Page 1

Part Lists Great Plains Manufacturing, Inc. 1

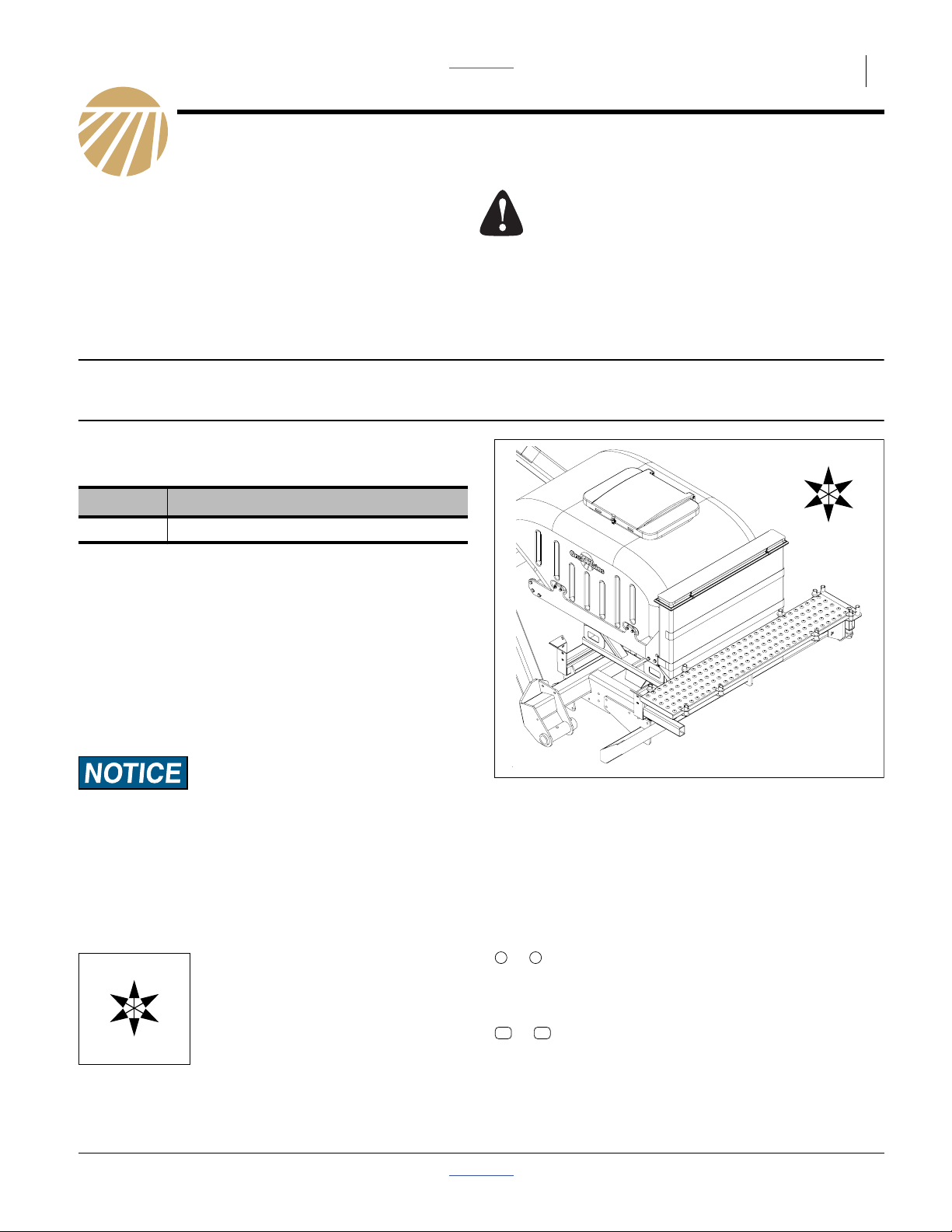

Yield-Pro®Planters Refuge Hopper Kit

Null4:

