Page 1

Great Plains Mfg., Inc.

Update Instructions

2004 Yield-Pro® 1625 Planter

Base Update 2005 Kit

Used with:

• 2004 Yield-Pro® 1625 Planter

General Information

When you see this symbol, the subsequent instructions and

warnings are serious - follow without exception. Your life and

!

!

the lives of others depend on it!

These instructions explain how to install the 2004 YieldPro® 1625 Planter Base Update 2005 Kit. Field Update

Kits are designed to improve the performance and reliability of the planter.This update includes Yield-Pro® support

stands, new heavy duty gauge wheel casters, replacement idlers, and airbox modifications.

These instructions apply to:

402-187A 2004 Yield-Pro® 1625 Planter Base

Update 2005 Kit

402-180A Yield-Pro® 1625 Fertilizer Update Kit

2005

Assembly Instructions for 402-187A

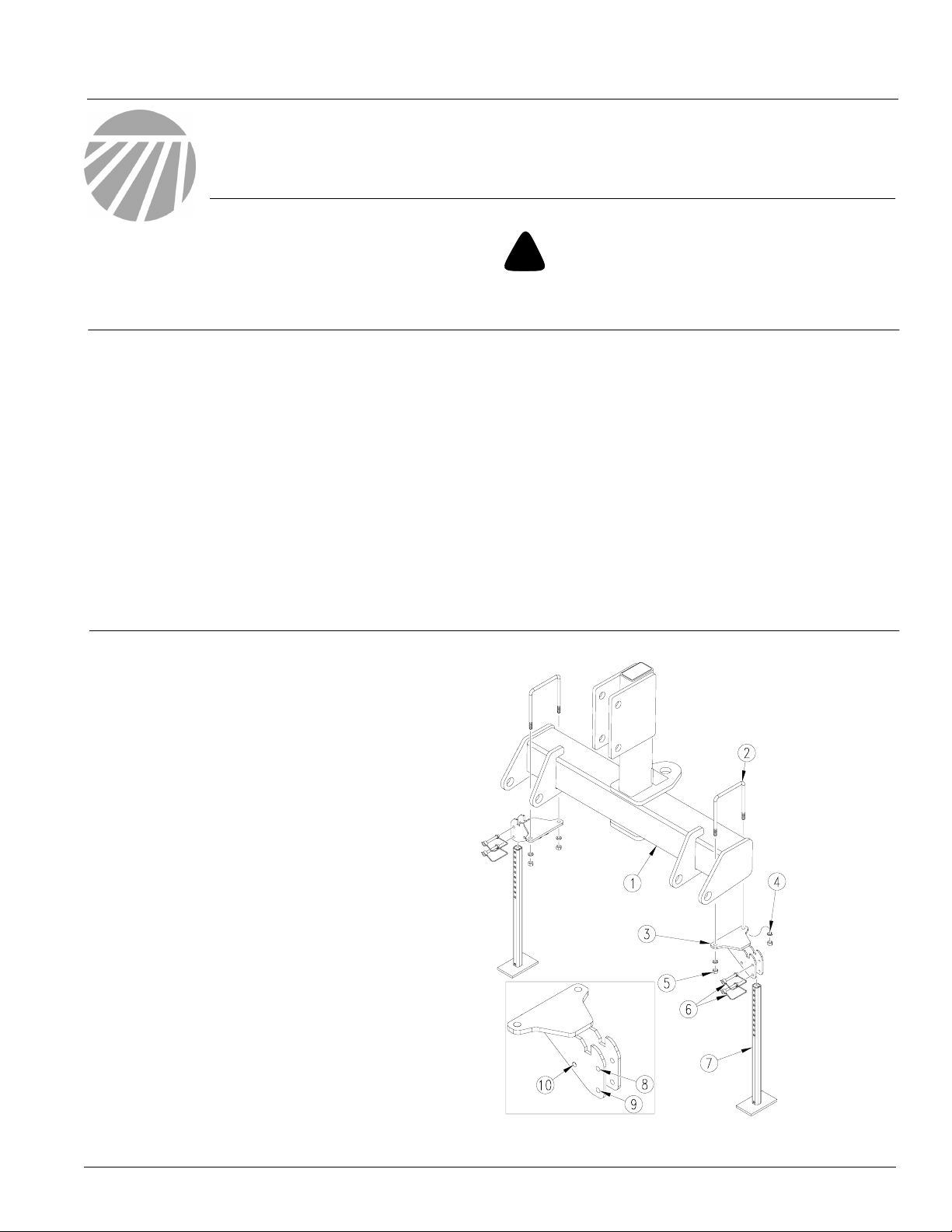

Install Yield-Pro® Support Stand

Refer to Figure 1

1. Attach park stand mount (3) to underside

of hitch crossbar weldment (1) on each

end of crossbar. Secure mount (3) to

crossbar (1) using 1/2-13 x 6 1/32 x 7 1/4

u-bolt (2), 1/2 lock washer (4), and 1/2-13

hex nut (5).

Before You Start

Starting on page 11 is a detailed listing of parts included in

the 2004 Yield-Pro® 1625 Planter Base Update 2005 Kit.

Use this list to inventory parts received.

Tools Required

• Basic Hand Tools

• Snap Ring Pliers

• Caulk Gun

• 2-ton Support Stand and Blocks

• Dial Type Inch-lb Torque Wrench

• Forklift

2. When in use, secure stand (7) to mount

(3) by inserting two 3/8 x 2 1/2 wire snap

lock pins (6) in the two outermost holes (8

and 9) on mount (3).

3. When stand (7) is not in use, remove bottom pin (6) from lower hole (9). Swing

stand underneath crossbar (1) and secure by inserting pin (6) below stand in innermost hole (10) on mount (3).

