator horn,

❏

scuff the sides of both fi berglass aileron horns around the

base and the bottom of the ailerons around the slots for the

horns so glue will adhere.

the horn and servo align and that the arm and pushrod are

centered in the opening. If necessary, adjust the bends in

the ends of the pushrod to achieve this alignment.

9. Use 30-minute epoxy to securely glue the aileron horn

❏

into the aileron.

10. Repeat the previous three steps for the right aileron

❏

servo.

7.

Use tape to hold the root ends of the ailerons centered

❏

and aligned with the wing. Connect one of the aileron pushrods

you made to a hole 6mm – 8mm out in the left aileron servo

arm and into the outer hole in one of the aileron horns.

11.

The same way you glued down the elevator servo,

❏

clean the aileron servos and the wing skin in the hatches

with a cloth dampened with denatured alcohol. With the radio

on and the ailerons centered, glue the servos into position

with Zap Goo. Temporarily place the hatch covers over the

servos to make sure the arms and pushrods are centered in

the openings. Make any adjustments necessary, remove the

hatches and make sure the servos are pressed down and

securely glued to the wing skin. Allow the glue to dry overnight.

8. Slit the edge of the left hatch cover opening so it can

❏

be fi t over the pushrod and placed over the hatch. Make sure

12. Use clear tape to hold the aileron hatch covers to the

❏

wing.

14

Page 15

PREPARE THE MODEL TO FLY

1-3/16" [30mm]

Recommended starting balance point

Do not overlook the following two important procedures.

The C.G. and control throws have been determined by

thorough testing and record keeping. Later, you may wish

to change the C.G. and throws to suit your taste, but the

C.G. and throws specifi ed in the manual are a safe starting

point and will give you the greatest chances for success.

Check the C.G.

1. Sharpen one end of the dowels for the included

❏

balance stand. Assemble and glue together the stand. (The

completed stand is pictured on page 16.)

2. Mark the leading edge of the bottom of the wing in

❏

alignment with the tips of the dowels.

3. Lay 2" [50mm] strips of vinyl tape (or similar) on the

❏

bottom of the wing aligned with the marks. Use a fi ne-point

felt-tip pen to draw lines across the strips 7/8", 1-3/16" and

1-1/2" [22mm, 30mm and 38mm] back from the leading edge.

4.

Attach a strip of the softer, “loop” side of the included

❏

Velcro strip to your battery—note that only a narrow strip is

required. This is enough to securely hold the battery in position

during fl ight and will make it easier to remove the battery.

5. Temporarily mount the prop and spinner and the wing.

❏

At this time all components must be installed in the model.

15

Page 16

6. Place the Rifl e on the C.G. stand supported by the

❏

dowels on the tape strips on the bottom of the wing. If

necessary, remove the wing to adjust the location of the

battery so the Rifl e balances at the middle marks 1-3/16"

[30mm] from the leading edge of the wing. NOTE: The Rifl e

fl ies well balanced anywhere between the forward and aft

balance marks, but for initial fl ights we advise beginning at

the recommended point.

8. Bevel the front of the included plastic “battery spatula”

❏

and slide it under the battery for easier removal.

Set the Control Throws

1. Remove the propeller and spinner.

❏

2. Connect the battery to the ESC and turn on the

❏

transmitter. If necessary, adjust the sub-trims in your

transmitter so the ailerons and elevator are centered.

7. Once you fi nd the location of the battery that allows

❏

the Rifl e to balance, remove the wing and mark the battery

location so it will be repeatable out at the fl ying fi eld.

3. Measure the throws and use the programming in your

❏

transmitter to make adjustments as necessary. NOTE: The

throws are measured at the widest part of the elevator and

ailerons.

16

Page 17

These are the recommended control surface throws:

ELEVATOR

LOW RATE

AILERONS

SPOILERONS

*Important: High-rate elevator is used for landing only. Do not

hand-launch or switch to high rates until the power has been

cut and you are ready to land.

HIGH RATE

3/16"

[5mm]

11°

Up

3/16"

[5mm]

9°

Up

5/16"

[8mm]

18°

Up*

5/16"

[8mm]

16°

Up

5/16" [8mm] 16° Up

(1/16" [1.5mm] 3° Up Elevator Mix)

3/16"

[5mm]

11°

Down

3/16"

[5mm]

9°

Down

1/4"

[6.5mm]

14°

Down

5/16"

[8mm]

16°

Down

4.

