Page 1

Assembly Instructions for the Ultra-Till

2/26/04

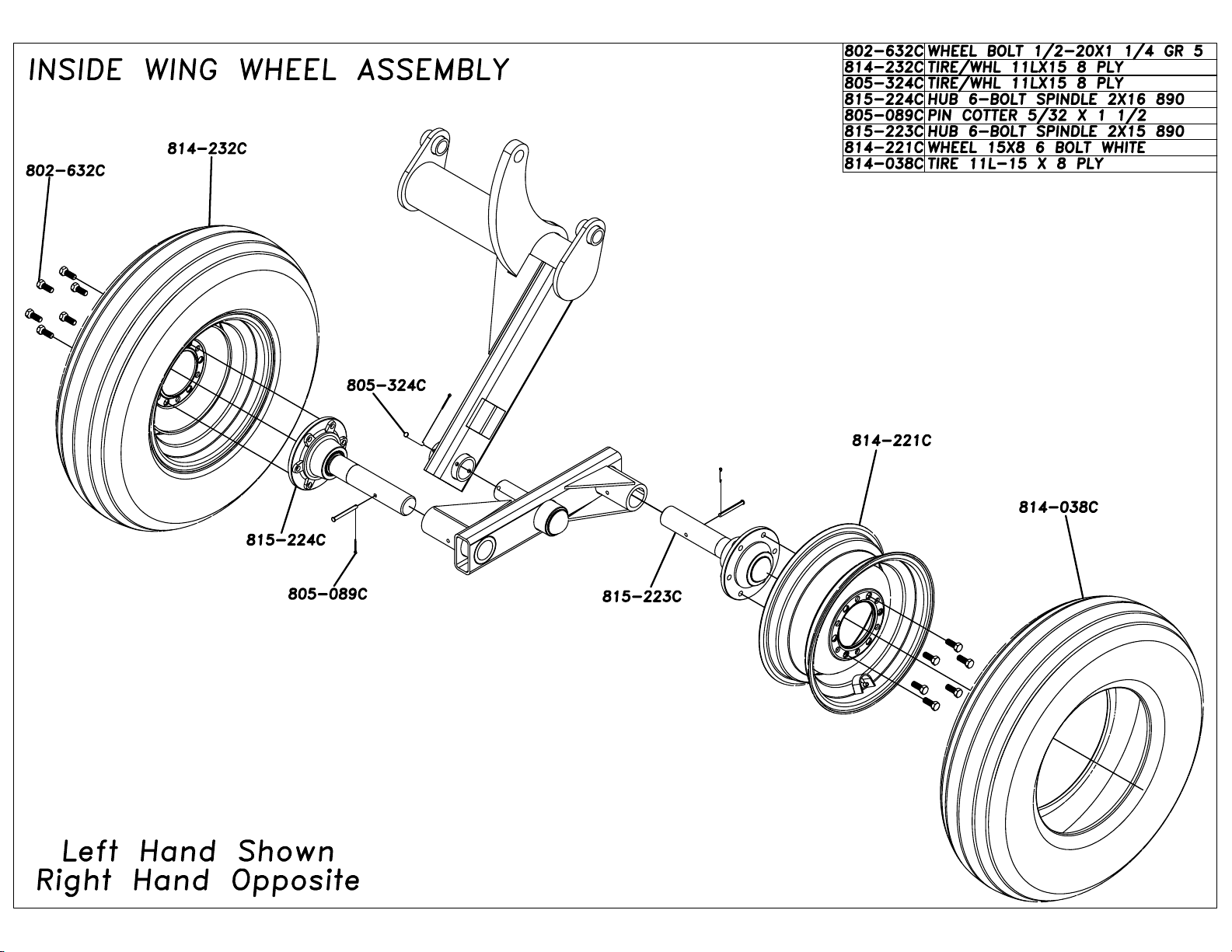

Thank you for purchasing the Great Plains Ultra-Till. To finish assembly you must first mount

the tires to the inside wings. Mount the tires as shown in layout (Inside Wing Wheel Assembly.) The

hub assemblies with the smaller titan tires pre-mounted get pinned on the caster wheel assemblies as

shown in layout (Caster Wheel Assembly – UT5042, UT5048, UT5052 ONLY.)

Then you must locate the correct coulter/disc gang assembly. The assembly should come to you

with a part number written on the gang. Simply match the part number on the gang frame with the

number located on the respective assembly layout and assemble as shown on the coulter/disc gang setup.

