Great Planes GPMA1801 User Manual

®

®

INSTRUCTION MANUAL

SPECIFICATIONS

Wingspan: 22.5 in [570 mm]

2

Wing Area: 166 in

Wing Loading: 27.8−29.5 oz/ft

[10.7 dm2]

2

[85−90 g/dm2]

Length: 34.5 in [875mm]

WARRANTY

Great Planes Model Manufacturing® Co. guarantees this kit to

be free from defects in both material and workmanship at the

date of purchase. This warranty does not cover any component

parts damaged by use or modification. In no case shall Great

Planes’ liability exceed the original cost of the purchased kit.

Further, Great Planes reserves the right to change or modify this

warranty without notice.

In that Great Planes has no control over the final assembly or

material used for final assembly, no liability shall be assumed nor

accepted for any damage resulting from the use by the user of

the final user-assembled product. By the act of using the

user-assembled product, the user accepts all resulting liability.

If the buyer is not prepared to accept the liability associated

with the use of this product, the buyer is advised to return

Weight Range: 32−34 oz

Radio: 4-channel,

™

,

[910−960 g]

Motor, ESC: 24-45-3790kV Ammo

35A ESC,

HyperFlow

™

56mm fan

4 micro servos,

mini receiver

this kit immediately in new and unused condition to the

place of purchase.

To make a warranty claim send the defective part or item to

Hobby Services at the address below:

Hobby Services

3002 N. Apollo Dr. Suite 1

Champaign IL 61822 USA

Include a letter stating your name, return shipping address, as

much contact information as possible (daytime telephone

number, fax number, e-mail address), a detailed description of

the problem and a photocopy of the purchase receipt. Upon

receipt of the package the problem will be evaluated as quickly

as possible.

READ THROUGH THIS MANUAL BEFORE STARTING CONSTRUCTION. IT CONTAINS IMPORTANT

INSTRUCTIONS AND WARNINGS CONCERNING THE ASSEMBLY AND USE OF THIS MODEL.

Entire Contents © 2011 Hobbico,® Inc. All rights reserved.

Champaign, Illinois

(217) 398-8970, Ext 5

airsupport@greatplanes.com

GPMA1801 Mnl

TABLE OF CO NTENTS

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Academy of Model Aeronautics . . . . . . . . . . . . . . . . . . 2

SAFETY PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . 2

DECISIONS YOU MUST MAKE . . . . . . . . . . . . . . . . . . . . 3

Battery and ESC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Servos, Receiver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

ADDITIONAL ITEMS REQUIRED. . . . . . . . . . . . . . . . . . . 4

Battery Chargers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Adhesives and Building Supplies. . . . . . . . . . . . . . . . . 4

Optional Supplies and Tools . . . . . . . . . . . . . . . . . . . . 4

KIT INSPECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

ORDERING REPLACEMENT PARTS . . . . . . . . . . . . . . . 4

KIT CONTENTS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

ASSEMBLY INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . 6

Assemble the Stand. . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Prepare the HyperFlow Fan Unit . . . . . . . . . . . . . . . . . 6

Test Run the Motor/Fan Unit . . . . . . . . . . . . . . . . . . . . 8

Surface Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Install the Fan Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Assemble the Wing . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Install the Wing Panels . . . . . . . . . . . . . . . . . . . . . . . 12

Install the Tail Section and Servos. . . . . . . . . . . . . . . 14

Finish the Model . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Apply the Decals . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

GET THE MODEL READY TO FLY. . . . . . . . . . . . . . . . . 19

Set the Control Throws . . . . . . . . . . . . . . . . . . . . . . . 19

Balance the Model (C.G.) . . . . . . . . . . . . . . . . . . . . . 19

Balance the Model Laterally . . . . . . . . . . . . . . . . . . . 20

PREFLIGHT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Identify Your Model . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Charge the Batteries . . . . . . . . . . . . . . . . . . . . . . . . . 20

Assemble the Bungee Launch. . . . . . . . . . . . . . . . . . 20

AMA SAFETY CODE (excerpts) . . . . . . . . . . . . . . . . . . 21

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Radio Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

CHECK LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

FLYING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Ground Check and Range Check . . . . . . . . . . . . . . . 22

Takeoff . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Hand-Launch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Bungee-Launch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Flying . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Landing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

