Page 1

Table of Contents Index

Operator

YP1225A & YP1625A

30- and 40-Foot 2-Section Yield-Pro® Planters

®

with Air-Pro

Manufacturing, Inc.

www.greatplainsmfg.com

Seed Meters

Read the operator manual entirely. When you see this symbol, the

subsequent instructions and warnings are serious - follow without

exception. Your life and the lives of others depend on it!

29618

Illustrations may show optional equipment not supplied with standard unit or may

depict similar YP1225 or YP1625 models where a topic is identical.

ORIGINAL INSTRUCTIONS

© Copyright 2012 Printed 2013-08-13 401-625M

Table of Contents Index

EN

Page 2

Table of Contents Index

Table of Contents Index

Page 3

Great Plains Manufacturing, Inc. Cover Index iii

Table of Contents

Important Safety Information ......................................1

Safety Decals .................................................................6

Introduction ................................................................11

Description of Unit ........................................................11

Intended Usage ........................................................11

Document Family .........................................................11

Covered Models ...........................................................11

Using This Manual........................................................11

Definitions................................................................. 12

Owner Assistance ........................................................12

Preparation and Setup ...............................................13

Initial Setup...................................................................13

Pre-Planting Setup .......................................................13

Hitching Tractor to Planter............................................14

Hydraulic Hookup .....................................................14

Hydraulic Hose Hookup............................................ 14

Protecting Hydraulic Motor Seals ............................. 15

3-Point Hitch.............................................................16

Hitching with Hydraulic Tongue (Option)..................16

Raising/Lowering Tongue......................................... 17

Hitching with Either Hitch..........................................17

Electrical Hookup......................................................17

Store Main Parking Stand.........................................18

Lock Up Fertilizer Drive ............................................ 18

Operating Instructions...............................................19

Pre-Start Checklist .......................................................19

Wing Lock Overview.....................................................19

Unfolding The Planter...................................................20

Prepare Hitched Tractor and Planter........................ 20

Prepare Transport Hooks ......................................... 20

Release Wing Locks................................................. 21

Re-Phase Fold Cylinders..........................................21

Partially Unfold .........................................................21

Lower Tongue ..........................................................21

Fully Unfold ..............................................................22

Remove and Store Transport Locks......................... 22

Unfold Closeout........................................................23

Raising/Lowering Planter .............................................24

Raising Planter .........................................................24

Lowering Planter ......................................................24

Re-phasing Lift System ............................................25

Folding the Planter .......................................................25

Shut off Fan and Hydraulic Drive..............................26

Set Tractor and Tongue ...........................................26

Raise Planter............................................................ 26

Install Lock Channels ............................................... 26

Activate Fold Solenoid Valves.................................. 27

Begin Folding ........................................................... 27

Raise Tongue...........................................................27

Complete Fold..........................................................27

Lower Tongue .......................................................... 27

Re-phasing Fold System.......................................... 27

Transporting................................................................. 28

Loading Materials......................................................... 29

Material Loading Overview....................................... 29

Mounting a Hopper or Bulk Seed Box...................... 29

Loading Hopper with Seed.......................................32

Using Auxiliary Hydraulic Circuit ..........................32

Dismounting a Hopper or Seed Box......................... 34

Fertilizer Tanks (Option) .............................................. 35

Filling Tanks ............................................................. 35

Ground Drive Pump ................................................. 35

Field Setup Checklist ................................................... 36

Monitor Operation ........................................................ 37

Electric Clutch Operation ............................................. 38

Hydraulic Drive Operation (Option).............................. 39

Air System Operation................................................... 40

Air System Overview................................................ 41

Fan Circuit Operation ........................................... 42

Fan General Operating Information ..................... 43

Recommended Initial Fan Speeds ....................... 43

Marker Operation ......................................................... 44

Field Operation ............................................................ 45

Skip and Double Checks...................................... 45

Parking......................................................................... 46

Storage ........................................................................ 47

Storage: Fertilizer Option ......................................... 47

Adjustments ............................................................... 48

Setting Material Rates.................................................. 49

Planting Rate............................................................ 49

Fan and Meter Pressurization Adjustment................... 51

Fill Disk with Ground Drive:.................................. 51

Furrow Check:...................................................... 52

Fine-Tuning Meter Pressurization ............................ 53

Checking Planting Rate ............................................... 54

Checking Singulated Rate........................................ 54

Setting Fertilizer Rate .................................................. 55

Marker Adjustments ..................................................... 56

Dual Marker Speed Adjustment ............................... 56

© Copyright 2005, 2006, 2007, 2008, 2009, 2010, 2011, 2012 All rights Reserved

Great Plains Manufacturing, Inc. provides this publication “as is” without warranty of any kind, either expressed or implied. While every precaution has been

taken in the preparation of this manual, Great Plains Manufacturing, Inc. assumes no responsibility for errors or omissions. Neither is any liability assumed for

damages resulting from the use of the information contained herein. Great Plains Manufacturing, Inc. reserves the right to revise and improve its products as

it sees fit. This publication describes the state of this product at the time of its publication, and may not reflect the product in the future.

2013-08-13 Cover Index 195-325M

Trademarks of Great Plains Manufacturing, Inc. include: Singulator Plus, Swath Command, Terra-Tine.

Registered Trademarks of Great Plains Manufacturing, Inc. include:

Air-Pro, Clear-Shot, Discovator, Great Plains, Land Pride, MeterCone, Nutri-Pro, Seed-Lok, Solid Stand,

Terra-Guard, Turbo-Chisel, Turbo-Chopper, Turbo Max, Turbo-Till, Ultra-Till, Ver ti-Till, Whirlfilter, Yield-Pro.

Brand and Product Names that appear and are owned by others are trademarks of their respective owners.

Printed in the United States of America

Page 4

iv YP1125A & YP1625A Table of Contents Index Great Plains Manufacturing, Inc.

Marker Disk Adjustment........................................... 56

Height Switch ............................................................... 57

Row Implement Adjustments ....................................... 58

Frame-Mounted Row Accessories........................... 58

Terra-Tine™ Adjustment...................................... 58

Frame-Mounted Coulters ..................................... 59

Vantage I Applicator............................................. 59

25 Series Row-Unit Adjustments ................................. 60

Row-Unit Down Pressure......................................... 61

Spring Down Pressure ......................................... 61

Unit-Mount Cleaner Adjustments ............................. 63

Unit-Mounted Coulter Adjustments .......................... 64

Row-Unit Opener Disc Adjustments......................... 65

Setting Planting Depth ......................................... 65

Side Gauge Wheel Adjustments .............................. 66

Adjusting Gauge Wheel Scrapers............................ 67

Meter Adjustments ................................................... 68

Meter Rain Cover ................................................. 68

Seed Inlet Shutter Adjustment ............................. 68

Optimal Seed Pool Slopes ................................... 69

Meter Re-Fill......................................................... 69

Air-Pro® Meter Disk Installation ............................... 70

Removing a Seed Disk......................................... 71

Row Unit Shut-Off .................................................... 71

Seed Firmer Adjustments ........................................ 74

Keeton® Seed Firmer Adjustment........................ 74

Seed-Lok® Seed Firmer Lock-Up ........................ 75

Seed-Lok® Seed Firmer Lock-Up (older style)..... 75

Press Wheel Adjustments........................................ 76

Press Wheel Centering ........................................ 76

Troubleshooting......................................................... 77

Planting Rate Problems ............................................... 77

Suggested Furrow Check:.................................... 77

Seed Pool Troubleshooting.......................................... 78

Seed Pool Recovery ................................................ 79

Population Troubleshooting Charts.............................. 79

Maintenance and Lubrication ................................... 88

Maintenance ................................................................ 88

Tongue Lift Cylinder Locks ...................................... 89

Material Clean-Out....................................................... 90

Hopper Clean-Out.................................................... 90

Air System Clean-Out .............................................. 91

Meter Clean-Out ...................................................... 92

Funnel Conversion ............................................... 92

Alternate Meter Clean-Out ................................... 93

Seed Tube Clean-Out .......................................... 93

Meter Brush Maintenance............................................ 94

Meter Brush Replacement ....................................... 95

Seed Disk Maintenance............................................96

Cleaning and Storing Seed Disks .........................96

Bleeding Hydraulics......................................................97

Bleeding Lift Hydraulics ............................................97

Bleeding Fold Cylinder Hydraulics............................97

Bleeding Marker Hydraulics......................................98

Marker Maintenance.....................................................98

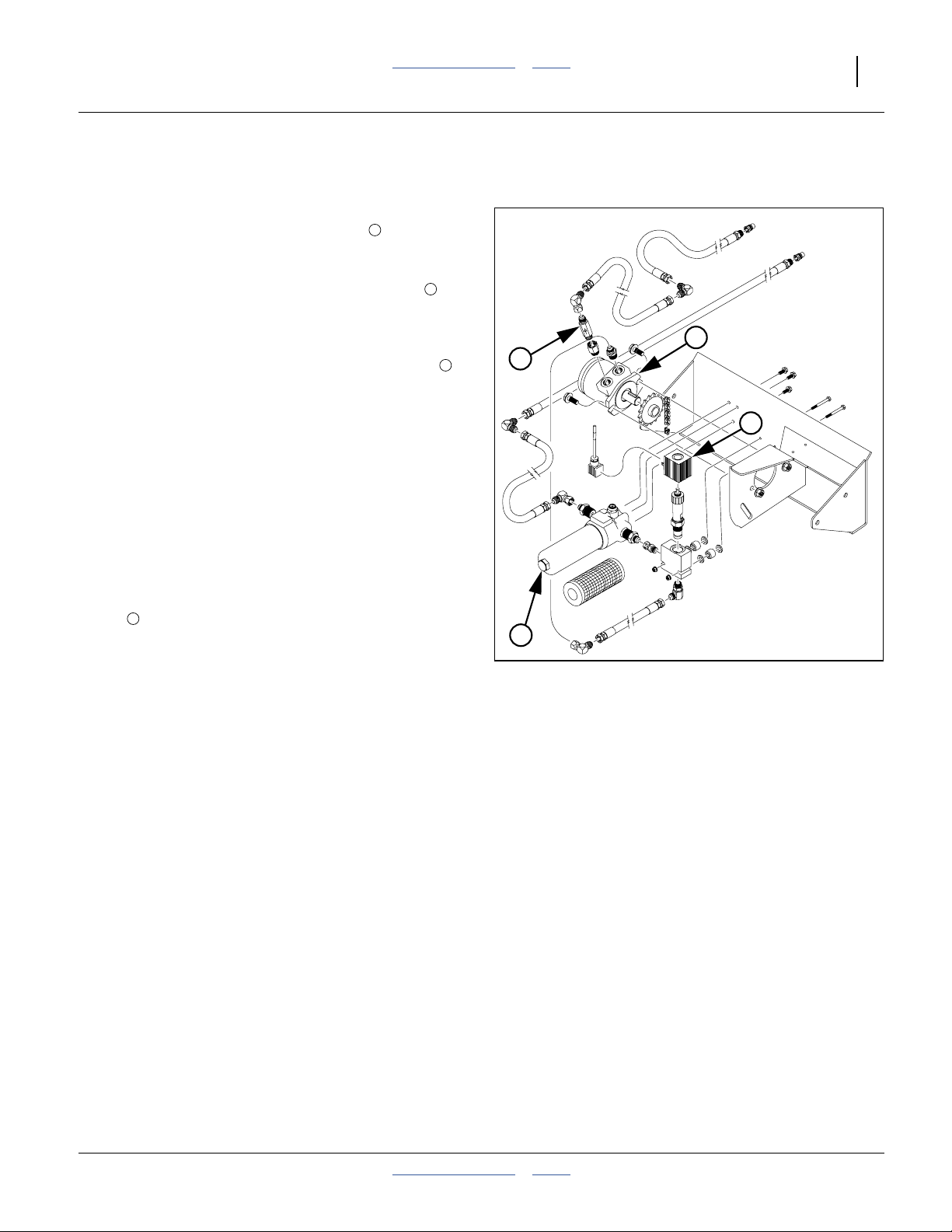

Hydraulic Drive Maintenance........................................99

Chain Maintenance.....................................................100

Meter Drive Chain.......................................................100

Disc Spreaders and Scrapers.....................................101

25 Series Row-Unit Side Wheels............................101

Fertilizer System Maintenance ...................................102

Liquid Fertilizer Strainer..........................................102

Seed Flap Replacement .............................................103

Lubrication ..................................................................104

Seed Lubricant ...........................................................111

Options and Accessories ........................................112

Appendix A - Reference Information ......................124

Specifications and Capacities.....................................124

YP1225 Models ......................................................124

YP1625 North America Models ..............................125

YP1625 Export Model.............................................126

Tire Inflation Chart ......................................................127

Hydraulic Diagrams ....................................................128

Chain Routing.............................................................137

Torque Values Chart ..................................................140

Appendix B - Pre-Delivery .......................................141

Appendix C - Initial Setup ........................................146

Hydraulic Charge and Bleed.......................................146

Console Installation ....................................................146

Monitor Setup .........................................................146

YP1225A Row Spacing Setup Data ...................146

YP1625A Row Spacing Setup Data ...................146

Level Planter...............................................................147

Wing Alignment ..........................................................148

Speed Calibration .......................................................149

Speed Sensor Operation ........................................149

Marker Setup ..............................................................150

Marker Extension....................................................150

Appendix D - Option Installation.............................151

122-278S Scraper Installation ....................................151

Appendix R - Row Pro..............................................152

Warranty .....................................................................159

Index ..........................................................................161

195-325M Table of Contents Index 2013-08-13

Page 5

Great Plains Manufacturing, Inc. Table of Contents Index 1

Important Safety Information

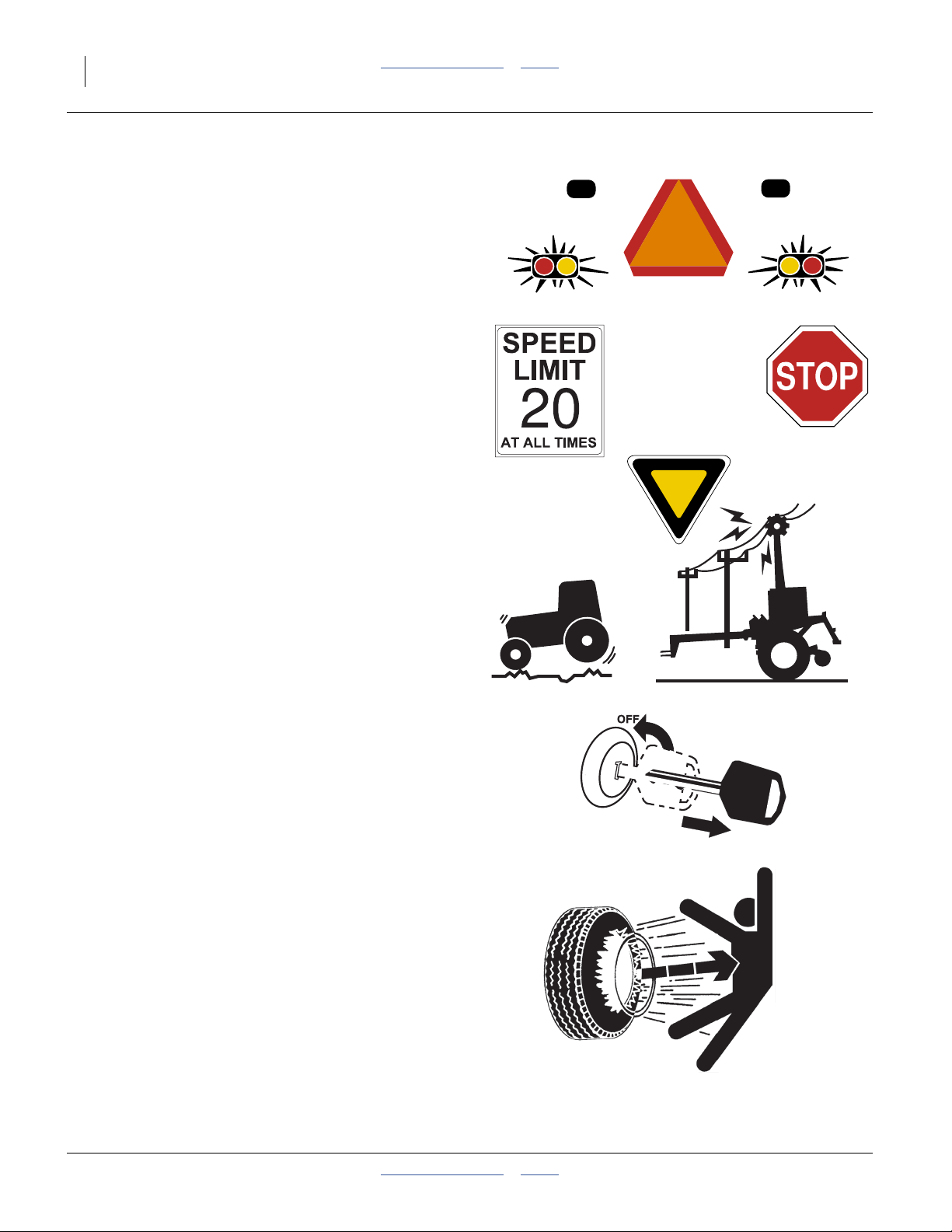

Look for Safety Symbol

The SAFETY ALERT SYMBOL indicates there is a

potential hazard to personal safety involved and extra

safety precaution must be taken. When you see this

symbol, be alert and carefully read the message that

follows it. In addition to design and configuration of

equipment, hazard control and accident prevention are

dependent upon the awareness, concern, prudence and

proper training of personnel involved in the operation,

transport, maintenance and storage of equipment.

Be Aware of Signal Words

Signal words designate a degree or level of hazard

seriousness.

DANGER indicates an imminently hazardous situation

which, if not avoided, will result in death or serious injury.

This signal word is limited to the most extreme situations,

typically for machine components that, for functional

purposes, cannot be guarded.

WARNING indicates a potentially hazardous situation

which, if not avoided, could result in death or serious

injury, and includes hazards that are exposed when

guards are removed. It may also be used to alert against

unsafe practices.

CAUTION indicates a potentially hazardous situation

which, if not avoided, may result in minor or moderate

injury. It may also be used to alert against unsafe

practices.

Prepare for Emergencies

▲ Be prepared if a fire starts

▲ Keep a first aid kit and fire extinguisher handy.

▲ Keep emergency numbers for doctor, ambulance, hospital

and fire department near phone.

Be Familiar with Safety Decals

▲ Read and understand “Safety Decals” on page 6,

thoroughly.

▲ Read all instructions noted on the decals.

▲ Keep decals clean. Replace damaged, faded and illegible

decals.

2013-08-13 Table of Contents Index 401-625M

Page 6

2 YP1125A & YP1625A Table of Contents Index Great Plains Manufacturing, Inc.

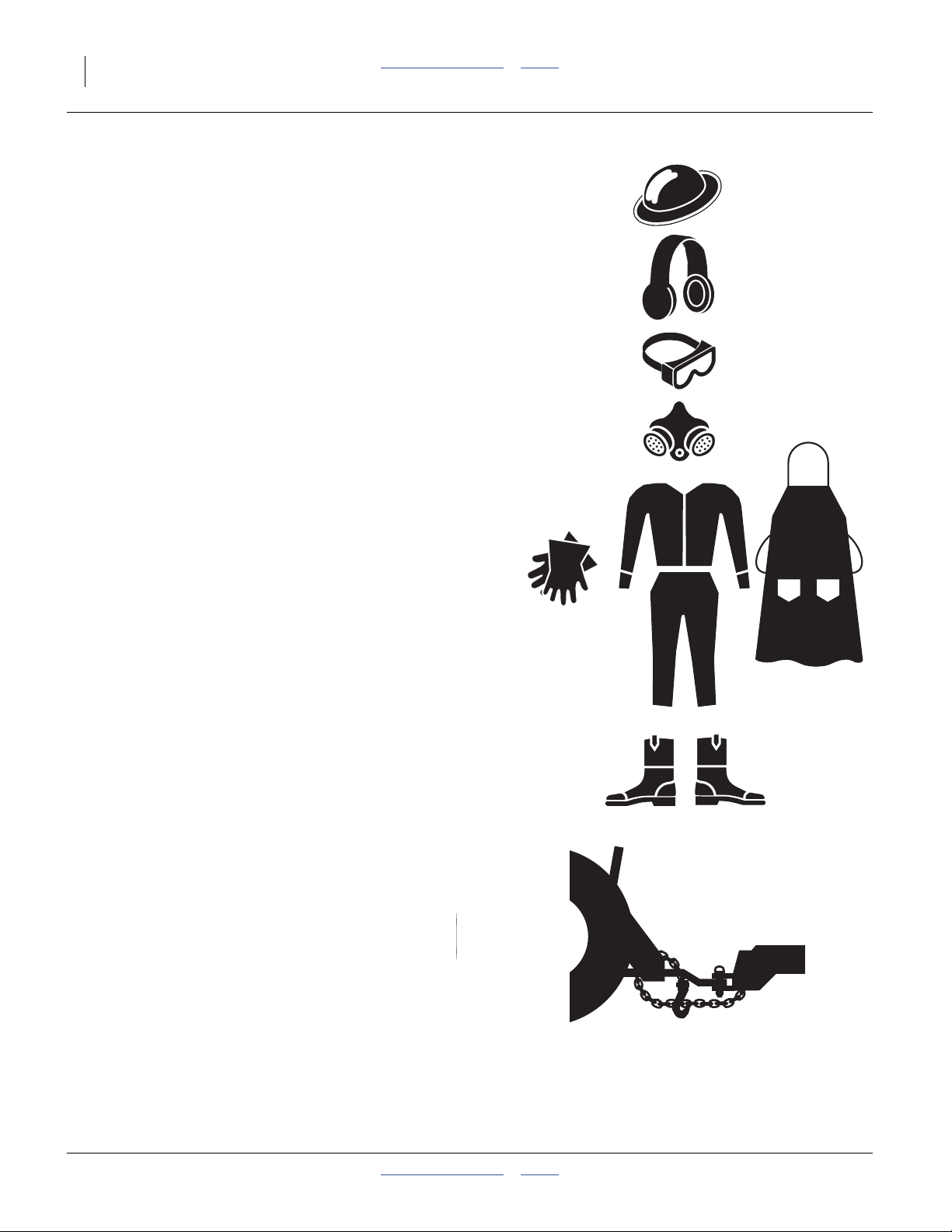

Wear Protective Equipment

Great Plains advises all users of chemical pesticides or

herbicides to use the following personal safety

equipment.

▲ Waterproof, wide-brimmed hat

▲ Waterproof apron.

▲ Face shield, goggles or full face respirator.

▲ Goggles with side shields or a full face respirator is

required if handling or applying dusts, wettable powders, or

granules or if being exposed to spray mist.

▲ Cartridge-type respirator approved for pesticide vapors

unless label specifies another type of respirator.

▲ Waterproof, unlined gloves. Neoprene gloves are

recommended.

▲ Cloth coveralls/outer clothing changed daily; waterproof

items if there is a chance of becoming wet with spray

▲ Waterproof boots or foot coverings

▲ Do not wear contaminated clothing. Wash protective

clothing and equipment with soap and water after each use.

Personal clothing must be laundered separately from

household articles.

▲ Clothing contaminated with certain pesticides must be

destroyed according to state and local regulations. Read

chemical label for specific instructions.

▲ Wear clothing and equipment appropriate for the job. Avoid

loose-fitting clothing.

▲ Prolonged exposure to loud noise can cause hearing

impairment or loss. Wear suitable hearing protection such

as earmuffs or earplugs.

▲ Avoid wearing entertainment headphones while operating

machinery. Operating equipment safely requires the full

attention of the operator.

Use A Safety Chain (Hydraulic Hitch)

▲ Use a safety chain to help control drawn machinery should

it separate from tractor draw bar.

▲ Use a chain with a strength rating equal to or greater than

the gross weight of towed machinery.

▲ Attach chain to tractor draw bar support or other specified

anchor location. Allow only enough slack to permit turning.

▲ Replace chain if any links or end fittings are broken,

stretched or damaged.

▲ Do not use safety chain for towing.

