Page 1

Uni-Press

1

Page 2

2

Page 3

DECLARATION OF CONFORMITY

Simba International Limited hereby declare that the Product described in this Operators Manual, and

defined by the Serial Number Plate attached to the Chassis of the Machine (a part copy of which is

detailed overleaf and must be completed indicating the relevant machine details), conforms with the

following Directives and Regulations, and has been certified accordingly.

EC Machinery Directive 89/392/EEC, as amended by 91/3688/EEC, 93/44/EEC, and 93/688/EEC.

In order to fulfill the requirements of health and safety described in the EC Directive, the following

standards and technical specifications have been taken into account:

EN 292 - 1

EN 292 - 2

THE MANUFACTURER

Simba International Limited

Woodbridge Road

SLEAFORD

NG34 7EW

Lincolnshire

NG34 7EW

England.

Telephone 01529 304654.

CERTIFIED ON BEHALF OF SIMBA INTERNATIONAL LIMITED.

Philip J. Wright. BSc (Hons) C Eng. MI Agr.E

Technical Director.

3

Page 4

WARRANTY

TERMS AND CONDITIONS

In this warranty Simba International Ltd., is referred to as “the Company”.

1. Subject to the provisions of this warranty the Company warrants each new machine sold by it to

besold free from any defect in material or workmanship for a period of 12 months from date of

installation with the end-user. Some specific items have additional warranty over and above the

standard 12 months. Details of these can be obtained upon request directly from the distributor or

Simba International Ltd.

2. If the machine or part thereof supplied by the Company is not in accordance with the warranty

given in clause 1 the Company will at its option:

(a) make good the machine or part thereof at the Company’s expense, or

(b) make an allowance to the purchaser against the purchase price of the machine or part thereof, or

(c) accept the return of the machine and at the buyers option either:

I) repay or allow the buyer the invoice price of the machine or part thereof, or

II) replace the machine or part thereof as is reasonably practical.

3. This warranty shall not oblige the Company to make any payment in respect of loss of profit or

other consequential loss or contingent liability of the Purchaser alleged to arise from any defect in

the machine or impose any liability on the Company other than that contained in clause 2.

4. Any claim under this warranty must be notified to the Company in writing specifying the matters

complained of within 14 days from the date of repair.

5. Any claim under this warranty must be made by the original purchaser of the machine and is not

assignable to any third party.

6. If the purchaser hires out the machine to any third party the warranty shall apply only to matters

notified to the Company in writing within 90 days of the date of delivery and clause 1 shall be read

as if the period of 90 days were substituted for the period of 12 months.

7. The warranty will cease to apply if:

(a) any parts not made, supplied or approved in writing by the Company are fitted to the machine or

(b) any repair is carried out to the machine other than by or with the express written approval of the

Company or

(c) any alterations not expressly authorized by the Company in writing are made to the machine or

(d) the machine is damaged by accident or

(e) the machine is abused or overloaded or used for a purpose or load beyond its design capabilities,

or used in conjunction with a tractor whose power output capability exceeds the stated implement

power requirement by more than 40%. For the purpose of these terms and conditions, “stated

implement power requirement” refers to wheeled tractors unless specifically stated. These power

requirements should be reduced by 20% when used in conjunction with tracked tractors.

(f) the machine is operated as part of a ‘cultivation train’ where more than one implement is being

towed, without the express written approval of Simba International Ltd.

(g) any maintenance is not carried out in accordance with the service schedules in the operator’s

manual.

(h) the Installation and Warranty Registration Certificate is not received by Simba International Ltd.,

Service Dept., Woodbridge Road, Sleaford, Lincolnshire, England, NG34 7EW, within 7 days of

installing a new machine.

