Great Plains Mfg., Inc.

Installation Instructions 1

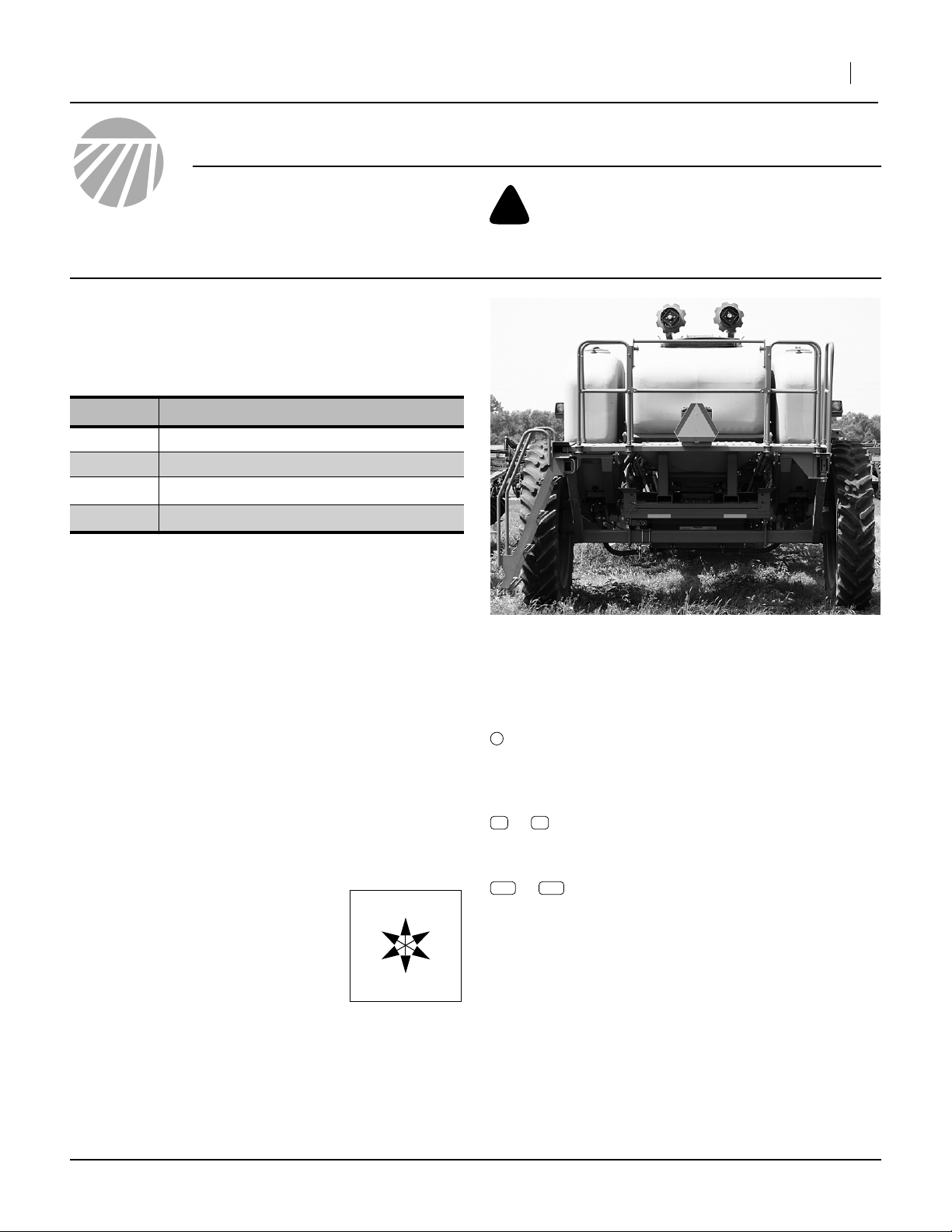

Fertilizer System

Yield-Pro Planters

Used with:

• YP1625

General Information

These instructions explain how to install a complete Fertilizer System. These kit add tanks, a ground drive pump

and two boom systems to a YP1625 planter that presently

has no fertilizer components.

These instructions apply to an installation of all of:

Kit Kit Description

407-122A YP FERTILIZER TANK KIT

407-133A YP 1625 FERT BOOM ONLY ASSY

407-134A YP1225 & Y1625 FERT PUMP ONLY

407-137A YP16 HI-RATE FERT MANIFOLD KIT

The 407-133A low rate or starter system is presumed to

be connected to the 407-122A tank system via the 407134A ground drive pump.

The 407-137A high rate system is presumed to be connected to a customer-provisioned pump and material supply system.

Each set of kits upgrades an entire planter.

When you see this symbol, the subsequent instructions

and warnings are serious - follow without exception.

!

Your life and the lives of others depend on it!

Figure 1

Tanks and Inlet Installed

27103

Tools Required

• current YP1625 Parts Manual (401-226P)

current YP1625 Operator Manual (401-226M)

• basic hand tools, including:

- pipe or tubing cutter,

- brush for liquid pipe sealant

• hoist or lift with a capacity of 500 pounds (227 kg)

• about two dozen UV-resistant cable ties at least 8

inches long

Notations and Conventions

“Left” and “Right” are facing in the

direction of machine travel. An orientation rose in the line art illustrations

shows the directions of Left, Right,

Front, Back, Up, Down.

U

F

L

D

R

B

Call-Outs

1

11 13

to

101 354

to

Single-digit callouts identify components in

the currently referenced Figure or Figures.

These numbers may be reused for different

items from page to page.

Two-digit callouts reference affected existing

parts from the table on page 35. The descriptions match those in your Parts Manual.

Three-digit callouts reference new parts from

the new parts lists beginning on page 28.

The descriptions match those on the cartons,

bags or item tags, as well as descriptions

your updated Parts Manual.

©Copyright 2007 Printed 02/29/2008 407-197M

2 Fertilizer System

Before You Start

Review these instructions, with the following objectives at

each step:

• Inventory: examine any called-for sub-assemblies

and make sure all parts are present.

• Inventory: Select any called-for individual parts

and group them according to steps.

• Comprehension: make sure you understand

where each part or assembly is installed, and

what tools are required for the task.

Pre-Assembly Preparation

Work Location

1. Move the planter to a location with:

• ample clearance for folding and unfolding,

• ample clearance for the hoist or lift,

• protected from wind,

• adequate illumination, and;

• a clean surface for easily recovering any dropped

parts.

Great Plains Mfg., Inc.

Prepare Planter

2. Hitch the planter to a suitable tractor per the instructions in the Operator Manual. Folding, unfolding,

raising, lowering, and simulated field operations are

necessary during this installation.

3. Secure the planter per the Parking instructions in the

Operator Manual (401-226M). Put the tractor in Park

and set the parking brake.

4. To provide convenient access to mount points,

remove any seed box or seed hopper* present.

Empty any hopper before removal.

* The fertilizer tanks are incompatible with the 150bu

hopper. Their mounting brackets use the same mount

points as 150bu hardware. If that was the seed container in use, it must be replaced by an 82bu hopper or

bulk seed boxes. Remove the empty hopper and all

frame hardware at tool bars.

407-197M 02/29/2008

Great Plains Mfg., Inc.

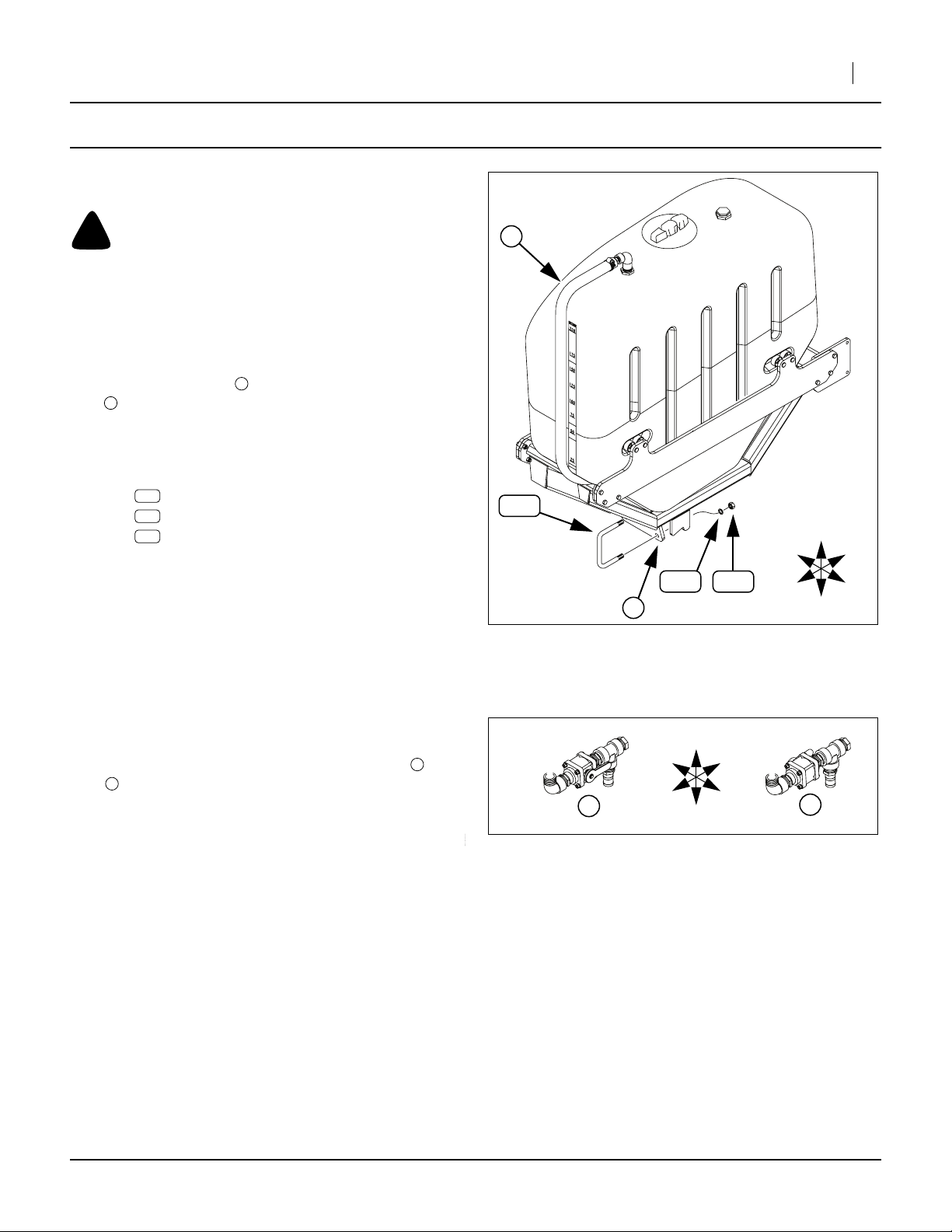

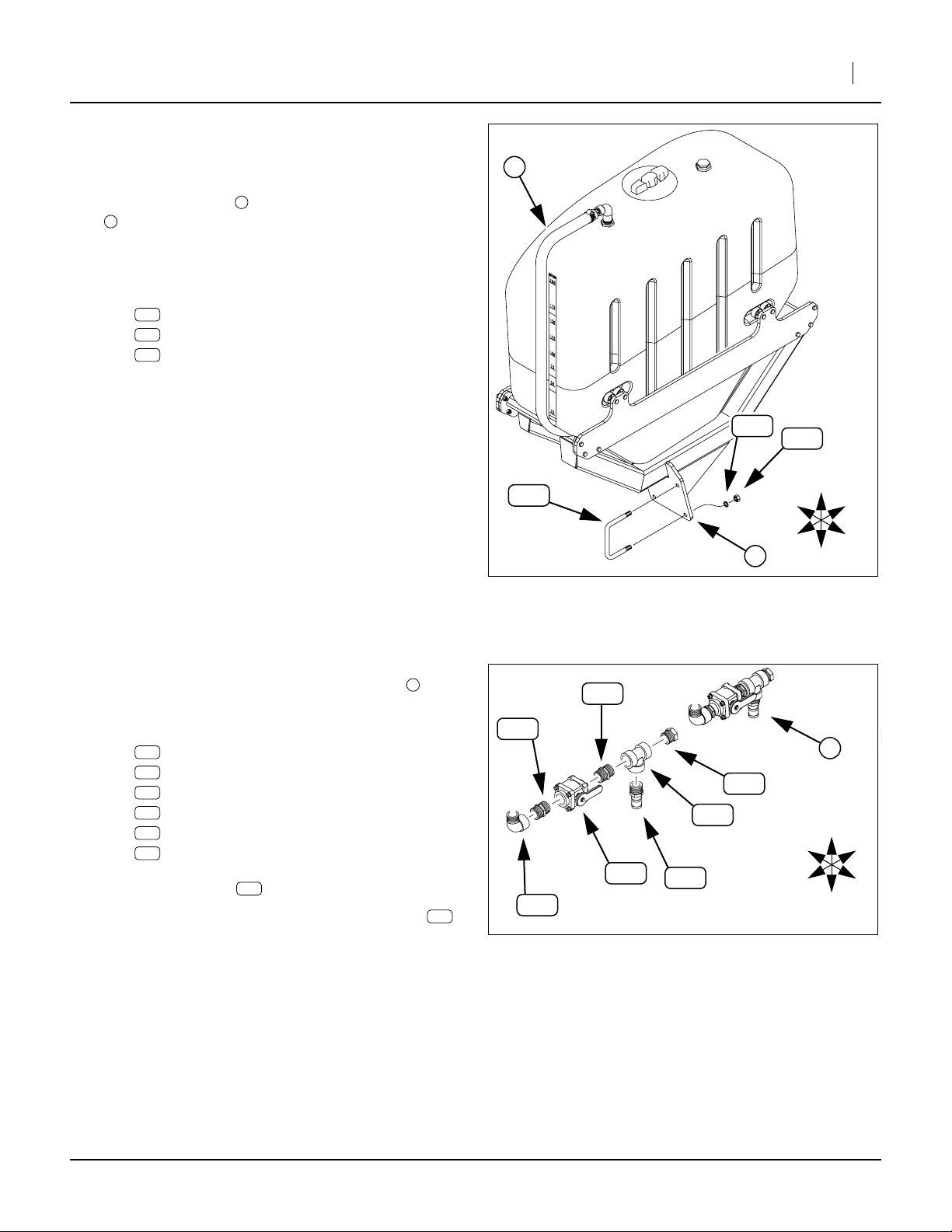

Install Tanks

This section installs most of the components of the 407122A kit.

