Page 1

Great Plains Mfg., Inc. Parts Installation Instructions 1

Air Drill Variable Rate Kit

Air Drill Carts and 6 & 9m Air Drills

Used with:

• ADC2350, ADC2350B

• NTA907HD, NTA3007HD

• NTA607HD, NTA2007HD

General Information

These instructions explain how to install a variable rate

controller on a compatible air cart or integrated air drill

that presently has only manual (crank-operated) rate

control. With Variable Rate installed, the seed monitor

directly controls material rate, independently, at each

updated meter.

These instructions apply to an installation of:

Kit Kit Description

166-193A ADC2350 VARIABLE RATE KIT (dual)

166-328A VARIABLE RATE ACTR KIT SGL BIN

166-339A VAR RATE ACTR KIT DUAL BIN

These kits apply to:

Cart or Drill Kit Compatibility

ADC2350

ADC2350B

NTA607HD 166-328A orb 166-339A

NTA907HD 166-193A

NTA2007HD 166-328A orb 166-339A

NTA3007HD 166-193A

a Drills with software version prior to 4.21 require the software

b A single hopper drill uses the 166-328A kit. A dual hopper drill

One “dual” kit includes two actuators, and updates one

air cart or one integrated air drill. One “sgl” (single) kit

includes one actuator and updates one meter.

The 166-193A kit includes new WSMT software for older

ADC2350/B air carts that have a Software Version that

lacks qualified variable rate support.

a

166-193A

a

166-193A

update included in this kit. See page 4.

may use either 166-328A or 166-339A, depending on whether

variable rate is desired for just one or both meters.

U

R

F

B

L

D

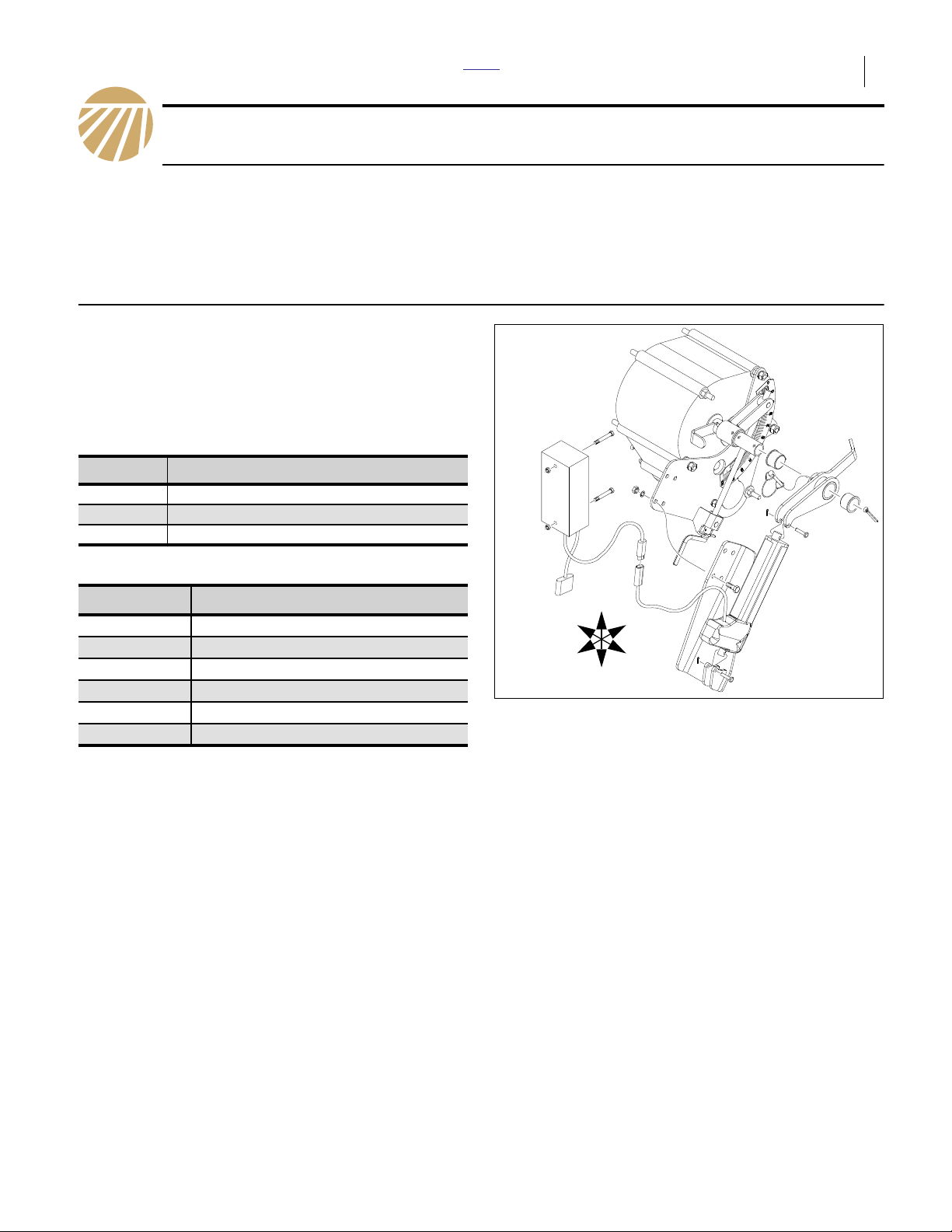

Figure 1

166-193A Kit Installation

29498

Related Documents

110011512 ACC User Manual, Levels 2 and 3

110011513 ACC User Manual, Level 1

11001-1507 Version 4 Software Update Guide

167-085B Seed Rate Manual (ADC & NTA models)

Have the Operator Manual at hand for drill movements.

167-085M Operator, ADC2350/2350B

166-207M Operator, NTA907/3007HD

166-283M Operator, NTA607/2007HD

Have the current Parts Manual at hand for parts ID.

167-085P Parts, ADC2350/2350B

166-207P Parts, NTA907/3007HD

166-283P Parts, NTA607/2007HD

6/23/2010 ©Copyright 2010 166-263M

Page 2

2 Air Drill Variable Rate Kit Front Parts Great Plains Mfg., Inc.

Notations and Conventions

“Left” and “Right” are facing in the

direction of machine travel. An orientation rose in the line art illustrations

shows the directions of Left, Right,

Front, Back, Up, Down.