© Copyright 2005 Printed

12/12/2005

23402

Figure 1

Support Stand

402-188M

Page 2

Base Update 2005 Kit

2

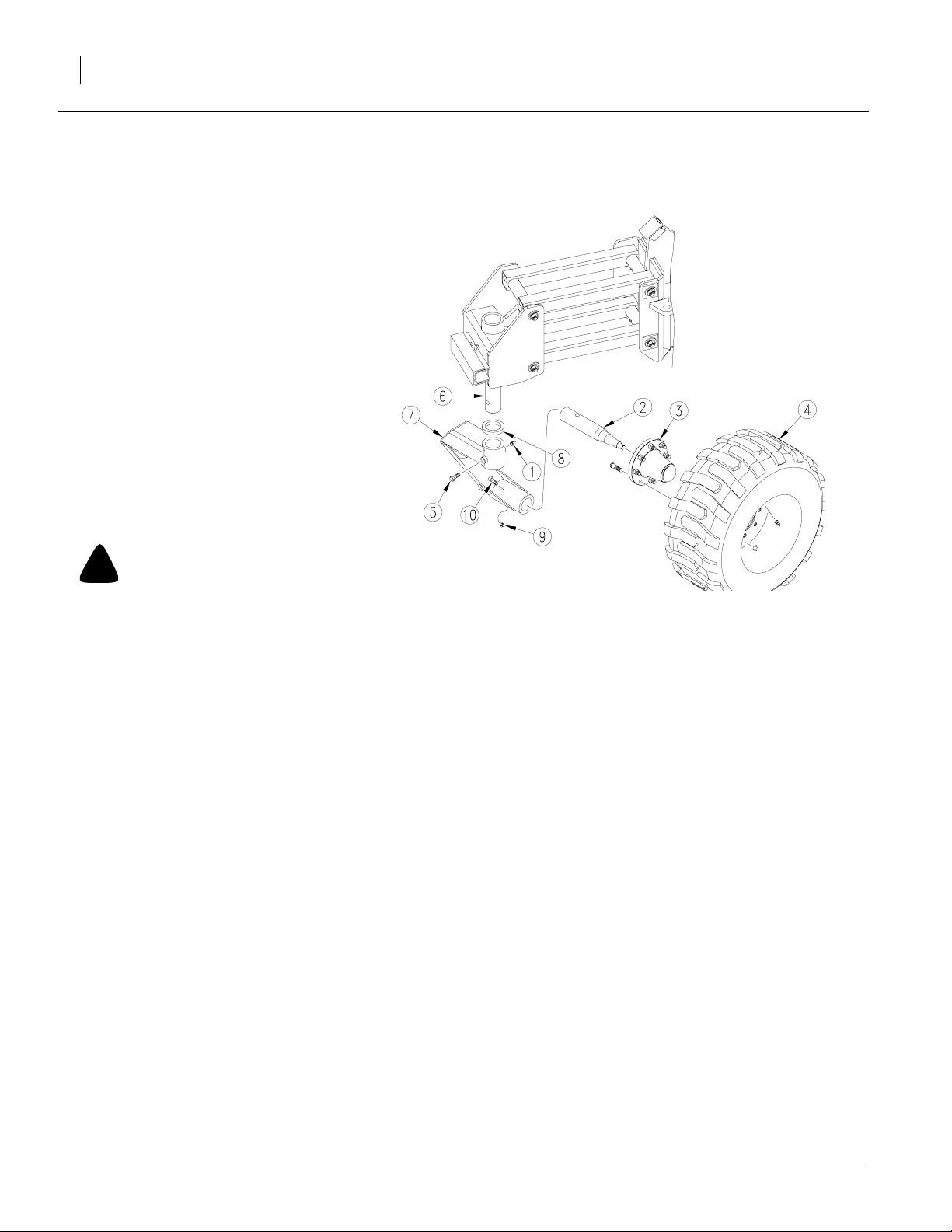

Replace Gauge Wheel Caster and AntiRotate Pins

Refer to Figure 2

NOTE: To replace gauge wheel caster and

and anti-rotate pins, the gauge wheels

will need to be blocked up so the weight

is off the tires. Blocks should have a minimum support capacity of 4 tons.

1. Once unit is blocked up and weight is off

tires, remove tire (4) from hub (3). Remove bolt (10) and lock nut (9) securing

spindle to caster. Slide spindle (2) and

hub (3) out of caster (7).

2. Remove bolt (5) and lock nut (1) securing vertical shaft caster (6) to caster (7).

Caster (7) and pivot thrust washer (8)

should fall to ground. Discard caster (7).

Keep pivot thrust washer (8) for reuse.

Great Plains Mfg., Inc.

!

To avoid injury, use extreme caution when removing caster (7) from vertical shaft (6). Caster

(7) is heavy and will fall once bolt (5) is removed.

3. Replace old caster (7) with new more

4. Reattach spindle (2) and hub (3) to cast-

5. Repeat steps 1 - 4 on opposite side of

CAUTION!

sturdy caster provided in kit. Attach caster and washer (8) removed in step 2 to

vertical shaft caster (6) with bolt (5) and

lock nut (1) removed in step 2.

er (7) with bolt (10) and lock nut (9) removed in step 1. Replace tire (4) on hub

(3) with tire tread in same direction as

