Page 1

Great Plains Mfg., Inc. Parts Installation Instructions 1

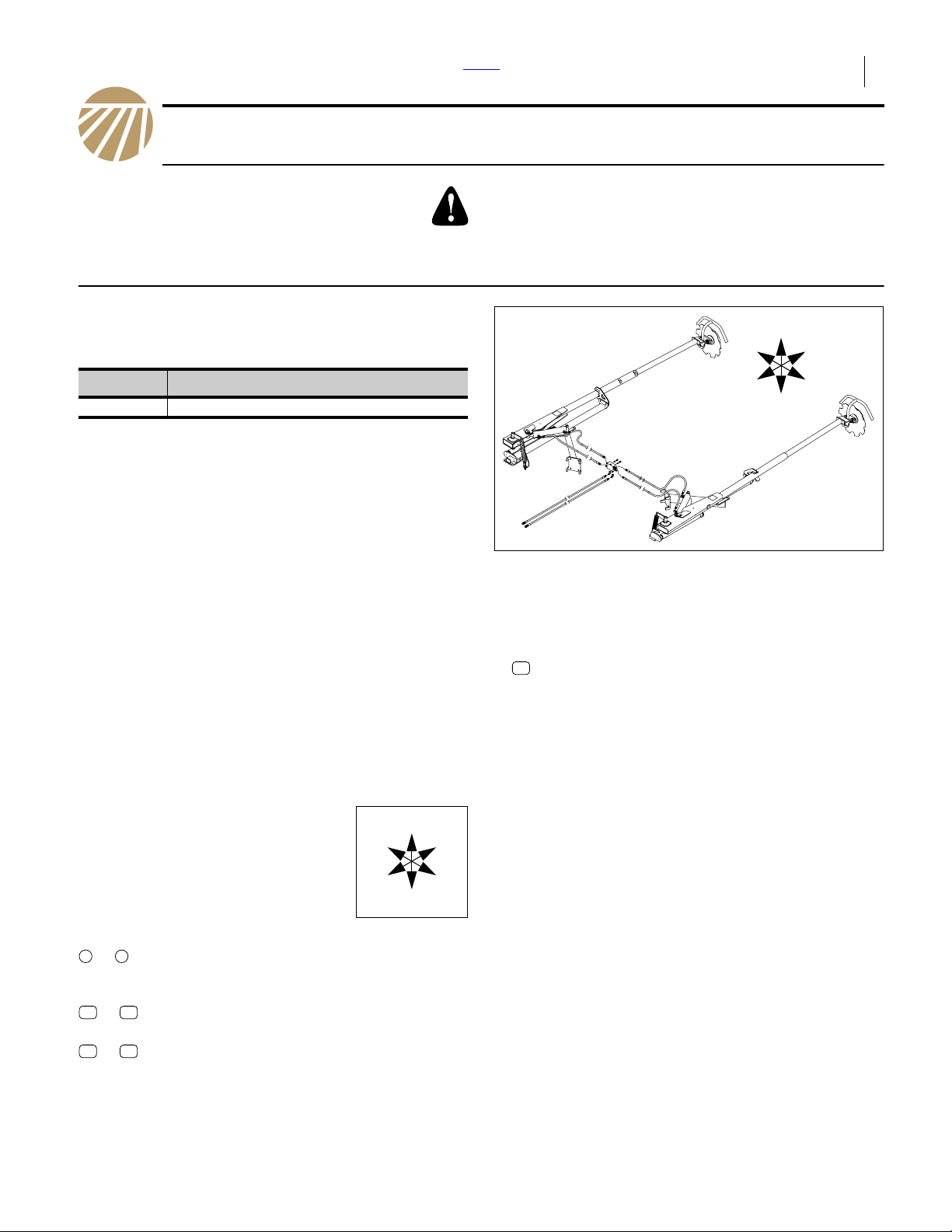

2013- Single Fold Marker

6 Meter / 20 Foot HD Air Drill Implements

Used with: When you see this symbol, the subsequent instructions and

• NTA607, NTA607HD

• NTA2007, NTA2007HD

General Information

These instructions explain how to install field markers on

a compatible air drill implement.

These instructions apply to an installation of a 2013- kit:

warnings are serious - follow without exception.

Your life and the lives of others depend on it!

R

U

B

Kit Kit Description

113-849A NTA607HD-NTA2007HD MARKER BDL

Note: Kits manufactured in 2014 or later are described in

manual 113-921M. Compare Part List illustrations

if uncertain which manual applies to your kit.

One kit includes two markers (left and right), an automatic sequence valve, all hydraulic hoses and fittings,

and all necessary mounting hardware.

One kit updates one air drill.

Related Documents

Have the Operator Manual at hand for drill movements.

166-283M NTA607HD/2007HD Operator Manual

166-372M NTA607/2007 Operator Manual

166-372M-ENG NTA607 Operator Manual (EU)

Have the current Parts Manual at hand for parts ID.

166-283P NTA607HD/2007HD Parts Manual

166-372P NTA607/2007 Parts Manual

Notations and Conventions

“Left” and “Right” are facing in the

direction of machine travel. An orientation rose in the line art illustrations

shows the directions of Left, Right,

Front, Back, Up, Down.

Call-Outs

Single-digit callouts identify components in

1 9

to

11 12

to

21 80

to

Null4:

the currently referenced Figure or Figures.

These numbers may be reused for different

items from page to page.

Two-digit callouts in the range 11 to 12 reference affected existing parts (see page 18).

Two-digit callouts in the range 21 to 80 reference new parts (see list on page 18).

R

F

U

B

L

D

F

L

D

Null4:

Figure 1

Marker Kit

31327

Parts and Tools Required

• Locate two existing QD fittings supplied with the air

cart (see Figure 22 on page 21):

12

811-070C CP 3/4FORB QD

These fittings were bundled with the marker QD ports

on the rear of the air cart, but are typically removed

prior to delivery (they present an open line risk should

anyone activate the marker circuit prior to marker

installation).

• You need a suitable tractor for positioning the air drill,

and having sufficient hydraulic circuits, with adequate

capacity to operate the markers (installing markers

increases the required circuits to 3).

• You need a hoist with 136 kg (300 pound) capacity.

• Have safety goggles and gloves for inspecting hydraulic connections.

• Other than the hoist, only basic hand tools are

required.

• A few cable ties are required to secure hoses.

If orange colored ties are available, 6 can also be used

to identify hoses.

• 5 liters (1.2 gallons) of hydraulic fluid is needed to

charge the marker system.

Null4:

2013-10-10 ©Copyright 2010 113-850M

Page 2

2 2013- Single Fold Marker Front Parts Great Plains Mfg., Inc.