401-625M Table of Contents Index 2013-08-13

Page 7

Great Plains Manufacturing, Inc. Table of Contents Index Important Safety Information 3

Avoid High Pressure Fluids

Escaping fluid under pressure can penetrate the skin,

causing serious injury.

▲ Avoid the hazard by relieving pressure before disconnecting

hydraulic lines.

▲ Use a piece of paper or cardboard, NOT BODY PARTS, to

check for suspected leaks.

▲ Wear protective gloves and safety glasses or goggles when

working with hydraulic systems.

▲ If an accident occurs, seek immediate medical assistance

from a physician familiar with this type of injury.

Handle Chemicals Properly

▲ Read and follow chemical manufacturer’s instructions.

▲ Wear protective clothing.

▲ Handle all chemicals with care.

▲ Agricultural chemicals can be dangerous. Improper use can

seriously injure persons, animals, plants, soil and property.

▲ Inhaling smoke from any type of chemical fire is a serious

health hazard.

▲ Store or dispose of unused chemicals as specified by the

chemical manufacturer.

▲ Before adding chemical to the tank, make sure tank is at

least half full. Do not pour concentrate into an empty tank.

▲ Never leave fill hose attached to the sprayer after filling

tank. Chemicals in tank can siphon out of tank and

contaminate freshwater source.

▲ Immediately and thoroughly flush any area of the body that

is contaminated by chemicals.

▲ Do not touch plumbing components with mouth or lips.

▲ If chemical is swallowed, carefully follow the chemical

manufacturer’s recommendations and consult with a doctor.

▲ If persons are exposed to a chemical in a way that could

affect their health, consult a doctor immediately with the

chemical label or container in hand. Any delay could cause

serious illness or death.

▲ Dispose of empty chemical containers properly. By law

rinsing of the used chemical container must be repeated

three times. Puncture the container to prevent future use. An

alternative is to jet-rinse or pressure rinse the container.

▲ After working with chemicals, wash hands and face before

eating. Shower when application is completed for the day.

▲ Never wash out the tanks within 100 feet (30m) of any

freshwater source or in a car wash.

▲ Rinse out the tank. Apply rinse water on last field treated.

Keep Riders Off Machinery

Riders obstruct the operator’s view. Riders could be

struck by foreign objects or thrown from the machine.

▲ Never allow children to operate equipment.

▲ Keep all bystanders away from machine during operation.

2013-08-13 Table of Contents Index 401-625M

Page 8

4 YP1125A & YP1625A Table of Contents Index Great Plains Manufacturing, Inc.

Use Safety Lights and Devices

Slow-moving tractors and towed implements can create

a hazard when driven on public roads. They are difficult

to see, especially at night.

▲ Use flashing warning lights and turn signals whenever

driving on public roads.

▲ Use lights and devices provided with implement

Transport Machinery Safely

Maximum transport speed for implement is 20 mph

(32 km/h). Some rough terrains require a slower speed.

Sudden braking can cause a towed load to swerve and

upset.

▲ Do not exceed 20 mph (32 km/h). Never travel speeds which

do not allow adequate control of steering and stopping.

Reduce speed if towed load is not equipped with brakes.

▲ Comply with state and local laws.

▲ Do not tow an implement that, when fully loaded, weighs

more than 1.5 times the weight of towing vehicle.

▲ Carry reflectors or flags to mark planter in case of

breakdown on the road.

▲ Keep clear of overhead power lines and other obstructions

when transporting. Refer to transport dimensions under

“Specifications and Capacities” on page 124.

▲ Do not fold or unfold the planter while the tractor is

moving.

Shutdown and Storage

▲ Lower planter, put tractor in park, turn off engine, and

remove the key.

▲ Secure planter using blocks and supports provided.

▲ Detach and store planter in an area where children

normally do not play.

Tire Safety

Tire changing can be dangerous and should be

performed by trained personnel using correct tools and

equipment.

▲ When inflating tires, use a clip-on chuck and extension hose

long enough for you to stand to one side–not in front of or

over tire assembly. Use a safety cage if available.

▲ When removing and installing wheels, use wheel-handling

equipment adequate for weight involved.

401-625M Table of Contents Index 2013-08-13

Page 9

Great Plains Manufacturing, Inc. Table of Contents Index Important Safety Information 5

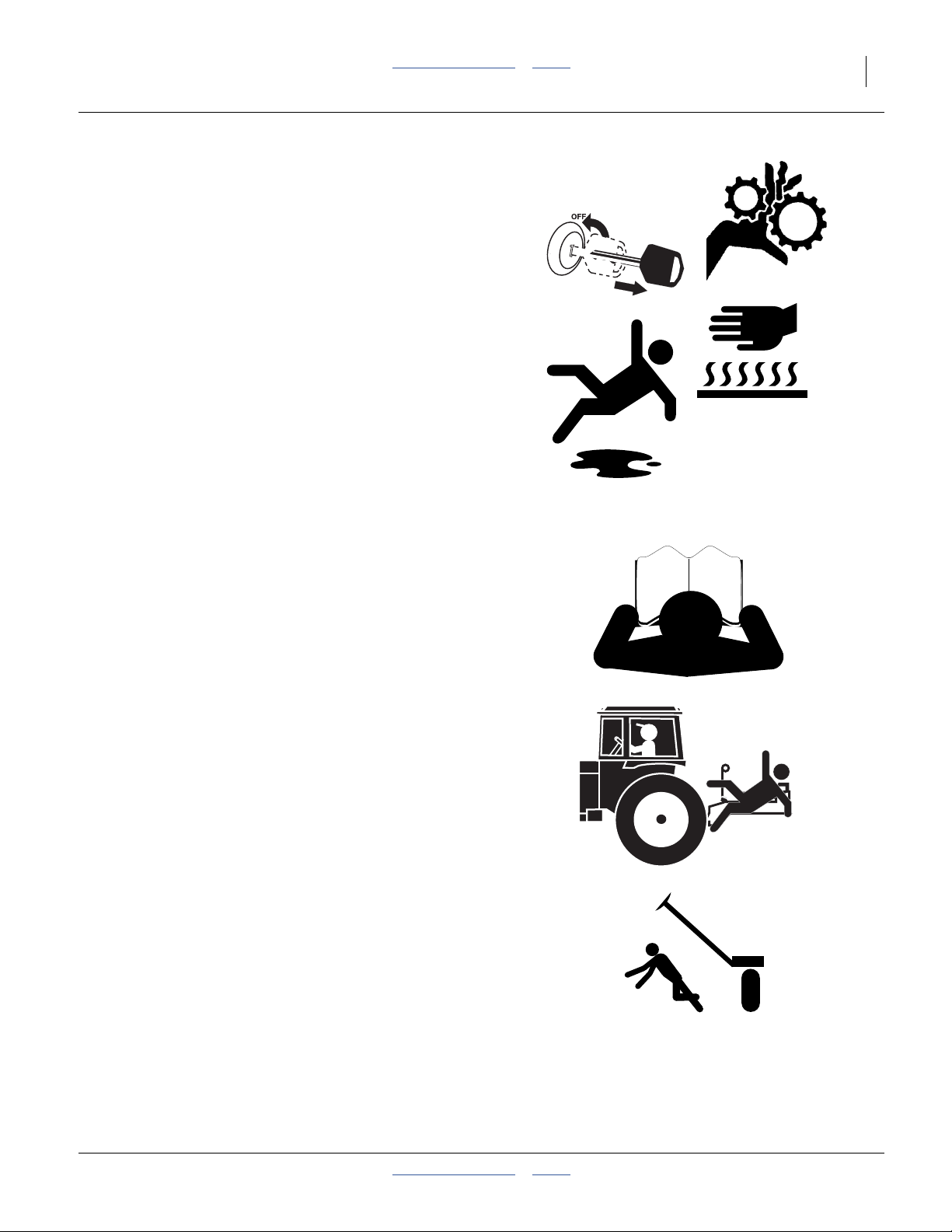

Practice Safe Maintenance

▲ Understand procedure before doing work. Use proper tools

and equipment. Refer to this manual for additional

information.

▲ Work in a clean, dry area.

▲ Lower the planter, put tractor in park, turn off engine, and

remove key before performing maintenance.

▲ Make sure all moving parts have stopped and all system

pressure is relieved.

▲ Allow planter to cool completely.

▲ Disconnect battery ground cable (-) before servicing or

adjusting electrical systems or before welding on planter.

▲ Inspect all parts. Make sure parts are in good condition and

installed properly.

▲ Remove buildup of grease, oil or debris.

▲ Remove all tools and unused parts from planter before

operation.

Safety At All Times

Thoroughly read and understand the instructions in this

manual before operation. Read all instructions noted on

the safety decals.

▲ Be familiar with all planter functions.

▲ Operate machinery from the driver’s seat only.

▲ Do not leave planter unattended with tractor engine

running.

▲ Do not dismount a moving tractor. Dismounting a moving

tractor could cause serious injury or death.

▲ Do not stand between the tractor and planter during

hitching.

▲ Keep hands, feet and clothing away from power-driven

parts.

▲ Wear snug-fitting clothing to avoid entanglement with

moving parts.

▲ Watch out for wires, trees, etc., when folding and raising

planter. Make sure all persons are clear of working area.

2013-08-13 Table of Contents Index 401-625M

Page 10

6 YP1125A & YP1625A Table of Contents Index Great Plains Manufacturing, Inc.

Safety Decals

Safety Reflectors and Decals

Your implement comes equipped with all lights, safety

reflectors and decals in place. They were designed to

help you safely operate your implement.

▲ Read and follow decal directions.

▲ Keep lights in operating condition.

▲ Keep all safety decals clean and legible.

▲ Replace all damaged or missing decals. Order new decals

from your Great Plains dealer. Refer to this section for

proper decal placement.

▲ When ordering new parts or components, also request

corresponding safety decals.

To install new decals:

1. Clean the area on which the decal is to be placed.

2. Peel backing from decal. Press firmly on surface,

being careful not to cause air bubbles under decal.

818-055C

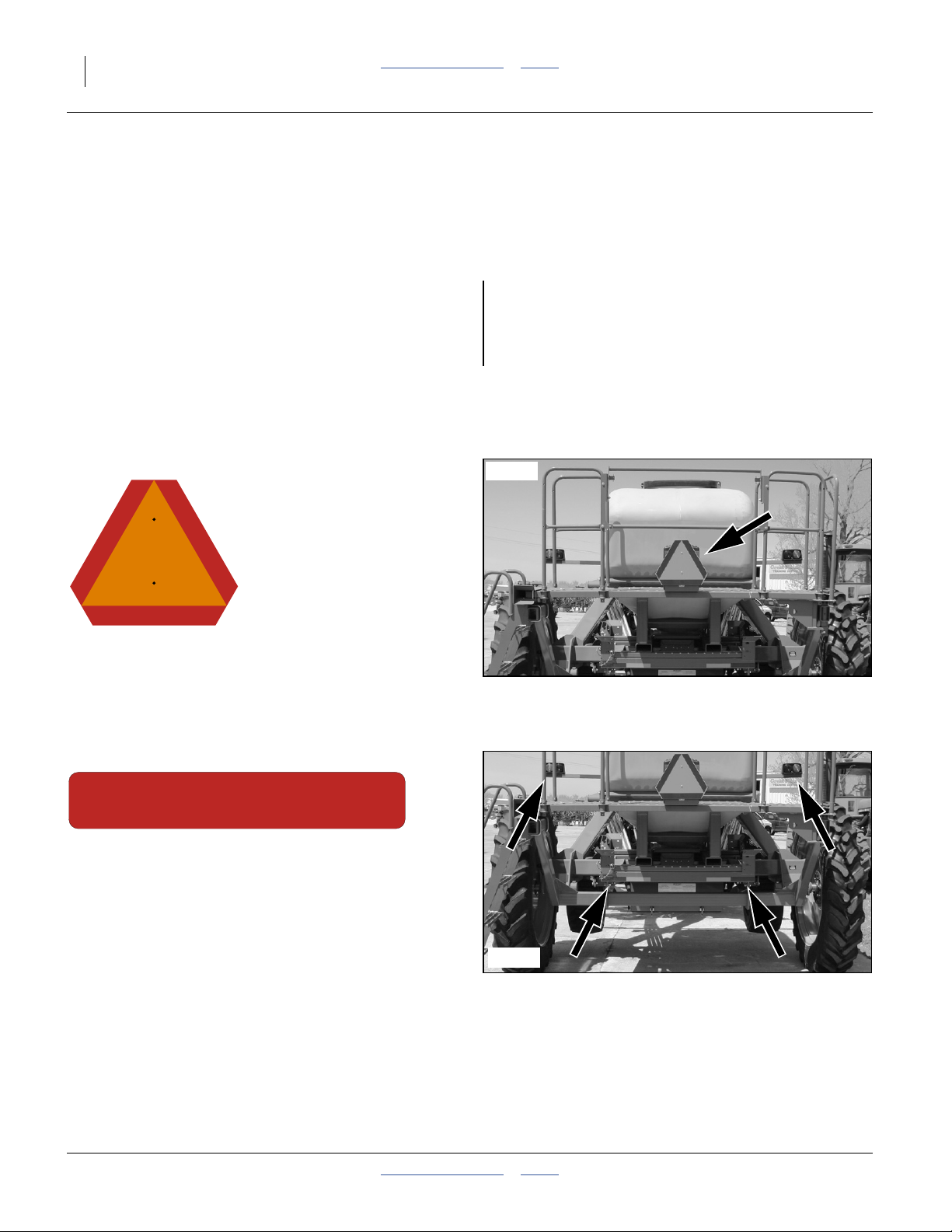

Slow Moving Vehicle Reflector

On the back of the planter, walkboard center;

1 total

See “Transporting” on page 28.

838-266C

Red Reflectors

On the back of seed frame each end,

and on the rear face of each light mounting bar;

4 total

29503

29503

401-625M Table of Contents Index 2013-08-13

Page 11

Great Plains Manufacturing, Inc. Table of Contents Index Important Safety Information 7

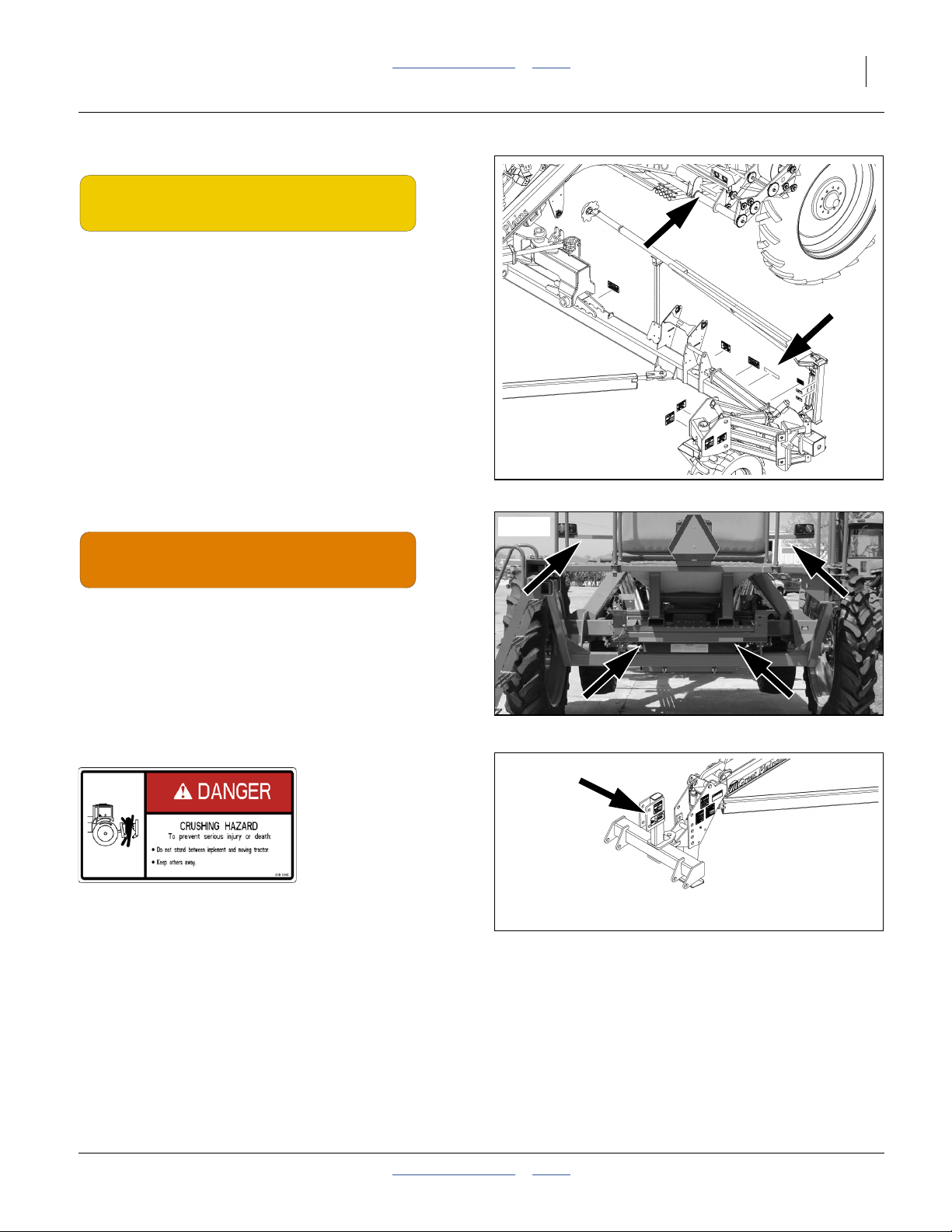

838-265C

Amber Reflectors

One each on rear face of wing tool bar at wing lock,

one each on front face of light bars;

4 total

29622

838-267C

Daytime Reflectors

On the back of seed frame, inside red reflectors,

on the rear face of the light bar;

4 total

818-590C

Danger: Crushing Hazard

On the hitch, one total.

See “Hitching Tractor to Planter” on page 14.

29503

29622

2013-08-13 Table of Contents Index 401-625M

Page 12

8 YP1125A & YP1625A Table of Contents Index Great Plains Manufacturing, Inc.

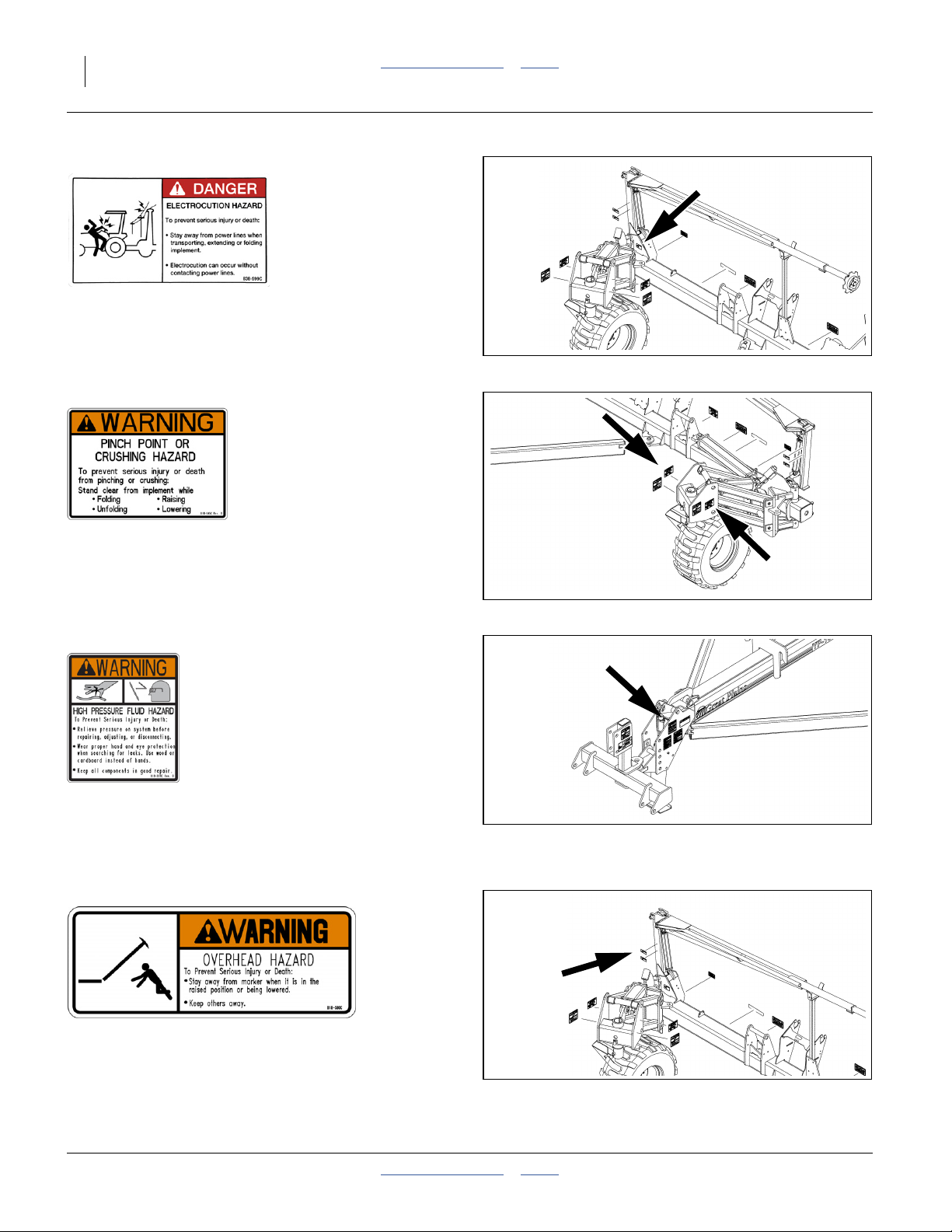

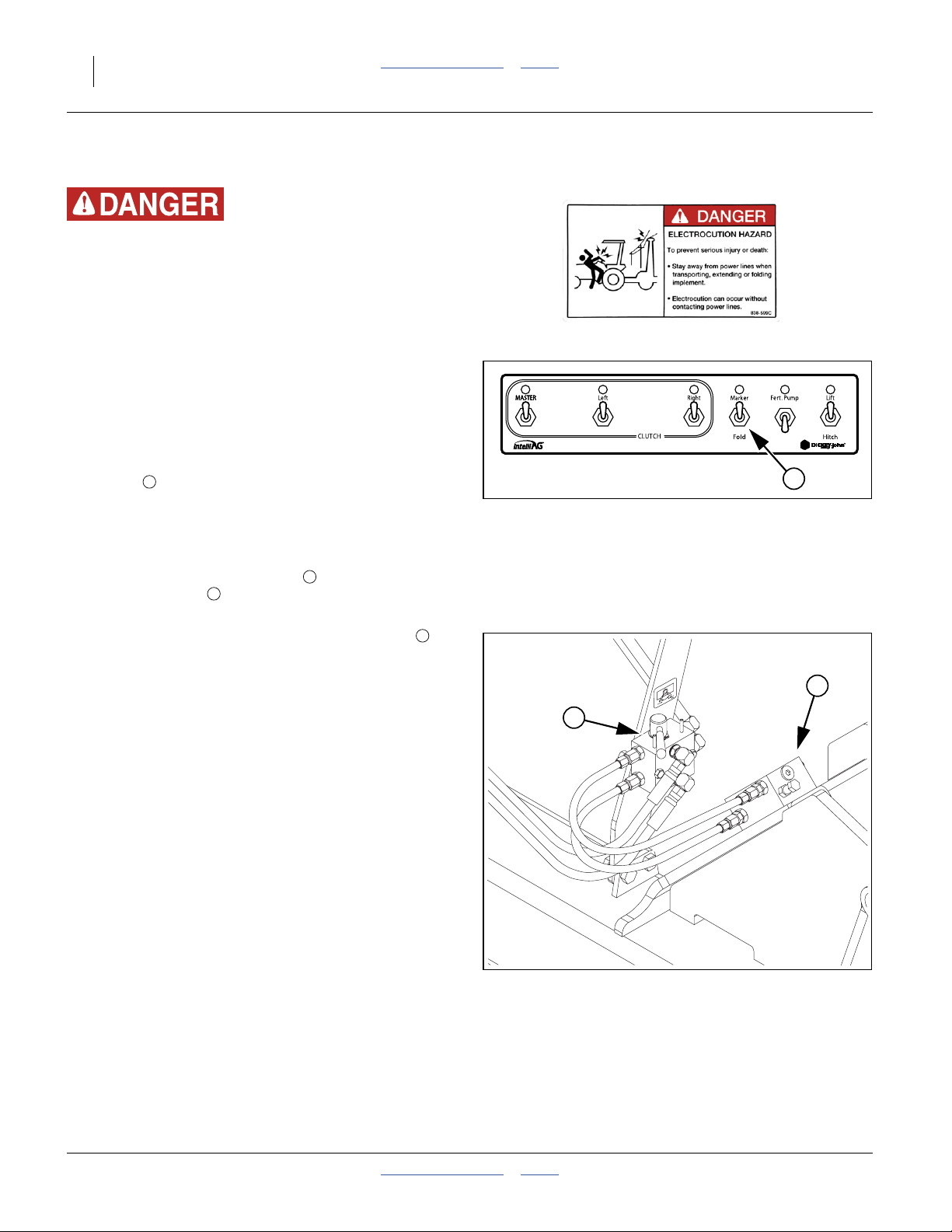

838-599C (Option)

Danger: Electrocution Hazard

On marker section each end, two total.

