Page 1

Operator’s/Parts Manual

John Deere 30’ Dual 750

Flat Fold Marker

Planting Components

Read the operator’s manual entirely.Whenyouseethissymbol, the subsequent

instructions and warnings are serious - follow without exception. Your life and

!

the lives of others depend on it!

Cover illustration may show optional equipment not supplied with standard unit.

© Copyright 2002 Printed 3/20/2003

13747

205-052M

Page 2

Table of Contents

General Information . . . . . . . . . . . . . . . . . . . . . . . . .1

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Using this Manual . . . . . . . . . . . . . . . . . . . . . . . . .2

Important Safety Information . . . . . . . . . . . . . . . . . .3

Owner’s Assistance . . . . . . . . . . . . . . . . . . . . . . . . .4

Operating and Assembly Instructions. . . . . . . . . . .5

General Operation & Repair . . . . . . . . . . . . . . . . .5

Transporting . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Hydraulic System. . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Adjusting the Hydraulics . . . . . . . . . . . . . . . . . . . .9

Maintenance & Lubrication . . . . . . . . . . . . . . . . . .10

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Breakaway Protection . . . . . . . . . . . . . . . . . . . . .10

Marker Transporting . . . . . . . . . . . . . . . . . . . . . .10

Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Flat Fold Marker Assembly . . . . . . . . . . . . . . . . .14

Disk Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . .16

Hydraulic Assembly. . . . . . . . . . . . . . . . . . . . . . .18

Hydraulic Cylinder. . . . . . . . . . . . . . . . . . . . . . . .20

Sequence Valve . . . . . . . . . . . . . . . . . . . . . . . . .22

Appendix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

© Copyright 2002Allrights Reserved

Great Plains Manufacturing, Inc. provides this publication“as is” without warranty of any kind, either expressed or implied. While every precaution has been takenin the

preparationofthismanual,GreatPlainsMan uf acturing,Inc.assumesno responsibility for errorsoromissions.Neither is any liabilityassumedfordamages resulting from

theuseof the information contained herein. Great Plains Manufacturing,Inc. reservestheright to reviseandimproveits products as it sees fit. This publication describes

the state of this product at the time of its publication, and may not reflect the product in the future.

Great Plains Manufacturing, Incorporated Trademarks

The following are trademarks of Great Plains Mfg., Inc.: Application Systems, Ausherman, Land Pride, Great Plains

All other brands and product names are trademarks or registered trademarks of their respective holders.

Printed in the United States of America.

3/20/2003

205-052M

Page 3

General Inf ormation

Important Notice

Great Plains Manufacturing, Inc. provides this

publication “as is” without warranty of any kind,

either expressed or implied, while every

precaution has been taken in the preparation of

this manual, Great Plains Manufacturing, Inc.

assumesno responsibility forerrors or omissions.

Neither is any liability assumed for damages

resulting from the use of the information

contained herein. Great Plains Manufacturing,

Inc. reserves the right to revise and improve its

products as it sees fit. This publication describes

the state of this product at the time of its

publication, and may not reflect the product at all

times in the future.

Printed in the United States of America.

For your convenience, record your Model and the

Date Purchased on page 4. Have this information

beforeyouwhen callinga GreatPlains Authorized

Dealer.

General Information

1

This Operator’s Manual applies to the

Product Name listed below:

Flat Fold Marker

3/20/2003

205-052M

Page 4

John Deere 30’ Dual 750

2

Introduction

GreatPlains welcomesyouto itsgrowingfamilyof

new product owners. This Flat Fold Marker has

been designed with care and built by skilled

workers using quality materials. Proper setup,

maintenance and safe operating practices will

help you get years of satisfactory use from the

machine.

Description of Unit

The parts on your Flat Fold Marker have been

specially designed and should only be replaced

with genuine Great Plains parts. Therefore,

shouldyour Flat Fold Markerrequire replacement

parts go to your Great Plains Dealer.

Using This Manual

This manual will familiarize you with safety,

assembly, operation, adjustments and

maintenance. Read this manual and follow the

recommendations to help ensure safe and

efficient operation.

The information in this manual is current at

printing. Some parts may change to assure top

performance.

Definitions

The following terms are used throughout this

manual.

Right-hand and left-hand as used in this manual

are determined by facing the direction the

machine will travel while in use unless otherwise

stated.

IMPORTANT: A crucial point of information

related to the preceding topic. For safe and

correct operation, read and follow the

directions provided before continuing.

NOTE: Useful information related to the

preceding topic.

205-052M

3/20/2003

Page 5

Important Safety Information

Look for Safety Symbol

The SAFETY ALERT SYMBOL indicates there is

apotential hazard to personal safetyinvolvedand

extrasafety precaution must be taken. When you

see this symbol, be alert and carefully read the

message that follows it. In addition to design and

configuration of equipment, hazard control and

accident prevention are dependent upon the

awareness, concern, prudence and proper

training of personnel involved in the operation,

transport, maintenance and storage of

equipment.

Be Aware of Signal Words

Signal words designate a degree or level of

hazard seriousness.

Important Safety Information

!

3

DANGER indicates an imminently hazardous

situation which, if not avoided, will result in death

or serious injury. This signal word is limited to the

most extreme situations, typically for machine

components that, for functional purposes, cannot

be guarded.

WARNING indicates a potentially hazardous

situation which, if not avoided, could result in

death or serious injury, and includes hazards that

are exposed when guards are removed. It may

also be used to alert against unsafe practices.

CAUTION indicates a potentially hazardous

situationwhich, if not avoided,may result in minor

or moderate injury.It may also be used to alert

against unsafe practices.

DANGER

!

WARNING

!

CAUTION

!

3/20/2003

205-052M

Page 6

John Deere 30’ Dual 750

4

Owner Assistance

If you need customer service or repair parts,

contact a Great Plains dealer.They have trained

personnel, repair parts and equipment specially

designed for Great Plains products.