4

Page 5

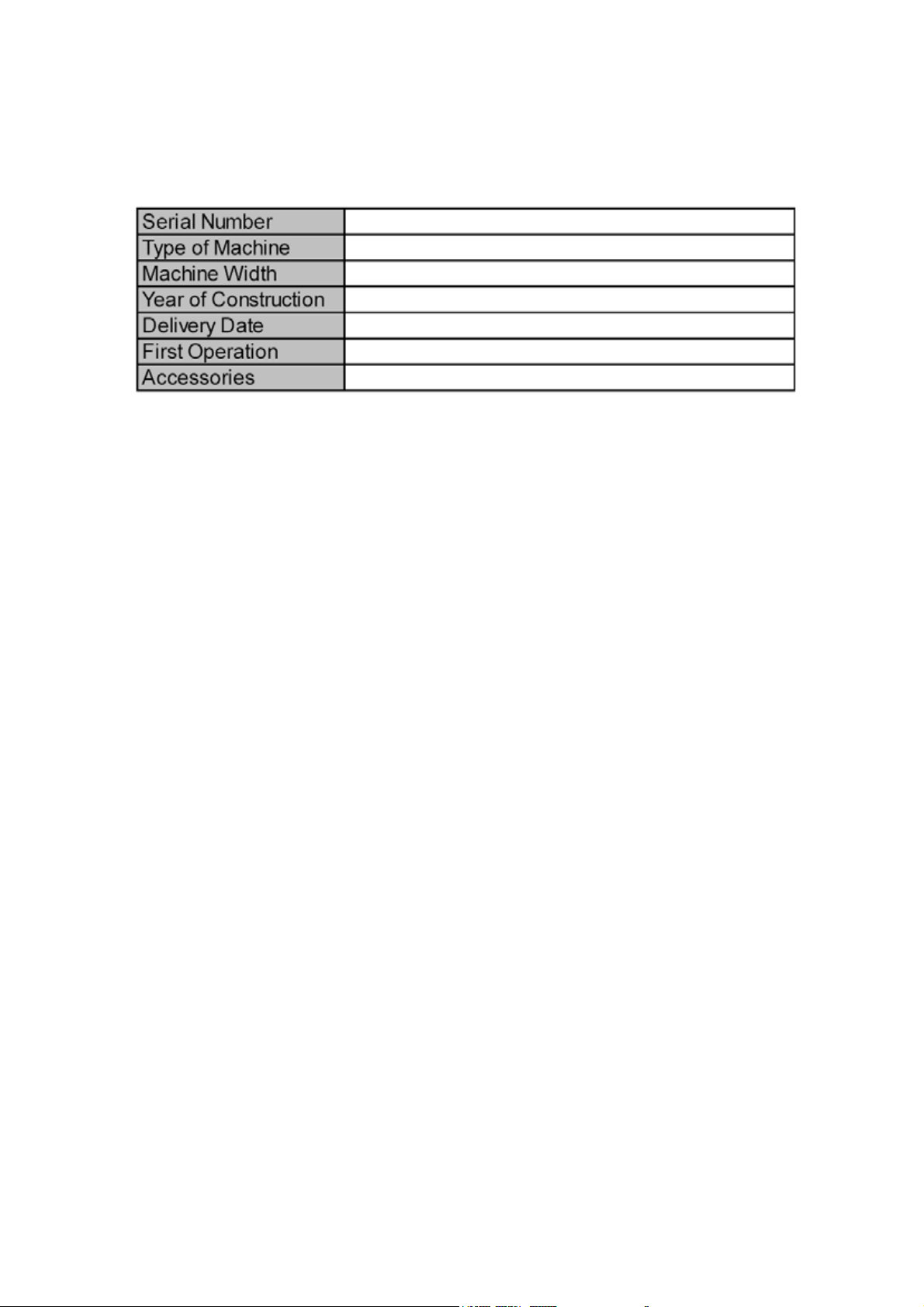

Machine Identification

Enter the relevant data in the following list upon

acceptance of the machine:

Dealer Address:

Name: ..................................................................

Street: ..................................................................

Place: ...................................................................