Used with any YP Planter with 82 bushel hopper:

• YP1225/1625

• YP1225A/1625A

• YP2425

• YP2425A

• YP4025

• YP4025A

• YP4010HDP

• YP4020P

• 3PYP

• 3PYPA

General Information

These instructions explain how to install a Yield-Pro

Refuge Hopper Kit. One kit updates one planter hopper:

Kit Kit Description

403-287A

Yield-Pro® Refuge Hopper Kit

Tools Required

• silicone

• basic hand tools

• acetylene torch

• grinder

• tape measure

®

When you see this symbol, the subsequent instructions

and warnings are serious - follow without exception.

Your life and the lives of others depend on it!

U

F

L

R

B

D

Work Location

Move the implement to a flat location for installation.

Equipment Damage Risk:

Do not get close to plastic hopper or hoses when using a torch, plastic

will melt and create holes.

Notations and Conventions

Null4:

U

F

L

D

“Left” and “Right” are facing in the

direction of machine travel. An orienta-

R

tion rose in the line art illustrations

shows the directions of Left, Right,

Front, Back, Up, Down.

B

Call-Outs

1 9

to

19

11

to

Figure 1

Yield-Pro® Refuge Hopper Kit

Single-digit callouts identify components in

the currently referenced Figure. These numbers may be reused for different items from

page to page.

Two-digit callouts in the range 11 to 19 reference new parts from the list on page 6.

