Page 1

Great Plains Mfg., Inc.

Installation Instructions 1

Opener Down Pressure Kit

V300 Drill

Used with:

• All model year V300 drills

General Information

These instructions explain how to install the Opener

Down Pressure Kit. This Option provides dynamic

hydraulic down force on the openers.

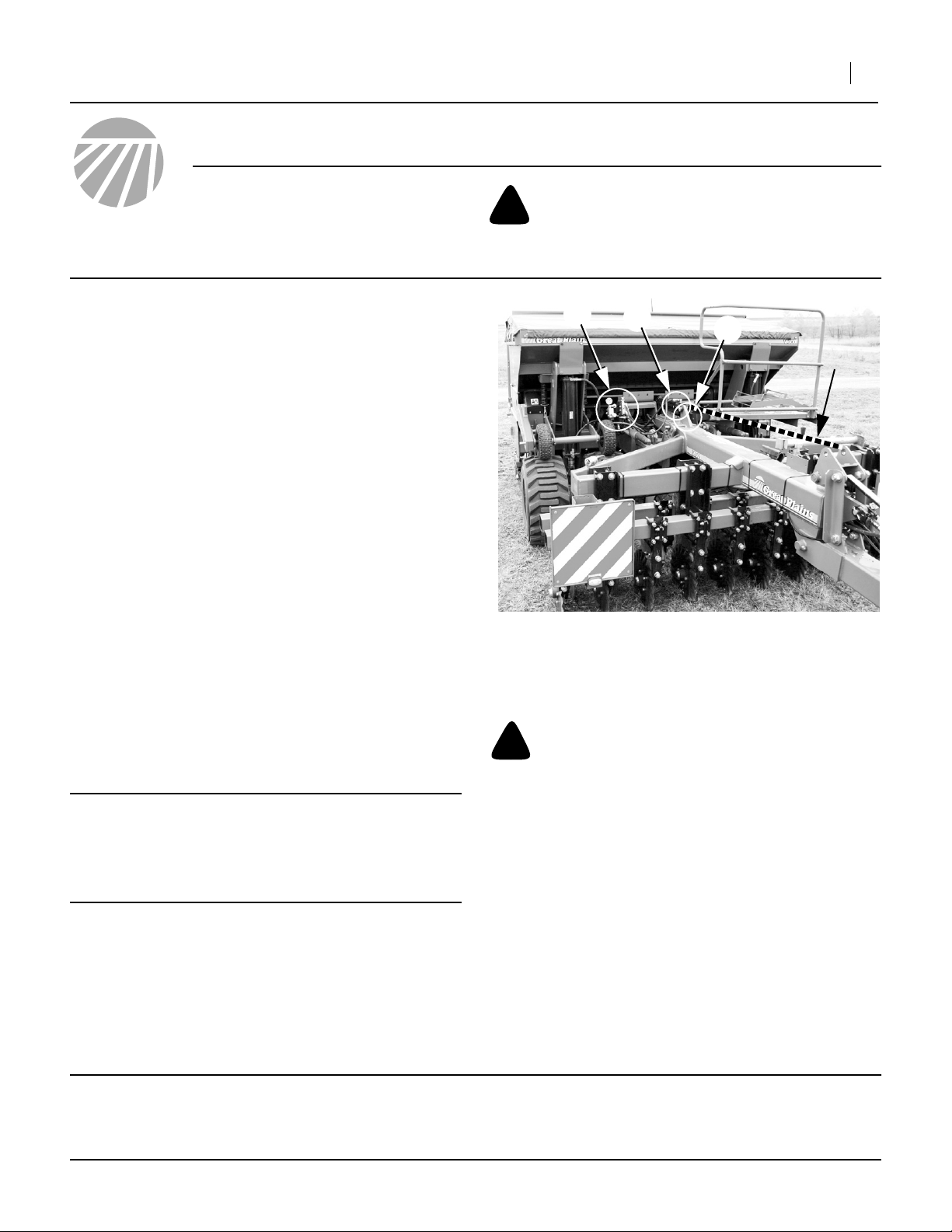

Refer to Figure 1

The kit replaces the level link arm ➀ (shown as a dotted

line in the figure) with a hydraulic cylinder ➁. The cylinder is controlled by a new valve assembly ➂ and

requires a new attachment point (lug) weldment ➃.

These instructions apply to:

148-765A Kit for Closed-Center Tractors

148-766A Kit for Open-Center Tractors

Due to shipping regulations, the kit does not include any

touch-up paint to restore the areas to be welded. Your

Great Plains dealer can provide it as Great Plains part:

821-001C PAINT GP GREEN SPRAY CAN

If this part is not available in your locale, use a green

exterior enamel paint close to Pantone 356.

When you see this symbol, the subsequent instructions

and warnings are serious - follow without exception.

!

Your life and the lives of others depend on it!

➂

➁

Figure 1

Upgrade Overview

➃

➀

25165

Before You Start

Each kit converts an entire drill. Inventory the contents

per the “Kit Parts List” on page 24.

IMPORTANT !

Make sure you have the correct kit for your tractor’s hydraulic system. If you have the incorrect

kit, it will not operate properly and can result in

equipment damage.

If necessary, move the implement to a well-lighted location suitable for disassembly. Make sure the ground/floor

under the tractor is non-flammable.

Note: Many of the hydraulic components are shipped

with protective caps. Leave these caps in place

until connections are made, to protect threads and

keep contaminants out of the hydraulic system.

©Copyright 2006 Printed 11/08/2006 148-771M

!

CAUTION

There will be sparks from welding. Dry grass, wood floor, or

areas with flammable fluid spills are not suitable locations for

installing this upgrade.

Lower the drill.

Park and secure the tractor, but leave it connected.

“Left” and “Right” are facing in the direction of machine

travel.

Have the following tools at hand:

• Wire or stick welder and welding tarps.

• Basic hand tools, including either adjustable openend wrenches or a set of fractional inch sizes.

• Paste or liquid tetrafluorethylene (Teflon®) pipe sealant (do not use pipe tape).

• Fluid collection pan.

Page 2

2 Opener Down Pressure Kit

Installation

Remove Level Link Arm

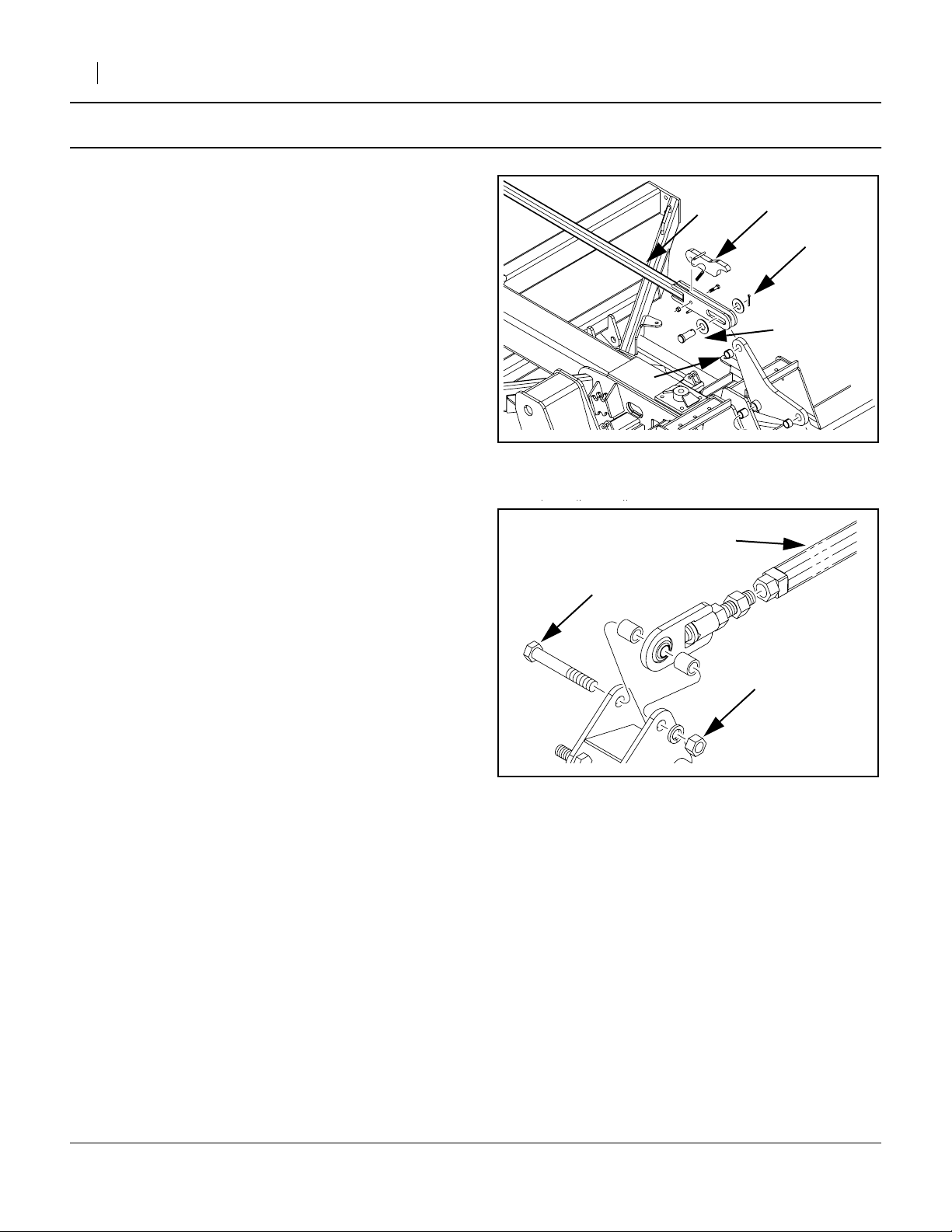

Refer to Figure 2

1. With the drill lowered, the link level arm ➀ is in nei-

ther tension nor compression. Open the float lock

lug ➁.

➄

➀

Great Plains Mfg., Inc.

➁

➂

➃

Refer to Figure 3

2. At the forward end of the level link ➀, remove bolt

➁ and nut ➂. This bolt and nut, and the washers,

are not re-used.

Refer to Figure 2

3. At the rear end of the link level arm, remove cotter

pin ➂ and clevis pin ➃. The pins (and the washers) are not re-used.

Note: There is a bushing ➄ in the rocker arm. Do not

remove it.

4. Remove the level link ➀ arm from the drill. It is not

re-used.

Figure 2

Relax Level Link

➁

Figure 3

Remove Level Link

25166

➀

➂

25167

148-771M 11/08/2006

Page 3

Great Plains Mfg., Inc.