before. NOTE: Center of tire will align

below center of pin (6). Tire should

not sit off to one side. Tighten all bolts.

planter.

23403

Figure 2

Replace Gauge Wheel Caster

402-188M 12/12/2005

Page 3

Great Plains Mfg., Inc.

Refer to Figure 3

1. Remove cotter pin and cylinder pin securing hydraulic cylinder to eyebolt weldment. Discard cylinder pin.

2. Remove cotter pin and cylinder pin securing opposite end of hydraulic cylinder to lower swivel

caster weldment. Discard cylinder pin.

3. Reattach cylinder to eyebolt weldment and lower

swivel caster using new cylinder pins provided in

kit. Secure cylinder pins with cotter pins previously removed.

NOTE: When installing new cylinder pins to reattach cylinders, note location of grease outlet

holes in center of pins. Install pins so that holes

are pointing upwards or towards the cylinder

main body.

4. Repeat steps 1-3 on opposite side of planter.

5. Remove blocks supporting planter.

Installation Instructions

3

12/12/2005

24004

Figure 3

Install Anti-Rotating Pins

402-188M

Page 4

Base Update 2005 Kit

4

Replace Idlers

Refer to Figure 4

1. Detach meter from opener and set meter aside.

NOTE: It is not necessary to detach hose

from meter.

2. Detach spring from idler bracket weldment. Remove snap ring (4) from front idler (10). NOTE: It

is not necessary to remove both snap rings.

Discard snap ring (4). Keep spring for reuse.