R

F

U

B

L

D

Before You Start

Compatibility

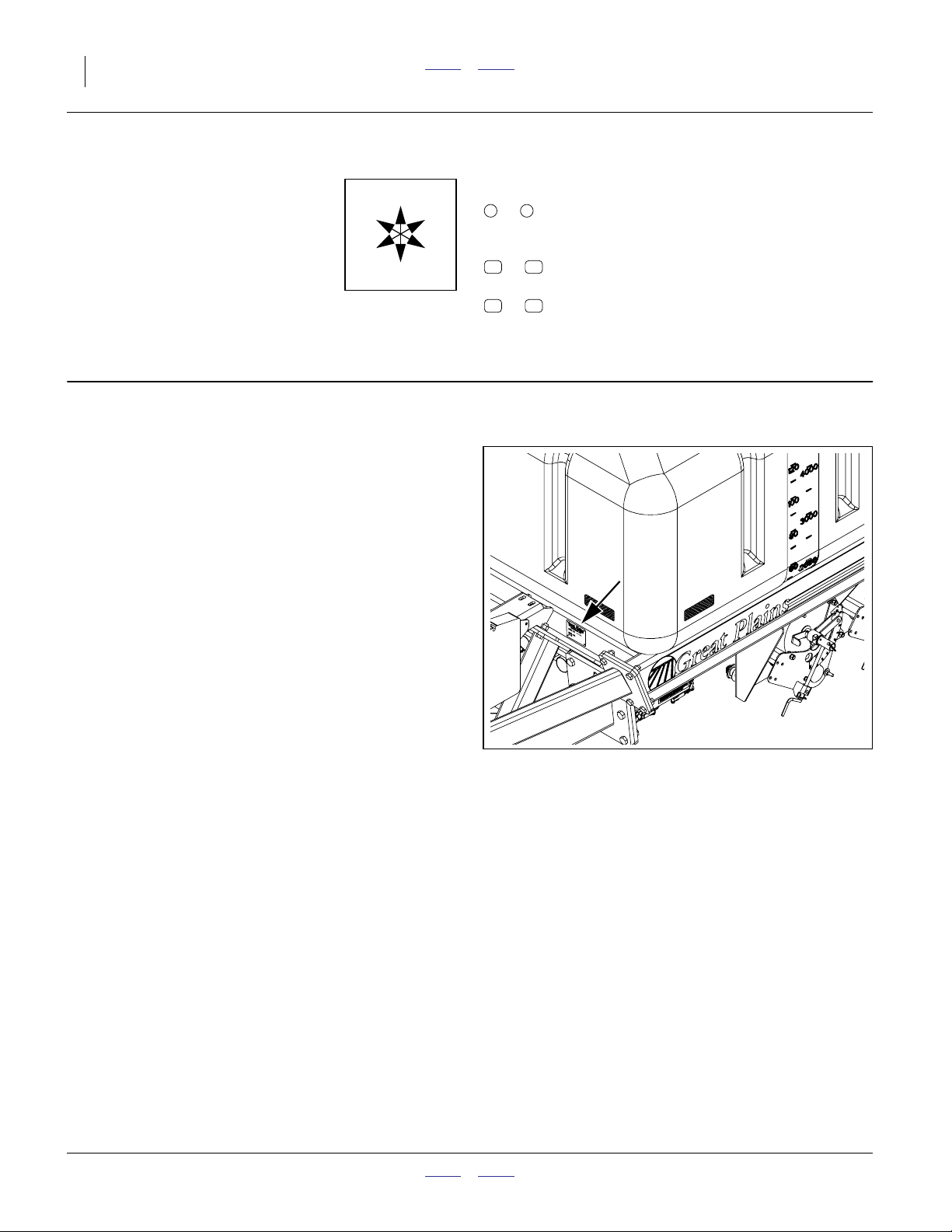

Refer to Figure 2

1. Check that linear actuators are not already installed

on the cart or integrated air drill. Variable Rate is a

feature that can be factory-installed.

2. Check the model number of the air cart or air drill to

ensure it is a compatible model. For example, this

kit is not compatible with the gearboxes used on

ADC1150, ADC2220 or ADC2250 air carts, nor

NTA1000, NTA1300 or NTA2000 integrated air drills.

Call-Outs

1 9

to

11 40

to

51 52

to

Single-digit callouts identify components in

the currently referenced Figure or Figures.

These numbers may be reused for different

items from page to page.

Two-digit callouts in the range 11 to 40 reference new parts (see list on page 20).

Two-digit callouts in the range 51 to 52 reference affected existing parts (see page 21).

Inventory

3. Make sure all parts are present.

Comprehension

4. Review these instructions. Make sure the installers

understand where each part or assembly is

installed, and what tools are required for the task.

Note: Illustrations in this manual, based on implement

Parts manual, may show exploded views that are

fully disassembled. Rely on the instructions for

required disassembly and reassembly steps.

Figure 2

ADC Model/Serial Number Plate

26428

166-263M Front Parts 6/23/2010

Page 3

Great Plains Mfg., Inc. Front Parts Installation Instructions 3

Pre-Assembly Preparation

Tools Required

• suitable tractor for positioning and operating the air

drill or cart

• the seed monitor console to be used with this implement (or a 2008 or later DICKEY-john® IntelliAG

10in LCD console)

• basic hand tools, including (for older ADC2350/B

only), a drill with bit size:

1

⁄4in (0.250in), letter size E, or 6.3mm

®

Prepare Drill

The mechanical installation may be performed on a disconnected air cart, but software update (if required), and

testing/configuration of the system require the complete

air drill, and an IntelliAG® virtual terminal.

Work Location

5. Move the air cart or air drill to a location with:

• room to fold it (NTA607/2007HD and NTA907/

3007HD only);

• access to tractor or hydraulic power;

• access to DICKEY-john® IntelliAG® console and

12Vdc power;

• adequate illumination; and,

• clear surface beneath for recovery of any falling

or dropped parts - if the surface is not clear, have

a tarp or drop cloth available.

6. NTA607/2007HD and NTA907/3007HD only:

Fold drill. Lower openers. This eases access to the

meters.

7. Shut off tractor or hydraulic source.

6/23/2010 Front Parts 166-263M

Page 4

4 Air Drill Variable Rate Kit Front Parts Great Plains Mfg., Inc.

Update Monitor Software

For models NTA607HD, NTA907HD, NTA2007HD or

NTA3007HD, continue at step 18 on page 5.

This step is performed first in the unlikely event that there

is any incompatibility between your IntelliAG® virtual terminal, and the latest version of the Air Cart Control software supplied in the kit.

If you are unable to update the seed monitor system, do

not continue the update. Have your Great Plains dealer

contact the factory for assistance.

Refer to Figure 3

8. Check the seed monitor Software Version per the

1

11001-1507 guide. If the Software Versiona is:

4.21 or higher,

you do not need to update the seed monitor software. If no update is required, continue at step 18

on page 5.

9. If you require a software update, and the SD card is

missing from the kit, contact Great Plains to obtain

the update.

10. Select from the kit one new:

38

11001-1507 ACC V4 SOFTWARE REPROGRAMMING

This is a DICKEY-john® manual describing the process of updating the software for the virtual terminal

(if needed) and the WSMT (if needed).

11. Follow the instructions in the reprogramming

manual to check the VT part number (on back of

38

terminal) and the software version of your seed

monitor (icon ).

2

12. Record Current Configuration

Monitor configuration may reset to defaults during

update. If either VT or WSMT will be updated,

record the current air drill configuration, particularly

the Material Library. Although newer virtual terminals support exporting the configuration to a blank

SD card, Great Plains recommends making a paper

record, as an imported SD configuration may be

altered during Auto Config at step 79.

13. Select from the kit one new:

37

INTELLI-AG SOFTWARE UPDATE SDC

This is a small Secure Digital (SD) flash memory

card. When instructed, the card is inserted in a

37

slot at the lower right corner of the VT bezel, behind

a flip-up door .