Before You Start

Compatibility

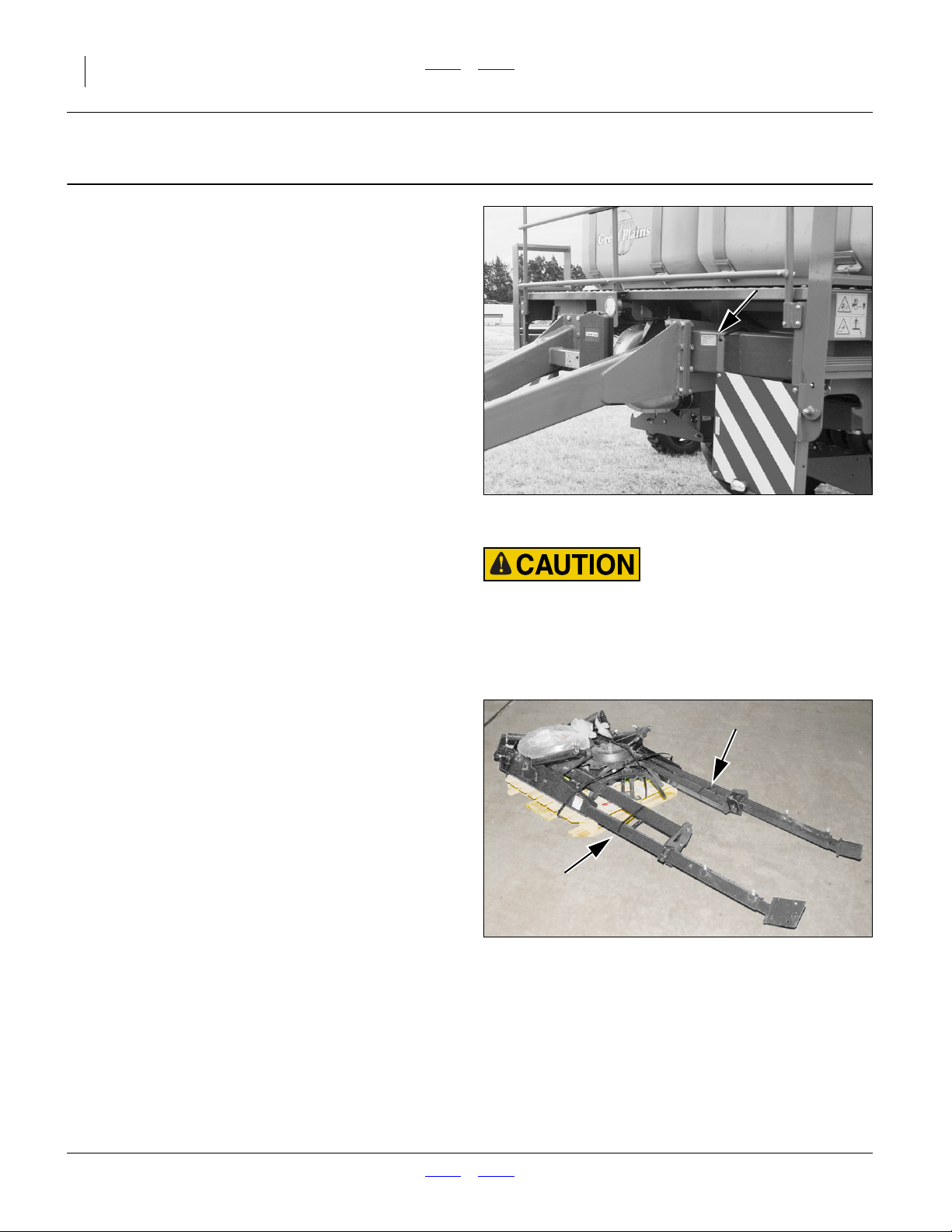

Refer to Figure 2

1. Check the model number of the air drill against the

list at the top of page 1 to ensure it is a compatible

model. For example, this kit is not compatible with

the NTA2000 integrated air drill (which uses a different marker kit).

Sequence

The mechanical installation may be performed on a disconnected implement, but testing of the system requires

the complete air drill.

If installing the markers as part of pre-delivery or export

final assembly, defer marker installation until after completing all items covered by manual 166-283Q.

Inventory

2. Make sure all parts are present.

Note: Delivered parts may be identified by Haukaas or

Great Plains part numbers. The Parts Lists beginning on page 18 show both numbers.

Note: Some parts are provided in left- and right-hand

versions with different part numbers. These are

not interchangeable and must be installed on the

implement side specified.

Null4:

Null4:

Null4:

Figure 2

NT607/2007HD Serial Number Plate

31174

Pinch / Crush Hazards:

Remove strapping only as instructed. The marker arms are

largely pre-assembled, and held closed by strapping. Premature removal creates pinch hazards and makes the assemblies

more hazardous to move and position.

Comprehension

3. Review these instructions. Make sure the installers

understand where each part or assembly is

installed, and what tools are required for the task.

Null4:

Null4:

Figure 3

Markers on Pallet

31361

113-850M Front Parts 2013-10-10

Page 3

Great Plains Mfg., Inc. Front Parts Installation Instructions 3

Pre-Assembly Preparation

Work Location

4. Move the air drill to a location with:

• room to fold it;

• access to tractor or hydraulic power;

• adequate illumination; and,

• clear surface beneath for recovery of any falling

or dropped parts - if the surface is not clear, have

a tarp or drop cloth available.

5. Raise drill. Unfold drill. Lower drill. This eases

access to the frames.

6. Set all hydraulic remote circuits to Float (to ensure

that pressure is relieved). Shut off tractor or hydraulic source.

Crushing Hazard:

Lower drill or support wing ends with gauge wheel lock channels. Although the center section may be held at raised by the

lift lock, unfolded wing ends slowly lower over time unless cylinder lock channels or external supports are used.