31315

© Copyright 2011 Printed 05/11/2011 Part Lists 403-287M

Page 2

2 Great Plains Manufacturing, Inc. Front Page Part Lists YP Refuge Hopper Kit

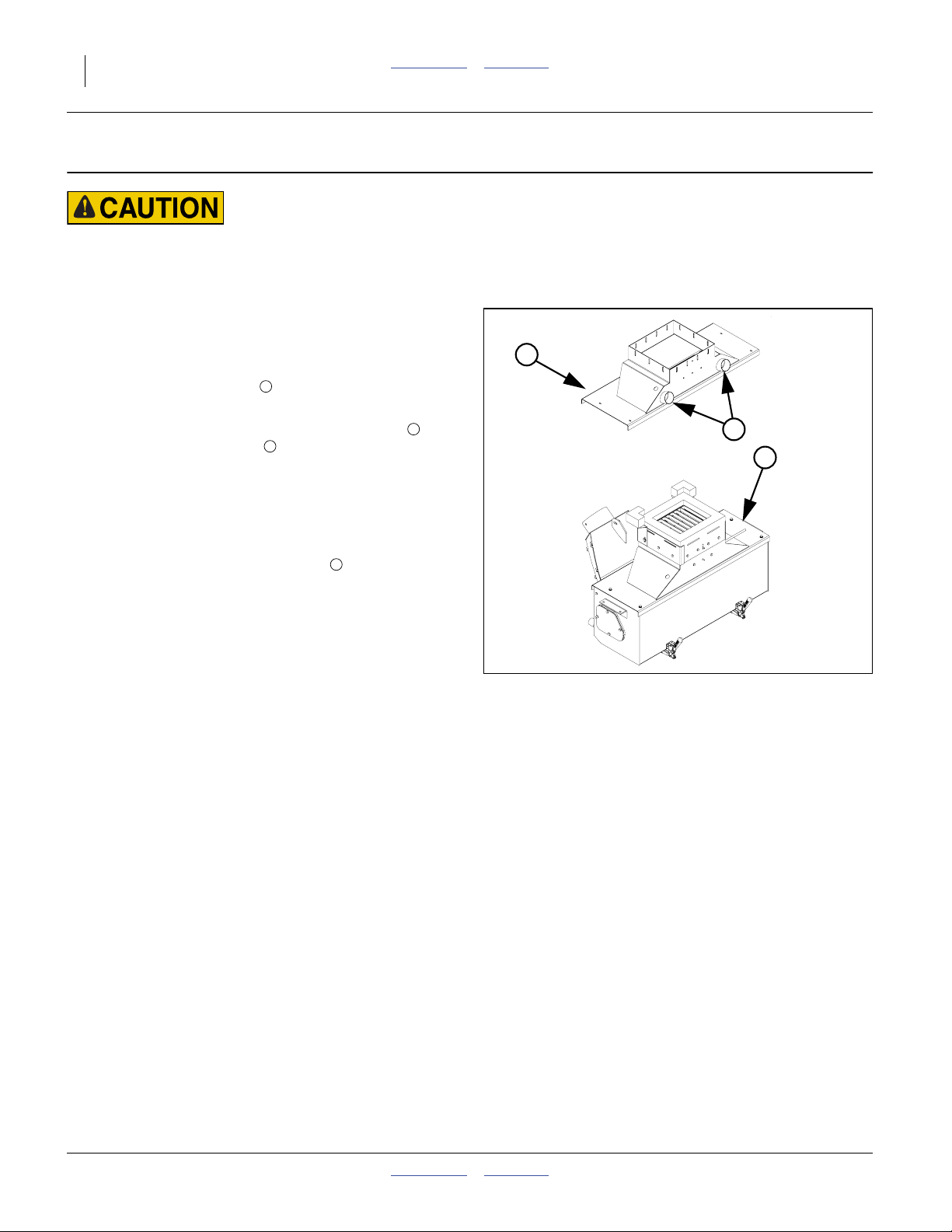

Replace Existing Airbox Cover

Heavy Load Hazard:

The airbox weighs approximately 315 pounds. It will require

more than one person to lift and install.

Remove Old Airbox Cover

Refer to Figure 2

1. Remove airbox from machine.

2. Remove old airbox top by unbolting

and pull off (save all fasteners).

3. Remove all parts and hardware from old top and

install them on new top .

1

1

2

Install New Airbox Cover

4. Clean off all old silicone on airbox.

5. Apply new silicone to airbox.

6. Install new top with 2 small inlets (facing back) to

airbox using fasteners saved from step 2.

3

2

3

1

Figure 2

Airbox Cover

31330

403-287M Front Page Part Lists 05/11/2011

Page 3

Install Refuge Hopper Front Page Part Lists Great Plains Manufacturing, Inc. 3

Install Refuge Hopper

Heavy Load Hazard:

The refuge hopper weighs approximately 170 pounds. It will

require more than one person to lift and install.

Refer to Figure 3

7. Reinstall airbox to frame with existing hardware

from step 1.

8. Swing walkboard out for easier access to install

refuge hopper.

9. Remove hardware from hopper mount straps on

back of 82 bushel hopper.

10. Place bottom refuge hopper brackets over planter

frame.

11. Secure refuge hopper with longer hardware supplied with kit on both sides of 82 bushel hopper

mount straps .

4

6

5

4

4

16

6

15

18

Select 6 ea. bolts, nuts, flat washers, lock washers:

15

802-057C HHCS 5/8-11X2 1/4 GR5

16

803-021C NUT HEX 5/8-11 PLT

17

804-021C WASHER FLAT 5/8 SAE PLT

18

804-022C WASHER LOCK SPRING 5/8 PLT

12. Attach two seed hoses (with clamps) to airbox

inlets and refuge hopper outlets.

Note: For seed flow the gates have only two options,

either open all the way or closed.

7

7

Figure 3

Hopper Mounting

17

5

31329

05/11/2011 Front Page Part Lists 403-287M

Page 4

4 Great Plains Manufacturing, Inc. Front Page Part Lists YP Refuge Hopper Kit

Adjust Walkboard

Remove Walkboard Extension

Note: This applies to all planters except the YP2425

and YP2425A which have dual hoppers and the

walkboard is not located at the rear.