3

1

10in Virtual Terminal and SD Card

14. Select one each new from the kit:

12

110011512 ACC USR MANUAL VER 4.2 LVL 2&3

13

110011513 ACC USER MANUAL VER 4.2 LVL 1

The new software introduces user access levels,

and requires a password, described in the Password Access manual .

15. Follow the instructions in the reprogramming

manual . Software is already provided on a formatted SD card, so perform no steps calling for:

- media formatting or

- extranet downloading.

16. The new variable rate controller is not yet installed,

and will not be detected by the new software. After

installing the new hardware, a complete Setup/Configuration is performed starting on page 15 of these

instructions.

17. Shut down the monitor. Shut off the tractor ignition

(to assure that monitor circuits are powered off).

38

2

Figure 3

3

37

29504

13

a. This is displayed as “Software Version” and is not the “O.S. Version” nor the “Bootloader Version”.

166-263M Front Parts 6/23/2010

Page 5

Great Plains Mfg., Inc. Front Parts Installation Instructions 5

Prepare Meters

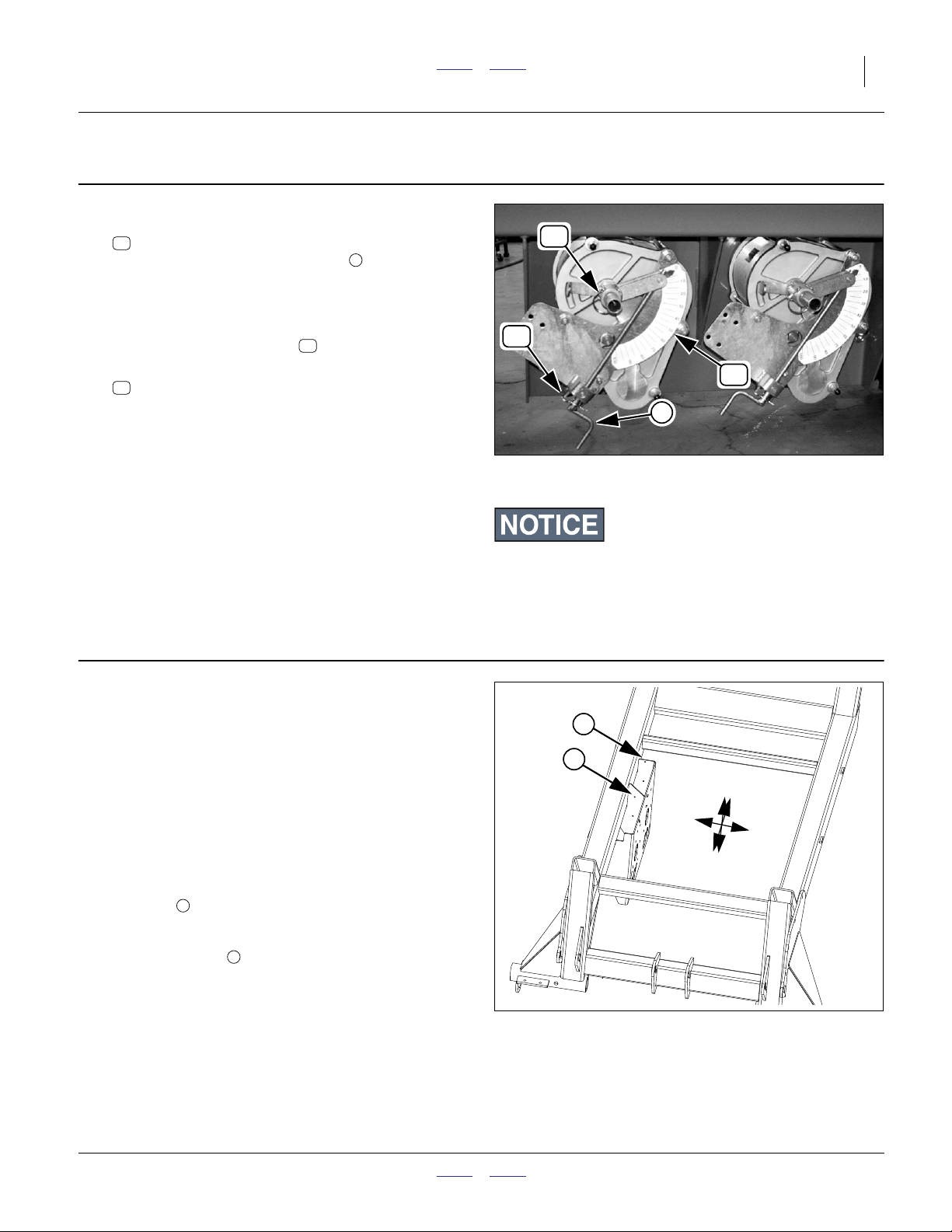

Refer to Figure 4

18. At a variable rate gearbox, remove the:

52

805-032C PIN HAIR COTTER .148 WIRE

then use the existing control crank actuator to set

the indicator to 0 on the 0-100 scale. This prevents

the jackscrew from obscuring the scale.

3

51

Adjust the final crank handle position to fully down,

and re-insert the cotter pin .

19. Remove and save the:

51

805-065C PIN WIRE RETAINING 1/4 X 1 3/4

This pin is re-used at step 41 to couple the new control arm to the gearbox control shaft.

Note: Removing this pin de-couples the gearbox control

shaft from the manual adjustment system. If it is

ever necessary to revert to manual control, move

the pin back to the manual arm.

20. Repeat step 18 and step 19 for the other meter.

52

Prepare ADC Driver Mounts

If your implement is an NTA607HD, NTA907HD,

NTA2007HD or NTA3007HD, continue at step 24 on

page 7.

On older ADC2350/B carts, the mounting holes for the

actuator driver modules may not be present, and must be

drilled. Newer ADC2350 carts, all NTA607/2007HD and

all NTA3007/907HD drills have holes present.

Refer to Figure 5

21. Locate the mounting holes on the ADC2350/B air

cart. These are 0.28x0.38in (7.1x95mm) slotted

holes 5.84in (14.8cm) apart.

52

50

3

Figure 4

Existing (Manual) Meters

Equipment Damage Risk:

Never operate the meters with pins in both the manual/crank

arm and the linear actuator arm.

26306

4

5

U

F

L

R

B

D

One pair is located on the forward break of the

gearbox mount plate.

The second pair are located on the brace plate at

the center of the gearbox mount plate.

If these holes are present, continue at to step 24 on

page 7.

