Page 1

Great Plains Manufacturing, Inc. General Information 1

Min-Till Ladder Kit

Installation Instructions for use with

Two- and Three-Section Folding Drills

Applies to Models:

• 2S-2600/2610/F/HD/HDF

• 3S-3000/F/HD/HDF

• 3S-4000/F/DH/HDF

When you see this symbol, the subsequent instructions

!

and warnings are serious - follow without exception.

Your life and the lives of others depend on it!

General Information

These instructions explain how to install the Min-Till Ladder Kit. This kit replaces the single fixed walkboard steps

with 3-step swing-down ladders.

Each kit converts an entire drill.

These instructions apply to:

Kit Kit Description

195-065A Min-Till Ladder Kit

This kit contains all components necessary for installation.

If installing this kit as part of Pre-Delivery, install the

walkboards (without any fixed steps) prior to installing

the ladders.

Before You Start

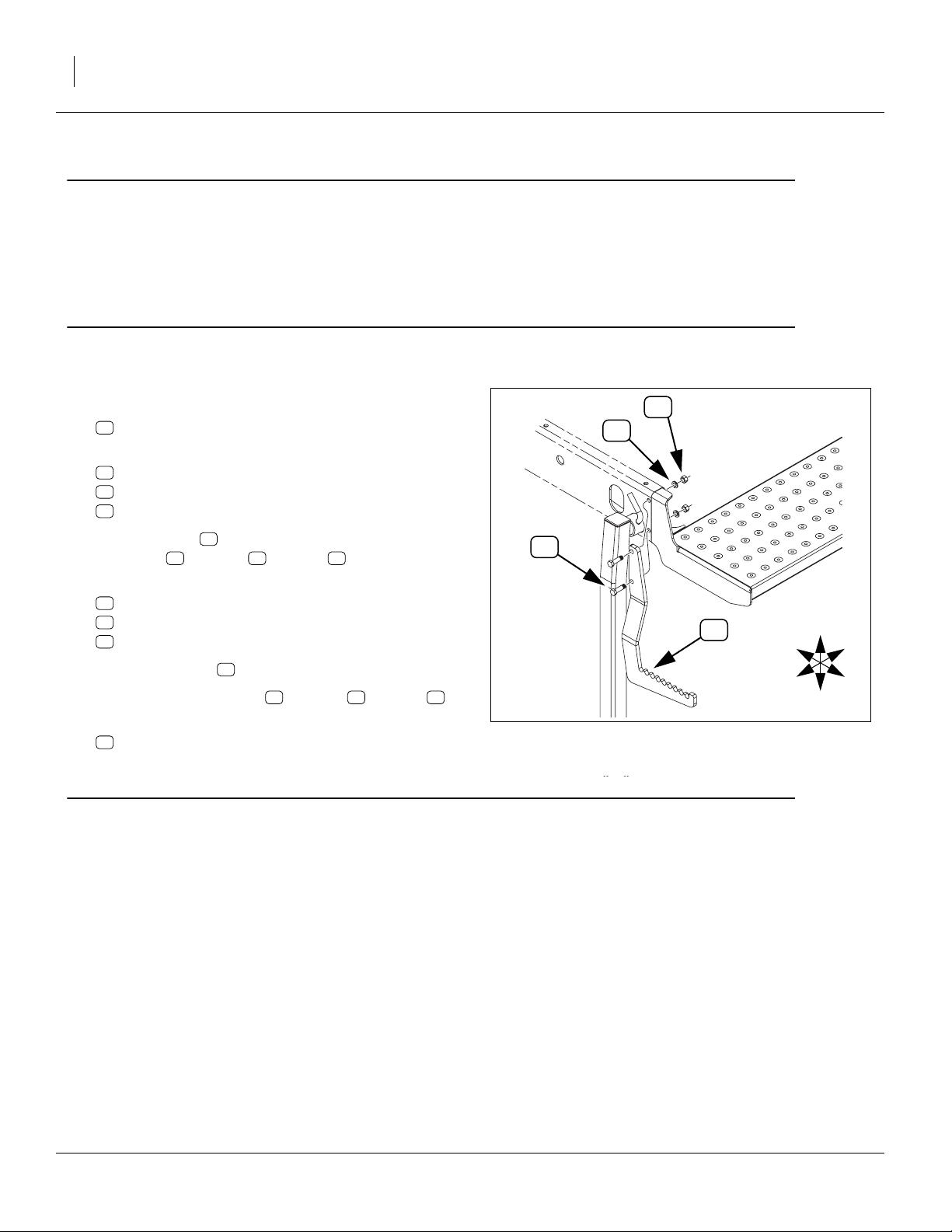

Refer to Figure 1

Review these instructions, and make sure you understand where and how the ladders install, and which existing parts are removed.

!

