Page 1

Table of Contents Appendix A

Manufacturing, Inc.

www.greatplainsmfg.com

Seed and Fertilizer Rate Charts for the YP2425A Yield-Pro® Planter with Air-Pro® seed meters

The following pages are to assist in the proper setting of seeding and

fertilizer rates for the 60-foot (18m) two-section Yield-Pro® Planter with

Air-Pro

Plains recommends checking singulated rates.

®

meters. To assure the most accurate seeding rates, Great

ORIGINAL INSTRUCTIONS

EN

© Copyright 2012 Printed 2012-02-29 401-626B

Page 2

Great Plains Mfg., Inc. Cover ii

Table of Contents

Introduction ..................................................................1

Models Covered .............................................................1

Document Family ........................................................... 1

Rate Setting Overview .................................................2

Setting Planting Rate......................................................2

Setting Fertilizer Rate.....................................................2

Population Reference Information..................................2

Kernels Per Pound...........................................................2

Seeds Per Unit ............................................................... 2

Seed Spacing ................................................................. 2

Spacing (U.S. Customary units, page 1 of 2) ......... 3

Air-Pro® Meter Disk Selection ........................................5

Meter Pressurization ......................................................8

Initial Meter Pressurization: Cotton.............................8

Initial Meter Pressurization: Milo.................................8

Initial Meter Pressurization: Soybeans .......................8

Initial Meter Pressurization: Sunflower .......................8

Initial Meter Pressurization: Round Corn........................ 8

Initial Meter Pressurization: Flat Corn ............................ 9

Factory Default Air Control Channel Screens ................ 9

Material 16 Setup.............................................................9

Control Channel 2 Setup .................................................9

Checking Planting Rate................................................10

Checking Singulated Rates .......................................... 10

Planting Rate ..............................................................12

Hydraulic Drive Meter Rate ..........................................12

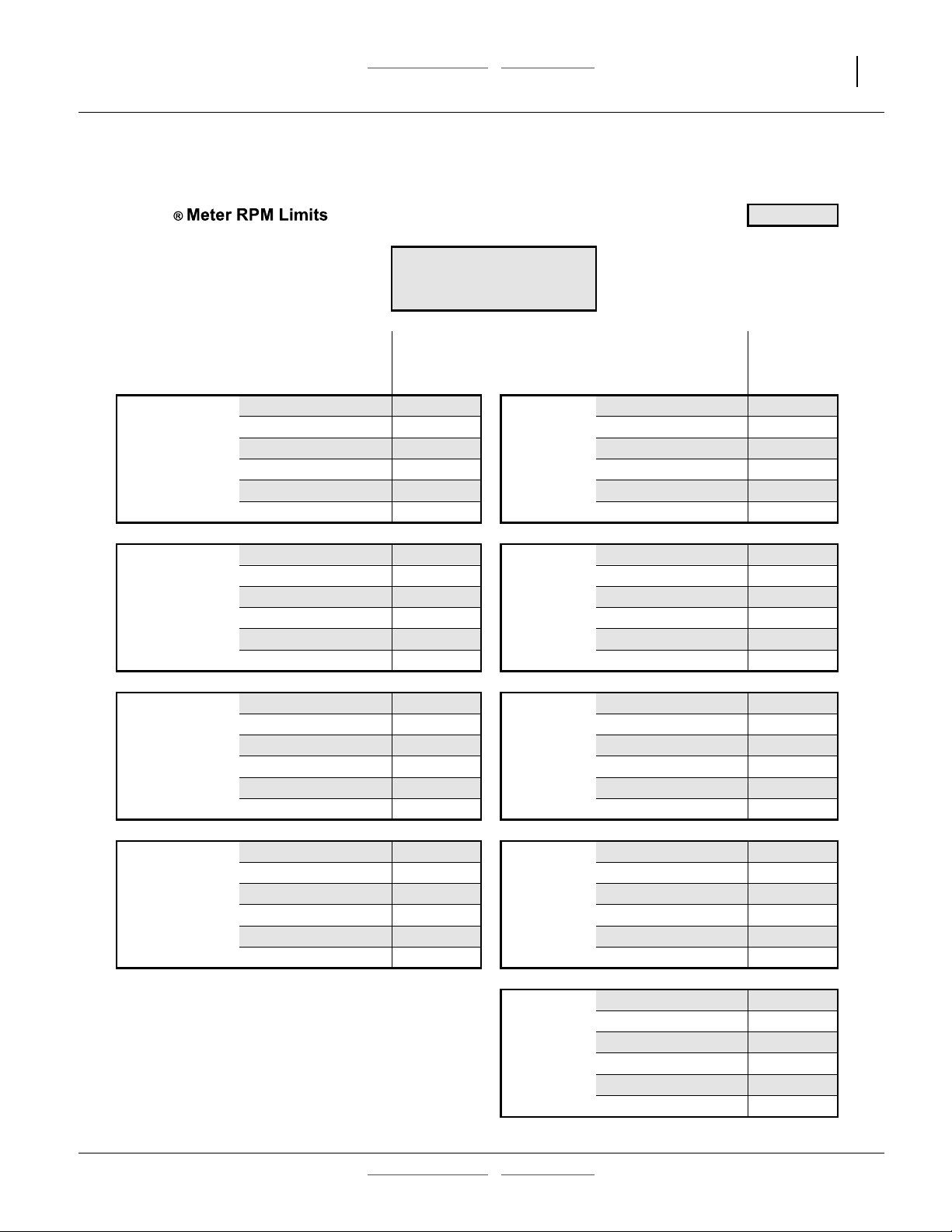

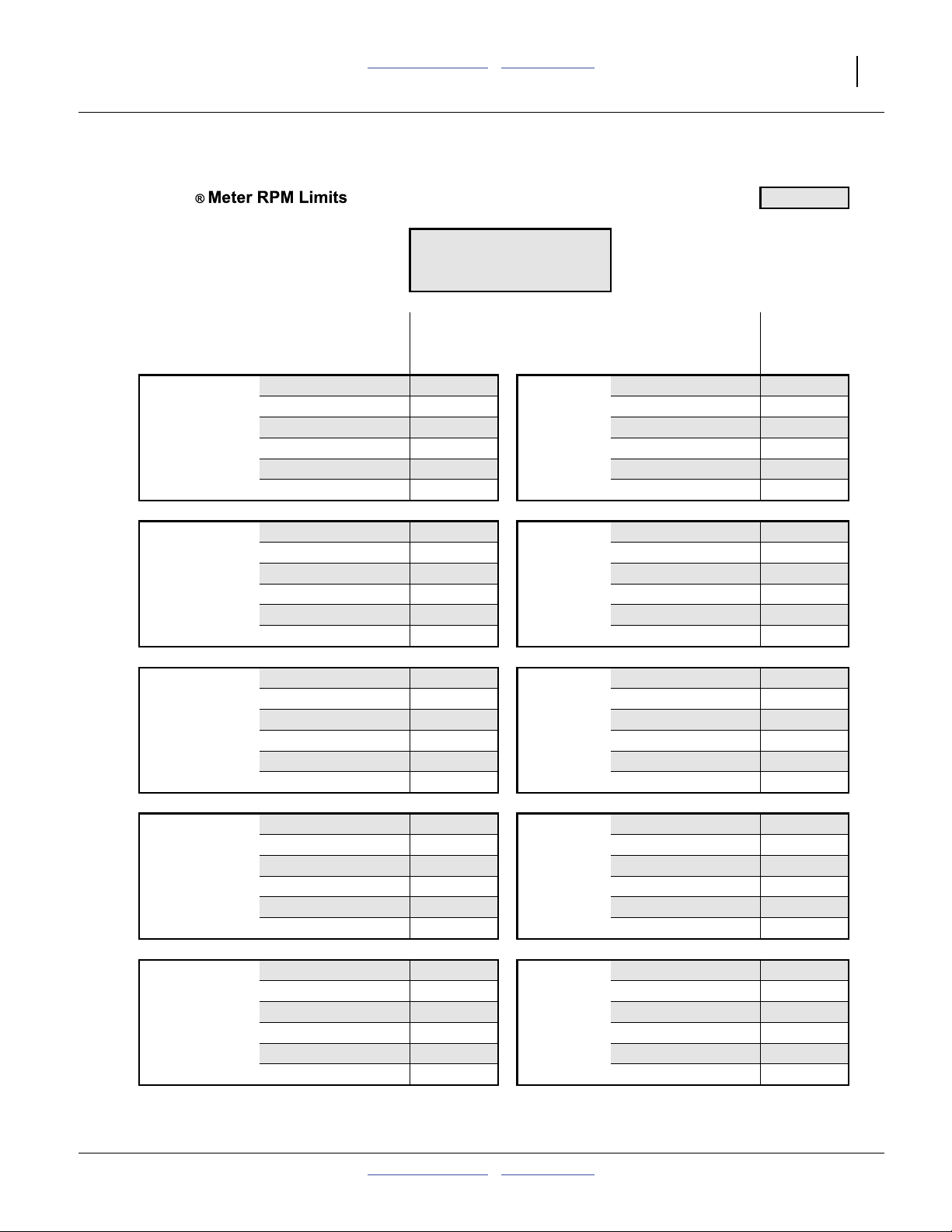

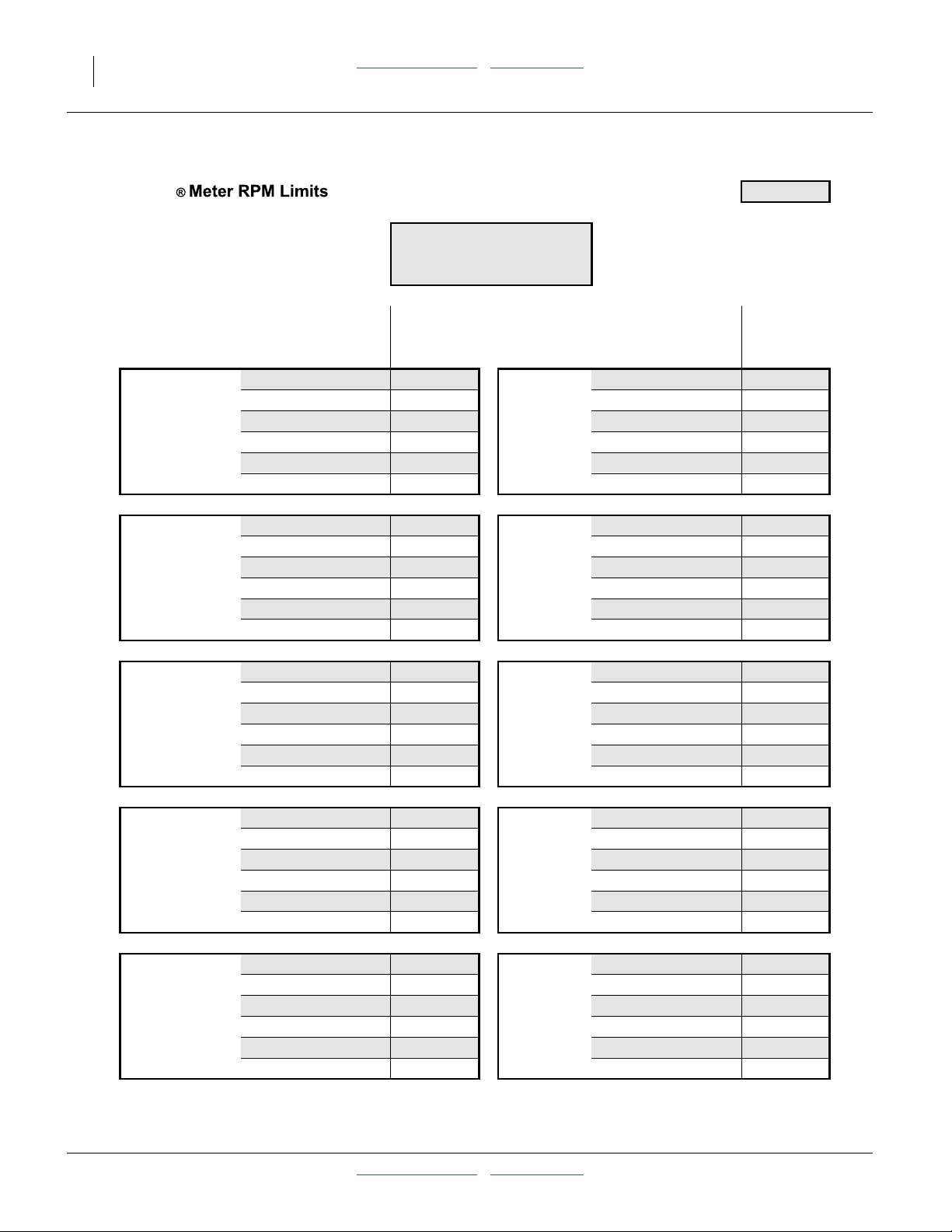

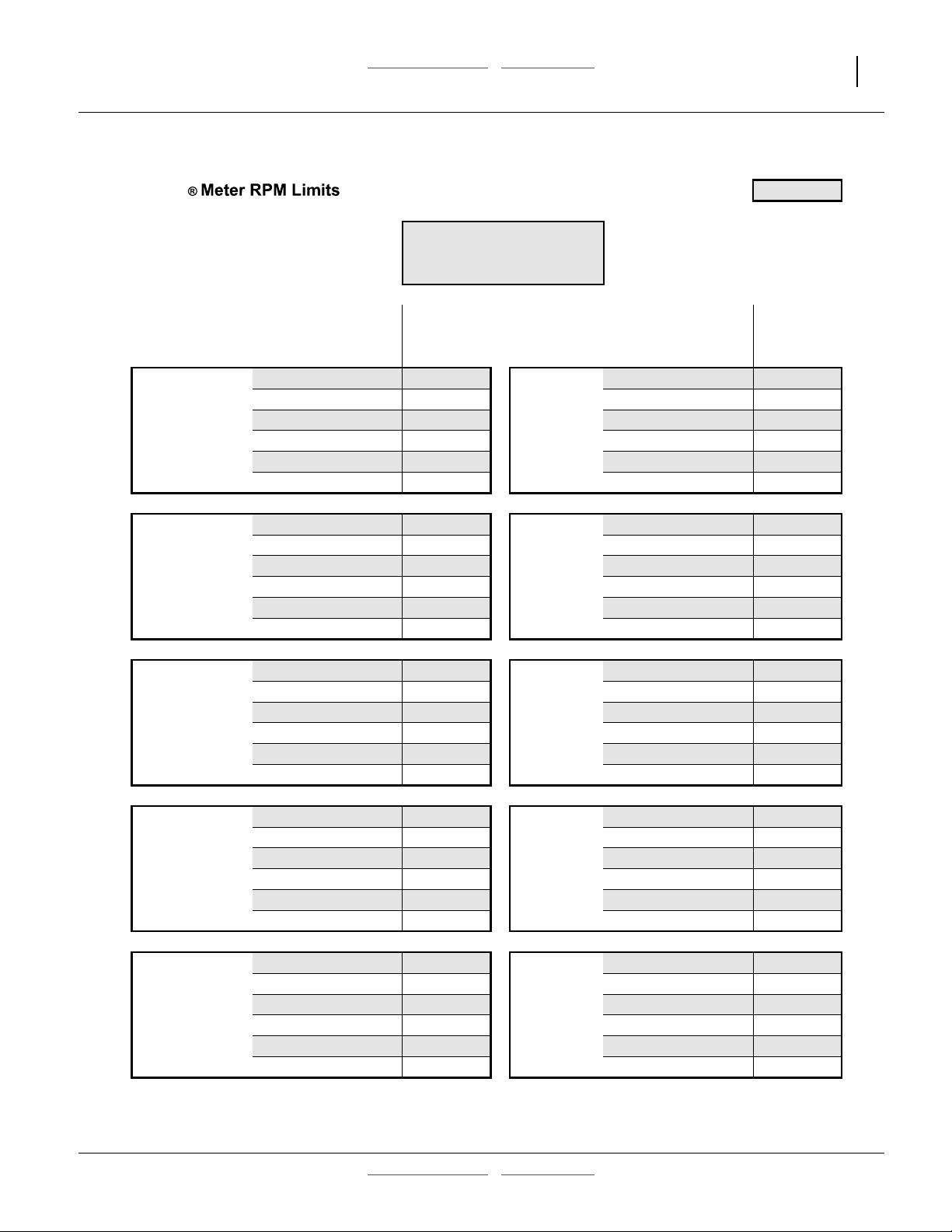

Meter RPM Limit Charts ............................................... 13

Meter RPM Limits: Corn 24 Cell................................... 13

Meter RPM Limits: Corn 40 Cell................................... 14

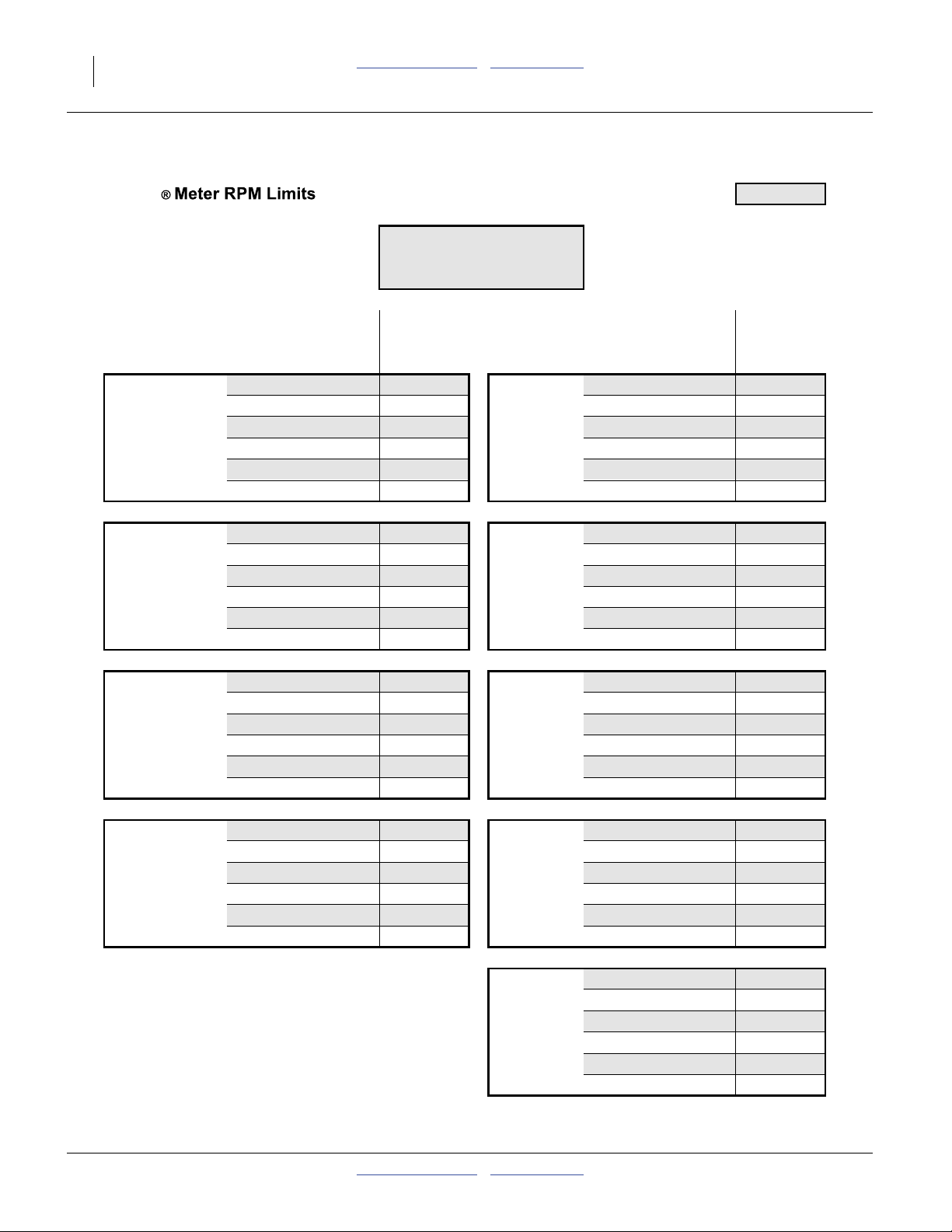

Meter RPM Limits: Cotton 60 Cell ................................ 15

Meter RPM Limits: Milo 65 Cell .................................... 16

Meter RPM Limits: Milo 130 Cell .................................. 17

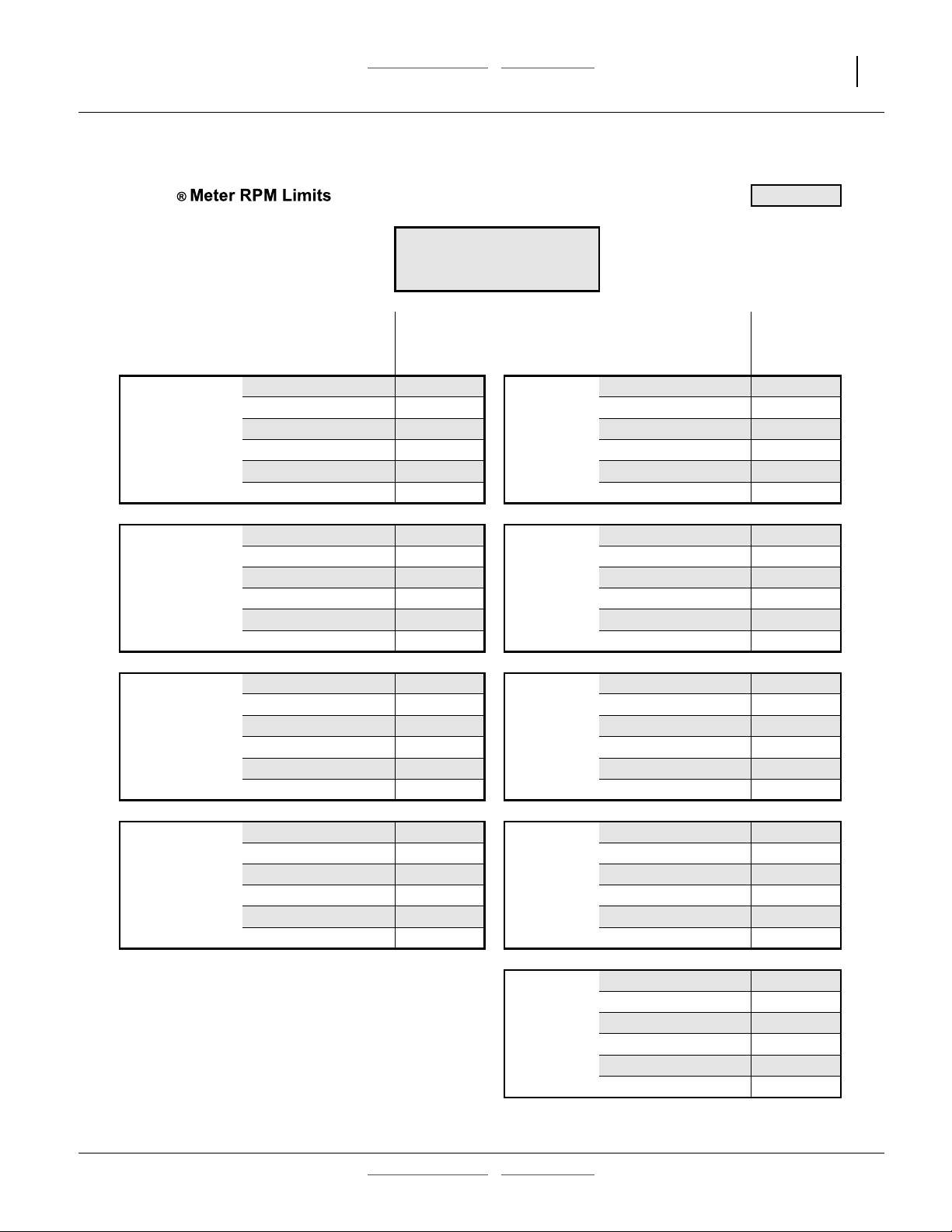

Meter RPM Limits: Soybeans 84 Cell........................... 18

Meter RPM Limits: Soybeans 168 Cell......................... 19

Meter RPM Limits: Sunflower 24 Cell........................... 20

Sprocket Indexing (Stagger) .....................................22

Indexing Preparation ....................................................23

Basic Indexing .............................................................. 23

Indexing Fine Adjustment.............................................25

Sprocket Indexing Charts ............................................. 26

30 inch Twin Row Sprocket Indexing ........................... 27

Volumetric Seeding....................................................28

General Information......................................................28

Related Documents ..................................................... 28

Clean-Out Meters......................................................... 28

Grain Shield ................................................................. 29

Install Discs / Set Shutters ........................................... 29

Take Note of Meter Pressure....................................... 30

Initial Meter Pressurization: Wheat ............................... 30

Calibrate....................................................................... 30

Furrow Checking Rate ................................................. 31

IntelliAg® Hydraulic Drive............................................. 32

Set Up A Material.......................................................... 33

Calibrate Speed Sensor................................................ 37

Meter RPM Limits: Volumetric ......................................38

Fertilizer Rate ............................................................. 39

Orifice Plate Selection.................................................. 39

Determine Orifice Size .................................................. 40

Strainer .........................................................................41

Ground Drive Fertilizer Rate ........................................ 42

JohnBlue Pump Rate.................................................... 42

JohnBlue Fertilizer Rates ..............................................43

JohnBlue Reference Data .............................................43

Setting Relief Valve.......................................................44

Appendix A ................................................................. 45

Seed Lubricants ........................................................... 45

Appendix B - Metric Charts....................................... 47

Disk Selection - Corn (metric) ...................................... 47

Disc Selection - Milo & Soybean (metric)..................... 48

Disc Selection - Sunflower, Volumetric, Blank ............. 49

Seed Spacing - Metric.................................................. 50

Meter Pressurization - Metric ....................................... 52

Initial Meter Pressurization: Cotton .......................... 52

Initial Meter Pressurization: Milo .............................. 52

Initial Meter Pressurization: Soybeans..................... 52