Weld Lug

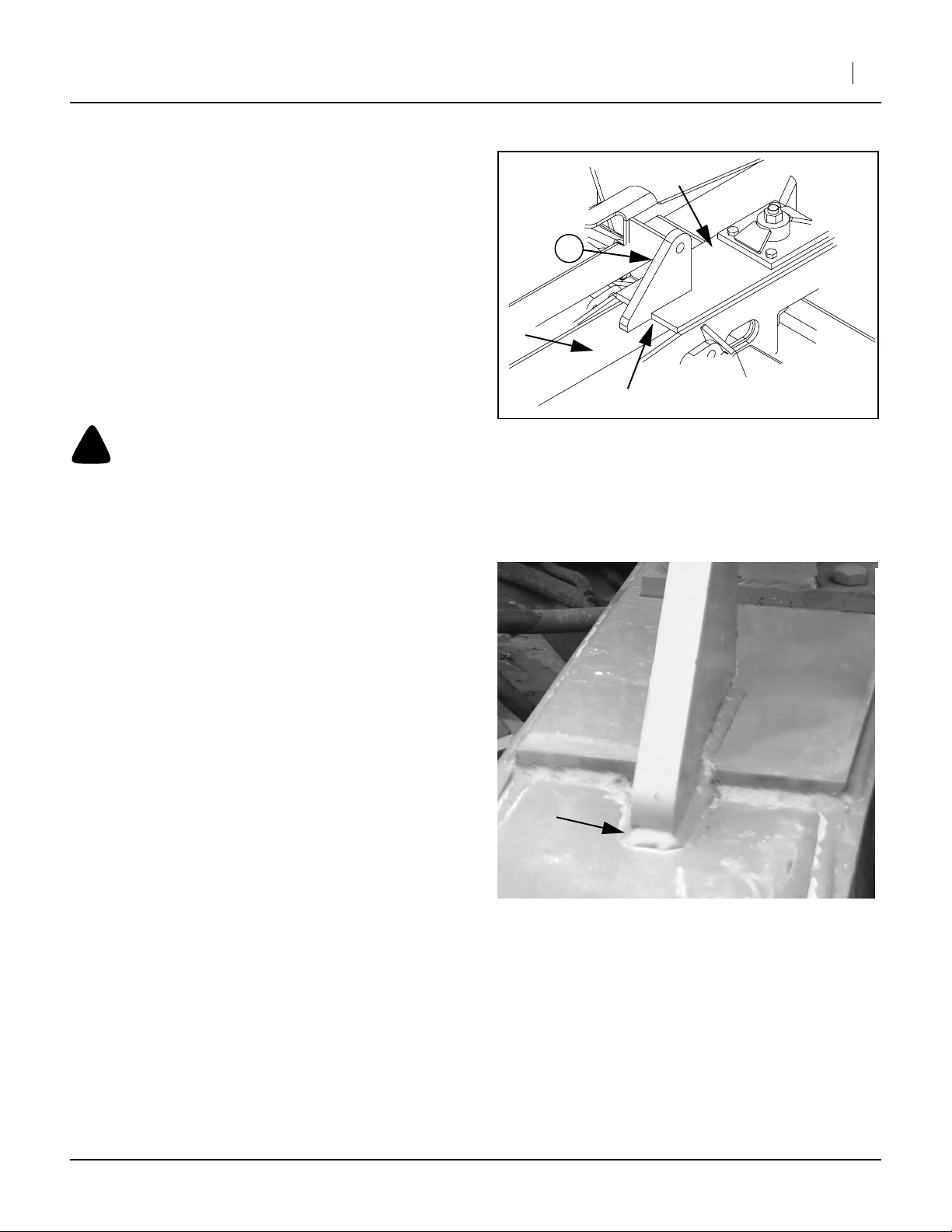

Refer to Figure 4

5. Select lug (25) 248-508D,

(TOP LINK CYL LUG).

6. Temporarily position the new top link cylinder lug

(25) against the pivot plate ➀ on the drill frame ➁.

7. Center the lug (25) left-to-right, and push it as far

back against the pivot plate ➀ as possible before it

begins to ride up on the existing weld fillet. This

may leave a vertical gap at ➂.

8. Scribe the outline of the lug (25) on the pivot plate

➀.

9. Brush or sand the paint from the inscribed area,

plus ~1.3cm outside that area.

Installation Instructions 3

➀

25

➁

➂

!

CAUTION

Use caution when using tools that emit sparks such as welders. Wear suitable protective equipment. Do not use sparkemitting tools in areas where flammable or explosive materials may be present. Do not allow anyone to enter the path of

sparks.

Refer to Figure 4

10. Protect any nearby hoses or cables with welding

tarps.

11. Re-position the lug (25) as in step 7. Tack-weld the

lug in two places. Re-check centering and 90

degree vertical alignment.

12. Make a high tensile strength 100% wire or stick

weld around the entire base of the lug, with a fillet

of approximately 1.3cm.

13. Allow lug to cool.

14. Brush or sand off any burrs or other weld artifacts,

and paint. Apply a metal primer if a matching green

exterior enamel paint is not immediately available.

Figure 4

Position Lug

25168

Figure 5

Weld Lug

25169

Drain Hydraulic System

This upgrade kit is inserted in the existing hydraulic system at two points. Removing the fittings at these two

points will result in some loss of fluid (which is why it is

important to perform this and later steps after the welding). The following steps minimize fluid loss.

15. Put the tractor hydraulic controls into “float” mode.

16. Shutdown the tractor hydraulic system.

11/08/2006 148-771M

17. Loosen the fitting at the top of the left lift cylinder,

enough to let air enter at that point.

18. Set a collection pan under the right lift cylinder.

19. Loosen the fitting there enough to begin draining

fluid into the pan.