6/23/2010 Front Parts 166-263M

4

5

Figure 5

ADC Driver Mounting Holes

29508

Page 6

6 Air Drill Variable Rate Kit Front Parts Great Plains Mfg., Inc.

Create ADC Driver Mounts

ADC Front Break Holes

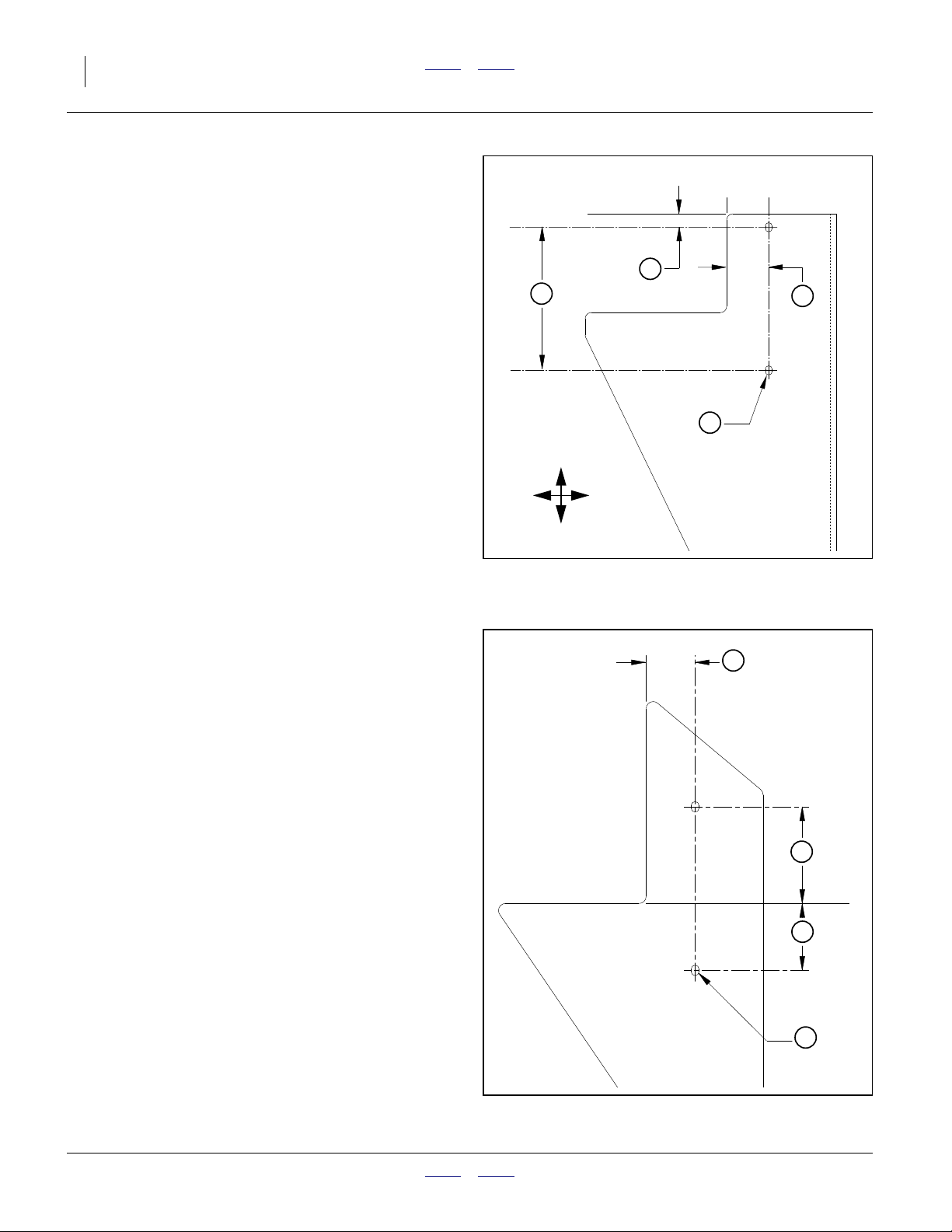

Refer to Figure 6

22. Drill and size two slotted holes in the front break of

the gearbox mount plate as follows:

123⁄32in

a

(1.72in)

(4.37cm)

9

⁄16in

b

(0.55in)

(1.4cm)

527⁄32in

c

(5.84in)

(14.8cm)

9

⁄32x3⁄8in

d

(0.28 x 0.38in)

(7.1 x 95mm)

Frame tool bar to

vertical slot center-lines

Top slot center from

top of gearbox mount plate

Slot to slot spacing,

center to center

Two slots, dimensions are

horizontal x vertical

c

U

b

a

d

If you are unable to make slotted holes, make two

circular holes 5.75 inches (14.6cm) apart.

DC Brace Plate Holes

Refer to Figure 7

23. Drill and size two slotted holes in the front break of

the gearbox mount plate as follows:

9

⁄32x3⁄8in

d

(0.28 x 0.38in)

(7.1 x 95mm)

13⁄4in

e

(1.75in)

(4.4cm)

225⁄64in

r

(2.39in)

(6.1cm)

329⁄64in

v

(3.45in)

(8.8cm)

r+v

527⁄64in (5.84in)

(14.8cm)

Two slots, dimensions are

horizontal x vertical

Frame tool bar to

vertical slot center-lines

Bottom of frame tool bar to

upper slot center

Bottom of frame tool bar to

lower center to center

Slot to slot spacing,

center to center

R

L

D

Figure 6

ADC Front Break Holes

29511

e

r

v

If you are unable to make slotted holes, make two

circular holes 5.75 inches (14.6cm) apart.

If you are unable to make two holes without performing major disassembly of the gearbox structures, make only the top hole.

