Great Plains YP1630F-1670 User Manual

Table of Contents Appendix

Manufacturing, Inc.

www.greatplainsmfg.com

Seed, Fertilizer and Treatment Rate

Charts for

Model YP1630F Planters

The following pages are to assist in the proper setting of seeding and

fertilizer rates for the planter.

To assure the most accurate application rates it is recommended that the planter be calibrated for the

desired materials at the time of planting.

ORIGINAL INSTRUCTIONS

© Copyright 2012 Printed 2012-12-04 401-832B

EN

Great Plains Manufacturing, Inc. Cover Appendix ii

Table of Contents

Introduction ..................................................................1

Models Covered .............................................................1

Setting Material Rates ....................................................1

Seed Rate ......................................................................2

About Finger Meter Charts .............................................2

Reading a Finger Meter Chart....................................3

About Brush Meter Charts..............................................4

Reading a Brush Meter Chart.....................................4

Seed Drive Setup ...........................................................5

Sprocket Storage........................................................5

Range Setup ..............................................................5

Transmission Setup....................................................6

Checking Planting Rate..................................................6

Checking Singulated Rates ........................................7

Seed Rate Charts...........................................................8

12 Finger Meter ..........................................................8

70 cm, Low Range..................................................8

70 cm, High Range.................................................9

30 inch, Low Range..............................................10

30 inch, High Range .............................................11

76.2 cm, Low Range.............................................12

76.2 cm, High Range............................................13

Brush Meter..............................................................14

70 cm....................................................................14

30 inch ..................................................................15

76.2 cm.................................................................16

Fertilizer Rate..............................................................17

Reading a Fertilizer Rate Chart................................17

Fertilizer Range Gears .............................................18

Setting Variable Rate Gearbox.................................18

Fertilizer Meter Calibration .......................................19

Density Adjustment ..............................................19

Fertilizer Rate Charts ................................................... 22

Fertilizer Low Range, 70 cm ....................................22

Fertilizer High Range, 70 cm....................................23

Fertilizer Low Range, 30 inch...................................24

Fertilizer High Range, 30 inch..................................25

Treatment Rate (Option)............................................26

Treatment Compatibility .......................................27

Reading a Treatment Rate Chart.................................27

Treatment Rate Calibration..........................................28

Treatment Rate Calibration Steps............................28

Collect A Treatment Sample ................................29

Calculate the Treatment Rate ..............................29

Treatment Rate Charts ................................................30

Herbicide, Clay Granules ......................................... 30

70 cm ...................................................................30

30 inch.................................................................. 31

76.2 cm (30 inch) .................................................32

Insecticide, Clay Granules .......................................33

70 cm ...................................................................33

30 inch.................................................................. 34

76.2 cm (30 inch) .................................................35

Sand Granules ......................................................... 36

70 cm ...................................................................36

30 inch.................................................................. 37

76.2 cm (30 inch) .................................................38

Appendix..................................................................... 39

Finger Meter Brush Adjustment ...................................39

© Copyright 2012 All rights Reserved

Great Plains Manufacturing, Inc. provides this publication “as is” without warranty of any kind, either expressed or implied. While every precaution has been

taken in the preparation of this manual, Great Plains Manufacturing, Inc. assumes no responsibility for errors or omissions. Neither is any liability assumed for

damages resulting from the use of the information contained herein. Great Plains Manufacturing, Inc. reserves the right to revise and improve its products as

it sees fit. This publication describes the state of this product at the time of its publication, and may not reflect the product in the future.

2012-12-04 Cover Appendix 401-832B

Trademarks of Great Plains Manufacturing, Inc. include: Singulator Plus, Swath Command, Terra-Tine.

Registered Trademarks of Great Plains Manufacturing, Inc. include:

Air-Pro, Clear-Shot, Discovator, Great Plains, Land Pride, MeterCone, Nutri-Pro, Seed-Lok, Solid Stand,

Terra-Guard, Turbo-Chisel, Turbo-Chopper, Turbo Max, Turbo-Till, Ultra-Till, Verti-Till, Whirlfilter, Yield-Pro.

Brand and Product Names that appear and are owned by others are trademarks of their respective owners.

Printed in the United States of America

Great Plains Manufacturing, Inc. Contents Appendix 1

Introduction

This manual is your guide to planter adjustments for

achieving specific seed population, fertilizer density and

treatment density targets.

Although some setup/adjustment material herein is

repeated from the planter Operator Manuals, you need to

be thoroughly familiar with planter operations and

adjustments before applying rate data from this manual.

Models Covered

5

This manual covers the following Great Plains 16-row

planter models. Not all models are available in all locales.

YP1630F-1630ND 30 inch, Narrow, Single row hopper

YP1630F-1630NS 30 inch, Narrow, Single row hopper

YP1630F-1630WD30 inch, Wide, Dual row hopper

YP1630F-1630WS 30 inch, Wide, Single row hopper

YP1630F-1670ND 70 cm, Narrow, Dual row hopper

YP1630F-1670NS 70 cm, Narrow, Single row hopper

YP1630F-1670WD70 cm, Wide, Dual row hopper

YP1630F-1670WS 70 cm, Wide, Single row hopper

Setting Material Rates

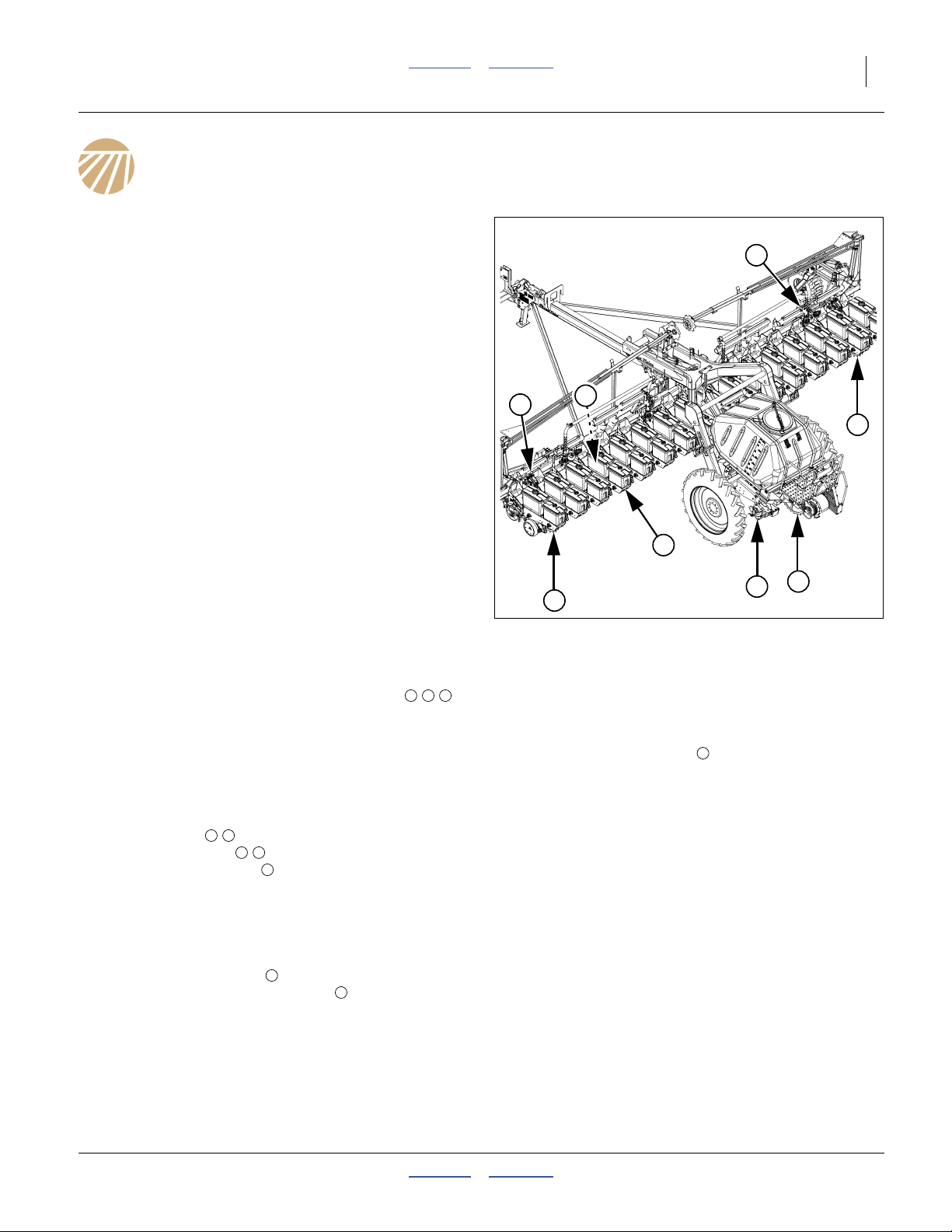

Refer to Figure 1

The YP1630F has three ground drive systems ( , , )

and three metering systems. Two of the metering

systems share a drive system. Details for rate settings,

and rate charts, are found in this manual. This page

provides an overview of the systems.