INTRODUCTION

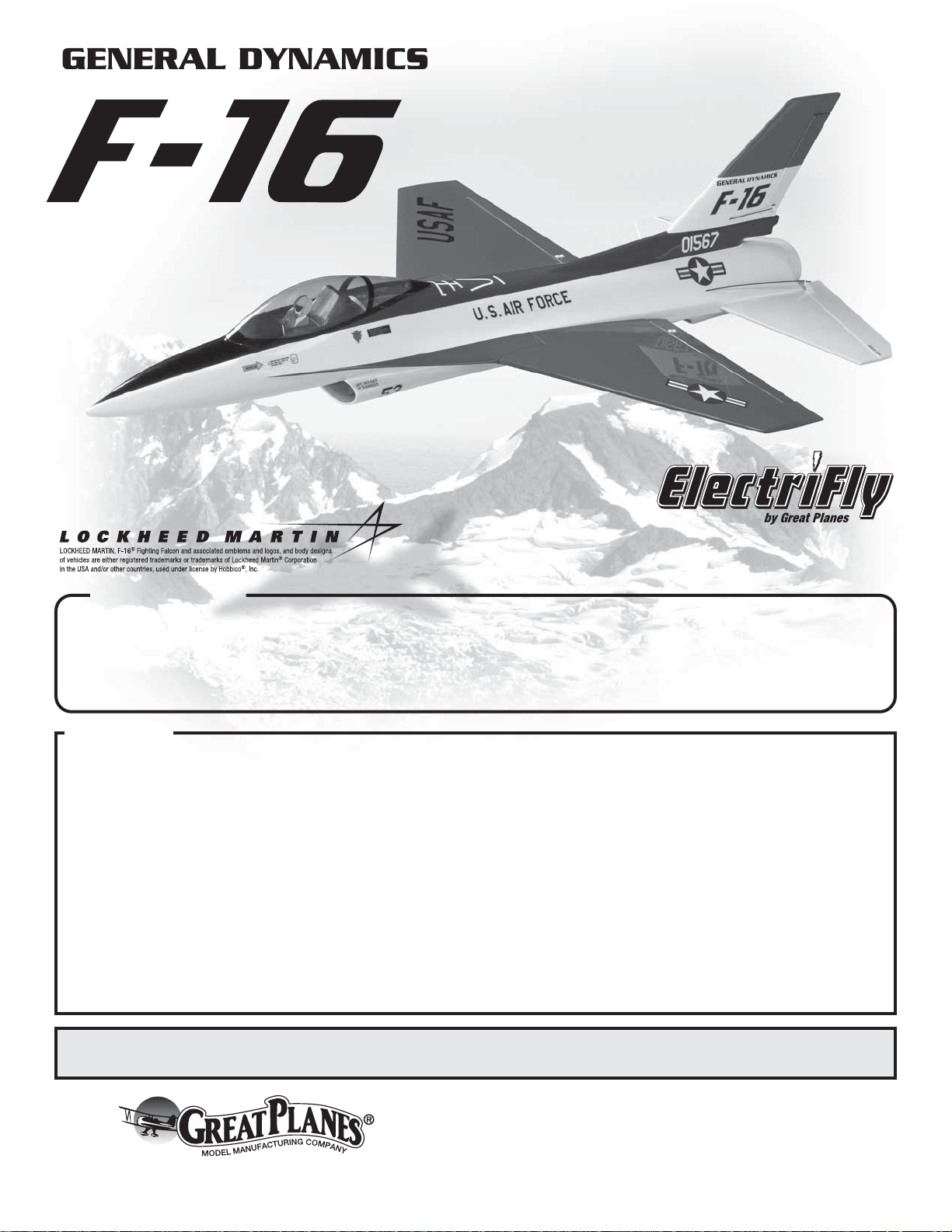

Thank you for purchasing the Great Planes F-16 EDF (electric

ducted fan) ARF. With average speeds approaching 100mph,

your jet will have onlookers’ full attention as it cuts across

the horizon like a full-scale F-16 on patrol. Execute a Split-S

to come in for a low, high-speed pass across the fl ight line.

The EDF’s whine at full-throttle will echo off nearby buildings,

reminding you to keep your fi ngers tight on the sticks — this

bird is moving fast! Fortunately, the F-16 is a very stable fl ier

and doesn’t require expert fl ying skills to pilot, but it’s not a

beginner’s jet. The recommended battery provides just the

right amount of fl ight time for a plane of this size and speed…

and when you do bring it in for a landing, it will slow nicely

on approach and simply “settle in” on the grass when it’s

done fl ying.

For the latest technical updates or manual corrections to the

F-16 visit the Great Planes web site at www.greatplanes.com.

Open the “Airplanes” link, then select F-16 ARF. If there is new

technical information or changes to this model a “tech notice”

box will appear in the upper left corner of the page.

Academy of Model Aeronautics

If you are not already a member of the AMA, please join! The

AMA is the governing body of model aviation and membership

provides liability insurance coverage, protects modelers’ rights

and interests and is required to fl y at most R/C sites.

Academy of Model Aeronautics

5151 East Memorial Drive

Muncie, IN 47302-9252

Tele. (800) 435-9262

Fax (765) 741-0057

Or via the Internet at: http://www.modelaircraft.org

IMPORTANT!!! Two of the most important things you can

do to preserve the radio controlled aircraft hobby are to avoid

fl ying near full-scale aircraft and avoid fl ying near or over

groups of people.

SAFETY PRE CAUTION S

Protect Your Model, Yourself & Others…

Follow These Important Safety Precautions

1. Your F-16 should not be considered a toy, but rather a

sophisticated, working model that functions very much like a

full-size airplane. Because of its performance capabilities, the

F-16, if not assembled and operated correctly, could possibly

cause injury to yourself or spectators and damage to property.

2

2. You must assemble the model according to the instructions.

Do not alter or modify the model, as doing so may result in an

unsafe or unfl yable model. In a few cases the instructions may

differ slightly from the photos. In those instances the written

instructions should be considered as correct.

3. You must take time to build straight, true and strong.

4. You must use an R/C radio system that is in good condition,

a correctly sized engine, and other components as specifi ed

in this instruction manual. All components must be correctly

installed so that the model operates correctly on the ground

and in the air. You must check the operation of the model and

all components before every fl ight.

5. If you are not an experienced pilot or have not fl own this type

of model before, we recommend that you get the assistance

of an experienced pilot in your R/C club for your fi rst fl ights.

If you’re not a member of a club, your local hobby shop has

information about clubs in your area whose membership

includes experienced pilots.