WARNING

If unfolded, the drill must be hitched to a tractor during

Opener Lift, to avoid negative tongue weight. Hitch loads can

range between +4000 pounds (folded) and -1000 pounds

(unfolded), depending on drill model and configuration.

Tools Required

• basic hand tools

• if unfolding is desired, a tractor with two hydraulic circuits and suitable hitch

These instructions presume an existing drill with fixed

steps. The installation may be done with the drill folded

or unfolded.

Figure 1

Ladder Installed

Notations and Conventions

“Left” and “Right” are facing in the

direction of machine travel. An orientation rose in the line art illustrations

shows the directions of Left, Right,

Front, Back, Up, Down.

1

11 26

to

51 55

to

callouts identify components in the currently

referenced Figure or Figures.

callouts reference new parts from the list on

page 6. The descriptions match those on the

cartons, bags or item tags, as well as your

updated Parts Manual.

callouts reference affected existing parts

from the table on page 7. The descriptions

match those in your Parts Manual.

U

F

L

R

B

D

27033

U

F

L

R

B

D

09/10/2007 195-066M

Page 2

2 Ladder Kit Great Plains Manufacturing, Inc.

Pre-Assembly Preparation

1. Inventory the contents per “New Parts: Kit 195065A” on page 6.

2. If the drill is unfolded, lower the parking stands, lower

the openers, and lower the drill.

Remove Fixed Steps

Begin with the left step.

Refer to Figure 2

3. Loosen both nuts

54

NUT HEX 1/2-13 PLT.

4. On the lower bolt only, remove and save:

54

NUT HEX 1/2-13 PLT

55

WASHER LOCK SPRING 1/2 PLT

53

HHCS 1/2-13X1 3/4 GR5

54

55

5. Swing the step backward, and re-install the saved

lower bolt , washer and nut .

6. Remove and save the upper:

54

NUT HEX 1/2-13 PLT

55

WASHER LOCK SPRING 1/2 PLT

53

HHCS 1/2-13X1 3/4 GR5

7. Remove the step . It is not re-used.

8. Re-install the saved bolt , washer and nut

9. Repeat step 3 through step 8 for the right hand step

52

(shown in Figure 8 on page 7).

51

53 55 54

51

53 55 54

Install Ladder Mounts

Where to place the top ladder mount depends on the drill

configuration.

If the drill has the Small Seeds Box installed (or will be),

the outer rear hole of the mount is the second row from

the rear edge of the walkboard (see Figure 3 on page 3).

If Small Seeds is not installed, the corner mount hole is

the third row from the rear edge (see Figure 4 on

page 3).

Regardless of drill configuration, the outer rear hole of

the top mount the second row in from the end of the

walkboard.