Tel.: ................................................................. ....

Dealer's Customer No.: ........................................

SIMBA Address: SIMBA

Woodbridge Road Ind. Est.

Sleaford

Lincolnshire

NG34 7EW

Tel.: 01529 304654

Fax: 01529 413468

E-Mail: simba.international@simba.co.uk

SIMBA Customer No.: .................................................................

5

Page 6

6

Page 7

SIMBA INTERNATIONAL LTD

Uni-Press

OPERATORS MANUAL & PARTS BOOK

CONTENTS PAGE

1.0 INTRODUCTION 9

Safety Guidelines 9

2.0 FOLDING & UNFOLDING 10

3.0 HITCHING UP 11

To a Tractor 11

To a Disc Harrow 11

4.0 PREPARING FOR WORK 13

5.0 OPERATION 14

Levelling Boards 15

Rear Drawbar 15

6.0 TRANSPORT 16

From Work to Road Transport 16

7.0 MAINTENANCE 17

Daily Service 17

Weekly Service 18

Axle Tightening Procedure 19

End of Season Service 19

Hydraulics 20

8.0 ASSEMBLY AND SPARE PARTS 21

Spares Index 21

7

Page 8

8

Page 9

1. INTRODUCTION

The Simba Folding Wing Uni-press is designed to give an improved surface cultivation

effect whilst also ensuring consolidation to depth. The Uni-press may be towed on its own or

in tandem behind another implement e.g. Disc Harrow.

The use of the Uni-press in tandem with a disc harrow for straw incorporation is to

consolidate the straw soil mix through the soil profile ensuring maximum straw soil contact

to increase the breakdown process and minimise slug problems.

The gangs are able to float over any undulations on the ground due to their floating

frames.

SAFETY

!- Never work on/or under machine unless it is fully supported

!- Always ensure area is clear before folding/unfolding machine

!- Ensure wing straps are fitted and taps are closed for road transport

!- As with any hydraulic system never place hands over suspected

leaks,high pressure oil can penetrate skin

!- Especially with mounted models make sure the front

axle of tractor is sufficiently ballasted.

!- Do not exceed 18Mph.

!- Operator should take extra care when operating machine near

other people.

!- Do not allow anyone to ride on moving machine

9

Page 10

2. FOLDING AND UNFOLDING

UNFOLDING

1. Ensure machine is fully raised.

2. Remove the transport strap from the rear wing cylinders.

3. Open the taps on the drawbar cylinders.

4. Ensure that the parking stands are in the fully raised position.

WARNING: FAILURE TO STOW THE PARKING STANDS BEFORE

THE PRESS IS UNFOLDED WILL RESULT IN SERIOUS DAMAGE TO

THE MACHINE.

5. Operate the hydraulics to fully unfold the wings.

6. Check the wing pressure on the gauge. If this is above or below the desired value then

pressurise the wings to fold which will zero the setting. Increase the pressure on the

cylinder side by adjusting the handwheel clockwise. By rotating anticlockwise the

pressure will be reduced (see Adjust The System Pressure for more details). Pressurise to

unfold until the required pressure is achieved.

7. Lower the machine to the ground until the chassis is level front to rear or the drawbar

cylinders touch the depth stops.

FOLDING

1. Raise the machine onto the transport wheels.

2. Operate the hydraulics to fully fold the wings.

3. Fit the transport strap across the pins on the rear wing cylinders for transport safety.

4. Close the taps on the drawbar cylinders.

5. Lower the parking stands if the press is to be unhitched from the tractor in the folded

position.

10

Page 11

3. HITCHING UP

HITCHING TRACTOR UP TO UNI-PRESS

NOTE:- When the Uni-press is parked, it SHOULD ideally be left in the unfolded, i.e. work,

position for stability, safety and ease of access for maintenance

1. Couple the six hydraulic hoses to the tractor ensuring that the two wing hoses are

together, the two drawbar cylinder hoses are together and the two levelling board hoses

are together.

