Great Planes GPMA1036 User Manual

WARRANTY

Great Planes Model Manufacturing Co. guarantees this kit to be free from defects in both material and

workmanship at the date of purchase. This warranty does not cover any component parts damaged by use or

modification. In no case shall Great Planes' liability exceed the original cost of the purchased kit. Further, Great

Planes reserves the right to change or modify this warranty without notice.

In that Great Planes has no control over the final assembly or material used for final assembly, no liability shall be

assumed nor accepted for any damage resulting from the use by the user of the final user-assembled product. By the

act of using the user-assembled product, the user accepts all resulting liability.

If the buyers are not prepared to accept the liability associated with the use of this product, they are advised

to return this kit immediately in new and unused condition to the place of purchase.

READ THROUGH THIS INSTRUCTION MANUAL

FIRST. IT CONTAINS IMPORTANT INSTRUCTIONS

AND WARNINGS CONCERNING THE ASSEMBLY

AND USE OF THIS MODEL.

ES03 V2.0 Entire Contents © Copyright 2002

1610 Interstate Drive, Champaign, IL 61822

(217) 398-8970, Ext 2

airsupport@greatplanes.com

INSTRUCTION MANUAL

TM

Length: 50" [1270mm] Weight: 5.5 - 6.5 lbs [2495 - 2948g]

Wingspan: 58.75" [1492mm] Wing Area: 742 sq in [ 47.9sq cm]

Wing Loading: 17.1 - 20.2 oz/sq ft [52.2 - 61.6 g/sq cm]

Radio: 4-ch (4 servos)

Engine: .40 - .51 two-stroke [6.5 - 8.4cc 2-stroke]

.52 - .70 four-stroke [8.5 - 11.5cc 4-stroke]

MADE IN

USA

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SAFETY PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . .

DECISIONS YOU MUST MAKE . . . . . . . . . . . . . . . . . . . . .

Engine Recommendations . . . . . . . . . . . . . . . . . . . . . . .

ADDITIONAL ITEMS REQUIRED . . . . . . . . . . . . . . . . . . .

Radio Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hardware and Accessories . . . . . . . . . . . . . . . . . . . . . .

Adhesives and Building Supplies . . . . . . . . . . . . . . . . . .

Optional Supplies and Tools . . . . . . . . . . . . . . . . . . . . . .

IMPORTANT BUILDING NOTES . . . . . . . . . . . . . . . . . . . .

COMMON ABBREVIATIONS . . . . . . . . . . . . . . . . . . . . . . .

KIT CONTENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ORDERING REPLACEMENT PARTS . . . . . . . . . . . . . . . .

BUILDING INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . .

WING ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Assemble the Wing Joiners . . . . . . . . . . . . . . . . . . . . . .

Join the Wing Panels . . . . . . . . . . . . . . . . . . . . . . . . . . .

Install the Aileron Servo Tray . . . . . . . . . . . . . . . . . . . . .

Install the Wing Bolt Plate . . . . . . . . . . . . . . . . . . . . . . .

INSTALL FUSELAGE COMPONENTS . . . . . . . . . . . . . . .

Install the Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Install the Pushrod Tubes . . . . . . . . . . . . . . . . . . . . . . . .

Assemble the Fuel Tank . . . . . . . . . . . . . . . . . . . . . . . . .

Complete the Engine & Fuel Tank Installation . . . . . . . .

MOUNT THE WING TO THE FUSELAGE . . . . . . . . . . . . . .

Mount the Wing to the Fuselage . . . . . . . . . . . . . . . . . .

INSTALL THE TAIL COMPONENTS . . . . . . . . . . . . . . . . .

Join the Elevator Halves . . . . . . . . . . . . . . . . . . . . . . . . .

Align & Install the Stabilizer . . . . . . . . . . . . . . . . . . . . . .

Install the Vertical Fin . . . . . . . . . . . . . . . . . . . . . . . . . . .

Install the Hinges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

INSTALL THE LANDING GEAR . . . . . . . . . . . . . . . . . . . . .

Mount the Main Landing Gear . . . . . . . . . . . . . . . . . . . .

Mount the Nose Gear . . . . . . . . . . . . . . . . . . . . . . . . . . .

RADIO INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . .

Install the Radio Components . . . . . . . . . . . . . . . . . . . .

Install the Pushrods & Control Horns . . . . . . . . . . . . . . .

FINAL ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Install the Wheels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Install the Canopy . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GET THE MODEL READY TO FLY . . . . . . . . . . . . . . . . . .

Check the Control Directions . . . . . . . . . . . . . . . . . . . . .

Set the Control Throws . . . . . . . . . . . . . . . . . . . . . . . . .

Balance the Model (C.G.) . . . . . . . . . . . . . . . . . . . . . . . .

Balance the Model Laterally . . . . . . . . . . . . . . . . . . . . . .

PREFLIGHT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ENGINE SAFETY PRECAUTIONS . . . . . . . . . . . . . . . . . .

AMA SAFETY CODE . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

IMAA SAFETY CODE . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CHECK LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FLYING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Takeoff . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Flight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Landing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Congratulations and thank you for purchasing the Great

Planes Easy Sport 40 ARF, with MonoKote covering! This

model has many features that are usually found only in kittype aircraft. These features include: rod-in-tube pushrods,

an adjustable glass-filled nylon engine mount, multiple color

covering and high quality Great Planes hardware. The

construction technique that is used for this aircraft results in

a model that is lighter and stronger than conventional, builtup balsa airplanes. The Easy Spor t 40 ARF will provide an

excellent second aircraft to help build confidence and assist

in perfecting your aerobatic skills.

The Great Planes Easy Sport 40 ARF is similar to the

original Easy Sport 40 kit. The Almost-Ready-to-Fly version

is stable enough to be a great second airplane, yet has

aerobatic capabilities which allows rapid advancement of

your aerobatic skills. This Easy Spor t has the same good

looks and excellent stability at low speeds that can be

found on the kit version and reflects the design expertise

and high quality standards of Great Planes kits.

For the latest technical updates or manual corrections to

the Easy Sport ARF visit the web site listed below and

select the Great Planes Easy Sport ARF. If there is new

technical information or changes to this model a “tech

notice” box will appear in the upper left corner of the page.

http://www.greatplanes.com/airplanes/index.html

1. Your Easy Sport ARF should not be considered a toy, but

rather a sophisticated, working model that functions very

much like a full-size airplane. Because of its performance

capabilities, the Easy Sport ARF, if not assembled and

operated correctly, could possibly cause injur y to yourself or

spectators and damage to property.

2. You must assemble the model according to the

instructions. Do not alter or modify the model, as doing so

may result in an unsafe or unflyable model. In a few cases

the instructions may differ slightly from the photos.In those

instances the written instructions should be considered

as correct.

3. You must take time to build straight, true and strong.

4. You must use an R/C radio system that is in first-class

condition, and a correctly sized engine and components

(fuel tank, wheels, etc.) throughout the building process.

5. You must correctly install all R/C and other components

so that the model operates correctly on the ground and in

the air.

PROTECT Y OUR MODEL,YOURSELF

& OTHERS...FOLLOW THIS

IMPORTANT SAFETY PRECAUTION

INTRODUCTIONTABLE OF CONTENTS

2

6. You must check the operation of the model before every

flight to insure that all equipment is operating and that the

model has remained structurally sound. Be sure to check

clevises or other connectors often and replace them if they

show any signs of wear or fatigue.

7. If you are not already an experienced R/C pilot, you

should fly the model only with the help of a competent,

experienced R/C pilot.

Remember: Take your time and follow the instructions to

end up with a well-built model that is straight and true.

If you have not flown this type of model before, we

recommend that you get the assistance of an

experienced pilot in your R/C club for your first flights.

You’ll learn faster and avoid risking your model before you

are truly ready to fly it. Your local hobby shop has

information about clubs in your area whose membership

includes experienced pilots.

In addition to joining an R/C club, we strongly recommend you

join the AMA (Academy of Model Aeronautics). AMA

membership is required to fly at AMA sanctioned clubs.There

are over 2,500 AMA chartered clubs across the country.