53

51

Figure 2

Remove Left Step

U

F

L

R

B

D

27035

195-066M 09/10/2007

Page 3

Great Plains Manufacturing, Inc. Install Ladder Mounts 3

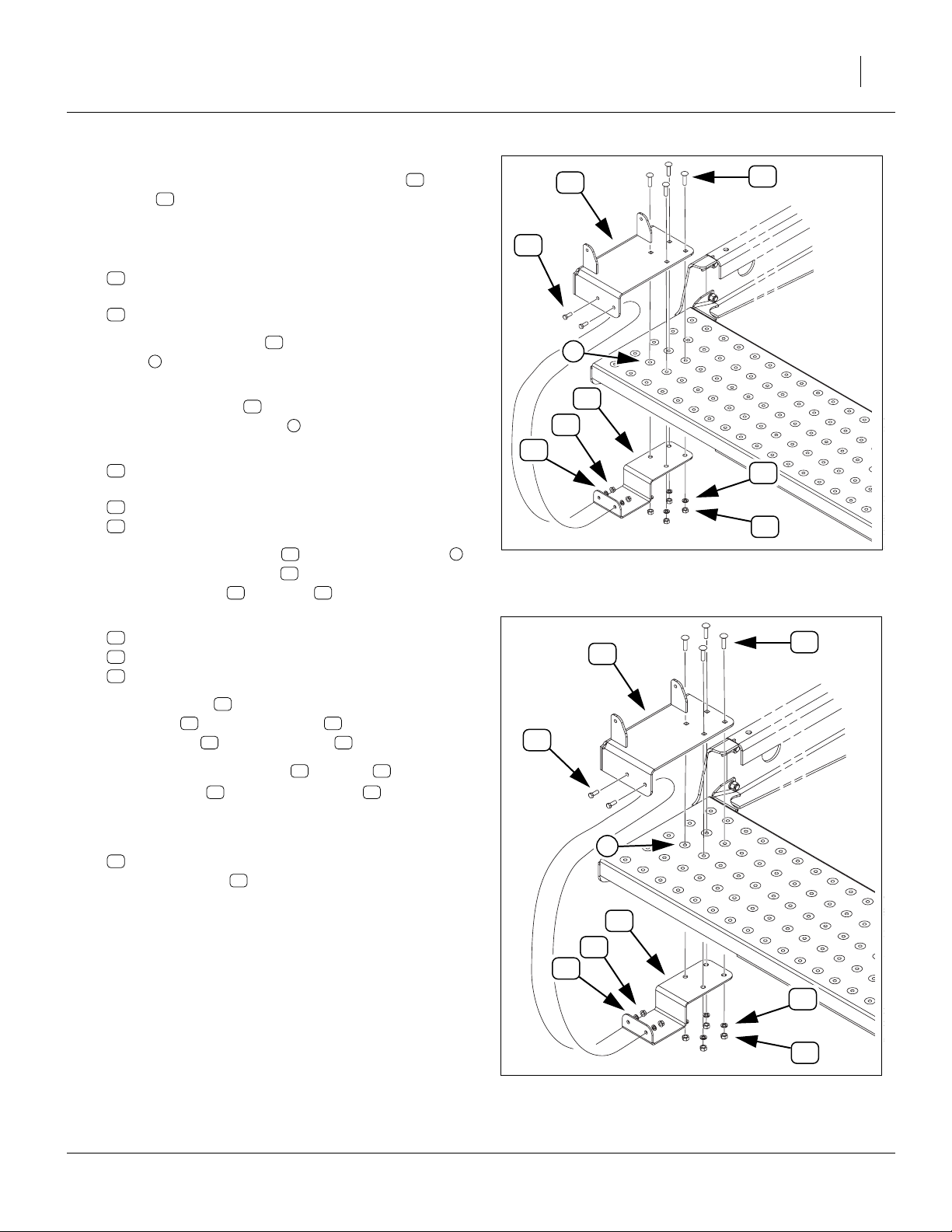

Refer to Figure 3 or Figure 4

Top mount weldments are provided in left-side ( ) and

right-side ( ) versions and are not interchangeable. All

other parts may be used on either end. Start with the left

wing:

10. Select one:

13

and four:

17

14

195-063H LADDER MOUNT TOP WELDMENT LH,

802-030C RHSNB 7/16-14X1 3/4 GR5.

13

13

16

17

11. Position the top mount over the four walkboard

4

holes appropriate for the drill’s configuration (see

page 2).

12. Insert the four bolts to loosely hold the top mount

in place on the walkboard .

13. Select one:

15

195-340D LADDER MOUNT BOTTOM PLATE

and four sets of:

23

804-014C WASHER LOCK 7/16 PLT

19

803-015C NUT HEX 7/16-14 PLT

14. Position the bottom plate under the walkboard

and inside the top mount . Loosely hold it in place

with the washers and nuts .

15. Select two sets of:

16

802-017C HHCS 3/8-16X1 GR5

22

804-013C WASHER LOCK SPRING 3/8 PLT

20

803-068C NUT HEX FLANGE 3/8-16 PLT

16. Insert the bolts through the side holes in both the

top mount and bottom plate , and secure with

lock washers and flange nuts .

17. Tighten the four

the top mount to the bottom plate .

16

13 15

22 20

7

13 15

13

17

4

15 4

13

23 19

⁄

in nuts on bolts , securing

16

19 17

22

16

4

15

20

Figure 3

Small Seeds Mount Location

13

23

19

27055

17

Refer to Figure 7 on page 6

18. Selecting one:

14

195-064H LADDER MOUNT TOP WELDMENT RH

in place of mount , repeat step 10 through step 17

for right wing section.

13

4

15

20

22

23

19

Figure 4

Location, No Small Seeds

09/10/2007 195-066M

27036

Page 4

4 Ladder Kit Great Plains Manufacturing, Inc.

Install Ladders

The ladders mount between the lugs of the upper

mounts. Flat washers are placed outside the ladder side

frames and inside the lugs (between ladder side frame

and mount). Bolt heads are to the inside, to minimize

obstructions to foot movement during climbing.

Refer to Figure 5

(which shows only the left side assembly,

on a drill without Small Seeds)

Start with the left walkboard.

19. Select one:

12

195-062H

LADDER WELDMENT 3-STEP NARROW

12

13

20. Lay the ladder on the walkboard with the swing

holes up and near the top mount lug holes. Align

12

13

the holes in the ladder in between the holes in the

lugs.

21. Select two sets of:

18

802-079C HHCS 3/8-16X1 1/4 GR5

24

804-016C WASHER FLAT 1/2 SAE PLT

21

803-209C NUT FLANGE LOCK 3/8-16 PLT

22. Insert a bolt through (in this order):

• the ladder side plate,

• a washer , and

• the mount lug.

Secure with lock nut .