Yourmachine’sparts werespecially designedand

should only be replaced with Great Plains parts.

Always use the model number when ordering

parts from your Great Plains dealer.

Record your Model and Date Purchased here for

quick reference:

Model:________________________________

Date Purchased:_________________________

Your Great Plains dealer wants you to be

satisfied with your new machine. If you do not

understand any part of this manual or are not

satisfied with the service received, please take

the following actions.

1. Discuss the matter with your dealership

service manager.Makesure they are awareof

any problems so they can assist you.

2. If you are still unsatisfied, seek out the owner

or general manager of the dealership.

3. For further assistance write to:

Product Support

Great Plains Mfg. Inc., Service Department

PO Box 5060

Salina, KS 67402-5060

205-052M

3/20/2003

Page 7

Operating and Assembly Instructions

Operating and Assembly Instructions

5

Most accidents are the result of negligence and

carelessness, usually caused by failure of the

operator to follow simple but necessary safety

precautions.The followingsafety precautions are

suggested to help preventsuch accidents. The

safe operation of any machinery is a major

concern to consumers and manufacturers.Your

Flat Fold Marker has been designed with many

built-in safety features. However, no one should

operate this product before carefully reading this

Operators Manual.

General Operation & Repair

1. Never allow the Flat Fold Marker to be

operatedby anyonewho isunfamiliar withthe

operation of all functions of the unit. All

operators should read and thoroughly

understand the instructions given in this

manual prior to moving the unit.

2. Makesuresafetyrules areunderstoodbefore

operating machinery or tractor.

3. Never permit any persons other than the

operator to ride on the tractor.

4. Never permit any persons to stand near the

Flat Fold Marker while it is in operation.

5. Regulate your speed to the field conditions,

maintaining complete control at all times.

implements by using suitable supports and

block wheels.

13. If a hydraulic leak develops, correct it

immediately. Escaping hydraulic oil can have

extremely high pressure. A stream of high

pressure oil may easily penetrate the skin as

with modern needle-less vaccination

equipment - but with the exception that

hydraulicfluid maycause blood poisoning. It is

imperative that the connections are tight and

that all lines and pipes are in good condition. If

an injury is caused by the escaping hydraulic

fluid, see doctor at once!

14. Use a piece of cardboard or wood to detect

leaks of hydraulic oil under pressure.

15. Be sure to relieve all hydraulic pressure before

disconnecting any lines or pipes between the

implement and the tractor hydraulic system.

Keepall guards and shields in place.

Transporting

16. Use goodjudgementwhentransporting tractor

and implements on the highway. Always

maintain complete control of the machine.

17. Limit transport speed to 20 mph. Transport

only with a farm tractor of sufficient size and

horse power.

3/20/2003

6. After repairing or adjusting, make sure all

tools and parts are removed from the

implement before attempting to operate it.

7. Do not grease or oil machine while it is in

operation.

8. Loosefitting clothing should not be worn as it

may catch in moving parts.

9. Never dismount from a moving tractor.

10. Do not leavethe tractor or the implement

unattended with the engine running.

11. Do not stand between the tractor and the

implement during hitching.

12. Detach and store implements in an area

where children normally do not play. Stabilize

18. Always make sure flashing safety lights, “Slow

Moving Vehicle” emblem, and reflectors are in

place and visible prior to transporting the

machine on public roads.

19. Know your state and local laws concerning

highway safety and regulations. Comply with

these laws when transporting machinery.

