Page 1

Operator’s Manual

Ultra-Till (Disc & Coulter)

Series I UT3030, UT5036,

UT5042, UT5048 & UT5052

Read the operator’s manual entirely. When you see this symbol, the subsequent

!

instructions and warnings are serious - follow without exception. Your life and the

lives of others depend on it

Cover illustration may show optional equipment not supplied with standard unit.

©Copyright 2009 Printed 2/18/2009 576-026M

Page 2

Great Plains Mfg., Inc. Table of Contents

Table of Contents

Important Safety Information ..........................1

Safety Rules...................................................6

Safety Decals ................................................7

Introduction ........................................................12

Description of Unit........................................12

Using this Manual ........................................12

Definitions..............................................12

Owner Assistance..........................................12

Assembly and Setup Assistance....................13

Product Support .....................................13

Pre-Assembly Checklist ........................13

Section 1 Assembly .............................................14

Center Frame, Torque Tube & Walking

Beam Assembly .......................................14

Inside Wing and Wheel Arm Assembly .......15

Brace Bar, Wing Brace & Rocker/Fold

Bracket Assembly ....................................16

Outside Wing Assembly ...............................17

Connecting Outside Wing and Wing Brace

Assembly .................................................18

Center Gang & Gang Hanger Assembly.......19

Center Truss, Hitch and Strut Assembly ......20

Self Level and Rest Pads Assembly .............21

Fold Cylinders, Rocker Arm and 3” Rollers

Assembly .................................................22

Center Wing Stop and Outside Wing Stop

Assembly .................................................23

Front Gauge Wheel Assembly .....................24

Hydraulic Gauge Wheel Assembly ..............25

Completing Setup .........................................26

Section 2 Hydraulics ..........................................28

3030 Hydraulic Down Pressure

Preparation and Setup ..............................28

5-Section Hydraulic Down Pressure

Preparation and Setup ..............................29

©

Copyright 2004 All rights Reserved

Great Plains Manufacturing, Inc. provides this publication “as is” without warranty of any kind, either expressed or implied. While every precaution has been taken in the

preparation of this manual, Great Plains Manufacturing, Inc. assumes no responsibility for errors or omissions. Neither is any liability assumed for damages resulting from

the use of the information contained herein. Great Plains Manufacturing, Inc. reserves the right to revise and improve its products as it sees fit. This publication describes

the state of this product at the time of its publication, and may not reflect the product in the future.

The following are trademarks of Great Plains Mfg., Inc.: Application Systems, Ausherman, Land Pride, Great Plains

All other brands and product names are trademarks or registered trademarks of their respective holders.

Great Plains Manufacturing, Incorporated Trademarks

Printed in the United States of America.

Section 3 Layouts ............................................... 30

UT3030D Machine Layout, Disc..................30

UT5036D Machine Layout, Disc..................32

UT5042D Machine Layout, Disc..................34

UT5052D Machine Layout, Disc..................37

UT3030C Machine Layout, Coulter

(S/N A1095A-).........................................40

UT5036C Machine Layout, Coulter

(S/N A1095A-).........................................42

UT5042C Machine Layout, Coulter

(S/N A1095A-).........................................44

UT5052C Machine Layout, Coulter

(S/N A1095A-).........................................47

UT3030C Machine Layout, Coulter

(S/N A1096A+)........................................50

UT5036C Machine Layout, Coulter

(S/N A1096A+)........................................52

UT5042C Machine Layout, Coulter

(S/N A1096A+)........................................54

UT5052C Machine Layout, Coulter

(S/N A1096A+)........................................57

Disc Gang Identification .............................. 60

Coulter Gang Identification .......................... 62

Section 4 Operating and Maintenance.............. 64

Adjustments Before Going to the Field .......64

Field Adjustments & General

Operating Instructions .................................. 65

Maintenance and Lubrication ....................... 66

Section 5 Specification and Capacities ............. 67

Appendix .............................................................68

Torque Values for Common Bolt Sizes ....... 68

Tire Inflation Chart ...................................... 68

Warranty ....................................................... 69

2/18/2009 Series I UT3030-UT5052 Ultra-Till 576-026M

Page 3

Great Plains Mfg., Inc. Important Safety Information

Important Safety Information

Look for Safety Symbol

The SAFETY ALERT SYMBOL indicates there is

a potential hazard to personal safety involved

and extra safety precaution must be taken.

When you see this symbol, be alert and carefully

read the message that follows it. In addition to

design and configuration of equipment, hazard

control and accident prevention are dependent

upon the awareness, concern, prudence and

proper training of personnel involved in the

operation, transport, maintenance and storage of

equipment.

Be Aware of Signal Words

!

Signal words designate a degree or level of hazard seriousness.

DANGER indicates an imminently hazardous situation, which, if not avoided, will result in death

or serious injury. This signal word is limited to

the most extreme situations, typically for

machine components that, for functional

purposes, cannot be guarded.

WARNING indicates a potentially hazardous

situation, which, if not avoided, could result in

death or serious injury, and includes hazards

that are exposed when guards are removed. It

may also be used to alert against unsafe

practices.

CAUTION indicates a potentially hazardous situation, which, if not avoided, may result in minor

or moderate injury. It may also be used to alert

against unsafe practices.

!

DANGE R

!

WA RN ING

!

CAUTION

10/28/2004 Series I UT3030-UT5052 Ultra-Till 576-026M

1

Page 4

Important Safety Information Great Plains Mfg., Inc.

Be Familiar with Safety Decals

• Read and understand “Safety Decals,” page

7, thoroughly.

• Read all instructions noted on the decals.

Keep Riders Off Machinery

• Riders obstruct the operator’s view. Riders

could be struck by foreign objects or thrown

from the machine.

• Never allow children to operate equipment.

• Keep all bystanders away from machine dur-

ing operation.

Shutdown and Storage

• Lower Series I Ultra-Till, put tractor in park,

turn off engine, and remove the key.

• Secure Series I Ultra-Till using blocks and

supports provided.

• Detach and store Series I Ultra-Till in an

area where children normally do not play.

Use Safety Lights and Devices

• Slow-moving tractors and towed implements

can create a hazard when driven on public

roads. They are difficult to see, especially at

night.

• Use flashing warning lights and turn signals

whenever driving on public roads.

• Use lights and devices provided with imple-

ment.

OFF

Series I UT3030-UT5052 Ultra-Till 576-026M 10/28/2004

4/11/2005

2

Page 5

Great Plains Mfg., Inc. Important Safety Information

Transport Machinery Safely

Maximum transport speed for implement is 20

mph. Some rough terrains require a slower

speed. Sudden braking can cause a towed load

to swerve and upset.

• Do not exceed 20 mph. Never travel at a

speed which does not allow adequate

control of steering and stopping. Reduce

speed if towed load is not equipped with

brakes.

• Comply with state and local laws.

• Do not tow an implement that, when fully

loaded, weighs more than 1.5 times the

weight of towing vehicle.

• Carry reflectors or flags to mark tractor and

implement in case of breakdown on the

road.

• Keep clear of overhead power lines and

other obstructions when transporting. Refer

to transport dimensions under

“Specifications and Capacities,” page 67.

• Do not fold or unfold the wings while the

tractor is moving.

Avoid High Pressure Fluids

Escaping fluid under pressure can penetrate the

skin, causing serious injury.

• Avoid the hazard by relieving pressure

before disconnecting hydraulic lines.

• Use a piece of paper or cardboard, NOT

BODY PARTS, to check for suspected

leaks.

• Wear protective gloves and safety glasses

or goggles when working with hydraulic

systems.

• If an accident occurs, see a doctor immedi-

ately. Any fluid injected into the skin must be

surgically removed within a few hours or

gangrene may result.

10/28/2004 Series I UT3030-UT5052 Ultra-Till 576-026M

8/9/2007

3

Page 6

Important Safety Information Great Plains Mfg., Inc.

Practice Safe Maintenance

• Understand procedure before doing work.

Use proper tools and equipment. Refer to

this manual for additional information.

• Work in a clean, dry area.

• Lower the Series I Ultra-Till, put tractor in

park, turn off engine, and remove key before

performing maintenance.

• Make sure all moving parts have stopped

and all system pressure is relieved.

• Inspect all parts. Make sure parts are in

good condition and installed properly.

• Remove buildup of grease, oil or debris.

• Remove all tools and unused parts from

Series I Ultra-Till before operation.

Prepare for Emergencies

• Be prepared if a fire starts.

• Keep a first aid kit and fire extinguisher

handy.

• Keep emergency numbers for doctor, ambu-

lance, hospital and fire department near

phone.

Wear Protective Equipment

• Wear protective clothing and equipment.

• Wear clothing and equipment appropriate for

the job. Avoid loose-fitting clothing.

• Because prolonged exposure to loud noise

can cause hearing impairment or hearing

loss, wear suitable hearing protection such

as earmuffs or earplugs.

• Because operating equipment safely

requires your full attention, avoid wearing

radio headphones while operating

machinery.

911

Series I UT3030-UT5052 Ultra-Till 576-026M 10/28/2004

4/11/2005

4

Page 7

Great Plains Mfg., Inc. Important Safety Information

Handle Chemicals Properly

• Agricultural chemicals can be dangerous.

Improper use can seriously injure persons,

animals, plants, soil and property.

• Read and follow chemical manufacturer’s

instructions.

• Wear protective clothing.

• Handle all chemicals with care.

• Avoid inhaling smoke from any type of

chemical fire.

• Store or dispose of unused chemicals as

specified by chemical manufacturer.

Use A Safety Chain

• Use a safety chain to help control drawn

machinery should it separate from tractor

drawbar.

• Use a chain with a strength rating equal to or

greater than the gross weight of towed

machinery.

• Attach chain to tractor drawbar support or

other specified anchor location. Allow only

enough slack in chain to permit turning.

• Replace chain if any links or end fittings are

broken, stretched or damaged.

• Do not use safety chain for towing.

Tire Safety

• Tire changing can be dangerous and should

be performed by trained personnel using

correct tools and equipment.

• When inflating tires, use a clip-on chuck and

extension hose long enough to you to stand

to one side–not in front of or over tire

assembly. Use a safety cage if available.

• When removing and installing wheels, use

wheel-handling equipment adequate for

weight involved.

10/28/2004 Series I UT3030-UT5052 Ultra-Till 576-026M

5

Page 8

Important Safety Information Great Plains Mfg., Inc.

Safety Rules

• Thoroughly read and understand the

instructions in this manual before operation.

Read all instructions noted on the safety

decals.

• Be familiar with all Series I Ultra-Till

functions.

• Operate machinery from the driver’s seat

only.

• Do not leave Series I Ultra-till unattended

with tractor engine running.

• Do not transport Series I Ultra-Till

transport pins and all wing locks are

installed.

• Limit transport speed to 20 m.p.h.

• Know the transport height of your unit and be

extremely careful of overhead electrical and

telephone lines when transporting the unit.

• Know the transport width of your machine and

the width of bridges, etc… on the transport

route.

• Make sure that no one is near the machine

during field operation and folding or unfolding

of wing sections.

• Prior to removing any lift cylinders from the

machine, lower implement to the ground, shut

off the tractor and release the pressure in the

lines.

• Do not depend on cylinders to hold the weight

of machine during storage; use the transport

locks.

• Do not walk or stand on any part of the

machine. Never allow anyone to ride on the

Series I Ultra-Till.

• Use extreme care when hitching or unhitching

the machine from the tractor. In some

situations with a heavy finishing attachment,

the machine may tip backward causing the

hitch to rise rapidly.

• Never stand with feet under any part of the

machine.

until the

• Never allow anyone to walk between the

tractor and Series I Ultra-Till while machine is

in operation.

• Keep hands and feet away from turbo blades.

They are quite sharp.

• Any moving piece of equipment is potentially

dangerous. Do not operate until you are

absolutely sure the area is clear of children,

pets and irresponsible persons.

• Escaping hydraulic fluid under pressure can

have sufficient force to penetrate the skin,

causing serious injury. To prevent injury

when working with hydraulics, follow the

instructions on page 3.

• Before transporting the unit on public roads,

check to make sure the safety reflectors are

clean and visible, and not missing or

damaged. Turn on tractor warning lights

when transporting.

• Make sure all safety signs are clean, readable

and not damaged. Contact Great Plains Mfg.

for free replacements if necessary.

Series I UT3030-UT5052 Ultra-Till 576-026M 10/28/2004

4/11/2005

6

Page 9

Great Plains Mfg., Inc. Important Safety Information

Safety Decals

Your implement comes equipped with all safety

decals in place. They were designed to help you

safely operate your implement.

• Read and follow decal directions.

• Keep all safety decals clean and legible.

• Replace all damaged or missing decals. Order

new decals from your Great Plains dealer.

Refer to this section for proper placement.

• When ordering new parts or components, also

request corresponding safety decals.

• To install new decals:

1. Clean the area on which the decal is to be

placed.

2. Peel backing from decal. Press firmly on

surface, being careful not to cause air

bubbles under decal.

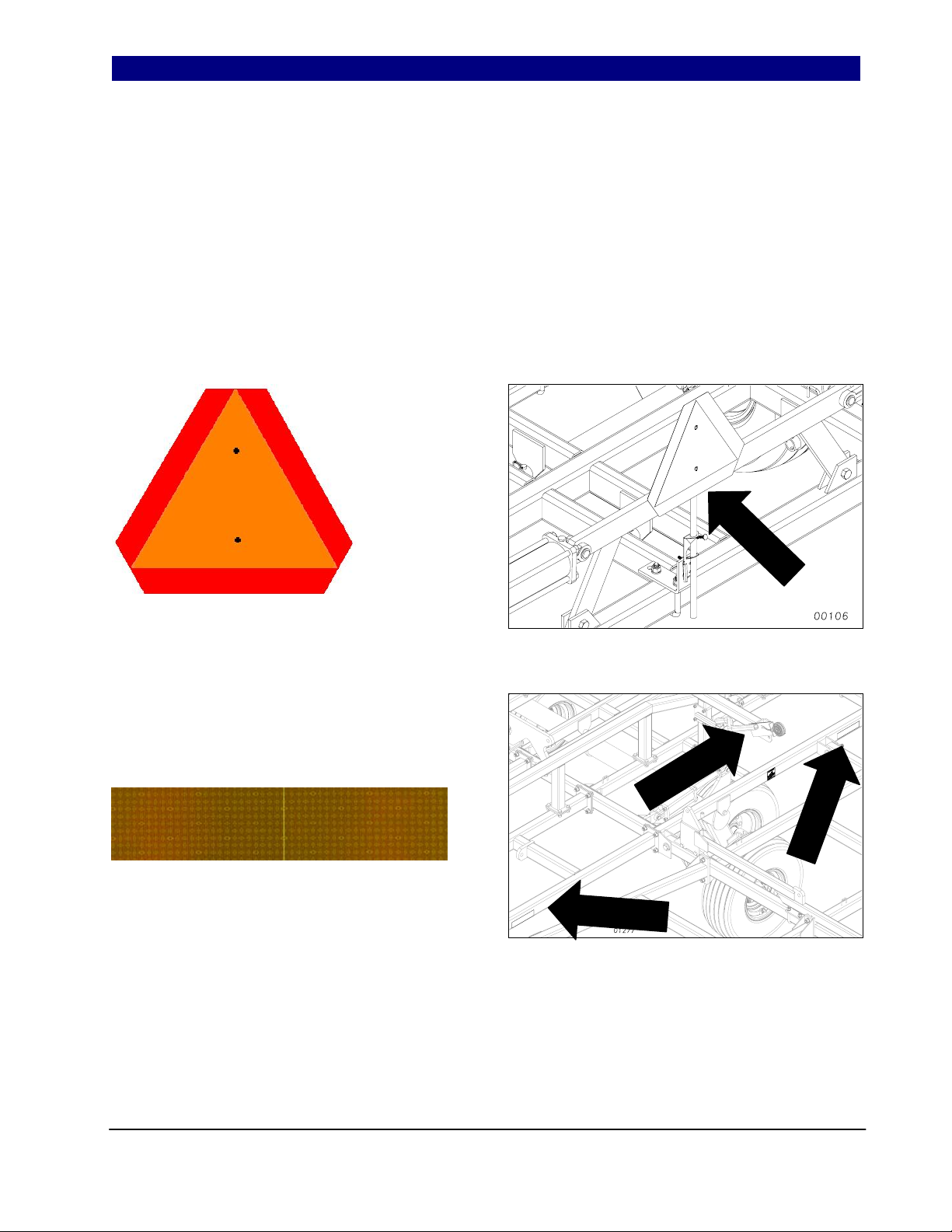

Slow Moving Vehicle Emblem

Quantity 1

Reflector – Amber

838-615C

Quantity 8: Two on light bracket, two on

center frame and two on center brace bar.

Two on rear of finishing attachment (not

shown), visible from side while folded for

transport.