Planting (Seed) Rate (page 2)

Seed rate is controlled by Range and Transmission

sprocket pairings ( , ) on each of two separate wing

ground drive systems ( , ) and by seed meter

configuration at each row ( , hidden by hopper). The

seed monitor console reports field rates for most seed

types.

4 5

1 2

6

Fertilizer Rate (page 17)

Dry fertilizer rate, from the central hopper, is controlled

by a variable rate gear box under the left side of the

hopper. The associated ground drive , under the right

side, has no adjustments. Fertilizer is delivered by the air

system, with blockage detection at the rows. The air

system must be adjusted to optimal pressure, but does

not adjust rate.

7

3

1 2 3

4

6

2

8

3

7

1

Figure 1

Planter Drive Systems

Treatment Rate (page 26, Option)

Planters with the optional second row hopper can deliver

a variety of granular materials with this system. Rate is

controlled by a knob and dial at each row. The

treatment meters have an agitator roller which shares the

seed drive system, but changes in seed rate sprockets

have only a minor effect on treatment rate.

About the Charts

The rate charts are independent of planter width and row

spacing. All charts except treatment are relatively

insensitive to ground speed.

Note: Units of Measure:

This manual provides most values in dual units of

measure (metric and U.S. customary).

8

34461

2012-12-04 Contents Appendix 401-832B

2 Great Plains Manufacturing, Inc. Contents Appendix YP1630F

Seed Rate

Rates are set separately for seed, fertilizer (page 17) and

treatments (Option, page 26).

Seed rate is determined by:

1. consulting the seed rate charts,

2. installing the correct meter (in the case of finger

meters, the appropriate finger sets, inserts and

brushes, and in the case of the brush meter, the

appropriate seed plates),

3. setting the Range and Transmission driving/driven

sprocket combinations on each wing, and

4. checking the rate.

There are separate charts for brush and finger pickup

meters. If you are unfamiliar with the charts, see

“Reading a Brush Meter Chart” below or “Reading a

Brush Meter Chart” on page 4.

To change meters, see “Exchanging Meters” in the

Operator manual.

Figure 2

Brush and Finger Pickup Meters

28133

About Finger Meter Charts

The charts are for meters with 12-fingers, and apply to

both Corn and Sunflower configurations.

1

2

3

Some sizes of sunflower seeds meter more reliably with

the corn finger set, insert and brush. See the table below.

See the Operator manual (401-832M) for meter

reconfiguration instructions.

Figure 3

22908

Finger Pickup Components

Finger Pickup: Sunflower Configurations

Oil Seed Size Confection Seed

#4 #3 #2

Meter Component

Finger Set

~16500 seeds/kg

(~7500 seeds/pound)

343067

s

~14300 seeds/kg

(~6500 seeds/pound)

343067

s

~12100 seeds/kg

(~5500 seeds/pound)

343029

c

(12-finger sunflower) (12-finger sunflower) (12-finger corn)

Backing Plate

342108

s

342108

s

342110

c

(Insert C) (Insert C) (Insert A)

Brush Block

343091

(brushless

s

343091

(brushless

block)

c. These components are included in the standard 890-856C Corn meter. 34573

s. These components are included in the standard 890-912C Sunflower meter, and the 403-659A Conversion Kit.

block)

s

343052

c

(adjustable

brush block)

(long, narrow, XL)

~6600 seeds/kg

(~3000 seeds/pound)

Not

recommended

for XL

confection

seed

401-832B Contents Appendix 2012-12-04

Great Plains Manufacturing, Inc. Contents Appendix Seed Rate 3

.

M

20 G

d

For Round Corn optimum meter speed is 45 to 75 RPM

0

M

(

30

h

r

)