Figure 7

ADC Brace Plate Holes

166-263M Front Parts 6/23/2010

d

29512

Page 7

Great Plains Mfg., Inc. Front Parts Installation Instructions 7

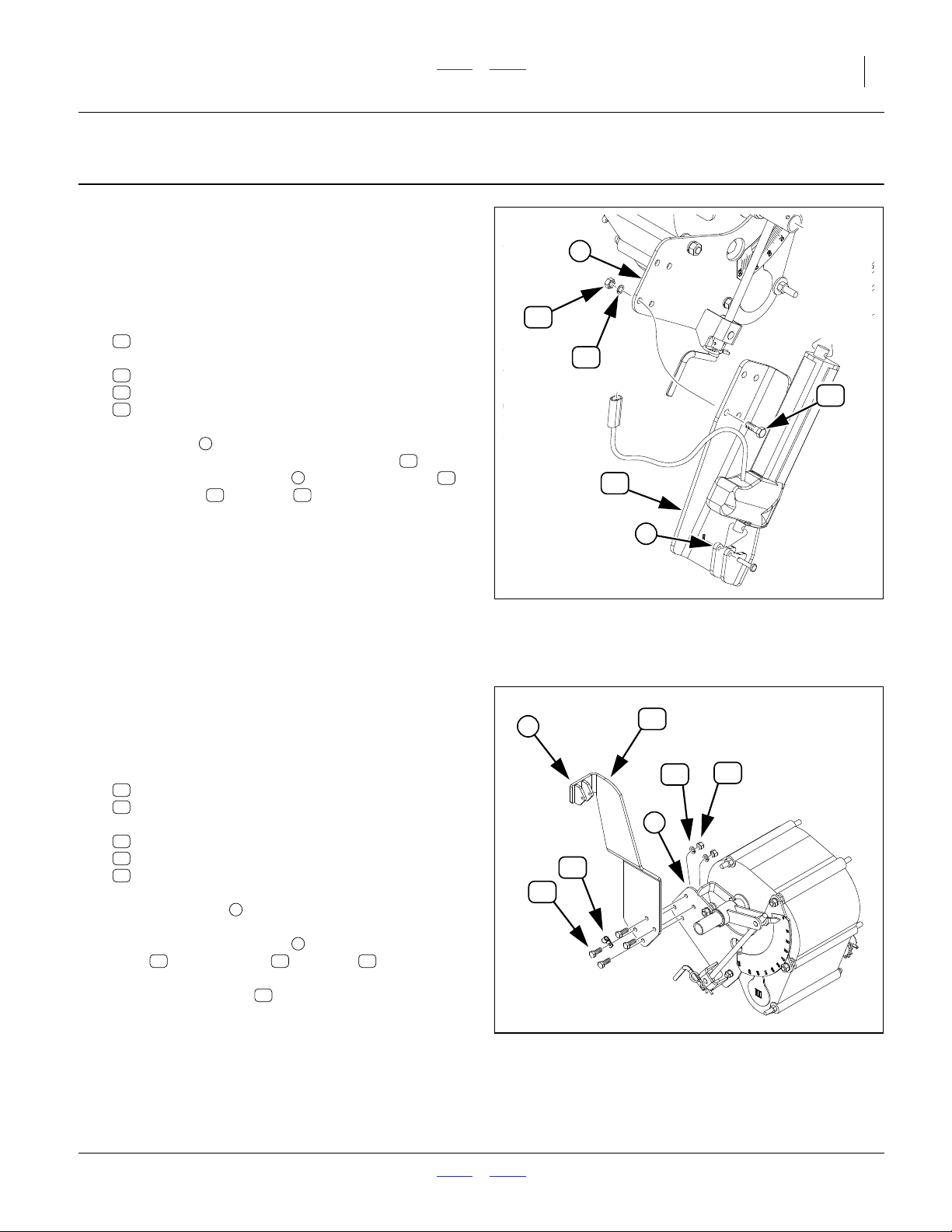

Install Linear Actuators

Install Linear Actuator Mounts

Install ADC or NTA907/3007HD Mounts

For models NTA607HD or NTA2007HD, continue at

step 27.

Refer to Figure 8

24. Select one new:

17

168-371H LINEAR ACTUATOR MOUNT WELDMENT

and four sets new:

22

802-017C HHCS 3/8-16X1 GR5

32

804-013C WASHER LOCK SPRING 3/8 PLT

29

803-014C NUT HEX 3/8-16 PLT

With the lug end down, and the lugs facing forward, install the actuator mount weldment on the

existing anchor weldment . Secure with bolts ,

lock washers and nuts .

25. Repeat step 24 for the other meter.

26. Continue at step 37 on page 9.

6

17

722

32 29

Install NTA607/2007HD Mounts

For models ADC2350/B or NTA907/3007HD, install

mounts per step 24 through step 25 above, then continue at step 37 on page 9.

Refer to Figure 9

27. Select one each new:

14

166-318H ACTUATOR MOUNT WELDMENT

21

800-238C .375 WIRING AND TUBE CLIP

and four sets new:

22

802-017C HHCS 3/8-16X1 GR5

32

804-013C WASHER LOCK SPRING 3/8 PLT

29

803-014C NUT HEX 3/8-16 PLT

With the lug end facing up and away from the

gearbox, install the actuator mount weldment on the

existing anchor weldment . Loosely secure with

22 32 29

bolts , lock washers and nuts .

8

9

7

29

32

17

6

Figure 8

ADC/NTA907/3007 Actuator Mount

8

14

32

9

21

22

22

29498

29

Place the wiring clip under the left lower bolt.

Tighten the other three bolts to Grade 5 torque

spec. Leave the bolt with the clip finger-tight until

step 59 on page 12.

28. If two meters are being upgraded, repeat step 27 for

the other meter.

6/23/2010 Front Parts 166-263M

21

Figure 9

NTA607/2007 Actuator Mount

31357

Page 8

8 Air Drill Variable Rate Kit Front Parts Great Plains Mfg., Inc.

Install Control Arm Weldments

Install ADC/NTA907/3007HD Arms

For NTA607/2007HD, continue at step 37.

Refer to Figure 10

29. Select one new:

16

168-370H ELECTRONIC CONTROL ARM WLDMNT

and two new:

40

890-202C

30. Press one bushing into the inside end of the

GAUGE WHEEL SFT PIVOT BUSHING

40 8

control arm tube (the side with the longer arm with

indicator point).

9

40

16

8

1

Using the existing

1

drill a

⁄4in hole through both sides of the bushing.

31. Press the other bushing into the outside end of

⁄4in holes in the tube as a guide,

40

the control arm tube.

32. With indicator tip to rear, and toward gearbox, place

arm weldment assembly on control shaft .

16 9

33. Select one saved:

51

805-065C PIN WIRE RETAINING 1/4 X 1 3/4

Align the arm tube and inside bushing with

the hole in the gearbox control shaft. The arm

9

840

indicator tip should be pointing near “0” on the

scale.

Secure the arm with the wire retaining pin .

51

34. Select one each new:

33

805-021C PIN COTTER 1/4 X 2 PLT

Insert the cotter pin through the end holes of the

33

gearbox control shaft. Spread tips to secure cotter.

35. Repeat step 29 through step 34 for the other meter.

36. Continue at step 45 on page 10.

51

40

Figure 10

ADC/NTA907/3007 Control Arm

33

29498

166-263M Front Parts 6/23/2010

Page 9

Great Plains Mfg., Inc. Front Parts Installation Instructions 9

Install NTA607/2007HD Arm(s)

For ADC/NTA907/3007HD, install arms per step 29

through step 35 on page 8, then continue at step 45 on

page 10.

Refer to Figure 11

(which depicts an ADC installation - the NTA installations

have a different appearance but use the same instructions)

37. Select one new:

16

168-370H ELECTRONIC CONTROL ARM WLDMNT

and two new:

40

890-202C

38. Press one bushing into the inside end of the

control arm tube (the side with the longer arm with

indicator point).

Using the existing

drill a1⁄4in hole through both sides of the bushing.

39. Press the other bushing into the outside end of

the control arm tube.

40. With indicator tip to rear, and toward gearbox, place

arm weldment assembly on control shaft .

41. Select one saved:

51

805-065C PIN WIRE RETAINING 1/4 X 1 3/4

GAUGE WHEEL SFT PIVOT BUSHING

40 8

1

⁄4in holes in the tube as a guide,

40

16 9

51

33

9

16

40

Align the arm tube and inside bushing with

the hole in the gearbox control shaft. The arm

9

840

indicator tip should be pointing near “0” on the

scale.

Secure the arm with the wire retaining pin .

51

42. Select one each new:

33

805-021C PIN COTTER 1/4 X 2 PLT

Insert the cotter pin through the end holes of the

33

gearbox control shaft. Spread tips to secure cotter.

43. If two meters are being upgraded, repeat step 37

through step 42 for the other meter.

44. Continue at step 50 on page 10.

40

8

Figure 11

Install Control Arm

31358

6/23/2010 Front Parts 166-263M

Page 10

10 Air Drill Variable Rate Kit Front Parts Great Plains Mfg., Inc.

Install Linear Actuators

Install ADC/NTA907/3007HD Actuator

For NTA607/2007HD, continue at step 50.