Installation Instructions 3

!

CAUTION

High profile hazard - install the tanks on a calm day or in a

location protected from wind.

Prepare Left Tank

Refer to Figure 2

5. The left tank and cradle is pre-assembled but does

not have an assembly part number. It is identified by

the mounting plate orientation. With the sight tube

2

facing forward, the plate is on the bottom right

(inside).

6. Remove and save the following parts:

Qty Call Part Description

4 803-027C NUT HEX 3/4-10 PLT

110

4 804-023C WASHER LOCK SPRING 3/4 PLT

114

2 806-050C U-BOLT 3/4-10 X 7 X 8 1/2

115

1

2

115

114

110

1

Figure 2

Left Tank, As Shipped

R

F

U

B

L

D

27087

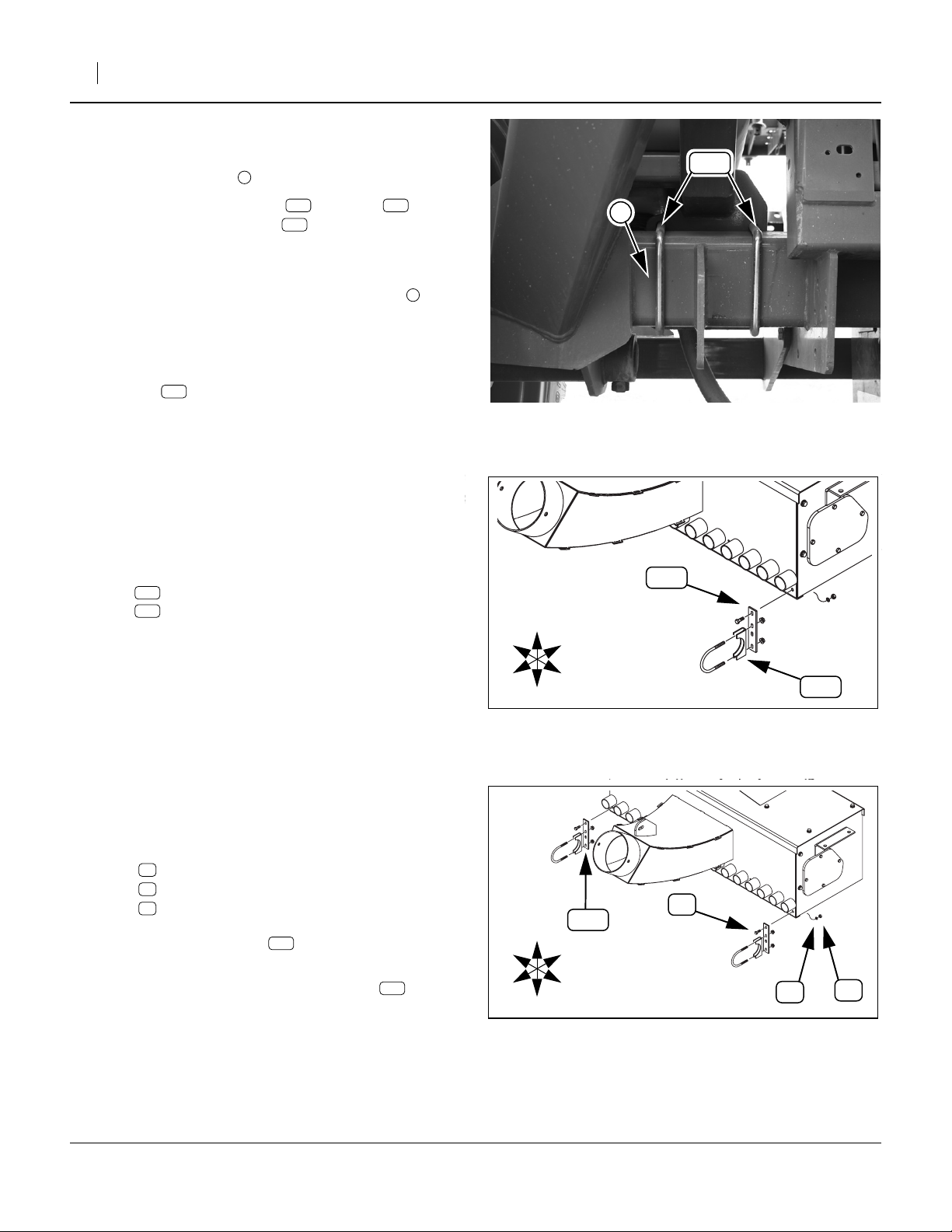

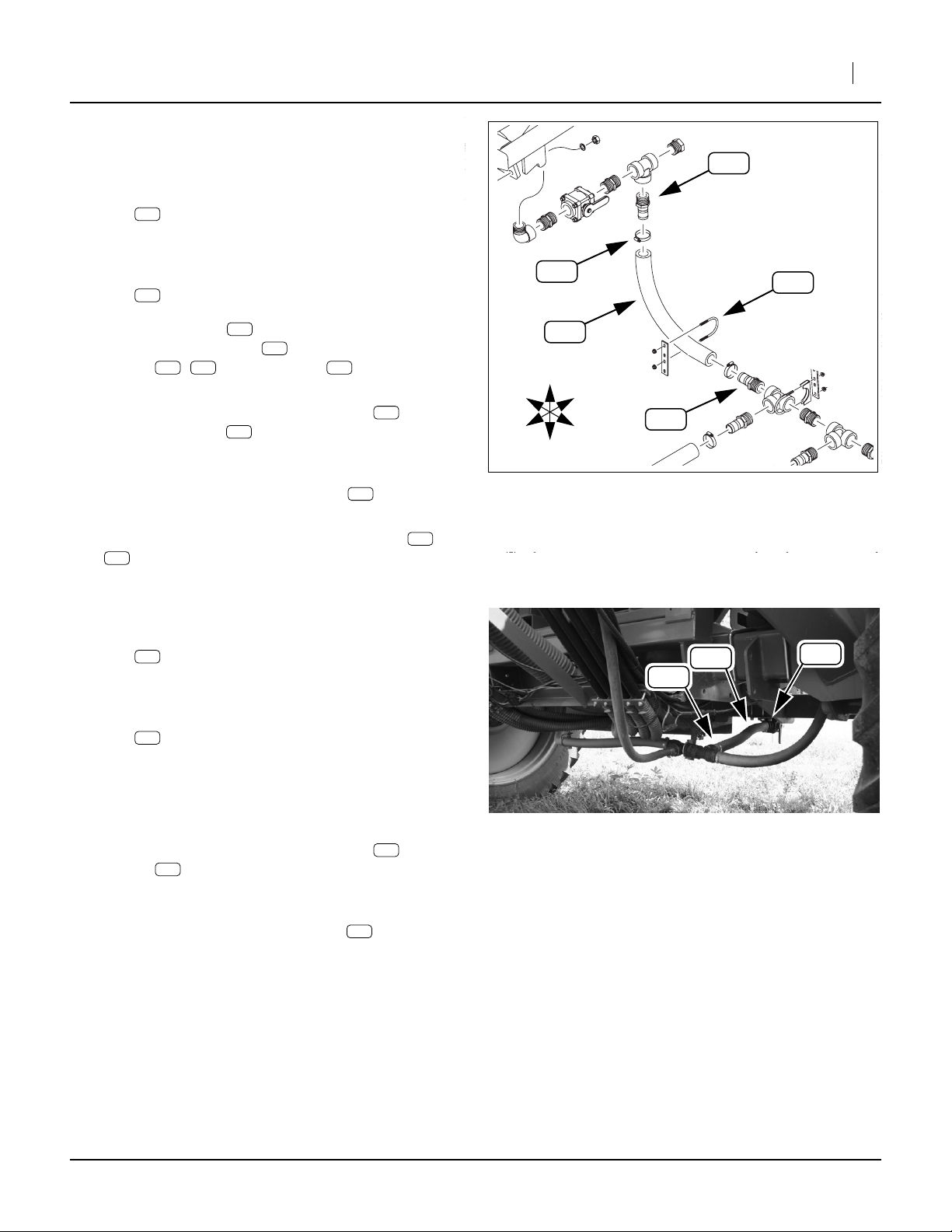

Prepare Left Tank Plumbing

Refer to Figure 3 and Figure 4

Each tank has a shut-off/clean-out assembly (left ,

R

right , and these are mirror images of each other).

The shut-off valve handles are to the inside (planter center) with handles pointing to planter rear when valves are

open.

02/29/2008 407-197M

L

R

Tank Fittings ID

U

R

F

D

Figure 3

B

L

L

99999

4 Fertilizer System

Install Left Tank Elbow

Refer to Figure 4

7. Select the left shut-off/clean-out assembly , consisting of:

L

Great Plains Mfg., Inc.

136

Qty Call Part Description

1 830-052C EL 1 1/2MNPT X 1 1/2FNPT POLYP

137

2 830-045C AD 1 1/2MNPT POLYPROP

136

1 829-013C VALVE 1 1/2FNPT BALL POLYPROP

131

1 830-031C TEE 1 1/2FNPT POLYPROP

135

1 830-024C PL 1 1/2MNPT POLYPROP

134

1 830-094C AD 1 1/2MNPT X 1 1/2HB POLYP

138

8. Remove the elbow (which is only loosely pre-

137

assembled to the fittings).

9. Select and open the can of sealant

Qty Call Part Description

1 890-310C RECTORSEAL 21 BLK THD SEALANT

147

10. Apply sealant to the male threads of the elbow ,

and thread it into the 1

1

⁄

in FNPT bulkhead at the

2

137

bottom of the tank. Close can when not in use.

Refer to Figure 5

11. Using a hoist or lift, position the U-bolt plate of the

cradle against the rear face of the left end of the

mainframe tool bar .

12. Loosely install the U-bolts , washers (not

shown in photo) and nuts (not shown in photo).

5

115

110

114

13. Adjust the position of the cradle as far to the left (outside) as possible. Tighten the nuts.

136

137

5

131

138

Figure 4

Left Tank Fittings

115

135

134

R

F

L

U

B

L

D

27086

14. Select the left shut-off/clean-out assembly . Oper-

L

ate the valve handle to the closed position. After

installation, the handle needs to be down in this position. Rotate the handle to open.

15. Apply sealant to the male threads of the forward

adaptor . Thread the fitting assembly into the

136

tank elbow. Adjust final rotation to place valve handle

to correct side so that handle closed will be down.

Figure 5

27089

Left Tank Cradle Mount

407-197M 02/29/2008

Great Plains Mfg., Inc.

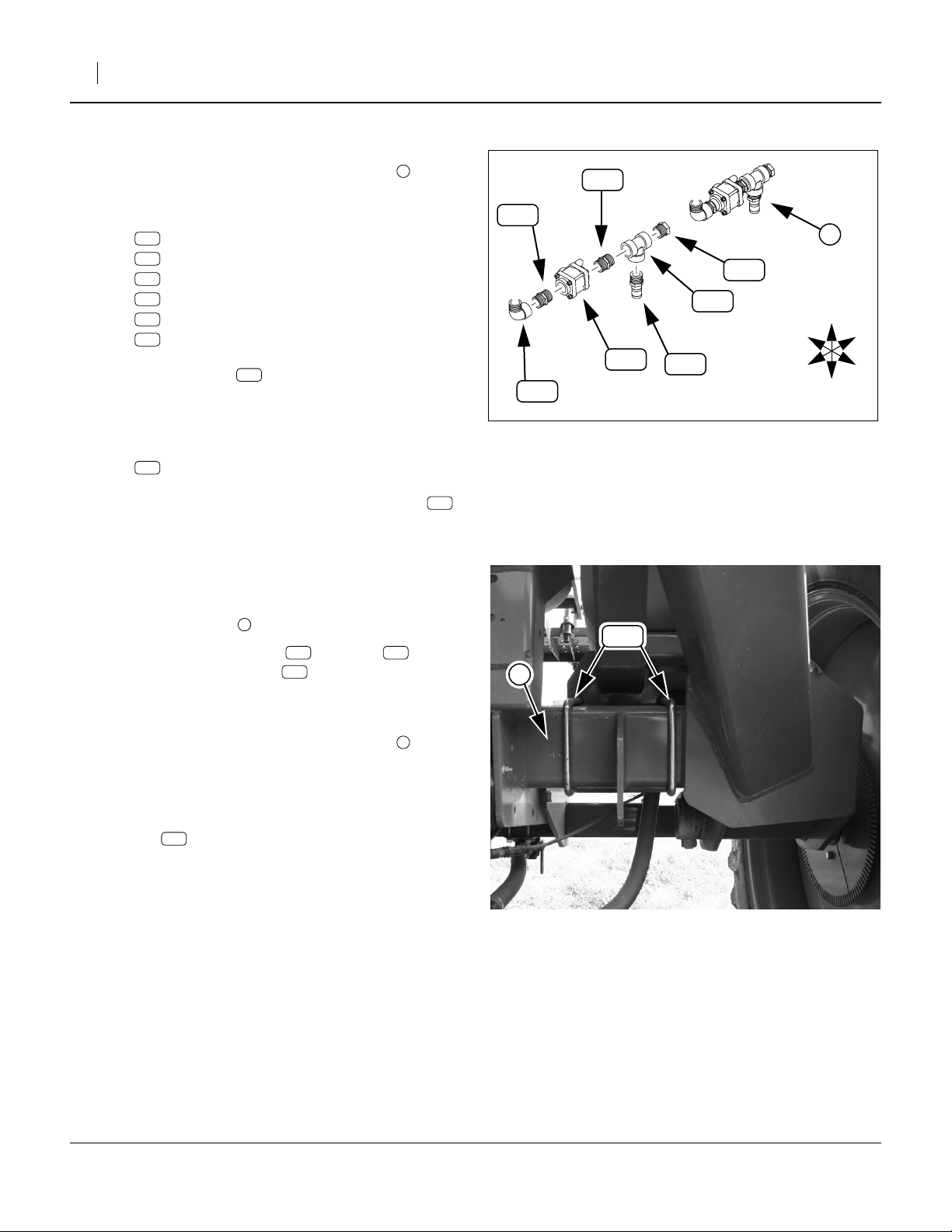

Prepare Right Tank

Refer to Figure 6

16. The right tank and cradle is pre-assembled but does

not have an assembly part number. It is identified by

the mounting plate orientation. With the sight tube

2

facing forward, the plate is on the bottom left

(inside).