2/18/2009 Series I UT3030-UT5052 Ultra-Till 576-026M

7

Page 10

Important Safety Information Great Plains Mfg., Inc.

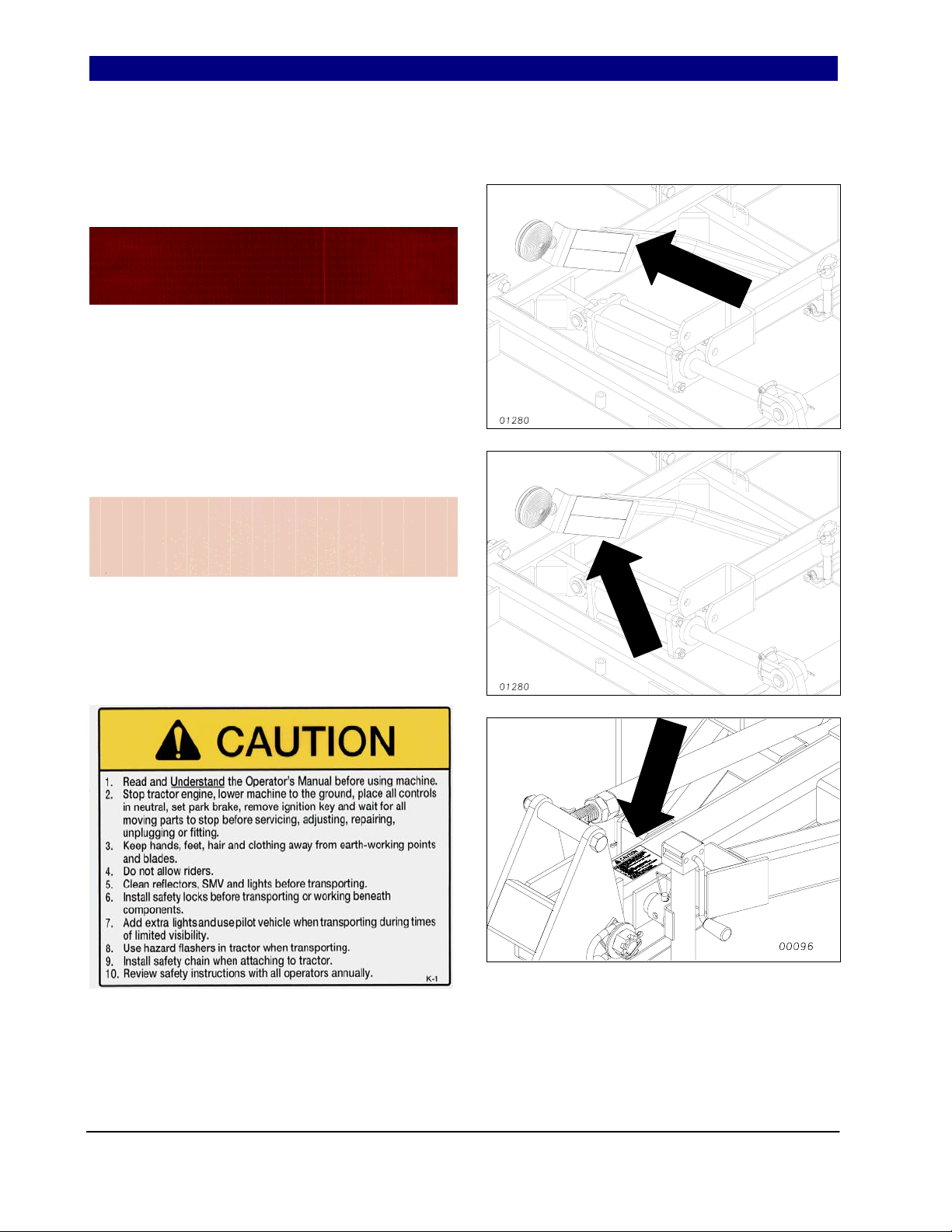

Reflector – Red

838-614C

Quantity 2:

Reflector – Florescent Orange

838-603C

Quantity 2:

Caution

838-598C

Quantity 1

Series I UT3030-UT5052 Ultra-Till 576-026M 2/18/2009

8

Page 11

Great Plains Mfg., Inc. Important Safety Information

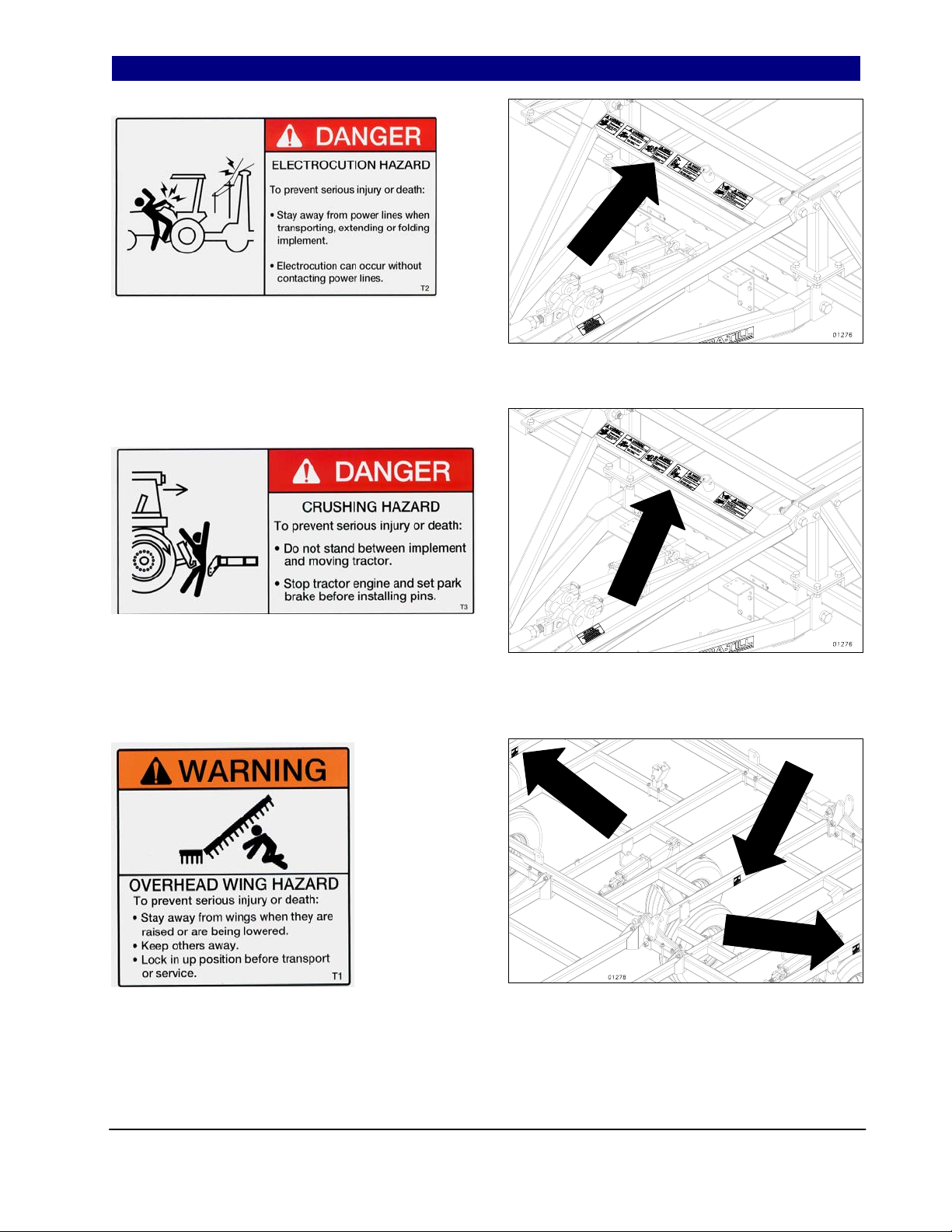

Danger Electrocution Hazard

838-599C

Quantity 1

Danger Crushing Hazard

838-600C

Quantity 1

Warning Overhead Wing Hazard

838-602C

Quantity 4: UT3030

Quantity 6: UT5036, 5042, 5048 & 5052

2/18/2009 Series I UT3030-UT5052 Ultra-Till 576-026M

9

Page 12

Important Safety Information Great Plains Mfg., Inc.

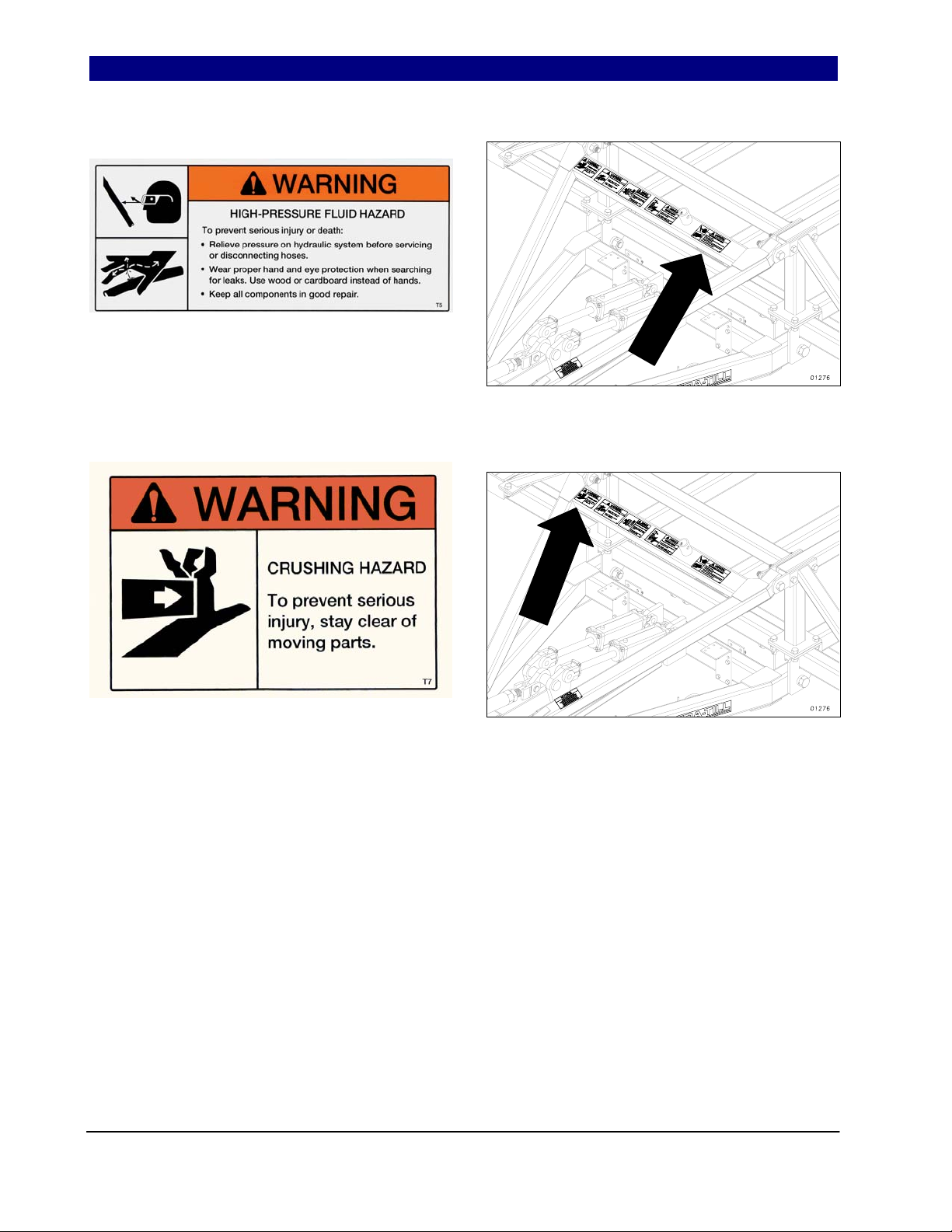

Warning High Pressure Fluid Hazard

838-094C

Quantity 1

Warning Crushing Hazard

838-611C

Quantity 1

Series I UT3030-UT5052 Ultra-Till 576-026M 2/18/2009

10

Page 13

Great Plains Mfg., Inc. Important Safety Information

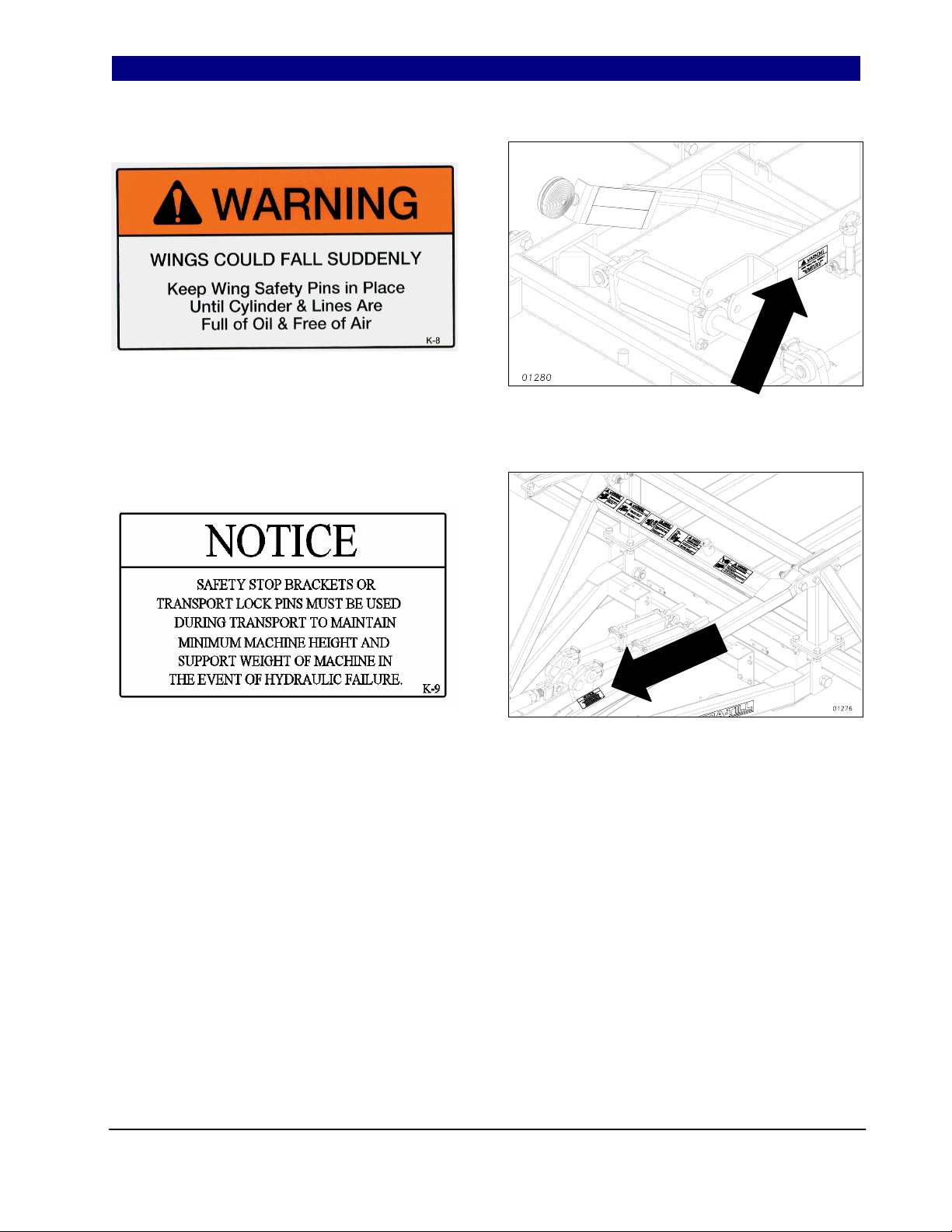

Warning Wing Falling Hazard

838-612C

Quantity 2

Notice

838-613C

Quantity 1

2/18/2009 Series I UT3030-UT5052 Ultra-Till 576-026M

11

Page 14

Introduction Great Plains Mfg., Inc.

Introduction

Great Plains welcomes you to its growing family of

new product owners. This implement has been

designed with care and built by skilled workers

using quality materials. Proper assembly,

maintenance and safe operation will help you get

years of satisfactory machine use from your

machine. To ease the assembly task and produce

a properly working machine, read this entire

manual before assembling or setting up new

equipment.

Description of Unit

The Series I 3030-5052Ultra-Till is a three or fivesection seedbed preparation tillage tool. Working

width ranges from 30 to 52 feet. The implement is

designed to combine discing/slicing, with shallow

harrowing in a vertical tillage field operation to

smooth, level and incorporate chemicals in a

single pre-plant pass.

Using This Manual

This manual will familiarize you with safety,

assembly, operation, adjustment, troubleshooting

and maintenance. Read this manual and follow

the recommendations to help ensure safe and

efficient operation.