Initial Meter Pressurization: Sunflower..................... 52

Initial Meter Pressurization: Round Corn ...................... 52

Initial Meter Pressurization: Flat Corn........................... 53

Sprocket Indexing Charts - Metric................................ 54

Furrow Check - Metric.................................................. 56

Meter RPM Limit - Metric ............................................. 57

Volumetric - Metric Charts ........................................ 65

Volumetric Furrow Checking Rate - Metric ..................66

Volumetric Meter RPM Limits - Metric ......................... 67

© Copyright 2005, 2006, 2007, 2008, 2009, 2010, 2011, 2012. All rights Reserved

Great Plains Manufacturing, Inc. provides this publication “as is” without warranty of any kind, either expressed or implied. While every precaution has

been taken in the preparation of this manual, Great Plains Manufacturing, Inc. assumes no responsibility for errors or omissions. Neither is any liability

assumed for damages resulting from the use of the information contained herein. Great Plains Manufacturing, Inc. reserves the right to revise and improve its products as it sees fit. This publication describes the state of this product at the time of its publication, and may not reflect the product in the

future.

2012-02-29 Cover 401-626B

Trademarks of Great Plains Manufacturing, Inc. include: Singulator Plus, Swath Command, Terra-Tine.

Registered Trademarks of Great Plains Manufacturing, Inc. include:

Air-Pro, Clear-Shot, Discovator, Great Plains, Land Pride, MeterCone, Nutri-Pro, Seed-Lok, Solid Stand,

Terra-Guard, Turbo-Chisel, Turbo-Chopper, Turbo Max, Turbo-Till, Ultra-Till, Verti-Till, Whirlfilter, Yield-Pro.

Brand and Product Names that appear and are owned by others are trademarks of their respective owners.

Printed in the United States of America

Page 3

Great Plains Manufacturing, Inc. Table of Contents Metric Charts 1

Introduction

This manual covers the following tasks for 60-foot

three-section Yield-Pro®Planters equipped with Air-Pro

seed meters:

• setting and checking seed rate for singulated crops

• applying liquid fertilizer from optional tanks on-board

the planter, or from a trailing cart.

This manual is your guide to planter adjustments for

achieving specific seed population targets. It also

includes information you may need to properly setup and

adjust a separately provisioned fertilizer tank and pump

system.

Although some setup/adjustment material herein is

repeated from the Operator’s Manual, you need to be

thoroughly familiar with planter operations and

adjustments before applying this Seed Rate manual and

its table data.

Models Covered

YP2425A-2430 24 Row, 30 inch Spacing

YP2425A-2470 24 Row, 70 cm Spacing

YP2425A-3620 36 Row, 20 inch Spacing

YP2425A-4715 47 Row, 15 inch Spacing

YP2425A-48TR 48 Row (24 Twin), 30 inch Spacing

®

Figure 1

Air-Pro® Seed Meter

29626

R

Document Family

401-626M Owner’s Manual (this document)

401-626B Seed Rate Charts

401-626P Parts Manual

DICKEY-john®IntelliAg® manuals:

110011508 Planter/Drill Control, User Level 1

110011501 Planter/Drill Control, User Level 2&3

110011518 YP2425A-48TR Quick-Start Guide

110011519 YP2425A-4715 Quick-Start Guide

110011520 YP2425A-2430 Quick-Start Guide

110011521 YP2425A-3620 Quick-Start Guide

110011522 YP2425A/AF-2470 QSG

Figure 2

Yield-Pro® Planter

L

29711

2012-02-29 Table of Contents Metric Charts 401-626B

Page 4

2 YP2425A Table of Contents Metric Charts Great Plains Manufacturing, Inc.

Rate Setting Overview

Setting Planting Rate

There are five or six steps to obtaining the desired

number of seeds per acre, depending on row

configuration. This data applies to the Air-Pro

when planting at one

1. For your crop, determine your intended population, in

seeds/acre or seeds/hectare. If you know only the

seed spacing or pounds/acre (kg/hectare), consult

the charts on page 2 through page 4.

2. For your crop, population and desired field speed,

verify the suitability and setup of your seed disk:

See “Air-Pro® Meter Disk Selection” on page 5.

3. Set initial seed inlet shutter per seed rate chart.

Set initial meter pressurization per page 8, 9.

4. Sprocket index for staggered twin-row

Twin-row planters, with certain crops, get maximum

benefit with precise seed spacing between adjacent

rows. See “Indexing Fine Adjustment” on page 25.

5. Set meter rate

This is done via the seed monitor. Once data about

your planter is entered, you select the seed rate

directly. Consult the manual for the seed monitor.

6. Check planting rate

See “Checking Planting Rate” on page 10.

a. Volumetric planting (more than one seed per cell), is not

covered by this manual.

a

seed per disc cell.

®

meter

Setting Fertilizer Rate

If your planter is equipped with one or both optional

fertilizer manifold systems, it does not include the tank.

If the planter has a Type 2b (formerly referred to as a

“starter”) manifold, it may rely on an off-planter pump, or

may use one or two ground drive pumps on the planter.

See “Ground Drive Fertilizer Rate” on page 42 for

ground drive pump configuration.

If the planter has a Type 3

“hi rate”) manifold, it relies on an off-planter pump,

typically the pump on a Great Plains PFC1600 or

PFC2000 tank cart.

Rate setting for the cart pump is found in the cart’s

Operator manual.

Rate is controlled by the pump. Consistent distribution

requires using the correct size orifices in the manifolds. If

the orifice size is too large, flow may not be even across

all rows. If the orifice size is too small, material may be

dumped at the relief valve.

See “Fertilizer Rate” on page 39 for orifice information.

b. Type 2 and Type 3 are described in the YP2425A

Operator manual, under Setup topic “Fertilizer

Connections”.

b

(formerly referred to as a

Population Reference Information

Seeds Per Unit

If only pounds/acre (kilograms/hectare) is known, obtain

the population count by multiplying the weight by the

“Kernels per pound” value from the seed container.

Example: Milo

Target rate: 4.5 pounds/acre

Seed density: 14500 seeds/pound

Population: = Rate × Density

= 4.5 × 14500, or:

65250 seeds/acre

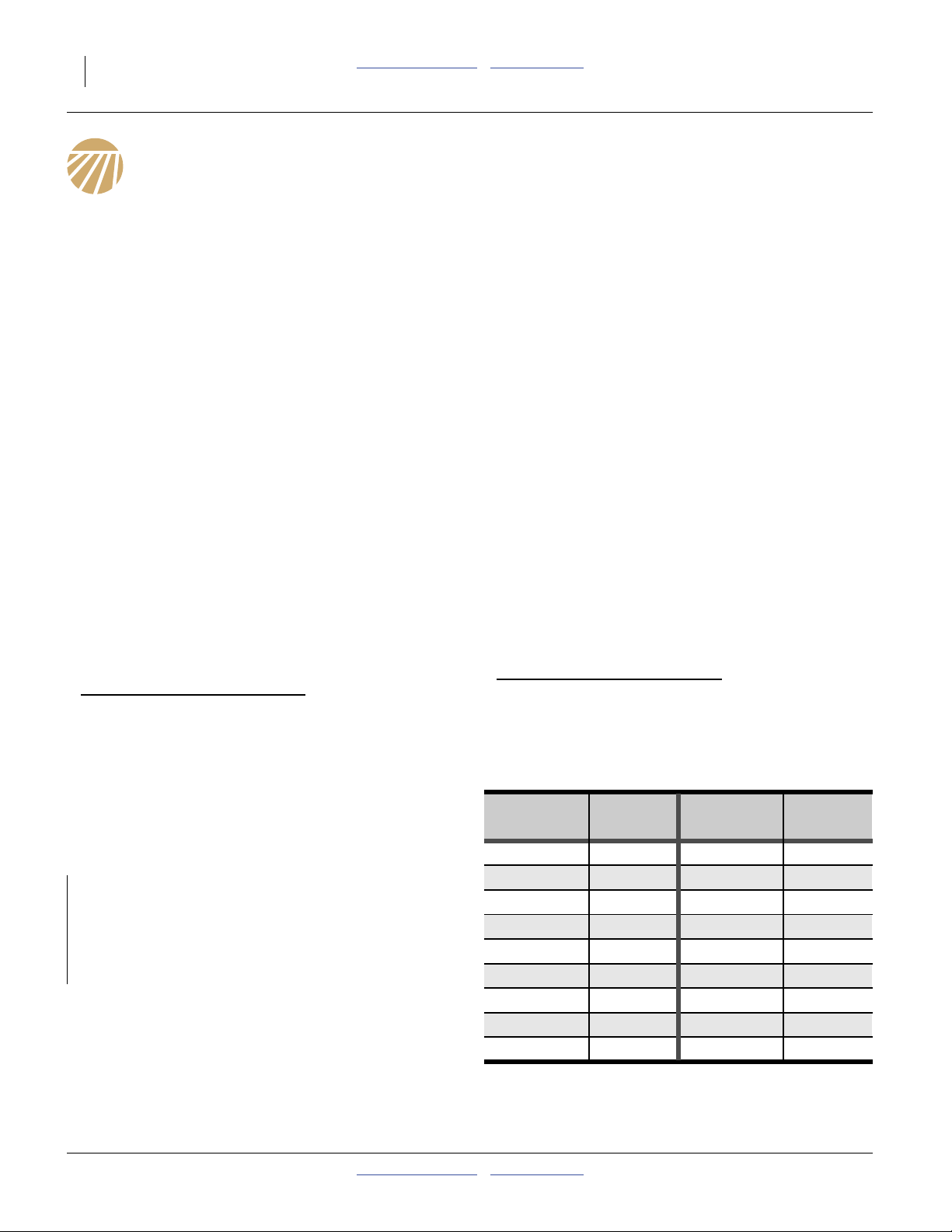

Seed Spacing

If only seed spacing is known, use the tables on the next

five pages to determine population.