Page 4

4 Opener Down Pressure Kit

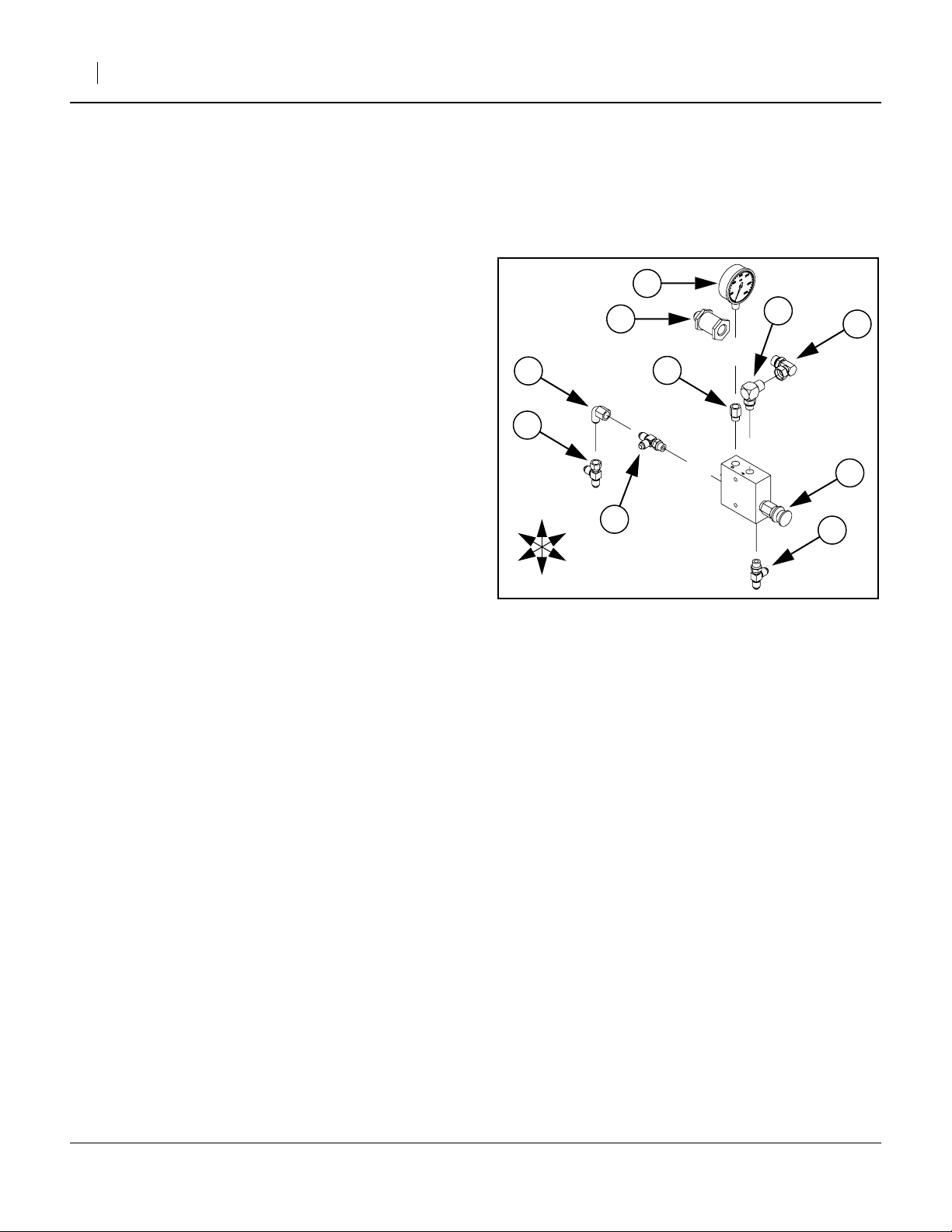

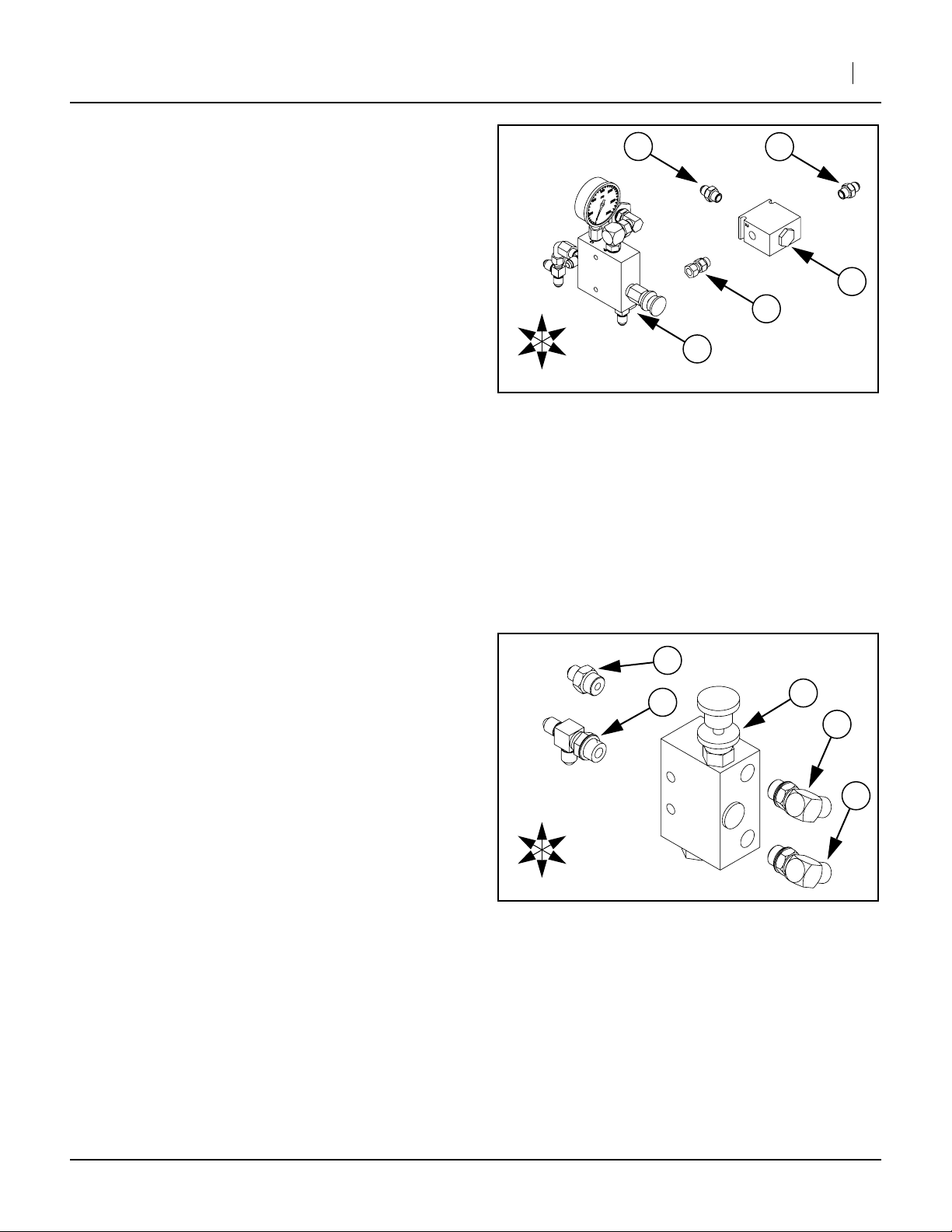

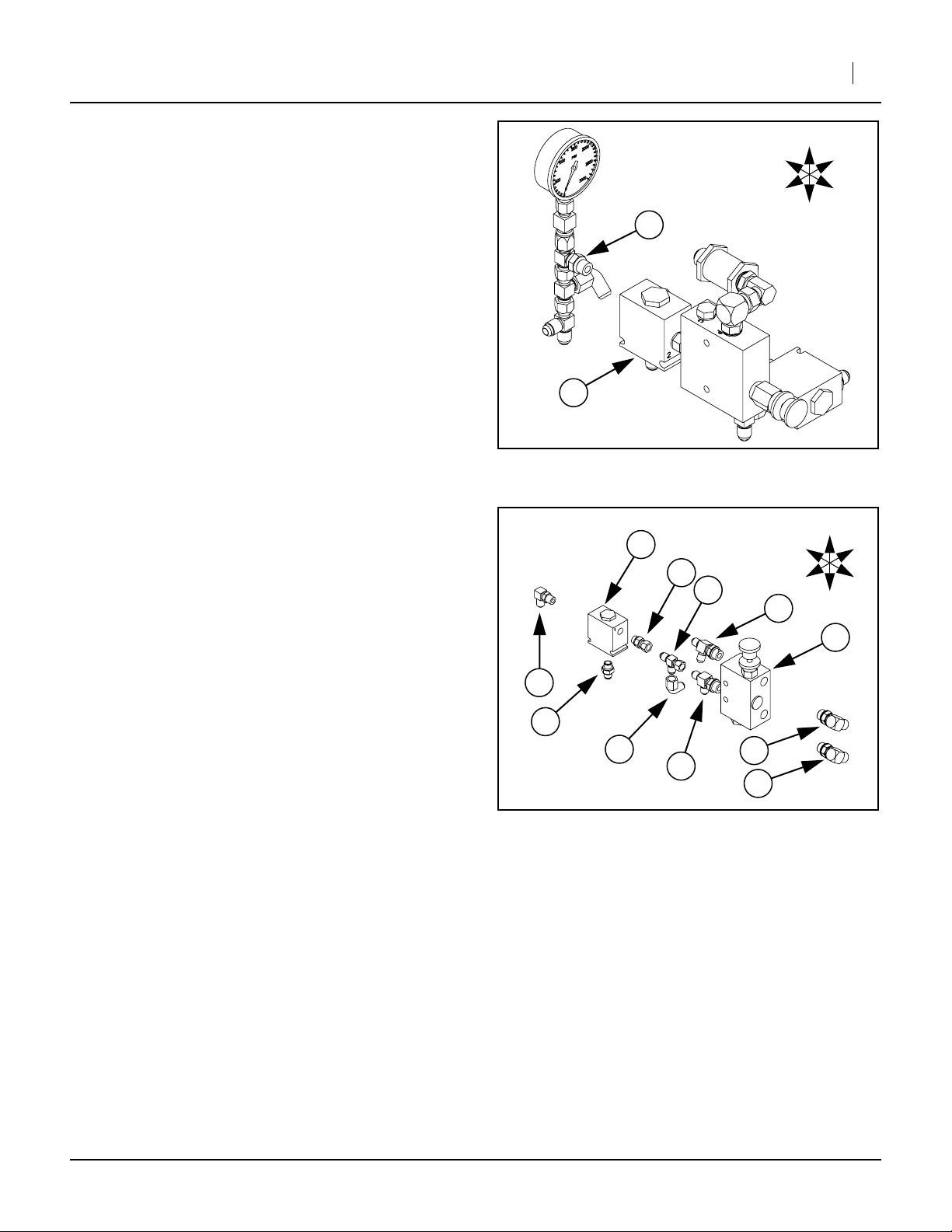

Assemble Closed-Center Valves

This section is for the 148-765A Closed-Center (CC) kit.

If you have the 148-766A Open-Center kit, see page 7.

Callout numbers are assigned from the “Kit Parts List”

on page 24.

Assemble CC Down Pressure Control Valve

Refer to Figure 6

20. Select the (44) 810-301C,

(VALVE PRESS REDUCING W/CHECK).

Note: The orientation of the valve is that the control

knob faces Front and is toward the Bottom of the

valve body.

21. Select a (58) 811-216C,

(EL 3/4MJIC 9/16MORB).

Screw the male O-ring boss end into the Top Front

port of valve body (44). Adjust the JIC end to face

Left and tighten jam nut.

22. Select the (65) 811-677C,

(AD 9/16MORB 1/4FNPT).

Screw the male O-ring boss end into the Top Rear

port of valve body (44). Do not fully tighten.

23. Select a (52) 811-064C,

(TE 9/16MJIC 9/16MJIC 9/16MORB).

Screw the male O-ring boss end into the Rear port

of valve body (44). Adjust the tee so the center port

faces Right and tighten jam nut.

24. Select a (66) 841-077C,

(EL 3/4FJIC 3/4MORB).

Screw the female JIC end onto fitting (58). Adjust

angle so that the ell points to the Rear, and tighten.

25. Select the (43) 810-300C,

(PRESSURE GAUGE 3000 PSI).

Apply TFE sealant to threads. Screw it into fitting

(65). Tighten gauge to come as close as possible

to suggested torque values, and still have gauge

facing Forward.

26. Select a (52) 811-064C,

(TE 9/16MJIC 9/16MJIC 9/16MORB).

Screw the male O-ring boss end into the Bottom

port of valve body (44). Adjust the tee so the center

port faces Left and tighten jam nut.

27. Select a (52) 811-064C,

(TE 9/16MJIC 9/16MJIC 9/16MORB).

Screw the female JIC end onto fitting (52) on the

Rear of valve body (44). Make the final turns to

leave the open end facing down.

28. Select the (49) 810-554C,

(FILTER INLINE 3/4FORB 3/4MJIC).

Screw it onto fitting (66) and tighten.

Great Plains Mfg., Inc.

Torque fittings and fasteners per “Torque Values” on

page 23.

A cluster of arrows in each diagram shows directions (T)

Top, (B) Bottom, (L) Left, (R) Right, (F) Front and (R)

Rear.

43

58

66

55

49

65

50

44

T

R

R

52

L

52

F

B

Figure 6

CC Down Pressure Valve

25170

148-771M 11/08/2006

Page 5

Great Plains Mfg., Inc.

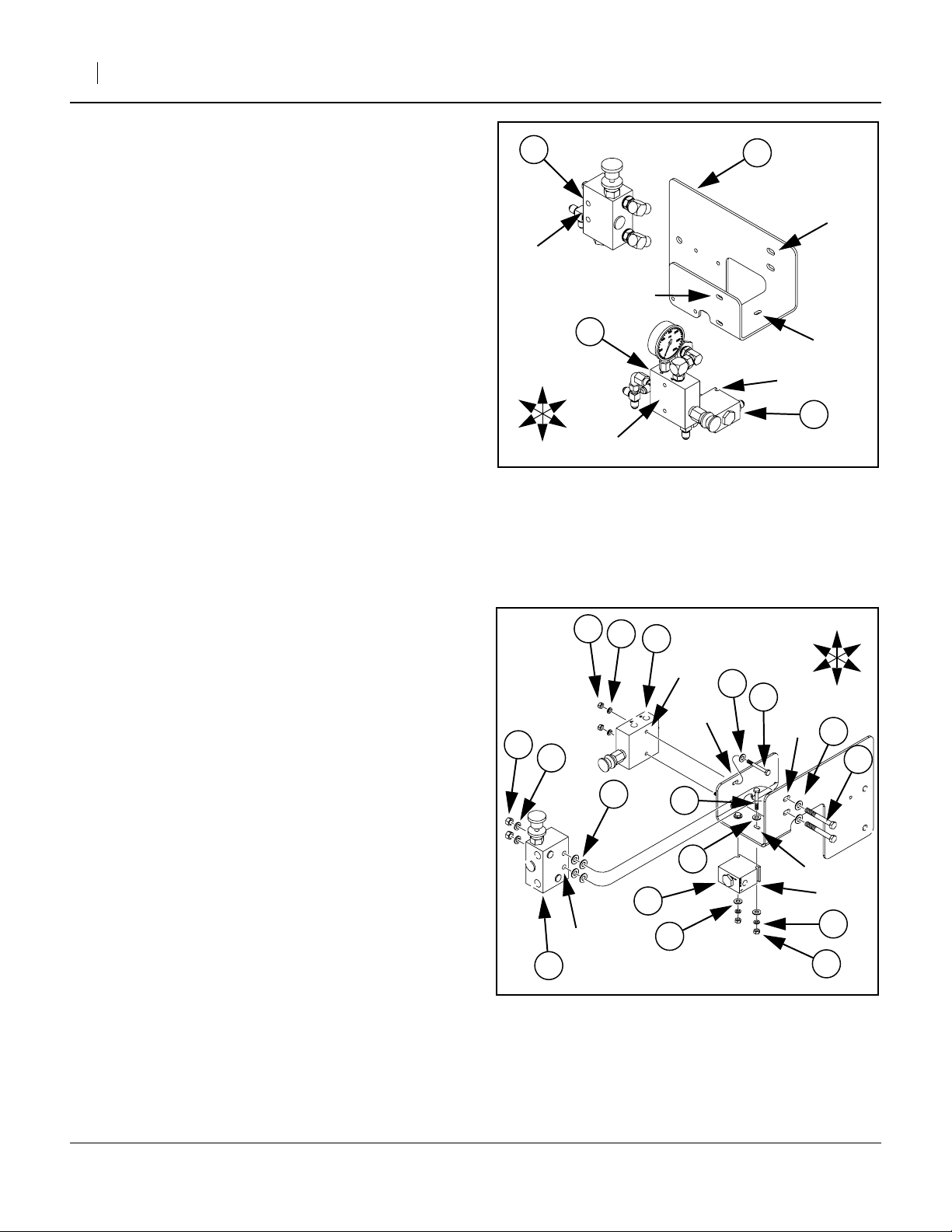

Assemble CC Check Valve

Refer to Figure 7

29. Select the (47) 810-428C,

(VALVE PO CHECK 4:1 W/9/16FORB).

Note: The ports of valve (47) are stamped with num-

bers “1”, “2” and “3”. Orient the valve so that Port

➀ is to the Left, port ➁ to the Right and port ➂ to

the Rear.

30. Select a (56) 811-170C,

(AD 9/16MORB 9/16MJIC).

Screw the male O-ring boss end into port ➀ of

valve body (44).

31. Select a (56) 811-170C,

(AD 9/16MORB 9/16MJIC).

Screw the male O-ring boss end into port ➂ of

valve body (44).

32. Select a (62) 811-627C,

(AD 9/16MORB 9/16FJIC).

Screw the male O-ring boss end onto check valve

assembly (47) at port ➁. Tighten jam nut.

R

R

T

B

Installation Instructions 5

56

➂

56

➀

➁

47

L

44

F

Figure 7

CC Check Valve

62

25171

33. Screw the check valve assembly (47), onto the

male JIC fitting at the Bottom of adjustment valve

assembly (44). Rotate check valve assembly (47)

so that port ➂ faces Rear before tightening JIC

nut.

Assemble CC Bypass Valve

Refer to Figure 8

34. Select the (48) 810-432C,

(HYDRAULIC BYPASS VALVE).

Note: Orient the valve (48) so that the adjustment knob

is on Top, toward Right and Front.

35. Select two (51) 811-063C,

(EL 3/4MJIC 3/4MORB).

Screw both into the Front ports of valve (48).

Rotate each to point to the Left and down before

tightening jam nuts.

36. Select a (59) 811-249C,

(TE 9/16MJIC 3/4MORB 9/16MJIC).

Screw the male O-ring boss end into the Rear Bottom port of valve (48). Point the center port of the

tee down before tightening jam nut.

37. Select a (54) 811-133C,

(AD 9/16MJIC 3/4MORB).

Screw the male O-ring boss end into the Rear Top

port of valve (48).