17. Remove and save the following parts:

Qty Call Part Description

4 803-027C NUT HEX 3/4-10 PLT

110

4 804-023C WASHER LOCK SPRING 3/4 PLT

114

2 806-050C U-BOLT 3/4-10 X 7 X 8 1/2

115

1

Installation Instructions 5

2

Install Right Tank Elbow

Refer to Figure 7

18. Select the right shut-off/clean-out assembly , consisting of:

Qty Call Part Description

1 830-052C EL 1 1/2MNPT X 1 1/2FNPT POLYP

137

2 830-045C AD 1 1/2MNPT POLYPROP

136

1 829-013C VALVE 1 1/2FNPT BALL POLYPROP

131

1 830-031C TEE 1 1/2FNPT POLYPROP

135

1 830-024C PL 1 1/2MNPT POLYPROP

134

1 830-094C AD 1 1/2MNPT X 1 1/2HB POLYP

138

19. Remove the elbow .

20. Apply sealant to the male threads of the elbow ,

and thread it into the 1

bottom of the tank.

137

1

⁄

in FNPT bulkhead at the

2

R

137

115

136

137

Figure 6

Right Tank, As Shipped

136

135

131

138

Figure 7

Right Tank Fittings

114

134

110

U

R

F

1

B

L

D

27087

R

U

R

F

B

L

D

27086

02/29/2008 407-197M

6 Fertilizer System

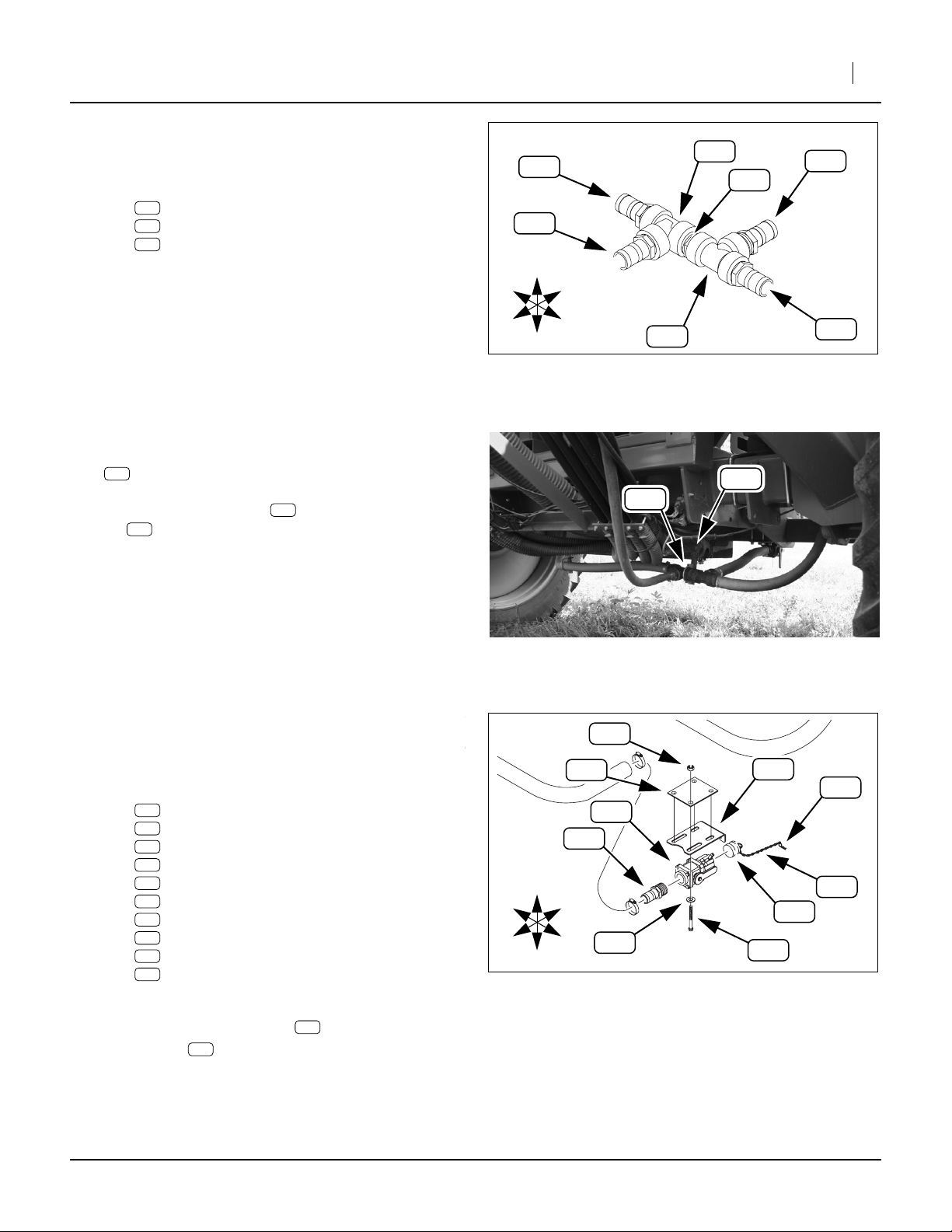

Refer to Figure 8

21. Using a hoist or lift, position the U-bolt plate of the

cradle against the rear face of the right end of the

mainframe tool bar .

5

Great Plains Mfg., Inc.

115

22. Loosely install the U-bolts , washers (not

shown in photo) and nuts (not shown in photo).

23. Adjust the position of the cradle as far to the right

(outside) as possible. Tighten the nuts.

24. Select the right shut-off/clean-out assembly .

Operate the valve handle to the closed position. After

installation, the handle needs to be down in this position. Rotate the handle to open.

25. Apply sealant to the male threads of the forward

adaptor . Thread the fitting assembly into the

tank elbow. Adjust final rotation to place valve handle

to correct side so that handle closed will be down.

136

115

110

114

R

Install Tank Interconnect Fittings

Refer to Figure 9

26. Select sets of mounting hardware, consisting of

(quantities are for both sets):

Qty Call Part Description

2 506-365D WET BOOM FLAT HOSE BRACKET

120

2 890-522C MUFFLER CLAMP 2.50 SIZE (which

148

27. Disassemble one of the clamps.

includes the bracket, U-bolt and nuts)

R

F

U

D

2

Figure 8

Right Tank Cradle Mount

120

B

L

Figure 9

Tank Interconnect Mounts

27090

148

27104

Refer to Figure 10

28. At each lower front corner of the seed box manifold,

remove and save the existing:

Qty Call Part Description

2 802-078C HHCS 1/4-20X5/8 GR5

11

2 803-006C NUT HEX 1/4-20 PLT

12

2 804-006C WASHER LOCK SPRING 1/4 PLT

13

29. Attach the bare bracket to the front lower left

corner of the manifold, using the saved fasteners.

30. Attach the still-assembled other bracket to the

front lower right corner of the manifold, using the

saved fasteners.

407-197M 02/29/2008

120

120

R

F

U

D

120

B

L

Interconnect Mount Points

11

Figure 10

13

12

27104

Great Plains Mfg., Inc.

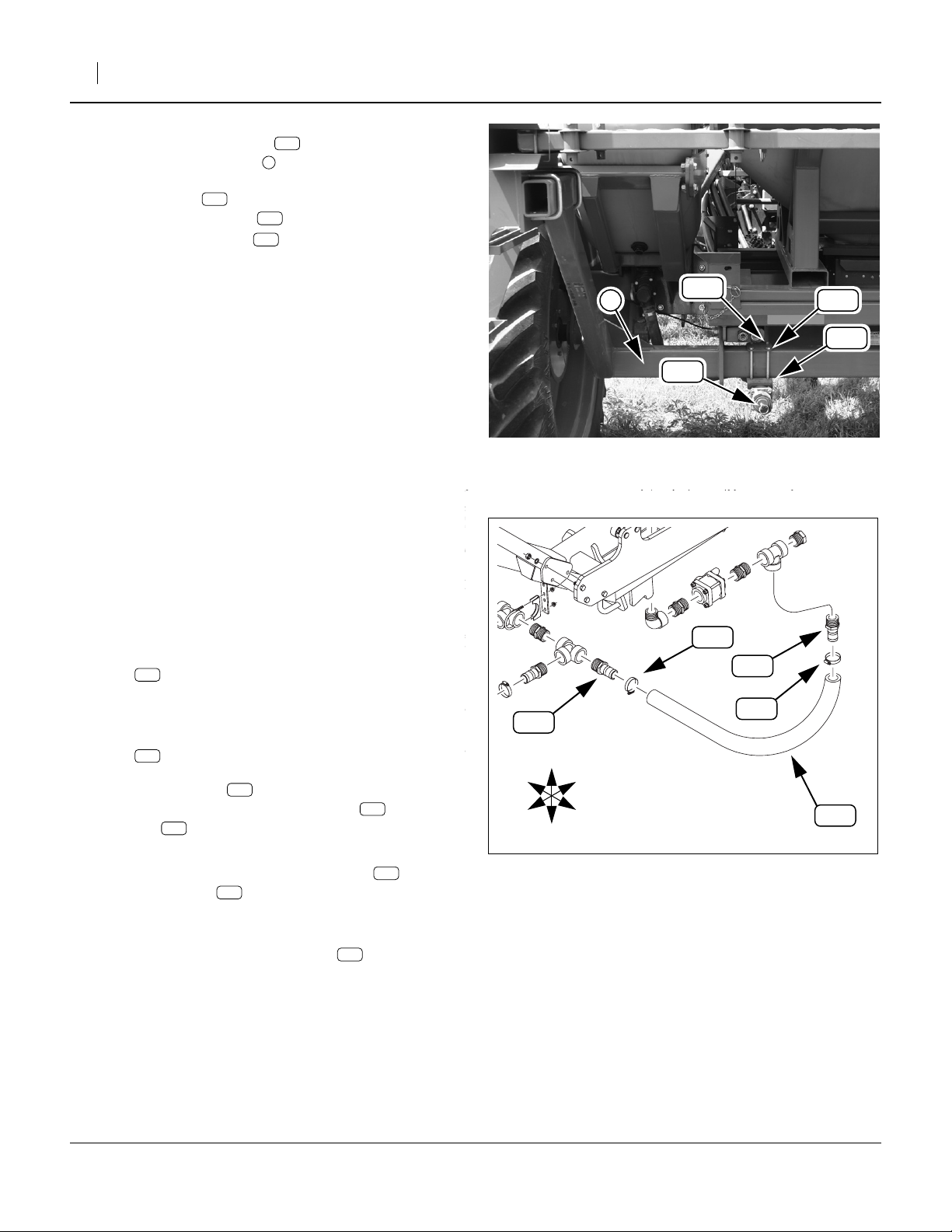

Refer to Figure 11

31. Select the inter-tank double-tee fitting assembly, consisting of:

Qty Call Part Description

1 830-045C AD 1 1/2MNPT POLYPROP

136

2 830-031C TEE 1 1/2FNPT POLYPROP

135

4 830-094C AD 1 1/2MNPT X 1 1/2HB POLYP

138

R

138

138

U

B

Installation Instructions 7

135

138

136

Refer to Figure 12 and Figure 11

32. Mount the inter-tank assembly on the left bracket

120

. Orient the tee assembly so that the left tee

faces to planter rear, and the right tee faces forward.

Use the removed clamp around the center adap-

136

tor or inside end of the right tee.

148

Install Quick-Fill Inlet

Refer to Figure 13

33. Select the quick-fill inlet assembly, consisting of:

Qty Call Part Description

1 148-410D VALVE MOUNT PLATE

103

1 411-273D VALVE MNT CLAMP PLT

118

1 502-060D DUST PLUG CHAIN 10

119

4 802-047C HHCS 1/2-13X6 GR5

124

4 803-147C NUT HEX NYLOCK 1/2-13

127

4 804-016C WASHER FLAT 1/2 SAE PLT

129

1 805-010C PIN HAIR COTTER .094

130

1 829-048C VALVE - 1 1/2FNPT X 2FCL POLYP

132

1 830-094C AD 1 1/2MNPT X 1 1/2HB POLYP

138

1 830-186C PL 2MCL POLY-GLASS

140

34. Partially disassemble the mounting hardware by

removing the four

clamp plate . Do not remove the bolts securing

the valve body to the mount.

