Page 1

Part Lists Great Plains Manufacturing, Inc. 1

Yield-Pro®Planter 1.6 Bu. Hopper Enhancement

Null4:

Used with YP425/625/825A Planters:

• YP425A s/n B1012N-

• YP625A s/n B1057Q-

• YP825A s/n B1016S-

• YP3P425A s/n B1006M-

• YP3P625A s/n B1008P-

• YP3P825A s/n B1013R-

Null4:

General Information

These instructions explain how to install a Yield-Pro®1.6

bushel hopper enhancement. One kit is required per

each planter hopper, either right hand or left hand. (This

enhancement is for planters prior to July 2011 that have

the lesser capacity 1 bu. hoppers.)

Kit Kit Description

403-609A RH 1.6BU HOPPER FLD KIT

403-610A LH 1.6BU HOPPER FLD KIT

Tools Required

• basic hand tools

• support stands

When you see this symbol, the subsequent instructions and warnings are serious - follow without exception. Your life

and the lives of others depend on it!

U

R

F

B

L

D

Work Location

Move the implement to a flat location for installation.

Crushing and Sharp Object hazards:

Be careful working near openers. Discs and other parts may

be sharp.

Notations and Conventions

Null4:

U

F

L

D

“Left” and “Right” are facing in the

direction of machine travel. An orienta-

R

tion rose in the line art illustrations

shows the directions of Left, Right,

Front, Back, Up, Down.