401-626B Table of Contents Metric Charts 2012-02-29

Kernels Per Pound

80,000 Seed Kernels 80,000 Seed Kernels

Bag Weight per Pound Bag Weight per Pound

67.5 lbs 1,185 45.0 lbs 1,778

65.0 lbs 1,231 42.5 lbs 1,882

62.5 lbs 1,280 40.0 lbs 2,000

60.0 lbs 1,333 37.5 lbs 2,133

57.5 lbs 1,391 35.0 lbs 2,286

55.0 lbs 1,455 32.5 lbs 2,462

52.5 lbs 1,524 30.0 lbs 2,667

50.0 lbs 1,600 27.5 lbs 2,909

47.5 lbs 1,684 25.0 lbs 3,200

29649

Page 5

Great Plains Manufacturing, Inc. Table of Contents Metric Charts Rate Setting Overview 3

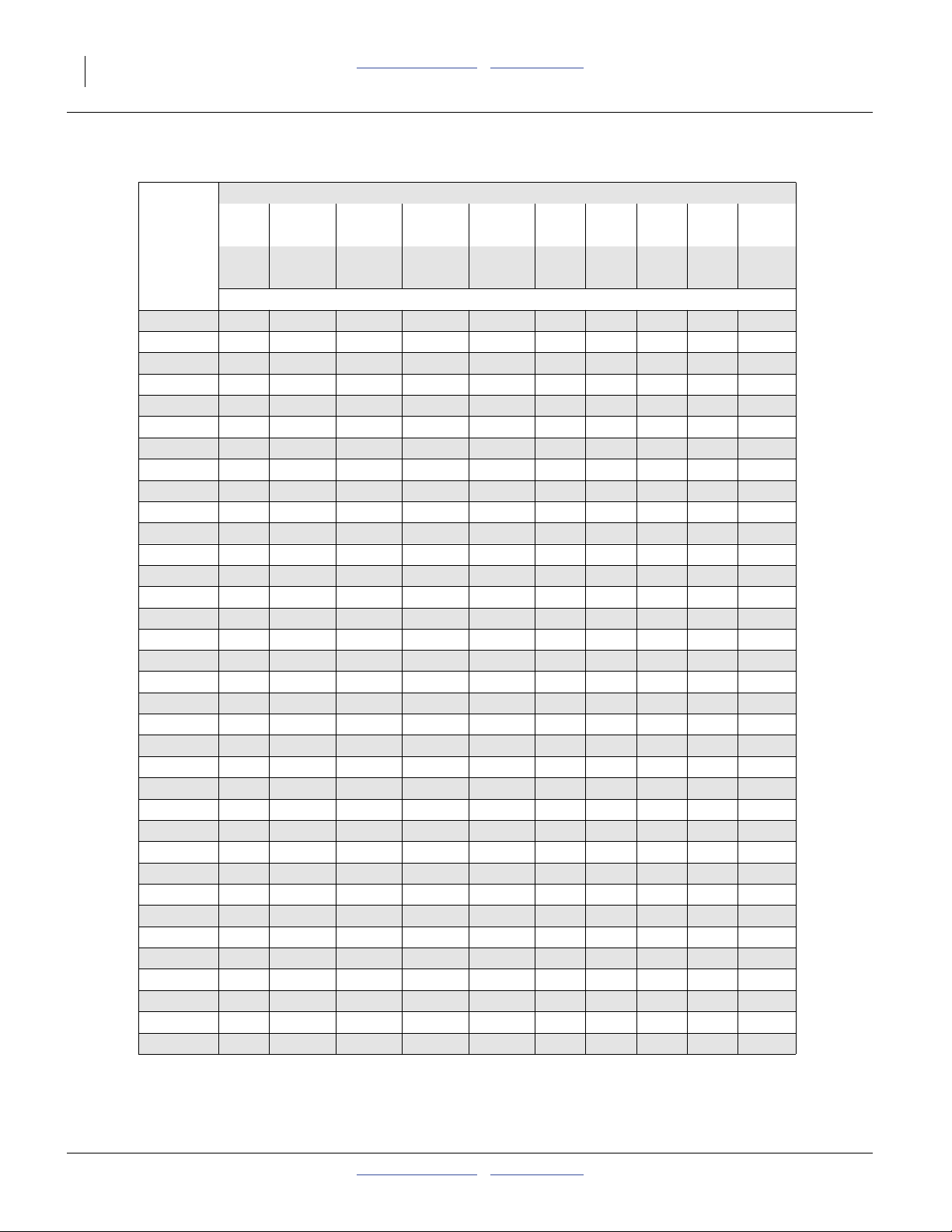

Spacing (U.S. Customary units, page 1 of 2)

Row Spacings

Twin Row Twin Row Twin Row Twin Row

30in 36in 38in 40in

Plant 10in 15in 20in 22in 30in 36in 38in 40in

Population Rows Rows Rows Rows Rows Rows Rows Rows

(seeds/acre)

14 000

15 000

16 000

17 000

18 000

19 000

20 000

21 000

22 000

23 000

24 000

25 000

26 000

27 000

28 000

29 000

30 000

31 000

32 000

33 000

34 000

35 000

36 000

37 000

38 000

39 000

40 000

41 000

42 000

43 000

44 000

45 000

46 000

47 000

48 000

49 000

50 000

44.8 29.9 24.9 23.6 22.4 20.4 14.9 12.4 11.8 11.2

41.8 27.9 23.2 22.0 20.9 19.0 13.9 11.6 11.0 10.5

39.2 26.1 21.8 20.6 19.6 17.8 13.1 10.9 10.3 9.8

36.9 24.6 20.5 19.4 18.4 16.8 12.3 10.2 9.7 9.2

34.8 23.2 19.4 18.3 17.4 15.8 11.6 9.7 9.2 8.7

33.0 22.0 18.3 17.4 16.5 15.0 11.0 9.2 8.7 8.3

31.4 20.9 17.4 16.5 15.7 14.3 10.5 8.7 8.3 7.8

29.9 19.9 16.6 15.7 14.9 13.6 10.0 8.3 7.9 7.5

28.5 19.0 15.8 15.0 14.3 13.0 9.5 7.9 7.5 7.1

27.3 18.2 15.2 14.4 13.6 12.4 9.1 7.6 7.2 6.8

26.1 17.4 14.5 13.8 13.1 11.9 8.7 7.3 6.9 6.5

25.1 16.7 13.9 13.2 12.5 11.4 8.4 7.0 6.6 6.3

24.1 16.1 13.4 12.7 12.1 11.0 8.0 6.7 6.3 6.0

23.2 15.5 12.9 12.2 11.6 10.6 7.7 6.5 6.1 5.8

22.4 14.9 12.4 11.8 11.2 10.2 7.5 6.2 5.9 5.6

21.6 14.4 12.0 11.4 10.8 9.8 7.2 6.0 5.7 5.4

20.9 13.9 11.6 11.0 10.5 9.5 7.0 5.8 5.5 5.2

20.2 13.5 11.2 10.6 10.1 9.2 6.7 5.6 5.3 5.1

19.6 13.1 10.9 10.3 9.8 8.9 6.5 5.4 5.2 4.9

19.0 12.7 10.6 10.0 9.5 8.6 6.3 5.3 5.0 4.8

18.4 12.3 10.2 9.7 9.2 8.4 6.1 5.1 4.9 4.6

17.9 11.9 10.0 9.4 9.0 8.1 6.0 5.0 4.7 4.5

17.4 11.6 9.7 9.2 8.7 7.9 5.8 4.8 4.6 4.4

17.0 11.3 9.4 8.9 8.5 7.7 5.7 4.7 4.5 4.2

16.5 11.0 9.2 8.7 8.3 7.5 5.5 4.6 4.3 4.1

16.1 10.7 8.9 8.5 8.0 7.3 5.4 4.5 4.2 4.0

15.7 10.5 8.7 8.3 7.8 7.1 5.2 4.4 4.1 3.9

15.3 10.2 8.5 8.1 7.6 7.0 5.1 4.2 4.0 3.8

14.9 10.0 8.3 7.9 7.5 6.8 5.0 4.1 3.9 3.7

14.6 9.7 8.1 7.7 7.3 6.6 4.9 4.1 3.8 3.6

14.3 9.5 7.9 7.5 7.1 6.5 4.8 4.0 3.8 3.6

13.9 9.3 7.7 7.3 7.0 6.3 4.6 3.9 3.7 3.5

13.6 9.1 7.6 7.2 6.8 6.2 4.5 3.8 3.6 3.4

13.3 8.9 7.4 7.0 6.7 6.1 4.4 3.7 3.5 3.3

13.1 8.7 7.3 6.9 6.5 5.9 4.4 3.6 3.4 3.3

12.8 8.5 7.1 6.7 6.4 5.8 4.3 3.6 3.4 3.2

12.5 8.4 7.0 6.6 6.3 5.7 4.2 3.5 3.3 3.1

Seed Spacing (inches)

32320A

2012-02-29 Table of Contents Metric Charts 401-626B

Page 6

4 YP2425A Table of Contents Metric Charts Great Plains Manufacturing, Inc.

Spacing (U.S. Customary units, page 2 of 2)

Row Spacings

Twin Row Twin Row Twin Row Twin Row

30in 36in 38in 40in

Plant 10in 15in 20in 22in 30in 36in 38in 40in

Population Rows Rows Rows Rows Rows Rows Rows Rows

(seeds/acre) Seed Spacing (inches)

50 000 12.5 8.4 7.0 6.6 6.3 5.7 4.2 3.5 3.3 3.1

55 000 11.4 7.6 6.3 6.0 5.7 5.2 3.8 3.2 3.0 2.9

60 000 10.5 7.0 5.8 5.5 5.2 4.8 3.5 2.9 2.8 2.6

65 000 9.7 6.4 5.4 5.1 4.8 4.4 3.2 2.7 2.5 2.4

70 000 9.0 6.0 5.0 4.7 4.5 4.1 3.0 2.5 2.4 2.2

75 000 8.4 5.6 4.6 4.4 4.2 3.8 2.8 2.3 2.2 2.1

80 000 7.8 5.2 4.4 4.1 3.9 3.6 2.6 2.2 2.1 2.0

85 000 7.4 4.9 4.1 3.9 3.7 3.4 2.5 2.0 1.9 1.8

90 000 7.0 4.6 3.9 3.7 3.5 3.2 2.3 1.9 1.8 1.7

95 000 6.6 4.4 3.7 3.5 3.3 3.0 2.2 1.8 1.7 1.7

100 000 6.3 4.2 3.5 3.3 3.1 2.9 2.1 1.7 1.7 1.6

105 000 6.0 4.0 3.3 3.1 3.0 2.7 2.0 1.7 1.6 1.5

110 000 5.7 3.8 3.2 3.0 2.9 2.6 1.9 1.6 1.5 1.4

115 000 5.5 3.6 3.0 2.9 2.7 2.5 1.8 1.5 1.4 1.4

120 000 5.2 3.5 2.9 2.8 2.6 2.4 1.7 1.5 1.4 1.3

125 000 5.0 3.3 2.8 2.6 2.5 2.3 1.7 1.4 1.3 1.3

130 000 4.8 3.2 2.7 2.5 2.4 2.2 1.6 1.3 1.3 1.2

135 000 4.6 3.1 2.6 2.4 2.3 2.1 1.5 1.3 1.2 1.2

140 000 4.5 3.0 2.5 2.4 2.2 2.0 1.5 1.2 1.2 1.1

145 000 4.3 2.9 2.4 2.3 2.2 2.0 1.4 1.2 1.1 1.1

150 000 4.2 2.8 2.3 2.2 2.1 1.9 1.4 1.2 1.1 1.0

155 000 4.0 2.7 2.2 2.1 2.0 1.8 1.3 1.1 1.1 1.0

160 000 3.9 2.6 2.2 2.1 2.0 1.8 1.3 1.1 1.0 1.0

165 000 3.8 2.5 2.1 2.0 1.9 1.7 1.3 1.1 1.0 1.0

170 000 3.7 2.5 2.0 1.9 1.8 1.7 1.2 1.0 1.0 0.9

175 000 3.6 2.4 2.0 1.9 1.8 1.6 1.2 1.0 0.9 0.9

180 000 3.5 2.3 1.9 1.8 1.7 1.6 1.2 1.0 0.9 0.9

185 000 3.4 2.3 1.9 1.8 1.7 1.5 1.1 0.9 0.9 0.8

190 000 3.3 2.2 1.8 1.7 1.7 1.5 1.1 0.9 0.9 0.8

195 000 3.2 2.1 1.8 1.7 1.6 1.5 1.1 0.9 0.8 0.8

200 000 3.1 2.1 1.7 1.7 1.6 1.4 1.0 0.9 0.8 0.8

225 000 2.8 1.9 1.5 1.5 1.4 1.3 0.9 0.8 0.7 0.7

250 000 2.5 1.7 1.4 1.3 1.3 1.1 0.8 0.7 0.7 0.6

275 000 2.3 1.5 1.3 1.2 1.1 1.0 0.8 0.6 0.6 0.6

300 000 2.1 1.4 1.2 1.1 1.0 1.0 0.7 0.6 0.6 0.5

32320B

401-626B Table of Contents Metric Charts 2012-02-29

Page 7

Great Plains Manufacturing, Inc. Table of Contents Metric Charts Rate Setting Overview 5

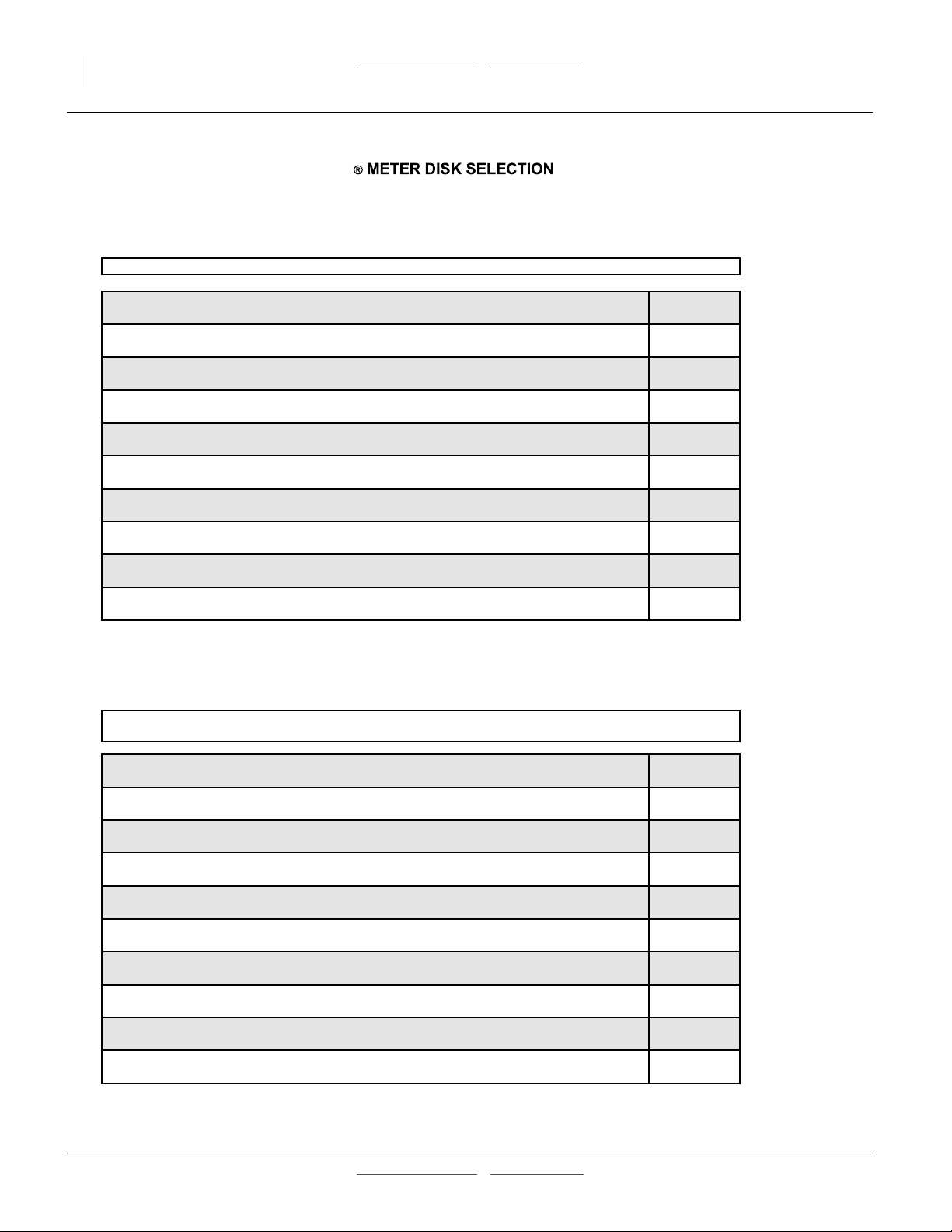

Air-Pro® Meter Disk Selection

CORN CORN

24 Cell Disk 40 Cell Disk

817-794C Corn Round Large 817-796C Corn Round Large

817-795C Corn Round Small 817-797C Corn Round Small

817-836C Corn Flat Large 817-838C Corn Flat Large

( Sweet Corn plants in Round Corn disks )

Seed Size Recommendations.