6. While this kit has been fl ight tested to exceed normal use,

if the plane will be used for extremely high stress fl ying, such

as racing, or if an engine larger than one in the recommended

range is used, the modeler is responsible for taking steps to

reinforce the high stress points and/or substituting hardware

more suitable for the increased stress.

7. WARNING: The fuselage and tail cone adapter included in

this kit are made of fi berglass, the fi bers of which may cause

eye, skin and respiratory tract irritation. Never blow into a

part to remove fi berglass dust, as the dust will blow back into

your eyes. Always wear safety goggles, a particle mask and

rubber gloves when grinding, drilling and sanding fi berglass

parts. Vacuum the parts and the work area thoroughly after

working with fi berglass parts.

and the

❍ Great Planes ElectriFly 24-45-3790kV Ammo inrunner

brushless motor (GPMG5185).

These components drop right in with no modifi cation.

The recommended battery is the:

❍ Great Planes ElectriFly 14.8V (4S) 2200mAh 25C

LiPo (GPMP0521).

Under “normal” fl ying conditions (mostly full throttle), this

provides average fl ight times of approximately 4 minutes

with approximately one more minute of motor run time for

additional landing attempts.

❍ The Great Planes ElectriFly SS-35 35 Amp brushless

ESC (GPMM1830) is also recommended.

Note: A precision 1.5mm Allen wrench will be required for

tightening the set screws in the brass fan adapter. Do not

attempt to use an economy wrench. You may strip out the

wrench or set screws, making it impossible to securely tighten

or remove them for replacement. The 1.5mm MIP Thorp Hex

Driver (MIPR9007) is recommended.

Servos, Receiver

A small receiver and four micro servos in the 20 oz-in torque

range are required. Two 6" [152mm] servo extensions are also

required. Part numbers are provided below:

We, as the kit manufacturer, provide you with a top quality,

thoroughly tested kit and instructions, but ultimately the

quality and fl yability of your fi nished model depends

on how you build it; therefore, we cannot in any way

guarantee the performance of your completed model,

and no representations are expressed or implied as to the

performance or safety of your completed model.

Remember: T ake your time and follo w the instructions to

end up with a well-built model that is straight and true.

DECISI ONS YOU MUST MAKE

This is a partial list of items required to fi nish the F-16 that may

require planning or decision making before starting assembly.

Order numbers are provided in parentheses.

Battery and ESC

The F-16 was designed for and comes equipped with the:

❍ Great Planes ElectriFly HyperFlow 56mm ducted fan

system (GPMG3910)

Suitable servo choices (in order of preference) for Futaba®

servos include:

❍ S3107 (standard micro – FUTM0025)

(shown in manual)

❍ S3156 (digital, metal gear, high-torque) (FUTM0656)

❍ S3153MG (digital, metal gear – FUTM0652)

❍ S3153 (digital – FUTM0653)

❍ S3117 (high-torque – FUTM0417)

❍ Hobbico® 6" Extension Futaba J (HCAM2000)

If you install a 4-channel receiver, a Y-harness is needed to

join the aileron servos together (FUTM4130). The aileron

servos can also be mixed together using a computerized

transmitter and 5+ channel receiver such as the Futaba

R617FS 7-Channel 2.4GHz FASST™ Receiver (FUTL7627).

3

ADD ITIONAL ITEMS R EQ UI RE D

Battery Chargers

● A LiPo-capable battery charger and a power source for the

battery charger are required. One recommended charger

is the Great Planes ElectriFly Triton

(GPMM3155). The Triton EQ can be powered either by an AC

or DC power source and features a built-in LiPo cell balancer.

● Another suitable LiPo battery charger is the Great Planes

PolyCharge4™ DC LiPo charger (GPMM3015). The

PolyCharge4 can charge up to four LiPo batteries at the

same time, but requires separate LiPo cell balancers, so

for each LiPo battery you wish to charge simultaneously

(up to 4), one Great Planes Equinox™ LiPo Cell Balancer

(GPMM3160) will be required. Additionally, the Equinox

comes with 2S and 3S charge adapters, so a 4S charge

adapter (GPMM3162) must also be purchased separately.

Finally, the PolyCharge4 does not have AC capability, so if

wall-charging from home is a priority, a separate A/C 12-Volt

power source must also be purchased. A suitable power

supply then for the PolyCharge4 is the Great Planes 12V

12A DC power supply (GPMP0901).

™

EQ AC/DC Charger

Adhesives and Building Supplies

Other than common hobby tools this is the list of adhesives

and building supplies that are required to fi nish the F-16:

❍ 1/2 oz. [15g] Thin Pro™ CA (GPMR6001)

❍ 1/2 oz. [15g] Medium Pro CA+ (GPMR6007)

❍ Pro 30-minute epoxy (GPMR6047)

❍ Drill bits: #60 .040" [1.07mm], #56 .047"

[1.18mm],1/16" [1.6 mm], 3/32" [2.4 mm]

❍ #1 Hobby knife (RMXR6909)

❍ #11 blades (5-pack, RMXR6930)

❍ Denatured alcohol (for epoxy clean up)

❍ Threadlocker thread locking compound (GPMR6060)

❍ Top Flite® Microballoons Filler 8 oz (TOPR1090)

❍ 220 grit sandpaper

❍ Masking tape

❍ Metal fi le or rotary tool

Optional Supplies and Tools

Here is a list of optional supplies and tools that will help you

build the F-16 ARF:

❍ Great Planes Pro Epoxy 6-Minute Formula 4 oz

(GPMR6042)

❍ Epoxy brushes 6, (GPMR8060)

❍ Mixing sticks (GPMR8055)

❍ Mixing cups (GPMR8056)

❍ Pliers with wire cutter (HCAR0630)

❍ T.A. Emerald Performance Duster Compressed Air

(TAEC1060)

❍ Hobby Heat™ Micro Torch II (HCAR0755)

❍ AccuThrow™ Defl ection Gauge (GPMR2405)

❍ CG Machine™ (GPMR2400)

❍ Hobbico Flexible 18" Ruler Stainless Steel

(HCAR0460)

❍ Top Flite MonoKote® trim seal iron (TOPR2200)

❍ Top Flite MonoKote heat gun (TOPR2000)

❍ Hobbico Pin Vise 1/16 Collet w/6 Bits (HCAR0696)

❍ Great Planes 1/8" x 3/8" [3.2 x 9.5mm] single-sided

adhesive foam tape (GPMQ4224)

❍ Petroleum Jelly

● The wing and horizontal stabilizer of the F-16 are factory-

covered with Top Flite MonoKote fi lm. Should repairs ever

be required, MonoKote can be patched with additional

MonoKote purchased separately. MonoKote is packaged in

six-foot rolls, but some hobby shops also sell it by the foot. If

only a small piece of MonoKote is needed for a minor patch,

perhaps a fellow modeler would give you some. MonoKote

is applied with a model airplane covering iron, but in an

emergency a regular iron could be used. A roll of MonoKote

includes full instructions for application. Following are the

colors used on this model and order numbers for six foot rolls.

White TOPQ0204 True Red TOPQ0227

KIT IN SPE CTIO N

Before starting to build, take an inventory of this kit to make

sure it is complete, and inspect the parts to make sure they

are of acceptable quality. If any parts are missing or are not

of acceptable quality, or if you need assistance with assembly,

contact Pr oduct Support. When reporting defective or missing

parts, use the part names exactly as they are written in the

Kit Contents list.

Great Planes Product Support

3002 N Apollo Drive, Suite 1 Ph: (217) 398-8970, ext. 5

Champaign, IL 61822 Fax: (217) 398-7721

E-mail: airsupport@greatplanes.com

❍ Hobbico® Hobby Syringe 12cc Curved Tip

(HCAR3785)

❍ 1/2 oz. [15g] Thick Pro CA- (GPMR6013)

❍ 2 oz. [57g] spray CA activator (GPMR6035)

❍ 4 oz. [113g] aerosol CA activator (GPMR6034)

❍ CA applicator tips (HCAR3780)

❍ CA debonder (GPMR6039)

ORDERING REPLACEM ENT PARTS

Replacement parts for the Great Planes F-16 ARF are available

using the order numbers in the Replacement Parts List that

follows. The fastest, most economical service can be provided

by your hobby dealer or mail-order company.

4

To locate a hobby dealer, visit the Great Planes web site at

www.greatplanes.com.

Select “Where to Buy” in the menu across the top of the page

and follow the instructions provided to locate a U.S., Canadian

or International dealer.

Parts may also be ordered directly from Hobby Services by

calling (217) 398-0007, or via facsimile at (217) 398-7721, but

full retail prices and shipping and handling charges will apply.

Illinois and Nevada residents will also be charged sales tax. If

ordering via fax, include a Visa® or MasterCard® number and

expiration date for payment.

Mail parts orders Hobby Services

and payments by 3002 N Apollo Drive, Suite 1

personal check to: Champaign IL 61822

Be certain to specify the order number exactly as listed in the

Replacement Parts List. Payment by credit card or personal

check only; no C.O.D.

