Great Plains NP3000A Operator Manual

Table of Contents Index

30-Foot Fertilizer Applicators

Operator Manual

Nutri-Pro® NP3000 and NP3000A

Manufacturing, Inc.

www.greatplainsmfg.com

Read the operator manual entirely. When you see this symbol, the

subsequent instructions and warnings are serious - follow without

exception. Your life and the lives of others depend on it!

31959

Illustrations may show optional equipment not supplied with standard unit, or may show

NP30, NP40 or NP4000 models where the topic function is identical.

EN

© Copyright 2013 Printed 2014-04-22 407-613M

Table of Contents Index

Table of Contents Index

Table of Contents Index

Great Plains Manufacturing, Inc. Table of Contents Index iii

Table of Contents

Important Safety Information ...................................... 1

Anhydrous Ammonia Safety...........................................1

Safety Decals ................................................................. 9

Introduction ................................................................18

Description of Unit ........................................................18

Models Covered .......................................................18

Intended Usage ........................................................18

Document Family......................................................18

Using This Manual........................................................19

Owner Assistance ........................................................20

Application Overview.................................................21

Anhydrous: System Components.................................21

NH3 System Narrative ..............................................22

Conventional Liquid: Applicator System Components .28

Hydraulic Drive System Components (Options).......28

Ground Drive System Components (Options)..........29

Liquid System Narrative ...........................................30

Trailing Nurse Tank Components.................................33

Nutri-Pro® Rear Hitch (Option) ..................................... 33

Hitch (Option) and Nurse Tank Components (User-Pro-

visioned) ...........................................................34

Preparation and Setup ...............................................35

Initial Setup...................................................................35

Post-Delivery/Seasonal Setup......................................35

NP3000A: Get Expert Advice .......................................36

Pre-Application Setup...................................................36

Hitching Tractor to Applicator .......................................36

2-Point Hitching ........................................................37

NP3000A: Emergency Shut-Off Rope......................38

Electrical Hookup......................................................40

Hydraulic Hose Hookup............................................ 41

Hydraulic Pump Hookup.......................................42

Raise Parking Stands ...........................................42

Leveling Implement ...................................................... 43

Set Application Depth...............................................43

2-Point Front-to-Back Level (Spacers) .....................43

Meter / Variable Rate Setup (Option) ...........................44

SCS 450 Setup Data ............................................ 46

Wash Water..................................................................46

Sealer Setup (NP3000A)..............................................46

Operating Instructions...............................................47

Pre-Start Checklist .......................................................47

Raising/Lowering Applicator.........................................48

Raise/Lower .............................................................48

Raising (Field, Unfolded) ......................................48

Raising (When Folded).........................................48

Lowering (Field, Unfolded) ...................................49

Lower (Service/Parking, Folded) ..........................49

Lift Cylinder Locks ....................................................50

Unfolding and Folding ..................................................51

Unfolding ..................................................................51

Unfolding (At Field)...............................................51

Unfolding (Service) ...............................................51

Folding..................................................................52

Transport...................................................................... 53

Transport Steps........................................................ 54

Final Applicator Setup.................................................. 54

Operations............................................................ 55

NH

3

NH

Nurse Tanks ..................................................... 55

3

NH3: Safing Applicator Before Cart Hitch.................55

NH3: Check Hydrostatic Relief Valves ..................... 56

NH3: Close Bleed Valves ......................................... 56

NH3: Check Hose Discharged..................................56

NH3: Hitching Nurse Tank ........................................ 57

NH3: Mechanical Cart Hitching............................. 57

NH3: Making Nurse Tank Connections .................... 58

NH3: Connect Cart Hose ...................................... 59

NH3: Dry Run ........................................................... 59

NH3: Pass Planning.................................................. 60

NH3: Start of Pass Planning ................................. 60

NH3: Monitor Operation............................................61

NH3: Field Application .............................................. 61

NH3: Starting Tank Flow....................................... 61

NH3: Starting Application...................................... 62

NH3: Suspending Application ............................... 63

NH3: Field Turns................................................... 63

NH3: Stopping Application.................................... 64

NH3: Breakaway Event............................................. 65

NH3: Unhitching Nurse Tank .................................... 67

NH3: Exchanging Nurse Tanks ............................ 67

NH3: Final Nurse Tank Unhitch ............................ 67

Liquid Operations......................................................... 68

Liq: Filling On-Board Tanks...................................... 68

Liq: Tank Quick-Fill .............................................. 68

Liq: Tank Lid Fill ................................................... 69

Liq: Hitching Conventional Nurse Tank....................70

Liq: Mechanical Cart Hitching .............................. 70

Liq: Making Nurse Tank Connections ..................70

Liq: Ground Drive Pump Start-Up ............................ 71

Liq: Prime the Ground Drive System.................... 71

Liq: Hydraulic Drive Start-Up.................................... 71

Liq: Field Operations (Either Pump).........................71

Liq: Fertilizer Operation............................................72

Liq: Monitor Operation (Option)................................ 73

Suspending Application............................................ 73

Liq: Stopping Application.......................................... 73

Field Set-Up Checklists................................................ 74

Field Operation Checklists ........................................... 76

Short-Term Parking...................................................... 77

Long-Term Storage...................................................... 77

Adjustments ............................................................... 78

Row Adjustments ......................................................... 79

Anhydrous Coulter Application Depth ...................... 79

Depth Reference Information ............................... 79

Anhydrous Coulter Castering ............................... 79

NH3 Sealer Adjustments .......................................... 80

Sealer Down-Pressure Adjustment ...................... 80

Sealer Spacing or Setback Adjustment................ 80

Sealer Angle Adjustment...................................... 80

Terra-Tine™ Adjustments (Option) .......................... 81

2014-04-22 Table of Contents Index 407-613M

iv NP3000/A Table of Contents Index Great Plains Manufacturing, Inc.

Vantage I Coulter Adjustments ................................ 82

Vantage I Coulter Height and Castering .............. 83

Tool Bar Height Adjustment ......................................... 84

Weight Transfer Adjustment ........................................ 85

Weight Transfer Safety Information ......................... 85

Terra-Tine™ Adjustments........................................ 87

Terra-Tine™ Down Force .................................... 87

Fertilizer Rates ........................................................... 88

Anhydrous Fertilizer Rate ............................................ 88

Conventional Liquid Fertilizer Rate .............................. 88

Rate Setting Steps: .................................................. 88

Determining Application Rate .................................. 88

Ground Drive:....................................................... 88

Ground Drive Rate: NP3000-1230 Standard ............... 89

NP3000-1230 Fertilizer Rate ................................... 89

NP3000-1230 JohnBlue Reference Data................. 89

Ground Drive Rate: NP3000-1230 Side Dress (SD).... 90

NP3000-1230SD Fertilizer Rate............................... 90

NP3000-1230SD JohnBlue Reference Data............ 90

Select and Install Orifice Plates ................................... 91

Determine Orifice Size ......................................... 91

Alternate Orifice Plates ........................................ 92

Tramlines and Doubled Rows .............................. 92

Row Shutoff ............................................................. 93

Strainer Adjustment ..................................................... 93

Ground Drive: Setting Relief Valve .............................. 94

Ground Drive: Set Pump Drive Range......................... 94

Ground Drive: Set Pump Rate Dial .............................. 95

Hydraulic Drive: Pump Pressure.................................. 96

Flow-Based Adjustment ........................................... 96

Dead-Head Adjustment............................................ 96

Troubleshooting......................................................... 97

Maintenance and Lubrication ................................. 105

Avoid Trapped Anhydrous ......................................... 106

Avoid Line Traps .................................................... 106

Avoid Ball Traps..................................................... 107

System Discharge...................................................... 108

Normal Discharge .................................................. 108

System Blow-Out ............................................... 109

Loop Clearing..................................................... 109

Clearing Plugged Tines.............................................. 110

Clearing Plugged Application Tubes...................... 110

Clearing Plugged Vapor Tubes.............................. 111

Hydrostatic Relief Valve Maintenance ....................... 112

Relief Valve Inspection ...........................................112

Valve Replacement.................................................113

Replacement Log .......................................................114

Metering System Maintenance ...................................117

Material Clean-Out (Liquid) ........................................118

Tank Clean-Out ......................................................118

Liquid Fertilizer Strainer Maintenance ........................119

Pump Maintenance and Repair ..................................120

Ace Hydraulic Pump ...............................................120

Coulter Disc Replacement..........................................120

NH3 Coulter Spring Setting.........................................121

Hydraulic Maintenance ...............................................122

Bleeding Lift Hydraulics ..........................................122

Bleeding Fold Hydraulics ........................................123

Wing Leveling .............................................................124

Rear Eyebolt Adjustment............................................124

Caster Brake Adjustment............................................125

Chain Maintenance.....................................................126

Lubrication and Scheduled Maintenance ...................127

Options ......................................................................131

Appendix A - Reference Information ......................142

Specifications and Capacities.....................................142

Tire Inflation Chart ......................................................143

Dimensions.................................................................144

Torque Values Chart ..................................................145

Plumbing Diagrams ....................................................146

Controller System Diagrams.......................................154

Hydraulic Diagrams ....................................................157

Chain Routing.............................................................159

Appendix B - Initial Setup ........................................160

Post-Delivery Checklist...............................................160

Lift-Assist Valve Setup................................................161

Appendix C - Option Setup......................................162

Hydraulic Pump Setup................................................162

Pump Fittings and Needle Valve ............................162

Console Installation ................................................163

Appendix D - Accessory Installation ......................164

Side Dress Installation................................................164

Conventional Liquid Side Dress..............................164

Reverting to Pre-Emergence ......................................174

Weight Kit Installation (s/n C1017A+).........................175

Warranty .....................................................................176

Index ..........................................................................177

407-613M Table of Contents Index 2014-04-22

Great Plains Manufacturing, Inc. Table of Contents Index 1

Important Safety Information

Anhydrous Ammonia Safety

The NP3000A Nutri-Pro® applicator includes several

manuals in addition to this Operator manual that contain

crucial safety information:

• 407-551M Using Anhydrous Ammonia Safely

• 016-0159-403 Raven AccuFlow™ Operator manual

• 016-0159-831 Raven SCS-450 Installation, Operation

and Service manual

• FVC062 Squibb-Taylor Flo-Max™ manual (breakaway

coupler)

Read all of these manuals. If you do not have the current

edition of one or more, contact Great Plains for a

replacement copy.

b

a

EPA EHS (Extremely Hazardous Substance):

Despite the common odor, anhydrous ammonia properties are

dramatically different from those of household ammonia

cleaning solutions (dilute ammonium hydroxide).

An uncontrolled release of NH3anhydrous ammonia can easily

be fatal or cause permanent disabling injury.

If you are new to NH3 operations, study everything you can

about this chemical and how to use it safely.

Suffocation, Blinding, Burning, Freezing, Disabling and

Disfigurement Hazards:

Your life and health,

the lives and health of your workers and community,

the continued commercial availability of anhydrous ammonia,

and continuation of agricultural NH3 transport exceptions

depend on you conducting meticulously careful operations.

Read All Manuals

The Anhydrous Safety manual (407-551M), this manual,

the meter manual and the breakaway coupler manual

(FVC062) are required reading for safe operations. All

operators of this equipment must read these manuals.

Even if you are an experienced anhydrous ammonia

operator, read the “Using Anhydrous Ammonia Safely”

manual (407-551M).

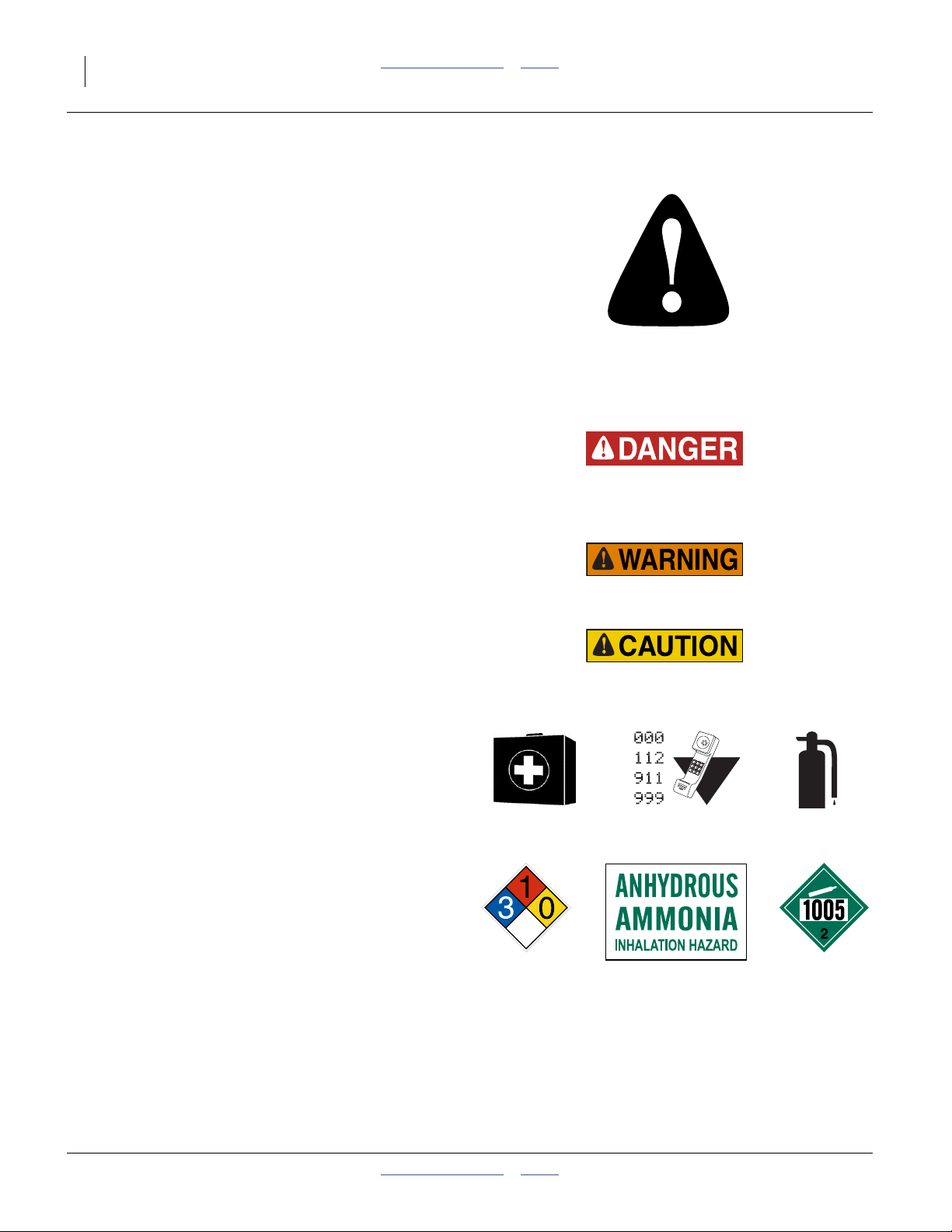

The diamond icons and decal image above appear in this

manual whenever a topic deals with anhydrous ammonia

safety. See the “Using Anhydrous Ammonia Safely”

manual (407-551M) for details on these signs. These

topics do not apply to NP3000 models configured only

for conventional liquid fertilizer.

a. AccuFlow™ is a trademark of Raven Industries.

b. Flo-Max™ is a trademark of Squibb-Taylor, Inc.