See “Marker Operation” on page 44.

29622

818-045C

Warning: Pinch-Crush

Above both tires, two total

818-339C

Warning: High Pressure Fluid Hazard

On the tongue, one total

See “Hydraulic Hose Hookup” on page 14.

818-580C (Option)

29622

29622

Warning: Overhead Hazard

On marker section each end, two total

See “Marker Operation” on page 44.

401-625M Table of Contents Index 2013-08-13

29622

Page 13

Great Plains Manufacturing, Inc. Table of Contents Index Important Safety Information 9

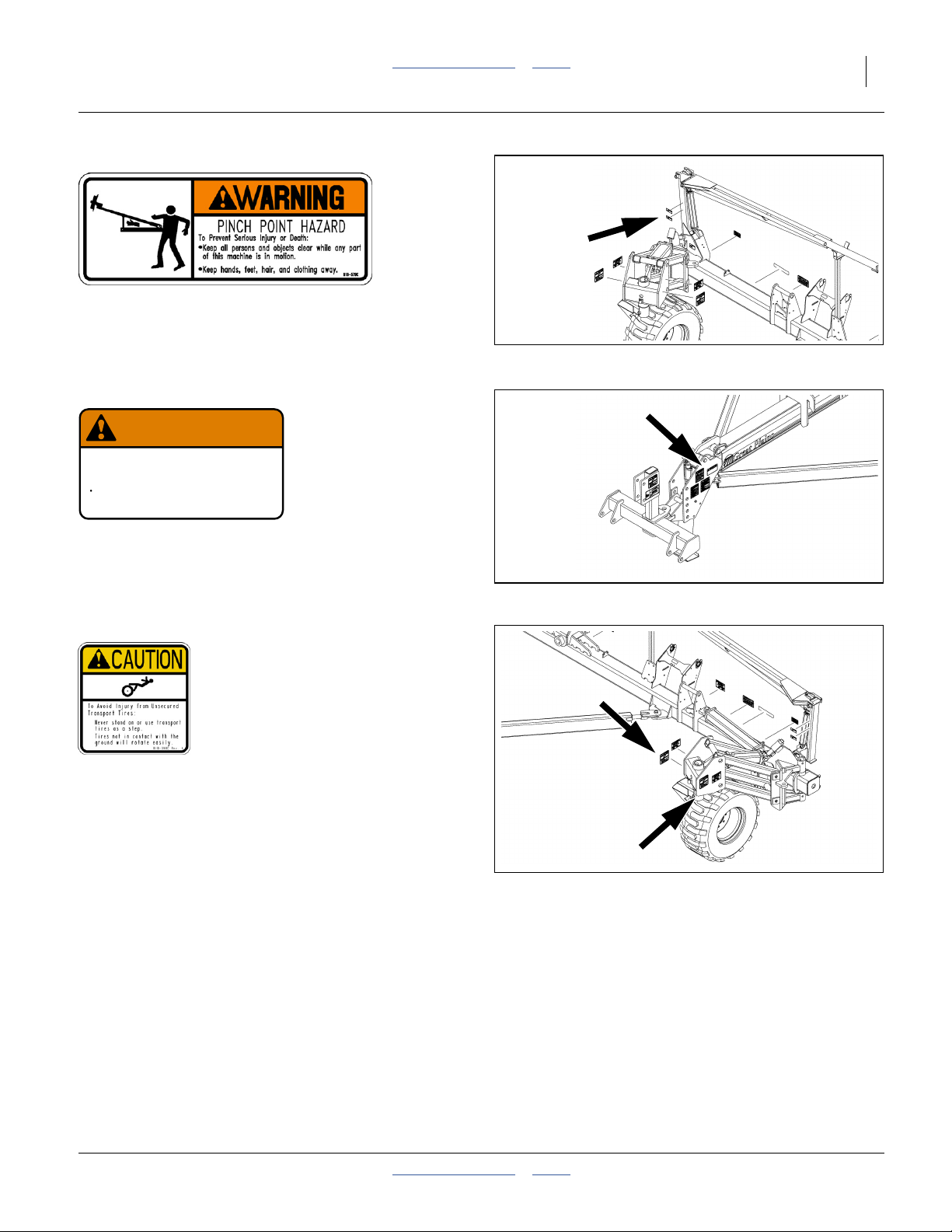

818-579C (Option)

Warning: Pinch-Shear Hazard

On marker section each end, two total

See “Marker Operation” on page 44.

29622

818-188C

WARNING

EXCESSIVE SPEED HAZARD

To Prevent Serious Injury or Death:

Do Not exceed 20 mph maximum transport

speed. Loss of vehicle control and/or machine

can result.

Warning: Excessive Speed

On the tongue, one total

See “Transporting” on page 28.

818-188C Rev. C

29622

818-398C

Caution: Tires Not A Step

Above both tires, two total

In transport configuration, wing gauge wheels are off the

ground and free to spin. In field configuration, at higher

row unit down-forces, wing gauge wheels may have little

or no ground traction.

29622

2013-08-13 Table of Contents Index 401-625M

Page 14

10 YP1125A & YP1625A Table of Contents Index Great Plains Manufacturing, Inc.

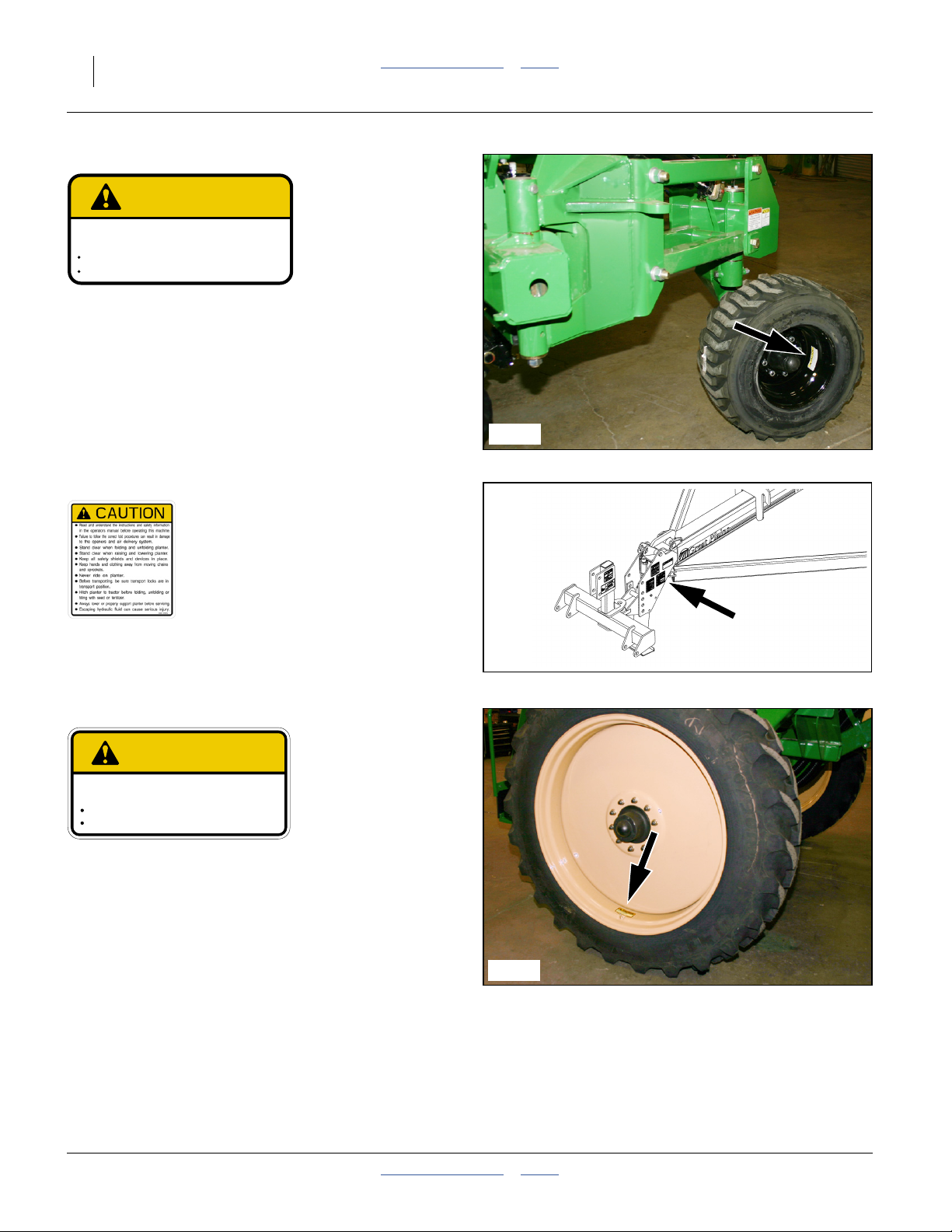

818-578C

CAUTION

To Avoid Injury or Machine Damage from improper Tire

Inflation or Torquing of Wheel Bolts:

Maximum inflation pressure of tires is 65 psi.

Torque wheel bolts to 240 lb-ft.

Caution: Tire Pressure

On hubcap side rim of each gauge wheel;

2 total

838-995C

818-578C

34547

Caution: General

On right side of hitch;

1 total

858-011C

CAUTION

To Avoid Injur y or Machine Damage from Improper Tire

Inflation or Torquing of Wheel Bolts:

Maximum inflation pressure of tires is 49 psi (338 kPa).

Torque wheel bolts to 315 ft-lb (427 N-m).

Warning: Tire Pressure

On outside rim of each main transport wheel;

2 total

858-011C

29622

34548

401-625M Table of Contents Index 2013-08-13

Page 15

Great Plains Manufacturing, Inc. Table of Contents Index 11

Introduction

Great Plains welcomes you to its growing family of new

product owners. This planter has been designed with

care and built by skilled workers using quality materials.

Proper setup, maintenance, and safe operating practices

will help you get years of satisfactory use.

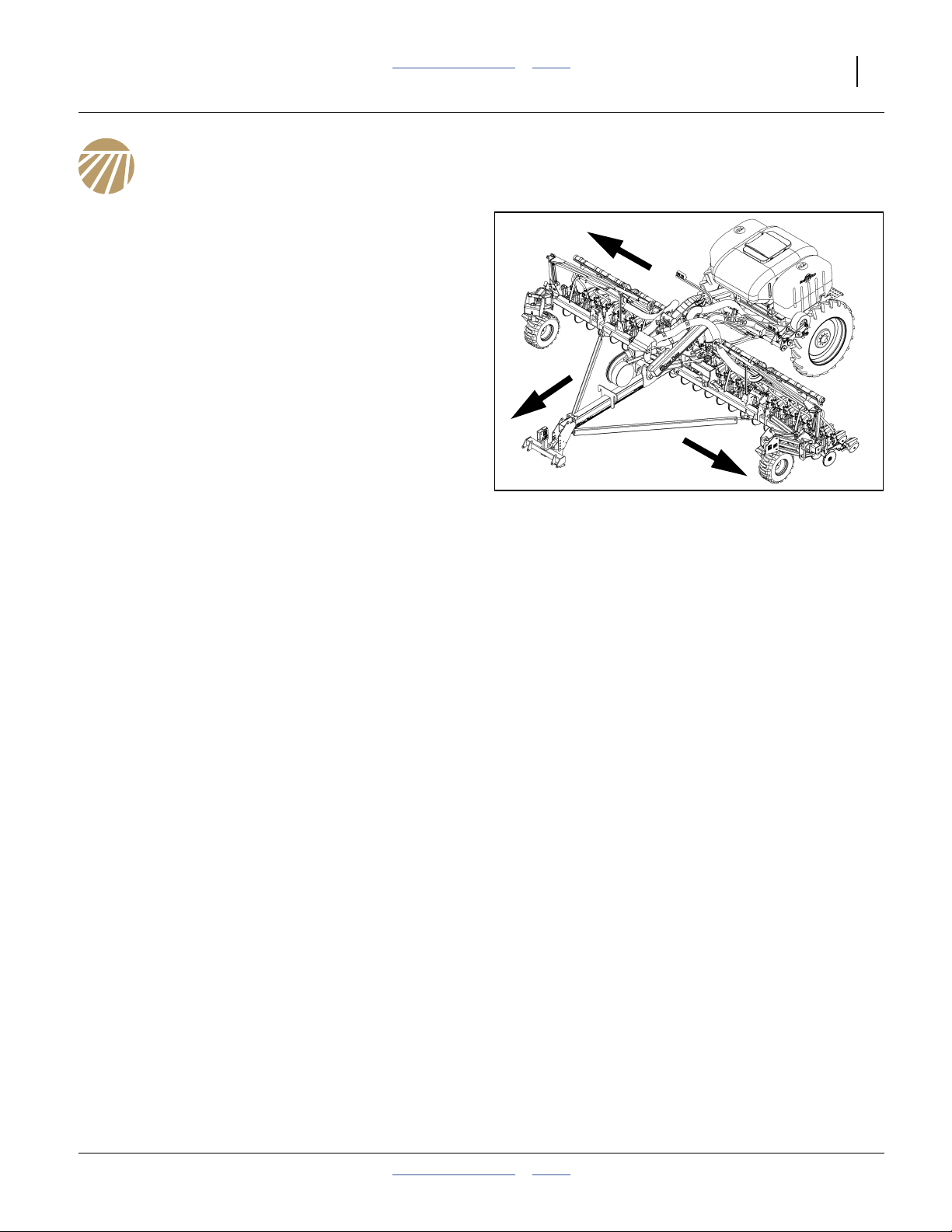

Description of Unit

The 30- and 40-Foot 2-Section Yield-Pro® Planters are

pull-type planting implements for use in conventional till,

minimum-till, or light no-till conditions.

Yield-Pro® Planters have 25 Series, side-depth-control

row-units and Air-Pro

unit-mounted coulters are suitable for light to moderate

no-till conditions only. The planter folds for transport.

Intended Usage

Use the planter to seed production-agriculture crops

only. Do not modify the planter for use with attachments

other than Great Plains options and accessories

specified for use with the planter.

®

seed meters. Optional

R

Figure 1

Left/Right Convention

L

27281

Document Family Covered Models

401-625M Operator Manual (this manual)

401-625B Seed Rate Manual

401-625P Parts Manual

DICKEY-john®IntelliAg® manuals:

110011508 Planter/Drill Control, User Level 1

110011501 Planter/Drill Control, User Level 2&3

110011440 A1 & AI-100 10-inch Virtual Terminal

110011606 AI-120 12-inch Virtual Terminal

DICKEY-john® Quick Start Guides

110011526 YP1225A-1230 12 Row 30-Inch

110011591 YP1225A-1820 18 Row 20-Inch

110011590 YP1225A-2315 23 Row 15-Inch

110011592 YP1225A-24TR 24 Twin Row 30-Inch

110011593 YP1225A-16TR36 16 Twin Row 30-Inch

110011602 YP1625A-1236 12 Row 36-Inch

110011527 YP1625A-1630 16 Row 30-Inch

110011603 YP1625A-1670 16 Row 70 cm

110011601 YP1625A-2420 24 Row 20-Inch

110011605 YP1625A-24TR36 24 Twin Row 36-Inch

110011600 YP1625A-3115 31 Row 15-Inch

110011604 YP1625A-32TR 32 Twin Row 30-Inch

YP1225A-1230 30-Foot, 12-Row, 30-Inch

YP1225A-16TR36 30-Foot, 16-Row (8 Twin), 36-Inch

YP1225A-1820 30-Foot, 18-Row, 20-Inch

YP1225A-2315 30-Foot, 23-Row, 15-Inch

YP1225A-24TR 30-Foot, 24-Row, (12 Twin) 30-Inch

YP1625A-1236 40-Foot, 12-Row, 36-Inch

YP1625A-1630 40-Foot, 16-Row, 30-Inch

YP1625A-1670 12-Meter, 16-Row, 70cm

YP1625A-24TR36 40-Foot, 24-Row, 20-Inch

YP1625A-2420 40-Foot, 24-Row (12 Twin), 36-Inch

YP1625A-3115 40-Foot, 31-Row, 15-Inch

YP1625A-32TR 40-Foot, 32-Row (16 Twin), 30-Inch

Using This Manual

This manual familiarizes you with safety, assembly,

operation, adjustments, troubleshooting and

maintenance. Read this manual and follow the

recommendations to help ensure safe and efficient

operation.

The information in this manual is current at printing.

Some parts may change to assure top performance.

2013-08-13 Table of Contents Index 401-625M

Page 16

12 YP1125A & YP1625A Table of Contents Index Great Plains Manufacturing, Inc.

Definitions

The following terms are used throughout this manual.

Right-hand and left-hand as used in

this manual are determined by facing

the direction the machine will travel

while in use unless otherwise stated.

An orientation rose in some line art

illustrations shows the directions of:

Up, Back, Left, Down, Front, Right.

R

F

U

B

L

D

A crucial point of information related to the preceding topic.

Read and follow the directions provided before continuing, to

ensure safety, avoidance of machine damage, and to achieve

desired field results.

Note: Useful information related to the preceding topic.

Owner Assistance

If you need customer service or repair parts, contact a

Great Plains dealer. They have trained personnel, repair

parts, and equipment specially designed for Great Plains

products.

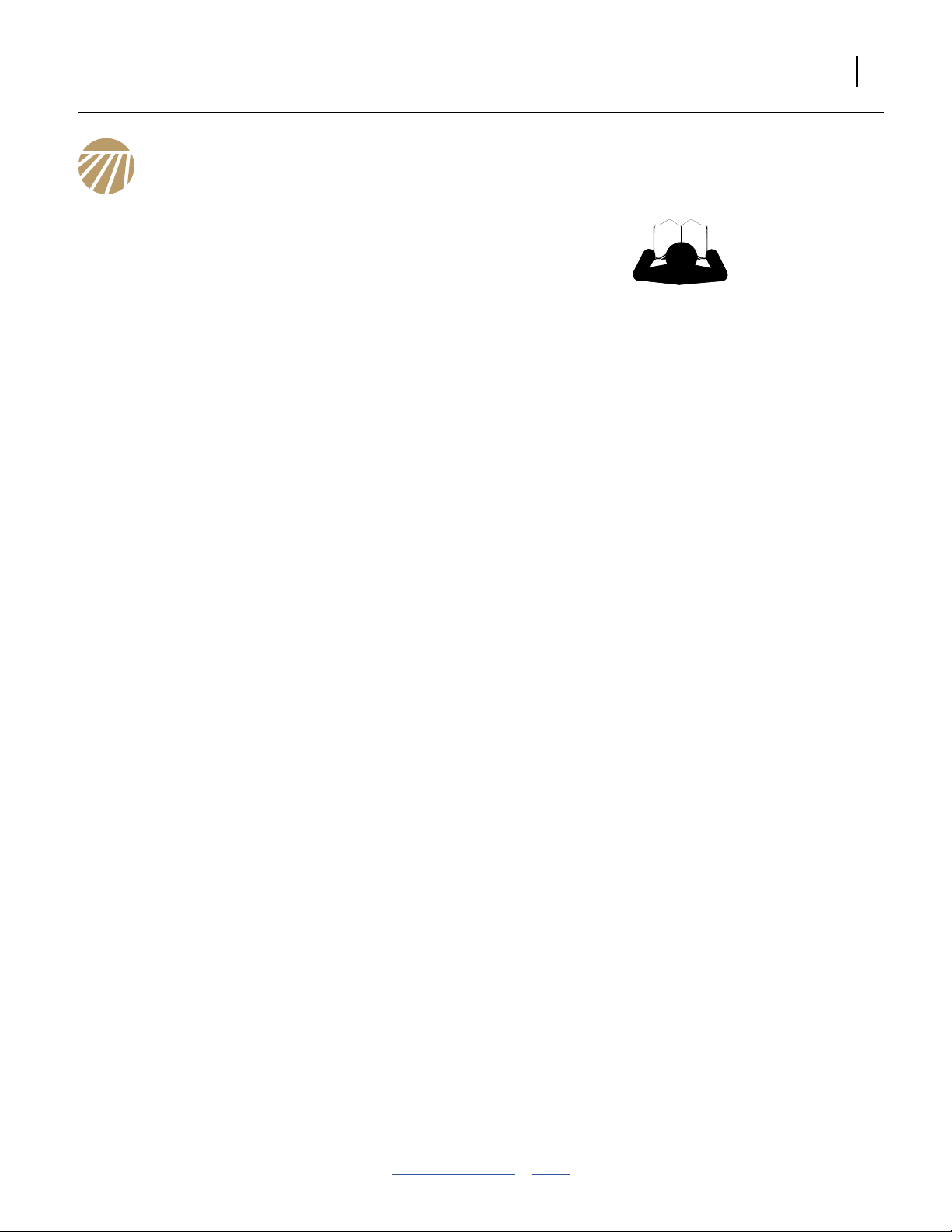

Refer to Figure 2

Your planter’s parts were specially designed and should

only be replaced with Great Plains parts. Always use the

serial and model number when ordering parts from your

Great Plains dealer. The serial-number plate is located

on the rear face of the right axle.

Record your Planter model and serial number here for

quick reference:

Model Number:__________________________

Serial Number: __________________________

Your Great Plains dealer wants you to be satisfied with

your new machine. If you do not understand any part of

this manual or are not satisfied with the service received,

please take the following actions.

1. Discuss the matter with your dealership service

manager. Make sure they are aware of any problems

so they can assist you.

2. If you are still unsatisfied, seek out the owner or

general manager of the dealership.

For further assistance write to:

U

L

B

F

R

D

Figure 2

Serial Number Plate

Product Support

Great Plains Mfg. Inc., Service Department

PO Box 5060

Salina, KS 67402-5060

27284

401-625M Table of Contents Index 2013-08-13

Page 17

Great Plains Manufacturing, Inc. Table of Contents Index 13

Preparation and Setup

This section helps you prepare your tractor and planter

for use. Before using the in the field, you must hitch the

planter to a suitable tractor and level the planter.

Initial Setup

If the planter has just been delivered, or broken down for

re-shipment, these items need to be completed prior to

first field use:

•“Hydraulic Charge and Bleed” on page 146, which

includes:

•“Console Installation” on page 146

•“Level Planter” on page 147, and

•“Marker Setup” on page 150.

You may also need to install features, options and

accessories that were not factory- or dealer-installed.

Pre-Planting Setup

The balance of this section covers items that need to be

completed or checked prior to each field use of the

planter.

1. Read and understand “Important Safety

Information” on page 1.

2. Check that all working parts are moving freely, bolts

are tight, and cotter pins are spread.

3. Check that all grease fittings are in place and

lubricated. See “Lubrication” on page 104.

4. Check that all safety decals and reflectors are

correctly located and legible. Replace if damaged.

See “Safety Decals” on page 6

5. Inflate tires to pressure recommended and tighten

wheel bolts as specified. See “Tire Inflation Chart”

on page 127.

6. If returning the planter to service from storage,

remove any grease used to protect cylinder rods.