The information in this manual is current at printing. Some parts may change to assure top

performance.

Definitions

The following terms are used throughout this

manual.

Your machine’s parts should only be replaced with

Great Plains parts. Always use the serial and

model number when ordering parts from your

Great Plains dealer. The serial-number and

patent plates are located on the center section of

the implement on the front frame tube as shown in

Figure A.

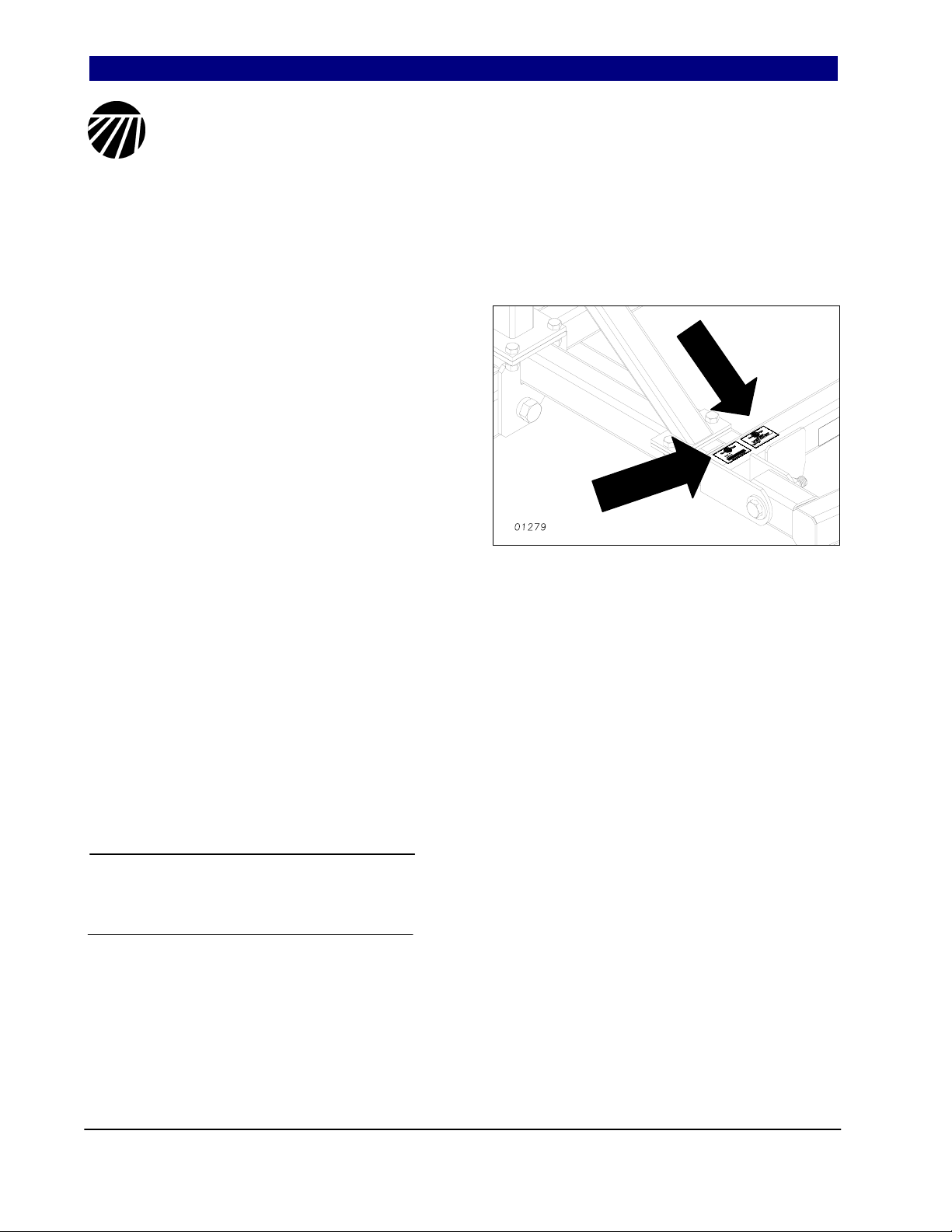

Figure A

Serial Number & Patent Plate

Record your implement model and serial numbers

here for quick reference.

Model Number: __________________________

Serial Number: ___________________________

Your Great Plains dealer wants you to be satisfied

with your new machine. If you do not understand

any part of this manual or are not satisfied with

the service received, please take the following

actions:

Right and left as used in this manual are determined by facing the direction the machine will

travel while in use unless otherwise stated.

IMPORTANT: A crucial point of information about

the preceding topic. For safe and correct operation,

read and follow the directions provided before

continuing.

NOTE: Useful information about the preceding topic.

Owner Assistance

If customer service or repairs are needed, contact

your Great Plains dealer. They have trained

personnel, parts and service equipment specially

designed for Great Plains products.

Series I UT3030-UT5052Ultra-Till 576-026M 2/18/2009

1. Discuss the matter with your dealer’s service

manager. Make sure they are aware of any

problems so they can assist you.

2. If you are still not satisfied, seek out the

dealership owner or general manager.

3. For further assistance, write to:

Product Support

Great Plains Mfg. Inc., Service Department

PO Box 5060

Salina, KS 67402-5060

gp_web_cs@greatplainsmfg.com

(800)255-9215

12

Page 15

Great Plains Mfg., Inc. Introduction

Assembly and Setup Assistance

To order additional copies of operator’s and parts

manuals, write to the following address. Include

model numbers in all correspondence.

If you do not understand any part of this manual

or have other assembly or setup questions, assistance is available. Contact

Product Support

Great Plains Mfg. Inc., Service Department

PO Box 5060

Salina, KS 67402-5660

Pre-Assembly Checklist

• Before assembling, read and understand “Im-

portant Safety Information,” beginning on

page 1.

• Have at least two people on hand while as-

sembling.

• Make sure assembly area is level and free of

obstructions (preferably an open concrete area).

• Have all major components.

• Have all fasteners and pins shipped with

Series I Ultra-Till.

• IMPORTANT: If a pre-assembled part or fas-

tener is temporarily removed, remember

where it goes. Keep the parts separated.

• Have a copy of the parts manual on hand. If

unsure of proper placement or use of any part

or fastener, refer to the parts manual.

• Check that all working parts are moving free-

ly, bolts are tight, and cotter pins are spread.

2/18/2009 Series I UT3030-UT5052Ultra-Till 576-026M

13

Page 16

Section 1: Assembly Great Plains Mfg., Inc.

Assembly

This section covers the proper assembly of the implement. The reference numbers on the

figures give you an indication of the order of assembly. For a complete breakdown of any part not

shown in this assembly section, refer to the parts manual for proper location. Refer to the Appendix

for proper bolt torque values.

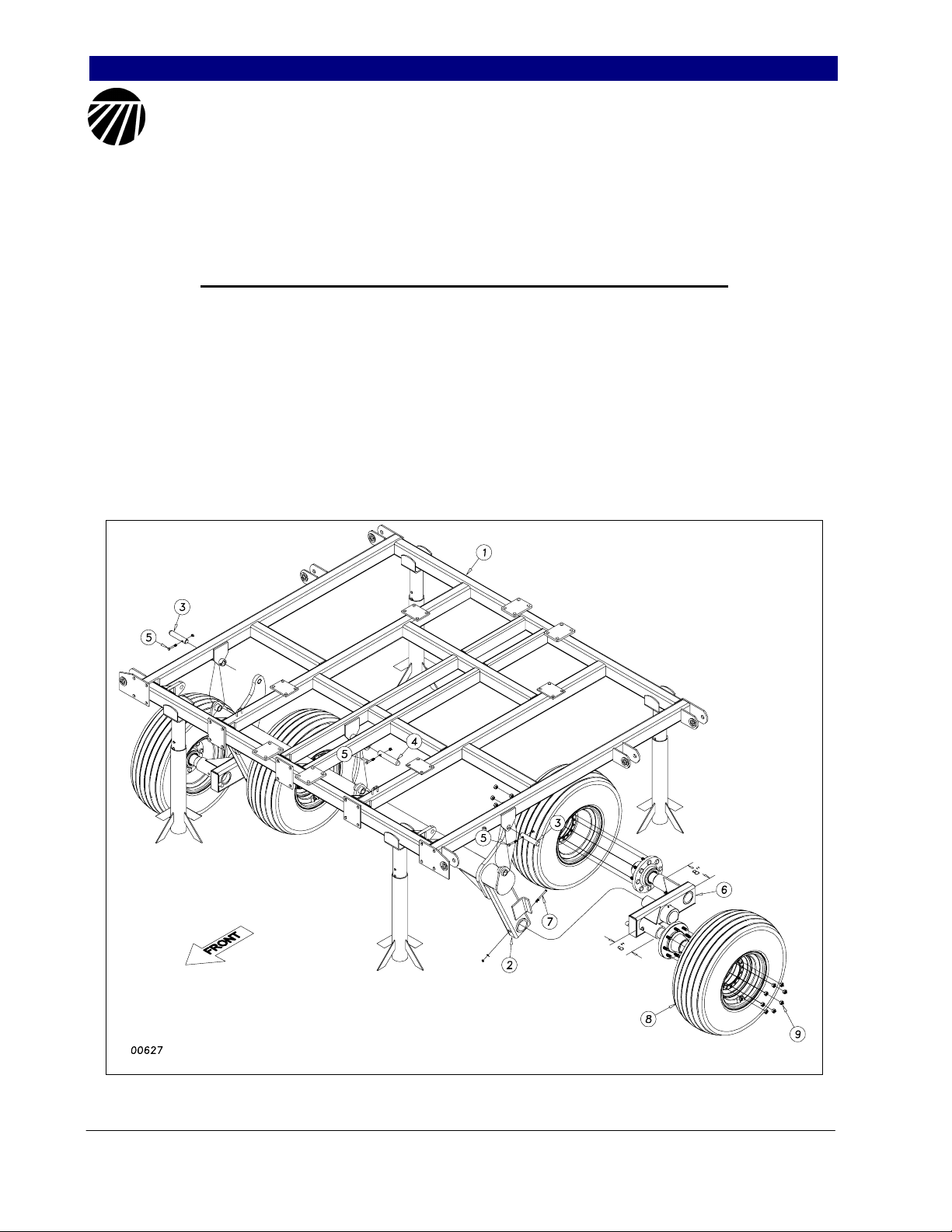

Center Frame, Torque Tube & Walking Beam Assembly

After uncrating the machine, place the

center frame (1) Figure 1, in the center of your

work area on stands. Pin the torque tube (2) to

the center frame with the 1 1/4 x 6 pins (3) and

1 1/4 x 7 pin (4) in center. Secure them with

3/8 x 2 1/4 Gr.8 hex bolts (5) & top lock nuts.

Slide the pivot spindle of the walking

beam assembly (6) into the sleeve at the end of

the torque tube wheel arm. It is a good idea to

put some form of anti-seize on the spindle

before you insert it. Line up the hole in the

spindle with the hole in the sleeve and secure

with 5/16 x 4 or 5/16 x 4 1/2 hex bolt (7) with

lock washer and hex nut.

When both walking beams have been

installed, bolt on the center transport tires (8),

using 5/8” lug nuts (9). See parts manual for

proper transport parts and sizes for your

machine model.

Figure 1

Series I UT3030-UT5052 Ultra-Till 576-026M 10/28/2004

4/11/2005

14

Page 17

Great Plains Mfg., Inc. Section 1: Assembly

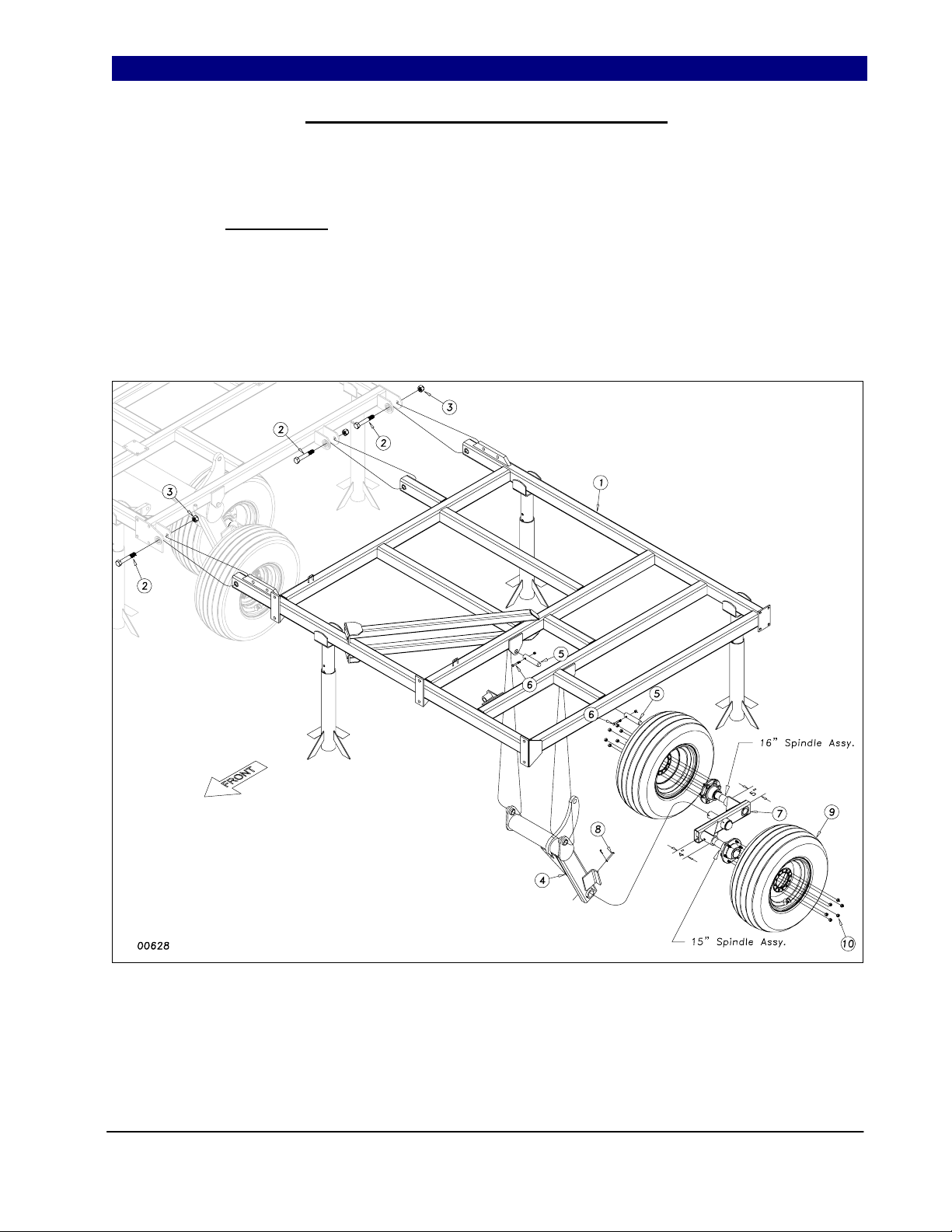

Inside Wing and Wheel Arm Assembly

Bolt the inside wing frames (1) Figure

2, to the center frame with three 1 x 6 hex bolts

(2) with nylon lock nuts (3). Draw the nuts

down tight but do not torque

Once the wings are attached, insert the

wheel arm bracket (4) into the wing frame

hangers and secure it just as you did on the

center with 1¼ x 6 pins (5). Secure the pins

with 3/8 x 2 1/4 Gr.8 hex bolts (6) & top lock

nuts.

.

(7) as shown in Figure 2 with the short 15

spindle toward the front. Use anti-seize

material on spindle. Secure the pivot spindle in

the sleeve with the 5/16 x 3 clevis pin (8) and

1/8 x 1 cotter.

with the 9/16” lug nuts (10).

Install the wing walking beam assembly

Bolt the 11L x 15, 8-ply tire (9) in place

Figure 2

10/28/2004 Series I UT3030-UT5052 Ultra-Till 576-026M

10/31/2005

15

Page 18

Section 1: Assembly Great Plains Mfg., Inc.