Among other benefits, the AMA provides insurance to its

members who fly at sanctioned sites and events. Additionally,

training programs and instructors are available at AMA club

sites to help you get started the right way. Contact the AMA at

the address or toll-free phone number below:

Academy of Model Aeronautics

5151 East Memorial Drive

Muncie, IN 47302-9252

Tele. (800) 435-9262

Fax (765) 741-0057

Or via the Internet at: http://www.modelaircraft.org

This is a partial list of items required to finish the Easy

Sport 40 ARF that may require planning or decision making

before starting to build.

❏ 4 Channel Radio with 4 Servos

This is the list of hardware and accessories required to

finish the Easy Sport ARF. Order numbers are provided

in parentheses.

❏ Muffler Extension (some engines) (OSMG2616 for

O.S..40 LA)

❏ Propellers (see engine instructions for sizes)

❏ 18” [457mm] Silicone fuel tubing (GPMQ4131)

❏ 1/4” [6.4mm] Latex foam rubber for receiver and

battery (HCAQ1000)

Note: Larger wheels than those included may be required

for operation on rough grass fields.

Hardware and Accessories

Radio Equipment

ADDITIONAL ITEMS REQUIRED

Engine Recommendations

The recommended engine size range for the Easy Sport

40 ARF is as follows:

.40 to .51 two-stroke

.52 to .70 four-stroke

The Easy Sport 40 ARF will fly well with any of the

recommended engine sizes. For “Hot Dogging” and

speedy performance, we suggest either an O.S..46 FX or

a SuperTigre GS-45, both 2-stroke engines. An O.S. FS70 Surpass II is a good choice for those who prefer

4-stroke engines.

DECISIONS YOU MUST MAKE

NOTE:We, as the kit manufacturer, can provide you with

a top quality kit and great instructions, but ultimately the

quality of your finished model depends on how you build

it; therefore, we cannot in any way guarantee the

performance of your completed model, and no

representations are expressed or implied as to the

performance or safety of your completed model.

3

In addition to common household tools and hobby tools,

this is the “short list” of the most important items required to

build the Easy Sport 40 ARF.

Great Planes Pro™ CA and

Epoxy glue are recommended.

❏ 1 oz.Thin Pro CA (GPMR6002)

❏ 1 oz. Medium Pro CA+ (GPMR6008)

❏ 6-Minute Epoxy (GPMR6045)

❏ 30-Minute Epoxy (GPMR6047)

❏ Hobby knife (HCAR0105)

❏ #11 blades (HCAR0211)

❏ Small T -pins (HCAR5100)

❏ Builder’s triangle (HCAR0480)

❏ Straightedge with scale (HCAR0475)

❏ Masking tape (TOPR8018)

❏ Epoxy Brushes (GPMR8060)

❏ Mixing Sticks (GPMR8055)

❏ Small Phillips and flat blade screwdrivers

❏ Hand or electric drill

❏ Hobby saw (razor saw)

❏ Non-elastic monofilament or Kevlar fishing line

❏ Isopropyl rubbing alcohol (70%)

❏ Felt-tip pen

❏ Drill Bits:1/16”,3/32”,7/64”,1/8”,1/4” [1.6, 2.4, 2.8, 3.2, 6.4mm]

❏ Sanding tools and sandpaper assortment

Here is a list of optional tools mentioned in the manual that

will help you build the Easy Sport 40 ARF.

❏ Great Planes CG Machine™ (GPMR2400)

❏ Top Flite Precision Magnetic Prop Balancer

™

(TOPQ5700)

❏ Top Flite Hot Sock™ iron cover (TOPR2175)

❏ Sealing Iron (TOPR2100)

❏ Heat Gun (TOPR2000)

❏ CA Debonder (GPMR6039)

❏ CA Applicator Tips (HCAR3780)

❏ R/C-56 Canopy Glue (JOZR5007)

❏ Threadlocker (GPMR6060)

❏ Builders Triangle Set (HCAR0480) (for fin alignment)

❏ Rotary tool such as Dremel

❏ Rotary tool reinforced cut-off wheel (GPMR8020)

❏ Dead Center

™

Engine Mount Hole Locator (GPMR8130)

❏ Great Planes AccuThrow Deflection Gauge (GPMR2405)