2013-08-13 Table of Contents Index 401-625M

Page 18

14 YP1125A & YP1625A Table of Contents Index Great Plains Manufacturing, Inc.

Hitching Tractor to Planter

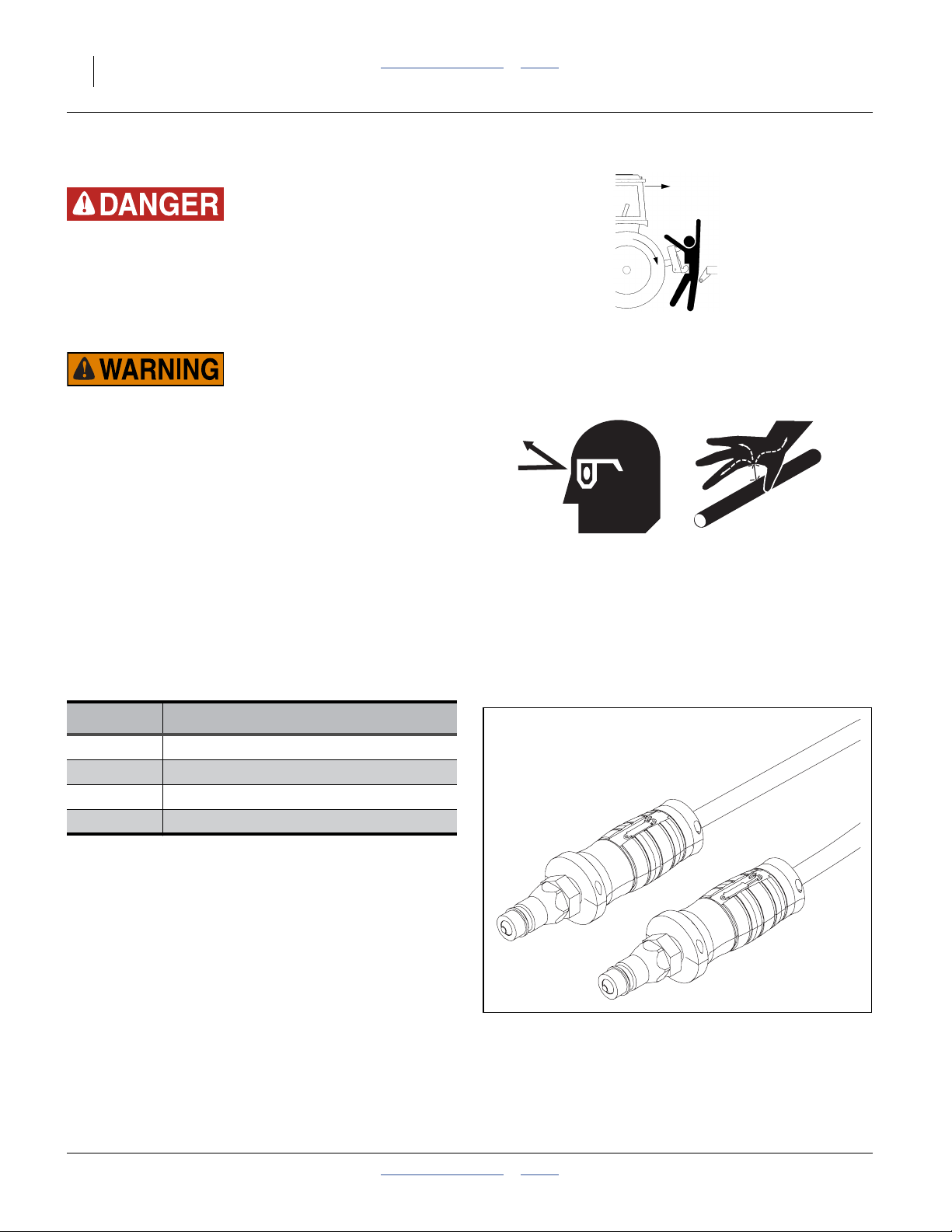

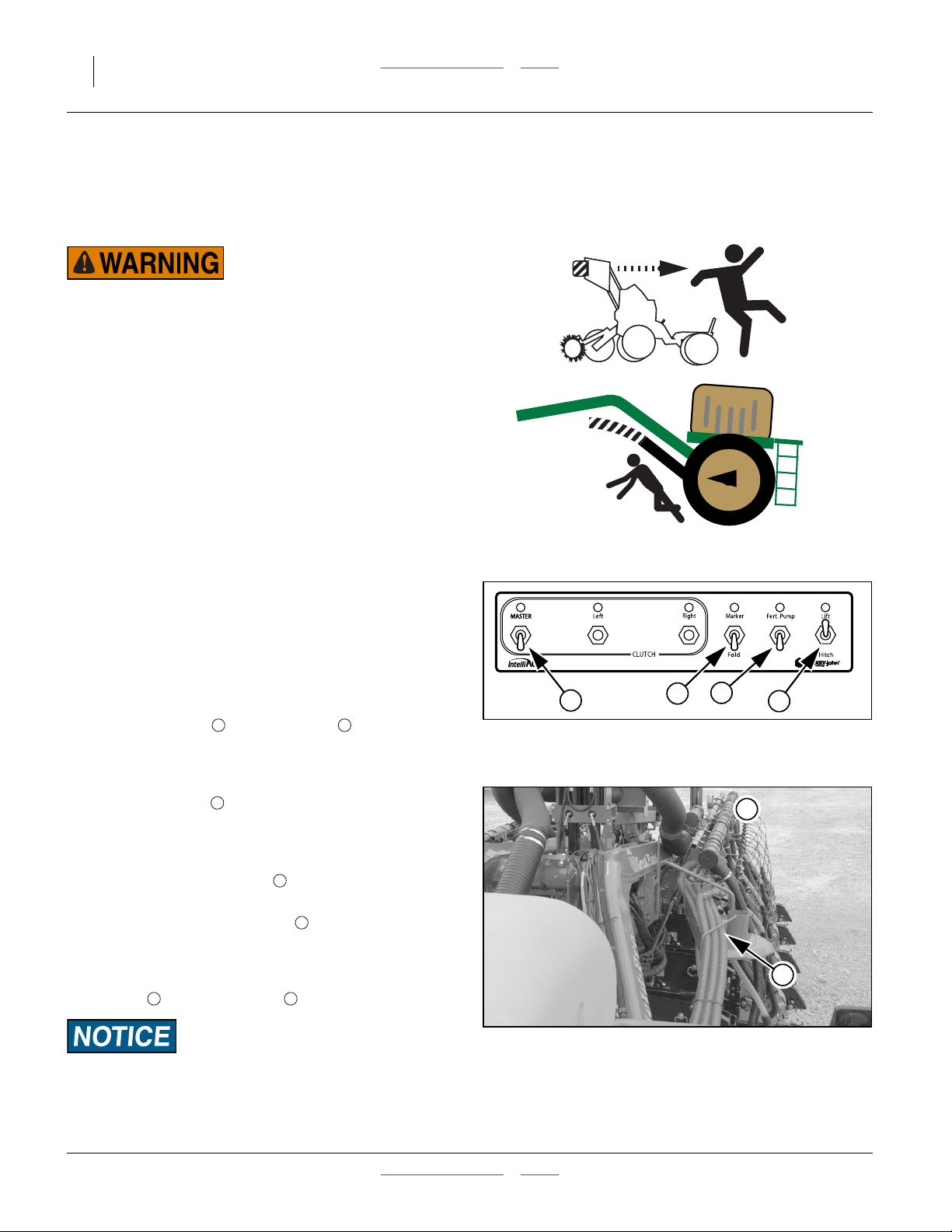

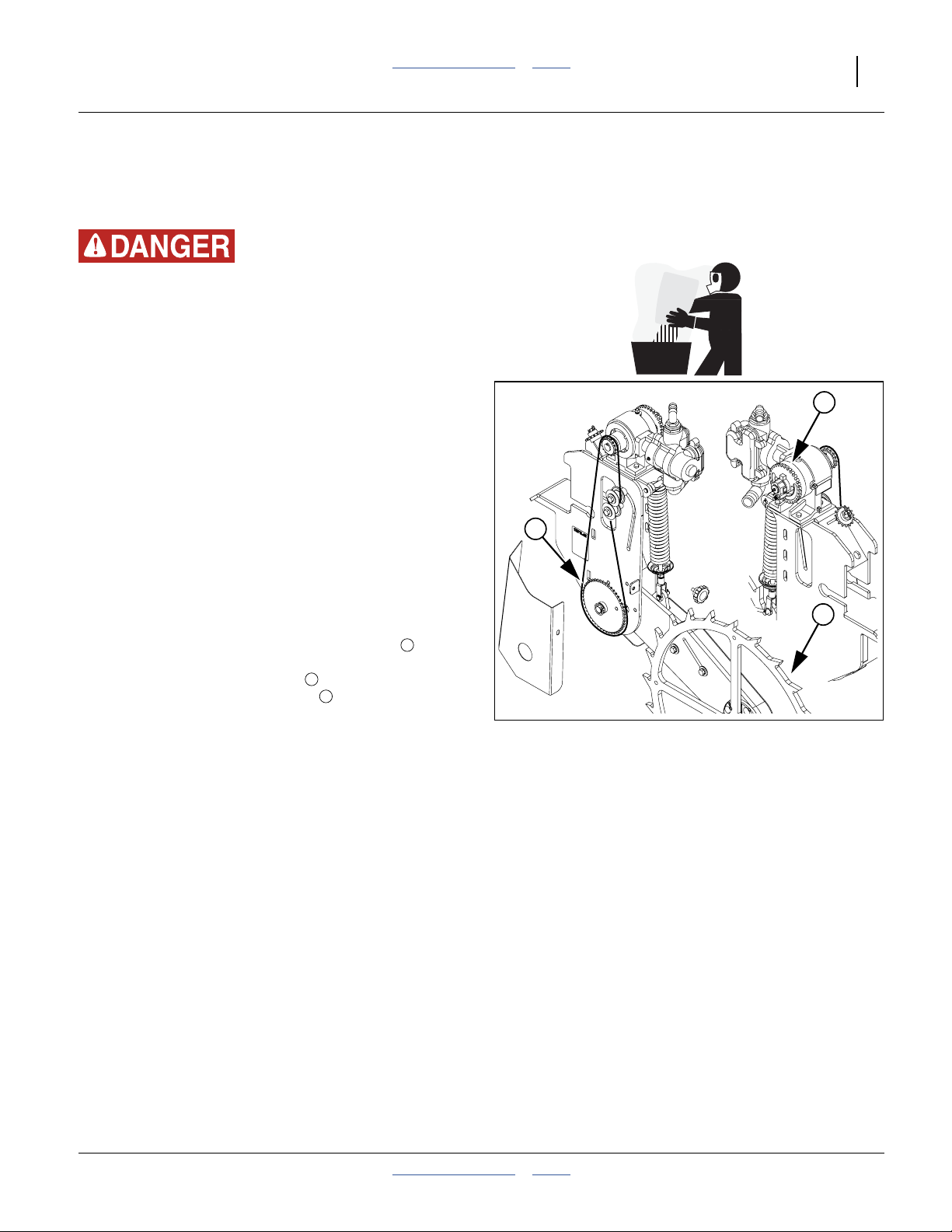

Crushing Hazard:

Do not stand or place any part of your body between planter

and moving tractor. You may be severely injured or killed by

being crushed between the tractor and planter. Stop tractor

engine and set park brake before attaching cables and hoses.

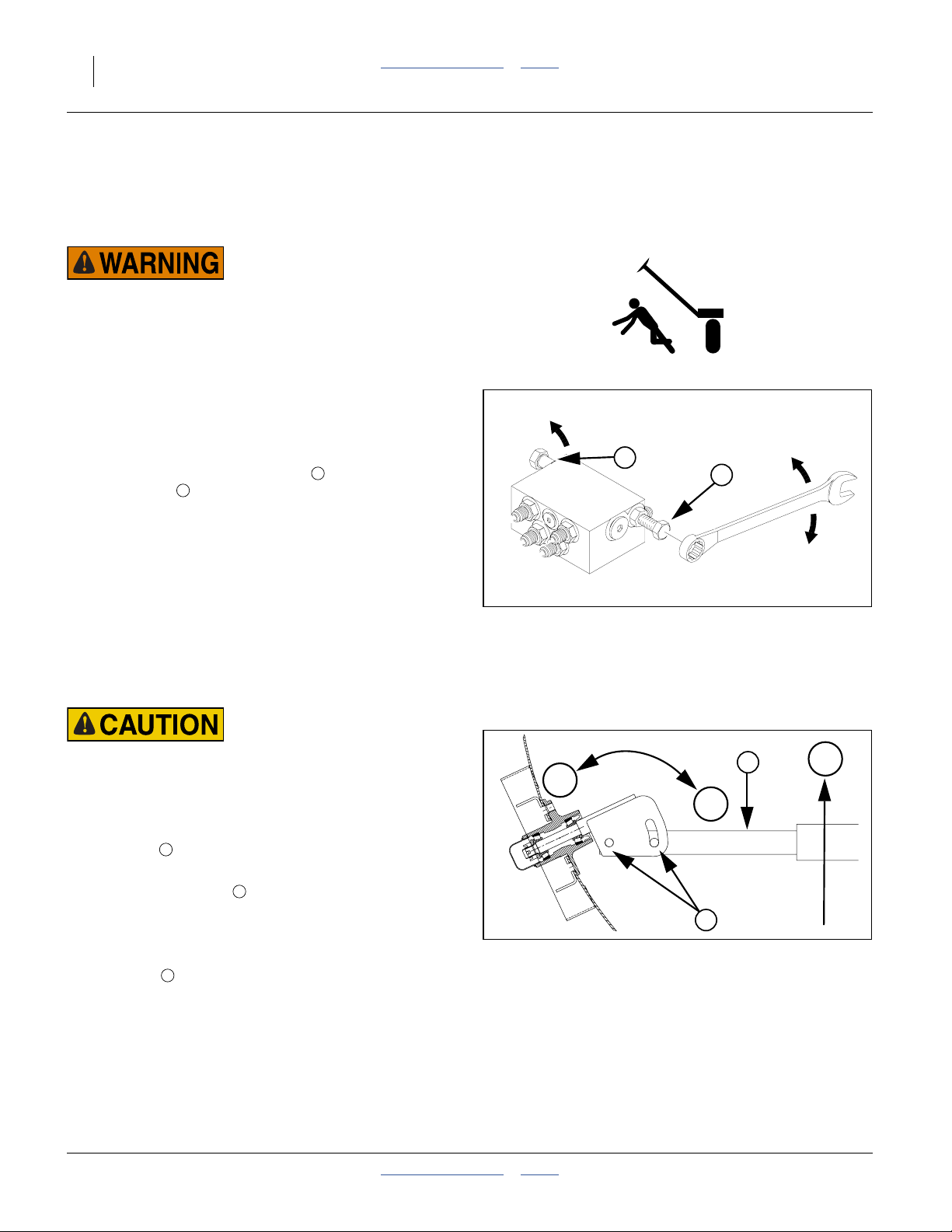

Hydraulic Hookup

High Pressure Fluid Hazard:

Relieve pressure before disconnecting hydraulic lines.

Escaping fluid under pressure can have sufficient pressure to

penetrate the skin causing serious injury. Use a piece of paper

or cardboard, NOT BODY PARTS, to check for leaks. Wear

protective gloves and safety glasses or goggles when working

with hydraulic systems. If an accident occurs, seek immediate

medical attention from a physician familiar with this type of

injury.

Hydraulic Hose Hookup

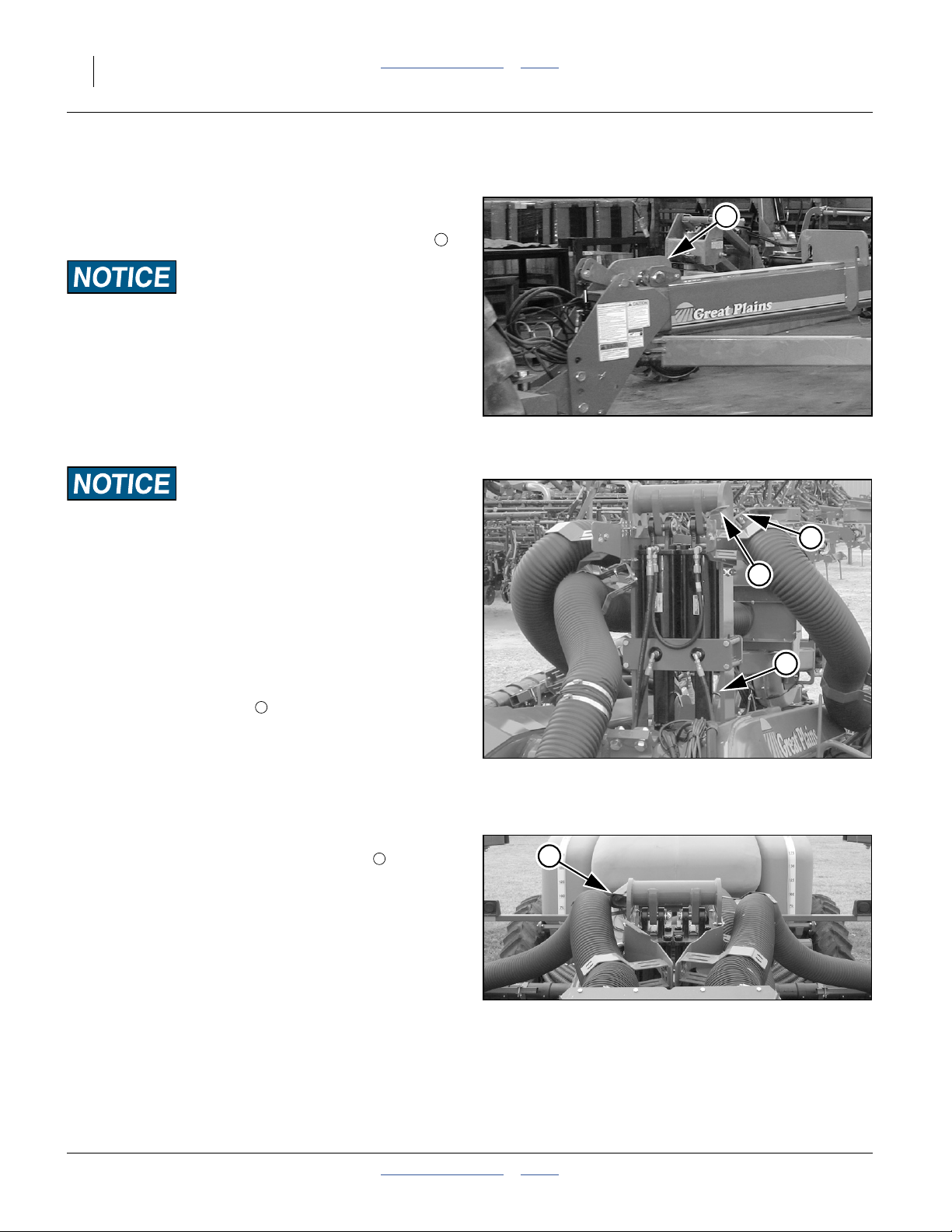

Refer to Figure 3

Great Plains hydraulic hoses have color coded handle

grips to help you hookup hoses to your tractor outlets.

Hoses that go to the same remote valve are marked with

the same color.

Current Style Color Coded Hose Handles

Color Hydraulic Function

Gray Fold/Marker

Blue Lift/Tongue

Black Fan

Yellow Hydraulic Drive (Option)

To distinguish hoses on the same hydraulic circuit, refer

to the symbol molded into the handle grip. Hoses with an

extended-cylinder symbol feed cylinder base ends.

Hoses with a retracted-cylinder symbol feed cylinder rod

ends.

For hydraulic fan and drive motors, connect the hose

under the retracted cylinder symbol to the pressure side

of the motor. Connect the hose under the extended

cylinder symbol to the return side of the motor.

The fan motor further requires hookup of a third line,

which returns hydraulic fluid from the fan motor case.

Figure 3

Color Coded Hose Handles

31733

401-625M Table of Contents Index 2013-08-13

Page 19

Great Plains Manufacturing, Inc. Table of Contents Index Preparation and Setup 15

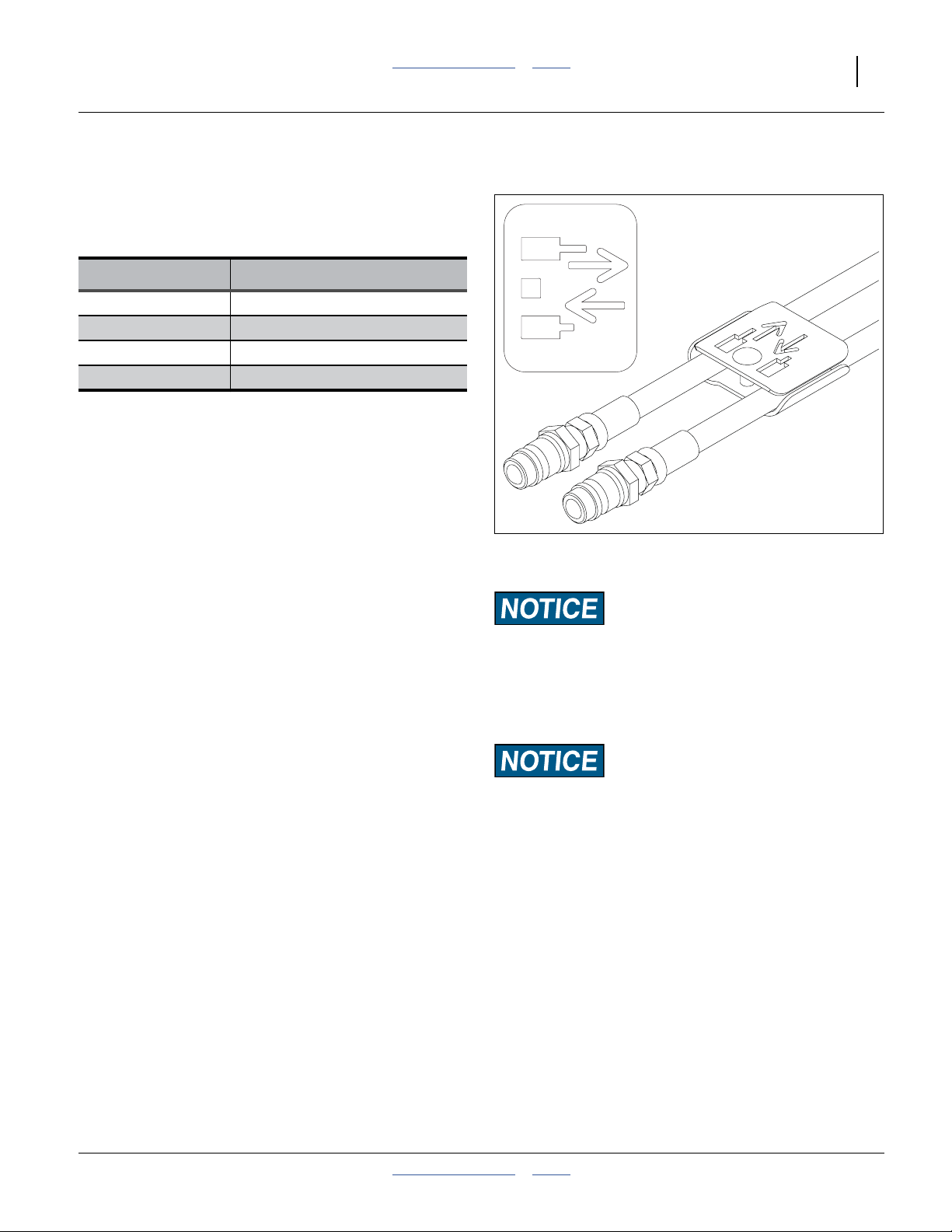

Older Style Hoses with Color Ties

Refer to Figure 4

Great Plains hydraulic hoses are color coded. Hoses that

go to the same remote valve are marked with the same

color tie.

Color Hydraulic Function

White Fold/Marker

Blue Lift/Tongue

Orange Fan

Yellow Hydraulic Drive (Option)

To distinguish hoses on the same hydraulic circuit, refer

to plastic hose label. Hose under extended-cylinder

symbol feeds cylinder base ends. Hose under

retracted-cylinder symbol feeds cylinder rod ends.

Protecting Hydraulic Motor Seals

Low Pressure (Case) Drain Connection

7. Attach case drain hose to low pressure drain

connection.

8. Connect low pressure return hose to low pressure

return connector.