Refer to Figure 12

45. Select one new:

39

833-456C LINEAR ACTUATOR 12V 8 IN 112LB

and two sets new:

35

805-397C PIN CLEVIS 1/4 X 1 23/64 USABL

34

805-307C PIN COTTER 3/32 X 1/2

46. With the cable end of the actuator down, and

cable exiting up, align the lower operating rod of the

actuator with the lugs in the mount weldment.

Secure with clevis pin and cotter pin .

47. Rotate the control arm weldment as needed to

align the hole of the linear actuator rod with lugs

in new control arm. Secure with clevis pin and

cotter pin .

48. Repeat step 45 through step 47 for the other meter

49. Continue at step 52 on page 11.

34

17

35 34

39

16

16

35

9

8

16

34

35

Install NTA607/2007HD Actuator

For ADC2350/B or NTA907/3007HD, install actuators per

step 45 through step 48 above, then continue at

page 11.

Refer to Figure 13

50. Select one each new:

39

833-456C LINEAR ACTUATOR 12V 8 IN 112LB

23

802-167C HHCS 1/4-20X1 1/2 GR5

28

803-007C NUT-LOCK 1/4-20 PLT

With cable exiting down, secure the base end of the

actuator between the ears of the mount weldment. Thread the lock nut onto the bolt until it

contacts an ear, then back off one full turn.

51. Select one each new:

25

28

Secure the rod end of the actuator between the

arms of the arm weldment. Thread the lock

nut onto the bolt until it contacts an arm, then

back off one full turn.

39 14

28 23

802-370C HHCS 1/4-20X1 3/4 GR5

803-007C NUT-LOCK 1/4-20 PLT

16

28 25

28

23

34

35

17

Figure 12

ADC & NTA907/3007HD Actuator

39

28

14

16

25

39

29498

Figure 13

NTA607/2007HD Actuator

166-263M Front Parts 6/23/2010

31359

Page 11

Great Plains Mfg., Inc. Front Parts Installation Instructions 11

Install Actuator Driver

About the Driver Module

Refer to Figure 14

The actuator driver is an electronic module that

adapts the linear actuator to the IntelliAG® WSMT.

It has two cable leads:

1

2-pin lead to the linear actuator, and;

2

6-pin lead to the existing WSMT harness.

18

24

18

1

2

30

Install ADC or NTA907/3007HD Driver

For NTA607/2007HD, continue at step 59 on page 12.

For NTA907/3007HD, continue at step 56.

52. Select two new:

18

464360033S1 G P ZEROMAX VALVE DRIVER

and four sets new:

24

802-274C HHCS 1/4-20X3 GR5

30

803-255C NUT HEX NYLOCK 1/4-20

ADC 2350/2350B Driver Installation

For NTA907/3007HD, continue at step 56.

Refer to Figure 15

On ADC2350/B, the driver modules mount vertically, with

the cable lead exiting from the bottom of the module.

53. Mount one driver on the back side of the forward

gearbox mounting plate break, at the holes identified or prepared at step 21.

54. Mount the other driver on the back side of the

gearbox brace plate, at the holes identified or

prepared at step 21.

55. Continue at step 62 on page 13.

NTA907/3007HD Driver Installation

Refer to Figure 16

On NTA907/3007HD, the driver modules mount horizontally, with the cable lead exiting from the rear of the module. The mount point is pairs of1⁄4in (6.4mm)

holes ( , ), spaced 5.75in (14.6mm) apart, at the outside (right) top edge of the gearbox mount plate.

56. Mount one driver at the forward hole pair ).

57. Mount the other driver at the back hole pair .

58. Continue at step 62 on page 13.

6 7

18

4

18

5

18 6

18 7

Figure 14

Actuator Driver Module

4

5

U

L

B

D

Figure 15

ADC Driver Mounting

6

6

7

7

Figure 16

NTA907/3007 Driver Mounting

29498

F

R

29508

U

L

B

F

R

D

29509

6/23/2010 Front Parts 166-263M

Page 12

12 Air Drill Variable Rate Kit Front Parts Great Plains Mfg., Inc.

Install NTA607/2007HD Driver

For ADC or NTA907/3007, install driver per page 11,

then continue at step 62 on page 13.

Refer to Figure 17 (a cut-away view)

On NTA607/2007HD, the driver modules mount vertically, with the cable lead exiting from the bottom of the

module. The module mounts to the rear face of the brace

1

plate (as shown). The module side with four visible

2

studs and nuts faces to cart right (away from cart).

59. Select one new:

18

464360033S1 G P ZEROMAX VALVE DRIVER

and two sets new:

26

802-804C HHCS 1/4-20X2 3/4 GR8 PLT

31

804-006C WASHER LOCK SPRING 1/4 PLT

27

803-006C NUT-HEX 1/4-20 PLT

Mount the driver module to the rear side of the

brace plate under the base end of an actuator (or

the actuator, if only one meter is being converted to

variable rate). Tighten the nuts and bolts only to

Grade 2 specification, to prevent deforming the

module housing.

Refer to Figure 18

60. Remove the bolt, clip , washer and nut securing

the clip to the mount (installed at step 27 on

page 7).

21

L

B

18

U

D

26

F

31

R

18

Figure 17

NT

A607/2007 Driver Mounting

27

1

2

18

31364

Route the two-pin lead through the clip . Resecure the clip to the weldment. Tighten fasteners

to no more than Grade 2 torque spec.

61. If two meters are being converted to variable rate,

repeat step 59 and step 60 for the other meter.

321

N ll4

2

3

21

Figure 18

NTA607/2007 Cable Clip

3

21

31363

166-263M Front Parts 6/23/2010

Page 13

Great Plains Mfg., Inc. Front Parts Installation Instructions 13

Connect Driver Leads

Refer to Figure 19

62. Connect the 2-pin lead of the forward actuator

driver to the 2-pin lead of the forward linear

actuator .

63. If two meters are being converted to variable rate,

connect the 2-pin lead of the rear actuator

driver to the 2-pin lead of the rear linear

actuator

18 2

39

18 2

39

1

1

3

20

18

1

2

39

Refer to Figure 19 and Figure 20

64.

Locate the harness connection points already

present on the air cart or air drill. The cables have

labels near the 6-pin connectors, and have labels

identifying the connectors as:

ZEROMAX 1 and ZEROMAX 2, or

FRONT and REAR

65. Remove dust caps from the connectors. The caps

are not re-used. If the harness connector leads are

coiled up and tied, and need to be uncoiled to reach

the driver module leads, cut the cable tie.

66. Connect the 6-pin lead of the forward actuator

driver to the 6-pin FRONT or #1 harness lead .

67. If two meters are being converted to variable rate,

connect the 6-pin lead of the rear actuator

driver to the 6-pin REAR or #2 harness lead .

68. Select all new:

Use four ties to secure the leads for each actuator

and driver. The NTA gearbox mount plate provides 6

0.21in (5.3mm) holes for this purpose.