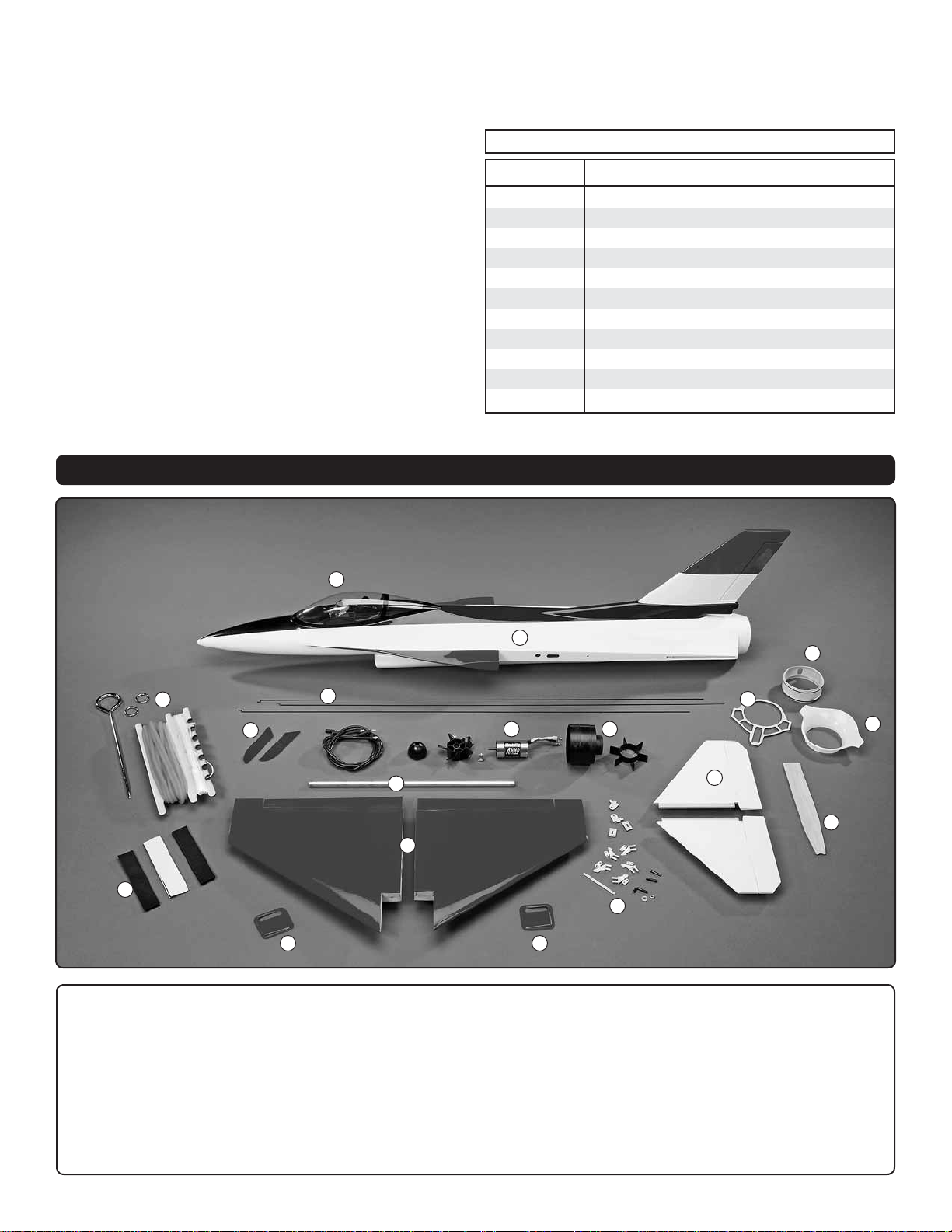

KIT CONTENTS

If additional assistance is required for any reason contact

Product Support by e-mail at productsupport@greatplanes.

com, or by telephone at (217) 398-8970.

REPLACEMENT PARTS LIST

Order No. Description

GPMA4250

GPMA4251

GPMA4252

GPMA4253

GPMA4254

GPMA4255

GPMA4256

GPMA4257

GPMG5185

GPMG3910

GPMA2885

Fuselage F-16 EDF ARF

Wing F-16 EDF ARF

Tail Surfaces F-16 EDF ARF

Cone Adapter F-16 EDF ARF

Front Flange F-16 EDF ARF

Hatch F-16 EDF ARF

Decals F-16 EDF ARF

Bungee Hook F-16 EDF ARF

Ammo 24-45-3790 In-Runner Brushless Motor

Hyperflow 370 EP Ducted Fan w/o Motor

Bungee Launcher Set

5

11

1. Fuselage

2

8

9

10

3

12 12

7. Hyperfl ow Fan (EDF)

1

15

6

7

4

13

14

16

17

13. Hardware

2. Canopy Hatch

3. Wing Panels

4. Horizontal Stabilizers

5. Bungee Launch

6. Ammo Motor

8. Pushrods

9. Grip Tape

10. Wing Tube

11. Hook & Loop

12. Aileron Servo Covers

5

14. Tail Cone Adapter

15. Plywood Former

16. Front Housing Flange

17. Fin Cover

ASS EM BLY IN STRUCTIO NS

NO

Fan Rotor Adapter

(Brass)

Motor

Shaft

The adapter is

not all the way on.

The adapter is

all the way

down onto the

motor shaft up

to the threads.

YES

S

OT

will allow removal of the motor without having to remove the

brass fan adapter.