20. Use warning flags or approved warning lights

at night and during other periods of poor

visibility. Do your best to prevent highway

accidents

205-052M

Page 8

John Deere 30’ Dual 750

6

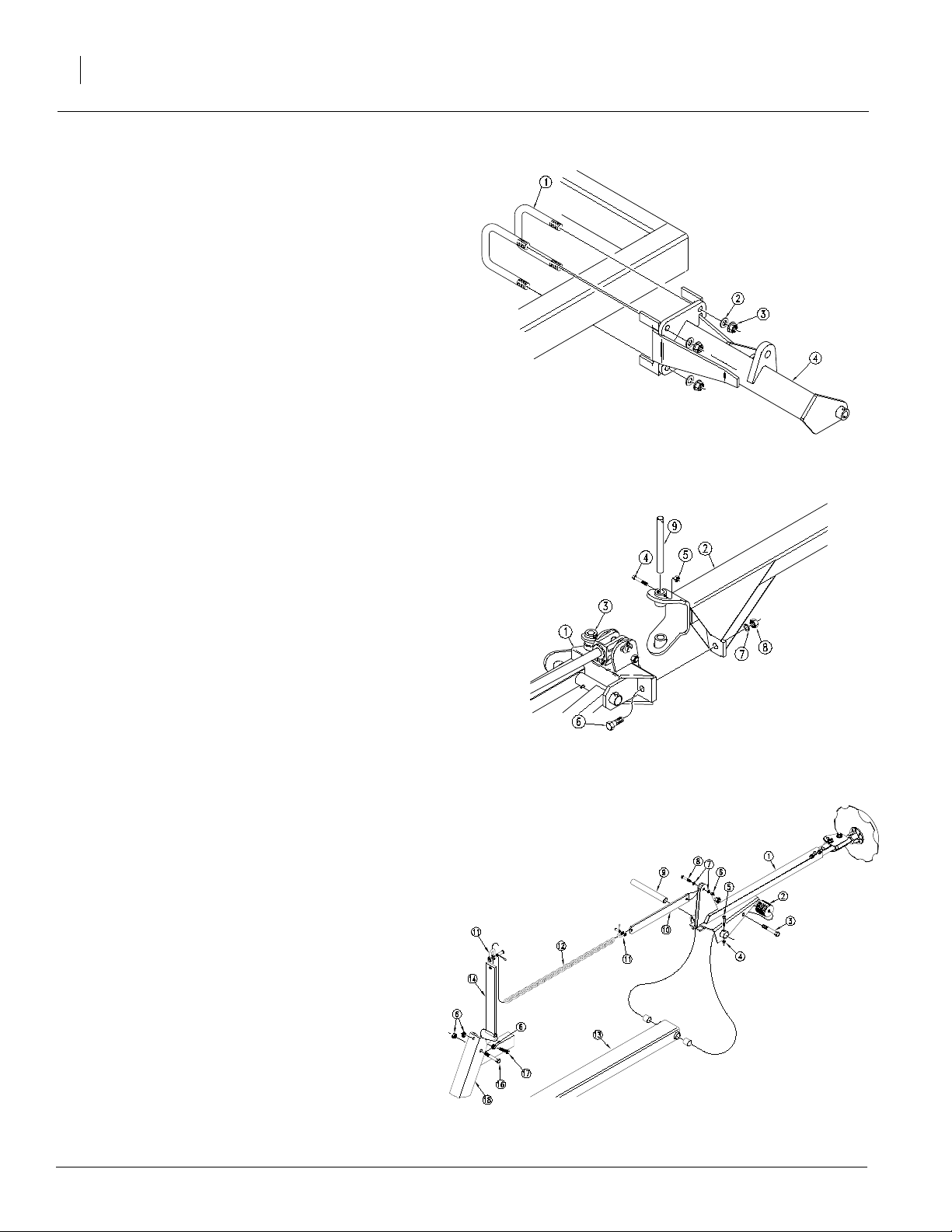

John Deere Dual 750 Marker

See the "Parts Section" of this manual to identify

individual components not mentioned in these

installation instructions.

1. Placedrill in a loweredfieldposition. Fromeachend

of the drill box allow 16 ft. clearance for marker

assembly.

Refer to Figure 1

2. Attach the marker first section with mount (4) to the

drill frame as illustrated using the 3/4" x 6 1/32" Ubolts (1), 3/4" flat washer (2) and 3/4" locking flange

nut (3).

Refer to Figure 2

3. Assemble the marker in a horizontal position,

remove the port plugs in the hydraulic cylinder to

allow the fold cylinder to be extended. Then fold the

firstsection andthe liftlug channel(1) toahorizontal

position.

4. With the shear bar positioned towards the front (2),

align the holes of the second section with the holes

of the lift lug channel (1) and insert the hinge pin (9)

and bolt into place with 5/16" x 2" Gr 5 bolt (4) and

locknut (5). Also place the 7/16" x 2 1/4" Gr 5 shear

bolt (6) in position with lock washer (7) and nut (8).

Refer to Figure 3

5. Placethethird section(1) overtheend ofthesecond

section (13) and insert hinge pin (9) through the

secondandthirdsection pivot. Secure the hinge pin

(9) with 5/16" x 2" long bolt (5) and lock nut (4).

6. Bolt the chain bar weldment (14) to the first section

(18) with 3/8" x 3 1/4" long bolt (16) and lock nut (6).

The chain bar weldment (14) should pivot freely on

the 3/8" bolt (16). Bolt the chain bar (10) to the third

section(1) with the3/8" x 11/2" long bolt(8),washer

(7) and lock nut (6). The chain bar (10) should pivot

freely on the 3/8" bolt (8). Connect the marker chain

(2) between the chain bar (10) and chain bar

weldment (14) with 5/16" utility clevis (11). With the

marker disk adjusted for seeding width and disk

touching the ground, adjust chain length to remove

the slack. Adjustment should be made at the utility

clevis (11) nearest to the drill.

13696

Figure 1

Marker Mount Assembly

13697

Figure 2

Second Section Pivot Assembly

7. Thepurposeof the 3/8" x21/2" long stop bolt(17)is

tohold tension onthe marker chain(12) ONLY when

the marker is in folded position. Therefore; the 3/8"

stop bolt (17) and lock nuts (6) should be positioned

in the first section (18) so the head of the stop bolt

extends as little as possible. After marker is folded,

adjust stop bolt to tighten chain.

205-052M

13724

Figure 3

Third Section Pivot and Chain Assembly

3/20/2003

Page 9

Refer to Figure 4

8. When mounting the marker carrier arm (1), first

mount the transport mount arm (2) to the drill frame

using 1/2" x 4 1/32" x 7 1/4" long U-bolt (3), flat

washers (4), and flanged nuts (5). The transport

mount arm should be 50" - 60" awayfrom the box

end as shown. Next attach the marker carrier arm

(1) to the transport mounting arm (2) using the 1/2"

x 2" x 3" long U-bolts (6), flat washers (9) and

flanged nuts (7). The marker carrier arm should be

set at 31 3/8" - 31 7/8" above the drill frame as

shown.

9. Mount the support arm saddle (8) to the marker

carrier arm (1) with 1/2" x 2" x 3" long U-bolts (6),

and flanged nuts (7). The support saddle should be

centered under the marker chain and the square

tube of the second section, when folded to prevent

wear.The support arm should support the second

section parallel with the seed box lid. Adjustment

can be made by loosening the U -bolts that clamp

the marker carrier and slide marker carrier (1) up or

down to parallel the marker with the drill box lid.

Operating and Assembly Instructions

13699

Figure 4

Marker Support Assembly

7

Refer to Figure 5

10. Fold the marker to transport position. With the

marker chain (12) in the slot of the support arm

saddle, take up the slack in the marker chain by

threading

3/8"x2 1/2" long stop bolt (17) out against the chain

barweldment (14), lockthisstop bolt in position with

the two lock nuts (6).

11. The marker blade comes factory assembled. The

width of the mark that the blade makes can be

adjusted by changing the angle of the blade.This is

done by loosening the two 1/2" bolts in the blade

adjuster, pivoting the blade to the preferred angle

and tightening the bolts.

Refer to Figure 6

12. If desired, the angle ofthe bladecan bereversedby

turning the blade adjuster upside down and

reversingthe blade so the depth band is on the

inside.