118

1

⁄

in nuts and the mount

2

127

F

R

F

D

U

D

L

Tank Interconnect Assembly

135

Figure 11

148

Figure 12

Tank Interconnect Mounted

127

118

132

138

B

L

129

Figure 13

Quick-Fill Inlet Assembly

138

27105

120

27092

103

130

119

140

124

22821

02/29/2008 407-197M

8 Fertilizer System

Refer to Figure 14

35. Position the mount plate with valve assembly

under the rear tool bar directly aft of the intercon-

nect tee assembly. Orient so that the quick-disconnect plug end of the assembly faces to the rear.

Place the clamp plate on the tool bar top and

secure with

140

1

⁄

in nuts .

2

103

1

118

127

Great Plains Mfg., Inc.

Install Inter-Tank Hoses

These hoses are cut-to-length from a coil supplied.

Excess material is supplied, so there will be some hose

left over.

Install Left Tank Hose

Refer to Figure 15

36. Select:

Qty Call Part Description

2 800-125C CLAMP WRM DRV#28 SS(1.31-2.25)

122

37. Select the coil of:

Qty Call Part Description

- 990-181R HOSE 1 1/2 ID 150PSI EPDM

151

38. From the adaptor at the tee on the left tank bottom fittings assembly, route the hose to the

adaptor at the left end of the inter-tank fitting

assembly. Route clear of planter moving parts.

39. Slide the end of the hose, and a clamp onto the

left end adaptor of the inter-tank fitting assem-

bly. Secure clamp.

40. Leaving some slack in the hose, cut it to length back

at the left tank tee. Place a clamp over the hose

end and secure to the tank tee.

148

138

151

122

148

122

148

R

F

U

D

1

127

140

Figure 14

Quick-Fill Mount Point

B

L

Figure 15

Left Inter-Tank Hose

118

103

27091

122

138

122

151

22821

407-197M 02/29/2008

Great Plains Mfg., Inc.

Install Right Tank Hose

Refer to Figure 16

41. Select:

Qty Call Part Description

2 800-125C CLAMP WRM DRV#28 SS(1.31-2.25)

122

42. Select the coil of:

Installation Instructions 9

138

Qty Call Part Description

- 990-181R HOSE 1 1/2 ID 150PSI EPDM

151

43. From the adaptor at the right tank fitting assembly tee, route the hose through the right bracket/

clamp ( , ) to the adaptor at the right end

120 148 148

138

151

of the inter-tank fitting assembly.

44. Slide the end of the hose, and a clamp onto the

right end adaptor of the inter-tank fitting assem-

138

122

bly. Secure clamp.

45. Leaving some slack in the hose, cut it to length back

at the right tank tee. Place a clamp over the

122

hose end and secure to the tank tee.

46. Tighten the nuts on the right bracket/clamp ( ,

148

).

120

Install Quick-Fill Hose

47. Select:

Qty Call Part Description

2 800-125C CLAMP WRM DRV#28 SS(1.31-2.25)

122

48. Select the coil of:

Qty Call Part Description

- 990-181R HOSE 1 1/2 ID 150PSI EPDM

151

R

F

122

151

U

D

B

148

L

Figure 16

Right Inter-Tank Hose

122

151

120

22821

122

Refer to Figure 17

49. From the (front) hose-barb adaptor end of the quickfill fitting assembly, route the hose to the left tee of

the inter-tank fitting assembly.

50. Slide the end of the hose, and a clamp onto the

left tee of the inter-tank fitting assembly. Secure

138

122

Figure 17

Quick-Fill Hose

27092

with clamp.

51. Leaving some slack in the hose, cut it to length back

at the quick-fill inlet. Place a clamp over the

122

hose end and secure to the inlet.

Deferred Tank Items

The tank kit includes hose used at the pump. It is deferred

until after pump installation, under the topic “Install

Pump-Strainer Hose” on page 12.

The supply hose from the inter-tank fittings to the manifold(s) is not yet installed. It is deferred until after pump

installation, under the topic “Install Supply Line from

Tanks” on page 12.

02/29/2008 407-197M

10 Fertilizer System

Install Ground Drive with Pump

This section installs most of the components of the 407134A kit.

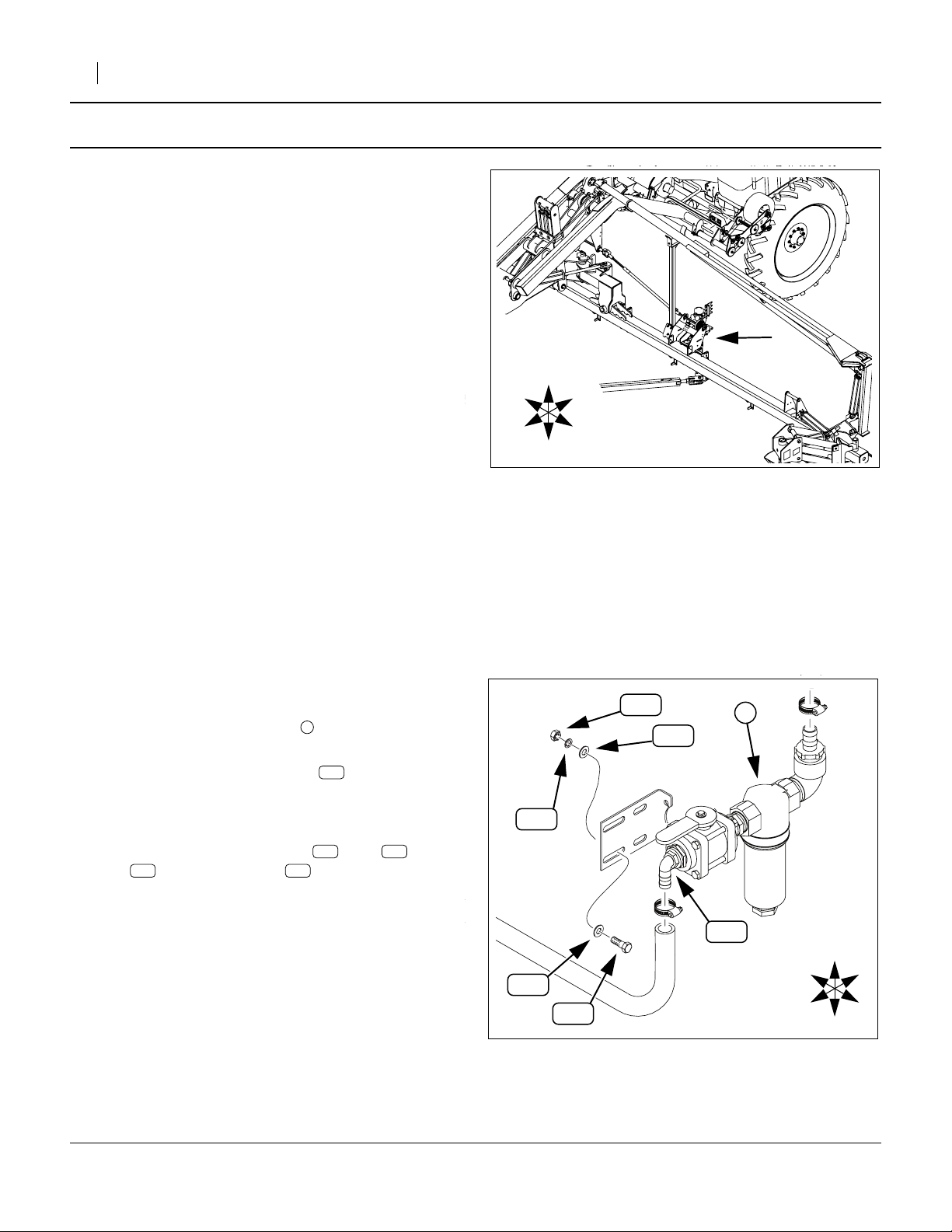

Refer to Figure 18,

which depicts the planter with row units removed for clarity.

The ground drive pump is installed on the left wing, at or

near the plates supporting the drive-line clutch.

If you are replacing a hydraulic fertilizer pump as part of

this installation, perform the installation per the instructions for that update kit (407-149M).

Determine Ground Drive Location

These instructions do not specify a precise location for

mounting the new ground drive, due to the wide variety of

factory configurations and end user modifications.

The hose connections to the fertilizer feed line, strainerto-pump line and pump-to-distribution manifold permit

considerable flexibility in placement of strainer and pump.

The strainer requires a vertical surface with mounting

holes, typically the inside or outside of either plate of the

wing drive shaft bracket.

The optimal placement for the drive unit itself is halfway

between rows (row units or row unit pairs in twin-row).

These instructions assume that the strainer is to be

mounted inside the wing drive shaft brackets, on the

inboard plate, and the ground drive assembly is mounted

about a foot outboard of the wing drive shaft brackets.

R

F

U

D

B

L

Figure 18

Location of Components

Great Plains Mfg., Inc.

25303

Install Strainer

Refer to Figure 20

52. Select the strainer assembly , which does not have

a specific part number as an assembly.

53. If necessary, adjust inlet elbow so that it points

up (or down) so that the hose can exit the mount

area.

54. If the mount plate is pre-assembled to the valve,

remove the three sets of bolts , nuts , wash-

293 292

ers and lock washers .

1

300

289 290

292

293

289

290

1

293

300

Figure 19

Strainer Components

R

F

U

B

L

D

27117

407-197M 02/29/2008

Great Plains Mfg., Inc.

Install Strainer Mount

Refer to Figure 20 (shown without strainer for clarity)

55. Make sure that at least two of the four slotted holes

in the mount can be aligned with holes at your

intended mounting point (in this illustration, the left

side of the inboard plate of the left wing drive shaft

bracket).

288

1

290

292

Installation Instructions 11

1

293

293

R

F

U

B

L

D

Mount is intended to place with the short bent

end to planter rear and facing away from the mounting surface.

56. Insert each bolt end through at least two of the

four holes in the mount and the frame plate .

57. Add the removed flat washer , lock washer

and nut to each bolt and finger tighten.

58. Hand-position valve/strainer assembly to determine:

• mounting clearance,

• hose clearance,

• operator access,

• clearance for valve operation,

• preferred inlet elbow orientation, and

• clearance for strainer maintenance.

59. Adjust mount to provide suitable final position

and tighten bolts/nuts.

288

290

288

289

289

293 292

1

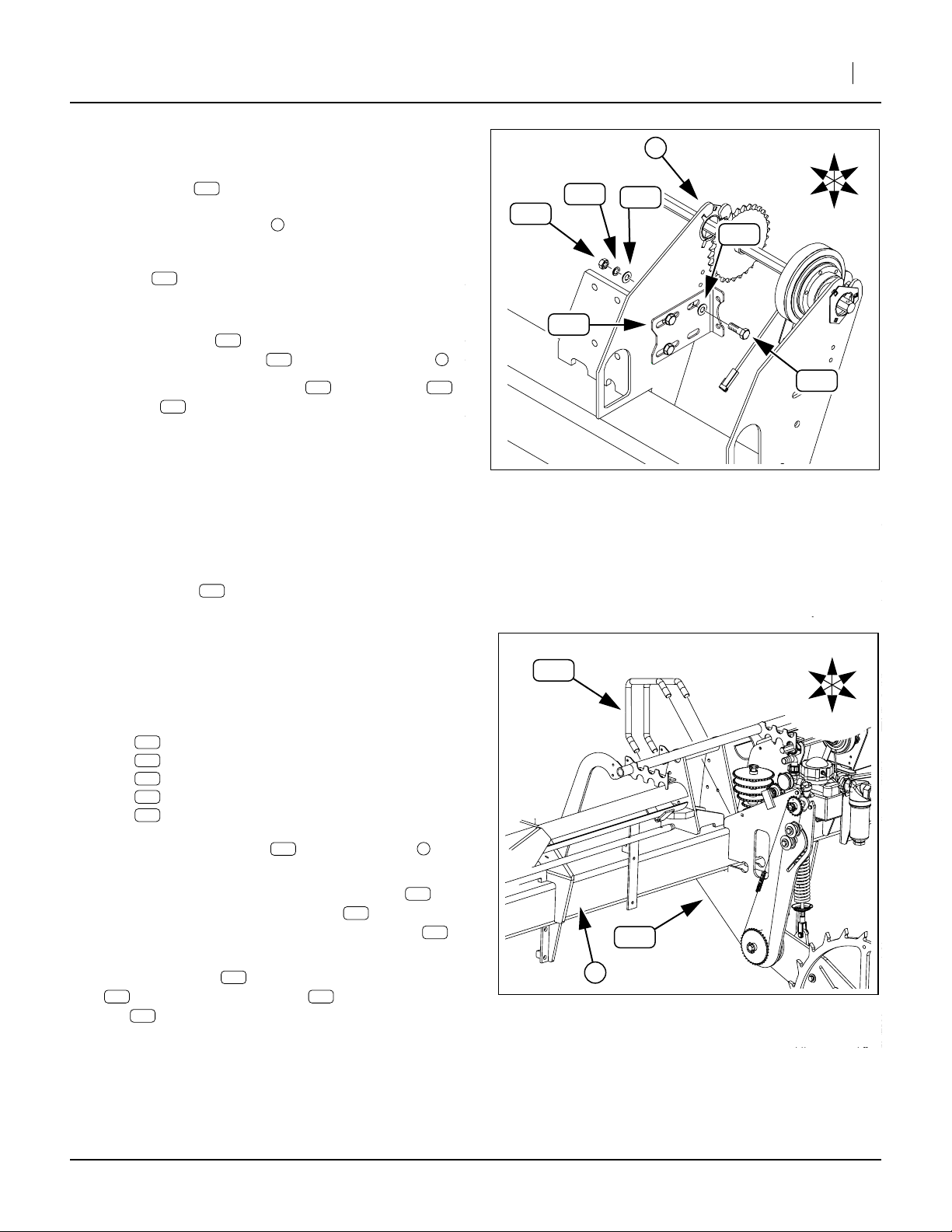

Install Ground Drive Assembly

Refer to Figure 21, which depicts the ground drive with guards

removed. Guards may be left in place until final sprocket mounting.