18 4

18 5

20

800-060C CABLE TIE .19X14.25 3DIA 50LB

3

3

Figure 19

Actuator Driver Leads

4

29498

5

Figure 20

Harness Connection

6/23/2010 Front Parts 166-263M

29513

Page 14

14 Air Drill Variable Rate Kit Front Parts Great Plains Mfg., Inc.

Install Master Switch

Refer to Figure 21 and Figure 22

69. In the tractor cab, locate the master switch connection lead . On newer air carts and all air drills, this

is an un-terminated 2-pin weatherpak connector.

On older air carts, this lead may already have a

master switch connected to it. If so, continue at

“ACC Re-Configuration” on page 15.

6

Refer to Figure 21 and Figure 22

70. Select one new:

19

467980124 ISO MASTER SWITCH

Set the switch to OFF.

71. Mount the switch near the monitor virtual terminal,

allowing enough cable length to reach the harness

connection located at step 69. Mount the switch

where it will be convenient for operations, but not

obstruct your view of the road.

72. Connect the 2-pin lead of the switch to harness

6

lead .

7

6

19

Figure 21

Cab Harness Connection

19

7

29514

Figure 22

Master Switch

166-263M Front Parts 6/23/2010

29505

Page 15

Great Plains Mfg., Inc. Front Parts Installation Instructions 15

ACC Re-Configuration

Before first use, the new master switch and actuator outputs must be configured into the seed monitor system.

Depending on VT part number and previous software

revision, it may also be necessary to re-load basic air drill

parameters, and your local Materials Library.

Follow the instructions in the new IntelliAG® Aircart Control Operator’s Manual. The instructions below in this

manual are an overview of the sequence, and provide

cross-reference to information sources if you do not have

a complete record of the previous drill configuration.

Initial Power-Up Steps

73. Check language and units preference.

74. Check/set date and time.

75. Perform an

Auxiliary Input/Function Assignment

This detects and assigns the new master switch.

76. If ON, set the new master switch to

OFF

(necessary to enter Configuration mode).

Load Drill Parameters

77. Enter System Mode:

Setup/Configuration

78. If the setup was lost during software update (or has

never been loaded), perform a

Module Configuration.

79. If you run an “Auto Config”, check the module

assignments against any record from step 12.

The new actuators are automatically detected by the

WSMT, and are not separately enumerated. When

present and connected, they enable the

“GRAN SEED/FERT CONTROL” modes hidden for

crank-adjusted drills.

29515

Update Material Library

In order to correlate actuator output with desired seed

rate (meter shaft rate), the system requires a Calibration

Constant for each material to be used.

If you already had a material library, re-load it from an SD

card or via the menus. Otherwise revise a default material name as the first Control setup.

• The example at right shows sample materials:

Wheat HRW, renamed from SEED 1

and

11-52-0 renamed from FERT 1

to be used for the first Control setup.

6/23/2010 Front Parts 166-263M

Example Material Library:

CH1 Wheat HRW

CH2 11-52-0

CH3 DISABLED

CH4 DISABLED

Wheat HRW 11-52-0

SEED 2 FERT 2

SEED 3 FERT 3

… …

Page 16

16 Air Drill Variable Rate Kit Front Parts Great Plains Mfg., Inc.

Create a Controlled Material

Re-define at least one material. Otherwise, create at

least one material. Some key steps:

80. Type must be set to GRAN SEED CONTROL or

GRAN FERT CONTROL.

81. Select or Disable: Preset Method

If using preset method, select initial rate increments

that are only a few percent, so as to have fine control of the meter scale indicator. These can be

changed to coarser increments after calibration.

82. Density must be accurately entered.

83. Enter the Cal Const if one is available for your seed

type. This value does not affect the calibration process, and is replaced during calibration, but is useful for comparison. The calibration constant

developed during calibration should be similar to the

chart number.

84. Set Variable Cal Const if one is available for your

seed. This is from a list of names pre-programmed

into the monitor software. It is usually not the same

name as the material name setup on page 15. In

this example, “Wheat 2S”, the “2S” refers to the

(factory standard) “2 star” meter flute configuration.

Pick a seed constant closest to yours in terms of

physical seed characteristics and meter flute configuration.

If a suitable Variable Cal Const is available, the system can more accurately compensate for manual

calibration cranking speeds that differ from field

rate.

If no suitable Variable Cal Const is available, crank

at an rpm near field speed at step 92.

Example Non-Preset Material Setup:

1-16 CH Wheat HRW Comment

Per meter

CHANNEL 1 or 2

GRAN SEED CONTROL

Type

Units Lb/ac with Rev/ac Example

Preset

Method

Target Rate 60.0 LB/AC Example

Max Rate 78.0 LB/AC Upper + limit

Min Rate 48.0 LB/AC Lower - limit

Inc/Dec % 1.0 % Example

Density 60.00 LBS/BU Example

#Towers 5

Cal Const 77591

Variable Cal

Const

Shaft RPM

Prod Level

Alarm

Seeds per

Pound

High Pop

Alarm

Low Pop

Alarm

ROW

WIDTH

ON(-)/

OFF(X)

PATTERN

Row Fail

Rate

or

GRAN FERT CONTROL

Disabled Example

Wheat 2S Optional

Low 10

High 50 RPM

0 LBS

3000 S/LB Example

20.0 % Example

20.0 % Example

__ IN

------------------------(unless tramline in use)

2 / 1 S/SEC

being configured

Must be one

of these

Per Implement

Optional: Use

nearest chart

value

Or use AutoUpdate Width

See ACC

manual

166-263M Front Parts 6/23/2010

Page 17

Great Plains Mfg., Inc. Front Parts Installation Instructions 17

Actuator Channel Setup

85. Assign material.

86. Type must be set to GRAN SEED CONTROL or

GRAN FERT CONTROL.

87. Check that other setting are as Required, and

reflect the actual configuration of the implement.

Example Channel Setup:

Parameter Value Comment

Per meter

CHANNEL 1 or 2

being configured

Type

Material

Name

Control

Mode

GRAN SEED CONTROL

or

GRAN FERT CONTROL

Wheat HRW

or

11-52-0

Auto Required

One of these

Required

Example

user-specified names

Drive Type Zero Max 1 or 2 Required

Drive Freq. 40 Hz Required

Input Fliter 50 % Required

Sensor

Constant

360 PUL/REV Required

Gear Ratio 1 Required

Meter Gear

Range

# Seed

Rows

Channel

Width

Flush

Enable

LOW or HIGH

32, 36, 40, 48, 50, 60, 65,

66, 80

(set to swath of implement or drill, in inches or

cm)

Disabled Data not used

One of these

Required

read-only, per

implement or

drill model

Required

Precharge(+)\D

0.0 SEC Data not used

elay(-)

6/23/2010 Front Parts 166-263M

Page 18

18 Air Drill Variable Rate Kit Front Parts Great Plains Mfg., Inc.

Calibrate

Calibrate Speed Sensor

88. Perform a Calibrate Ground Speed.

Calibrate Material

Perform a calibration. The procedure is similar to that for

crank-set operations.

89. Consult the Seed Rate manual (167-085B) for (the

approximate) manually-set rate for your material.