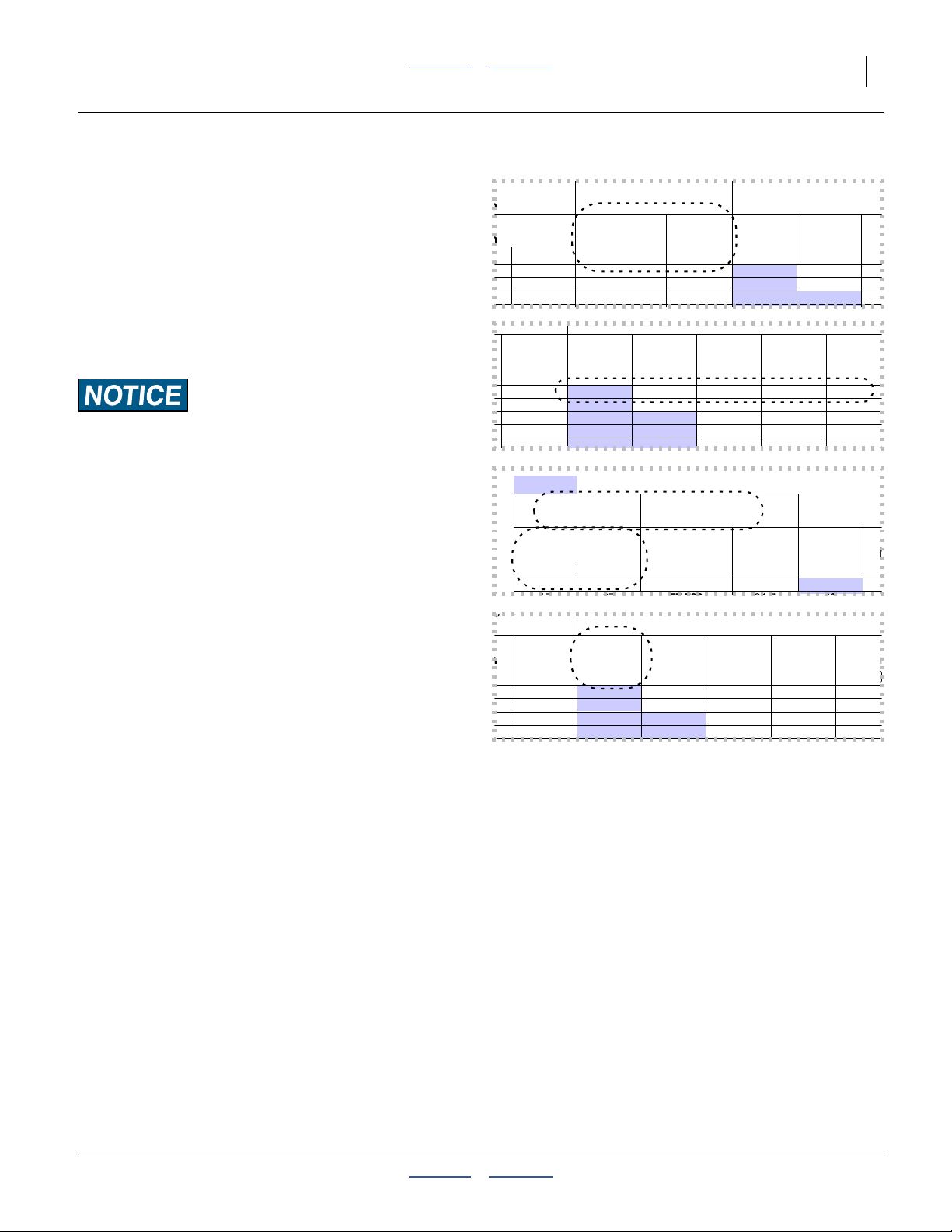

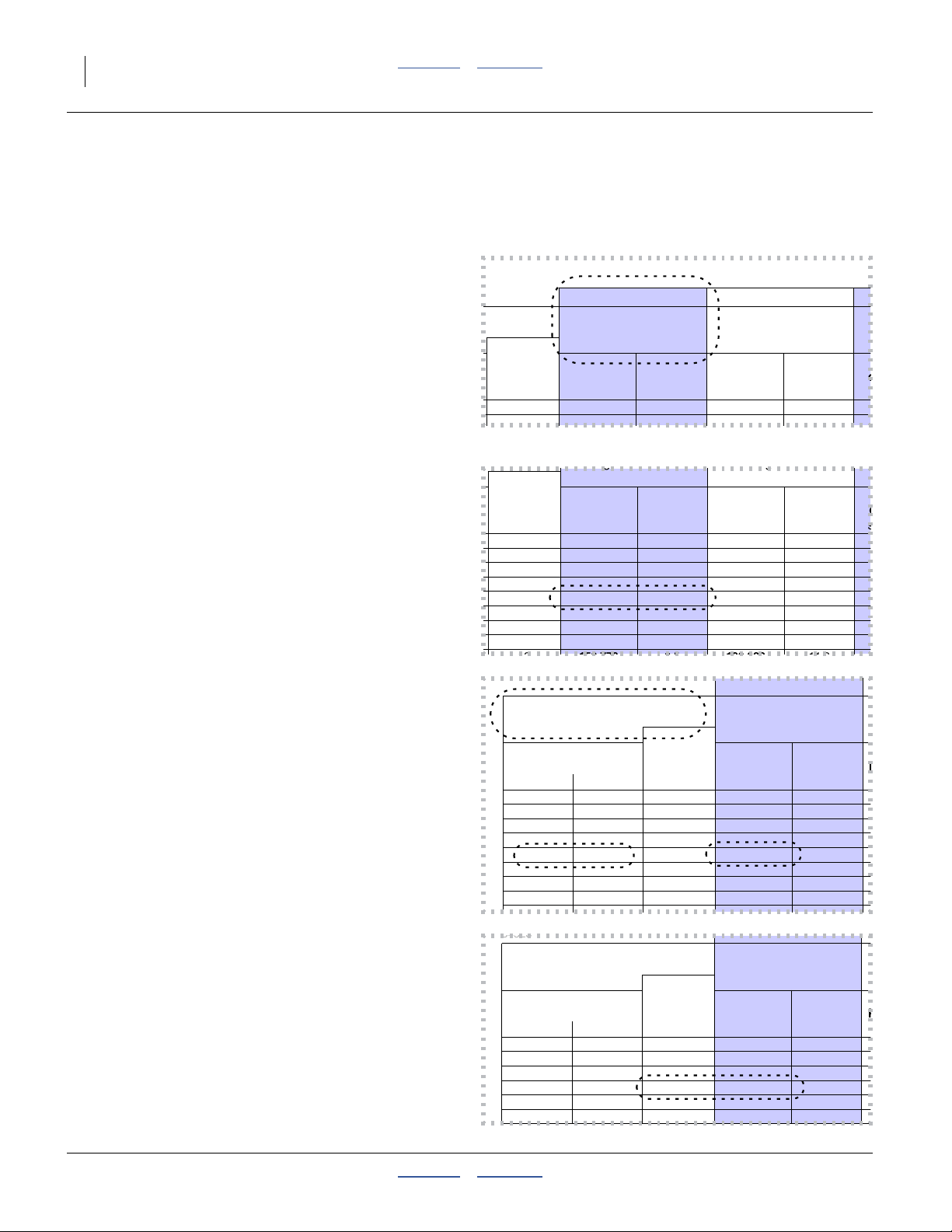

Reading a Finger Meter Chart

Note: Actual charts begin on page 8.

Images at right are excerpts.

Seed Rate: Population

1. Find the chart (Low or High range) which covers your

population.

2. Find the desired seed population or seed spacing.

Seed Rate: Meter rpms

3. Note the range of meter rpms suitable for that

population.

Inconsistent Population Risk:

The shaded rpms are the recommended rpms for most

consistent results. Use the recommended driving speed if

possible. The unshaded rpms are acceptable. Blank cells are

outside the range of reliable meter operation.

Seed Rate: Sprocket Combinations

4. Configure the Range and Transmission sprockets.

The numbers in the Driving/Driven columns are the

number of teeth (T) stamped on the sprockets

required.

Seed Rate: Planting Ground Speed

5. Observe the recommended planting speed. Speed

directly controls meter rpm.

ange Driving =30

rockets

smission

binations Population Spacing

Driven (seeds/ha) (cm)

28

27

26

=

Seed

Spacing

(cm)

25.6

24.7

23.8

22.9

Driven =

20

Seed Seed

55 735

57 799

60 022

11.3 kph 10.5 kph 9.7 kph 8.9 kph 8 kph

Meter Meter Meter Meter Meter

(rpm) (rpm) (rpm) (rpm) (rpm)

61 57 52 48

63 59 54 50 45

66 61 56 52 47

68 63 58 54 49

25.6

24.7

23.8

11.3 kph 10.5 kph 9

Meter Meter

(rpm) (rpm) (

61 57

63 59

66 61

round Spee

( Shaded & Non-shaded areas )

Range Driving =30

Sprockets

Transmission

Combinations Population Spacing

Driving Driven (seeds/ha) (cm)

17 28

=

20 Ground Speed

Seed

Spacing

(cm)

25.6

24.7

23.8

22.9

11.3 kph 10.5 kph 9.7 kph 8.9 kph 8 kp

Meter Meter Meter Meter Mete

(rpm) (rpm) (rpm) (rpm) (rpm

61 57 52 48

63 59 54 50 45

66 61 56 52 47

68 63 58 54 49

Driven =

20

Seed Seed

55 735

25.6

11.3 kph 1

Meter

(rpm)

61

2012-12-04 Contents Appendix 401-832B

4 Great Plains Manufacturing, Inc. Contents Appendix YP1630F

o

s

gg

o

s

P

34523

60 Cell

P

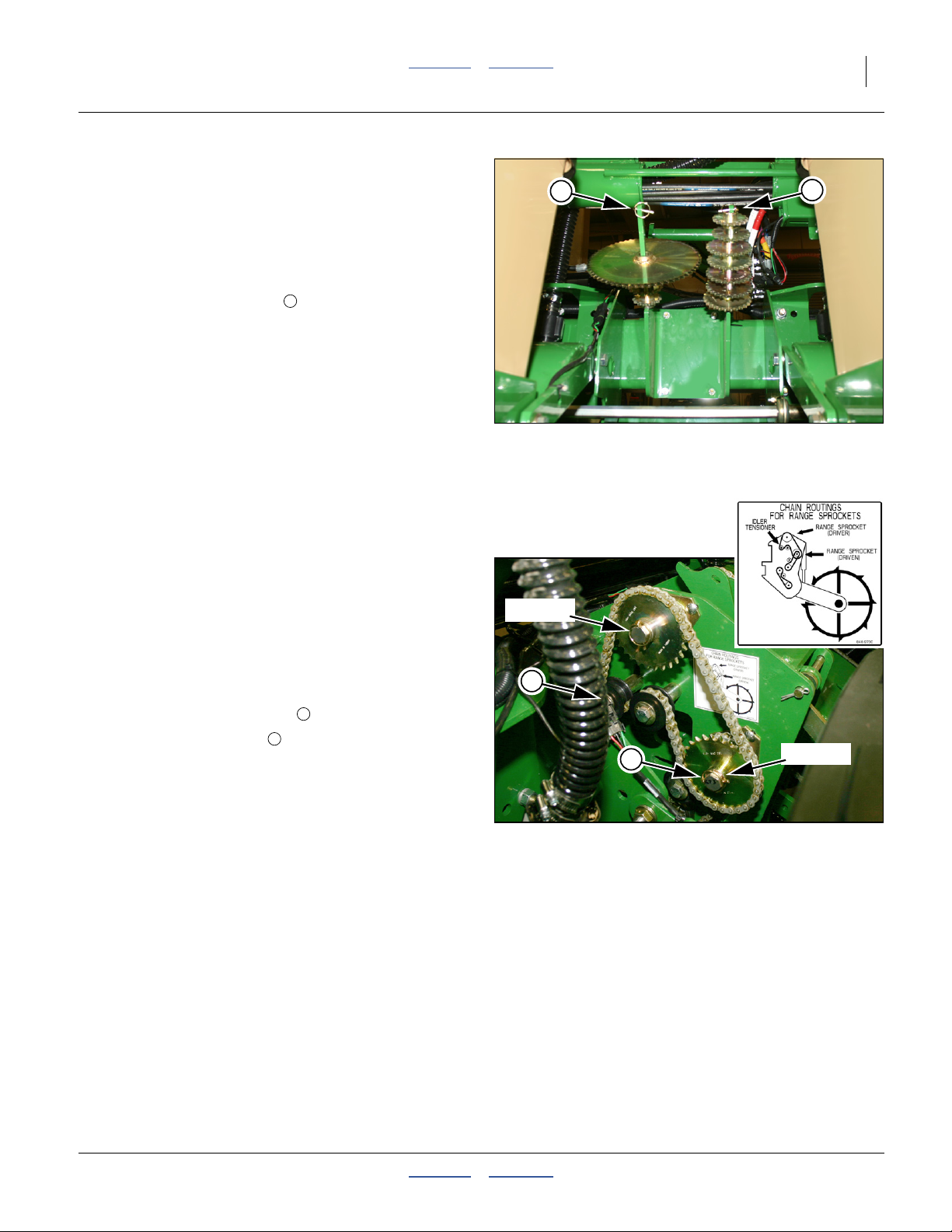

About Brush Meter Charts

The charts are for plates by cell count, and apply to any

seed compatible with the plate.

Reading a Brush Meter Chart

For brush meters, the chart has separate columns based

on the cell count of the seed plate installed. For plate

selection see “Seed Plates” in the Options section of the

Operator manual. To change plates, see “Installing

Brush Meter Plates” in the Operator manual.

Note: Actual charts begin on page 14.

Images at right are excerpts.

Seed Rate: Cell Count

1. Use the chart columns for your seed plate, based on

the cell count.

60 Cell 48 Cell

:20

:30 High Rate Milo/ High Rate

Maximum Grain Sorghum Acid-delinted Cotton

Planting Seed Seed Seed Seed

Speed Population Spacing Population Spacing P

(kph)

13

Soybean or Specialty Soybean or

(seeds/ha) (cm) (seeds/ha) (cm) (

123 853

70 cm Rows

11.5

99 083

14.4

Seed Rate: Population

2. Find the desired seed population or seed spacing.

Seed Rate: Sprocket Combinations

3. Configure the Transmission sprockets.

The numbers in the Driving/Driven columns are the

number of teeth (T) stamped on the sprockets

required.