Corn Round Large Seeds per Pound

1700 (or fewer)

Unit Weight (or heavier)

47 pounds

Corn Round Small Seeds per Pound

1650 (or more)

Corn Flat Large Seeds per Pound

1650 (or fewer)

Corn Flat Small Seeds per Pound

1650 (or more)

ATTENTION: This Corn is planted with the Corn Round Small Disks!!!!!!

40in Rows

38in Rows

36in Rows

30in Rows

22in Rows

Twin Row 40in

20in Rows

Twin Row 38in

Twin Row 36in

Twin Row 30in

15in Rows

Below 19 400 Population @ 5.5 MPH 24 Cell Disk

Above 19 400 Population @ 5.5 MPH 40 Cell Disk

Below 20 500 Population @ 5.5 MPH 24 Cell Disk

Above 20 500 Population @ 5.5 MPH 40 Cell Disk

Below 21 600 Population @ 5.5 MPH 24 Cell Disk

Above 21 600 Population @ 5.5 MPH 40 Cell Disk

Below 25 900 Population @ 5.5 MPH 24 Cell Disk

Above 25 900 Population @ 5.5 MPH 40 Cell Disk

Below 35 300 Population @ 5.5 MPH 24 Cell Disk

Above 35 300 Population @ 5.5 MPH 40 Cell Disk

Below 38 900 Population @ 5.5 MPH 24 Cell Disk

Above 38 900 Population @ 5.5 MPH 40 Cell Disk

Below 40 900 Population @ 5.5 MPH 24 Cell Disk

Above 40 900 Population @ 5.5 MPH 40 Cell Disk

Below 43 200 Population @ 5.5 MPH 24 Cell Disk

Above 43 200 Population @ 5.5 MPH 40 Cell Disk

Below 51 800 Population @ 5.5 MPH 24 Cell Disk

Above 51 800 Population @ 5.5 MPH 40 Cell Disk

Unit Weight (or lighter)

48.5 pounds

Unit Weight (or lighter)

48.5 pounds

Unit Weight (or lighter)

48.5 pounds

(Recommended)

COTTON

60 Cell Disk

817-857C

Seed Size Recommendations.

This disk should plant all seed sizes and row spacings for Cotton.

32228A

2012-02-29 Table of Contents Metric Charts 401-626B

Page 8

6 YP2425A Table of Contents Metric Charts Great Plains Manufacturing, Inc.

AIR-PRO

MILO / PELLETIZED SUGAR BEET MILO / PELLETIZED SUGAR BEET

65 Cell Disk 130 Cell Disk

817-849C 817-800C

Seed Size Recommendations.

These disks should plant all seed sizes of Milo and Pelletized Sugar Beets.

(Recommended)

40in Rows Below 48 300 Population @ 6 MPH 65 Cell Disk

Above 48 300 Population @ 6 MPH 130 Cell Disk

38in Rows Below 50 800 Population @ 6 MPH 65 Cell Disk

Above 50 800 Population @ 6 MPH 130 Cell Disk

36in Rows Below 53 600 Population @ 6 MPH 65 Cell Disk

Above 53 600 Population @ 6 MPH 130 Cell Disk

30in Rows Below 64 300 Population @ 6 MPH 65 Cell Disk

Above 64 300 Population @ 6 MPH 130 Cell Disk

22in Rows Below 87 700 Population @ 6 MPH 65 Cell Disk

Above 87 700 Population @ 6 MPH 130 Cell Disk

Twin Row 40in Below 96 500 Population @ 6 MPH 65 Cell Disk

20in Rows Above 96 500 Population @ 6 MPH 130 Cell Disk

Twin Row 38in Below 101 600 Population @ 6 MPH 65 Cell Disk

Above 101 600 Population @ 6 MPH 130 Cell Disk

Twin Row 36in Below 107 200 Population @ 6 MPH 65 Cell Disk

Above 107 200 Population @ 6 MPH 130 Cell Disk

Twin Row 30in Below 128 700 Population @ 6 MPH 65 Cell Disk

15in Rows Above 128 700 Population @ 6 MPH 130 Cell Disk

10in Rows Below 193 000 Population @ 6 MPH 65 Cell Disk

Above 193 000 Population @ 6 MPH 130 Cell Disk

SOYBEAN SOYBEAN

84 Cell Disk 168 Cell Disk

817-798C 403-551D

Seed Size Recommendations.

Small edible beans (navy, black jack, black eye peas, etc) will plant with this disk also.

40in Rows Below 76 900 Population @ 6 MPH 84 Cell Disk

38in Rows Below 81 000 Population @ 6 MPH 84 Cell Disk

36in Rows Below 85 500 Population @ 6 MPH 84 Cell Disk

30in Rows Below 102 500 Population @ 6 MPH 84 Cell Disk

22in Rows Below 139 800 Population @ 6 MPH 84 Cell Disk

Twin Row 40in Below 153 800 Population @ 6 MPH 84 Cell Disk

20in Rows Above 153 800 Population @ 6 MPH 168 Cell Disk

Twin Row 38in Below 161 900 Population @ 6 MPH 84 Cell Disk

Twin Row 36in Below 170 900 Population @ 6 MPH 84 Cell Disk

Twin Row 30in Below 205 100 Population @ 6 MPH 84 Cell Disk

15in Rows Above 205 100 Population @ 6 MPH 168 Cell Disk

10in Rows Below 307 700 Population @ 6 MPH 84 Cell Disk

These disks should plant all seed sizes of Soybeans.

(Recommended)

Above 76 900 Population @ 6 MPH 168 Cell Disk

Above 81 000 Population @ 6 MPH 168 Cell Disk

Above 85 500 Population @ 6 MPH 168 Cell Disk

Above 102 500 Population @ 6 MPH 168 Cell Disk

Above 139 800 Population @ 6 MPH 168 Cell Disk

Above 161 900 Population @ 6 MPH 168 Cell Disk

Above 170 900 Population @ 6 MPH 168 Cell Disk

Above 307 700 Population @ 6 MPH 168 Cell Disk

32228B

401-626B Table of Contents Metric Charts 2012-02-29

Page 9

Great Plains Manufacturing, Inc. Table of Contents Metric Charts Rate Setting Overview 7

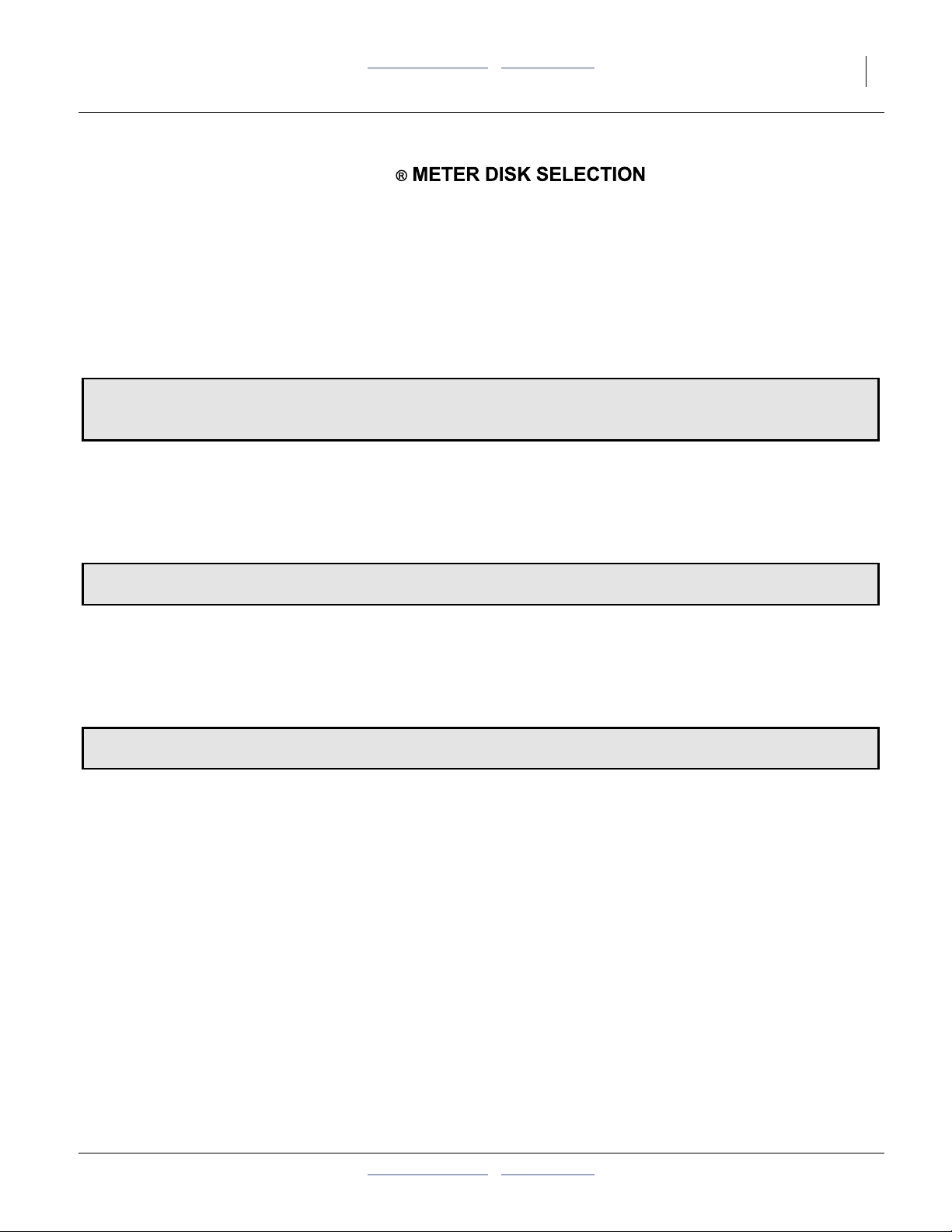

817-851C SUNFLOWER OIL LARGE

Volumetric No.1 84 Cell Disk

817-867C

Air Meter Blank Disk

817-841C

AIR-PRO

SUNFLOWER

24 Cell Disk

This disk should plant all seed sizes of popcorn.

Seed Size Recommendations.

Sunflower Oil Large Seeds per Pound

2's - most 3's 8500 (or fewer)

And a few of the larger 4's (or fewer)

Available for:

Wheat

These disks are used in (Off Row Meters) when changing from 15" to 30" Rows.

Twin Row 30" to 30" Rows. Twin Row 40" to 40" Rows. (etc)

32228C

2012-02-29 Table of Contents Metric Charts 401-626B

Page 10

8 YP2425A Table of Contents Metric Charts Great Plains Manufacturing, Inc.

(y)

Meter Pressurization

Refer to the Operator Manual for the procedure for fine

tuning meter pressurization.

Start with pressures from below and on page 9, which

are based on crop, and for corn, seed shape and density.

Note: These are suggested initial (starting) pressures.

Use the seed monitor console to adjust them up or

down per the procedure in the YP2425A Operator

Manual.

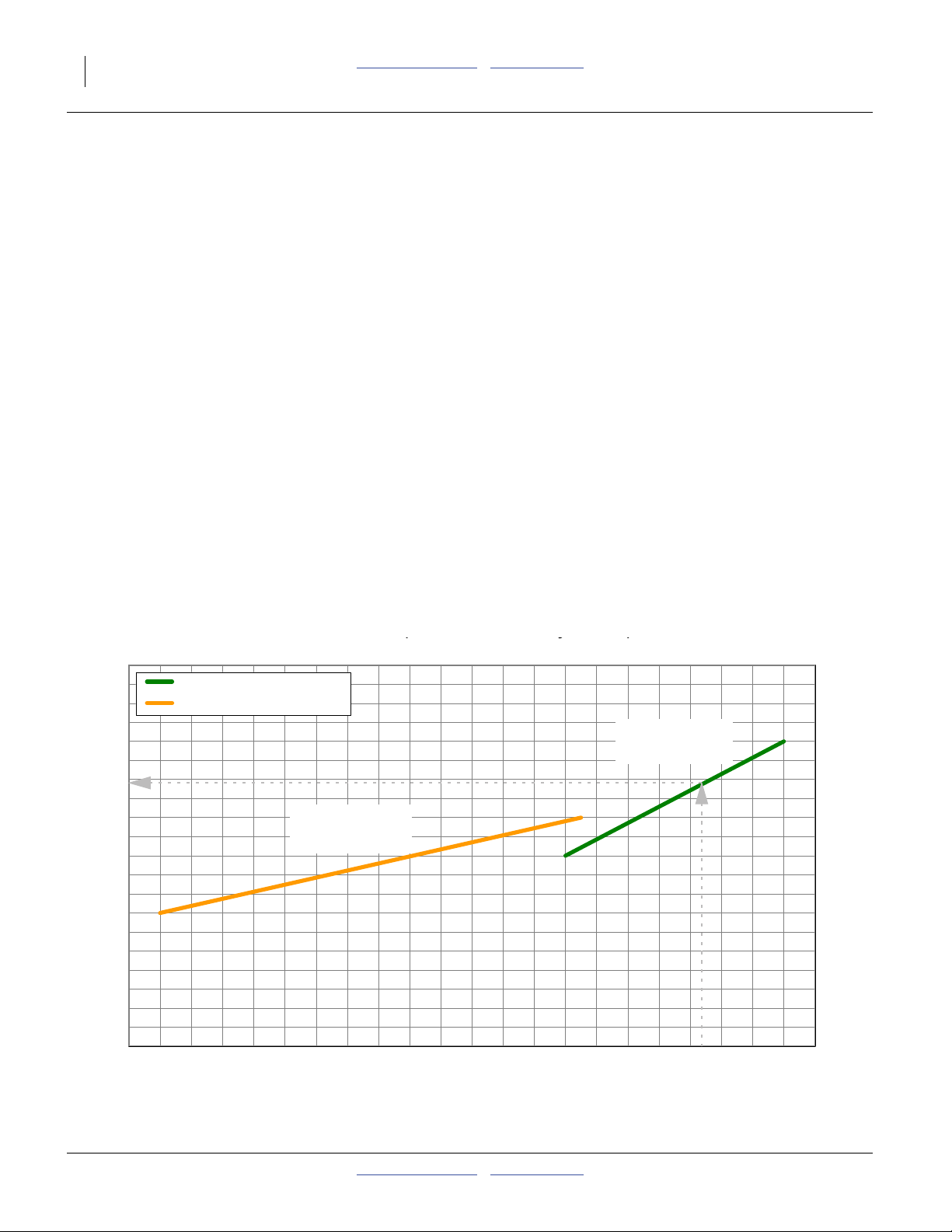

Corn: Reading a Pressure Chart (below, next page)

1. Pick the chart based on seed shape (flat, round).

Example: large round corn

2. Pick a line based on seed size (large, small).

Example: the right line below

3. Find the seed density on the bottom scale.

Example: 1260 seeds/pound

4. Read the suggested starting pressure on the left

scale, where the line (example shown as dotted

gray) intersects the density.

Example: 3.4 inches of water

Initial seed inlet Shutter for corn is: 3

Initial Meter Pressurization: Cotton

1.5 inches of water (any seed density)

Initial seed inlet Shutter: 2

Initial Meter Pressurization: Milo

1.5 inches of water (all disk, any seed density)

Initial seed inlet Shutter: 1

Initial Meter Pressurization: Soybeans

2.0 inches of water (84 cell disk, any seed density)

3.0 inches of water (168 cell disk, any seed density)

Initial seed inlet Shutter: 2

Initial Meter Pressurization: Sunflower

Disk: 817-851C SUNFLOWER OIL LARGE

8500 seeds/pound (or fewer):

8500 - 7000 s/lb 1.25 inches of water

7000 - 5500 s/lb 1.75 inches of water

5500 s/lb and fewer 2.25 inches of water

Adjust pressure as needed for desired population.