9. If the tractor has a limited number of remotes

capable of continuous flow, use them for the

hydraulic fan and optional hydraulic drive. (See

“Specifications and Capacities” on page 124 for

tractor requirements.)

Figure 4

Older Style Hoses w/Label

Motor Seal Damage Risk:

Case Drain Hose must be attached first,

prior to inlet and return hoses being connected.

Case Drain Hose must be detached last,

to prevent damage to the fan motor.

27270

Hydraulic Motor Performance Risk:

DO NOT hook case drain line to a “power-beyond port”.

2013-08-13 Table of Contents Index 401-625M

Page 20

16 YP1125A & YP1625A Table of Contents Index Great Plains Manufacturing, Inc.

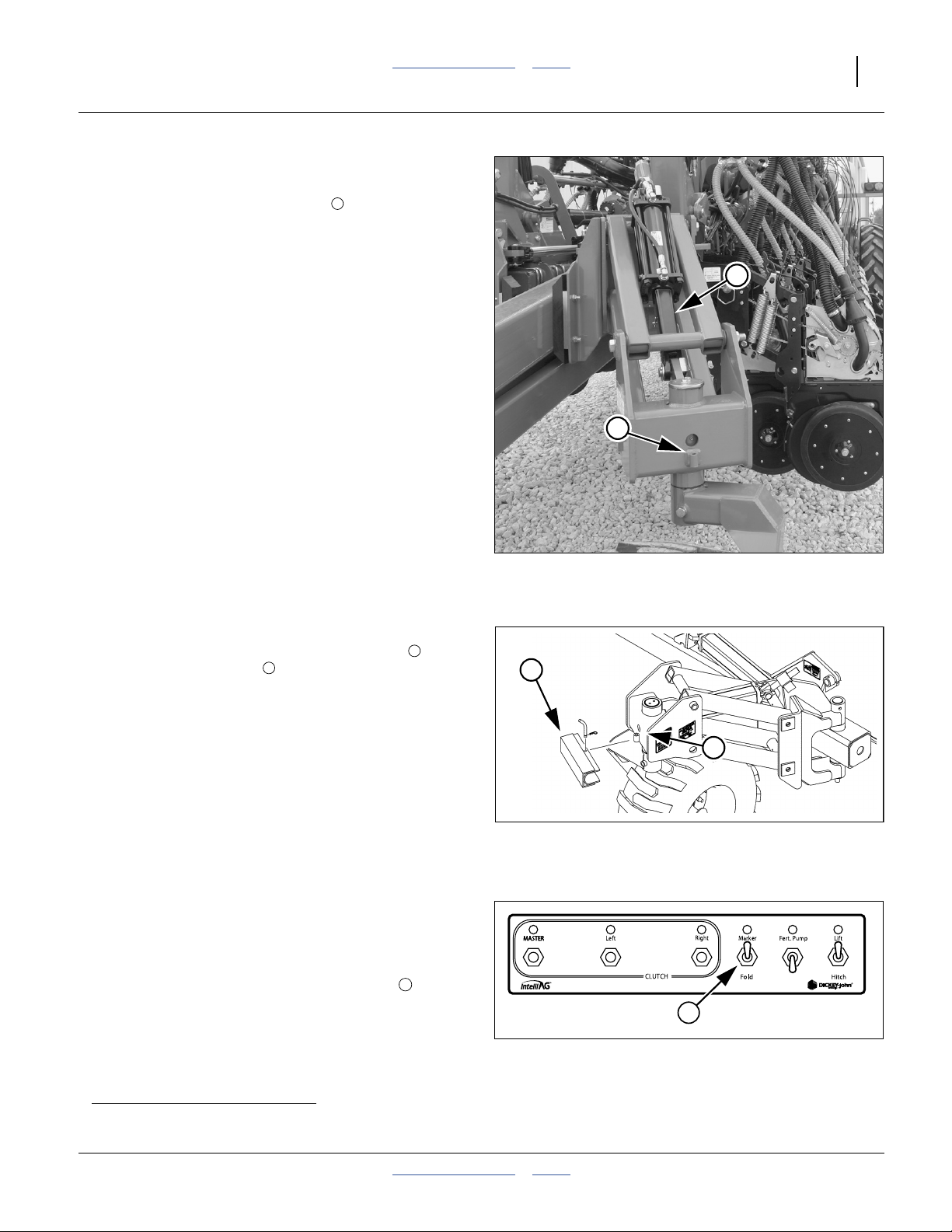

3-Point Hitch

Refer to Figure 5

10. Connect your tractor 3-point to the planter 3-point

hitch. If using quick hitch be sure planter locks into

hitch securely.

11. Raise tractor 3-point just enough to relieve pressure

off of the parking stand.

12. Store 3-point stands . There are two methods:

1

a. Remove lower pins . Swing stand under hitch.

Reinsert pin beneath stand at inner hole.

b. Remove both pins. Invert stand. Re-pin.

Load Sway Hazard:

Adjust 3-point hitch arms and sway blocks to minimize any

side-to-side sway to assure proper tracking in the field, and

safe road travel.

13. Connect hydraulic hoses to tractor remotes. See

“Hydraulic Hose Hookup” on page 14

2

Hitching with Hydraulic Tongue (Option)

Refer to Figure 6 (showing bypass valve closed)

1. Move the tractor to near hitching position.

2. Connect the hydraulic hoses for the tongue circuit.

This needs to be done before hitching in order to

raise and lower the tongue. See “Hydraulic Hose

Hookup” on page 14. Allow slack for hitch

movements. Close the tongue cylinder bypass valve.

3. Make electrical connections for at least the planter

monitor circuit (necessary to control planter hydraulic

systems). See page 17.

4. Check that hitch local bypass valve is closed.

Refer to Figure 7

5. Set the cab CFM (Clutch Folding Module) Lift/Hitch

switch to Hitch.

6. Retract the Hitch/Lift circuit to set the tongue height

to clear the draw-bar. Back the tractor into alignment

and pin the draw-bar.

Local Float on Hydraulic Tongue

Refer to Figure 6

The hydraulic tongue must be in Float during planter

moves.

If it is necessary to move the planter without first

connecting it to a tractor that has a float-capable circuit

for the hydraulic tongue, open the bypass valve on the

tongue cylinder. This provides local floating capability at

the tongue.

2

3

3

OPEN

3

CLOSED

Hitching with Hydraulic Tongue

2

Figure 5

3-Point Hitch Stands Stored

Figure 6

Figure 7

CFM for Hydraulic Hitching

1

29732

28477

2

28483

401-625M Table of Contents Index 2013-08-13

Page 21

Great Plains Manufacturing, Inc. Table of Contents Index Preparation and Setup 17

Raising/Lowering Tongue

In addition to hitching, tongue raising and lowering is

required during fold and unfold to engage and disengage

the wing locks.

With the standard 3-point hitch, the planter tongue is

raised and lowered by raising and lowering the 3-point.

With the optional hydraulic tongue, the planter tongue is

raised by extending the hitch cylinder, and lowered by

retracting the hitch cylinder.

h

Hitching with Either Hitch

7. Set the initial tongue height, using 3 point or cylinder

of hydraulic tongue. Distance , measured at top of

tongue tube is:

46 inches (117 cm) above ground level for YP12, or

42 inches (107 cm) above ground level for YP16.

Additional planter leveling information is found on

page 147.

8. Connect other hydraulic hoses to tractor remotes.

See “Hydraulic Hose Hookup” on page 14

h

Figure 8

Base Height

25316

Electrical Hookup

Refer to Figure 9

Your planter is equipped with two standard systems

requiring separate electrical connections. You may also

have optional equipment requiring additional

connections.

Make sure tractor is shut down with accessory power off

before making connections.

These connections may be made in any order. The key

requirement is that all connections be made prior to

planter movement.

9. Plug the planter light cable to the tractor.

10. Connect monitor lead to monitor harness. (See

page 146 for console installation.)

11. Connect any optional harnesses.

1

2

Figure 9

Connector Identification

1

2

25236

25237

2013-08-13 Table of Contents Index 401-625M

Page 22

18 YP1125A & YP1625A Table of Contents Index Great Plains Manufacturing, Inc.

Store Main Parking Stand

Refer to Figure 10

12. Remove the lower pin holding the parking

7

stand . Swing the parking stand back and up until it

is above the rear hole . Place the holding pin in the

rear hole and allow the parking stand to rest on it.

This will be the transport position for the parking

stand.

13. Adjust the top link of a 3-point long enough so the

ball swivel does not bottom out when fully raised.

14. Secure hoses using hose post loops (not shown) so

that hoses have ample slack for lifts and turns, but

cannot get caught in tongue lock or ball swivel.

Failure to do so could cause hose to be crushed

requiring hose replacement.

15. If equipped with hydraulic hitch option, connect

safetychainto a suitable anchor point on the tractor.

5

6

6

7

Storing Parking Stand

5

Figure 10

22813

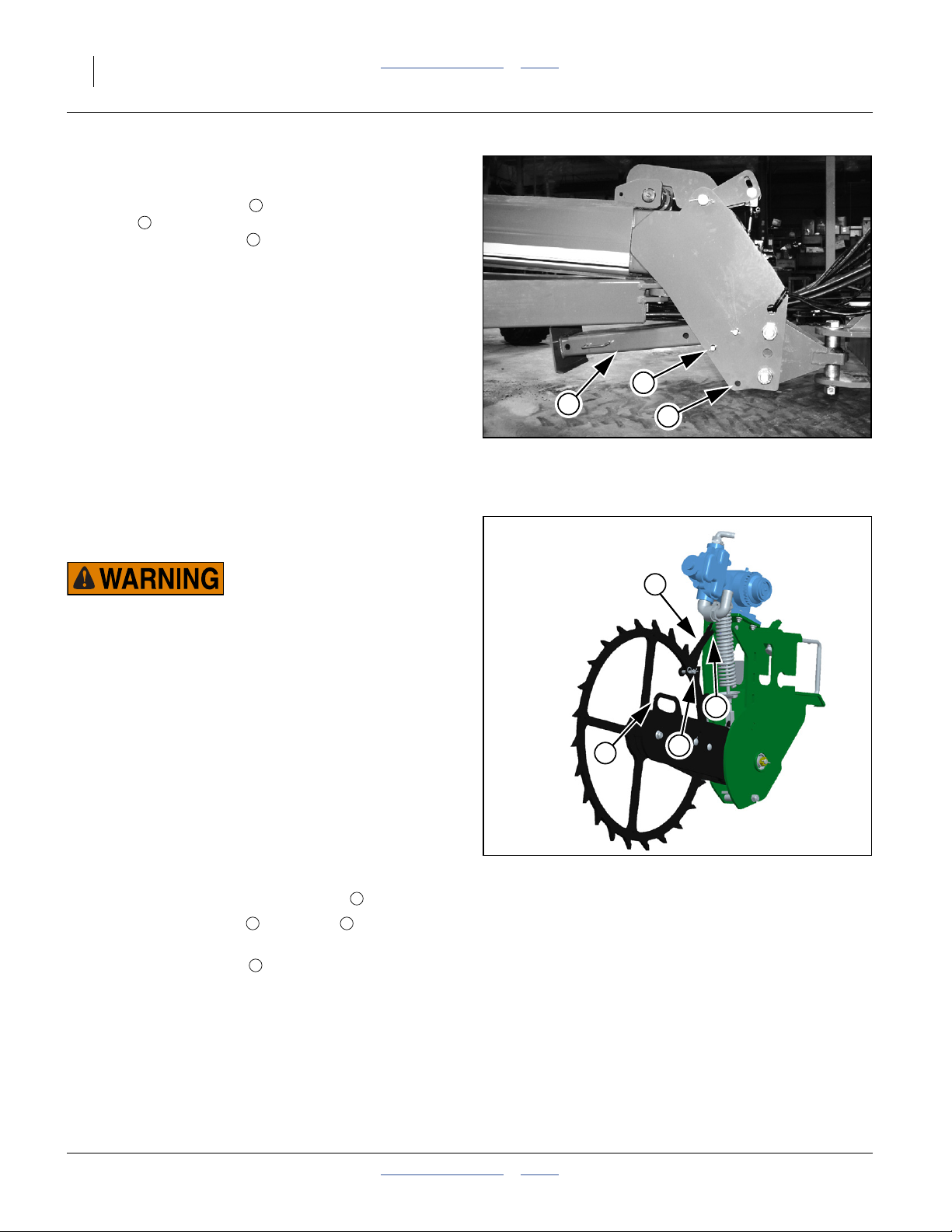

Lock Up Fertilizer Drive

YP1225A serial number B1059E+

YP1625A serial number B1106F+

Loss of Control and Sharp Object/Crushing Hazards:

Do not lift or lower wheel by spoke or rim; use handle only.

Keep legs and feet out from under wheel. 90 pounds (41 kg)

force is required to lift wheel. If you lose your grip before

pinning, or after unpinning, the arm snaps down rapidly. The

traction teeth and the force of the wheel impact can inflict

serious injury.

The liquid fertilizer option uses a piston pump driven by a

ground contact wheel. When not using the fertilizer drive,

preserve the pump by locking up the ground wheel. On

older models remove the chain.

Note: Do not operate planter pump when not applying

material.

Refer to Figure 11

For YP1225A and YP1625A planters:

16. Remove clevis pin from storage hole .

17. Release the lock arm , lift handle to lift ground

wheel up to position it in-between lock arm.

18. Secure with pin clevis and cotter pin.

5 7

6

4

5

4

7

Locked Up Fertilizer Drive

6

Figure 11

32364

401-625M Table of Contents Index 2013-08-13

Page 23

Great Plains Manufacturing, Inc. Table of Contents Index 19

Operating Instructions

This section covers general operating procedures.

Experience, machine familiarity and the following

information will lead to efficient operation and good

working habits. Always operate farm machinery with

safety in mind.

Pre-Start Checklist

1. Carefully read “Important Safety Information” on

page 1.

2. Lubricate planter as indicated under “Lubrication”

on page 104.

3. Check all tires for proper inflation. See “Tire

Inflation Chart” on page 127.

4. Check all bolts, pins and fasteners. Torque as shown

in “End of “Appendix A - Reference Information”.”

on page 140.

5. Check planter for worn or damaged parts. Repair or

replace parts before going to the field.

6. Check hydraulic hoses, fittings and cylinders for

leaks. Repair or replace before going to the field.

7. Be sure hydraulic hoses are securely held out of the

ball swivel area at hitch. Failure to do so could cause

hoses to pinch requiring hose replacement.

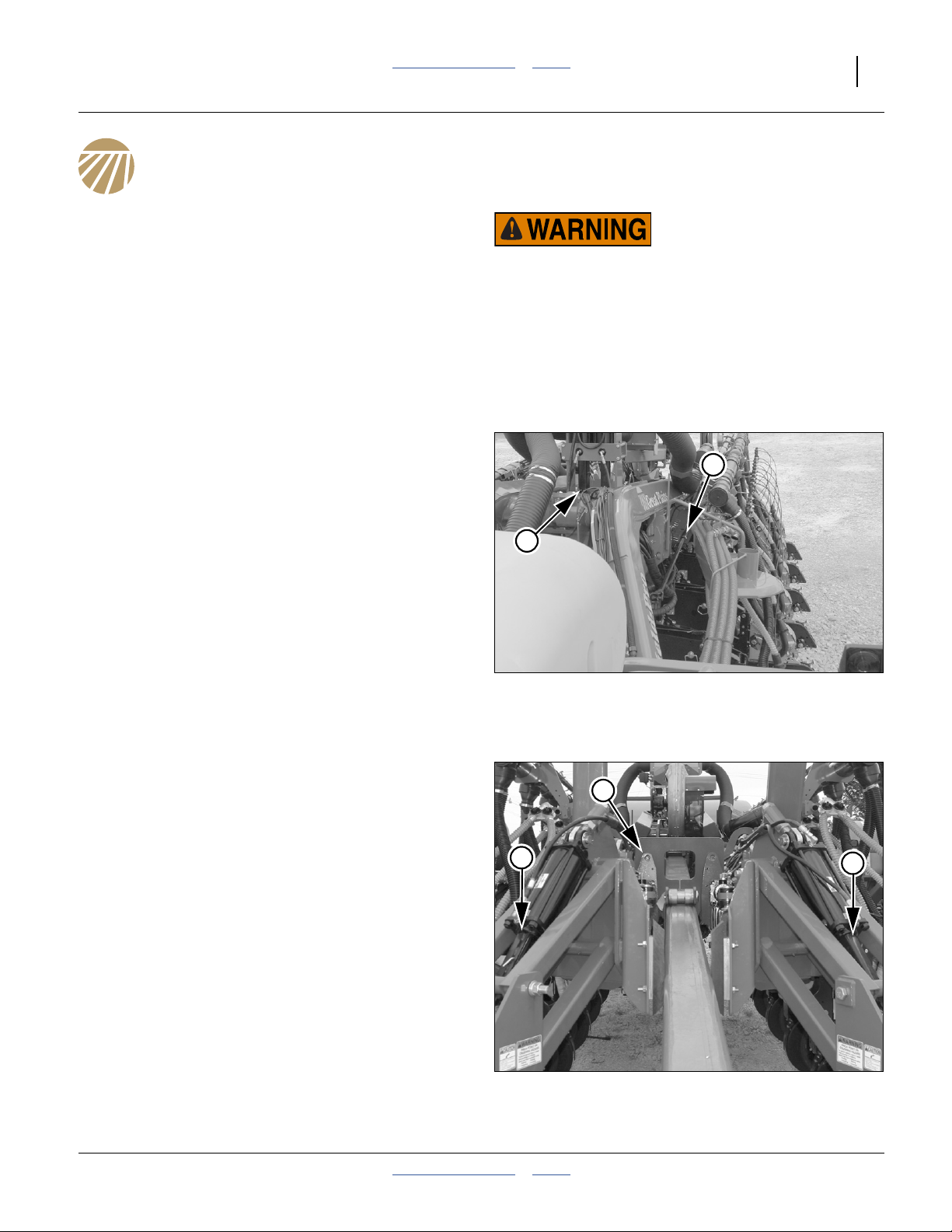

High Pressure Fluid Hazard:

Check all hydraulic lines and fittings before applying pressure.

Escaping fluid under pressure can have sufficient pressure to

penetrate the skin. Fluid escaping from a very small hole can

be almost invisible. Use paper or cardboard, not body parts,

and wear heavy gloves to check for suspected leaks. If an accident occurs, seek immediate medical attention from a physician familiar with this type of injury.