Note: Brush meter charts use a single Range sprocket

setup: (20T Driving, 30T Driven)

Maximum Grain Sorghum Acid-delinted Cotton

Planting Seed Seed Seed Seed

Speed Population Spacing Population Spacing P

(kph)

13

13

13

13

13

13

13

13

34523

Range

(seeds/ha) (cm) (seeds/ha) (cm) (

123 853

128 441

133 381

138 424

138 716

143 551

144 496

149 072

11.5

11.1

10.7

10.3

10.3

10.0

9.9

9.6

99 083

102 752

106 704

110 739

110 973

114 841

115 596

119 258

14.4

13.9

13.4

12.9

12.9

12.4

12.4

12.0

60 Cell

Driving: 20

Soybean or

Sprockets Driven: 30 High Rate Milo/

(All Cell Counts)

Maximum Grain Sorghum

Transmission Planting Seed Seed

Combinations Speed Population Spacing

Driving Driven (kph)

17 28 13

17 27 13

17 26 13

19 28 13

17 25 13

19 27 13

17 24 13

19 26 13

(seeds/ha) (cm)

123 853

128 441

133 381

138 424

138 716

143 551

144 496

149 072

11.5

11.1

10.7

10.3

10.3

10.0

9.9

9.6

Seed Rate: Planting Ground Speed

4. Observe the range of recommended planting

speeds.

Range

Driving: 20

Soybean or

Sprockets Driven: 30 High Rate Milo/

(All Cell Counts)

Maximum Grain Sorghum

Transmission Planting Seed Seed

Combinations Speed Population Spacing

401-832B Contents Appendix 2012-12-04

Driving Driven (kph)

17 28 13

17 27 13

17 26 13

19 28 13

17 25 13

19 27 13

(seeds/ha) (cm)

123 853

128 441

133 381

138 424

138 716

143 551

11.5

11.1

10.7

10.3

10.3

10.0

Great Plains Manufacturing, Inc. Contents Appendix Seed Rate 5

Seed Drive Setup

With the meters set up, the rate is adjusted by separate

Range and Transmission sprocket pairing at a ground

drive on each wing.

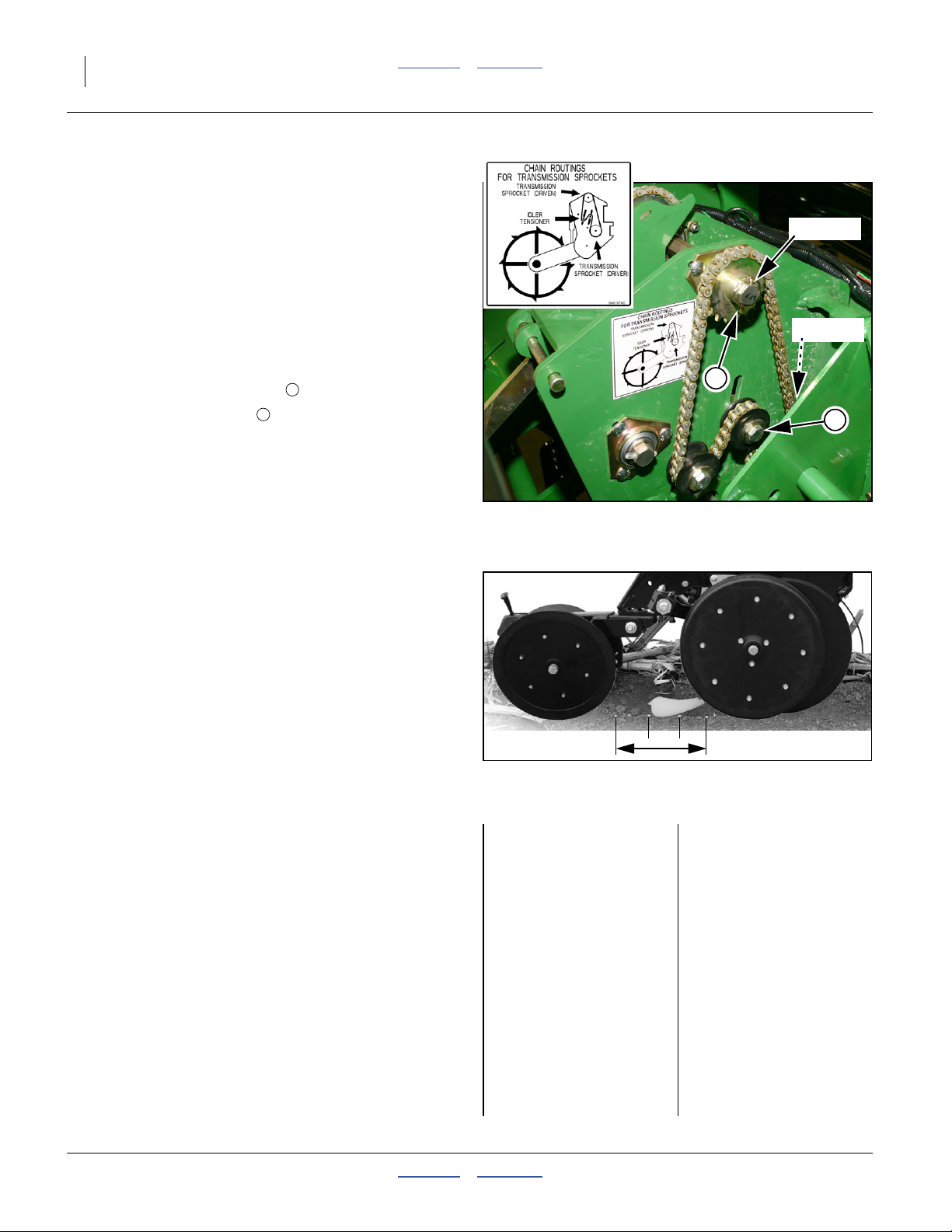

Sprocket Storage

Refer to Figure 4

Each wing has a pair of trees containing both Range

and Transmission sprockets for that wing.

Note: The planter includes a standard set of sprockets

common to several implement models. Some

sprockets may not be used in presently offered

YP1630F configurations.

1

Range Setup

Refer to Figure 5

Range provides coarse seed rate control, and uses only

Driving:Driven sprocket combinations:

30T:20T or 30T:30T.

To change Range drive:

1. Consult the seed rate chart for your crop, meter, and

finger or cell count.

2. For your desired seed population, find the Range

sprocket pairing at the top of the chart.

3. Loosen the tensioning idler to obtain chain slack.

4. Remove the lynch pins at each Range sprocket

that needs to be changed.

5. Exchange sprockets with those required from the

storage trees. Re-install pins.

6. Engage the idler for 6 to 7 mm (1⁄4inch) of chain

slack at longest chain span.