Initial seed inlet Shutter: 2

Meter Pressure (in/water)

Meter Pressurization in inches of Water

4.5

3.5

2.5

1.5

0.5

5

4

3

2

1

0

3100

25.8

Initial Meter Pressurization: Round Corn

Linear (Round Corn Large)

Linear (Round Corn Small)

Example

817-795C & 817-797C

Round Corn-Small

27002900

29.627.6

Pressure/Seed Comparison

Disks

23002500

2100

150017001900

Disks

817-794C & 817-796C

Round Corn-Large

53.347.142.138.134.832.0

Example

11001300

72.761.5

900

88.9

5

4.5

4

3.5

3

2.5

2

1.5

1

0.5

0

Meter Pressurization in inches of Water

Meter Pressure (in/water)

Seeds Per Pound

Unit Weight (80K)

401-626B Table of Contents Metric Charts 2012-02-29

29725

Page 11

Great Plains Manufacturing, Inc. Table of Contents Metric Charts Rate Setting Overview 9

(y)

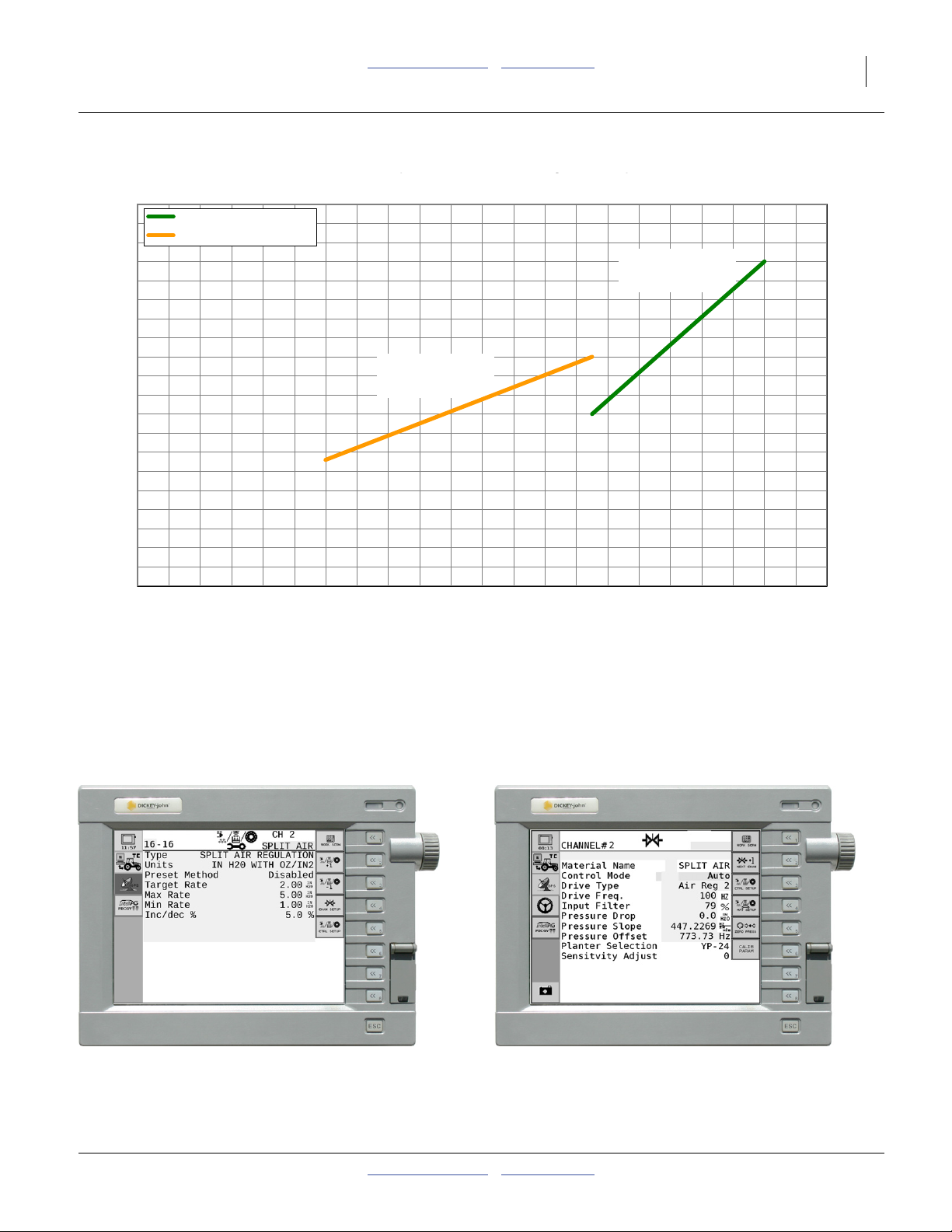

Initial Meter Pressurization: Flat Corn

Pressure/Seed Comparison

4.5

3.5

5

Linear (Flat Corn Large)

Linear (Flat Corn Small)

Disks

4

817-836C & 817-838C

Flat Corn-Large

5

4.5

4

3.5

Meter Pressurization in inches of Water

Meter Pressure (in/water)

Meter Pressure (in/water)

3

2.5

2

1.5

1

Disks

817-795C & 817-797C

Flat Corn-Small

Meter Pressurization in inches of Water

0.5

0

3100

2900

230025002700

2100

38.134.832.029.627.625.8

Seeds Per Pound

Unit Weight (80K)

42.1

47.1

53.3

Factory Default Air Control Channel Screens

Material 16 Setup Control Channel 2 Setup

61.5

3

2.5

2

1.5

1

0.5

0

90011001300150017001900

88.972.7

29726

29753

2012-02-29 Table of Contents Metric Charts 401-626B

29794

Page 12

10 YP2425A Table of Contents Metric Charts Great Plains Manufacturing, Inc.

Checking Planting Rate

Singulated seed charts are based on cleaned and sized

seed singulated with the recommended disk. Extreme

seed size variations and foreign material can affect the

planting rate.

Any material difference between chart and field rates

implies a mechanical malfunction, a planter setup error

or extremely worn planter components. You can verify

your setup and planter performance by measuring seed

placement and spacing over a relatively short distance.

The columns to the right provide example data for a rate

check, in U.S. customary units and a similar example

metric units.

Checking Singulated Rates

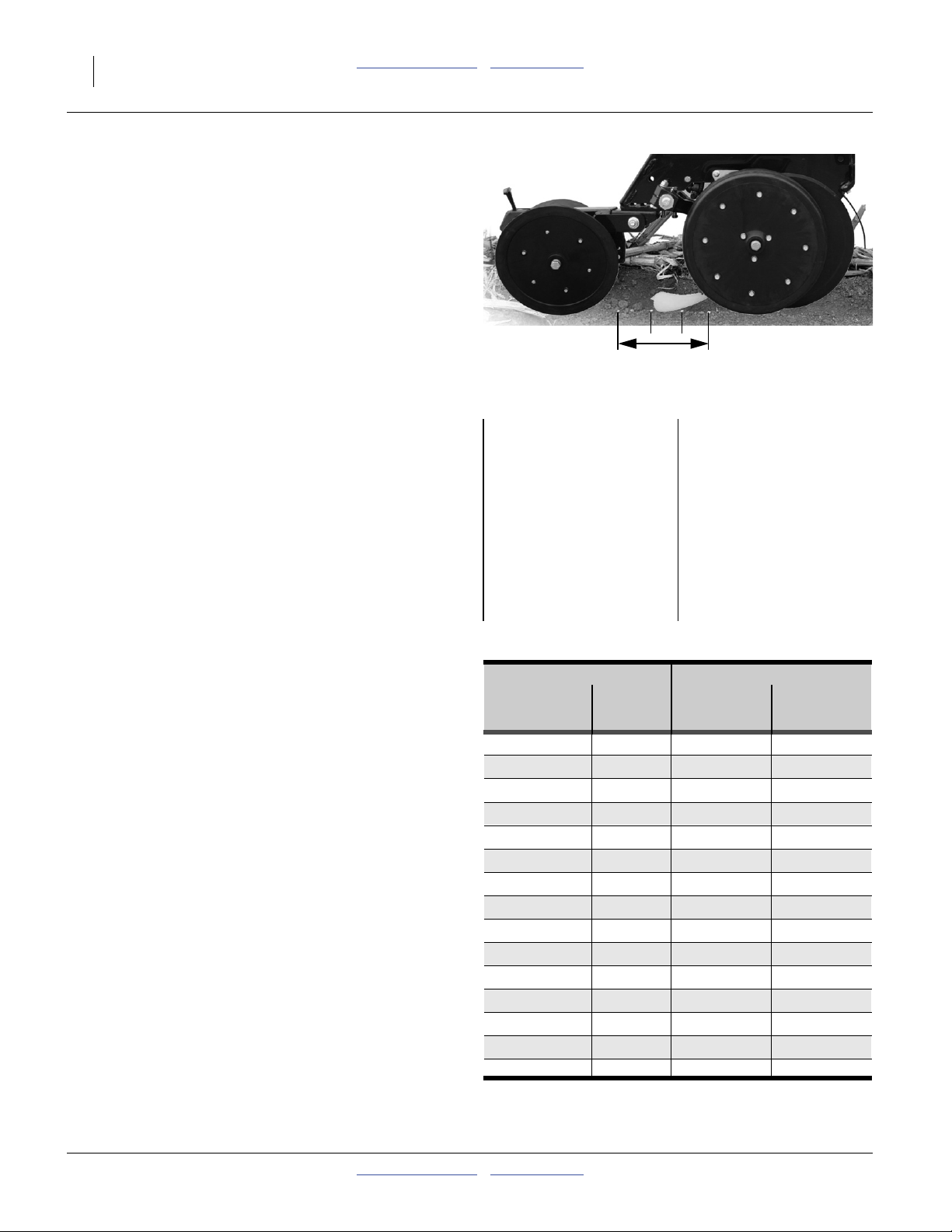

1. Determine the sample distance to check. Find your

row spacing in the table at right.

2. Note the number of rows to sample. Adjust the

planting depth to a shallow setting on one or two

outside rows (per table). Tie up the press wheel

arms with wire or bungee to prevent furrow closure.

3. For populations above 100 000 seeds/acre, use a

sample size of 1/1000th acre.

For populations below 100 000 seeds/acre, use a

sample size of 1/200th acre.

4. Configure the planter for the chart rate, either using

the chart settings for sprockets, or, with hydraulic

drive, selecting the rate on the seed monitor.

Figure 3

Furrow Check

US Example:

Planter: YP2425A-2430

Crop: Soybeans

Density: 3000 seeds/lb

Seed Disk: 817-798C

Target Population:

123,000 seeds/acre

Maximum Planting Speed:

5 mph

Chart Seed Spacing:

1.7 inches

Metric Example:

Planter: YP2425A-2470

Crop: Soybeans

Density: 6614 seeds/kg

Seed Disk: 817-798C

Target Population:

438 000 seeds/hectare

Maximum Planting Speed:

5 kph

Chart Seed Spacing:

3.2 cm

Rate check data is from sheet “Check” in:

Rows to Sample Length of Sample Run

Row Row 1/1000th 1/200th

Spacing* Count Acre Acre

7.5in Single 4 17ft 5in

8in Single 4 16ft 4in

9.5in Single 4 13ft 9in

10in Single 2 26ft 2in

15in Single 2 17ft 5in 87ft 1in

20in Single 1 26ft 2in 130ft 8in

22in Single 1 23ft 9in

118ft 10in

30in Single 1 17ft 5in 87ft 1in

36in Single 1 14ft 6in 72ft 7in

38in Single 1 13ft 9in 68ft 9in

40in Single 1 13ft 1in 65ft 4in

30in Twin 1 pair 17ft 5in 87ft 1in

36in Twin 1 pair 14ft 6in 72ft 7in

38in Twin 1 pair 13ft 9in 68ft 9in

40in Twin 1 pair 13ft 1in 65ft 4in

* Not all spacings may be offered on implements

covered by this manual.

29247

31442

401-626B Table of Contents Metric Charts 2012-02-29

Page 13

Great Plains Manufacturing, Inc. Table of Contents Metric Charts Rate Setting Overview 11

5. Plant at the desired planting speed for slightly more

than the computed sample run length.

6. Measure off the sample distance, balanced in

between where seeding started and stopped.

7. Count the number of seeds over the distance

measured. Also note the consistency of the seed

spacing.

8. Compute the rate for a full acre or hectare.

For a 1/1000th sample, multiply the counted seeds

by 1000.

For a 1/200th sample, multiply the counted seeds by

200.

9. If the field and chart rates vary by more than a few

percent, re-check planter setup, including meter disk

or cell count, air system, hydraulic drive setup, chain

slack, etc. If seed spacing is irregular, this suggests

a seed delivery problem, and not a rate setup

problem.

10. While planting, pay attention to the seed monitor. In

addition to confirming the single-row furrow check, it

will also provide field rate data on all the other rows,

and alert you to any irregularities or stoppages.

USc Example:

Sample size:

1/1000th ac

Plant for approximately:

25 feet

Measure the central:

17 feet 5 inches

USc Example:

Seeds counted:

121

Computed for full acre:

121 × 1000 = 121,000

This differs from chart by:

1.8%

Metric Example:

Sample size:

1/200th ha

Plant for approximately:

20 meters

Measure the central:

14.29 meters

Metric Example:

Seeds counted:

300

Computed for full hectare:

300 × 1000 = 300,000

This differs from chart by:

0.6%

2012-02-29 Table of Contents Metric Charts 401-626B

Page 14

12 YP2425A Table of Contents Metric Charts Great Plains Manufacturing, Inc.

Planting Rate

Singulated planting employs the seed monitor in

“PLANTER CONTROL” mode.

Hydraulic Drive Meter Rate

Hydraulic drive meter rate is set directly on the seed

monitor in the tractor. Consult the monitor manual for

detailed instructions, which may vary slightly over time

with firmware updates to the monitor system.

Enter/update your planter configuration (width/row-count,

single-row/twin, disk cell count, etc.). Once entered,

specify the population directly in seeds/acre or seeds/ha.

Enter meter RPM limits for your disk (pages 13-20).

Note: For consistent results, and least meter wear, do not

exceed the recommended ground speed.

For step 1 through step 4, any needed data not provided

in this manual can be found in one or more of:

DICKEY-john

®

Quick Start Guide

Planter Operator Manual

Refer to the DICKEY-john®IntelliAg® Planter/Drill

Control Operator’s Manual for details on setup item.

Note: The monitor must be in User Level 2 to change

some of these parameters.

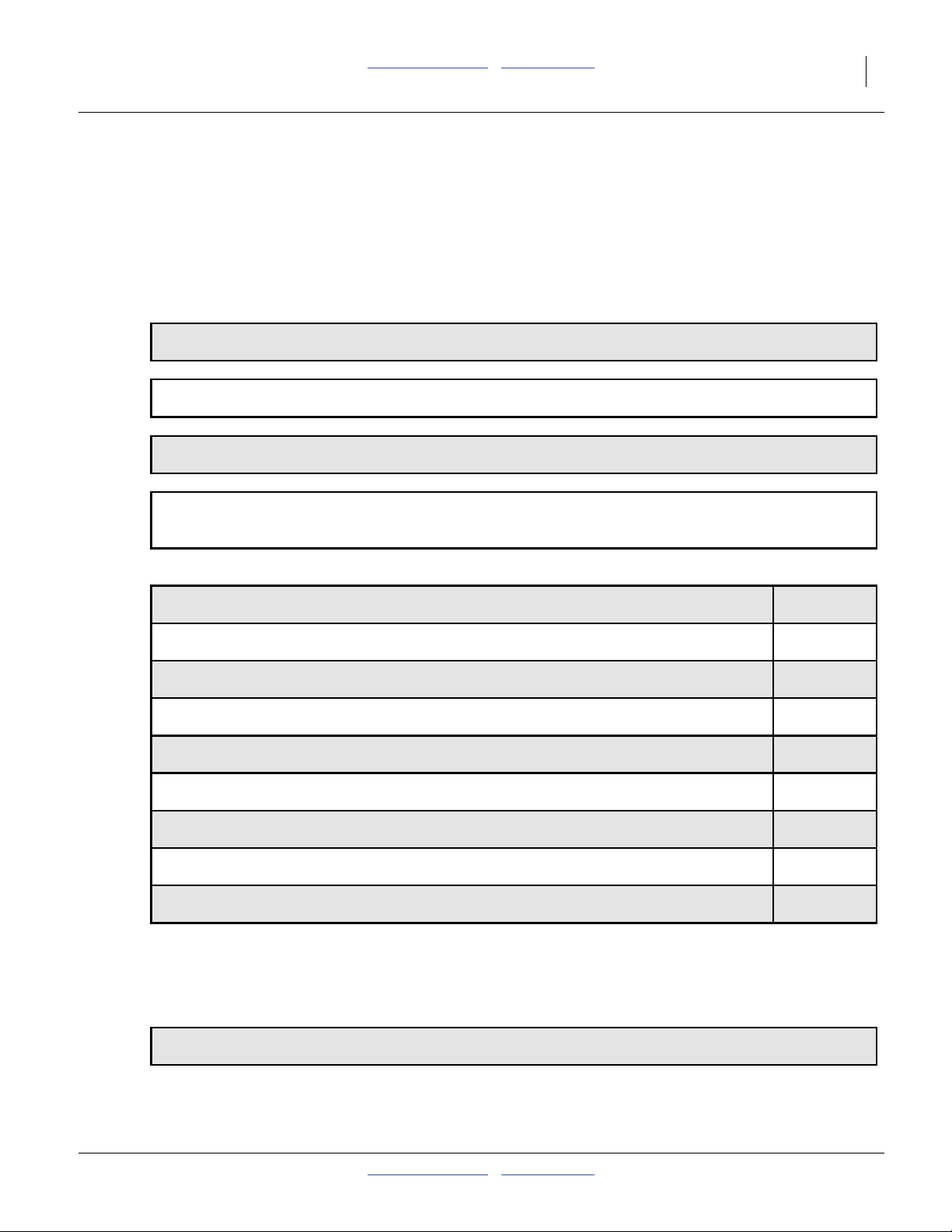

1. For a crop not previously planted with this planter,

create a “Material Name” for the crop. Selecting a

named material is a required step in later screens.

2. Verify, and as needed setup or update the “Material”

record for the singulated seed to be planted.

The table at right lists the parameters that need to be

reviewed or set. <angle bracket> values are your

choice/preference when not from meter rpm chart.

3. Verify, and as necessary setup or update the

“Channel” assigned to the planter’s hydraulic drive.

If the monitor resets to defaults, Gear Ratio may be

incorrect.

Count rows individually for “# Seed Rows”. A twin

pair (if both openers are in use) counts as 2 rows.

“Channel Width” is swath.

4. In the Material Library screen, makes sure that the

Material (SOYBEANS in our example) is assigned to

the Channel (CH 1 in our example) which controls

the planter’s hydraulic drive.

5. Perform a Valve Calibration for the control channel.

6. Switch the seed monitor from Setup/Configuration

mode to Operate mode. Load seed. Move the planter

to the field.