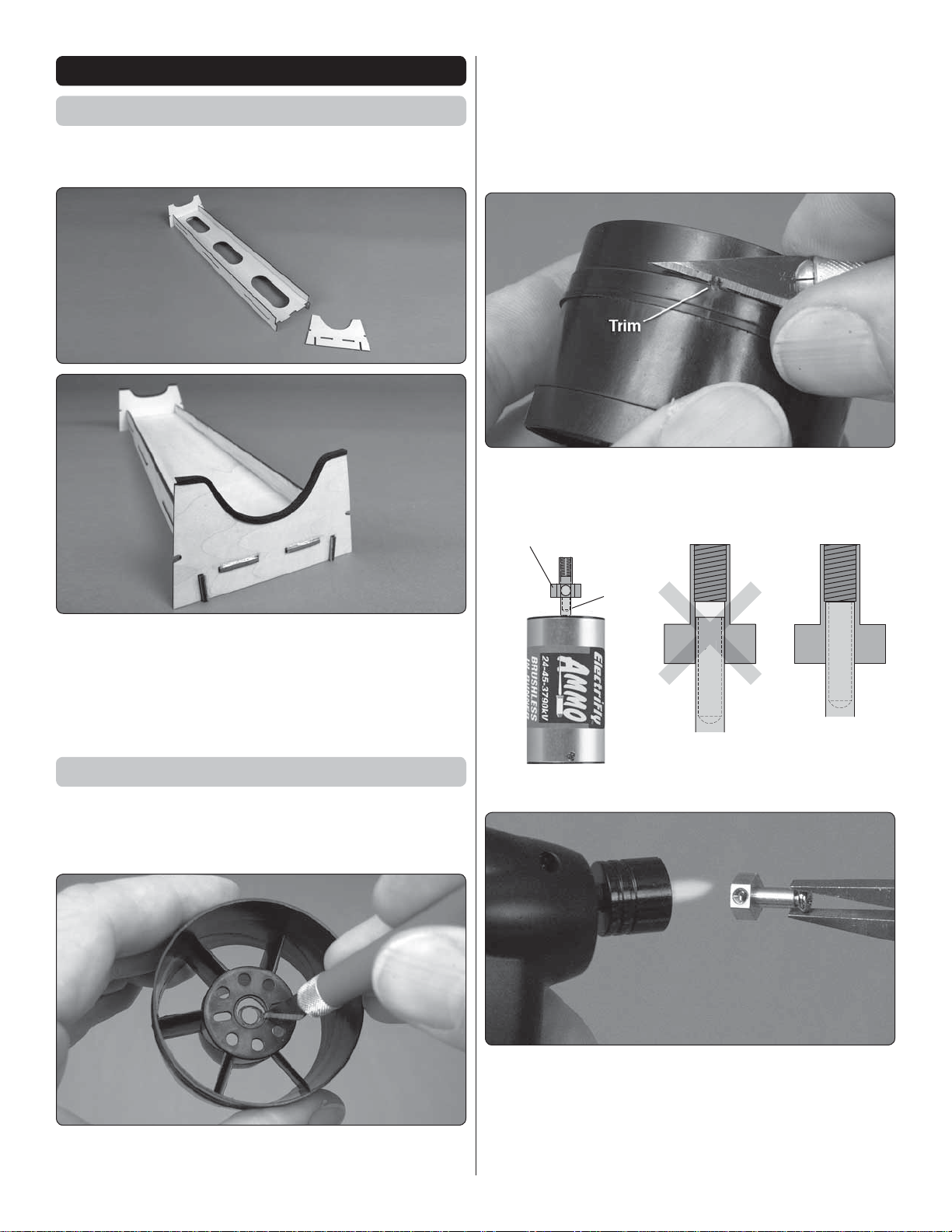

Assemble the Stand

The included plywood stand is used to support your F-16

during assembly and transport.

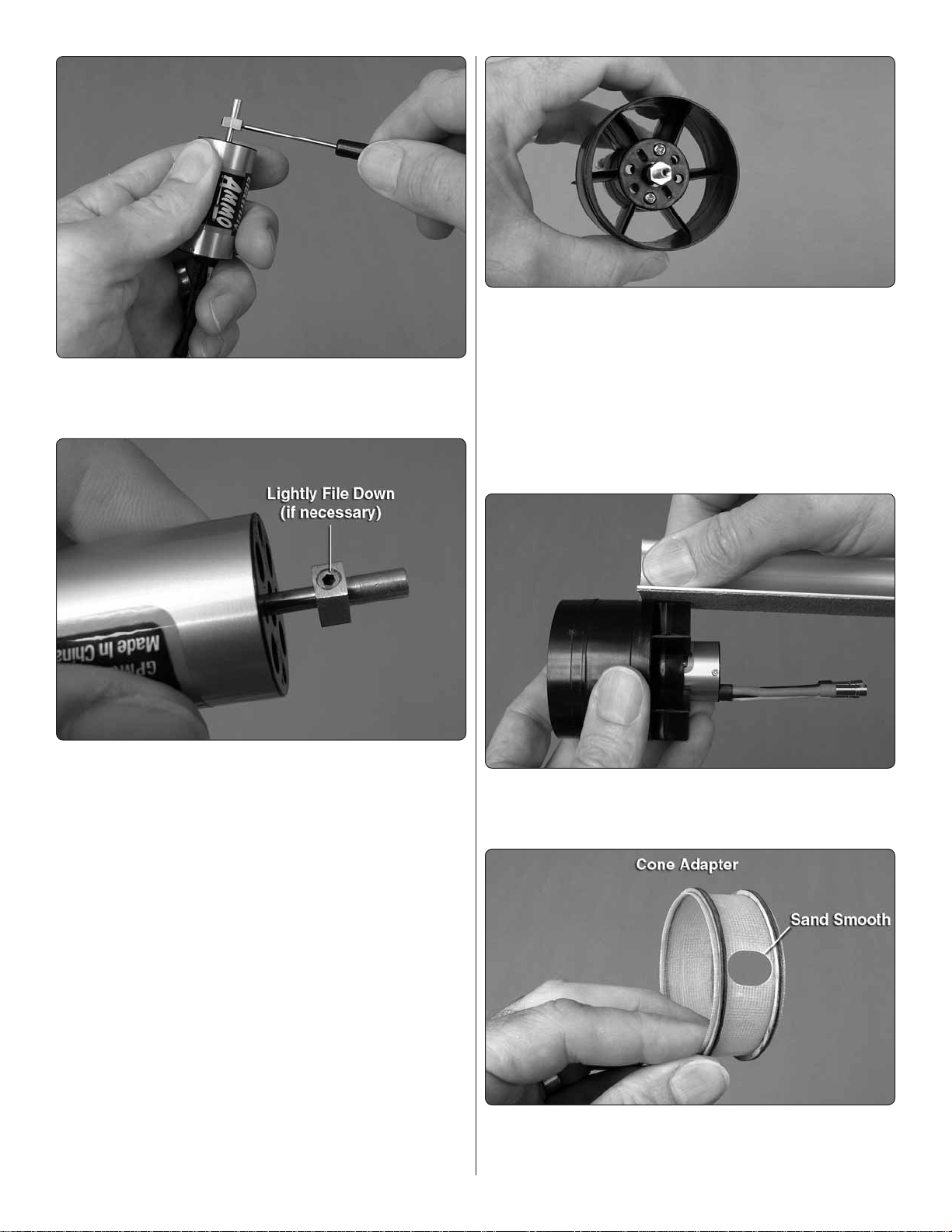

3. As shown in the HyperFlow manual, trim the three

❏

alignment guides from inside the fan housing. (Also as noted

in the HyperFlow manual, a rotary tool with a sanding drum

makes this easier.)