60. Select:

Qty Call Part Description

1 407-146K FERTILIZER PUMP DRIVE

199

4 806-102C U-BOLT 3/4-10 CORNER 7 SQ

296

4 804-025C WASHER FLAT 3/4 SAE PLT

295

4 804-023C WASHER LOCK SPRING 3/4 PLT

294

4 803-027C NUT HEX 3/4-10 PLT

291

288

296

Figure 20

Install Strainer Mount

289

F

L

25305

U

R

B

D

199

1

291

199

1

Figure 21

Install Ground Drive

25307

61. Position the two U-bolts over the tool bar at

the mount location.

62. Use a hoist or lift to hold the drive assembly at

the mount point. Insert the U-bolts . Temporarily hold the assembly in place with four nuts

(not shown in figure).

63. Remove one nut at a time. Place a flat washer

295 294

(not shown), lock washer (not shown) and

291

nut on the U-bolt. Tighten each until the drive

assembly’s mount is flat against the tool bar.

Tighten to torque spec.

02/29/2008 407-197M

291

296

296

12 Fertilizer System

Install Pump-Strainer Hose

64. Select (from the 407-122A tank parts):

Qty Call Part Description

- 990-082R HOSE 1 ID 200PSI EPDM

150

1 800-123C CLAMP WRM DRV #16 SS (.68-1.5)

121

1 800-125C CLAMP WRM DRV#28 SS(1.31-2.25)

122

65. Route hose from strainer outlet to pump inlet .

66. Connect hose at inlet and secure with clamp

121

.

150

67. Allowing some slack in hose, back at pump inlet ,

cut hose to length.

68. Secure hose to pump inlet with clamp .

1 2

2

2

122

R

F

U

D

Great Plains Mfg., Inc.

121

2

150

122

B

1

L

Install Supply Line from Tanks

This section connects the tanks to the ground drive pump

system.

69. Select (from the 407-122A tank parts):

Qty Call Part Description

- 990-082R HOSE 1 ID 200PSI EPDM

150

2 800-125C CLAMP WRM DRV#28 SS(1.31-2.25)

122

12 - - cable ties

Refer to Figure 23

70. Route the hose from the inter-tank tee assembly…

Figure 22

Install Strainer Mount

Figure 23

Supply Hose at Inter-Tank

27113

27092

407-197M 02/29/2008

Great Plains Mfg., Inc.

Refer to Figure 24

71. …up the seed tube bundle…

Installation Instructions 13

Refer to Figure 25

72. …under the hose restraint straps at the left wing

1

pivot and along the top of the air system support

frame…

Figure 24

Supply Hose At Seed Rack

1

1

27095

Figure 25

27096

Supply Hose At Pivot

02/29/2008 407-197M

14 Fertilizer System

Refer to Figure 26

73. Slip the end of the hose onto the inlet elbow (not

visible in photograph) and secure with clamp .

74. Working back toward the tanks, use cable ties to

secure hose every two feet or so leave ample slack

for folding an unfolding. Do not tie the last four feet of

hose.

75. Leaving ample slack (but no so much that hose

droops below inter-tank tees), cut hose to length and

secure to tee with clamp .

122

300

122

Ground Drive Deferred Item

The hose to the relief valve is installed after the starter

boom system, at “Pump to Starter Relief Valve Hose”

on page 17.

Great Plains Mfg., Inc.

2

Install High Rate Boom

This section installs most of the components of the 407137A kit.

Install the high rate boom first, as it contains components

necessary for installing dual booms.

These instructions presume that the high rate (H.R.)

boom is to be connected to a customer-supplied fertilizer

source, typically a tractor-mounted tank. Tank, strainer,

pump, power source and supply line to the planter are

customer-provisioned and installed.

The high rate boom is presumed to be concentrated fertilizer that cannot be applied directly to the seed furrow. The

most likely delivery method is via tubes to zone coulters

at the front of the rows.

Figure 26

Supply Hose At Strainer

27098

407-197M 02/29/2008

Great Plains Mfg., Inc.

Install Boom Mounts

76. Select:

Qty Call Part Description

12 407-253D FERT BOOM MOUNTING BRACKET

311

24 802-159C HHCS 5/16-18X1 GR5

322

24 803-177C NUT HEX FLG TP LK 5/16-18ZNYCR

324

77. If also installing the starter boom, select:

Installation Instructions 15

U

3

2

R

B

323

6

F

L

D

1

310

Qty Call Part Description

12 407-252D HI-RATE CENTER BOOM SUPPORT

310

12 806-152C U-BOLT 1/4-20 X 1.125 X 2 RND

325

24 803-088C NUT HEX LOCK 1/4-20 FLG

323

Refer to Figure 27

78. Install the fertilizer boom mounting brackets 12

of the 14 air pipe rest support brackets . Skip the

positions closest to planter center.

At the outside positions, a full pair of bolts and

lock nuts are used to secure the bracket

under the rest supports .

At inner positions, only one bolt and lock nut

is used (at the rear hole). The forward hole is occu-

pied by the existing long bolt and nut holding

the clamp plate .

79. Loosely attach a center boom support to each

boom mounting bracket using a U-bolt (loop

forward) and two lock nuts . Install the U-bolts at

the lower position , and not the upper .

Refer to Figure 28

80. Select the four boom assemblies , which do not

have a specific assembly part number.

324 311

1

322 324

3 4

2

311 325

323

5 6

1

311

1

322

310

5

4

324

Figure 27

High Rate Boom Mount

333

322

325

311

27100

81. If the booms do not have end caps , also select:

Qty Call Part Description

4 830-061C CA 3/4FNPT POLYPROP

333

333

2

1

3

Figure 28

High Rate Boom Assembly

02/29/2008 407-197M

27099

16 Fertilizer System

Refer to Figure 28 on page 15

H.R. Boom Identification and Orientation

• The high rate boom sections have nozzles

without 800-367C AD PUSH 1/4TUBEX1/4MNPT.

They may have pre-installed:

830-071C AD 1/4MNPT X 3/8HB POLYPROP.

• Each wing has two boom sections. The open

thread ends are adjacent, and are to be mated by

a tee in a later step.

• The end of the boom with the four closely-spaced

nozzles is the outside end (wing tip or planter

2

center). The ends with the sparsely-spaced noz-

3

zles are where the tee connection will be made.

• The cap is on the outside end.

333

• The nozzles face to planter front. If the sections

are not so pre-assembled, adjust the nozzles.

82. Lay the four booms, oriented as above along the

tops of the wing seed tube supports.

Join H.R. Booms Sections with Tees

83. Select:

Great Plains Mfg., Inc.

338

Qty Call Part Description

2 830-028C TEE 3/4FNPT POLYPROP

330

2 830-123C EL 3/4MNPT X 3/4HB POLYPROP

338

Refer to Figure 29

84. Apply thread sealant, and join each pair of boom

sections with a tee .

85. Apply thread sealant, and screw in the elbow .

330

330

Set its final orientation facing forward.

Mount H.R. Booms

Refer to Figure 30

86. Loosely mount each boom in the lower position

311 310

of + using the U-bolts and lock nuts loosely

installed at Step 79.

87. Adjust the boom to roughly align its ends with the

ends of the tube of the air system support frame.

Tighten the lock nuts.

325

323

330

Figure 29

High Rate Boom Tee

310

325

311

Figure 30

Boom Mount and Extension

27113

27100

407-197M 02/29/2008

Great Plains Mfg., Inc.

Install H.R. Relief Valve

When used with a customer-provisioned material source,

Great Plains does not specify the precise location of the

high rate relief valve. For minimum hose length, it needs

to be close to one of the center elbow/tees of a starter

wing boom. You may wish to locate it on the right wing so

that there is no confusion about which gauge is which

when viewed from the tractor.

Refer to Figure 31

88. Select the relief valve assembly , which does not

have a specific part number.

89. Select (or remove from assembly above):

Qty Call Part Description

1 401-528D AIR TUBE SUPPORT CLAMP

307

2 890-521C MUFFLER CLAMP 1.63 SIZE

349

90. Install the relief valve on the air system support

frame tube, with the valve toward planter center, and

the gauge face facing planter center (facing forward

during field operations).

1

Installation Instructions 17

349

1

349

307

Figure 31

H.R. Relief Valve Assembly

27094

Pump to Starter Relief Valve Hose

Specific instructions are not provided, as Great Plains

cannot know where your pump is located, nor what supply

line it brings to the planter.

91. These parts are provided:

Qty Call Part Description

- 990-082R HOSE 1 ID 200PSI EPDM

353

2 800-257C CLAMP WRM DRV #20SS (.81-1.75)

320

H.R. Hose to Right Wing Boom

92. Select:

Qty Call Part Description

- 990-081R HOSE 3/4 ID 200PSI EPDM

352

2 800-123C CLAMP WRM DRV #16 SS (.68-1.5)

318

Refer to Figure 32

93. Connect the hose to the adaptor at the outlet tee

of the relief valve assembly. Secure with clamp .

94. Route the hose to the elbow and tee at the center of the right wing boom.

95. Allowing a small amount of slack, cut hose to length

and secure with clamp .

318

4

318

338

353

318

4

318

352

338

Figure 32

27113

H.R. Relief Valve to Right Boom

02/29/2008 407-197M

18 Fertilizer System

H.R. Hose to Left Wing Boom

96. Fold the planter to ensure that an adequate length of

hose is installed between the wings.

97. Select:

Qty Call Part Description

- 990-081R HOSE 3/4 ID 200PSI EPDM

352

2 800-123C CLAMP WRM DRV #16 SS (.68-1.5)

318

Great Plains Mfg., Inc.

352

5

318

Refer to Figure 33 and Figure 34

98. Route the hose:

• from the H.R. relief valve

• to the left wing hydraulic hose bundle (under the

seed meter conduit, above the row unit tool bar)

• along the hydraulic bundle to the left wing

• to the elbow/tee at the center of the right boom.

99. Connect the hose to the adaptor at the outlet tee

of the relief valve assembly. Secure with clamp .

5

318

100. Allowing some slack, use cable ties every 16in or so

to secure the hose to the hydraulic bundle.

Refer to Figure 35 (which depicts a low rate boom on older

mount brackets)

101. At the left wing cut the hose to length at the elbow/

tee at the center of the boom and secure with clamp

318

.

Figure 33

H.R. Relief Valve to Left Boom

Figure 34

Wing-to-Wing Hose at Center

27113

27101

318

Figure 35

Wing-to-Wing Hose at Left Wing

407-197M 02/29/2008

27102

Great Plains Mfg., Inc.

Install H.R. Orifices

Refer to Figure 36

The nozzles do not have orifice plates pre-installed, as

there is a choice of 3 sizes included. Consult the planter

Operator and Seed Rate manuals and determine which

plate size is the most likely for your next application.

102. Select one of the following sets:

Qty Call Part Description

32 832-053C ORIFICE SPR SYS CP4916-34 SS

346

32 832-054C ORIFICE SPR SYS CP4916-48 SS

347

32 832-056C ORIFICE SPR SYS CP4916-28 SS

348

103. Twist to unlock each nozzle, insert a plate,. and relock.

Note: You can skip any positions that are to be capped at

Step 108.

Note: No special precautions are necessary at this time,

but after using the system, always wear protective

gloves when changing orifice plates.

4

Installation Instructions 19

4

Figure 36

H.R. Orifice Installation

21983

Install H.R. Drop Lines

If your planter has fewer than 32 high rate zones, some

positions get caps instead of drop lines.

104. Raise the planter and install transport locks.

105. Lower the row units.

106. Select:

Qty Call Part Description

- 990-080R HOSE 3/8 ID 150PSI EPDM

350

64 800-126C CLAMP WRM DRV #5 SS (.44-.70)

319

16 832-042C NOZZLE SHUT OFF CAP W/ GASKET

344

32 800-303C CABLE TIE 2 DIA MIN - BLK

321

107. If not already installed on the nozzles, select:

Qty Call Part Description

32 830-071C AD 1/4MNPT X 3/8HB POLYPROP

334

Not all of the caps may be used.

02/29/2008 407-197M

20 Fertilizer System

Refer to Figure 37 (which does not depict clamps or adaptors,

and does depict an older mount no longer used).

108. If the nozzle has no associated applicator, install a

344

cap .

109. At each nozzle connected to a zone, route the hose

from the nozzle down to the row unit applicator (typically a tube on a zone coulter).

Great Plains Mfg., Inc.

1

334

110. Connect the hose end to the tube (not shown),

and secure with a clamp (not shown).

111. Use a cable tie (not shown) to secure the hose

350

319

321

as needed to the applicator structure.

