Great Plains YP1630F-1670 Operator Manual

Table of Contents Index

Operator

YP1630F-1630 and YP1630F-1670

12 m 2-Section Yield-Pro® Dry Fertilizer Planters

Manufacturing, Inc.

www.greatplainsmfg.com

Read the operator manual entirely. When you see this symbol, the

subsequent instructions and warnings are serious - follow without

exception. Your life and the lives of others depend on it!

34460

Illustrations may show optional equipment not supplied with standard unit or may

depict similar YP1625/A or PD8070 models where a topic is identical.

ORIGINAL INSTRUCTIONS

© Copyright 2012 Printed 2012-12-27 401-832M

Table of Contents Index

EN

Table of Contents Index

Table of Contents Index

Great Plains Manufacturing, Inc. Cover Index iii

Table of Contents

Important Safety Information ......................................1

Safety Decals .................................................................6

Introduction ................................................................15

Description of Unit ........................................................15

Document Family .........................................................15

Covered Models ...........................................................15

Intended Usage ........................................................15

Using This Manual........................................................15

Definitions................................................................. 15

Owner Assistance ........................................................16

Preparation and Setup ...............................................17

Initial Setup...................................................................17

Pre-Planting Setup .......................................................17

Hitching Tractor to Planter............................................18

Hydraulic Hookup .....................................................18

3-Point Hitch.............................................................18

Hydraulic Hose Hookup............................................ 19

Raising/Lowering Tongue....................................19

Electrical Hookup......................................................20

Store Main Parking Stand.........................................20

Monitor Setup ...............................................................21

Marker Setup (Option)..................................................21

Operating Instructions...............................................22

Pre-Start Checklist .......................................................22

Wing Lock Overview.....................................................22

Unfolding the Planter....................................................23

Prepare Hitched Tractor and Planter........................ 23

Prepare Transport Hooks ......................................... 23

Release Wing Locks................................................. 24

Re-Phase Fold Cylinders..........................................24

Partially Unfold .........................................................24

Lower Tongue ..........................................................24

Fully Unfold ..............................................................24

Remove and Store Transport Locks......................... 25

Unfold Closeout........................................................26

Raising/Lowering Planter .............................................27

Raising Planter .........................................................27

Lowering Planter ......................................................27

Re-phasing Lift System ............................................27

Folding the Planter .......................................................28

Shut off Fan..............................................................28

Set Tractor and Tongue ...........................................28

Raise Planter............................................................28

Install Lock Channels ...............................................29

Activate Fold Solenoid Valves.................................. 29

Begin Folding ........................................................... 29

Raise Tongue...........................................................30

Complete Fold..........................................................30

Lower Tongue .......................................................... 30

Re-phasing Fold System.......................................... 30

Lock Up Dry Fertilizer Drive ..................................... 30

Transporting................................................................. 31

Transport Weights....................................................31

Loading Materials......................................................... 32

For Loading All Materials ......................................... 32

Loading Seed ........................................................... 33

Seed Drive Clutch .................................................... 34

Meter Clutch Disengagement............................... 34

Meter Shaft Alignment.......................................... 34

Loading Fertilizer...................................................... 35

Hopper Safety Information ...................................35

Swing-Down Railing Section ................................ 36

Load Fertilizer ...................................................... 37

Loading Treatments (Option) ................................... 38

Treatment Compatibility .......................................38

Inspect Hoppers ................................................... 38

Set Meters to Zero ............................................... 38

Load Treatment.................................................... 38

Treatment Drive Clutch ............................................ 39

Disabling Unused Drives.............................................. 40

Wing Drive Lockup ................................................... 40

Fertilizer Drive Lockup ............................................. 40

Field Setup Checklist ................................................... 41

Monitor Operation ........................................................ 42

Fan General Operating Information ............................. 42

Starting Fan.............................................................. 42

Stopping Fan............................................................42

Marker Operation ......................................................... 43

Field Operation ............................................................ 44

Parking......................................................................... 45

Storage ........................................................................ 46

Adjustments ............................................................... 47

Setting Material Rates.................................................. 48

Planting (Seed) Rate................................................48

Dry Fertilizer Rate .................................................... 48

Treatment Rate (Option) .......................................... 48

Marker Adjustments ..................................................... 49

Dual Marker Speed Adjustment ............................... 49

Marker Disk Adjustment ........................................... 49

Row Implement Adjustments ....................................... 50

© Copyright 2012 All rights Reserved

Great Plains Manufacturing, Inc. provides this publication “as is” without warranty of any kind, either expressed or implied. While every precaution has been

taken in the preparation of this manual, Great Plains Manufacturing, Inc. assumes no responsibility for errors or omissions. Neither is any liability assumed for

damages resulting from the use of the information contained herein. Great Plains Manufacturing, Inc. reserves the right to revise and improve its products as

it sees fit. This publication describes the state of this product at the time of its publication, and may not reflect the product in the future.

2012-12-27 Cover Index 401-832M

Trademarks of Great Plains Manufacturing, Inc. include: Singulator Plus, Swath Command, Terra-Tine.

Registered Trademarks of Great Plains Manufacturing, Inc. include:

Air-Pro, Clear-Shot, Discovator, Great Plains, Land Pride, MeterCone, Nutri-Pro, Seed-Lok, Solid Stand,

Terra-Guard, Turbo-Chisel, Turbo-Chopper, Turbo Max, Turbo-Till, Ultra-Till, Ver ti-Till, Whirlfilter, Yield-Pro.

Brand and Product Names that appear and are owned by others are trademarks of their respective owners.

Printed in the United States of America

iv YP1630F Table of Contents Index Great Plains Manufacturing, Inc.

Frame-Mounted Row Accessories........................... 50

Frame-Mounted Coulters ..................................... 50

Dry Fertilizer Applicator Adjustments....................... 50

Applicator Release Height.................................... 50

30 Series Row-Unit Adjustments ................................. 51

Row Unit Down Pressure......................................... 52

Unit-Mounted Coulter Adjustments .......................... 53

Row-Unit Opener Disc Adjustments......................... 53

Setting Planting Depth ......................................... 53

Side Gauge Wheel Adjustments .............................. 54

Adjusting Gauge Wheel Scrapers............................ 55

Seed Meter Setup and Adjustment .......................... 56

Exchanging Meters .................................................. 57

Seed Meter Adjustments.......................................... 58

Finger Meter Adjustments .................................... 58

Finger Meter Brush Adjustment ........................... 58

Finger Meter Inserts ............................................. 59

Sunflower Meter Configurations........................... 59

Brush Meter Adjustments..................................... 60

Installing Brush Meter Plates ............................... 60

Seed Firmer Adjustments ........................................ 61

Keeton® Seed Firmer Adjustment........................ 61

Seed-Lok® Seed Firmer Lock-Up ........................ 61

Press Wheel Adjustments........................................ 62

Press Wheel Down Pressure ............................... 62

Press Wheel Centering ........................................ 62

Press Wheel Stagger ........................................... 63

Press Wheel Angle............................................... 63

Troubleshooting......................................................... 64

Planting Rate Problems ............................................... 64

Suggested Furrow Check:.................................... 64

Seed Population Troubleshooting Charts .................... 65

Maintenance and Lubrication ................................... 72

Maintenance ................................................................ 72

Frame Lift Cylinder Locks ........................................ 73

Ground Drive Springs .............................................. 73

Material Unloading and Clean-Out............................... 74

Seed Unloading and Clean-Out ............................... 74

Seed Hopper Clean-Out....................................... 74

Finger Meter Clean-Out ....................................... 75

Brush Meter Clean-Out ........................................ 75

Seed Tube Clean-Out .......................................... 75

Fertilizer Unloading and Clean-Out.......................... 76

Fertilizer Unloading .............................................. 76

Fertilizer Clean-Out.................................................. 77

Problem Clean-Out .............................................. 78

Removing Meter Box............................................ 78

Hopper Entry ........................................................ 79

Treatment Unloading and Clean-Out (Option) ......... 81

Treatment Meter Gate Calibration (Option) ................. 82

Meter Maintenance ...................................................... 83

Finger Pickup Meter Maintenance ........................... 83

Finger Set Inspection ........................................... 83

Finger Meter Re-Assembly Steps.........................83

Precautions...........................................................83

Population Max™ Annual Maintenance................84

Population Max™ Installation ...............................84

Skip Stop™ Annual Maintenance .........................85

Skip Stop™ Installation.........................................85

Exchanging Finger Sets ...............................................86

Install Corn Finger Set ..........................................89

Meter Drive Adjustments ..........................................90

Brush Meter Maintenance.........................................91

Seed Plate Maintenance...........................................92

Cleaning and Storing Seed Disks .........................92

Bleeding Hydraulics ..................................................93

Bleeding Lift Hydraulics ........................................93

Bleeding Fold Cylinder Hydraulics........................93

Bleeding Marker Hydraulics..................................94

Marker Maintenance.....................................................94

Chain Maintenance.......................................................95

30 Series Opener Disks and Scrapers .....................96

30 Series Row-Unit Side Wheels..............................97

Lubrication ....................................................................98

Seed Lubricants..........................................................104

Options and Accessories ........................................105

Appendix A - Reference Information ......................110

Specifications and Capacities.....................................110

YP1630F-1630 30 inch Models ..............................110

YP1630F-1670 70 cm Models ................................111

Tire Inflation Chart ......................................................111

Hydraulic Diagrams ....................................................112

Chain Routing.............................................................115

Torque Values Chart ..................................................119

Appendix C - Initial Setup ........................................120

Hydraulic Charge and Bleed.......................................120

Seed Monitor Console Installation..............................120

Seed Monitor Console Quick-Start .............................120

Power-Up The Console ..........................................121

Set Metric Mode......................................................121

About Row Count and Spacing...............................121

Set Planter Row Count ...........................................122

Set Planter Row Spacing........................................122

Row Setup ..............................................................122

Level Planter...............................................................123

Wing Alignment ..........................................................124

Speed Calibration .......................................................125

Speed Sensor Operation ........................................125

Marker Extension........................................................125

Appendix D - Option Installation.............................126

122-278S Scraper Installation ....................................126

Warranty .....................................................................127

Index ..........................................................................129

401-832M Table of Contents Index 2012-12-27

Great Plains Manufacturing, Inc. Table of Contents Index 1

Important Safety Information

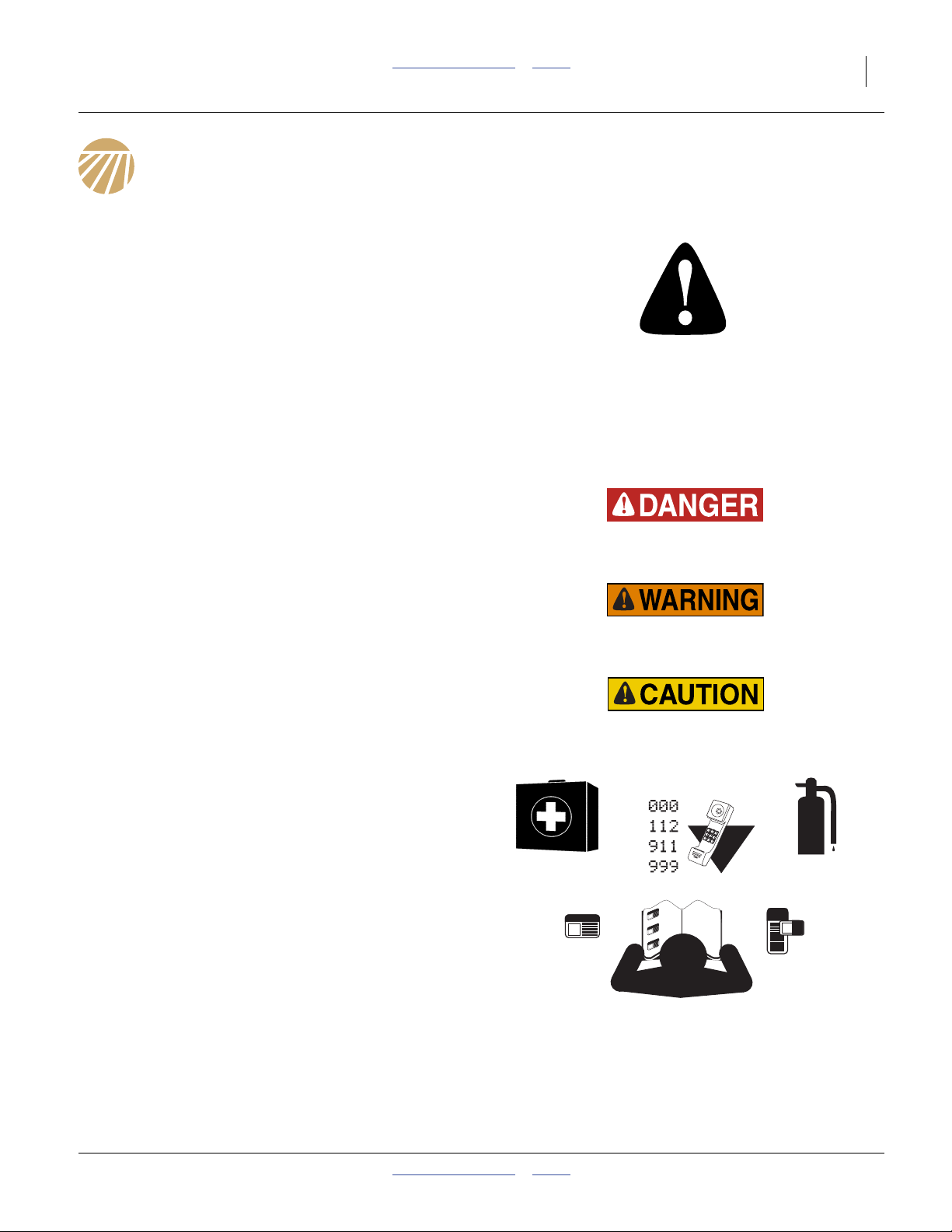

Look for Safety Symbol

The SAFETY ALERT SYMBOL indicates there is a

potential hazard to personal safety involved and extra

safety precaution must be taken. When you see this

symbol, be alert and carefully read the message that

follows it. In addition to design and configuration of

equipment, hazard control and accident prevention are

dependent upon the awareness, concern, prudence and

proper training of personnel involved in the operation,

transport, maintenance and storage of equipment.