R

R

T

B

54

59

48

51

51

L

F

Figure 8

CC Bypass Valve

25172

11/08/2006 148-771M

Page 6

6 Opener Down Pressure Kit

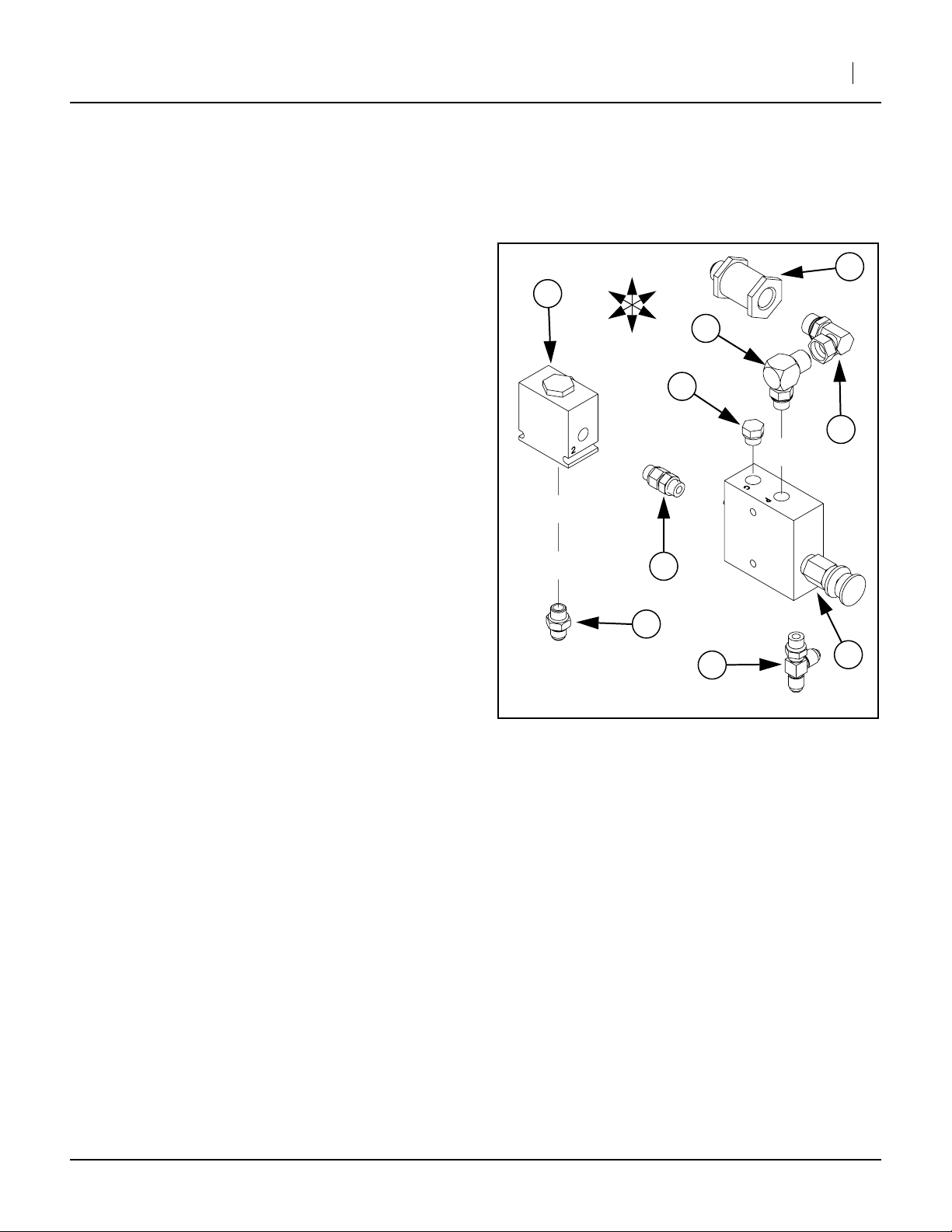

Assemble CC Valves on Mount

Refer to Figure 9 & Figure 10. Figure 10 shown exploded for clarity.

38. Select the (23) 248-506D,

(OPNR DOWN PRESSURE VALVE MNT).

Orient it so that the smaller of the two vertical

plates is to the Right, and the horizontal base plate

is at the Bottom.

Note: Both valve assemblies mount on the Right side of

the vertical plates. The check valve mounts under

the base.

39. Align the mounting holes ➀ of the adjustment

valve assembly (44) with the holes in the small vertical plate ➁. Align the notches ➂ in the check

valve assembly (47) with the holes under the base

plate ➃. This two valve assembly mounts outside

and under the mount.

40. Select two each:

(31) 802-551C, HHCS 1/4-20X2 1/4 GR5,

(39) 804-075C, WASHER FLAT 1/4 USS PLT,

(36) 804-006C, WASHER LOCK SPRING 1/4 PLT,

(32) 803-006C, NUT HEX 1/4-20 PLT.

From inside the mount, place a washer (39) on

each bolt (31) and insert the bolt out through plate

holes ➁, into the holes ➀ in the adjustment valve

(44) and loosely fit a lock washer (36) and nut (32).

R

R

48

➄

➁

44

T

L

F

B

➀

Figure 9

Mount Closed Center Valves

Great Plains Mfg., Inc.

23

➅

➃

➂

47

25173

41. Select two each:

(31) 802-551C, HHCS 1/4-20X2 1/4 GR5,

(36) 804-006C, WASHER LOCK SPRING 1/4 PLT,

(32) 803-006C, NUT HEX 1/4-20 PLT.

and four each:

(39) 804-075C, WASHER FLAT 1/4 USS PLT,

From inside the mount, place a washer (39) on

each bolt (31), down through the plate hole ➃ into

the notches ➂ of the check valve (47) and loosely

fit another washer (39), lock washer (36) and nut

(32).

42. Snug the valve assemblies (44)(47) against the

mounting plate (23), seat bolts deeply in notches,

and tighten all bolts and nuts.

43. Select two each:

(28) 802-024C, HHCS 3/8-16X3 GR5,

(37) 804-013C, WASHER LOCK SPRING 3/8 PLT

(33) 803-014C, NUT HEX 3/8-16 PLT

Select also six:

(40) 804-087C, WASHER FLAT 3/8 HARD

ASTMF436

From the Left outside of the mount, insert each bolt

(28) through one washer (40), then through the

plate holes ➅. Slide on two additional washers (40)

as spacers, then the bypass valve assembly (48)

via holes ➄. Fasten with a lock washer (37) and a

nut (33).

33

37

48

32

36

44

➀

➁

40

➄

Closed Center Fasteners

31

39

47

39

Figure 10

39

31

R

F

➅

T

R

L

B

40

28

➃

➂

36

32

25174

148-771M 11/08/2006

Page 7

Great Plains Mfg., Inc.

Installation Instructions 7

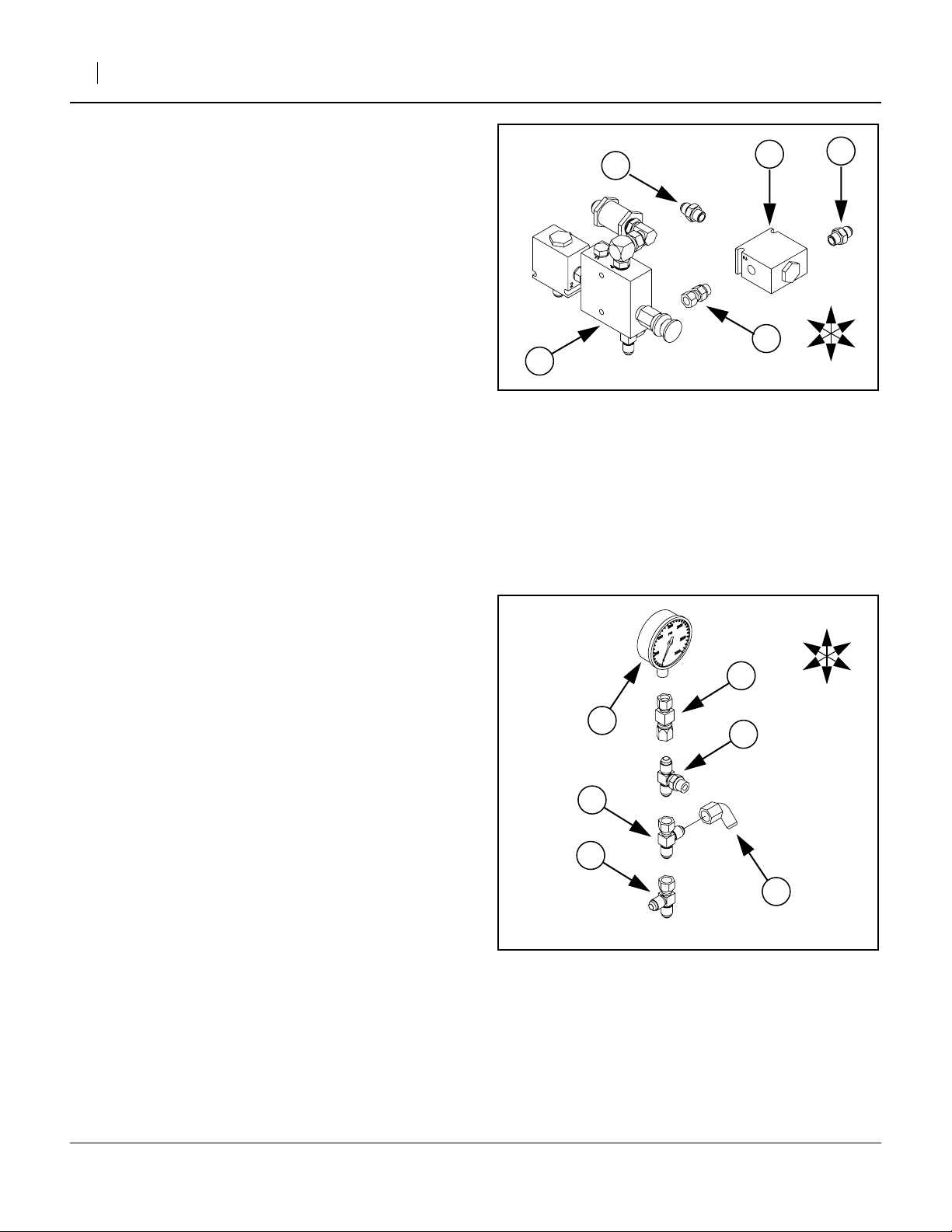

Assemble Open-Center Valve

This section is for the 148-766A Open-Center (OC) kit. If

you have the 148-765A Closed-Center kit, see page 4.

Callout numbers are assigned from the “Kit Parts List”

on page 24.

Assemble OC Down Pressure Control Valve and Shuttle Valve

Refer to Figure 6

44. Select the (44) 810-301C,

(VALVE PRESS REDUCING W/CHECK).

Orient it so that the control knob is on the Front,

toward the Bottom.

45. Select a (58) 811-216C,

(EL 3/4MJIC 9/16MORB).

Screw the male O-ring boss end into the Top Front

port of valve body (44). Adjust the JIC end to face

Left and tighten jam nut.

46. Select a (64) 811-675C,

(PL 9/16MORB HEX HEAD).

Screw the plug into the Top Rear port of valve body

(44) and tighten.

47. Select a (63) 811-636C,

(AD 9/16MORB STRAIGHT UNION).

Screw the male O-ring boss end into the Rear port

of valve body (44) Do not fully tighten at this time.

48. Select a (52) 811-064C,

(TE 9/16MJIC 9/16MJIC 9/16MORB).

Screw the male O-ring boss end into the Bottom

port of valve body (44). Adjust the tee so the center

port faces Left and tighten jam nut.

49. Select a (66) 841-077C,

(EL 3/4FJIC 3/4MORB).

Screw the female JIC end onto fitting (58). Adjust

angle so that the ell points to the Rear, and tighten.

50. Select the (49) 810-554C,

(FILTER INLINE 3/4FORB 3/4MJIC).

Screw it onto fitting (66) and tighten.

51. Select the (45) 810-343C,

(VALVE PO CHECK 2:1 W/9/16FORB).

Note: The ports of valve (45) are stamped with num-

bers “1”, “2” and “3”. Orient the check valve so

that port ➁ is to the Front, port ➀ to the Rear and

port ➂ at the Bottom.

Torque fittings and fasteners per “Torque Values” on

page 23.

A cluster of arrows in each diagram shows directions (T)

Top, (B) Bottom, (L) Left, (R) Right, (F) Front and (R)

Rear.

45

R

R

T

L

F

58

49

B

➀

64

➁

66

➂

63

56

52

Figure 11

OC Down Pressure Valve

44

25175

52. Select a (56) 811-170C,

(AD 9/16MORB 9/16MJIC).

Screw the O-ring boss end into port ➂ on the Bottom of check valve (45), and tighten.

53. Orient check valve (45) so that the hex nut is on

Top. Lay the Right faces of entire assembly on a

flat surface, and tighten union (63).

11/08/2006 148-771M

Page 8

8 Opener Down Pressure Kit

Assemble OC Check Valve Group

Great Plains Mfg., Inc.

54. Select a (47) 810-428C,

(VALVE PO CHECK 4:1 W/9/16FORB).

Note: The ports of check valve (47) are stamped with

numbers “1”, “2” and “3”. Orient the valve so that

Por t ➀ is to the Left, port ➁ to the Right and port

➂ to the Rear.

55. Select a (56) 811-170C,

(AD 9/16MORB 9/16MJIC).

Screw the male O-ring boss end into port ➀ of

valve body (47).

56. Select a (56) 811-170C,

(AD 9/16MORB 9/16MJIC).

Screw the male O-ring boss end into port ➂ of

valve body (47).

57. Select a (62) 811-627C,

(AD 9/16MORB 9/16FJIC).

Screw the male O-ring boss end onto check valve

assembly (47) at port ➁. Tighten jam nut.

58. Screw the check valve assembly (47), onto the

male JIC fitting at the Bottom of adjustment valve

assembly (44). Rotate check valve assembly (47)

so that port ➂ faces Rear before tightening JIC nut.

Assemble the OC Gauge Tree

Refer to Figure 13

59. Select a (60) 811-439C,

(TE 9/16MORB 9/16MJIC 9/16MJIC).

Orient the tee end ports up and down. The O-ring

boss port will face Front in final assembly.