4. Trim any fl ashing from around the fan housing so the

❏

fi berglass cone adapter will fi t well.

Test-fi t, then glue together the plywood parts of the stand as

shown in the photos. The stand may be used as-is, or you

could add foam tape cut into 1/8" [3mm] wide strips that can be

adhered to the forward and aft saddles. The foam will adhere

best if you fi rst sand the edges of the stand, then seal with

medium CA before applying the foam.

Prepare the HyperFlow Fan Unit

1. Review steps 1 through 6 for Installing a Brushless

❏

Motor on pages 6 and 7 of the separate HyperFlow instruction

manual, but don’t perform any of the steps yet.

2. Enlarge the hole in the fan housing as shown. Once the

❏

fan unit and motor have been installed in the fuselage, this

P

FLAT

5. Press the brass fan rotor adapter onto the motor shaft—

❏

make sure one of the set screw holes in the adapter is aligned

with the fl at spot on the shaft and make certain the adapter

goes on all the way up to the threads. If you can’t get the

adapter to go all the way, use a hobby torch to heat the adapter

fi rst. Then, slide it into the shaft.

6

6. Add a small drop of threadlocker to the threads on the

❏

set screws for the adapter. Then, use a quality 1.5mm Allen

wrench to tighten set screws.

10. Mount the motor to the fan housing–you can use the

❏

3 x 5mm screws included with the Ammo motor (and a drop

of threadlocker on the threads). Any set of holes in the fan

housing that align with the holes in the motor may be used,

but we used the outer holes in the motor. Use care not to

overtighten the screws so much that you damage the plastic.

11. Glue the stator extension to the fan housing as shown

❏

in the HyperFlow manual. Make sure the little notches in the

stator fi t around the housing.

7. Test fi t only the fan rotor to the rotor adapter. If the head

❏

of the set screw opposite the fl at spot is protruding from the

adapter and making it diffi cult to install the fan rotor, cover the

front of the motor with a cloth or paper towel and use a metal

fi le to fi le down the screw so the fan will fi t properly.

8. Test mount the fan rotor to the adapter with the rotor

❏

cone, the 3mm Phillips screw and the 3mm washer that came

with the fan unit—the HyperFlow instructions specify using

a 3mm x 8mm screw, but the 3 x 5mm screw included with

the fan may be used.

Hint: For optimal performance it is desirable for the fan rotor

to turn as concentrically (“true”) as possible. T est fi t the rotor

in different orientations around the adapter, spinning it b y hand

each time. When y ou fi nd the orientation that is the truest, use

a hobby knife to lightly scratch a small “X” at the base of the

rotor where it aligns with the fl at spot on the motor. When you

mount the rotor later, do so in this orientation.

9. Remove the cone and rotor and set them aside.

❏

12. Lightly sand the edge of each blade on the stator

❏

extension to remove any fl ashing and to make sure they are

even with the fan housing.

13. Use medium-grit sandpaper to smooth the rough edges

❏

around the motor wire hole in the fi berglass tail cone adapter

so it won’t damage the motor wires.