112. Allowing a small amount of slack, cut the hose to

length at the nozzle. The Figure notwithstanding, do

not loop the line or allow it to sag.

113. Connect the hose end to the nozzle with an

adaptor and a clamp .

334 319

350

Install Starter Boom

This section installs the 407-133A kit, and all remaining

components that are to be used.

This boom/manifold system is presumed to be used with

low rate “starter” fertilizers safe to apply directly to the

seed furrow. The drop-lines from the nozzles are typically

connected to a delivery system on the seed tube. The

present kit only includes the components to deliver fertilizer to the vicinity of the row unit seed meter. The final

tubing is separately ordered or supplied (such as that

included with Keeton seed firmers).

The boom manifold is supplied as four partially preassembled segments, which mount on the air system

support frame.

350

Figure 37

H.R. Drop Line

22820

407-197M 02/29/2008

Great Plains Mfg., Inc.

Installation Instructions 21

Prepare Starter Booms

Refer to Figure 38

114. Select the four boom assemblies , which do not

have a specific assembly part number.

115. If the booms do not have end caps , also select:

Qty Call Part Description

4 830-061C CA 3/4FNPT POLYPROP

176

Boom Identification and Orientation

• The low rate starter boom sections have nozzles

with 800-367C AD PUSH 1/4TUBEX1/4MNPT and

without 830-071C AD 1/4MNPT X 3/8HB POLYPROP.

• Each wing has two boom sections. The open

thread ends are adjacent, and are to be mated by

a tee in a later step.

• The end of the boom with the four closely-spaced

nozzles is the outside end (wing tip or planter

center). The ends with the sparsely-spaced noz-

zles are where the tee connection will be made.

• The cap is on the outside end.

• The nozzles face to planter rear. If the sections

are not pre-assembled this way, adjust the nozzles.

116. Lay the four booms, oriented as above along the

tops of the wing seed tube supports.

2

3

176

1

176

176

2

Figure 38

High Rate Boom Assembly

1

3

99999

Join Starter Booms Sections with Tees

117. Select:

Qty Call Part Description

2 830-028C TEE 3/4FNPT POLYPROP

173

2 830-123C EL 3/4MNPT X 3/4HB POLYPROP

180

Refer to Figure 39

118. Apply thread sealant, and join each pair of boom

sections with a tee .

119. Apply thread sealant, and screw in the elbow .

Set its final orientation facing forward.

173

180

173

Figure 39

Starter Boom Tee

180

27113

02/29/2008 407-197M

22 Fertilizer System

Mount Starter Booms

The starter boom mounts to components installed for the

high rate boom.

Refer to Figure 40

120. Select:

Qty Call Part Description

12 806-152C U-BOLT 1/4-20 X 1.125 X 2 RND

168

24 803-088C NUT HEX LOCK 1/4-20 FLG

166

121. Loosely mount each boom in the wing’s the boom

mounting brackets (or the upper position of

311 310

+ ) using the U-bolts and lock nuts.

311

122. Adjust the boom to roughly align its ends with the

ends of the tube of the air system support frame.

Tighten the lock nuts.

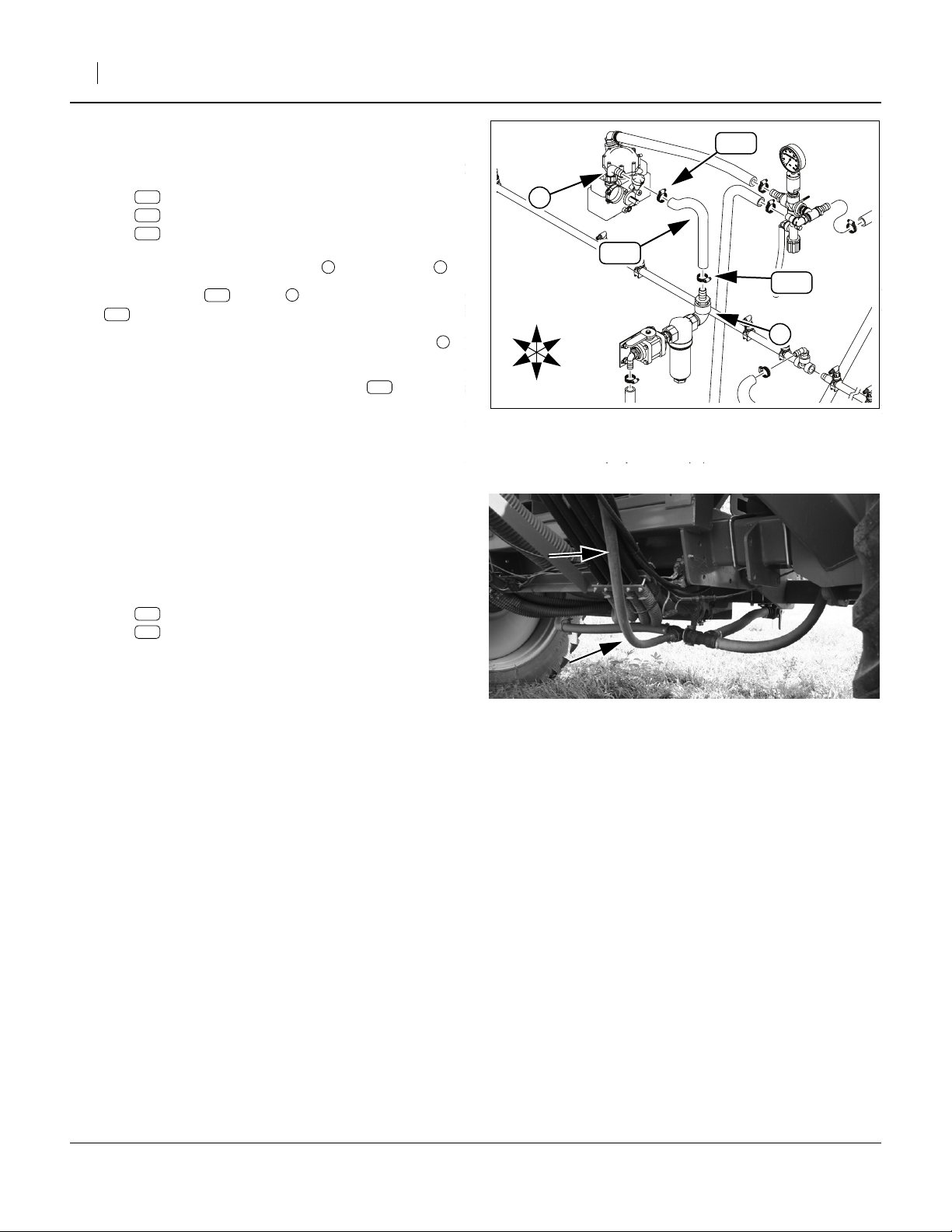

Install Starter Relief Valve

Refer to Figure 41

123. Select the relief valve assembly , which does not

have a specific part number.

124. Select (or remove from assembly above):

1

Great Plains Mfg., Inc.

310

166

168

311

Figure 40

Starter Boom Tee

27100

192

1

Qty Call Part Description

1 401-528D AIR TUBE SUPPORT CLAMP

153

2 890-521C MUFFLER CLAMP 1.63 SIZE

192

125. Install the relief valve:

• near the ground drive pump (on the left wing),

• on the air system support frame tube,

• with the valve toward planter center, and

• the gauge face facing planter center (facing for-

ward during field operations).

153

Figure 41

Starter Relief Valve Assembly

192

27094

407-197M 02/29/2008

Great Plains Mfg., Inc.

Pump to Starter Relief Valve Hose

126. Select:

Qty Call Part Description

- 990-082R HOSE 1 ID 200PSI EPDM

195

2 800-257C CLAMP WRM DRV #20SS (.81-1.75)

163

Refer to Figure 42

127. Route the hose from the outlet elbow of the pump

to the inlet adaptor of the relief valve.

3

Installation Instructions 23

163

2

2

195

163

3

128. Secure the hose to the relief valve with a clamp

163

.

195

129. At the pump end, allowing some slack, cut the hose

to length and secure it to the outlet elbow with a

clamp .

163

2

Starter Hose to Left Wing Boom

130. Select:

Qty Call Part Description

- 990-081R HOSE 3/4 ID 200PSI EPDM

194

2 800-257C CLAMP WRM DRV #20SS (.81-1.75)

163

Refer to Figure 43

131. Connect the hose to the adaptor at the outlet

194

tee of the relief valve assembly. Secure with clamp

163

.

132. Route the hose to the elbow and tee at the

194 180

center of the left wing boom.

133. Allowing a small amount of slack, cut hose to length

and secure with clamp .

163

4

Figure 42

Pump to Starter Relief Valve

4

194

27113

163

180

163

Figure 43

Starter Relief Valve to Left Boom

02/29/2008 407-197M

27113

24 Fertilizer System

Starter Hose to Right Wing Boom

134. Fold the planter to ensure that an adequate length of

hose is installed between the wings.

135. Select:

Qty Call Part Description

- 990-081R HOSE 3/4 ID 200PSI EPDM

194

2 800-257C CLAMP WRM DRV #20SS (.81-1.75)

163

Great Plains Mfg., Inc.

194

5

163

Refer to Figure 44 and Figure 45

136. Route the hose :

194

• from the starter relief valve

• to the left wing hydraulic hose bundle or the high

rate hose (under the seed meter conduit, above

the row unit tool bar)

• along the hydraulic/high rate hose bundle to the

right wing

• to the elbow/tee at the center of the right boom.

137. Connect the hose to the adaptor at the outlet tee

of the relief valve assembly. Secure with clamp .

5

163

138. Allowing some slack, use cable ties every 16in or so

to secure the hose to the hydraulic/high rate bundle.

Refer to Figure 46 (which depicts older mount brackets)

139. At the right wing cut the hose to length at the elbow/

tee at the center of the boom and secure with clamp

163

.

Figure 44

Starter Relief Valve to Right Boom

Figure 45

Wing-to-Wing Hose at Center

27113

27101

163

Figure 46

Wing-to-Wing Hose at Right Wing

407-197M 02/29/2008

27102

Great Plains Mfg., Inc.

Install Starter Orifices

Refer to Figure 47

The nozzles do not have orifice plates pre-installed, as

there is a choice of 3 sizes included. Consult the planter

Operator and Seed Rate manuals and determine which

plate size is the most likely for your next application.

140. Select one of the following sets:

Qty Call Part Description

32 832-053C ORIFICE SPR SYS CP4916-34 SS

189

32 832-054C ORIFICE SPR SYS CP4916-48 SS

190

32 832-056C ORIFICE SPR SYS CP4916-28 SS

191

141. Twist to unlock each nozzle, insert a plate, and relock.

Note: You can skip any positions that are to be capped at

Step 146.

Note: No special precautions are necessary at this time,

but after using the system, always wear protective

gloves when changing orifice plates.

4

Installation Instructions 25

4

Figure 47

Starter Orifice Installation

21983

02/29/2008 407-197M

26 Fertilizer System

Install Starter Drop Lines

If your planter has fewer than 32 row units, some positions get caps instead of drop lines.

142. Raise the planter and install transport locks.

143. Lower the row units.

144. Select:

Qty Call Part Description

- 990-109R TUBE NYLON 1/4OD X 062WL

196

16 832-042C NOZZLE SHUT OFF CAP W/ GASKET

187

32 830-383C CP 1/4 PUSH LOK POLY

186

32 800-303C CABLE TIE 2 DIA MIN - BLK

164

145. If not already installed on the nozzles, select:

Qty Call Part Description

32 800-367C AD PUSH 1/4TUBEX1/4MNPT

165

Not all of the caps may be used.

Refer to Figure 48.

146. If the nozzle has no associated row unit, install a cap

186

.

147. At each nozzle connected to a row, route the hose

from the nozzle down to the row unit applicator (typically a tube on a seed firmer).

196

186

1

Figure 48

Starter Drop Line

Great Plains Mfg., Inc.

165

22820

148. Connect the hose end to the tube (not shown),

using a push-lok adaptor .

149. Use a cable tie (not shown) to secure the hose

196

186

164

as needed to the applicator structure. Allow slack for

row unit motion.

150. Allowing a small amount of slack, cut the hose to

length at the boom nozzle. The Figure notwithstanding, do not loop the line or allow it to sag.

151. Connect the hose end to the nozzle with an

adaptor .

165

196

407-197M 02/29/2008

Great Plains Mfg., Inc.

Closeout

Installation Instructions 27

Set Drive Type

Refer to Figure 49

To complete the installation the Driving and Driven

sprockets need to be mounted on the ground drive. If

you do not know the next fertilizer rate desired, pick a

suitable rate to use for a water test.

Setup and use of the Fertilizer System is described in

the planter Operator Manual.

To change sprockets, remove the knob securing the

drive guard , and remove the guard. Remove the linch

pins securing the sprockets on drive shafts and storage shafts . Exchange sprockets per the Drive Type

table of the Fertilizer Rate chart, and re-pin.

2

4

1

3

Water Test the Systems

152. Using the instructions in the Operator Manual for

fertilizer fill, load the tanks with an amount of water

equal to one acre’s application, plus 50 gallons.

153. Lock-up all row units with lock-up pins.

154. Set down-force cams to “0” (out of detent) on other

rows, to reduce wear.

155. On suitable flat ground, lower row units to field

position and operate the planter to fully charge the

boom systems with water.

156. Stop the planter. Raise it and install transport

locks. Put tractor in Park with brake set.

157. Manually operate the ground drive wheel, while an

assistant checks each row unit for water flow.

158. Once it is determined that all drop lines are working:

• Note the scale readings on the tanks.