11248

Figure 5

Blade Adjustment

3/20/2003

11757

Figure 6

Reversed Blade Adjustment

205-052M

Page 10

John Deere 30’ Dual 750

8

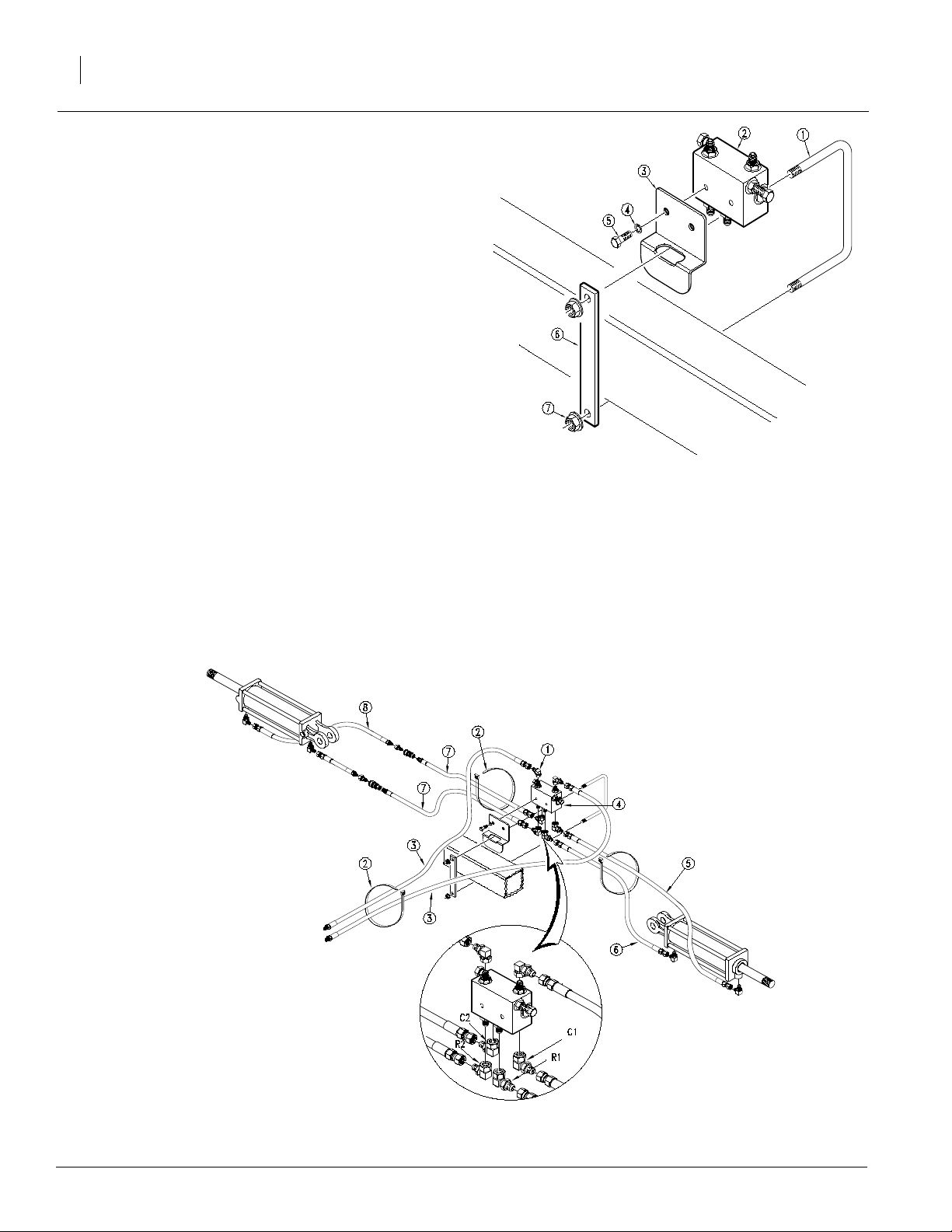

Refer to Figure 7

13. Install themarkervalvemount (3)close to thecenter

hitch on the tool bar frame of the front drill using the

U-bolt (1), bracket (6) and flange nut (7). Assemble

the valve (2) to the mount with the 4-port side

downward using two 3/8" x 3/4" long bolts (5) and

lock washers (4).

Refer to Figure 8

14. Route thehoses alongthe coulter frametube andtie

them to the tube with the releasable cable ties (2).

Connectthehosestothesequencevalve(4) withsix

JIC elbows (1). Note the port markings and refer to

Figure 8 for the proper connections.

15. Connect two252" long hoses(3)to the twotop ports

of the sequence valvewith two elbows (1) and route

them to the tongue and through the hose loop. Use

releasable cable ties sent with assembly to secure

hose to frame.

13700

Figure 7

Marker Valve

16. Use the 163" (5) and 136" (6) hose to connect the

marker on the front drill. Next, use the two 156" (7)

long hoses to go from the sequence valvealong the

dual hitch frame to the front of the second drill. The

remaining 252" hoses go to the marker on the

second drill. Quick connectors (purchased

separately)are used for easyremoval of the second

drill.

205-052M

13701

Figure 8

Marker Hydraulic Assembly

3/20/2003

Page 11

Hydraulic System

Adjusting The Hydraulics

1. Be sure tractor hydraulic reservoir is full.

2. With the markers in field position, crack the

hydraulics hose fittings located at the base end of

one of the cylinders. With the tractor at an idle

speed, activate the tractor hydraulics valve until

hydraulicoilseeps outaround thehose end.Tighten

the hose end fittings. Repeat this process for the

hose at the rod end of the cylinder.Crackthe fittings

on the back side of the sequence valve until

hydraulic oil seeps out. Tighten and repeat for the

opposite cylinder.

3. Cycle each cylinder 3 or 4 times slowly. Both arms

shouldmoveto the verticalpositionon thefirstmove

and then they should lower and raise alternately as

the hydraulic lever is operated.