If you prefer, also program in some negative exponential

❏

(less control throw around center stick). Exponentials are a

matter of personal taste and also related to your control throws

(which are also a matter of personal taste to an extent), but

we’ve found that approximately 40% and 30% expo works for

high and low-rate elevator respectively, while 35% and 25%

work well for high- and low-rate ailerons respectively.

5.

Spoilerons (“up” aileron defl ection) assist on landing

❏

by inducing drag to slow the model down. While spoilerons

aren’t absolutely necessary for landing (the fi rst half of our

testing regimen was conducted without spoilerons), spoilerons

defi nitely help on landing by shortening the glide. Spoilerons are

especially helpful during calm conditions where, without a head

wind, the Rifl e will just keep fl oating and fl oating by. In addition

to spoilerons, approximately 1/16" [1.5mm] of “up” elevator mix

to spoilerons is desirable. Upon deployment of spoilerons, the

Rifl e will initially balloon upward, but after it bleeds off enough

speed and nears the landing zone the “up” elevator mix will

partially dampen out your minute elevator corrections, helping

maintain a more even glide path. It is recommended to link your

spoilerons to an easily accessible, adjustable slider or dial so

you can modulate the precise degree of spoilerons depending

on the fl ying conditions and airspeed.

FINAL PREPARATIONS

Identify Your Model

No matter if you fl y at an AMA sanctioned R/C club site or

if you fl y somewhere on your own, you should always have

your name, address, telephone number and AMA number

on or inside your model. It is required at all AMA R/C club

fl ying sites and AMA sanctioned fl ying events. Fill out the

identifi cation label on the decal sheet and stick it on or inside

your model.

Propeller Balancing

You probably won’t fi nd anybody who will recommend you

not balance your propellers. But realistically, fi nding a

balancer that can detect extremely minute differences in

the propeller blade weight of a prop that weighs fractions of

an ounce to begin with, and taking the time to painstakingly

balance a consumable propeller that may last only a single

fl ight anyway, seems futile. We’ve put hundreds of fl ights on

our Ammo motors with props straight out of the package.

Whenever running up the motor before you launch, listen

and feel for excess vibration. If the prop is out-of-balance,

either “re clock” it on the spinner shaft until you get it to run

smoothly, or discard the propeller altogether.

17

Page 18

Prefl ight Ground Check

SPEED setup SPORT setup

BATTERY

PROPELLER

MOTOR

MAX. CURRENT

MAX. WATTS

MAX. RPM

28-45-3600 Ammo (GPMG5220)

3S 2200mAh 30C 2S 2200mAh 30C

APC 4.5 x 4.1 APC 5.25 x 6.25

STATIC IN-FLIGHT STATIC IN-FLIGHT

48A 42A - 45A 45A 34A

520W 475W 300W 230W

34,000rpm 34,400rpm 21,000rpm 21,650rpm

1. Perform a thorough prefl ight exam, double-checking

❏

that everything on the model is safe, sound and secure.

Pay special attention to the servos and linkages and apply

moderate pressure to all the control surfaces, ensuring that

the horns, servos and control surfaces are secure.

2. Review the check list to make sure you haven’t left

❏

anything out:

CHECK LIST

ESC bullets secured to motor bullets with heat-shrink

❏

tubing

Motor securely mounted, threadlocker on screws

❏

Propeller and spinner securely mounted

❏

Motor/prop/spinner turn freely

❏

C.G. checked, battery location marked on wing saddle

❏

Throws checked, controls respond in the correct

❏

direction

Servos leads/servo extensions securely connected

❏

to receiver

Receiver antennas oriented/positioned as specifi ed

❏

by the radio manufacturer

Horizontal stabilizer screws secure with threadlocker

❏

Set a Flight Timer

First on your agenda before fl ying should be setting a fl ight

timer based on a conservative estimate of the length of time

you can fl y. This is both so the motor does not quit unexpectedly

(causing an unplanned landing) and/or so you do not over

discharge your battery. The Rifl e isn’t your typical sport model

that drains the battery slowly. In order to achieve maximum

speed the motor and batteries are pushed near their limit

making it even more important to know what the limits are

and therefore when to stop. The recommended 28-45-3600

Ammo powered by either the sport setup or the speed setup

can withstand continuous, all-out, full-throttle fl ying for the

practical duration of the battery. As shown in the table at the

bottom of the page, the sport setup will draw about 34A at

full-throttle in-fl ight and the speed setup will draw about 45A

at full-throttle in-fl ight. To convert this to fl ight time, divide the

capacity you wish to drain from your battery (the size of your

“fuel tank”) by the current and convert to minutes:

You should strive to consume no more than 80% of your

battery during a fl ight. If using the recommended 2200mAh

battery, your capacity available is then 1760mAh (2200mAh x

.8 = 1760mAh). Convert the capacity to Amp hours by dividing

by 1000; 1760mAh/1000 = 1.76Ah. For the speed setup,

divide 1.76Ah by the average, in-fl ight current (45A) to arrive

at a fl ight time of .039 hours which equals 2.35 minutes (two

minutes, 21 seconds). If using full-throttle exclusively, this is

the recommended run time for the 3S speed setup—2:20. If

you won’t be fl ying full-throttle exclusively, you may lengthen

your fl ight time accordingly.

Though the average, maximum current for the 2S sport

setup is 34A, it is likely that you won’t be fl ying full-throttle

the whole time as it is intended more for beginners or sport

fl ying. Practically, an average fl ight time for the sport setup is

more like 4-1/2 minutes or longer.

Set your timer accordingly. If possible, link your timer to the

throttle stick so you won’t be counting the time that you are

power off. Tip: If your transmitter has two timers, set one

timer a minute shorter than the fi nal timer to act as a “wakeup call” alerting you that you have one minute left.

18

Page 19

Spare Propellers

FLYING

As specifi ed, the APC 5.25 x 6.25 speed 400 propeller is

recommended for the 2S sport setup. However, there are a

few different propeller options for the speed setup. The 4.5 x

4.1 is the fi rst choice, but a 4.7 x 4.25 pulls only slightly more

current and is therefore a suitable option.

In any case, when you get to fl ying your Rifl e often you’ll

want to stock your fl ight box with plenty of spare propellers.

Breaking propellers is one of those funny things where

one day you’ll get fi ve, six, seven or more landings without

breaking a prop. Then, you’ll get that one perfect landing and

the prop will break anyway.

Select a Proper Flying Site

If you’re already experienced with this type of small,

extremely fast airplane, you already know your preferred

fl ying site and fl ying conditions, or are experienced enough

so that you can fl y anywhere any time! But if this is your

fi rst outing with your Rifl e, think about the optimum time and

place to fl y. Clear, blue skies with a moderate breeze and

the sun at your back are the best. A 5mph – 10mph breeze

will not only assist with your fi rst hand-launch, it will also

assist with your fi rst landing. Finally, you’ll also want a site

free from obstacles and pedestrians—the fewer distractions

the better! If you’re a little apprehensive, maybe you could

sneak-in the maiden at your local R/C club site early in the

morning before anybody else arrives.

For obvious reasons, it would also be prudent to have a

spotter keep an eye on your Rifl e with you. Later, after you’ve

become accustomed to fl ying your Rifl e and have your skills

and confi dence where you want, you’ll be able to fl y in any

and all reasonable conditions.

Motor Safety Precautions

Failure to follow these safety precautions may result

in severe injury to yourself and others.

Wear safety glasses whenever running motors.

Keep your face and body as well as all spectators away from

the plane of rotation of the turning propeller.

Keep loose clothing and objects such as pencils or

screwdrivers that may fall out of shirt or jacket pockets away

from the prop.

One fi nal note: Do not fl y unless your senses and decisionmaking abilities are sharp. You’ll need clear vision, quick

reaction time, and full command of all the basics — having

the correct model programmed into your radio, remembering

to do a fi nal control check before launching, and knowing

not to fl y if the conditions exceed your skill level. Always

make sure you’re well-rested and, if the weather is hot, stay

hydrated.

Hand Launch

Experienced pilots already know what to do—make a fi nal

control check, point the Rifl e into the wind, nail the throttle

and throw it hard! But less-experienced pilots should read all

of the fl ying instructions thoroughly.

NOTE: Flying on high-rate or low-rate aileron is up to the

pilot’s preference, but the Rifl e should be launched and

fl own only on low-rate elevator. High-rate elevator is

intended for landing only.

While fl ying with your peers keep in mind that the Rifl e isn’t

your “regular” type of plane. It’s understandable that the

speed and sound can be intimidating and/or distracting to

other pilots who are fl ying—some don’t seem to mind, but

others get nervous or agitated, so always try to be a good

sport and respect your fellow club members’ air space.

Fortunately, the Rifl e is quick to prep and fl ies for such a

short time that it’s easy to “sneak in” a fl ight between the

others whenever there’s a lull in the action.