60. Select a (61) 811-582C,

(AD 9/16FJIC 1/4FNPT).

Screw JIC end onto the Top of fitting (60). Tighten.

61. Select a (50) 811-061C,

(TE 9/16MJIC 9/16MJIC 9/16FJIC).

Screw female JIC end onto the Bottom of fitting

(60). Orient the side port to point Left, and tighten.

62. Select a (55) 811-169C,

(EL 9/16MJIC 9/16FJIC).

Screw it onto the center port off tee fitting (50). Orient the male end to point down and slightly forward, and tighten.

63. Select a (50) 811-061C,

(TE 9/16MJIC 9/16MJIC 9/16FJIC).

Screw female JIC end onto the Bottom of fitting

(50). Orient the side port to point Right. Tighten.

64. Select a (43) 810-300C,

(PRESSURE GAUGE 3000 PSI).

Apply pipe compound and screw into fitting (61).

Tighten so that the gauge faces Front.

44

50

50

56

Figure 12

OC Check Valve

43

Figure 13

OC Gauge Tree

➂

➁

61

60

47

62

55

➀

R

R

R

R

56

T

L

F

B

25176

T

L

F

B

25177

148-771M 11/08/2006

Page 9

Great Plains Mfg., Inc.

Installation Instructions 9

Connect Gauge Tree to Valve Assembly

Refer to Figure 14

65. Screw the center port of tee (60) onto the Rear

port ➀ of adjustment valve (45).

66. Orient gauge tree so that gauge is on Top.Tighten

the connection between tee (60) and check valve

(45) port ➀.

Assemble OC Bypass Valve Group

Refer to Figure 15

67. Select a (48) 810-432C,

(HYDRAULIC BYPASS VALVE).

Note: Orient the valve (48) so that the adjustment knob

is on Top, toward Right and Front.

68. Select two (51) 811-063C,

(EL 3/4MJIC 3/4MORB).

Screw both into the Front ports of valve (48).

Rotate each to point to the Left and down before

tightening jam nuts.

69. Select a (59) 811-249C,

(TE 9/16MJIC 3/4MORB 9/16MJIC).

Screw the male O-ring boss end into the Rear Bottom port of valve (48). Point the center port of the

tee down before tightening jam nut.

70. Select a (59) 811-249C,

(TE 9/16MJIC 3/4MORB 9/16MJIC).

Screw the male O-ring boss end into the Rear Top

port of valve (48). Point the center port of the tee

Right and down before tightening jam nut.

71. Select a (50) 811-061C,

(TE 9/16MORB 9/16MJIC 9/16MJIC).

Screw the male O-ring boss end into the Rear Top

port of the Bottom tee (59).

72. Select a (55) 811-169C,

(EL 9/16MJIC 9/16FJIC).

Screw female JIC end into the center (Bottom) port

of tee (50)

73. Select the (46) 810-344C,

(VALVE SHUTTLE 9/16FORB PORTS).

Note: The ports of valve (46) are stamped with numbers

“1”, “2” and “3”. Orient the shuttle valve so that port

➀ is to the Front, port ➁ to the Rear and port ➂ at

the Bottom.

74. Select a (53) 811-065C,

(EL 9/16MJIC 9/16MORB).

Screw the male ORB end into the Rear port ➁ of

shuttle valve (46). Orient the JIC end to point down.

75. Select a (56) 811-170C,

(AD 9/16MORB 9/16MJIC).

Screw the male ORB end into the Bottom port ➂ of

shuttle valve (46) and tighten.

T

R

R

B

60

➀

45

➁

53

➂

Figure 14

OC Gauge Tree to Valves

46

62

50

➀

59

25178

T

R

R

B

48

➂

56

55

59

Figure 15

OC Bypass Valve Group

76. Select a (62) 811-627C,

(AD 9/16MORB 9/16FJIC).

Screw the male ORB end into Front port ➀ of shuttle valve (46) and tighten.

77. Mate the shuttle valve (46) group to the bypass

valve (48) group at fittings (62) and (50). Tighten, so

that valve (46) port ➂ is down, and both valves align

when their Left sides are on a flat surface.

51

51

25179

L

F

L

F

11/08/2006 148-771M

Page 10

10 Opener Down Pressure Kit

Assemble OC Valves on Mount

Refer to Figure 16

78. Select the (23) 248-506D,

(OPNR DOWN PRESSURE VALVE MNT).

Orient it so that the smaller of the two vertical

plates is to the Right, and the horizontal base plate

is at the Bottom.

Note: Both valve assemblies mount on the Right side of

the vertical plates. The check valve mounts under

the base.

79. Position the adjustment valve assembly (44) so

that:

• The mounting holes (44) of the adjustment valve

align with the holes ➀ in the small vertical plate.

• The notches (45) in the shuttle valve align with

the holes ➁ with the holes in the small vertical

plate.

• The notches (47) in the check valve align with

the holes ➂ in the mount base.

46

➄

➁

Great Plains Mfg., Inc.

➃

➀

➂

47

R

48

23

T

L

45

44

Figure 16

Mount Open Center Valves

R

F

B

25180

148-771M 11/08/2006

Page 11

Great Plains Mfg., Inc.

Installation Instructions 11

Refer to Figure 17, shown exploded for clarity.

80. Select two each:

(31) 802-551C, HHCS 1/4-20X2 1/4 GR5,

(39) 804-075C, WASHER FLAT 1/4 USS PLT,

(36) 804-006C, WASHER LOCK SPRING 1/4 PLT,

(32) 803-006C, NUT HEX 1/4-20 PLT.

Insert the bolt (31) through the valve (44), and then

the mount (23) plate holes ➀. Loosely fit a flat

washer (39), lock washer (36) and nut (32).

81. Select two each:

(31) 802-551C, HHCS 1/4-20X2 1/4 GR5,

(39) 804-075C, WASHER FLAT 1/4 USS PLT,

(36) 804-006C, WASHER LOCK SPRING 1/4 PLT,

(32) 803-006C, NUT HEX 1/4-20 PLT.

Insert the bolt out through the mount (23) holes ➁,

into the shuttle valve notches (45). Loosely fit a flat

washer (39), lock washer (36) and nut (32).

82. Select two each:

(31) 802-551C, HHCS 1/4-20X2 1/4 GR5,

(36) 804-006C, WASHER LOCK SPRING 1/4 PLT,

(32) 803-006C, NUT HEX 1/4-20 PLT,

and four each:

(39) 804-075C, WASHER FLAT 1/4 USS PLT,

From inside the mount (23), place a washer (39) on

each bolt (31), down through the plate hole ➂ into

the check valve notches (47). Loosely fit another

flat washer (39), lock washer (36) and nut (32).

83. Snug the valve assembly (44)(45)(47) against the

mounting plate (23), seat all bolts deeply in

notches, and tighten all bolts and nuts.

Refer to Figure 18

84. Select two each:

(28) 802-024C, HHCS 3/8-16X3 GR5,

(37) 804-013C, WASHER LOCK SPRING 3/8 PLT

(33) 803-014C, NUT HEX 3/8-16 PLT

Select also six:

(40) 804-087C, WASHER FLAT 3/8 HARD

ASTMF436

From the Left outside of the mount, insert each bolt

(28) through one washer (40), then through the

plate holes ➃. Slide two additional washers (40) as

spacers, then the bypass valve assembly (48).

Fasten with a lock washer (37) and a nut (33).

85. Select two each:

(31) 802-551C, HHCS 1/4-20X2 1/4 GR5,

(39) 804-075C, WASHER FLAT 1/4 USS PLT,

(36) 804-006C, WASHER LOCK SPRING 1/4 PLT,

(32) 803-006C, NUT HEX 1/4-20 PLT.

From outside the mount, insert each bolt (31), then

through the plate hole ➄ into the notches of the

shuttle valve (46) and loosely fit a flat washer (39),

lock washer (36) and nut (32).

86. Snug the valve assembly (48)(46) against the

mounting plate (23), seat all bolts deeply in notches,

and tighten all bolts and nuts.

31

33

37

32

36

45

39

36

39

➀

44

31

39

47

36

Figure 17

Open Center Fasteners (R)

23

32

36

39

45

40

T

R

48

Open Center Fasteners (L)

F

Figure 18

L

B

R

32

➃

R

F

➂

40

T

R

L

B

31

➁

23

39

32

25181

➄

31

28

25182

11/08/2006 148-771M

Page 12

12 Opener Down Pressure Kit

Install Cylinder

The (42) 810-162C cylinder is supplied with 1in pins

and cotter pins in the base end. There may also be a pin

in the rod end. There may also be one or two washers

on each pin. These parts are not called out separately.

87. Select the (42) 810-162C,

(CYL 3.5X8X1.25 ROD (TIE ROD)).

Leave the protective caps in the ports.

88. If present, remove the pre-installed pin from the

rod end of the cylinder (42). This pin, cotter pin and

any washer(s) are not re-used.

89. Remove the pre-installed pin ➀ from the base end

of the cylinder (42). Save all parts.

90. Mount the base end of cylinder (42) on the frame

lug (25) welded earlier. Re-insert the pin components removed in step 89 and secure the cotter

pin.

91. Select the (67) 890-005C,

(BUSHING CYL 1 1/4 X 1 X 1).

Insert it inside the existing bushing in the rocker

arm ➁.

42

57

➁

➀

25

Figure 19

Down Pressure Cylinder

Great Plains Mfg., Inc.

24

27

67

T

R

F

R

L

B

25183

92. Select the:

(24) 248-507D, CYLINDER PIN and

(27) 800-245C, SNAP RING EXT 1 5304

93. Remove the protective caps from the cylinder

ports. Extend and rotate the rod (42) until the clevis

holes align with the top hole in the rocker arm ➁.

94. Insert pin (24), attaching rod (42) to rocker arm ➁.

95. Insert snap ring (27) in between the right face of

the rocker arm and the right lug of the clevis of rod

(42). Fully seat the snap ring.

96. Select two (57) 811-171C,

(EL 3/4MORB 9/16MJIC) ells.

Install the O-ring boss ends in the cylinder ports.

Before tightening, adjust the base end fitting to

point Right and slightly toward the Rear (approximately aimed at the valve assembly location).

Adjust the rod end fitting to point Right and Front.

Refer to Figure 20

97. Select the (12) 148-768S,

(5.625 CYL DEPTH CHNL ASSY).

Place it over the cylinder (42) rod, and slide to the

Rear up against the clevis end.

98. Select the (30) 802-114C,

(HHCS 3/8-16X2 1/2 GR5) and

(35) 803-078C,

(NUT LOCK 3/8-16 NYLON INSERT).

Insert the bolt (30) in the depth channel (12) and

secure it with the lock nut (35).

30

Figure 20

Cylinder Channel

R

F

12

35

42

T

R

L

B

25184

148-771M 11/08/2006

Page 13

Great Plains Mfg., Inc.

Install Valve Assembly

Refer to Figure 21 (Closed Center valve assembly shown, but Open

Center mounting shown - both are similar.)

The valve mounting bracket (23) itself mounts, via two

holes, to the right side of the right weight hanger ➀.

99. Select the two (29) 802-082C,

(HHCS 1/2-13X1 3/4 GR5) bolts,

and insert them through the valve assembly

mounting plate (23).

Note: If you are installing the Closed Center kit, omit

next step. Resume with step 101.

100. Select the four (41) 804-113C,

(WASHER FLAT 1/2 USS HARD PLT).

Slide them over the bolts (29).

101. Move the entire valve mount assembly (23) Left, so

the bolts (29) pass through the holes in the weight

hanger ➀.

102. Select two each (38) 804-015C,

(WASHER LOCK SPRING 1/2 PLT) and

(34) 803-020C,

(NUT HEX 1/2-13 PLT),

and tighten them onto the bolts.

R

F

T

B

Installation Instructions 13

B

23

L

Figure 21

Mount Valve Assembly

41

➀

29

38

34

25135

11/08/2006 148-771M

Page 14

14 Opener Down Pressure Kit

Great Plains Mfg., Inc.

Attach Closed-Center Hoses

This page is for the 148-765A Closed-Center kit. If you

have the 148-766A Open-Center kit, skip to page 15.

Refer to Figure 22. Although the valve assembly is complete at this

step, this figure is shown in exploded view to clarify bottom and rear

connections.

103. A. Select a 43cm hose (18) 811-702C,

(HH3/8R2 017 9/16FJIC).

Attach one end to the bottom port of the tee on the

bottom of adjustment valve (44). Attach the other

end to the bottom (center) port of the tee at the

rear lower port of bypass valve (48).