2014-04-22 Table of Contents Index 407-613M

2 NP3000 and NP3000A Table of Contents Index Great Plains Manufacturing, Inc.

Look for Safety Symbol

The SAFETY ALERT SYMBOL indicates there is a

potential hazard to personal safety involved and extra

safety precaution must be taken. When you see this

symbol, be alert and carefully read the message that

follows it. In addition to design and configuration of

equipment, hazard control and accident prevention are

dependent upon the awareness, concern, prudence and

proper training of personnel involved in the operation,

transport, maintenance and storage of equipment.

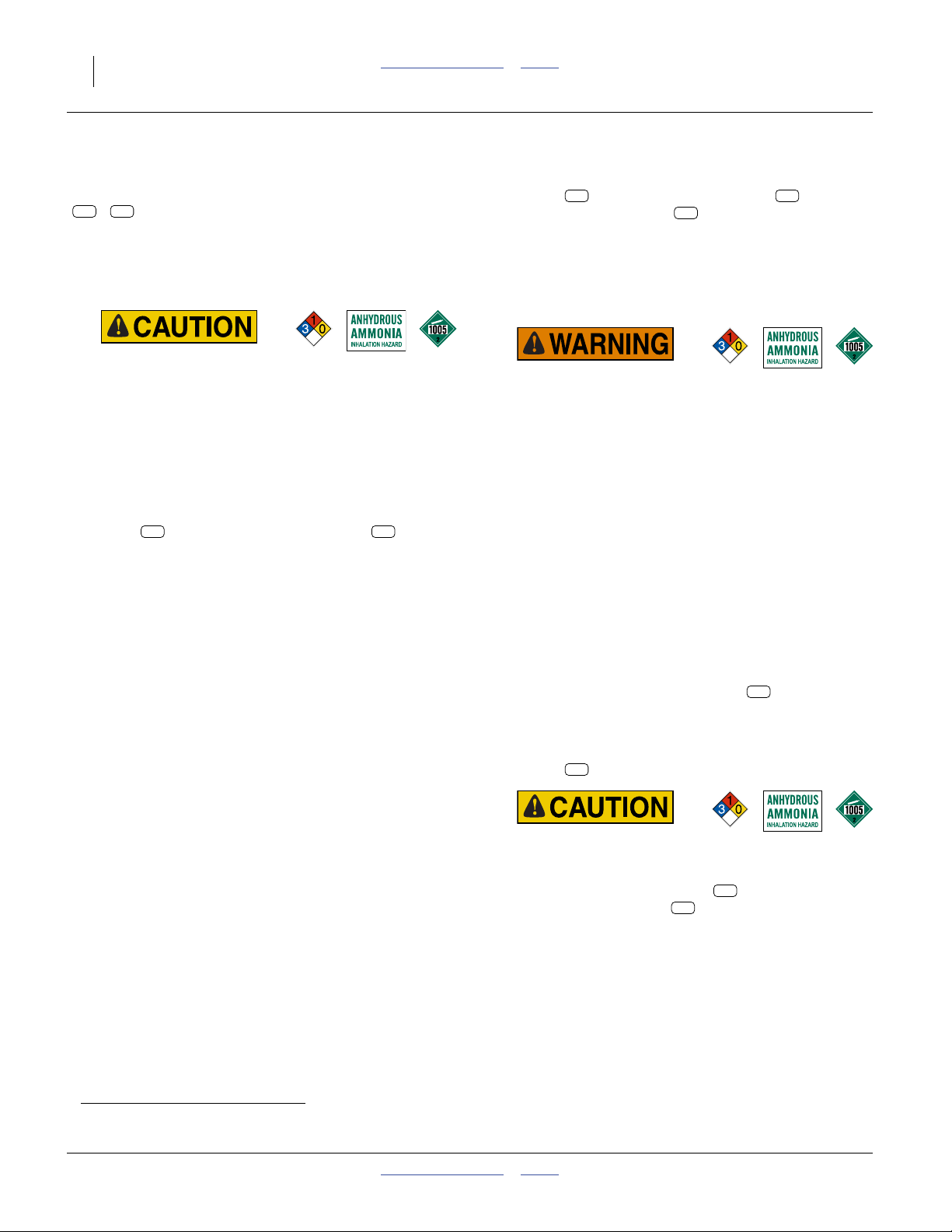

Be Aware of Signal Words

Signal words designate a degree or level of hazard

seriousness.

DANGER indicates an imminently hazardous situation

which, if not avoided, will result in death or serious injury.

This signal word is limited to the most extreme situations,

typically for machine components that, for functional

purposes, cannot be guarded.

WARNING indicates a potentially hazardous situation

which, if not avoided, could result in death or serious

injury, and includes hazards that are exposed when

guards are removed. It may also be used to alert against

unsafe practices.

CAUTION indicates a potentially hazardous situation

which, if not avoided, may result in minor or moderate

injury. It may also be used to alert against unsafe

practices.

Prepare for Emergencies

▲ Be prepared if a fire starts.

▲ Keep a first aid kit and fire extinguisher handy.

▲ Keep emergency numbers for doctor, ambulance, hospital

and fire department near phone. Know the reporting

requirement for spills or releases of the chemicals you are

using. Have contact numbers available.

▲ For anhydrous ammonia operations, have additional

contact information for:

• national response center

• regional (state) response center

• local response center

▲ If a fire threatens an anhydrous ammonia tank, evacuate the

area. The tank may heat up faster than the relief valve can

vent the rising pressure, resulting in a catastrophic gas

release and possibly an explosion.

407-613M Table of Contents Index 2014-04-22

Great Plains Manufacturing, Inc. Table of Contents Index Important Safety Information 3

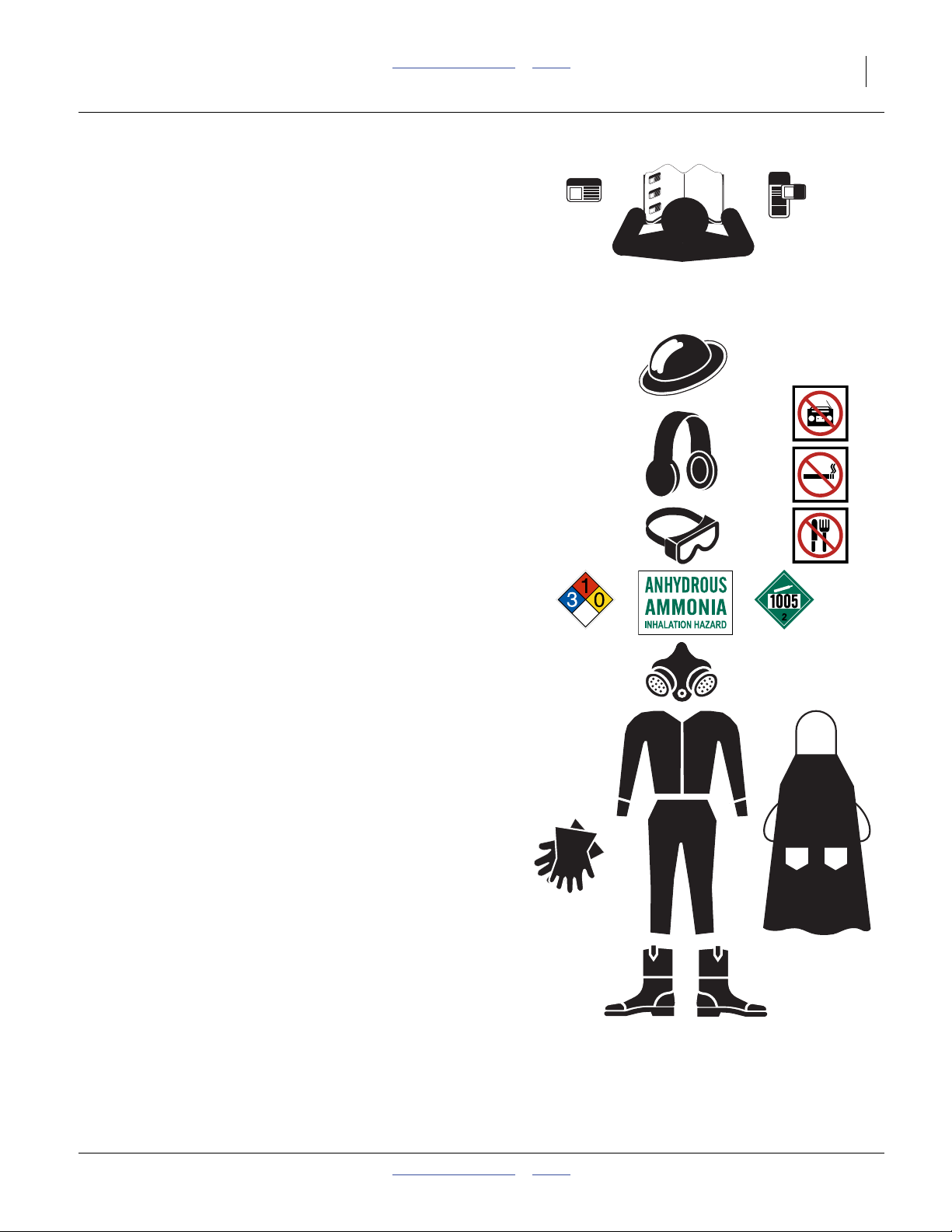

Be Familiar with Safety Decals

▲ Read and understand “Safety Decals”onpage9,

thoroughly.

▲ Read all instructions noted on the decals.

▲ Keep decals clean. Replace damaged, faded and illegible

decals.

Wear Protective Equipment (PPE)

▲ Wear clothing and equipment appropriate for the job. Avoid

loose-fitting clothing.

▲ Waterproof, wide-brimmed hat

▲ Face shield, goggles or full face respirator.

▲ Prolonged exposure to loud noise can cause hearing

impairment or loss. Wear suitable hearing protection such

as earmuffs or earplugs.

▲ Avoid wearing entertainment headphones while operating

machinery. Operating equipment safely requires the full

attention of the operator.

▲ See manual 407-551M for specific requirements and

recommendations for NH

▲ Goggles with side shields or a full face respirator are

required if handling or applying dusts, wettable powders, or

granules or if being exposed to spray mist.

▲ Cartridge-type respirator approved for pesticide vapors

unless conventional liquid fertilize label specifies another

type of respirator.

▲ Waterproof, unlined gloves. Neoprene is recommended.

▲ Cloth coveralls/outer clothing changed daily; waterproof

items if there is a chance of becoming wet with spray.

▲ Waterproof apron

▲ Waterproof boots or foot coverings

▲ Do not wear contaminated clothing. Wash protective

clothing and equipment with soap and water after each use.

Personal clothing must be laundered separately from

household articles.

▲ Clothing contaminated with certain pesticides must be

destroyed according to state and local regulations. Read

chemical label for specific instructions.

PPE.