NOTE: If meter drive units have been timed for

staggered drop on twin row spaced planters, do

not remove drive chain from sprocket without

first noting which sprocket tooth is up. Check

that sprocket is timed with same tooth up when

chain is reinstalled or re-time meters when finished according to the instructions in operator’s

manual.

3. On backside of drive mount weldment (2), remove bolt (6) and washer (8) securing idler pivot

(3) and idler bracket weldment (1) to drive mount

weldment (2). Keep bolt (6) and washer (8) for

reuse.

Great Plains Mfg., Inc.

23405

4. Remove idlers (5 and 10), bushings (7 and 9),

idler bracket weldment (1), and idler pivot (3).

Discard idlers (5 and 10), bushings (7 and 9),

idler bracket weldment (1), and idler pivot (3).

5. Turn sprocket by hand for two rotations. Insert

meter drive adapter tool into hub of sprocket.

NOTE: To test torque, remove chain from

sprocket. Complete test with parts at temperatures of 65 degrees or higher. Using 5/8"

socket and an inch-lb torque wrench, measure

drive torque by rotating sprocket in normal direction of travel.

NOTE: Meter drive units with torque readings in

excess of 10 inch-lbs should be replaced. Units

with torque variation, as sprocket is rotated,

greater than 3 inch-lbs should be replaced. Order assmebly 403-117s, one per row as needed.

NOTE: It is not necessary to completely remove

chain from row unit while replacing idlers.

6. Secure idler pivot (3) and bushing (9) to drive

mount weldment using bolt (6) and washer (8)

removed in step 2.

NOTE: DO NOT apply any lubricant or anti-sieze

compounds to these parts when reassembling.

7. Attach idler bracket weldment (1) to idler pivot

(3). Route chain through idlers (5 and 10) as

idlers (5 and 10) are reassembled.

23406

Figure 4

Idler Assembly

8. Place idlers (5 and 10) on idler bracket weldment. Secure idlers (5 and 10 ) to idler bracket

weldment (1) with snap rings (4).

9. Reattach spring to idler bracket weldment (1)

and replace meter.

10. Repeat steps 1-9 for all other openers.

11. Check meter timing on twin row spaced planters.

402-188M 12/12/2005

Page 5

Great Plains Mfg., Inc.

Install Hopper Water Guard Weldment

Refer to Figure 5

1. Be sure hopper is empty. Remove hopper assembly from planter frame and support securely.

NOTE: Before removing parts to install hopper

water guard weldment, mark line on door guide

along bottom of plastic hopper to note door

height. This ensures door is replaced at same

height.

2. Unscrew stop bolt (4). Remove door (3) from

door guide (6). Keep stop bolt (4) and door (3)

for reuse.

3. Remove the two side bolts (7) on both sides of

hopper (1). NOTE: Do not remove bolts se-

curing door guide to front or back of hopper.

Keep removed bolts (7), flat washers, and hex

lock nuts for reuse.

4. Slide water guard (5) all the way up on hopper

(1). Use bolts (7) from step 3 to attach weldment (5) to hopper (1). NOTE: Hopper Water

Guard Weldment attaches to hopper with

double bevelled rain gutter oriented to rear

over door. Other three edges will slope

downward.

Installation Instructions

NOTE: Hopper shown removed from frame for clarity

only. Do not remove hopper from frame.

Figure 5

Hopper Water Guard Weldment

23409

5

5. Using line marked on door guide (6), replace

door (3) at same height as before. Tighten all

bolts.

6. Apply a layer of silicon around joint between

hopper (1) and guard (5).

Important! It is important that guard be sealed completely to hopper to avoid getting water into seed

manifold.

Update Manifold

1. Disconnect level sensor from harness.

Refer to Figure 6

NOTE: Before removing top of manifold, measure distance

from top of meter top seal (A) to top of angle on manifold (B).

Record this dimension to use when reassembling manifold.

Refer to Figure 7

2. Remove bolts (1) securing top manifold weldment (3) to

manifold . Detach top manifold weldment (3).

3. Remove corner seal mount weldments (2) from top of old

manifold. Keep weldments and all hardware for reuse.