Experienced pilots or new pilots with a few fl ights under their

belt will be able to launch the Rifl e on their own, but it may

be best for inexperienced pilots to get an assistant to launch

it for them. This way, your fi ngers will be at the controls

ready to make the corrective inputs right away. Try to fi nd an

experienced R/C pilot to do the launch. With all due respect,

please don’t solicit your child or signifi cant other. Those not

experienced in R/C usually underestimate the velocity with

which the plane must be thrown and don’t understand the

importance of keeping the wings level and launching at the

correct angle.

Once you’ve found your assistant, pick weather conditions

that are favorable. The most critical part of the fl ight will be

the launch. Once your Rifl e is up-and-away it’ll be safely out

of the grasp of the earth. Launching for experienced pilots is

second-nature, but there is plenty opportunity for beginners to

botch the fi rst launch if conditions are not right. In addition to

fi nding a competent launcher, your chances for success will

be increased ten-fold if you can throw it directly into a breeze.

Launching in cross winds or on calm days is fi ne for experts,

but if you can make that toss into a nice breeze—say a good

fi ve or ten mph—your fl ight will be just about guaranteed!

19

Page 20

12'

[3.5m]

The tendency may be for motor torque to cause the Rifl e to

roll left, but with a good launch into the wind you may not

notice any torque at all and the Rifl e will aggressively climb

skyward.

Sometimes, during the thrill of the launch it can be easy

Hint:

to forget good mechanics (such as keeping the wings level or

throwing the plane hard enough). But one trick is to actually

look at the plane, not where you are throwing it. If you watch

what the plane is doing right from the start you can remember

to keep the wing level and to throw it at the correct angle.

However, actually looking at an object you are throwing is

counter-intuitive, so this usually takes a little practice.

Once your Rifl e is up-and-away the fi rst thing will be simply

to fl y it. Remember to throttle back and fl y a circuit before

reaching for the trims.

When ready, hold the fuselage under the wing right about at

the C.G. Have your assistant “cock” the Rifl e overhead ready

to throw it in launch position. Envision trying to throw the

Rifl e over a 12' [3.5m] barrier about 12' [3.5m] away.

Double-check that the ailerons, elevator and spoilerons

are responding to your control inputs correctly, then

advance the throttle to full and throw the Rifl e immediately.

Throw it hard, at about a 20° to 30° angle with the wing level.

Flying

Once your Rifl e is airborne the fi rst order of business will be

to get it trimmed for straight-and-level fl ight. You can nudge

the trims yourself, or have your assistant work the trims for

you while you focus on fl ying the plane.

One of the initial challenges of fl ying the Rifl e is keeping it

within visual sight. This should be easy to do with the 2S

sport setup because it’s lighter and not as fast to begin

with, making it more natural to fl y slowly. With either setup,

just remember to throttle back to slow things down. Give

yourself time to think and react.

The second order of business once airborne will be to

simulate a few landings and learn how slowly the Rifl e will

glide and test its stall reaction. Don’t wait until the end of the

fl ight to do this; otherwise, you might run out of battery. Take

your Rifl e up to a high altitude, fl y it into the wind, cut the

throttle and fl y it around. Add more and more up elevator until

it either gets too low or actually stalls. Release the elevator,

allow it to build up a little speed, and then gently add throttle

to climb and do it again. Do this a few times also practicing

with spoilerons and low and high rate elevator. This will show

you the glide envelope and give you a more accurate idea of

what will happen when it’s actually time to land.

20

Page 21

Landing

Throttle down, switch to high rates, glide around for about half a circuit,

then extend your spoilerons before entering the landing approach.

1. Cut throttle

2. Glide

3. Get into the

landing pattern

The perfect landing approach is a large, descending 180° turn.

2. Continue increasing “up” elevator holding, holding, holding the Rifle off the

ground until it just won’t stay airborne anymore and finally touches down.

1.

Gradually increase “up” elevator floating the

Rifle about a foot or so above the ground.

The procedure is simple and quick; when you hear your timer, cut the power, switch to high rates, glide around for about

half-a-lap, extend the spoilerons, glide around for another half-a-lap, then bring it around and land.

But the tendency for beginners with the Rifl e is to land too long. If this happens, simply throttle up gently, go around and try

again. You either entered the landing pattern too early (before bleeding off enough speed), or your approach was too close

or too high. The more speed you bleed off (or the more head wind there is) the nearer your approach can be and the easier

it will be to track the Rifl e all the way in.