Be Aware of Signal Words

Signal words designate a degree or level of hazard

seriousness.

DANGER indicates an imminently hazardous situation

which, if not avoided, will result in death or serious injury.

This signal word is limited to the most extreme situations,

typically for machine components that, for functional

purposes, cannot be guarded.

WARNING indicates a potentially hazardous situation

which, if not avoided, could result in death or serious

injury, and includes hazards that are exposed when

guards are removed. It may also be used to alert against

unsafe practices.

CAUTION indicates a potentially hazardous situation

which, if not avoided, may result in minor or moderate

injury. It may also be used to alert against unsafe

practices.

Prepare for Emergencies

▲ Be prepared if a fire starts

▲ Keep a first aid kit and fire extinguisher handy.

▲ Keep emergency numbers for doctor, ambulance, hospital

and fire department near phone.

Be Familiar with Safety Decals

▲ Read and understand “Safety Decals” on page 6,

thoroughly.

▲ Read all instructions noted on the decals.

▲ Keep decals clean. Replace damaged, faded and illegible

decals.

2012-12-27 Table of Contents Index 401-832M

2 YP1630F Table of Contents Index Great Plains Manufacturing, Inc.

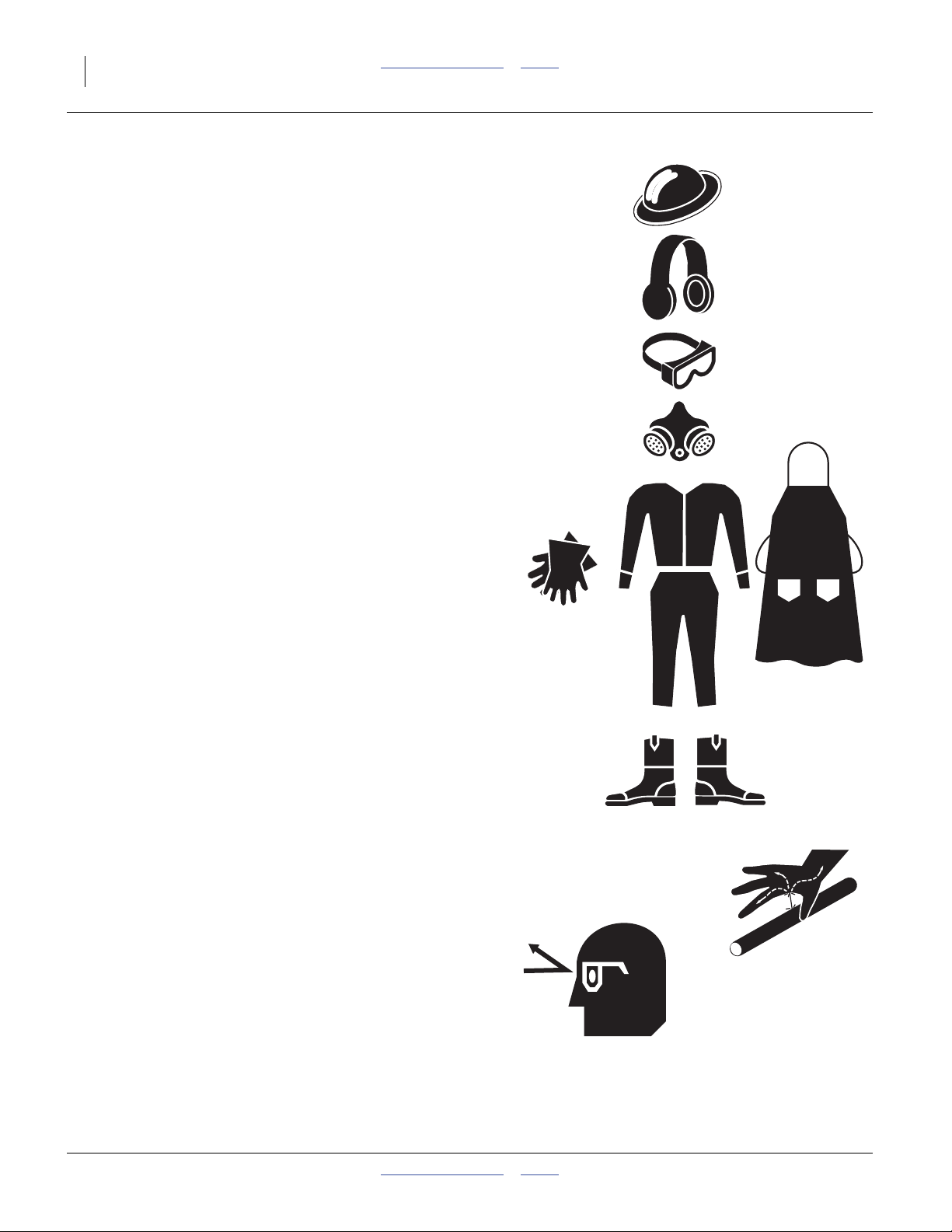

Wear Protective Equipment

Great Plains advises all users of chemical pesticides or

herbicides to use the following personal safety

equipment.

▲ Waterproof, wide-brimmed hat

▲ Waterproof apron.

▲ Face shield, goggles or full face respirator.

▲ Goggles with side shields or a full face respirator is

required if handling or applying dusts, wettable powders, or

granules or if being exposed to spray mist.

▲ Cartridge-type respirator approved for pesticide vapors

unless label specifies another type of respirator.

▲ Waterproof, unlined gloves. Neoprene gloves are

recommended.

▲ Cloth coveralls/outer clothing changed daily; waterproof

items if there is a chance of becoming wet with spray

▲ Waterproof boots or foot coverings

▲ Do not wear contaminated clothing. Wash protective

clothing and equipment with soap and water after each use.

Personal clothing must be laundered separately from

household articles.

▲ Clothing contaminated with certain pesticides must be

destroyed according to state and local regulations. Read

chemical label for specific instructions.

▲ Wear clothing and equipment appropriate for the job. Avoid

loose-fitting clothing.

▲ Prolonged exposure to loud noise can cause hearing

impairment or loss. Wear suitable hearing protection such

as earmuffs or earplugs.

▲ Avoid wearing entertainment headphones while operating

machinery. Operating equipment safely requires the full

attention of the operator.

Avoid High Pressure Fluids

Escaping fluid under pressure can penetrate the skin,

causing serious injury.

▲ Avoid the hazard by relieving pressure before disconnecting

hydraulic lines.

▲ Use a piece of paper or cardboard, NOT BODY PARTS, to

check for suspected leaks.

▲ Wear protective gloves and safety glasses or goggles when

working with hydraulic systems.

▲ If an accident occurs, seek immediate medical assistance

from a physician familiar with this type of injury.

401-832M Table of Contents Index 2012-12-27

Great Plains Manufacturing, Inc. Table of Contents Index Important Safety Information 3

Handle Chemicals Properly

▲ Read and follow chemical manufacturer’s instructions.

▲ Wear protective clothing.

▲ Handle all chemicals with care.

▲ Agricultural chemicals can be dangerous. Improper use can

seriously injure persons, animals, plants, soil and property.

▲ Inhaling smoke from any type of chemical fire is a serious

health hazard.

▲ Store or dispose of unused chemicals as specified by the

chemical manufacturer.

▲ Immediately and thoroughly flush any area of the body that

is contaminated by chemicals.

▲ If chemical is swallowed, carefully follow the chemical

manufacturer’s recommendations and consult with a doctor.

▲ If persons are exposed to a chemical in a way that could

affect their health, consult a doctor immediately with the

chemical label or container in hand. Any delay could cause

serious illness or death.

▲ Dispose of empty chemical containers properly. By law

rinsing of the used chemical container must be repeated

three times. Puncture the container to prevent future use. An

alternative is to jet-rinse or pressure rinse the container.

▲ After working with chemicals, wash hands and face before

eating. Shower when application is completed for the day.

▲ Never wash out the tanks within 100 feet (30m) of any

freshwater source or in a car wash.

▲ Rinse out the tank. Apply rinse water on last field treated.

Keep Riders Off Machinery

Riders obstruct the operator’s view. Riders could be

struck by foreign objects or thrown from the machine.

▲ Never allow children to operate equipment.

▲ Keep all bystanders away from machine during operation.

Use Safety Lights and Devices

Slow-moving tractors and towed implements can create

a hazard when driven on public roads. They are difficult

to see, especially at night.

▲ Use flashing warning lights and turn signals whenever

driving on public roads.

▲ Use lights and devices provided with implement

2012-12-27 Table of Contents Index 401-832M

4 YP1630F Table of Contents Index Great Plains Manufacturing, Inc.

Transport Machinery Safely

Maximum transport speed for implement is 32 km/h

(20 mph). Some rough terrains require a slower speed.

Sudden braking can cause a towed load to swerve and

upset.

▲ Do not exceed 32 km/h (20 mph). Never travel speeds which

do not allow adequate control of steering and stopping.

Reduce speed if towed load is not equipped with brakes.

▲ Comply with state and local laws.

▲ Do not tow an implement that, when fully loaded, weighs

more than 1.5 times the weight of towing vehicle.

▲ Carry reflectors or flags to mark planter in case of

breakdown on the road.

▲ Keep clear of overhead power lines and other obstructions

when transporting. Refer to transport dimensions under

“Specifications and Capacities” on page 110.

▲ Do not fold or unfold the planter while the tractor is

moving.

Shutdown and Storage

▲ Lower planter, put tractor in park, turn off engine, and

remove the key.

▲ Block tires with wheel chocks provided.

▲ Secure planter using blocks and supports provided.

▲ Detach and store planter in an area where children

normally do not play.

Tire Safety

Tire changing can be dangerous and should be

performed by trained personnel using correct tools and

equipment.

▲ When inflating tires, use a clip-on chuck and extension hose

long enough for you to stand to one side–not in front of or

over tire assembly. Use a safety cage if available.

▲ When removing and installing wheels, use wheel-handling

equipment adequate for weight involved.

401-832M Table of Contents Index 2012-12-27

Great Plains Manufacturing, Inc. Table of Contents Index Important Safety Information 5

Practice Safe Maintenance

▲ Understand procedure before doing work. Use proper tools

and equipment. Refer to this manual for additional

information.

▲ Work in a clean, dry area.

▲ Lower the planter, put tractor in park, turn off engine, and

remove key before performing maintenance.

▲ Make sure all moving parts have stopped and all system

pressure is relieved.

▲ Allow planter to cool completely.

▲ Disconnect battery ground cable (-) before servicing or

adjusting electrical systems or before welding on planter.

▲ Inspect all parts. Make sure parts are in good condition and

installed properly.

▲ Remove buildup of grease, oil or debris.

▲ Remove all tools and unused parts from planter before

operation.

Safety At All Times

Thoroughly read and understand the instructions in this

manual before operation. Read all instructions noted on

the safety decals.

▲ Be familiar with all planter functions.

▲ Operate machinery from the driver’s seat only.

▲ Do not leave planter unattended with tractor engine

running.

▲ Do not dismount a moving tractor. Dismounting a moving

tractor could cause serious injury or death.