3

2014-04-22 Table of Contents Index 407-613M

4 NP3000 and NP3000A Table of Contents Index Great Plains Manufacturing, Inc.

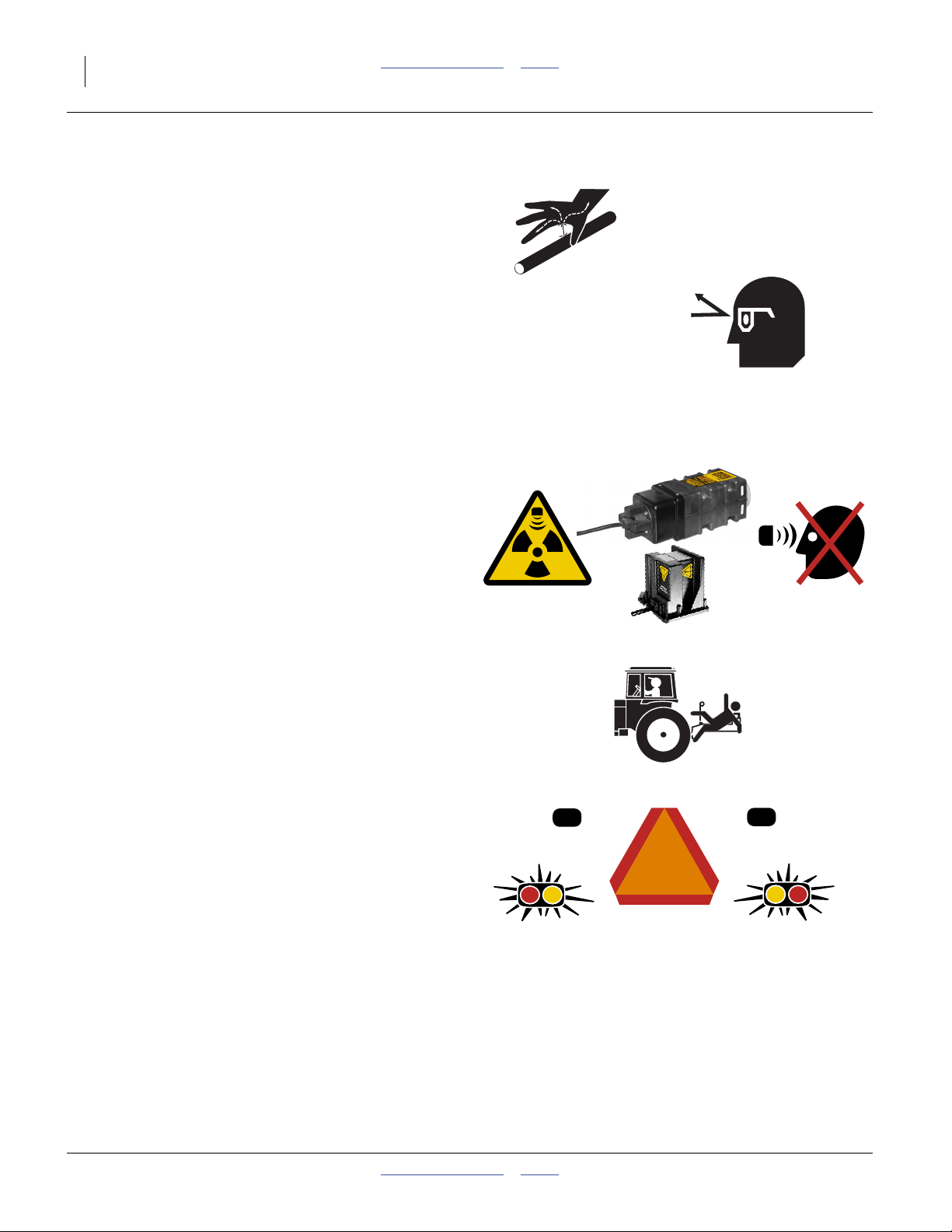

Avoid High Pressure Fluids

Escaping fluid under pressure can penetrate the skin,

causing serious injury. This fertilizer applicator requires a

Power-Beyond port, which is always under pressure

when the tractor is running.

▲ Avoid the hazard by relieving pressure before disconnecting

hydraulic lines.

▲ Use a piece of paper or cardboard, NOT BODY PARTS, to

check for suspected leaks.

▲ Wear protective gloves and safety glasses or goggles when

working with hydraulic systems.

▲ If an accident occurs, seek immediate medical attention

from a physician familiar with this type of injury.

Minimize Radiation Exposure

The optional DICKEY-john® RVS II and RVS III Radars

are intentional radiators of RF energy. Although its

radiated energy level is far below the limits set by

EN 61010-1:1993 A2:1995-Chapter 12.4, it is advisable

not to look directly into the face of the unit.

The radar must radiate toward the ground and at least

20 cm (8 inches) away from a human during use to

comply with the RF human exposure limits as called out

in FCC 47 CFR Sec.2.1091. DO NOT RE-MOUNT OR

USE THE RADAR IN A MANNER INCONSISTENT

WITH ITS DEFINED USE.

Keep Riders Off Machinery

Riders obstruct the operator’s view. Riders could be

struck by foreign objects or thrown from the machine.

▲ Never allow children to operate equipment.

▲ Keep all bystanders away from machine during operation.

Use Safety Lights and Devices

Slow-moving tractors and towed implements can create

a hazard when driven on public roads. They are difficult

to see, especially at night.

▲ Use flashing warning lights and turn signals whenever

driving on public roads.

▲ Use lights and devices provided with implement.

407-613M Table of Contents Index 2014-04-22

Great Plains Manufacturing, Inc. Table of Contents Index Important Safety Information 5

Tires Not a Step

Do not use gauge wheel or lift-assist tires as steps. A tire

could spin underfoot, resulting in a fall onto the applicator

or ground, possibly causing serious injury.

▲ The gauge wheel tires can be in poor ground contact at any

time, even with the fertilizer applicator lowered in the field.

They can appear to be in ground contact, and spin easily, in

multiple conditions.

▲ The lift-assist tires can be in poor ground contact, or out of

ground contact, whenever the fertilizer applicator is

lowered.

Remain Clear of Overhead Lines

▲ If the fertilizer applicator contacts a power line, lethal

voltage may be present on all metal parts. At higher voltage,

the applicator does not need to be in line contact for the

hazard to exist. Maintain at least 10 foot (3 m) clearance.

▲ Electrocution can occur without direct contact between the

energized fertilizer applicator and a person near the

fertilizer applicator.

▲ Watch for sagging, damaged or low electrical lines. The

folded fertilizer applicator could contact lines lower than

13 feet 2 inches (4 m). Overhead lines at farm structures

are a particular hazard.

▲ Watch for all electrical lines during folding and unfolding

operations. Use a spotter during folding and unfolding.

Know the location and height of all lines during transport

and in fields.

▲ If an electrical hazard is observed while on the ground near

the applicator, hop at least 100 feet (30 m) away with both

feet together and summon professional help. At higher

voltage, lethal voltage gradients can also be present at the

soil surface.

▲ Consult your tractor manual for advice on how to respond

to an electrical hazard event while in the cab.

2014-04-22 Table of Contents Index 407-613M

6 NP3000 and NP3000A Table of Contents Index Great Plains Manufacturing, Inc.

Transport Machinery Safely

Maximum transport speed for applicator is 20 mph (32

kph), 13 mph (22 kph) in turns. Some rough terrains

require a slower speed. Sudden braking can cause a

towed load to swerve and upset.

▲ Do not transport an applicator that weighs over 20,000

pounds (9060 kg). Loading liquid fertilizer tanks or

transporting with a nurse tank hitch to the applicator can

easily exceed this limit.

▲ Tow nurse tank separately. Do not tow a nurse tank in train

with the applicator on public roads.

▲ Never park an anhydrous ammonia tank on public roads or

anywhere near sites with high occupancy or high-risk

populations, such as shopping areas, events, schools,

hospitals, retirement communities, etc.

▲ Avoid transporting an anhydrous ammonia tank through

populated areas.

▲ Do not tow a lift-assisted 2-point applicator or nurse tank

that, when fully loaded, weighs more than 1.5 times the

weight of towing vehicle.

▲ Do not transport a 2-point applicator that exceeds the

capacity or ballasting of the tractor. There may not be

enough front wheel traction for safe steering.

▲ Carry reflectors or flags to mark fertilizer applicator in

case of breakdown on the road.

▲ Keep clear of overhead power lines and other obstructions

when transporting. Refer to transport dimensions under

“Specifications and Capacities” on page 142.

▲ Do not exceed 20 mph (32 km/h). Never travel at a speed

which does not allow adequate control of steering and

stopping. Reduce speed if towed load is not equipped with

brakes.

▲ Reduce speed on rough roads.

▲ Comply with national, regional and local laws.

▲ Do not fold or unfold the fertilizer applicator while the

tractor is moving (other than field lift).

407-613M Table of Contents Index 2014-04-22

Great Plains Manufacturing, Inc. Table of Contents Index Important Safety Information 7

Handle Chemicals Properly

See manual 407-551M for specific requirements and

recommendations for NH

For Conventional Liquid Materials

Agricultural chemicals can be dangerous. Improper use

can seriously injure persons, animals, plants, soil and

property.

▲ Read and follow chemical supplier instructions.

▲ Wear protective clothing.

▲ Handle all chemicals with care.

▲ Agricultural chemicals can be dangerous. Improper use can

seriously injure persons, animals, plants, soil and property.

▲ Inhaling smoke from any type of chemical fire is a serious

health hazard.

▲ Store or dispose of unused chemicals as specified by the

chemical manufacturer.

▲ If chemical is swallowed, carefully follow the chemical

manufacturer’s recommendations and consult with a doctor.

▲ If persons are exposed to a chemical in a way that could

affect their health, consult a doctor immediately with the

chemical label or container in hand. Any delay could cause

serious illness or death.

▲ Dispose of empty chemical containers properly. By law

rinsing of the used chemical container must be repeated

three times. Puncture the container to prevent future use. An

alternative is to jet-rinse or pressure rinse the container.

▲ Wash hands and face before eating after working with

chemicals. Shower as soon as application is completed for

the day.

▲ Apply only with acceptable wind conditions. Wind speed

must be below 5 mph (8 km/h). Make sure wind drift of

chemicals will not affect any surrounding land, people or

animals.

▲ Never wash out a tank within 100 feet (30 m) of any

freshwater source or in a car wash.

.

3

Shutdown and Storage

▲ Lower fertilizer applicator, put tractor in park, turn off

engine, and remove the key.

▲ Secure fertilizer applicator using locks and supports

provided.

▲ Detach and store fertilizer applicator in an area where

children normally do not play.

▲ Park an anhydrous ammonia applicator downwind of

occupied areas until it is purged of NH3 residues.

▲ Do not leave NH3 nurse tanks unattended.

2014-04-22 Table of Contents Index 407-613M

8 NP3000 and NP3000A Table of Contents Index Great Plains Manufacturing, Inc.

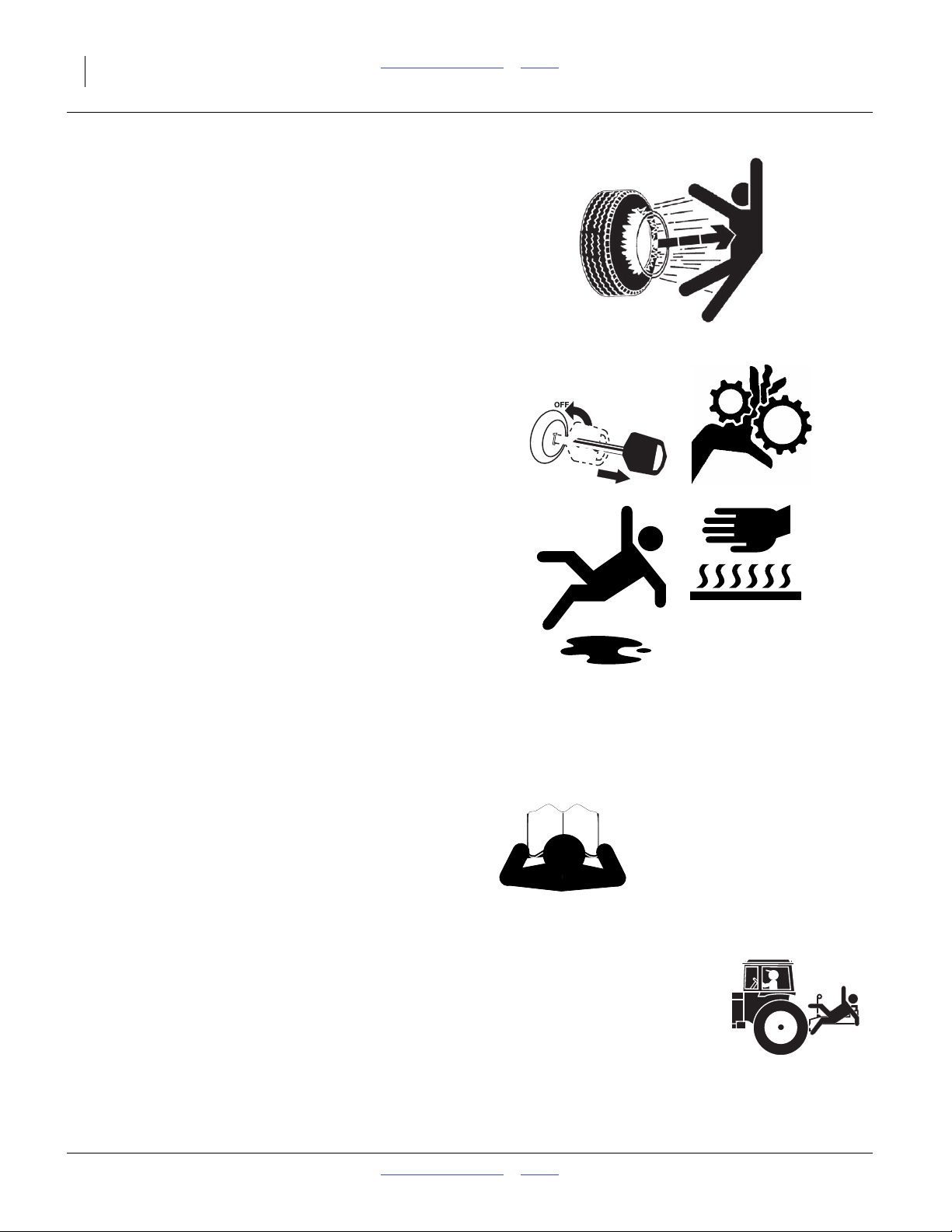

Tire Safety

Tire changing can be dangerous and should be

performed by trained personnel using correct tools and

equipment.

▲ When inflating tires, use a clip-on chuck and extension hose

long enough for you to stand to one side–not in front of or

over tire assembly. Use a safety cage if available.

▲ When removing and installing wheels, use wheel-handling

equipment adequate for weight involved.

Practice Safe Maintenance

▲ Understand procedure before doing work. Use proper

tools and equipment. Refer to this manual.

▲ Work in a clean, dry area.

▲ Lower the fertilizer applicator, put tractor in park, turn off

engine, and remove key before performing maintenance. If

work must be performed with applicator raised, use blocks

or jackstands rated for the fertilizer applicator weight.

▲ Make sure all moving parts have stopped and all system

pressure is relieved.

▲ Allow applicator to cool completely.

▲ Disconnect battery ground cable (-) before servicing or

adjusting electrical systems.

▲ Welding: Disconnect battery ground. Avoid fumes from

heated paint.

▲ Inspect all parts. Make sure parts are in good condition

and installed properly.

▲ Remove buildup of grease, oil or debris.

▲ Remove all tools and unused parts from fertilizer

applicator before operation.