7

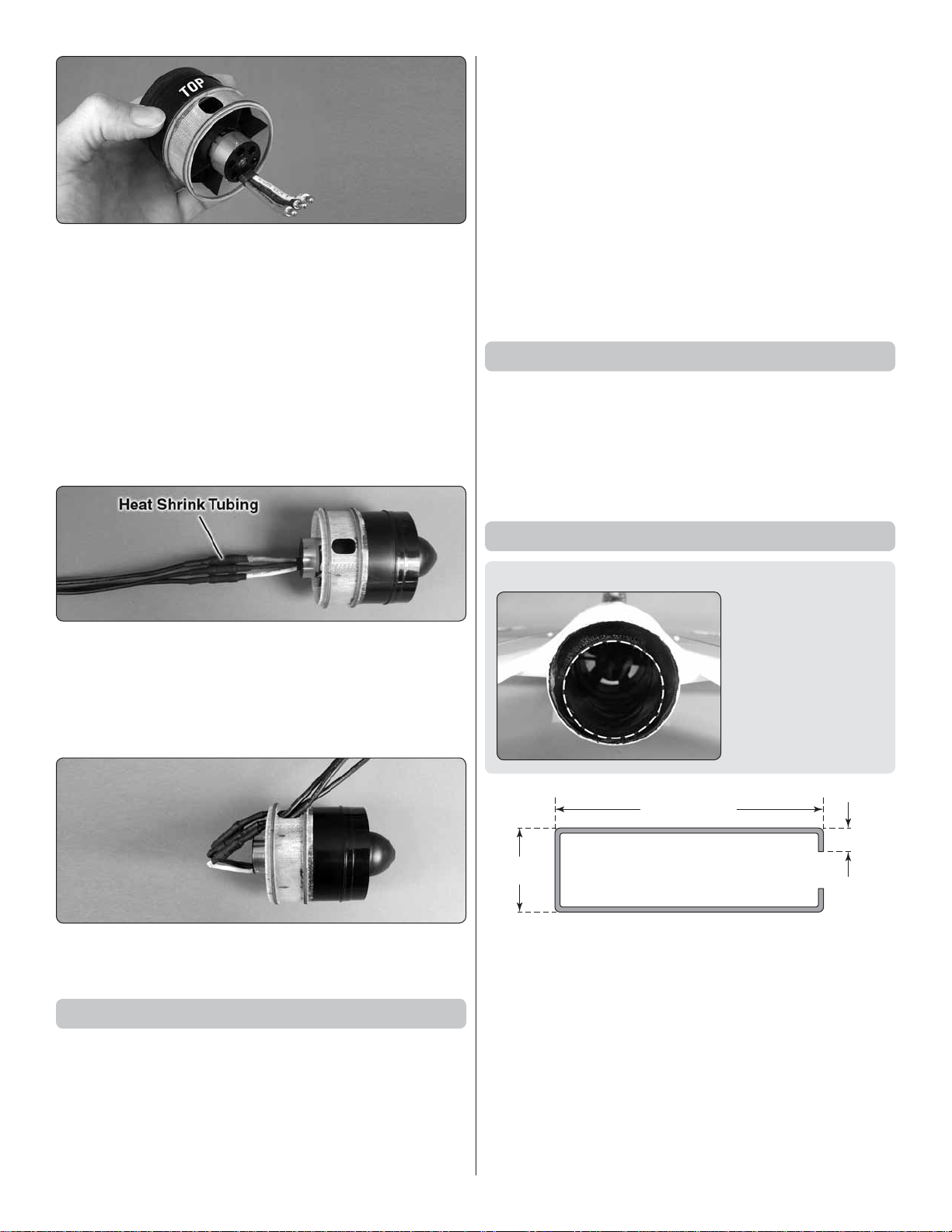

14. Test fi t but do not glue the cone adapter to the rear of

ROTOR PULLER

1" [25mm]

3-1/2" [90mm]

1/4" [6mm]

❏

the fan housing. Note that the hole in the housing should be

180° from the side of the motor where the wires exit—this will

be the top of the unit. Once you have the housing and adapter

mated correctly, permanently glue the two together by adding

a few drops of thin CA to the seam around the outside. Also

apply a few drops of medium CA to each stator blade where

it contacts the inside of the adapter. Note: Apply the CA

sparingly and with care. Otherwise it will run all over the place.

15. Install the fan rotor onto the motor noting the orientation

❏

you marked earlier (for minimal run out)—be certain to use

a small drop of thread locking compound on the 3mm screw.

2. Follow all the precautions and run the motor at no more

❏

than 1/4 throttle as described by the “PREPARE TO RUN

THE FAN” instructions on the back cover of the HyperFlow

fan instructions. (If the motor is turning backwards switch any

two of the motor wires with each other.) Check for vibration

and/or unusual noises and do not proceed until resolving

any problems.

3. Continue with the rest of the break-in procedure until

❏

the system is fully broken-in. Or, if you’re satisfi ed with the

way the unit is performing, stop now and mount the unit in

the fuselage as described in the next section. Be certain to

complete the break-in procedure before fl ying your F-16 for

the fi rst time.

Surface Preparation

There are several steps in this manual that require you to

glue parts to the fi berglass fuselage. Anytime this is done,

the fi berglass should fi rst be cleaned with a cloth dampened

with denatured alcohol, sanded with 220 grit sandpaper, then

cleaned again with denatured alcohol. Doing this will ensure

a strong glue bond.

16. Cut the included heat shrink tubing into three equal

❏

lengths. Connect the motor lead extensions to the motor wires.

Slide the heat shrink pieces onto the motor lead extensions

and use a heat source (heat gun or lighter) to shrink the

tubing around the connections in order to prevent them from

becoming inadvertently disconnected.

17. Carefully slide the motor lead wires through the hole

❏

in the top of the cone adapter as shown.

Test Run the Motor/Fan Unit

1. You may perform either a brief test-run of the motor/fan

❏

unit, or do the complete break-in procedure as described on

the back cover of the HyperFlow instruction manual. In either

case prepare to run the motor by connecting the ESC to

your receiver and to the motor wires coming from the motor.

Reverse the throttle channel in your transmitter and turn on

the transmitter. Connect your motor battery to the ESC.

Install the Fan Unit

DESIGNER NOTE: The aft end of the tail cone is not

centered within the aft

end of the fuselage and

this can be seen by

looking at the plane

from the back side. This

is an intentional part of

the design to maximize

fl ight performance of

the aircraft.

It’s a good idea to test fi t the fan without glue so you can

make sure it fi ts properly. Once permanently installed, the

fan unit will not be possible to remove. However, the motor

may be removed by taking off the fan rotor, unscrewing the

motor mounting screws and taking the motor out the back

through the tail cone. Once out the tail cone, the motor wires

can be disconnected. If you can’t get a good enough grip with

your fi ngers to pull the fan rotor off the adapter, make a rotor

puller from an 8-1/2" [215mm] piece of 2-56 pushrod wire

by bending it as shown. Insert the short hooks on the ends

of the puller under the fan hub and pull.

8

Loading...

Loading...