4. Foldandunfoldthemarker(s) slowlyin order towork

all theairoutofyourmarker hydraulics.Use caution

when folding and unfolding the marker for the first

time, and check for pinching and kinking of hoses.

!

CAUTION

Never allow anyone near the drill when cycling the markers.

Hydraulic System

!

CAUTION

Excessive folding speeds can cause marker damage!

!

CAUTION

Escaping Fluid under pressure can have sufficient force to

penetrate the skin. Check all hydraulic lines and hoses before

applying pressure. Fluid escaping from a very small hole can

be almost invisible. Use paper or cardboard, not body parts,

to check for suspected leaks. If injured, seek medical

assistance from a doctor that is familiar with this type of

injury.Foreign fluids in the tissue must be surgicallyremoved

within a few hours or gangrene will result.

General Notes

The markers cycle in the following sequence

(1)Right Up, Left Up

(2)Right Down, Left Up

(3)Right Up, Left Up

(4)Right Up, Left Down

(5)Sequence Repeats

9

5. The marker hydraulic system is equipped with

needle valves to control how fast each marker

operates. The needle valves are built into the

sequencevalvebody.Therearetwo hexadjustment

heads, one for raising the markers, and one for

lowering the markers. These are stamped in the

valve body. To adjust the speed of each marker,

screwthe needle valveclockwise to adjust the raise

or lower marker speed to a low setting. Fold the

marker up and down a few times and recheck for

pinching and kinking of hoses. With the tractor

engine at an operating rpm, adjust the needle valve

to limit the marker to a safe operating speed.

Excessive folding speeds can cause marker

damage.

NOTE: JIC fittings do not require high torque. JIC and ORingfittings do not require sealant. Alwaysuse liquid pipe

sealant when adding or replacing pipe thread fittings. To

avoid possible danger of cracking hydraulic fittings from

over tightening,

DO NOT use plastic sealant tape.

3/20/2003

205-052M

Page 12

John Deere 30’ Dual 750

10

Maintenance and Lubrication

Maintenance

Proper servicing and adjustment is the key to the long

life of any farm implement. With careful and systematic

inspection, you can avoidcostly maintenance, time and

repair.

Breakaway Pr otection

The marker arm is attached to the marker body with a

7/16" breakaway bolt. If excessive force is put on the

markerduring operation,theboltwillbreak,allowingthe

marker arm to swing away rather than cause damage to

the marker.

NOTE: The breakaway bolt is a 7/16"-14 x 2 1/4"

long grade 5 (G.P. # 802-234C). It is identified as a

grade 5 by having three marks on the head. If it

breaks, it must be replaced by an equivalent grade

5 bolt to prevent marker damage.

Marker Transporting

Alwaystransport the marker with it folded in the flat fold

position.

205-052M

3/20/2003

Page 13

Lubrication Symbols

50

Maintenance and Lubrication

As

Required

11

Lubrication is required every 50 hours of operation.

10

Lubrication

13441

Use a multi-purpose spray lub. Use as required.

Do not over lubricate.

Seasonally

Lubrication is requiredLubrication is required every 10 hours of operation.

25

1st Hinge Zerk

Type of Lubrication: NLGI Grade 2 or 3 grease lubricant

3/20/2003

25

2nd Hinge Zerk

13723

Type of Lubrication: NLGI Grade 2 or 3 grease lubricant

205-052M

Page 14

John Deere 30’ Dual 750

12

Lubrication

25

3rd Hinge Zerk

13702

12436

Type of Lubrication: NLGI Grade 2 or 3 grease lubricant

Seasonally

Disk Bearings

Type of Lubrication: NLGI Grade 2 or 3 grease lubricant

205-052M

3/20/2003

Page 15

Troubleshooting

Problem Solution

Troubleshooting

13

Hydraulic marker functioning

improperly

Blade does not mark

Hydraulic marker functioning

improperly

Check all hose fittings and connections for air and oil leaks.

The chain on the folding marker should be slack when the marker is both fully extended

and fully raised.

Check tractor hydraulic oil level.

Check all bolts and fasteners.

If needle valve is plugged; open valve, cycle markers, and reset the needle valve.

Double selector valve positioned for fold cylinders. Shift valve to marker sequence posi-

tion.

The marker folding linkage and chain must have enough slack to allow the marker disk to

drop down into depression in the field. Maximum down float should be limited by the

slots at the rod end of the marker cylinder, and not by the chain. Read the adjustments

section of this manual when adding slack to chain.

The blade may be reversed to pull dirt in or throw dirt out depending on soil conditions.

An optional smooth blade is available through your Great Plains dealer. The notch blade

comes with your marker as standard equipment.

Check all hose fittings and connections for air and oil leaks.

The chain on the folding marker should be slack when the marker is both fully extended

and fully raised.

Check tractor hydraulic oil level.

Check all bolts and fasteners.

Blade does not mark

If needle valve is plugged; open valve, cycle markers, and reset the needle valve.

Double selector valve positioned for fold cylinders. Shift valve to marker sequence posi-

tion.

The marker folding linkage and chain must have enough slack to allow the marker disk to

drop down into depression in the field. Maximum down float should be limited by the

slots at the rod end of the marker cylinder, and not by the chain. Read the adjustments

section of this manual when adding slack to chain.

The blade may be reversed to pull dirt in or throw dirt out depending on soil conditions.

An optional smooth blade is available through your Great Plains dealer. The notch blade

comes with your marker as standard equipment.