Install Arm Mechanisms

Install Arm Mounts

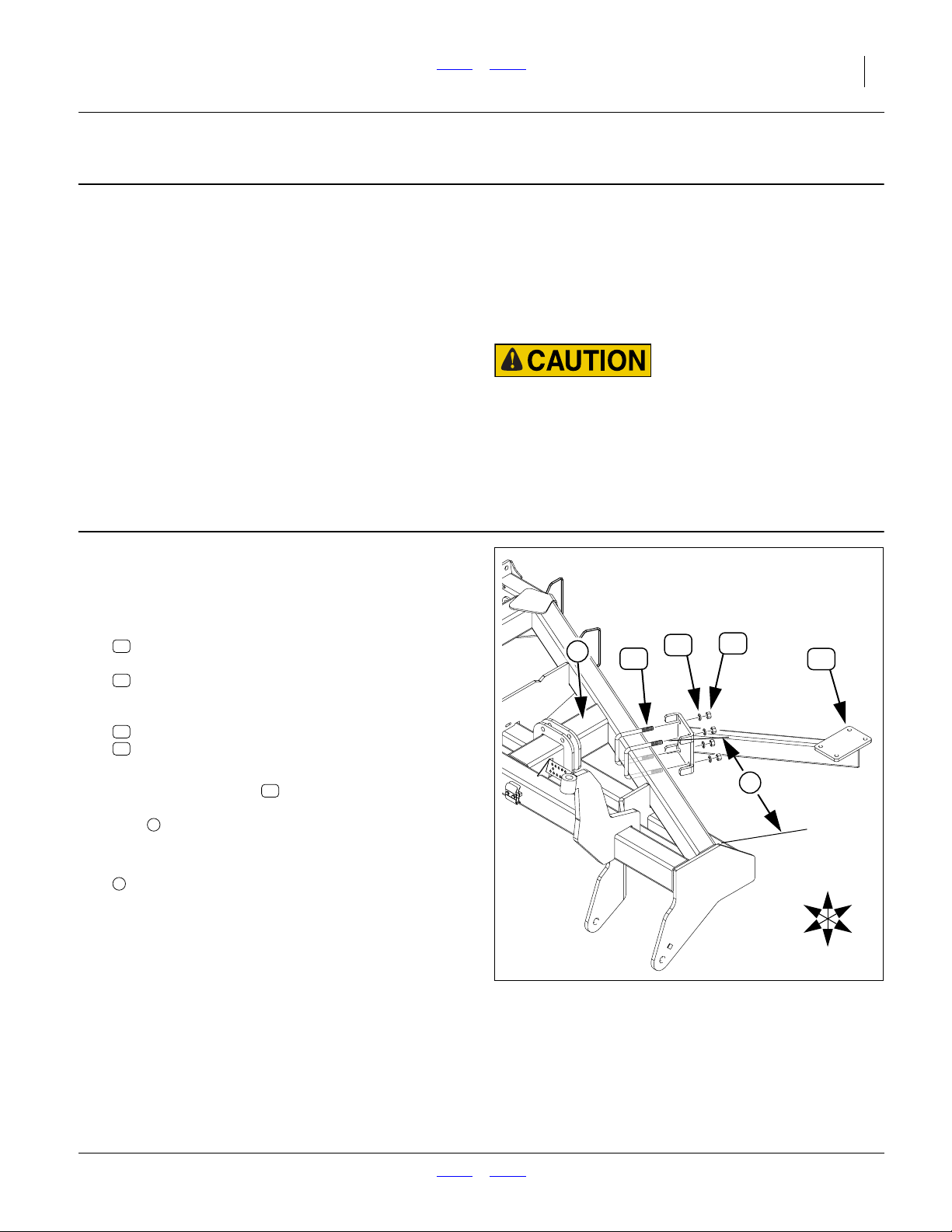

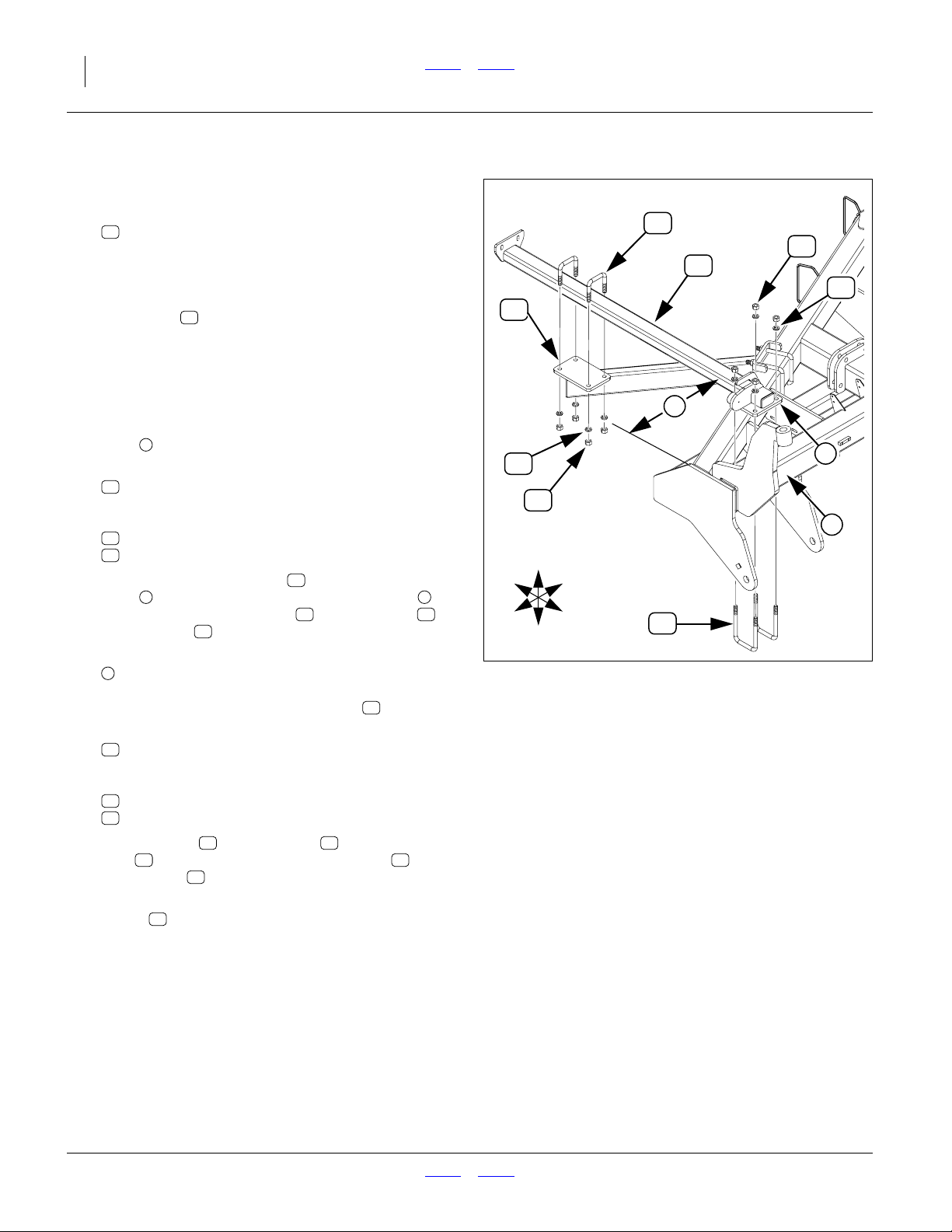

Install Left Mount

Refer to Figure 4

7. Select one new:

68

SFM-8670 Mounting Bracket Left SFM

two new:

22

FNS-024346 806-044C 5/8x5-1/16x5-1/2"

U-bolt U-BOLT 5/8-11 X 5 1/32 X 6

and four sets new:

38

FNS-56RPC 5/8"-11 NC Hex Nut

41

FNS-66RP 5/8" Split L/W YZ

8. With the arm to the rear, flat plate up, loosely install

the mounting bracket on the rear wing tool bar,

just outboard (left) of the wing cylinder mount

1

tube .

9. Adjust the initial position of the bracket for a distance:

2

74.0 cm (291⁄8 in.)

measured from the left outside face of a mount tab

to the left rear end of the rear tool bar (due to weld

fillets, this measurement is approximate).

Leave fasteners finger-tight until step 20.

Null4:

68

Null4:

1

41

22

38

68

2

U

R

F

B

L

D

Figure 4

Install Left Mount

31337

2013-10-10 Front Parts 113-850M

Page 4

4 2013- Single Fold Marker Front Parts Great Plains Mfg., Inc.

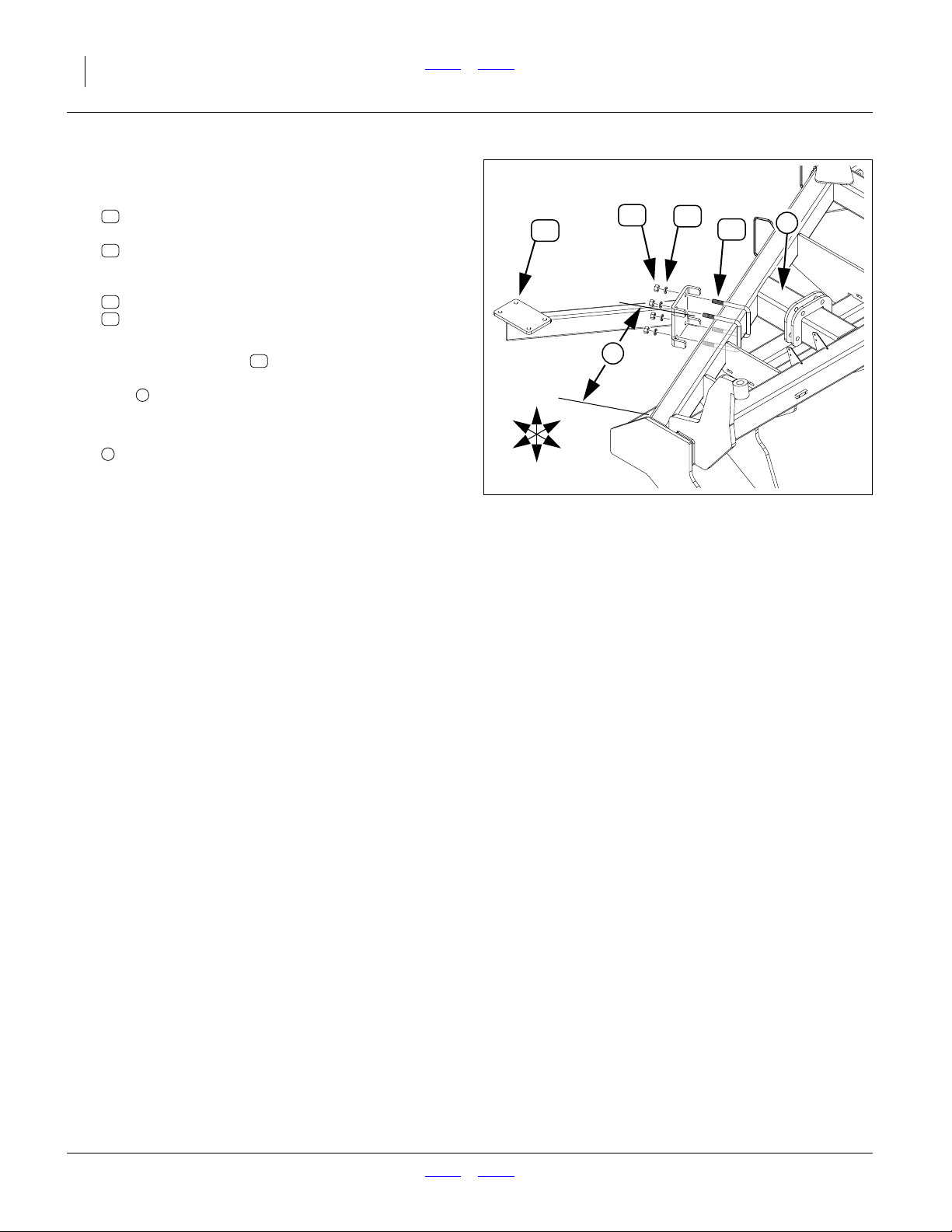

Install Right Mount

Refer to Figure 5

10. Select one new:

67

SFM-8669 Mounting Bracket Right SFM

two new:

22

FNS-024346 806-044C 5/8x5-1/16x5-1/2"

U-bolt U-BOLT 5/8-11 X 5 1/32 X 6

and four sets new:

38

FNS-56RPC 5/8"-11 NC Hex Nut

41

FNS-66RP 5/8" Split L/W YZ

11. With the arm to the rear, flat plate up, loosely install

the mounting bracket on the rear wing tool bar,

just outboard (right) of the wing cylinder mount

1

tube .

12. Adjust the initial position of the bracket for a distance:

3

74.9 cm (291⁄2 in.)

measured from the from right outside face of a

mount tab to the right rear end of the rear tool bar

(due to weld fillets, this measurement is approximate).

67

Null4:

B

R

67

U

L

F

D

38

41

3

Figure 5

Install Right Mount

22

1

31338

Leave fasteners finger-tight until step 28.

Null4:

113-850M Front Parts 2013-10-10

Page 5

Great Plains Mfg., Inc. Front Parts Installation Instructions 5

Install Arm Assemblies

Install Left Arm Assembly

Refer to Figure 6 (which, for clarity, depicts only the arm

subframe - what is installed is an entire arm assembly)

13. Select one new:

55

SFM-8657 Subframe Left - SFM

(which is an entire left arm assembly)

55

26

38

To reduce weight during installation, and reduce

arm length during system charge, remove the third

stage arm ( , not shown).

63

14. Leave in place any straps holding the arm in the

fully folded position. Remove only such straps as

are necessary to free the arm from the shipping

crate or pallet.

41

68

6

41

38

Secure the arm in a hoist, with the forward mounting

4

plate facing down.

15. Select two new:

23

FNS-02291 806-080C 5/8x4-1/16x6-1/2 Sq-

U-Bolt for 4x5 U-BOLT 5/8-11 X 4 1/32 X 6

and four sets new:

38

FNS-56RPC 5/8"-11 NC Hex Nut

41

FNS-66RP 5/8" Split L/W YZ

16. Position the arm assembly with the mounting

4 5

plate over the left end of the front tool bar .

Loosely secure with U-bolts , lock washers

and hex nuts .