1

4

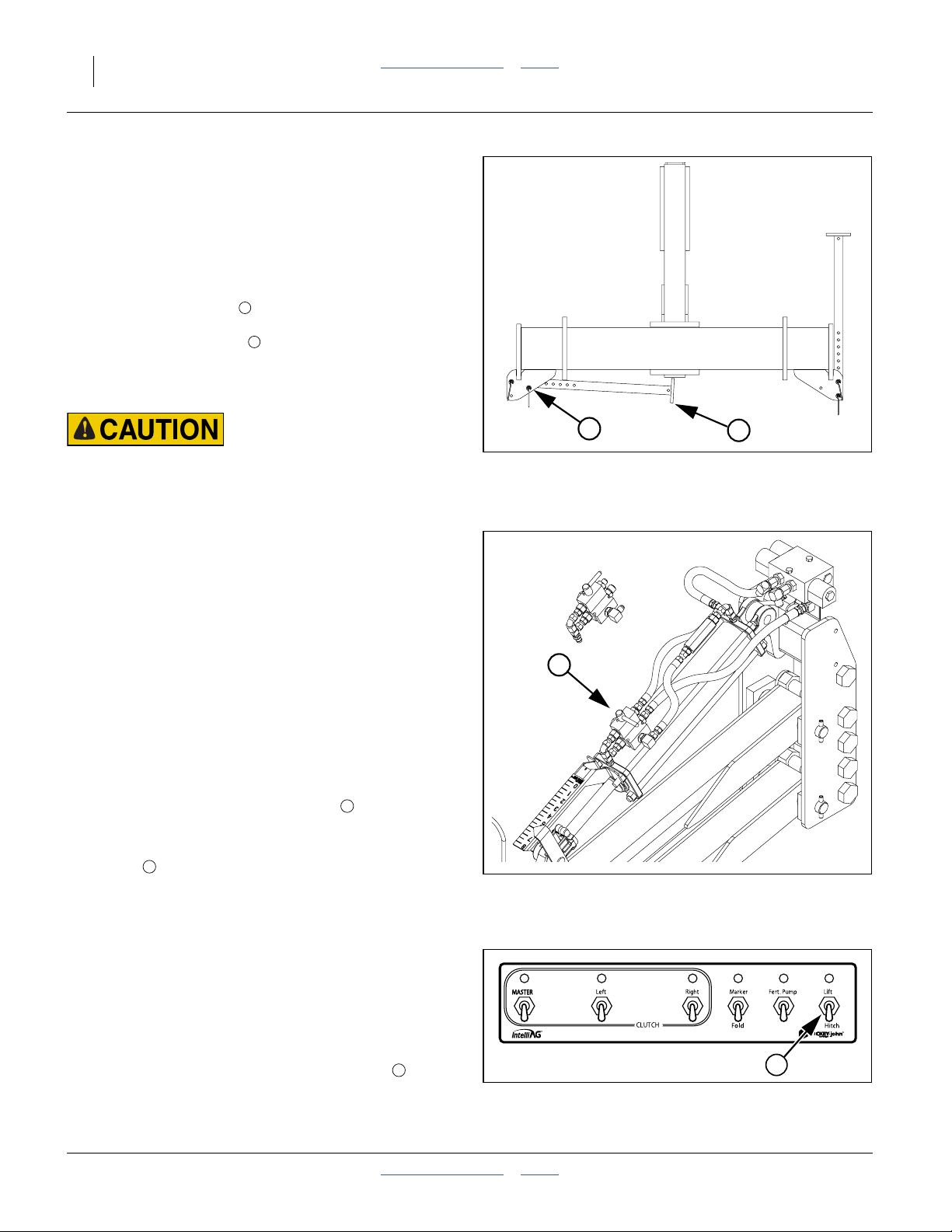

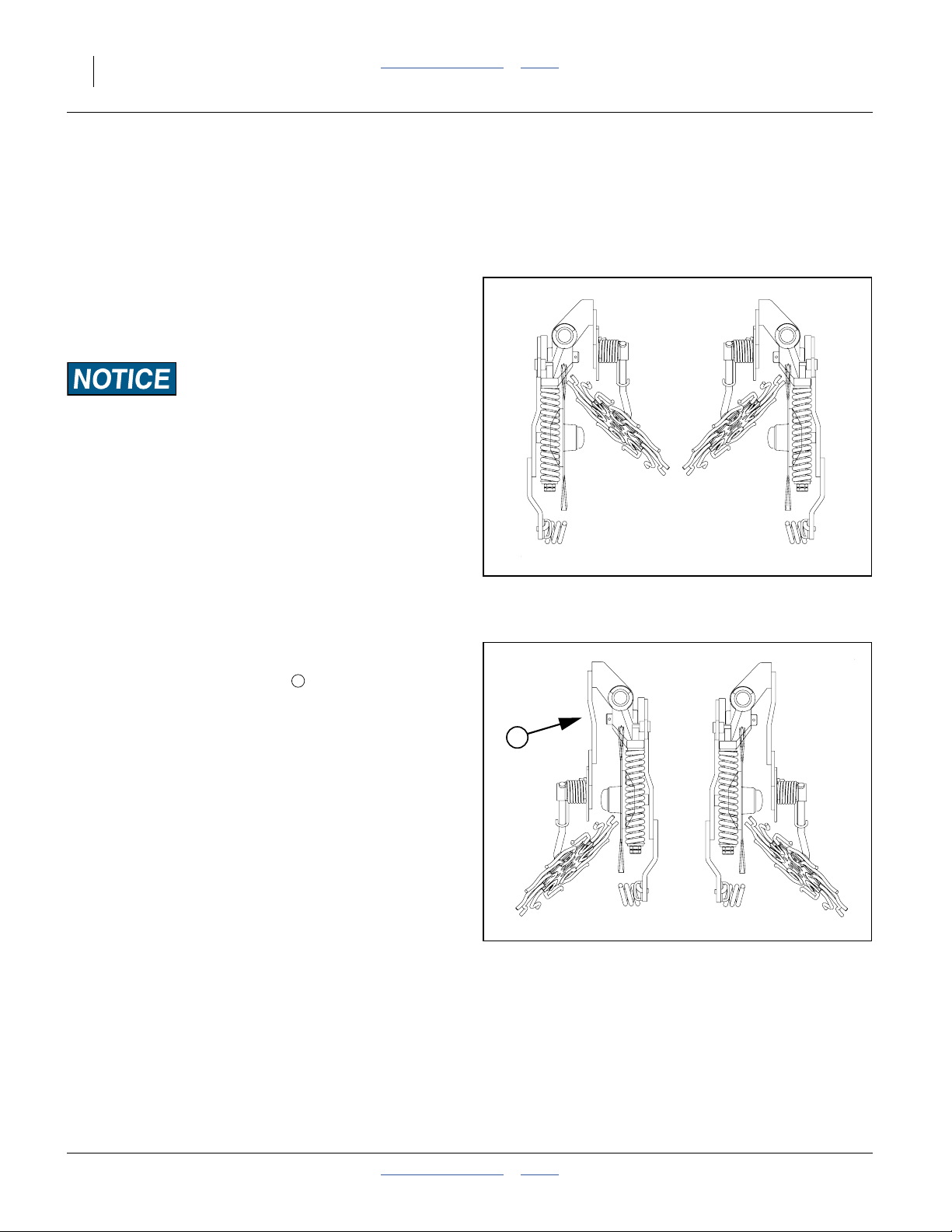

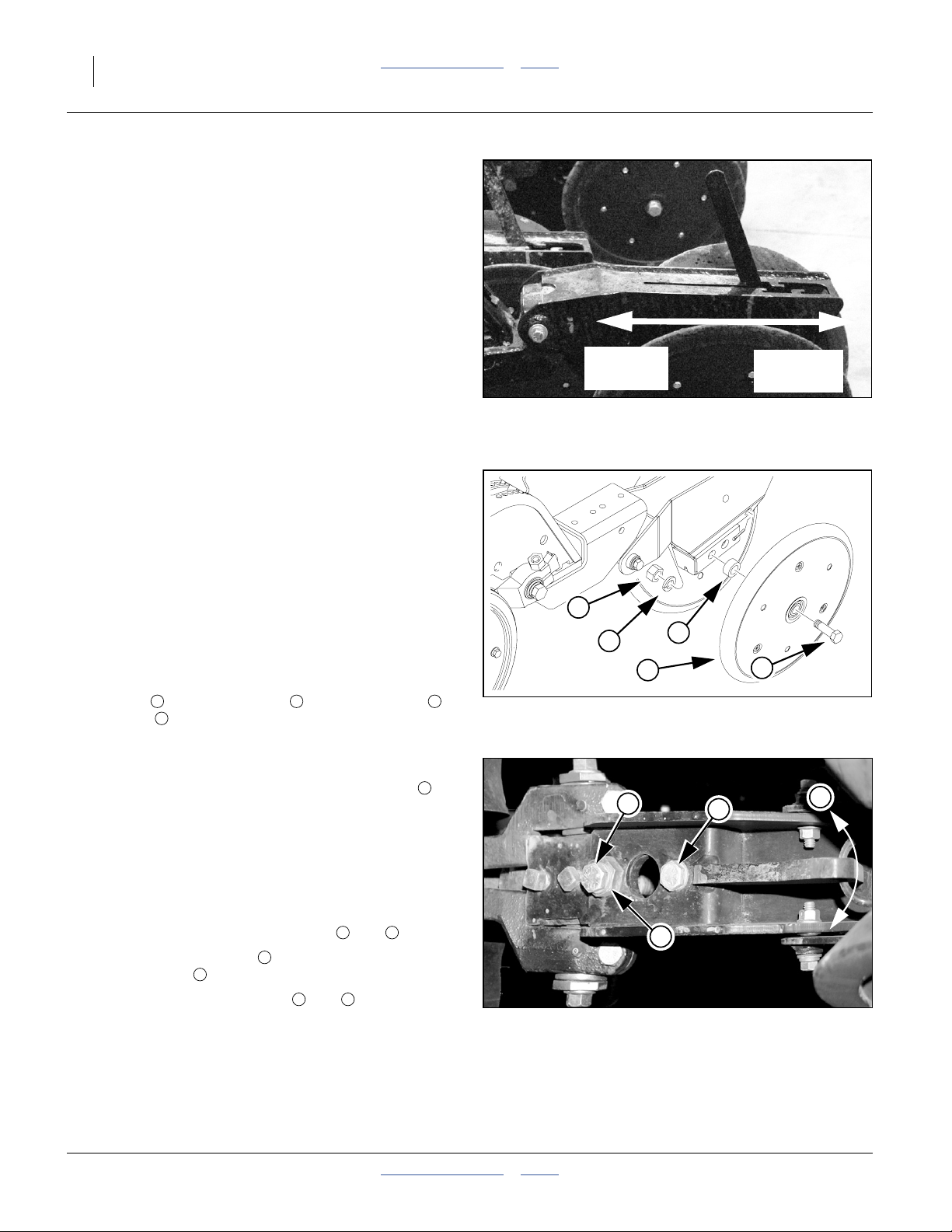

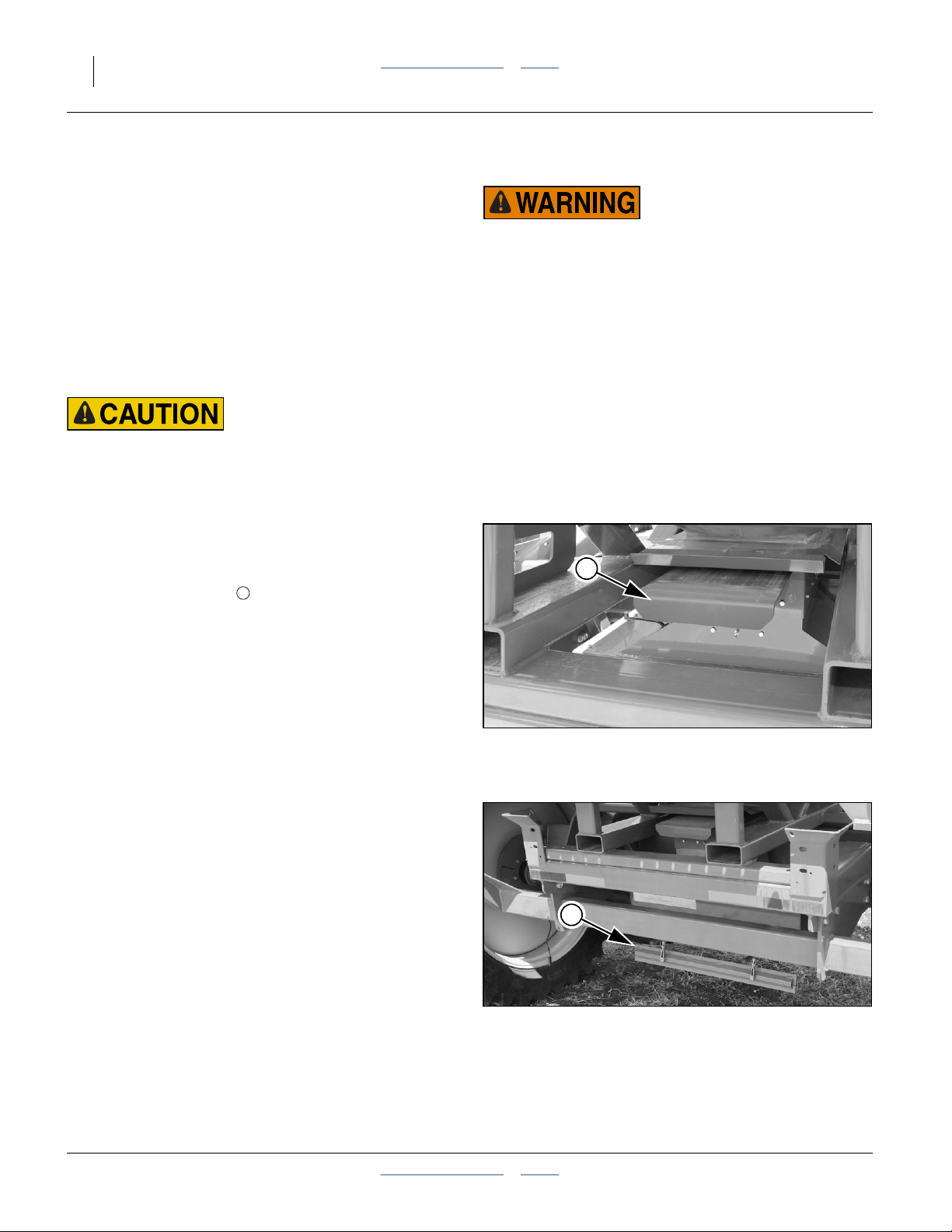

Wing Lock Overview

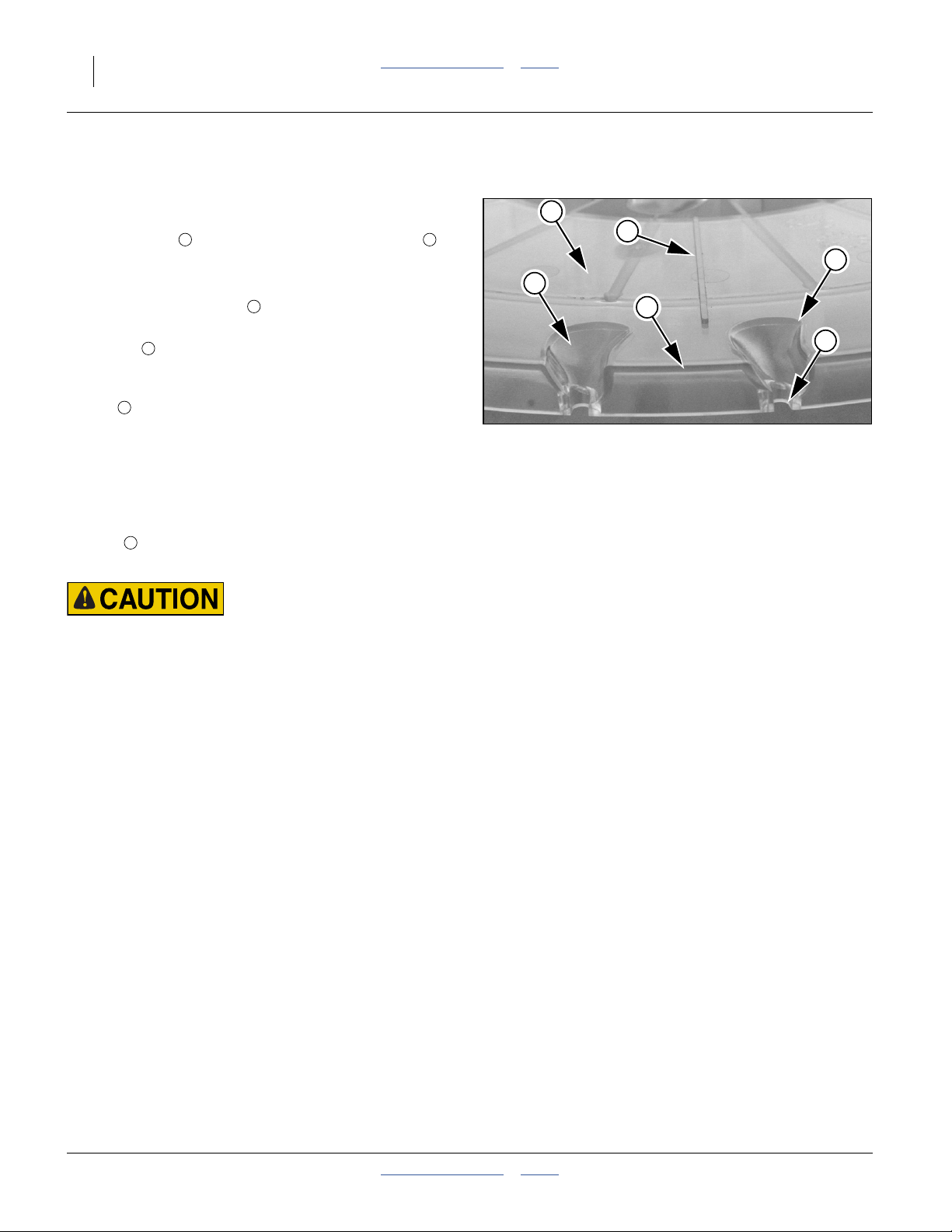

Refer to Figure 12 and Figure 13

The YP1225A & YP1625A planters include four sets of locks for the frame and wings:

1. Transport hooks behind the wing pivots:

These prevent the planter frame from fully lowering

when folded. The planter frame is raised to allow the

wings to clear the hooks. See page 20 and 26.

2. Wing locks at mid-tongue and inside wing casters:

These prevent the planter from unfolding while in

transport. The tongue (hitch) is raised to allow the

hooks to clear the locks. See page 21 and 26.

3. Transport lock channels at wing caster cylinders:

These lock channels prevent the frame from fully

lowering during transport and maintenance. They

are installed prior to folding, and removed after

unfolding. See page 22 and 26.

4. Lift cylinder lock channels above frame pivots:

These lock channels are only required during

maintenance. However, if installed, they must be

removed after unfolding. See page 22 and 89.

3

Lift Locks and Transport Hook

2

Wing Lock and Transport Locks

Figure 12

Figure 13

29734

3

29735

2013-08-13 Table of Contents Index 401-625M

Page 24

20 YP1125A & YP1625A Table of Contents Index Great Plains Manufacturing, Inc.

Unfolding The Planter

The distance between the tractor and the seed structure

decreases by about 10 feet (3 m) during unfolding.

Planter, tractor, or both will move during this operation.

Crushing, Pinch-Point and Overhead Hazards:

To prevent serious injury or death:

▲ Unfold only on hard level ground. Allow ample room.

▲ Allow no one on or near the planter during unfolding.

▲ Stay clear of the wing sweep arcs. The sweep arcs of the

wings have numerous pinch and crush points in the mechanism. Coulters and row openers are sharp.

▲ Allow no one near planter during unfold. The seed structure

usually moves forward during unfolding.

▲ Do not unfold with planter lowered.

▲ Unfold only with markers resting in transport cradles.

▲ Unfold only if hydraulics are bled free of air and fully

charged with hydraulic oil.

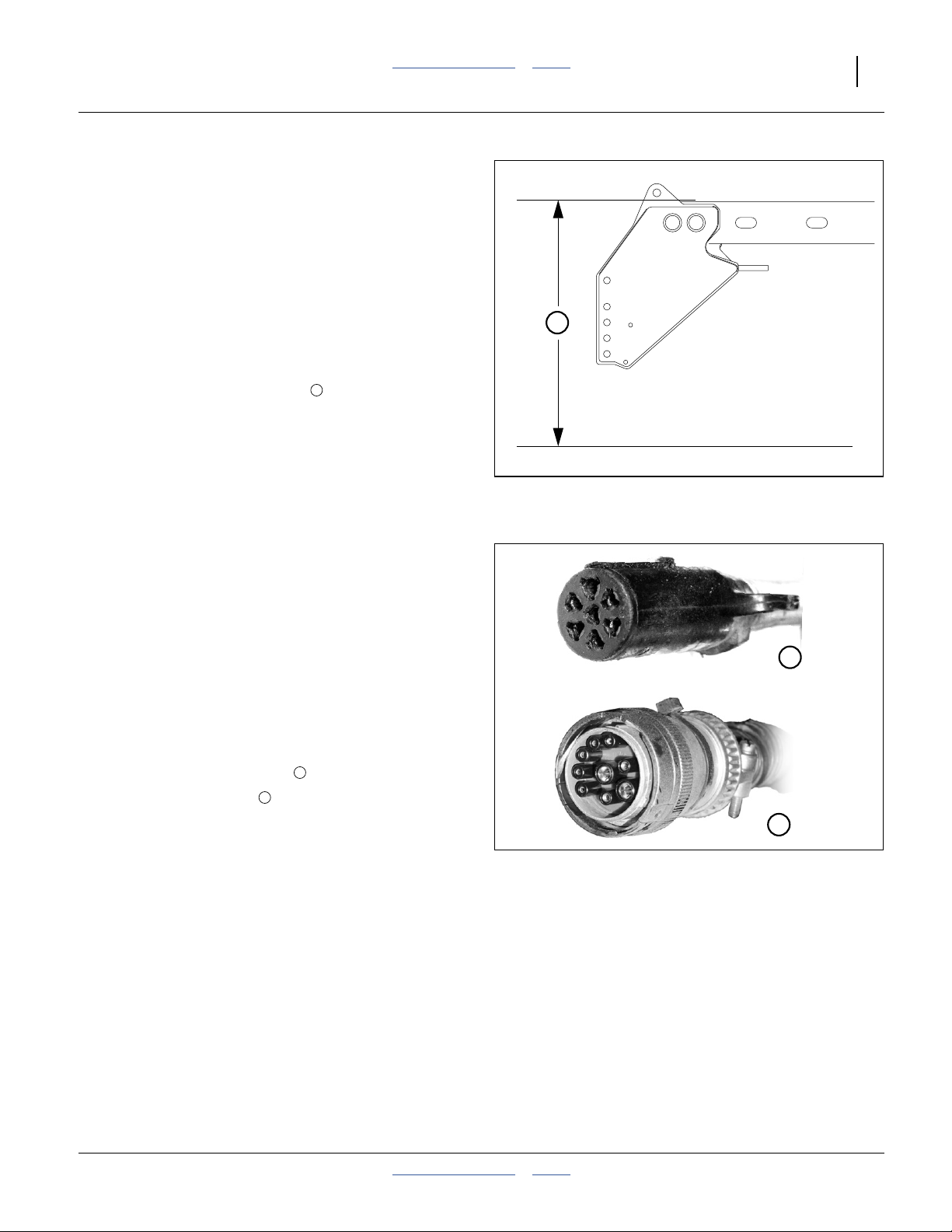

Prepare Hitched Tractor and Planter

1. Move planter to level ground.

2. If tractor movement is not desired, put tractor in Park

and/or set parking brakes, or telescoping movement

of planter may cause tractor to move backward.

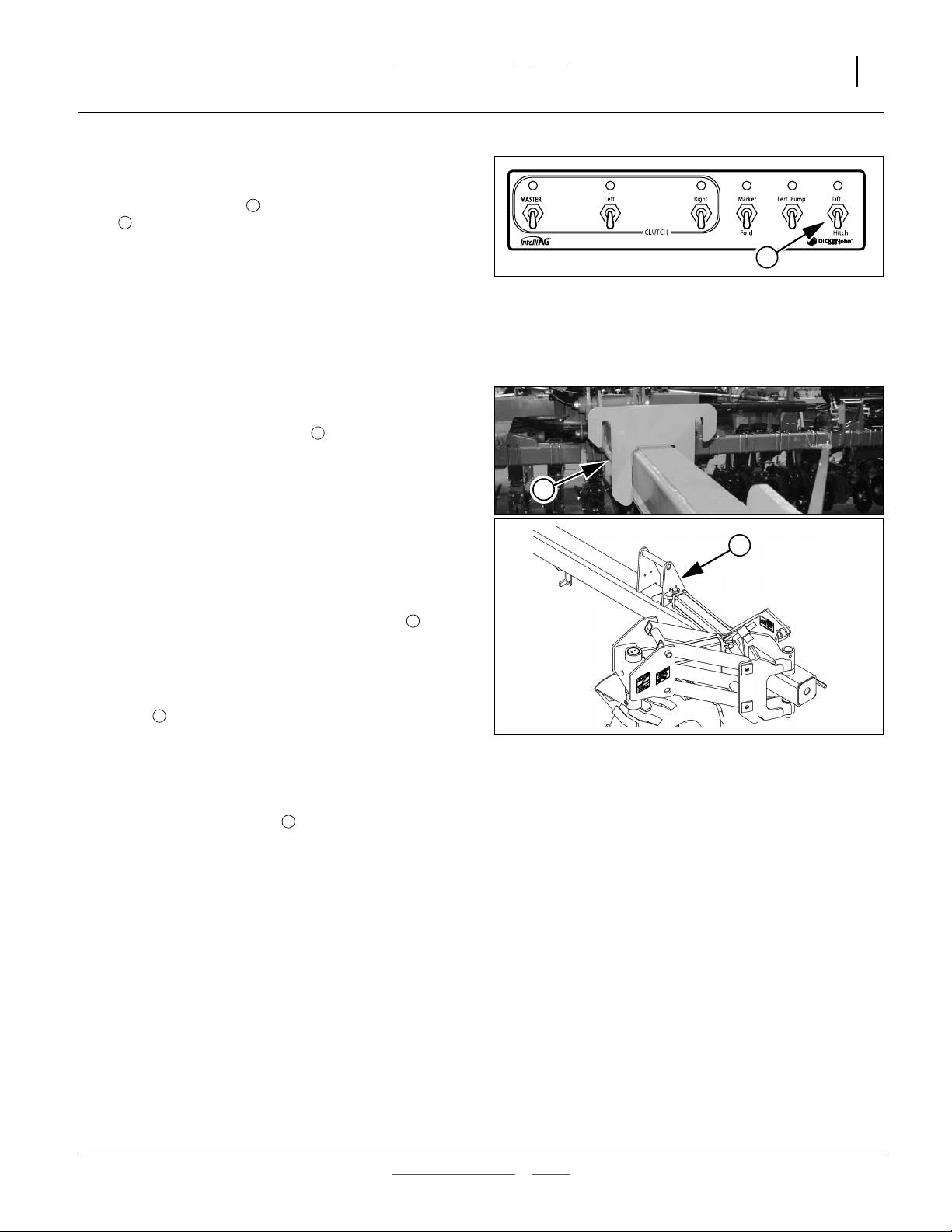

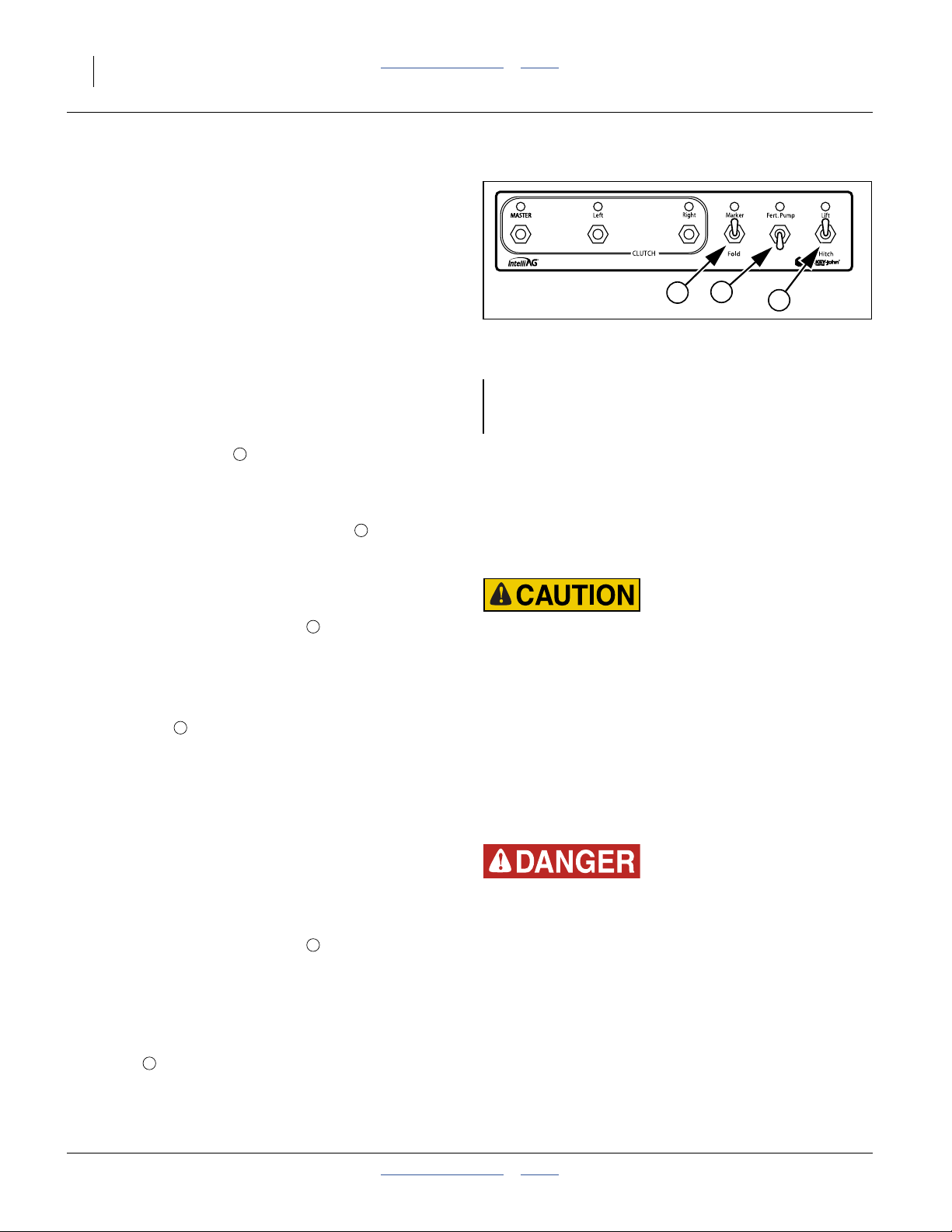

3. On the CFM (Clutch Folding Module), set the

following switches to OFF (down):

MASTER switch and Fert.Pump .