3/20/2003

205-052M

Page 16

John Deere 30’ Dual 750

14

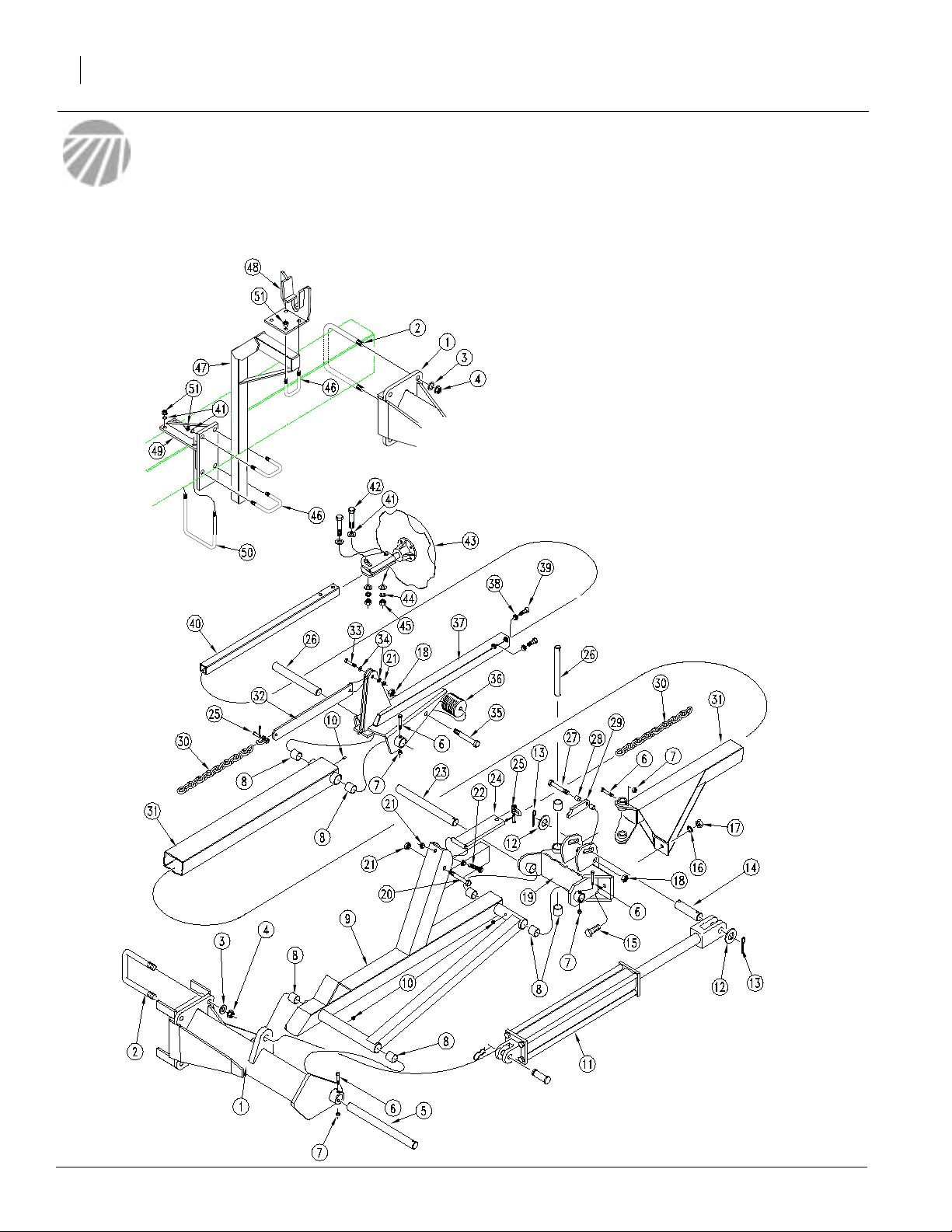

Parts

Flat Fold Marker Assembly

13703

205-052M

3/20/2003

Page 17

Ref. Part No. Description

1. 205-048H DUAL JD750 MARKER MOUNT LH Shown.

205-047H DUAL JD750 MARKER MOUNT RH

2. 806-123C U-BOLT 3/4-10 X 6 1/32 X 6 3/4

3. 804-024C WASHER FLAT 3/4 USS PLT

4. 803-181C NUT HEX FLANGE LOCK 3/4-10 PLT

5. 113-312D FIRST PIVOT SHAFT

6. 802-115C HHCS 5/16-18X2 GR5

7. 803-011C NUT LOCK 5/16-18 PLT

8. 890-005C BUSHING CYL 1 1/4 X 1 X 1

9. 113-180H LH FIRST SECTION Shown.

113-188H RH FIRST SECTION

10. 800-001C GREASE ZERK STRAIGHT 1/4-28

11. 810-118C CYL 2.5X20X1.12 ROD (TIE)1 PIN

12. 804-029C WASHER FLAT 1 SAE

13. 805-058C PIN COTTER 3/16 X 2

14. 113-248D PIN 1 OD X 4.34 USABLE

15. 802-234C HHCS 7/16-14X2 1/4 GR5

16. 804-014C WASHER LOCK 7/16 PLT

17. 803-015C NUT HEX 7/16-14 PLT

18. 803-019C NUT LOCK 1/2-13 PLT

19. 113-350H NO-TILL BREAKAWAY JOINT LH Shown.

113-351H NO-TILL BREAKAWAY JOINT RH

20. 802-168C HHCS 3/8-16X3 1/4 GR5

21. 803-013C NUT LOCK 3/8-16 PLT

22. 802-261C HHCS 3/8-16X2 1/2 GR5 FTHD

23. 113-313D SECOND PIVOT SHAFT

24. 113-200H CHAIN BAR WELDMENT

25. 890-018C 5/16 x 1 1/4 UTILITY CLEVIS

26. 113-311D HINGE PIN

27. 802-201C HHCS 1/2-13X4 3/4 GR5

28. 113-325D STOP BUSHING

29. 113-324D CYLINDER STOP

30. 113-328D 24’ MARKER CHAIN

113-319D MARKER CHAIN 30’

31. 113-342H NO-TILL MARKER 24’ 2ND SECTION

113-341H NO-TILL MARKER 30’ 2ND SECTION

32. 113-323D CHAIN BAR

33. 802-022C HHCS 3/8-16X1 1/2 GR5

34. 804-011C WASHER FLAT 3/8 USS PLT

35. 802-260C HHCS 1/2-13X7 GR5

36. 113-398D RUBBER TUBE RD 3 OD X 5 LONG

37. 113-344H NO-TILL MARKER 24’ 3RD SECTION

113-343H NO-TILL MARKER 30’ 3RD SECTION

38. 803-036C NUT HEX JAM 1/2-13 PLT

39. 801-013C SCREW SET SQ HD 1/2-13X1 1/2G5

40. 113-379D NO-TILL 24’ 4TH SECT TUBE

113-378D NO-TILL 30’ 4TH SECT TUBE

41. 804-017C WASHER FLAT 1/2 USS PLT

42. 802-041C HHCS 1/2-13X3 1/2 GR5

43. 113-360S NOTILL MRKR DSK & 4BLT HUB ASY Refer to page 16 for breakdown.