38

55

23 41

17. Adjust the horizontal position to:

6

18.26 cm (73⁄16 in,)

measured from the outside face of the wing end

plate to the left side of the subframe tube.

55

18. Select two new:

26

FNS-02284

5/8-11x3-1/16x3-1/2 Sq-U-Bolt for3x2

and four sets new:

38

FNS-56RPC 5/8"-11 NC Hex Nut

41

FNS-66RP 5/8" Split L/W YZ

19. Using U-bolts , lock washers and hex

38 55

nuts , loosely secure the arm subframe to the

mount plate .

26 41

68

20. As necessary, adjust the final position of the

mount so that the arm subframe is parallel to the

68

wing end plate.

5

Null4:

Install Left Arm (Subframe Shown)

4

23

Figure 6

R

F

U

B

L

D

31339

Secure all fasteners to torque spec.

Null4:

2013-10-10 Front Parts 113-850M

Page 6

6 2013- Single Fold Marker Front Parts Great Plains Mfg., Inc.

Install Right Arm Assembly

Refer to Figure 7 (which, for clarity, depicts only the arm

subframe - what is installed is an entire arm assembly)

21. Select one new:

56

SFM-8658 Subframe Right SFM

(which is an entire right arm assembly)

26

38

56

To reduce weight during installation, and reduce

arm length during system charge, remove the third

stage arm ( , not shown).

63

22. Leave in place any straps holding the arm in the

fully folded position. Remove only such straps as

are necessary to free the arm from the shipping

crate or pallet.

67

41

3

Secure the arm in a hoist, with the forward mounting

1

plate facing down.

23. Select two new:

23

FNS-02291 806-080C 5/8x4-1/16x6-1/2 Sq-

U-Bolt for 4x5 U-BOLT 5/8-11 X 4 1/32 X 6

and four sets new:

38

FNS-56RPC 5/8"-11 NC Hex Nut

41

FNS-66RP 5/8" Split L/W YZ

24. Position the arm assembly with the mounting

1 2

plate over the right end of the front tool bar .

Loosely secure with U-bolts , lock washers

and hex nuts .

38

56

23 41

25. Adjust the horizontal position to:

3

19.84 cm (713⁄16 in,)

measured from the outside face of the wing end

plate to the right side of the subframe tube.

56

26. Select two new:

26

FNS-02284

5/8-11x3-1/16x3-1/2 Sq-U-Bolt for3x2

and four sets new:

38

FNS-56RPC 5/8"-11 NC Hex Nut

41

FNS-66RP 5/8" Split L/W YZ

27. Using U-bolts , lock washers and hex

38 56

nuts , loosely secure the arm subframe to the

mount plate .

26 41

67

28. As necessary, adjust the final position of the

mount so that the arm subframe is parallel to the

67

wing end plate.

Null4:

B

R

41

38

U

L

F

D

Install Right Arm (Subframe Shown)

23

Figure 7

1

2

31340

Secure all fasteners to torque spec.

Null4:

113-850M Front Parts 2013-10-10

Page 7

Great Plains Mfg., Inc. Front Parts Installation Instructions 7

Install Hydraulic Components

Before working with hydraulic components, review the

connector identification, torque specifications and sealant recommendations on page 15.

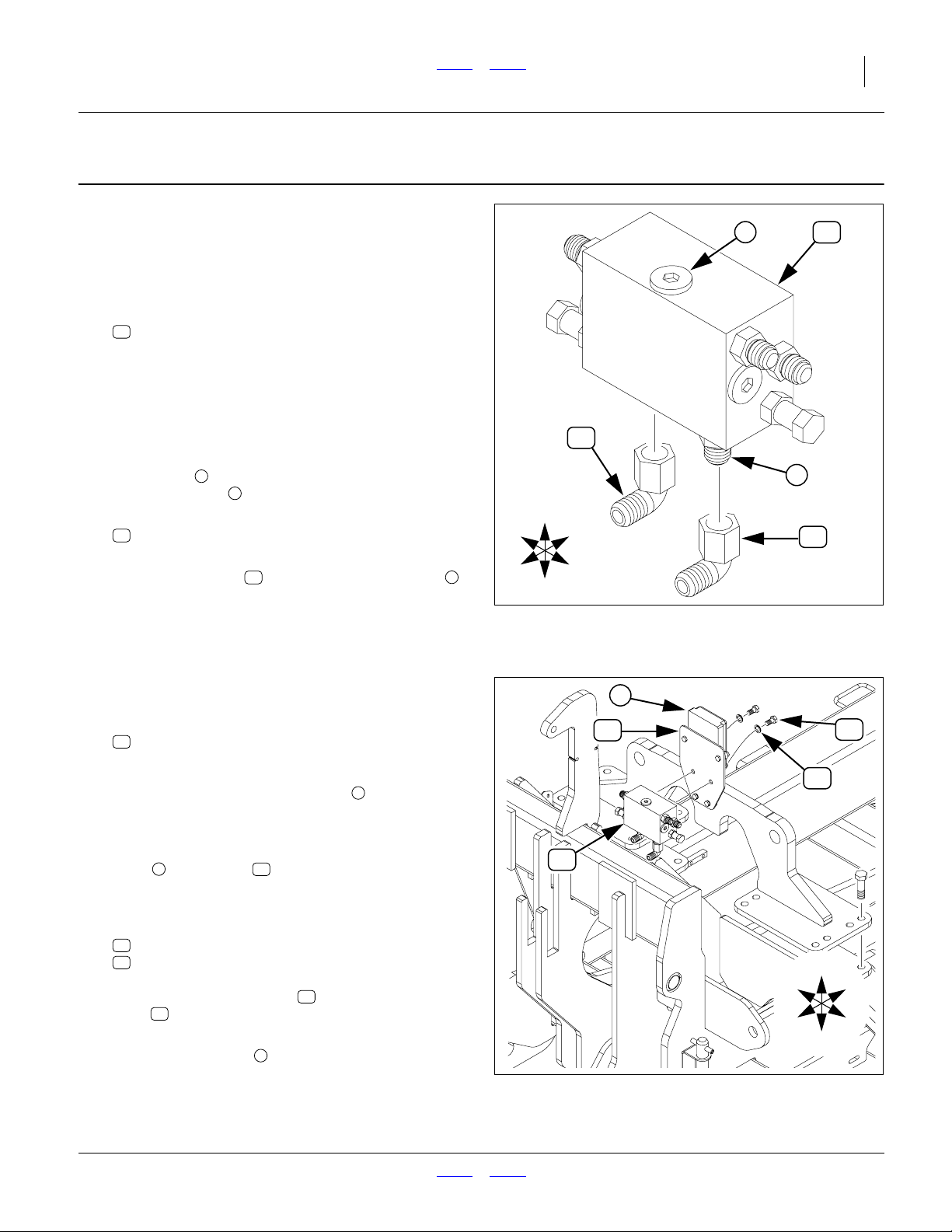

Prepare Sequence Valve

Refer to Figure 8

29. Select one new:

74

HYD-2480

SQV-SHOEMAKER #4129 (SIDE PORTS)

If the valve has elbows pre-installed, skip to step 32.

30. Examine the valve body to establish which faces are

front and top. The front face is blank except for

stamped text. The rear face has two3⁄8-16 threaded

holes (not shown). The top face has a single hex

socket plug . The bottom face has two MJIC/

MORB adaptors (the supply/return ports).

31. Select two new:

76

HYD-65000606

9/16 MJ - 9/16 FJS 90 DEG SWIVEL

32. Secure the elbows to the supply/return ports ,

with the MJIC ends of the elbows facing forward.

Null4:

4

5

76 5

R

F

Null4:

4

76

U

B

L

D

Figure 8

Prepare Sequence Valve

74

5

76

31343

Install Sequence Valve

Refer to Figure 9

33. On the implement center section, locate the:

11

160-762D WSMB MODULE MOUNT PLATE

It is pre-installed near the cart-implement hitch, and

has a DICKEY-john®WSMB-POM mounted. The

cables exiting the below the POM slightly interfere

with valve installation, so it is temporarily removed.

34. Remove and save the fasteners securing the

611

POM to the plate . Without disconnecting the

harness connections, carefully move the POM out

of the way.

35. Select two sets new:

70

FNS-120C5PC 3/8x3/4" UNC HCS GR5 YZ

71

FNS-62RP 3/8" Split L/W YZ

Mount the sequence valve on the front of the

11

plate , with the supply/return ports and elbows on

the bottom.

36. Re-secure the POM in its original location.

Null4:

74

6

6

Null4:

74

6

11

Figure 9

Mount Sequence Valve

R

F

70

71

U

B

L

D

31342

2013-10-10 Front Parts 113-850M

Page 8

8 2013- Single Fold Marker Front Parts Great Plains Mfg., Inc.