7. Repeat for other wing.

2

3

1

DRIVING

2

Figure 4

Sprocket Storage

3

Figure 5

Range Drive

1

34496

DRIVEN

34497

2012-12-04 Contents Appendix 401-832B

6 Great Plains Manufacturing, Inc. Contents Appendix YP1630F

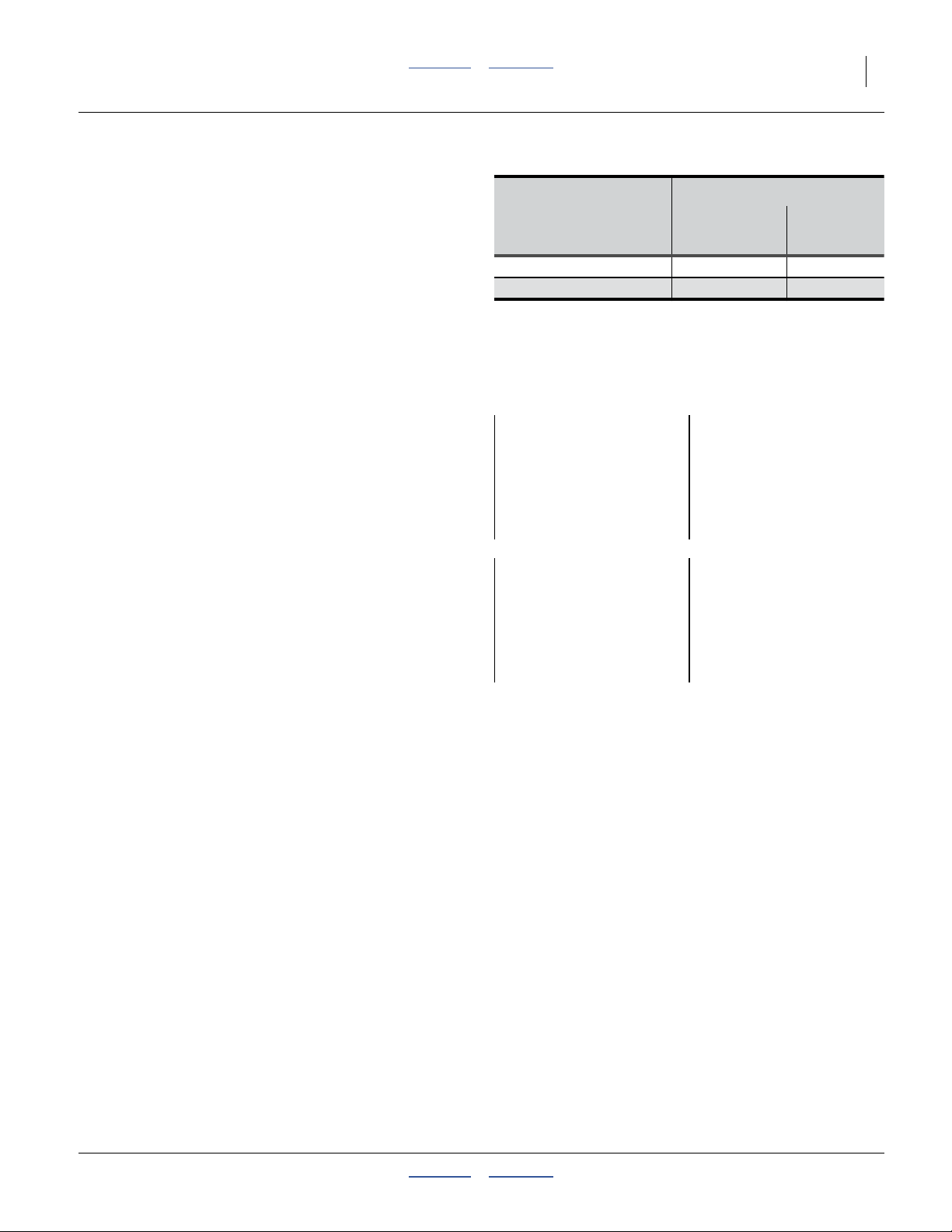

Transmission Setup

Refer to Figure 6

Range provides fine seed rate control, and uses only

pairings from Sprocket sizes:

17T, 19T, 23T, 24T, 25T, 26T, 27T, 28T

Pairings are always unequal except for 23T:23T

To change Range drive:

1. Consult the seed rate chart for your crop, meter, and

finger or cell count.

2. For your desired seed population, find the Range

sprocket pairing at the top of the chart.

3. Loosen the tensioning idler to obtain chain slack.

4. Remove the lynch pins at each Range sprocket

that needs to be changed.

5. Exchange sprockets with those required from the

storage trees. Re-install pins.

6. Engage the idler for 13 mm (

at longest chain span.

7. Repeat for other wing.

2

3

1

⁄2inch) of chain slack

3

Figure 6

Transmission Drive

DRIVEN

DRIVING

2

34498

Checking Planting Rate

Singulated seed charts are based on cleaned and sized

seed singulated with the recommended meter and wheel

or finger count. Extreme seed size variations, foreign

material and solid conditions can affect the planting rate.

Any material difference between chart and field rates

implies a mechanical malfunction, a planter setup error,

unsuitable planting conditions (such as excessive wheel

slippage) or extremely worn planter components.

You can verify your setup and planter performance by

measuring seed placement and spacing over a relatively

short distance.

The columns to the right provide example data for a rate

check, in metric units and similar example in U.S.

customary units.

Furrow Check

Metric Example:

Planter: YP1630F-1670

Crop: Corn

Meter: 12 finger pickup

Target Population:

81 200 seeds/hectare

Range Sprockets:

DRIVING: 30

DRIVEN: 20

Transmission Sprockets:

DRIVING: 23

DRIVEN: 26

Planting Speed:

8 kph

Chart Seed Spacing:

17.6 cm

Figure 7

USc Example:

Planter: YP1630F-1630

Crop: Corn

Meter: 12 finger pickup

Target Population:

30,200 seeds/acre

Range Sprockets:

DRIVING: 30

DRIVEN: 20

Transmission Sprockets:

DRIVING: 23

DRIVEN: 26

Maximum Planting Speed:

5 mph

Chart Seed Spacing:

6.9 inches

29247

401-832B Contents Appendix 2012-12-04

Great Plains Manufacturing, Inc. Contents Appendix Seed Rate 7

Checking Singulated Rates

1. Determine the sample distance to check. Find your

row spacing in the table at right.

2. Note the number of rows to sample. Adjust the

planting depth to a shallow setting on one or two

outside rows (per table). Tie up the press wheel

arms with wire or bungee to prevent furrow closure.

3. Decide whether to use 1/1000th or 1/200th of a

hectare or acre as the sample size. 1/200th provides

a more accurate sample.

4. Configure the planter for the chart rate, either using

the chart settings for sprockets, or, with hydraulic

drive, selecting the rate on the seed monitor.

5. Plant at the desired planting speed for slightly more

than the computed sample run length.

6. Measure off the sample distance, balanced in

between where seeding started and stopped.

7. Count the number of seeds over the distance

measured. Also note the consistency of the seed

spacing.

8. Compute the rate for a full acre or hectare.

For a 1/1000th sample, multiply the counted seeds

by 1000.

For a 1/200th sample, multiply the counted seeds by

200.

9. If the field and chart rates vary by more than a few

percent, re-check planter setup, including meter

wheel or finger count, air system, tire size, tire

pressures, sprocket or hydraulic drive setup, chain

slack, etc. If seed spacing is irregular, this suggests

a seed delivery problem, and not a rate setup

problem.

10. While planting, pay attention to the seed monitor. In

addition to confirming the single-row furrow check, it

will also provide field rate data on all the other rows,

and alert you to any irregularities or stoppages.

Rows to Sample Length of Sample Run

Row

Spacing

70 cm 1 ha: 14.29 m 71.45 m

30 inches 1 ac: 17 ft. 5 in. 87 ft. 1 in.

Metric Example:

Sample size:

1/1000th ha

Plant for approximately:

20 meters

Measure the central:

14.29 meters (1429 cm)

Metric Example:

Seeds counted:

82

Computed for full hectare:

82 x 1000 = 82 000

This differs from chart by

less than 1%

Rows

to Count

1/1000th 1/200th

USc Example:

Sample size:

1/1000th ac

Plant for approximately:

25 feet

Measure the central:

17 feet 5 inches

USc Example:

Seeds counted:

31

Computed for full acre:

31 x 1000 = 31,000

This differs from chart by

less than 1%

2012-12-04 Contents Appendix 401-832B

8 Great Plains Manufacturing, Inc. Contents Appendix YP1630F

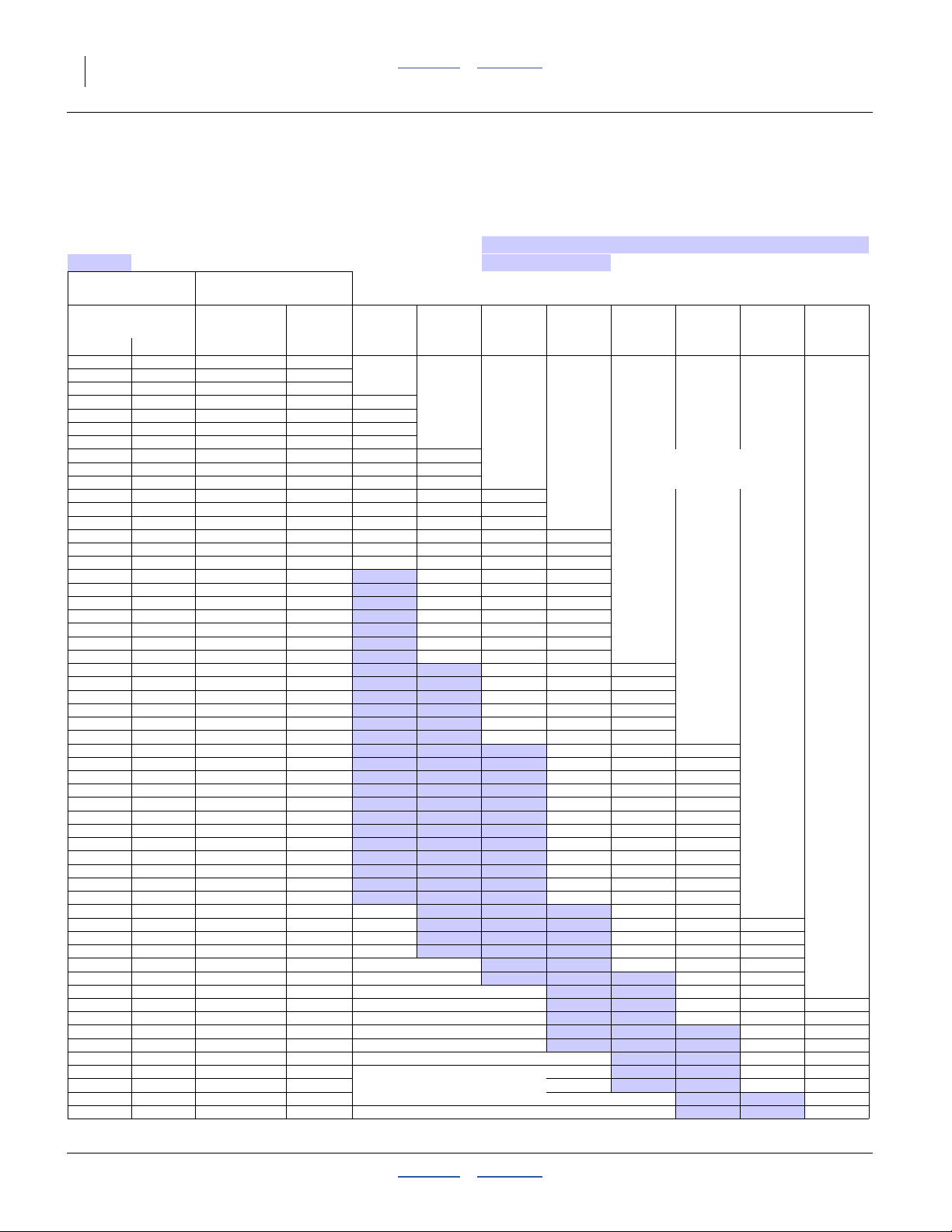

YP1630F 70cm Rows Low Range

12 Finger Meter

ATTENTION ! ! !