▲ Do not stand between the tractor and planter during

hitching.

▲ Keep hands, feet and clothing away from power-driven

parts.

▲ Wear snug-fitting clothing to avoid entanglement with

moving parts.

▲ Watch out for wires, trees, etc., when folding and raising

planter. Make sure all persons are clear of working area.

2012-12-27 Table of Contents Index 401-832M

6 YP1630F Table of Contents Index Great Plains Manufacturing, Inc.

Safety Decals

Safety Reflectors and Decals

Your implement comes equipped with all lights, safety

reflectors and decals in place. They were designed to

help you safely operate your implement.

▲ Read and follow decal directions.

▲ Keep lights in operating condition.

▲ Keep all safety decals clean and legible.

▲ Replace all damaged or missing decals. Order new decals

from your Great Plains dealer. Refer to this section for

proper decal placement.

▲ When ordering new parts or components, also request

corresponding safety decals.

To install new decals:

1. Clean the area on which the decal is to be placed.

2. Peel backing from decal. Press firmly on surface,

being careful not to cause air bubbles under decal.

818-055C

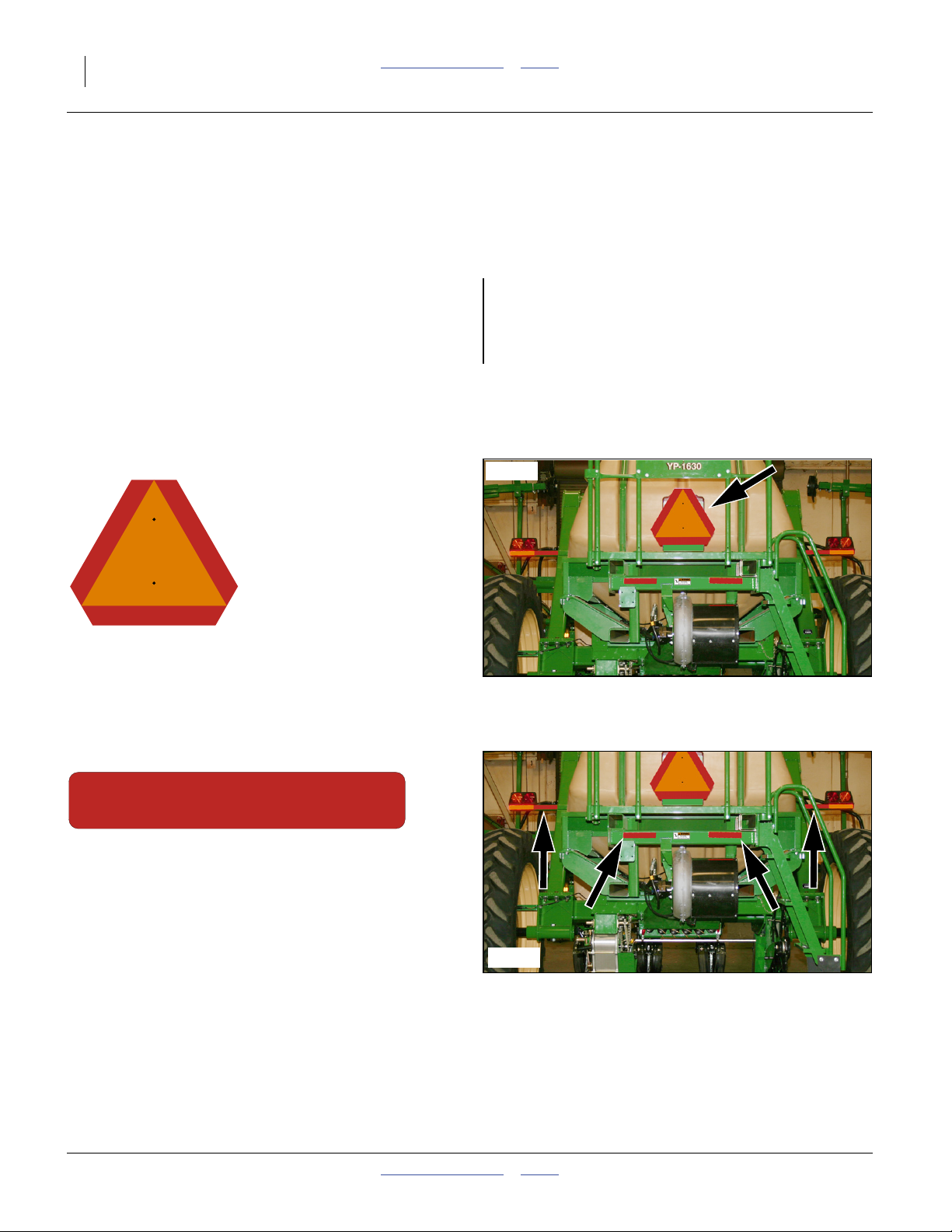

Slow Moving Vehicle Reflector

On the back of the planter, walkboard center;

1 total

See “Transporting” on page 31.

838-266C

Red Reflectors

On the back of fertilizer hopper frame each end,

and on the inside rear face of each light mounting bar;

4 total

34535

34535

401-832M Table of Contents Index 2012-12-27

Great Plains Manufacturing, Inc. Table of Contents Index Important Safety Information 7

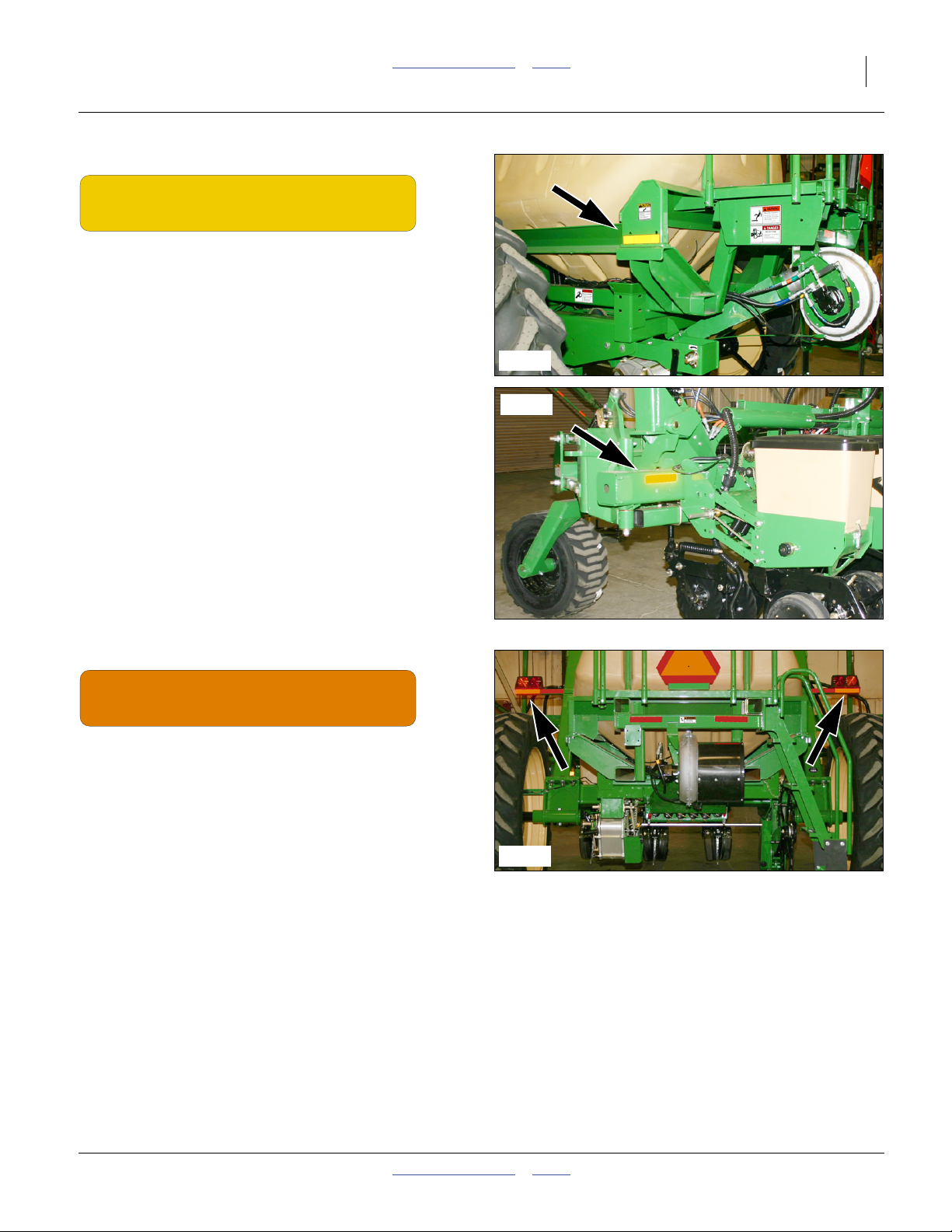

838-265C

Amber Reflectors

One each on rear face of wing tool bar at wing lock,

one each rear outside corner face of fertilizer frame;

4 total

34536

34537

838-267C

Daytime Reflectors

On the back of seed frame, outside red reflectors,

on the rear face of the light bar;

2 total

34535

2012-12-27 Table of Contents Index 401-832M

8 YP1630F Table of Contents Index Great Plains Manufacturing, Inc.

818-323C (Option)

Danger: Chemical Hazard

On the rear walkboard face of the central dry fertilizer

hopper, and on the underside of treatment hopper

(option) lids;

1 or 17 total

34544

34539

818-590C

Danger: Crushing Hazard

On the left side of the 3-point hitch:

1 total.

See “Hitching Tractor to Planter” on page 18.

34541

401-832M Table of Contents Index 2012-12-27

Great Plains Manufacturing, Inc. Table of Contents Index Important Safety Information 9

838-599C

34542

Danger: Electrocution Hazard

On front face of marker mount, near gauge wheel pivot;

2 total

See “Marker Operation” on page 43.

848-583C

Danger: Do Not Ride

On the left and right ends of the walkboard frame;

2 total

818-045C

Warning: Pinch-Crush

On both sides of wing gauge wheel caster weldments;

4 total

34536

34540

2012-12-27 Table of Contents Index 401-832M

10 YP1630F Table of Contents Index Great Plains Manufacturing, Inc.

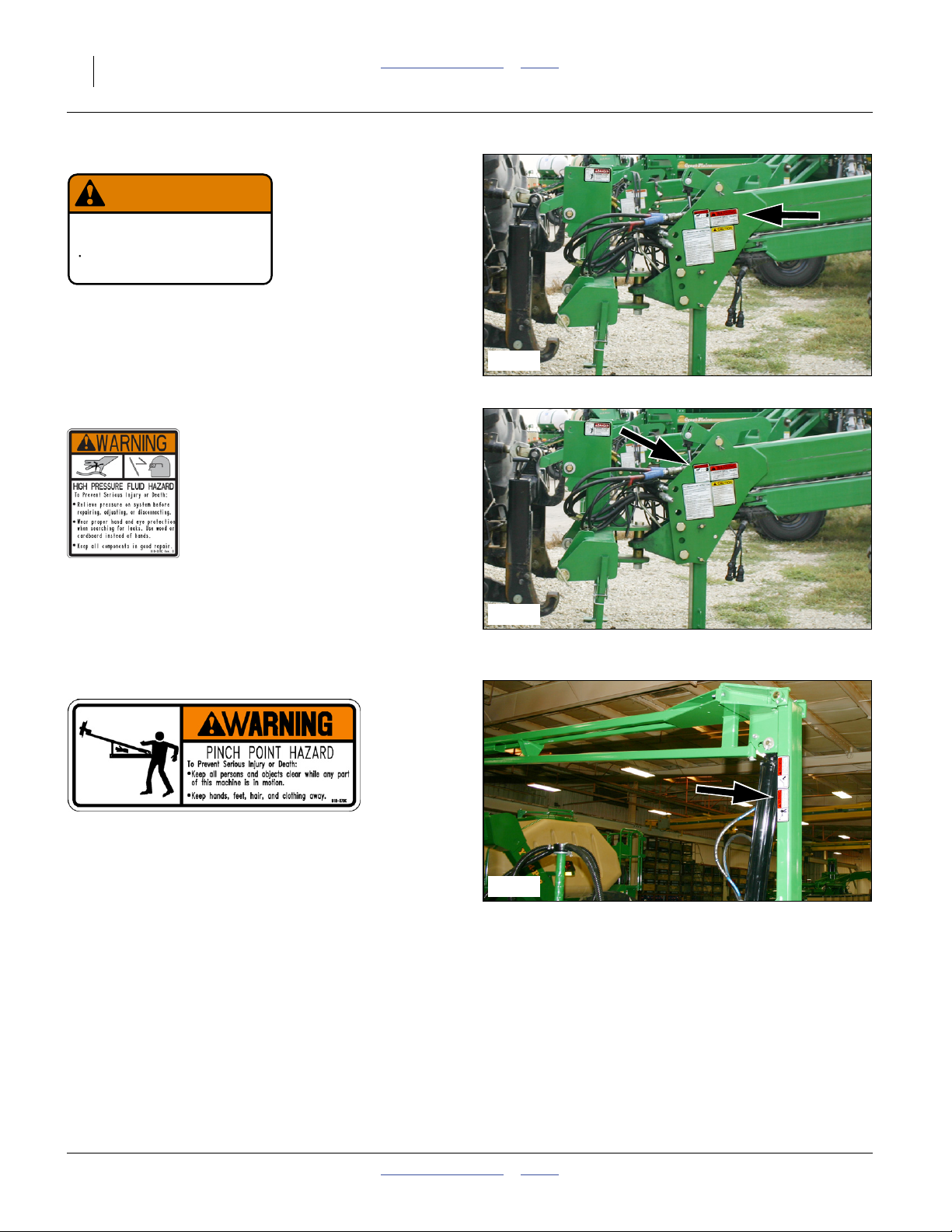

818-188C

WARNING

EXCESSIVE SPEED HAZARD

To Prevent Serious Injury or Death:

Do Not exceed 20 mph maximum transport

speed. Loss of vehicle control and/or machine

can result.