44. 804-015C WASHER LOCK SPRING 1/2 PLT

45. 803-020C NUT HEX 1/2-13 PLT

46. 806-005C U-BOLT 1/2-13 X 2 X 3 GR 5

47. 113-197H MARKER CARRIER

48. 113-365H NO-TILL SADDLE REST WELDMENT

49. 205-036H TRANSPORT ARM MOUNT WLDMNT

50. 806-069C U-BOLT 1/2-13 X 4 1/32 X 7 1/4

51. 803-169C NUT HEX FLG. LOCK 1/2-13 PLT.

Parts

15

3/20/2003

205-052M

Page 18

John Deere 30’ Dual 750

16

Disk Assembly

12426

205-052M

3/20/2003

Page 19

Ref. Part No. Description

1. 113-563S MARKER DISC & HUB ASSEMBLY

113-564S REP BY 113-563S

113-372S REP BY 113-564S

2. 113-562H 1 SPINDLE MARKER WELDMENT

3. 816-014C TINE GAUGE MARKER HUB SEAL

4. 822-030C BEARING CONE L44643

5. 822-080C BEARING CUP L44610

6. 890-614C GREASE CAP #1505

7. 815-001C TINE GW HUB

8. 804-025C WASHER FLAT 3/4 SAE PLT

9. 803-053C NUT HEX SLOTTED 3/4-16

10. 805-019C PIN COTTER 5/32 X 1 PLT

11. 820-094C 16 4-BOLT NOTCHED MARKER DISK

12. 133-369H DEPTH BAND 10 4-BOLT 4B.C.

13. BO-47 NEILSON STUD 1/2-20UNF X 1 13/16

14. 803-159C NUT LUG 1/2-20 X 60 DEG PLT

Parts

17

3/20/2003

205-052M

Page 20

John Deere 30’ Dual 750

18

Hydraulic Assembly

13725

205-052M

3/20/2003

Page 21

Ref. Part No. Description

1. 810-118C CYL 2.5X20X1.12 ROD (TIE)1 PIN

2. 811-065C EL 9/16MJIC 9/16MORB

3. 811-248C HH1/4R1 163 9/16FJIC

4. 811-130C HH1/4R1 252 1/2MNPT 9/16FJIC

5. 802-014C HHCS 3/8-16X3/4 GR5

6. 804-013C WASHER LOCK SPRING 3/8 PLT

7. 148-425D MARKER VALVE MOUNT

8. 811-169C EL 9/16MJIC 9/16FJIC

9. 800-035C CABLE TIE .31X28 8DIA 120LB

10. 811-167C HH1/4R1 136 9/16FJIC

11. 806-022C U-BOLT 3/8-16 X 6 1/32 X 5 PLT

12. 803-068C NUT HEX FLANGE 3/8-16 PLT

13. 205-029D U-BOLT BRACKET

14. 810-197C VALVE,SEQUENCE SHOEMAKER

15. 811-436C HH1/4R1 156 9/16FJIC 1/2MNPT

16. 817-348C PLASTIC HOSE LABEL

Parts

19

3/20/2003

205-052M

Page 22

John Deere 30’ Dual 750

20

Hydraulic Cylinder (810-118C)

10035

205-052M

3/20/2003

Page 23

Ref. Part No. Description

1. 1M6006 CLEVIS

2. 2M3326 ROD

3. 3R0310 MW HEAD

4. 4M3108 MW PISTON

5. 5M3128 TUBE

6. 6R0158 BASE MIDWAY

7. 7M3328 TIE ROD

8. 2A0208 CLEVIS PIN

9. * WIPER SEAL

10. * O-RING

11. * BACK UP (ROD)

12. * O-RING

13. * BACK UP (PISTON)

14. 2A0022 PISTON NUT

15. 2A0012 CLEVIS NUT

16. 2A0012 TIE ROD NUT

17. 802-023C HHCS 3/8-16X1 3/4 GR5

18. 2A0132 PIN CLIP

19. 810-210C SEAL KIT MW 2.5 CYL 3A3102

Parts

21

* AVAILABLE IN SEAL KIT.

3/20/2003

205-052M

Page 24

John Deere 30’ Dual 750

22

Sequence Valve

12024

205-052M

3/20/2003

Page 25

Ref. Part No. Description

1. 3089 BODY, SEQUENCE VALVE

2. 1088-908 O-RING

3. 1132-08 PLUG, HEX SOCKET

4. 1179 NEEDLE, FLOW CONTROL

5. 1217 PIN, .125" SPRING PIN

6. 1211 SPRING, COMPRESSION

7. * O-RING Seal kit only

8. * RING, TEFLON BACK-UP Seal kit only

9. 1180 SCREW, FLOW CONTROL ADJUSTMENT

10. 1218 HEX, JAM NUT ZINK PLATED

11. * SPRING, DETENT Seal kit only

12. * CHROMIUM STEEL BALLS Seal kit only

13. * CHROMIUM STEEL BALL Seal kit only

14. * SPRING Seal kit only

15. 1088-906 O-RING

16. 1182 FITTING, PORT ADAPTOR

17. 1132-05 HEX, SOCKET O-RING PLUG

18. 1088-905 O-RING

19. 1092-6-6 CONNECTOR, STRAIGHT

20. 2153 SPOOL, MARKER SEQUENCE .055" ORIFICE

810-456C SEAL KIT SHOEMAKER #1223 Not shown

Parts

23

3/20/2003

205-052M

Page 26

John Deere 30’ Dual 750

24

Appendix

Torque V alues Chart

Bolt Head Identification

Bolt Head Identification

Bolt Size

(Inches)