Great Plains always recommends test stand calibration of the finger meter to the population and ground speed desired .

For Round Corn optimum meter speed is 45 to 75 RPM For Flat Corn optimum meter speed is 60 to 75 RPM

( Shaded & Non-shaded areas ) (Shaded area)

Range Driving =30

Sprockets

Transmission

Combinations Population Spacing

Driving Driven (seeds/ha) (cm)

17 28

17 27

17 26

19 28

17 25

19 27

17 24

19 26

17 23

19 25

19 24

23 28

19 23

23 27

24 28

23 26

24 27

25 28

17 19

23 25

24 26

25 27

26 28

23 24

24 25

25 26

26 27

27 28

23 23

28 27

27 26

26 25

25 24

24 23

28 26

27 25

26 24

25 23

19 17

28 25

27 24

26 23

28 24

27 23

23 19

28 23

24 19

25 19

23 17

26 19

24 17

27 19

25 17

28 19

26 17

27 17

28 17

(For all seed corn types)

Driven =

30 Ground Speed

Seed Seed

37 157

38 533

40 015

41 528

41 615

43 066

43 349

44 722

45 234

46 511

48 449

50 271

50 556

52 132

52 456

54 138

54 399

54 642

54 757

56 303

56 491

56 666

56 828

58 649

58 751

58 845

58 932

59 013

61 199

63 466

63 553

63 647

63 749

63 860

65 907

66 095

66 299

66 521

68 399

68 543

68 849

69 181

71 399

71 842

74 083

74 503

77 304

80 525

82 799

83 746

86 399

86 967

89 998

90 188

93 598

97 198

100 798

38.4

37.1

35.7

34.4

34.3

33.2

33.0

31.9

31.6

30.7

29.5

28.4

28.3

27.4

27.2

26.4

26.3

26.1

26.1

25.4

25.3

25.2

25.1

24.4

24.3

24.3

24.

24.2

23.3

22.5

22.5

22.4

22.4

22.4

21.7

21.6

21.5

21.5

20.9

20.8

20.7

20.6

20.0

19.9

19.3

19.2

18.5

17.7

17.3

17.1

16.5

16.

15.9

15.8

15.3

14.7

14.2

11.3 kph 10.5 kph 9.7 kph 8.9 kph 8 kph 7.2 kph 6.4 kph 5.6 kph

Meter Meter Meter Meter Meter Meter Meter Meter

(rpm) (rpm) (rpm) (rpm) (rpm) (rpm) (rpm) (rpm)

45

46

47

47

49 45

50 46 Not Recommended

51 47

53 49 45

55 51 47

55 51 47

57 53 49 45

57 53 49 45

59 55 51 47

60 55 51 47

60 56 51 47

60 56 51 47

62 57 53 48

62 57 53 49

62 58 53 49

62 58 53 49

64 60 55 50 46

64 60 55 51 46

2

4

64 60 55 51 46

65 60 55 51 46

65 60 55 51 46

67 62 57 53 48

70 65 60 55 50 45

70 65 60 55 50 45

70 65 60 55 50 45

70 65 60 55 50 45

70 65 60 55 50 45

72 67 62 57 52 46

72 67 62 57 52 47

73 67 62 57 52 47

73 68 62 57 52 47

75 70 64 59 54 48

75 70 64 59 54 48

75 70 65 59 54 48

70 65 60 54 49

73 67 61 56 50 45

73 67 62 56 51 45

75 70 64 58 52 46

70 64 58 52 47

73 67 60 54 48

69 63 57 50

71 65 58 52 45

72 66 59 52 46

74 68 61 54 47

75 68 61 54 48

70 63 56 49

71 64 56 49

Not Recommended 73665951

68 61 53

71 63 55

34518

401-832B Contents Appendix 2012-12-04

Great Plains Manufacturing, Inc. Contents Appendix Seed Rate 9

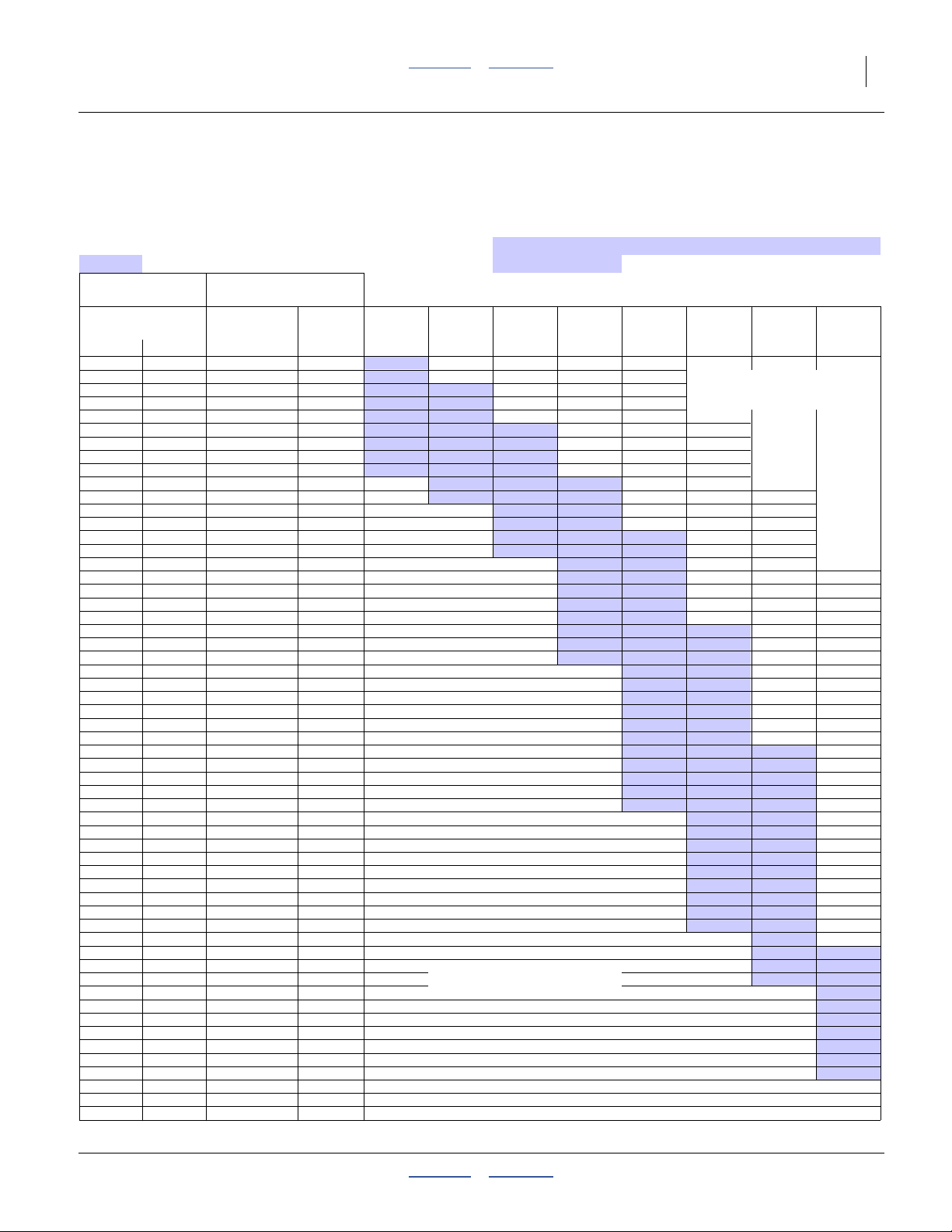

YP1630F 70cm Rows High Range

12 Finger Meter

ATTENTION ! ! !

Great Plains always recommends test stand calibration of the finger meter to the population and ground speed desired .