Safety At All Times

Thoroughly read and understand the instructions in this

manual before operation. Read all instructions noted on

the safety decals.

▲ Be familiar with all applicator functions.

▲ Operate machinery from the driver’s seat only.

▲ Do not leave applicator unattended with tractor engine

running.

▲ Do not stand between the moving tractor and applicator

during hitching.

▲ Keep hands, feet and clothing away from power-driven

parts.

▲ Wear snug-fitting clothing to avoid entanglement with

moving parts.

▲ Make sure all persons are clear of working area.

407-613M Table of Contents Index 2014-04-22

Great Plains Manufacturing, Inc. Table of Contents Index Important Safety Information 9

Safety Decals

Safety Reflectors and Decals

Your implement comes equipped with all lights, safety

reflectors and decals in place. They were designed to

help you safely operate your implement.

▲ Read and follow decal directions.

▲ Keep lights in operating condition.

▲ Keep all safety decals clean and legible.

▲ Replace all damaged or missing decals. Order new decals

from your Great Plains dealer. Refer to this section for

proper decal placement.

▲ When ordering new parts or components, also request

corresponding safety decals.

To install new decals:

1. Clean the area on which the decal is to be placed.

2. Peel backing from decal. Press firmly on surface,

being careful not to cause air bubbles under decal.

31960

818-055C

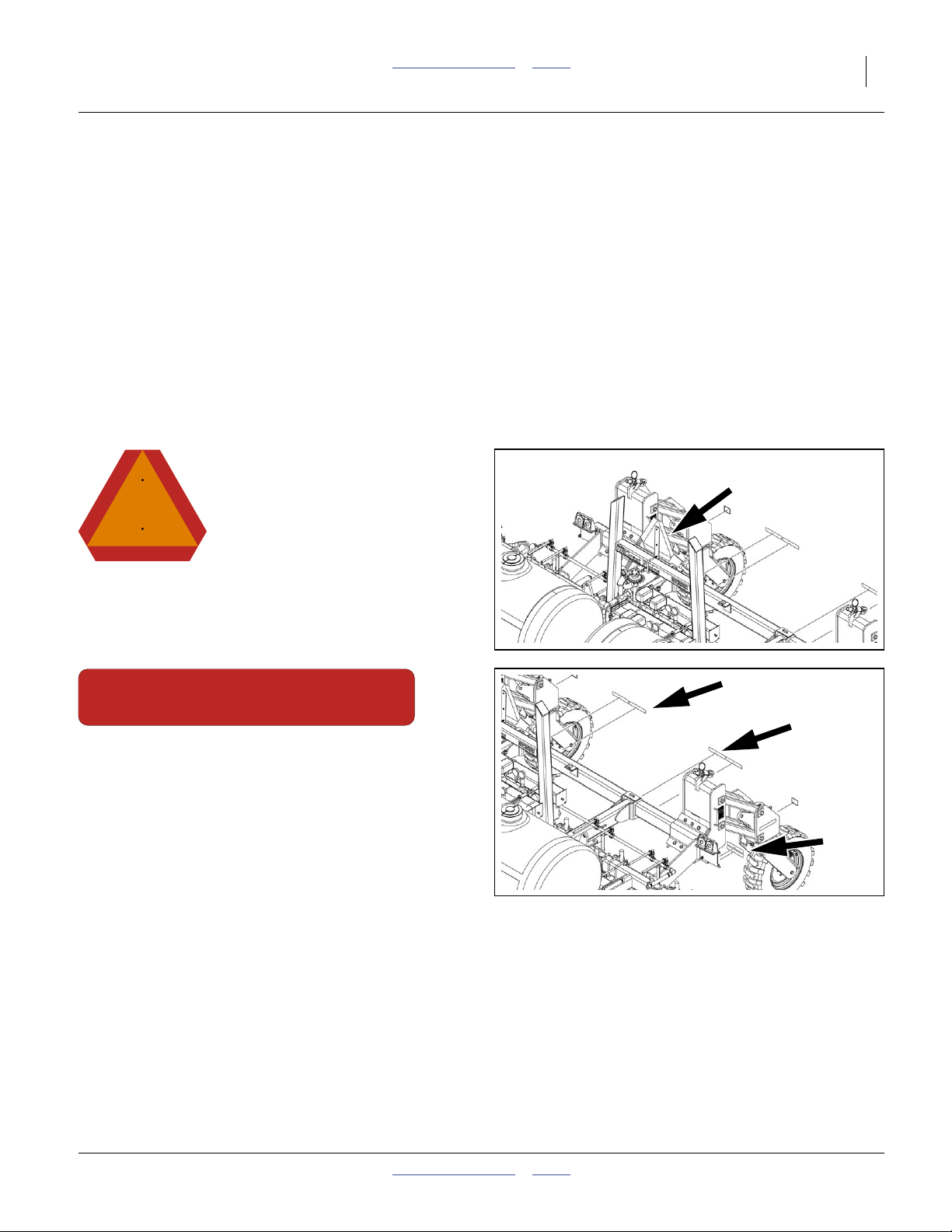

Slow Moving Vehicle Reflector

On a mount attached to the transport rest assembly;

1 total

838-266C

Red Reflectors

On the rear face light bracket, and

rear face of lift assist mount carrier tube;

4 total

31960

2014-04-22 Table of Contents Index 407-613M

10 NP3000 and NP3000A Table of Contents Index Great Plains Manufacturing, Inc.

31960

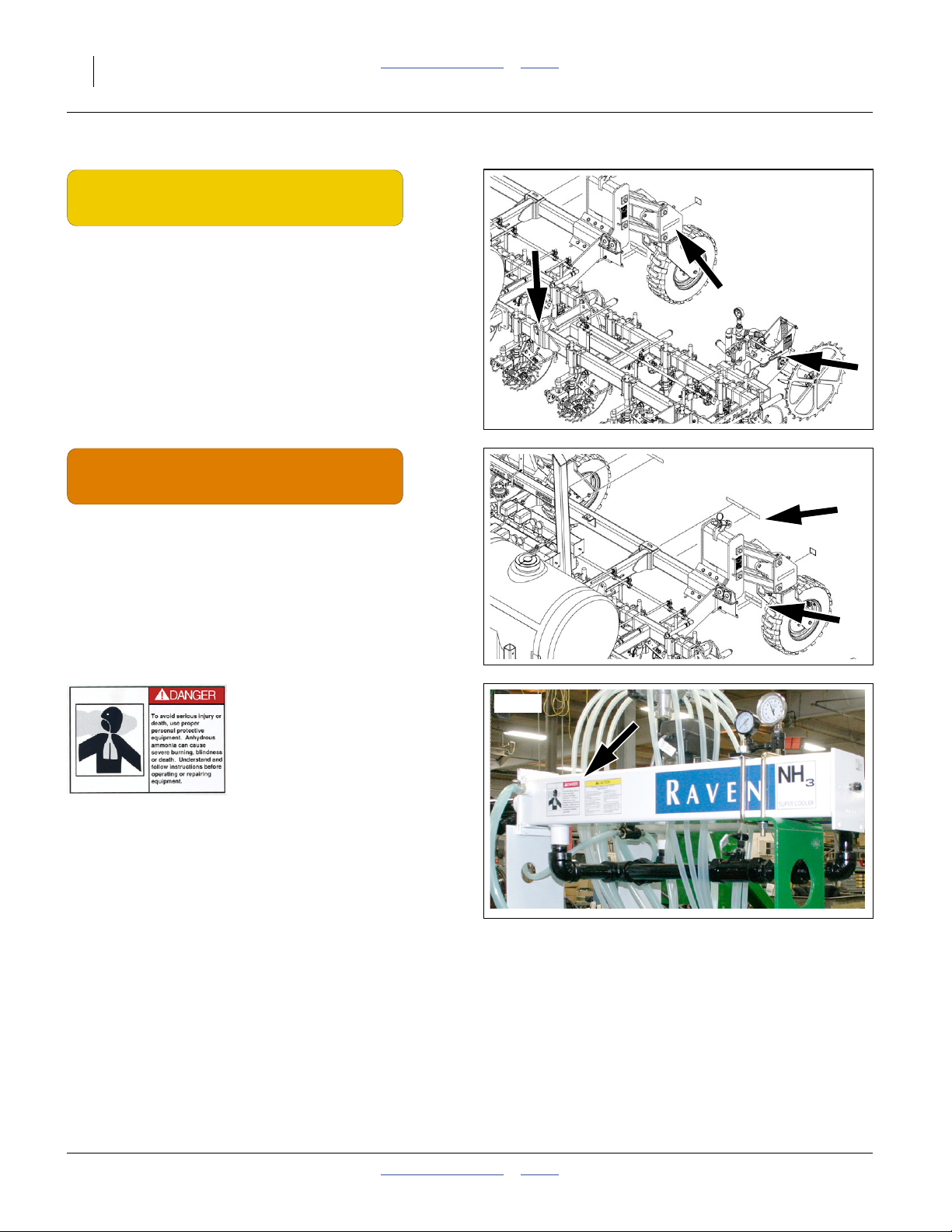

838-265C

Amber Reflectors

On the outside faces of casters,

on the outside faces of lift assist braces,

Option: on the outside face of each ground drive pump;

4, 5 or 6 total

31960

838-267C

Daytime Reflectors

On the rear face of light bracket (below reds),

rear face of lift assist mount carrier tube (outboard of

reds);

4 total

Raven 039-0159-034 (Option) Danger: Ammonia

On front or back side of Raven AccuFlow™;

2 or 4 total

Order replacement from Raven Industries.

31603

407-613M Table of Contents Index 2014-04-22

Great Plains Manufacturing, Inc. Table of Contents Index Important Safety Information 11

31618

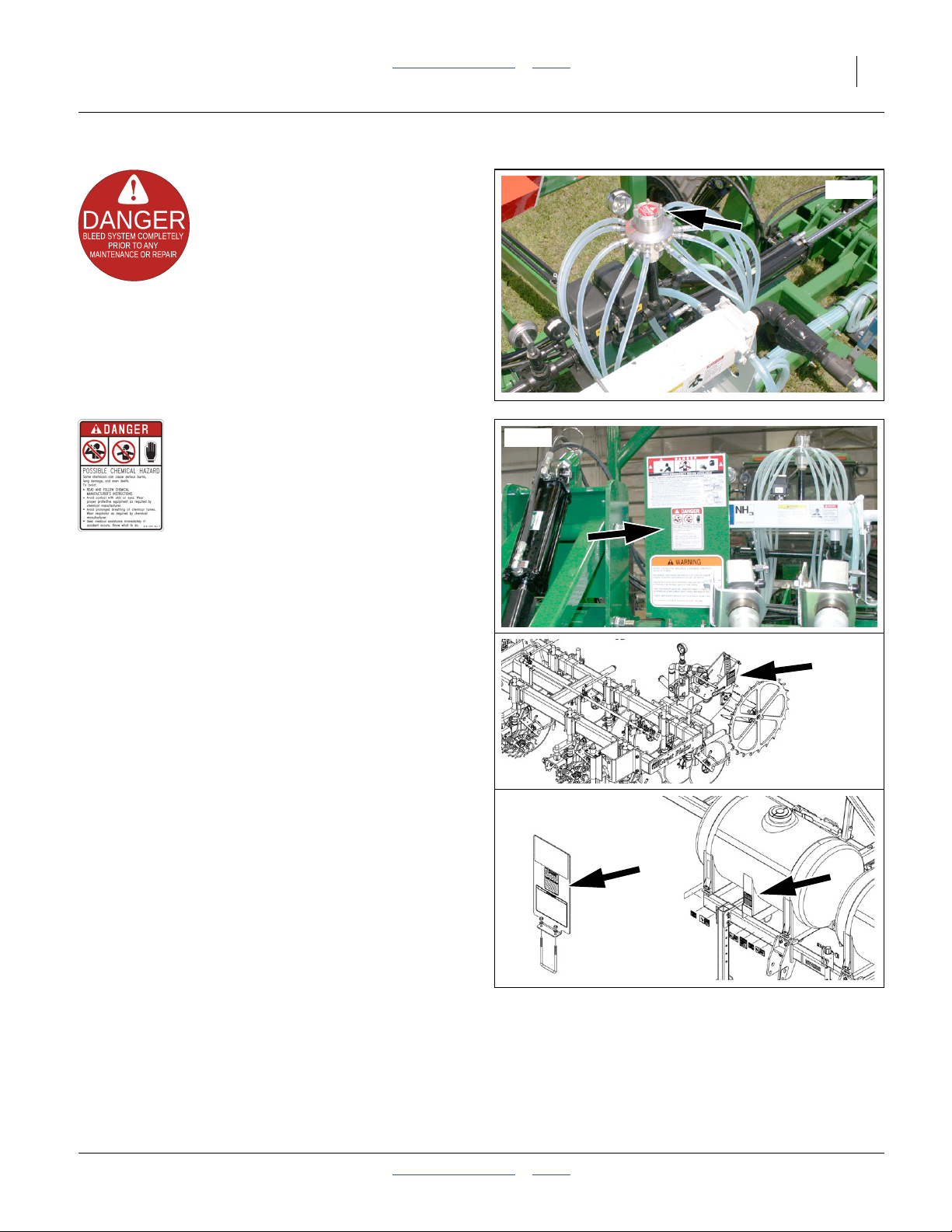

115527-01 (Option) Danger: Bleed System

On top of CDS-John Blue Impellicone® flow divider;

1 total

31604

818-323C Danger: Possible Chemical Hazard

NH3 models: On decal mount near Flo-Max™ coupler:

1 total

See “NH3 Operations” on page 55 and separate manual

“Using Anhydrous Ammonia Safely” (407-551M).

Conventional Models: On left face of ground drive pump

mount;

1 total

See “Liquid Operations” on page 68.

Conventional Models: On decal mount at optional rear

hitch and/or on front face of each center tank leg;

1 total

See “Liquid Operations” on page 68.