104. B. Select the 1.1m hose (20) 811-922C,

(HH3/8R2 045 9/16FJIC).

Attach one end to the end/rear/bottom port of the

tee at the end of the fitting tree at the rear port of

adjustment valve (44). Attach the other end to the

fitting at the base end of the down pressure cylinder (42).

105. C. Select a 43cm hose (18) 811-702C,

(HH3/8R2 017 9/16FJIC).

Attach one end to the rear port (#3) of the check

valve (47) under the mounting bracket. Attach the

other end to the fitting at the rear (center) port of

the tee at the end of the fitting tree at the rear port

of adjustment valve (44).

106. D. Select the 56cm hose (21) 811-926C,

(HH3/8R2 022 9/16FJIC).

Attach one end to the left port (#1) of the check

valve (47) under the mounting bracket. Attach the

other end to the fitting at the rod end port of the

down pressure cylinder (42).

107. Not shown:

Disconnect the “to tractor”/raise hose ➀ at the top

(base end) of the left lift cylinder ➁.

E. Shown:

Connect the “to tractor”/raise hose ➀ to the fitting at

the front bottom port of bypass valve (48).

108. Select an ell (57) 811-171C,

(AD 9/16MORB 9/16MJIC).

Remove the existing ell at the top (base end) of the

left lift cylinder ➁. Replace it with ell (57).

109. F. Select the 2.7m hose (17) 811-699C,

(HH3/8R2 106 9/16FJIC).

Attach one end to the rear port of the tee at the rear

lower port of bypass valve (48). Attach the other end

to the fitting ➁,(57) at the top (base end) of the left

lift cylinder.

T

R

F

B

L

17

B

57

F

57

18

48

19

44

➃

H

22

J

C

20

➂

A

G

E

B

47

D

18

➀

Figure 22

Closed Center Hoses

110. Not shown:

Disconnect the “from tractor”/lower hose ➂ at the

bottom (rod end) of the right lift cylinder ➃.

G. Shown:

Connect the “from tractor”/lower hose ➂ to the fitting

at the front top port of bypass valve (48).

111. Select an ell (57) 811-171C,

(AD 9/16MORB 9/16MJIC).

Remove the existing ell at the bottom (rod end) of

the right lift cylinder ➃. Replace it with ell (57)

112. H. Select a 1.3m hose (19) 811-705C,

(HH3/8R2 050 9/16FJIC).

Attach one end to the right-facing center port of the

tee at the rear port of adjustment valve (44). Attach

the other end to the fitting ➃,(57) at the bottom (rod

end) of the right lift cylinder.

113. K. Select the 38cm hose (22) 841-136C,

(HH3/8R2 015 9/16FJIC 3/4FJIC).

Connect one end to the in-line filter on the adjustment valve assembly (44). Attach the other end to

the top rear port of the bypass valve (48).

➁

21

42

25128

148-771M 11/08/2006

Page 15

Great Plains Mfg., Inc.

Installation Instructions 15

Attach Open-Center Hoses

This page is for the 148-766A Open-Center kit. If you

have the 148-765A Closed-Center kit, use page 14.

Refer to Figure 23. Although the valve assembly is complete at this

step, this figure is shown in exploded view to clarify bottom and rear

connections.

114. A. Select a 43cm hose (18) 811-702C,

(HH3/8R2 017 9/16FJIC).

Attach one end to the bottom port of the tee on the

bottom of adjustment valve (44). Attach the other

end to the bottom (center) port of the tee at the

rear lower port of bypass valve (48).

115. B. Select a 43cm hose (18) 811-702C,

(HH3/8R2 017 9/16FJIC).

Attach one end to the fitting on the bottom port (#3)

of the shuttle valve (46) on the rear of the bypass

valve (48). Attach the other end to the center/bottom port of the tee on the rear upper port of bypass

valve (48).

116. C. Select a 43cm hose (18) 811-702C,

(HH3/8R2 017 9/16FJIC).

Attach one end to the ell on the rear port (#1) of

the shuttle valve (46) on the rear of the bypass

valve (48). Attach the other end to the fitting on the

bottom port (#3) of the shuttle valve (46) on the

rear of the adjustment valve (44).

117. D. Select the1.1m hose (20) 811-922C,

(HH3/8R2 045 9/16FJIC).

Attach one end to the bottom end fitting port of the

gauge tree (42). Attach the other end to the fitting

at the base end of the down pressure cylinder (42).

118. E. Select a 43cm hose (18) 811-702C,

(HH3/8R2 017 9/16FJIC).

Attach one end to the rear port (#3) of the check

valve (47) under the mounting bracket. Attach the

other end to the left-facing (center) port of the tee

in the middle of the gauge fitting tree (42).

119. F. Select the56cm hose (21) 811-926C,

(HH3/8R2 022 9/16FJIC).

Attach one end to the left port (#1) of the check

valve (47) under the mounting bracket. Attach the

other end to the fitting at the rod end port of the

down pressure cylinder (42).

120. Not shown:

Disconnect the “to tractor”/raise hose ➀ at the top

(base end) of the left lift cylinder ➁.

G. Shown:

Connect the “to tractor”/raise hose ➀ to the fitting at

the front bottom port of bypass valve (48).

121. Select an ell (57) 811-171C,

(AD 9/16MORB 9/16MJIC).

Remove the existing ell at the top (base end) of the

left lift cylinder ➁. Replace it with ell (57).

➃

48

➂

57

44

46

➀

J

46

G

19

K

42

22

C

B

A

18

D

20

Figure 23

Open Center Hoses

17

L

F

T

R

F

B

L

B

➁

57

H

E

18

47

21

42

25131

11/08/2006 148-771M

Page 16

16 Opener Down Pressure Kit

Great Plains Mfg., Inc.

Refer to Figure 24

122. H. Select the 2.7m hose (17) 811-699C,

(HH3/8R2 106 9/16FJIC).

Attach one end to the ell at the tee in the fitting tree

between bypass valve (48) and its shuttle valve

(46). Attach the other end to the fitting ➁,(57) at

the top (base end) of the left lift cylinder.

123. Not shown:

Disconnect the “from tractor”/lower hose ➂ at the

bottom (rod end) of the right lift cylinder ➃.

J. Shown:

Connect the “from tractor”/lower hose ➂ to the fitting at the front top port of bypass valve (48).

124. Select an ell (57) 811-171C,

(AD 9/16MORB 9/16MJIC).

Remove the existing ell at the bottom (rod end) of

the right lift cylinder ➃. Replace it with ell (57)

125. K. Select a 1.3m hose (19) 811-705C,

(HH3/8R2 050 9/16FJIC).

Attach one end to the right-facing (center) port of

the tee low in gauge fitting tree (42). Attach the

other end to the fitting ➃,(57) at the bottom (rod

end) of the right lift cylinder.

126. L. Select a 38cm hose (22) 841-136C,

(HH3/8R2 015 9/16FJIC 3/4FJIC).

Connect one end to the in-line filter on the adjustment valve assembly (44). Attach the other end to

the top rear port of the bypass valve (48).

➃

48

➂

57

44

46

J

46

G

18

A

K

B

19

42

T

R

F

B

L

B

17

57

➁

22

H

L

E

18

C

F

47

21

D

➀

20

Figure 24

Open Center Hoses

42

25131

148-771M 11/08/2006

Page 17

Great Plains Mfg., Inc.

Purge and Re-phase System

!

WARNING

Escaping fluid under pressure can have sufficient pressure to

penetrate the skin causing serious injury. Avoid the hazard by

relieving pressure before disconnecting hydraulic lines. Use a

piece of paper or cardboard, NOT BODY PARTS, to check for

leaks. Wear protective gloves and safety glasses or goggles

when working with hydraulic systems. If an accident occurs,

see a doctor immediately. Any fluid injected into the skin must

be surgically removed within a few hours or gangrene will

result.

Refer to Figure 25

127. Close the Bypass valve (48) (turn fully clockwise).

128. Close the Adjustment valve (44) (turn fully clockwise), and open (clockwise) on full turn.

129. Purge the hydraulic system of air per the instructions in the Operator’s Manual.

130. Re-phase the lift cylinders per the instructions in

the Operator’s Manual.

131. Inspect the system for leaks. Raise and lower drill

once or twice, and note where the new hoses rub

other implement components, or need to be protected from other moving parts.

Post-Installation Lift Cycle

The gauge wheel lift cylinders are on the same circuit

as the new pressure compensating system (although

the lift cylinders do not rely on the compensated pressure). Be aware of, and check, the new lift/lower

sequencing.

43

Installation Instructions 17

➁

Figure 25

Closed Center Valves

48

➀

44

25185

Raising:

a. Gauge wheels lift drill.

b. Opener sub-frame lifts openers.

Lowering:

a. Gauge wheels lower drill onto cylinder stops of

gauge wheel cylinders.

b. Opener sub-frame lowers opener to the ground

and pressure compensating valve pressurizes

openers to selected setting.

132. Select ties (26) 800-035C,

(CABLE TIE .31X28 8DIA 120LB).

Secure the new hoses as necessary to protect

them in field operations.

11/08/2006 148-771M

Page 18

18 Opener Down Pressure Kit

Calibrate Bypass Valve (CC only)

Refer to Figure 26

If your tractor has Open Center hydraulics, refer to

“Open Center Operation” on page 21. If you are

unsure what type of hydraulic system is on your tractor,

contact your tractor manufacturer.

Note: Refer to “Post-Installation Lift Cycle” on

page 17 to know what to expect the drill to do as

hydraulics are cycled.

Tractors with Pressure Compensating Closed Center Hydraulics (PC Closed)

133. Release locking disk ➀. Close bypass valve (48)

for no oil flow by turning knob on valve clockwise

completely. Tighten locking disk ➀. Always operate the drill with the bypass valve closed.

Tractors with Load Sensing Closed Center Hydraulics (LS Closed) or Pressure Flow Compensating

(PFC) Systems

43

➁

Figure 26

Closed Center Valves

Great Plains Mfg., Inc.

48

➀

44

25185

IMPORTANT !

Failure to use the bypass valve on load-sensing

tractors may cause major tractor damage.

134. Release locking disk ➀. Close bypass valve (48) for

no oil flow by turning knob on valve clockwise completely. Tighten locking disk ➀.

135. With tractor at half throttle, adjust flow-control valve

on tractor so openers raise and lower at a reasonable speed. Keep tractor at one-half throttle for

remaining steps.

Note: Faster opener raise/lower increases potential for

oil over-heating, excess wear and tractor damage.

136. Engage tractor hydraulics and lower openers. Lock

hydraulic lever on tractor for continuous operation.

137. Release locking disks ➀ and ➁. Adjust pressurecontrol valve (44) for opener down pressure so

gauge (43) is at 1800 psi.

138. While watching gauge (43), slowly turn knob on

bypass valve (48) counterclockwise. Adjust bypass

valve (48) just until needle on gauge (43) begins to

move down from 1800 psi. Use locking disk ➀ to

lock bypass valve at this setting. (See also note

below.)

139. Adjust pressure-control valve (44) to desired opener

down pressure per “Closed Center Field Opera-

tion” on page 19. Tighten locking disk ➁.

Note: The higher the bypass pressure, the greater the

potential for oil over-heating and tractor damage.

At the same time, for proper opener operation the

bypass valve must be set at least 300 psi above

the opener down-pressure setting when the tractor

is at one-half throttle. Therefore, you should set

the bypass valve as low as possible while staying

at least 300 psi above the opener down pressure

setting.

While 1800 psi is a good starting point for setting the

bypass valve, if you consistently operate the drill with low

opener down pressure you can set the bypass valve

below 1800 psi. If you consistently operate the drill with

very high opener down pressure, you may need a

bypass-valve setting above 1800 psi.

148-771M 11/08/2006

Page 19

Great Plains Mfg., Inc.

Operation

Installation Instructions 19

Closed Center Field Operation

The openers are mounted on floating opener frames

which follow the contour of the ground while maintaining

constant opener down pressure.

1. Lower the opener frames by pushing FORWARD on

the tractor remote hydraulic lever. The remote lever

must be LOCKED OPEN in this position to provide

constant pressure/flow to the openers.

John Deere tractors with Sound-Gard ® Body:

Use lever lock clip, John Deere part number

R52667, to lock lever forward. See your tractor

dealer for clip purchase and installation.

John Deere 7000 Series tractors: Rotate valve

detent selector to motor position to lock lever in forward position.

John Deere 8000 Series tractors: Set timer to continuous. Push lever forward until detent clicks.