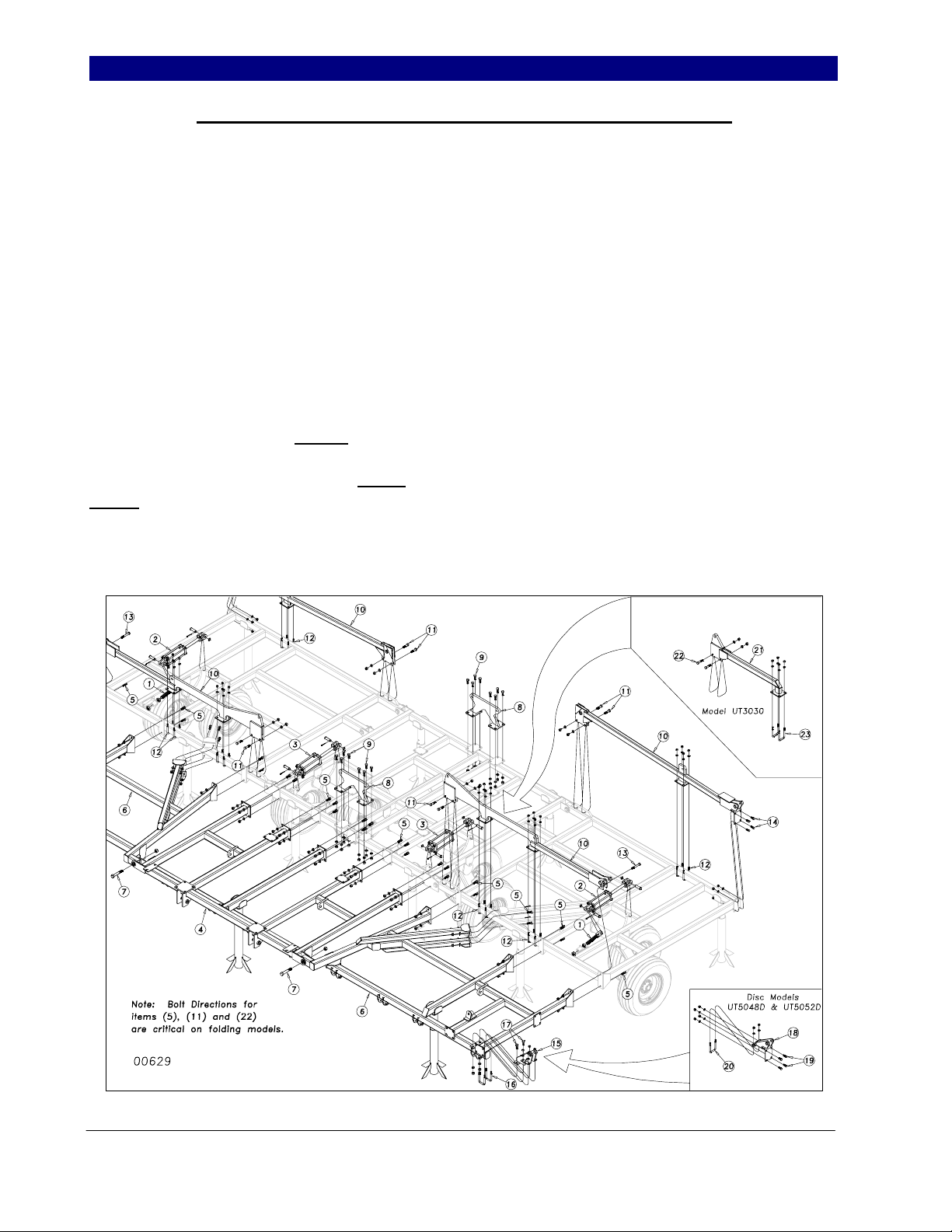

Brace Bar, Wing Brace & Rocker/Fold Bracket Assembly

Install the 1 1/4 x 9 1/2 eye bolt (1)

Figure 3, in the mounting bracket of the wing

with a 1 1/4 ” jam nut on each side of the

bracket. Install the wing lift cylinders (2)

between the eyebolt and the lever on the wheel

bracket and the master lift cylinder (3) on the

center frame (see hydraulics in parts manual for

sizes). Secure the cylinders with 1 x 3 clevis

pins, 1” machine washer and 3/16 x 2 cotter

pin.

Bolt the center brace bar (4) and wing

brace bars (6) to the front of the center frame

and wing frame with 3/4 x 2 hex bolts (5) with

lock washers and hex nuts. Do not tighten

bolts. Use a 1 x 6 hex bolt (7) and nylon lock

nut in the hinge. Draw nut tight but do not

torque. Tighten all other bolts evenly to

prevent bind at hinge.

Bolt the center fold bracket(s) (8) to the

center frame with eight 3/4 x 2 hex bolts (9)

with lock washer and hex nuts.

rocker/fold bracket(s) (10) to the wings using

two 3/4 x 3 hex bolts (11) with lock washers

and hex nuts, along with 5/8 x 3 x 5 1/2 u-bolts

(12) with lock washer and hex nuts. The front

bracket uses a 3/4 x 5 bolt (13) to attach the

outer end. The rear bracket uses four 5/8 x 1

1/2 bolts (14) with lock washers and hex nuts to

attach the outer end. On coulter models, bolt

the inside hinge (15) to the wing brace using

5/8 x 3 x 5 1/2 u-bolts (16) and 3/4 x 2 bolts

(17) with lock washers and hex nuts. On disc

models shown, bolt the inside hinge (18) using

5/8 x 1 1/2 hex bolts (19) and 5/8 x 3 x 5 1/2 ubolts (20) with lock washer and hex nuts.

to the wing with 3/4 x 3 hex bolts (22) and 5/8

x 3 x 5 1/2 u-bolts (23) with lock washers and

hex nuts.

On 5-section models, bolt the

On UT3030, attach the fold bracket (21)

Figure 3

Series I UT3030-UT5052 Ultra-Till 576-026M 10/28/2004

4/11/2005

16

Page 19

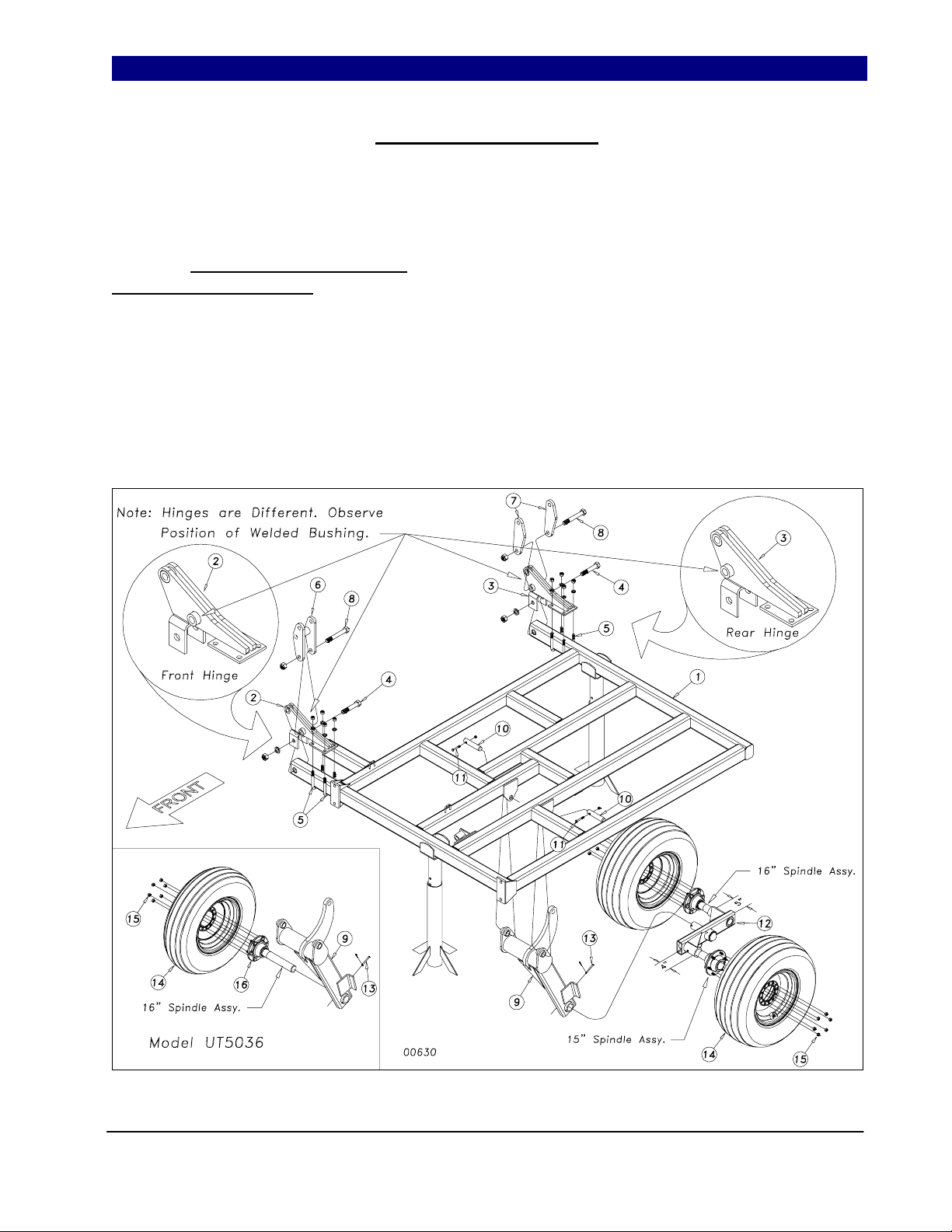

Great Plains Mfg., Inc. Section 1: Assembly

Outside Wing Assembly

On 5-section models, preassemble the

outside wing (1) by attaching the outside hinges

(2) and (3) to the wing with 1 x 6 hex bolt (4)

and 5/8 x 3 x 5 1/2 u-bolts (5) as shown in

Figure 4 (Note: hinges (2) and (3) are

different from each other). Use a nylon lock

nut on the 1 x 6 hex bolt (4) with lock washers

and hex nuts on the u-bolts (5). Attach the Fold

H-Bracket (6), bulge side in and up, to the front

hinge with the 1 x 7 Gr.8 special thread hex

bolt (8). Attach the two Rocker (7) to the rear

hinge, bulge side out and up, with the same 1 x

7 Gr.8 special thread hex bolt (8). Use 1” nylon

lock nuts on these bolts.

as we did the inside ones, using the 1 1/4 x 6

pins (10) and 3/8 x 2 1/4 Gr.8 hex bolts (11) &

lock nuts. Slide the walking beam assembly

(12) into the wheel bracket sleeve as shown in

Figure 4. Again, it is recommended to use

some form of anti-seize product on the spindle.

Secure with 5/16 x 3 clevis pin (13) and 1/8 x

1” cotter pin. Note that the shorter 15” long

spindle assembly goes to the front. Bolt on the

11L x 15 tire and wheels (14) with the 9/16”

lug nuts (15).

and a 16” Hub & Spindle assembly (16) as

shown in insert.

Attach the outside wheel bracket (9) just

Model UT5036 uses one 11L x 15 tire

Figure 4

10/28/2004 Series I UT3030-UT5052 Ultra-Till 576-026M

10/31/2005

17

Page 20

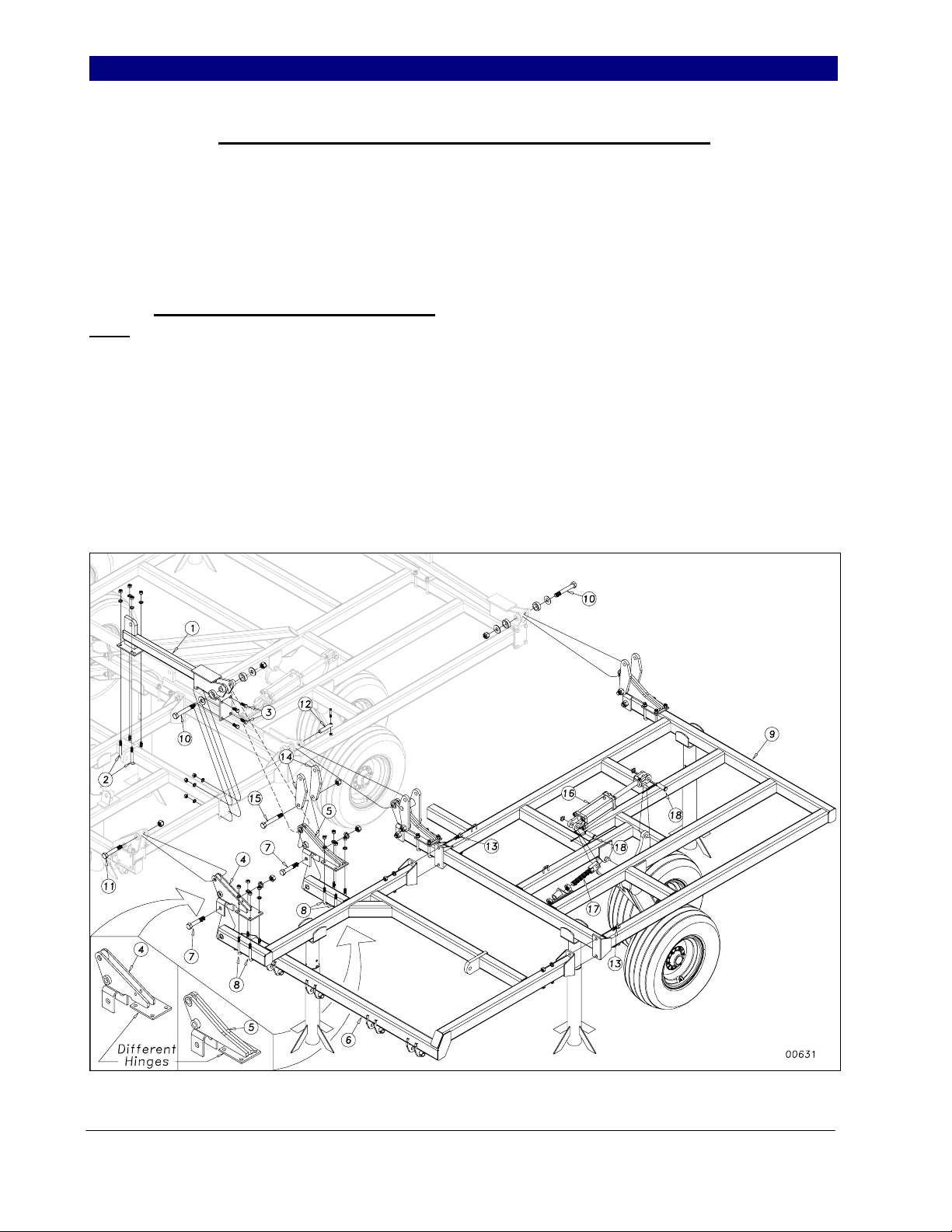

Section 1: Assembly Great Plains Mfg., Inc.

Connecting Outside Wing and Wing Brace Assembly

On models UT5042, UT5048 &

UT5052, bolt the auxiliary fold bracket (1) to

the inside wing brace with two 5/8 x 3 x 5 1/2

u-bolts (2) and four 5/8 x 1 1/2 hex bolts (3)

using lock washers and hex nuts, see Figure 5.

Bolt the outside wing fold hinges (4) and (5) as

shown, (Note: Hinges (4) and (5) are not the

same) to the outside wing brace (6) with 1 x

5½ hex bolts (7) and 5/8 x 3 x 5 1/2 u-bolts (8)

using lock washers and hex nuts.

On all 5-section models, bolt the outside

wing brace (6) to the plates on the outside wing

(9) with 3/4 x 2 hex bolts (13), with lock

washers and hex nuts. Bolt and pin the outside

wing assembly to the inside wing frame with 1

x 7 GR 8 hex bolts (10), with rollers and flat

washers and 1 x 6 Gr.8 hex bolt (11) and 1 x 5

hardened pin (12). Securing bolts with 1” nylon

lock nuts and the 1 x 5 pin (12) with 3/8 x 2 1/4

GR 8 hex bolt and lock nut.

On models UT5042, UT5048 &

UT5052, bolt the two rockers (14) (as shown)

to the wing fold hinge (5) with 1 x 7 Gr.8

special thread hex bolt (15). Secure with Nylon

lock nut.

Attach the outside rephasing lift

cylinder (16) (See hydraulics in parts manual

for proper cylinder sizes) between the lever on

the wheel bracket and the 1 1/4 x 9 1/2 eye bolt

(17) in the wing bracket. Use 1 x 3½ clevis

pins (18) with 1” machine washer and 3/16 x 2

cotter pins and 1 1/4 ” jam nuts on the eye-bolt.