2. Connect the tractor to the drawbar using the hydraulics to raise or lower the height of the

shackle.

3. Carefully operate the hydraulics to lower the drawbar and tilt the Uni-press onto the road

transport wheels. Fully extend the drawbar cylinders.

4. This allows the levelling boards to be fully raised so that when the Uni-press is folded the

levelling boards do not protrude beyond the 3m transport width. Fully raise the levelling

boards.

5. Ensure that the wing strap is fitted to tie the two wing sections together.

6. Ensure that parking stands are locked up into the gangs.

HITCHING A DISC HARROW UP TO THE UNI-PRESS

NOTE:- When the Uni-press is parked, it SHOULD ideally be left in the unfolded, i.e. work,

position.

1. Remove the transport straps from the disc harrow, exercise great CARE when extending

the axle cylinder.

2. Reverse the disc harrow up to the Uni-press drawbar ensuring that the two drawbars are

aligned allowing a slight clearance to enable the machines to be coupled together.

3. Lower the disc harrow to the ground.

4. Connect the four hydraulic hoses from the Uni-press into the disc harrow rear outlets

ensuring that the two wing hoses are together and the two drawbar cylinder hoses are

together. Ensure that the folding circuits and lift drawbar circuits are coupled correctly.

5. Raise the Uni-press drawbar above the disc drawbar (200mm approx.).

6. Close the two shut off taps on the Uni-press drawbar cylinder.

7. Raise the disc harrow to the same height as the Uni-press drawbar then reverse the disc

harrow to couple the two machines together.

11

Page 12

8. Open the shut off taps on the Uni-press drawbar. Operate the hydraulics to lower the

drawbar tilting the Uni-press onto the road transport wheels. Fully extend the drawbar

cylinders.

9. Fully raise the levelling boards so that when the Uni-press is folded the free ends of the

levelling boards do not protrude beyond the 3m transport width.

10. Operate the hydraulics to fold the wings.

11. Operate the hydraulics to lift the disc harrow into the transport position.

12. Fit the disc harrow transport straps.

13. Fit the Uni-press wing transport strap to tie the two wing sections together.

14. Ensure that parking stands are locked up into the gangs.

When the Uni-press is used in tandem with a disc harrow the disc should be set to the

operators manual i.e. front disc gang to be 50mm closer to the ground than the corresponding

disc blade on the rear gang.

With both machines in the transport position i.e. raised and folded, the top frame of the

disc harrow should be slightly nose down or horizontal even when the downward load from

the Uni-press is applied to the drawbar of the disc harrow.

The frame may be levelled by altering the rearward tilt of the Uni-press to increase or

reduce the loading on the disc rear drawbar.

12

Page 13

4. PREPARING THE UNI-PRESS FOR WORK

1. Ensure that the machine is fully raised.

2. Remove the transport strap from the wings.

3. Open the taps on the drawbar cylinders.

4. Ensure that the wing parking stands are fully raised and locked into the wings.

WARNING: FAILURE TO STOW THE PARKING STANDS BEFORE THE

UNI-PRESS IS UNFOLDED WILL RESULT IN SERIOUS DAMAGE TO

THE MACHINE.

5. Operate the hydraulics to fully unfold the wings.

6. Operate the hydraulics to fully raise the levelling boards. Ensure that the levelling boards

raise evenly.

7. Lower the machine to the ground until the chassis is level front to rear or the drawbar

cylinders touch the depth stops.

8. Draw the Uni-press into work then set the desired pitch of the machine by adding or

removing shims from the drawbar cylinder. The chassis should ideally be set to run level.

13

Page 14

5. OPERATION

In work the wing cylinders should be fully extended and the chassis horizontal front to rear.

The gangs are able to float over any undulations on the ground due to their floating frames.