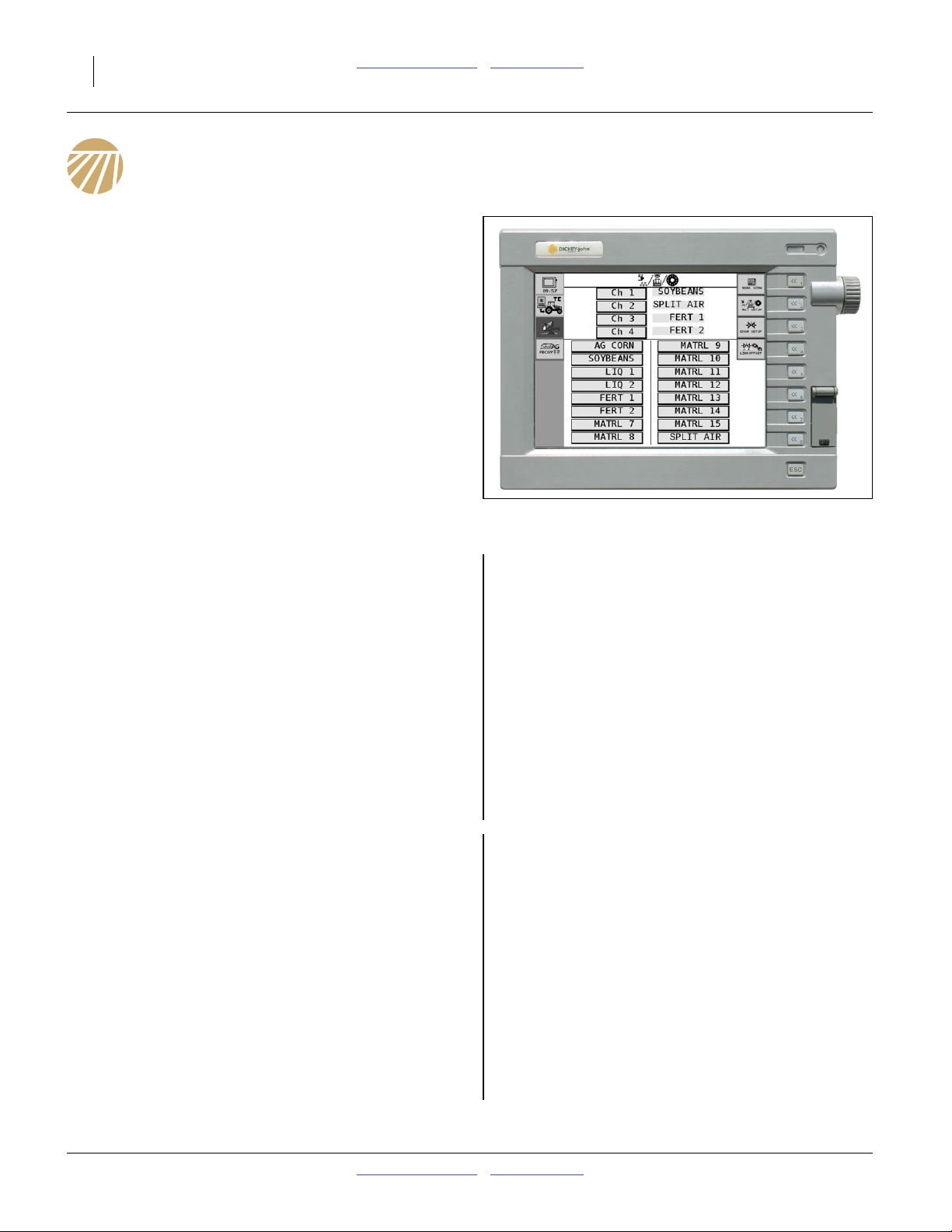

Figure 4

Typical Control Setup Screen

Material Data Required

Material Name <crop name, such as “SOYBEANS”>

Channel “CH 1”

Type “PLANTER CONTROL”

Preset Method “Disabled” unless populations vary

Target Rate <your election>

Max Rate <110% of Target> is suggested

Min Rate <90% of Target> is suggested

Inc/Dec “1.0%” is suggested

Seeds Per Rev <seed disk cell count>

Disc Low Limit <rpm from seed rate chart>

Disc High Limit <rpm from seed rate chart>

High Pop Alarm <“20%”> is suggested

Low Pop Alarm <“20%”> is suggested

Prod Level Alarm 0

Channel Data Required

CHANNEL 1 (must be channel specified above)

Type “PLANTER CONTROL”

Material Name (must be material name specified above)

Control Mode Auto

Drive Type PWM 1

Drive Freq. 100 Hz

Input Filter 50%

Gear Ratio 1.900

Sensor Constant 360

# Seed Rows <based on planter model/row setup>

Channel Width <based on planter model/row setup>

Precharge Time 0

Delay Time 0

Flush Enable Disabled

29750

401-626B Table of Contents Metric Charts 2012-02-29

Page 15

Great Plains Manufacturing, Inc. Table of Contents Metric Charts Planting Rate 13

Air-Pro

Meter RPM Limit Charts

Initial Seed Inlet Shutter Setting: 3

CORN

24 Cell Disk

Planting Maximum Minimum Planting Maximum Minimum

Speed Population Population Speed Population Population

(mph) (seeds/acre) (seeds/acre) (mph) (seeds/acre) (seeds/acre)

Twin Row 30in 4.0 71 280 23 760 22in Rows 4.0 48 600 16 200

15in Rows 4.5 63 360 21 120 Max Min 4.5 43 200 14 400

Max Min 5.0 57 024 19 008 rpm rpm 5.0 38 880 12 960

rpm rpm 5.5 51 840 17 280 30 10 5.5 35 345 11 782

30 10 6.0 47 520 15 840 6.0 32 400 10 800

6.5 43 865 14 622 6.5 29 908 9 969

817-794C Round Corn Large

817-795C Round Corn Small

817-836C Flat Corn Large

Twin Row 36in 4.0 59 400 19 800 30in Rows 4.0 35 640 11 880

Max Min 4.5 52 800 17 600 Max Min 4.5 31 680 10 560

rpm rpm 5.0 47 520 15 840 rpm rpm 5.0 28 512 9 504

30 10 5.5 43 200 14 400 30 10 5.5 25 920 8 640

6.0 39 600 13 200 6.0 23 760 7 920

6.5 36 554 12 185 6.5 21 932 7 311

Twin Row 38in 4.0 56 274 18 758 36in Rows 4.0 29 700 9 900

Max Min 4.5 50 021 16 674 Max Min 4.5 26 400 8 800

rpm rpm 5.0 45 019 15 006 rpm rpm 5.0 23 760 7 920

30 10 5.5 40 926 13 642 30 10 5.5 21 600 7 200

6.0 37 516 12 505 6.0 19 800 6 600

6.5 34 630 11 543 6.5 18 277 6 092

Twin Row 40in 4.0 53 460 17 820 38in Rows 4.0 28 137 9 379

20in Rows 4.5 47 520 15 840 Max Min 4.5 25 011 8 337

Max Min 5.0 42 768 14 256 rpm rpm 5.0 22 509 7 503

rpm rpm 5.5 38 880 12 960 30 10 5.5 20 463 6 821

30 10 6.0 35 640 11 880 6.0 18 758 6 253

6.5 32 898 10 966 6.5 17 315 5 772

40in Rows 4.0 26 730 8 910

Max Min 4.5 23 760 7 920

rpm rpm 5.0 21 384 7 128

30 10 5.5 19 440 6 480

6.0 17 820 5 940

6.5 16 449 5 483

29652A

2012-02-29 Table of Contents Metric Charts 401-626B

Page 16

14 YP2425A Table of Contents Metric Charts Great Plains Manufacturing, Inc.

Air-Pro

Initial Seed Inlet Shutter Setting: 3

CORN

40 Cell Disk

Planting Maximum Minimum Planting Maximum Minimum

Speed Population Population Speed Population Population

(mph) (seeds/acre) (seeds/acre) (mph) (seeds/acre) (seeds/acre)

Twin Row 30in 4.0 118 800 39 600 22in Rows 4.0 81 000 27 000

15in Rows 4.5 105 600 35 200 Max Min 4.5 72 000 24 000

Max Min 5.0 95 040 31 680 rpm rpm 5.0 64 800 21 600

rpm rpm 5.5 86 400 28 800 30 10 5.5 58 909 19 636

30 10 6.0 79 200 26 400 6.0 54 000 18 000

6.5 73 108 24 369 6.5 49 846 16 615

817-796C Round Corn Large

817-797C Round Corn Small

817-838C Flat Corn Large

Twin Row 36in 4.0 99 000 33 000 30in Rows 4.0 59 400 19 800

Max Min 4.5 88 000 29 333 Max Min 4.5 52 800 17 600

rpm rpm 5.0 79 200 26 400 rpm rpm 5.0 47 520 15 840

30 10 5.5 72 000 24 000 30 10 5.5 43 200 14 400

6.0 66 000 22 000 6.0 39 600 13 200

6.5 60 923 20 308 6.5 36 554 12 185

Twin Row 38in 4.0 93 789 31 263 36in Rows 4.0 49 500 16 500

Max Min 4.5 83 368 27 789 Max Min 4.5 44 000 14 667

rpm rpm 5.0 75 032 25 011 rpm rpm 5.0 39 600 13 200

30 10 5.5 68 211 22 737 30 10 5.5 36 000 12 000

6.0 62 526 20 842 6.0 33 000 11 000

6.5 57 717 19 239 6.5 30 462 10 154

Twin Row 40in 4.0 89 100 29 700 38in Rows 4.0 46 895 15 632

20in Rows 4.5 79 200 26 400 Max Min 4.5 41 684 13 895

Max Min 5.0 71 280 23 760 rpm rpm 5.0 37 516 12 505

rpm rpm 5.5 64 800 21 600 30 10 5.5 34 105 11 368

30 10 6.0 59 400 19 800 6.0 31 263 10 421

6.5 54 831 18 277 6.5 28 858 9 619

40in Rows 4.0 44 550 14 850

Max Min 4.5 39 600 13 200

rpm rpm 5.0 35 640 11 880

30 10 5.5 32 400 10 800

6.0 29 700 9 900

6.5 27 415 9 138

29652B

401-626B Table of Contents Metric Charts 2012-02-29

Page 17

Great Plains Manufacturing, Inc. Table of Contents Metric Charts Planting Rate 15

Air-Pro

Initial Seed Inlet Shutter Setting: 2

COTTON

60 Cell Disk

817-857C Cotton

Planting Maximum Minimum Planting Maximum Minimum

Speed Population Population Speed Population Population

(mph) (seeds/acre) (seeds/acre) (mph) (seeds/acre) (seeds/acre)

Twin Row 30in 4.0 190 080 29 700 22in Rows 4.0 129 600 20 250

15in Rows 4.5 168 960 26 400 Max Min 4.5 115 200 18 000

Max Min 5.0 152 064 23 760 rpm rpm 5.0 103 680 16 200

rpm rpm 5.5 138 240 21 600 30 10 5.5 94 255 14 727

30 10 6.0 126 720 19 800 6.0 86 400 13 500

6.5 116 972 18 277 6.5 79 754 12 462

Twin Row 36in 4.0 158 400 24 750 30in Rows 4.0 95 040 14 850

Max Min 4.5 140 800 22 000 Max Min 4.5 84 480 13 200

rpm rpm 5.0 126 720 19 800 rpm rpm 5.0 76 032 11 880

30 10 5.5 115 200 18 000 30 10 5.5 69 120 10 800

6.0 105 600 16 500 6.0 63 360 9 900

6.5 97 477 15 231 6.5 58 486 9 138

Twin Row 38in 4.0 150 063 23 447 36in Rows 4.0 79 200 12 375

Max Min 4.5 133 389 20 842 Max Min 4.5 70 400 11 000

rpm rpm 5.0 120 051 18 758 rpm rpm 5.0 63 360 9 900

30 10 5.5 109 137 17 053 30 10 5.5 57 600 9 000

6.0 100 042 15 632 6.0 52 800 8 250

6.5 92 347 14 429 6.5 48 738 7 615

Twin Row 40in 4.0 142 560 22 275 38in Rows 4.0 75 032 11 724

20in Rows 4.5 126 720 19 800 Max Min 4.5 66 695 10 421

Max Min 5.0 114 048 17 820 rpm rpm 5.0 60 025 9 379

rpm rpm 5.5 103 680 16 200 30 10 5.5 54 568 8 526

30 10 6.0 95 040 14 850 6.0 50 021 7 816

6.5 87 729 13 708 6.5 46 173 7 215

40in Rows 4.0 71 280 11 138

Max Min 4.5 63 360 9 900

rpm rpm 5.0 57 024 8 910

30 10 5.5 51 840 8 100

6.0 47 520 7 425

6.5 43 865 6 854

29652C

2012-02-29 Table of Contents Metric Charts 401-626B

Page 18

16 YP2425A Table of Contents Metric Charts Great Plains Manufacturing, Inc.

Air-Pro

Initial Seed Inlet Shutter Setting: 2

MILO

65 Cell Disk

817-849C Milo

Planting Maximum Minimum Planting Maximum Minimum

Speed Population Population Speed Population Population

(mph) (seeds/acre) (seeds/acre) (mph) (seeds/acre) (seeds/acre)

10in Rows 4.0 289 575 48 263 22in Rows 4.0 131 625 21 938

Max Min 4.5 257 400 42 900 Max Min 4.5 117 000 19 500

rpm rpm 5.0 231 660 38 610 rpm rpm 5.0 105 300 17 550

30 5 5.5 210 600 35 100 30 5 5.5 95 727 15 955

6.0 193 050 32 175 6.0 87 750 14 625

6.5 178 200 29 700 6.5 81 000 13 500

Twin Row 30in 4.0 193 050 32 175 30in Rows 4.0 96 525 16 088

15in Rows 4.5 171 600 28 600 Max Min 4.5 85 800 14 300

Max Min 5.0 154 440 25 740 rpm rpm 5.0 77 220 12 870

rpm rpm 5.5 140 400 23 400 30 5 5.5 70 200 11 700

30 5 6.0 128 700 21 450 6.0 64 350 10 725

6.5 118 800 19 800 6.5 59 400 9 900

Twin Row 36in 4.0 160 875 26 813 36in Rows 4.0 80 438 13 406

Max Min 4.5 143 000 23 833 Max Min 4.5 71 500 11 917

rpm rpm 5.0 128 700 21 450 rpm rpm 5.0 64 350 10 725

30 5 5.5 117 000 19 500 30 5 5.5 58 500 9 750

6.0 107 250 17 875 6.0 53 625 8 938

6.5 99 000 16 500 6.5 49 500 8 250

Twin Row 38in 4.0 152 408 25 401 38in Rows 4.0 76 204 12 701

Max Min 4.5 135 474 22 579 Max Min 4.5 67 737 11 289

rpm rpm 5.0 121 926 20 321 rpm rpm 5.0 60 963 10 161

30 5 5.5 110 842 18 474 30 5 5.5 55 421 9 237

6.0 101 605 16 934 6.0 50 803 8 467

6.5 93 789 15 632 6.5 46 895 7 816

Twin Row 40in 4.0 144 788 24 131 40in Rows 4.0 72 394 12 066

20in Rows 4.5 128 700 21 450 Max Min 4.5 64 350 10 725

Max Min 5.0 115 830 19 305 rpm rpm 5.0 57 915 9 653

rpm rpm 5.5 105 300 17 550 30 5 5.5 52 650 8 775

30 5 6.0 96 525 16 088 6.0 48 263 8 044

6.5 89 100 14 850 6.5 44 550 7 425

29652D

401-626B Table of Contents Metric Charts 2012-02-29

Page 19

Great Plains Manufacturing, Inc. Table of Contents Metric Charts Planting Rate 17

Air-Pro

Initial Seed Inlet Shutter Setting: 2

MILO

130 Cell Disk

817-800C Milo

Planting Maximum Minimum Planting Maximum Minimum

Speed Population Population Speed Population Population

(mph) (seeds/acre) (seeds/acre) (mph) (seeds/acre) (seeds/acre)

10in Rows 4.0 579 150 96 525 22in Rows 4.0 263 250 43 875

Max Min 4.5 514 800 85 800 Max Min 4.5 234 000 39 000

rpm rpm 5.0 463 320 77 220 rpm rpm 5.0 210 600 35 100

30 5 5.5 421 200 70 200 30 5 5.5 191 455 31 909

6.0 386 100 64 350 6.0 175 500 29 250

6.5 356 400 59 400 6.5 162 000 27 000

Twin Row 30in 4.0 386 100 64 350 30in Rows 4.0 193 050 32 175

15in Rows 4.5 343 200 57 200 Max Min 4.5 171 600 28 600

Max Min 5.0 308 880 51 480 rpm rpm 5.0 154 440 25 740

rpm rpm 5.5 280 800 46 800 30 5 5.5 140 400 23 400

30 5 6.0 257 400 42 900 6.0 128 700 21 450

6.5 237 600 39 600 6.5 118 800 19 800

Twin Row 36in 4.0 321 750 53 625 36in Rows 4.0 160 875 26 813

Max Min 4.5 286 000 47 667 Max Min 4.5 143 000 23 833

rpm rpm 5.0 257 400 42 900 rpm rpm 5.0 128 700 21 450

30 5 5.5 234 000 39 000 30 5 5.5 117 000 19 500

6.0 214 500 35 750 6.0 107 250 17 875

6.5 198 000 33 000 6.5 99 000 16 500

Twin Row 38in 4.0 304 816 50 803 38in Rows 4.0 152 408 25 401

Max Min 4.5 270 947 45 158 Max Min 4.5 135 474 22 579

rpm rpm 5.0 243 853 40 642 rpm rpm 5.0 121 926 20 321

30 5 5.5 221 684 36 947 30 5 5.5 110 842 18 474

6.0 203 211 33 868 6.0 101 605 16 934

6.5 187 579 31 263 6.5 93 789 15 632

Twin Row 40in 4.0 289 575 48 263 40in Rows 4.0 144 788 24 131

20in Rows 4.5 257 400 42 900 Max Min 4.5 128 700 21 450

Max Min 5.0 231 660 38 610 rpm rpm 5.0 115 830 19 305

rpm rpm 5.5 210 600 35 100 30 5 5.5 105 300 17 550

30 5 6.0 193 050 32 175 6.0 96 525 16 088

6.5 178 200 29 700 6.5 89 100 14 850

29652E

2012-02-29 Table of Contents Metric Charts 401-626B

Page 20

18 YP2425A Table of Contents Metric Charts Great Plains Manufacturing, Inc.

Air-Pro

Initial Seed Inlet Shutter Setting: 2

SOYBEAN

84 Cell Disk

817-798C Soybean

Planting Maximum Minimum Planting Maximum Minimum

Speed Population Population Speed Population Population

(mph) (seeds/acre) (seeds/acre) (mph) (seeds/acre) (seeds/acre)