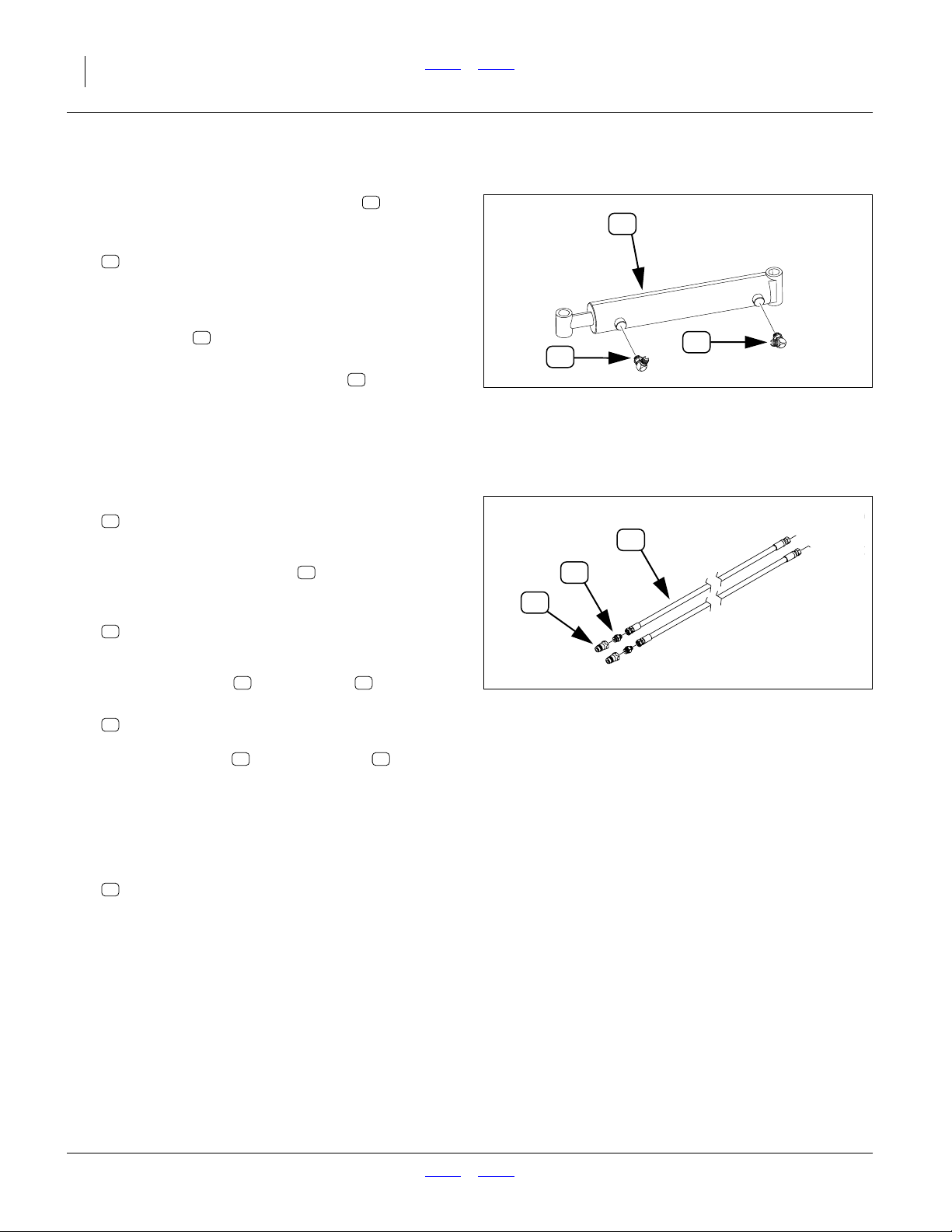

Install Cylinder Fittings

Refer to Figure 10

If elbows are pre-installed on the cylinders , skip to

step 38.

48

48

37. Select four new:

49

HYD-2787 #6ORBx9/16"JICM 90 6801-0606

Loosely install the MORB ends of the elbows at the

cylinder ports.

38. If the elbows were pre-installed, loosen the jam

nuts.

39. Adjust the orientation of the elbows so that the

MJIC inlets face up, and toward each other at

roughly a 45° angle. Tighten the jam nuts to ORB

49

49

Null4:

49

49

Figure 10

Cylinder Elbows

31344

torque spec.

Prepare Supply Hoses

Refer to Figure 11

40. Select two new:

72

HP-9JF100.375

3/8" HOSE X 100" 9/16 JICF ENDS

72

If the MORB-MJIC adaptors are already

75

installed on one end of each hose, skip to step 42.

41. Select two new:

75

HYD-6400680

ADAPTER 9/16 (#6) JICM - 3/4" (#8) ORB

Install one adaptor on each hose .

75 72

42. Select two existing:

12

811-070C CP 3/4FORB QD

Install one coupler on each adaptor .

12 75

43. If orange cable ties are available, secure one tie to

each hose end near the FJIC fitting. It is not necessary to separately identify one hose from the other.

Prepare Cylinder Hoses

44. Select two (of four):

73

HP-9JF154

3/8" HOSE X 154" 9/16 JICF ENDS

If orange ties are available, secure one tie to each

hose end near the FJIC fitting. If orange ties are not

available, use tape, tags or indelible marking pen to

identify hose ends or connectors as “R”. These are

the rod-end hoses.

Null4:

Null4:

12

75

Figure 11

Marker Supply/Return Hoses

31336

113-850M Front Parts 2013-10-10

Page 9

Great Plains Mfg., Inc. Front Parts Installation Instructions 9

Install Cylinder Hoses

Install Left Cylinder Hoses

8

7

4

3

5

Null4:

Left Cylinder Hose Routing

Refer to Figure 12 (a composite image)

45. Select two hoses:

73

HP-9JF154

3/8" HOSE X 154" 9/16 JICF ENDS

One with orange tie or “R” tag, and one without.

46. Connect one end of the hose with the orange/R

marking to sequence valve port R.

47. Connect the unmarked hose to sequence valve

port C

48. Route the hoses under the clamp on the rear

face of the wing lock lug. Leave clamps lightly snug

at this time, to allow for sag and slack adjustment at

step 52.

49. Route the hoses under the clamp at mid-wing

near the fold cylinder rod end.

50. Route the hoses to the front of the wing, under the

adjustment valve assembly and under the outer

wing clamp .

51. At the cylinder, connect the orange/R hose to the

elbow fitting at the rod end.

Connect the unmarked hose to the elbow at the

base end .

52. Adjust hose sag and slack per suggestions at right.

53. Tighten all clamps.

3

4

5

1

2

Figure 12

73

2

6

1

Left Sag and Slack:

• Allow just enough sag at the wing pivot so that the

hose is near, but no lower than the wing pivot pin .

• Where the hoses naturally cross each other at the

cylinder, secure a cable tie.

• Add a second tie approximately 40cm (16in) away, to

bundle the hoses.

• Create enough slack at this location for a loop no

higher than the eyebolt on the gauge wheel. The rod

end hose must follow the rod end of the cylinder as it

swings out and toward the rear during marker extension.

• Balance remaining slack at the adjustment valves and

at the sequence valve.

• Check that all slack is clear of moving parts.

C

R

31345

6

7

Null4:

2013-10-10 Front Parts 113-850M

Page 10

10 2013- Single Fold Marker Front Parts Great Plains Mfg., Inc.

Install Right Cylinder Hoses

Refer to Figure 13

54. Select two hoses:

73

HP-9JF154

3/8" HOSE X 154" 9/16 JICF ENDS

One with orange tie or “R” tag, and one without.

55. Connect one end of the hose with the orange/R

marking to sequence valve port R.

56. Connect the unmarked hose to sequence valve

port C

57. Route the hoses under the clamp on the rear

1

face of the wing lock lug. Leave clamps lightly snug

at this time, to allow for sag and slack adjustment at

step 61.

58. Route the hoses under the clamp at mid-wing

2

near the fold cylinder rod end.

59. Route the hoses to the front of the wing, under the

adjustment valve assembly and under the outer

wing clamp .

3

60. At the cylinder, connect the orange/R hose to the

elbow fitting at the rod end.

4

Connect the unmarked hose to the elbow at the

base end .

5

61. Adjust hose sag and slack:

• Allow just enough sag at the wing pivot so that

the hose is near, but no lower than the wing

pivot pin.

• Where the hoses naturally cross each other at

6

the cylinder, secure a cable tie.

• Add a second tie approximately 40cm (16in)

away, to bundle the hoses.

• Create enough slack at this location for a loop no

higher than the spring holder on the marker.

64

The rod end hose must follow the rod end of the

cylinder as it swings out and toward the rear during marker extension.

• Balance remaining slack at the adjustment valves

and at the sequence valve.

Check that all slack is clear of moving parts.

Null4:

64

3

73

R

1

Figure 13

Right Cylinder Hose Routing

6

4

5

2

C

31346

62. Tighten all clamps.

Null4:

113-850M Front Parts 2013-10-10

Page 11

Great Plains Mfg., Inc. Front Parts Installation Instructions 11

Install Supply Hoses

Refer to Figure 14

63. Select two new:

72

HP-9JF100.375

3/8" HOSE X 100" 9/16 JICF ENDS

As prepared at step 40 through step 43.