32339

31960

32339

2014-04-22 Table of Contents Index 407-613M

12 NP3000 and NP3000A Table of Contents Index Great Plains Manufacturing, Inc.

.eps

35.8%

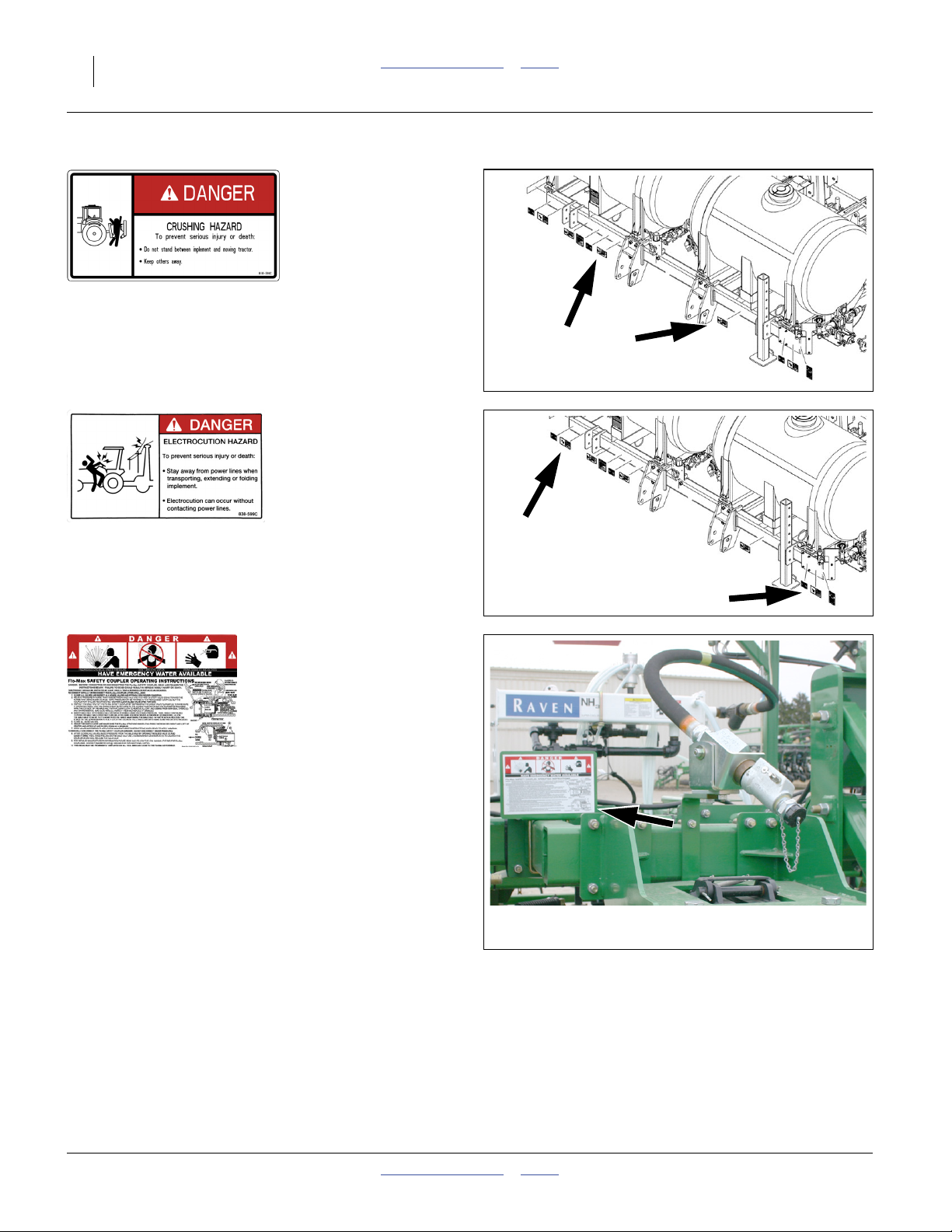

818-590C Danger: Hitch Crush

On front of frame tube, both sides of hitch;

2 total

31960

.eps

30.7%

838-599C Danger: Electrocution

On frame tube, outside parking stands;

2 total

848-534C (Squibb-Taylor FM125-2000) Danger: Safety Coupler (Option)

On decal mount near Flo-Max™ coupler;

1 total

This decal summarizes the mechanical procedure for

coupler re-connection after a breakaway event. Rely on

these instructions only if the Squibb-Taylor Flo-Max™

manual is not available. See “NH3: Breakaway Event”

on page 65.

31960

31529

407-613M Table of Contents Index 2014-04-22

Great Plains Manufacturing, Inc. Table of Contents Index Important Safety Information 13

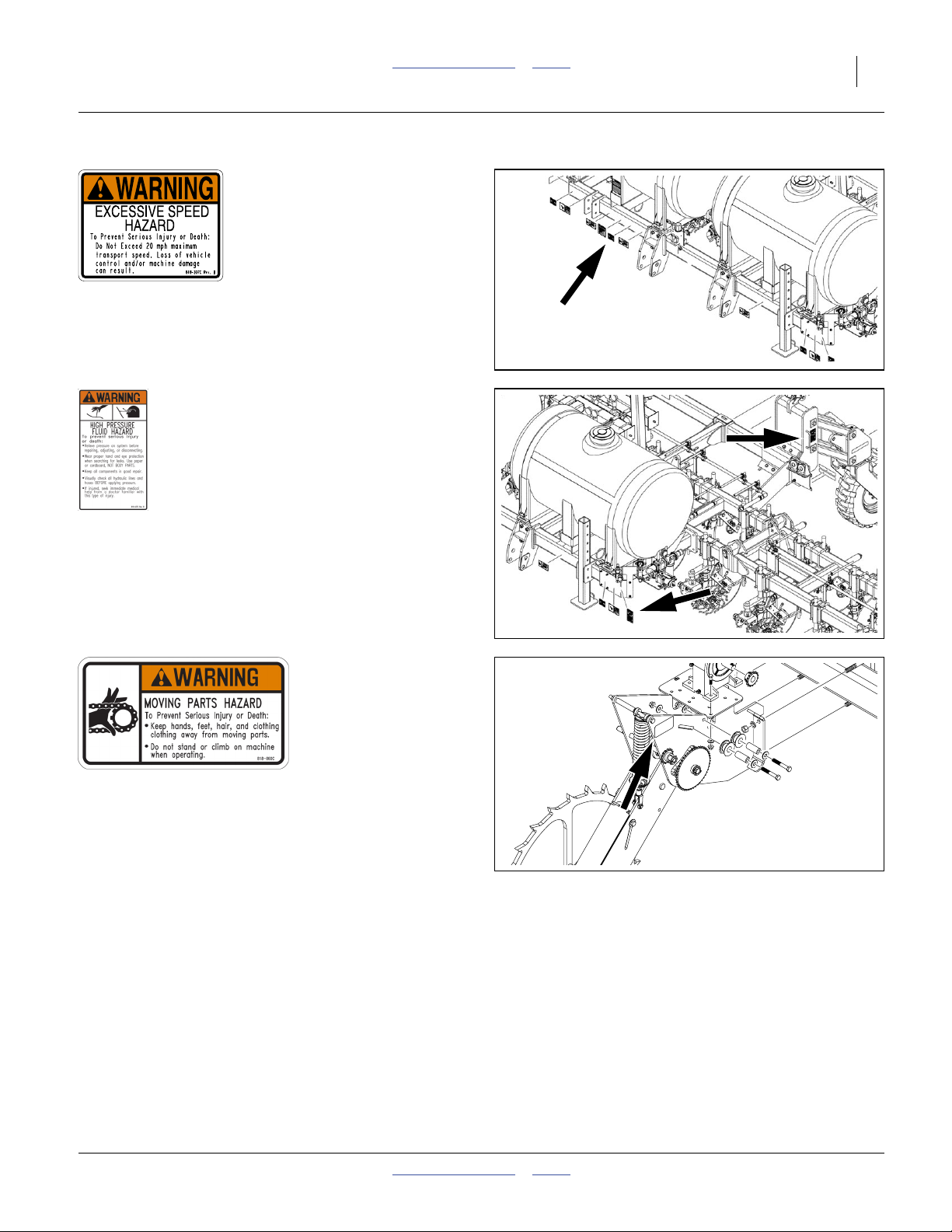

818-337C Warning: Speed

On front face of front tool bar, right of center;

1 total

31960

818-437C Warning: High Pressure Fluid Hazard

on front face of front tool bar, left end,

on each lift-assist mount;

3 total

818-860C (Option) Warning: Moving Parts

Option: on mount of each ground drive,

0, 1 or 2 total

31960

31085

2014-04-22 Table of Contents Index 407-613M

14 NP3000 and NP3000A Table of Contents Index Great Plains Manufacturing, Inc.

31604

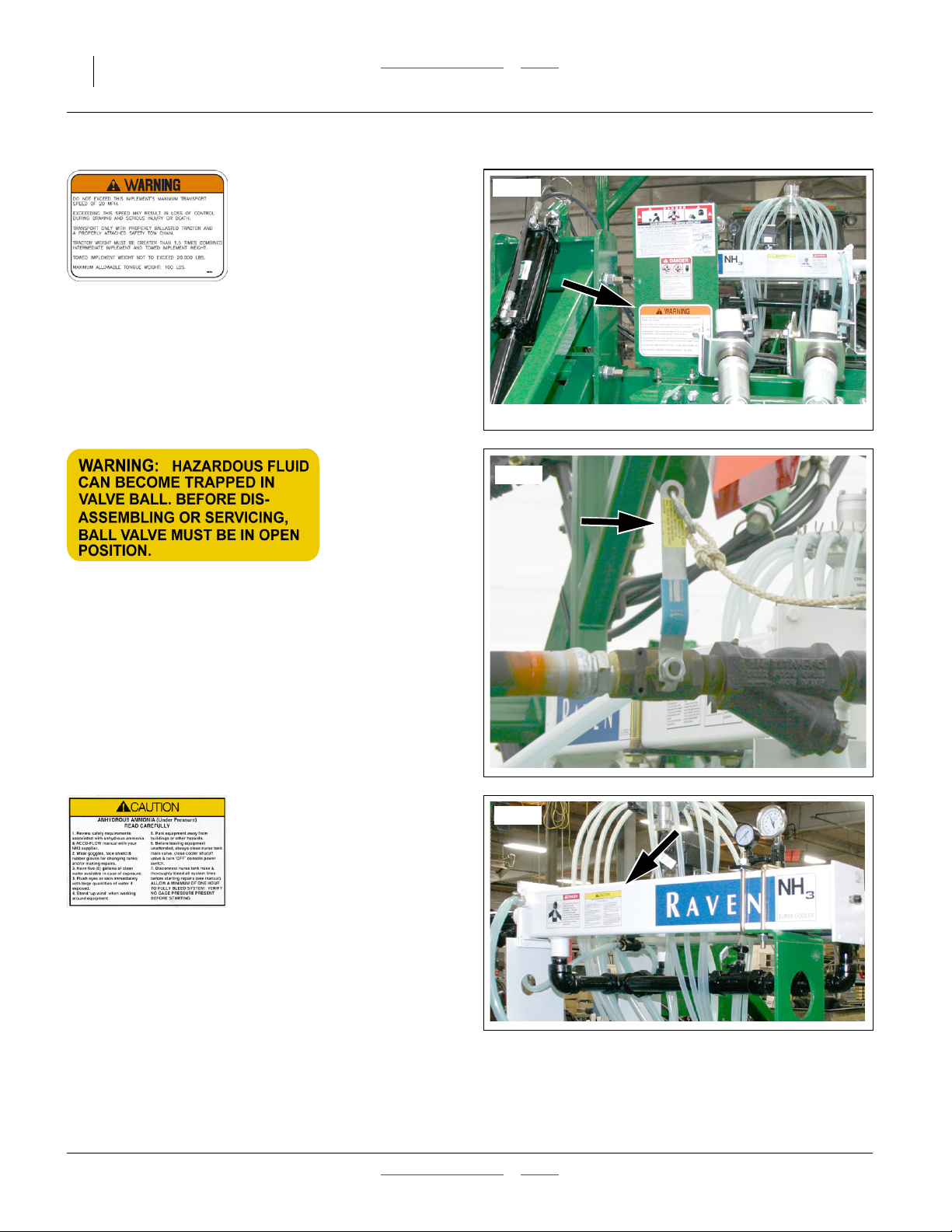

848-551C Warning: Towing

On decal mount near Flo-Max™ coupler:

1 total

See “Transport” on page 53 and “Liq: Hitching

Conventional Nurse Tank” on page 70 for further

information.

31528

(no part number) Warning: Ball Valve (Option)

This decal should not apply to 2013+ NP3000A

applicators, but might be encountered on nurse tank

valves, or if repairs are made with old-stock after-market

parts. See “Avoid Ball Traps” on page 107.

Older unvented ball valves can trap fluid inside the ball if

closed with the line fully charged. Great Plains ball

valves shipped in 2011 and later have a bleed orifice on

the downstream side of the valve ball and do not require

this decal.

Raven 039-0159-035 Caution: Ammonia (Option)

On front or back side of Raven AccuFlow™;

2 or 4 total

Order replacement from Raven Industries.