90. Check that final Range gear pairing is the same on:

• the chart,

• the meter, and

• the Meter gear Range in the Channel Setup.

91. Enter the calibration screen.

At this time, the linear actuator becomes active. The

scale indicator moves to approximately mid-scale,

then stops.

Pointing to a specific value is not required, but

needs to be in the range 30° to 95°. Great Plains

recommends using a scale setting that is close to

your expected target rate.

Example Calibration Screen:

Parameter Value Comment

CHANNEL 1 Example

material Wheat HRW Example

Density 60.0 LB/BU Example

Calibration

Constant

Target Meter

rpm

# Meter

Revs

77591 PUL/FT From chart

20 RPM Example

30 REV Example

Pulse Count 0 PUL Pre-Cal.

New Calib

Const

Total #

Towers

Amount

Dispensed

______ PUL/FT

5

Per Implement

______ LBS From Scale

Use the Inc+/Dec- softkeys on the monitor console

to adjust the indicator to the target rate, or at least to

within the 30°-95° range.

92. Manually crank the meter for at least the number of

turns shown in the instruction of the Seed Rate

Manual for1⁄10ha or1⁄10ac.

The exact number of revolutions, cranking rateb,

and precise starting and stopping handle angles are

not critical, as the system reads meter revolutions

accurately, and can compensate for shaft speed,

seed size and partial turns.

What matters is getting a large sample, to reduce

errors and increase confidence in the calibration.

Note: By calibrating at the target rate, and for1⁄10ha, you

establish a comfort level that the drill is set up correctly, in particular, that you are in the correct gear

Range for the desired application rate.

93. Weigh the dispensed material and enter it in the

menu. The monitor computes a Calibration Constant for this material. Save this result.

Example:

ADC2350B cart and NTA3510 drill

Wheat, 2-star meter, single seed hopper in use

High Range at gearbox

Target rate of 133 kg/ha would be a scale setting of:

50° (from Seed Rate manual charts)

A sample size of1⁄10ha requires crank:

77 turns (from Seed Rate manual instructions)

b. If no “Variable Cal Const” was selected at step 84, crank at for most accurate results:

ADC2350/B, NTA907/3007HD: 2 to 2

NTA607/2007HD: 1 to 1

166-263M Front Parts 6/23/2010

3

⁄

revolutions per second

4

1

⁄

revolutions per second

2

Page 19

Great Plains Mfg., Inc. Front Parts Installation Instructions 19

Cart/Drill Operation

The air drill previously operated in

“GRAN SEED MONITOR” and/or

“GRAN FERT MONITOR” modes.

With the linear actuators now installed and operating,

you will normally operate in

“GRAN SEED CONTROL” and/or

“GRAN FERT CONTROL” mode.

If it is necessary to revert to manual meter setting, move

the pin from the linear actuator arm back to the crankdriven arm.

Cart/Drill Maintenance

This update causes no changes to drill maintenance.

6/23/2010 Front Parts 166-263M

Page 20

20 Air Drill Variable Rate Kit Front Parts Great Plains Mfg., Inc.

Appendix

New Parts

Quantities are units (“ea”). The part call-out numbers in this list match all Figures in

these installation instructions. Part descriptions match

those in your updated Parts Manual.

Kit Contents

Quantity in Kit:

166-

Callout

11 1 1 1 166-263M MANUAL INSTALL ADC2350 VAR RT

12 1 110011512 ACC USR MANUAL VER 4.2 LVL 2&3

13 1 110011513 ACC USER MANUAL VER 4.2 LVL 1

14 1 2 166-318H ACTUATOR MOUNT WELDMENT

15 1 2 166-319H GEARBOX ACTUATOR ARM WLDMNT

16 2 168-370H ELECTRONIC CONTROL ARM WLDMNT

17 2 168-371H LINEAR ACTUATOR MOUNT WELDMENT

18 In 1 2 464360033S1 G P ZEROMAX VALVE DRIVER

19 In 1 1 467980124 ISO MASTER SWITCH

20 8 4 8 800-060C CABLE TIE .19X14.25 3DIA 50LB

21 1 2 800-238C .375 WIRING AND TUBE CLIP

22 8 4 8 802-017C HHCS 3/8-16X1 GR5

23 1 2 802-167C HHCS 1/4-20X1 1/2 GR5

24 4 802-274C HHCS 1/4-20X3 GR5

25 1 2 802-370C HHCS 1/4-20X1 3/4 GR5

26 2 4 802-804C HHCS 1/4-20X2 3/4 GR8 PLT

27 2 4 803-006C NUT-HEX 1/4-20 PLT

28 2 4 803-007C NUT-LOCK 1/4-20 PLT

29 8 4 8 803-014C NUT HEX 3/8-16 PLT

30 4 803-255C NUT HEX NYLOCK 1/4-20

31 2 4 804-006C WASHER LOCK SPRING 1/4 PLT

32 8 4 8 804-013C WASHER LOCK SPRING 3/8 PLT

33 2 805-021C PIN COTTER 1/4 X 2 PLT

34 4 805-307C PIN COTTER 3/32 X 1/2

35 4 805-397C PIN CLEVIS 1/4 X 1 23/64 USABL

36 1 823-273C ADC2350 INTELLIAG VAR RATE KIT

39 2 1 2 833-456C LINEAR ACTUATOR 12V 8 IN 112LB

40 4 2 4 890-202C GAUGE WHEEL SFT PIVOT BUSHING

193A

36

36

37 1 <npn> INTELLI-AG SOFTWARE UPDATE SDC

38 1 11001-1507 ACC V4 SOFTWARE REPROGRAMMING

18 2 464360033S1 G P ZEROMAX VALVE DRIVER

19 1 467980124 ISO MASTER SWITCH

166-

328A

166-

339A

Part

Number

Part Description

166-263M Front Parts 6/23/2010

Page 21

Great Plains Mfg., Inc. Front Parts Installation Instructions 21

Existing Parts

The part call-out numbers in this list match all Figures in

these installation instructions. Part descriptions match

those in your updated Parts Manual.

The Part Disposition column indicates whether the part is

re-used or discarded.

Callout

51 805-065C PIN WIRE RETAINING 1/4 X 1 3/4 Removed and saved.

52 805-032C PIN HAIR COTTER .148 WIRE Removed and re-installed

Part

Number

Part Description Part Disposition

Abbreviations

ACC Air Cart Control LB Pound

ACTR Actuator NTA No-Till Air

ADC Air Drill Cart PLT Plated

DIA Diameter RT Rate

G P Great Plains SD, SDC Secure Digital Card

GR5 Grade 5 SFT Shaft

GR8 Grade 8 USABL Usable

HD Heavy Duty V Volt

HEX Hexagonal VAR Variable

HHCS Hex Head Cap Screw WLDMNT Weldment

IN Inch WSMT Working Set MasTer

ISO

International Standards Organization

(ISO 11783 CANbus)

X by

6/23/2010 Front Parts 166-263M

Page 22

Front Parts

Great Plains Manufacturing, Inc.

Corporate Office P.O. Box 5060

Salina, Kansas 67402-5060 USA

Front Parts

Loading...

Loading...