23466

Figure 6

Manifold

4. Remove top corner seals (4) from corner seal mount weldments (2) . Discard top corner seals.

12/12/2005

Figure 7

Disassemble Manifold

23461

402-188M

Page 6

Base Update 2005 Kit

6

Refer to Figure 8

5. Remove level sensor (1) and shroud (2) from

old top manifold weldment. Keep sensor (1),

shroud (2), and hardware for reuse. Discard

old top manifold weldment.

Great Plains Mfg., Inc.

23415

Figure 8

Manifold Shroud

Refer to Figure 9

6. Remove gates (1) from rear part of inside manifold. Keep all hardware for reuse. Discard gates (1).

7. Replace gates with left and right-hand

seed chamber dividers (2). Note orientation of dividers (2) with tabs to bottom.

NOTE: Seed chamber dividers (2) come

in a pair of left and right-hand dividers.

With the dividers properly oriented in the

manifold, the end with the long tab will be

toward the center and the tabs will line up

with the outlets. If the tabs do not correctly line up with outlets, the dividers are not

properly oriented in manifold.

8. Secure seed chamber dividers (2) using

hardware removed from gates.

23465

Figure 9

Manifold Seed Chamber Dividers

402-188M 12/12/2005

Page 7

Great Plains Mfg., Inc.

Refer to Figure 10

9. Remove nine center screws (3) from front row

of screws securing manifold slat assembly (1)

to manifold (2).

10. Place air deflector (4) on top of manifold slat

assembly (1) with turned up edge toward rear

of manifold (2). Secure air deflector (4) to manifold slat assembly (1) using the nine center

screws (3) removed in step 6 above.

Installation Instructions

23463

NOTE: Front of manifold removed for clarity only. Do NOT

remove front of manifold.

7

Refer to Figure 11

11. Reinstall level sensor (1) and shroud (2) to new

manifold top weldment provided in kit. NOTE:

Orient level sensor as shown in inset. Use

hardware removed in step 4. Reconnect level

sensor to harness.

12. Reattach top manifold weldment to manifold

using bolts from step 2.

Figure 10

Manifold Air Deflector

23415

23489

12/12/2005

Figure 11

Manifold Shroud

402-188M

Page 8

Base Update 2005 Kit

8

Refer to Figure 12

13. Slide previously removed corner seal mount

weldments (3) along front corners between

top of manifold (1) and seal holder weldment

(2).

14. Attach new seal holder weldment (2) to new

manifold top weldment (1) using 1/4-20 x 5/8

bolts, 1/4 flat washers, 1/4 lock washers, and

1/4-20 hex nuts.

15. Secure corner seal mount weldments (3) to

manifold top weldment (1) and seal holder

weldment (2). Use 1/4-20 x 1 bolts , 1/4 flat

washers, 1/4 lock washers, and 1/4-20 hex

nuts. Attach top corner seals to corner seal

mount weldments. NOTE: Top of corner

seals need to be 1.19" above top of main

seal.

Great Plains Mfg., Inc.

23464

Figure 12

Seal Holder Weldment

Refer to Figure 13

16. Place seed strainer grate weldment (2) in seal

holder weldment (3).

17. Peel release paper from back of meter top seal

(1). Stick seal (1) on seal holder weldment (3).

18. Measure distance from top of meter top seal

(A) to top angle on manifold (B). NOTE : See

Figure 6 on page 5. Make sure new seal (1) is

replaced at same height as old seal.

Install Fan Inlet Rain Shield

Refer to Figure 14

1. Attach fan inlet rain shield (1) to outside of

fan using four #12-14 x 3/4 hex head

screws (2).

23462

Figure 13

Top Seal

NOTE: Shield should overlap intake screen

mounting plate against fan housing.

23417

Figure 14

Fan Inlet Rain Shield

402-188M 12/12/2005

Page 9

Great Plains Mfg., Inc.

Replace Transport Support Hook Weldment

Refer to Figure 15

NOTE: To replace transport support hook weldments, make sure the planter is unfolded. Failure to

unfold planter may result in injury or damage to the

machine or mechanic.

1. Remove one 3/8 x 2 1/2 roll pin from pivot shaft.

2. Slide transport pivot shaft from weldment. Remove and discard weldment and spring from

toolbar. Keep roll pins and pivot shaft for reuse.