Refer to Figure 4

13. Walkboard should still be swung out to side.

14. It is necessary to make room to fit the refuge hopper on the planter.

Using a torch cut off the smaller walkboard extension piece. (You will be cutting through the bracket

that is welded to the bottom of both walkboard sections).

15. It is recommended to use a grinder to smooth the

edges. Spray with aerosol spray paint to prevent

rusting.

Null4:

Move Walkboard Back 43⁄4inches

Refer to Figure 5

16. To allow room for the refuge hopper, move the walkboard mount back 43⁄4 inches to back set of

prepunched holes on the frame. Attach with existing

hardware.

Figure 4

Walkboard Extension

13128

Figure 5

Walkboard Set Back

403-287M Front Page Part Lists 05/11/2011

31331

Page 5

Adjust Walkboard Front Page Part Lists Great Plains Manufacturing, Inc. 5

Refuge Hopper Parts List

F

UD

LRB

Figure 6

Refuge Hopper

Null4:

Callout Quantity Part Number Part Description

1 2 123-356D 10’ EWNT SGS LID LATCH

2 1 403-288H REFUGE HOPPER LID WELD

3 1 403-292H YP REFUGE TANK WELDMENT

4 2 403-513D REFUGE HOPPER GATE

5 2 502-060D DUST PLUG CHAIN 10.

6 2 800-051C RING, SPLIT 1-1/4 I.D

7 6 800-101C RIVET POP 1/8X.265LG FLG

8 6 801-003C SCREW RD HD SLT 10-24X1/2 P

9 3 802-078C HHCS 1/4-20X5/8 GR5

10 2 802-283C HHCS 1/4-20X1/2 GR2

11 6 803-001C NUT HEX 10-24 PLT

12 2 803-006C NUT-HEX 1/4-20 PL

13 3 803-007C NUT-LOCK 1/4-20 PLT

14 6 804-004C WASHER INTERNAL STAR #10 PL

15 10 804-046C WASHER FLAT #10 SAE PLT +

16 1 816-004C VINYL SEAL 3/8 X 1/2 (PER FT)

17 2 816-112C RUBBER LATCH 37-11-065-10

18 2 816-113C LATCH KEEPER 37-15-061-1

31332

05/11/2011 Front Page Part Lists 403-287M

Page 6

6 Front Page Part Lists

Appendix

Part Lists

New Parts

The part call-out numbers in this list match all Figures in

these installation instructions. Part descriptions match

those in your updated Parts Manual.

Quantities are units (“ea”).

Kit Contents

403-287A

Yield-Pro® Refuge Hopper Kit

Callout Quantity Part Number Part Description

11 1 403-287M YP REFUGE HOPPER KIT MANUAL

12 1 403-294L YP REFUGE HOPPER ASSEMBLY

13 1 403-295H YP REFUGE FILL TOP WELDMENT

14 4 800-399C CLAMP WRM DRV (2.5-4.5)

15 6 802-057C HHCS 5/8-11X2 1/4 GR5

16 6 803-021C NUT HEX 5/8-11 PLT

17 6 804-021C WASHER FLAT 5/8 SAE PLT

18 6 804-022C WASHER LOCK SPRING 5/8 PLT

19 2 990-266R HOSE 3 ID RF

Abbreviations

FLG Flange PL/PLT Plated

GR2 Grade 2 RD Round

GR5 Grade 5 RFH Rubber Flexible Hose

HD Head SAE Society of Automotive Engineers (standards)

HEX Hexagonal (6 sided) SGS Small Grass Seeds

HHCS Hex Head Cap Screw (Bolt) SLT Slotted

ID Inside Diameter W/ With

LG Long X by

OD Outside Diameter YP Yield-Pro®

Great Plains Manufacturing, Inc.

Corporate Office P.O. Box 5060

Salina, Kansas 67402-5060 USA

403-287M Front Page Part Lists 05/11/2011

Loading...

Loading...