Warning: Excessive Speed

On left side of tongue near hitch;

1 total

See “Transporting” on page 31.

818-339C

818-188C Rev. C

34541

Warning: High Pressure Fluid Hazard

On left side of tongue near hitch;

1 total

See “Hydraulic Hose Hookup” on page 19.

818-579C

Warning: Pinch-Shear Hazard

On marker section each end, two total

See “Marker Operation” on page 43.

34541

34543

401-832M Table of Contents Index 2012-12-27

Great Plains Manufacturing, Inc. Table of Contents Index Important Safety Information 11

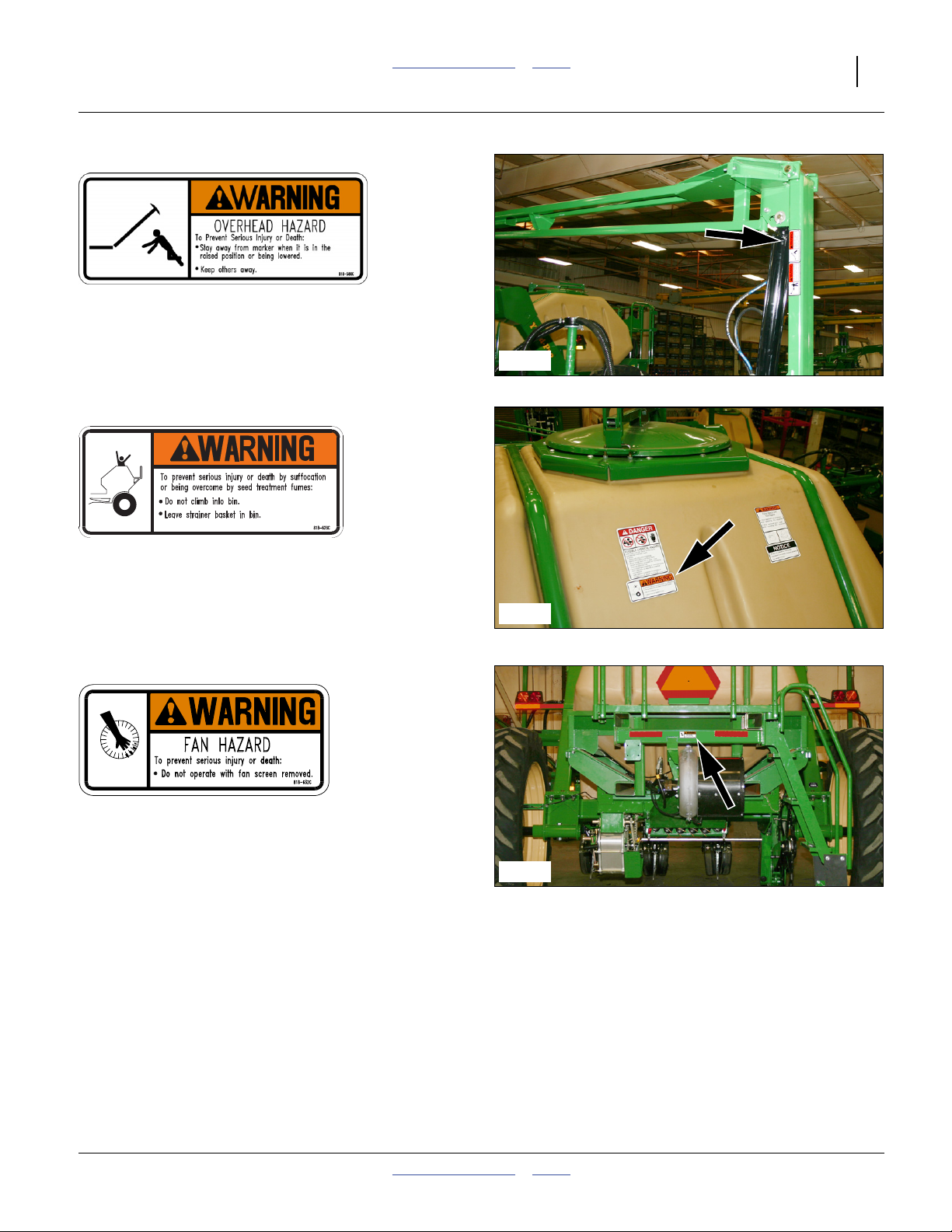

818-580C

Warning: Overhead Hazard

On marker section each end, two total

See “Marker Operation” on page 43.

34543

818-628C

Warning: Confined Space

On the rear walkboard face of the central dry fertilizer

hopper;

1 total

818-632C

Warning: Fan Hazard

On center rear face of walkboard frame;

1 total

34544

34535

2012-12-27 Table of Contents Index 401-832M

12 YP1630F Table of Contents Index Great Plains Manufacturing, Inc.

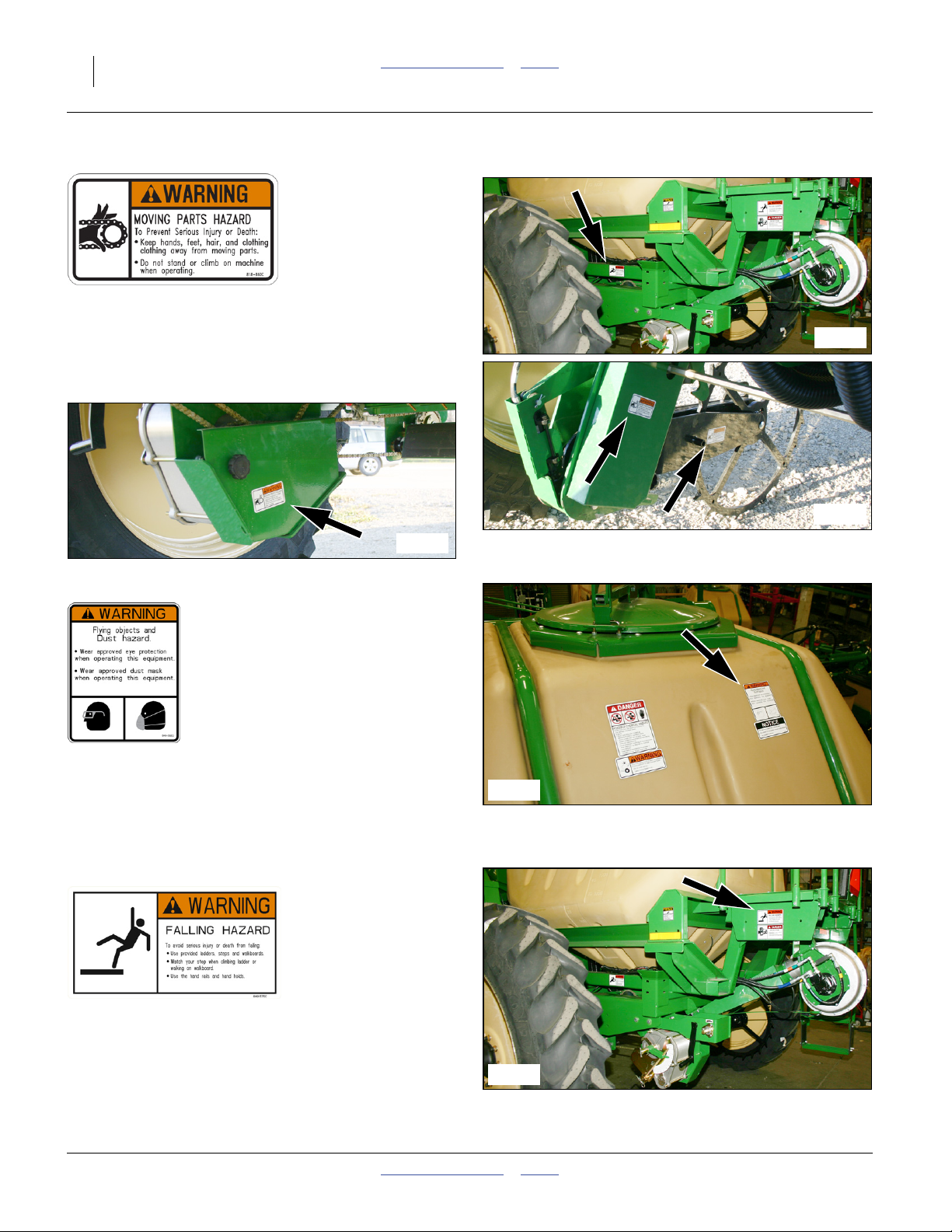

818-860C

Warning: Moving Parts

On outer face of central hopper lower support tubes,

on variable rate gearbox input chain guards,

on all ground drive arm guards

on all removable ground drive guards;

14 total

34536

34546

848-392C

Warning: Eye and Dust Hazards

On the rear walkboard face of the central dry fertilizer

hopper;

1 total

848-575C

34545

34544

Warning: Falling Hazard

On the left and right ends of the walkboard frame;

2 total

34536

401-832M Table of Contents Index 2012-12-27

Great Plains Manufacturing, Inc. Table of Contents Index Important Safety Information 13

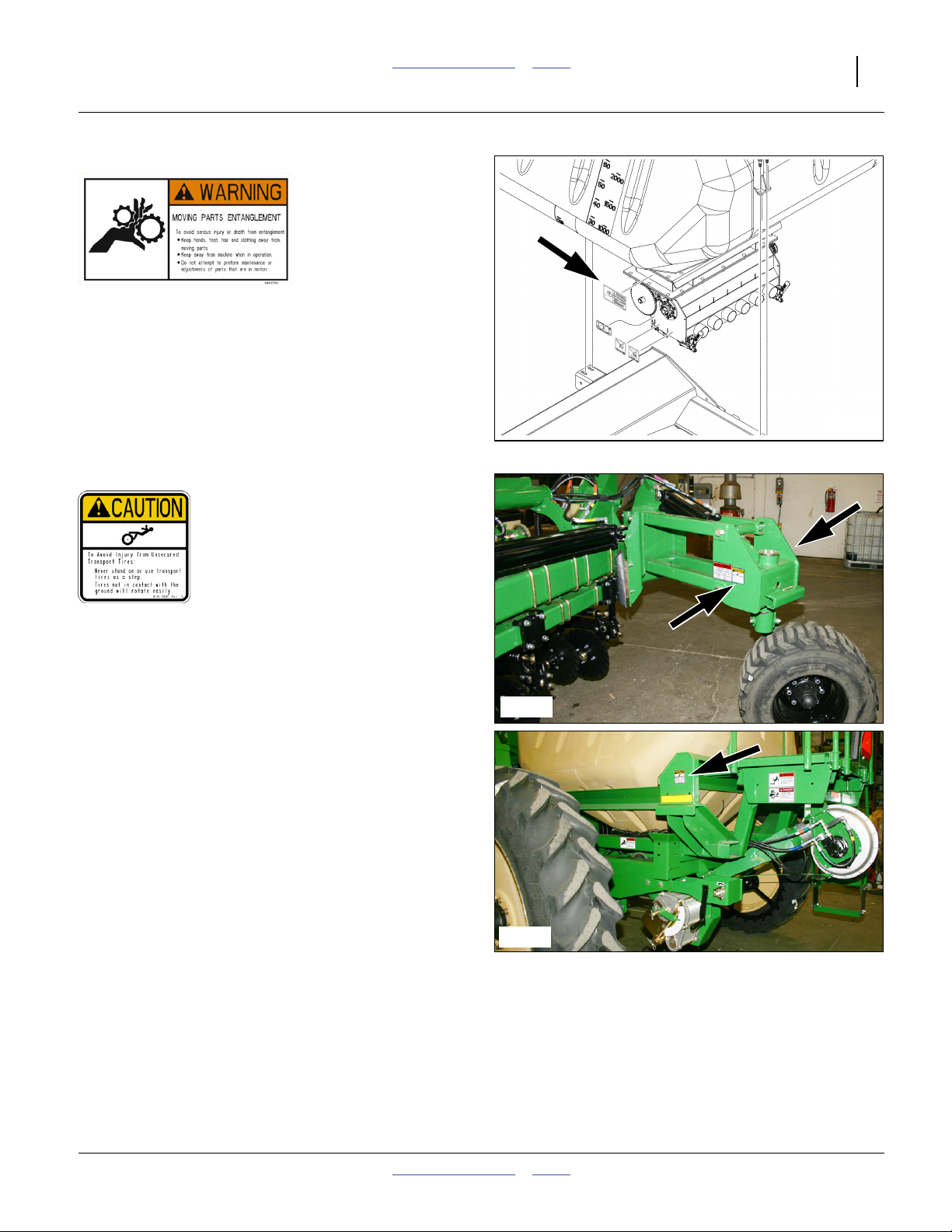

848-576C

Warning: Moving Parts

On inlet of fertilizer meter, above final range gears;

1 total

34410

818-398C

Caution: Tires Not A Step

On both sides of wing gauge wheel caster weldments,

and on rear outer corners of central hopper frame;

4 total

In transport configuration, wing gauge wheels are off the

ground and free to spin. In field configuration, at higher

row unit down-forces, wing gauge wheels may have little

or no ground traction.