Figure 5

Series I UT3030-UT5052 Ultra-Till 576-026M 10/28/2004

4/11/2005

18

Page 21

Great Plains Mfg., Inc. Section 1: Assembly

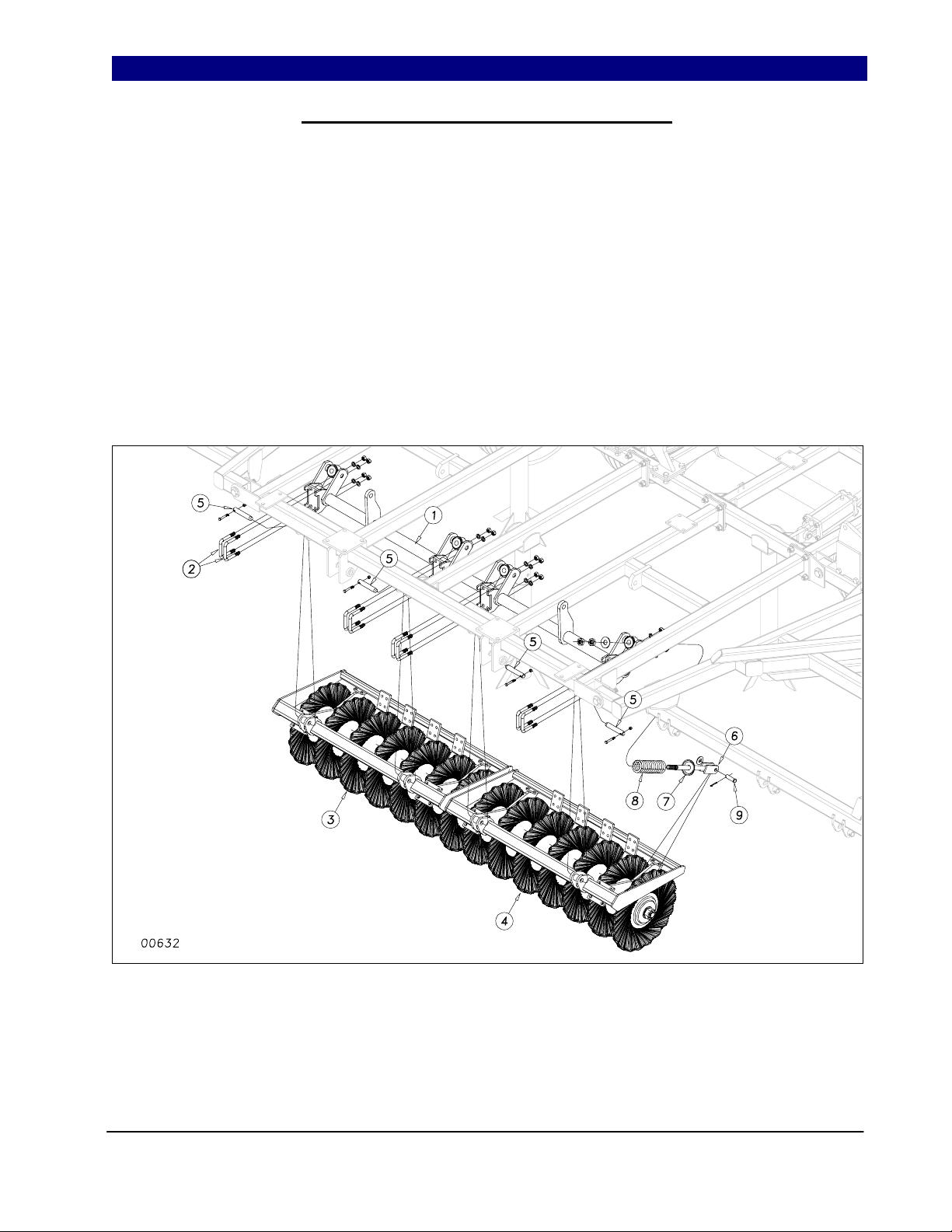

Center Gang & Gang Hanger Assembly

At this time it is best to hang the center

gangs and center gang hanger tubes before you

install the hitch and hitch strut assembly.

U-bolt the center gang hanger tube(s)

(1) to the center brace bar with 5/8 x 4 x 4 1/4

u-bolts (2), with lock washers and hex nuts, See

Figure 6. Line up the levers on the hanger tubes

with the ratchet jack/cylinder mounts on the

brace bar. Pin the preassembled center gangs

(3) & (4) to the center frame with the 1 x 5 1/2

pins (5) see Section 3 Machine Layout for

proper gang sizes. Secure with 3/8 x 2 1/4 GR 8

hex bolts and lock nuts. Slide the spring

washer (7) & spring (8) on to the gang spring

bolt (6) as shown and slide it up into the cast

swivel on the gang hanger tubes. Place a 1”

flat washer on the spring bolt and thread the 1”

hex nut and 1” jam nut onto the spring bolt (6).

Pin the other end to the gang with 3/4 x 2 1/2

clevis pins (9), secure with 1/8 x 1 1/2 cotters.

Finally tighten down the nuts on the spring bolt

until the spring has a preload length of 8 3/4”.

Figure 6

10/28/2004 Series I UT3030-UT5052 Ultra-Till 576-026M

4/11/2005

19

Page 22

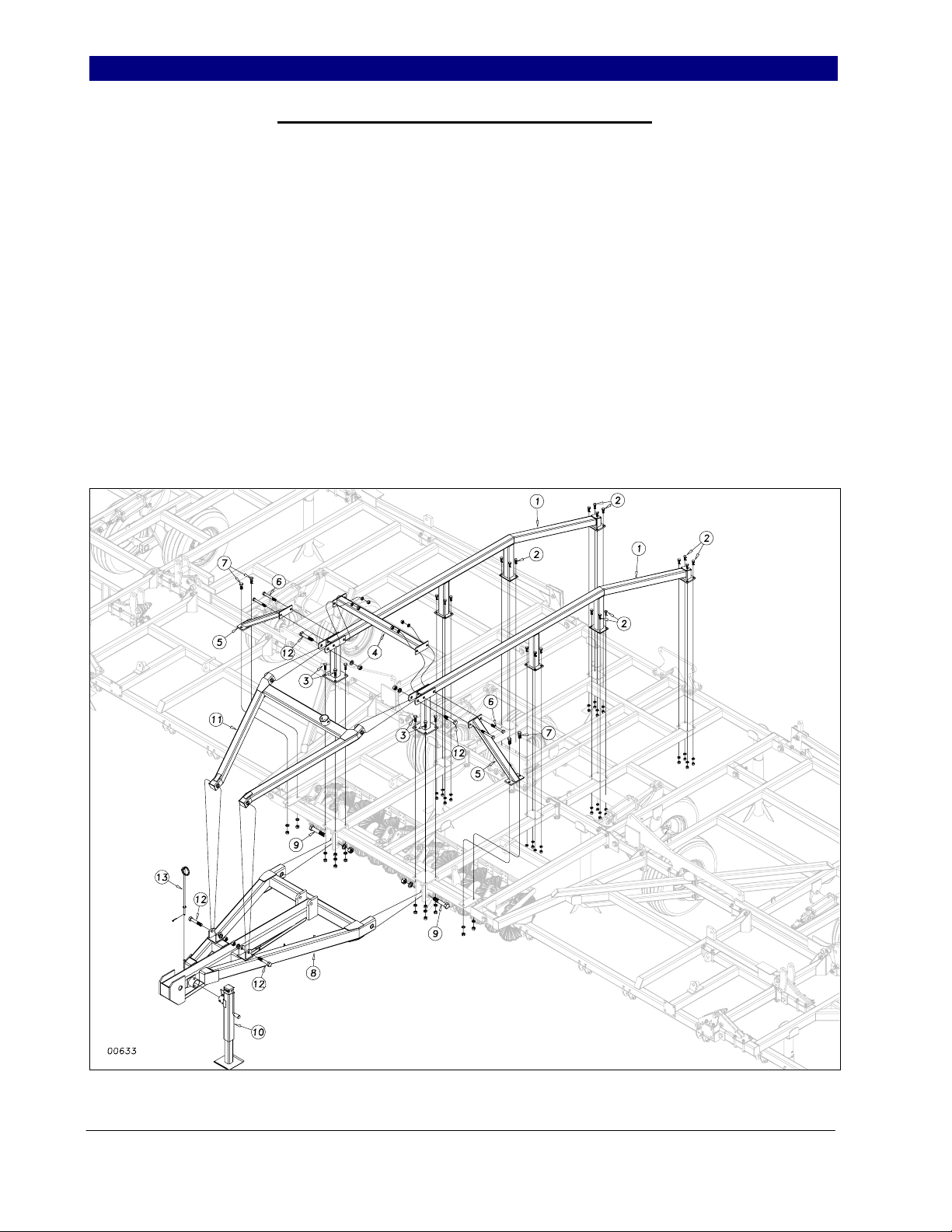

Section 1: Assembly Great Plains Mfg., Inc.

Center Truss, Hitch and Strut Assembly

Bolt the center frame truss (1) Figure 7,

to the top side of the center frame and brace

bar. Use 3/4 x 2 bolts (3) on the front plates

and 5/8 x 1 1/2 bolts (2) on the rear two plates.

Use lock washers and hex nuts on all of these

bolts. On 5-section models, bolt the truss cross

bar (4) with the truss legs (5) through the truss

frame (1) with the 3/4 x 6 bolt (6), lock washers

and hex nuts. Use two 3/4 x 2 hex bolts (7)

with lock washers and hex nuts, at the base of

the truss legs.

Slide the back of the hitch (8) between

the plates at the front of the brace bar as shown.

Use two 1 1/4 x 7 Gr. 8 bolts (9) and 1 1/4 lock

washers and hex nuts to secure the hitch.

Mount the tongue jack (10) to the front of the

hitch to support it.

Use 1 x 5 1/2 bolts (12) to attach the

hitch strut (11) between the front of the truss

and the hitch. Use lock washers and hex nuts

on these bolts.

Slide the hose support (13) rod into the

tube at the front of the hitch and secure it with a

1/8 x 1 1/2 cotter pin. For hydraulic valve

mounting bracket placement, see hydraulics in

parts manual, for bolts and hardware.

Figure 7

Series I UT3030-UT5052 Ultra-Till 576-026M 10/28/2004

4/11/2005

20

Page 23

Great Plains Mfg., Inc. Section 1: Assembly

Self Level and Rest Pads Assembly

Slide the H-bracket (1) down over the

hitch pole as shown in Figure 8. Bolt in place

with a 3/4 x 8 bolt (2) and 3/4” lock nut. Draw

this nut up but do not torque

pivot. Pin the self leveling rephasing cylinders

(3) to the hitch and H-bracket (1) with 1” x 3

1/2” clevis pins (4), machine washers and 3/16

x 2 cotter pins (see Hydraulics in parts manual

for proper size of cylinders).

Slide the side plate weldment (5) over

the end of the hitch and bolt in place as shown

with the 1 1/2 x 12 safety chain hitch bolt (6).

Secure with 1½ slotted hex nut and 1/4 x 3

cotter pin. Use the 1½ machine washers as

needed for proper fit. Connect the turnbuckle

(7) between the side plate assembly (5) and the

H-bracket (1). Use a 1 x 3 3/8 usable clevis pin

(8) with machine washer and 3/16 x 2 cotter pin

, as this part must

at the back end of turnbuckle. Use a 1 x 9 Gr.8

bolt (9) with a nylon lock nut at the tee end of

the turnbuckle. Snug, but do not torque

lock nut.

Insert the hitch clevis (10) into the front

of the side plate weldment (5) and bolt in place

with a 1 1/2 x 9 3/8 hitch bolt (11). Secure

with slotted hex nut, machine washers and 1/4

x 3 cotter pin, using the 1½ machine washers

again as needed for proper fit.

Install the turnbuckle wrench (12) on

the storage pins of the hitch weldment.

On 5-section models, u-bolt the cylinder

rest pads (13) to the back bar of the center

frame using a 1/2 x 3 x 5 u-bolt (14) with lock

washers and hex nuts. Place the edge of the

rest pads (13) 29 5/8” out from the hole in the

fold bracket as shown.

nylon

Figure 8

10/28/2004 Series I UT3030-UT5052 Ultra-Till 576-026M

21

Page 24

Section 1: Assembly Great Plains Mfg., Inc.

Fold Cylinders, Rocker Arm and 3” Rollers Assembly

Connect the base end of all the fold

cylinders (1) to their respective fold brackets

as shown in Figure 9 with 1” x 3 1/2 clevis

pins (2) with 1” machine washer and 3/16 x 2

cotter pins (See Hydraulics in parts manual

for cylinder sizes and placement). Do Not

Connect Rod End Of Cylinders Before They

Are Charged With Oil. Support the cylinders

with 2 x 4 blocks of wood so the cylinders

rods will clear the machine when they are fully

extended.

On 5-section models, bolt the hose

holders (3) to the center frame with a 1/2 x 4

1/2 hex bolts (4), using lock washers and hex

nuts.

You are now ready to connect the

hydraulic hoses to the cylinders and charge the

fold system (see Hydraulics parts manual for

hydraulic fold layout).

After plumbing the hoses and fittings,

repeatedly extend and retract the fold cylinders

until all the air is purged from the system.

Once the fold cylinders are fully

charged with oil and free of air, connect the

inside cylinders to the rockers and fold

brackets with 1” x 3 1/2 clevis pin (5) with 1”

machine washer and 3/16 x 2 cotter pins. On

5-section machines, connect the outside

cylinder rod ends using 1 x 7 Gr.8 special

thread hex bolts (6) to the outside wing rockers

and H-brackets. Use 1” flat washers and fold

rollers (7) as shown in Figure 9. Secure with

1” nylon lock nuts. Rollers must turn freely!

Figure 9

Series I UT3030-UT5052 Ultra-Till 576-026M 10/28/2004

22

Page 25

Great Plains Mfg., Inc. Section 1: Assembly

Center Wing Stop and Outside Wing Stop Assembly

U-bolt the center wing stop (1) to the

second bar from the rear on the center frame as

shown in Figure 10. Use 5/8 x 3 x 5 1/2 ubolts (2) with lock washers and hex nuts.

Center the wing stop from side to side. Insert

the 3/4 x 5 1/4 usable transport lock pins (3) in

the holders on the wing stop.

On models UT5048 & UT5052, u-bolt

the front and rear center wing stops (4 & 5) to

the center frame using 5/8 x 3 x 4 1/2 u-bolts

(6) and 5/8 x 3 x 6 1/2 u-bolts (7) with lock

washers and hex nuts.

On 5-section models, u-bolt the wing

lock mount (8) on the inside wing with 1/2 x 3

x 5 u-bolts (9). Bolt the wing latch (10) to the

wing lock mount (8) with a 3/4 x 4 1/2 bolt

(11). Slide a 3/4 flat washer (12) between the

latch and the mount on each side to take out

the slop. Use a 3/4” lock nut on the bolt but do

not torque down. The latch must move freely.

U-bolt the wing lock “T” bracket (13)

on the outside wing two 5/8 x 4 x 4 1/4 u-bolts

(14). On model UT5052, u-bolt the wing lock

“T” bracket (15) to the outside wing frame

with two 1/2 x 3 x 5 u-bolts (16). Refer to

Section 4 Machine Layout for the exact

location of the wing lock mount and lock “T”

bracket. Use lock washers and hex nuts on

these u-bolts.

On models UT5048 & UT5052, bolt

the wing rest (17) to the rocker/fold bracket, as

shown, with four 1/2 x 1 1/2 hex bolts (18)

using lock washers and hex nuts.

Figure 10

10/28/2004 Series I UT3030-UT5052 Ultra-Till 576-026M

11/22/2004

23

Page 26

Section 1: Assembly Great Plains Mfg., Inc.