• Lower the row units and operate the planter for

one acre.

• Compare the water consumption to the rate

selected by the Drive Type.

159. Drain any residual water from the system.

U

D

R

B

4

F

L

4

3

2

1

3

Figure 49

Ground Drive Type

25319

02/29/2008 407-197M

28 Fertilizer System

Parts Lists

New Parts

This manual covers the installation of four different fertilizer kits. Parts are listed for each kit separately.

The part call-out numbers in this list match all Figures in

these installation instructions. Parts used in multiple kits,

or multiple sub-assemblies, have multiple call-out numbers for the same part number and description.

Quantities are units (“ea”) unless otherwise noted.

Callout Range Page Kit Kit Description

Part descriptions match those in your updated Parts

Manual.

Your kit(s) includes the parts in the lists. Many are provided as pre-assembled sub-assemblies that do not have

specific Great Plains part numbers.

Indented quantities are per parent sub-assembly.

Great Plains Mfg., Inc.

101 151

through

152 197

through

198 305

through

306 354

through

28 407-122A YP FERTILIZER TANK KIT

30 407-133A YP 1625 FERT BOOM ONLY ASSY

31 407-134A YP1225 & Y1625 FERT PUMP ONLY

34 407-137A YP16 HI-RATE FERT MANIFOLD KIT

List: Kit 407-122A YP FERTILIZER TANK KIT

Callout Quantity Part Number

101

102

103

104

105

106

107

108

109

110

111

112

113

114

115

116

117

118

119

120

121

1 407-122A YP FERTILIZER TANK KIT

1 407-197M YP1625 FERT KITS INSTALL MANUAL

1 148-410D VALVE MOUNT PLATE

1 407-124S FERT TANK AND CRADLE ASSY

4 407-116D TANK CRADLE SIDE BAR

1 407-118H 200 GAL TANK SUPPORT FRAME

1 407-121H 200 GAL TANK SUPPORT FRAME RH

24 802-055C HHCS 5/8-11X2 GR5

24 803-021C NUT HEX 5/8-11 PLT

8 803-027C NUT HEX 3/4-10 PLT

40 804-015C WASHER LOCK SPRING 1/2 PLT

24 804-021C WASHER FLAT 5/8 SAE PLT

24 804-022C WASHER LOCK SPRING 5/8 PLT

8 804-023C WASHER LOCK SPRING 3/4 PLT

4 806-050C U-BOLT 3/4-10 X 7 X 8 1/2

16 816-170C RD BUMP STOP 2 X 1 X 1/2-13

2 817-555C BULK PLANTER 200 GAL FERT TANK

1 411-273D VALVE MNT CLAMP PLT

1 502-060D DUST PLUG CHAIN 10

2 506-365D WET BOOM FLAT HOSE BRACKET

6 800-123C CLAMP WRM DRV #16 SS (.68-1.5)

Part Description

(407-122A YP FERTILIZER TANK KIT)

407-197M 02/29/2008

Great Plains Mfg., Inc.

Installation Instructions 29

Callout Quantity Part Number

122

123

124

125

126

127

128

129

130

131

132

133

134

135

136

137

138

139

140

141

142

143

144

145

146

147

148

149

150

151

8 800-125C CLAMP WRM DRV#28 SS(1.31-2.25)

2 802-034C HHCS 1/2-13X1 1/4 GR5

4 802-047C HHCS 1/2-13X6 GR5

16 802-258C HHCS 1/2-13X1 GR5

4 803-020C NUT HEX 1/2-13 PLT

4 803-147C NUT HEX NYLOCK 1/2-13

4 804-015C WASHER LOCK SPRING 1/2 PLT

4 804-016C WASHER FLAT 1/2 SAE PLT

1 805-010C PIN HAIR COTTER .094

2 829-013C VALVE 1 1/2FNPT BALL POLYPROP

1 829-048C VALVE - 1 1/2FNPT X 2FCL POLYP

4 830-021C PL 3/4MNPT POLYPROP

2 830-024C PL 1 1/2MNPT POLYPROP

4 830-031C TEE 1 1/2FNPT POLYPROP

5 830-045C AD 1 1/2MNPT POLYPROP

2 830-052C EL 1 1/2MNPT X 1 1/2FNPT POLYP

6 830-094C AD 1 1/2MNPT X 1 1/2HB POLYP

2 830-123C EL 3/4MNPT X 3/4HB POLYPROP

1 830-186C PL 2MCL POLY-GLASS

1 830-254C AD 1 1/2MNPT X 1HB POLYPROP

4 830-295C SP 3/4FNPT DBL THD BH PO BANJO

2 830-380C EL 3/4MNPT X 3/4FNPT SS

2 830-381C AD 3/4MNPT X 3/4HB SS

2 838-228C DECAL GREAT PLAINS ON LOGO SML

2 838-823C DECAL YP FERTILIZER LEVEL

1 can 890-310C RECTORSEAL 21 BLK THD SEALANT

2 890-522C MUFFLER CLAMP 2.50 SIZE

14 ft 990-078R HOSE 3/4ID X 1/8 WL CLEAR PVC

25 ft 990-082R HOSE 1 ID 200PSI EPDM

11 ft 990-181R HOSE 1 1/2 ID 150PSI EPDM

Part Description

(407-122A YP FERTILIZER TANK KIT)

02/29/2008 407-197M

30 Fertilizer System

List: Kit 407-133A YP 1625 FERT BOOM ONLY ASSY

Great Plains Mfg., Inc.

Callout Quantity Part Number

152

153

154

155

156

157

158

159

160

161

162

163

164

165

166

167

168

169

170

171

172

173

174

175

176

177

178

179

180

181

182

183

184

185

186

187

188

1 407-133A YP 1625 FERT BOOM ONLY ASSY

1 401-528D AIR TUBE SUPPORT CLAMP

4 407-134D MANIFOLD 40 FT TWIN ROW

12 407-137D FERTILIZER BOOM MOUNT

1 507-034V GAUGE PROTECTOR ASSY

3 801-071C SRHMS 5-40X5/8 SS

1 507-039D GAUGE PROTECTOR BOTTOM

1 507-040D GAUGE PROTECTOR TOP

1 816-144C DIAPHRAGM - GAUGE PROTECTOR

1 818-344C DECAL NOTICE GAUGE PROTECTOR

4 800-123C CLAMP WRM DRV #16 SS (.68-1.5)

4 800-257C CLAMP WRM DRV #20SS (.81-1.75)

32 800-303C CABLE TIE 2 DIA MIN - BLK

32 800-367C AD PUSH 1/4TUBEX1/4MNPT

26 803-088C NUT HEX LOCK 1/4-20 FLG

24 803-177C NUT HEX FLG TP LK 5/16-18ZNYCR

12 806-152C U-BOLT 1/4-20 X 1.125 X 2 RND

13 806-192C U-BOLT 5/16-18X1 1/2X2 1/2 RND

32 829-089C NOZZLE BODY 3/4 WET BOOM CLAMP

1 829-104C GAUGE 160 PSI 4IN STAINLESS ST

1 829-105C VALVE RELIEF 0-150 PSI POLYP

2 830-028C TEE 3/4FNPT POLYPROP

1 830-029C TEE 1FNPT POLYPROP

1 830-043C AD 1MNPT POLYPROP

4 830-061C CA 3/4FNPT POLYPROP

1 830-086C AD 1MNPT X 3/4HB POLYPROP

1 830-087C AD 1MNPT X 1HB POLYPROP

1 830-121C EL 3/4MNPT X 3/8HB POLYPROP

2 830-123C EL 3/4MNPT X 3/4HB POLYPROP

1 830-126C EL 1MNPT X 3/4HB POLYPROP

1 830-142C AD 1MNPT X 3/4FNPT POLYPROP

1 830-192C AD 1/4MNPT CLOSE X 7/8 SS

1 830-237C CR 1FNPT

1 830-258C AD 1MNPT X 1/4FNPT POLYPROP

32 830-383C CP 1/4 PUSH LOK POLY

16 832-042C NOZZLE SHUT OFF CAP W/ GASKET

32 832-051C NOZZLE CAP QUICK X 90X1/4 FNPT

Part Description

(407-133A YP 1625 FERT BOOM ONLY ASSY)

407-197M 02/29/2008

Great Plains Mfg., Inc.

Installation Instructions 31

Callout Quantity Part Number

189

190

191

192

193

194

195

196

197

32 832-053C ORIFICE SPR SYS CP4916-34 SS

32 832-054C ORIFICE SPR SYS CP4916-48 SS

32 832-056C ORIFICE SPR SYS CP4916-28 SS

1 890-521C MUFFLER CLAMP 1.63 SIZE

3 ft 990-080R HOSE 3/8 ID 150PSI EPDM

27 ft 990-081R HOSE 3/4 ID 200PSI EPDM

25 ft 990-082R HOSE 1 ID 200PSI EPDM

96 ft 990-109R TUBE NYLON 1/4OD X 062WL

9 ft 990-181R HOSE 1 1/2 ID 150PSI EPDM

Part Description

(407-133A YP 1625 FERT BOOM ONLY ASSY)

List: Kit 407-134A YP1225 & Y1625 FERT PUMP ONLY

Callout Quantity Part Number

198

199

200

201

202

203

204

205

206

207

208

209

210

211

212

213

214

215

216

217

218

219

220

221

222

223

1 407-134A YP1225 & Y1625 FERT PUMP ONLY

1 407-146K FERTILIZER PUMP DRIVE

1 117-099H SPKT 40C38 X 7/8 HEX BORE

1 120-339H SPKT 40C14 X 7/8 HEX BORE

1 121-763S OPENER SPRING ROD ASSY. SHRT.

1 121-154D SPRING STOP STAMPING

1 121-166D ADJ. YOKE END

1 802-550C HHCS 1/2-13X10 SPTHD GR8

1 803-036C NUT HEX JAM 1/2-13 PLT

1 803-193C NUT HEX FLANGE 1/2-13 GR G PLT

1 807-159C SPRING COMP 2 1/2ODX3/8X12 7/8

1 812-236C OPNR SPRING RD TRUNION CASTING

1 816-306C PLUG, SPRING ROD CASTING

1 136-108D CHAIN RL #40 137 PITCHES

1 136-155D CHAIN RL #40 120 PITCHES

1 168-127D 3/16 X 1 KEY

1 188-006V BRG .880 HEX BORE 205DD

1 188-002D 205 BRG OUTER RACE

1 188-009D .880 HEX BORE INNER RACE

2 816-087C SEAL TRIPLE LIP 205

1 817-054C 205 NYLON BALL RETAINER

9 827-008C 5/16 CHROME STEEL BALL-GR 100

2 204-084SU GP25S NARROW HUB ASM

1 800-005C RING FC HOUSING

1 204-328D NARROW COULTER HUB

1 822-215C BRG BALL 1.18IDX2.44OD 5206KPP

Part Description

(407-134A YP1225 & Y1625 FERT PUMP ONLY)

02/29/2008 407-197M

32 Fertilizer System

Great Plains Mfg., Inc.

Callout Quantity Part Number

224

225

226

227

228

229

230

231

232

233

234

235

236

237

238

239

240

241

242

243

244

245

246

247

248

249

250

251

252

253

254

255

256

257

258

259

260

261

1 402-025S LOCK COLLAR, 7/8 HEX W/ SET SC

1 402-058D COLLAR LOCK 7/8 HEX

2 801-035C SCREW SET 5/16-18 SKT KP X 3/8

1 402-058D COLLAR LOCK 7/8 HEX

2 801-035C SCREW SET 5/16-18 SKT KP X 3/8

1 407-139D DRIVE ADAPTER 7/8 HEX 3/4 RND

2 407-141H SPKT STORAGE MNT

1 407-142H FERT DRIVE CONT WHL SPKT WLMT

1 407-143H FERT CONT WHL ARM WLMT

1 407-144H FERTILIZER CONTACT WHEEL WLMT

1 407-145H FERT DRIVE SPKT WLMT

1 407-150H SPKT 40C13 X 7/8 HEX BORE

1 407-151H SPKT 40C39 X 7/8 HEX BORE

1 407-152H SPKT 40C40 X 7/8 HEX BORE

1 407-167D BRG SPACER

1 407-168D FERT DRIVE CONT WHL JACK SHAFT

2 407-169D IDLER PIVOT TUBE

2 407-170D TUBE RND 1 OD X 7/32WL X 2.25

1 407-172D 7/8 HEX X 3/4 LNG SPKT SPACER

1 407-187H MOUNT

1 407-190S PUMP HYPRO D30AP SUB-ASY

1 407-173D STAINLESS FITTING

1 816-045C O-RING 15/16 I.D. X 1-1/8 O.D.

1 830-041C AD 1/2MNPT POLYPROP

1 830-048C EL 1/2MNPT X 1/2FNPT POLYP

1 831-061C PUMP HYPRO D30AP-A DIAPHRAM

1 407-192H CONTACT WHL DR SHLD UPPER

1 407-193H CONTACT WHL DR SHLD LWR

1 407-195H FERT PUMP UPPER SHLD MNT WLMT

1 407-289D FERT PUMP MNT STALK SHIELD

2 802-032C HHCS 1/2-13X3/4 GR5

2 802-041C HHCS 1/2-13X3 1/2 GR5

2 802-128C HHCS 1/2-13X2 GR5

3 802-155C RHSNB 3/8-16X1 1/4 GR5

8 802-331C RHSNB 1/2-13X1 3/4 GR5

3 802-714C HHCS M8X1.25X25 GR8.8 ZNYCR

3 803-014C NUT HEX 3/8-16 PLT

8 803-020C NUT HEX 1/2-13 PLT

Part Description

(407-134A YP1225 & Y1625 FERT PUMP ONLY)

407-197M 02/29/2008

Great Plains Mfg., Inc.