34540

34536

2012-12-27 Table of Contents Index 401-832M

14 YP1630F Table of Contents Index Great Plains Manufacturing, Inc.

818-578C

CAUTION

To Avoid Injury or Machine Damage from improper Tire

Inflation or Torquing of Wheel Bolts:

Maximum inflation pressure of tires is 65 psi.

Torque wheel bolts to 240 lb-ft.

Caution: Tire Pressure

On hubcap side rim of each gauge wheel;

2 total

838-995C

818-578C

34547

Caution: General

On right side of tongue near hitch;

1 total

858-011C

CAUTION

To Avoid Injur y or Machine Damage from Improper Tire

Inflation or Torquing of Wheel Bolts:

Maximum inflation pressure of tires is 49 psi (338 kPa).

Torque wheel bolts to 315 ft-lb (427 N-m).

Warning: Tire Pressure

On outside rim of each main transport wheel;

2 total

858-011C

34541

34548

401-832M Table of Contents Index 2012-12-27

Great Plains Manufacturing, Inc. Table of Contents Index 15

Introduction

Great Plains welcomes you to its growing family of new

product owners. This planter has been designed with

care and built by skilled workers using quality materials.

Proper setup, maintenance, and safe operating practices

will help you get years of satisfactory use.

Description of Unit

The YP1630F 12 m 2-Section Yield-Pro

Dry Fertilizer Planters are pull-type planting implements

for use in conventional till, minimum-till, or light no-till

conditions.

®

Yield-Pro

row-units, finger pickup or brush seed meters and row

seed hoppers. Dry fertilizer is air-delivered from a central

bulk hopper. Optional treatment hoppers are available for

rows. Optional unit-mounted coulters are suitable for light

to moderate no-till conditions only. The planter folds for

4.0 m (Narrow) or 4.2 m (Wide) transport.

Planters have 30 Series, side-depth-control

®

Document Family

401-832M Operator Manual (this manual)

401-832B Seed Rate Manual

401-832P Parts Manual

11001-1372

Bulletin A-27aDwyer Magnehelic® instructions

a. These are supplier part numbers.

a

DICKEY-john® PM400 Console Manual

Covered Models

All Models are 16 Row

YP1630F-1630ND 30 inch, Narrow, Dual row hoppers

YP1630F-1630NS 30 inch, Narrow, Single row hopper

YP1630F-1630WD30 inch, Wide, Dual row hopper

YP1630F-1630WS 30 inch, Wide, Single row hopper

YP1630F-1670ND 70 cm, Narrow, Dual row hopper

YP1630F-1670NS 70 cm, Narrow, Single row hopper

YP1630F-1670WD70 cm, Wide, Dual row hopper

YP1630F-1670WS 70 cm, Wide, Single row hopper

Intended Usage

Use the planter to seed production-agriculture crops

only. Do not modify the planter for use with attachments

other than Great Plains options and accessories

specified for use with the planter.

R

L

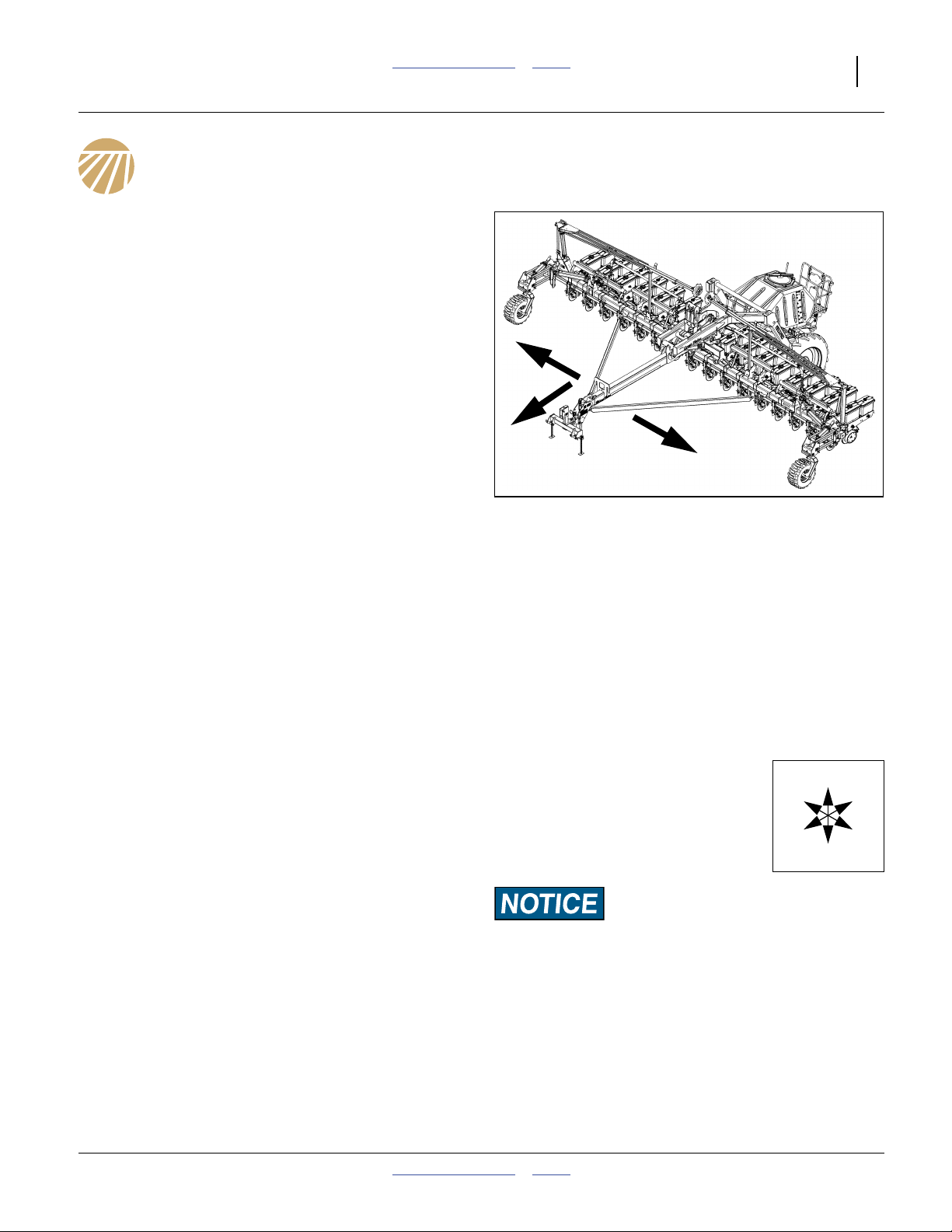

Figure 1

Left/Right Convention

34460

Using This Manual

This manual familiarizes you with safety, assembly,

operation, adjustments, troubleshooting and

maintenance. Read it and follow the recommendations to

help ensure safe and efficient operation.

The information in this manual is current at printing.

Some parts may change to assure top performance.

Definitions

The following terms are used throughout this manual.

Right-hand and left-hand as used in

this manual are determined by facing

the direction the machine will travel

while in use unless otherwise stated.

An orientation rose in some line art

illustrations shows the directions of:

Up, Back, Left, Down, Front, Right.

Economic and/or Liability Risks:

A crucial point of information related to the preceding topic.

Read and follow the directions provided before continuing, to

ensure safety, avoidance of machine damage, and to achieve

desired field results.

Note: This format indicates a useful point of information

related to the preceding topic.

R

F

U

B

L

D

2012-12-27 Table of Contents Index 401-832M

16 YP1630F Table of Contents Index Great Plains Manufacturing, Inc.

Owner Assistance

If you need customer service or repair parts, contact a

Great Plains dealer. They have trained personnel, repair

parts, and equipment specially designed for Great Plains

products.