64. Connect the FJIC ends of the hoses to the MJIC

ports on the bottom of the sequence valve .

65. Route the hoses through the hose clamp

mounted upper the right side of the top hitch tool

bar. Leave clamps lightly snug at this time, to allow

for sag and slack adjustment at step 69.

Null4:

Refer to Figure 15

66. Route the left hose through the mid-hitch

clamp , which may have only one available clamping location.

67. Use a tie wrap to loosely secure the right hose to

the left hose near the mid clamp.

68. Route both hoses through the front clamp .

69. Adjust sag and slack:

• Allow enough slack near the sequence valve to

• allow most of the slack between the top and

• Allow only enough slack between the mid and

• Allow enough slack at the QD end of the hoses

Check that all slack is clear of moving parts.

70. Tighten all clamps.

Null4:

3

a

allow hose disconnection.

b

mid clamps. The distance between them

increases during lift.

c

front clamps to prevent hose kinking.

d

to allow easy disconnection. If the implement is

lowered during marker assembly, there will be

ample slack for the small change in distance from

the front clamp to the panel outlet during raise/

lower.

2

74

1

4

5

Null4:

Null4:

R

F

74

U

B

L

D

4

3

5

72

Figure 14

Valve to Hitch Hose Routing

b

2

c

d

Figure 15

Lower Hitch Hose Routing

1

31347

72

a

31348

2013-10-10 Front Parts 113-850M

Page 12

12 2013- Single Fold Marker Front Parts Great Plains Mfg., Inc.

Charge and Bleed System

Refer to Figure 16

71. Put on gloves and safety glasses.

72. Connect the QD ends of the marker supply

hoses to cart outlets A and B. Either hose may

be connected to either port.

73. Remove any strapping that holds the marker arms

closed.

Pinch / Crush / Striking Hazards:

Clear all objects from the sweep arcs of the marker arms.

Have all persons stand clear. The next steps fully deploy the

arms, and the motion may be sudden and irregular due to air

in the system.

74. Set the remote circuit assigned to the markers to

Neutral. Activate hydraulic power.

Note: Implement is still lowered. Normally, the imple-

75. While charging the system, bleed the markers per

the instructions in the 166-283M Operator Manual,

Maintenance topic.

76. Slowly move the marker circuit lever to Extend.

Observe which marker begins to move, and if neither, slowly reverse the lever to Retract.

77. Continuing slow operation, gradually extend a

marker arm on one side. When it reaches full extension, slowly reverse the lever and fold the marker.

When fully folded, set lever to Neutral.

78. Slowly reverse the lever. The other marker should

begin to deploy. Fully extend the marker, then fully

fold it.

79. Set circuit to Float and shut off hydraulic power.

Inspect the system for hydraulic leaks.

80. Repeat step 76 through step 78 two more times.

81. Perform another leak inspection.

82. Fold both markers. Set circuit to Neutral. Shut off

hydraulic power.

72

ment is raised for marker operations. With no third

stage arm or disk assembly installed, the markers

are short enough and light enough that they will

not strike the ground during initial exercising.

72

A

B

72

Null4:

Figure 16

Cart Hose Connections

High Pressure Fluid Hazard:

Escaping fluid under pressure can have sufficient pressure to

penetrate the skin causing serious injury. Avoid the hazard by

relieving pressure before disconnecting hydraulic lines. Use a

piece of paper or cardboard, NOT BODY PARTS, to check for

leaks. Wear protective gloves and safety glasses or goggles

when working with hydraulic systems. If an accident occurs,

seek immediate medical assistance from a physician familiar

with this type of injury.

31349

Null4:

113-850M Front Parts 2013-10-10

Page 13

Great Plains Mfg., Inc. Front Parts Installation Instructions 13

Install Marker Disk and Guard

Install Third Stage Arm

Start with the left marker.

Refer to Figure 17

83. If pre-installed, loosen the jam nuts and set

screws in the second stage arm .

45 62

37

1

If not pre-installed, select two sets new:

37

FNS-54JPC 1/2"- 13 NC Jam Nut

45

FNS-8A41BPC 1/2 x1-1/2"SQ HD SET YZ

Place a jam nut on a set screw . Screw this

37 45

assembly a few turns into the threaded holes on the

outer end of the arm .

62

84. Select one new:

63

SFM-8665 Third Stage Arm SFM

Orient the disk mounting lug so that it is angled in

1

(toward implement center with markers folded).

Insert the third stage arm fully into the second

stage arm .

62

63

85. Tighten the set screws to1⁄2 turn beyond finger

tight. (The initial marker extension is set at step 96.)

86. Repeat step 83 through step 85 for the right side.

The lug is angled in on the right side as well.

Install Bearing Assembly and Guard

Start with the left marker.

Refer to Figure 18

87. Select one each new:

53

SA-9041 Disc Assy Complete w/o DISC/GAUGE

54

SFM-8223 Disc Guard

and two sets new:

34

FNS-241C5PC 1/2x1-3/4"" Carriage Bolt 5 YZ

43

FNS-74RP 1/2" Flat Washer

47

FNS-94SLN 1/2" Stover Nut UNC YZ

Loosely mount the bearing assembly under the

arm lug , and the guard on top of the lug, bent

63 54

tube facing to implement rear (with arm folded).

Figure 18 shows the carriage bolt in the inside

small slotted hole for a left arm installation. This

2

provides maximum angles for throwing dirt inward in

operation. This is a user preference issue.

88. Repeat step 87 and step 87 for the right side. Use

the alternate small slotted hole.

53

34

Null4:

53

63

34

3762

45

Figure 17

Install Third Stage Arm

47

43

54

52

2

63

31350

39

39

Null4:

Figure 18

31351

Install Bearing Assembly

2013-10-10 Front Parts 113-850M

Page 14

14 2013- Single Fold Marker Front Parts Great Plains Mfg., Inc.

Install Disc and Depth Gauge

Start with the left marker.

Sharp Object Hazard:

Wear gloves and be cautious when working with marker discs.

The edges are sharp.

Refer to Figure 19

89. Select one each new

44

FNS-79NP 1" Flat Washer

50

MIS-2192 Nylon Depth Guage

52

MIS-2526 18" Notched Blade

39

FNS-59JPC 1" - 8 Jam Nut PLT

54

39

39

Place the disc blade on the disc axle .

52 79

The disc is shown concave side toward arm, but it

may be mounted concave side out per user preference.

Add the depth gauge , rim side toward arm, the

flat washer and a jam nut . Avoid crushing the

44 39

50

nylon depth gauge when tightening the first (inner)

jam nut.

90. Select one each new

42

FNS-69RP 1" Split L/W YZ

39

FNS-59JPC 1" - 8 Jam Nut PLT

Add the lock washer and the second jam nut

42 39

to the axle. Tighten the second jam nut, against the

first, to Class 5.8 (Grade 2) torque specification.

91. Adjust the bearing assembly for the desired disc

53

angle of throw.

92. Adjust the guard so that the double-end tube is

aligned with the disc edge.

93. Secure the bearing/guard fasteners to torque spec.

94. Repeat step 89 through step 93 for the right marker.

Set Initial Extension and Tension

Null4:

53

79

Figure 19

Install Disc & Depth Gauge

52

44

50

42

31352

95. With the implement still lowered, extend a marker

on one side. At full retraction, it should remain suspended above the ground. Set the circuit to Neutral

and shut off hydraulics.

96. Set the approximate initial marker extension per the

instructions in the 166-283M Operator manual.

Because the implement is typically not into the

ground at this time, the setting is approximate.

97. Set the initial marker tension to 23 kg (50 lbs.) per

the instructions in the 166-283M Operator manual.

Null4:

113-850M Front Parts 2013-10-10

Page 15

Great Plains Mfg., Inc. Front Parts Installation Instructions 15

Close-Out

98. Fold the markers.

99. Raise the implement.

100. Fold the implement.

101. Lower the implement into lift lock.

Appendix

Hydraulic Connector Identification

Refer to Figure 20 (a hypothetical fitting)

Leave any protective caps in place until immediately prior

to making a connection.

1

NPT - National Pipe Thread

Note tapered threads, no cone/flare, and no O-ring.

Apply liquid pipe sealant for hydraulic applications

(do not use tape sealant, which can foul filters).

2

JIC - Joint Industry Conference (SAE J514)

Note straight threads and the 37° cone on

“M” fittings (or 37° flare on “F” fittings). Use no

sealants (tape or liquid) on JIC fittings.

3

ORB - O-Ring Boss (SAE J514)

Note straight threads and elastomer O-Ring .

Prior to installation, to prevent abrasion during tightening, lubricate O-Ring with clean hydraulic fluid.

Use no sealants (tape or liquid) on JIC fittings.

ORB fittings that need orientation, such as the ell

depicted, also have a washer and jam nut

(“adjustable thread port stud”). Back jam nut away

from washer. Thread fitting into receptacle until

O-Ring contacts seat. Unscrew fitting to desired

orientation. Tighten jam nut to torque specification.