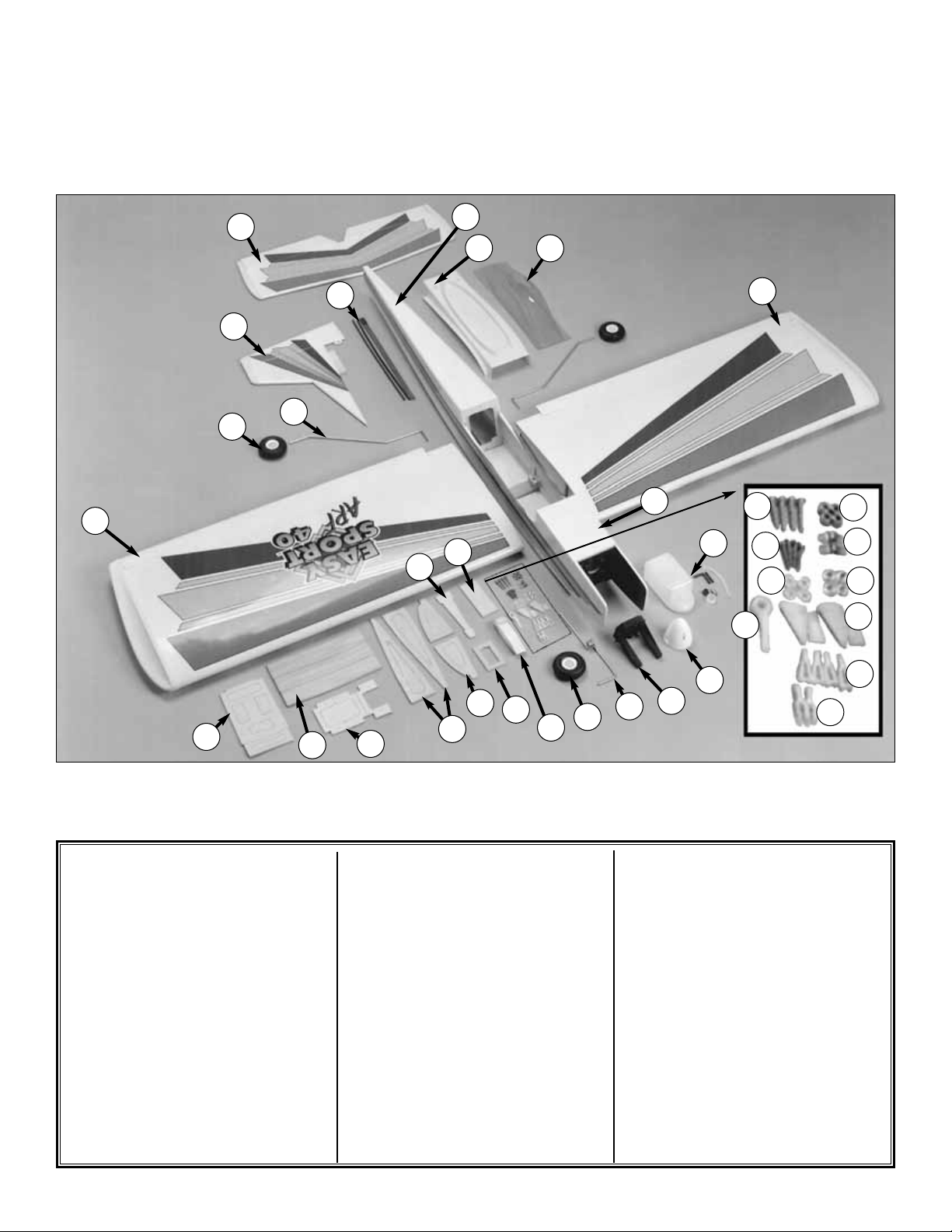

There are two types of screws used in this kit:

Sheet metal screws are designated by a number and a length.

For example #6 x 3/4”

This is a number six screw that is 3/4”long.

Machine screws are designated by a number, threads per

inch, and a length.

For example 4-40 x 3/4”

This is a number four screw that is 3/4” long with forty

threads per inch

.

When you see the term

test fit

in the instructions, it means

that you should first position the part on the assembly

without using any glue, then slightly modify or

custom fit

the part as necessary for the best fit.

Whenever the term

glue

is written you should rely upon

your experience to decide what type of glue to use.When a

specific type of adhesive works best for that step, the

instructions will make a recommendation.