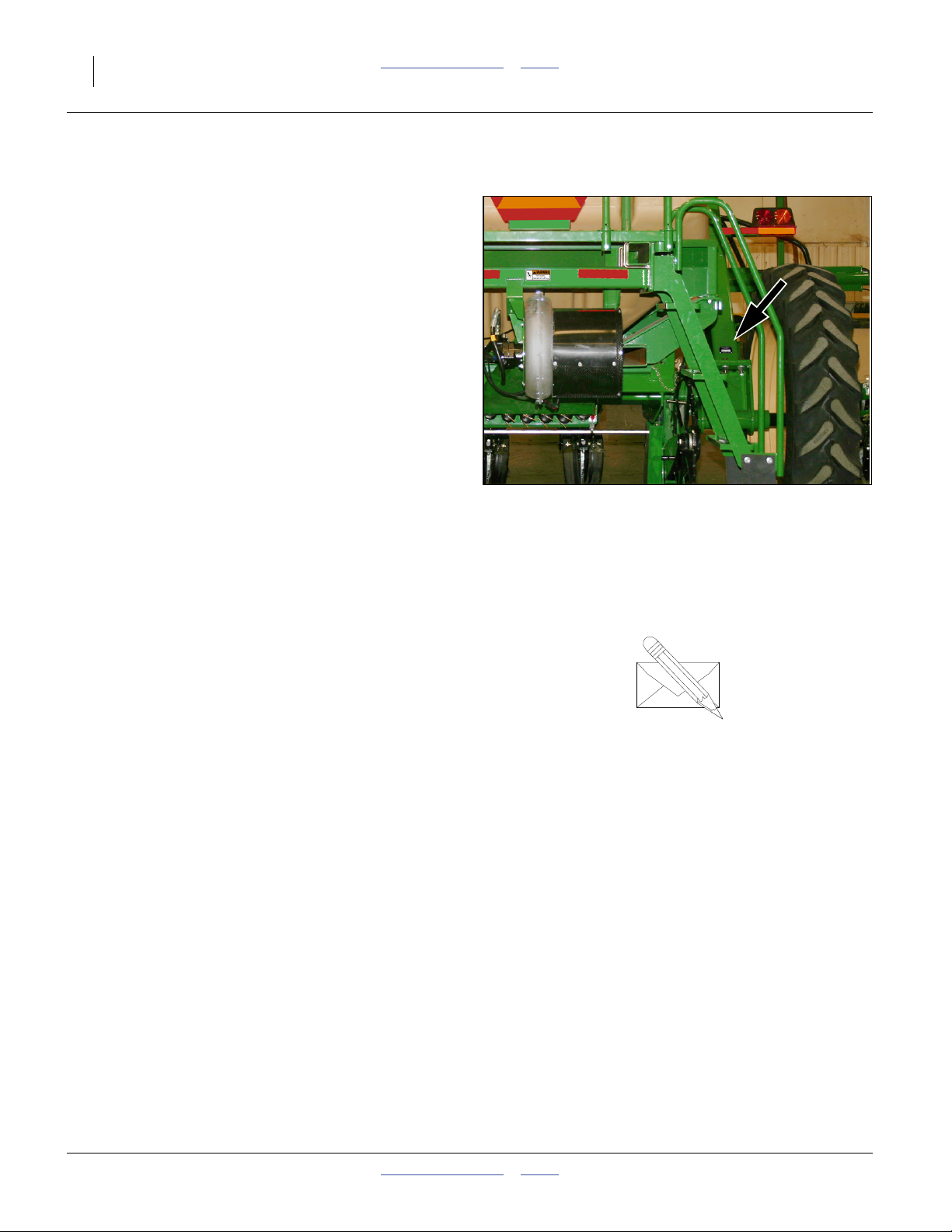

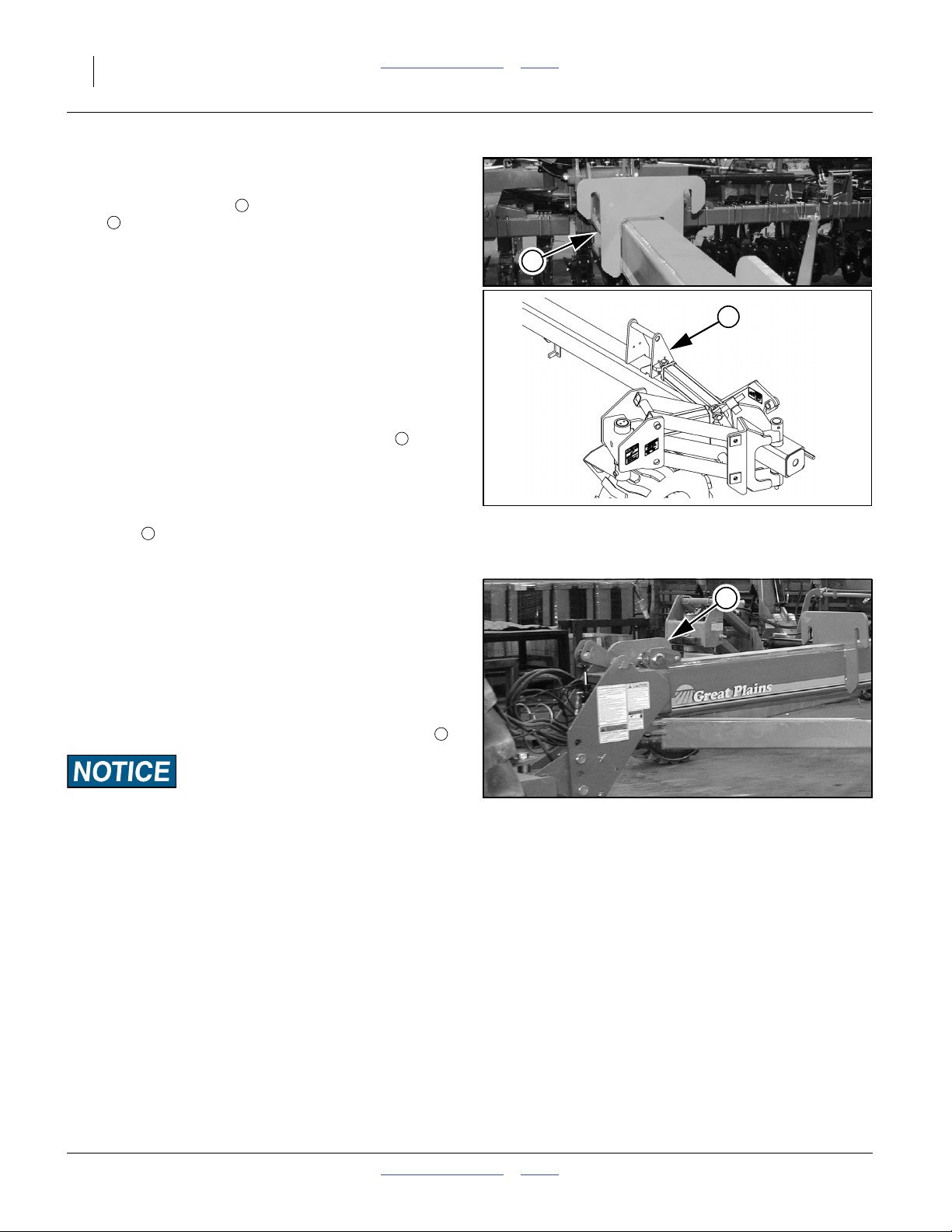

Refer to Figure 2

Your planter’s parts were specially designed and should

only be replaced with Great Plains parts. Always use the

serial and model number when ordering parts from your

Great Plains dealer. The serial-number plate is located

near the right main transport tire, on the rear face of the

right riser of the front frame weldment.

Record your Planter model and serial number here for

quick reference:

Model Number:__________________________

Serial Number: __________________________

Your Great Plains dealer wants you to be satisfied with

your new machine. If you do not understand any part of

this manual or are not satisfied with the service received,

please take the following actions.

1. Discuss the matter with your dealership service

manager. Make sure they are aware of any problems

so they can assist you.

2. If you are still unsatisfied, seek out the owner or

general manager of the dealership.

Figure 2

Serial Number Plate

For further assistance write to:

Product Support

Great Plains Mfg. Inc., Service Department

PO Box 5060

Salina, KS 67402-5060

34535

401-832M Table of Contents Index 2012-12-27

Great Plains Manufacturing, Inc. Table of Contents Index 17

Preparation and Setup

This section helps you prepare your tractor and planter

for use. Before using the YP1630F in the field, you must

hitch the planter to a suitable tractor and level the

planter.

Initial Setup

If the planter has just been delivered, or broken down for

re-shipment, these items need to be completed prior to

first field use:

“Appendix C - Initial Setup” on page 120, which

includes:

“Hydraulic Charge and Bleed” page 120,

“Seed Monitor Console Installation” page 120,

“Seed Monitor Console Quick-Start” page 120,

“Level Planter” page 123,

“Wing Alignment” page 124,

“Speed Calibration” page 125, and

“Marker Extension” on page 125.

You may also need to install features, options and

accessories that were not factory- or dealer-installed.

Pre-Planting Setup

The balance of this section covers items that need to be

completed or checked prior to each field use of the

planter.

1. Read and understand “Important Safety

Information” on page 1.

2. Check that all working parts are moving freely, bolts

are tight, and cotter pins are spread.

3. Check that all grease fittings are in place and

lubricated. See “Lubrication” on page 98.

4. Check that all safety decals and reflectors are

correctly located and legible. Replace if damaged.

See “Safety Decals” on page 6.

5. Inflate tires to pressure recommended and tighten

wheel bolts as specified. See “Tire Inflation Chart”

on page 111.

6. If returning the planter to service from storage,

remove any grease used to protect cylinder rods.

2012-12-27 Table of Contents Index 401-832M

18 YP1630F Table of Contents Index Great Plains Manufacturing, Inc.

Hitching Tractor to Planter

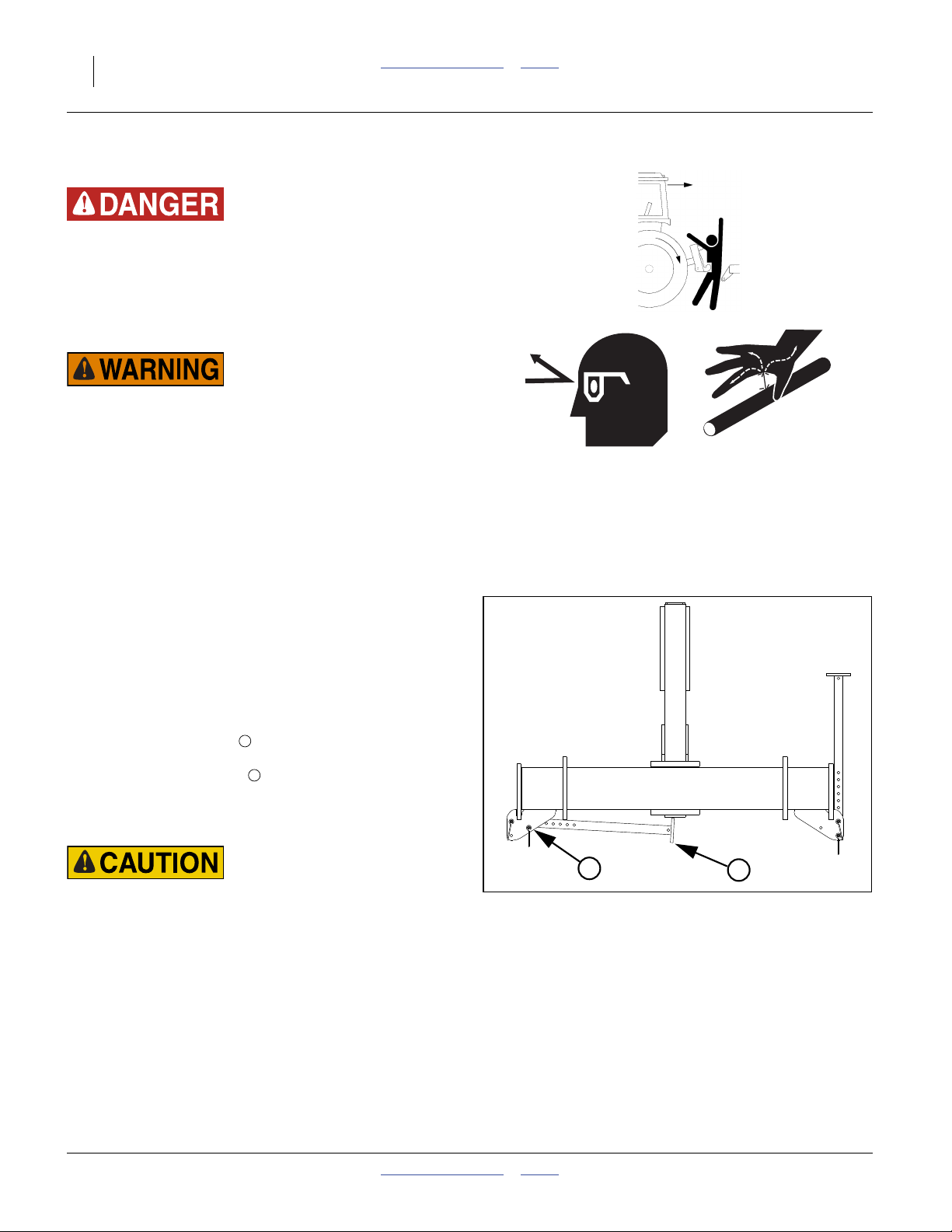

Crushing Hazard:

Do not stand or place any part of your body between planter

and moving tractor. You may be severely injured or killed by

being crushed between the tractor and planter. Stop tractor

engine and set park brake before attaching cables and hoses.

Hydraulic Hookup

High Pressure Fluid Hazard:

Relieve pressure before disconnecting hydraulic lines.

Escaping fluid under pressure can have sufficient pressure to

penetrate the skin causing serious injury. Use a piece of paper

or cardboard, NOT BODY PARTS, to check for leaks. Wear

protective gloves and safety glasses or goggles when working

with hydraulic systems. If an accident occurs, seek immediate

medical attention from a physician familiar with this type of

injury.

3-Point Hitch

Refer to Figure 3

7. Connect your tractor 3-point to the planter 3-point

hitch. If using quick hitch be sure planter locks into

hitch securely.

8. Set tractor brakes and/or put tractor in Park.

9. Raise tractor 3-point just enough to relieve pressure

off of the parking stand.

10. Store 3-point stands . There are two methods:

a. Remove lower pins . Swing stand under hitch.

Reinsert pin beneath stand at inner hole.

b. Remove both pins. Invert stand. Re-pin.

Load Sway Hazard:

Adjust 3-point hitch arms and sway blocks to minimize any

side-to-side sway to assure proper tracking in the field, and

safe road travel.