Case-IH Magnum tractors: Lock lever forward in

detent position. You may need to turn up detent

pressure to its maximum setting. Do not tie hydraulic

lever past detent position with a strap. See your tractor dealer for hydraulic-system details.

Other tractors: Lock lever forward in detent position. You may need to turn up detent pressure to

maximum or use a mechanical detent holder to hold

lever forward. See your tractor dealer for proper

means of providing constant flow to openers.

Refer to Figure 27

43

2. With the tractor hydraulic lever locked forward,

release the lock disk ➀, turn the knob on the pressure control valve (44) as shown in Figure 27. Watch

the pressure gauge (43) and dial in the desired pressure on the openers. Clockwise increases the pressure and counterclockwise decreases pressure.

Once the pressure is set, lock the knob with the lock

disk ➀.

Note: Refer to “Post-Installation Lift Cycle” on page 17

to know what to expect the drill to do as hydraulics

are cycled.

The recommended pressure range for drilling is between

200 psi and 1400 psi. Setting the opener down pressure

above 1600 psi will raise the drive wheels off the ground

when the seed box is empty causing skips and poor seed

metering. See the following table for the relationship

between psi and down force.

The following down-forces are per-opener, with no extra

weight on the hangers (at the lower down-force values).

Higher down-force values may require weights on the

hangers. Consult the Operator’s Manual for further information.

Adjustment Valve Table

System

PSI

200 62 137

300 77 170

400 84 185

500 96 212

600 110 243

700 123 272

800 139 306

900 155 341

1000 173 380

1100 194 427

1200 217 479

1300 249 548

1400 268 591

Down Force

Pounds Kg

➀

Figure 27

Closed Center Valves

11/08/2006 148-771M

44

25185

Page 20

20 Opener Down Pressure Kit

Great Plains Mfg., Inc.

Refer to Figure 28

➁

➂

➀

Figure 28

Opener Adjustment

3. After the opener pressure is set, opener depth ➀ is

controlled by the press wheel adjustment. Attached

to the rear of each opener is one of several optional

press wheels. The press wheels close the furrow

and gently press soil over the seed while also providing depth control for the opener. To adjust the

position of the press wheel, which automatically

changes the seeding depth of the opener, lift the “T”

handle located on top of the opener and slide it for-

ward ➁ or rearward ➂ until the seeding depth is

correct, as shown in Figure 2-10. Moving the handle

forward ➁ plants shallower while moving the handle

rearward ➂ plants deeper. A spring loaded pin

holds the “T” handle at the setting to maintain the

proper depth. Lift the opener frames slightly to take

the pressure off the “T” handles when adjusting the

press wheel depth.

Note: The opener pressure setting controls the soil firm-

ing pressure on the press wheel as well as the disk

penetrating force. DO NOT use more opener down

pressure than necessary to obtain the desired

opener penetration and to maintain the proper

firming action over the seed. Set the planting

depth with the depth controlling press wheel and

only use enough opener pressure to cut the proper

seed groove and maintain the desired soil firming

action. Excessive opener force will lead to excessive wear and damage of the opener components.

15659

Priority Flow Hydraulic Systems

On some tractors with load-sensing hydraulics, the circuit

#1 is capable of taking nearly 100 percent of available

hydraulic flow. Operating the openers or markers on circuit #1 will starve the other circuit, making one function

inoperable.

To operate markers and constant opener down pressure

at the same time, connect the openers to circuit #2 and

the markers to circuit #3.

Note: On some tractors with very positive remote

hydraulic checks, a slight increase in the reading

on the pressure gauges may occur after the tractor

remote lever is returned to neutral. This is caused

by back pressure on the opener cylinders and

should be ignored. The NET OPERATING PRESSURE on the opener cylinders is maintained at the

pressure you selected while the tractor remote

lever was held forward–not at the “apparently

increased” pressure. Reactivating the tractor lever

forward will confirm this.

148-771M 11/08/2006

Page 21

Great Plains Mfg., Inc.

Installation Instructions 21

Open Center Operation

This section covers Non-Active Hydraulic Systems -Tractors with open-center hydraulic systems or fixed-displacement hydraulic pumps.

If your tractor has Closed Center hydraulics, refer to

“Closed Center Field Operation” on page 19. If you are

unsure what type of hydraulic system is on your tractor,

contact your tractor manufacturer.

Refer to Figure 29

43

48

➀

44

➁

Figure 29

Open Center Valves

Note: Refer to “Post-Installation Lift Cycle” on page 17

to know what to expect the drill to do as hydraulics

are cycled.

1. Release locking disk ➀. Close bypass valve (48) for

no oil flow by turning knob on valve clockwise completely. Always operate the drill with the bypass

valve closed. Lock disk ➀.

2. Lower the opener frames by pushing FORWARD on

the tractor remote hydraulic lever. The remote lever

must be TEMPORARILY LOCKED OPEN in this

position while the pressure adjustment is being

made to provide constant pressure and flow to the

openers.

John Deere tractors with Sound-Gard ® Body:

Use lever lock clip, John Deere part number

R52667, to lock lever forward. See your tractor

dealer for clip purchase and installation.

25186

John Deere 7000 Series tractors: Rotate valve

detent selector to motor position to lock lever in forward position.

John Deere 8000 Series tractors: Set timer to continuous. Push lever forward until detent clicks.

Case-IH Magnum tractors: Lock lever forward in

detent position. You may need to turn up detent

pressure to its maximum setting. Do not tie hydraulic

lever past detent position with a strap. See your tractor dealer for hydraulic-system details.

Other tractors: Lock lever forward in detent position. You may need to turn up detent pressure to

maximum or use a mechanical detent holder to hold

lever forward. See your tractor dealer for proper

means of providing constant flow to openers.

3. Release locking disk ➁. With the tractor hydraulic

lever locked forward, turn the knob on the pressure

control valve (44) as shown in Figure 29. Watch the

pressure gauge (43) and dial in the desired pressure

on the openers. Clockwise increases the pressure,

and counterclockwise decreases pressure. Once

the pressure is set, lock each knob with the lock disk

➁. The recommended pressure range for drilling is

between 200 psi and 1400 psi. Setting the opener

down pressure above 1600 psi. will raise the drive

wheels off the ground when the seed box is empty

causing skips and poor seed metering. See the following table for the relationship between psi and

down force..

Adjustment Valve Table

System

PSI

200 62 137

300 77 170

400 84 185

500 96 212

600 110 243

700 123 272

800 139 306

900 155 341

1000 173 380

1100 194 427

1200 217 479

1300 249 548

1400 268 591

As a general starting point, set hydraulic down pressure

to 800 psi. For most field conditions, adjust down pressure between 200 and 1400 psi. Setting the opener down

pressure above 1600 psi. will raise the drive wheels off

Down Force

Pounds Kg

11/08/2006 148-771M

Page 22

22 Opener Down Pressure Kit

Great Plains Mfg., Inc.

the ground when the seed box is empty causing skips

and poor seed metering. Refer to the chart on the previous page for approximate force at the openers for a given

pressure setting.

4. After the opener pressure is set, RETURN THE

TRACTOR REMOTE HYDRAULIC LEVER TO ITS

NEUTRAL POSITION. This “locks in” the previously

selected pressure and the opener frames remain in

a fixed position.

Note: On some tractors with very positive remote

hydraulic checks, a slight increase in the reading

on the pressure gauges may occur after the tractor

remote lever is returned to neutral. This is caused

by back pressure on the opener cylinders and

should be ignored. The NET OPERATING PRESSURE on the opener cylinders is maintained at the

pressure you selected while the tractor remote

lever was held forward–not at the “apparently

increased” pressure. Reactivating the tractor lever

forward will confirm this.

Each time the drill is lowered, hold the tractor remote

hydraulic lever forward for a few seconds to recharge the

circuit, then return it to its neutral position. The tractor

and drill should be on level ground when you return the

tractor lever to neutral.

The open center hydraulic kit allows the tractor operator

to momentarily operate the opener down pressure circuit

as an active circuit. When approaching a mound or valley

where active hydraulics is desirable, the tractor operator

can MOMENTARILY PUSH THE TRACTOR REMOTE

HYDRAULIC LEVER FORWARD which will allow the

opener frames to follow the uneven terrain with constant

opener down pressure. As soon as the drill returns to

level ground RETURN THE TRACTOR REMOTE

HYDRAULIC LEVER TO ITS NEUTRAL POSITION to

“lock in” the preset pressure once again. DO NOT activate the tractor remote hydraulic lever for more than 20

seconds at a time, once every 2 minutes. Always wait

until the tractor and drill are on level ground before

returning the tractor remote hydraulic lever to its neutral

position. The tractor remote hydraulic lever can be

momentarily bumped forward any time on level ground to

assure the preset pressure is correctly locked in and to

reset the system if it has not been operated for a long

period of time.

Note: The opener pressure setting controls the soil firm-

ing pressure on the press wheel as well as the disk

penetrating force. DO NOT use more opener down

pressure than necessary to obtain the desired

opener penetration and to maintain the proper

firming action over the seed. Set the planting

depth with the depth controlling press wheel and

only use enough opener pressure to cut the proper

seed groove and maintain the desired soil firming

action. Excessive opener force will lead to excessive wear and damage of the opener components.

Refer to Figure 30f

➁

➂

➀

Figure 30

Opener Adjustment

5. After the opener pressure is set, opener depth ➀ is

controlled by the press wheel adjustment. Attached

to the rear of each opener is one of several optional

press wheels. The press wheels close the furrow

and gently press soil over the seed while also providing depth control for the opener. To adjust the

position of the press wheel, which automatically

changes the seeding depth of the opener, lift the “T”

handle located on top of the opener and slide it for-

ward ➁ or rearward ➂ until the seeding depth is

correct, as shown in Figure 2-10. Moving the handle

forward ➁ plants shallower while moving the handle

rearward ➂ plants deeper. A spring loaded pin

holds the “T” handle at the setting to maintain the

proper depth. Lift the opener frames slightly to take

the pressure off the “T” handles when adjusting the

press wheel depth.

6. After opener down pressure is set, return tractor

hydraulic lever to neutral. This locks in the selected

pressure, and opener frames will remain fixed in this

position.

IMPORTANT !

Open-center tractors and tractors with fixed-displacement pumps are not designed to provide a

continuous supply of pressurized oil to remote

valves. Locking hydraulic lever forward on these

tractors can cause overheating of hydraulic oil

and tractor damage. After setting opener down

pressure, always return hydraulic lever to neutral.

15659

148-771M 11/08/2006

Page 23

Great Plains Mfg., Inc.

Maintenance

Installation Instructions 23

In-Line Hydraulic Filter

25187

If raising or lowering times slow noticeably, check the inline filter, and clean as necessary.

Installation Reference Information

Connector Identification

➁

➂

➇

➆

➅

➄

➀

➀ JIC - Joint Industry Conference (SAE J514)

Note straiight threads ➁ and the

37° cone ➂ on “M” fittings (or 37° flare on “F”).

➃ ORB - O-Ring Boss (SAE J514)

Note the straight threads ➄ and,

elastomer O-Ring ➅.

Fittings needing orientation, such as the ell above,

also have a washer ➆ and

jam nut ➇ (“adjustable thread port stud”)

➃

25188

To clean the filter:

1. Set tractor’s opener down-force hydraulic circuit to

float.

2. Shut down tractor.

3. Loosen connections at the in-line filter and allow a

few minutes for drain-back.

4. Disconnect and cap the hose to the filter.

5. Disassemble the filter in place.

6. Remove the 50 micron screen. Wash with solvent

and use compressed air to dislodge any debris.

Note: If the filter screen needs to be replaced, order an

810-553C from your Great Plains dealer.

7. Reassemble filter and reconnect hose.

8. Complete a hydraulic system purge and re-phase

per your Operator’s manual.

Torque Values

Fastener/Fitting Ft-Lbs N-m

1

⁄4 NPT

1

⁄4-20 GR5

3

⁄8-16 GR5

1

⁄2-13 GR5

9

⁄16 JIC

9

⁄16 ORB w/jam nut

9

⁄16 ORB straight

3

⁄4 JIC

3

⁄4 ORB w/jam nut

3

⁄4 ORB straight

1.5-3.0 turns past finger tight

811

31 42

76 105

18-20 24-27

12-16 16-22

18-24 24-32

27-39 37-53

20-30 27-41

27-43 37-58

- NPT - National Pipe Thread (not shown)

have tapered threads, no cone/flare, no O-ring.