B

Call-Outs

110

to

11 21

to

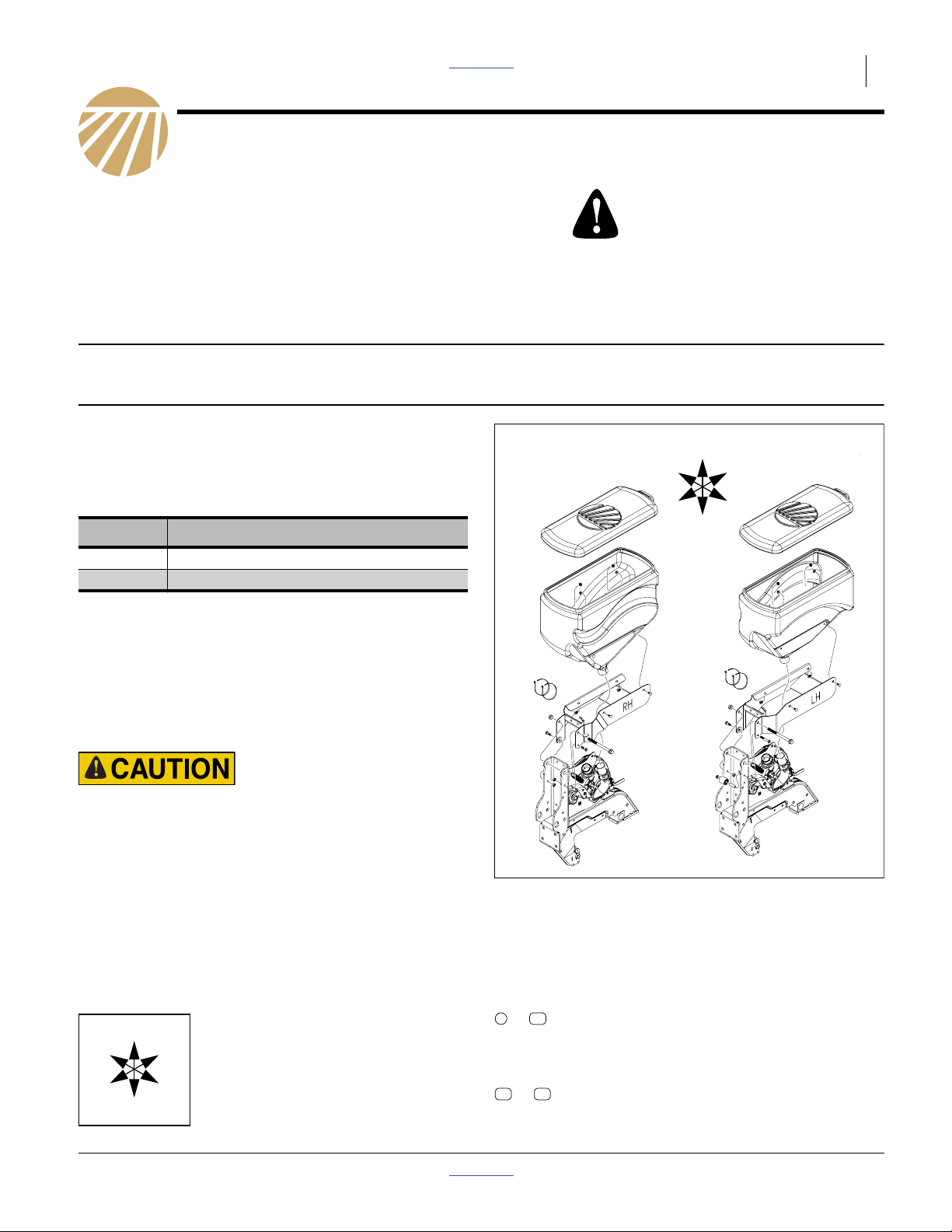

Figure 1

Right Hand and Left Hand

Hopper Enhancement Kits

Single-digit callouts identify components in

the currently referenced Figure. These numbers may be reused for different items from

page to page.

Two-digit callouts in the range 11 to 21 reference new parts from the list on page 5.