1

2

2

Figure 3

3-Point Hitch Stands Stored

1

29732

401-832M Table of Contents Index 2012-12-27

Great Plains Manufacturing, Inc. Table of Contents Index Preparation and Setup 19

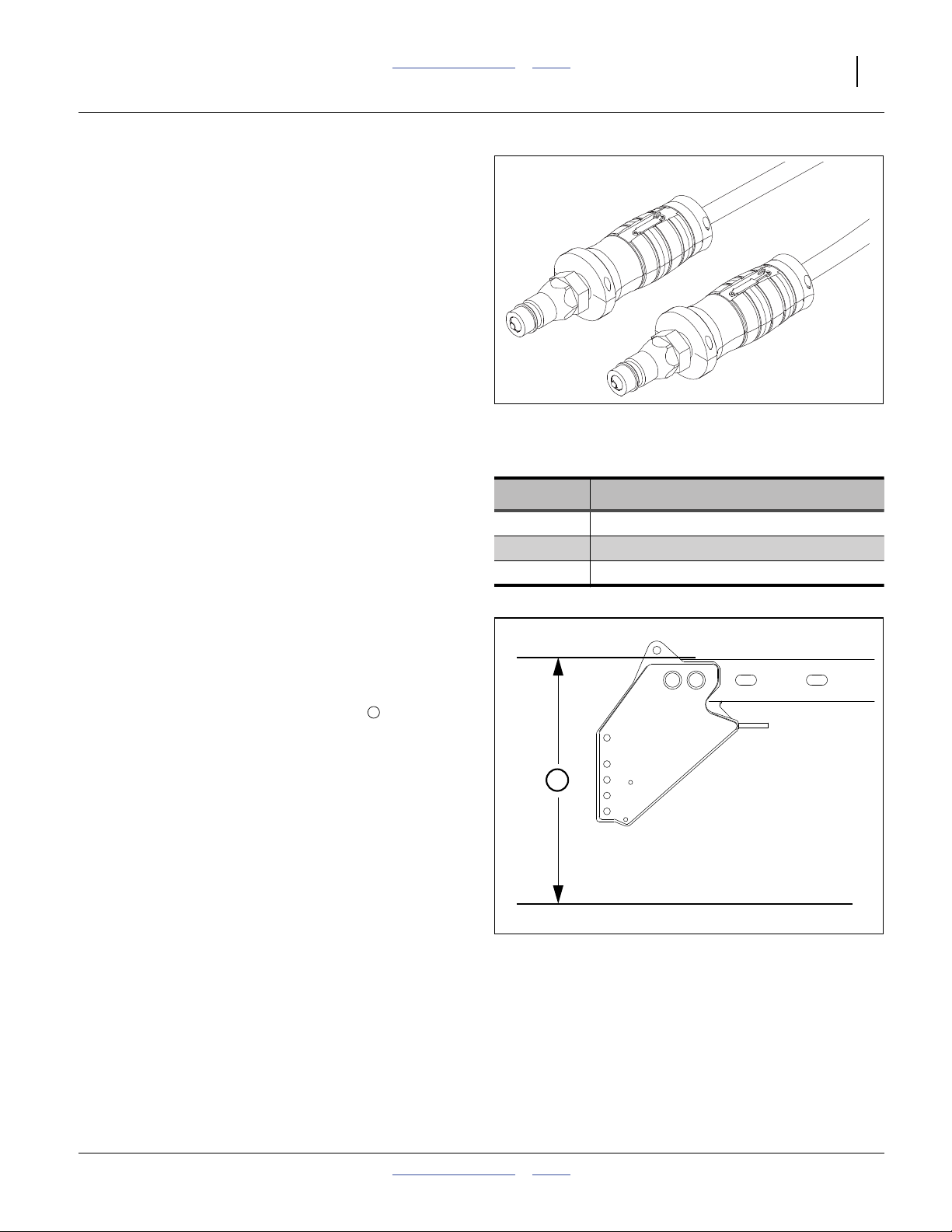

Hydraulic Hose Hookup

Refer to Figure 4

Great Plains hydraulic hoses have color coded handle

grips to help you hookup hoses to your tractor outlets.

Hoses that go to the same remote valve are marked with

the same color.

To distinguish hoses on the same hydraulic circuit, refer

to the symbol molded into the handle grip. Hoses with an

extended-cylinder symbol feed cylinder base ends.

Hoses with a retracted-cylinder symbol feed cylinder rod

ends.

For hydraulic fan and drive motors, connect the hose

under the retracted cylinder symbol to the pressure side

of the motor. Connect the hose under the extended

cylinder symbol to the return side of the motor.

If the tractor has a limited number of remotes capable of

continuous flow, use one for the hydraulic fan. (See

“Specifications and Capacities” on page 110 for tractor

requirements.)

Figure 4

Color Coded Hose Handles

Color Coded Hose Handles

Color Hydraulic Function

Gray Fold/Marker

Blue Lift

Black Fan

31733

Raising/Lowering Tongue

In addition to hitching, tongue raising and lowering is

required during fold and unfold to engage and disengage

the wing locks. The planter tongue is raised and lowered

by raising and lowering the 3-point.

11. Set the initial tongue height. Distance , measured

h

at top of tongue tube is:

42 inches (107 cm) above ground level

Additional planter leveling information is found on

page 123.

12. Connect other hydraulic hoses to tractor remotes.

See “Hydraulic Hose Hookup” on page 19.

h

Figure 5

Tongue Height

25316

2012-12-27 Table of Contents Index 401-832M

20 YP1630F Table of Contents Index Great Plains Manufacturing, Inc.

Electrical Hookup

Refer to Figure 6 (depicting an SAE J560b lighting

connector; your connector may vary if it has been replaced

due to different electrical conventions)

Your planter is equipped with systems that require

separate electrical connections. For future reference,

note any optional connectors on this checklist.

a

❑ Lighting connector (standard)

b

❑ Monitor connector (standard, See page 120 for

console installation.)

c

❑ Speed Sensor connector (standard)

❑ __________________________

Make sure tractor is shut down with accessory power off

before making connections.

a

b

c

Figure 6

Connector Identification

25236

31033

31950

Store Main Parking Stand

Refer to Figure 7

13. Raise the 3-point hitch slightly.

14. Remove the lower pin holding the parking

stand . Swing the parking stand back and up until it

is above the rear hole . Place the holding pin in the

rear hole and allow the parking stand to rest on it.

This is the transport position for the parking stand.

15. Adjust the top link of a 3-point long enough so the

ball swivel does not bottom out when fully raised.

16. Secure hoses using hose post loops (not shown) so

that hoses have ample slack for lifts and turns, but

cannot get caught in tongue lock or ball swivel.

Failure to do so could cause hose to be crushed

requiring hose replacement.

7

5

6

6

7

Storing Parking Stand

5

Figure 7

22813

401-832M Table of Contents Index 2012-12-27

Great Plains Manufacturing, Inc. Table of Contents Index Preparation and Setup 21

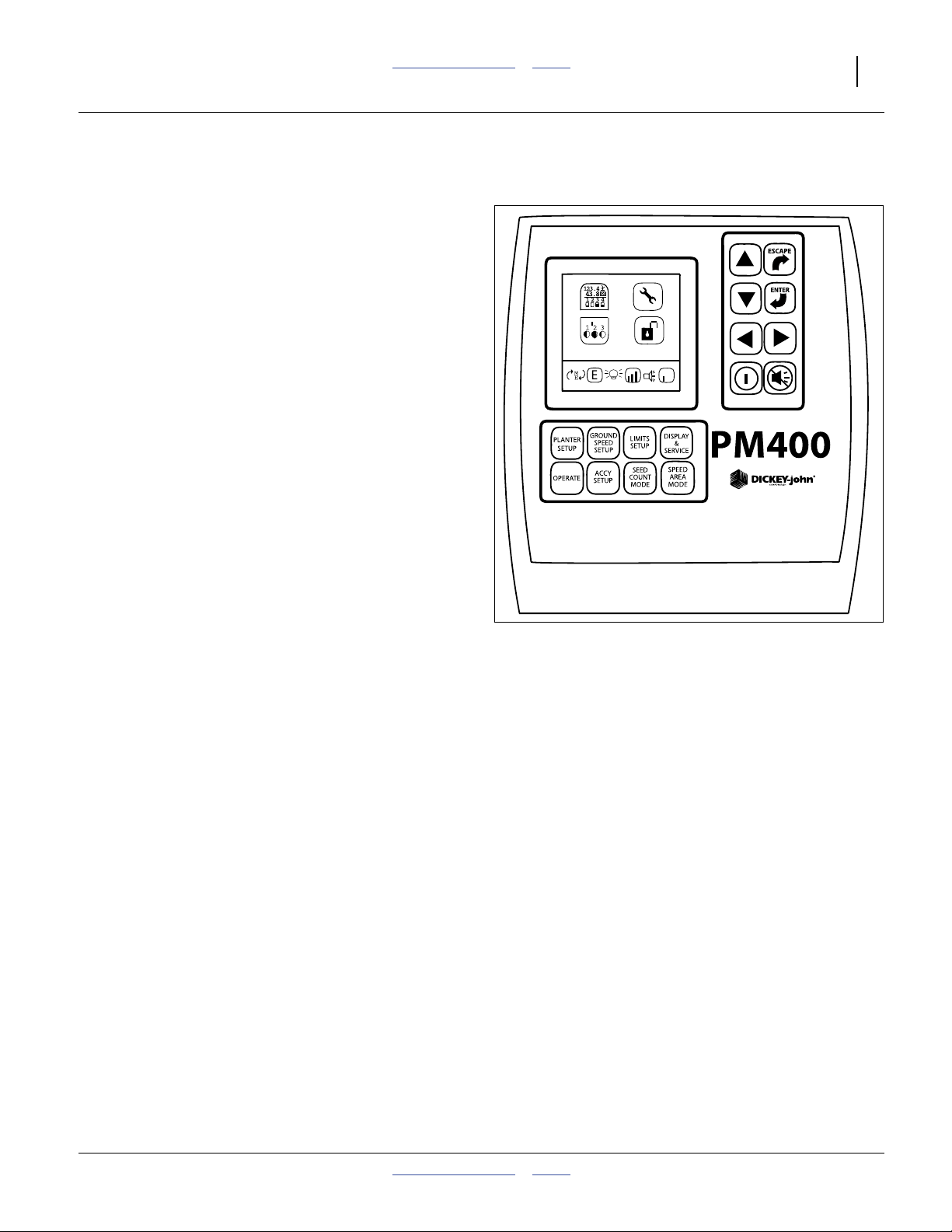

Monitor Setup

Refer to Figure 8

The standard DICKEY-john® PM400 system monitors

the following elements of a YP1630F planter:

• seeds at each row unit seed tube;

• dry fertilizer at each tower outlet;

• ground speed; and,

• fertilizer meter shaft speed.

See “Seed Monitor Console Installation” on page 120.

Refer to the DICKEY-john® PM400 Console Manual

(11001-1372) for monitor operations.

After installation, and prior to first field use, the monitor

must be setup with the row spacing and speed sensor

constant, as well as your preferences for information

display. Row count is auto-assigned, but any other

DICKEY-john

your planter.

Row spacing data may be found in the Appendix.

For speed setup, Great Plains recommends using the

122 m (400-foot) speed calibration described in the

DICKEY-john® manual. Perform the calibration run in

representative field conditions, as soil conditions, surface

looseness and other tillage practices can cause

variations in the effective rolling radius of the ground

drive wheel.

Prior to each planting session, set any desired limits for

speed and population for the current crop.

®

defaults are not likely to be correct for

Figure 8

Monitor Primary Screen

31807

Marker Setup (Option)

Prior to first use, check and adjust:

•“Dual Marker Speed Adjustment” on page 49.

Prior to first use, and whenever changing row spacings,

set or reset:

•“Marker Extension” on page 125.

Prior to each planting session, check and adjust:

•“Marker Disk Adjustment” on page 49.

2012-12-27 Table of Contents Index 401-832M

22 YP1630F Table of Contents Index Great Plains Manufacturing, Inc.

Operating Instructions

This section covers general operating procedures.

Experience, machine familiarity and the following

information will lead to efficient operation and good

working habits. Always operate farm machinery with

safety in mind.

Pre-Start Checklist

1. Carefully read “Important Safety Information” on

page 1.

2. Lubricate planter as indicated under “Lubrication”

on page 98.

3. Check all tires for proper inflation. See “Tire

Inflation Chart” on page 111.

4. Check all bolts, pins and fasteners. Torque as shown

in “Torque Values Chart” on page 119.

5. Check planter for worn or damaged parts. Repair or

replace parts before going to the field.

6. Check hydraulic hoses, fittings and cylinders for

leaks. Repair or replace before going to the field.

7. Be sure hydraulic hoses are securely held out of the

ball swivel area at hitch. Failure to do so could cause

hoses to pinch requiring hose replacement.

High Pressure Fluid Hazard:

Check all hydraulic lines and fittings before applying pressure.

Escaping fluid under pressure can have sufficient pressure to

penetrate the skin. Fluid escaping from a very small hole can

be almost invisible. Use paper or cardboard, not body parts,

and wear heavy gloves to check for suspected leaks. If an

accident occurs, seek immediate medical attention from a

physician familiar with this type of injury.