Optimum performance has been found to be achieved when the press roll rings have worn

away the painted finish leaving a smooth shiny surface. When the press roll rings are new or

rusty, soil may tend to pick up on the surface and blockage may occur, this will reduce when

the rings are shiny again.

The Uni-press should be run with the chassis level front to rear by extending the drawbar

cylinders to the necessary position. In practice it is possible to use the Uni-press on ground

conditions that are unsuitable to achieve the desired effect, and it is usually possible to

operate the press without regular blockage under such unsuitable conditions, assuming that

the axles are tight and rings smooth. As such, especially under wet conditions, it is advisable

to check on the cultivation effect of the disc and Uni-press combination.

When the Uni-press is used tilted onto the rear row of rings (on machines configured with

two rows of rings) for increased consolidation/ clod breaking action the loading on the disc

harrow drawbar is increased. This will cause the rear of the disc to dig deeper moving the

rear gang to the right. Shortening the disc harrow levelling springs should allow the disc

harrow to pull straight again.

It is not necessary to tilt the Uni-press onto the transport wheels during headland turns

whether the machine is used independently or in tandem with a disc harrow.

14

Page 15

LEVELLING BOARDS

The action of the sprung leaf type levelling boards is to carry and drop soil to level in

front of the press rings, to rub clod against clod for additional soil breakdown, to force clods

down into the soil profile and to present remaining clods passing between the leaves into the

front row of press rings.

With the chassis set level, lower the levelling boards until they are carrying soil. The

levelling boards will need to be set higher during 1st pass operations especially on ploughed

land where large clods may not be able to pass under or between the sprung leaves.

The boards need to carry a certain amount of soil to effect a levelling operation and also

to give a clod to clod crushing action. Use the hydraulics to raise and lower the boards to

carry more or less soil when levelling the headland troughs for example.

When reversing the Uni-press into corners when working headlands ensure that the

levelling boards are fully raised and the machine tilted onto the rear set of rings far enough to

allow the lower ends of the sprung leaves to clear the ground.

REAR DRAWBAR

Some Uni-press models are fitted with an optional hydraulic rear drawbar. This may be

used to trail a second roll. The hydraulic cylinders on the front and rear drawbars are linked

together for headland turns and for coupling up to other implements.

In work the Uni-press lift circuit should be run in the FLOAT position on the tractor spool to

allow the combination to find the easiest line of pull, ensuring the rear drawbar cylinder is

isolated in the work (lower) setting. Also ensure the the rear drawbar cylinder is isolated off

for safety during transport.

15

Page 16

6. TRANSPORT

With both machines in the transport position i.e. raised and folded, the top frame of the disc

harrow should be slightly nose down or horizontal even when the downward load from the

Uni-press is applied to the drawbar of the disc harrow. The top frame should NEVER be tail

low in transport as this will give a high negative loading on the tractor which could lead to

loss of traction to the rear wheels.

Extreme caution must be taken when the Uni-press is transported up steep gradients

and across side slopes. On the wide models, higher drawbar loading can be achieved by

shortening the drawbar cylinder.

Prior to leaving the field to travel on a public highway ensure that any clods of soil

are removed from the machine to prevent them from fouling the road.

NOTE: MAXIMUM ROAD TRANSPORT SPEED 20 MPH (30 KPH).

CHANGING FROM WORK TO ROAD TRANSPORT

1.Remove the disc harrow wing locking bolts.

2.Open the taps on the Uni-press drawbar and wing fold cylinders (if fitted).

3.Operate the hydraulics to raise the disc and Uni-press.

4.Operate the hydraulics to fold the wings on both the disc harrow and the Uni-press.

5.Fit the wing transport chains to both machines.

6.Fit the transport straps to the disc harrow.

7.Close the taps on the Uni-press drawbar and wing fold cylinders.

NOTE: It may be necessary to shorten the levelling springs until the top frame of the

disc harrow is horizontal or slightly nose down before moving the machines.

Shortening the Uni-press drawbar cylinder will increase the loading on the rear of the

disc frame. If necessary this can be used to level the disc top frame for road transport.