32233

© Copyright 2011 Printed 08/16/2011 Part Lists 403-612M

Page 2

2 Great Plains Manufacturing, Inc. Front Page Part Lists YP 1.6 Bu Hopper Enhancement

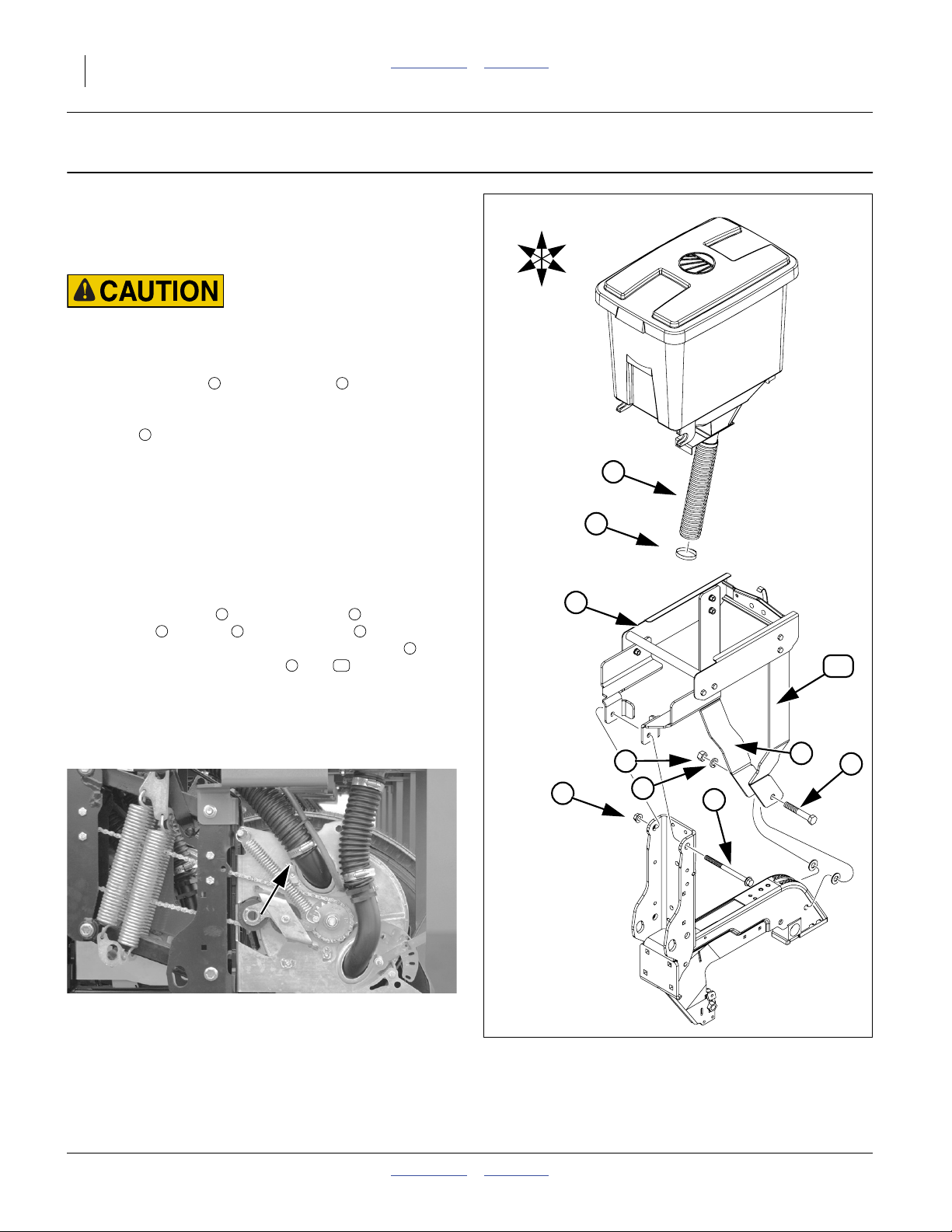

Remove Old Hopper

Refer to Figure 2

Before beginning, raise machine up in air at a sufficient

angle so springs are relaxed with no tension remaining

on the parallel arms. Support with stands.

Crushing Hazard:

Do not work around heavy equipment without support stands

appropriate to the amount of weight they must bear.

1. Remove clamp at base of hose on the old hopper.

This releases the hopper and all parts above

2

hose as one unit. Discard all parts, they will not

be reused.

2. Disconnect the air inlet hose from the seed meter by

removing its clamp (see photo below). Save the

clamp for later assembly.

3. If a blockage monitor is present, disconnect the wire

leading to it by removing the zip tie holding it in

place. (Do this at the same time as disconnecting

the other hoses.)

4. Remove hex nut and 65⁄8inch bolt , also remove

hex nut , washer and 4 inch bolt .

This releases the hopper support weldment and

RH and LH hopper braces and from the

opener arm.

5 6 7

1 2

3 4

8

910

R

F

U

B

L

D

2

1

8

10

Discard the hopper support weldment and braces.

Retain the opener arm.

5

3

6

Figure 2

Remove Old Hopper

4

9

7

32233

403-612M Front Page Part Lists 08/16/2011

Page 3

Install New Right Hand Hopper Front Page Part Lists Great Plains Manufacturing, Inc. 3

Install New Right Hand Hopper

Refer to Figure 3

The right hand and left hand opener mounts are offset.

Be sure the placement is correct for right/left offset orientation.

R

U

B

Install Hopper Support Mount

5. Select:

12

1 403-565H RH HOPPER MOUNT WLDMNT

18

2 802-017C HHCS 3/8-16X1 GR5

19

1 802-323C HHCS 1/2-13X6 1/2 GR5

20

1 803-169C HEX FLGLOCK 1/2-13 PLT

21

2 803-209C FLANGE LOCK 3/8-16 PLT

Secure mount to opener arm bracket using bolt

and nut , just below this hardware insert bolts

and flange locks . Tighten.

20 18

21

Place Hopper on Mount

6. Select:

13

1 403-594K HOPPER ASSEMBLY RH

31

4 802-092C RHSNB 5/16-18X3/4 GR5

32

4 803-177C NUT HEX FLG TP LK 5/16-18ZNYCR

Place new 1.6 bu hopper on hopper mount

and adjoin bottom opening to seed tube. Secure

hopper to mount with four carriage bolts and

32

nuts .

13 12

Connect Meter Air Hose

7. Select one:

16

800-060C CABLE TIE .19X14.25 3DIA 50

31

19

F

16

17

20

D

13

L

32

31

98

99

12

19

Route the air hose through the top left hand corner

of the mount and reconnect it to the air inlet elbow

on the tube meter securing with the clamp saved

earlier.

8. Secure the air hose to the tab mount with the

cable tie .

16

99

18

18

21

21

Connect Blockage Monitor Wire

9. Select one:

17

800-112C CABLE TIE .19X7.25 1.75D 50

Route the blockage monitor cable through the hole

in the front of the mount and reconnect to the

harness. Secure the cable to the mount with

cable tie through hole in the mount and

opener.