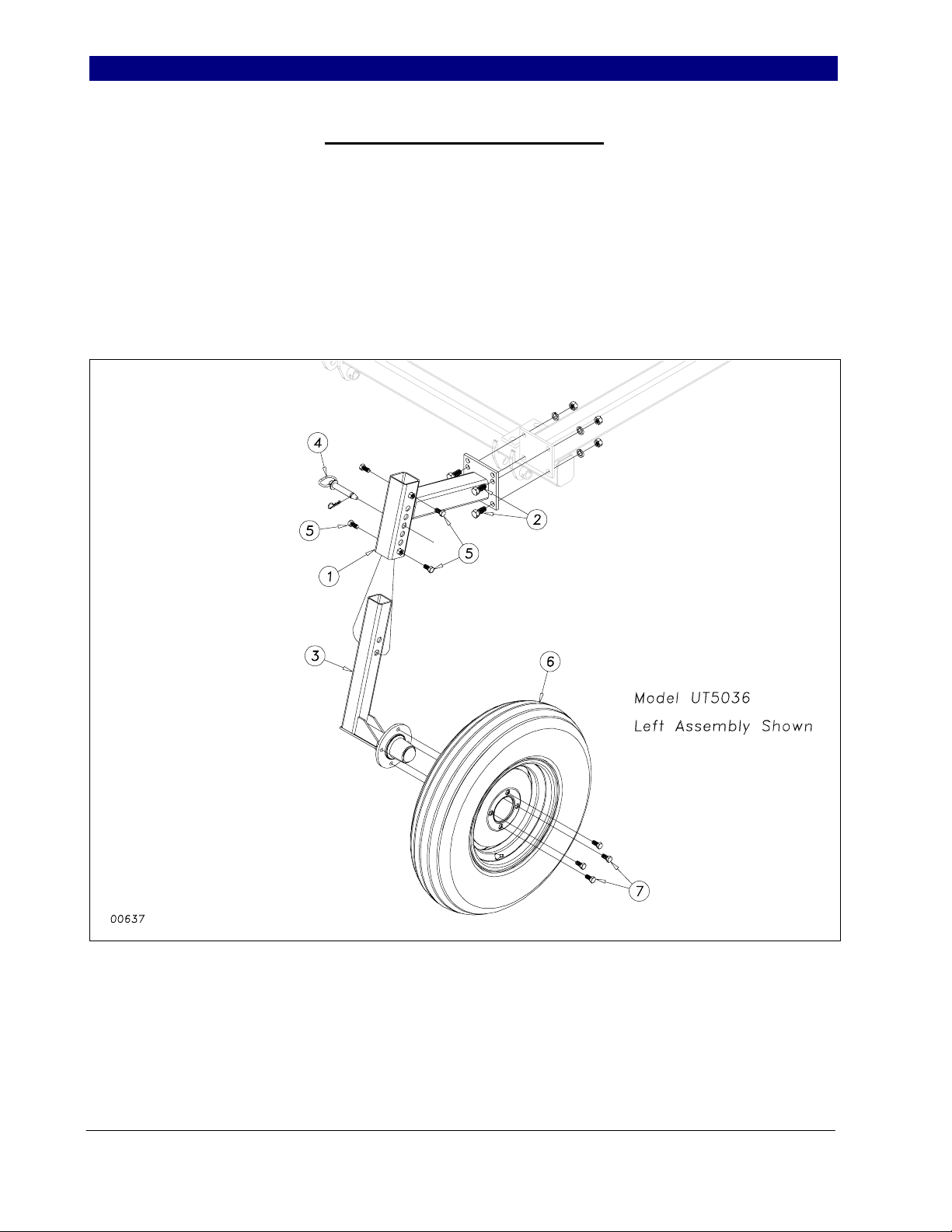

Front Gauge Wheel Assembly

On model UT5036, bolt the gauge

wheel bracket (1) to the front plate of wing

brace as shown in Figure 11 using the 5/8 x 1

1/2 hex bolts (2), lock washers and hex nuts.

Slide the gauge wheel arm/hub assembly (3)

up into the gauge wheel bracket (1) and pin

with the 3/4 x 4 3/8 usable pin (4). Use four

1/2 x 1 1/4 hex bolts (5) to secure the arm and

make it rigid. Bolt on the 4-bolt rim and tire

(6) with four 1/2 x 1 lug bolts (7). For

directions on the proper setting for the gauge

wheel during operation, refer to Section 4

Operating and Maintenance.

Figure 11

Series I UT3030-UT5052 Ultra-Till 576-026M 10/28/2004

10/31/2005

24

Page 27

Great Plains Mfg., Inc. Section 1: Assembly

Hydraulic Gauge Wheel Assembly

On models UT5042, UT5048 &

UT5052, bolt the gauge wheel arm mount

clevis (1) to the front bar of wing brace as

shown in Figure 12 using the 5/8 x 1 1/2 hex

bolts (2), lock washers and hex nuts. Insert the

linkage arms (3) and (4) into the arm clevis

(1). Assemble with 1 x 6 hex bolt (5) and

nylon lock nut. Do not torque down. Insert

the clamp bushings (6) into the front of the

linkage arms (3) and (4). Bolt the pivot bracket

(7) to the arms as shown with 3/4 x 4 1/2 hex

bolt (8) using lock washer and hex nuts. Insert

the appropriate left or right gauge wheel arm

(9) into the pivot bracket (7) and install the

friction cap (10), spring (11), spring cover

(12), 3/4” hex nut (13) and 3/4” jam nut (14)

to secure the assembly. Insert the hub and

spindle assembly (15) into the gauge wheel

arm (9), using anti-seize material on the

spindle. Secure with 5/16 x 3 clevis pin (16)

and 1/8 x 1 cotter. Bolt on the rim and tire

assembly (17) with six 1/2 x 1 1/4 lug bolts

(18). Install the gauge wheel hydraulic

cylinders (or ratchet jacks) as per hydraulic

layout for your machine, Section 2. Use 1 x 8

1/2 eye-bolts with 1” jam nuts at the base of

the cylinders. For directions on the proper

setting for the hydraulic gauge wheel during

operation, refer to Section 4 Operating and

Maintenance.

Figure 12

10/28/2004 Series I UT3030-UT5052 Ultra-Till 576-026M

4/5/2007

25

Page 28

Section 1: Assembly Great Plains Mfg., Inc.

Completing Setup

Install the plastic end caps into the

open ends of all the 4x3 frame tubes.

Finish plumbing the Ultra-till hydraulic

lift and gang systems from the layouts in

Hydraulics in parts manual. Cycle the

hydraulic systems to purge the cylinders of air

while checking for leaks.

You should now be ready to add the

harrow modules and the remaining gangs to

the machine. If the machine has a finishing

attachment you would install it last. See the

machine layout section 4 for proper module

dimensions and gang sizes for your unit.

The parts manual shows the harrow

module assembly with parts along with gang

parts and identification drawings.

Once the harrow modules and gangs

are installed and all of the hydraulic

procedures have been completed, you may fold

the machine to check for clearance and proper

module placement. Slowly fold the machine

while watching that hoses do not become

pinched or kinked and watch that modules

clear all obstructions.

Once the machine is folded completely,

begin to unfold slowly. Be Sure No One Is

Under The Wings When You Unfold The

Machine. Once the machine is unfolded, add

the safety decals and the product decals. Refer

to the Important Safety Information section

(page 7) for the proper placement of safety

decals.

Install the safety chain, SMV sign &

safety lights in accordance with local and state

laws. See parts manual (Frame section) for

assembly drawings and parts list.

At this point, set up of the machine is

complete and you are ready to add any

finishing attachment, rear hitches, etc… to the

machine. Be sure to consult the operating

instructions, Section 4, for the first time field

adjustments before going to the field for the

first time.

Series I UT3030-UT5052 Ultra-Till 576-026M 10/28/2004

4/11/2005

26

Page 29

Great Plains Mfg., Inc. Section 1: Assembly

This page intentionally left blank.

10/28/2004 Series I UT3030-UT5052 Ultra-Till 576-026M

27

Page 30

Section 2: Hydraulics Great Plains Mfg., Inc.

3030 Ultra-Till Hydraulic Down Pressure Preparation and Setup

Note: This setup procedure is for tractors with closed-center or pressure

compensated flow hydraulic systems. Open center hydraulics not supported.

1. Adjust the bypass/pressure reducing

valve by turning knob (1), Figure 1,

clockwise all the way in and then backing

out 1 full turn.

2. On tractor, adjust flow-control valve to low

side of flow rate. NOTE

flow of oil through the system the greater

potential for oil heating, premature wear

or tractor damage.

3. Lock the fold hydraulic lever for

continuous downward oil flow.

4. Adjust bypass/pressure reducing valve

knob (2) on implement so the pressure

gauge reads 1,400 psi. Never exceed

1,600 psi.

5. While watching pressure gauge, slowly open

valve knob (1) until gauge reads 1,300 psi.

Pressure might rise and then fall off as knob

is opened. If pressure exceeds 1,600 psi

: The faster the

during this step, the tractor flow is too high,

reduce tractor flow. Lock valve knob (1) at

1,300 psi.

6. Finally adjust valve (2) to the desired wing

down pressure setting of 400 to 800 psi.

Never exceed 1,000 psi.

7. In field operation, Lock the fold

hydraulic lever for continuous

downward oil flow. If wings are

running too high, increase pressure

setting, knob (2), to level machine. If

center is too high, decrease pressure

setting with knob (2) on valve.

Caution: Never leave tractor valve

8.

centered when unfolded with

!

machine in motion. Machine

damage may occur when wings flex

up or down (see page 91).

Figure 1

Series I UT3030-UT5052 Ultra-Till 576-026M 3/5/2008

28

Page 31

Great Plains Mfg., Inc. Section 2: Hydraulics

5-Section Ultra-Till Hydraulic Down Pressure Preparation and Setup

Note: This setup procedure is for tractors with closed-center or pressure

compensated flow hydraulic systems. Open center hydraulics not supported.

1. Adjust the bypass valve by turning knob

(1), Figure 2, clockwise all the way in and

then backing out 1 full turn.

2. On tractor, adjust flow-control valve to low

side of flow rate. NOTE

flow of oil through the system the greater

potential for oil heating, premature wear

or tractor damage.

3. Lock the fold hydraulic lever for

continuous downward oil flow.

4. Adjust pressure reducing valves knob (2

& 3) on implement so the pressure

gauges reads 1200 psi each. Never

exceed 1400 psi.

5. While watching pressure gauges, slowly

open bypass valve, knob (1) until gauges

reads around 1100 psi. Pressure might rise

and then fall off as knob is opened. If

pressure exceeds 1400 psi during this step,

: The faster the

the tractor flow is too high, reduce tractor

flow. Lock bypass valve knob (1) at 1100 psi.

6. Finally adjust valve knobs (2 & 3) to the

desired wing down pressure setting of 400 to

700 psi. Never exceed 900 psi.

7. In field operation, Lock the fold

hydraulic lever for continuous

downward oil flow. If wings are

running too high, increase pressure

setting to the appropriate valve, knob

(2 or 3), to level machine. If center is

too high, decrease pressure setting

with knob (2) on Inside wing valve.

Caution: Never leave tractor valve

8.

centered when unfolded with

!

machine in motion. Machine

damage may occur when wings flex

up or down (see page 91).

Figure 2

3/5/2008 Series I UT3030-UT5052 Ultra-Till 576-026M

29

Page 32

Section 3: Layouts Great Plains Mfg., Inc.

UT3030D Machine Layout, Disc

00543

Series I UT3030-UT5052 Ultra-Till 576-026M 3/5/2008

30

Page 33

Great Plains Mfg., Inc. Section 3: Layouts s

UT3030D Machine Layout, Disc

00544

3/5/2008 Series I UT3030-UT5052 Ultra-Till 576-026M

31

Page 34

Section 3: Layouts Great Plains Mfg., Inc.

UT5036D Machine Layout, Disc

00545

Series I UT3030-UT5052 Ultra-Till 576-026M 3/5/2008

32

Page 35

Great Plains Mfg., Inc. Section 3: Layouts s

UT5036D Machine Layout, Disc

00546

3/5/2008 Series I UT3030-UT5052 Ultra-Till 576-026M

33

Page 36

Section 3: Layouts Great Plains Mfg., Inc.

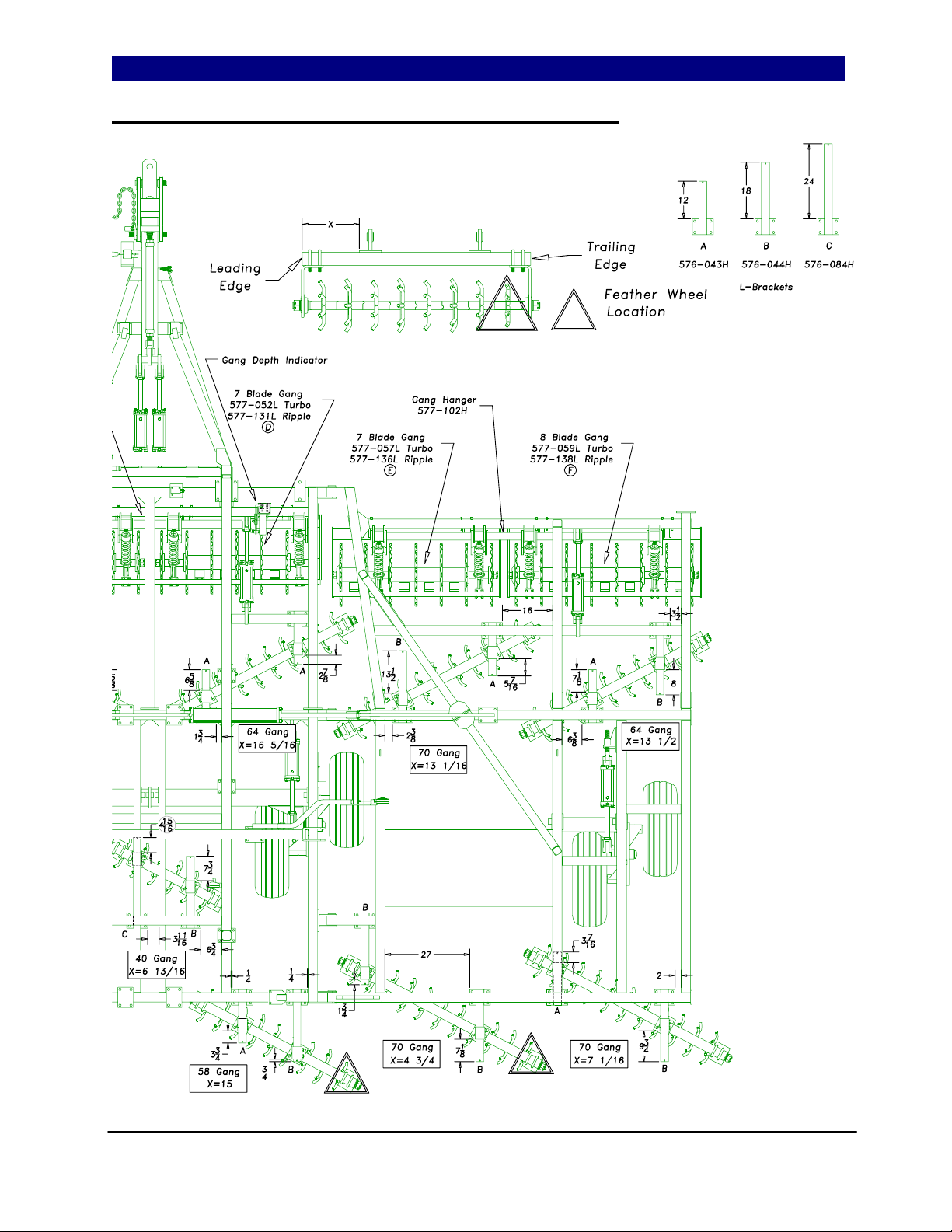

UT5042D Machine Layout, Disc

00547

Series I UT3030-UT5052 Ultra-Till 576-026M 3/5/2008

34

Page 37

Great Plains Mfg., Inc. Section 3: Layouts s

UT5042D Machine Layout, Disc

00548

3/5/2008 Series I UT3030-UT5052 Ultra-Till 576-026M

35

Page 38

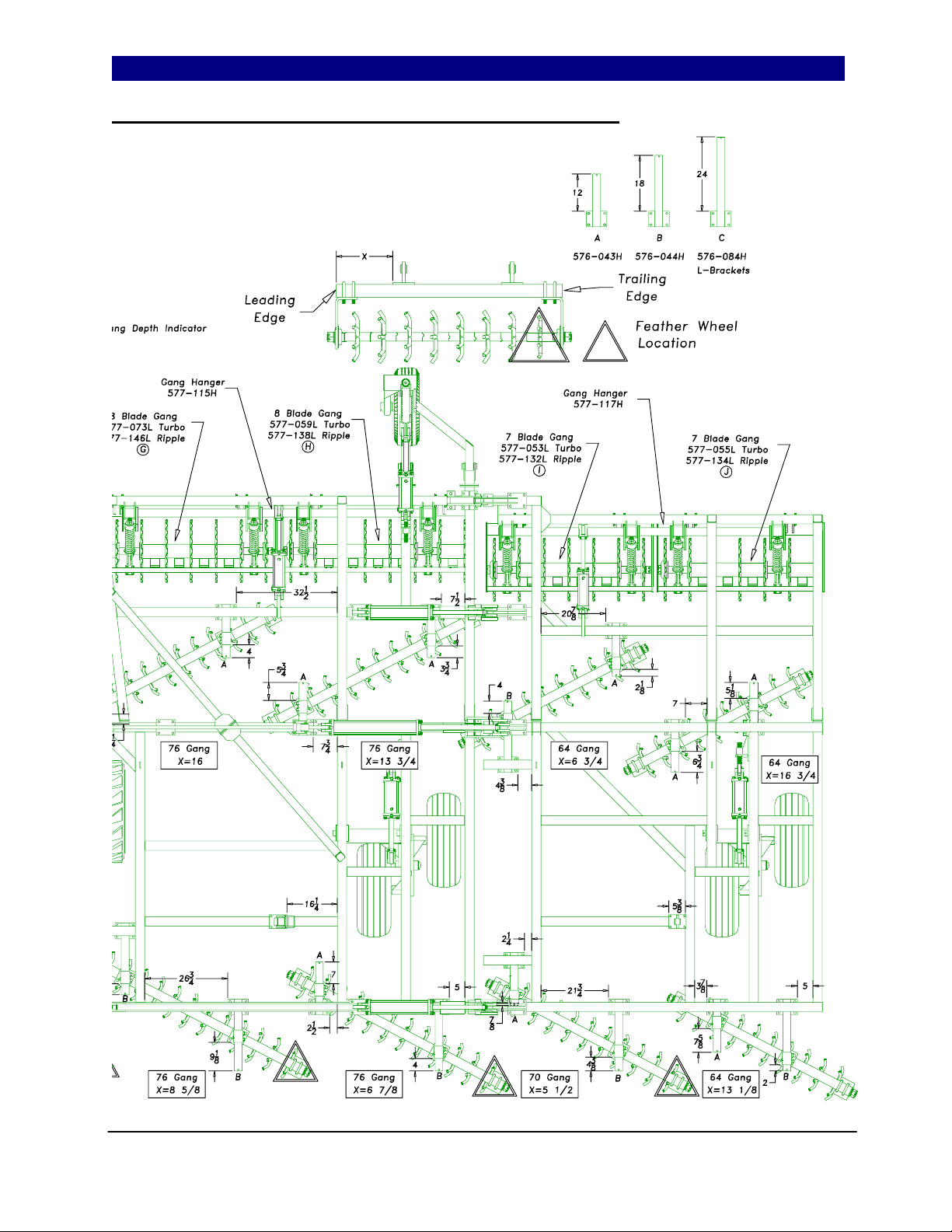

Section 3: Layouts Great Plains Mfg., Inc.