Whenever just

epoxy

is specified you may use

either

30minute (or 45-minute) epoxy or6-minute epoxy. When 30minute epoxy is specified it is highly recommended that

you use only 30-minute (or 45-minute) epoxy, because you

will need the working time and/or the additional strength.

Photos and sketches are placed before the step they

refer to. Frequently you can study photos in following steps

to get another view of the same parts.

The Easy Sport 40 ARF is factory-covered with Top Flite

MonoKote film. Should repairs ever be required, MonoKote

can be patched with additional MonoKote purchased

separately. MonoKote is packaged in six-foot rolls, but some

hobby shops also sell it by the foot. If only a small piece of

MonoKote is needed for a minor patch, perhaps a fellow

modeler would give you some. MonoKote is applied with a

model airplane covering iron, but in an emergency a regular

iron could be used. A roll of MonoKote includes full

instructions for application.Following are the colors used on

this model and order numbers for six foot rolls.

White . . . . . . . .TOPQ0204

Red . . . . . . . . .TOPQ0201

Gray . . . . . . . . .TOPQ0220

Royal Blue . . . .TOPQ0221

Important Building Notes

Optional Supplies and Tools

Adhesives and Building Supplies

4

5

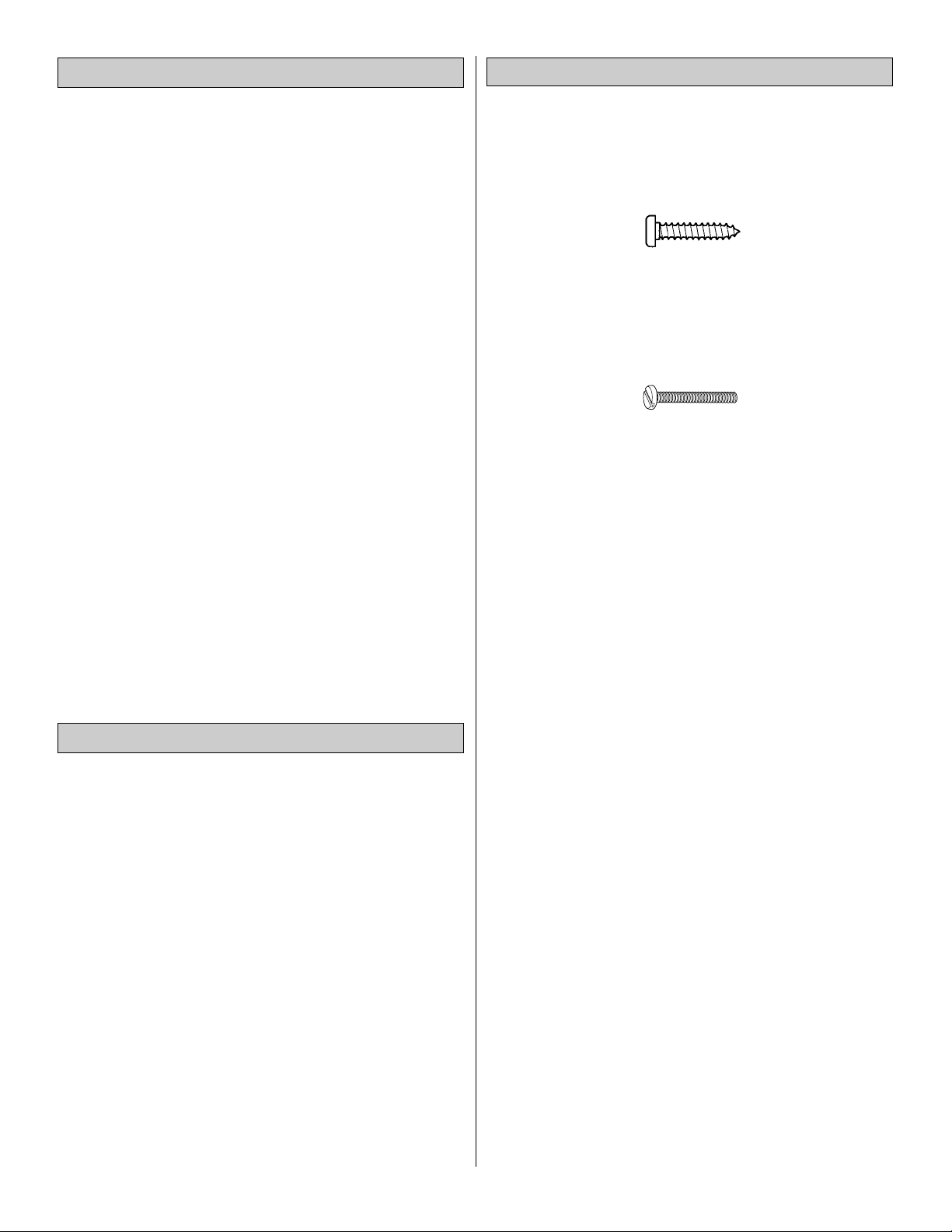

1 Stabilizer/Elevator Assembly

2 Rudder/Fin Assembly

3 Wheels

4 Main Landing Gear Wire

5 Pushrods

6 Right Wing Panel

7 Servo Tray

8 Wing Joiner