10in Rows 4.0 461 538 62 370 22in Rows 4.0 209 790 28 350

Max Min 4.5 410 256 55 440 Max Min 4.5 186 480 25 200

rpm rpm 5.0 369 230 49 896 rpm rpm 5.0 167 832 22 680

37 5 5.5 335 664 45 360 37 5 5.5 152 575 20 618

6.0 307 692 41 580 6.0 139 860 18 900

6.5 284 023 38 382 6.5 129 102 17 446

Twin Row 30in 4.0 307 692 41 580 30in Rows 4.0 153 846 20 790

15in Rows 4.5 273 504 36 960 Max Min 4.5 136 752 18 480

Max Min 5.0 246 154 33 264 rpm rpm 5.0 123 077 16 632

rpm rpm 5.5 223 776 30 240 37 5 5.5 111 888 15 120

37 5 6.0 205 128 27 720 6.0 102 564 13 860

6.5 189 349 25 588 6.5 94 674 12 794

Twin Row 36in 4.0 256 410 34 650 36in Rows 4.0 128 205 17 325

Max Min 4.5 227 920 30 800 Max Min 4.5 113 960 15 400

rpm rpm 5.0 205 128 27 720 rpm rpm 5.0 102 564 13 860

37 5 5.5 186 480 25 200 37 5 5.5 93 240 12 600

6.0 170 940 23 100 6.0 85 470 11 550

6.5 157 791 21 323 6.5 78 895 10 662

Twin Row 38in 4.0 242 915 32 826 38in Rows 4.0 121 457 16 413

Max Min 4.5 215 924 29 179 Max Min 4.5 107 962 14 589

rpm rpm 5.0 194 332 26 261 rpm rpm 5.0 97 166 13 131

37 5 5.5 176 665 23 874 37 5 5.5 88 333 11 937

6.0 161 943 21 884 6.0 80 972 10 942

6.5 149 486 20 201 6.5 74 743 10 100

Twin Row 40in 4.0 230 769 31 185 40in Rows 4.0 115 385 15 593

20in Rows 4.5 205 128 27 720 Max Min 4.5 102 564 13 860

Max Min 5.0 184 615 24 948 rpm rpm 5.0 92 308 12 474

rpm rpm 5.5 167 832 22 680 37 5 5.5 83 916 11 340

37 5 6.0 153 846 20 790 6.0 76 923 10 395

6.5 142 012 19 191 6.5 71 006 9 595

29652F

401-626B Table of Contents Metric Charts 2012-02-29

Page 21

Great Plains Manufacturing, Inc. Table of Contents Metric Charts Planting Rate 19

Air-Pro

Initial Seed Inlet Shutter Setting: 2

SOYBEAN

168 Cell Disk

403-551D Soybean

Planting Maximum Minimum Planting Maximum Minimum

Speed Population Population Speed Population Population

(mph) (seeds/acre) (seeds/acre) (mph) (seeds/acre) (seeds/acre)

10in Rows 4.0 923 076 124 740 22in Rows 4.0 419 580 56 700

Max Min 4.5 820 512 110 880 Max Min 4.5 372 960 50 400

rpm rpm 5.0 738 461 99 792 rpm rpm 5.0 335 664 45 360

37 5 5.5 671 328 90 720 37 5 5.5 305 149 41 236

6.0 615 384 83 160 6.0 279 720 37 800

6.5 568 047 76 763 6.5 258 203 34 892

Twin Row 30in 4.0 615 384 83 160 30in Rows 4.0 307 692 41 580

15in Rows 4.5 547 008 73 920 Max Min 4.5 273 504 36 960

Max Min 5.0 492 307 66 528 rpm rpm 5.0 246 154 33 264

rpm rpm 5.5 447 552 60 480 37 5 5.5 223 776 30 240

37 5 6.0 410 256 55 440 6.0 205 128 27 720

6.5 378 698 51 175 6.5 189 349 25 588

Twin Row 36in 4.0 512 820 69 300 36in Rows 4.0 256 410 34 650

Max Min 4.5 455 840 61 600 Max Min 4.5 227 920 30 800

rpm rpm 5.0 410 256 55 440 rpm rpm 5.0 205 128 27 720

37 5 5.5 372 960 50 400 37 5 5.5 186 480 25 200

6.0 341 880 46 200 6.0 170 940 23 100

6.5 315 582 42 646 6.5 157 791 21 323

Twin Row 38in 4.0 485 829 65 653 38in Rows 4.0 242 915 32 826

Max Min 4.5 431 848 58 358 Max Min 4.5 215 924 29 179

rpm rpm 5.0 388 664 52 522 rpm rpm 5.0 194 332 26 261

37 5 5.5 353 331 47 747 37 5 5.5 176 665 23 874

6.0 323 886 43 768 6.0 161 943 21 884

6.5 298 972 40 402 6.5 149 486 20 201

Twin Row 40in 4.0 461 538 62 370 40in Rows 4.0 230 769 31 185

20in Rows 4.5 410 256 55 440 Max Min 4.5 205 128 27 720

Max Min 5.0 369 230 49 896 rpm rpm 5.0 184 615 24 948

rpm rpm 5.5 335 664 45 360 37 5 5.5 167 832 22 680

37 5 6.0 307 692 41 580 6.0 153 846 20 790

6.5 284 023 38 382 6.5 142 012 19 191

29652G

2012-02-29 Table of Contents Metric Charts 401-626B

Page 22

20 YP2425A Table of Contents Metric Charts Great Plains Manufacturing, Inc.

Air-Pro

Initial Seed Inlet Shutter Setting: 2

SUNFLOWER OIL LARGE

24 Cell Disk

817-851C Sunflower Oil Large

8500 seeds/lb (or fewer)

Planting Maximum Minimum Planting Maximum Minimum

Speed Population Population Speed Population Population

(mph) (seeds/acre) (seeds/acre) (mph) (seeds/acre) (seeds/acre)

Twin Row 30in 4.0 71 280 23 760 22in Rows 4.0 48 600 16 200

15in Rows 4.5 63 360 21 120 Max Min 4.5 43 200 14 400

Max Min 5.0 57 024 19 008 rpm rpm 5.0 38 880 12 960

rpm rpm 5.5 51 840 17 280 30 10 5.5 35 345 11 782

30 10 6.0 47 520 15 840 6.0 32 400 10 800

6.5 43 865 14 622 6.5 29 908 9 969

Twin Row 36in 4.0 59 400 19 800 30in Rows 4.0 35 640 11 880

Max Min 4.5 52 800 17 600 Max Min 4.5 31 680 10 560

rpm rpm 5.0 47 520 15 840 rpm rpm 5.0 28 512 9 504

30 10 5.5 43 200 14 400 30 10 5.5 25 920 8 640

6.0 39 600 13 200 6.0 23 760 7 920

6.5 36 554 12 185 6.5 21 932 7 311

Twin Row 38in 4.0 56 274 18 758 36in Rows 4.0 29 700 9 900

Max Min 4.5 50 021 16 674 Max Min 4.5 26 400 8 800

rpm rpm 5.0 45 019 15 006 rpm rpm 5.0 23 760 7 920

30 10 5.5 40 926 13 642 30 10 5.5 21 600 7 200

6.0 37 516 12 505 6.0 19 800 6 600

6.5 34 630 11 543 6.5 18 277 6 092

Twin Row 40in 4.0 53 460 17 820 38in Rows 4.0 28 137 9 379

20in Rows 4.5 47 520 15 840 Max Min 4.5 25 011 8 337

Max Min 5.0 42 768 14 256 rpm rpm 5.0 22 509 7 503

rpm rpm 5.5 38 880 12 960 30 10 5.5 20 463 6 821

30 10 6.0 35 640 11 880 6.0 18 758 6 253

6.5 32 898 10 966 6.5 17 315 5 772

40in Rows 4.0 26 730 8 910

Max Min 4.5 23 760 7 920

rpm rpm 5.0 21 384 7 128

30 10 5.5 19 440 6 480

6.0 17 820 5 940

6.5 16 449 5 483

29652H

401-626B Table of Contents Metric Charts 2012-02-29

Page 23

Great Plains Manufacturing, Inc. Table of Contents Metric Charts Planting Rate 21

2012-02-29 Table of Contents Metric Charts 401-626B

Page 24

22 YP2425A Table of Contents Metric Charts Great Plains Manufacturing, Inc.

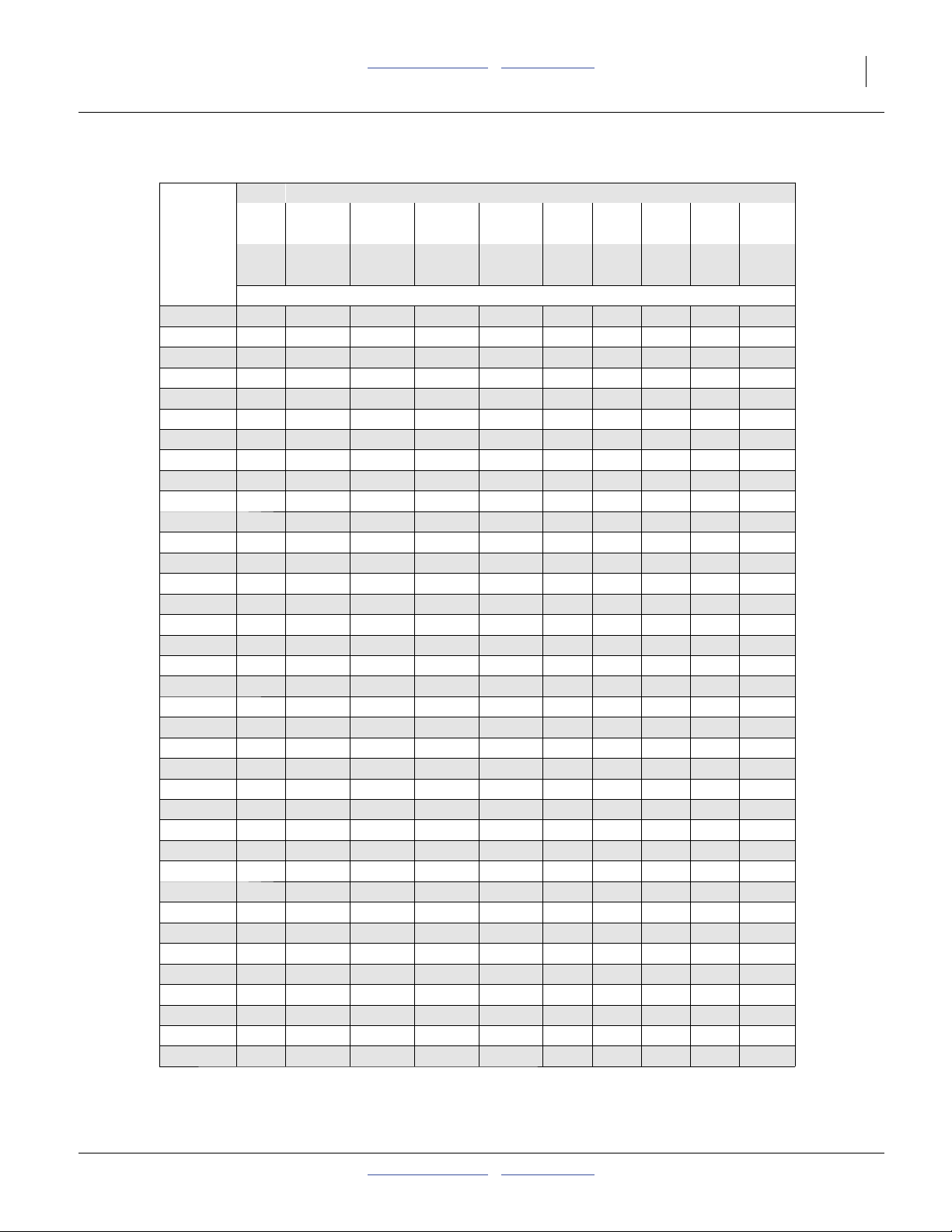

Air-Pro® Meter Stagger Timing Chart

Sprocket Indexing (Stagger)

28420

If you are planting:

• with a seed disc having 24 cells or less,

• twin-row crops,

• at seed populations below 45,000 seeds/ac

(111 000 seeds/ha),

you can synchronize each pair of adjacent meters in a

twin row so that you achieve the maximum seed-to-seed

spacing between the units of the pair.

If the initial indexing does not provide equal spacing, see

“Indexing Fine Adjustment” on page 25.

If you are planting:

- single-row,

- or with seed discs or 25 cells or more,

- or a volumetric crop,

- or twin row with seed spacings below

91⁄4inch (23.5 cm),

this section of the manual, and the sprocket indexing

charts, do not apply to your operations.

Due to limitations on the number of sprocket teeth and

Source:

Dated:

wheel cell count, it may not be possible to obtain perfect

Provider

stagger. Charts and fine adjustment provide the optimal

File:

Sheet:

available stagger.

Rendered:

Export As:

Import As:

Set front meter to tooth “1”. Page 1 of 2

Set rear meter to indicated Initial tooth number.

Advance or Retard to adjust - see instructions in Seed Rate Manual.

Population Initial Rear 20% Rear Seed Drop Adjust 40% Rear Seed Drop Adjust

Seeds/Acre Tooth Number Retard Advance Retard Advance

Thumbnail view. Actual charts begin on page 26.

/files/manual/docs/gp/401-625b/charts/ods/reference/air_pro_meter_timing.ods

2009-08-11T11:49

GWA

/files/iso/text/29500/29715.ods

29715

2010-04-27T11:55

/files/iso/text/29500/29715A.pdf

/files/iso/text/29500/29715A.eps

These Columns are for Fine Adjustment Only

17000 7 3 4 6 16

17500 19 10 16 13 16

18000 19 10 16 13 16

18500 3 7 19 10 16

19000 4 6 19 9 12

19500 4 1 15 17 12

20000 18 11 15 14 12

20500 8 2 15 5 8

21000 8 5 11 5 8

21500 14 15 11 18 8

22000 14 15 11 18 4

22500 12 9 7 1 4

23000 10 19 7 3 4

23500 10 19 7 3 4

24000 16 13 3 10 19

24500 6 13 3 10 19

25000 6 4 3 7 19

25500 1 17 18 14 15

26000 2 17 18 14 15

26500 2 8 18 11 15

27000 5 5 18 18 11

27500 5 2 14 18 11

28000 17 12 14 15 11

28500 9 1 14 3 7

29000 9 6 10 3 7

29500 13 16 10 19 7

30000 13 16 10 19 3

30500 13 10 6 7 3

31000 9 10 6 4 3

RJN

By:

Twin Row 30in

29715A

401-626B Table of Contents Metric Charts 2012-02-29

Crushing Hazard:

Install transport locks. Do not rely on hydraulics to hold the

planter at raised. This adjustment takes some time.

Page 25

Great Plains Manufacturing, Inc. Table of Contents Metric Charts Sprocket Indexing (Stagger) 23

/

Indexing Preparation

Tools required:

•7⁄8inch (23 mm) open end wrench

•3⁄8inch socket wrench, or

any socket wrench with3⁄8in. (9.5 mm) square

drive

• 812-391C timing tool (located under walkboard)

1. Find (in page 26-27) the sprocket indexing chart for

your row spacing, cell count and desired seed

population. Note the “Initial Rear Tooth Number”

value in the second column.

2. Raise the planter.

Chain geometry changes slightly when lowered. The

indexing charts account for this change, and assume

the planter is raised. Also, raising the planter

disengages the drive clutches, allowing you to turn

the drive shaft with a hand tool.

3. Clean out meters. Leave seed discs out.

See Operator Manual for procedure.

°

Note: The 812-391C tool was introduced in late 2010.

Check latest Parts manual for storage mount

hardware part numbers.

Note: Sprocket indexing is possible with seed present

and discs installed, but if so, you must perform

step 9 (chain taut check) by rotating the drive shaft

forward to remove slack. Reverse meter rotation,

with seed present, is not recommended.

812-391C Timing Tool

Figure 5

31445

Basic Indexing

Refer to Figure 6 (which depicts tooth 1 slightly ahead of the

index rib at 2:00)

4. Use drive shaft to set front row unit to index 1.

Observe the meter drive sprocket at a front (short

mount) row unit on each wing. Use the wrench, from

the rear of the shaft, to rotate the shaft forward

(wrench up and forward).

Stop rotation when the tip of the tooth stamped “1”

is aligned with a rib cast into the meter housing. In

general, the 2:00 rib is the easiest to use, as it is

visible from the side and from behind the meter.

5. Check front sprocket synchronization.

Inspect all meter drive sprockets on front row units.