3. Replace weldment and spring with new weldment and spring provided in kit.

4. Replace pivot shaft and repin hook to toolbar using 3/8 x 2 1/2 roll pins.

5. Repeat steps on opposite side of planter.

Roll Pin

Installation Instructions

Weldment

Pivot Shaft

Figure 15

Transport Support Hook Weldment

9

24002

Install Hose Wrap and Cable Ties

Refer to Figure 16

1. If not cut already, cut spiral hose wrap in four

pieces. One piece will measure 4 foot, one piece

will measure 3 foot, and the remaining two pieces will measure 1 foot each.

NOTE: When wrapping hoses, only fertilizer

hose may be left out of hose wrap.

2. Using the 3 foot section, wrap all hydraulic lines

and electrical harness lines between left-hand

side toolbar/wing and center mainframe.

3. Start wrapping directly below fold cylinder rod

pin. Continue to wrap hoses up to the hose guide

on the toolbar pivot pin.

4. Using the 4 foot section, wrap all hydraulic lines

and electrical harness lines between right-hand

side toolbar/wing and center mainframe.

5. Start wrapping directly below fold cylinder rod

pin and continue to wrap beyond the hose guide

to control the hoses going on to the fan.

Refer to Figure 17

23421

Figure 16

Spiral Hose Wrap

6. If fertilizer hose is left out of hose wrap, route fertilizer hose along front of the hydraulic lines

crossing below tongue. All hoses must be routed

through hose clips forward of opener mounts to

avoid piniching when the wings flex up and

down.

12/12/2005

Figure 17

Fertilizer Hose

402-188M

Page 10

Base Update 2005 Kit

10

Refer to Figure 18

7. Remove 3/8-16 x 2 3/4 bolt from marker pivot

pin. Secure 13/16 hose clip to pivot pin using

removed bolt. Using hose clip, secue hydraulic

hose that goes to gauge wheel lift cylinder.

8. The two 1 foot sections will wrap hydraulic hoses going to gauge wheel lift cylinder. Start

wrapping hoses from hose clip out toward cylinder.

9. Repeat steps 4 and 5 on opposite side of

planter.

Great Plains Mfg., Inc.

23419

Figure 18

Hose Clip and Spiral Hose Wrap

Refer to Figure 19

10. Cover hoses entering pullbars with vinyl

sleeves - shiny side of sleeve against hoses.

Position hose sleeve with 10" of sleeve inside

pullbar and 14" outside . This covers hoses

passing through tongue and hitch area. Secure sleeve in place with velcro strips and use

a cable tie at each end to keep it from sliding.

11. Wrap hoses exiting pullbars with vinyl sleeves

- shiny side of sleeve against hoses. Sleeve

will extend 2-3" past support ring below pullbar pivot pin. Use cable tie at each end to keep

sleeve in place.

IMPORTANT! This is the end of instructions for the 2004 YP1625 Base Update

2005 Kit. If the planter is equipped with

fertilizer, please continue on to the next

Figure 19

Vinyl Sleeves

page for instructions on installing the

YP1625 Fertilizer Kit Update.

402-188M 12/12/2005

Page 11

Great Plains Mfg., Inc.

Assembly Instructions for 402-180A

Replace Nozzle Body Clamp

Refer to Figure 1

1. Detach nozzle body from nozzle body

clamp. Remove old clamp from supply tube.

Keep elbow fitting and orifice plate for reuse. Discard check valve and clamp.

NOTE: New nozzle body clamp has check valve

built into it. Separate check valve is no longer

necessary.

2. Attach new nozzle body clamp to fertilizer

supply tube. Reinstall orifice plate, elbow

fitting, and nozzle body.

3. Repeat steps for all clamps.

Installation Instructions

Figure 1

Nozzle Body Clamp

11

23422

Replace Fertilizer Hose Plastic Coupler

Refer to Figure 2

1. Uncouple fertilizer hose. Remove slip-on

coupler attaching fertilizer supply line to

opener attachment tube.

2. Replace coupler with new push-lok connector. Recouple hose.

3. Repeat steps for all hoses.

23423

Figure 2

Push-Lok Connector

12/12/2005

402-188M

Page 12

Base Update 2005 Kit

12

Replace Upper Sight Glass Fitting and Add

Decal

Refer to Figure 2

1. Remove hose from top, upper sight glass fitting by cutting hose at end of old hose barb.

NOTE: New fitting is longer and will make

up cut off length.