9 Plywd Wing Hold-Down Plates

10 Aft Root Ribs

11 Forward Root Ribs

12 Aileron Servo Tray

13 Stabilizer Mounting Base

14 Wing Bolt Plate

15 Wing Tape

16 6-32 x 1" Screws

17 Wheel Collars

18 6-32x3/4" Sheet Metal Screws

19 Nylon Landing Gear Straps

20 #6 Flat Washers

21 Silicone Clevis Retainers

22 Nylon Steering Arm

23 Nylon Control Horns

24 Nylon Clevis

25 Swivel Clevis

26 Nose Gear Wire

27 Engine Mount R & L

28 Spinner

29 Fuel T ank Assembly

30 Left Wing Panel

31 Canopy

32 Wing Fairing

33 Fuselage

34 Hatch

29

34

16

17

18

20

22

19

21

23

24

25

30

31

32

33

2

3

4

5

6

7

8

9

10

11

12

13

14

15

3

26

27

28

1

PARTS LIST

Before starting to build, use the Kit Contents list to take an inventory of this kit to make sure it is complete, and inspect

the parts to make sure they are of acceptable quality. If any par ts are missing or are not of acceptable quality, or if you

need assistance with assembly, contact Product Support. When repor ting defective or missing parts, use the part names

exactly as they are written in the Kit Contents list on this page.

Great Planes Product Support:Telephone: (217) 398-8970 Fax: (217) 398-7721 E-mail:

airsupport@greatplanes.com

6

Note: As epoxy is used for most of this kit’s assembly, it’s a

good idea to keep rubbing alcohol and paper towels handy

for cleanup. Before the epoxy has had time to cure, moisten

a paper towel with alcohol and clean off any e xcess epoxy.