Installation Instructions 33

Callout Quantity Part Number

262

263

264

265

266

267

268

269

270

271

272

273

274

275

276

277

278

279

280

281

282

283

284

285

286

287

288

289

290

291

292

293

294

295

296

297

298

299

300

1 407-171D FERT VALVE MNT

3 802-034C HHCS 1/2-13X1 1/4 GR5

3 803-020C NUT HEX 1/2-13 PLT

4 803-027C NUT HEX 3/4-10 PLT

3 804-015C WASHER LOCK SPRING 1/2 PLT

6 804-016C WASHER FLAT 1/2 SAE PLT

4 804-023C WASHER LOCK SPRING 3/4 PLT

4 804-025C WASHER FLAT 3/4 SAE PLT

2 806-102C U-BOLT 3/4-10 CORNER 7 SQ

1 829-013C VALVE 1 1/2FNPT BALL POLYPROP

1 830-045C AD 1 1/2MNPT POLYPROP

1 830-052C EL 1 1/2MNPT X 1 1/2FNPT POLYP

2 830-127C EL 1MNPT X 1HB POLYPROP

2 803-053C NUT HEX SLOTTED 3/4-16

2 803-147C NUT HEX NYLOCK 1/2-13

2 804-013C WASHER LOCK SPRING 3/8 PLT

12 804-015C WASHER LOCK SPRING 1/2 PLT

1 804-017C WASHER FLAT 1/2 USS PLT

2 804-061C WASHER MACH 1.50 X 1.00 X 18GA

1 804-093C WASHER FLAT 3/4 HARD ASTMF436

6 804-113C WASHER FLAT 1/2 USS HARD PLT

3 804-157C WASHER SPRING LOCK M8 PLT

2 805-064C PIN COTTER 7/64 X 1 LONG

2 805-104C PIN COTTER 3/16 X 1 1/2 PLT

1 805-127C PIN CLEVIS 1/2 X 1 3/4

1 805-180C PIN ROLL 1/4 X 1 1/2 LG PLT

1 805-234C PIN CLEVIS 1/2 X 4 PLATED

4 805-240C PIN LINCH 3/16 X 1 9/16 LONG

2 808-147C SPKT 40C15 X 7/8 HEX BORE

1 808-149C SPKT 40C19 X 7/8 HEX BORE

1 808-156C SPKT 40C30 X 7/8 HEX BORE

1 808-219C SPKT 40C12 X 7/8 HEX BORE

1 808-249C SPKT 40C18 X 7/8 HEX BORE

1 808-251C SPKT 40C36 X 7/8 HEX BORE

1 808-276C SPKT 40C20 X 7/8 HEX BORE

1 808-338C SPKT 40C16 X 7/8 HEX BORE

1 817-358C KNOB 3/8-16 MALE THD 2 3/8OD

4 817-406C IDLER 1 PC 2.38X1.01X1.062

1 848-095C DECAL FERT DRIVE

Part Description

(407-134A YP1225 & Y1625 FERT PUMP ONLY)

02/29/2008 407-197M

34 Fertilizer System

Great Plains Mfg., Inc.

Callout Quantity Part Number

301

302

303

304

305

1 830-141C AD 1MNPT X 1/2FNPT POLYPROP

1 830-145C AD 1 1/2MNPT X 1FNPT POLYPROP

1 830-254C AD 1 1/2MNPT X 1HB POLYPROP

1 830-300C AD 1FNPT POLYPROP

1 831-029C STRAINER BANJO LST150-80 MESH

Part Description

(407-134A YP1225 & Y1625 FERT PUMP ONLY)

List: Kit 407-137A YP16 HI-RATE FERT MANIFOLD KIT

Callout Quantity Part Number

306

307

308

309

310

311

312

313

314

315

316

317

318

319

320

321

322

323

324

325

326

327

328

329

330

331

332

333

334

1 407-137A YP16 HI-RATE FERT MANIFOLD KIT

1 401-528D AIR TUBE SUPPORT CLAMP

4 407-134D MANIFOLD 40 FT TWIN ROW

12 407-137D FERTILIZER BOOM MOUNT

12 407-252D HI-RATE CENTER BOOM SUPPORT

12 407-253D FERT BOOM MOUNTING BRACKET

1 507-034V GAUGE PROTECTOR ASSY

3 801-071C SRHMS 5-40X5/8 SS

1 507-039D GAUGE PROTECTOR BOTTOM

1 507-040D GAUGE PROTECTOR TOP

1 816-144C DIAPHRAGM - GAUGE PROTECTOR

1 818-344C DECAL NOTICE GAUGE PROTECTOR

4 800-123C CLAMP WRM DRV #16 SS (.68-1.5)

64 800-126C CLAMP WRM DRV #5 SS (.44-.70)

4 800-257C CLAMP WRM DRV #20SS (.81-1.75)

32 800-303C CABLE TIE 2 DIA MIN - BLK

24 802-159C HHCS 5/16-18X1 GR5

26 803-088C NUT HEX LOCK 1/4-20 FLG

48 803-177C NUT HEX FLG TP LK 5/16-18ZNYCR

24 806-152C U-BOLT 1/4-20 X 1.125 X 2 RND

13 806-192C U-BOLT 5/16-18X1 1/2X2 1/2 RND

32 829-089C NOZZLE BODY 3/4 WET BOOM CLAMP

1 829-104C GAUGE 160 PSI 4IN STAINLESS ST

1 829-105C VALVE RELIEF 0-150 PSI POLYP

2 830-028C TEE 3/4FNPT POLYPROP

1 830-029C TEE 1FNPT POLYPROP

1 830-043C AD 1MNPT POLYPROP

4 830-061C CA 3/4FNPT POLYPROP

32 830-071C AD 1/4MNPT X 3/8HB POLYPROP

Part Description

(407-137A YP16 HI-RATE FERT MANIFOLD KIT)

407-197M 02/29/2008

Great Plains Mfg., Inc.

Installation Instructions 35

Callout Quantity Part Number

335

336

337

338

339

340

341

342

343

344

345

346

347

348

349

350

352

353

354

1 830-086C AD 1MNPT X 3/4HB POLYPROP

1 830-087C AD 1MNPT X 1HB POLYPROP

1 830-121C EL 3/4MNPT X 3/8HB POLYPROP

2 830-123C EL 3/4MNPT X 3/4HB POLYPROP

1 830-126C EL 1MNPT X 3/4HB POLYPROP

1 830-142C AD 1MNPT X 3/4FNPT POLYPROP

1 830-192C AD 1/4MNPT CLOSE X 7/8 SS

1 830-237C CR 1FNPT

1 830-258C AD 1MNPT X 1/4FNPT POLYPROP

16 832-042C NOZZLE SHUT OFF CAP W/ GASKET

32 832-051C NOZZLE CAP QUICK X 90X1/4 FNPT

32 832-053C ORIFICE SPR SYS CP4916-34 SS

32 832-054C ORIFICE SPR SYS CP4916-48 SS

32 832-056C ORIFICE SPR SYS CP4916-28 SS

1 890-521C MUFFLER CLAMP 1.63 SIZE

99 ft 990-080R HOSE 3/8 ID 150PSI EPDM

27 ft 990-081R HOSE 3/4 ID 200PSI EPDM

25 ft 990-082R HOSE 1 ID 200PSI EPDM

9 ft 990-181R HOSE 1 1/2 ID 150PSI EPDM

Part Description

(407-137A YP16 HI-RATE FERT MANIFOLD KIT)

Existing Parts Affected

The following existing parts may be involved in the kit

installation. The Disposition column indicates whether

parts are left in place, moved or not re-used.

Callout Part No. Part Description Part Disposition

11

802-078C HHCS 1/4-20X5/8 GR5 Removed and re-installed.

12

803-006C NUT HEX 1/4-20 PLT Removed and re-installed.

13

804-006C WASHER LOCK SPRING 1/4 PLT Removed and re-installed.

The part call-out numbers in the list match all Figures in

the installation instructions. Descriptions match those in

your drill Parts manual.

02/29/2008 407-197M

36 Fertilizer System

Reference Information

Torque Values

Great Plains Mfg., Inc.

Bolt

Size

in-tpi

1

⁄4-20

1

⁄4-28

5

⁄16-18

5

⁄16-24

3

⁄8-16

3

⁄8-24

7

⁄16-14

7

⁄16-20

1

⁄2-13

1

⁄2-20

9

⁄16-12

9

⁄16-18

5

⁄8-11

5

⁄8-18

3

⁄4-10

3

⁄4-16

7

⁄8-9

7

⁄8-14

1-8

1-12

11⁄8-7

11⁄8-12

11⁄4-7

11⁄4-12

13⁄8-6

13⁄8-12

11⁄2-6

11⁄2-12

Bolt Head Identification

Bolt Head Identification

Bolt

Size

Grade 2 Grade 5 Grade 8 Class 5.8 Class 8.8 Class 10.9

1

N-m2ft-lb

7.4 5.6 11 8 16 12

8.5 6 13 10 18 14

15 11 24 17 33 25

17 13 26 19 37 27

27 20 42 31 59 44

31 22 47 35 67 49

43 32 67 49 95 70

49 36 75 55 105 78

66 49 105 76 145 105

75 55 115 85 165 120

95 70 150 110 210 155

105 79 165 120 235 170

130 97 205 150 285 210

150 110 230 170 325 240

235 170 360 265 510 375

260 190 405 295 570 420

225 165 585 430 820 605

250 185 640 475 905 670

340 250 875 645 1230 910

370 275 955 705 1350 995

480 355 1080 795 1750 1290

540 395 1210 890 1960 1440

680 500 1520 1120 2460 1820

750 555 1680 1240 2730 2010

890 655 1990 1470 3230 2380

1010 745 2270 1670 3680 2710

1180 870 2640 1950 4290 3160

1330 980 2970 2190 4820 3560

Torque tolerance + 0%, -15% of torquing values. Unless otherwise specified use torque values listed above.

3

N-m ft-lb N-m ft-lb

mm x pitch

M 5 X 0.8

M 6 X 1

M 8 X 1.25

M 8 X 1

M10 X 1.5

M10 X 0.75

M12 X 1.75

M12 X 1.5

M12 X 1

M14 X 2

M14 X 1.5

M16 X 2

M16 X 1.5

M18 X 2.5

M18 X 1.5

M20 X 2.5

M20 X 1.5

M24 X 3

M24 X 2

M30 X 3.5

M30 X 2

M36 X 3.5

M36 X 2

1. in-tpi = nominal thread diameter in inches-threads per inch

2. N· m = newton-meters

3. ft-lb = foot pounds

4. mm x pitch = nominal thread diameter in millimeters x thread

pitch

4

5.8 8.8 10.9

N-m ft-lb N-m ft-lb N-m ft-lb

43659 7

7 5 11 8 15 11

17 12 26 19 36 27

18 13 28 21 39 29

33 24 52 39 72 53

39 29 61 45 85 62

58 42 91 67 125 93

60 44 95 70 130 97

90 66 105 77 145 105

92 68 145 105 200 150

99 73 155 115 215 160

145 105 225 165 315 230

155 115 240 180 335 245

195 145 310 230 405 300

220 165 350 260 485 355

280 205 440 325 610 450

310 230 650 480 900 665

480 355 760 560 1050 780

525 390 830 610 1150 845

960 705 1510 1120 2100 1550

1060 785 1680 1240 2320 1710

1730 1270 2650 1950 3660 2700

1880 1380 2960 2190 4100 3220

407-197M 02/29/2008

Great Plains Mfg., Inc.

Installation Instructions 37

Abbreviations

AD Adaptor NPT (Female/Male) National Pipe Thread

ADJ. Adjustable OD Outside Diameter

ASM Assembly OPNR Opener

ASSY Assembly PL Plug

ASTM American Society for Testing and Materials PLT Plated

ASY Assembly PO Polymer

BH BulkHead POLYP Polypropylene

BRG Bearing PSI Pounds per Square Inch

CA Cap PVC PolyVinyl Chloride

CP Coupler RD Rod, Round or Rubber Duro

CR Cross RH Right Hand

DBL Double RHSNB Round Head Shank Neck Bolt

DIA Diameter RL Roller

DR Drive SC Screw

DRV Drive SHLD Shield

EL Elbow SHRT Short

EPDM Ethylene Propylene Diene Monomer rubber SKT Socket

FC Feeder Cup SML Small

FCL Female Cam Lock SP Special

FERT Fertilizer SPKT Sprocket

FLG Flanged SPR Spray or Spring

GAL Gallon SPTHD Special Thread

GR Grade SQ Square

HB Hose Barb SRHMS Slotted Round Head Machine Screw

HEX Hexagonal (6-sided) SS Stainless Steel

HH Hydraulic Hose SYS System

HHCS Hex Head Cap Screw (Bolt) THD Thread

HI High TP LK Top Lock

HYD Hydraulic USS U.S. Standard

ID Inside Diameter WHL Wheel

KP Knurled cup Point WL Wall

LH Left Hand WLMT Weldment

LNG Long WRM Worm

MCL Male Cam Lock ZNYCR Zinc Chromate

MNT Mount

02/29/2008 407-197M

38 Fertilizer System

Great Plains Mfg., Inc.

Great Plains Manufacturing, Inc.

Corporate Office P.O. Box 5060

Salina, Kansas 67402-5060 USA

407-197M 02/29/2008

Loading...

Loading...