16

Page 17

7. MAINTENANCE

WARNING: WHEN WORKING ON MACHINE ALWAYS ENSURE IT IS

FULLY SUPPORTED SHOULD BALANCE OF WEIGHT BE ALTERED, IF

A ROLL GANG IS REMOVED FOR EXAMPLE.

THE WING CIRCUIT IS CONTROLLED BY AN OVERCENTRE VALVE WHICH

POSITIVELY LOCKS OIL FLOW UNTIL PRESSURISED BY THE TRACTOR.

SYSTEM PRESSURE CAN BE RETAINED IN THE CIRCUIT EVEN AFTER DE-

PRESSURISATION OF THE TRACTOR QUICK RELEASE COUPLINGS.

EXERCISE EXTREME CARE WHEN CHECKING THE VALVE OR CIRCUITS, AND

UNDER NO CIRCUMSTANCES ATTEMPT TO ADJUST OR LOOSEN FITTINGS

WITHOUT PRIOR REFERENCE TO YOUR AUTHORISED SIMBA DEALER, AND

DETAILED MAINTENANCE INSTRUCTIONS.

PLEASE REFER TO YOUR SIMBA DEALER IN THE EVENT THAT A CIRCUIT

CONTAINING AN OVERCENTRE VALVE REQUIRES MAINTENANCE.

All nuts and bolts should be kept dirt free, threads well greased and as tight as recommended.

However bolts at pivot points should not be over tightened.

NEW MACHINES

On a new machine tighten all nuts and bolts after 5 hours work and again after 15

hours. This also applies to parts that have been moved or replaced. After the initial 15 hours

of work a once a week check is sufficient.

NOTE: When tightening the main axle castle nuts, loosen the bearing pillars to avoid

preloading the bearings housings and pillars (see Weekly Service Section 3).

DAILY SERVICE

1.Grease roll axle bearings until grease shows

2.Grease all grease points until grease shows.

3.Check roll rings for damage. Broken rings may lead to damage or failure of other

components.

4.Check hydraulic connections for leaks. Leaking hydraulics may allow the machine to lower

in work or road transport.

17

Page 18

WEEKLY SERVICE

1. Grease roll axle bearings until grease shows

2. Tighten all nuts and bolts including wheel nuts. Vibration through the machine may cause

the nuts and bolts to work loose leading to wear.

IMPORTANT: - Never use a hammer to assist tightening of nuts and bolts.

- Using an incorrect size or grade of bolt may result in damage to the machine.

MAXIMUM NUT AND BOLT TORQUES

M16 GRADE 8.8 - 24 KG.M. (176 lb.ft.)

M20 GRADE 8.8 - 48 KG.M. (352 lb.ft.)

M30 GRADE 8.8 - 150 KG.M. (1100 lb.ft.)

M36 GRADE 8.8 - 280 KG.M. (2055 Ib.ft.)

WHEEL NUT TORQUES

6 STUD HUBS M18 - 27.7 KG.M. (200 lb.ft)

3. Check that roll axles are tight. If the roll axles are allowed to run loose the rings will

become worn and may not be able to be tightened correctly as a result. An axle that

blocks

regularly is an indication that the axle is not tight as there is no drive between each ring.

a). Loosen the bearing pillar 'U' bolts on one pillar. This allows the pillar to move slightly

when the tension is applied to the main axle castle nuts when tightening the axle. This

ensures that the bearings are not preloaded, which could lead to unwarrantable early

failure.

NOTE: When the axle needs tightening again, loosen the bearing pillar 'U' bolts that were

not loosened the previous time. This will avoid the necessity of having to adjust the

position of the scrapers each time. To maintain the front to rear tracking of the axles the

corresponding pillars should be loosened.

b). Remove the split pin from the axle.

c). Tighten the axle until the single belleville washer in each triple pack is fully

compressed

ensuring that the split pin can then be refitted.

d). Tighten the bearing pillar 'U' bolts.