1 2

Prepare Transport Hooks

Refer to Figure 15

The transport hooks , behind/above wing pivots,

prevent the frame from fully lowering when the planter is

fully folded. To clear the hooks, the frame is fully raised.

Refer to Figure 14

4. Set CFM Lift/Hitch switch to “Lift” to enable lift

cylinder hydraulics.

5. Set CFM Marker/Fold switch to “Fold” to enable

fold cylinder hydraulics.

6. Activate lift hydraulics. Raise planter until lift

hydraulics are fully raised. This raises the wing

frames above the hooks .

6 5

5

3

4

2

1

4

Figure 14

CFM for Unfold

3

28484

6

5

Figure 15

Planter Damage Risk:

Be sure planter’s lift hydraulics are fully raised before

unfolding or frame and/or hook damage WILL occur.

401-625M Table of Contents Index 2013-08-13

Transport Hook

29734

Page 25

Great Plains Manufacturing, Inc. Table of Contents Index Operating Instructions 21

Release Wing Locks

Refer to Figure 17

A pair of inverted hooks on the tongue tube engage

8

locks on each wing when the planter is folded.

Prior to unfolding, this lock system must be released by

raising the tongue.

7. This step is slightly different depending on hitch type.

Release Wing Lock with 3-Point Hitch

a. Raise the 3-point hitch to disengage the wing

lock. Continue at step 8.

Release Wing Lock with Hydraulic Hitch

Refer to Figure 16

a. Set CFM Lift/Hitch switch to Hitch.

b. Raise hydraulic tongue to disengage wing lock.

7

6

Figure 16

CFM: Wing Unlock

(Hydraulic Hitch Only)

6

28483

Re-Phase Fold Cylinders

8. The fold system uses re-phasing cylinders. It is

necessary to re-phase cylinders so wing gauge

wheels run in their fully rotated positions in front of

planter. To re-phase fold cylinders:

Move and hold lever for Marker/Fold in Fold direction

(typically Extend) for 30 seconds. This causes wings

to push against the tongue transport hooks .

7

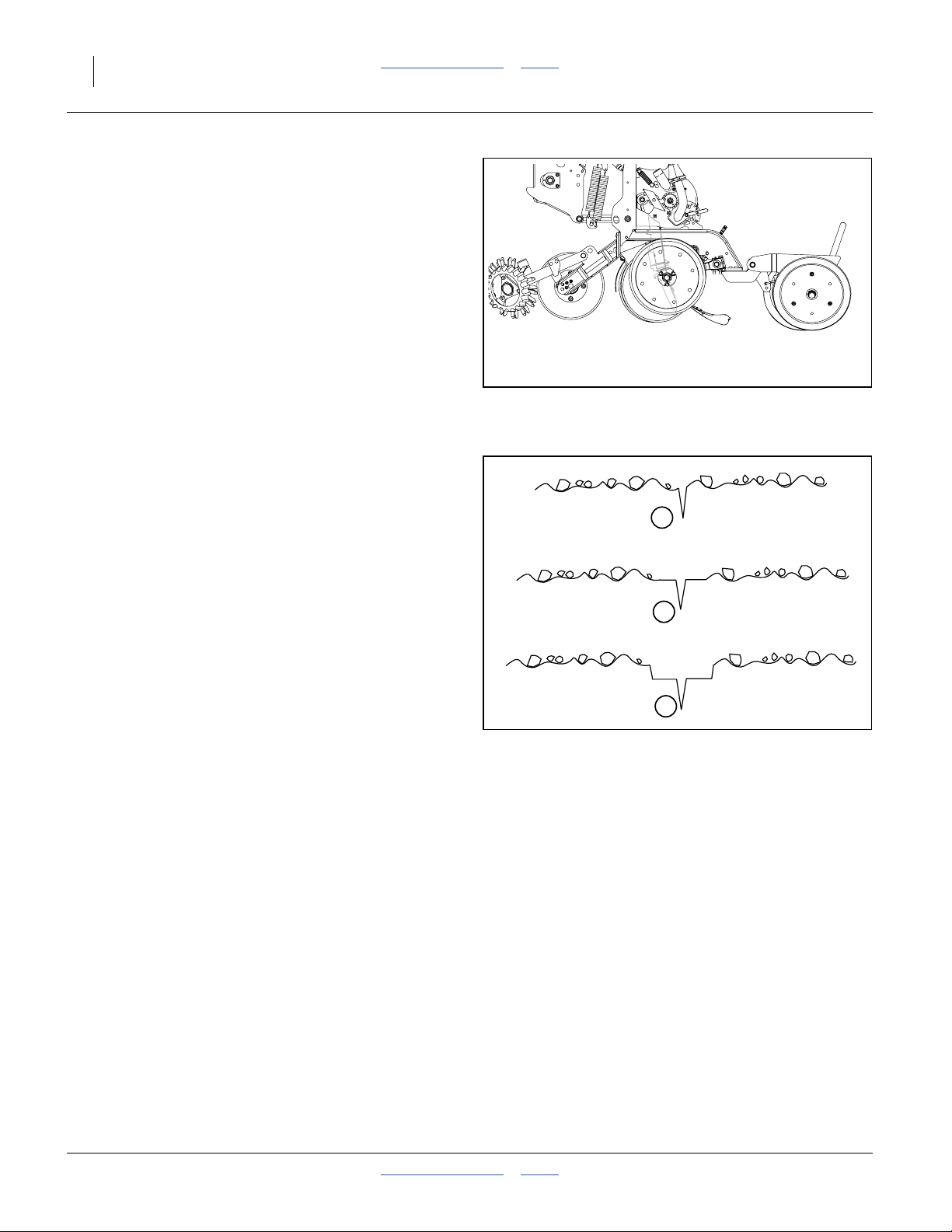

Partially Unfold

Refer to Figure 17

9. Reverse fold circuit lever until wings clear transport

hooks by a few feet.

7

Lower Tongue

10. Lower 3-point hitch or hydraulic tongue to planting

position. See page 17 and page 147 for correct hitch

height and depth control settings. If hydraulic tongue,

set CFM Lift/Hitch switch to Lift.

6

7

8

Figure 17

Wing Hook & Wing Lock

22815

27288

2013-08-13 Table of Contents Index 401-625M

Page 26

22 YP1125A & YP1625A Table of Contents Index Great Plains Manufacturing, Inc.

Fully Unfold

Refer to Figure 18

11. Unfold the planter fully to planting position. Unfolding

is complete when the large roller bushing on top of

the tongue is engaged by the tongue safety latch .

Planter Damage Risk:

Failure to lower the tongue before unfolding WILL result in

opener or seed delivery system damage. Press wheel assembly

components can strike air system components near the air box

manifold.

9

9

Planter Damage Risk:

Do not plant if the tongue latch is not fully down over the

roller. Frame and opener damage is likely if the planter is

operated with the latch open.

Remove and Store Transport Locks

The planter needs to still be in full lift to remove these

locks.

Remove/Store Center Lift Locks

Refer to Figure 19

12. Remove lock channels from vertical cylinders

above pivots.

Refer to Figure 19 and Figure 20

13. Store lock channels horizontally on tabs at top

right side of lift cylinder weldment.

1

2

Figure 18

Tongue Latch Engaged

28488

2

2

1

Figure 19

Frame Lift Locks

29738

2

Figure 20

Lift Cylinder Lock Stored

401-625M Table of Contents Index 2013-08-13

29736

Page 27

Great Plains Manufacturing, Inc. Table of Contents Index Operating Instructions 23

Remove/Store Caster Lift Locks

Refer to Figure 21

14. Remove transport lock channels from lift cylinders

located on gauge wheels.

3

3

4

Refer to Figure 21 and Figure 22

15. Transfer lift cylinder transport lock channels to

their storage positions .

4

3

Unfold Closeout

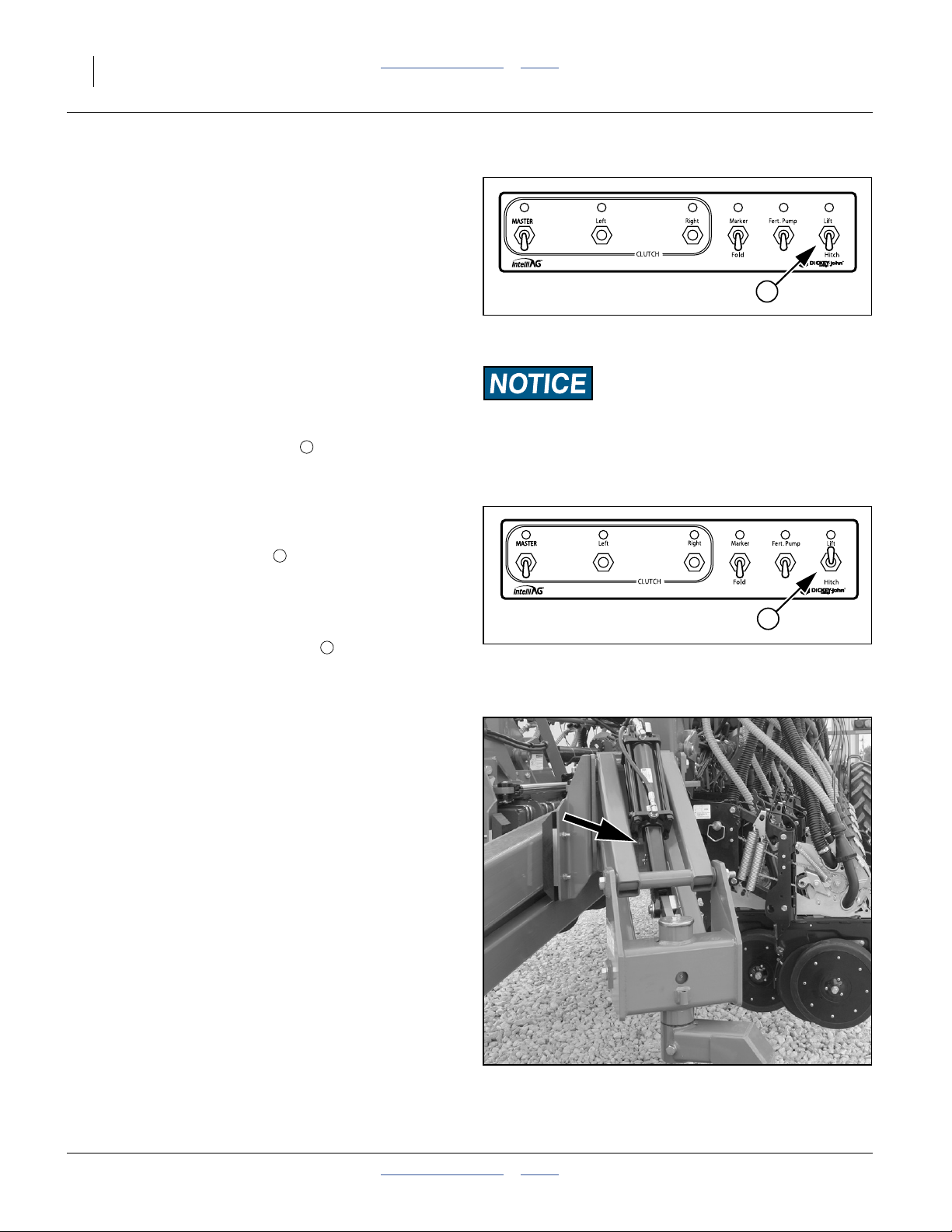

16. As appropriate for the next planned activity, activate

lift hydraulics and lower planter.

17. To disable fold hydraulics, and lock caster armsa in

field position, set CFM Marker/Fold switch to

“Marker”.

Note: Set switch to “Marker” even if Markers are not

installed. This switch position disables all fold

solenoid valves.

5

Figure 21

Caster Lift Cylinder Lock

29737

3

4

Figure 22

Transport Cylinder Lock Storage

27290

5

Figure 23

CFM After Unfold

28485

a. YP1125A s/n A1154K+ and YP1625A s/n A1172B+

2013-08-13 Table of Contents Index 401-625M

Page 28

24 YP1125A & YP1625A Table of Contents Index Great Plains Manufacturing, Inc.

Raising/Lowering Planter

The planter mainframe raises and lowers independently

of the tongue.

• The planter may be fully raised at any time (and must

be raised for folding).

• The planter may be lowered onto its transport lock

channels at any time.

• The planter may be fully lowered, with lock channels

removed, only when unfolded.

Refer to Figure 24

The CFM “CLUTCH” switch positions are not shown

because they normally require no attention during lift or

lower. Lifting the planter automatically disengages the

entire drive system.

The “Fert.Pump” switch has no function on YP1225A

& YP1625A planters as shipped by Great Plains because

the optional fertilizer system for these planters uses a

ground-drive pump that has no electrical control.

Leave or set the CFM Marker/Fold switch in “Marker”

position to prevent unintended folding.

1

2

Figure 24

CFM for Lift/Lower

If your planter has an aftermarket pumping system

compatible with the IntelliAg® system, the “Fert.Pump”

switch may require operator attention during lift/lower.

1

2

3

28485

Raising Planter

The planter may be raised at any time.

1. Set the CFM “Lift/Hitch” switch to Lift to enable the

lift cylinder circuit.

2. Move the Lift/Hitch circuit lever to extend the lift

cylinders.

3. Set the circuit to Neutral to hold the planter at lift.

The switch may be left in the “Lift” position.

4. Install lock channels if raising for transport, parking,

storage, adjustments or maintenance.

3

3

Lowering Planter

If lock channels are installed, the planter may be lowered

at any time. if lock channels are not installed, lower only

when unfolded, such as for field turns.

Install lock channels (page 23) as appropriate for next

activity.

1. Set the CFM “Lift/Hitch” switch to Lift to enable the

lift cylinder circuit.

2. Move the Lift/Hitch circuit lever to retract the lift

cylinders until settled on lock channels or fully

lowered to ground.

3. Set the lift circuit to Neutral for field operation. The

switch may be left in the “Lift” position.

3

3

Lowering Planter Hazard:

Use transport locks. A raised planter slowly lowers when held

up solely by circuit neutral. Anyone beneath the row units

could be trapped and injured. Rely on circuit neutral to hold

the planter raised only for brief periods, such as field turns

and during lock channel installation. Use lock channels at all

other times.

Note: After every few hours of operation (or earlier, if

uneven lift is observed), re-phase the lift circuit.

At a lift operation, hold the circuit in Extend for

30 seconds.

Crushing Hazard:

Keep all persons away from frame sections during lift and

lower. Area under row units is particularly dangerous. Sharp

coulter and opener blades descend with hundreds of pounds of

down-force.

Note: Unless lock channels are installed, lower the

planter only when fully unfolded. Lowering when

folded is prevented by the transport locks.

401-625M Table of Contents Index 2013-08-13

Page 29

Great Plains Manufacturing, Inc. Table of Contents Index Operating Instructions 25

Re-phasing Lift System

Over a period of normal use the cylinders may get out of

phase. This will cause some planter sections to run

higher than others. If this is the case, it will be necessary

to re-phase lift cylinders.

Note: Lift cylinders can only be re-phased when planter is

unfolded.

To re-phase cylinders:

1. Raise the implement completely and hold the

hydraulic remote lever on for several seconds until all

cylinders are fully extended. Do this every 8 to

10 times you raise planter out of ground.

2. When all cylinders are fully extended, momentarily

reverse hydraulic remote lever to retract system

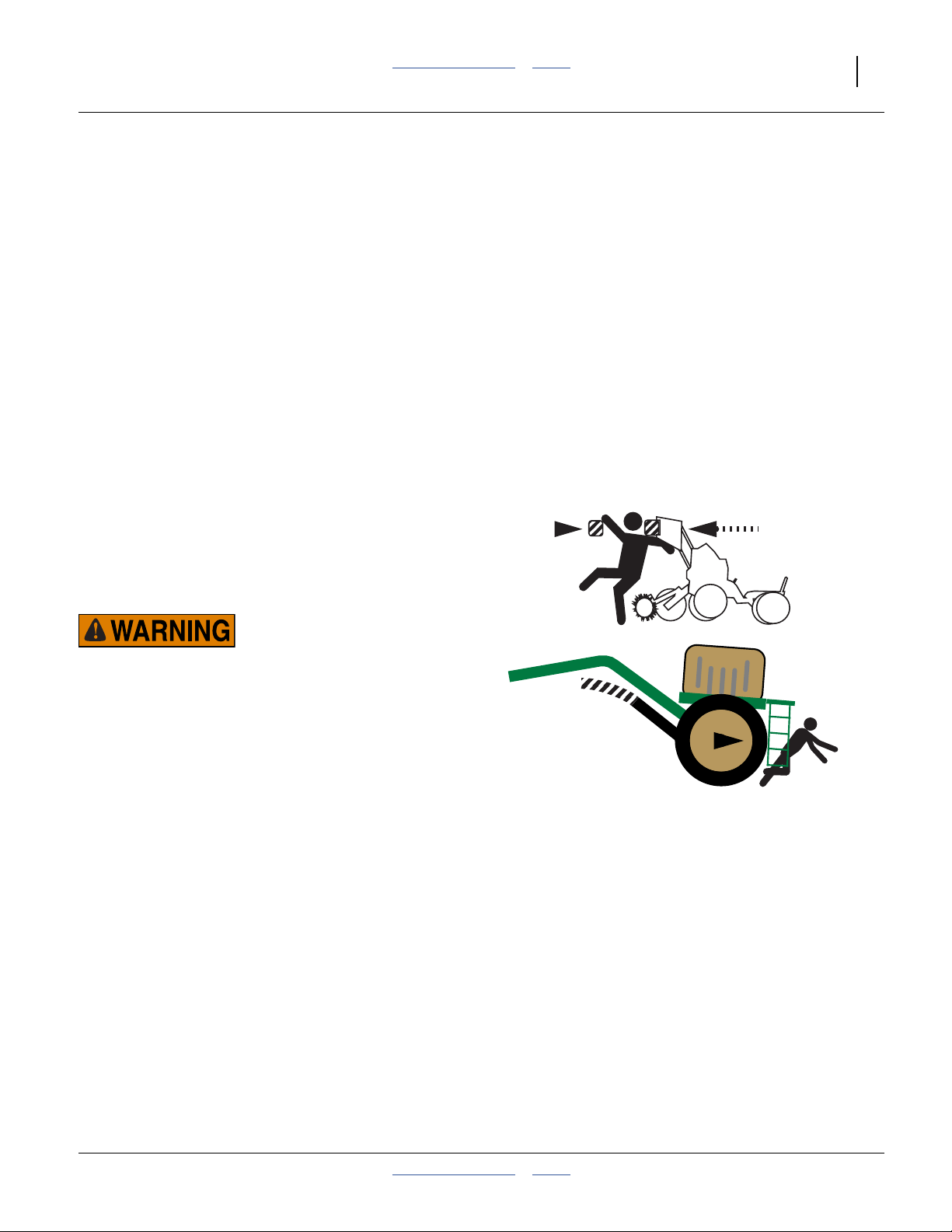

1

⁄2inch to maintain levelness.

Folding the Planter

The planter must be raised for folding. The tongue is

raised and lowered during the sequence.

The distance between the tractor and the seed structure

increases by about 10 feet (3 m) during folding. Planter,

tractor, or both will move during this operation.

Pinch Point and Crushing Hazard:

To prevent serious injury or death:

▲ Fold only with planter raised and lock channels installed.

▲ Fold only if hydraulics are bled free of air and fully charged

with hydraulic oil.

▲ Stay away from frame sections when they are being raised

or lowered.

▲ Keep away and keep others away when folding or unfolding

planter.

▲ Fold markers onto cradles before folding planter.

2013-08-13 Table of Contents Index 401-625M

Page 30

26 YP1125A & YP1625A Table of Contents Index Great Plains Manufacturing, Inc.

Shut off Fan and Hydraulic Drive

1. Set circuit levers for seed box fan and optional

hydraulic meter drive to Neutral.

Set Tractor and Tongue

2. Raise and move planter to a level area.

3. If tractor movement during folding is not desired, put

tractor in Park and/or set parking brake.

4. This step is slightly different depending on hitch type:

Prepare 3-Point Hitch for Fold

a. Fully lower 3-point hitch. Continue at step 5.

Figure 25

CFM: Prepare Hitch for Fold

1

28487

Prepare Hydraulic Hitch for Fold

Refer to Figure 25

a. Set CFM Lift/Hitch switch to “Hitch”.

b. Retract hitch cylinder to fully lower tongue.

1

Raise Planter

Refer to Figure 26

5. Set CFM Lift/Hitch switch to “Lift”.

6. Activate circuit lever to extend lift cylinders until

planter is fully raised.

7. Set circuit to Neutral to hold at lift.

8. On hydraulic hitch, return switch to “Hitch”.

9. Put tractor in Park and/or set parking brake, and shut

off tractor.

2

2

Install Lock Channels

Only wing (gauge wheel) lock cylinders need to be

installed for transport. The center is adequately

supported by the wing hooks and locks when folded.

For servicing, or to hold at lift when unfolded, also install

center section lift locks (see page 89)

Refer to Figure 27

10. Remove lift cylinder transport lock channels from

their storage positions.

11. Place transport lock channels on lift cylinders

located on gauge wheels.

Equipment Damage Risk:

Tongue must be lowered at start of fold to ensure that press

wheel assemblies remain clear of air system.

2

Figure 26

CFM: Raise Planter

28484

Figure 27

Transport Cylinder Lock in Use

401-625M Table of Contents Index 2013-08-13

29737

Page 31

Great Plains Manufacturing, Inc. Table of Contents Index Operating Instructions 27

Activate Fold Solenoid Valves

Refer to Figure 28

12. Set CFM Marker/Fold switch to “Fold”. This opens

the solenoid valves for tongue lock, fold cylinders

and caster arm

a

cylinders.

3

Begin Folding

13. Extend the fold cylinders and fold the planter until the

wing tubes are within a few feet (a meter or so) of the

tongue.

Raise Tongue

14. Raise 3-point hitch or hydraulic hitch until wing

hooks on tongue clear locks on wings.

4 5

Complete Fold

15. Continue or resume folding until the wing locks

contact lock plate (under hooks).

16. Set CFM Marker/Fold switch to “Markers”.

Note: When folded, set the “Marker/Fold” switch to

“Marker”, whether Markers are installed or not. In

this position, the switch disables all solenoid valves

for fold, locking the fold system.

3

Lower Tongue

17. Lower 3-point hitch or hydraulic tongue until wing

hooks rest on wing locks.

Re-phasing Fold System

Over a period of normal use, the cylinders may get out of

phase. This is evident by wing gauge wheels not running

in their fully rotated positions in front of the planter.

Note: Planter must be folded to re-phase fold system.

See “Re-Phase Fold Cylinders” on page 21.

3

Figure 28

CFM: Commence Fold

2

28484

4

5

Figure 29

Wing Hook & Wing Lock

22815

27288

a. Feature on YP1225A s/n A1154K+ and YP1625A s/n A1172B+ planters.