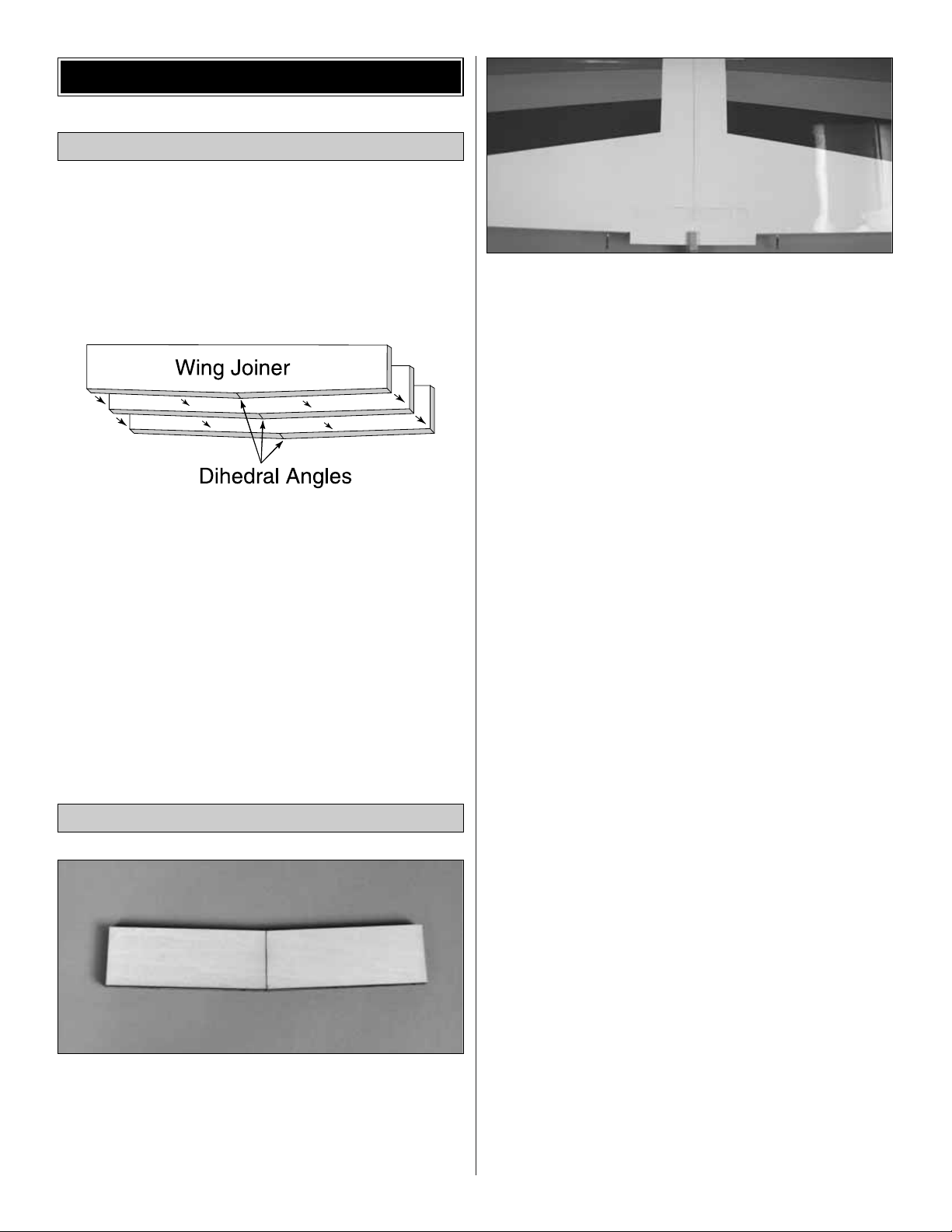

❏ 1. Lightly sand the edges of the three plywood wing

joiners to remove any rough edges. Use 6-minute epoxy to

glue the three pieces together. Be sure that the slight

dihedral angle is on the same edge of all three pieces.

Clamp the wing joiners together or weigh them down on a

flat surface while the epoxy cures.

❏ 1. Draw a centerline on the wing joiner as shown in the

photo. Test fit the wing joiner into each wing panel. You

must be certain that the joiner fits all the way into the wing

panels. The joiner should fit snugly into each wing panel.

Sand the joiner if it does not fit snugly or does not fit

completely into the wing panels.

❏ 2. Sand the inside of both wing roots for a nice flush fit.

Test fit the panels together with the wing joiner in place.

The angled edge of the joiner points towards the bottom of

the wing. Check the alignment of the leading and trailing

edges. They should line up nicely with the roots fitting

together without any gaps. Sand the root ribs if any

imperfections are keeping the wing halves from fitting

together properly.

Carefully read and practice the following step

completely before mixing any epoxy. The entire step

must be completed before the epoxy begins to set.

❏ 3. When you are satisfied with the fit, pull the panels apart

and mix up a large batch (about 3/4 oz.) of 30-minute

epoxy. Using an epoxy mixing stick, liberally spread epoxy

inside both of the joiner slots and on one half of the joiner

itself.Next, quickly install the glued end of the joiner into one

of the slots. Spread more epoxy onto the root ribs and the

protruding end of the wing joiner. Slide the two wing panels

together. The epoxy should squeeze out around the edges.

This is a good sign that there is enough epoxy to securely

join the two wing halves. Double check the alignment and

wipe off any excess glue with a paper towel and rubbing

alcohol. Hold the two wing halves together using masking

tape. Continually check the alignment of the wing halves

while the epoxy cures.

❏ 4. Once the glue has cured, check the joint for any small

gaps and fill them with epoxy. Wipe off any excess epoxy

using a paper towel and rubbing alcohol. The paper towel

can also be used to remove any fingerprints or epoxy

residue that may have been left behind.