08/16/2011 Front Page Part Lists 403-612M

17 98

12

12

Figure 3

Right Hand Hopper

32233

Page 4

4 Great Plains Manufacturing, Inc. Front Page Part Lists YP 1.6 Bu Hopper Enhancement

Install New Left Hand Hopper

Refer to Figure 4

The right hand and left hand opener mounts are offset.

Be sure the placement is correct for right/left offset orientation.

The left hand mount has a 3/8in bolt that is reused

(from the existing assembly). It attaches the idler spool

on the bracket.

23

Install Hopper Support Mount

10. Select:

14

1 403-564H LH HOPPER MOUNT WLDMNT

18

1 802-017C HHCS 3/8-16X1 GR5

19

1 802-323C HHCS 1/2-13X6 1/2 GR5

20

1 803-169C HEX FLG LOCK 1/2-13 PLT

21

2 803-209C FLANGE LOCK 3/8-16 PLT

R

F

U

B

L

D

32

15

Secure mount to opener arm bracket using bolt

and nut .

Just below this hardware insert ildler spacer

tube , idler spool , and secure with saved bolt

23 21

bolt and flange lock . Tighten.

20

25 24

and flange lock . On opposite side insert

18 21

Place Hopper on Mount

11. Select one each:

15

1 403-595K HOPPER ASSEMBLY LH

31

4 802-092C RHSNB 5/16-18X3/4 GR5

32

4 803-177C NUT HEX FLG TP LK 5/16-18ZNYCR

Place new 1.6 bu hopper on hopper mount

and adjoin bottom opening to seed hose. Secure

hopper to mount with four carriage bolts and four

32

nuts .

15 14

Connect Meter Air Hose

12. Select one:

16

800-060C CABLE TIE .19X14.25 3DIA 50

Route the air hose through the top left hand corner

of the mount and reconnect it to the air inlet elbow

on the tube meter securing with the clamp saved

earlier. Secure the air hose to the tab mount with

the cable tie .

16

Connect Blockage Monitor Wire

13. Select one:

17

800-112C CABLE TIE .19X7.25 1.75D 50

Route the blockage monitor cable through the hole

in the front of the mount and reconnect to the

harness. Secure the cable to the mount with

cable tie through hole in the mount and

opener.

17 98

14

31

14

99

19

20

18

21

21

17

24

16

25

23

Figure 4

Left Hand Hopper

31

14

19

32233

403-612M Front Page Part Lists 08/16/2011

Page 5

Appendix Front Page Part Lists Great Plains Manufacturing, Inc. 5

Appendix

Part Lists

New Parts

The part call-out numbers in this list match all Figures in

these installation instructions. Part descriptions match

those in your updated Parts Manual.

Quantities are units (“ea”).

Kit Contents

403-609A RH 1.6BU HOPPER FLD KIT

403-610A LH 1.6BU HOPPER FLD KIT

Quantity in Kit:

Callout 403-609A 403-610A Part Number Part Description

11 1 1 403-612M MANUAL 1.6 BU HOPPER ENHANCEMENT

12 1 0 403-565H RH HOPPER MOUNT WLDMNT

13 1 0 403-594K HOPPER ASSEMBLY RH

14 0 1 403-564H LH HOPPER MOUNT WLDMNT

15 0 1 403-595K HOPPER ASSEMBLY LH

16 1 1 800-060C CABLE TIE .19X14.25 3DIA 50

17 1 1 800-112C CABLE TIE .19X7.25 1.75D 50

18 2 2 802-017C HHCS 3/8-16X1 GR5

19 1 1 802-323C HHCS 1/2-13X6 1/2 GR5

20 1 1 803-169C HEX FLG LOCK 1/2-13 PLT

21 2 2 803-209C FLANGE LOCK 3/8-16 PLT

Other Parts

The part call-out numbers in this list match all Figures in

these installation instructions. Part descriptions match

those in your updated Parts Manual.

Callout Quantity Part Number Part Description

31 4 802-092C RHSNB 5/16-18X3/4 GR5

32 4 803-177C NUT HEX FLG TP LK 5/16-18ZNYCR

08/16/2011 Front Page Part Lists 403-612M

Page 6

6 Front Page Part Lists

Great Plains Manufacturing, Inc.

Corporate Office P.O. Box 5060

Salina, Kansas 67402-5060 USA

403-612M Front Page Part Lists 08/16/2011

Loading...

Loading...