2013-08-13 Table of Contents Index 401-625M

Page 32

28 YP1125A & YP1625A Table of Contents Index Great Plains Manufacturing, Inc.

Transporting

The tractor must weigh at least 2/3 (67%) of the planter

plus any materials loaded. See table below for typical

planter weights. Have your planter weighed if the tractor

capability is not clearly above requirements.

Before transporting, follow and check these items:

• Set the tractor 3-point hitch control for depth control

operation. If the 3-point hitch control is set for load

control, the auto load control response may

automatically adjust too high in some circumstances,

causing the wing locks to disengage on the road.

• Empty seed box. Empty seed box before transporting

if at all possible.

• The planter can be transported with a full box of grain,

but the added weight increases stopping distance and

decreases maneuverability.

• Transport planter only while in folded position. Refer to

“Folding the Planter” on page 25 and make sure

cylinder lock channels are in place.

• Warning lights. Always use warning lights when

transporting the planter.

• Road rules. Comply with all national, regional, and

local safety laws when traveling on public roads.

• Clearance. Remember that the planter is wider than

the tractor. Allow safe clearance.

• Transporting with Markers. Always transport markers

in the folded position. Make sure second marker

section rests securely on transport carrier.

Loss of Control Hazard:

Do not exceed 20 mph (32 km/h).

Use a tractor rated for the load.

Towing the planter at high speeds or with a vehicle that is not

heavy enough could lead to loss of vehicle control, resulting in

a serious road accident, injury and death.

Weights of Representative Planter

Configurations

Base Planter Weight

Typical Empty Standard* Planter

Typical Full Standard* Planter

Typical Empty Maximum* Planter

Typical Full Maximum* Planter

-1230 -16TR36 -1820 -2315 -24TR -1670

15540 lb 16410 lb 16850 lb 17940 lb 18160 lb 7570 kg

16400 lb 17280 lb 17710 lb 18800 lb 19020 lb 7960 kg

21650 lb 22530 lb 22960 lb 24050 lb 24270 lb 10340 kg

18460 lb 19560 lb 20120 lb 21500 lb 21780 lb 9000 kg

28500 lb 29610 lb 30170 lb 31550 lb 31830 lb 13560 kg

Note: the weight of a specific planter

can vary significantly.

Base Planter Weight

Typical Empty Standard* Planter

Typical Full Standard* Planter

Typical Empty Maximum* Planter

Typical Full Maximum* Planter

* Typical Standard configuration is: markers, 82 bushel hopper, no fertilizer, no coulters

Typical Maximum configuration is: markers, 82 bushel hopper, starter fertilizer system, UM coulters

401-625M Table of Contents Index 2013-08-13

-1236 -1630 -2420 -24TR36 -3115 -32TR

15800 lb 16670 lb 18420 lb 18420 lb 19940 lb 20160 lb

16660 lb 17530 lb 19280 lb 19280 lb 20810 lb 21030 lb

21910 lb 22780 lb 24530 lb 24530 lb 26060 lb 26270 lb

18720 lb 19830 lb 22050 lb 22050 lb 23990 lb 24270 lb

28770 lb 29880 lb 32100 lb 32100 lb 34040 lb 34320 lb

YP1225A- YP1625A-

YP1625A-

Page 33

Great Plains Manufacturing, Inc. Table of Contents Index Operating Instructions 29

Loading Materials

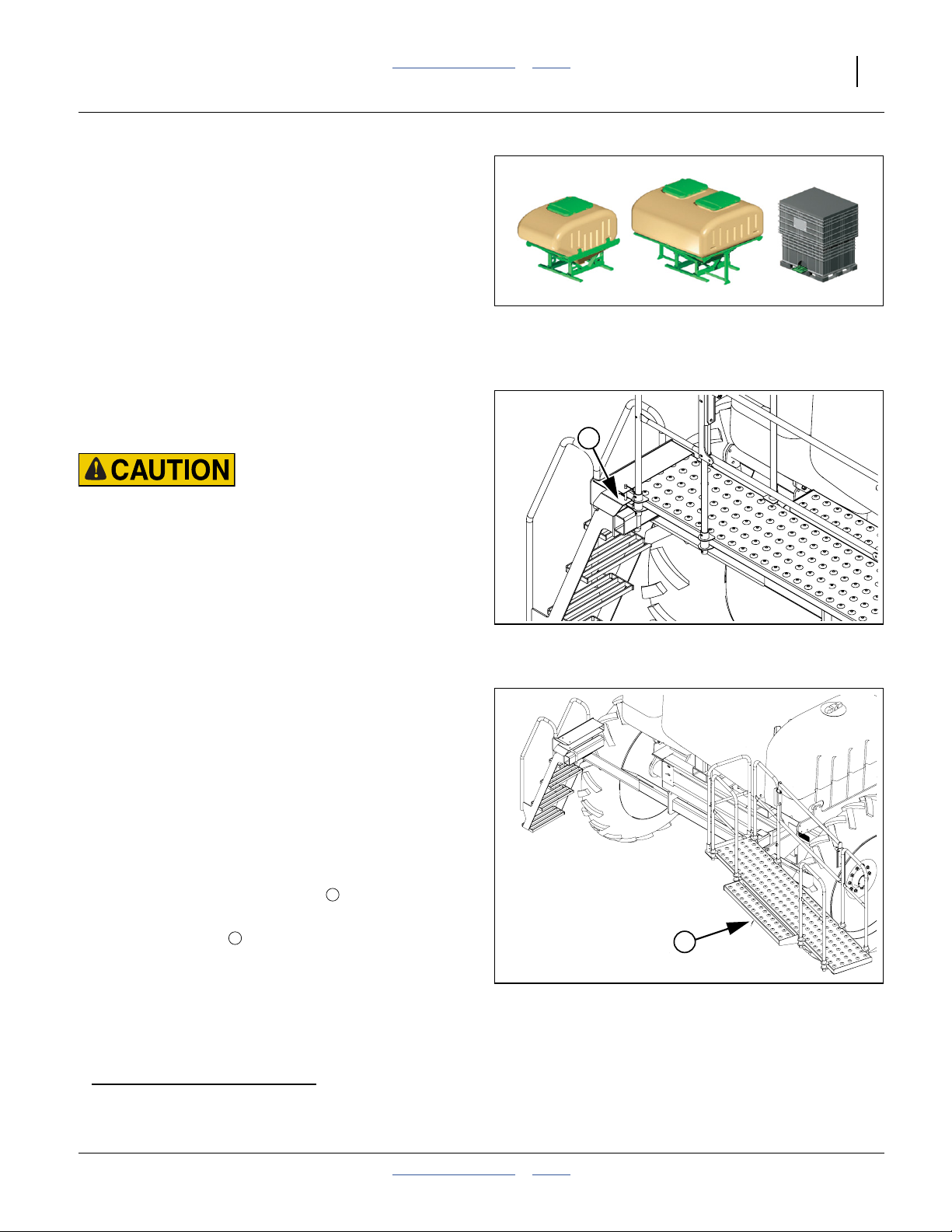

The YP1225A & YP1625A planters accept the Great

Plains 82 bu. hopper,150 bu.

a

hopper, or bulk seed

boxes that meet the PioneerbPROBOX® specification.

Material Loading Overview

• With hoppers, seed is loaded from above, with the

hopper already mounted on the planter.

• With a bulk seed box, seed is pre-loaded by the seed

supplier, and the box is mounted on the planter

already loaded.

• If the optional fertilizer system is installed, liquid

fertilizer is normally pumped in from below via the

quick-fill system, but may also be gravity-loaded from

above with the tank caps removed.

Tipping and Overload Hazard:

Place or remove a hopper only when empty. A full hopper can

weigh between 5,000 and 10,000 lbs (2700-4500 kg), which is

above the lifting and balance capability of most tractors and

farm forklifts.

Mounting a Hopper or Bulk Seed Box

These steps cover mounting a hopper or seed box on a

planter that has no seed container. If a seed container

needs to be removed first, see page 34.

1. Move the planter to an area of level ground and

sufficient room to maneuver a tractor or fork-loader.

2. If changing between hopper and bulk seed box, use

the Accessory Sensor Setup menu on the seed

monitor console to disable the hopper sensor and

avoid nuisance alarms. See DICKEY-john® Quick

Start Guide.

3. Place tractor in park, shut off engine, and remove the

key. If using the same tractor for container mounting,

block the planter transport tires.

Refer to Figure 31

4. Remove the walkboard lock pin .

Refer to Figure 32

5. Swing walkboard all the way to the right.

2

1

Figure 30

82 bu. and 150 bu. Hoppers,

and a Bulk Seed Box

1

Figure 31

Walkboard Lock Pin

2

29486

24010

Figure 32

24005

Walkboard Open

a. The 150 bu. hopper is incompatible with on-board fertilizer tanks.

b. PROBOX

2013-08-13 Table of Contents Index 401-625M

®

is a registered trademark of Pioneer Hi-Bred International, Inc.

Page 34

30 YP1125A & YP1625A Table of Contents Index Great Plains Manufacturing, Inc.

Refer to Figure 33

6. Secure walkboard with keeper.

Note: If planter is lowered, walkboard will stay open by

itself once fully opened. There is a keeper near the

walkboard pivot that can hold the walkboard open

in all conditions.

Refer to Figure 34

7. Remove pins at the corners of the airbox frame.

1

Irritation and Chronic Exposure Hazard:

Wear gloves. DO NOT use hands or any part of your body to

mix seed lubricant. Wear a respirator when transferring and

mixing. Avoid breathing lubricant dust. Not an acute hazard.

May cause mechanical eye or skin irritation in high concentrations. As with all mineral spills, minimize dusting during

clean-up. Prolonged inhalation may cause lung injury. Product can become slippery when wet.

8. When using a bulk seed box,

new meters for the first time, or

at the start of each season,

measure out approximately 4 gallons (15 liters) of

seed into a pail. Add1⁄2cup (120 ml) of Ezee Glide

Plus seed lubricant to the pail. Mix and pour into air

box before mounting hopper.

Flow Inconsistency and Stoppage Risk:

Ezee Glide Plus is mandatory for all seed, especially treated

or inoculated seed. Failure to use this seed lubricant as

recommended can cause inconsistent seed flow to meters, and

clogging at meters. See “Seed Lubricant” on page 111.

Note: On a new planter, the interior surfaces of the seed

hoses are somewhat tacky until they are coated

with seed lubricant. Before planting for the first

time, and at the start of each season, add1⁄3cup

(80 ml) Ezee Glide Plus seed lubricant to bottom of

airbox.

Note: The monitor system includes a level sensor located

below hopper to warn when box is empty. This

typically provides three to four acres (1.2 to 1.6 ha)

of run time before rows start going empty.

9. At the airbox seed inlet, inspect the seals for wear

and damage.

10. If mounting a seed box, add Ezee Glide Plus to the

seed box at this time. It may be easier to add it while

the box is still at ground level.

Figure 33

Walkboard Keeper

1

Figure 34

Airbox Frame Corner Pin

29485

22749

401-625M Table of Contents Index 2013-08-13

Page 35

Great Plains Manufacturing, Inc. Table of Contents Index Operating Instructions 31

Tipping and Overload Hazard:

Make sure your tractor or fork lift is rated for and configured

to lift the hopper or bulk seed box. A full bulk seed box can

weight over 2500 lbs. Do not let anyone stand under or in front

of the elevated seed box.

Refer to Figure 35

11. Approach the hopper or seed box from the back (the

side with the slide gate). Align the forks with the slots

in the rear of the seed box or hopper and slowly drive

forward until forks are completely under the seed box

or hopper.

Note: Bulk hopper frame has two sets of lifting points.

One set is for normal loading and is tubes. The

other set is to allow picking it up from the side for

placing in storage near a wall.

Note: It may be necessary to adjust the seal on top of air

box to getfull contact with the bottom of seed box or

hoppers. This is a one-time adjustment.

Figure 35

Approaching Hopper

25255

Refer to Figure 36

12. Slowly lift the full seed box or empty hopper, and

place it in the planter airbox frame.

13. Install the box retaining pins in frame corners.

Refer to Figure 37

14. Unless you are at the field to plant, close the slide

2

gate at the base of the hopper.

15. Return the walkboard to the closed position and

install the latching pin.

16. If installing an empty hopper for planting, load seed

(and lubricant). Otherwise, skip to step 24 on

page 33.

Figure 36

Fork-Lifting Seed Box

2

24037

Figure 37

29495

Hopper Slide Gate Closed

2013-08-13 Table of Contents Index 401-625M

Page 36

32 YP1125A & YP1625A Table of Contents Index Great Plains Manufacturing, Inc.

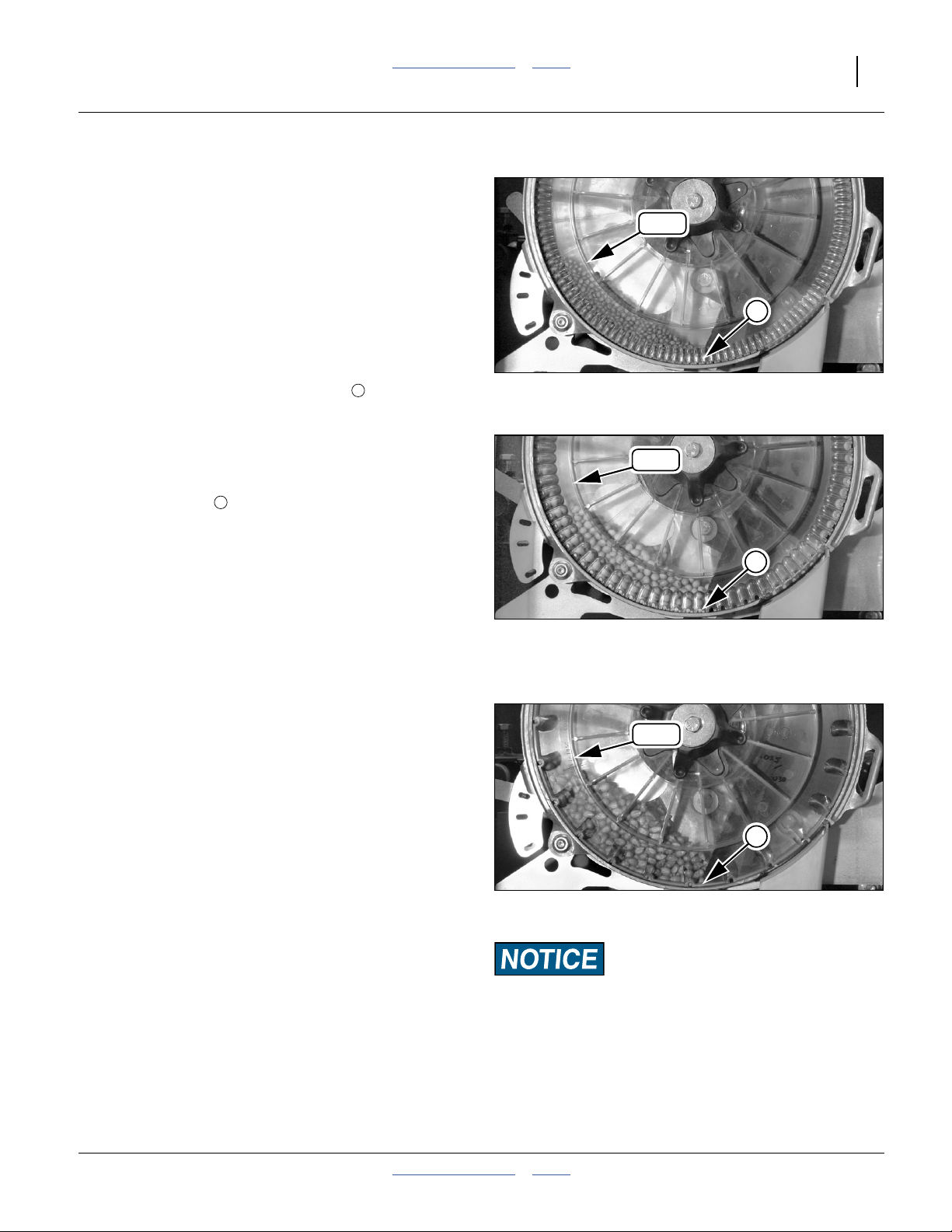

Loading Hopper with Seed

Refer to Figure 38

17. At the top of the hopper, release the lid latch(es) .

and open the lid(s):

18. Check that the strainer basket is clean and in

place.

4

3

4

3

Do not operate without a strainer:

It is an important safety feature that prevents accidental entry

into the hopper. It also prevents larger foreign matter from

clogging the air system.

19. Inspect the hopper itself to ensure that it contains

only expected material.

Refer to Figure 39

If using an auger to load seed, access to the top of the

hopper is eased by swinging down the top section of the

center walkboard railing.

20. At each end of the swing-down section, pull the

cross pins inward until the pins clear the holes .

Swing the railing section in or out (it is easier to close

if swung in).

5 6

Figure 38

Hopper Latch and Strainer

29487

6

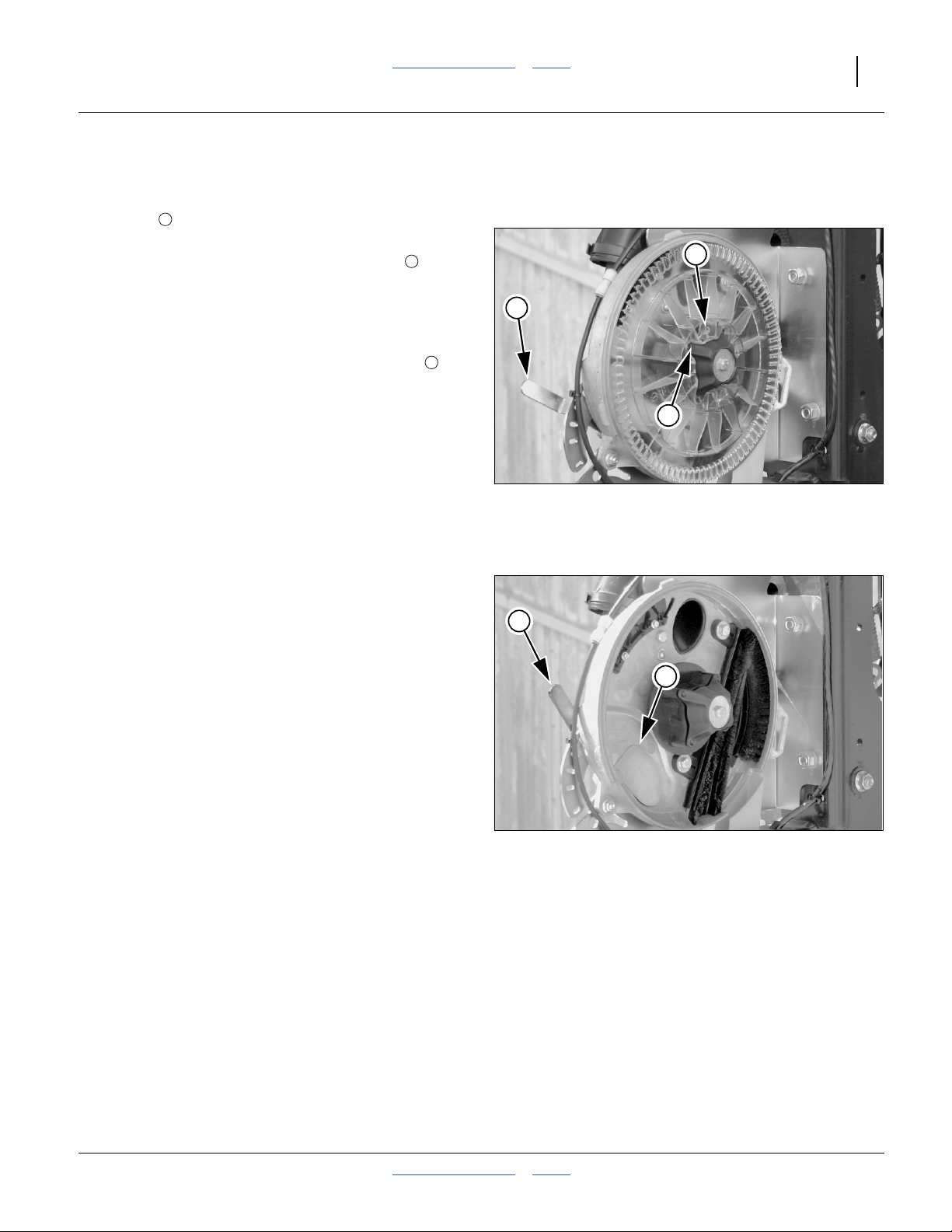

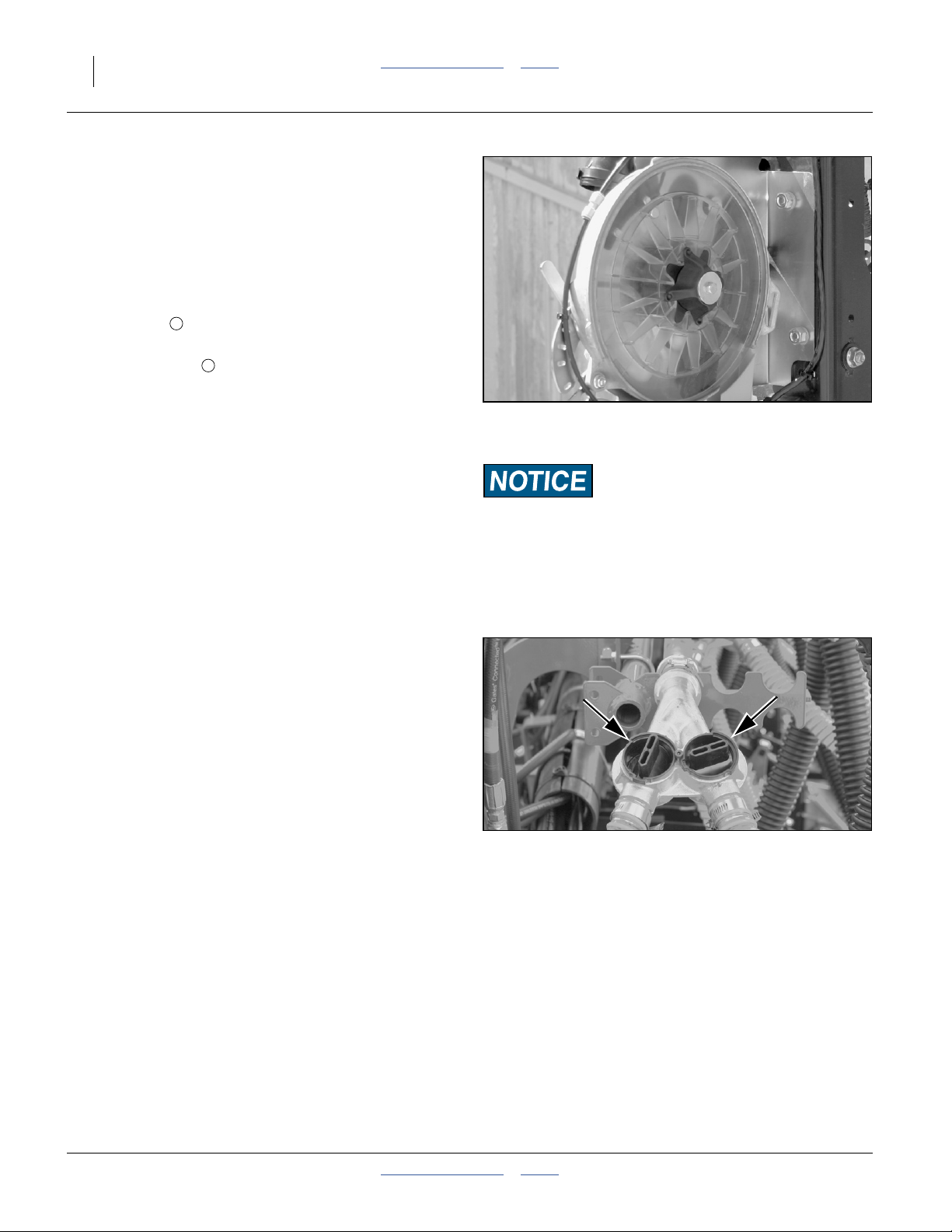

Using Auxiliary Hydraulic Circuit

The optional auxiliary hydraulic kit includes a manual