31603

407-613M Table of Contents Index 2014-04-22

Great Plains Manufacturing, Inc. Table of Contents Index Important Safety Information 15

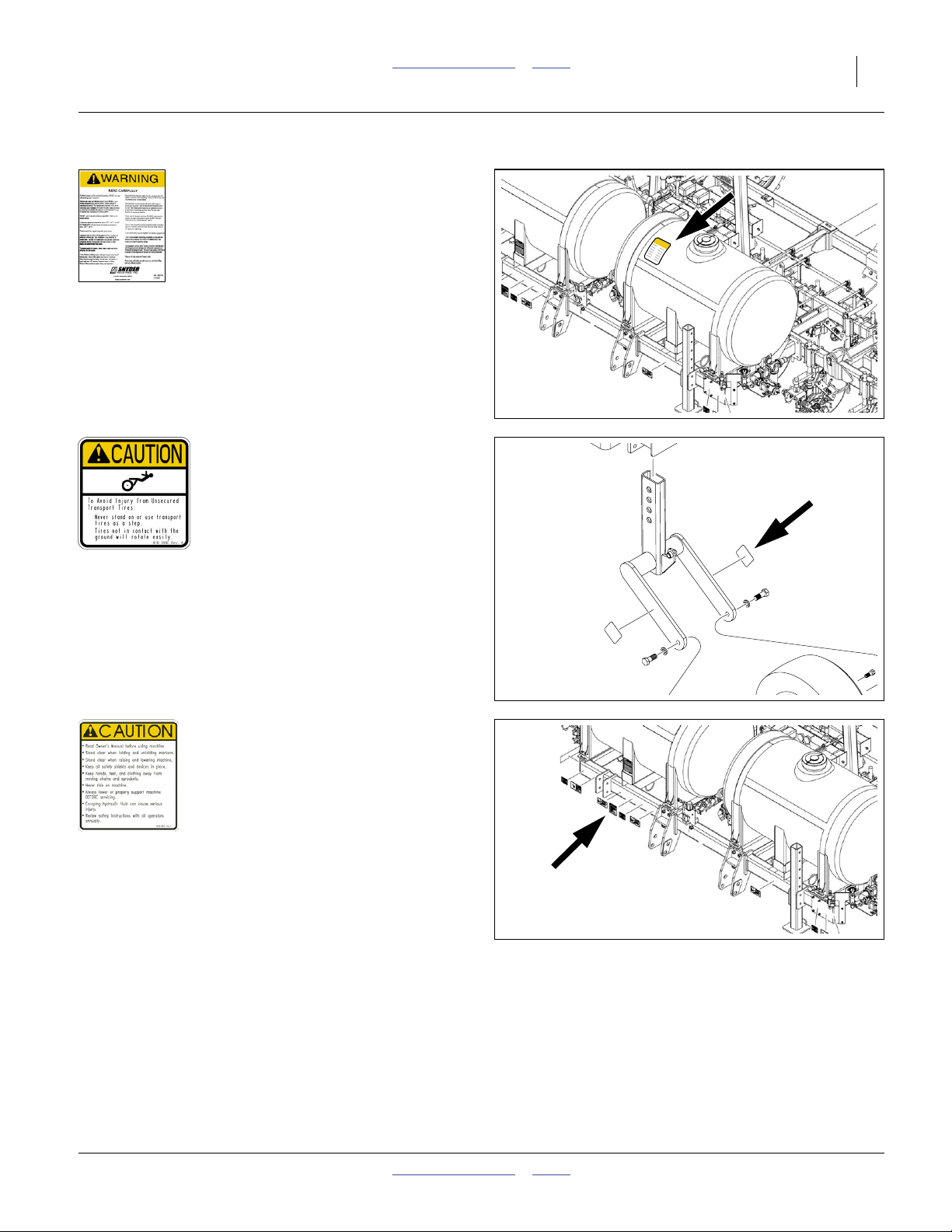

Snyder 997176 (Option) Warning: Tank Installation and Use

On upper front face of each tank:

0 or 2 total

Replacement decals available from Snyder Industries:

www.snydernet.com

31690

31921

818-398C Caution: Tires Not a Step

Outside faces of manual gauge wheel arms;

2 total

818-587C Caution: Read Operator’s Manual

On front face of front tool bar, right of center;

1 total

31960

2014-04-22 Table of Contents Index 407-613M

16 NP3000 and NP3000A Table of Contents Index Great Plains Manufacturing, Inc.

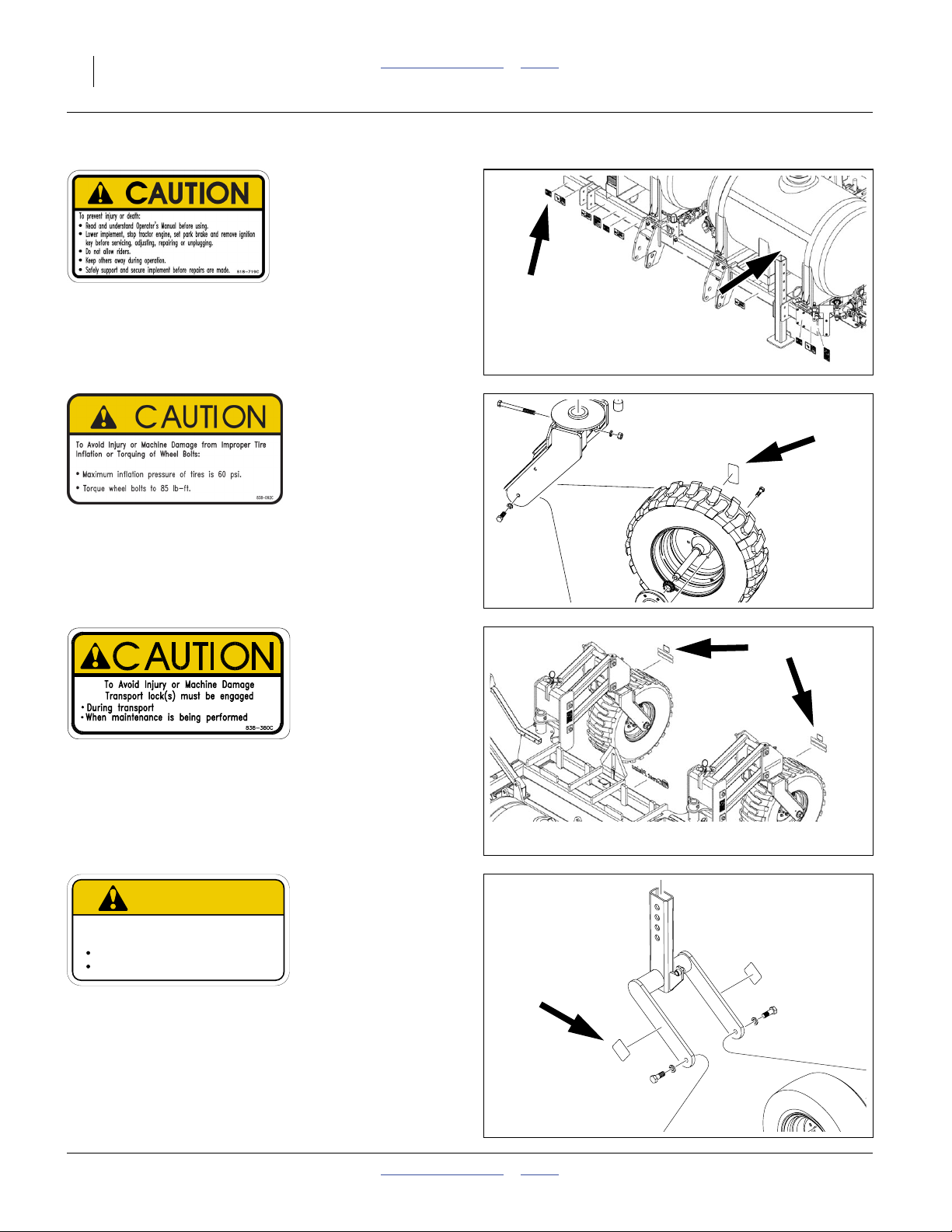

818-719C Caution: Read Operator’s Manual

On front face of front tool bar, right of center;

1 total

31960

838-092C Caution: Tire Pressure and Bolt Torque

Each lift-assist tire rim;

2 total

838-380C Caution: Transport Locks

On rear face of caster weldments, above red reflectors;

2 total

See “Important Safety Information” on page 1.

CAUTION

To Avoid Injur y or Machine Damage from Improper Tire

Inflation or Torquing of Wheel Bolts:

Maximum inflation pressure of tires is 90 psi.

Torque wheel bolts to 120 lb-ft.

838-595C

31045

32339

31921

838-595C Caution: Tire Pressure and Bolt Torque

Inside faces of manual gauge wheel arms;

2 total

407-613M Table of Contents Index 2014-04-22

Great Plains Manufacturing, Inc. Table of Contents Index Important Safety Information 17

848-736C Caution: General

On front face of front tool bar, both sides;

2 total

31960

31599

848-539C General Safety: First Aid Water (Option)

On left and right sides of the wash water tank;

2 total

See “Ammonia Emergency Action” in the “Using

Anhydrous Ammonia Safely” manual (407-551M), and

“Wash Water” on page 46.

2014-04-22 Table of Contents Index 407-613M

18 NP3000 and NP3000A Table of Contents Index Great Plains Manufacturing, Inc.

Introduction

Great Plains welcomes you to its growing family of new

product owners. The 30-Foot Fertilizer Applicator

(NP3000 and NP3000A) has been designed with care

and built by skilled workers using quality materials.

Proper setup, maintenance, and safe operating practices

will help you get years of satisfactory use from the

machine.

Description of Unit

The Nutri-Pro® is an applicator implement for

conventional liquid fertilizer, anhydrous ammonia (NH

or both. It has a working width (swath) of 30 feet (9.1 m).

The applicator has single or triple coulters with tines for

sub-soil application from optional on-board or

user-provisioned tanks.The NP3000/A has a lift-assisted

2-point hitch.

When configured for conventional liquid fertilizer, the

NP3000 model is designed for use with

an optional ground-drive CDS-John Blue® piston pump,

an optional variable-rate Ace hydraulic drive pump, or

a user-provisioned pump.

When configured for anhydrous ammonia the NP3000A

model relies on NH3 vapor pressure from a separately

provisioned trailing nurse tank.

A Raven SCS 450 console is available for sectional and

variable-rate control.

Models Covered

Conventional Liquid Fertilizer Models

NP3000-1230 30-Foot, 12-Row, 30 inch

NP3000-1230+SD 32.5-Foot, 13-Row, 30-inch

Anhydrous Model (configurable for two materials)

NP3000A-12C30 30-Foot, 12-Row, 30 inch

NP3000A-12C30+SD 32.5-Foot, 13-Row, 30-inch

Intended Usage

Use the NP3000/A Fertilizer Applicator to apply

compatible fertilizers. Do not modify Great

Plains-provisioned components, or install

user-provisioned components, except as authorized or

recommended by Great Plains.

)

3

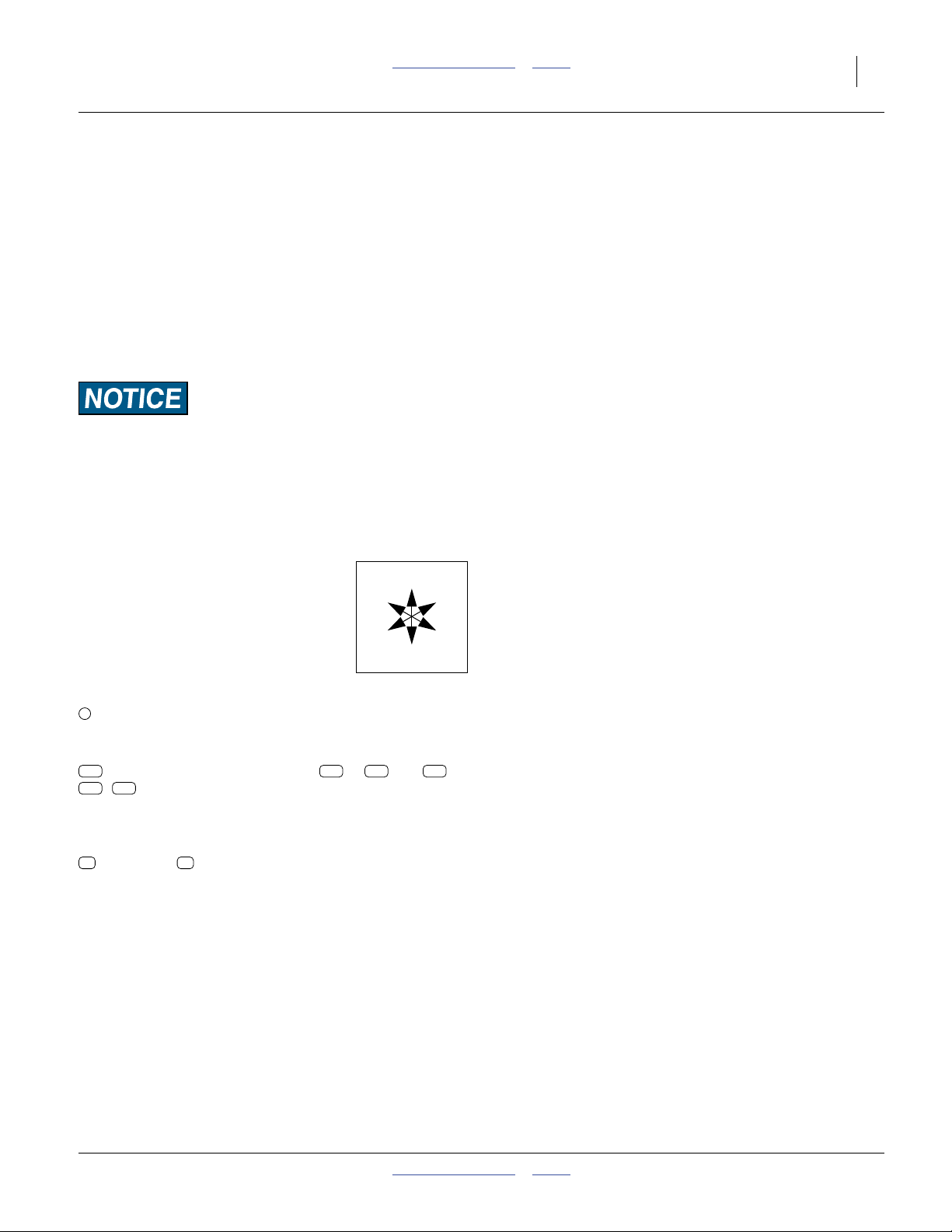

U

R

F

D

R

L

Figure 1

NP3000/A Fertilizer Applicator

Document Family

407-613M NP3000/Aa Operator/Rate Manual

(this document)

407-613P NP3000 and NP3000A Parts manual

407-613Q NP3000/A Pre-Delivery manual

Manuals for Options:

407-551M Using Anhydrous Ammonia Safely

12-M-29 CDS-John Blue® IP-1300/1800

Impellicone® parts

016-0159-403 Raven AccuFlow™ Operator manual

016-0159-831 Raven SCS-450 Installation, Operation

and Service manual

FVC062 Squibb-Taylor Flo-Max™ manual

12-M-43 CDS-John Blue NGP Pump Parts and

Instructional manual

HYD-MAN

b

Ace Pump Instruction manual

a. For NP30A and NP40A, see manual 407-502M.