For Round Corn optimum meter speed is 45 to 75 RPM For Flat Corn optimum meter speed is 60 to 75 RPM

( Shaded & Non-shaded areas ) (Shaded area)

Range Driving =30

Sprockets

Transmission

Combinations Population Spacing

Driving Driven (seeds/ha) (cm)

17 28

17 27

17 26

19 28

17 25

19 27

17 24

19 26

17 23

19 25

19 24

23 28

19 23

23 27

24 28

23 26

24 27

25 28

17 19

23 25

24 26

25 27

26 28

23 24

24 25

25 26

26 27

27 28

23 23

28 27

27 26

26 25

25 24

24 23

28 26

27 25

26 24

25 23

19 17

28 25

27 24

26 23

28 24

27 23

23 19

28 23

24 19

25 19

23 17

26 19

24 17

27

25 17

28 19

26 17

27 17

28 17

(For all seed corn types)

Driven =

Seed Seed

55 735

57 799

60 022

62 292

62 423

64 599

65 024

67 083

67 851

69 767

72 674

75 406

75 834

78 199

78 684

81 206

81 599

81 963

82 135

84 455

84 737

84 999

85 241

87 974

88 127

88 268

88 399

88 520

91 798

95 198

95 329

95 470

95 623

95 790

98 860

99 142

99 448

99 781

102 598

102 814

103 273

103 772

107 098

107 763

111 124

111 755

115 956

120 787

124 198

125 619

19

129 598

130 450

134 998

135 282

140 398

145 798

151 197

20 Ground Speed

11.3 kph 10.5 kph 9.7 kph 8.9 kph 8 kph 7.2 kph 6.4 kph 5.6 kph

Meter Meter Meter Meter Meter Meter Meter Meter

(rpm) (rpm) (rpm) (rpm) (rpm) (rpm) (rpm) (rpm)

25.6

24.7

23.8

22.9

22.9

22.1

22.0

21.3

21.1

20.5

19.7

18.9

18.8

18.3

18.2

17.6

17.5

17.4

17.4

16.9

16.9

16.8

16.8

16.2

16.2

16.

16.2

16.1

15.6

15.0

15.0

15.0

14.9

14.9

14.5

14.4

14.4

14.3

13.9

13.9

13.8

13.8

13.3

13.3

12.9

12.8

12.3

11.8

11.5

11.4

11.0

11.0

10.6

10.6

10.2

9.8

9.4

2

61 57 52 48

63 59 54 50 45

66 61 56 52 47 Not Recommended

68 63 58 54 49

68 63 59 54 49

71 66 61 56 51 45

71 66 61 56 51 46

73 68 63 58 52 47

74 69 64 58 53 48

71 65 60 55 49

74 68 63 57 51 45

71 65 59 53 47

71 65 59 53 47

73 67 61 55 49

74 68 62 55 49

70 64 57 51

70 64 57 51 45

71 64 58 51 45

71 64 58 51 45

73 66 59 53 46

73 66 60 53 46

73 66 60 53 47

73 67 60 53 47

Not Recommended 73 64

69 62 55 48

69 62 55 48

69 62 55 48

69 62 55 48

69 62 55 48

72 65 57 50

74 67 60 52

75 67 60 52

75 67 60 52

75 67 60 52

75 67 60 52

70 62 54

70 62 54

70 62 54

70 62 55

72 64 56

72 64 56

73 65 57

73 65 57

75 67 59

67 59

70 61

70 61

34519

66

68

69

71

71

74

74

2012-12-04 Contents Appendix 401-832B

10 Great Plains Manufacturing, Inc. Contents Appendix YP1630F

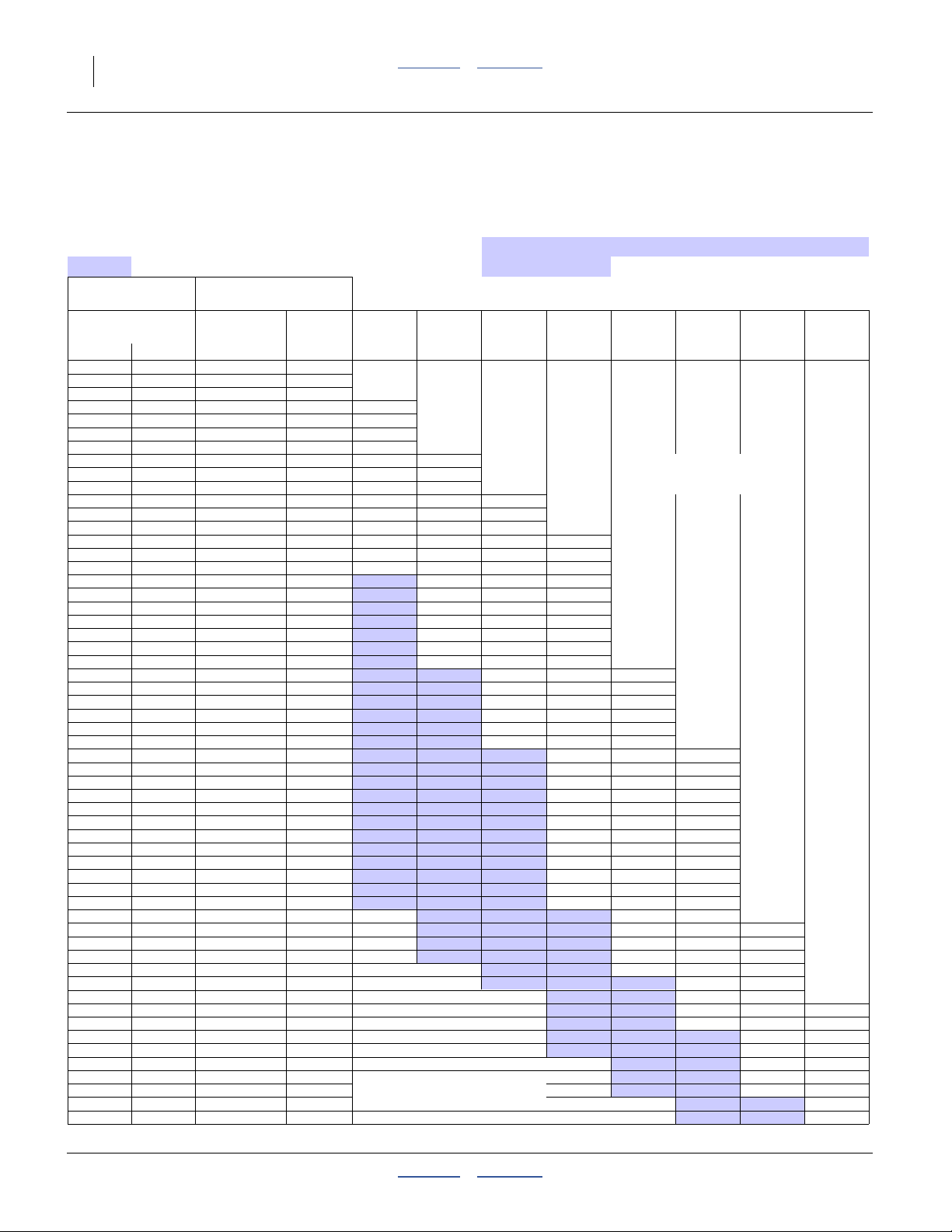

YP1630F 30in Rows Low Range

12 Finger Meter

ATTENTION ! ! !

Great Plains always recommends test stand calibration of the finger meter to the population and ground speed desired.

For Round Corn optimum meter speed is 45 to 75 RPM For Flat Corn optimum meter speed is 60 to 75 RPM

( Shaded & Non-shaded areas ) (Shaded area)

Range Driving =30

Sprockets

Transmission

Combinations Population Spacing

Driving Driven (seeds/acre) (inches)

17 28

17 27

17 26

19 28

17 25

19 27

17 24

19 26

17 23

19 25

19 24

23 28

19 23

23 27

24 28

23 26

24 27

25 28

17 19

23 25

24 26

25 27

26 28

23 24

24 25

25 26

26 27

27 28

23 23

28 27

27 26

26 25

25 24

24 23

28 26

27 25

26 24

25 23

19 17

28 25

27 24

26 23

28 24

27 23

23 19

28 23

24 19

25 19

23 17

26 19

24 17

27 19

25 17

28 19

26 17

27 17

28 17

(For all seed corn types)

Driven =

30 Ground Speed

Seed Seed

13 814

14 325

14 876

15 439

15 471

16 010

16 116

16 626

16 816

17 291

18 012

18 689

18 795

19 381

19 501

20 126

20 224

20 314

20 357

20 932

21 002

21 066

21 127

21 804

21 842

21 877

21 909

21 939

22 752

23 594

23 627

23 662

23 700

23 741

24 502

24 572

24 648

24 730

25 428

25 482

25 596

25 719

26 544

26 709

27 542

27 698

28 739

29 936

30 782

31 134

32 120

32 331

33 458

33 529

34 797

36 135

37 473

15.1

14.6

14.1

13.5

13.5

13.1

13.0

12.6

12.4

12.1

11.6

11.2

11.1

10.8

10.7

10.4

10.3

10.3

10.3

10.0

10.0

9.9

9.9

9.6

9.6

9.6

9.

9.5

9.2

8.9

8.8

8.8

8.8

8.8

8.5

8.5

8.5

8.5

8.2

8.2

8.2

8.1

7.9

7.8

7.6

7.5

7.3

7.0

6.8

6.7

6.5

6.