11/08/2006 148-771M

Page 24

Great Plains Mfg., Inc.

24 Opener Down Pressure Kit

Kit Parts List

Opener Down Pressure Kits

The part call-out numbers in this list match all Figures in the installation instructions, but not the support parts lists

starting on page 26. Your kit includes:

Quantity per 401-

(Callout) Part No.

(11) 148-771M 1 1 This manual

(12) 148-768S 1 1 5.625 CYL DEPTH CHNL ASSY

(13) 113-357D 2 2 RUBBER CYL LOCK CHANNEL PAD

(14) 148-767H 1 1 5.625 CYL DEPTH CHNL WLMT

(15) 148-769V 1 0 VALVE ASSY- C.C. HOSE BUNDLE

(16) 148-770V 0 1 VALVE ASSY- O.C. HOSE BUNDLE

(17) 811-699C 1 1 HH3/8R2 106 9/16FJIC

(18) 811-702C 2 4 HH3/8R2 017 9/16FJIC

(19) 811-705C 1 1 HH3/8R2 050 9/16FJIC

(20) 811-922C 1 1 HH3/8R2 045 9/16FJIC

(21) 811-926C 1 1 HH3/8R2 022 9/16FJIC

(22) 841-136C 1 1 HH3/8R2 015 9/16FJIC 3/4FJIC

(23) 248-506D 1 1 OPNR DOWN PRESSURE VALVE MNT

(24) 248-507D 1 1 CYLINDER PIN

(25) 248-508D 1 1 TOP LINK CYL LUG

(26) 800-035C 6 6 CABLE TIE .31X28 8DIA 120LB

(27) 800-245C 1 1 SNAP RING EXT 1 5304

(28) 802-024C 2 2 HHCS 3/8-16X3 GR5

(29) 802-082C 2 2 HHCS 1/2-13X1 3/4 GR5

(30) 802-114C 1 1 HHCS 3/8-16X2 1/2 GR5

(31) 802-551C 4 8 HHCS 1/4-20X2 1/4 GR5

(32) 803-006C 4 8 NUT HEX 1/4-20 PLT

(33) 803-014C 2 2 NUT HEX 3/8-16 PLT

(34) 803-020C 2 2 NUT HEX 1/2-13 PLT

(35) 803-078C 1 1 NUT LOCK 3/8-16 NYLON INSERT

(36) 804-006C 4 8 WASHER LOCK SPRING 1/4 PLT

(37) 804-013C 2 2 WASHER LOCK SPRING 3/8 PLT

(38) 804-015C 2 2 WASHER LOCK SPRING 1/2 PLT

(39) 804-075C 6 10 WASHER FLAT 1/4 USS PLT

(40) 804-087C 6 6 WASHER FLAT 3/8 HARD ASTMF436

(41) 804-113C 4 4 WASHER FLAT 1/2 USS HARD PLT

(42) 810-162C 1 1 CYL 3.5X8X1.25 ROD (TIE ROD)

(43) 810-300C 1 1 PRESSURE GAUGE 3000 PSI

-765A -766A

Part Description

148-771M 11/08/2006

Page 25

Great Plains Mfg., Inc.

Quantity per 401-

(Callout) Part No.

(44) 810-301C 1 1 VALVE PRESS REDUCING W/CHECK

(45) 810-343C 0 1 VALVE PO CHECK 2:1 W/9/16FORB

(46) 810-344C 0 1 VALVE SHUTTLE 9/16FORB PORTS

(47) 810-428C 1 1 VALVE PO CHECK 4:1 W/9/16FORB

(48) 810-432C 1 1 HYDRAULIC BYPASS VALVE

(49) 810-554C 1 1 FILTER INLINE 3/4FORB 3/4MJIC

(50) 811-061C 1 3 TE 9/16MJIC 9/16MJIC 9/16FJIC

(51) 811-063C 2 2 EL 3/4MJIC 3/4MORB

(52) 811-064C 2 1 TE 9/16MJIC 9/16MJIC 9/16MORB

(53) 811-065C 0 1 EL 9/16MJIC 9/16MORB

(54) 811-133C 1 0 AD 9/16MJIC 3/4MORB

(55) 811-169C 1 2 EL 9/16MJIC 9/16FJIC

(56) 811-170C 2 4 AD 9/16MORB 9/16MJIC

(57) 811-171C 4 4 EL 3/4MORB 9/16MJIC

(58) 811-216C 1 1 EL 3/4MJIC 9/16MORB

(59) 811-249C 1 2 TE 9/16MJIC 3/4MORB 9/16MJIC

(60) 811-439C 1 1 TE 9/16MORB 9/16MJIC 9/16MJIC

(61) 811-582C 0 1 AD 9/16FJIC 1/4FNPT

(62) 811-627C 1 2 AD 9/16MORB 9/16FJIC

(63) 811-636C 0 1 AD 9/16MORB STRAIGHT UNION

(64) 811-675C 0 1 PL 9/16MORB HEX HEAD

(65) 811-677C 1 0 AD 9/16MORB 1/4FNPT

(66) 841-077C 1 1 EL 3/4FJIC 3/4MORB

(67) 890-005C 1 1 BUSHING CYL 1 1/4 X 1 X 1

-765A -766A

Part Description

Installation Instructions 25

11/08/2006 148-771M

Page 26

26 Opener Down Pressure Kit

Support Parts - V300 Drill, Closed-Center Down-Pressure

The part call-out numbers in this section do not match the merged list in the installation instructions.

Great Plains Mfg., Inc.

25128

148-771M 11/08/2006

Page 27

Great Plains Mfg., Inc.

Installation Instructions 27

Closed Center Down-Pressure Components

Ref. Part No. Part Description Comment

1 148-768S 5.625 CYL DEPTH CHNL ASSY

2 890-005C BUSHING CYL 1 1/4 X 1 X 1

3 148-771M MANUAL 04 HOSE SUPPORT UPDATE

4 248-506D OPNR DOWN PRESSURE VALVE MNT

5 248-507D CYLINDER PIN

6 248-508D TOP LINK CYL LUG

7 800-035C CABLE TIE .31X28 8DIA 120LB

8 800-245C SNAP RING EXT 1 5304

9 802-024C HHCS 3/8-16X3 GR5

10 802-082C HHCS 1/2-13X1 3/4 GR5

11 802-114C HHCS 3/8-16X2 1/2 GR5

12 802-551C HHCS 1/4-20X2 1/4 GR5

13 803-006C NUT HEX 1/4-20 PLT

14 803-014C NUT HEX 3/8-16 PLT

15 803-020C NUT HEX 1/2-13 PLT

16 803-078C NUT LOCK 3/8-16 NYLON INSERT

17 804-006C WASHER LOCK SPRING 1/4 PLT

18 804-013C WASHER LOCK SPRING 3/8 PLT

19 804-015C WASHER LOCK SPRING 1/2 PLT

20 804-075C WASHER FLAT 1/4 USS PLT

21 804-087C WASHER FLAT 3/8 HARD ASTMF436

22 804-113C WASHER FLAT 1/2 USS HARD PLT

23 810-162C CYL 3.5X8X1.25 ROD (TIE ROD)

24 810-300C PRESSURE GAUGE 3000 PSI

25 810-301C VALVE PRESS REDUCING W/CHECK

26 810-428C VALVE PO CHECK 4:1 W/9/16FORB

27 810-432C HYDRAULIC BYPASS VALVE

28 810-554C FILTER INLINE 3/4FORB 3/4MJIC

29 811-061C TE 9/16MJIC 9/16MJIC 9/16FJIC

30 811-063C EL 3/4MJIC 3/4MORB

31 811-064C TE 9/16MJIC 9/16MJIC 9/16MORB

32 811-133C AD 9/16MJIC 3/4MORB

33 811-169C EL 9/16MJIC 9/16FJIC

34 811-170C AD 9/16MORB 9/16MJIC

35 811-171C EL 3/4MORB 9/16MJIC

36 811-216C EL 3/4MJIC 9/16MORB

37 811-249C TE 9/16MJIC 3/4MORB 9/16MJIC

38 811-627C AD 9/16MORB 9/16FJIC

39 811-677C AD 9/16MORB 1/4FNPT

40 841-077C EL 3/4FJIC 3/4MORB

41 811-699C HH3/8R2 106 9/16FJIC

42 811-702C HH3/8R2 017 9/16FJIC

43 811-705C HH3/8R2 050 9/16FJIC

44 811-922C HH3/8R2 045 9/16FJIC

45 811-926C HH3/8R2 022 9/16FJIC

46 841-136C HH3/8R2 015 9/16FJIC 3/4FJIC

11/08/2006 148-771M

Page 28

28 Opener Down Pressure Kit

Support Parts - V300 Drill, Open-Center Down-Pressure

The part call-out numbers in this section do not match the merged list in the installation instructions.

Great Plains Mfg., Inc.

25131

148-771M 11/08/2006

Page 29

Great Plains Mfg., Inc.

Installation Instructions 29

Open Center Down-Pressure Components

Ref. Part No. Part Description Comment

1 148-768S 5.625 CYL DEPTH CHNL ASSY

2 890-005C BUSHING CYL 1 1/4 X 1 X 1

3 148-771M MANUAL 04 HOSE SUPPORT UPDATE

4 248-506D OPNR DOWN PRESSURE VALVE MNT

5 248-507D CYLINDER PIN

6 248-508D TOP LINK CYL LUG

7 800-035C CABLE TIE .31X28 8DIA 120LB

8 800-245C SNAP RING EXT 1 5304

9 802-024C HHCS 3/8-16X3 GR5

10 802-082C HHCS 1/2-13X1 3/4 GR5

11 802-114C HHCS 3/8-16X2 1/2 GR5

12 802-551C HHCS 1/4-20X2 1/4 GR5

13 803-006C NUT HEX 1/4-20 PLT

14 803-014C NUT HEX 3/8-16 PLT

15 803-020C NUT HEX 1/2-13 PLT

16 803-078C NUT LOCK 3/8-16 NYLON INSERT

17 804-006C WASHER LOCK SPRING 1/4 PLT

18 804-013C WASHER LOCK SPRING 3/8 PLT

19 804-015C WASHER LOCK SPRING 1/2 PLT

20 804-075C WASHER FLAT 1/4 USS PLT

21 804-087C WASHER FLAT 3/8 HARD ASTMF436

22 804-113C WASHER FLAT 1/2 USS HARD PLT

23 810-162C CYL 3.5X8X1.25 ROD (TIE ROD)

24 810-300C PRESSURE GAUGE 3000 PSI

25 810-301C VALVE PRESS REDUCING W/CHECK

26 810-343C VALVE PO CHECK 2:1 W/9/16FORB

27 810-344C VALVE SHUTTLE 9/16FORB PORTS

28 810-428C VALVE PO CHECK 4:1 W/9/16FORB

29 810-432C HYDRAULIC BYPASS VALVE

30 810-554C FILTER INLINE 3/4FORB 3/4MJIC

31 811-061C TE 9/16MJIC 9/16MJIC 9/16FJIC

32 811-063C EL 3/4MJIC 3/4MORB

33 811-064C TE 9/16MJIC 9/16MJIC 9/16MORB

34 811-065C EL 9/16MJIC 9/16MORB

35 811-169C EL 9/16MJIC 9/16FJIC

36 811-170C AD 9/16MORB 9/16MJIC

37 811-171C EL 3/4MORB 9/16MJIC

38 811-216C EL 3/4MJIC 9/16MORB

39 811-249C TE 9/16MJIC 3/4MORB 9/16MJIC

40 811-439C TE 9/16MORB 9/16MJIC 9/16MJIC

41 811-582C AD 9/16MORB 1/4FNPT

42 811-627C AD 9/16MORB 9/16FJIC

43 811-636C AD 9/16MORB STRAIGHT UNION

44 811-675C PL 9/16MORB HEX HEAD

45 841-077C EL 3/4FJIC 3/4MORB

46 811-699C HH3/8R2 106 9/16FJIC

47 811-702C HH3/8R2 017 9/16FJIC

48 811-705C HH3/8R2 050 9/16FJIC

49 811-922C HH3/8R2 045 9/16FJIC

50 811-926C HH3/8R2 022 9/16FJIC

51 841-136C HH3/8R2 015 9/16FJIC 3/4FJIC

11/08/2006 148-771M

Page 30

30 Opener Down Pressure Kit

Great Plains Mfg., Inc.

Great Plains Manufacturing, Inc.

Corporate Office: PO Box 5060

Salina, KS 67402-5060 USA

148-771M 11/08/2006

Loading...

Loading...