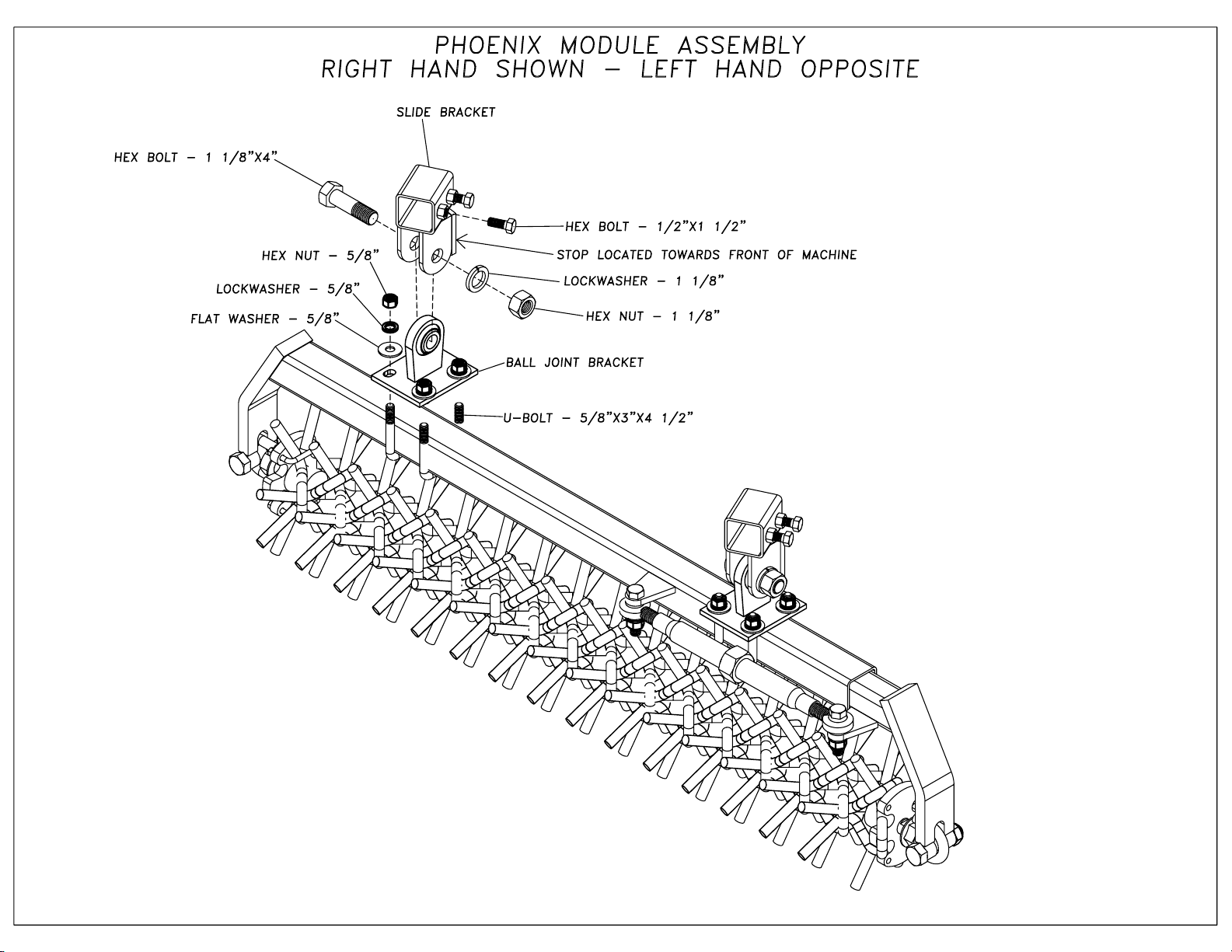

The next step is to start assembling the ball joint brackets on the phoenix module, so they can be

hung on the Ultra-Till frame. Assemble ball joint brackets as shown on (Phoenix Module Assembly.)

Leave all the nuts loose so the ball joint bracket can slide on phoenix module. On the end of the phoenix

module there is a number written in white paint. This will assist you in location of these modules.

Simply match the number on the side of the phoenix module to the number given in the respective

layout and assemble accordingly. Once phoenix module is hung tighten nuts on ball joint bracket to the

x dimension given for each individual module. This will place the phoenix modules in the correct

location and alignment. Once this is done, double check the machine with the layouts provided and

make sure there is no interference. This should complete the assembly of your Great Plains Ultra-Till.

Page 2

Page 3

Page 4

Page 5

Page 6

Page 7

Page 8

Page 9

Page 10

Great Plains Mfg., Inc. Section 2: Hydraulics

5-Section Ultra Till Hydraulic Down Pressure Preparation and Setup

Note: This setup procedure is for tractors with closed-center or pressure compensated flow

hydraulic systems. For open-center hydraulic systems contact your dealer for instructions.

1. Adjust the bypass valve by turning knob

(1), Figure 2, clockwise all the way in and

then backing out 1 full turn.

2. On tractor, adjust flow-control valve to low

side of flow rate. NOTE: The faster the

flow of oil through the system the greater

potential for oil heating, premature wear

or tractor damage.

3. Lock the fold hydraulic lever for

continuous downward oil flow.

4. Adjust pressure reducing valves knob (2

& 3) on implement so the pressure

gauges reads 1200 psi each. Never

exceed 1400 psi.

5. While watching pressure gauges, slowly

open bypass valve, knob (1) until gauges

reads around 1100 psi. Pressure might rise

and then fall off as knob is opened. If

pressure exceeds 1400 psi during this step,

the tractor flow is too high, reduce tractor

flow. Lock bypass valve knob (1) at 1100 psi.

6. Finally adjust valve knobs (2 & 3) to the

desired wing down pressure setting of 400 to

700 psi. Never exceed 900 psi.

7. In field operation, Lock the fold

hydraulic lever for continuous

downward oil flow. If wings are

running too high, increase pressure

setting to the appropriate valve, knob

(2 or 3), to level machine. If center is

too high, decrease pressure setting

with knob (2) on Inside wing valve.

Figure 2

3/11/2004 Series I UT3030-UT5052 Ultra Till 786-026M

41

Loading...

Loading...