When the Rifl e is a foot or so off the ground just keep holding…holding…holding elevator, keeping it off the ground as long

as possible and causing it to touch down at the slowest possible speed. It takes repetition and experience, but when you get

better at judging precisely how slowly your Rifl e can glide you’ll be able to make your approaches shorter—you may even

end up landing short one day!

CAUTION: Whenever adding power from a glide, apply throttle slowly—whenever the wing is fl ying slowly (during a glide)

it will not have the authority to overcome sudden motor torque caused by jamming the throttle stick quickly.

21

Page 22

After you land, always use a LiPo battery checker (GPMM3205)

To perform a “pylon” turn,

bank the wing vertically

and pull full, low-rate elevator.

to check the individual cell voltages of your battery. The “resting,”

“open” voltage of each cell when the batteries “recover” a few

minutes after your fl ight should be no less than 3.7V per cell

(which also equates to 20% capacity remaining). Adjust your

timer accordingly so as not to over discharge your batteries.

Also note the capacity that goes back into your battery after

a charge. The battery should take no more than 80% of its

capacity to recharge (indicating that no more than 80% was

used during the fl ight). Again, adjust your fl ight time and set

your timer accordingly.

Lateral Balance

Ballast such as shot or strips can be added to the wing simply

by using a Dremel tool or even a hobby knife to carefully cut

a small section from the bottom fi berglass wing skin at the tip,

then removing the foam and installing the weight with epoxy.

Eventually, when you begin fl ying more frequent, high-

speed “pylon-style” turns, you’ll want to make sure the Rifl e

is laterally balanced and turns correctly. When performing

a full-throttle pylon turn, roll the wing vertically, then pull full

(low-rate) elevator. Notice whether the plane rolls in either

direction with the application of only elevator. If the high wing

rolls out of the turn it will probably also yaw upward resulting

in an increase in altitude. In this case the high wing is heavy

and ballast should be added to the low wing. If the plane

does the opposite—the high wing rolls into the turn and the

fuselage yaws downward—the low wing is heavy and weight

needs to be added to the high wing.

22

Page 23

Final Thoughts

1. Pull to

vertical

up line

2. Half

roll

3. Graceful pull

with large,

descending

arc back to

horizontal

flight

Another maneuver to have in your repertoire is the “humpty bump.” The humpty not only makes it easier to align your Rifl e

over the runway and low (for thrilling speed passes when you want to show off to any spectators), it can also be a safer

maneuver as the plane is never on a trajectory inward. Like all maneuvers with the Rifl e, the humpty happens fast—you can

delay a few seconds on the up line after the initial pull to vertical, but after that you have to get in the half roll and pull back

to the down line quickly. Otherwise, if you become complacent the Rifl e may climb out of sight! And other than the instant

when the Rifl e is inverted at the top of the arc, you always have a good look at it from the top or bottom improving your ability

to track it.

The “sweet spot” for a speed setup is a fl ying weight of about 26 – 28 oz. turning a 4.5 x 4.1 propeller around 35,000rpm

(in the neighborhood of 600 watts “in” given typical motor effi ciency). If you adhere to that you’re pretty much looking at

3S setups with motors in the 120g – 140g range, 40mm – 50mm in length. This is pretty much what you’ll get with the

recommended 3S Ammo speed setup. We understand that the tendency for this type of plane is to “stuff” in as much power

as possible (and we’ve already done that ourselves!), but in order to get all this power you’ll need a bigger motor, ESC and

battery. Then, the Rifl e becomes heavier, making it less practical either by complicating launches and/or shortening the fl ight

time considerably. Props smaller than 4.5 x 4.1 simply don’t provide enough thrust to overcome the drag of the airframe

resulting in little or no increase in speed no matter what RPM you are turning, so should you decide to experiment, keep

the minimum prop size to 4.5 x 4.1.

Practically, the amount of power you can jam into the Rifl e is limited by the size of the battery that will fi t and a reasonable

weight and fl ying time—you can stuff in only so much motor and battery until the Rifl e is either too heavy and/or the fl ying

time is ridiculously short. Sure, you can come up with a motor, propeller and battery that will make 1500 watts, but then it

will be too heavy (severely compromising the launch) or will fl y for less than a minute. Basically, just about anything that can

be powered by 2200mAh 3S battery and fl y for around two minutes at full throttle is practical.

23

Page 24

Loading...

Loading...