1

in-tpi

1/4" - 20 7.4 5.6 11 8 16 12 M 5 X 0.8 4 3 6 5 9 7

1/4" - 28 8.5 6 13 10 18 14 M 6 X 1 7 5 11 8 15 11

5/16 - 18 15 11 24 17 33 25 M 8 X 1.25 17 12 26 19 36 27

5/16" - 24 17 13 26 19 37 27 M 8 X 1 18 13 28 21 39 29

3/8" - 16 27 20 42 31 59 44 M10 X 1.5 33 24 52 39 72 53

3/8" - 24 31 22 47 35 67 49 M10 X 0.75 39 29 61 45 85 62

7/16" - 14 43 32 67 49 95 70 M12 X 1.75 58 42 91 67 125 93

7/16" - 20 49 36 75 55 105 78 M12 X 1.5 60 44 95 70 130 97

1/2" - 13 66 49 105 76 145 105 M12 X 1 90 66 105 77 145 105

1/2" - 20 75 55 115 85 165 120 M14 X 2 92 68 145 105 200 150

9/16" - 12 95 70 150 110 210 155 M14 X 1.5 99 73 155 115 215 160

9/16" - 18 105 79 165 120 235 170 M16 X 2 145 105 225 165 315 230

5/8" - 11 130 97 205 150 285 210 M16 X 1.5 155 115 240 180 335 245

5/8" - 18 150 110 230 170 325 240 M18 X 2.5 195 145 310 230 405 300

3/4" - 10 235 170 360 265 510 375 M18 X 1.5 220 165 350 260 485 355

3/4" - 16 260 190 405 295 570 420 M20 X 2.5 280 205 440 325 610 450

7/8" - 9 225 165 585 430 820 605 M20 X 1.5 310 230 650 480 900 665

7/8" - 14 250 185 640 475 905 670 M24 X 3 480 355 760 560 1050 780

1" - 8 340 250 875 645 1230 910 M24 X 2 525 390 830 610 1150 845

1" - 12 370 275 955 705 1350 995 M30 X 3.5 960 705 1510 1120 2100 1550

1-1/8" - 7 480 355 1080 795 1750 1290 M30 X 2 1060 785 1680 1240 2320 1710

1 1/8" - 12 540 395 1210 890 1960 1440 M36 X 3.5 1730 1270 2650 1950 3660 2700

1 1/4" - 7 680 500 1520 1120 2460 1820 M36 X 2 1880 1380 2960 2190 4100 3220

1 1/4" - 12 750 555 1680 1240 2730 2010

1 3/8" - 6 890 655 1990 1470 3230 2380

1 3/8" - 12 1010 745 2270 1670 3680 2710

1 1/2" - 6 1180 870 2640 1950 4290 3160

1 1/2" - 12 1330 980 2970 2190 4820 35604mm x pitch = nominal thread diameter in millimeters x thread pitch

Grade 2 Grade 5

N · m2ft-lb3N · m ft-lb N · m ft-lb mm x pitch4N · m ft-lb N · m ft-lb N · m ft-lb

Torque tolerance + 0%, -15% of torquing values. Unless otherwise specified use torque values listed above.

Grade 8

Bolt Size

(Metric)

1

in-tpi = nominal thread diameter in inches-threads per inch

5.8 8.8 10.9

Class 5.8 Class 8.8 Class 10.9

2

N· m = newton-meters

3

ft-lb= foot pounds

205-052M

3/20/2003

Page 27

Warranty

Great Plains Manufacturing, Incorporated warrants to the original purchaser that this seeding equipment will be free from defects in material

and workmanship for a period of one year from the date of original purchasewhenused as intended and under normal service and conditions

for personal use; 90 days for commercial or rental purposes. This Warranty is limited to the replacement of any defective part by Great Plains

Manufacturing, Incorporated and the installation by the dealer of any

such replacement part. Great Plains reserves the right to inspect any

equipment or part which are claimed to have been defective in material

or workmanship.

This Warranty does not apply to any part or product which in Great

Plains’ judgement shall have been misused or damaged by accident or

lack of normal maintenance or care, or which has been repaired or altered in a way which adversely affects its performance or reliability, or

which has been used for a purpose for which the product is not designed. This Warranty shall not apply if the product is towed at a speed

in excess of 20 miles per hour.

Claims under this Warranty must bemade tothe dealerwhichoriginally

sold the product and all warranty adjustments must by made through

such dealer. Great Plains reserves the right to make changes in materials or design of the product at any time without notice.

This Warranty shall not be interpreted to render Great Plains liable for

damages of any kind, direct, consequential, or contingent, to property.

Furthermore,Great Plains shallnotbe liable fordamagesresulting from

any cause beyond its reasonable control. This Warranty does not extend to loss of crops, losses caused by harvest delays or any expense

or loss for labor, supplies, rental machinery or for any other reason.

No other warranty of any kind whatsoever, express or implied, is

made with respect to this sale; and all implied warranties of merchantability and fitness for a particular purpose which exceed

the obligations set forth in this written warranty are hereby disclaimed and excluded from this sale.

This Warranty is not valid unless registered with Great Plains Manufacturing, Incorporated within 10 days from the date of original purchase.

Appendix

25

3/20/2003

205-052M

Page 28

Great Plains Manufacturing, Inc.

Corporate Office: P.O.Box 5060

Salina, Kansas 67402-5060 USA

Loading...

Loading...