Join the Wing Panels

Assemble the Wing Joiners

WING ASSEMBLY

7

❏ 1. Lay the 1/8” [3.2mm] ply aileron servo tray on the

bottom of the wing. Center the tray over its mounting area

and draw a line on the covering around it using a felt-tip

marking pen.

❏ 2. Remove the covering inside the lines with a hobby

knife, being careful not to cut into the wood.Glue the ser vo

tray in place with 6-minute epoxy or medium CA.

❏ 3. After the glue has cured, trim the wood inside the

servo tray. Trial fit the servo in the tray, trimming the tray

and wing as needed.

❏ 1. Position the 1/8” [3.2mm] ply wing bolt plate 1/4”

forward of the trailing edge of the top of the wing. Use the

centerline on the wing bolt plate to center it on the centerline

of the wing.Draw a line around the plate on the covering using

a felt-tip pen. Remove the covering inside the lines with a

hobby knife , being careful not to cut into the wood.

❏ 2. Glue the wing bolt plate in position with 6-minute

epoxy or medium CA.

❏ 3. Turn the wing over and remove the covering from the

holes for the wing bolts. Using a 1/4” [6.4mm] drill bit, drill

holes through the wing bolt plate for the wing bolts.

Note:The following steps depict the installation of a 2-stroke

engine. The steps are similar if you are using a 4-stroke

engine, although some changes to the throttle pushrod

routings will need to be made.

❏ 1. Remove the center spreader from the engine mount

halves.Trim any excess flashing with a hobby knife or file.

❏ 2. This is a good time to fuelproof the engine

compartment. Lightly brush a mixture of 30-minute epoxy

thinned with isopropyl alcohol into the engine

compartment. Be careful not to get any of the epoxy into

the blind nuts that are located in the firewall.

Install the Engine

INSTALL FUSELAGE COMPONENTS

Install the Wing Bolt Plate

Install the Aileron Servo Tray

❏ 3. Fit the two halves of the engine mount together. Use

four #6 flat washers and four 6-32 x 1" [25.4mm] phillips

head screws to attach the engine mount to the firewall.

Blind nuts have already been installed in the firewall for this

purpose. Don’t tighten the screws completely yet, as the

mount will need to be adjusted to fit the engine.

❏ 4. Test fit the engine to the mount. Adjust the width of

the mounting rails to accommodate the engine without

being too tight or too loose. Tighten the mount screws so

that you can mark the engine screw holes without allowing

the rails to move. When you tighten the screws, slide the

mount as close to the right side of the fuselage as you can.

❏ 5. Position the engine so that the drive washer is

4-1/2" [114mm] from the firewall. Using one of the 17-1/2"

[444mm] push rods, sharpen the non-threaded end using a

file or sandpaper. Use this shar pened wire to scribe the four

mounting holes onto the rails. Use a 7/64" [2.8mm] drill bit to

drill pilot holes through the rails for the #6 sheet metal screws.

❏ 6. Attach the engine to the rails using four #6 x 3/4"

[19mm] sheet metal screws.

❏ 1. Locate the pushrod exit slot under the covering on the

tail section of the fuselage by lightly pressing with your

fingers. The slot should be located 4" [102mm] from the

rear the fuselage and 3/4" [19mm] from the bottom of the

fuselage. Trim the covering to provide access to the

pushrod exit.

❏ 2. Trim one of the pushrod tubes to 12" [305mm]. After

roughening the tube with 220-grit sand paper, install the

tube into the upper right hole in the firewall. This will be

used for the throttle pushrod. Leave about 1/4" [6.4mm] of

the tube exposed in front of the firewall. Glue the pushrod

tube to both sides of the firewall using medium CA.

Note: Depending on the engine you use, the location of the

pushrod holes may vary.

❏ 3. Trim the remaining pushrod tube to 13-1/2" for use as

the nose wheel pushrod tube. After roughening the tube

with 220-grit sand paper, install the tube into the lower left

hole in the firewall.This tube should be installed flush with

the front of the firewall. Glue the pushrod tube in place to

the former at the LE of the wing.

Install the Pushrod Tubes

#6 x 3/4" [19mm] Sheet Metal Screw (4)

8

Loading...

Loading...