4 5

5 7

8 9

Marker Operation

Marker operation is covered thoroughly in the 166-283M

Operator manual.

Marker Maintenance

Marker maintenance is covered thoroughly in the166283M Operator manual.

1

9

8

4

5

2

Null4:

Hydraulic Connector ID

Null4:

Null4:

Fittings Torque Values

Fitting Ft-Lbs N-m

1

⁄4 NPT 1.5-3.0 turns past finger tight

9

⁄16 JIC 18-20 24-27

9

⁄16 ORB w/jam nut 12-16 16-22

9

⁄16 ORB straight 18-24 24-32

3

⁄4 JIC 27-39 37-53

3

⁄4 ORB w/jam nut 20-30 27-41

3

⁄4 ORB straight 27-43 37-58

Figure 20

7

5

3

31282

Null4:

2013-10-10 Front Parts 113-850M

Page 16

16 2013- Single Fold Marker Front Parts Great Plains Mfg., Inc.

Torque Chart

8.5 13 18

15 24 33

17 26 37

27 42 59

31 47 67

43 67 95

49 75 105

66 105 145

75 115 165

95 150 210

105 165 235

130 205 285

150 230 325

235 360 510

260 405 570

225 585 820

250 640 905

340 875 1230

370 955 1350

480 1080 1750

540 1210 1960

680 1520 2460

750 1680 2730

890 1990 3230

1010 2270 3680

1180 2640 4290

1330 2970 4820

61014 5 811

11 17 25 12 19 27

13 19 27 13 21 29

20 31 44 24 39 53

22 35 49 29 45 62

32 49 70 42 67 93

36 55 78 44 70 97

49 76 105 66 77 105

55 85 120 68 105 150

70 110 155 73 115 160

79 120 170 105 165 230

97 150 210 115 180 245

110 170 240 145 230 300

170 265 375 165 260 355

190 295 420 205 325 450

165 430 605 230 480 665

185 475 670 355 560 780

250 645 910 390 610 845

275 705 995 705 1120 1550

355 795 1290 785 1240 1710

395 890 1440 1270 1950 2700

500 1120 1820 1380 2190 3220

555 1240 2010

655 1470 2380

745 1670 2710

870 1950 3160

980 2190 3560

M 6 X 1

M 8 X 1.25

M 8 X 1

M10 X 1.5

M10 X 0.75

M12 X 1.75

M12 X 1.5

M12 X 1

M14 X 2

M14 X 1.5

M16 X 2

M16 X 1.5

M18 X 2.5

M18 X 1.5

M20 X 2.5

M20 X 1.5

M24 X 3

M24 X 2

M30 X 3.5

M30 X 2

M36 X 3.5

M36 X 2

a. in-tpi = nominal thread diameter in inches-threads per inch

b. N· m = newton-meters

c. mm x pitch = nominal thread diameter in mm x thread pitch

d. ft-lb = foot pounds

71115

17 26 36

18 28 39

33 52 72

39 61 85

58 91 125

60 95 130

90 105 145

92 145 200

99 155 215

145 225 315

155 240 335

195 310 405

220 350 485

280 440 610

310 650 900

480 760 1050

525 830 1150

960 1510 2100

1060 1680 2320

1730 2650 3660

1880 2960 4100

+ 0%, -15% of torquing values. Unless otherwise specified use torque values listed above.

Null4:

113-850M Front Parts 2013-10-10

25199m

25199

Page 17

Great Plains Mfg., Inc. Front Parts Installation Instructions 17

Parts Lists

39

47

43

42

59

44

68

47

54

B

R

58

43

U

D

51

L

F

55

38

41

22

67

26

49

41

46

33

44

48

27

38

38

41

51

38

33

56

63

Null4:

39

61

35

50

28

35

31

52

33

37

25

47

53

51

34

45

47

62

29

}

40

36

Figure 21

Marker Kit Mechanical Components

43

38

32

47

66

38

57

38

60

23

64

47

69

30

31333

2013-10-10 Front Parts 113-850M

Page 18

18 2013- Single Fold Marker Front Parts Great Plains Mfg., Inc.

Existing Parts

The part call-out numbers in this list match all Figures in

these installation instructions. Part descriptions match

those in your updated Parts Manual.

The Part Disposition column indicates whether the part is

re-used or discarded.

Figure 22

Callout

11 1

12 2

a This part is pre-installed on the implement and left in place.

b This coupler is supplied with the NTA607HD or NTA2007HD air cart.

Quantity

Required

a

b

Great Plains

Part Number

160-762D WSMB MODULE MOUNT PLATE

811-070C CP 3/4FORB QD

New Parts

113-849A Kit Contents

Great Plains part numbers and descriptions are listed

above Haukaas equivalents. For replacements, order the

Great Plains part numbers.

Quantities are units (“ea”).

Figure 21

Callout

21 1

22 4

23 4

24 1

Quantity

in Kit

Haukaas Part No.

GP Part Number

-

113-850M

FNS-024346

806-044C

FNS-02291

806-080C

9269

828-064C

Great Plains Part Description

Haukass Part Description

MANUAL 20FT SWING-ARM MARKER

5/8x5-1/16x5-1/2" U-bolt

U-BOLT 5/8-11 X 5 1/32 X 6

5/8x4-1/16x6-1/2 Sq-U-Bolt for 4x5

U-BOLT 5/8-11 X 4 1/32 X 6

Great Plains Single Fold Markers

HAUKAAS MARKER (NTA607HD)

Great Plains Part Description

The part call-out numbers in this list match all Figures in

these installation instructions. Part descriptions match

those in your updated Parts Manual.

9269 828-064C (9269 828-064C) Bundle Contents

Haukaas part numbers and descriptions are listed first.

New parts in the kit show these identifications.

Figure 21

Callout

25 4

26 4

27 2

28 2

29 16

30 2

31 2

113-850M Front Parts 2013-10-10

Quantity

in Kit

Haukaas Part No.

GP Part Number

BRG-2450

BRG-2450

FNS-02284

806-157C

FNS-02392

FNS-02392

FNS-124-5PC

802-223C

FNS-131B5PC

802-029C

FNS-142B5PC

802-130C

FNS-143C8PC

802-853C

Haukass Part Description

Great Plains Part Description

1-1/4"- Bearing &Housing Assembly (4 Blt)

HAUKAAS 1-1/4 BRG & HSNG COMP

5/8-11x3-1/16x3-1/2 Sq-U-Bolt for3x2

U-BOLT 5/8-11 X 3 1/32 X 3 1/2

5/8-11x6" I-BOLT (4" THREAD) #104

HAUKAS 5/8-11X6 I-BLT(4"THREAD

3/8x4" UNC HCS GR5 YZ

HHCS 3/8-16X4 GR5

7/16x1-1/2" UNC HCS GR5 YZ

HHCS 7/16-14X1 1/2 GR5

1/2 X 2-1/2"" HCS GR 5 YZ

HHCS 1/2-13X2 1/2 GR5

1/2 x 3-3/4" NC 8PL

HHCS 1/2-13X3 3/4 GR8

For replacements, order the Great Plains part numbers

(if different) shown below the Haukaas numbers.

Page 19

Great Plains Mfg., Inc. Front Parts Installation Instructions 19

Figure 21

Callout

32 2

33 6

34 2

35 12

36 16

37 4

38 2

39 4

40 16

41 48

42 2

43 16

44 4

45 4

46 6

47 12

48 2

49 4

50 2

51 4

52 2

53 2

54 2

Quantity

in Kit

a

a

Haukaas Part No.

GP Part Number

FNS-163-5PC

802-059C

FNS-241B5PC

802-106C

FNS-241C5PC

802-331C

FNS-52RPC

803-014C

FNS-53RPC

803-015C

FNS-54JPC

803-036C

FNS-56RPC

803-021C

FNS-59JPC

803-030C

FNS-63RP

804-014C

FNS-66RP

804-022C

FNS-69RP

804-027C

FNS-74RP

804-113C

FNS-79NP

804-029C

FNS-8A41BPC

801-013C

FNS-8CB-1BP

805-104C

FNS-94SLN

803-342C

HYD-236801

HYD-236801

HYD-2787

811-065C

MIS-2192

MIS-2192

MIS-2325

800-001C

MIS-2526

MIS-2526

SA-9041

SA-9041

SFM-8223

SFM-8223

Haukass Part Description

Great Plains Part Description

5/8 X 3"" UNC HCS GR5 YZ

HHCS 5/8-11X3 GR5

1/2x1-1/2" Carriage Bolt 5P

RHSNB 1/2-13X1 1/2 GR5

1/2x1-3/4"" Carriage Bolt 5 YZ

RHSNB 1/2-13X1 3/4 GR5

3/8" NC Hex Nut

NUT HEX 3/8-16 PLT

7/16"- 14 NC Hex Nut

NUT HEX 7/16-14 PLT

1/2"- 13 NC Jam Nut

NUT HEX JAM 1/2-13 PLT

5/8"-11 NC Hex Nut

NUT HEX 5/8-11 PLT

1" - 8 Jam Nut PLT

NUT HEX JAM 1-8 PLT

7/16" Split L/W PLT

WASHER LOCK 7/16 PLT

5/8" Split L/W YZ

WASHER LOCK SPRING 5/8 PLT

1" Split L/W YZ

WASHER LOCK SPRING 1 PLT

1/2" Flat Washer

WASHER FLAT 1/2 USS HARD PLT

1" Flat Washer

WASHER FLAT 1 SAE

1/2 x1-1/2"SQ HD SET YZ

SCREW SET SQ HD 1/2-13X1 1/2G5

3/16 x 1-1/2 Cotter-Pin

PIN COTTER 3/16 X 1 1/2 PLT

1/2" Stover Nut UNC YZ

NUT HEX TOP LOCK 1/2-13 PLT

Cylinder,Hyd 2-1/2 x 12 PAL 1200132

HAUKAAS CYL 2-1/2X12PAL1200132

#6ORBx9/16"JICM 90 6801-0606

EL 9/16MJIC 9/16MORB

Nylon Depth Guage

HAUKAAS NYLON DEPTH GAUGE

.250 Grease Zirk (GF641)