18

12

24

13

21

23. Repeat step 19 through step 22 for right wing walkboard.

24. Swing both ladders down to check operation and

position for decal placement.

18

Figure 5

Ladder Installation

21

24

27037

195-066M 09/10/2007

Page 5

Great Plains Manufacturing, Inc. Install Reflectors and Decals 5

Install Reflectors and Decals

The new ladder top mount may obscure existing decals

and reflectors on the walkboard. The ladder kit includes

replacements to apply as needed.

To install new reflectors and decals:

• Clean and dry the area where the reflector or decal

is to be placed.

• Peel backing from reflector or decal. Press firmly

on surface, being careful not to cause air bubbles

under reflector or decal.

Refer to Figure 6

Start on the left walkboard, outer end:

25. Select one:

26

838-265C DECAL REFLECTOR AMBER 1 1/2X9

25

Place the reflector decal on the outside of the ladder

mount , between the ladder side plates (so it

won’t be damaged by ladder operation)

26. Select one:

26

Place the reflector decal on the rear and corner of the

ladder mount . This decal is slightly longer than

that side of the mount. Wrap the excess around the

corner.

27. Select one:

25

Place the 838-102C Danger decal forward of and

near the top of the ladder, where it is visible to climbers.

28. Repeat step 25 through step 27 for right wing walkboard ladder.

13 12

838-265C DECAL REFLECTOR AMBER 1 1/2X9

13

838-102C

DECAL WARNING FALLING HAZARD

25

Operations

Swing ladders up and onto walkboards during:

• folding and unfolding,

• transport,

• field operations,

• unattended parking, and;

• storage.

12

26

Figure 6

Replacement Decals

26

13

27016

09/10/2007 195-066M

Page 6

6 Ladder Kit Great Plains Manufacturing, Inc.

Parts Lists

New Parts: Kit 195-065A

25

17

26

24

18

12

13

16

15

Your kit includes the parts illustrated above and listed

below. The part call-out numbers in this list match all Figures in the installation instructions.

20

Figure 7

New Parts

21

14

23

19

27034

Left- and right-hand kit parts are identical except for:

top mount: Left: , Right: .

13 14

Callout Quantity Part Number Part Description

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

195-066M 09/10/2007

1 195-066M This manual (not shown above)

2 195-062H LADDER WELDMENT 3-STEP NARROW

1 195-063H LADDER MOUNT TOP WELDMENT LH

1 195-064H LADDER MOUNT TOP WELDMENT RH

2 195-340D LADDER MOUNT BOTTOM PLATE

4 802-017C HHCS 3/8-16X1 GR5

8 802-030C RHSNB 7/16-14X1 3/4 GR5

4 802-079C HHCS 3/8-16X1 1/4 GR5

8 803-015C NUT HEX 7/16-14 PLT

4 803-068C NUT HEX FLANGE 3/8-16 PLT

4 803-209C NUT FLANGE LOCK 3/8-16 PLT

4 804-013C WASHER LOCK SPRING 3/8 PLT

8 804-014C WASHER LOCK 7/16 PLT

4 804-016C WASHER FLAT 1/2 SAE PLT

2 838-102C DECAL WARNING FALLING HAZARD

4 838-265C DECAL REFLECTOR AMBER 1 1/2X9

Page 7

Great Plains Manufacturing, Inc. Parts Lists 7

Existing Parts Affected

54

55

53

51

Existing Parts Affected

The following existing parts may be involved in the kit

installation. The Disposition column indicates whether

parts are left in place, moved or not re-used.

Figure 8

The part call-out numbers in the list match all Figures in

the installation instructions. Descriptions match those in

your drill Parts manual.

52

Existing Parts List

Callout Part No. Part Description Part Disposition

51

195-121D STEP LH Removed. Not re-used.

52

195-122D STEP RH Removed. Not re-used.

53

802-082C HHCS 1/2-13X1 3/4 GR5 Saved and re-used.

54

803-020C NUT HEX 1/2-13 PLT Saved and re-used.

27035

55

804-015C WASHER LOCK SPRING 1/2 PLT Saved and re-used.

09/10/2007 195-066M

Page 8

Reference Information

Abbreviations Torque Values

GR Grade

HHCS Hex Head Cap Screw (Bolt)

LH Left Hand

PLT Plated

RH Right Hand

RHSNB Round Head Shank Neck Bolt

SAE Society of Automotive Engineers

(mechanical standard)

EOD

Fastener/Fitting Ft-Lbs N-m

3

⁄

-16 Grade 5

8

7

⁄

-14 Grade 5

16

1

⁄

-13 Grade 5

2

31 42

67 49

105 76

Great Plains Manufacturing, Inc.

Corporate Office: P.O. Box 5060

Salina, Kansas 67402-5060 USA

Loading...

Loading...