Check that all springs are taut, and no chains have

slack. All sprockets should be at “1”. If not, use

step 6 through step 10 to set them to 1. Although

front sprockets machine-wide may be at 1 after this

check, sprockets do not remain in sync wing-to-wing,

due to clutch operation.

With Swath Command™, front sprockets are not

synchronized planter-wide. With row clutches, each

front sprocket must be checked when timing the

mating rear sprocket of the row pair. The front row

can be advanced by manually turning the tandem

sprocket forward until the front sprocket is at 1. Then

set the rear sprocket. Check that the front sprocket

has not moved.

2

1

1

Figure 6

Sprocket Indexing Reference

Equipment Damage Risk:

Do not apply significant force to meter disk, or drive hub may

be damaged.

Note: Without Swath Command™: In the future, finding

front sprockets out of sync on a wing suggests idler

spring problems, and/or worn chain. Row drive

systems must be in reliable working order for

effective sprocket indexing.

2

29630

2012-02-29 Table of Contents Metric Charts 401-626B

Page 26

24 YP2425A Table of Contents Metric Charts Great Plains Manufacturing, Inc.

Refer to Figure 7

6. At the rear (long mount) row unit of each pair, note

which sprocket tooth is at the index mark . If the

2

sprocket is already at the chart value, skip to

step 12. Otherwise, complete step 7 through step 10

for that row.

2

Refer to Figure 8

7. Place the timing tool over the meter shaft. Attach

3

a3⁄8inch (10 mm) socket wrench to aid in rotation.

Sweep the toolatooth under the chain, rotating in the

direction opposite of that desired for sprocket

adjustment.

Each clockwise rotation of the timing tool advances

the sprocket by one tooth.

Figure 7

29628

Sprocket Index Check

Each counter-clockwise rotation of the timing tool

retards the sprocket by one tooth.

8. Advance or retard the sprocket until the desired tooth

number is at the index mark. Hold the sprocket

stationary, and re-mount the chain, making sure the

chain is taut in the top loop.

9. Rotate meter shaft backward, or rotate wing drive

shaft forward to tension chain. Re-check that front

3

row sprocket is still at “1”.

10. Check the position of the rear row sprocket. The

tooth tip at, or just ahead of the index mark must be

the tooth called for by the chart. If not, release spring

and re-mount chain.

11. Repeat step 4 through step 10 for each row pair.

12. Re-install seed discs and meter covers. No particular

disc orientation is required during seed disc

installation. The disc is symmetrical about all four

seat lobes.

Figure 8

Adjusting Sprocket Index

31444

a. If the timing tool is not available, remove the idler tensioning spring to adjust the sprocket position. Rotate meter shaft backward (if

meter empty, otherwise forward one full rotation), and re-check indexing with normal tension on chain.

401-626B Table of Contents Metric Charts 2012-02-29

Page 27

Great Plains Manufacturing, Inc. Table of Contents Metric Charts Sprocket Indexing (Stagger) 25

Ad

Indexing Fine Adjustment

If, after indexing, the twin-row side-to-side seed stagger

is substantially imbalanced, it is possible to make small

adjustments that may correct it. Imbalance can occur

over time as row unit chains wear and stretch.

The Indexing charts on page 26 and 27 provide columns

for alternate rear row sprocket alignments. These

settings move the placement of the rear seed drop. The

amount of movement is given as a percentage (±20% or

±40%) of the in-row seed spacing.

Refer to Figure 9

Adjustments are made only to the rear row timing.

• Advancing the timing (dropping the seed sooner,

moves the seed position back).

• Retarding the timing moves the seed position forward.

40% Rear Timing Adjustments

Figure 9

If an adjustment is made, test it on one row pair before

adjusting the entire planter.

Indexing Adjustment Steps

1. Make sure the current front sprocket index is 1, and

the current rear sprocket index number matches the

“Initial” number in the indexing chart for the

population being planted.

2. Measure the actual stagger at the rear row seeds.

3. Determine by how many inches (or cm) the rear

seed placement needs to move in order to be

centered between the front seed placements.

4. Determine the percent of seed spacing, and whether

advance or retard, required to adjust the rear seed

drop to the desired spot.

5. In the tables (thumbnail view of one shown at right),

find the new rear sprocket tooth setting for the

percent retard or advance desired.

Example:

The front sprocket is “1”. At a target population of

31,500 seeds/ac, the rear sprocket is at tooth “17”.

At this population, spacing in a single row is:

13.3 inches

The rear row seeds would be ideally at:

6.6 inches

ahead or behind the front row seeds.

We find that the rear seeds are being placed:

1.5 inches behind the front seeds.

We need to move the rear seeds back another 5.1 in.

A 40% advance is 5.3 inches at this seed spacing.

vance or Retard to adjust - see instructions in Seed Rate Manual.

Population Initial Rear 20% Rear Seed Drop Adjust 40% Rear Seed Drop Adjust

Seeds/Acre Tooth Number Retard Advance Retard Advance

31000 9 10 6 4 3

31500 17 14 1 4 18

32000 17 14 2 11 18

32500 5 14 2 8 18

33000 5 18 5 8 14

33500 2 18 17 15 14

34000 1 18 17 12 14

Example:

34500 1 3 9 12 14

35000 6 3 9 19 10

Moving the rear sprocket from tooth 17 to tooth 18

35500 6 3 13 19 10

provides a 40% advance.

36000 10 7 13 16 10

36500 10 7 13 4 6

37000 10 7 9 4 6

37500 14 11 17 4 1

38000 14 11 17 8 2

38500 14 11 5 8 2

39000 18 11 2 8 5

39500 18 15 2 12 17

40000 18 15 1 12 17

40500 3 15 1 12 9

41000 3 19 6 16 9

41500 3 19 6 16 13

42000 7 19 10 16 13

42500 7 4 10 16 13

43000 7 4 10 16 9

43500 11 4 14 16 17

44000 11 8 14 16 17

These Columns are for Fine Adjustment Only

29717

2012-02-29 Table of Contents Metric Charts 401-626B

Page 28

26 YP2425A Table of Contents Metric Charts Great Plains Manufacturing, Inc.

Air-Pro® Meter Stagger Timing Chart

Sprocket Indexing Charts

30 inch Twin Row Sprocket Indexing

Note: This is NOT a seed rate chart.

This is a chart for staggering seed spacing

between rows of a twin-row planter.

Set front meter to tooth “1”. Page 1 of 2

Set rear meter to indicated Initial tooth number.

Advance or Retard to adjust - see instructions in Seed Rate Manual.

Population Initial Rear 20% Rear Seed Drop Adjust 40% Rear Seed Drop Adjust

Seeds/Acre Tooth Number Retard Advance Retard Advance

17000 7 3 4 6 16

17500 19 10 16 13 16

18000 19 10 16 13 16

18500 3 7 19 10 16

19000 4 6 19 9 12

19500 4 1 15 17 12

20000 18 11 15 14 12

20500 8 2 15 5 8

21000 8 5 11 5 8

21500 14 15 11 18 8

22000 14 15 11 18 4

22500 12 9 7 1 4

23000 10 19 7 3 4

23500 10 19 7 3 4

24000 16 13 3 10 19

24500 6 13 3 10 19

25000 6 4 3 7 19

25500 1 17 18 14 15

26000 2 17 18 14 15

26500 2 8 18 11 15

27000 5 5 18 18 11

27500 5 2 14 18 11

28000 17 12 14 15 11

28500 9 1 14 3 7

29000 9 6 10 3 7

29500 13 16 10 19 7

30000 13 16 10 19 3

30500 13 10 6 7 3

31000 9 10 6 4 3

Verify sprocket tooth position with the top length of chain taut.

Twin Row 30in

These Columns are for Fine Adjustment Only

29715A

401-626B Table of Contents Metric Charts 2012-02-29

Page 29

Great Plains Manufacturing, Inc. Table of Contents Metric Charts Sprocket Indexing (Stagger) 27

Air-Pro® Meter Stagger Timing Chart

30 inch Twin Row Sprocket Indexing

Note: This is NOT a seed rate chart.

This is a chart for staggering seed spacing

between rows of a twin-row planter.

Verify sprocket tooth position with the top length of chain taut.

Twin Row 30in

Set front meter to tooth “1”. Page 2 of 2

Set rear meter to indicated Initial tooth number.

Advance or Retard to adjust - see instructions in Seed Rate Manual.

These Columns are for Fine Adjustment Only

Population Initial Rear 20% Rear Seed Drop Adjust 40% Rear Seed Drop Adjust

Seeds/Acre Tooth Number Retard Advance Retard Advance

31000 9 10 6 4 3

31500 17 14 1 4 18

32000 17 14 2 11 18

32500 5 14 2 8 18

33000 5 18 5 8 14

33500 2 18 17 15 14

34000 1 18 17 12 14

34500 1 3 9 12 14

35000 6 3 9 19 10

35500 6 3 13 19 10

36000 10 7 13 16 10

36500 10 7 13 4 6

37000 10 7 9 4 6

37500 14 11 17 4 1

38000 14 11 17 8 2

38500 14 11 5 8 2

39000 18 11 2 8 5

39500 18 15 2 12 17

40000 18 15 1 12 17

40500 3 15 1 12 9

41000 3 19 6 16 9

41500 3 19 6 16 13

42000 7 19 10 16 13

42500 7 4 10 16 13

43000 7 4 10 16 9

43500 11 4 14 16 17

44000 11 8 14 16 17

44500 11 8 14 16 5

45000 15 8 18 16 2

29715B

2012-02-29 Table of Contents Metric Charts 401-626B

Page 30

28 YP2425A Table of Contents Metric Charts Great Plains Manufacturing, Inc.

Volumetric Seeding

General Information

Refer to Figure 10

These instructions explain how to operate and calibrate

the Air-Pro® No. 1 84 cell volumetric seed disc .

Related Documents

These are the current seed monitor manuals relied upon

for the user interface instructions in this document:

DICKEY-john®IntelliAg

110011508 PDC User Level 1 (ver. 2.4)

110011501 PDC User Levels 2&3 (ver. 2.4)

®

1

Clean-Out Meters

Possible Chemical Hazard:

Avoid contact with seed treatment residues inside meters and

on removed meter discs. Wear gloves unless all recent planting

involved untreated seeds. Consult the MSDSa for any treated

seeds recently planted. See planter Operator manual for brush

cleaning instructions.

1. Perform a meter clean-out per the instructions in

your planter Operator manual.

2. Remove and store the current seed discs. Perform a

brush inspection and cleaning as necessary.

3. Continue at “Install Discs / Set Shutters” on

page 29.

1

Figure 10

Volumetric Seed Disc

Figure 11

Engage Clean-Out Funnel

31551

29612

a. Material Safety Data Sheet

401-626B Table of Contents Metric Charts 2012-02-29

Page 31

Great Plains Manufacturing, Inc. Table of Contents Metric Charts Volumetric Seeding 29

Grain Shield

To order the grain shield use the following Great Plains

part number:

403-596A VOLUMETRIC METER GRAIN SHIELD

When planting with the volumetric disk, a very small

percentage of grain may be lost out the opening at the

back of the seed tube. If the amount of loss is more than

you desire the grain shield can be installed to stop this.

Note: It is highly recommended that the grain shield be

removed from the meter when going back to larger

singulated seed.

Refer to Figure 12

To install:

4. Remove the strip and block brush assembly. Save

the washer for reuse in step 6.

5. Remove the

5

⁄16inch hex-headed bolt and discard, it

is replaced with the5⁄16inch button head cap screw.

6. Position the grain shield and reinstall with the

5

⁄16inch button head cap screw and saved

2

3

washer.

7. Re-install the strip and block brush assembly.

3

Figure 12

Grain Shield Installed

2

31552B

Install Discs / Set Shutters

8. Install the 817-867C volumetric discs as you would

any other seed disc. See Operator manual for

details.

Refer to Figure 13

9. Set the seed inlet shutter on each meter. See the

rate charts for your crop for suggested initial values.

See the planter Operator manual for instructions on

setting the inlet shutter.

4

4

Figure 13

Grain Shield, Brushes, Installed

31555B

2012-02-29 Table of Contents Metric Charts 401-626B

Page 32

30 YP2425A Table of Contents Metric Charts Great Plains Manufacturing, Inc.

Take Note of Meter Pressure

Due to delivery of multiple seeds per disc cell, a

volumetric crop requires a specific value of disc

pressurization.

Initial Meter Pressurization: Wheat

2.0 inches of water Hard Red Winter (HRW)

2.5 inches of water Soft Red Winter (SRW)

Note: Do not operate below 2.0 inches of water

10. Note the suggested initial meter pressure. Have this

value at hand in the tractor cab.

Calibrate

Calibration is essential for accurate populations:

• Seed monitors cannot accurately count individual

seeds in volumetric planting, both due to the small

seed size, and due to multiple seeds per cell being

often detected as one seed.

• Ground drive charts are only approximate, and only for

the seed variety and conditions used to develop the

chart.

• Your own rate records may also be approximate. The

same seed variety planted at a different date can

require a rate adjustment due to different seed density,

different weather, different field speed, etc.

11. Calibrate your seed rate.

Population Risk:

Volumetric planting based strictly on ground drive charts is

likely to be inaccurate. Volumetric planting based on seed

monitor seed counts is certain to be inaccurate.

Calibrate. Check your actual rate by weight or by furrow

count. Check your seed consumption when refilling.

For hydraulic drive planters, use the “Spreader

Calibration” feature of the seed monitor.

For ground drive (or hydraulic drive) planters, rely on

a “seeds per row foot” furrow check, the next topic.

401-626B Table of Contents Metric Charts 2012-02-29

Page 33

Great Plains Manufacturing, Inc. Table of Contents Metric Charts Volumetric Seeding 31

Furrow Checking Rate

a. Configure the planter for the approximate rate, based

on the charts.

b. Set the meter pressure to the chart value.

c. Prime the meters. See your planter Operator manual

for the steps.

d. Plant for a short distance, just until the air delivery

system is stabilized, and the meters are all delivering

seed.

e. Select one or more rows to sample.

Row Spacing Seeds per Population Pounds per acre

Inches Row Foot Seeds/Acre

f. Set the planting depth to shallow for the sample

row(s). Set the press wheels to minimum force. Use a

wire to tie up the press wheel assembly.

g. Resume planting for a short distance.

h. Use a sampled row lengtha of one foot.

Count the seeds.

i. Find the nearest “Seeds per Row Foot” in the table for

your row spacing.

j. Look up the Population, or “Pounds per acre”.

at 12500 s/lb at 15000 s/lb at 17500 s/lb

9.5in Rows 45 2 500 000

41 2 250 000

36 2 000 000

32 1 750 000

27 1 500 000

23 1 250 000

18 1 000 000

14 750 000

10in Rows 48 2 500 000

43 2 250 000

38 2 000 000

33 1 750 000

29 1 500 000

24 1 250 000

19 1 000 000

14 750 000

One Row of Twin Row 30in 72 2 500 000

or 65 2 250 000

15in Rows 57 2 000 000

50 1 750 000

43 1 500 000

36 1 250 000

29 1 000 000

22 750 000

200 167 143

180 150 129

160 133 114

140 117 100

120 100 86

100 83 71

80 67 57

60 50 43

200 167 143

180 150 129

160 133 114

140 117 100

120 100 86

100 83 71

80 67 57

60 50 43

200 167 143

180 150 129

160 133 114

140 117 100

120 100 86

100 83 71

80 67 57

60 50 43

32325A

a. You can interpolate rows for more precise rate results. Doubling or tripling the sample length improves accuracy.

2012-02-29 Table of Contents Metric Charts 401-626B

Page 34

32 YP2425A Table of Contents Metric Charts Great Plains Manufacturing, Inc.

Volumetric Monitor Setup

In volumetric planting, the seed monitor operates

basically as a blockage detector. Any seed drop rate

information is only approximate.

DICKEY-john®IntelliAg® Volumetric

In volumetric planting, the seed monitor is operated in:

“GRAN SEED CONTROL” (hydraulic drive) or

“GRAN SEED MONITOR” (ground drive).

This is a change from the:

“PLANTER CONTROL” (hydraulic drive) and

“MONITOR ONLY” (ground drive)

modes used for singulated crops.

IntelliAg® Hydraulic Drive

The planter needs to be hitched to the tractor in which

the DICKEY-john® virtual terminal (VT) is installed.

1. Power up the seed monitor (usually via tractor

ignition). Clear or resolve any alarms. The system is

in User Level 1.

2. Change monitor to User Level 2. See PDC manual,

or consult with dealer for procedure.

29500

Figure 14

Typical Control Setup Screen

3. At the monitor main menu, press the

Row Monitor softkey, then push the Row I/O

soft key. Change the POP/Block pattern to “Every

Row Blockage.”

Figure 15

Every Row Blockage Screen

401-626B Table of Contents Metric Charts 2012-02-29

31649a

31649b

Page 35

Great Plains Manufacturing, Inc. Table of Contents Metric Charts Volumetric Seeding 33

Set Up A Material

Add at least one volumetric seed to the monitor’s

Material Library. Settings for volumetric have crucial

differences from settings for singulated seeds (and are

also different from ground drive volumetric).

15 different materials can be configured for use as

planter controls, or granular seed controls. Reference the

System Configuration section in the PDC manual for

additional information.

Material Setup

Setup

Item

Matrl

Label

Type

Units Lb/ac with lb/hr

Preset

Method

Density 60.0 lb/bu

Spreader

Constant

Low Shaft

RPM

High Shaft

RPM

Prod Level

Alarm

Seeds per

Pound

High Pop

Alarm

Low Pop

Alarm

Pattern

Row Fail

Rate

Value or

Default

<your choice>

GRAN SEED

CONTROL

Disabled