6.2

6.2

6.0

5.8

5.6

7 mph 6.5 mph 6 mph 5.5 mph 5 mph 4.5 mph 4 mph 3.5 mph

Meter Meter Meter Meter Meter Meter Meter Meter

(rpm) (rpm) (rpm) (rpm) (rpm) (rpm) (rpm) (rpm)

45

46

47

47

49 45

50 46 Not Recommended

51 47

53 49 45

55 51 47

55 51 47

57 53 49 45

57 53 49 45

59 55 51 47

60 55 51 47

60 56 51 47

60 56 51 47

62 57 53 48

62 57 53 49

62 58 53 49

62 58 53 49

64 60 55 50 46

64 60 55 51 46

5

5

64 60 55 51 46

65 60 55 51 46

65 60 55 51 46

67 62 57 53 48

70 65 60 55 50 45

70 65 60 55 50 45

70 65 60 55 50 45

70 65 60 55 50 45

70 65 60 55 50 45

72 67 62 57 52 46

72 67 62 57 52 47

73 67 62 57 52 47

73 68 62 57 52 47

75 70 64 59 54 48

75 70 64 59 54 48

75 70 65 59 54 48

70 65 60 54 49

73 67 61 56 50 45

73 67 62 56 51 45

75 70 64 58 52 46

70 64 58 52 47

73 67 60 54 48

69 63 57 50

71 65 58 52 45

72 66 59 52 46

74 68 61 54 47

75 68 61 54 48

70 63 56 49

71 64 56 49

Not Recommended 73665951

68 61 53

71 63 55

34516

401-832B Contents Appendix 2012-12-04

Great Plains Manufacturing, Inc. Contents Appendix Seed Rate 11

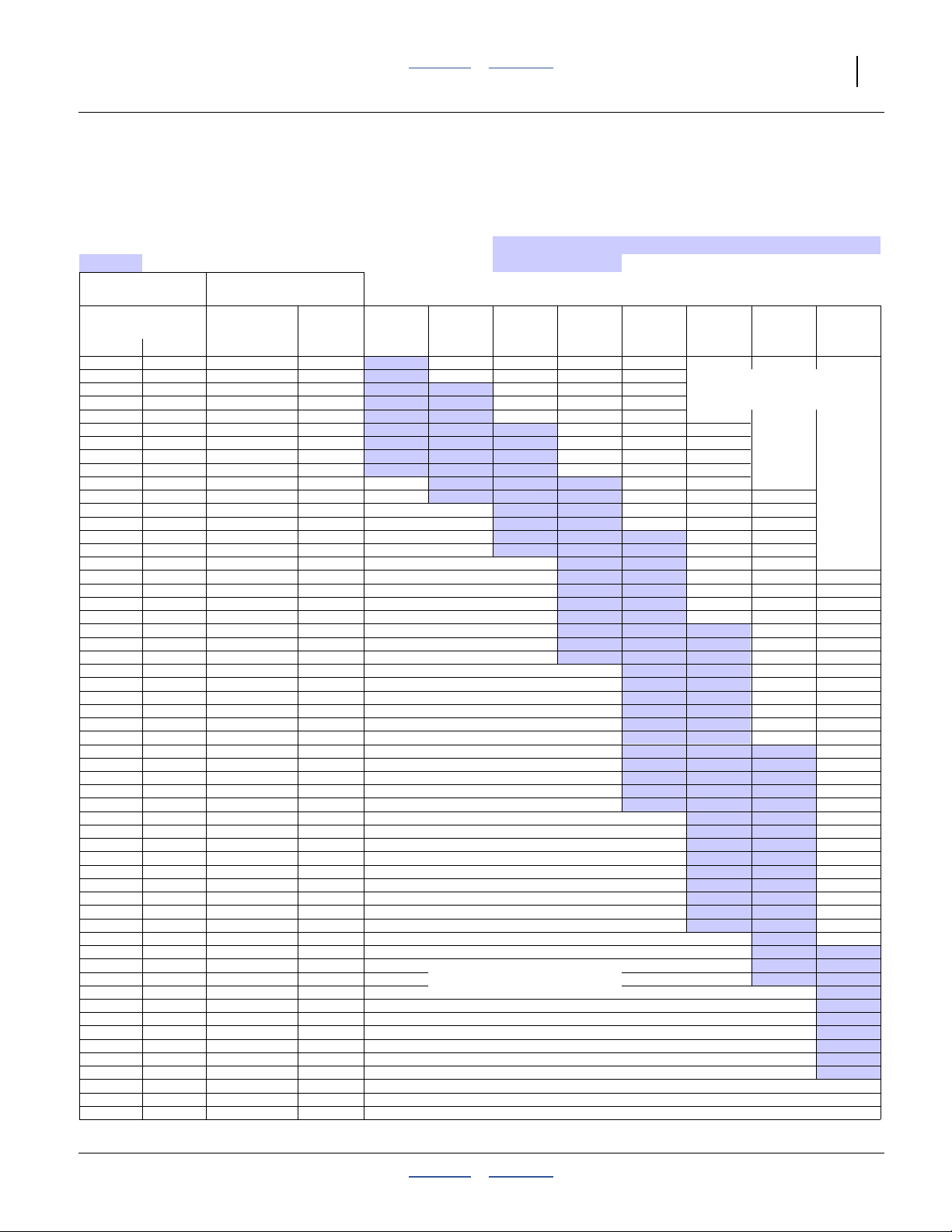

YP1630F 30in Rows High Range

12 Finger Meter

ATTENTION ! ! !

Great Plains always recommends test stand calibration of the finger meter to the population and ground speed desired .

For Round Corn optimum meter speed is 45 to 75 RPM For Flat Corn optimum meter speed is 60 to 75 RPM

( Shaded & Non-shaded areas ) (Shaded area)

Range Driving =30

Sprockets

Transmission

Combinations Population Spacing

Driving Driven (seeds/acre) (inches)

17 28

17 27

17 26

19 28

17 25

19 27

17 24

19 26

17 23

19 25

19 24

23 28

19 23

23 27

24 28

23 26

24 27

25 28

17 19

23 25

24 26

25 27

26 28

23 24

24 25

25 26

26 27

27 28

23 23

28 27

27 26

26 25

25 24

24 23

28 26

27 25

26 24

25 23

19 17

28 25

27 24

26 23

28 24

27 23

23 19

28 23

24 19

25 19

23 17

26 19

24 17

27

25 17

28 19

26 17

27 17

28 17

(For all seed corn types)

Driven =

Seed Seed

20 720

21 488

22 314

23 158

23 207

24 016

24 174

24 939

25 225

25 937

27 018

28 033

28 192

29 072

29 252

30 190

30 336

30 471

30 535

31 397

31 502

31 600

31 690

32 706

32 762

32 815

32 864

32 909

34 128

35 392

35 440

35 493

35 550

35 611

36 753

36 858

36 971

37 095

38 143

38 223

38 393

38 579

39 815

40 063

41 312

41 547

43 108

44 905

46 173

46 701

19

48 180

48 497

50 188

50 293

52 195

54 203

56 210

20 Ground Speed

7 mph 6.5 mph 6 mph 5.5 mph 5 mph 4.5 mph 4 mph 3.5 mph

Meter Meter Meter Meter Meter Meter Meter Meter

(rpm) (rpm) (rpm) (rpm) (rpm) (rpm) (rpm) (rpm)

10.1

9.7

9.4

9.0

9.0

8.7

8.6

8.4

8.3

8.1

7.7

7.5

7.4

7.2

7.1

6.9

6.9

6.9

6.8

6.7

6.6

6.6

6.6

6.4

6.4

6.

6.4

6.4

6.1

5.9

5.9

5.9

5.9

5.9

5.7

5.7

5.7

5.6

5.5

5.5

5.4

5.4

5.3

5.2

5.1

5.0

4.9

4.7

4.5

4.5

4.3

4.3

4.2

4.2

4.0

3.9

3.7

4

61 57 52 48

63 59 54 50 45

66 61 56 52 47 Not Recommended

68 63 58 54 49

68 63 59 54 49

71 66 61 56 51 45

71 66 61 56 51 46

73 68 63 58 52 47

74 69 64 58 53 48

71 65 60 55 49

74 68 63 57 51 45

71 65 59 53 47

71 65 59 53 47

73 67 61 55 49

74 68 62 55 49

70 64 57 51

70 64 57 51 45

71 64 58 51 45

71 64 58 51 45

73 66 59 53 46

73 66 60 53 46

73 66 60 53 47

73 67 60 53 47

Not Recommended 73 64

69 62 55 48

69 62 55 48

69 62 55 48

69 62 55 48

69 62 55 48

72 65 57 50

74 67 60 52

75 67 60 52

75 67 60 52

75 67 60 52

75 67 60 52

70 62 54

70 62 54

70 62 54

70 62 55

72 64 56

72 64 56

73 65 57

73 65 57

75 67 59

67 59

70 61

70 61

34517

66

68

69

71

71

74

74

2012-12-04 Contents Appendix 401-832B

Loading...

Loading...