UT5042D Machine Layout, Disc

00549

Series I UT3030-UT5052 Ultra-Till 576-026M 3/5/2008

36

Page 39

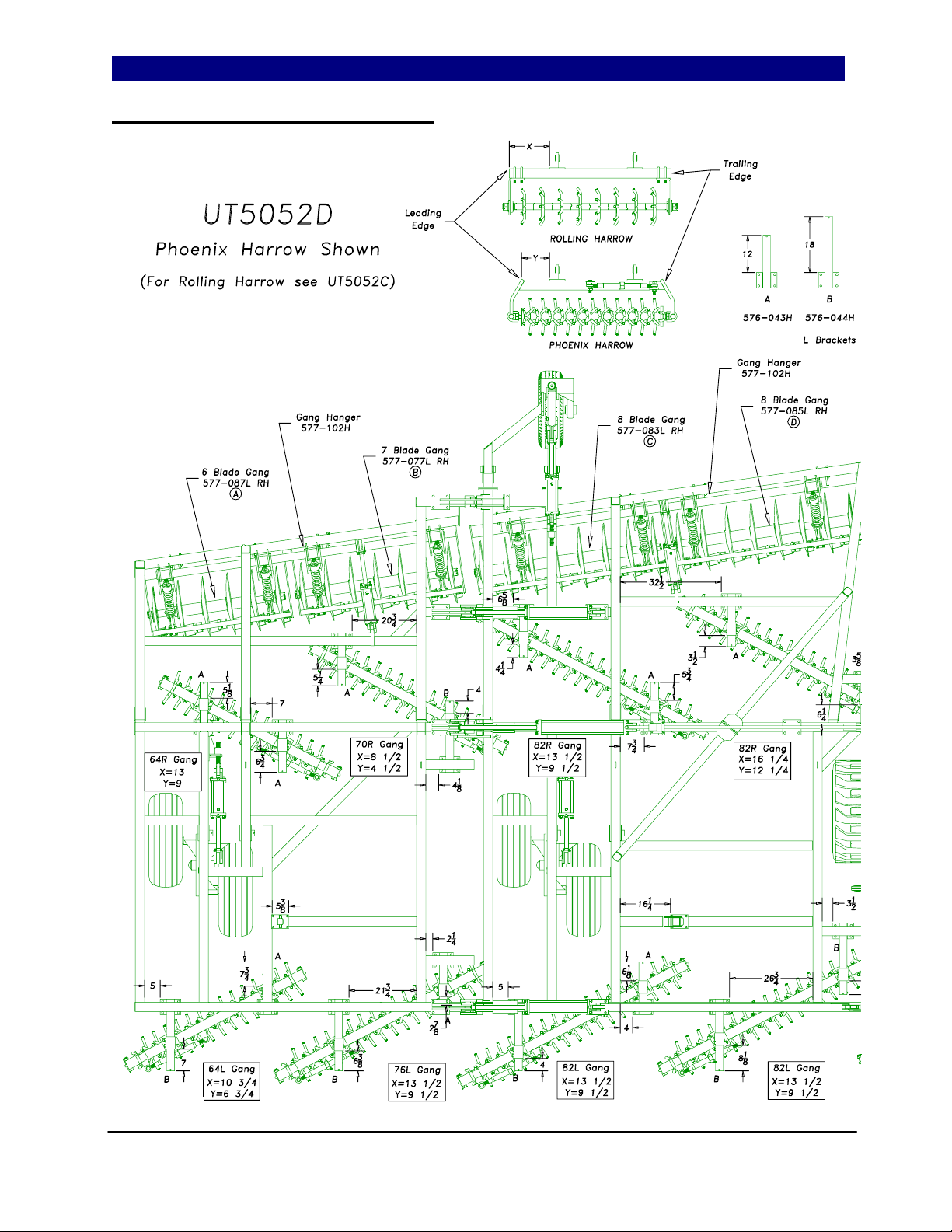

Great Plains Mfg., Inc. Section 3: Layouts s

UT5052D Machine Layout, Disc

00553

3/5/2008 Series I UT3030-UT5052 Ultra-Till 576-026M

37

Page 40

Section 3: Layouts Great Plains Mfg., Inc.

UT5052D Machine Layout, Disc

00554

Series I UT3030-UT5052 Ultra-Till 576-026M 3/5/2008

38

Page 41

Great Plains Mfg., Inc. Section 3: Layouts s

UT5052D Machine Layout, Disc

00555

3/5/2008 Series I UT3030-UT5052 Ultra-Till 576-026M

39

Page 42

Section 3: Layouts Great Plains Mfg., Inc.

UT3030C Machine Layout, Coulter (S/N A1095A-)

00556

Series I UT3030-UT5052 Ultra-Till 576-026M 3/5/2008

40

Page 43

Great Plains Mfg., Inc. Section 3: Layouts s

UT3030C Machine Layout, Coulter (S/N A1095A-)

00557

3/5/2008 Series I UT3030-UT5052 Ultra-Till 576-026M

41

Page 44

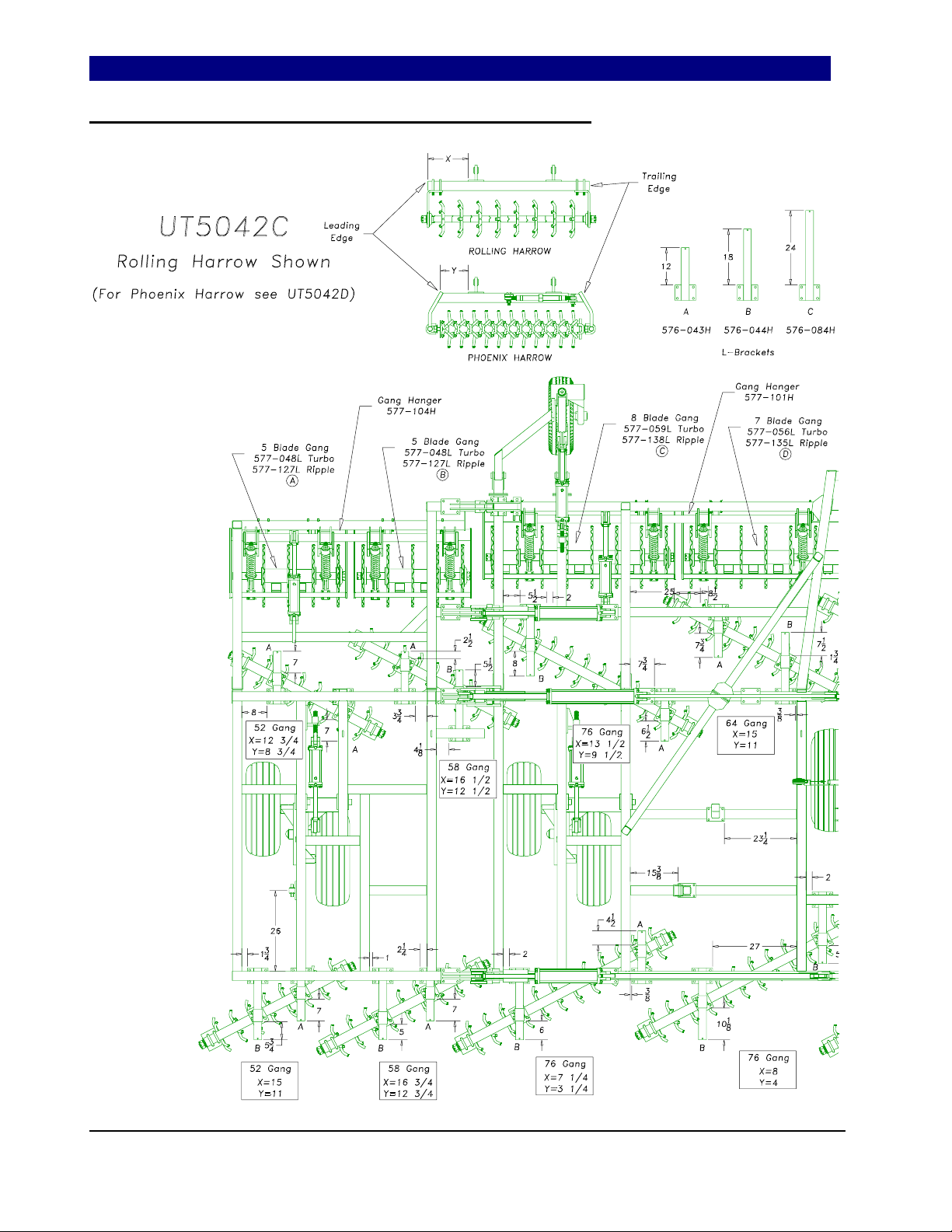

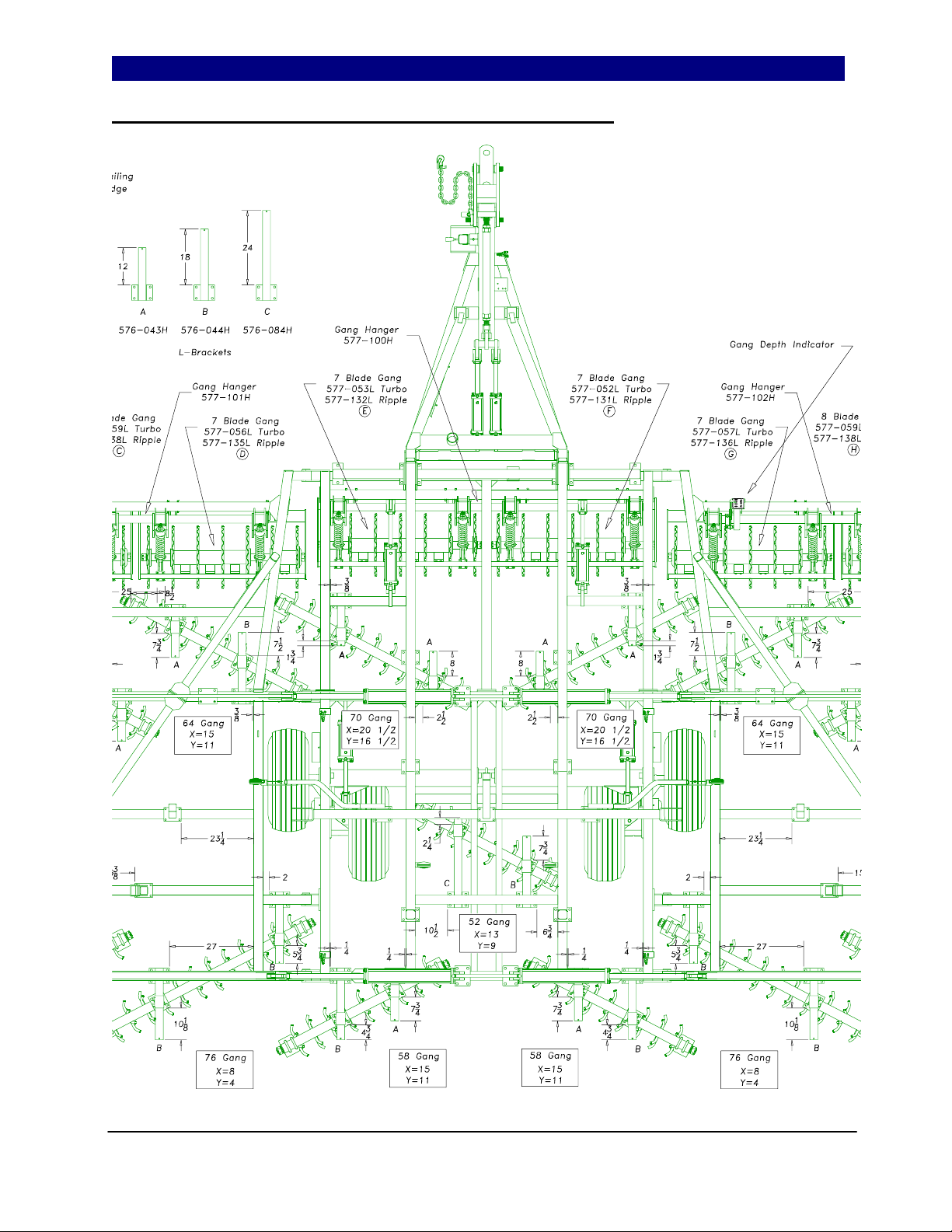

Section 3: Layouts Great Plains Mfg., Inc.

UT5036C Machine Layout, Coulter (S/N A1095A-)

00558

Series I UT3030-UT5052 Ultra-Till 576-026M 3/5/2008

42

Page 45

Great Plains Mfg., Inc. Section 3: Layouts s

UT5036C Machine Layout, Coulter (S/N A1095A-)

00559

3/5/2008 Series I UT3030-UT5052 Ultra-Till 576-026M

43

Page 46

Section 3: Layouts Great Plains Mfg., Inc.

UT5042C Machine Layout, Coulter (S/N A1095A-)

00560

Series I UT3030-UT5052 Ultra-Till 576-026M 3/5/2008

44

Page 47

Great Plains Mfg., Inc. Section 3: Layouts s

UT5042C Machine Layout, Coulter (S/N A1095A-)

00561

3/5/2008 Series I UT3030-UT5052 Ultra-Till 576-026M

45

Page 48

Section 3: Layouts Great Plains Mfg., Inc.

UT5042C Machine Layout, Coulter (S/N A1095A-)

00562

Series I UT3030-UT5052 Ultra-Till 576-026M 3/5/2008

46

Page 49

Great Plains Mfg., Inc. Section 3: Layouts s

UT5052C Machine Layout, Coulter (S/N A1095A-)

00566

3/5/2008 Series I UT3030-UT5052 Ultra-Till 576-026M

47

Page 50

Section 3: Layouts Great Plains Mfg., Inc.

UT5052C Machine Layout, Coulter (S/N A1095A-)

00567

Series I UT3030-UT5052 Ultra-Till 576-026M 3/5/2008

48

Page 51

Great Plains Mfg., Inc. Section 3: Layouts s

UT5052C Machine Layout, Coulter (S/N A1095A-)

00568

3/5/2008 Series I UT3030-UT5052 Ultra-Till 576-026M

49

Page 52

Section 3: Layouts Great Plains Mfg., Inc.

UT3030C Machine Layout, Coulter (S/N A1096A+)

00968

Series I UT3030-UT5052 Ultra-Till 576-026M 3/5/2008

50

Page 53

Great Plains Mfg., Inc. Section 3: Layouts s

UT3030C Machine Layout, Coulter (S/N A1096A+)

00969

3/5/2008 Series I UT3030-UT5052 Ultra-Till 576-026M

51

Page 54

Section 3: Layouts Great Plains Mfg., Inc.

UT5036C Machine Layout, Coulter (S/N A1096A+)

00970

Series I UT3030-UT5052 Ultra-Till 576-026M 3/5/2008

52

Page 55

Great Plains Mfg., Inc. Section 3: Layouts s

UT5036C Machine Layout, Coulter (S/N A1096A+)

00971

3/5/2008 Series I UT3030-UT5052 Ultra-Till 576-026M

53

Page 56

Section 3: Layouts Great Plains Mfg., Inc.

UT5042C Machine Layout, Coulter (S/N A1096A+)

00972

Series I UT3030-UT5052 Ultra-Till 576-026M 3/5/2008

54

Page 57

Great Plains Mfg., Inc. Section 3: Layouts s

UT5042C Machine Layout, Coulter (S/N A1096A+)

00973

3/5/2008 Series I UT3030-UT5052 Ultra-Till 576-026M

55

Page 58

Section 3: Layouts Great Plains Mfg., Inc.