GREASE ZERK STRAIGHT 1/4-28

18" Notched Blade

HAUKAAS 18" NOTCHED DISC BLADE

Disc Assy Complete w/o DISC/GAUGE

HAUKAS DISC ASY W/O DISC/GAGE

Disc Guard

HAUKAAS DISC GUARD

2013-10-10 Front Parts 113-850M

Page 20

20 2013- Single Fold Marker Front Parts Great Plains Mfg., Inc.

Figure 21

Callout

55 1

56 1

57 1

58 1

59 1

60 1

61 2

62 2

63 2

64 2

65 2

66 2

67 1

68 1

69 2

a Some of this count is found in subordinate kits.

Quantity

in Kit

Haukaas Part No.

GP Part Number

SFM-8657

SFM-8657

SFM-8658

SFM-8658

SFM-8659

SFM-8659

SFM-8660

SFM-8660

SFM-8661

SFM-8661

SFM-8662

SFM-8662

SFM-8663

SFM-8663

SFM-8664

SFM-8664

SFM-8665

SFM-8665

SFM-8666

SFM-8666

SFM-8667

SFM-8667

SFM-8668

SFM-8668

SFM-8669

SFM-8669

SFM-8670

SFM-8670

SPR-2395

SPR-2395

Haukass Part Description

Great Plains Part Description

Subframe Left - SFM

HAUKAAS SUBFRAME LEFT SFM

Subframe Right SFM

HAUKAAS SUBFRAME RIGHT SFM

End Bushing Right SFM

HAUKAAS END BUSHING RIGHT SFM

End Bushing Left SFM

HAUKAAS END BUSHING LEFT SFM

Pivot Frame Left SFM

HAUKAAS PIVOT FRAME LEFT SFM

Pivot Frame Right SFM

HAUKAAS PIVOT FRAME RIGHT SFM

Primary Arm SFM

HAUKAAS PRIMARY ARM SFM

Second Stage Arm SFM

HAUKAAS SECOND STAGE ARM SFM

Third Stage Arm SFM

HAUKAAS THIRD STAGE ARM SFM

Spring Holder SFM

HAUKAAS SPRING HOLDER SFM

Arm Rest SFM

HAUKAAS ARM REST SFM

Cylinder Pin SFM

HAUKAAS CYLINDER PIN SFM

Mounting Bracket Right SFM

HAUKAAS MOUNTING BRACKET RIGHT

Mounting Bracket Left SFM

HAUKAAS MOUNTING BRACKET LEFT

DSA/MED/CB Spring 02-200934-1

HAUKAAS MEDIUM CB SPRING

Null4:

113-850M Front Parts 2013-10-10

Page 21

Great Plains Mfg., Inc. Front Parts Installation Instructions 21

9269 Hydraulic Package Contents

Unless the part has only a Great Plains part number,

Haukaas part numbers and descriptions are listed first.

New parts in the kit show these identifications.

For replacements, order the Great Plains part numbers

(if different) shown below the Haukaas numbers.

49

49

73

71

70

73

73

75

12

74

76

Null4:

Figure 22

Callout

12

49

70 2

71 10

72 2

73 4

74 1

75 2

76 2

a Some of this count is found in the SA-9041 bundle (page 19).

Quantity

in Kit

See

page 18

See

page 19

a

Haukaas Part No.

GP Part Number

-

811-070C

HYD-2787

811-065C

FNS-120C5PC

802-014C

FNS-62RP

804-013C

HP-9JF100.375

HP-9JF100.375

HP-9JF154

HP-9JF154

HYD-2480

HYD-2480

HYD-6400680

811-133C

HYD-65000606

811-169C

72

Null4:

Figure 22

Haukaas Hydraulic Package

Haukass Part Description

Great Plains Part Description

CP 3/4FORB QD

#6ORBx9/16"JICM 90 6801-0606

EL 9/16MJIC 9/16MORB

3/8x3/4" UNC HCS GR5 YZ

HHCS 3/8-16X3/4 GR5

3/8" Split L/W YZ

WASHER LOCK SPRING 3/8 PLT

3/8" HOSE X 100" 9/16 JICF ENDS

3/8" HOSE X 100" 9/16 JICF ENDS

3/8" HOSE X 154" 9/16 JICF ENDS

3/8 HYD HOSE X 154 9/16FJIC

SQV-SHOEMAKER #4129 (SIDE PORTS)

HAUKAAS SQV-SHOEMAKER #4129

ADAPTER 9/16 (#6) JICM - 3/4" (#8) ORB

AD 9/16MJIC 3/4MORB

9/16 MJ - 9/16 FJS 90 DEG SWIVEL

EL 9/16MJIC 9/16FJIC

73

49

49

31336

2013-10-10 Front Parts 113-850M

Page 22

22 2013- Single Fold Marker Front Parts Great Plains Mfg., Inc.

SA-9041 Disc Assembly Contents

Haukaas part numbers and descriptions are listed first.

New parts in the kit show these identifications.

For replacements, order the Great Plains part numbers

(if different) shown below the Haukaas numbers.

79

Null4:

Figure 23

Callout

35

46

71

77 8

78 2

79 2

80 4

Quantity

in Kit

See

page 19

See

page 19

See

page 21

Haukaas Part No.

GP Part Number

FNS-52RPC

803-014C

FNS-8CB-1BP

FNS-8CB-1BP

FNS-62RP

804-013C

FNS-221B5PC

802-453C

SA-8056

SA-8056

SA-8084

SA-8084

BRG-2476

BRG-2476

77

71

80

Null4:

Haukaas Disc Assembly

Haukass Part Description

Great Plains Part Description

3/8" NC Hex Nut

NUT HEX 3/8-16 PLT

3/16 x 1-1/2 Cotter-Pin

3/16 x 1-1/2 Cotter-Pin

3/8" Split L/W YZ

WASHER LOCK SPRING 3/8 PLT

3/8x1-1/2" Carriage Bolt 5 PL

RHSNB 3/8-16X1 1/2 GR5

Disc Assembly Bracket

HAUKAAS DISC ASSEMBLY BRACKET

Disc Axle

HAUKAAS DISC AXLE

1" Bearing & Housing Assembly (2 Blt)

HAUKAAS 1" BRG & HSG COMP 2BLT

Figure 23

35

{

46

78

31334

113-850M Front Parts 2013-10-10

Page 23

Great Plains Mfg., Inc. Front Parts Installation Instructions 23

Abbreviations

AD Adaptor L/W Lock Washer

BLT Bolt MED Medium

BRG Bearing MIS Miscellaneous

CB Counter-Balance MJ MJIC

COMP Complete MJIC Male JIC

CYL Cylinder MORB Male ORB

DEG Degree NC National Coarse

EL Elbow NTA No-Till Air

FJS Female JIC Swivel ORB O-Ring Boss

FNS Fastener PLT Plated

FORB Female ORB QD Quick Disconnect

FT Foot RHSNB Round Head Shank Neck Bolt

GR5 Grade 5 SA Stabilizer Arm

HCS Hex Cap Screw SAE Society of Automotive Engineers (standard)

HD Head SFM Single Fold Marker

HEX Hexagonal SPR Spring

HHCS Hex Head Cap Screw SQ Square

HSNG Housing SQV Sequence Valve

HYD Hydraulic UNC Unified National Coarse

IN Inch USS United States Standard (heavy duty)

JIC Joint Industry Conference (standard) W/O Without

JICF JIC Female X by

JICM JIC Male YZ Yellow Zinc plated

Null4:

2013-10-10 Front Parts 113-850M

Page 24

24 2013- Single Fold Marker Front Parts Great Plains Mfg., Inc.

EOD

Great Plains Manufacturing, Inc.

Corporate Office P.O. Box 5060

Salina, Kansas 67402-5060 USA

113-850M Front Parts 2013-10-10

Loading...

Loading...