18

Page 19

DOUBLE DISC RING AXLE MAINTENANCE

The axles on this roller are tensioned by the main axle through the centre of the rings and

bearings.

SPECIALIST EQUIPMENT IS REQUIRED TO DISASSEMBLE THESE

AXLES, PLEASE REFER TO PARTS LISTINGS FOR DETAILS.

CONSULT YOUR APPROVED SIMBA DEALER UNDER ALL

CIRCUMSTANCES IF DISASSEMBLY IS REQUIRED FOR ANY

REASON.

Maintenance of these rollers is limited to daily greasing of the bearings to flush out

dirt, and regular inspection to ensure the assemblies are tight, and scrapers are correctly set.

The axles can be tightened provided the bearing pillar ‘U’ bolts are loosened to avoid

preloading the bearings as they move sideways to each other.

Ensure the bearing pillars are re- tightened to the mainframe after this.

4.Check tyre pressures. Running the machine with tyres at the incorrect pressure may cause

excessive wear, overheating and possible failure.

TYRE SIZE MAX. P.S.I. MAX. BAR

400/60-15.5, 10 PLY 50 3.5

5.Check wing to gang pivot bolts are tight.

END OF SEASON SERVICE

1.The Uni-press MUST be left parked in the unfolded (work) position.

2.Grease roll axle bearings until grease shows.

3.Grease the four wing pivot bolts.

4.Grease any exposed areas of hydraulic cylinder rod to prevent them from becoming pitted.

5.Wheel bearings are prepacked with grease at the factory but should be inspected and

regreased.

6.Check for worn or damaged components. Replace if necessary to avoid damaging other

components.

7.Check that the roll axles are tight. Tighten if necessary.(see Weekly Service section)

8.Tighten all nuts and bolts. (see Weekly Service section)

19

Page 20

WING FLOAT / CONTOURING

The main wing sections are capable of following contours by means of a pressurised

hydraulic system. A low pressure (approx. 10 to 20 bar) is set and held in the wing folding

cylinders automatically as the unfolding procedure is carried out. In the unlikely event that

this pressure needs to be adjusted refer to the following procedure.

To Adjust the System Pressure

PLEASE NOTE: - A low oil flow should be used, i.e., tractor tickover or low flow selected.

It is normal to operate at 10-20 bar. This can be increased to 40-50 bar max, or reduced to 5

bar as conditions determine. Higher pressure will cause the wing tips to dig in causing the

centre of the machine to lift it out. Too little pressure will cause the wing tips to lift out & the

centre of the machine to dig in. When towing another implement behind the Press, the

pressure may need increasing to compensate.

In all cases the normal adjustment method is to minimise system pressure & then increase by

adjusting the pressure valve until the desired pressure is achieved.

In all cases, regardless of tractor make, adjustment should start from zero (minimum

pressure) and gradually increase up to desired pressure value.

With the machine off the ground,

1. Pressurise the wings to unfold. As the unfolding begins the pressure reading on the gauge

will drop. When the wings have fully unfolded the pressure reading will start to climb.

Keep pressurising the wings until the gauge has stabilised at the pre-set pressure. The

standard factory setting is 15 bar.

2. If the system needs adjusting:- Partially fold the wings & hold them in this position. To

adjust the pressure utilise valve 3 (shown below). Unscrew the adjusting screw until no

resistance can be felt (almost fully unscrewed position). Unfold the wings fully as before,

checking the gauge reading. Maintain hydraulic pressure unfolding wings & adjust the

screw whilst pressurising.

y Turning adjuster clockwise increases pressure.

y Turning adjuster anti-clockwise decreases pressure.

Once desired pressure is achieved lock the valve. As a check, partially fold the wings,

stop, and then unfold again maintaining pressure until the gauge stabilises at your desired

setting.

20

Loading...

Loading...