For NP30L and NP40L, see manual 407-313M.

For 2012- NP4000, see manual 407-776M.

For 2013+ NP4000/A, see manual 417-199M.

b. Available from Ace Pump Corporation:

http://www.acepumps.com

31959

B

L

407-613M Table of Contents Index 2014-04-22

Great Plains Manufacturing, Inc. Table of Contents Index Introduction 19

Using This Manual

This manual familiarizes you with safety, assembly,

operation, adjustments, troubleshooting, and

maintenance. Read this manual and follow the

recommendations to help ensure safe and efficient

operation.

The information in this manual is current at printing.

Some parts may change to assure top performance.

“Option” refers to components not part of the standard

product, and not “optional” steps. If the component is

installed, the instructions apply.

Identifies an Economic (not a Safety) Risk:

NOTICE provides a crucial point of information related to the

current topic. Read and follow the instructions to avoid damage

to equipment and ensure desired field results.

Note: This form sets off useful information about the

current topic, or forestalls possible

misunderstanding.

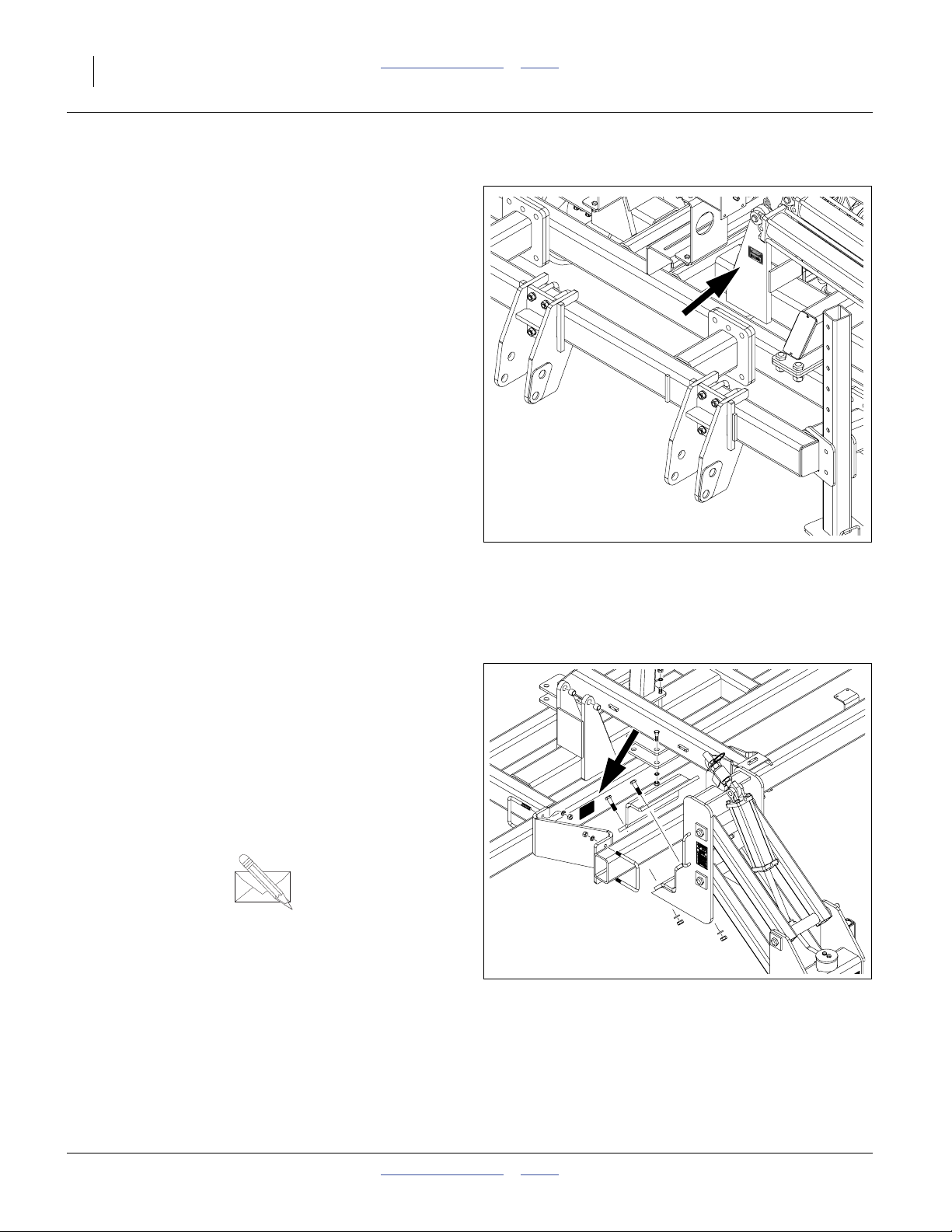

Right-hand and left-hand as used in

this manual are determined by facing

the direction the machine will travel

while in use unless otherwise stated.

An orientation rose in some line crt

illustrations shows the directions of:

Up, Back, Left, Down, Front, Right.

R

F

U

B

L

D

Single-digit and single-letter callouts refer to local

1

illustrations. The callout numbers/letters may be

re-used for different items on other pages.

Two-digit callouts in the range to and to

A00

L00

24 24

refer to the same tank and Nutri-Pro®plumbing

L51

system components throughout this manual. “A00”

references are for Anhydrous. “L00” references are

for conventional Liquid.

Callouts and above refer to parts of Options

(see Appendix C).

A11 A36 L11

2014-04-22 Table of Contents Index 407-613M

20 NP3000 and NP3000A Table of Contents Index Great Plains Manufacturing, Inc.

Owner Assistance

If you need customer service or repair parts, contact a

Great Plains dealer. They have trained personnel, repair

parts and equipment specially designed for Great Plains

products.

Refer to Figure 2 or Figure 3

Your machine’s parts were specially designed and

should only be replaced with Great Plains parts. Always

use the serial and model number when ordering parts

from your Great Plains dealer.

For 2013 and later applicators, the serial number plate is

located on the center section, on the front face of the left

front fold cylinder mount.

For 2012 and earlier applicators, the serial-number plate

is located on the rear face of the center frame, ahead of

the left caster pivot.

Record your fertilizer applicator model and serial number

here for quick reference:

Model Number:__________________________

Serial Number: __________________________

Your Great Plains dealer wants you to be satisfied with

your new machine. If you do not understand any part of

this manual or are not satisfied with the service received,

please take the following actions.

1. Discuss the matter with your dealership service

manager. Make sure they are aware of any problems

so they can assist you.

2. If you are still unsatisfied, seek out the owner or

general manager of the dealership.

For further assistance write to:

Figure 2

2013+ Serial Number Location

M # NP40A-25S20

36030

Product Support

Great Plains Mfg. Inc., Service Department

PO Box 5060

Salina, KS 67402-5060

gp_web_cs@greatplainsmfg.com

785-823-3276

Figure 3

2012- Serial Number Plate

407-613M Table of Contents Index 2014-04-22

31885

Great Plains Manufacturing, Inc. Table of Contents Index 21

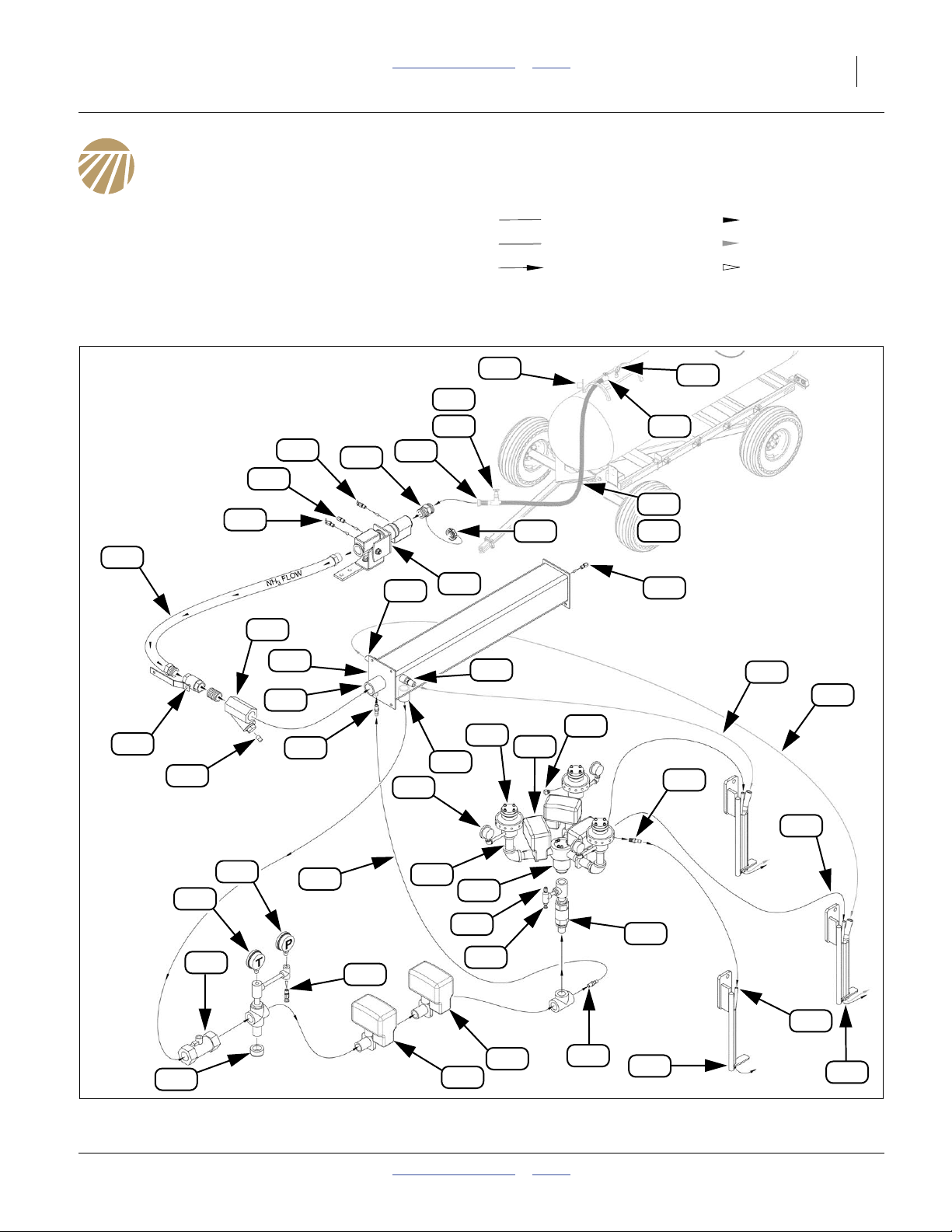

Application Overview

Legend:

Tank, plumbing and setup requirements differ for

anhydrous (A) and conventional systems (L). The next

few pages provide an overview of both systems.

Anhydrous: System Components

Single-Cooler Section Control Configuration - see

page 146 through page 150 for alternates.

Callout numbers A11 through A36 identify the same

applicator and tank components throughout this manual.

Liquid NH

NH3 Vapor Vapor Flow

Direction of Flow Exception Flow

3

Liquid Flow

A17

A18

A20

A15

A16

A19

A13

A21

A22

A34

A12

A7

A47

A42

A10

A11

A14

A24

A6

A47

A40

A11

A39

A17

A15

A8

A9

A23

A48

A48

A44

A43

A45

A27

A25

A28

A33

A29

A41

A38

A37

A36

A35

A45

A31

A26

Anhydrous Ammonia (NH3) Plumbing (Single-Cooler w/ Section Control)

2014-04-22 Table of Contents Index 407-613M

A30

Figure 4

A32

A46

A49

34958

22 NP3000 and NP3000A Table of Contents Index Great Plains Manufacturing, Inc.

NH3 System Narrative

This list describes a single-cooler anhydrous system with

section control. A dual-cooler system has two of

components through , and two additional

dual-tube tines . A single-section system lacks

components through and has only one of .

Refer to Figure 6 on page 29

A11.Acme cap

Suffocation, Blinding and Burning Hazards:

See “NH3: Safing Applicator Before Cart Hitch” on

page 55, for safe opening procedure.

This captive cap protects the inlet when no nurse

tank is connected. NH3might be sealed behind this

cap.

A12.Acme inlet

The nurse tank hose coupler connects here and

must have 13⁄4-4 female Acmea swivel coupler. See

page 58 for nurse tank connection.

A13.Coupler Inlet Bleed Valve

Suffocation, Blinding and Burning Hazards:

See “About Bleed Valves:” on page 38.

This fitting is carefully opened at normal and

abnormal disconnects, to bleed NH3 liquid and

vapor from the hoses (or to bleed just the nurse tank

hose upon breakaway). It is also opened prior to

Acme cap removal to verify that the line is

discharged. See “NH3: Making Nurse Tank

Connections” on page 58, “NH3: Unhitching

Nurse Tank” on page 67 and “NH3: Breakaway

Event” on page 65.

A11 A24

A49

A35 A39 A40

A7

A14.Breakaway Coupler

Upon Event: Probable Chemical Hazard:

See “NH3: Breakaway Event” on page 65.

This assembly is designed to separate and seal the

lines if between 300 to 400 pounds of pull force is

applied to the nurse tank hose. In normal

operations, this does not happen.