2. Unscrew elbow fitting and hose barb from top

of tank only. Replace sight glass fitting with

stainless steel elbow and hose barb fitting.

3. Reattach hose to new fitting.

Great Plains Mfg., Inc.

Cut Hose

Here

23424

Refer to Figure 5

4. Install level decal to front of tank as

shown. To simplify installation 4 inches

may be cut from decal. Cut 1 1/2" below

the 50 gallon mark. Make the second cut

5 1/2" below the 50 gallon mark. Then install decal above and below frame tube

so that 50 gallon mark is 1 1/2" upslope

from top of frame tube as shown.

Figure 2

Sight Glass Fittings

23426

23425

Figure 3

Fertilizer Tank

402-188M 12/12/2005

Page 13

Great Plains Mfg., Inc.

402-187A 2004 Yield-Pro® 1625 Planter Base Update 2005 Kit

Your kit includes:

Qty. Part No. Part Description

4 148-283H COULTER COMMAND CYLINDER PIN

1 401-226M MANUAL OP 12 & 16 ROW YP PLTR

2 401-258H YP HITCH PARK SUPPORT STAND

2 401-262H PARK STAND MOUNT

2 401-267H TRANSPORT SUPPORT HOOK WLDMT

2 402-158H 16R CASTER LOWER WLDMT

1 402-188M MANUAL 2004 YP BASE UPDATE 2005

32 403-105D IDLER PIVOT

32 403-115H IDLER BRACKET WELDMENT

1 403-164H MANIFOLD FRONT TOP WELDMENT 2

1 403-165H SEAL HOLDER WELDMENT

1 403-188H HOPPER WATER GUARD WELDMENT

1 403-189H SEED STRAINER GRATE WLDMNT

1 403-316D AIR DEFLECTOR

1 403-317D SEED CHAMBER DIVIDER LH

1 403-318D SEED CHAMBER DIVIDER RH

1 403-336D METER DRIVE ADAPTER

2 800-064C HOSE CLIP 13/16 ID

4 800-073C GREASE ZERK 1/4-28 X 90-DEG

12 800-082C CABLE TIE .31 X 21.5 6DIA 120LB

64 800-085C SNAP RING EXT 1 HEAVY

4 802-318C HHCS 3/8-16 X 5 GR5

4 802-800C HWH #12-14 X 3/4

4 803-014C NUT HEX 3/18-16 PLT

4 803-020C NUT HEX 1/2-13 PLT

4 804-015C WASHER LOCK SPRING 1/2 PLT

2 804-028C WASHER FLAT 1 USS PLT

1 805-024C PIN ROLL 3/16 X 1 1/2 PLT

4 805-212C PIN WIRE SNAP LOCK 3/8 X 2 1/2

2 806-060C U-BOLT 1/2-13 X 6 1/32 X 7 1/4

2 807-260C SPRING COMP 1.460D .148W X 4.0LG

1 816-478C AUX METER TOP SEAL

2 816-479C SEAL TOP CORNER

4 816-480C HOSE WRAP 3.0-4.5 X 24 LG VELCR

64 817-083C PRESS WHEEL ARM PIVOT BUSHING

64 817-406C IDLER 1 PC 2.38 X 1.0 X 1.062

1 817-624C FAN INLET RAIN SHIELD

1 890-179C SILICON 35YR CLEAR 10 OZ

9 990-228R SPIRAL HOSE WRAP 1 ID PLASTIC

Installation Instructions

13

402-180A Yield-Pro® 1625 Planter Fertilizer Update Kit 2005

Your kit includes:

Qty. Part No. Part Description

32 829-089C NOZZLE BODY 3/4 WET BOOM CL

2 830-380C EL 3/4 MNPT X 3/4 FNPT SS

2 830-381C AD 3/4 MNPT X 3/4 HB SS

32 830-383C CP 1/4 PUSH LOK POLY

2 838-823C DECAL YP FERTILIZER LEVEL

12/12/2005

402-188M

Loading...

Loading...