UT5042C Machine Layout, Coulter (S/N A1096A+)

00974

Series I UT3030-UT5052 Ultra-Till 576-026M 3/5/2008

56

Page 59

Great Plains Mfg., Inc. Section 3: Layouts s

UT5052C Machine Layout, Coulter (S/N A1096A+)

00978

3/5/2008 Series I UT3030-UT5052 Ultra-Till 576-026M

57

Page 60

Section 3: Layouts Great Plains Mfg., Inc.

UT5052C Machine Layout, Coulter(S/N A1096A+)

00979

Series I UT3030-UT5052 Ultra-Till 576-026M 3/5/2008

58

Page 61

Great Plains Mfg., Inc. Section 3: Layouts s

UT5052C Machine Layout, Coulter (S/N A1096A+)

00980

3/5/2008 Series I UT3030-UT5052 Ultra-Till 576-026M

59

Page 62

Section 3: Layouts Great Plains Mfg., Inc.

Disc Gang Identification

00534

Series I UT3030-UT5052 Ultra-Till 576-026M 3/5/2008

60

Page 63

Great Plains Mfg., Inc. Section 3: Layouts s

Disc Gang Identification

00535

3/5/2008 Series I UT3030-UT5052 Ultra-Till 576-026M

61

Page 64

Section 3: Layouts Great Plains Mfg., Inc.

Coulter Gang Identification

00537

Series I UT3030-UT5052 Ultra-Till 576-026M 3/5/2008

62

Page 65

Great Plains Mfg., Inc. Section 3: Layouts s

Coulter Gang Identification

00538

3/5/2008 Series I UT3030-UT5052 Ultra-Till 576-026M

63

Page 66

Section 4: Operating and Maintenance Great Plains Mfg., Inc.

Operating and Maintenance

Proper servicing and maintenance is the key to the long life of all farm equipment. With careful and

systematic inspection of your Ultra-till, you can avoid costly maintenance downtime and repair.

Adjustments Before Going to the Field:

1. IMPORTANT!! If you have not thoroughly

read and understood the safety section at the

front of this manual, do so at this time. DO

NOT proceed without fully understanding the

safety considerations of this machine.

2. Make sure your tractor horsepower matches

the implement you are pulling. This is

important so the implement can do the best

possible job. (Minimum of 7-8 HP per Ft.)

3. Hitch the tractor to the Ultra-till. This tool is

equipped with a reversible single tang hitch.

Use the correct size hitch pin to insure proper

performance and to minimize wear. Raise

any 3-pt arms and/or hitch attachments to

its fully raised position to clear implement.

4. For TWO-WHEEL DRIVE and MFWD

tractors, pin drawbar in fixed center position

for field and transport. For FOUR-WHEEL

DRIVE and TRAC-DRIVE tractors, leave

one hole clearance on each side of

drawbar for field position, hitch damage

may occur if pinned solid. Pin in center

position for transport to maintain

maximum steering control.

5. Check safety chain to insure that it is properly

attached. Make sure all warning lights are

hooked up and functioning correctly.

6. Clean all hydraulic couplings and connect to

tractor. Each hydraulic coupling has a colored

handle on it and is marked with a cylinder,

either extending or retracting.

A. Red – Disc Gangs.

B. Green – Fold/Hydraulic Down Pressure

C. Black – Main Lift.

7. If machine is folded, remove the transport pins

from the wing stops. (DO NOT remove pins if

the wing is leaning against the pins or putting

pressure on the pins. Use the hydraulics to

pull the wings in completely before unpinning

them.) Once the pins are removed, slowly

unfold the unit. Make sure no one is under

the wings during the unfolding process.

Check again for hydraulic leaks and watch

that hoses do not get pinched in hinges, wings

stops, etc.

8. After the machine is completely unfolded,

raise and lower the Ultra-till several times to

purge air from the hydraulic system. Again

check for hydraulic leaks and tighten or

replace if necessary.

9. Check the tire pressure for proper inflation

and check the tightness of the lug bolts and

lug nuts. See tire inflation chart in the

appendix section of this manual.

10. Check for any bolts that may need tightened

or retightened. Grease all the hinge points.

The hubs come pre-greased and will not need

more grease at this time.

11. Put transport lock in place and refold the

machine slowly. Put wing stop pins in place.

You are now ready to go to the field. (It is

very important not to run the machine

down the road without the transport locks

in place.)

12. Leveling the unit:

side levelness of the unit best before you

install the modules.

a). On a good level surface, lower the machine until

the cylinders are completely retracted and measure

down from the bottom of the center frame to the

ground. (Take note of this measurement.)

b). Repeat this process at each section to prelevel the machine adjusting the eyebolt on

each cylinder.

13. Front to rear leveling should be done in the

field with modules installed. This is adjusted

with the turnbuckle on the hitch.

You can adjust the side to

Series I UT3030-UT5052 Ultra-Till 576-026M 8/9/2007

64

Page 67

Great Plains Mfg., Inc. Section 4: Operating and Maintenance

Field Adjustments & General Operation Instructions

1. The Ultra-till is designed as a primary/

secondary vertical tillage tool and is designed

to leave a finished seedbed following some

form of fall or spring tillage. In a min-till/no till

operation, it may be used as a primary onepass vertical tillage tool. For best results, if at

all possible, run the machine at a slight angle

to the rows. This will improve trash flow and

help spread the residue more evenly

throughout the field.

2. The ideal working speed for turbo blades is 7

to 10 MPH. If the Ultra-till is equipped with

disc-blades, then no more than 7 MPH is

recommended due to the possibility of ridging.

3. Before starting in the field: Set the depth of the

gangs at 0 inches on the gauge. Let the

machine all the way down until the cylinders

are retracted. Set your leveling front to back

with the turnbuckle on the hitch by lengthening

or shortening. Re-set the depth of gangs

between 2 to 3 on the gauge.

4. Set the hydraulic down pressure using the

instructions provided on pages 28 & 29.

Caution: Never leave tractor valve

5.

!

CAUTION

centered when unfolded with

machine in motion. Machine damage

may occur when wings flex. The hydraulic

down pressure cylinders have no wing flex

capability and oil flow is required when the

wings flex up or down. You must have the

tractor fold hydraulic lever in continuous

downward flow or “float” position before

the wings can flex over terrain in the raised

or lowered lift position.

6. If possible, have someone observe the

machine during first time operation for

levelness – front to rear and wings to center

frame. Adjust each as needed. If ground is

soft, and the blades are running too deep,

raise the gangs to desired depth. You may

need to readjust front to back. If the ground is

hard this may raise the front and again the

front to back may need to be changed (Note:

To change front to rear, either extend to raise

the front, or shorten the turnbuckle to lower

front.) On 5-section Ultra-tills with the

hydraulic gauge wheels, set the wheels in field

position to be 1” to 2” off the ground.

7. For a final adjustment on the hydraulic down

pressure, note the action of the gang bolts as

the machine operates through the field by

watching the nuts at the top of the bolts (as

shown by arrows). If the center gang bolts are

more active than the wings, the pressure to the

wings may need to be increased. If the wing

gang bolts are cycling extensively but the

center is not, the pressure to the wings needs

to be decreased. On a five-section machine,

you need to set the outside wings with one

valve and the inside wings with the other (the

valves are marked as to which is which). Once

you have all the spring bolts across the

machine working evenly, lock the valves in

place. You may need to re-adjust these valves

as field conditions change, (i.e. ground

becomes harder as it dries out or wetter after a

rain).

8. If a basket is added for leveling, use the

eyebolt to increase or decrease down

pressure. (Note: Shorten for less pressure or

lengthen for more.)

8/9/2007 Series I UT3030-UT5052 Ultra-Till 576-026M

65

Page 68

Section 4: Operating and Maintenance Great Plains Mfg., Inc.

Maintenance and Lubrication

1. Always install all transport locks when working

on or doing maintenance to the Ultra-till. If

folded, be sure your wing stop pins are in

place. Read and understand all safety decals

on your equipment.

2. During the first season of operation, and

periodically after that, check your bolts for

tightness.

3. Check scrapers and make sure gangs turn

freely.

4. Check and tighten any hydraulic leaks. Check

hoses for any leaks. It is important that there

are no leaks on the equipment that may

change the depth when in field position.

5. Grease disc gang bearings, rolling harrow

bearings and wheel bearings sparingly

greasing may cause damage to seals and

reduce the life of the bearing. Grease hinge

points periodically:

. Over

Disc & Coulter Gang Bearings

Grease every 50 hours (sparingly)

Wheel Bearings

Grease every 50 hours (sparingly) and

check for endplay.

All Hinge Points

Grease every 10 hours.

Walking Beam Pivot Bearings

Grease every 100 hours (sparingly) and

check for endplay.

Phoenix Rotary Modules

Grease every 10 hours.

Great Plains Rolling Spike

Grease every 50 hours. (sparingly)

6. If machine is stored outdoors over the winter

months it is a good idea to fold the machine

then set it down on the ground so all of the

cylinders are retracted to protect the cylinder

rods. This will extend the life of the cylinder

seals and reduce internal and external leaks

that cause future problems maintaining a level

machine.

7. If you choose to sharpen the boron disc

blades, they must be ground instead of rolled.

By following and maintaining a routine service and

lubrication program, your tillage equipment will give

you many years of service.

For more information on operating, adjusting

or maintaining your Great Plains Ultra-till

contact your local Great Plains dealer or call:

Great Plains Mfg. at (800) 255-9215

For the most current manual information visit

the web site at: www.greatplainsmfg.com

Series I UT3030-UT5052 Ultra-Till 576-026M 8/9/2007

66

Page 69

Great Plains Mfg., Inc. Section 5: Specifications and Capacities

Specifications and Capacities

Ultra-Till Specifications

Model Approx. Aprox.

No. Width Coulters Modules Center 1st 2nd Height Width Weight Horsepower

UT3030 30' 44 13 10' 9' 6" 14' 4" 14' 8" 12,000 lbs. 150-200

UT5036 36' 52 17 10' 8' 6" 4' 12' 8" 16' 7" 14,700 lbs. 180-250

UT5042 42' 64 21 10' 9' 6" 6' 6" 14' 3" 16' 7" 17,450 lbs. 200-300

UT5048 48' 70 21 12' 6" 10' 6" 6' 6" 15' 6" 18' 11" 20,220 lbs. 250-350

UT5052 52' 78 21 12' 6" 10' 6" 8' 6" 15' 6" 18' 11" 21,500 lbs. 300+

With a continued commitment to constantly improving our products, these specifications are subject to change without notice.

Number of Section Size

Transport

8/9/2007 Series I UT3030-UT5052 Ultra-Till 576-026M

67

Page 70

Appendix Great Plains Mfg., Inc.

Appendix

Torq ue Values C hart fo r Common Bo lt Sizes

Bolt Head Id en tifica tion Bolt Head Ide n tifica tion

Bolt Size

(inches)

¹

in-tpi

1/4" - 20 7.4 5.6 11 8 16 12 M 5 X 0.8 4 3 6 5 9 7

1/4" - 28 8.5 6 13 10 18 14 M 6 X 1 7 5 11 8 15 11

5/16" - 18 15 11 24 17 33 25 M 8 X 1.25 17 12 26 19 36 27

5/16" - 24 17 13 26 19 37 27 M 8 X 1 18 13 28 21 39 29

3/8" - 16 27 20 42 31 59 44 M10 X 1.5 33 24 52 39 72 53

3/8" - 24 31 22 47 35 67 49 M10 X 0.75 39 29 61 45 85 62

7/16" - 14 43 32 67 49 95 70 M12 X 1.75 58 42 91 67 125 93

7/16" - 20 49 36 75 55 105 78 M12 X 1.5 60 44 95 70 130 97

1/2" - 13 66 49 105 76 145 105 M12 X 1 90 66 105 77 145 105

1/2" - 20 75 55 115 85 165 120 M14 X 2 92 68 145 105 200 150

9/16" - 12 95 70 150 110 210 155 M14 X 1.5 99 73 155 115 215 160

9/16" - 18 105 79 165 120 235 170 M16 X 2 145 105 225 165 315 230

5/8" - 11 130 97 205 150 285 210 M16 X 1.5 155 115 240 180 335 245

5/8" - 18 150 110 230 170 325 240 M18 X 2.5 195 145 310 230 405 300

3/4" - 10 235 170 360 265 510 375 M18 X 1.5 220 165 350 260 485 355

3/4" - 16 260 190 405 295 570 420 M20 X 2.5 280 205 440 325 610 450

7/8" - 9 225 165 585 430 820 605 M20 X 1.5 310 230 650 480 900 665

7/8" - 14 250 185 640 475 905 670 M24 X 3 480 355 760 560 1050 780

1" - 8 340 250 875 645 1230 910 M24 X 2 525 390 830 610 1150 845

1" - 12 370 275 955 705 1350 995 M30 X 3.5 960 705 1510 1120 2100 1550

1-1/8" - 7 480 355 1080 795 1750 1290 M30 X 2 1060 785 1680 1240 2320 1710

1 1/8" - 12 540 395 1210 890 1960 1440 M36 X 3.5 1730 1270 2650 1950 3660 2700

1 1/4" - 7 680 500 1520 1120 2460 1820 M36 X 2 1880 1380 2960 2190 4100 3220

1 1/4" - 12 750 555 1680 1240 2730 2010

1 3/8" - 6 890 655 1990 1470 3230 2380

1 3/8" - 12 1010 745 2270 1670 3680 2710

1 1/2" - 6 1180 870 2640 1950 4290 3160

1 1/2" - 12 1330 980 2970 2190 4820 3560

N · m²ft-lb

Torque tolerance + 0%, -15% of torquing v a lues. U nless otherwise specified use torque values listed above.

³

N · m ft-lb N · m ft-lb mm x p i tc h N · m ft-lb N · m ft-lb N · m ft-lb

Bolt Size

(metric)

4

¹ in-tpi = nominal thread diameter in inches-threads per inch

² N· m = newton-meters

4

mm x pitch = nominal thread diameter in millimeters x thread pitch

³ ft-lb= foot pounds

Class 10.9Grade 2 Grade 5 Grade 8 Class 5.8 Class 8.8

Disc or Coulter Gang Bolt Torque 1 1/2”-6 650-750 Foot-pounds (175 lbs on 4’ cheater).

Tire Inflation Chart

Inflation

Tire Size

6.70 x 15" 4-Ply 32 11L x 15" 8-Ply Rib Implement 36

7.50 x 10" 10-Ply 80 11L x 15" F-Ply Rib Implement 90

9.5L x 15" 8-Ply Rib Implement 44 12.5L x 15" F-Ply Rib Implement 90

9.5L x 15" 12-Ply Rib Implement 64 395/55B 16.5 NHS Skid Steer 60

PSI

Tire Size

Series I UT3030-UT5052 Ultra-Till 576-026M 3/5/2008

Inflation

PSI

68

Page 71

Great Plains Mfg., Inc. Appendix

Warranty

Great Plains Manufacturing, Incorporated warrants to the original purchaser

that this tillage equipment will be free from defects in material and

workmanship for a period of one year from the date of original purchase when

used as intended under normal service conditions for personal use; 90 days for

commercial or rental purposes. This Warranty is limited to the replacement of

any defective part by Great Plains Manufacturing, Incorporated and the

installation by the dealer of any such replacement part. Great Plains reserves

the right to inspect any equipment or part which are claimed to have been

defective in material or workmanship. This Warranty does not apply to any

part or product which in Great Plains’ judgment shall have been misused or

damaged by accident or lack of normal maintenance or care, or which has

been repaired or altered in a way which adversely affects its performance or

reliability, or which has been used for a purpose for which the product is not

designed. This Warranty shall not apply if the product is towed at a speed in

excess of 20 miles per hour.

Claims under this Warranty must be made to the dealer which originally sold

the product and all warranty adjustments must by made through such dealer.

Great Plains reserves the right to make changes in materials or design of the

product at any time without notice. This Warranty shall not be interpreted to

render Great Plains liable for damages of any kind, direct, consequential, or

contingent, to property. Furthermore, Great Plains shall not be liable for

damages resulting from any cause beyond its reasonable control. This

Warranty does not extend to loss of crops, losses caused by harvest delays or

any expense or loss for labor, supplies, rental machinery or for any other

reason.

No other warranty of any kind whatsoever, express or implied, is made

with respect to this sale; and all implied warranties of merchantability

and fitness for a particular purpose which exceed the obligations set forth

in this written warranty are hereby disclaimed and excluded from this

sale.

This Warranty is not valid unless registered with Great Plains Manufacturing,

Incorporated within 10 days from the date of original purchase.

8/9/2007 Series I UT3030-UT5052 Ultra-Till 576-026M

69

Page 72

Great Plains Manufacturing, Inc.

Corporate Office: PO. Box 5060

Salina, Kansas 67402-5060 USA

Loading...

Loading...