Should the hitch fail, and both safety chains fail, or

an operator makes serious basic safety errors, the

breakaway separates to protect the hoses from

rupture. Spring-loaded checks inside the breakaway

seal both ends of the now-broken connection. If the

line was charged, 60 cc of liquid NH3is released on

breakaway.

Resetting a parted breakaway coupler is a complex

operation requiring tools. Consult the breakaway

manual for details. More significant matters are

safing the applicator and nurse tank, then correcting

the cause of the breakaway. See “NH3: Breakaway

Event” on page 65.

A15.Breakaway Hydrostatic Relief Valve

In normal operation, this valve does not activate.

It is designed to open at 375 psi, well above the

250-265 psi operating pressure of the nurse tank’s

main pressure relief valve.

Operator action is periodic inspection, and to

replace this hydrostatic relief valve, a time-dated

part, when it reaches the end of its operating life

(see page 114). See “Hydrostatic Relief Valve

Maintenance” on page 112 for maintenance.

Valve function: when operating valves are closed on

both sides of the breakaway (or on just the

applicator side upon a breakaway event), NH3 can

be trapped in the breakaway coupler. As the NH

warms, it could create dangerously high pressure.

This relief valve opens to vent excess pressure.

3

a. Acme refers to the ANSI/ASME B1.5-1997 screw thread, which has a trapezoidal thread profile.

407-613M Table of Contents Index 2014-04-22

Great Plains Manufacturing, Inc. Table of Contents Index Application Overview 23

A16.Coupler Outlet Bleed Valve

Suffocation, Blinding and Burning Hazards:

See “About Bleed Valves:” on page 38.

This fitting is kept closed in normal operations.

When the breakaway is properly coupled, the inlet

bleed valve bleeds the entire assembly, and

A13

applicator supply hose. On breakaway, this valve is

used to bleed the applicator side of the

disconnection. See “NH3: Breakaway Event” on

page 65.

A17.Supply Hose

This connects the breakaway coupler to the

emergency shut-off valve. Operator action is to

replace this hose, a time-dated part, when it

reaches the end of its operating life (see page 114).

A18.Emergency Shut-off Valve

The handle of this is valve has a rope which is

routed to the tractor cab (see page 38). Closing this

valve stops NH3flow to the cooler, metering system

and tines. There can still be a substantial amount of

NH3 in the system, for some time, with this valve

closed. See the “Using Anhydrous Ammonia

Safely” manual (407-551M) for emergency

operation.

A19.Strainer

This filter contains a 20 mesh screen and two

ceramic magnets to remove debris from the NH

flow.

A20.Strainer Magnets

These capture ferrous metal debris of any size.

They need to be cleaned every 4 to 5 tank loads.

See page 117.

A21.AccuFlow™ Super Cooler (Heat Exchanger)

For effective application, NH3needs to remain in the

liquid state until released underground. This is

accomplished by refrigeration. Some of the flow is

tapped , fed back to the cooler at , vaporized

and used to chill the fluid passing from to .

A32 A34

A22 A24

A22.Cooler Intake

Liquid NH

enters the cooler here.

3

A23.Cooler Hydrostatic Relief Valve

In normal operation, this valve never activates. NH

3

can get trapped in the system between the

emergency shut-off valve and the On/Off

valve , if both valves are closed while the system

A31

A18

is charged. As the liquid warms and pressure rises,

this valve protects the system with periodic

releases.

This valve is set to activate at 350 psi, higher than

the nurse tank’s relief valve.

Operator action is periodic inspection, and to

replace this hydrostatic relief valve, a time-dated

part, when it reaches the end of its operating life

(see page 115). See “Hydrostatic Relief Valve

Maintenance” on page 112 for maintenance.

A24.Cooler Outlet

Chilled liquid NH3 exits the cooler here.

A25.Flow Meter

This fitting converts fluid flow to pulses for the

SCS 450 controller. It has a range of 1-60 gpm. A

tag on the cable lead provides a “METER CAL”

number specific to the installed meter (and accurate

only for NH3 fluid flow, and not NH3 vapor flow).

A26.Drain Cap

The plumbing cross and lower cap below the

temperature gauge are provided to allow the gauge

3

probe to be exposed to the full NH3 stream. This

cap does not require periodic clean-out.

A27.Temperature Gauge

This gauge reports the temperature of the chilled,

flowing, NH3. When NH3 is not flowing, this gauge

slowly drifts up to ambient temperature.

Checking the temperature and pressure gauges

A28

against the chart in the “Using Anhydrous

Ammonia Safely” manual (407-551M), or in the

Raven AccuFlow™ manual, indicates whether the

flowing NH3 is in a liquid state.

Normal field temperatures of the chilled flowing NH

3

are in the range 20 to 83°F (-7 to 28°C).

2014-04-22 Table of Contents Index 407-613M

24 NP3000 and NP3000A Table of Contents Index Great Plains Manufacturing, Inc.

A28.Pressure Gauge

This gauge reports the pressure of the NH

exits the cooler. If line valves are closed, a pressure

reading above zero indicates NH

between the emergency shut-off valve and the

On/Off solenoid valve (the Control Valve

A31 A30

is present

3

A18

does not completely close).

Checking the pressure and temperature against

the chart in the “Using Anhydrous Ammonia

Safely” manual (407-551M), or in the Raven

AccuFlow™ manual, indicates whether the flowing

NH3 is in a liquid state.

When valves are open but NH3 is not flowing, this

gauge normally reads within 5 psi of the nurse tank

pressure gauge . If they are materially different

A17

at zero flow, one of the gauges may be defective.

When NH3 is flowing, the pressure reported by this

gauge is lower than the tank pressure.

A28

A29.Cooler Bleed Valve

Suffocation, Blinding and Burning Hazards:

See “About Bleed Valves:” on page 38.

This valve is normally closed. It is used to bleed

trapped NH3 from the cooler system when valves

are closed. It can also be used to accelerate

clearing the cooler system for maintenance.

A30.Control Valve

This is a variable electronic valve controlled by the

SCS 450. It is the primary control point for

application rate. When power is off, this valve

remains at its most recent setting.

This valve has a visible indicator above the valve

ball casing, indicating whether open, closed or in

between.

When commanded to a rate of zero, this valve does

not completely close. Use shut-off valves to

completely stop flow. A full slew from fully open to

minimum takes approximately 9 seconds.

A27

after it

3

A31.Master Shut-Off Valve

This is the normal control for starting and stopping

total application flow in the field (for turns, etc.). This

component is an open/close solenoid valve

controlled by the “MASTER” switch on the SCS 450.

When power is off, this valve remains at its most

recent setting.

This valve has a visible indicator above the valve

ball casing, indicating whether open or closed.

Operation of this valve is essentially instantaneous.

Its valve ball is equipped with a downstream relief

orifice.

A32.Refrigerant Tap

A small amount of the NH3flow is taken at this point

to provide refrigeration at the cooler. There are no

operational items for this fitting.

A33.Refrigerant Line

This tubing passes tapped refrigerant NH3 to the

cooler. Operator action is to replace this tubing,

a time-dated part, when it reaches the end of its

operating life. See page 115.

A34.Cooler Refrigerant Inlet

Tapped refrigeration flow enters the cooler at this

fitting, and is vaporized to chill the liquid entering at

fitting . There are no operational items for this

A22

fitting.

A35.Section Control Check Valve

(Section Control Option Only)

This prevents back flow when section shut-off

valves are off with NH3 present. There are no

A39

operational items for this fitting.

A36.Section Control Bleed Valve

Suffocation, Blinding and Burning Hazards:

See “About Bleed Valves:” on page 38.

(Section Control Option Only)

This valve is normally closed. It is used to bleed

trapped NH3 from the section control system if all

section valves are closed.

A39

407-613M Table of Contents Index 2014-04-22

Great Plains Manufacturing, Inc. Table of Contents Index Application Overview 25

A37.Section Control Relief Valve

(Section Control Option Only)

In normal operation, this valve never activates.

NH3can get trapped in the system between the

section control check valve and the section

shut-off valves , if all section valves are closed

A39

A35

while the system is charged. As the liquid warms

and pressure rises, this relief valve protects the

system with periodic releases.

This valve is set to activate at 350 psi.

Operator action is periodic inspection, and to

replace this hydrostatic relief valve, a time-dated

part, when it reaches the end of its operating life

(see page 115). See “Hydrostatic Relief Valve

Maintenance” on page 112 for maintenance.

A38.Section Flow Divider

(Section Control Option Only)

This is a CDS-John Blue®Impellicone® manifold.

It evenly splits the NH3 flow for distribution through

the row flow dividers . There are no operational

A40

items for this component.

A39.Section Shut-Off Valves

(Section Control Option Only)

These are the normal controls for suspending

per-section application flow in the field (for point

rows, pass overlap, etc.). These are open/close

solenoid valves controlled by the “BOOMS”

switches on the SCS 450.

When used with the SCS 450 or other suitable

sectional application controller, shutting off a

section causes the total flow to be reduced by1⁄3 of

the all-sections-on rate, keeping the rate constant

for the section(s) still active.

Each section valve has a visible indicator above the

valve ball casing, indicating whether open or closed.

Operation of each section valve is essentially

instantaneous. However, there is considerable

residual NH3in the section flow divider and delivery

tubes after shut-off. When console power is off, the

valves remain at their most recent setting.

The valve balls are equipped with a downstream

relief orifice.

A40.Row Flow Divider(s)

This is a CDS-John Blue®Impellicone® manifold. It

evenly splits the NH3flow for distribution through the

delivery tubes . There are no operational items

A45

for this component.

A41.Flow Divider Manifold Inlet

NH3 liquid flow enters the flow divider here.

A42.Flow Divider Pressure Gauge

This gauge reports the pressure prior to flow

division. It normally reads lower than the cooler and

nurse tank pressure gauges.

A43.Flow Divider Outlet

Each of these ports receives an equal fraction of the

NH3 liquid flow.

A44.Flow Divider Plug

Unused ports are plugged with a steel NPT plug.

Unused ports do not affect flow balance at the other

ports.

A45.Delivery Tube

This tubing passes NH3 liquid flow to the tines.

Operator action is to replace this tubing, a

time-dated part, when it reaches the end of its

operating life. See page 116.

A46.Coulter Tine (Single)

Tines inject the liquid NH3. All but two (or four) of the

rows are equipped with tines having a single smaller

liquid delivery tube. Tines need frequent inspection

for wear and damage.

A47.Cooler Vapor Outlets (2)

Two vapor outlets direct the now-gaseous

refrigerant flow (that entered at ) to two special

tines per cooler.

A49

A34

A48.Vapor Tube

This tubing passes NH3vapor flow to the dual tines.

Operator action is to replace this tubing,

a time-dated part, when it reaches the end of its

operating life. See page 116.

A49.Coulter Tine (Dual)

There are two of these special tines per cooler (four

total on a dual-cooler applicator). They direct the

vaporized refrigerant NH3 gas into the soil at the

larger rear vapor tube. They are otherwise identical

to the single-tube tines .

A46

2014-04-22 Table of Contents Index 407-613M

26 NP3000 and NP3000A Table of Contents Index Great Plains Manufacturing, Inc.

The following callouts are for trailing nurse tank cart

components. See the “Using Anhydrous Ammonia

Safely” manual (407-551M) for all nurse tank callouts

( - ). The present manual lists only those required

A1

A36

for applicator field operations.

A6.Acme Parking Plug

A threaded stud (or other means) for storage of the

outlet hose when not coupled to the applicator.

Excess NH3 Release Hazard:

If the outlet hose is entirely dismounted (both ends free)

for transport and storage, and both ends are 13⁄4-4 Acme,

be sure about which end is which. Installing a hose

backwards can result in needless excess NH3 release at

unhitching, or a line segment unprotected by bleed and/

or relief valves.

A7.Acme Female Hose Coupler

This end of the hose connects the tank withdrawal

valve to the leading applicator inlet at the

A13 A12

breakaway coupler. For use with a Nutri-Pro

®

applicator, the outlet end of the hose must be

equipped with a 13⁄4-4 female Acme fitting.

The outlet end of the hose has a swivel collara or

shroud containing the female Acme fitting. This

allows connection without needing to twist the hose.

Acme hose couplers are intended for hand

tightening only. Do not use tools to make the

cart-applicator connection. A liquid-tight seal is

made by the gasket in the male Acme fitting on the

applicator break-away coupler.

For dual-tank carts, each tank usually has its own

hose.

A8.Outlet Hose Assembly

The hose may have zero, one or two operating

valves , one or more bleed valves , and a

hydrostatic relief valve . The outlet end may

A10 A11

A12

have an Acme. plug.

Hose valves are typically hand wheel valves, or

lever valves. Read any documents provided for the

valves. Have the terminal or dealer explain how the

valves work.

Suffocation, Blinding and Burning Hazards:

Never test an anhydrous ammonia hose valve unless you

are absolutely certain the hose and valve bodies are

empty, or both hose ends are securely connected to

sealed systems.

▲ A two-valve hose can contain a substantial amount of

NH

even when completely disconnected. See “Avoid

3

Line Traps” on page 106.

▲ Older ball valves can contain NH3 inside the ball

when closed, even though disconnected at both ends.

See “Avoid Ball Traps” on page 107.

Follow instructions for bleeding and checking. Never use

a valve handle as a carrying handle. Keep hands clear of

bleed valves when carrying a hose.

A9.Nurse Tank Hose Body

NH3 hoses are time-dated components. Operator

action is to replace the assembly when it

A8

reaches the end of its operating life.

A10.Hose Valve(s)

The hose may have zero, one or two operating

valves .

A10

Excess NH3 Release and Trapping Hazards:

Understand hose and tank withdrawal valve functions

and sequencing. This manual presumes a hose with a

single outlet-end shut-off valve , and a tank outlet

with a withdrawal valve . If the hose in use is

A10

A15

different, have the hose provider explain the correct

order for operations.

a. Acme collars may be aluminum, but all internal coupler components must be NH3-safe, typically stainless steel.

407-613M Table of Contents Index 2014-04-22

Loading...

Loading...