1

4

2

2

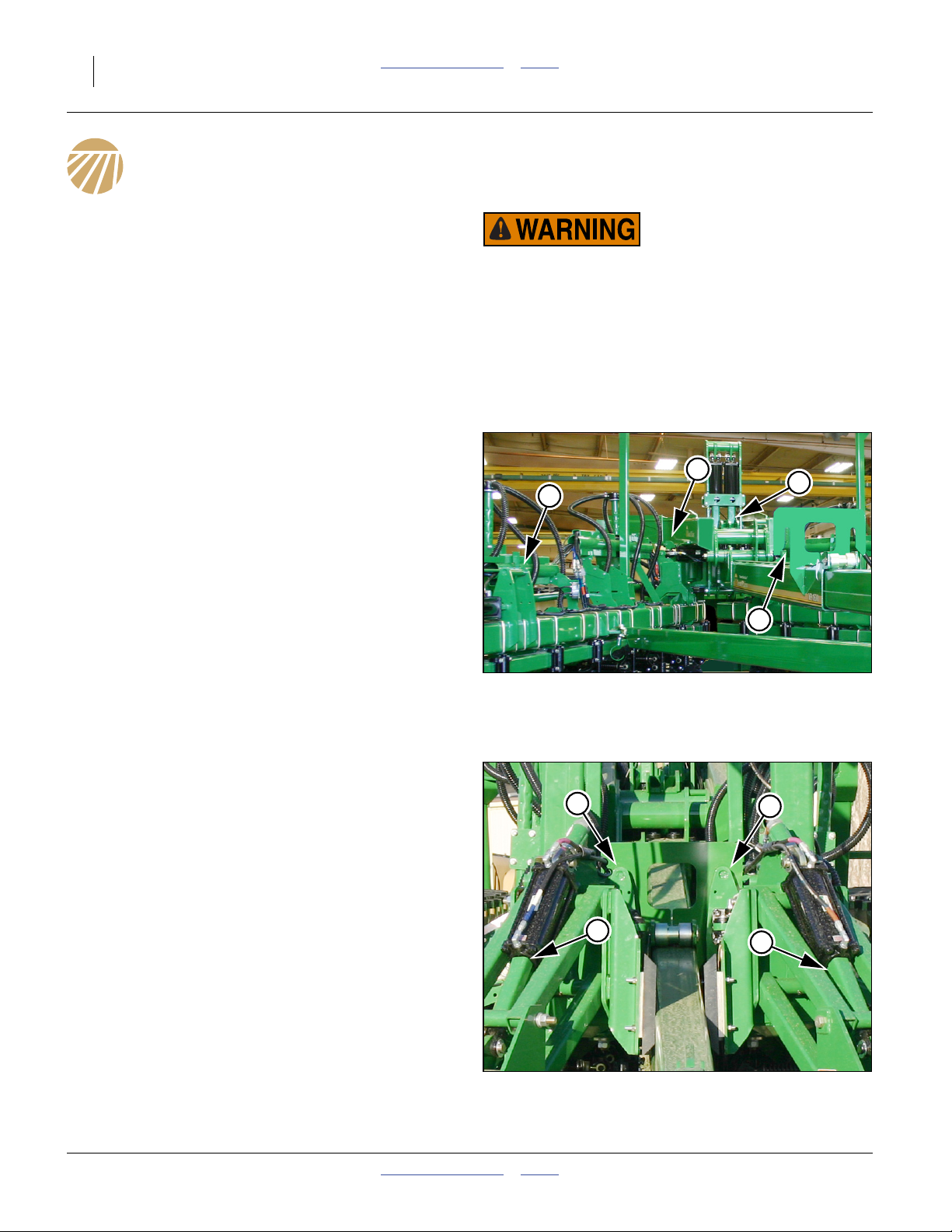

Wing Lock Overview

Refer to Figure 9 and Figure 10

The YP1630F planters include four sets of locks for the

frame and wings:

1. Transport hooks behind the wing pivots:

These prevent the planter frame from fully lowering

when folded. The planter frame is raised to allow the

wings to clear the hooks. See page 23 and 28.

2. Wing locks at mid-tongue and inside wing casters:

These prevent the planter from unfolding while in

transport. The tongue (hitch) is raised to allow the

hooks to clear the locks. See page 24 and 28.

3. Transport lock channels at wing caster cylinders:

These lock channels prevent the frame from fully

lowering during transport and maintenance. They

are installed prior to folding, and removed after

unfolding. See page 25 and 29.

4. Lift cylinder lock channels above frame pivots:

These lock channels are only required during

maintenance. However, if installed, they must be

removed after unfolding. See page 25 and 73.

Figure 9

Lift Locks and Transport Hook

2

3

Figure 10

Wing Lock and Transport Locks

2

3

34571

34550

401-832M Table of Contents Index 2012-12-27

Great Plains Manufacturing, Inc. Table of Contents Index Operating Instructions 23

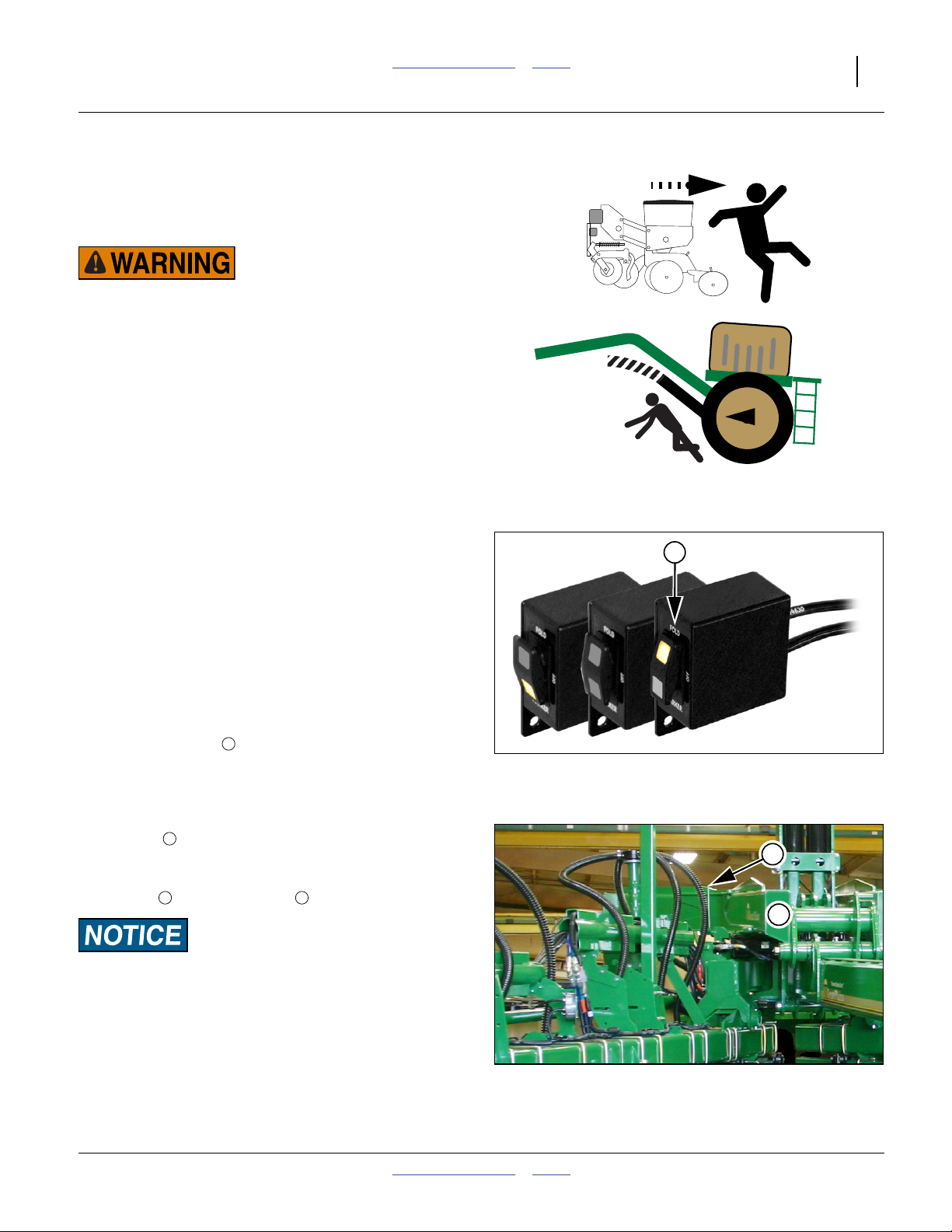

Unfolding the Planter

The distance between the tractor and the central cart

decreases by about 10 feet (3 m) during unfolding.

Planter, tractor, or both will move during this operation.

Crushing, Pinch-Point and Overhead Hazards:

To prevent serious injury or death:

▲ Unfold only on hard level ground. Allow ample room.

▲ Allow no one on or near the planter during unfolding.

▲ Stay clear of the wing sweep arcs. The sweep arcs of the

wings have numerous pinch and crush points in the

mechanism. Coulters and row openers are sharp.

▲ Allow no one near planter during unfold. The fertilizer cart

usually moves forward during unfolding.

▲ Do not unfold with planter lowered.

▲ Unfold only with markers resting in transport cradles.

▲ Unfold only if hydraulics are bled free of air and fully

charged with hydraulic oil.

F

Prepare Hitched Tractor and Planter

1. Move planter to level ground.

2. If tractor movement is not desired, put tractor in Park

and/or set parking brakes, or telescoping movement

of planter may cause tractor to move backward.

Prepare Transport Hooks

Refer to Figure 12

The transport hooks , behind/above wing pivots,

prevent the frame from fully lowering when the planter is

fully folded. To clear the hooks, the frame is fully raised.

Refer to Figure 11

3. Set Hydraulic Selector Marker/Fold switch to

“FOLD” to enable fold cylinder hydraulics.

4. Activate lift hydraulics. Raise planter until lift

hydraulics are fully raised. This raises the wing

frames above the hooks .

Planter Damage Risk:

Be sure planter’s lift hydraulics are fully raised before

unfolding or frame and/or hook damage WILL occur.

F

6 5

5

Figure 11

Hydraulic Selector Switch

34552

5

6

Figure 12

Transport Hook

2012-12-27 Table of Contents Index 401-832M

34571

24 YP1630F Table of Contents Index Great Plains Manufacturing, Inc.

Release Wing Locks

Refer to Figure 13

A pair of inverted hooks on the tongue tube engage

8

locks on each wing when the planter is folded.

Prior to unfolding, this lock system must be released by

raising the tongue. Raise the 3-point hitch to disengage

the wing lock.

7

7

Re-Phase Fold Cylinders

5. The fold system uses re-phasing cylinders. It is

necessary to re-phase cylinders so wing gauge

wheels run in their fully rotated positions in front of

planter. To re-phase fold cylinders:

Move and hold lever for Marker/Fold in Fold direction

(typically Extend) for 30 seconds. This causes wings

to push against the tongue transport hooks .

7

Partially Unfold

Refer to Figure 13

6. Reverse fold circuit lever until wings clear transport

hooks by a few feet.

7

Lower Tongue

7. Lower 3-point hitch or hydraulic tongue to planting

position. See page 19 and page 123 for correct hitch

height and depth control settings.

Fully Unfold

Refer to Figure 14

8. Unfold the planter fully to planting position. Unfolding

is complete when the large roller bushing on top of

the tongue is engaged by the tongue safety latch .

9

8

Figure 13

Wing Hook & Wing Lock

9

22815

27288

Planter Damage Risk:

Do not plant if the tongue latch is not fully down over the

roller. Frame and opener damage is likely if the planter is

operated with the latch open.

401-832M Table of Contents Index 2012-12-27

Figure 14

Tongue Latch Engaged

28488

Great Plains Manufacturing, Inc. Table of Contents Index Operating Instructions 25

Remove and Store Transport Locks

The planter needs to still be in full lift to remove these

locks.

Remove/Store Center Lift Locks

Refer to Figure 15

9. Remove lock channels from vertical cylinders

above pivots.

1

2

2

1

Refer to Figure 15 and Figure 16

10. Store lock channels horizontally on tubes at sides

of lift cylinder weldment.

2

Figure 15

Frame Lift Locks Installed

2

Figure 16

Lift Cylinder Lock Stored

34550

34549

2012-12-27 Table of Contents Index 401-832M

26 YP1630F Table of Contents Index Great Plains Manufacturing, Inc.

Remove/Store Caster Lift Locks

Refer to Figure 17

11. Remove transport lock channels from lift cylinders

located on gauge wheels.

Refer to Figure 17 and Figure 18

12. Transfer lift cylinder transport lock channels to

their storage positions .

4

3

3

3

Unfold Closeout

13. As appropriate for the next planned activity, activate

lift hydraulics and lower planter.

14. To disable fold hydraulics, and lock caster arms in

field position, set Hydraulic Selector Marker/Fold

switch ( or in Figure 19 on page 27) to center/off

or Marker.

Note: The center/off switch position disables all

M O

Fold/Marker solenoid valves.

4

Figure 17

Caster Lift Cylinder Lock

34550

3

4

Figure 18

Transport Cylinder Lock Storage

27290

401-832M Table of Contents Index 2012-12-27

Loading...

Loading...